Graphical abstract

Keywords: Ultrasonic assisted curing, Mechanism, Application, Meat product

Highlights

-

•

The ultrasonic technology progress in meat processing was overviewed.

-

•

Ultrasound reduced nutrient loss, maintain texture and speed meat curation.

-

•

Ultrasound maintain flavor and water during curation of the meat products.

-

•

Ultrasound technology and their applications in meat processing were discussed.

Abstract

Curation meat products involves multiple stages, including pre-curing processing (thawing, cleaning, and cutting), curing itself, and post-curing processing (freezing, and packaging). Ultrasound are nonthermal processing technology widely used in food industry. This technology is preferred because it reduces the damages caused by traditional processing techniques on food, while simultaneously improving the nutritional properties and processing characteristics of food. The utilization of ultrasonic-assisted curing technology has attracted significant attention within the realm of meat product curing, encouraging extensive research efforts. In terms of curing meat products, ultrasonic-assisted curing technology has been widely studied due to its advantages of accelerating the curing speed, reducing nutrient loss, and improving the tenderness of cured meats. Therefore, this article aims to comprehensively review the application and mechanism of ultrasound technology in various stages of meat product curing. Furthermore, it also elaborates the effects of ultrasonic-assisted curing on the tenderness, water retention, and flavor substances of the meat products during the curing process. Besides, the implication of the ultrasound in the processing of meat curation plays a potent role together with other technologies or methods. The use of ultrasound technology in the process of meat curation was analyzed, which might be a theoretical insight for the industrialization prospects of the meat product.

1. Introduction

The use of curation technologies plays an important role in the preservation of the meat products, while also contributing to maintain texture and flavor, which are extremely important for the consumer acceptance. Meat curation commonly uses various traditional curing methods, including dry, wet, brine injection, and mixed curing. The process of the curation often comprises the phenomena of the two-material transfer. The first phenomenon involves the outward migration process of water from the meat, while the second phenomenon entails the penetration and diffusion process of the components of the curing liquid into the interior of the meat [1]. The traditional curing methods are widely used due to their simple operation and low production cost. However, traditional curing methods have several drawbacks, including a lengthy curing time, a slow rate of liquid penetration, and a lack of salt and condiments. Therefore, on the basis of these factors, unpleasant and non-consistent taste, flavor, unstable quality, and other related challenges related to the acceptance of the product [2]. The presences of these challenges drawn the attention of the food scientists to identify new technologies or methods that can stimulate the process of the curation and maintain the quality of the meat-based products.

Advanced techniques including, vacuum curing technology [3], tumbling curing technology [4], and ultra-high pressure curing technology [5], are currently in practice. The Vacuum curing technology can be used by placing the meat and curing liquid together in vacuum-sealed container. During this process the meat absorbed the specific liquid, which reduced the oxidation process, thereby improving the effect of curation [6]. The tumbling often utilized rolling with a large drum by blending meat effectively, thus disperse the curation liquid uniformly on the surface of the meat. In this process, the equipment physically interacts with the meat through collision and rubbing, thus improving the penetration of the liquid by damaging the muscle fibers enhancing the texture and color of the meat [7]. Ultra-high pressure curing technology is a method used to cure meat products and liquids by subjecting them to high pressure within a specialized container. During the curing process of meat products, a moderate pressure of 100–1000 Mpa is applied to accelerate the curing liquid penetration. This not only enhances the tenderness and flavor of meat products but also helps inactivate spoilage microorganisms. This, in turn, helps in extending the shelf life of meat products [8]. Since the current advanced curing technology has made significant improvements in the curing effect and efficiency, it still cannot meet the current requirements of the meat product industry for efficient curing, and these advanced technologies have some problems. Vacuum curing, as an example, is known for its time-consuming process of establishing and maintaining a vacuum environment, resulting in high energy consumption. Similarly, the industrial practice of rolling and kneading curing typically requires a substantial amount of time, which can results in generation of excessive heat and have adverse effects on the quality and shape of meat products [9]. Ultimately, when subjected to intense pressure during the curing process, the protein in meat products experiences oxidation and discoloration. Moreover, it is noteworthy that certain meat products may also undergo undesirable alterations in terms of their taste and flavor [10].

In recent years, ultrasound has emerged as a green and non-destructive processing technology that finds extensive applications in various areas of food processing. These applications include ultrasonic-assisted thawing, ultrasonic-assisted cleaning, ultrasonic-assisted cutting, ultrasonic-assisted freezing. Ultrasonic waves, as a non-thermal processing technology, offer several advantages in food processing. These include shorter processing times, lower temperature conditions, improved taste and nutritional value of food, and the absence of toxic compound formation in food resulting from high temperatures [11], [12]. Currently, there is a growing interest in utilizing ultrasonic technology for the curing of meat products. By altering the structure of muscle fibers and enhancing the permeability of biofilms, ultrasound has the potential to significantly improve the curing process. This technology enables the reduction of curing time, enhances meat product quality, and ensures uniform curing without compromising the overall quality. Moreover, it has been observed that ultrasonic treatment can greatly enhance tenderness, water retention, sodium chloride permeability, and flavor of meat products. To address the limitations associated with individual curing technologies such as vacuum curing, rolling curing, and ultra-high pressure curing, researchers have begun exploring the combination of ultrasonic waves with other technologies to overcome their respective shortcomings [13], [14]. Therefore, this review primarily focuses on summarizing the application of ultrasound technology, including its combination with other technologies, in the curing process of meat products. It covers the utilization of ultrasound during the pre-processing, curing, and post-processing storage stages of meat product curing. Furthermore, this article highlights the influence of ultrasonic-assisted curing on meat quality, offering a solid theoretical foundation for enhancing and refining meat product curing processes in the future.

2. Ultrasonic equipment and the basic principles of its use

2.1. Introduction of ultrasonic equipment in the process of meat products curing

Currently, there is a limited availability of ultrasonic equipment specifically designed for meat processing. As a result, most researchers utilize modified ultrasonic water baths and ultrasonic probe equipment for conducting experiments. Fig. 1 shows the two main types of ultrasonic equipment commonly employed in meat processing for tasks such as cleaning, marinating, and thawing [15]. Ultrasonic water baths and ultrasonic probes are two commonly used pieces of laboratory equipment in the field of ultrasonic technology. They have distinct characteristics and serve different purposes in various applications. Ultrasonic water baths typically consist of a water tank and are designed for various sample handling and experimental operations. An ultrasonic probe connects an ultrasonic generator to a probe, providing higher customization and precision. Probes of varying shapes and sizes can be customized based on various sample properties, such as muscle composition, muscle type, and dimensional characteristics, in order to fulfill specific processing needs [16]. Consequently, ultrasonic probes are often utilized for more intricate and sophisticated experimental operations. These devices combine the generation and propagation principles of ultrasonic technology. Their fundamental structure comprises an ultrasonic generator, transducer, and control system, among other components. The transducer, situated at the operational tip, facilitates the transmission of ultrasonic energy to the food, enabling the execution of various processing operations. The control system is responsible for overseeing and managing the operation of the ultrasonic processing device.

Fig. 1.

There are two main types of ultrasonic equipment used in meat processing. (a) Ultrasonic water bath equipment. (b) Ultrasonic probe.

2.2. Fundamental principles of ultrasonic waves

Ultrasound refers to sound waves with a frequency higher than 20 kHz. Typical ultrasonic equipment, such as ultrasonic cleaning machines, ultrasonic inspection equipment, and ultrasonic cell crushers, employs frequencies ranging from 20 to 100 MHz (Fig. 2) [17]. The utilization of ultrasound in the food field can be divided into two types according to the used sound power (W), sound intensity (W/m2), or sound energy density (W/m3) used or according to the application situation: high frequency and low intensity detection of ultrasound (frequency > 1 MHz, intensity < 1 W/cm2) and low-frequency high-intensity power ultrasound (20–100 kHz, 10–1000 W/cm2) [18]. Among them, high-frequency and low-intensity ultrasonic waves have minimal impact on the physical and chemical properties of food, and can provide information on the physical and chemical properties, structure and composition of food, and are often used in food testing [19], while power ultrasound is extensively used in food processing. The theoretical foundation for processing is often attributed to the three key mechanisms of action of ultrasonic waves, which encompass the cavitation effect, mechanical effect, and thermal effect.

Fig. 2.

Classification of the sound waves.

