Abstract

Previous studies in the literature have illustrated that the strength properties of the parent concrete (PC), that might come from an assortment of origins, may considerably affect the characteristics of Recycled Concrete Aggregates (RCAs) and Recycled Aggregate Concrete (RAC). The effects of PC strength on physical, mechanical, long-term, and microstructural properties of RCAs and RACs have been extensively studied. These properties include water absorption, specific gravity, compressive strength, elastic modulus, splitting tensile strength, flexural strength, durability, and microstructure. These studies examining the influence of source concrete grade on the characteristics of RCA as well as RAC have been comprehensively reviewed in this paper. Upon reviewing the literature, it was found that the porosity of the source concrete and the crushing procedure of the source concrete aggregates were the two main causes of variability in the results of the RCA characteristics. Contrary to the widespread perception that, quote, “RACs in general have lower quality than virgin aggregate concrete”, studies on the effects of parent concrete on RAC characteristics have shown that RACs produced with aggregates obtained from recycling high-strength concrete (not less than 80 MPa) can have equivalent or better characteristics than conventional natural aggregate concrete. Therefore, by carefully considering the quality of the RCAs, it is possible to produce high-performance RAC without the need for additional natural aggregates. The limitations of previous studies have been identified in this work, and recommendations for further research have been provided.

Keywords: Construction and demolition waste, Parent concrete, Recycled concrete aggregates, Mechanical characteristics, Adhered mortar content

1. Introduction

Concrete has been used more widely in modern construction projects due to its durability, affordability, and safety. The production of concrete requires a significant amount of non-replenishable natural materials, such as fine sand and coarse aggregate gravels. Sand and gravel mining and preparation also require a significant amount of energy. The energy consumption involves those required during quarry, production, transportation and aggregate crushing. Ittepie et al. [1] determined the energy consumption per ton of virgin aggregates and RCAs. They discovered that the energy consumed during the making of one ton of virgin aggregates (21,112 kJ/t) is about 30.5% higher than the energy consumed during the production of recycled concrete aggregate (16,178 kJ/t).

Similarly, a substantial amount of concrete waste is being produced by the construction firm causing the scarcity of natural materials, massive energy usage and environmental degradation [2]. The construction and building industry is, thus, considered a vital source of environmental deterioration and is associated with the production of construction waste [2]. Concrete structures generally also have a service life limited only to a few decades [3] and, consequently, the adverse environmental effects come to play continuously in shorter spans of time. According to a study by the authors [4], the construction sector solely produces roughly 75 billion metric tons (mt) of concrete by product annually. China alone produced 2.36 billion mt of construction and demolition (C&D) waste in 2018, then comes the United States (USA) (approximately 600 million mt) and the federal state of India (about 530 million mt) [5]. A significant amount of C&D waste was also produced by European countries with France and Germany contributing the most, with 240 and 225 million mt, respectively [5]. In many developing countries, handling solid waste is a problem for most, and construction waste is emerging as a serious environmental issue. More than half of Sub-Saharan Africa's population now lives in cities, which is predicted to increase garbage production by up to 1 kg per person [6]. Additionally, in other African nations such as Zimbabwe, Tanzania, and Mauritius, mixed municipal solid waste generation rates range from 0.7 kg per person per day in Zimbabwe to 1.1 kg per person per day, of which up to 30% is construction and demolition waste [6].

A global solution is needed immediately to deal with the pressing problem of the deposition and disposal of these huge amounts of wastes. On the other hand, the traditional practice of sending a major proportion of construction and demolition wastes to landfills is being hampered by a sharp price increase and environmental concerns [7]. Furthermore, construction and demolition wastes are very likely to contain potentially harmful materials, including varnishes, sealants, adhesives, and mercury; these will undoubtedly contaminate the soil and groundwater reserves. Therefore, more sound technologies, such as, for example, working on waste recycling process and those converting wastes for potential reuse, are urgently needed to handle these vast amounts of construction and demolition wastes.

RAC can minimize greenhouse gas release by 65% and non-replenishable energy by 58% compared to NAC, according to a study in Hong Kong [8]. The higher proportion of accumulated concrete waste from demolition is made up of aggregates [5]. On the other hand, aggregates are finite resources, and as urbanization in developing nations picks up speed, demand for them will only rise. Future availability of these construction materials will very likely catastrophic as a result of their shortage. The necessity to become more sustainable has become clear as a result of the problems the building sector has been facing. Consequently, reusing some of the RCAs from the C&D waste in the manufacture of fresh concrete material is one potential approach for the wise use of materials. By protecting virgin aggregate reserves, reducing greenhouse gas release, minimizing nonrenewable energy use during aggregate production process, and protecting useable land from being a landfill site, this will help the building sector become more sustainable [9].

