Abstract

Wind energy conversion systems (WECS) have gained increasing attention in recent years as promising renewable energy sources. Despite their potential, a clear research gap exists: the majority of WECS underperform in low wind speed conditions, limiting their applicability in many regions. To address this problem, this study proposes a novel approach by developing a 100 W micro wind turbine using Polylactic Acid (PLA) to generate efficient power in low wind speed conditions. The proposed wind turbine design employs Blade Element Momentum Theory (BEMT), which is commonly used for modeling wind turbine performance. Geometric design, mechanical analysis, and aerodynamic analysis are the fundamental considerations for designing any machine. In this work, the CREO 3.0 three-dimensional modeling software is used to create the geometric design of the proposed work. The airfoil SD7080 is selected due to its superior aerodynamic performance, and mechanical properties such as Young's modulus, density, and Poisson's ratio are attained to evaluate the wind blade's performance. Additionally, ANSYS 15.0 is used to conduct a detailed analysis of the proposed wind turbine, evaluating properties such as equivalent stress, deformation, and equivalent strain. Both simulation (ANSYS 15.0) and experimental setups are used to investigate the proposed wind turbine's performance, and the corresponding results are presented and discussed in this manuscript. The results indicate a significant performance improvement of the proposed wind blade when compared to conventional and ABS wind blades, demonstrating its potential as a more efficient solution for WECS. This proposed wind turbine design overcomes the problems like underprformance in low wind speed conditions and the wind turbine efficiency in all regions.

Keywords: Micro wind turbines, Wind blades, Poly lactic acid, Acrylonitrile butadiene styrene, Polylactic acid, Wind energy conversion system

1. Introduction

Energy resources available in nature can be converted and utilized for various useful purposes. The available energy sources on the earth can be classified into two different types conventional energy sources and non-conventional sources. In recent decades, conventional energy resources are almost depleted because of more consumption which increases pollution and fuel cost. The whole world is looking for an alternative to conventional energy resources and renewable energy sources will be the best option for the replacement of it. Many kinds of renewable energy sources are available in nature and it can be extracted from light, heat, wind, water, atoms, and so on. These sources can be converted into electricity with the proper arrangements. One of the renewable energy conversion methods is wind power generation, where the kinetic energy in the wind flow can be converted into electric energy. The power generation from the wind has many constraints like uncertainty, uneven wind flow, and so on [1,2]. In the wind energy conversion system, two important parts are very essential for generating power and they are the wind turbine and wind blade. The modeling and design of these two parts will define the power output. There are many research works carried out in these areas for improving stability, generating capability, adaptability to the environment, and so on. The selection of a wind turbine is mostly depending on the required power output and the selection of a wind blade is to achieve the efficiency of the wind turbine. The wind blade should possess good structural properties and dynamic characteristics. The structural properties of the wind blades depend on the type of built-in material, that should withstand various environmental conditions and should be capable of generating power. Based on the construction the wind turbines are further divided into two categories such as horizontal axis wind turbines (HAWT) and vertical axis wind turbines (VAWT). Based on the operation, it is classified into two types high-speed wind turbines and low-speed wind turbines. Wind blades are an important element in the wind energy conversion system. The rotation of wind blades rotates the wind turbine, which generates power. Wind blades should possess, high lift force, so that they will rotate at low wind speed. Along with this, some more factors like the angle of attack, twist angle, the angle of attack, and chord length define the performance of wind blades [3].

Microturbines are small in size and will be used for low-power applications. The micro wind turbine and its blade should have less cut-in speed and economic feasibility. The cut in speed can be minimized by increasing the number of blades. The effectiveness of wind blades can be enhanced by modifying their structural properties, made-up material, modifying aerodynamic structure, blade coating materials, and infills. There are much research work is carried out in this area on obtaining efficient performance from the wind turbine and wind blades.

There are two faces in wind blades called the suction face and pressure face. The wind blades used in the WECS, experience two kinds of loads tension load on the pressure side, and compression load on the suction side. In addition to that, it also experiences gravitation load, which creates the above two loads (tension & compression) on the blade. Different types of wind blade structures are preferred with respect to the loads that act on them. The tension load and the compression load are different with respect to the size of the wind blade, wind turbine rating, power generation capability, and the place where it is installed. Based on this consideration the designing of wind blades and the material used for the construction differs. Also, some constraints like placements of WECS, and cost were considered. The length and size of the wind blade are increased with respect to the wind turbine size which directly increases the weight of the blade and the gravitational load that acts on it. The term tip clearance is another factor considered to avoid the collision between the wind blade and the wind tower. On considering all these factors, the wind blade should have a low gravitation load, tension load, low compression load, low cost, good structural property, good aerodynamic property, and a long life span [4]. In the early stages of WECS, the components are manufactured by hand layup technology. For the fabrication, glass fiber material layers are created, and these layers and bonded together using adhesive resins and rollers. This method of design and fabrication is efficient under low and medium-sized WECS. For large-sized applications, more fiber contents are used for the fabrication process [5]. The quality of fabrication is enhanced by the use of vacuum fusion and pre-impregnated technology [6]. Later, the resin infusion method is introduced for the effective manufacturing of large wind blades. The fiber is bonded together and the resin is applied for filling the pores and empty spaces. This method improves the quality of wind blades [7]. This method is effective and cheaper than the vacuum fusion methods. For further enhancement of the performance, 3-D woven composites are used [8].

The structure of the wind blades is damaged when it is subjected to structural analysis. The composite materials as well as the adhesive resigns experience damages [9,10]. The lighting phenomenon is another factor that causes damage to wind blades and turbines [11]. Burning, cracks, and separation of layers in blades are some of the effects due to the lightning effect [12]. The wind velocity will affect the aerodynamics of the wind blades and reduces the performance. The uneven distribution of weight over the blade due to wind velocity leads to the failure of WECS. The wind blade should be designed with proper chord length, tip ratio, and even surface for avoiding these kinds of failures [13,14]. As the WECS are placed in open environmental conditions, it experiences ice loading like transmission lines [15]. The effect of ice loading disrupts the aerodynamic property of wind blades and leads to unbalanced load distribution [16].