2.2.1. Cavitation effect

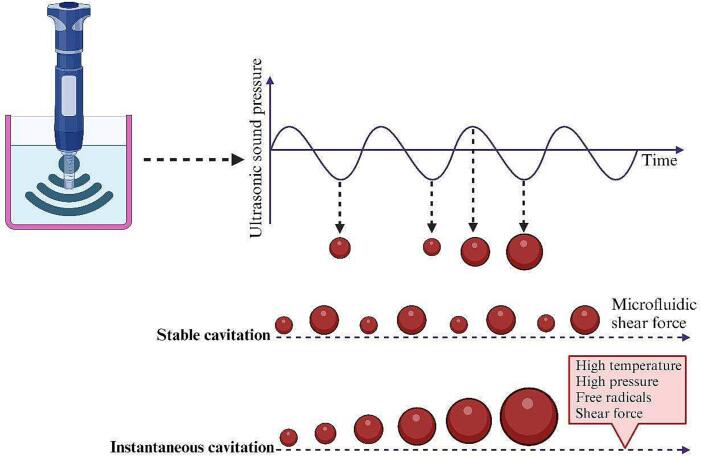

The phenomenon of cavitation induced by ultrasonic waves pertains to the presence of vacuum or tiny bubbles containing a small quantity of gas or steam within the liquid medium. They vibrate and grow under the action of ultrasonic waves. When these bubbles reach a certain size, they will become unstable and violently collapse and rupture, accompanied by high temperatures and high pressure [20]. Ultrasonic cavitation is usually divided into two types: steady-state cavitation and instantaneous cavitation (as shown in Fig. 3). Steady-state cavitation is a continuous phenomenon where the bubble shape remains stable within a liquid. Even in the cases of stable cavitation, the presence of acoustic flow can lead to increased stress around the bubble, potentially resulting in changes to certain biological functions [21]. Instantaneous cavitation is a short-lived and violent phenomenon in which bubbles rapidly expand and collapse in a very short period of time, producing strong shock waves and local temperature increases. The formation and collapse of such bubbles disrupts the cell membranes of biological tissues. In the ultrasonic-assisted curing process of meat products, instantaneous cavitation is usually utilized [22]. The swift formation and subsequent collapse of bubbles due to instantaneous cavitation can significantly improve the transfer and penetration of materials between the curing liquid and meat products. Instantaneous cavitation can release a high amount of energy within a brief timeframe, thereby accelerating the diffusion rate of solute molecules within the curing liquid into the meat products. This acceleration promotes the more uniform penetration of seasonings and nutrients into the internal tissues of the meat products. Additionally, instantaneous cavitation can also destroy the muscle fiber structure in meat products, relax the myofibrillar protein structure, dissolve muscle protein, thereby improving the water retention of meat products [23].

Fig. 3.

Schematic diagram of the ultrasonic cavitation process.

2.2.2. Mechanical effects

Ultrasonic waves exert a significant influence on the pressure within a material as they propagate across it, resulting in substantial pressure fluctuations. It can generate efficient turbulence and movement in the liquid, disrupt the composition of the medium, break down the particles in the liquid, and achieve outcomes that regular low-frequency mechanical agitation cannot do [24]. The strength of the mechanical action of ultrasonic waves is determined by the frequency and intensity of the waves [20]. When ultrasonic waves propagate in liquids, although the displacement amplitude of the particle is very small, the particle acceleration caused by the ultrasound is very large. When an ultrasonic wave with a frequency of 20 kHz and an intensity of 1 W/cm2 propagates in water, the sound pressure amplitude it generated is 173 kPa, which means that the sound pressure amplitude changes between −173 and 173 kPa 20,000 times per second. The maximum particle acceleration reaches 1.44 × 104 m/s2, which is about 1500 times the acceleration of gravity. The ultrasonic effect produced in this case can destroy the original structure of the medium [25]. Concurrently, the mechanical impact of ultrasonic waves can induce the hard connective tissues within meat products to expand and soften throughout the curing process, thus expediting the penetration of marinating liquids into the meat products.

2.2.3. Thermal effect

The thermal effect of ultrasonic waves refers to the phenomenon that as ultrasonic waves propagate through a medium, their energy is continuously absorbed by the medium, causing the temperature of the medium to rise [26]. The absorption of sound energy can result in three types of heating: overall heating within the medium, local heating outside the boundary, and local heating at the wave front caused by cavitation forming a shock wave. Simultaneously, due to the vibration of ultrasonic waves, the medium will generate strong high-frequency vibrations, and the media will generate heat due to mutual friction [27]. Therefore, the thermal effect of ultrasonic waves comes from the heat generated by ultrasonic cavitation and the medium that absorbs the sound energy and converts it to heat [28]. The former causes the medium to generate high temperatures locally, while the latter causes the overall temperature of the medium to increase. During the curing of meat products, this slight temperature increase can enhance the diffusion of solutes in the curing solution and accelerate material exchange [29]. Moreover, the ultrasound thermal effect stimulates the cleaning and thawing process of the meat product prior to curation.

3. Application of ultrasonic-assisted treatment for curing meat products

3.1. Ultrasonic-assisted pretreatment before curing

Ultrasound is a versatile technique that can be used for diverse operations such as thawing, cleaning, and cutting, making it a useful tool for preparing meat prior to curing. Ultrasonic have the abilities to accelerate the thawing process, enhance cleaning efficiency, and facilitate uniform cutting of meat products, making them ideal for preparing meat for curing.

3.1.1. Ultrasonic-assisted thawing of meat products (UAT)

Thawing is an important process before meat products are processed or cured. Thawing is the process of melting the ice crystals of frozen meat products, and the generated water is absorbed by the material and returns to the fresh state of the meat products before freezing [30]. Improper thawing methods will not only lead to the loss of water and nutrients, but also cause the water retention of meat products to deteriorate. For a long time, the most common thawing method in meat product processing is to use heat conduction to achieve thawing of meat products, such as air thawing and water thawing. However, during the traditional thawing process, potential chemical and physical changes as well as microorganisms can cause damage to the texture, color, or flavor of meat products, resulting in not only the loss of meat juice, but also the loss of other nutrients with the juice [31]. In addition, damage to the entire muscle structure during the thawing process leads to a reduction in the sensory quality of frozen meat products and a loss of nutrients [32]. Therefore, it is important to select the appropriate thawing method and conditions. Owing to its “mechanical effect” and “cavitation effect”, ultrasonic waves can enhance heat and mass transfer, substantially reducing thawing time, preserving the quality of frozen food, and exhibited extensive application in the thawing process of frozen food [33]. Recent research shows that compared with meat products thawing in water, ultrasonic-assisted thawing (UAT) can accelerate the thawing process of meat products, achieve rapid thawing under low temperature conditions, and improve the thawing quality of frozen meat. For example, the thawing quality of frozen fish [34], pork [35], beef [36], mutton [37], and chicken [38] has been improved through UAT. UAT preserves the original color and quality of the fish and inhibits lipid oxidation. The muscle structure of the fish is not destroyed. Xu et al. [37] found that UAT improved the water-holding capacity of frozen mutton and increased the color of the mutton, reduced the sulfhydryl content in the mutton and inhibited protein oxidation.

However, most studies usually choose one natural frequency to perform thawing experiments on food, and there are fewer studies on UAT in different frequency modes. Wang et al. [39] used multi-frequency ultrasound to thaw quick-frozen small yellow croaker. By evaluating the physical and chemical quality, water-holding capacity, and microstructure of thawed small yellow croaker under different working modes, they found that the samples thawed at 20/40 kHz combined with dual-frequency sequential ultrasound were better. Wu et al. [36] studied the impacts of UAT in different frequency modes (single frequency, dual frequency, and triple frequency) on the thawing efficiency and food quality of frozen beef. The results showed that the quality of beef treated with single frequency 22 kHz and dual frequency 22/33 kHz UAT was improved, the beef had higher water retention, the microstructure of beef was not destroyed and the muscle fiber distribution was more compact and regular.

In summary, ultrasonic-assisted thawing lays the foundation for further processing of meat products. The application of ultrasonic technology efficiently reduces the thawing time of frozen meat and effectively inhibits microbial growth throughout the thawing process, thereby ultimately enhancing the post-thawing safety of the food. Additionally, ultrasonic-assisted thawing minimizes the loss of moisture in meat products, exerting a positive influence on the diffusion of brining solution during subsequent curing processes. The uniformity achieved in the thawing process through ultrasound assistance contributes to the preservation of the texture and moisture distribution in meat products, consequently elevating the uniformity of the subsequent curing process. Significantly, ultrasonic thawing enhances the microstructural integrity of meat products, resulting in decreased oxidation of meat proteins and lipids This improvement in microstructural integrity also contributes to the production of higher quality meat substrates for the subsequent curing process.