It has been proposed to use recycled concrete aggregates (RCAs) in place of natural aggregate (NAs) when producing structural concrete. These aggregates are mostly derived from construction waste and demolished concrete buildings. Despite the fact that RAC, which is made by partially or entirely substituting NAs with RCAs, has notable financial and environmental advantages [[10], [11], [12]], its application in the construction industry has been restricted thus far due to worries about RCA's lower quality when compared to NAs [13]. The performance of RAC is impacted by the varying features of RCAs from different sources [[14], [15], [16]]. For instance, Liu et al. [14] and Zhou et al. [15] discovered that the shear capacity, compressive behavior, and modulus of rapture of concrete produced from various types of RCAs varied. Numerous investigations were performed over the last thirty years to comprehend the performance of RAC applying coarse RCAs [13]. A review of literature on RCAs and RACs reveals that even though there are contradictory results, high quantity of research on the effect of source concrete have been reported thus far. It has, indeed, been demonstrated that the characteristics of RCAs and RACs' mechanical and long term properties are affected by the quality of the parent concrete (PC).

With respect to RCA and RAC behaviors, different studies report contrasting results when parent concrete strength is increased. Some sources indicate that values of these properties increase, while others suggest no effect or even a decrease. Specifically, the density of RCA is reported to improve [17] with a rise in the source concrete quality while [[18], [19], [20]] reported an increase in density as the source concrete quality decreased.

The specific gravity of RCA is reported to improve in quality with an increase in the parent concrete strength [[17], [21], [22]] while it was reported that an increase in specific gravity was obtained as the parent concrete strength tended to decrease [[20], [23]]. Water absorption of RCA might increase [20,[23], [24], [25]] or decrease [17,21,22,26,27]; Los Angeles coefficient of RCA can either increase [26] or remain the same [28,29]; and adhered hardened paste quantity of RCA can either show a rise [17,18,20,21,23] or a fall [[30], [31], [32]] with the increment in source concrete quality.

Furthermore, the influence of increased source concrete quality on the properties of RAC also presents conflicting results across different studies. Compressive strength of RAC can either increase [[22], [23], [24],26,29,30], have no effect [18,35], or decrease [20,21], while split tensile strength of RAC might either increase [[22], [23], [24],26,29,30] or remain the same [18]. Drying shrinkage of RAC can either stay the same [26,36] or increase [22,30,37,38], and the slump of fresh RAC can either decrease [30] or show no change [18,39]. Similarly, Young's modulus of RAC might increase [26,30] or show no effect [35,37].

These contradictory findings highlight the need for a comprehensive perception of the interaction between parent concrete strength and the characteristics of RCA and RAC. These inconsistencies might arise due to variations in methodologies used in different studies, which could contribute to the divergent conclusions. Understanding the implications of these contradictory results is crucial for the practical application of RCA and RAC in construction projects.

Summarized literature studies have presented three main arguments to demonstrate the impact of source concrete quality on RAC characteristics. The first argument posits that high quality source concrete yields better quality RAC due to a denser and stronger bond connecting the adhered mortar and virgin aggregates. The second argument suggests that lower parent concrete strength leads to higher-quality RCA, as the low-strength attached mortar can be easily separated from the aggregates, resulting in cleaner aggregates for high-quality RAC. The third argument contends that parent concrete strength has no bearing on RAC quality, with the primary determinant being the type and number of crushers used to process the waste concrete, irrespective of parent concrete strength. Consequently, brainstorming the mechanics governing the influence of source concrete quality on the characteristics of RCAs and RACs is quite important.

This study provides a thorough analysis of the research exploring the effects of source concrete grade on the behavior of RCA and RAC. Numerous studies have focused on physical and strength characteristics of recycled aggregates and RAC including water absorption, specific gravity, compressive behavior, elastic modulus, splitting tensile behavior, flexural capacity, durability, and microstructure. However, this study presents the cutting-edge analysis and, hence, it is the first literature review to discuss how parent concrete strength affects RCA and RAC features.

2. Research goal, extent, and originality

Various researches have been conducted to date to demonstrate by what means the strength of parent concrete from various sources affects the properties of RCAs and RACs [17,18,23,24,32,38]. But there are inconsistencies in the findings of these literary works as described in the introduction section of this article. Due to these and other similar inconsistencies given in the published works, investigators and construction collaborators may have difficulty deciding which of these ideas to adopt in their practical applications.

The objective of this literature review is to investigate the connection between parent concrete's (PC) strength and the characteristics of RCAs and RACs. The review seeks to address the inconsistencies found in previous studies and provide directions for future research.

The scope of this study includes an analysis of the physical, mechanical, and long term attributes of RCAs and RAC blends. Key characteristics such as water absorption, load carrying capacity in compression, modulus of elasticity, tensile capacity, modulus of rupture, and microstructure are explored. The review aims to determine the impact of PC strength on these properties and identify the optimal conditions for producing high-performance RAC without the need for additional natural aggregates.