The material preferred for fabricating the wind blades should have important properties like stiffness, tensile strength compression strength, and fewer pores. Conventional glass and epoxy resin materials have more weight. The glass alone has more weight almost 75 % of the weight of E-glass, S2-glass R-glass, and other glass materials are used with the composite material [17]. The wind stands TM glass fibers are developed with enhanced performance than the above-mentioned glass fibers [18]. The introduction of carbon fiber as the alternative for glasses improves efficiency more [19]. Aramid fibers have more mechanical strength as compared to carbon fibers [20]. Another fiber called basalt has better mechanical strength which is 15 % greater than the carbons [21]. Hybrid composite materials are developed using the combination of glass, fiber, or glass and basalt [22]. The 88.4 m of wind blade is constructed using carbon and glass as hybrid composite materials [23].

Later the usage of commonly available fibers like sisal, jute, and hemp was used. These materials have several advantages low cost, high availability, reduced usage of chemicals, and eco-friendly [24]. Thermoplastics-based wind blades are developed which have higher strength, reasonable cost, and more life span [25]. In recent decades, polymer-based wind blades were fabricated. In comparison to the previous generation materials, polymers have more advantages. The carbon nanotubes based wind blades are fabricated, and their performance was compared with the fiber-reinforced wind blades [26]. From the comparison, the carbon nanotube-based material has a 1500 % greater life span than the fiber-reinforced material. Various studies are carried out by changing the percentage of carbon nanotubes and the corresponding results, advantages, and disadvantages were observed [[27], [28], [29], [30], [31], [32]].

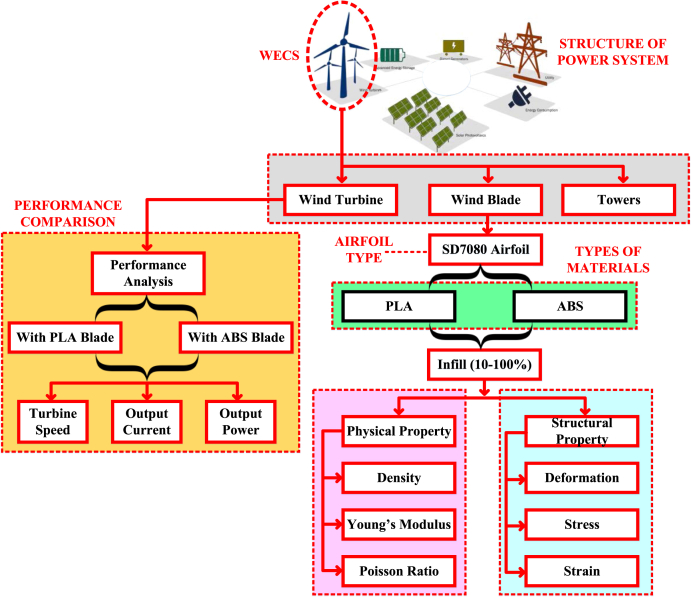

This work aims to investigate the potential of Poly Lactic Acid (PLA) as a material for wind turbine blades in low wind speed conditions, compared to the commonly used Acrylonitrile Butadiene Styrene (ABS) material. The low efficiency of wind energy conversion systems (WECS) in low wind speed conditions is a major challenge to their widespread adoption. Thus, this study seeks to address this issue by exploring a new material for wind turbine blades that can improve the efficiency of WECS. The proposed work models a 100 W wind turbine using both PLA and ABS materials and conducts aerodynamic and structural analysis, as well as performance validation, to compare the effectiveness of the two materials. The results of this study could provide valuable insights into the potential of PLA as a viable alternative material for wind turbine blades, ultimately contributing to the development of more efficient and sustainable WECS. A 100 W wind turbine is modeled with these two kinds of materials and the corresponding aerodynamic analysis, structural analysis, and performance validation is carried out in this work as shown in Fig. 1. This manuscript is organized as follows: Section 2 describes the methodology, Section 3 carries the results of physical properties, Section 4 shows the structural properties of these two materials, Section 5 describes the hardware setup and performance analysis, and based on the results and observations the work concluded in Section 6.

Fig. 1.

Proposed methodology.

2. Modeling of wind blade

When designing wind turbine blades, various parameters are considered, including power output, tip speed ratio, chord length, and twist angle. These parameters are particularly important for micro wind turbines, which have different aerodynamic properties compared to large turbines. The Reynolds number, a measure of the airfoil's performance, is an important consideration for wind turbines and can be calculated using equation (1).

| (1) |

The Reynolds number (Re) is calculated using equation (1), where u represents the wind velocity in meters per second. The Reynolds number is influenced by wind speed and chord length, which are crucial factors for wind turbine performance. A lower Reynolds number leads to a decrease in lift coefficient and an increase in drag coefficient, reducing the efficiency of the wind turbine. The primary goal of the proposed study is to develop a micro wind turbine with an airfoil design that maximizes the drag to lift ratio. The power output of the wind turbine is expressed using equation (2).

| (2) |

The power coefficient (Cp) can be determined using equation (2), where A is the swept area of the rotor. The tip ratio is another crucial factor in wind turbine design and is calculated by dividing the speed of the rotor by the wind speed, as shown in equation (3).

| (3) |

The maximum power coefficient of a wind turbine is influenced by two key factors: chord length and twist angle. The formula for calculating these parameters is shown in equation (4).

| (4) |

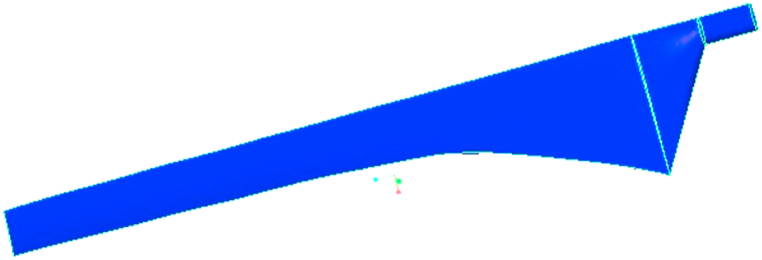

Based on the Blade Element Momentum theory (BEMT) the wind turbine is modeled. The airfoil SD7080 is used for wind blade modeling. There are several advantages like Aerodynamic Efficiency, Low Reynolds Number Performance, Structural Robustness, Versatility of the airfoil SD7080 makes it as an optimum solution for designing the low wind speed applications. Also, this airfoil has several significance like a high lift-to-drag ratio and high lift coefficient over the other airfoils. The significance of this airfoil fulfills the requirements of wind turbines for low wind speed applications. The aerodynamic behavior of the wind turbines has differed with respect to the size. Small-scale wind turbines have considerably different aerodynamic behaviors than large-scale wind turbines. The proposed wind blade is constructed using this selected SD7080 airfoil, and the 3-D modeling of this combination is been designed using CREO 3.0. The specifications of the proposed wind turbine and its power rating is given in Table 1. The proposed wind blade has been modeled in the CREO as shown in Fig. 2. The various steps involved in the designing and analysis of the proposed wind turbine in both CREO and ANSYS are as follows;

Table 1.

