Abstract

In response to the heightened awareness of infectious diseases and the growing emphasis on personal protection in daily life, the utilization of natural bioresources for textile fabric dyeing has garnered substantial research attention. This is particularly due to their ability to confer antibacterial and UV protection properties to fabrics. In this study, the dyeing properties of Mimusops elengi Linn extract, alone and mordanted, were evaluated on blended wool/acrylic and silk fabrics, along with an assessment of their antibacterial and UV protection characteristics. The dyed fabrics exhibited good color strength and color fastness. Quantitative assessment of antibacterial activity was conducted using the reduction percentage test, while UV protection properties were determined through the measurement of Ultraviolet Protection Factor (UPF). Aqueous extract alone, when applied to blended wool/acrylic fabric, demonstrated an impressive 99.88 % reduction against Staphylococcus aureus, and 48.33 % for silk fabric, albeit less effective against Escherichia coli. Notably, when fabrics were dyed with a combination of leaves extract and various metal salt mordants, a substantial improvement in antibacterial properties was observed. Zinc and copper salts, in particular, exhibited the ability to enhance antibacterial properties to almost 100 % against Staphylococcus aureus and Escherichia coli in both blended wool/acrylic and silk fabrics. Concurrently, this combination contributed to an increase in the UV protection property of both fabrics. The findings underscore the potential of plant-based natural dye for blended wool/acrylic and silk fabrics, imparting antimicrobial and UV protection properties. This has significant implications in preventing the spread of infections and skin diseases, emphasizing the vital role of such textiles in promoting health and well-being.

Keywords: Natural dyes, Blended wool/acrylic, Silk, Color strength, Antibacterial property, UV protection

Highlights

-

•

The leaf extract of Mimusops elengi demonstrated exceptional dyeing capabilities on blended wool/acrylic and silk fabrics.

-

•

A diverse range of color shades was achieved by employing various metal salts as mordants in the dyeing process.

-

•

Fabrics dyed with the leaf extract and metal salt mordants, exhibited a significant enhancement in antibacterial properties.

-

•

The UV protection property of both dyed fabrics experienced an increase.

1. Introduction

In the contemporary context, there is a discernible surge in the demand for eco-friendly and sustainable green products across various facets of daily life. The ongoing challenges posed by the Covid-19 pandemic have accentuated concerns regarding infectious diseases, prompting a heightened focus on textiles-an indispensable aspect of human existence. In response, considerable attention has been directed toward imbuing textile products with additional properties, particularly antimicrobial activity, to fortify their capacity to resist viral or bacterial incursions [1,2].

Textiles, particularly apparel and home textiles in direct contact with the human body, create an ideal environment for the proliferation of various microorganisms implicated in infectious diseases. Beyond posing a threat to health, these microorganisms contribute to undesirable effects such as dermal infections, malodorousness, fabric discoloration, and deterioration. To mitigate these issues, the development of garments endowed with antibacterial properties has become imperative. Consequently, various synthetic antibacterial finishes, including triclosan, organometallics, phenolic compounds, N-halamines, and quaternary ammonium compounds, have been employed in textile manufacturing. The anticipated leading antimicrobial products include phenolic compounds, iodophors, nitrogen compounds, and organometallics, all of which are commercially available in the market [3,4]. However, the health and environmental implications stemming from the toxicity of these chemical agents underscore a critical concern [5].

Concurrently, the market offers a plethora of synthetic antimicrobial drugs aimed at reducing the lethality of infectious diseases. Nevertheless, the prolonged or improper use of these drugs has led to the emergence of multidrug-resistant microorganisms, posing a substantial threat to human health [6]. Reports indicate a significant increase in healthcare-associated infections related to Staphylococcus aureus in the year 2020 [7]. Recognizing this formidable challenge, there is a growing consensus that disease prevention holds greater merit than cure, offering a means to alleviate suffering and economic burden. Consequently, prioritizing the development of healthcare textile products assumes paramount importance.

In this context, the practice of dyeing apparel and textile products with natural dyes has garnered substantial attention due to its high environmental compatibility, minimal health risks in everyday use, and a host of other advantageous properties [1,[8], [9], [10]]. Thus, the quest for new sources of natural dyes emerges as a highly promising imperative in the pursuit of innovative and sustainable textile solutions.

Plant extracts, or their active constituents, represent a highly promising reservoir of natural dyes, offering a myriad of advantages such as renewability, minimal side effects, cost-effectiveness, and enhanced accessibility, coupled with antimicrobial and UV protection properties [11]. Mimusops elengi, a prominent evergreen medicinal plant of the Sapotaceae family, has garnered attention for its multifaceted medicinal properties. Various components of the plant, including alkaloids, phenolics, flavonoids, terpenoids, tannins, saponins, and glycosides, have been identified as valuable for pharmaceutical applications [[12], [13], [14]]. Phenolic compounds, notably flavonoids and tannins, prevalent in all-natural dyes, exhibit exceptional antibacterial and sun protection properties, aligning with the requirements of functional textiles [7,15]. The aqueous and alcoholic extracts of Mimusops elengi leaves have demonstrated effectiveness against bacterial strains, with identified active phytoconstituents such as Quercitin, Myricitin, Hentriacontane, and Kaempferol derivatives [16,17]. All of these compounds contain several (-OH) groups in their structures.

Motivated by these inherent characteristics, this study seeks to investigate the antibacterial and UV protection properties inherent in Mimusops elengi leaf extract through the dyeing process of protein-based natural fibers, namely wool and silk. The selection of these natural fibers is particularly significant as they exhibit heightened susceptibility to microbial attacks owing to their inherent moisture retention properties. The polymer linkages present in natural fibers can be more readily targeted by microbial enzymes [18], especially following fabric processing stages wherein protective layers are typically removed. Furthermore, natural fibers possess the potential to serve as nutrient sources for microbes in the form of carbohydrates or proteins [19].