The novelty of this review lies in its focus on investigating the relationship between PC strength and the qualities of RCAs and RACs, which has not been extensively reviewed previously. While there have been numerous review studies [5,[40], [41], [42]] focusing on physical and mechanical properties, long term behaviors, and system performance of RAC, none of them have specifically examined the impact of PC quality on the properties of RCAs and RACs.

By addressing these gaps in the existing literature, this review provides valuable insights for researchers, construction stakeholders, and policymakers interested in employing RCA in concrete production. Furthermore, the review will contribute to a more sustainable approach in dealing with the effects of the manufacturing of concrete upon the ecosystem, as it highlights the potential of RAC as a more sustainable alternative to natural aggregate concrete.

3. Methods

The characteristics of RCAs andRACs and their relationship to the quality of the PC were the subject of the comprehensive literature review to identify relevant research articles, reports, and publications. The search examined academic journals in the disciplines of civil engineering, construction, and materials science as well as databases like Google Scholar and Scopus.

In accordance with the already established inclusion and exclusion criteria, the literature search results were reviewed. In this review, researches that specifically examined the features of RCAs and RAC in relation to PC strength were considered. Studies that did not offer thorough details on the durability, microstructure, or mechanical characteristics of recycled aggregates and concrete were disregarded.

The research objectives were used to extract and organize the relevant information from the studies that were selected. Water absorption characteristics, load carrying capacity in compression, modulus of elasticity, tensile capacity, modulus of rupture, and microstructure features of RCAs and RAC blends were among the most significant data retrieved. Additionally, information was extracted on the PC's quality and how it affected the characteristics of the RCA and RAC.

To uncover any conflicts or inconsistencies in earlier research findings, the extracted data was examined. Trends and patterns in the correlations between PC strength and the RCA and RAC parameters were examined. Any gaps in the current body of research were also noted.

Based on the outcomes of the state of the art review, suggestions for more research were put forward. These suggestions were made in an effort to rectify the shortcomings of earlier research and offer suggestions for further study. The areas of research that were deemed to be insufficient or in need of more thorough investigation were underlined.

4. Review of the state of the art

The characteristics of RCA and the results of their integration in RAC have attracted the interest of numerous studies in recent years [5,6,9,13,25,26]. It is generally understood that the PC's quality, the production process, and the aggregate size distribution all have varying impacts on the amount and calibre of mortar adhering as well as water absorption [18]. A sizable number of studies on the behavior of RACs have been published in the literature during the past three decades [12,15,19,21,23,28]. Particularly, there have been numerous studies done on the effect of PC strength on the behavior of RCAs and RAC blends. Different researchers [19,21,24,26,27,29] arrived at different conclusions about the impact of source concrete grade on RAC behavior. To visualize and identify the causes of variability in findings in the literature, subsequent sections discuss the impact of source concrete strength to the physical, mechanical, and durability behavior of recycled aggregates and concrete.

4.1. Impact of source concrete strength on physical characteristics of RCA

4.1.1. Aggregate shape and appearance

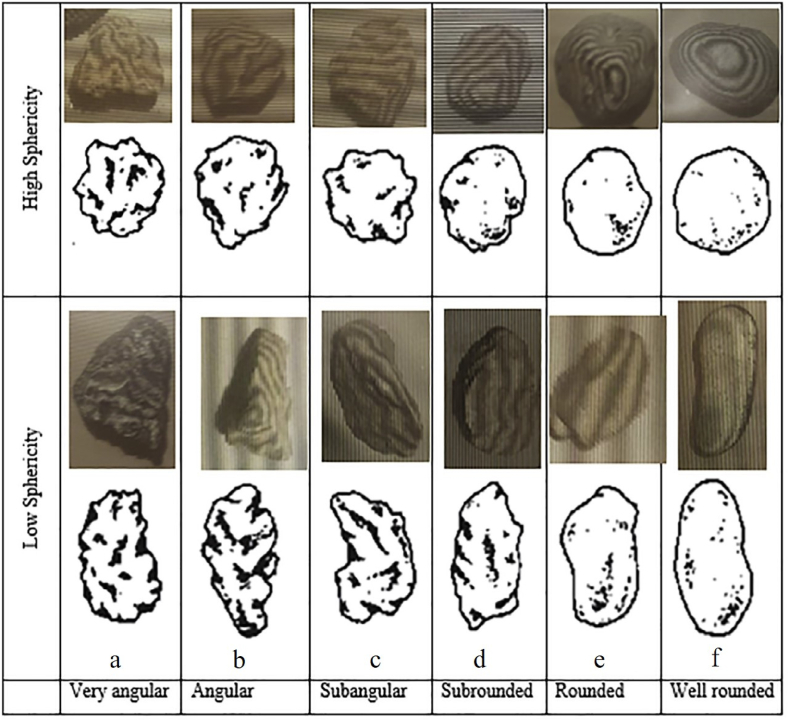

The characteristics of concrete both in plastic and hardened state may be substantially impacted by the form and appearance of the aggregates [43]. As the aggregate surface becomes more angular and rough, the connection between adhered mortar and aggregates becomes stronger. This will consequently influence the compressive behavior and modulus of rupture of concrete to increase. On the other hand, utilizing this kind of material with angular and rough surface makes concrete less workable thereby calling for more water to improve workability. Regarding of RCA, the attached mortar strength can also influence the morphological characteristics of the aggregates [44]. Fig. 2. Shows the roundness and irregularity characteristics of some granular materials.