Specifications of proposed wind turbine.

| S.No | Parameters | Range |

|---|---|---|

| 1 | Rated Power | 100Wp |

| 2 | Airfoil | SD7080 (9.2 %) |

| 3 | Type of blade | Horizontal |

| 4 | Number of Blades | 5 |

| 5 | Radius | 0.415 m |

| 6 | Root-Chord Length | 0.0802 m |

| 7 | Tip-Chord Length | 0.0280 m |

Fig. 2.

Proposed wind blade model.

CREO Process:

-

•

Start with initialization steps, illustrating the setup of the design environment in CREO 3.0.

-

•

sketching the base geometry of the wind blade with detailing specific dimensions and parameters.

-

•

Application of the SD7080 airfoil profile to the blade design and its integration and refinement.

-

•

Finalization and export processes.

ANSYS Process:

-

•

Importing the CREO model into ANSYS 15.0.

-

•

Initiate meshing process, highlighting the type of elements used, mesh density, and refinements.

-

•

Setting boundary conditions and load application, were explaining how real-world wind conditions were simulated.

-

•

Solution process, detailing solver settings and iterative refinements.

-

•

Execute post-processing steps, explaining extraction and interpretation of results such as equivalent stress, deformation, and strain.

Twist angle and chord length can be obtained based on the wind turbine radius. For better efficiency of the proposed, the turbine should have the optimum twist angle and chord length. The chord length can be defined as the distance between the front and back edges of the wind blade. The twist angle will be reduced with respect to the increase in turbine radius size. The chord length also has been varying with respect to the radius of the wind turbine. The first step in wind turbine modeling is to define its mechanical structure. In this work, the objective is to design a micro wind turbine and wind blade. The wind blade has been modeled with the SD7080 airfoil and the structural properties like turbine radius and chord length are need to fixed. For that, the wind turbine radius with the above specification has been increased from 0.07 m to 0.415 m for analyzing the performance. On the 0.07 m radius, the wind turbine has 30° twist angles and 0.08 m of chord length. When the radius of the turbine increases that reduce the twist angle and chord length. On the 0.12 m radius, the twist angle is reduced to 20° and the chord length reduces to 0.8 m. On the 0.17 m radius, the wind turbine has a 11°-twist angle and 0.04 m of chord length. For 0.22 m–0.42 m, the chord length remains the same at 0.03 m, whereas the twist angle reduces gradually from 7 m to 1 m. The selected wind turbine radius and its corresponding variation of twist angle, and radius vs. chord length are given in Table 2 and it was plotted in Fig. 3.

Table 2.

Wind turbine radius vs. twist angle/chord length.

| S.No | Turbine Radius (M) | Twist Angle (0) | Chord Length (M) |

|---|---|---|---|

| 1 | 0.07 | 30 | 0.08 |

| 2 | 0.09 | 22 | 0.06 |

| 3 | 0.12 | 17 | 0.05 |

| 4 | 0.14 | 13 | 0.05 |

| 5 | 0.17 | 11 | 0.04 |

| 6 | 0.19 | 9 | 0.04 |

| 7 | 0.22 | 7 | 0.03 |

| 8 | 0.24 | 6 | 0.03 |

| 9 | 0.27 | 5 | 0.03 |

| 10 | 0.29 | 4 | 0.03 |

| 11 | 0.32 | 3 | 0.03 |

| 12 | 0.34 | 3 | 0.03 |

| 13 | 0.37 | 2 | 0.03 |

| 14 | 0.39 | 2 | 0.03 |

| 15 | 0.42 | 1 | 0.03 |

Fig. 3.

Selection of wind turbine radius and corresponding chord length, twist angle.

The wind blades on the proposed wind turbine are fabricated using PLA material. The material used in the wind blades is very essential for power generation, life span, stability, and so on. Conventional wind blades are mostly constructed using composite materials in order to achieve stability in extreme weather conditions. Recently, Acrylonitrile Butadiene Styrene (ABS) material-based wind blade is modeled to overcome the limitations of composite material-based wind turbines. It has several advantages as compared to composite materials such as, ease of fabrication, environmental sustainability, cost-effectiveness, consistency of materials, design flexibility, recyclability, thermal stability, combinations of materials. In bad weather conditions, the composite material-based blades may fail to withstand. Also, at low wind speeds, these blades do not rotate due to the low lift force which directly reduces the power generation.

The ABS materials-based construction of blades has overcome these above problems. By comparing the chemical properties, and structural properties the PLA material possesses good characteristics over the ABS materials. The objective is to fabricate an efficient wind blade and turbine for low wind applications with better performance. For that, the PLA material is been used for the construction of the proposed wind blades. The performance characteristics of the proposed wind blade constructed using PLA must have better performance than the composite materials and ABS materials. From the literature, the ABS material has better performance. So, the modeling and structure of the proposed wind blade with the selected SD7080 airfoil are fabricated on both ABS and PLA materials. The 3-D printer is used for the fabrication of these above two wind blades. The CREO software creates the 3-D model of the wind blade that was fed to the 3D printer, which constructs blades using PLA material. Later the ABS material-based blades are constructed by the 3D printer.

The analysis has been carried out as follows; i) physical properties using OptiMatter, ii) structural analysis using ANSYS, iii) creating the experimental setup, and, iv) Performance analysis. Detailed modeling, fabrication, and validation of the wind blade are carried out and the corresponding observations and results were obtained and discussed in this work.