3.1.2. Ultrasonic-assisted cleaning of meat products

It is imperative to thoroughly wash and decontaminate both newly acquired and thawed meat products prior to their subsequent handling and preparation. In the realm of industrial production, the cleansing process for meat products predominantly hinges on the utilization of high-pressure jets of potable water [40]. However, it is important to acknowledge that conventional water spray cleaning techniques are inefficient and result in excessive consumption of water resources. Furthermore, there exists a potential risk of bacterial dissemination, as supported by empirical evidence [41]. Among these methods, spraying with hot water or steam has been found to effectively reduce the number of microorganisms. However, it is important to note that the use of high-temperature water or steam can have a negative impact on the nutritional composition and sensory characteristics of meat [42]. Ultrasonic-assisted cleaning is a method that utilizes mechanical effects, cavitation effects, and thermal effects to effectively remove dirt. When ultrasonic waves propagate through a liquid medium, the high-frequency vibrations cause rapid alternations in the liquid molecules, resulting in the generation of cavitation bubbles. When the sound intensity reaches a certain level, these bubbles collapse rapidly, creating powerful micro-explosions and shock waves that effectively remove surface materials from the cleaning object, achieving thorough cleaning. In addition to its cleaning capabilities, ultrasonic-assisted cleaning can also contribute to the microbial decontamination of meat products [43], [44]. As an example, Lillard and co-workers found that using ultrasonic cleaning on broiler skin was successful in decreasing Salmonella populations. The application of sonication (20 kHz, 15 or 30 min) resulted in a reduction of Salmonella in peptone by around 1–1.5 logs. In addition, authors have shown that the use of ultrasound in conjunction with other purifying and preservation techniques, such as hypochlorite, mild heat, pressure, steam, or organic acids, might boost the antibacterial impact of meat products [45]. In another recent study, Royintarat and his group demonstrated that ultrasonic-assisted plasma-activated water sterilization yields superior sterilizing results. The results show that this method can reduce the number of E. coli and Staphylococcus aureus in chicken with a thickness of 4 mm by 1.5 log (CFU)/g, respectively, and 0.9 log (CFU)/g, effectively achieving the purpose of sterilization. Ultrasonic-assisted cleaning can also be used to treat meat cutting knives to reduce biofilm adhesion [46]. Another study conducted by Brasil et al. [47] investigated the efficacy of utilizing ultrasonic waves in conjunction with chlorinated water and detergent for the purpose of cleaning blades in slaughterhouses. The results showed that ultrasonic cleaning of knives effectively reduced biofilm formation. Additionally, it was observed that the combination of ultrasonic waves with chlorinated water and detergent led to a significant reduction in sticking, while ensuring more uniform cleaning. The more important is the unchanged structure of the knives during the whole of the cleaning.

Several benefits are related to the ultrasonic curation of the meat. Ultrasound helps to remove quickly, the dirt and microbes from the surface of the meat, which significantly clean the meat product before curation, thus protecting the meat products from contamination. Besides, during cleaning process of the meat it also enhance the relaxation of muscle in meat product, thus contributes to the enhancement of the meat quality and its curation. Before proper curation of the meat, it needs to cleaned and cut. To enhance the curing process, it is beneficial to divide the meat products into suitably sized portions, which will increase the surface area in contact with the curing liquid. This step helps to expedite the curing process and enables smoother subsequent processing.

3.1.3. Ultrasonic-assisted cutting of meat products

Cutting is an essential operation in the production of meat products, as it involves dividing the meat into specific sizes and geometric shapes. The process of cutting is integral to the production of meat products and plays a crucial role in shaping the final product [48]. The current mainstream method for cutting meat products is still the traditional cutting approach, which involves direct contact. This method applies substantial force to the target, effectively separating the meat products into desired portions [49]. However, the traditional cutting method is not without its drawbacks, as it is both inefficient and prone to certain issues during the cutting process. The continuous contact between cutting tools and meat products can result in cross-contamination, accelerate the spoilage of the meat products, and generate unnecessary food residues [50]. Furthermore, the excessive force needed not only compromises the quality of the slices and produces excessive amounts of grains and debris, but also leads to musculoskeletal disorders in workers and damage to the cutting devices [51]. Cutting meat products can be challenging due to their sticky texture. Hence, it is crucial to develop efficient and effective new cutting devices to address the challenges faced in food cutting, thereby replacing traditional cutting devices.

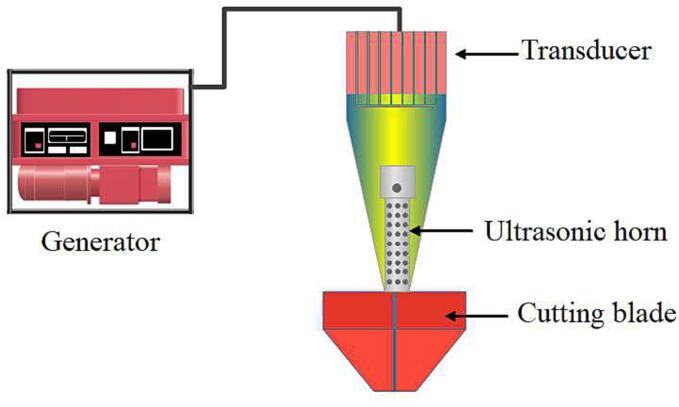

The ultrasonic-assisted cutting device is composed of an ultrasonic generator, an ultrasonic transducer, a horn, and a cutting knife, as depicted in Fig. 4. The transducer converts electrical energy into mechanical vibration, which is then amplified by the horn and transmitted to the blade. The ultrasonic cutting device utilizes an intermittent processing strategy that combines ultrasonic vibrations. This device utilizes wave energy for cutting processes, resulting in minimal cutting force and energy consumption[52]. The ultrasonic-assisted cutting device is designed to cut materials without the need for a sharp edge or excessive pressure. Additionally, it ensures that there is no chipping or damage to the material being cut. For instance, King and colleagues examined the impact of ultrasonic cutting on two segments of horse flesh. They discovered that higher vibration speeds resulted in reduced cutting force, both initially and after the meat products were thawed [53]. Due to the ultrasonic reciprocating vibration of the cutting device, the friction between the blade and the object is minimized, resulting in a reduced likelihood of the object sticking to the blade during cutting. The machine is capable of processing adhesive and resilient meat products, while simultaneously minimizing pollution during the cutting procedure. Inhibit the proliferation of germs on the surfaces of products [54], [55]. Precision and repeatability of cuts reduce losses associated with cuts and better standardize part weight and size. Compared to traditional cutting methods, ultrasonic-assisted cutting has greater self-cleaning capabilities, which can reduce contamination and food safety risks.

Fig. 4.

Schematic diagram of ultrasonic cutting equipment.

Ultrasonic-assisted cutting creates favorable conditions for the subsequent marination of meat products. The high-frequency vibration in ultrasonic-assisted cutting opens the tissue structure of meat products, creating a looser fiber structure, enhancing tenderness and taste, and facilitating improved penetration of the marinade.

3.2. Ultrasonic-assisted curing meat products

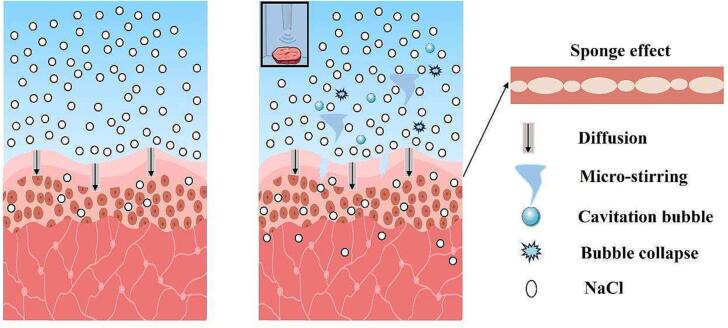

Ultrasound is widely used in meat curing due to its pronounced acoustic cavitation effect, which increases mass transfer efficiency and reduces curing time. Fig. 5 illustrates a schematic diagram of the potential mechanism of ultrasonic-assisted curing of meat products. The mechanical influence of ultrasonic waves expedites mass transfer within the curing liquid, promoting swift and even diffusion of solute molecules from the liquid into the interior of meat products. Furthermore, the hydrodynamic effect of ultrasonic waves generates minute water flows and vortices, which significantly enhance the coverage of the marination liquid on the surface of the meat products. As ultrasonic waves pass through the meat products, their mechanical effects induce subtle alterations in the cell walls, cell membranes, and other meat structures, subsequently enhancing cell permeability. This alteration facilitates improved penetration of the subsequent pickling liquid into the meat products. Simultaneously, the sponge effect exhibits alternating compression and release during the marination of meat products, preserving the smoothness of small channels and pores within the tissue of meat products, thereby enhancing the transmission and flow of liquid [56]. Conversely, the cavitation effect assists in the formation of tiny cracks in the muscle fiber structure, promoting the diffusion and uniform distribution of mass. The improvement through ultrasound is primarily attributed to the creation of micro-jets, micro-channels, effects of acoustic flow, sponge effect, and inertial flow. Briefly, curation through main utilized mechanical, cavitation, sponge, and fluid dynamic effects, that simultaneously effect the meat product and curing liquid, thereby making the curation liquid uniform and stimulate the process of curation and maintain the quality of the meat products.