Fig. 2.

Comparing the Moiré visual assessment of aggregates' roundness and irregularity to Powers' [45] visual assessment of granular materials, a. Very angular shape at both low sphericity and high sphericity cases, b. Angular shape at both low sphericity and high sphericity cases, c. Sub angular shape at both low sphericity and high sphericity cases, d. Sub round shape at both low sphericity and high sphericity cases, e. round shape at both low sphericity and high sphericity cases, f. well round shape at both low sphericity and high sphericity cases: obtained from Marie and Mujalli [44].

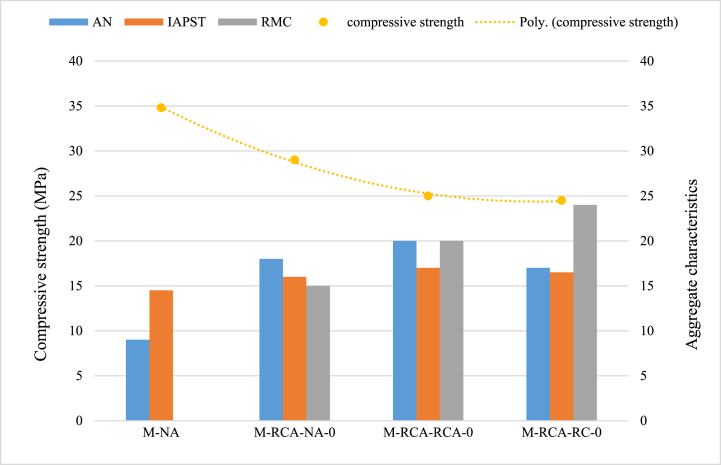

There hasn't been any investigation in the literature that indicates how the quality of the source concrete of the RCA affects the configuration of recycled aggregates except the study by Marie and Mujalli [44]. They [44] carried out a study on the impact of the design characteristics of PC on the morphological behavior of RCA. In their study, they used three distinct varieties of coarse aggregates made from crushed laboratory cubes that have been produced from concrete samples of various PC strength and crushed natural limestone. The three parent concrete mixtures they used were: natural aggregate concrete with 0% RCA replacement; RAC with 20% replacement of NA with RCA (M-RCA-NA-0); RAC with 20% replacement of new RCA with old recycled aggregates (aggregate are recycled for the second time) (M-RCA-RCA-0) and concrete made with rubber (RC), which substitutes fragmented rubber for 20% of the virgin fine aggregates (M-RCA-RC-0). The angularity number (AN) of coarse aggregates, the index of aggregate particle shape and texture (IAPST), and the residual mortar content (RMC) were impacted by the properties of the source concrete (Fig. 1).

Fig. 1.

The relationship between the morphological characteristics AN, IAPST, and RMC and the compressive load carrying behavior of source concrete [44]. Note: The left vertical axis of the graph shows the compressive load carrying capacity of parent concrete, while the right vertical axis shows the values of AN, IAPST, and RMC. The polyline graph shows the compressive load carrying capacity of parent concrete.

The angularity number, which was first proposed by Shergold [46], could be calculated using the concept of the proportion of empty spaces or voids. The percentage by cubic measure of voids in the single-size aggregate that are greater than the proportion by cubic measure of voids in the precisely shaped aggregate (33%) can be used to calculate the angularity value, which is a measurement of the shape's property [44]. This means that aggregates that were perfectly round and of a single size had voids of around 33% by volume. It can also be inferred that less porous concrete is produced using aggregates with higher angularity numbers. Similarly, one can understand from this study [44] that RCAs have more angularity number than virgin aggregates. This may be as a result of the hardened cement plaster glued to the aggregates that makes the elongated NA more angular by filling the gaps in the recycled aggregates.

Another behavior that can be observed from the findings of the article [44] is that RCAs manufactured from stronger source concrete have a higher angularity number because weaker parent concretes had less attached mortar (Fig. 1). Because the crushing procedure easily removes the less dense attached mortars, the quantity of the latter in low-strength parent concrete recycled aggregates is generally low.