This study employed an environmentally friendly extraction method, using boiling distilled water to extract colorants from leaves. The obtained results demonstrated the effectiveness of this approach. While contemporary practices lean towards microwave-assisted extraction techniques for colorants from various parts of plant that contributes to reduce energy consumption [20,21]. For mordanting, fabric samples were immersed in a dye solution containing 3 % of each metal salt simultaneously. Dyeing processes were carried out at 90 °C for 60 min, with a material-to-liquor ratio of 1:20 for blended wool/acrylic and 1:50 for silk fabric. This comprehensive exploration aligns with our commitment to advancing knowledge in the domain of natural dyes and their multifaceted applications in textile science [22,23].

The rationale behind this study is rooted in addressing contemporary challenges related to health, hygiene, and sustainability in textile applications. With a surge in awareness regarding infectious diseases, there is a growing need for multifunctional textiles that not only offer aesthetic appeal but also provide practical benefits such as antimicrobial activity and UV protection. This research seeks to contribute valuable insights into the application of Mimusops elengi Linn leaves extract in textile dyeing, emphasizing its potential to yield fabrics with enhanced antibacterial properties and UV protection, thereby fostering the development of textiles aligned with modern health and sustainability considerations.

2. Experimental section

2.1. Chemicals and reagents

For this study, 30 % blended wool (70 % acrylic, knit fabric, weight: 199 g/m2) and 100 % degummed and bleached silk (woven fabric, weight: 22 g/m2) were selected as textile substrates. Copper (II) sulfate pentahydrate (98 %, Sigma-Aldrich), Iron (II) sulfate heptahydrate (99 %, Sigma-Aldrich), Zinc Chloride (99 %, Sigma-Aldrich), and laboratory-grade potash alum (KAl(SO₄)₂.12H₂O) were utilized without further purification.

2.2. Extraction of dye

The leaves of Mimusops elengi underwent a thorough washing to remove dirt and impurities. Subsequently, they were air-dried at room temperature for 15 days and transformed into a powdered form using a blender machine. Crude color components were extracted from the leaves powder through a boiling water method. One hundred grams of leaves powder were soaked in boiling distilled water (500 mL) for 15 min in a conical flask. The extract was collected by filtration through a Nylon mesh fabric (mesh size 280). The residue underwent two additional boiling cycles with fresh distilled water (300 + 300 mL) for 15 min each to collect the maximum extract. The filtrates were combined, filtered through a fine mesh fabric to ensure clarity, and finally, the solution was concentrated to 500 mL through evaporation, ready for application in the dyeing process.

2.3. Dyeing and mordanting

The dyeing of blended wool/acrylic and silk fabrics employed the exhaust dyeing method (Rapid Machinery-Smart dyer, SD-16, Xiamen Precision Co. Ltd., China) at 90 °C for 60 min [22,23]. For mordanting, fabric samples were immersed in the dye solution containing 3 % of each metal salt simultaneously. All dyeing processes were conducted at 90 °C for 60 min, maintaining a material-to-liquor ratio of 1:20 for blended wool/acrylic and 1:50 for silk fabric. Post-dyeing, samples were rinsed with tap water, washed with laundry detergent at 50 °C for 15 min, and finally, rinsed again with tap water before air-drying. This meticulous process ensures the proper fixation and retention of the dyestuff on the fabric substrates.

2.4. Characterization

2.4.1. Color strength analysis

Color strength (K/S) values were determined employing the light reflectance technique through a spectrophotometer (Premier Color Scan, SS 5100H). The Kubelka–Munk equation (equation (1)) was utilized for this calculation:

| (1) |

Here, R represents the decimal fraction of the reflectance of dyed fabrics at the wavelength of maximum absorbance (λmax = 400 nm). The absorption coefficient (K) and scattering coefficient (S) are integral to this equation. Additionally, color coordinates including L* (lightness, where white = 100 and black = 0), a* (red = positive value, green = negative value), and b* (yellow = positive value, blue = negative value) were determined utilizing the CIE L*a*b* system on the same spectrophotometer, under illuminant D65 and a 10° standard observer.

2.4.2. Fourier transform infrared (FTIR) spectroscopy

Fabric samples were subjected to Fourier transform infrared (FTIR) spectroscopy using a PerkinElmer Spectrum Two spectrophotometer (Beaconsfield, UK). The samples were ground into powder form and pressed with KBr into a pellet. Spectra were recorded in the wave number range of 400–4000 cm⁻1 at a resolution of 2 cm⁻1 in transmittance mode.

2.4.3. Antibacterial activity assessment

Antibacterial activities against two bacterial species, Gram-positive Staphylococcus aureus (ATCC: 6538) and Gram-negative Escherichia coli (ATCC: 11775), were evaluated following the ASTM E2149-01 standard (ASTM International 2001). One gram of fabric was introduced into a 50 ml liquid solution containing approximately 5 × 10⁵ CFU/ml bacteria. This solution was then placed in a shaker incubator and agitated at 37 °C for 24 h. Subsequently, dilution and inoculation were performed in agar, followed by incubation at 37 °C for an additional 24 h. Post-incubation, bacterial colonies were counted on petri dishes, and the bacteria reduction rate was computed using the formula (equation (2)) [24]:

| (2) |

Here, A represents the number of bacterial colonies recovered from the inoculated treated sample fabric, and B represents the number of bacterial colonies recovered from the inoculated untreated control fabric.