3. Physical properties of wind blades

The physical properties of the proposed wind blades are evaluated based on three properties as young's modulus, density, and, Poisson's ratio. Young's modulus is a parameter used to measure the stiffness of elastic materials. It is defined as the ratio between strain along an axis and strain along that axis. In physics, the density of a substance refers to how much mass or density the substance has in each volume. Poisson's ratio is defined as the ratio of the deflection in directions perpendicular to the direction of stress to the deflection in the direction of stress when a material is subjected to stress in one direction.

The proposed wind blade is modeled and fabricated with two materials. The Optimatter software is been used as the software interface to fabricate and analyze the proposed wind blade model. There are many optimizing options are available in the optimatter software, which provides the possibilities for additional analysis. Wind blades can be constructed by different levels of infills. The 3-D printing software gives the option to select the infill range, and this option is also considered for the physical properties. The concept behind the selection of infill is useful to construct a three-dimensional model with a specific weight, and a specific amount of material to be used. In some cases, the 3-D model requires only the skeleton, whereas in some cases it should be solid, which means the 3-D model should be fabricated without any void. The less amount of infills requires less quantity of fabricated materials. For obtaining a detailed analysis, the infill of the proposed wind blade is tested from 0 % to 100 %.

At zero percentage of infill, it constructs the wind blade as a skeleton without any fill inside the blade. On this condition, wind blades with PLA material and ABS material were having zero young's modulus, zero density, and zero Poisson's ratio. At ten percent of infills, the wind blade with PLA material possesses 0.35 kg/m3 of density, 0.4 N/m2 of young's modulus, and a Poisson ratio of 0.184. Whereas, the wind blade with ABS material possesses 0.3 kg/m3 of density, 0.3 N/m2 of young's modulus, and a Poisson ratio of 0.146. In this scenario, the proposed PLA material has abetter physical properties than the ABS material. At twenty percent of infills, the wind blade with PLA material possesses 0.45 kg/m3 of density, 0.5 N/m2 of young's modulus, and a Poisson ratio of 0.205. Whereas, the wind blade with ABS material possesses 0.39 kg/m3 of density, 0.4 N/m2 of young's modulus, and a Poisson ratio of 0.175. Similarly, the young’ modulus, density, and Poisson's ratio of both ABS and PLA materials were observed up to 100 % of infill. On 50 % of PLA infill, the proposed wind blade has 0.75 kg/m3 of density, 0.9 N/m2 of young's modulus, and Poisson ratio of 0.289 and the ABS infill has 0.56 kg/m3 of density, 0.6 N/m2 of young's modulus and Poisson ratio of 0.175. At a hundred percent of infills, the wind blade with PLA material possesses 1.25 g/m3 of density, 3 N/m2 of young's modulus, and a Poisson ratio of 0.552. Whereas, the wind blade with ABS material possesses 1.08 kg/m3 of density, 1.7 N/m2 of young's modulus, and a Poisson ratio of 0.417. The obtained results of PLA material and ABS material for every 10 % of infills are given in Table 3 and Table 4. For the addition of every ten percent of infill, that increases the density of 0.1 kg/m3. The young's modulus is been raised uniformly 0.1 N/m2 up to forty percent of infill. From 40 to 50 percent increases the value of young's modulus by 0.2 N/m2. From 50 to 90 percent of infill, it increases by 0.3 N/m2. At the final stage of 90 percent to 100 percent of infill, young's modulus is raised by 0.6 N/m2.

Table 3.

Properties of proposed wind blade with PLA material.

| S. No | Infill percentage | Wind blade with PLA Material |

||

|---|---|---|---|---|

| Density |

Young's Modulus |

Poisson Ratio |

||

| kg/m3 | (N/m2) | – | ||

| 1 | 0 | 0 | 0 | 0 |

| 2 | 10 | 0.35 | 0.4 | 0.184 |

| 3 | 20 | 0.45 | 0.5 | 0.205 |

| 4 | 30 | 0.55 | 0.6 | 0.231 |

| 5 | 40 | 0.65 | 0.7 | 0.256 |

| 6 | 50 | 0.75 | 0.9 | 0.289 |

| 7 | 60 | 0.85 | 1.2 | 0.333 |

| 8 | 70 | 0.95 | 1.5 | 0.371 |

| 9 | 80 | 1.05 | 1.9 | 0.424 |

| 10 | 90 | 1.15 | 2.4 | 0.484 |

| 11 | 100 | 1.25 | 3 | 0.552 |

Table 4.

Properties of proposed wind blade with ABS material.

| S. No | Infill percentage | Wind blade with ABS Material |

||

|---|---|---|---|---|

| Density |

Young's Modulus |

Poisson Ratio |

||

| kg/m3 | (N/m2) | – | ||

| 1 | 0 | 0 | 0 | 0 |

| 2 | 10 | 0.3 | 0.3 | 0.146 |

| 3 | 20 | 0.39 | 0.4 | 0.175 |

| 4 | 30 | 0.47 | 0.4 | 0.179 |

| 5 | 40 | 0.56 | 0.5 | 0.216 |

| 6 | 50 | 0.65 | 0.6 | 0.229 |

| 7 | 60 | 0.73 | 0.8 | 0.273 |

| 8 | 70 | 0.82 | 0.9 | 0.3 |

| 9 | 80 | 0.9 | 1.1 | 0.321 |

| 10 | 90 | 0.99 | 1.3 | 0.385 |

| 11 | 100 | 1.08 | 1.7 | 0.417 |

The physical properties of the proposed wind blade fabricated with PLA and ABS materials were compared and plotted as a comparative graph. Fig. 4 shows the density of two blades in different infill ranges. Fig. 5 shows the young's modulus and Fig. 6 shows the Poisson ratio on different infill percentages. On 100 percent of infill, the PLA material has more density as compared with ABS. Young's modulus is an important physical property of any element that defines the behavioral changes to the material when some forces are applied to it. The young's modulus for the wind blade should be high, as it requires to be implemented in external weather conditions. Many forces will act on the material, and it changes its characteristics. The material with a high young's modulus and Poisson ratio will restrict these kinds of behavioral changes under dynamic environmental conditions. On comparing the values of both PLA and ABS materials, the wind blade fabricated with the PLA material has significantly high values than the ABS material. From the analysis ofthe physical properties of wind blades, the proposed wind blade with PLA material has better physical characteristics as compared with the wind blade with ABS materials. The greater performance against the ABS material indicates that, the proposed PLA material wind blade will perform better than the composite materials-based wind blades.

Fig. 4.