The IAPST (index of aggregate particle shape and texture) is another metric for particle shape and surface texture. This value is a quantitative evaluation of the recycled aggregate morphology and textural properties that could influence aggregate performance [47]. Recycled aggregates have a higher IAPST than natural aggregates because recycled particles tend to shatter into little blocks rather than flaky particles. Generally, the morphological properties of RCA are superior to those of virgin aggregates, while increased parent concrete strength improves the morphological characteristics of the RCAs in contrast to low-strength parent concrete. Conversely, though, the compressive load carrying capacity of RAC decreased with increased parent concrete (Fig. 1). Because of the higher amount of attached cement paste in the RCAs manufactured from better quality source concretes, the shape and texture of the RCAs have higher angularity number, and the flakiness index of these aggregates is low in contrast to natural aggregates and weak strength PC aggregates. This enhances the morphological behavior of these aggregates. But since the degree of cement paste adhered to these RCAs is high in volume compared to low-strength PC aggregates, the compressive load carrying capacity of those aggregates is lower with the contrast to virgin aggregates and weaker PC RCAs [44].

Even though a comprehensive examination of the form and external appearance properties of RCAs made from various types of aged PC was already conducted [44], conclusions were more general as it was reported, quote, “both parent concrete and crushing procedures affected the aggregate morphology [44]”. As a result, a more detailed research on the consequence of strength of source concrete on the aggregates' morphological behavior while considering a constant crushing procedure should be conducted. Testing the validity of the existing techniques and developing more direct and simple methods of study are also areas for further research.

4.1.2. Water absorption

The water absorption of recycled concrete aggregates (RCA) refers to the amount of water that the aggregate may retain while submerged in water. There are various techniques for calculating RCA's hygroscopicity. The saturated-surface-dry (SSD) approach is one such technique. The aggregate is first dried to a consistent mass. The mass is then measured again after being submerged in water for a predetermined amount of time. The volume of water that the aggregate absorbs is represented by the difference in mass.

The hygroscopicity rate can have an impact on the behavior of both plastic and hardened states of concrete [48,49]. Concrete manufactured from recycled materials exhibited reduced strength in compression and thawing and freezing resilience when compared to concrete produced from virgin aggregates [50,51]. Nevertheless, the aggregate's ability to absorb water also impacts the fresh properties of concrete [52]. As a result, the Spanish Structural Concrete Code EHE-08 [53] limits the values for natural aggregates on this attribute to those that are lower than 5% while allowing values of not more than 7% for the RCAs applied in the production of structural concrete.

Aggregates' capacity for absorbing water is dependent upon either a fixed level of porosity in the particles or a mean number for a mix of different materials with varying degrees of absorption [23]. More moisture is often absorbed by RCAs than by NAs. Generally, in order to get the same workability, concrete manufactured using RCA and virgin fine aggregates typically consumes nearly 5% additional water than natural aggregate concrete [48]. This is because there is more absorption with recycled aggregates. Some researchers contend that because weaker strength concretes have an elevated water-to-cement ratio and the recycled aggregates are produced from low strength original concretes, the standard of the cement paste that had set and adhered to these RCAs can generally be low. Hence, the mortar obtained with them is more porous, leading to increased water absorption [23,26]. According to a study [20], because there is higher mortar employed, RCAs constructed from harder PCs have higher water absorption. Contrary to Ref. [20],because higher strength source concrete aggregates are not as porous as aggregates from weaker strength parent concrete, recycled aggregates from high-strength source concrete with higher mortar content had shown less water absorption behavior [17,21].

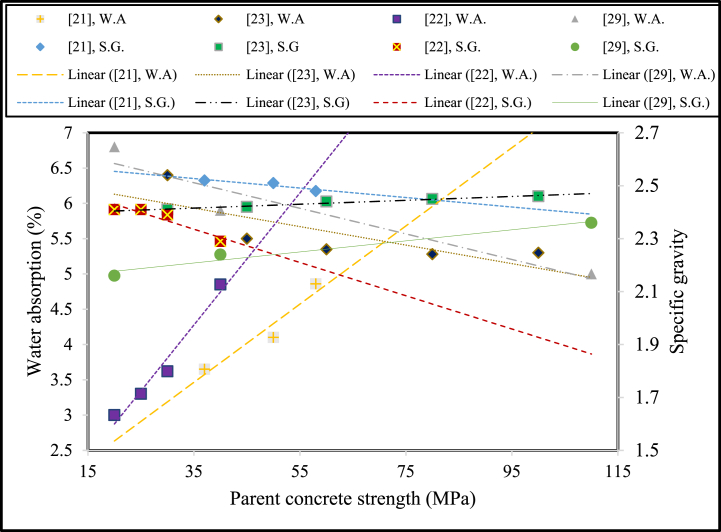

According to Kou and Poon [30], RCA manufactured using source concrete with low grade has greater degree of water absorption compared to RCA made from stronger source concrete. Andreu & Miren [27] used RCA from diverse sources to create high-performance concrete mixtures. The aggregates from the PCs with compressive load carrying capacity of 40 MPa, 60 Mpa, and 100 MPa absorbed water at rates of 5.91%, 4.90%, and 3.74%, respectively, with a maximum variance of 58%. The rise in the grade of source concrete increases the submerged water absorption capacity (from 33% to 38% [25,54,55]) and through a capillary (from 75% to 85% [33]). The findings of some references reported, as illustrated in Fig 3, provide information on how different parent concrete strengths might cause distinctions between specific gravity and water absorption. The studies on reference number [20,23] found an increase in water absorption, while studies [21,22] discovered that when source concrete strength boosted there was a decline in water absorption. Similarly, studies [21,22] found an increase in specific gravity, while [20,23] discovered that when source concrete strength increased, its specific gravity dropped.