2.4.4. Color fastness

The color fastness to washing of dyed samples was evaluated in accordance with ISO 105–C06 A2S: 2010, employing a wash fastness tester (Gyrowash, James H. Heal & Co. Ltd. UK). Alterations and staining of color resulting from washing were meticulously examined by comparing untreated fabrics with treated fabric samples, utilizing color change and color staining gray scales.

2.4.5. UV protection assessment

Conforming to the AS/NZ 4399: 2016 standard, the total spectral transmittance of all dyed fabric samples was quantified to ascertain their UPF values. This measurement was accomplished using a UV–Vis spectrophotometer (Shimadzu UV-1800 spectrophotometer) within the wavelength range of 290–400 nm. The UPF, defined as the average effective ultraviolet radiation (UVR) irradiance of unprotected skin divided by the average effective UVR irradiance of colored fabric-protected skin, was calculated using the formula (equation (3)):

| (3) |

where,

Eλ is the solar UVR spectral irradiance in W.m−2 nm−1

Sλ is the solar spectral irradiance in Wm−2 nm−1

Tλ is the spectral transmittance of fabric (%)

Δλ is the wavelength interval of the measurement in nm (5 nm)

λ is the wavelength in nm (290–400 nm)

3. Results and discussion

In the pursuit of developing high-quality multifunctional protective textiles that align with the heightened awareness of health and hygiene, this research aimed to identify an effective natural dye and suitable mordants for achieving both UV-protection and antimicrobial functions on fabrics. The crude aqueous extract obtained from the leaves of Mimusops elengi served as the natural dye in this study. The extraction process, outlined in the experimental section, is notably straightforward, and the accessibility of Mimusops elengi leaves in tropical regions renders the dye extraction cost-effective. For the extraction of dye molecules from plant sources, various techniques and solvents are also being used by researchers [25,26]. However, extraction in boiling water has proven to be a very simple and eco-friendly process.

The extracted crude reddish-brown aqueous solution was directly applied to blended wool/acrylic and silk fabrics, and the color coordinates (L*, a*, b*), color strength (K/S), and resulting colors (photographs) are detailed in Table 1, Table 2. In the absence of a mordant (treated with dye extract only), the color strength values were 1.151 and 2.215 for blended wool/acrylic and silk, respectively. Mordanting the fabrics with different metal salts gave different shades and colors. A light reddish-brown color was observed for both fabrics when treated with the dye extract only, and the use of various metal salt mordants produced a spectrum of shades, with iron salt resulting in the darkest shades for both fabrics.

Table 1.

Color strengths and obtained colors of dyed blended wool/acrylic.

| Sample | L* | a* | b* | K/S Value | Color obtained |

|---|---|---|---|---|---|

| Treated with dye | 71.676 | 4.069 | 11.964 | 1.151 |  |

| Treated with dye + ZnCl2 | 68.686 | 1.838 | 16.887 | 1.589 |  |

| Treated with dye + FeSO4·7H2O | 58.683 | 0.194 | 6.307 | 1.745 |  |

| Treated with dye + KAl(SO4)2·12H2O | 64.810 | 2.622 | 16.991 | 1.868 |  |

| CuSO4·5H2O | 58.290 | −0.067 | 17.378 | 3.061 |  |

Table 2.

Color strengths and obtained colors of dyed silk.

