Abstract

Near misses are referred to in literature as precursors of occupational accidents. These events, and their relationships with occupational accidents in various economic sectors have been the subject of research in several countries around the world. In Poland, there has not been a lot of research with regards to near misses in the construction industry, and the published materials are of a very general nature. This article aims to fill the existing research gap regarding the relationship between near misses and occupational accidents in the Polish construction industry. The aim of the research presented in the article was to identify the qualitative and quantitative structure of hazardous events in the construction industry, and to estimate the a posteriori probability of the occurrence of such events. The research was carried out on the basis of information obtained from the hazardous event registration system from a large Polish enterprise that carried out construction works in Poland in the years 2015–2022. Identified dangerous events in the construction industry were divided into two generic groups, i.e. occupational accidents and near misses. Within each group, eight categories of hazardous events were identified, and subcategories were defined within each category. The power of each set and subset of events was then calculated. The posterior probability of the occurrence of events classified into individual sets was estimated using Bayes' theorem. Cross-validation of the obtained results was performed. Conclusions resulting from the conducted analyzes were formulated. The most common category of the analyzed dangerous events in the construction industry is "being hit by objects"; "being run over/falling over" and "work environment". Knowledge of the most common causes of near misses will allow actions that aim to reduce the number of occupational accidents to be determined.

Keywords: Construction industry, Occupational accidents, Near misses, Occupational safety, Safety management

1. Introduction

Many scientific articles emphasize that the construction industry is very dangerous. Despite many preventive actions in the area of occupational safety in the construction industry, dangerous events still occur. In order to reduce their number, the causes of events, as well as their sources, should be investigated, and the results of these analyzes should be implemented into engineering practice [[1], [2], [3]].

Researchers dealing with the issues of occupational safety emphasize the importance of research concerning so-called near misses, classifying them as pre-accident events. There are studies supporting the thesis that a significant proportion of accidents in the construction industry can be prevented through better safety management, which is based on information taken from near misses, and stored in the information systems of enterprises [[3], [4], [5]]. In sectors such as civil aviation, the chemical industry, medicine, rail transport or nuclear power generation, near miss reporting systems have been in use for a long time [6]. Jones et al. proved that with an increase in identified near misses, the accident rate in the chemical industry decreases [7,8]. It should therefore be assumed that in the construction industry the introduction of such measures on a large scale will also indicate the directions of corrective actions, and in turn reduce the number of occupational accidents. In Poland, the number of accidents in the construction industry is very high, but there has not been a lot of research conducted within the area of near misses. The published materials concerning this subject are of a very general and theoretical nature. At this point, it should also be noted that only a small number of construction companies in Poland registers near misses. Such registration is not obligatory and not restricted by labor law provisions. Such an obligation applies to enterprises that have an implemented safety management system. The topic of near misses in the Polish construction industry and its various aspects constitute an extensive research gap, the filling of which will complement knowledge that can be useful when managing occupational safety. Due to the perceived potential of using information about near misses to improve occupational safety in the Polish construction industry, it was decided to undertake research within this area. This research aims to define the relationship between near misses and occupational accidents in the Polish construction industry, and involves the following:

-

•

identification of the qualitative and quantitative structure of near misses in the Polish construction industry,

-

•

identification of the probability of the occurrence of identified near misses and the formulation of conclusions resulting from the conducted research.

The research was carried out on the basis of data obtained from the system for registering dangerous events from a large Polish enterprise that carried out construction works in Poland in the years 2015–2020. The authors are not aware of any other research carried out in Polish construction enterprises regarding the structure of near misses, which take into account various causes of these events and their frequency. The presented results constitute a small part of the analysis that was undertaken within research entitled "Modeling the impact of near misses on occupational accidents in the construction industry (SAFCON)".

2. Literature review

All the events that cause disturbances in the production system, and which may cause material losses, injury to employees, and also their death, are called dangerous events. In turn, dangerous events can be classified as near misses and occupational accidents. The sources of dangerous events are: dangerous working conditions and the dangerous behavior of employees. Unsafe working conditions are caused by e.g. poor organization of the workplace and work process, faulty machines, damaged tools, or deformed scaffoldings. Dangerous behaviors include: disregarding occupational health and safety rules, ignorance and non-compliance with safety regulations and rules, a lack of training, ineffective supervision, recklessness, haste, routine, or the disobeying of security measures [9]. Heinrich, who is a pioneer in the study of industrial accidents, claims that an accident is a sequence of several factors that create a domino effect [10]. The work environment is the first element of the domino, and then it is a man, a threat, an accident and an injury. According to Heinrich's research [10] for every serious or fatal accident, there are 29 minor accidents and 300 non-injury accidents (the ratio of accidents to near misses is 1:10). According to Bird's research [11], for every accident resulting in a serious injury, there are 10 accidents resulting in a minor injury, 30 accidents resulting in property damage, and 600 non-injury incidents (in this case, the ratio of accidents to near misses is 1:15).

A near miss, according to PN-N-18001:2004 [12], is also called a non-traumatic accident. Occupational Health and Safety (OSHA) defines a near miss as a dangerous work-related event in which an employee could have been injured if the circumstances had been different [13]. In turn, a sudden event caused by an external cause, which resulted in injury or death and occurred in connection with work, is called an occupational accident [14].

An effective way to prevent accidents is to identify near misses and their causes [1]. A near miss is defined as a type of accident precursor [5,15]. The authors of paper [16] showed a close relationship between near misses and occupational accidents, and found that these events often have common causes. Knowledge concerning near misses has a major impact on occupational safety education, and also sets directions for achieving zero accidents [17]. Due to the complexity and variability of a construction site, near misses in the construction industry can be of a different nature [17].

The process of managing these events is serially dependent [18]. In the first three stages, it consists of disclosing knowledge about near misses, and involves detection, reporting and identification. The next five steps deal with the management and use of knowledge regarding near misses, and includes prioritization, cause and effect analysis, the adoption of a solution, dissemination, and evaluation in conjunction with project characterization [2]. Duan et al. [17] defined the main directions of future development necessary to minimize accidents. These are: improving the method of collecting data on near misses; improving the event analysis model, while taking into account their characteristics; establishing an event analysis framework; and building a highly integrative event management platform [17]. The factors that make the reporting of near misses difficult include: fear of disciplinary action, and the fact that it is time-consuming [17]. Therefore, it is important to disseminate knowledge about the potential of near miss analysis [16]. However, it is equally important to act quickly when eliminating threats. Such activities may be supported by innovative Information and Communication Technologies (ICT) tools, thanks to which the management of data concerning dangerous events (including the process of event assessment) may be accelerated [16]. Encouraging the reporting of near misses is a major challenge for construction organizations [19]. Near miss registration systems are mandatory in construction companies that have a safety management system in place. According to Raviv et al. [20], who investigated hazardous events involving tower cranes, there is a gap in the methodology of the technical examination of the content of reported near misses.