Fig. 3.

Figure shows how the absorption of water and specific gravity of RCAs vary inconsistently with the strength of the source concrete. Note: W.A in the legend of this table represents the water absorption value of recycled aggregates; S.G. represents the specific gravity of recycled aggregates and values in square brackets are the reference numbers.

Working with RCA is quite difficult because of its heterogeneous nature. RCAs have a variety of origins and qualities compared to natural aggregates which often come from the same resource. This results in quality variations across various batches of recycled aggregates. Natural aggregate type and size used in the manufacturing of source concrete, service time and loading condition of the source concrete, aggregate crushing type and number of crushing operations, and grades of the source concrete all impact the characteristics of RCAs, including the moisture absorbance of RCAs. Researchers’ exposure to these inconvenient situations may be the corollary to the divergent results of the above studies. For instance, Pedamini et al. [20] used a jaw crusher to produce their recycled aggregates and found a rise in the moisture absorption of RCA with the rise in the quality of the source concrete. On the other hand, Duan et al. [21] produced aggregates by crushing the source concrete by hammer and then by mini crusher, and they concluded that aggregates from stronger parent concrete have less water absorption. In this case, the crushing procedure is the cause of the divergence in the results reported by the authors. As a result, more detailed and systematic research on the source-concrete impact on RCA characteristics is expected.

There have been no studies found in the literature that specifically study the impact of the quality of source concrete and hardened cement paste content of RCAs on the water absorption of RAC. However, it is evident that introducing adhered hardened cement paste to RCA will enhance the RAC's capacity to absorb water. This is because the availability of adhered mortar in the recycled aggregates applied in the manufacturing of RAC will absorb additional water in contrast to virgin aggregates. Consequently, this absorption of extra water by the recycled aggregates incorporated in RAC leads to a rise in the overall moisture absorption of the RAC. But a further experimental study to prove the provided argument is needed.

4.1.3. Density and specific gravity

The density of a particle of an aggregate is defined as the total weight of the particle substance divided by the amount of space covered by its individual particles. Because the porosity of the hardened cement paste phase is higher compared to the aggregate phase, the relative density and density of RCA are substantially lower. In fact, the great quantity of hardened cement paste that is attached to each piece of crushed clay brick minimizes the particle density and rise the moisture intake value [56]. Rao [23] found that the mass over volume and relative density of RCA made from parent concrete with elevated grade are comparatively smaller, and the moisture intake is generally a little higher, however insignificant it can be, than those made from source concrete with lower strength. They hypothesized that this was due to RCAs found from higher-strength source concrete have adhering mortar with a comparatively significant quantity of distant, permeable, lighter cement paste as opposed to lower-strength parent concrete.

Similarly, for comparable aggregate dimensions, RCAs produced from low strength source concrete have higher dry state densities [18,19]. Furthermore, De Juan and Gutiérrez [24] discovered that the density of recycled aggregates dropped as their strength and adhered hardened cement past content increased. Contrarily, it was determined that as the source concrete strength increased, the dry density and relative density of the RCAs increased [17].

Fig. 3 illustrates how the strengths of different parent concrete might cause variations in specific gravity. The density of particles can be taken as an indirect measure to determine the volume of pores with respect to the total volume of a particle. A single natural aggregate particle has a small volume of pores compared to its total volume. Regarding RCAs, the mortar adhered to the aggregates influences the density and the porosity of the aggregate particle. The ambiguity here is whether the grade of the adhered mortar influences the density of RCAs (high strength parent concrete produces high-quality aggregates [17]) or whether the amount of attached mortar influences the properties of RCAs (lower strength source concrete produces high-quality recycled aggregates [18,20,23]). This inconsistency could result from a number of causes, such as the type of crusher used, the number of times the material is crushed, and the presence of impurities in the parent concrete. As a result, developing consistent methods for determining the effects of source concrete on the density and relative density of RCAs is an area for future research.

4.1.4. Mortar content

Natural aggregates and RCAs differ primarily in that the latter, as obtained from construction and demolition wastes, have some amount of mortar attached to them. This mortar makes the aggregates weaker in quality compared to the corresponding natural aggregates [5,7,15,18,19]. The quality and amount of this adhered mortar depend mainly on the source concrete's strength and the technique of crushing the aggregates. In this section, the review of available literature on the impact of source concrete quality on the mortar content of RCAs is discussed.