Fig. 5.

The diagram illustrated the mechanism of meat curation through ultrasound.

3.2.1. Ultrasonic-assisted liquid curing (UALC)

Liquid immersion curing is a common method used to impart specific tastes and flavors to meat products by soaking them in a pre-prepared curing liquid. Nevertheless, certain seasonings or additives might not readily dissolve in the liquid or may exhibit uneven distribution throughout the dissolution process, thereby impacting the consistency and stability of the curing solution [57]. Furthermore, the process of liquid soaking and curing typically entails a significant amount of time for the curing liquid to thoroughly permeate the meat products. Simultaneously, the process of liquid soaking and curing necessitates a substantial quantity of curing liquid, resulting in the squandering of seasonings. Additionally, the characteristics of certain ingredients can also limit the penetration of the curing liquid. In response to these challenges, ultrasonic-assisted liquid curing (UALC) harnesses the mechanical and cavitation effects generated by ultrasonic waves within the liquid. This technique significantly reduces the curing time and enhances the efficiency of the curing process [58]. During the preparation process of the curing liquid, ultrasonic waves play a crucial role in accelerating the dissolution of condiments and additives. This is achieved through the mechanical effect and cavitation effect generated within the liquid. As a result, chemical reactions are promoted, leading to an enhanced flavor and improved quality characteristics of the curing liquid. Additionally, the use of ultrasonic waves improves the uniformity and stability of the curing liquid, thereby positively impacting the overall curing effect on meat products [59]. In a study conducted by Andrey and colleagues, the researchers examined the interaction between ultrasonic salt solution and pork. The findings revealed that the solubility of sodium chloride in the ultrasonic marinade was enhanced [60]. Similarly, Sanches and co-workers discovered that the use of UALC resulted in a more efficient beef curing process, leading to a higher NaCl content in a shorter duration. Additionally, the implementation of UALC allowed for a reduction in the amount of NaCl required in the brine solution. Simultaneously, ultrasound treatment effectively reduces the water activity, temperature and myofibrillar protein denaturation enthalpy of the marinade without negatively affecting the pH value, color and oxidative stability [61]. Another research was conducted to investigate the impact of various ultrasonic frequencies (23.6, 26.8, 32.3, 40, and 55 kHz) on the mass transfer of sodium chloride (NaCl) in pig muscles, as well as the underlying mechanisms involved. Based on the findings, it has been determined that the NaCl content of pork was significantly higher at an ultrasonic frequency of 26.8 kHz compared to static curing, with an increase of 63.8 % [62]. However, Inguglia et al. [63] evaluated the effect of ultrasound on accelerating curing of chicken breast at different frequencies (25, 45 or 130 kHz) and found that at a frequency of 130 kHz, higher NaCl absorption and faster curing were achieved. Therefore, different ultrasound conditions may have different effects on different types of meat products. Table 1 summarizes the optimal ultrasonic conditions used in the curing process of different meat products and outlines the influence on the curing liquid and the quality of meat products.

Table 1.

Study on the influence of ultrasonic-assisted liquid immersion curing on curing solution and curing effect.

| Device type | Meat species | Ultrasonic condition | Effect on curing solution | Effect on meat | Ref. |

|---|---|---|---|---|---|

| Probe | Pork | F = 20 kHz P = 200 W T = 10 min |

Ultrasound improved the solubility of NaCl. | [59] | |

| Probe | Beef |

F = 20 kHz P = 600 W |

Increase the content of NaCl in brine. Ultrasound helps reach a higher NaCl content in a shorter time on beef wet salting. |

Ultrasound assisted curing didn't affect lipid and color stability of salted beef. Salting with ultrasound reduced denaturation temperature and enthalpy of proteins. |

[60] |

| Probe | Beef | F = 20 kHz P = 400 W, 600 W, 1000 W |

Improve the uniformity and stability of brine. | Disruption of beef tissue due to mechanical effects (cavitation) promoted penetration of NaCl from brine to beef. Increase the level of lipid oxidation. |

[63] |

| Probe | Pork loin | F = 20 kHz P = 100 W T = 180 min |

Improve the diffusion rate of NaCl. | Changes of microstructure of pork tissue. Forming pores on the surface of meat fibers. Reduce water binding capacity. |

[64] |

| Probe | Mutton | P = 450 W, 900 W, 1350 W T = 30 min 2 cm above the sample |

Reduce the amount of salt added in brine. | Improve the permeability and curing efficiency of muscle tissue. | [65] |

| Probe | Fish | F = 20.5 kHz P = 100 W, 300 W, 500 W T = 60 min 3 cm above the sample |

Improve the diffusion rate of NaCl. | Improve the transfer rate of NaCl. Reduce the hardness and chewiness of fish. Improve quality characteristics. |

[66] |

| Bath | Rabbit | F = 40 kHz P = 110 W |

The concentration of NaCl in curing solution increased. | Increase the absorption of NaCl in rabbit meat.Reduce soaking time. | [67] |

| Bath | Pork | F = 26.8 kHz Intensity: 0.25 W/cm2 |

Improve the diffusion rate of NaCl. Enhance the migration ability of marinade to pork. |

Accelerate the relaxation of myofibril structure. Improve the mass transfer of pork in the curing process. |

[61] |

| Bath | Chicken | F = 25, 45, 130 kHz P = 4.7 W, 5.5 W, 7.2 W T = 60, 180, 360 min |

Reduce the amount of salt added in brine. |

130 kHz achieved higher sodium absorption. Reduce the time required for marinade to penetrate meat. |

[62] |

| Bath | Pork | F = 20 kHz P = 350 W Intensities: 31.02 W/cm2 |

Improve the uniformity of curing solution. | Accelerate protein oxidation and proteolysis of cured pork. Improve muscle fiber structure. |

[68] |

| Bath | Pork | F = 20 kHz P = 600 W |

Improving the distribution of NaCl in brine. | Shorten curing time. Improve salt gain. Increase the salt diffusion coefficient in meat. |

[69] |

(Note: P: Power; F: Frequency; T: Time).

3.2.2. Ultrasonic-assisted solid curing (UASC)

In the process of solid curing, either dry salt or a mixture of salts (such as NaCl, nitrate, and nitrite) is typically utilized to directly apply or evenly coat the surface of meat products. This process allows the salt to penetrate the meat, resulting in the desired flavor and texture [70], [71]. It is commonly utilized in the process of curing ham, bacon, dried sausages, and air-dried poultry products. However, the process of solid curing typically requires a significant amount of time. The cell membrane's high resistance to mass transfer further contributes to this slow process. As a result, the curing can be uneven, and there is a risk of deterioration in the interior of the meat product [72]. Furthermore, the excessive amount of salt added to the meat products leads to a significant increase in osmotic pressure outside the meat. Consequently, this causes an increase in water seepage, ultimately resulting in higher weight loss for the meat products. Adding a significant amount of salt to meat products results in a substantial increase in their salt content. Researchers are currently exploring various potential applications of UASC (Ultrasonic-assisted solid curing) in the curing of processed meat products. The acceleration of the diffusion and dispersion of marinade ingredients in meat can be achieved by utilizing ultrasound [73]. For instance, Barretto and team employed ultrasound to enhance the distribution of NaCl in dry-cured ham, resulting in a more efficient and uniform curing process. This technique reduced the required amount of NaCl and also led to a noticeable improvement in the color of the dry-cured ham [74]. In addition, Zhou et al. [75] explored the effect of ultrasound on the proteolysis and mouthfeel development of defective dry-cured ham. Ultrasound (1000 W) was found to improve the overall mouthfeel quality of the ham and reduce bitterness. These laboratory-scale experiments demonstrated the feasibility of UASC. In another investigation, McDonnell et al. [76] demonstrated the application of ultrasonic waves in industrial ham curing. Some studies have also shown that ultrasonic treatment can also accelerate lipid oxidation, produce more volatile compounds, and improve the sensory properties of dry-cured meat products [77]. Table 2 outlines the best ultrasonic conditions utilized in the curing process of various meat products, as well as the impact on meat product quality.