Marks et al. [21] implemented a near miss reporting program, and indicated that data concerning near misses can be reported, collected and analyzed by construction personnel. In turn, Wu et al. [22] stated that the real-time tracking of a construction site is an effective means of stopping and preventing near misses. Stressors directly related to construction work, which cause injuries or near misses, include: job requirements, seniority, job supervision, training, the safety climate, the use of skills, responsibility for the safety of others, and hours of exposure to hazards [23]. Zhou et al. on the basis of data concerning hazardous events, which were obtained during the construction of a subway in the city of Wuhan, China, characterized the time series of near misses using complex network theory [24]. Simulations of cause and effect relationships allowed for the capturing of a compromise between working hours and the number of the notifications of near misses [25]. High performance in detecting falling objects, and in the classification of the causes of near misses, was achieved using real-time construction site monitoring [1].

This short review of literature shows how important information about near misses is with regards to the prevention of accidents. There has been a lot of publications concerning the dissemination of knowledge, real-time event analysis, and research that focuses on the specific cause of events, e.g. falling objects [1] or working on scaffolding [26]. These studies only cover a small area concerning knowledge about near misses. Therefore, research was undertaken to define the structure of both near misses and occupational accidents in the Polish construction industry, as well as to determine the relationships between the individual elements of the defined structures. The acquired knowledge will help to precisely indicate the directions of educational and preventive activities.

3. Research methodology

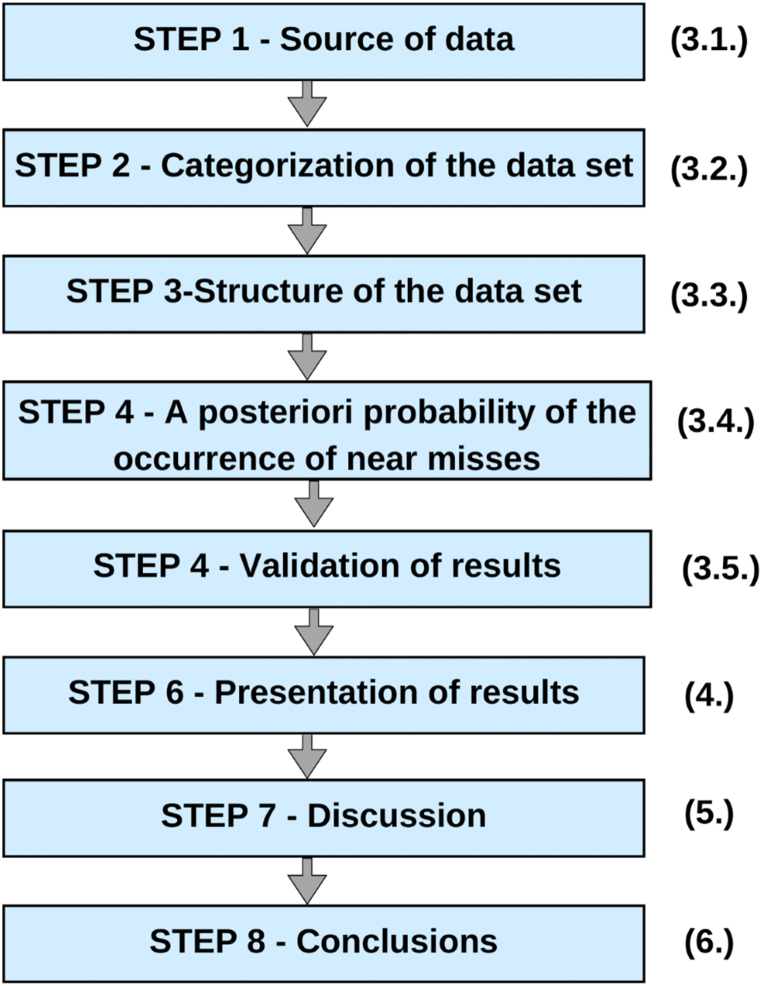

The research was conducted on the basis of data regarding occupational accidents and near misses registered in a large construction company in the years 2015–2020. The company carried out construction works throughout the whole of Poland. The research methodology is presented in Fig. 1.

Fig. 1.

Scheme of the methodology adopted in the research.

3.1. Source of data

The data concerning the occupational accidents and near misses was obtained from the company's existing system for registering dangerous events. A database was also created, a fragment of which is presented in Table 1.

Table 1.

Fragment of the database regarding near misses and occupational accidents.

| Data of event | Place of event | Area/Region | Brief description of event | Qualification | Category of event | Direct cause |

|---|---|---|---|---|---|---|

| 18.12.2017 | Radomin | Northern Region (KI) | As a result of bad weather conditions, the driver lost control of the vehicle and went off the road. | Accident resulting in sick leave | Being run over\Hit | Collision |

| 09.01.2018 | Construction of S8 | Central Region (KI) | On the DD1 section of the road, a passenger car heading towards Białystok hit the mini guard system. | Near miss | Being run over\Hit | Collision |

| 10.01.2018 | Construction of the junction transfer station at the main railway station in Olsztyn | Northern Region (KI) | The excavator operator, while moving around the construction site with a raised excavator arm, damaged and broke a trams’ electric traction that was not under voltage. | Near miss | Electricity | Damage to electrical installations |

| 10.01.2018 | ICT Kostrzyn nad Odrą | Western Region (KO) | An employee fell into a tank from a height of approximately 7 m while securing technological openings | Accident resulting in sick leave | Falling of a person | Falling of a person from a height (over 1 m) |

The size of the set was 2,197 dangerous events, including 621 occupational accidents and 1,576 near misses. The set of all the hazardous events (SHE) is therefore the sum of the set of accidents (SA) and the set of near misses (SNM):

| (1) |

where: - set of all events.

3.2. Categorization of the data set

The set of all the hazardous events (SHE) is the sum of the set of accidents (SA) and the set of near misses (SNM):

| (2) |

where:

- set of all events.

Eight categories of dangerous events were distinguished:

- being hit by objects,

SHE2-being run over by a vehicle/being hit by a vehicle,

- human environment,

- fall of a person

SHE5-electricity,

- fire/explosion/finding of unexploded munition,

- collapse/burial/being trapped,

- contact with moving machine parts.Within each category, several subcategories are listed.

The set of occupational accidents is the sum of elements .