Some experts believe that in the crushing procedure of the low-strength source concrete, most of the mortar that was used separates from the primary aggregate due to a weakened bonding between the aggregate and the cement mortar. This hardened cement paste is broken down into small fragments, whereby the filtering and sieving procedure subsequently takes off. Consequently, there is less mortar in the RCA made from this parent low quality concrete. Because of this, the mortar composition of the recycled concrete aggregate increases in a manner consistent with the parent concrete's increasing strength [18,20,21,23]. Conversely, several studies have demonstrated a reverse trend, wherein fewer mortars are attached due to the stronger source concrete grade [[30], [31], [32]]. The crushing procedure is to blame for this opposing trend. Because of the extensive automated crushing procedures, RA supplied from the crusher facility often has less associated mortar [57].

Construction and demolition wastes pass through a number of crushing steps in aggregate crushing plants to remove and reduce the quantity of hardened mortar adhered to the RCA. Aggregates passing through a two-step crushing process contain less mortar adhered than aggregates collected from demolition waste manually. Additionally, de Juan et al. [24] discovered that there wasn't any obvious correlation between the strength of source concrete and the recycled concrete mortar content. The inconsistent findings inside the written works on the effect of source concrete on mortar content call for further studies to identify the underlying causes.

4.1.5. The role of parent concrete strength in aggregate abrasion, crushing, and impact resistances

The resistance of aggregates to abrasion, aggregate crushing strength, and impact value are other important parameters that heavily influence the quality of an aggregate. Abrasion resistance measures the degree of degradation of aggregates affected by impact and abrasion in an abrasion machine against the abrasive impact of steel balls. Likewise, the crushing value of aggregates offers a relative measurement of RCAs resistance to crushing by applying a compressive stress progressively. In a similar manner, the particles impact resistance offers a relative assessment of the resilience of an aggregate against sudden shock or damage. Parent concrete quality has, thus, an effect on the materials' abrasion value, crushing value, and impact. According to a study by Nagataki et al. [29], particle Los Angeles abrasion loss is independent of source concrete's strength. However, a study by Gebremariam et al. [58] discovered that the Los Angeles resistance of RCA was benefited by an increase in source concrete strength.

Impact resistance of aggregates decreased with the increase in parent concrete strength [23,44], and the crushing resistance of aggregates also decreased as the strength of the parent concrete increases [24]. On the other hand, as strength of source concrete increased, recycled aggregates' impact and breaking ability rose as well [58]. Additional study on aggregate abrasion resistance, crushing resistance, and impact resistance is needed on aggregates produced from multiple sources to further strengthen those study results from the literature.

4.2. Impact of source concrete strength on fresh and hardened qualities of RAC

The mechanical characteristics of concrete on plastic and hardened state RAC include workability, compressive strength, split tensile strength, flexural strength, and elastic modulus. The determination of these mechanical properties involves conducting various tests on the RAC samples. These tests are performed in accordance with standardized procedures and guidelines. It is important to note that the mechanical behavior of RAC can be influenced by factors such as the strength of the source concrete and mortar content. Therefore, it is crucial to consider these factors when evaluating and determining the mechanical characteristics of RAC. The subsequent sections will discuss these properties in detail.

4.2.1. Workability (slump values)

Slump value of concrete refers to how quickly freshly mixed concrete may be mixed, placed, solidified, and finished with little loss of homogeneity [59]. Quality, aesthetics, and even manpower cost for refining and placing techniques are all strongly impacted by workability. The slump value and other factors of each concrete mix design are impacted by the quantity, caliber, and characteristics of the water reducing admixtures. Particle size and morphology, water/cement ratio and admixtures properties are some of the elements influencing the serviceableness and workability of concrete [30,59].

High amount of mortar is required to completely cover the surface of the aggregates as their surface area grows. As a result, mixes containing smaller particles are less workable than those containing bigger aggregates under similar conditions of water-cement ratio. Aggregates that are long, angular, and flaky are also more challenging to mix and placement because they exhibit comparatively larger surface area which, thus, reduces workability [60]. In the case of the percentage of water to cement, greater volume of paste covers the outermost layer of the aggregates with the correct quantity of water for speedier consolidation and a better finish. Strength is often indicated by the percentage of cement or cement-based substances in the mixture. The malleability of newly mixed concrete is changed by many admixtures, either on purpose or as an unintended consequence. Surfactants, similar to superplasticizers, reduce the binding force between aggregate and cement particles, enabling flowable mixtures without the negative effects of too much water on strength and segregation [60]. In RAC, the workability is more influenced by the quality of the parent concrete, the size of recycled aggregates, the mortar content of the particles, and the number of pores in the RCAs.