| Sample | L* | a* | b* | K/S Value | Color obtained |

|---|---|---|---|---|---|

| Treated with dye extract | 62.840 | 8.968 | 16.410 | 2.215 |  |

| Treated with dye + ZnCl2 | 61.886 | 5.450 | 21.116 | 2.915 |  |

| Treated with dye + FeSO4·7H2O | 45.170 | 0.389 | 3.419 | 3.410 |  |

| Treated with dye + KAl(SO4)2·12H2O | 60.836 | 5.742 | 21.214 | 2.825 |  |

| CuSO4·5H2O | 56.546 | 6.746 | 20.352 | 3.479 |  |

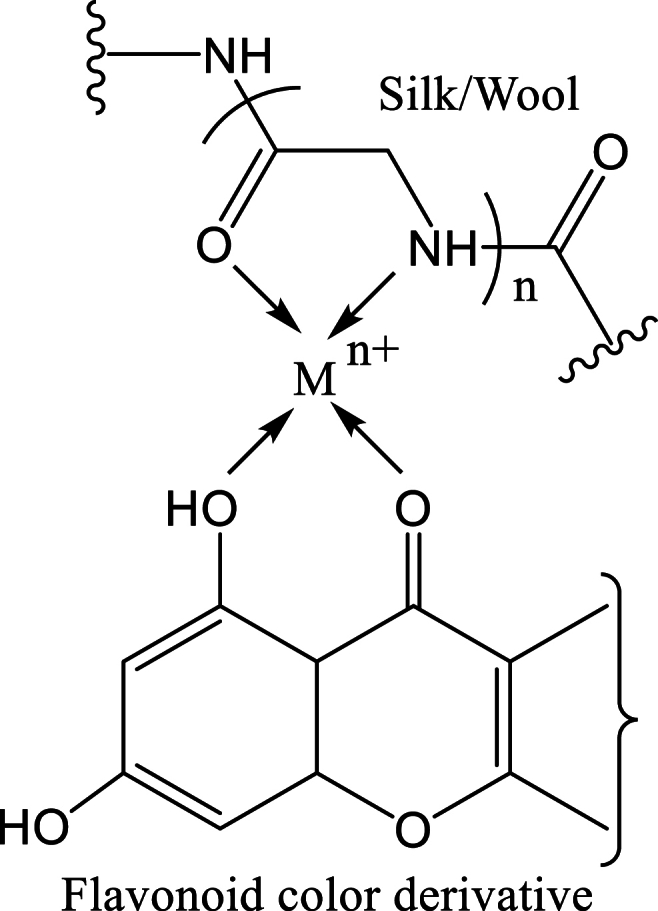

Despite the generally higher dye absorption capabilities of natural protein fibers, blended wool/acrylic fabrics often exhibited lower K/S values compared to silk fabrics. This discrepancy can be attributed to compositional differences, with synthetic fibers (acrylic) displaying a lower affinity for natural dye [27,28]. Mordants play a crucial role in bestowing color upon fabrics, with varying mordants yielding different shades. The effectiveness of the color intensity, represented by K/S values, relies on the specific metal salt utilized. The coordination capabilities of metal ions enhance the interaction between the fabric and dye components, which is supposed to lead to an increased absorption of dye. Metal ions in mordants demonstrate the capacity to form coordination complexes with the fabric and dye molecules through donor atoms found in their functional groups, including amino, keto, and hydroxy. Consequently, a ternary complex is established where the fabric and dye molecules bind to the metal ions via chelation. This formation results in an increase in both the K/S values and the fastness properties of the dyed fabrics. Scheme 1 illustrates a typical example of such a ternary complex.

Scheme 1.

A ternary complex formation (fiber–metal–dye).

The order of color strength for dyed samples, from lowest to highest, is as follows:

Blended Wool/Acrylic:

Treated with neat dye < dye + ZnCl2 < dye + FeSO4·7H2O < dye + KAl(SO4)2.12H2O < dye + CuSO4·5H2O

Silk:

Treated with neat dye < dye + KAl(SO4)2.12H2O < dye + ZnCl2 < dye + FeSO4·7H2O < dye + CuSO4·5H2O

The variations in color coordinates (L*, a*, b*) values with different mordanting agents led to discernible color changes. The lightness (L*) values decreased, while color yield increased for both fabrics when metal salts were introduced. Positive values of a* and b* for most samples suggest a shift in fabric color from red to yellow, with only the copper-mordanted sample of blended wool/acrylic fabric exhibiting a negative a* (greenness). Iron mordanting resulted in lower L*, a*, and b* values for both fabrics, indicating a decrease in brightness and a shift to a slightly darker shade. These nuanced color variations underscore the impact of mordanting agents on the final aesthetic properties of the dyed fabrics.

3.1. Wash fastness evaluation

The wash fastness outcomes for all dyed samples, encompassing assessments of color change and color staining on adjacent multifiber fabrics, are meticulously documented in Table 3, Table 4. The color fastness results have been interpreted against a gray scale ranging from 1 to 5, where 1 denotes poor, 2 signifies fairly good, 3 implies good, 4 indicates very good, and 5 represents excellent.

Table 3.

Color fastness to washing of dyed blended wool/acrylic fabric.

| Sample | Color change | Color staining to |

|||||

|---|---|---|---|---|---|---|---|

| Acetate | Cotton | Nylon | polyester | Acrylic | Wool | ||

| Treated with dye | 4–5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Treated with dye + ZnCl2 | 4–5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Treated with dye + FeSO4·7H2O | 3–4 | 5 | 5 | 5 | 5 | 5 | 5 |

| Treated with dye + KAl(SO4)2·12H2O |

4–5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Treated with dye + CuSO4·5H2O | 4 | 5 | 5 | 5 | 5 | 5 | 4–5 |

Table 4.

Color fastness to washing of dyed silk fabric.

| Sample | Color change | Color staining to |

|||||

|---|---|---|---|---|---|---|---|

| Acetate | Cotton | Nylon | polyester | Acrylic | Wool | ||

| Treated with dye | 4 | 5 | 5 | 5 | 5 | 5 | 5 |

| Treated with dye + ZnCl2 | 4 | 5 | 5 | 5 | 5 | 5 | 5 |

| Treated with dye + FeSO4·7H2O | 3 | 5 | 5 | 5 | 5 | 5 | 5 |

| Treated with dye + KAl(SO4)2·12H2O |

3–4 | 5 | 5 | 5 | 5 | 5 | 5 |

| Treated with dye + CuSO4·5H2O | 3–4 | 5 | 5 | 5 | 5 | 5 | 5 |

A discernible spectrum of color change due to washing was observed, spanning from 3 (good) to 5 (excellent). Notably, the color fastness to wash was notably superior for blended wool/acrylic dyed with the neat extract, zinc, and alum mordants when compared to iron and copper mordants. The superior outcomes predominantly fell within the very good (4) to excellent (5) range. In contrast, the color fastness of iron and copper mordanted dyed wool/acrylic demonstrated a range from 3 to 4. In the case of silk, color changes due to washing were confined within the range of 3–4 for all scenarios.

For all dyed fabrics, the results pertaining to color staining on adjacent multifiber fabrics were consistently excellent (5), underscoring the commendable color fastness and minimal transference of color to neighboring materials. These findings substantiate the efficacy of the dyeing process, particularly when employing zinc and alum mordants, in conferring robust wash fastness attributes to the dyed fabrics.