The set of near misses is the sum of elements (.

where:

I – the number of categories of occupational accidents, the number of categories of near misses.

J – the number of subcategories of occupational accidents, the number of subcategories of near misses.

K – the number of items in set SAj

L – the number of items in set NMj

Fig. 2 shows a schematic diagram of the structure of the set of dangerous events (SHE).

Fig. 2.

Scheme of classifying a set of dangerous events.

3.3. Structure of the data set

Table 2 shows the categories of accidents (Ai) and near misses (NMi), and also their subcategories.

Table 2.

Classification of occupational accidents and near misses.

| Category Ai, NMi; i = 1, ….I | Subcategory Ai,j,NMi,j; i = 1, ….I; j = 1, …,J | |

|---|---|---|

| A1, NM1 | Being hit by objects | A1,1, NM1,1 Being hit by a falling object/material; |

| A1,2, NM1,2 Being hit by an object in motion; | ||

| A1,3, NM1,3 Being crushed/hit by transported items; | ||

| A1,4, NM1,4 Being hit by a stationary object; | ||

| A2, NM2 | Being run over by a vehicle/hit by a vehicle | A2,1, NM2,1 Collision; |

| A2,2, NM2,2 Being run over by a machine/vehicle; | ||

| A2,3, NM2,3 Being hit by a machine/vehicle; | ||

| A2,4, NM2,4 Hitting an object with a construction vehicle/machine; | ||

| A3, NM3 | Working environment | A3,1, NM3,1 Contact with sharp/rough objects; |

| A3,2, NM3,2 Excessive physical exertion; | ||

| A3,3, NM3,3 Irritaion of the eyes; | ||

| A3,4, NM3,4 Collapse/fainting; | ||

| A3,5, NM3,5 Contact with a hazardous/chemical substance; | ||

| A3,6, NM3,6 Burning; | ||

| A3,7, NM3,7 Internal cause; | ||

| A3,8, NM3,8 Manifestation of aggression from people or animals; | ||

| A3,9, NM3,9 Hardware failure/damage; | ||

| A3,10, NM3,10 Epilepsy; | ||

| A3,11, NM3,11 Excessive noise, pressure; | ||

| A3,12, NM3,12 Myocardial infarction; | ||

| A3,13, NM3,13 Dissociation; | ||

| A4, NM4 | Fall of a person | A4,1, NM4,1 Falling, tripping, or slipping on the same level; |

| A4,2, NM4,2 Fall of a person from a height; | ||

| A4,3, NM4,3 Falling of a person to a lower level, e.g. into an excavation, depression, channel, etc. | ||

| A5, NM5 | Electricity | A5,1, NM5,1 Breakage/failure of an underground power line; |

| A5,2, NM5,2 Damage to other installations; | ||

| A5,3, NM5,3 Breakage/failure of an overhead power line; | ||

| A5,4, NM5,4 Damage to an insulation/casing pipe; | ||

| A5,5, NM5,5 Ground fault; | ||

| A5,6, NM5,6 Contact with an underground power line; | ||

| A5,7, NM5,7 Electric shock, contact with electricity/electric discharge, electric arc burn; | ||

| A5,8, NM5,8 Contact with an overhead power line; | ||

| A5,9, NM5,9 Cable damage; | ||

| A6, NM6 | Fire/Explosion/Finding unexploded munition | A6,1, NM6,1 Finding unexploded munition; |

| A6,2, NM6,2 Damage to a gas pipeline; | ||

| A6,3, NM6,3 Fire/explosion; | ||

| A6,4, NM6,4 Incandescense/glowing; | ||

| A6,5, NM6,5 Damage to a casing pipe/steam trap failure; | ||

| A7, NM7 | Collapse/Being covered/Being trapped | A7,1, NM7,1 Being hit/crushed by a falling material factor (collapsing formwork, collapsed structure, stored material, etc.); |

| A7,2, NM7,2 Overturning of machines and vehicles; | ||

| A7,3, NM7,3 Subsidence of walls of excavations/embankments; | ||

| A8, NM8 | Contact with moving machine parts | A8,1, NM8,1 Contact with a moving element of machines, devices, power tools; |

| A8,2, NM8,2 Being hit by a machine, device, or power tool during operation; | ||

| A8,3, NM8,3 Getting caught by the moving parts of machines, devices, power tools; | ||

3.4. A posteriori probability of the occurrence of near misses

The probability a posteriori of the occurrence of a given category and subcategory of events was calculated based on the size of individual sets (power of sets). The probability of an occupational accident (Ai) or near miss (NMi) under the condition of the occurrence of a dangerous event (SHE) was calculated from the following formula:

where:

– the size of the SA set,

– the size of the SHE set: the sum of the number of occupational accidents and the number of near misses.

The SA set is the sum of the SAi:i = 1, …,I subsets, the SNM set is the sum of the SNMi.:i = 1, …,I subsets.

3.5. Validation of results

Cross-validation of the obtained test results was performed. Data regarding each category of events was divided into 6 folds, each of which contained the results from the 12 months of the following year. Five randomly selected folds constituted the training set, while the sixth fold constituted the testing set. It was examined whether the probability distributions of the occurrence of an accident or a near miss in individual categories in the teaching and testing folds were comparable. Six cross comparisons were performed. The compatibility of the distributions was checked using the Kolmogorov Smirnov test. The null hypothesis (H0) of this test assumes that two samples have the same distribution. The testing fold was then added to the training sets, and one of the training folds was the testing fold. The p-value for the Kolmogorov Smirnov test, which was determined on the basis of the test statistics, was compared with the significance level α:

-

•

if p ≤ α ⇒ H0 is rejected while H1 is adopted – this means that two samples have the same distribution,

-

•

if p > α ⇒ there are no grounds to reject hypothesis H0 – this means that the distributions of the two samples differ.

4. Results

The dangerous events were classified into two generic groups, namely: occupational accidents and near misses. The following categories were distinguished in each group: (NM1), (NM2), (NM3) (NM4), (NM5), (NM6), (NM7), (NM8), (A1), (A2), (A3) (A4), (A5), (A6), (A7), (A8). Within each category, subcategories (Ai.j) and (NMi.j) were also listed. There are 2.54 near misses for every single occupational accident. Table 3 summarizes the numerical values of probabilities for listed near misses and occupational accidents. In order to refer to the results of research by other researchers, the percentage share of individual categories and subcategories in a given group of dangerous events, i.e. near misses and occupational accidents, is also given.

Table 3.