Density with respect to infills.

Fig. 5.

Young's modulus with respect to infills.

Fig. 6.

Poisson ration with respect to infills.

4. Structural analysis of wind blades

The structural analysis of the proposed wind blade is obtained based on the infill amount and types of material. This analysis has been carried out by using the ANSYS 15.0 software. The validation has been taken under different wind speeds and different infill amounts. The following properties like deformation, stress,and, strain were taken for the structural analysis. The term deformation can be defined as the rate of change in the shape of the material due to the applied stress. Stress can be defined as the amount of applied force on the blade. The wind flow is one kind of force, and it creates stress on the wind blades that leads to the deformation of blades. For designing an effective wind blade, it is very essential to obtain the characteristics under different environmental factors and different wind speeds.

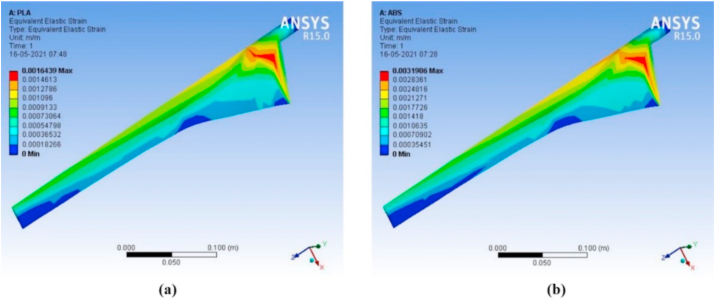

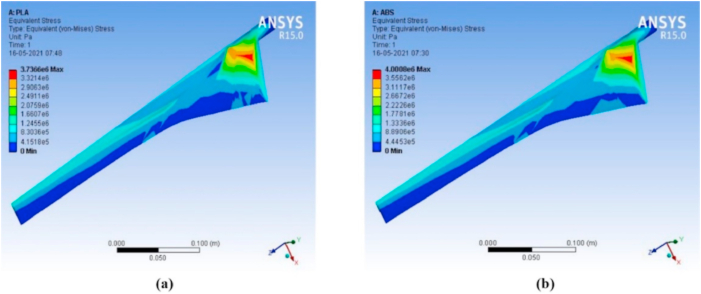

The contour diagram obtained from the ANSYS platform is shown in Fig. 7, Fig. 8, Fig. 9, Fig. 10. Fig. 7 (a) and 7(b) shows the contour of the equivalent strain of PLA and ABS wind blades respectively with an infill of 90 % on 8 m/s wind speed. The wind blade constructed using PLA material experienced maximum stress of 0.00164 m, whereas the wind blade constructed by ABS experienced maximum stress of 0.00379 m. The proposed PLA material-based wind blades have better performance than ABS. Fig. 8(a) and (b) were shown the contour stress experienced by the wind blades under the wind speed of 8 m/s. Fig. 9(a) and (b) shows the contour stress experienced by the wind blades under the wind speeds of 15 m/s. Under 8 m/s of wind speed, the PLA material wind blade experiences 3.73 × 106 Pa of stress, and at 15 m/s of wind speed, it experiences 1.31 × 107 Pa of stress. At the same time, the ABS material has experienced 4.0 × 106 Pa and 1.41 × 107 Pa of stress under 8 m/s and 15 m/s wind speed respectively. The total deformation property of the proposed wind blades is obtained at 15 m/s of wind speed are shown in Fig. 10 (a) and Fig. 10 (b). Both blades are experiencing deformation at the outer edge. PLA material has a deformation rate of 0.0299 m and ABS material has a deformation rate of 0.0629 m. On comparing the strain, stress, and deformation of the proposed blade model with two kinds of build-up material, the blade with PLA has better properties than the ABS material.

Fig. 7.

Equivalent strain contour of (a) blade constructed using PLA (a) blade constructed using ABSon 8 m/s wind speed.

Fig. 8.

Equivalent stress contour of (a) blade constructed using PLA (a) blade constructed using ABSon 8 m/s wind speed.

Fig. 9.

Equivalent stress contour of (a) blade constructed using PLA (a) blade constructed using ABSon 15 m/s wind speed.

Fig. 10.

Total deformation contour of (a) blade constructed using PLA (a) blade constructed using ABSon 15 m/s wind speed.

The numerical values of the wind blade with PLA material and ABS material is given in Table 5 and Table 6.

Table 5.

Structural properties wind blade constructed using PLA material.

| S. No | Wind Speed |

PLA |

||

|---|---|---|---|---|

| Total Deformation |

Stress |

Strain |

||

| (m/s) | mm | Pa | m | |

| 1 | 1 | 0.12679 | 0.038598 | 9.01 × 107 |

| 2 | 2 | 0.50717 | 0.15439 | 3.60 × 108 |

| 3 | 3 | 1.1411 | 0.34738 | 8.10 × 108 |

| 4 | 4 | 2.0287 | 0.61756 | 1.44 × 109 |

| 5 | 5 | 3.1698 | 0.96494 | 2.25 × 109 |

| 6 | 6 | 4.5646 | 1.3895 | 3.24 × 109 |

| 7 | 7 | 6.2129 | 1.8913 | 4.41 × 109 |

| 8 | 8 | 8.1148 | 2.4703 | 5.76 × 109 |

| 9 | 9 | 10.27 | 3.1264 | 7.29 × 109 |

| 10 | 10 | 12.679 | 3.8598 | 9.01 × 109 |

| 11 | 11 | 15.342 | 4.6703 | 1.09 × 1010 |

| 12 | 12 | 18.258 | 5.5581 | 1.30 × 1010 |

| 13 | 13 | 21.428 | 6.523 | 1.52 × 1010 |

| 14 | 14 | 24.852 | 7.5651 | 1.77 × 1010 |

| 15 | 15 | 28.529 | 8.6845 | 2.03 × 1010 |

Table 6.