Table 2.

Effect of ultrasonic-assisted solid curing on the quality of meat products.

| Meat species | Ultrasonic condition | Effect on meat | Ref. |

|---|---|---|---|

| Bacon | F = 20 kHz P = 250 W, 500 W, 750 W |

Improve the overall flavor characteristic of unsmoked bacon. | [77] |

| Ham | P = 1000 W T = 50℃ |

Improve the overall taste of ham and reduce bitterness. Increase the release of protease in dry-cured ham muscle tissue. |

[74] |

|

Ham |

F = 20 kHz Intensity:54.9 W/cm2 |

Improving the physical and chemical properties of recombinant cooked ham. Reduce the use of sodium. Increase yield and improve color. |

[73] |

| Sausages | F = 25 kHz P = 128 W |

Promote the formation of lipid oxidation derivative compounds during hydrolysis and storage of protein. | [76] |

| Chinese bacon | P = 0, 200 W, 400 W, 600 W | Increase the content of esters in volatile compounds during curing stage of bacon. Enhance the flavor quality of bacon. |

[78] |

| Smoked lamb | F = 26 kHz Intensity:1 W/cm2 |

Improve the sanitary conditions in the curing process of raw meat. Speed up the product yield. Improve the sensory properties of mutton. |

[79] |

(Note: P: Power; F: Frequency; T: Time).

3.2.3. Ultrasonic-assisted monitoring of cured meat products

Different types of meat products may have different requirements for the absorption and permeability of seasoning liquid during the curing process due to differences in tissue structure, moisture content, protein content [80], [81]. Therefore, in order to achieve optimal curing effect, it is necessary to adjust the curing time and the quantity of curing liquid based on the specific characteristics of the meat products to ensure that the meat products obtain the ideal texture, taste, and flavor during the curing process. However, traditional salt content monitoring technology is destructive, time-consuming, and labor-intensive and has failed to achieve the purpose of quality control. Therefore, the meat industry is actively exploring non-destructive technologies to more effectively measure the salt content in the curing process of meat products in real time. The non-invasive nature of ultrasonic technology makes it highly promising for monitoring salt content during the curing process of meat products. Through ultrasonic-assisted monitoring of key indicators during the curing process of meat products, real-time monitoring and control of the curing process can be achieved, which helps optimize the curing process and improve the quality and taste of meat products. As an example, Prados et al. [82] employed ultrasonic technology to predict the salt content in cured pork. They successfully demonstrated the viability of utilizing low-intensity ultrasound for assessing the rise in salt content in cured pork. The study offered a theoretical foundation for the customization of industrial online quality control equipment, leading to enhanced uniformity in the salt content of cured meat. Similarly, in another study, Perez and his group successfully demonstrated the practicality of utilizing ultrasound for real-time monitoring of the ham curing process in industrial production. The utilization of ultrasonic experimental technology in industrial applications, specifically by placing ham slices on ultrasonic transducers and conducting pulse-echo measurements, has the potential to enhance process and product control. Nevertheless, the conventional contact ultrasonic online monitoring technology has certain drawbacks. It necessitates direct contact with the object being measured, which can potentially result in damage or deformation of the object. Additionally, it is susceptible to cross-contamination and fails to meet the specific safety and production line speed requirements of the meat industry [83]. Fariñas et al. [84] used contact and non-contact ultrasonic technology to monitor the physical and chemical changes of steak during the dry curing process and found that the non-contact ultrasonic technology showed performed similarly to the contact ultrasonic technology. Non-contact ultrasonic technology has higher safety, convenience and accuracy in monitoring, which is very beneficial for industrial applications [85]. In addition, Contreras et al. [86] were the first to used ultrasound to detect problems after curing ham. Ultrasound has effectively characterized the issue of dehydration following the curing of ham. It has been determined that ultrasound, a non-destructive technology, is effective in detecting the texture of cured ham as well as changes in salt and moisture levels.

3.3. Ultrasonic-assisted post-processing

With the deepening of research, researchers have found that ultrasound can be utilized not only in one or more stages of meat product pickling pretreatment and pickling to enhance the quality of meat products but also during the storage process of pickled meat products.

3.3.1. Ultrasonic-assisted freezing of meat (cured) products (UAF)

Freezing is a widely used preservation technique for meat products. It effectively inhibits the growth of microorganisms, slows down enzyme activity, and helps preserve the original flavor and nutritional value of the meat products [87]. Cured meat products can also be stored by freezing them. The quality of the food is significantly influenced by the formation, size, and distribution of ice crystals during the freezing process. Smaller ice crystals are beneficial as they do not cause damage to the cell structure or fiber network of the meat products, thereby helping to maintain their texture and taste. Additionally, even distribution of ice crystals ensures a more uniform freezing of the meat products. Conversely, if the distribution of ice crystals is uneven, certain portions of the meat products may be over-cooled while others may not be adequately cooled [88]. Traditional freezing methods, such as blast freezing and low-temperature freezing, have slow freezing speeds and can easily form large and uneven ice crystals in meat products, which can easily lead to tissue damage and uneven cooling of meat products. The advent of ultrasonic technology offers a new way to overcome these problems. As demonstrated in the Fig. 6, ultrasonic technology can effectively control the crystallization of water, reduce the size of ice crystals, and prevent damage to the microstructure of meat products [89]. UAF(Ultrasonic-assisted freezing) uses high-frequency vibration to create localized pressure and temperature changes, accelerate liquid movement within meat products, increase heat and mass transfer, reduce freezing time, and form small and uniform meat products ice crystals [90]. The researchers found that UAF effectively reduced the amount of supercooling required for ice crystal nucleation and accelerated ice crystal formation. Chen et al. [91] compared the diameter of ice crystals formed by UAF with the diameter of ice crystals formed without UAF and found that the diameter of ice crystals formed by UAF was 21.5 % smaller, indicating that ultrasound effectively reduced the size of ice crystals. In addition, UAF promotes the formation of smaller and more uniform ice crystals, improving the microstructure of frozen meat products and enhancing meat product quality. In this regard, Zhang et al. [92] studied the effects of UAF on the freezing efficiency and quality of pork and found that when the ultrasonic power was at 180 W, the freezing time was the shortest, the ice crystal size was the smallest and most uniformly distributed, and the loss of pork after thawing was also the lowest. Similarly, in another investigation, Sun et al. [93] explored the effects of UAF on the primary, secondary, and tertiary structures of carp myofibrillar protein under different ultrasound power levels. It was found that appropriate ultrasonic power (175 W) can better maintain the microstructure, inhibit protein oxidation, reduce ice crystal damage to muscle tissue, and improve the quality of carp.

Fig. 6.

Comparison between ultrasonic-assisted freezing technology and traditional freezing technology.

3.3.2. Ultrasonic-assisted cured meat packaging

The packaging of cured meat products is a crucial aspect of the post-processing of meat products. Effective packaging plays a crucial role in preserving the quality and safety of meat products. It not only enhances the shelf life of these products but also safeguards them against external contamination and oxidation. By employing appropriate packaging techniques, meat products can retain their optimal taste and nutritional value, ensuring a satisfying consumer experience. The packaging materials presently utilized for cured meat consist of plastic film, aluminum foil, and paper packaging materials [94]. However, certain conventional packaging materials, particularly plastic films, possess inexpensive attributes and effective barrier properties. Unfortunately, these materials are not biodegradable, leading to significant environmental concerns globally in terms of both immediate and long-term pollution [95]. Consequently, there is a general trend in the packaging industry towards the development of new packaging materials that are biodegradable or edible biopolymers. This evolution is driven by the need to address the environmental concerns associated with traditional packaging materials [96], [97].

Edible films, employed for safeguarding and packaging food, are usually crafted from natural macromolecules such as proteins, lipids, and polysaccharides, or other substances related to food [98], [99]. Edible films provide several benefits, including safety, convenience, non-toxicity, hygiene, and biodegradability. They are used as carriers for additives and inner packaging, and they provide a promising alternative to plastic packaging with vast development prospects [100], [101]. However, edible films frequently have low mechanical strength, are prone to rupture, and have poor water resistance, needing treatment to improve these features. Ultrasonication is a typical non-thermal processing technique that, among other things, can change the structure of edible film materials, increase solubility, promote gelation, and cause foaming [102]. For instance, Cheng and team adopted ultrasound to process pea protein isolate (PPI) to produce protein-based edible films, which revealed a considerable change in the protein's secondary structure. As a result, the tensile strength of the PPI film increased, contributing to improved durability and robustness in meat product packaging [103]. Similarly, in another research, authors observed greater film transparency after ultrasonic treatment of quinoa protein, improving the visual appeal of meat product packaging. Animal proteins (casein, whey, gelatin, and egg white) outperform plant proteins in terms of adherence and functionality [104]. Rodriguez-Turienzo et al. [105] found that treatment of whey protein-based films at 35 kHz for 15 and 60 min boosted the film's antioxidant properties, delaying lipid oxidation in frozen fish blocks. Qu et al. [106] established an effective sweep-frequency pulse ultrasonic film preparation method. At a scanning frequency of 28 ± 0.5 kHz, a power density of 100 W/L, and a treatment time of 10 min, ultrasonic processing significantly improved the tensile strength and elongation at break of collagen-chitosan (TSC-CTS) composite films, and significantly reduced the water vapor permeability. Additionally, the film exhibited strong antioxidant and antibacterial activity after ultrasonic treatment, which preserved the freshness and quality of meat products. The widespread application of ultrasound in the development of edible film materials has provided a number of excellent packaging materials for meat curing.