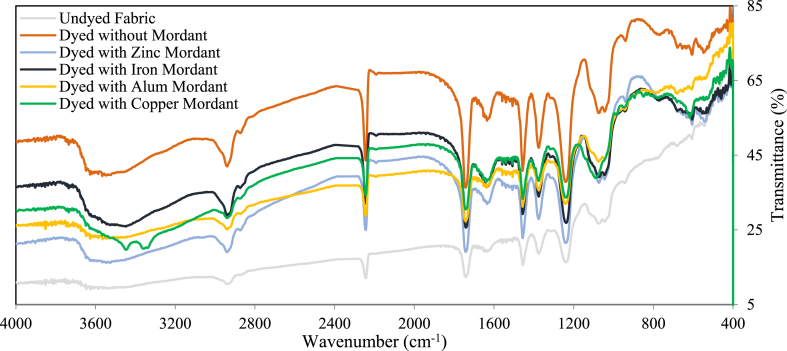

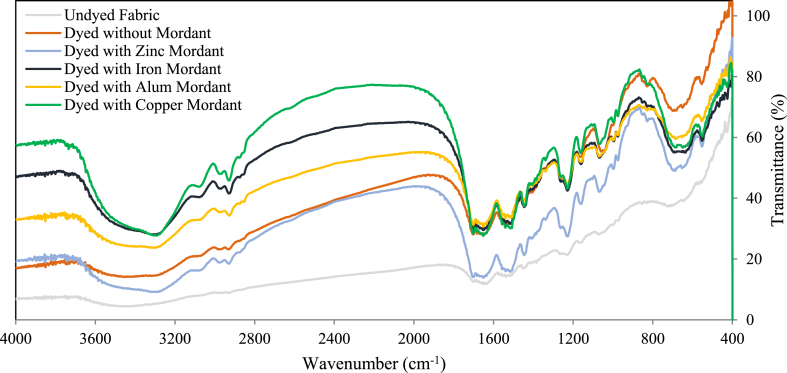

3.2. FTIR analysis of dyed fabrics

The FTIR spectra for both undyed and dyed blended wool/acrylic and silk fabrics are elucidated in Fig. 1, Fig. 2, respectively. In Fig. 1, the primary characteristic peaks for all dyed and undyed wool/acrylic fabrics are prominently situated at approximately 2940 cm−1 (C–H stretching), 2244 cm−1 (C N stretching), 1742 cm−1 (C O stretching), and 1456 cm−1 and 1375 cm−1 (C–H bending) [29,30]. Conversely, the main characteristic peaks for both dyed and undyed silk fabrics (Fig. 2) manifest around 2928 cm−1 (C–H stretching), 1652 cm−1 (amide I), 1515 cm−1 (amide II), and 1228 cm−1 (amide III) [31,32].

Fig. 1.

FTIR Spectra of blended wool/acrylic fabrics.

Fig. 2.

FTIR Spectra of silk fabrics.

A noteworthy alteration was discerned in the range of 3300–3600 cm−1, corresponding to O–H and N–H peaks, for both fabric types. The modifications in peak intensities and minor peak shifts strongly imply the absorption of dye and the intricate interaction between metals and the dyed fabrics [32]. This FTIR analysis provides valuable insights into the molecular changes occurring during the dyeing process, offering a comprehensive understanding of the chemical transformations and interactions within the fabric structures.

3.3. Antibacterial evaluation of dyed fabrics

The dyed and undyed fabric samples underwent comprehensive analysis to assess their antibacterial efficacy against two prevalent human pathogenic strains, namely S. aureus and E. coli. The outcomes are meticulously presented in Table 5, revealing a distinctive antibacterial performance based on the dyeing methodology and mordant utilization.

Table 5.

Antibacterial activity of dyed blended wool/acrylic and silk fabric.

| Sample | Bacteria | Antibacterial activity (% R) |

|

|---|---|---|---|

| Blended wool/acrylic | Silk | ||

| Untreated | S. aureus | – | – |

| E. coli | – | – | |

| Treated with dye | S. aureus | 99.88 | 48.33 |

| E. coli | 1.42 | 1.42 | |

| Treated with dye + ZnCl2 | S. aureus | 99.88 | 99.77 |

| E. coli | 99.14 | 82.85 | |

| Treated with dye + FeSO4·7H2O | S. aureus | 99.77 | 56.77 |

| E. coli | 22.85 | 15.00 | |

| Treated with dye + KAl(SO4)2·12H2O | S. aureus | 99.00 | 79.00 |

| E. coli | 14.28 | 1.00 | |

| Treated with dye + CuSO4·5H2O | S. aureus | 99.88 | 99.88 |

| E. coli | 99.85 | 99.57 | |

In undyed fabrics, no discernible antibacterial effect was observed. However, upon dyeing with the neat leaves extract, notable antibacterial activities were recorded, reaching 99.88 % and 48.33 % against S. aureus in blended wool/acrylic and silk fabrics, respectively. Conversely, no antibacterial effect was evident against E. coli in fabrics dyed solely with the neat leaves extract. Intriguingly, the introduction of mordants in conjunction with the leaves extract for dyeing resulted in a substantial augmentation of antibacterial activities against both tested bacteria.

The most pronounced antibacterial effects were observed in the dyed samples mordanted with zinc and copper, a phenomenon consistent across both blended wool/acrylic and silk fabrics. Conversely, minimal alterations in antibacterial effects were noted in iron-mordanted samples, closely mirroring the outcomes of the un-mordanted fabrics. This suggests that the neat M. elengi leaves extract primarily exhibits efficacy against S. aureus bacteria (99.88 % in blended wool/acrylic and 48.33 % in silk). However, the combined utilization of leaves dye extract with copper or zinc salt mordants proves exceptionally effective against both tested bacteria, approaching a near-complete inhibition (∼100 %), validating its efficacy across both fabric types.

Numerous herbal extracts are known to harbor bioactive compounds, including tannins, terpenoids, flavonoids, phenolic acids, alkaloids, among others, which confer antimicrobial effects on textiles [3]. Previous studies on M. elengi leaves extracts have demonstrated resistance against specific bacterial strains [12,13], and the presence of active ingredients such as phenolic acids and flavonoid derivatives has been reported [16]. These compounds are recognized for their capacity to impede microorganism growth by inhibiting nucleic acid synthesis [3]. The extent of antibacterial activity is intricately tied to the concentration of these active ingredients. Furthermore, the nature of the mordant plays a pivotal role in augmenting antibacterial activity, influencing factors such as dye-fiber bond formation and interaction with cellular proteins, thereby contributing to the inhibition of bacterial growth [33].