Structural properties wind blade constructed using ABSmaterial.

| S. No | Wind Speed |

ABS |

||

|---|---|---|---|---|

| Total Deformation |

Stress |

Strain |

||

| (m/s) | mm | Pa | m | |

| 1 | 1 | 0.26585 | 0.071214 | 8.97 × 107 |

| 2 | 2 | 1.0634 | 0.28486 | 3.59 × 108 |

| 3 | 3 | 2.3927 | 0.64092 | 8.08 × 108 |

| 4 | 4 | 4.2536 | 1.1394 | 1.44 × 109 |

| 5 | 5 | 6.6463 | 1.7803 | 2.24 × 109 |

| 6 | 6 | 9.5706 | 2.5637 | 3.23 × 109 |

| 7 | 7 | 13.027 | 3.4895 | 4.40 × 109 |

| 8 | 8 | 17.014 | 4.5577 | 5.74 × 109 |

| 9 | 9 | 21.534 | 5.7683 | 7.27 × 109 |

| 10 | 10 | 26.585 | 7.1214 | 8.97 × 109 |

| 11 | 11 | 32.168 | 8.6169 | 1.09 × 1010 |

| 12 | 12 | 38.282 | 10.255 | 1.29 × 1010 |

| 13 | 13 | 44.929 | 12.035 | 1.52 × 1010 |

| 14 | 14 | 52.107 | 13.958 | 1.76 × 1010 |

| 15 | 15 | 59.816 | 16.023 | 2.02 × 1010 |

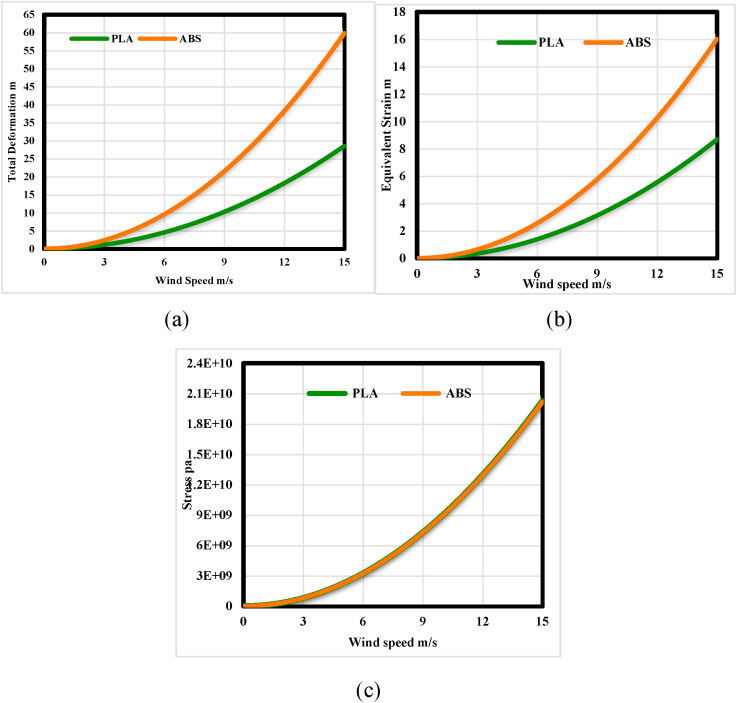

For representing the performance variation between the PLA and ABS material wind blades are compared at the same infill amount of 90 % and 15 m/s of wind speed. The corresponding deformation rate, stress, and strain experienced by the wind blades are compared and plotted as the comparative graph. Fig. 11(a) shows the deformation rate, Fig. 11 (b) shows the stress, and Fig. 11 (c) shows the strain, at the different infill ranges of the PLA material. Similarly, Fig. 12(a) shows the deformation rate, Fig. 12 (b) shows the stress, and Fig. 12 (c) shows the strain, at the different infill ranges of the ABS material. Fig. 13 (a), Fig. 13 (b) and Fig. 13 (c) shows the comparison between the PLA material and ABS material at the infill range of 90 %.

Fig. 11.

Structural properties of PLA material with different infill amount (a) Total Deformation (b) Strain (c) Stress.

Fig. 12.

Structural properties of ABS material with different infill amounts (a) Total Deformation (b) Strain (c) Stress.

Fig. 13.

Structural properties of ABS and PLA material with 90 percent infill (a) Total Deformation (b) Strain (c) Stress.

On this infill range, the PLA material experiences 59.816 mm of deformation and the ABS material experiences 28.529 mm of deformation. Almost the ABS material deformed twice as the PLA material. This clearly states that the PLA material has better stability and lifetime as compared to the ABS material. The manufacturing cost for both ABS and PLA are mostly the same. For the same cost, it is possible to fabricate the most reliable and stable wind blades using the PLA material identified through this detailed modeling and analysis. Along with the physical and structural analysis, the power generation using these blades is also obtained by the experimental setups.

5. Experimental setup

The proposed PLA material-based wind blade has better physical and structural properties. But the purpose of designing a wind blade is to be attached to the wind turbine for generating electric power. For that, the performance of the proposed wind blade has been validated in a real-time setup under different wind speeds. Apart from the physical properties, the wind blade must be efficient to generate rated power when it is used in real-time.

The construction of the experimental setup is shown in Fig. 14. A wind tunnel of 113 cm diameter is used in the laboratory to access and control the wind flow to the wind generator. A 3-φ AC motor with a 5.5Hp centrifugal fan is used as the wind source. This fan can rotate at 1440 rpm and the rotation can be adjusted based on the required wind speed. In this validation, the generated current, generated power output, and turbine speed are measured under 0 m/s to 12 m/s of wind speed. Five wind blades with SD780 airfoil constructed using PLA material are attached to the wind turbine of a 100 W powerpermanent magnet generator. The wind energy conversion system is constructed with five wind-blade wind generators. As shown in Fig. 14, the fan is fixed at one end of the wind tunnel and the wind turbine with proposed wind blades is fixed at another end of the wind tunnel. Also, a controller is interfaced with the fan for generating wind force with the required wind speed. The wind speed in the tunnel is measured by the Lutron AM 4201 digital anemometer. It can measure the wind speed between 0.4 m/s and 30 m/s. A Lutron DT830Ddigital multi-meter is used for measuring the electrical parameters of voltage and current. Across the wind turbine output terminals, two 50 W LED bulbs are connected as load. A normal digital tachometer is used to measure the wind turbine speed, as it is rotated by the blades. These are the major components used in the experimental setup.

Fig. 14.

Experimental setup of Micro wind turbine.

The experimental testing was carried out using the all equipment and the photograph of the experimental testing is shown in Fig. 15. The 3-phase AC motor controls with the wind velocity controller, and based on the wind velocity, the wind blade attached to the wind turbine starts to rotate. The wind blade starts rotating from 3 m/s of wind speed. The corresponding measurements like wind speed, turbine speed, generated current, and power were obtained.