List of categories and subcategories of near misses and occupational accidents.

| No. | Category and subcategory of events | Number of |

Percentage share of each category and subcategory in the group of |

Probability of the occurrence of |

|||

|---|---|---|---|---|---|---|---|

| near misses | occupational accidents | near misses | occupational accidents | near misses | occupational accidents | ||

| 1. | Being hit by objects | 447 | 188 | 28,36 | 30,27 | 0,203 | 0,086 |

| 1.1. | Being hit by a falling object/material | 218 | 46 | 13,83 | 7,41 | 0,099 | 0,021 |

| 1.2. | Being hit by an object in motion | 96 | 68 | 6,09 | 10,95 | 0,044 | 0,031 |

| 1.3. | Being crushed/hit by transported items | 115 | 45 | 7,30 | 7,25 | 0,052 | 0,020 |

| 1.4. | Being hit by a stationary object | 18 | 29 | 1,14 | 4,67 | 0,008 | 0,013 |

| 2. | Being run over by a vehicle/hit by a vehicle | 330 | 34 | 20,94 | 5,48 | 0,150 | 0,015 |

| 2.1. | Collision | 182 | 12 | 11,55 | 1,93 | 0,083 | 0,005 |

| 2.2. | Being run over by a machine/vehicle | 90 | 12 | 5,71 | 1,93 | 0,041 | 0,005 |

| 2.3. | Being hit by a machine/vehicle | 46 | 9 | 2,92 | 1,45 | 0,021 | 0,004 |

| 2.4. | Hitting an object with a construction vehicle/machine | 12 | 1 | 0,76 | 0,16 | 0,005 | 0,000 |

| 3. | Working environment | 138 | 167 | 8,76 | 26,89 | 0,063 | 0,076 |

| 3.1. | Contact with sharp/rough objects | 54 | 116 | 3,43 | 18,68 | 0,025 | 0,053 |

| 3.2. | Excessive physical exertion | 12 | 19 | 0,76 | 3,06 | 0,005 | 0,009 |

| 3.3. | Irritaion of the eyes | 19 | 8 | 1,21 | 1,29 | 0,009 | 0,004 |

| 3.4. | Collapse/fainting | 6 | 6 | 0,38 | 0,97 | 0,003 | 0,003 |

| 3.5. | Contact with a hazardous/chemical substance | 9 | 2 | 0,57 | 0,32 | 0,004 | 0,001 |

| 3.6. | Burning | 6 | 5 | 0,38 | 0,81 | 0,003 | 0,002 |

| 3.7. | Internal cause | 6 | 4 | 0,38 | 0,64 | 0,003 | 0,002 |

| 3.8. | Manifestation of aggression from people or animals | 8 | 2 | 0,51 | 0,32 | 0,004 | 0,001 |

| 3.9. | Hardware failure/damage | 9 | 0 | 0,57 | 0,00 | 0,004 | 0,000 |

| 3.10. | Epilepsy | 4 | 2 | 0,25 | 0,32 | 0,002 | 0,001 |

| 3.11. | Excessive noise, pressure | 4 | 1 | 0,25 | 0,16 | 0,002 | 0,000 |

| 3.12. | Myocardial infarction | 1 | 1 | 0,06 | 0,16 | 0,000 | 0,000 |

| 3.13. | Dissociation | 0 | 1 | 0,00 | 0,16 | 0,000 | 0,000 |

| 4 | Fall of a person | 97 | 160 | 6,15 | 25,76 | 0,044 | 0,073 |

| 4.1. | Falling, tripping, or slipping on the same level | 64 | 105 | 4,06 | 16,91 | 0,029 | 0,048 |

| 4.2. | Fall of a person from a height | 18 | 28 | 1,14 | 4,51 | 0,008 | 0,013 |

| 4.3. | Falling of a person to a lower level, e.g. into an excavation, depression, channel, etc. | 15 | 27 | 0,95 | 4,35 | 0,007 | 0,012 |

| 5 | Electricity | 242 | 3 | 15,36 | 0,48 | 0,110 | 0,001 |

| 5.1. | Breakage/failure of an underground power line | 72 | 0 | 4,57 | 0,00 | 0,033 | 0,000 |

| 5.2. | Damage to other installations | 42 | 0 | 2,66 | 0,00 | 0,019 | 0,000 |

| 5.3. | Breakage/failure of an overhead power line | 30 | 0 | 1,90 | 0,00 | 0,014 | 0,000 |

| 5.4. | Damage to an insulation/casing pipe | 24 | 0 | 1,52 | 0,00 | 0,011 | 0,000 |

| 5.5. | Ground fault | 23 | 0 | 1,46 | 0,00 | 0,010 | 0,000 |

| 5.6. | Contact with an underground power line | 19 | 0 | 1,21 | 0,00 | 0,009 | 0,000 |

| 5.7. | Electric shock, contact with electricity/electric discharge, electric arc burn | 10 | 3 | 0,63 | 0,48 | 0,005 | 0,001 |

| 5.8. | Contact with an overhead power line | 11 | 0 | 0,70 | 0,00 | 0,005 | 0,000 |

| 5.9. | Cable damage | 11 | 0 | 0,70 | 0,00 | 0,005 | 0,000 |

| 6 | Fire/Explosion/Finding unexploded munition | 183 | 1 | 11,61 | 0,16 | 0,083 | 0,000 |

| 6.1. | Finding unexploded munition | 59 | 0 | 3,74 | 0,00 | 0,027 | 0,000 |

| 6.2. | Damage to a gas pipeline | 56 | 0 | 3,55 | 0,00 | 0,025 | 0,000 |

| 6.3. | Fire/explosion | 40 | 1 | 2,54 | 0,16 | 0,018 | 0,000 |

| 6.4. | Incandescense/glowing | 20 | 0 | 1,27 | 0,00 | 0,009 | 0,000 |

| 6.5. | Damage to a casing pipe/steam trap failure | 8 | 0 | 0,51 | 0,00 | 0,004 | 0,000 |

| 7 | Collapse/Being covered/Being trapped | 101 | 14 | 6,41 | 2,25 | 0,046 | 0,006 |

| 7.1. | Being hit/crushed by a falling material factor (collapsing formwork, collapsed structure, stored material, etc.) | 49 | 6 | 3,11 | 0,97 | 0,022 | 0,003 |

| 7.2. | Overturning of machines and vehicles | 37 | 3 | 2,35 | 0,48 | 0,017 | 0,001 |

| 7.3. | Subsidence of walls of excavations/embankments | 15 | 5 | 0,95 | 0,81 | 0,007 | 0,002 |

| 8 | Contact with moving machine parts | 38 | 54 | 2,41 | 8,70 | 0,017 | 0,025 |

| 8.1. | Contact with a moving element of machines, devices, power tools | 16 | 30 | 1,02 | 4,83 | 0,007 | 0,014 |

| 8.2. | Being hit by a machine, device, or power tool during operation | 13 | 17 | 0,82 | 2,74 | 0,006 | 0,008 |

| 8.3. | Getting caught by the moving parts of machines, devices, power tools | 9 | 7 | 0,57 | 1,13 | 0,004 | 0,003 |