Furthermore, it is imperative to acknowledge the significance of the sealing procedure with regard to the package. It ensures the protective function of the packaging and the long life of the packaged goods. In this case, efficient and reliable sealing processes are essential to producing sustainable packaging [107]. The main sealing methods currently used for cured meats include heat sealing technology, vacuum sealing and manual sealing. However, some traditional sealing methods require higher temperatures to complete the sealing process, which will adversely affect the texture, taste and nutritional value of cured meats. Moreover, the traditional sealing processes consume a lot of energy, increasing production costs and environmental impact. Therefore, ultrasonic sealing, as an efficient and environmentally friendly sealing technology and means, provides a more reliable and efficient sealing solution for the meat products industry [108]. The importance of ultrasonic-assisted cured meat packaging lies in improving the accuracy and efficiency of meat packaging process. It not only ensures the firmness and sealing of the packaging but also reduces energy consumption and environmental pollution during the packaging process. In addition, because it does not require the use of external heat sources during the sealing process, it can prevent heat damage to the cured meat. The emergence of this technology not only promotes the technological upgrading of the meat industry, but also provides more sustainable and reliable packaging solutions for the food industry.

4. Ultrasound combined with other technologies

Ultrasonic technology offers numerous advantages compared to existing curing technologies, including non-thermal treatment, fast and efficient processing, and the ability to enhance the functionality of meat products. Furthermore, the utilization of ultrasonic technology, in combination with other technologies, can effectively overcome their inherent limits and facilitate the advancement of more efficient and eco-friendly methods for food processing. A summary of the various meat curing technologies in combination with ultrasound is presented in Table 3.

Table 3.

Application of ultrasonic combined with other technologies in curing meat products.

| Method | Meat species | Advantage | Ref. |

|---|---|---|---|

| Ultrasonic combined with tumbling | Pork | Effectively improve the penetration efficiency of NaCl in meat and improve the texture properties of meat products. | [8] |

| Ultrasonic combined with vacuum |

Beef | Shorten the curing time of beef pieces. Improve salt diffusion in beef. |

[109] |

| Ultrasound combined with supercritical fluid | Ham | Effectively inactivate Escherichia coli and microflora in dry-cured ham. Extend the shelf life of dry-cured ham. |

[111] |

| Ultrasound combined with microbubbles | Pork | Greatly affect mass transfer, NaCl absorption and diffusion and water binding capacity. | [64] |

| Ultrasound combined with high pressure carbon dioxide | Ham |

Combined treatment showed a faster inactivation rate. | [112] |

| Ultrasound combined with peracetic acid | Loin | Improve the efficiency of bacterial inactivation. | [113] |

| Ultrasonic combined with vacuum tumbling | Pork | Induce protein oxidation. Reduced the particle size of myofibrillar proteins. |

[110] |

| Ultrasonic combined with sodium bicarbonate | Reduce cooking loss and shearing force. Improve chicken breast tenderness effectively. |

[24] |

In industrial production, the process of tumbling curing usually requires a longer duration to achieve the expected curing effects. In a study conducted by Li and co-workers, ultrasound was used in combination with tumbling curing. The inclusion of ultrasound greatly improved the absorption of the curing solution, resulting in a reduction in curing time. The implementation of this innovative approach effectively reduced the negative impact of temperature increase on the quality of meat products. As a result, the tenderness and sensory characteristics of chicken breast meat were significantly enhanced [109]. While vacuum curing helps improve curing efficiency, it requires a longer time to create and maintain a vacuum environment, resulting in significant energy consumption. The combination of ultrasonic technology and vacuum curing has been found to effectively reduce energy consumption and enhance the curing efficiency of meat products [110]. Furthermore, the advantages of ultrasonic waves and vacuum tumbling can be combined by integrating both technologies. This combination has the potential to enhance the curing process, leading to more effective results and potentially improving the quality of meat products [111]. During the curing process, supercritical fluid curing in the supercritical state effectively preserves the nutritional components of meat products. However, the limited permeability of supercritical fluid presents challenges in facilitating the penetration of marinades into the interior of meat products, leading to a relatively slow curing rate. By integrating ultrasound technology, the permeation speed of the curing solution is enhanced, effectively addressing the issue of inadequate penetration of marinades during supercritical fluid curing [112]. These combinations offer novel strategies to overcome constraints in conventional curing techniques, offering prospects for increased productivity, greater meat quality, and decreased processing durations in the meat sector.

5. Effect of ultrasonic-assisted curing on the quality of meat products

Ultrasonic waves have been found to have a beneficial impact on cured meat products, as they induce unique physical and chemical effects that ultimately enhance the overall quality of these meat products. In the pre-treatment stage and marinating process of meat products, ultrasonic-assisted curing has been found to have similar effects on various aspects of meat product quality [114]. It notably contributes to enhancing tenderness, improving water holding capacity, and influencing meat color. For example, Ozuna et al. [115] conducted an evaluation on the effects of high-intensity ultrasound and NaCl concentration on the quality and microstructural changes of pork tenderloin. The findings revealed that the application of ultrasonic pretreatment resulted in enhanced tenderness and improved water retention capacity of the cured meats, as substantiated by observations of the microscopic structure. In a concurrent study, Kang and colleagues discovered that the application of ultrasound during the meat products curing process can effectively improve the water-retention capacity and tenderness of beef [116]. Ultrasonics play a significant role in influencing the microbial total count in meat products throughout various stages of the process, including ultrasonic-assisted thawing, cleaning, cutting, curing, and preservation. In the pre-processing stage, the high-frequency ultrasonic vibrations and micro-streams generated exert a mechanical effect on microbial cells, resulting in their death or damage. Ultrasound is utilized in the curing process to enhance the penetration of the curing solution. This facilitates the effective contact between antimicrobial substances present in the curing ingredients and microbes, thereby influencing the distribution and growth of microbe. It is noteworthy that the formation of flavor compounds in meat products occurs primarily during the ultrasonic-assisted curing process. At this stage, ultrasound has significant potential for flavor enhancement, effectively improving the overall flavor characteristics of cured meat [78]. Table 4 summarizes the effects of the different stages of the ultrasonic-assisted curing technology on the quality of the meat products.

Table 4.

Study on the influence of different ultrasonic-assisted curing at different stages on the quality of meat products.

|

Ultrasound parameters (Freq/intensity/time) |

Action stage | Meat type | Tenderness | WHC | Other relevant effects | Ref. |

|---|---|---|---|---|---|---|

| 40 kHz,11 W/cm2,60 min | Pretreatment | Beef | The shear force is significantly reduced. The meat quality is more tender. |

With the increase of WHC, the meat quality is more smooth and juicy. | Increase lipid oxidation | [78] |

| 40 kHz, 1,500 W. Six different times (10, 20, 30, 40, 50 or 60 min) |

During the curing | Beef | Reduce shear force. | Increase the water loss of meat. Reduce WHC. |

Contraction of muscle fibers, destruction of endocardium and reduction of perimuscular thickness. | [117] |

| 45 kHz,2 W/cm2,2 min | Pretreatment | Beef | Change the meat tissue and increase the gap between fibers. | Improve WHC. | [118] | |

| 20 kHz,25 W/cm2,Two different times(20,40 min) | Pretreatment | Beef |

Significantly reduce shear force. Myofibril disintegration. |

Accelerate the activation and autolysis of μ calpain. | [119] | |

| 20 kHz,9 and 54.9 W/cm2,120 min | During the curing | Pork |

Reduce WBSF at intensity of 54.9 W/cm2. | Low effect on mass transfer in pork. Only at 54.9 W mass transfer coefficient was higher than contron. |