Fig. 15.

Experimental testing of wind turbine.

The normal tachometer is used for measuring the rotor speed. A digital anemometer is been used for measuring the velocity of the wind. The wind velocity controller controls the wind velocity inside the wind tunnel, the operating range is 3–8 m/s. Due to an aeroelastic phenomenon, when the wind speed was raised beyond 13 m/s, the vibration was sensed during the experiment. Therefore, the wind turbine was not evaluated in excess of 12 m/s. The wind turbine blade tip velocity ratio was discovered to rise with increased wind speed between 7 and 8 m/s.

The wind blades start rotating when the fan is started and it rotates the wind turbine. It starts to generate power with respect to the turbine speed. At 2 m/s of wind speed, the turbine rotates at the speed of 264 rpm. At the low wind speed, the proposed wind blade starts to rotate and starts to generate power. The basic requirement of a low wind speed wind conversion system is to construct the blades to access the low wind speed for rotation. The proposed SD7080 airfoil constructed using PLA material accesses a very low wind speed of 2 m/s and it rotates the turbine with the speed of 264 rpm. The corresponding power output is around 10 W with a 2 A current. From this observation, it infers that the proposed wind blade is most useful for low wind speed applications. The turbine speed and the power generation are increased by increasing the wind speed. The wind turbine generates half of the rated power output at the wind speed of 8 m/s whereas the wind turbine rotates at 1116 rpm. At the wind speed of 12 m/s, the turbine achieves the full-rated power output. At this condition, the wind turbine rotates at, 1640 rpm. The entire experimental setup vibrated as the windspeed increased beyond 13 m/s due to the aeroelastic phenomenon. So that the experimental setup is not validated beyond 12 m/s. In this case, at the wind speed of 12 m/s, the wind turbine achieves the rated power generation. For further analysis for varying the wind speed to more than 13 m/s, additional support should be provided to the experimental setup. The obtained results from the experimental setup are plotted as graphs as shown in Fig. 16 where, Fig. 16 (a) shows the turbine speed, Fig. 16 (b) shows the output current and Fig. 16 (c) shows the output power generated under the different widn speeds from 2 m/s to 13 m/s.

Fig. 16.

(a) Wind turbine speed (b) Output Current (c) Output power.

6. Conclusion

In this paper, a new kind of polymer material-based wind blade is proposed with the use of an SD7080 airfoil. The proposed wind blade is modeled using the CREO software, and its structural analysis is carried out using the ANSYS software. The physical properties and structural analysis of the designed wind blade are analyzed on two different polymer materials of PLA and ABS. The ABS has good performance over existing composite materials-based wind blades. From the analysis obtained from the physical and structural analysis of the polymer material wind blades, the PLA performs better than the ABS material. The physical properties of solid materials like young's modulus, density, and Poisson's ratio are taken into the consideration. In structural analysis, the wind blades with different infills from 10 % to 100 % are tested at different wind speeds. The corresponding structural analysis result of deformation, stress, and strain was observed. From the results, the proposed PLA material-based wind blade experiences less stress and strain as compared to ABS. Also, the PLA material has a very less deformation level which is almost half as compared with the ABS material. Apart from the structural analysis, the performance analysis in terms of power generation, turbine speed, and current output is also measured by the proper experimental setup. Ina conclusion, in this, the fabricated PLA material-based wind blade for micro wind turbines is proposed. The properties and performance of these proposed wind blades are validated and analyzed in different platforms and proper hardware setup and the corresponding results were attained. From the results, the proposed wind blade is most suitable for low wind speed applications. The fabricating cost of the PLA material is also very and it can be reused.

Funding

This research received no external funding.

Institutional review board statement

Not applicable.

Informed consent statement

Not applicable.

Data availability statement

No data was used for the research described in the article.

Additional information

No additional information is available for this paper.

CRediT authorship contribution statement

Suresh A: Writing – original draft, Methodology, Investigation, Formal analysis, Data curation. Raja kumar S: Writing – review & editing, Software, Resources, Conceptualization. Belqasem Aljafari: Writing – review & editing, Visualization, Resources, Project administration. Sudhakar Babu Thanikanti: Validation, Resources, Project administration, Funding acquisition.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Contributor Information

Suresh A, Email: sureshkgari@gmail.com.

Raja kumar S, Email: rajkumar1998@yahoo.co.in.

Belqasem Aljafari, Email: bhaljafari@nu.edu.sa.

Sudhakar Babu Thanikanti, Email: sudhakarbabu66@gmail.com.

References

- 1.Zervos A. European Renewable Energy Council; Brussels, Belgium: 2009. Renewable Energy Technology Roadmap 20% by 2020. [Google Scholar]

- 2.European Wind Energy Association . European Wind Energy Association; Bruxelles, Belgium: 2011. EU Energy Policy to 2050; p. 48. [Google Scholar]

- 3.MARE-WINT . In: New Materials and Reliability in Offshore Wind Turbine Technology. Ostachowicz W., McGugan M., Schröder-Hinrichs J.U., Luczak M., editors. Springer; Heodelberg, Germany: 2016. [Google Scholar]

- 4.Mishnaevsky L., Jr., Brøndsted P., Nijssen R.P.L., Lekou D.J., Philippidis T.P. Materials of large windturbine blades: recent results in testing and modelling. Wind Energy. 2012;15:83–97. [Google Scholar]

- 5.Walker, K. Renewable energy embraces graphene: improved wind turbine technology. Available online:http://www.azocleantech.com/article.aspx?ArticleID=455.