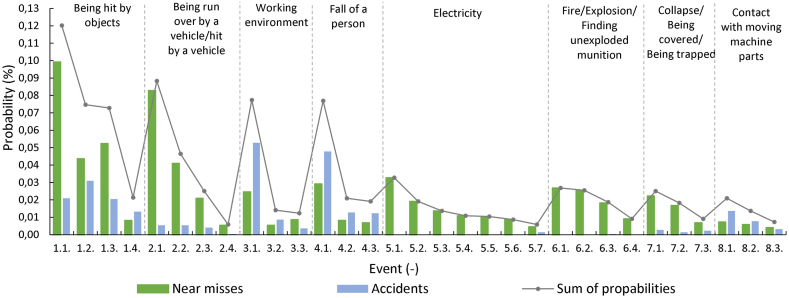

Fig. 3 presents a graph that shows the structure of the set of dangerous events (SHE) and the numerical values of the probabilities of the occurrence of individual categories of near misses (NMi) and occupational accidents (Ai), as well as their subcategories: Ai,j, NMi,j.

Fig. 3.

Scheme of the categorization of near misses NMi and occupational accidents Ai, and also their subcategories Ai,j, NMi,j and the probabilities of their occurrence.

Most dangerous events were related with the “fall of materials/objects” (SHE1). There are four sub-categories in this category. The most numerous of the subcategories is “being hit by a falling object/material” (SHE1,1). The second most numerous subcategory, in terms of the number of dangerous events, is “being run over by a vehicle/hit by a vehicle” (SHE2). In this category, collisions in the man-machine, machine-machine and machine-object systems were the most common. In the SHE1 and SHE2 categories, the number of near misses is greater than the number of accidents. In the SHE3 “work environment” category, as many as 13 subcategories were distinguished. In the SHE3 category and SHE4 “human fall” category, the relationship between the number of near misses and occupational accidents is the opposite to that in the previously mentioned SHE1 and SHE2 categories. This means that more accidents than near misses were recorded. In the “electricity” (SHE5), “fire/explosion/finding of unexploded munition” (SHE6) and “collapse/burial/being trapped” (SHE7) categories, a very large number of near misses, and a small number of occupational accidents, were recorded. In turn, in the category of “contact with moving parts of machines” (SHE8), the fewest near misses were recorded. There are even fewer of them than there are occupational accidents in the same category.

Fig. 4 shows a graph of the probability of the occurrence of a near miss and occupational accident in individual subcategories. The graph does not include information regarding such subcategories for which the sum of event probabilities is less than, or equal to, 0.005. These were considered to be isolated and difficult to analyze incidents.

Fig. 4.

Graph of the probability of occurrence of a dangerous event in specific subcategories.

The highest probability of the occurrence of a near miss is in the “being hit by a falling object/material” (NM1.1) and “collision” (NM2.1) subcategories. The highest probability of an accident was recorded for the “contact with sharp, rough objects” (A3.1) and “falling, tripping, slipping on the same level” (A4.1) subcategories.

In most of the analyzed articles concerning dangerous events, occupational accidents in a given category are analyzed as a percentage with regards to all the accidents. Fig. 5a presents the percentage share of near misses and Fig. 5b presents the percentage of occupational accidents that were registered in particular categories.

Fig. 5.

Percentage share of: a) near misses, and b) occupational accidents, which were registered in particular categories.

The most numerous categories are NM1 and A1, which contain 28.36% of all the near misses and 30.27% of the occupational accidents. The percentage distribution of near misses in other categories differs significantly. The highest percentage of accidents can be seen for the “being hit by objects” (A1), “work environment” (A3), and “human fall” (A4) categories. These categories, due to their incidence rate, can be considered to be one of the most dangerous. In the case of near misses, the highest percentages were recorded in the “being hit by objects” (NM1), ”being run over by a vehicle/hit by a vehicle” (NM2), “electricity” (NM5) and “fire/explosion/finding of unexploded munition” (NM6) categories. The largest percentage differences in the distribution of near misses and accidents were observed for the “fall of a person” category, and it amounted to as much as 19.61%. Table 4 shows the results of the Kolmogorov Smirnov test for each category of events.

Table 4.

Validation results of the probability of the occurrence of a hazardous event.

| No. | Category | Near miss |

Accident |

|---|---|---|---|

| p | p | ||

| Category 1 | Being hit by objects | 0,322 | 0,396 |

| Category 2 | Being run over by a vehicle/hit by a vehicle | 0,122 | 0,203 |

| Category 3 | Working environment | 0,143 | 0,189 |

| Category 4 | Fall of a person | 0,436 | 0,514 |

| Category 5 | Electricity | 0,120 | 0,174 |

| Category 6 | Fire/Explosion/Finding unexploded munition | 0,124 | 0,155 |

| Category 7 | Collapse/Being covered/Being trapped | 0,231 | 0,245 |

| Category 8 | Contact with moving machine parts | 0,092 | 0,116 |

In each category of occupational accidents and near misses, the calculated expected value from six samples (the Kolmogorov Smirnov statistics) is greater than the significance level α, and therefore the probability distributions for the teaching and testing folds are statistically comparable. The results of the conducted cross-validation showed that the model does not overfit, as evidenced by comparable statistics for the two distributions. Moreover, the distributions are consistent, and the trend only results from the difference in frequencies, and not the probability distribution.

5. Discussion

The research conducted by the authors of this article, covering the years 2015–2021, shows that there are 2.54 near misses for each occupational accident. These proportions are different in particular years, and have a downward trend. When compared to the research by Heinrich and Bird, the number of near misses per accident is much lower. The authors of the article point out a possible reason for the downward trend in this phenomenon, namely: the enthusiasm for reporting such incidents has waned among employees, and not all incidents were reported. This may be influenced by the following factors mentioned in paper [17]: the reporting of incidents is often associated with a fear of disciplinary action, and it is also time-consuming. Identification systems of hazardous events can have flaws. Moreover, these events are reported by different employees, which can also introduce an element of uncertainty and subjectivity. Moreover, according to the authors, there is one more factor that significantly reduces the number of dangerous events in large Polish construction companies. This factor involves a significant increase in the level of safety culture, which is related to the implementation of safety management systems.