[120] | |

| 25 kHz. Nominal power 500 W. 0, 3, 6 and 9 min |

During the curing | Italian salami | Accelerate the oxidation reaction between lipid and protein. Help to maintain total heme pigment. |

[121] | ||

| 15 kHz, 2200 W. Power density was 0.14 W / g. For (0, 0.5, 1, 2, 3, 4 and 6 min) |

During the curing | Pork loin |

Reduce shear force significantly. |

Increases MFI to 15 %, from 44.9 to 54.3 after 4 min. |

[122] | |

| 40 kHz,300 W, (10,20,30,40 min) |

Pretreatment | Chicken |

Improve tenderness. | WHC increases first(10 and 20 min) and then decreases(40 min) with the increase of ultrasonic time. | The gel structure is compact(US 20 min), more protein aggregation and more cavities(US 40 min). | [123] |

| 20 kHz,300 W,50 min | During the curing | Chicken | Reduce shear force significantly. | Improve WHC. Reduce cooking loss. |

Reduce the surface hydrophobicity of protein. | [13] |

| 15.6 W/cm2,5 min | During the curing | Chicken | Reduce shear force significantly. | Induce complex gel network to keep moisture. Higher WHC. |

[124] | |

| 40 kHz,110 W, 12.25 W/cm2 | During the curing | Rabbit | Increases hardness. | Increase weight loss. Reduce WHC. |

Increases L* and produces a reduction of the negative impact of high NaCl concentrations on a*. |

[67] |

| 20.5 kHz, 300 W,60 min | Pretreatment | Fish | Reduce the hardness and chewiness of fish. | Improve WHC. | Significant increase in NaCl transfer rate. Improve protein degradation. |

[66] |

5.1. Tenderness

The tenderness of meat products is a crucial attribute that is affected by the composition, structural organization, and integrity of skeletal muscle. Currently, shear force is widely used as an indicator to assess tenderness, with lower shear force values indicating higher tenderness [126]. In recent years, there has been a considerable amount of research on the use of ultrasound in tenderizing meat products. Relevant studies on the effect of ultrasonic-assisted curing technology on tenderness are summarized in Table 4.

When ultrasound is used during the pre-processing stage, it can significantly disrupt the structural integrity of muscle tissues, thereby affecting the tenderness of the meat. For example, Wang and colleagues discovered that ultrasound had a positive impact on the tenderness of beef during the post-mortem aging process [120]. In a separate study conducted by Shi et al., chicken breast meat that underwent ultrasound pretreatment showed a significant decrease in shear force compared to the control group. This resulted in a notable improvement in meat tenderness [125]. Additionally, Zou et al.[25] demonstrated that the use of 350 W ultrasound combined with sodium bicarbonate solution in an assisted curing technique effectively increased the myofibril fragmentation index (MFI) and reduced the shear force in chicken breast meat, thereby improving tenderness. Furthermore, the application of ultrasound during the curing process also plays a role in improving the tenderness of meat. This is achieved through noticeable changes such as loosening, rupture, and bending of muscle fibers. Some researchers suggest that the ultrasound-induced improvement in meat tenderness, whether during the preprocessing or curing stages, is due to the cavitation effect of ultrasound, which disrupts myofibrillar proteins and connective tissues while damaging lysosomes and allowing lysosomal proteases to exert tenderizing effects. Others suggest that the mechanical action of ultrasound during the curing process, working synergistically with salt, is more conducive to disrupting the structure of myofibrillar proteins, ultimately increasing meat tenderness [124].

It has been reported that, the impact of ultrasonic technology on tenderness is influenced by both the power and frequency of the ultrasonic waves. According to the findings of Lyng and co-workers, it was determined that the application of high-intensity ultrasonic treatment did not yield any favorable effects on the tenderness of steak [127]. Chang et al. [118] found that low-frequency and high-power ultrasound could improve the tenderization effect. Leong et al. [128] found that the shear effect was strongest between 20 and 200 kHz and weakest above 1 MHz. However, McDonnell et al. [76] discovered that the tenderizing impact of low-frequency ultrasonic treatment on beef was restricted to the surface, with no discernible effect on muscle tenderness within the meat. It can be seen that due to differences in factors such as ultrasonic equipment and raw materials, the results of the effects of different ultrasonic frequencies and powers on shear force cannot be unified.

5.2. Water holding capacity (WHC)

The concept of water holding capacity (WHC) pertains to the intrinsic capability of muscular tissues to uphold their initial hydration levels and undergo osmotic processes to acquire additional water when subjected to external influences, such as compressive forces, freezing, thawing. The measurement of WHC in meat serves as a paramount criterion for the assessment of meat product quality [129]. WHC of meat is influenced by various factors, including livestock and poultry species, muscle location, pH levels, and post-mortem time [130]. Relevant research on the effect of UAC on water retention is shown in Table 4.

Recently, many researchers have conducted extensive studies on the WHC of beef products using ultrasound during the curing process. Pena et al. [117] found that ultrasound treated meat exhibited improved tenderness and juiciness. This observation is aligns with the findings of Stadnik et al. [119], who used ultrasound for pretreating beef and observed an improvement in the WHC of the beef. Additionally, Xiong et al. [14] observed a significant reduction in cooking loss of chicken meat when ultrasound was applied during the curing process compared to the traditional curing group. The occurrence of this phenomena can be ascribed to the breakdown of muscle fiber structure caused by cavitation, resulting in the release of salt-soluble myofibrillar proteins that gather on the surface of the flesh. The coagulation hinders the escape of water during the cooking process, thereby diminishing the amount of moisture lost in the meat. Moreover, the curative solution's ability to deeply penetrate enhances the ion intensity within the muscle, hence promoting protein–protein interactions and facilitating the binding of additional free water. These findings indicate that the impact of ultrasound on the WHC of beef products is stronger when used during the curing process rather than the pre-processing stage [131].

In the application research of UAC technology, ultrasonic time is one of the important factors affecting the WHC of meat products. Siró et al. [129] found that the WHC of pork increased with increasing ultrasonic time. However, Li et al. [124] studied the effect of ultrasonic treatment on the functional properties of low-salt chicken breast dough and found that as the ultrasonic time increased, the WHC first increased and then decreased. Pohlman et al. [132] found that ultrasonic time had no significant effect on the cooking loss of beef. Chang et al. [118] found that ultrasonic treatment increased the cooking loss of meat products and decreased the WHC with increasing time. The observed phenomenon could potentially be attributed to protein denaturation or excessive tissue structure degradation in the meat product. These factors can result in a decrease in the water holding capacity (WHC) of the muscle fibers, ultimately leading to higher cooking losses.

5.3. Meat flavor

The degradation of water-soluble and fat-soluble precursors in meat is the primary source of volatile flavor compounds. These precursors, such as amino acids and fatty acids, play a crucial role as pre-flavor substances. The content and type of amino acids and fatty acids, along with the subsequent reactions they undergo, significantly impact the flavor of meat. For instance, free fatty acids resulting from protein hydrolysis can undergo the Maillard reaction with reducing sugars, leading to the production of a variety of aromatic compounds. Fatty acids are the primary source of aldehydes in volatile flavor substances, as they undergo thermal degradation during heating, resulting in the release of aroma. Aroma is generated through chemical reactions involving the decomposition, oxidation, and reduction of pre-flavor substances. Aroma substances encompass aldehydes, alcohols, acids, ketones, as well as nitrogen-containing and sulfur-containing compounds. In the studies of Kang et al. [133] and Wang et al. [120], ultrasonic treatment had a positive effect on the degradation and oxidation of proteins and lipids in beef curing compared to static curing processing. This observation suggests that an increased production of free amino acids leads to a greater generation of aroma compounds. Hence, the utilization of UAC treatment has the potential to enhance pre-flavor substances through the augmentation of free amino acid content and the facilitation of lipid degradation, consequently leading to the improved formation of flavor substances. Numerous studies have demonstrated that the utilization of UAC can enhance the concentration of flavor compounds in meat products. Zou et al. [64] observed that through the application of ultrasound, the volatile flavor compounds in spiced beef, especially aldehydes, ketones, and alcohols, significantly increased, and the concentration of total volatile compounds significantly increased compared with the control group (P < 0.05). Although UAC technology is widely used in the meat industry, it is mainly used to improve the meat quality of pigs, poultry, cattle, and sheep. There are few relevant studies in the field of fish curing technology. In the same line, Bai et al. [67] treated sea bass with ultrasonic waves and found that UAC significantly increased protein degradation, total free amino acid contents, and the relative levels of volatile flavor compounds such as aldehydes and esters. It is evident that UAC technology, when compared to traditional curing methods, has the ability to enhance the content and variety of flavor compounds in meat products, resulting in an improved flavor profile.