- 6.Watson J.C., Serrano J.C. Composite materials for wind blades. Wind Syst. Mag. 2010;46–51 http://www.ppgfiberglass.com/getmedia/0b0f3799-494a-40e8-b67d-b64fc7ee8adc/WindSystems_PPG.pdf.aspx Available online: [Google Scholar]

- 7.Beckwith S.W. Resin infusion technology. SAMPE J. 2007;43:66–70. [Google Scholar]

- 8.Mohamed M.H., Wetzel K.K. 3D woven carbon/glass hybrid spar cap for wind turbine rotor blade. Trans. ASME J. Sol. Energy Eng. 2006;128:562–573. [Google Scholar]

- 9.Debel C. In: Dansk MetallurgiskSelskab (DMS): Lyngby, Denmark. MaterialeopførselogSkadesanalyse, Somers M.A.J., editors. 2004. Identification of damage types in wind turbine blades tested to failure; pp. 123–127. [Google Scholar]

- 10.Sørensen B.F., Jørgensen E., Debel C.P., Jensen F.M., Jensen H.M., Jacobsen T.K., Halling K. Roskilde; Denmark: 2004. ImprovedDesign Of Large Wind Turbine Blade Of Fibre Composites Based On Studies Of Scale Effects (Phase 1) Summary Report; Risoe-R No. 1390-EN; ForskningscenterRisoe; p. 36. [Google Scholar]

- 11.Garolera A.C., Madsen S.F., Nissim M., Myers J.D., Holboell J. Lightning damage to wind turbine bladesfrom wind farms in the US. IEEE Trans. Power Deliv. 2016;31:1043–1049. [Google Scholar]

- 12.Yasuda Y., Yokoyama S., Minowa M., Satoh T. Classification of lightning damage to wind turbine blades. IEEE J. Trans. 2012;7:559–566. [Google Scholar]

- 13.Sareen A., Sapre C.A., Selig M.S. Effects of leading edge erosion on wind turbine blade performance. Wind Energy. 2014;17:1531–1542. [Google Scholar]

- 14.Keegan M.H., Nash D.H., Stack M.M. On erosion issues associated with the leading edge of wind turbineblades. J. Phys. D Appl. Phys. 2013;46 [Google Scholar]

- 15.Cattin R. Icing of wind turbines: vindforsk projects, a survey of the development and research needs. ELFORSK Report. 2012;12:13. http://winterwind.se/2012/wp-content/uploads/2012/08/Icing_of_windturbines_elforsk_report_12_13_draftversion_120127.pdf Available online. [Google Scholar]

- 16.Battisti L. Wind Turbines in Cold Climates, Green Energy and Technology. Springer; Cham, Switzerland: 2015. Relevance of icing for wind turbines. [Google Scholar]

- 17.Mishnaevsky L., Jr., Brøndsted P. Statistical modelling of compression and fatigue damage of unidirectionalfiber reinforced composites. Compos. Sci. Technol. 2009;69:477–484. [Google Scholar]

- 18.Ashwill T.D. Proceedings of the 50th AIAA Structures, Structural Dynamics & Materials Conference,Palm Springs, CA, USA. 2009. Materials and innovations for large blade structures: research opportunities in wind EnergyTechnology. 4–7 May. [Google Scholar]

- 19.Carbon Fiber vs. Fiberglass: A Comparison between the Two Materials Which Material Is Superior?. Available online: https://infogr.am/carbon-fiber-vs-fiberglass.

- 20.Mengal A.N., Karuppanan S., Wahab A.A. Basalt carbon hybrid composite for wind turbine RotorBlades: a short review. Adv. Mater. Res. 2014;970:67–73. [Google Scholar]

- 21.Abashidze S., Marquis F.D., Abashidze G.S. Hybrid fiber and nanopowder reinforced composites for windturbine blades. J. Mater. Res. Technol. 2015;4:60–67. [Google Scholar]

- 22.Ong C.-H., Tsai S.W. Sandia National Laboratories Contractor Report; Sandia NL; Albuquerque, NM, USA: 2000. The Use of Carbon Fibers in Wind Turbine Blade Design: A SERI-8 Blade ExampleSAND2000-0478. [Google Scholar]

- 23.Wind Power Monthly Webpage. Available online: https://www.windpowermonthly.com/article/1419306/turbines-year-rotor-blades.

- 24.Kalagi G., Patil R., Nayak N. Natural fiber reinforced polymer composite materials for wind TurbineBlade applications. Int. J. Sci. Dev. Res. 2016;1:28–37. [Google Scholar]

- 25.Lystrup A., Andersen T.L., Knudsen H., Vestergaard T., Lilleheden L., Vestergaard J. vol. 16. Risø National Laboratory: Roskilde, Denmark; 1998. Hybrid Yarn forThermoplasticFibre Composites; Summary of Technical Results; Final Report for MUP2 Framework ProgramNo. 1994-503/0926-50; Risø-R-1034(EN) 87-550-2366-5. [Google Scholar]

- 26.Yavari F., Rafiee M.A., Rafiee J., Yu Z.-Z., Koratkar N. Dramatic increase in fatigue life in HierarchicalGraphene composites. ACS Appl. Mater. Interfaces. 2010;2:2738–2743. doi: 10.1021/am100728r. [DOI] [PubMed] [Google Scholar]

- 27.Merugula L., Khanna V., Bakshi B.R. Reinforced wind turbine blades—an environmental life CycleEvaluation. Environ. Sci. Technol. 2012;46:9785–9792. doi: 10.1021/es301343p. [DOI] [PubMed] [Google Scholar]

- 28.Kinloch A.J., Taylor A.C., Techapaitoon M., Teo W.S., Sprenger S. From matrix nano- and micro-phasetougheners to composite macro-properties. Philos. Trans. A Math. Phys. Eng. Sci. 2016;374 doi: 10.1098/rsta.2015.0275. [DOI] [PubMed] [Google Scholar]

- 29.Khare K.S., Khare R. Effect of carbon nanotube dispersion on glass transition in cross-linked epoxy-carbonnanotube nanocomposites: role of interfacial interactions. J. Phys. Chem. B. 2013;117:7444–7454. doi: 10.1021/jp401614p. [DOI] [PubMed] [Google Scholar]

- 30.Dai G.M., Mishnaevsky L., Jr. Carbone nanotube reinforced hybrid composites: computational modellingof environmental fatigue and usability for wind blades. Compos. Part B. 2015;78:349–360. [Google Scholar]

- 31.Dai G.M., Mishnaevsky L., Jr. Fatigue of multiscale composites with secondary nanoplatelet reinforcement:3D computational analysis. Compos. Sci. Technol. 2014;91:71–81. [Google Scholar]

- 32.Pontenfisso A., Mishnaevsky L., Jr. Nanomorphology of graphene and CNT reinforced polymer and itseffect on damage: micromechanical numerical study. Compos. B. 2016;96:338–349. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No data was used for the research described in the article.