The literature concerning the subject contains a lot of information about occupational accidents in the construction industry. The structure of accidents, their causes, the factors that generate them, and also other aspects were analyzed. The results of these studies, in many cases, are consistent with the results obtained in the presented article. Much less information can be found on near misses.

Being hit by objects/materials (A1, NM1) is a major hazard on construction sites. The source of injury to a worker may be hits by falling objects, hits by moving objects, hitting a stationary object, or the falling of transported materials. In the conducted research, such events accounted for 28.36% of all the examined near misses. Falling objects (NM1.1) accounted for 13.83% of near misses and for 7.41% of the accidents from the A1.1 subcategory. According to research conducted by Drozd [27], being hit by falling material factors (A1.1) was a hazard that caused 11.5% of construction accidents in the Polish Malopolska region in 2015. In turn, the results presented by Weiwei Wu et al. [22] are definitely different from the results of our research. According to Weiwei Wu, from the accident record statistics of the US Department of Occupational Health and Safety Administration from 1995 to 2008, accidents caused by being hit (A1) accounted for 14.94% of all the accidents. Within this category, 42.42% applied to the subcategory of being hit by a falling object/material (A1.1) [22]. As can be seen, the obtained statistical data varies significantly. The reason for this is probably due to different methodologies for collecting information about dangerous events, which are used in individual studies, as well as different working conditions, and the knowledge and experience of employees. However, the problem of employees being hit by falling objects is serious, because this is the cause of accidents that is most often indicated by researchers in various countries. Weiwei Wu [28] after conducting research regarding the proactive prevention of accidents that are caused by falling objects (A1.1) on construction sites, found that 66% of accidents in this category are avoidable. He proposed the implementation of a wireless network system, the Radio Frequency Identification (RFID) technique, and the Wireless Sensor Network (WSN) to track accidents based on real-time information. These activities were meant to act as proactive prevention.

The number of accidents in the falls category presented by Wu et al. [22] is 49.05%, which is 23.29 % higher than the research conducted in the article. In turn, the “falling, tripping, or slipping on the same level” (A4.1) subcategory includes the largest number of events in category A4. According to Drozd [27], falls at the same level and from a height are the most common direct causes of injury to an employee. Event A4.1 accounted for 21.5% of all the studied accidents [27]. Similar conclusions were drawn in the research of Szóstak et al. [27], who examined accidents involving construction scaffolding. Over 77% of accidents on construction scaffolding were caused by a slip, trip or fall of an employee, and only 20% of accidents were related to damage to scaffolding elements [27]. Moreover, in the report of the "Agreement for Safety in Construction" Association [29] (bringing together 16 large construction companies in Poland (2019)), which was based on the database of accidents from the years 2009 and 2019, the largest number of registered accidents were accidents from this category. In 2019, the share of accidents in this category, when compared to the total number, was 43%, while in 2009 it was as high as 61%. In the research conducted by the authors, the number of near misses in the NM4.1 subcategory was only equal to 4.06%. A greater percentage of this subcategory were accidents (A4.1), which amounted to 16.91%.

The highest probability of an occupational accident was found for subcategories A3.1 and A4.1. Subcategory A3.1 includes contact with sharp or rough objects that can easily cause injuries in the form of cuts. These are usually common, but light injuries. In turn, subcategory A4.1 includes events related to a fall on the same level, i.e., tripping over elements protruding from the floor, such as nails.

In the electricity category (A5), only 3 accidents were recorded, while the number of near misses is more than 80 times higher. In eight sub-categories of near misses in the electricity category, no accidents were recorded. According to the authors of paper [30], in the category of electric shocks, the difference between an accident and a near miss is mainly due to the amount of released energy. In the analyzed incidents, in many cases, employees were not injured due to a too small electrical discharge. In the conducted studies, electric shocks (A5.7) accounted for 0.48% of the accidents. However, in the research of Drozd [27], electric shocks (A5.7) accounted for 7% of all the accidents. Other researchers present for the accidents of the electrocution category a result of 12.18% [15] and 10.8% [31]. The analysis of events showed that the majority of accidents in the A5,j category are caused by improper human actions. Nearly 75% of events in this category are related to the failure of installations. “Breakage/failure of an underground power line” (A5.1) is the most numerous subcategory of this group. In addition, earthworks employees very often encounter unexploded munition during excavating works (A6.1). This is the largest subgroup of the “Fire/Explosion/Finding unexploded munition” (A6) category. Unexploded munition are projectiles that did not explode after hitting the target, and any explosives without proper supervision and control [32]. It should be noted here that unexploded munition can very often be found at Polish construction sites, and it is a remnant of World War II. If unexploded munition (A6.1) is found, very strict procedures are followed, and therefore accidents in this category are very rare. All the events of this type that were identified in the research were classified as near misses.

Due to the insignificant description of some events, verification of the correctness of the classification of events by the people responsible for safety at construction sites was difficult. However, the number of events, counted in thousands, allowed trends in a given category to be exposed. In Polish law, there are no provisions that clearly allow for the categorization of dangerous events. Therefore, many companies, including production enterprises, have their own data sheets of near misses and accidents.

6. Conclusion

The article presents the results of analyzes carried out on the basis of a set of near misses and occupational accidents that were registered in the hazardous event registration system in a large Polish construction company. The structure of near misses and occupational accidents was defined, and the relationships between individual types of events were determined. The following conclusions were formulated:

-

1.

Based on the analysis of a set of 2,197 dangerous events, including 621 occupational accidents and 1,576 near misses, it can be stated that in the examined enterprise, on average, there are 2.54 near misses for each occupational accident. This number varies depending on the direct cause of the event.

-

2.

8 categories of direct causes of dangerous events were defined, namely: being hit by objects, being run over, working environment factors, falling, electricity, fire, explosion, finding unexploded munition, collapse, being buried, entrapment, and contact with moving machine elements. Within each of these categories, several subcategories were distinguished.

-

3.

The frequency of the occurrence of accidents in each category varies. Most often, an accident is the result of being hit by objects (30.27%). The subsequent common causes include: working environment factors (26.89%), falling on the same level and falling from a height (25.76%), contact with moving machine elements (8.7%), being run over and hit by a vehicle (5.48%), collapsing/burying/entrapment (2.25%), electricity (0.48%), and fire/explosion (0.16).

-

4.

Each accident is preceded by the occurrence of near misses. The eight categories of hazardous events include: a) categories in which each accident is preceded by several near misses, b) categories in which there is less than one near miss event, c) categories in which there is a large number of near misses and a negligible number of near misses. Category a) includes: causes related to the work environment, human falls, and contact with moving machine elements. The number of near misses per accident ranges from 0.6 (falling of a person) to 0.83 (work environment). Category b) includes: being hit by objects, collapsing/burying/trapping, and being hit/run over by a vehicle. The number of near misses per accident ranges from 2.37 (being hit by objects) to 9.7 (collapsing/burying/entrapment). Category c) includes: electricity, fire and explosion. The number of near misses per accident ranges from 80.1 (electricity) to 183 (fire/explosion/discovery of unexploded munition).