6. Summary

Ultrasound is a highly efficient and environmentally friendly technology that has greatly improved numerous processes in the food industry. The utilization of ultrasonic technology in meat product processing represents an innovative approach. This article provides a comprehensive review of the application of ultrasound in various stages of meat product processing, including pre-curing processes such as thawing, cleaning, and cutting, as well as during the curing process itself, and post-curing processes like freezing and packaging UAC technology offers an effective solution to address the challenges associated with time-consuming processes, low efficiency, and significant quality loss during meat product curing. Additionally, it has the ability to prolong the shelf life of cured meat. By appropriately adjusting the steps of UAC, it is possible to improve the tenderness, WHC, and flavor of meat products to different extents. The structure, specifications, and performance parameters of ultrasonic instruments require further study and refinement. When combined with other meat curing techniques, the application of UAC technology yields improved results in terms of the overall quality of the final product. Furthermore, it helps to tackle or overcome the limitations associated with these individual techniques, making it a promising area for future research.

7. Future perspective

In ultrasonic equipment, the ultrasonic probe, being a critical component, is susceptible to damage and cannot operate continuously at high temperatures for extended durations. Therefore, there is a need for the development of high-quality probes capable of prolonged usage. More research is needed on the metal contamination that may be caused by the contact between the medium and the ultrasonic probe. Simultaneously, exploring the effects of ultrasonic treatment on the quality, structure, and nutritional components of food remains an important area for future research. Furthermore, the current research on ultrasonic technology in meat curing is limited in depth and scope, indicating the need for more extensive and comprehensive studies in this field. To enhance the effective utilization of ultrasonic technology, both independently and in combination with other techniques, in meat curing, it is crucial to establish clear research directions for the future of meat curing. Additionally, it is vital to expedite the application of laboratory-proven ultrasonic technology in real-world production settings, facilitating the industrial transformation of scientific research findings and improving efficiency within the food processing industry. It can offer a more comprehensive perspective on the challenges, cost-effectiveness, and scalability of commercial meat processing facilities.

CRediT authorship contribution statement

Biao Li: Writing – review & editing, Writing – original draft, Formal analysis, Conceptualization. Mingming Zhong: Writing – review & editing, Formal analysis. Yufan Sun: Writing – review & editing, Formal analysis. Qiufang Liang: Formal analysis. Lipeng Shen: Formal analysis. Abdul Qayum: Writing – review & editing, Formal analysis. Arif Rashid: Writing – review & editing, Formal analysis. Abdur Rehman: Writing – review & editing, Formal analysis. Haile Ma: Resources. Xiaofeng Ren: Writing – review & editing, Funding acquisition.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

The authors wish to express their appreciation for the support obtained from the Youth Foundation of Jiangsu Provence (BK20220525); General Program of Jiangsu Education Department (22KJB550004); Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Data availability

No data was used for the research described in the article.

References

- 1.Cárcel J.A., Benedito J., Bon J., Mulet A. High intensity ultrasound effects on meat brining. Meat Sci. 2007;76:611–619. doi: 10.1016/j.meatsci.2007.01.022. [DOI] [PubMed] [Google Scholar]

- 2.Li H., Feng J., Shi S., Wang X., Xia X. Evaluation of effects of ultrasound-assisted saucing on the quality of chicken gizzards. Ultrason. Sonochem. 2022;86 doi: 10.1016/j.ultsonch.2022.106038. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.A. Derossi, T.D. Pilli, C. Severini, The Application of Vacuum Impregnation Techniques in Food Industry, Scientific, Health and Social Aspects of the Food Industry, (2012) Ch. 2. 10.5772/31435.

- 4.Kim H.W., Hwang K.E., Song D.H., Kim Y.J., Lim Y.B., Choi J.H., Choi Y.S., Kim H.Y., Kim C.J. Effects of soy sauce on physicochemical and textural properties of tumbled chicken breast. Poult. Sci. 2014;93:680–686. doi: 10.3382/ps.2012-02930. [DOI] [PubMed] [Google Scholar]

- 5.Picon A., Nuñez M. Volatile compounds in high-pressure-treated dry-cured ham: A review. Meat Sci. 2022;184 doi: 10.1016/j.meatsci.2021.108673. [DOI] [PubMed] [Google Scholar]

- 6.Chen X., Luo J., Lou A., Wang Y., Yang D., Shen Q.W. Duck breast muscle proteins, free fatty acids and volatile compounds as affected by curing methods. Food Chem. 2021;338 doi: 10.1016/j.foodchem.2020.128138. [DOI] [PubMed] [Google Scholar]

- 7.Kim S.Y., Song D.H., Ham Y.K., Choi Y.S., Choi J.H., Kim H.W. Efficacy of tumbling in soy sauce marination of pork loins: effects of tumbling time and temperature. J. Food Sci. Technol. 2019;56:5282–5288. doi: 10.1007/s13197-019-03997-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.S. Guillou, M. Lerasle, H. Simonin, M. Federighi, High‐pressure processing of meat and meat products, Emerging technologies in meat processing: Production, processing and technology, (2017) 37-101. doi: 10.1002/9781118350676.ch3.

- 9.Zhang R., Zhang J., Zhou L., Wang L., Zhang W. Influence of ultrasound-assisted tumbling on NaCl transport and the quality of pork. Ultrason. Sonochem. 2021;79 doi: 10.1016/j.ultsonch.2021.105759. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Bak K.H., Bolumar T., Karlsson A.H., Lindahl G., Orlien V. Effect of high pressure treatment on the color of fresh and processed meats: A review. Crit. Rev. Food Sci. Nutr. 2019;59:228–252. doi: 10.1080/10408398.2017.1363712. [DOI] [PubMed] [Google Scholar]

- 11.Barbhuiya R.I., Singha P., Singh S.K. A comprehensive review on impact of non-thermal processing on the structural changes of food components. Food Res. Int. 2021;149 doi: 10.1016/j.foodres.2021.110647. [DOI] [PubMed] [Google Scholar]

- 12.Rehman A., Jafari S.M., Tong Q., Karim A., Mahdi A.A., Iqbal M.W., Aadil R.M., Ali A., Manzoor M.F. Role of peppermint oil in improving the oxidative stability and antioxidant capacity of borage seed oil-loaded nanoemulsions fabricated by modified starch. Int. J. Biol. Macromol. 2020;153:697–707. doi: 10.1016/j.ijbiomac.2020.02.292. [DOI] [PubMed] [Google Scholar]

- 13.Lan W., Zhang B., Zhou D., Xie J. Ultrasound assisted slightly acidic electrolyzed water treatment on the protein structure stability of vacuum-packaged sea bass (Lateolabrax japonicas) during refrigerated storage. J. Food Saf. 2022;42:e13009. [Google Scholar]

- 14.Xiong G., Fu X., Pan D., Qi J., Xu X., Jiang X. Influence of ultrasound-assisted sodium bicarbonate marination on the curing efficiency of chicken breast meat. Ultrason. Sonochem. 2020;60 doi: 10.1016/j.ultsonch.2019.104808. [DOI] [PubMed] [Google Scholar]

- 15.Al-Hilphy A.R., Al-Temimi A.B., Al Rubaiy H.H.M., Anand U., Delgado-Pando G., Lakhssassi N. Ultrasound applications in poultry meat processing: A systematic review. J. Food Sci. 2020;85:1386–1396. doi: 10.1111/1750-3841.15135. [DOI] [PubMed] [Google Scholar]

- 16.Firouz M.S., Sardari H., Chamgordani P.A., Behjati M. Power ultrasound in the meat industry (freezing, cooking and fermentation): Mechanisms, advances and challenges. Ultrason. Sonochem. 2022;86 doi: 10.1016/j.ultsonch.2022.106027. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Awad T.S., Moharram H.A., Shaltout O.E., Asker D., Youssef M.M. Applications of ultrasound in analysis, processing and quality control of food: A review. Food Res. Int. 2012;48:410–427. doi: 10.1016/j.foodres.2012.05.004. [DOI] [Google Scholar]

- 18.Alarcon-Rojo A.D., Janacua H., Rodriguez J.C., Paniwnyk L., Mason T.J. Power ultrasound in meat processing. Meat Sci. 2015;107:86–93. doi: 10.1016/j.meatsci.2015.04.015. [DOI] [PubMed] [Google Scholar]

- 19.Charoux C.M.G., Ojha K.S., O'Donnell C.P., Cardoni A., Tiwari B.K. Applications of airborne ultrasonic technology in the food industry. J. Food Eng. 2017;208:28–36. doi: 10.1016/j.jfoodeng.2017.03.030. [DOI] [Google Scholar]