3.4. UV protection evaluation of dyed fabrics

Contemporary researchers are increasingly driven to explore UV protective textiles in response to the detrimental effects of UV radiations. A plethora of approaches, encompassing both natural and synthetic origins, are being harnessed for the development of UV protective clothing. Beyond investigating the dyeing and antibacterial properties of un-mordanted and mordanted dye extracts, this study delves into their UV protection capabilities on blended wool/acrylic and silk fabrics, evaluating UV transmittance (UV-A and UV-B %) and UPF values (Table 6).

Table 6.

UPF values and the UV protection category of dyed blended wool/acrylic and silk fabrics.

| Sample | Blended wool/acrylic fabric |

Silk fabric |

||

|---|---|---|---|---|

| UPF | UV protection category | UPF | UV protection category | |

| Untreated | 97 | Excellent | 10 | Insufficient protection |

| Treated with dye | 675 | 15 | Good protection | |

| Treated with dye + ZnCl2 | 1485 | 22 | ||

| Treated with dye + FeSO4·7H2O | 4525 | 16 | ||

| Treated with dye + KAl(SO4)2·12H2O | 1061 | 15 | ||

| CuSO4·5H2O | 4626 | 15 | ||

UV protective textiles necessitate the capacity to block UVA (315–400 nm) and UVB (290–315 nm) rays, quantified by the average ultraviolet protection factor (UPF) value. In adherence to the AS/NZ 4399: 1996 standard classification, UPF values falling within the ranges of 15–24 signify good protection, 25 to 39 denote very good protection, and 40+ signifies excellent protection [[34], [35], [36]].

While untreated blended wool/acrylic already exhibits an excellent UPF value of 97, the study investigates the impact of dyeing on these fabrics. Notably, the UPF values of various samples of dyed blended wool/acrylic fabric - dyed with leaves extract alone, dye + ZnCl2, dye + FeSO4·7H2O, dye + KAl(SO4)2·12H2O, dye + CuSO4·5H2O - were found to be 675, 1485, 4525, 1061, and 4626, respectively. The inherent low porosity, substantial weight, and thickness of wool/acrylic fabrics contribute to their excellent UV protection properties. Furthermore, dyeing with metal mordants enhances color depth (Cu mordant) and darkness (Fe mordant), resulting in a significant increase in UPF values [37,38]. Flavonoid derivatives also play a role in UV protection through intramolecular proton transfer [15].

In contrast, untreated silk fabric, with an initial UPF of 10 (insufficient protection), exhibited increased UPF values of 15, 22, 16, 15, and 15 when dyed with leaves extract alone, dye + ZnCl2, dye + FeSO4·7H2O, dye + KAl(SO4)2·12H2O, dye + CuSO4·5H2O, respectively. The inherently thin and lightweight nature of silk fabrics often translates to poor UV protection ability. The enhanced UV protection properties achieved through dyeing are particularly significant, making silk fabrics more versatile and appealing [34]. The UPF rating for these treated fabrics falls within the range of 15–24, classifying them as providing “good protection." Therefore, in addition to the demonstrated antibacterial action, the application of dye extracts, either alone or in combination with metal salt mordants, proves instrumental in improving UV protection for both wool/acrylic and silk fabrics.

4. Conclusion

This research rigorously investigated the dyeing properties of Mimusops elengi leaves extract alone and mordanted on blended wool/acrylic and silk fabrics, alongside an evaluation of their antibacterial and UV protection characteristics. The findings underscore the Mimusops elengi leaves extract as a potent natural dye source for textile applications, demonstrating its versatility in producing varied colors and shades when combined with different metal salts as mordants.

In the realm of antibacterial efficacy, the blended wool/acrylic fabric, treated solely with leaves extract, exhibited exceptional activity against S. aureus, although no antibacterial effect was observed against E. coli. Contrastingly, fabrics mordanted with Zinc and copper ions showcased outstanding antibacterial activity (∼100 %) against both bacterial strains, signifying a significant enhancement in antimicrobial properties.

The UV protection analysis revealed commendable levels for dyed silk fabrics and a substantial augmentation in UV protection properties for all blended wool/acrylic fabrics. Notably, the incorporation of metal salts, played a pivotal role in elevating the UV protection attributes. In summary, the dyeing process involving Mimusops elengi leaves extract and selected metal salts, emerges as an efficient approach for conferring antibacterial and UV protective finishes to blended wool/acrylic and silk textiles.

Funding statement

This research received support from the R & D project (2021–2022), Ministry of Science and Technology, Government of the People's Republic of Bangladesh (No. 39.00.0000.012.002.07.21.62).

Additional information

No further additional information is provided for this paper.

CRediT authorship contribution statement

Shahin Hossain: Writing – original draft, Methodology, Investigation, Funding acquisition, Formal analysis, Data curation, Conceptualization. M. Abdul Jalil: Writing – review & editing, Visualization, Validation, Supervision, Formal analysis, Data curation, Conceptualization. Tarikul Islam: Formal analysis, Data curation. Rois Uddin Mahmud: Formal analysis, Data curation. Abdul Kader: Formal analysis, Data curation. Md Khayrul Islam: Formal analysis, Data curation.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Contributor Information

Shahin Hossain, Email: mdshahin_ru@buft.edu.bd.

M. Abdul Jalil, Email: abduljalil@buft.edu.bd.

Tarikul Islam, Email: mti@just.edu.bd.

Rois Uddin Mahmud, Email: roisuddin@buft.edu.bd.

Abdul Kader, Email: abdul_kader@buft.edu.bd.

Md Khayrul Islam, Email: engr.kislam@ius.edu.bd.