-

5.

The highest probability of an accident is associated with the categories: being hit by objects (P(A1) = 0.086); environmental factors (P(A3) = 0.076); and the falling of a person (P(A4) = 0.073).

-

6.

The number of near misses preceding an accident, which was defined in the article, indicates when an accident caused by a specific cause can be expected in the future.

6.1. The importance of the research for science

The recording and analysis of near misses are an important source of knowledge that should be used in scientific research concerning occupational safety management. Based on the presented research, the following conclusions, which are important for scientific considerations, were formulated:

-

1.

The carried out analyzes allowed for the identification of the causes that result in the highest probability of generating an accident, as well as those for which this probability is negligible. The knowledge that can be acquired within this area should be used for accident prevention. However, in order for the research results to be generalized for the entire economic sector, such research should also be carried out in other Polish enterprises.

-

2.

The analysis of information about near misses will allow for the determination of the circumstances of such events, and may be the basis for developing new safety procedures, or correcting the existing ones, when performing specific construction works.

-

3.

Implementation of the conclusions from the research conducted in the enterprise will contribute to many accidents being avoided, and thus to increasing the level of work safety in the construction industry. Defining how and with what probability near misses influence the occurrence of occupational accidents in the construction industry will contribute to more precise accident forecasting, and a proper assessment of occupational risk.

6.2. The importance of the research for construction practice

Near misses and their relationships with occupational accidents are a rich source of knowledge that should be used when managing work safety on construction sites. The conducted analyzes led to the following conclusions for construction practice:

-

1.

The occurrence of near misses caused by a specific cause should be an indication for management staff that special attention should be paid to the conditions in which work is performed, and whether the preparation of employees to perform this work is appropriate. This is because another similar event may result in the employee's injury or death.

-

2.

The occurrence of a near miss caused by specific reasons should be a signal that working conditions at a construction site should be checked, including: designating danger zones in the vicinity of works at height; using protective barriers when working at height and in excavations; using sensor systems for vehicles to detect threats in the so-called dead zones in the vicinity of construction machines and during the transport of elements; and paying special attention to order in the workplace to reduce the risk of falling, tripping, or slipping at the same level. This enables managers to take more targeted risk monitoring and management actions.

-

3.

The research results can be used in trainings dedicated to employees, inspectors and construction managers regarding occupational safety, the aim of which would be to raise awareness of the threats occurring in the work environment and their possible effects. The research results could lead to the development of new safety standards and their better enforcement.

-

4.

The recording of information regarding near misses and occupational accidents should be mandatory in every construction company. All possible actions should be taken to disseminate knowledge about near misses, as well as to provide precise information on how to report these events.

6.3. Research limitations and directions for future research

The weakness of the conducted research is that it is limited to only one large construction company. This is due to the fact that in Poland access to data concerning near misses is limited, because recording such events is not obligatory. Only companies that have an implemented safety management system are obliged to do so. To date, other large enterprises that have a system for registering dangerous events have not agreed to share their data. However, it should be added that the examined company carried out construction works (as a general contractor) throughout the whole country, and employed smaller companies as subcontractors. The hazardous event registration system that was analyzed by the authors also registered events involving smaller enterprises. This allows the authors to assume that the degree of generalization of the formulated conclusions is quite high. The topic is developmental. The authors see the possibility of further research directions, the aim of which will be to determine mathematical models based on linear regression, artificial intelligence and machine learning. Such models could be used to predict the probable moment of an occupational accident within particular event categories, based on knowledge about near misses. In addition, activities are also undertaken to obtain permission to access the systems for registering dangerous events in other construction companies, which will allow for comparison of the obtained results.

Data availability statement

Data included in article/supp. Material/referenced in article.

Financing

The article was developed within research project No. 536828 - "Modelling the impact of near misses on occupational accidents in the construction industry (SAFCON)" - funded by the National Science Centre, Poland under contract No. 2021/43/O/ST8/00724.

CRediT authorship contribution statement

Zuzanna Woźniak: Visualization, Methodology, Formal analysis. Bożena Hoła: Supervision, Project administration, Methodology.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Contributor Information

Zuzanna Woźniak, Email: zuzanna.wozniak@pwr.edu.pl.

Bożena Hoła, Email: bozena.hola@pwr.edu.pl.

References

- 1.Li Chengqian, Ding Lieyun. Falling objects detection for near miss incidents identification on construction site. Computing in Civil Engineering 2019: Data, Sensing, and Analytics - Selected Papers from the ASCE International Conference on Computing in Civil Engineering. 2019:138–145. 2019. [Google Scholar]

- 2.Zhou Zhipeng, Li Chaozhi, Mi Chuanmin, Qian Lingfei. Exploring the potential use of near-miss information to improve construction safety performance. Sustainability. 2019;11(5) [Google Scholar]

- 3.Simone F., Ansaldi S.M., Agnello P., Patriarca R. Industrial safety management in the digital era: Constructing a knowledge graph from near misses. Comput. Ind. 2023;146 doi: 10.1016/J.COMPIND.2022.103849. [DOI] [Google Scholar]

- 4.Edwin Sawacha, Naoum Shamil, Fong Daniel. Factors affecting safety performance on construction sites. Int. J. Proj. Manag. 1999;17(5):309–315. https://www.sciencedirect.com/science/article/abs/pii/S0263786398000428 [Google Scholar]

- 5.Gnoni Maria Grazia, Saleh J.H. Near-miss management systems and observability-in-depth: Handling safety incidents and accident precursors in light of safety principles. Saf. Sci. 2017;91:154–167. doi: 10.1016/J.SSCI.2016.08.012. [DOI] [Google Scholar]

- 6.Van Der Schaaf Tjerk, Kanse Lisette. Biases in incident reporting databases: an empirical study in the chemical process industry”. Saf. Sci. 2004;42(1):57–67. https://www.sciencedirect.com/science/article/abs/pii/S0925753503000237 [Google Scholar]

- 7.Jones Simon, Kirchsteiger Christian, Bjerke Willy. The importance of near miss reporting to further improve safety performance”. J. Loss Prev. Process. Ind. 1999;12(1):59–67. https://www.sciencedirect.com/science/article/abs/pii/S0950423098000382 [Google Scholar]

