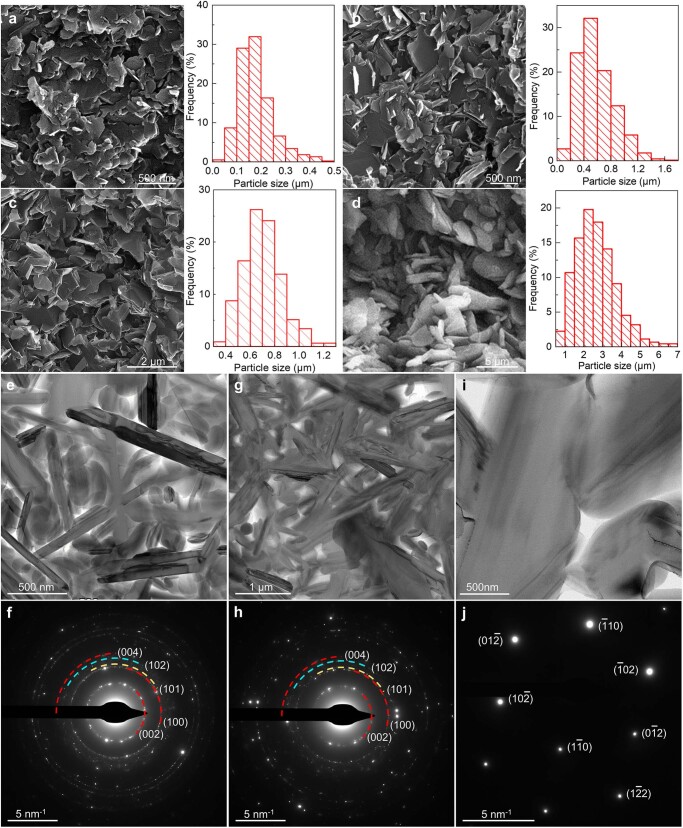

Extended Data Fig. 2. Morphology of fracture surface and microstructure of BN ceramics prepared by SPS sintering oBN under different conditions.

a, 1,600 °C for 5 min. b, 1,600 °C for 10 min. c, 1,700 °C for 10 min. d, 1,800 °C for 10 min. The fracture surfaces were formed by directly breaking bulk ceramics with mechanical pliers. At 1,600 °C, the size of the nanoplates increases with dwelling time, from 5 min to 10 min. For a constant dwelling time of 10 min, the size of the nanoplates increases with temperature from 1,600 °C to 1,700 °C and 1,800 °C. The average lateral sizes of the nanoplates calculated from the corroded surface of the samples are ca. 173 nm, 583 nm, 704 nm, and 2.65 μm, respectively, in a through d. The STEM images and SAED patterns of the ceramics sintered at e, f 1,600 °C for 10 min, g, h 1,700 °C for 10 min, and i, j 1,800 °C for 10 min. With the increase of sintering temperature or time, the size of plates in ceramics increased from nanometer to micrometer. In f and h, the diffraction rings corresponding to different crystal planes of hBN were marked. There were additional new diffraction halos and dispersive diffraction spots between the (100) and (004) diffraction rings. In j, an ordinary hBN single crystal diffraction pattern taken from [221] zone axis was identified in the ceramic from a high sintering temperature of 1,800 °C.