References

- 1.Yılmaz F., Aydınlıoğlu Ö., Benli H., Kahraman G., Bahtiyari M.İ. Treatment of originally coloured wools with garlic stem extracts and zinc chloride to ensure anti-bacterial properties with limited colour changes, Color. Technol. 2020;136:147–152. doi: 10.1111/cote.12444. [DOI] [Google Scholar]

- 2.Shabbir M., Rather L.J., Mohammad F. Exploring the potential of tannin based colorants towards functional value addition of wool textiles. Fibers Polym. 2019;20:1812–1819. doi: 10.1007/s12221-019-9059-9. [DOI] [Google Scholar]

- 3.Morais D.S., Guedes R.M., Lopes M.A. Antimicrobial approaches for textiles: from research to market. Materials. 2016;9:498. doi: 10.3390/ma9060498. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Simoncic B., Tomsic B. Structures of novel antimicrobial agents for textiles - a review. Text. Res. J. 2010;80:1721–1737. doi: 10.1177/0040517510363193.Z. [DOI] [Google Scholar]

- 5.Uddin F. Environmental concerns in antimicrobial finishing of textiles. Int. J. of Text. Sci. 2014;3(1A):15–20doi. doi: 10.5923/s.textile.201401.03. [DOI] [Google Scholar]

- 6.Yu W Qin, Lin J., Fang S., Qiu J. Antibacterial mechanisms of polymyxin and bacterial resistance. BioMed Res. Int. 2015 doi: 10.1155/2015/679109. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Novi V.T., Gonzalez A., Brockgreitens J., Abbas A. Highly efficient and durable antimicrobial nanocomposite textiles. Sci. Rep. 2022;12 doi: 10.1038/s41598-022-22370-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Ghaheh F.S., Mortazavi S.M., Alihosseini F., Fassihi A., Nateri A.S., Abedi D. Assessment of antibacterial activity of wool fabrics dyed with natural dyes. J. Clean. Prod. 2014;72:139–145. doi: 10.1016/j.jclepro.2014.02.050. [DOI] [Google Scholar]

- 9.Motaghi Z. An economical dyeing process for cotton and wool fabrics and improvement their antibacterial properties and UV protection. J. Nat. Fibers. 2018;15:777–788. doi: 10.1080/15440478.2017.1364204. [DOI] [Google Scholar]

- 10.Bernhard A., Caven B., Wright T., Burtscher E., Bechtold T. Improving the ultraviolet protection factor of textiles through mechanical surface modification using calendaring. Text. Res. J. 2022;92:1405–1414. doi: 10.1177/00405175211046624. [DOI] [Google Scholar]

- 11.Nasr A., Zhou X., Huang S.P., Wang Y., Li X., Zhu G.P. Comparative effects of some extraction solvents on the antimicrobial activity of Eucalyptus camaldulensis leaf, bud, capsule and seed crude extracts. Nat. Prod. Res. 2019;33:2560–2565. doi: 10.1080/14786419.2018.1455049. [DOI] [PubMed] [Google Scholar]

- 12.Baliga M.S., Pai R.J., Bhat H.P., Palatty P.L., Boloor R. Chemistry and medicinal properties of the Bakul (Mimusops elengi Linn): a review. Food Res. Int. 2011;44:1823–1829. doi: 10.1016/j.foodres.2011.01.063. [DOI] [Google Scholar]

- 13.Sircar B., Mandal S. Antibacterial Activity of Mimusops elengi leaf, seed and bark extracts alone and in combination with antibiotics against human pathogenic bacteria. Transl. Med. 2016;6:187–192. doi: 10.4172/2161-1025.1000188. [DOI] [Google Scholar]

- 14.Ganesh G., Abhishek T., Saurabh M., Sarada N.C. Cytotoxic and apoptosis induction potential of Mimusops elengi L. in human cervical cancer (SiHa) cell line. J. King Saud Univ. Sci. 2014;26:333–337. doi: 10.1016/j.jksus.2013.10.002. [DOI] [Google Scholar]

- 15.Silva P.M.S., Fiaschitello T.R., Queiroz R.S., Freeman H.S., Costa S.A., Leo P., Montemor A.F., Costa S.M. Natural dye from Croton urucurana Baill. bark: extraction, physicochemical characterization, textile dyeing and color fastness properties. Dyes Pigm. 2020;173 doi: 10.1016/j.dyepig.2019.107953. [DOI] [Google Scholar]

- 16.Sayed D.F., Afifi A.H., Temraz A., Ahmed A.H. Metabolic Profiling of Mimusops elengi Linn. Leaves extract and in silico anti-inflammatory assessment targeting NLRP3 inflammasome. Arab. J. Chem. 2023;16 doi: 10.1016/j.arabjc.2023.104753. [DOI] [Google Scholar]

- 17.Gami B., Pathak S., Parabia M. Ethnobotanical, phytochemical and pharmacological review of Mimusops elengi Linn. Asian Pac. J. Trop. Biomed. 2012;2:743–748. doi: 10.1016/S2221-1691(12)60221-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Gupta D., Bhaumik S. Antimicrobial treatments for textiles. Indian J. Fibre Text. Res. 2007;32:254–263. [Google Scholar]

- 19.Gao Y., Cranston R. Recent advances in antimicrobial treatments of textiles. Text. Res. J. 2008;78:60–72. doi: 10.1177/0040517507082332. [DOI] [Google Scholar]