- 8.Gnoni Maria Grazia, Tornese Fabiana, Guglielmi A., Pellicci M., Campo G., De Merich D. Near miss management systems in the industrial sector: a literature review. Saf. Sci. 2022;150 doi: 10.1016/J.SSCI.2022.105704. [DOI] [Google Scholar]

- 9.Woźniak Zuzanna, Hoła Bożena, Jan Ciszewski, Stelmaszczyk Marcin. The importance of potentially accidental events for work safety in the construction industry. Przegląd Budowlany R. 2022;93 https://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-e916945b-c78b-4242-9466-dc5bb980684f No 9–10. [Google Scholar]

- 10.Heinrich H.W. Mc Graw Hill Book Company, Inc; New York, Toronto, London: 1959. Industrial Accidents Prevention. [Google Scholar]

- 11.Frank Bird. International Safety Academy; 1974. Management Guide to Loss Control. [Google Scholar]

- 12.PN-N-18001 . Requirements"; 2004. Occupational Health and Safety Management Systems. [Google Scholar]

- 13.Near Miss Definition Per OSHA – What Is A Near Miss? https://safetystage.com/incident-reporting/near-miss-definition-osha.

- 14.Chancellery of the Prime Ministerin Poland (Act from October 30, 2002) on social insurance for accidents at work and occupational diseases. J. Law. 2002;199(1673):12513. [Google Scholar]

- 15.Wu Weiwei, Gibb Alistair G.F., Li Qiming. Accident precursors and near misses on construction sites: an investigative tool to derive information from accident databases”. Saf. Sci. 2010;48(7):845–858. https://www.sciencedirect.com/science/article/abs/pii/S0925753510001098 [Google Scholar]

- 16.Gnoni Maria Grazia, Lettera Gianni. Near-miss management systems: a methodological comparison”. J. Loss Prev. Process. Ind. 2012;25(3):609–616. https://www.sciencedirect.com/science/article/abs/pii/S0950423012000186 [Google Scholar]

- 17.Duan Pinsheng, Zhou Jianliang. 2022. A Science Mapping Approach-Based Review of Near-Miss Research in Construction”. Engineering, Construction and Architectural Management.https://www.emerald.com/insight/content/doi/10.1108/ECAM-09-2021-0797/full/html [Google Scholar]

- 18.Wang Fan, Li Heng, Dong Chao. Understanding near-miss count data on construction sites using greedy D-vine copula marginal regression”. Reliab. Eng. Syst. Saf. 2021;213 https://www.sciencedirect.com/science/article/abs/pii/S0951832021005305 [Google Scholar]

- 19.Love Peter E.D., Kiril Tenekedjiev. Understanding near-miss count data on construction sites using Greedy D-vine Copula Marginal Regression: a comment”. Reliab. Eng. Syst. Saf. 2022;217 https://www.sciencedirect.com/science/article/abs/pii/S0951832021005305 [Google Scholar]

- 20.Raviv Gabriel, Fishbain Barak, Shapira Aviad. Analyzing risk factors in crane-related near-miss and accident reports”. Saf. Sci. 2017;91:192–205. Analyzing risk factors in crane-related near-miss and accident reports. [Google Scholar]

- 21.Marks Eric, Teizer Jochen, Hinze Jimmie. Construction Research Congress 2014: Construction in a Global Network - Proceedings of the 2014 Construction Research Congress. 2014. Near miss reporting program to enhance construction worker safety performance”; pp. 2315–2324. [Google Scholar]

- 22.Wu Weiwei, Yang Huanjia, David A., Chew S., Yang Shuang-hua, Alistair G., Gibb F., Li Qiming. Towards an autonomous real-time tracking system of near-miss accidents on construction sites”. Autom. ConStruct. 2010;19(2):134–141. https://www.sciencedirect.com/science/article/abs/pii/S0926580509001873 [Google Scholar]

- 23.Goldenhar Linda M., Williams Larry J., Naomi i, Swanson G. Modelling relationships between job stressors and injury and near-miss outcomes for construction labourers”. Work and Stresss. 2010;17(3):218–240. https://www.tandfonline.com/doi/abs/10.1080/02678370310001616144 [Google Scholar]

- 24.Zhou Cheng, Ding Lieyun, Miroslaw J., Skibniewski, Hanbin Luo, Shuangnan Jiang. Characterizing time series of near-miss accidents in metro construction via complex network theory”. Saf. Sci. 2017;98:145–158. https://linkinghub.elsevier.com/retrieve/pii/S0925753517303697 2023. [Google Scholar]

- 25.Bugalia Nikhil, Yu Maemura, Ozawa Kazumasa. A system dynamics model for near-miss reporting in complex systems”. Saf. Sci. 2021;142 https://www.sciencedirect.com/science/article/abs/pii/S0925753521002125 [Google Scholar]

- 26.Szóstak Mariusz, Hoła Bożena, Bogusławski Paweł. Identification of accident scenarios involving scaffolding”. Autom. ConStruct. 2021;126 https://www.sciencedirect.com/science/article/abs/pii/S0926580521001412 [Google Scholar]

- 27.Drozd Wojciech. JOURNAL OF CIVIL ENGINEERING. ENVIRONMENT AND ARCHITECTURE JCEEA, t”; 2016. Characteristics of construction sites with regards to hazards related to occupational safety. [Google Scholar]

- 28.Wu Weiwei, Yang Huanjia, Li Qiming, Chew David. An integrated information management model for proactive prevention of struck-by-falling-object accidents on construction sites”. Autom. ConStruct. 2013;34:67–74. https://www.sciencedirect.com/science/article/abs/pii/S092658051200177X [Google Scholar]

- 29.Agreement for Safety in the Construction Industry. 2019. http://www.porozumieniedlabezpieczenstwa.pl/images/baza_wiedzy/raport/Budownictwo_polskie_w_latach_2009_-_2019_-_raport.pdf The Polish construction industry between 2009-2019". [Google Scholar]

- 30.Cambraia Fabricio Borges, Abreu Saurin Tarcisio, Torres Formoso Carlos. Identification, analysis and dissemination of information on near misses: a case study in the construction industry. Saf. Sci. 2010;48(1):91–99. [Google Scholar]

- 31.Goh Yang Miang, Ubeynarayana C.U. Construction accident narrative classification: an evaluation of text mining techniques. Acident analysis and prevention. 2017;108:122–130. doi: 10.1016/J.AAP.2017.08.026. [DOI] [PubMed] [Google Scholar]

- 32.“Unexploded munition - Regional Crisis Management Center in Oświęcim” http://pczk.powiat.oswiecim.pl/warto-wiedziec-5/niewypaly-niewybuchy/(February 4, 2023).

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supp. Material/referenced in article.