- 20.Yameen M., Asghar F., Adeel S., Haider M.Z., Özomay M., Aftab M., Mia R. Enhancing wool dyeing with clove bud (Syzygium aromaticum) based natural dye via microwave treatment using a central composite design. Sci. Prog. 2023;106:4. doi: 10.1177/00368504231215593. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Adeel S., Rehman F.U., Khosa M.K., Rajab S., Zia K.M., Zuber M., Batool F. Eco-friendly isolation of colorant from Arjun bark for dyeing of bio-mordanted cotton fabric. J. Nat. Fibers. 2022;19:4684–4695. doi: 10.1080/15440478.2020.1870618. [DOI] [Google Scholar]

- 22.Hossain S., Jalil M.A., Kamal S.A.B., Kader A. A natural dye extracted from the leaves of Mimusops Elengi Linn and its dyeing properties on cotton and silk fabrics. J. Text. Inst. 2021;112:455–461. doi: 10.1080/00405000.2020.1763057. [DOI] [Google Scholar]

- 23.Hossain S., Jalil M.A., Kader A., Kamal S.A.B. Excellent dyeing properties of a natural dye extracted from the leaves of Phoenix dactylifera Linn on cotton and silk fabrics. J. Nat. Fibers. 2022;19:9803–9812. doi: 10.1080/15440478.2021.1993410. [DOI] [Google Scholar]

- 24.Yılmaz F. Investigating the usage of eucalyptus leaves in antibacterial finishing of textiles against Gram-positive and Gram-negative bacteria. J. Text. Inst. 2021;112:341–345. doi: 10.1080/00405000.2020.1753394. [DOI] [Google Scholar]

- 25.Naveed T., Rehman F., Sanbhal N., Ali B.A., Yueqi Z., Farooq O., Wang W. Novel natural dye extraction methods and mordants for textile applications. Surf. Rev. Lett. 2020;27(4) doi: 10.1142/S0218625X1950135X. [DOI] [Google Scholar]

- 26.Adeel S., Kiran S., Shahid M., Habib S.R., Habib N., Hussain M. Ecofriendly application of coconut coir (Cocos nucifera) extract for silk dyeing. Environ. Sci. Pollut. Control Ser. 2021;29(1):564–572. doi: 10.1007/s11356-021-15669-6. [DOI] [PubMed] [Google Scholar]

- 27.Vuthiganond N., Chitichotpanya P., Nakpathom M., Mongkholrattanasit R. Ecological dyeing of acrylic yarn with colorant derived from natural lac dye. J. Met. Mater. Miner. 2022;32:71–78. doi: 10.55713/jmmm.v32i4.1529. [DOI] [Google Scholar]

- 28.Che J., Yang X. A recent (2009–2021) perspective on sustainable color and textile coloration using natural plant resources. Heliyon. 2022;8 doi: 10.1016/j.heliyon.2022.e10979. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.El-Shishtawy R.M., El-Zawahry M.M., Ahmed N.S.E. One-bath union dyeing of a modified wool/acrylic blend with acid and reactive dyes. Color. Technol. 2011;127(1):28–38. doi: 10.1111/j.1478-4408.2010.00275.x. [DOI] [Google Scholar]

- 30.Elagib T.H.H., Hassan E.A.M., Liu B., Han K., Yu M. Evaluation of composite PAN fibers incorporated with carbon nanotubes and titania and their performance during the microwave-induced pre-oxidation. Carbon Lett. 2020;30:235–245. doi: 10.1007/s42823-019-00092-2. [DOI] [Google Scholar]

- 31.Hossain S., Jalil M.A., Mahmud R.U., Kader A. Natural dyeing of silk and jute fabric with the aqueous extract of coconut leaves – an eco-friendly approach. Pigment Resin Technol. 2023 doi: 10.1108/PRT-10-2022-0125. [DOI] [Google Scholar]

- 32.Santos F.V., Yoshioka S.A., Branciforti M.C. Large-area thin films of silk fibroin prepared by two methods with formic acid as solvent and glycerol as plasticizer. J. Appl. Polym. Sci. 2021;138 doi: 10.1002/app.50759. [DOI] [Google Scholar]

- 33.Ibrahim N.A., El-Gamal A.R., Gouda M., Mahrous F. A new approach for natural dyeing and functional finishing of cotton cellulose. Carbohydr. Polym. 2010;82:1205–1211. doi: 10.1016/j.carbpol.2010.06.054. [DOI] [Google Scholar]

- 34.Cheng T.-H., Yang Z.-Y., Tang R.-C., Zhai A.-D. Functionalization of silk by silver nanoparticles synthesized using the aqueous extract from tea stem waste. J. Mater. Res. Technol. 2020;9:4538–4549. doi: 10.1016/j.jmrt.2020.02.081. [DOI] [Google Scholar]

- 35.Periyasamy A.P. Natural dyeing of cellulose fibers using syzygium cumini fruit extracts and a bio-mordant: a step toward sustainable dyeing. Sustain. Mater. Technol. 2022;33 doi: 10.1016/j.susmat.2022.e00472. [DOI] [Google Scholar]

- 36.Gawish S.M., Helmy H.M., Farouk A.N. Ramadan R., Mashaly H.M. UV protection properties of cotton, wool, silk and nylon fabrics dyed with red onion peel, madder and chamomile extracts. J. Textile Sci. Eng. 2016;6:266. doi: 10.4172/2165-8064.1000266. [DOI] [Google Scholar]

- 37.El-Sayed H., Mowafi S., Basuoni A.S. One-pot multi-functional finishing of wool fabric using reactive nonionic softener. Heliyon. 2022;8 doi: 10.1016/j.heliyon.2022.e10985. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Grifoni D., Bacci L., Zipoli G., Carreras G., Baronti S., Sabatini F. Laboratory and outdoor assessment of UV protection offered by flax and hemp fabrics dyed with natural dyes. Photochem. Photobiol. 2009;85:313–320. doi: 10.1111/j.1751-1097.2008.00439.x. [DOI] [PubMed] [Google Scholar]