By the increase in source concrete's compressive load carrying capacity from where the various RCAs were obtained, increased, it was noted that the slump of the concrete mixtures reduced [30]. This is because RCAs with lower water absorption values come from parent concretes with higher strengths. Contrary to the above argument, however, Akbarnezhad et al. [18] commented on the findings of Grubl and Ruhl [39] where, the latter, argued that the load carrying capacity of the source concrete had almost little bearing on the strength of either the fresh and hardened concrete. Based on the authors' perspective, the method used for crushing the parent concrete has a significant effect on these characteristics [18]. It was determined that the initial free water content of the concrete mixes had a huge impact on the workability of the mix, as determined by Kou and Poon [30]. Two series of mixes were created by Kou and Poon [30], one for high-strength RAC (Series II) with a 0.35 percentage of water to cement and compressive strength of 65 MPa and the other for normal-strength (Series I), which had a 0.5 percentage of water to cement and compressive load carrying capacity of 45 MPa. Their objective was to investigate how the resilience of the original concrete affects the slump value of the RCA concrete. The initial slump of superior-performing RAC mixes was decreased because RCA, which was created from source concrete with an increased strength, has a minimum moisture intake capacity. Additionally, it was discovered that raising the source concrete's strength decreased the slump of normal grade RAC mixes [30]. Recycled aggregates' workability is generally determined by their ability to absorb water and the crushing process used to create them, according to studies on the qualities of fresh RCA concrete that were conducted. Therefore, when using these properties, the utmost caution should be used.

4.2.2. Compressive strength

The compressive strength of concrete is a measure used to establish the ability of the concrete to withstand the applied compressive loads and stresses. As a result of the adhering mortar porous behavior, RACs compressive strength is affected by factors like water absorption, density, parent concrete grade, and porosity [26]. Studies conducted on the compressive cube and cylinder load carrying capacity of RAC produced from variable parent concrete grades are reviewed subsequently.

Padmini et al. [20] investigated the characteristics of RCAs made from source concrete that had three grades and was composed of three aggregate sizes at their maximums (10, 20, and 40 mm). A general correlation has been established for RAC between the cement content, aggregate relative to cement ratio, compressive load carrying capacity, and water to cement proportion, and it has been contrasted to the relationship for PC. It was determined that for a given compressive load carrying capacity, the RAC demanded a smaller w/c ratio compared to the source concrete whereby the RAC was formed, and the difference between the two materials' strengths grew as strength levels increased. The authors also came to the conclusion that, for a certain target mean strength, the achieved strength rose with an increase in the RCA's maximum size. With increasing concrete strength, the strength gap between PC and RAC widened. Their conclusion, therefore, was that the reduced strength of RAC was not significantly affected by the presence of adhering mortar.

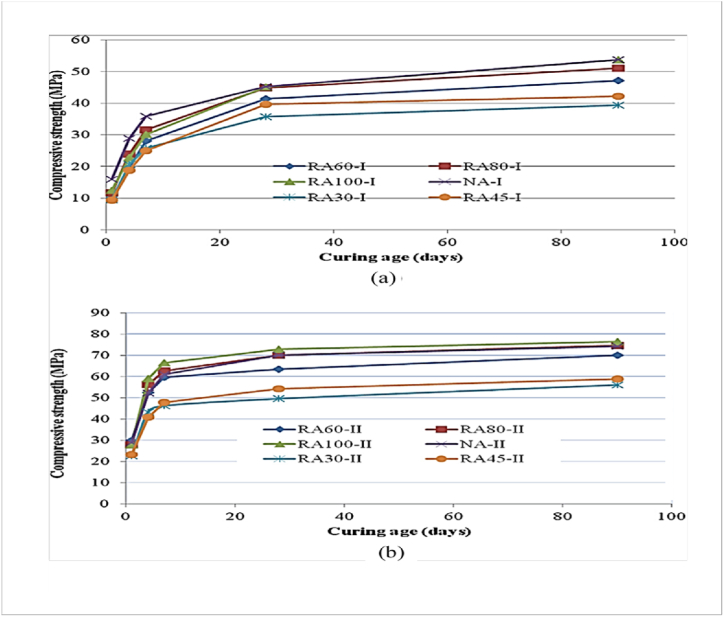

Kou and Poon [30] developed two series of mixes: normal-strength concrete, with a w/c mix ratio of 0.5 and 45 MPa compressive load carrying capacity, and high-strength RAC made with a w/c mix ratio of 0.35 and a 28-day compressive load carrying capacity of 65 MPa, using recycled aggregates obtained from source concretes with capacity of 30, 45, 60, 80, and 100 MPa. It was discovered that the compressive load carrying capacity of RAC mixes from PC of 80 MPa and 100 MPa was similar or even a little more elevated at 28 days in contrast to NAC (Fig. 4). But, at all curing times, the compressive load carrying capacity of the normal and high strength RAC made with parent concrete aggregates of 30 and 45 MPa load carrying capacity was significantly decreased from that of the correlated NAC.

Fig. 4.

Compressive strength increases with ageing (a) in Series I mixes and (b) in Series II mixes. Note: [Reprinted from Ref. [30] with permission from Elsevier].

In the normal strength concrete, it was seen that 0.4 and 1.1% of the compressive load carrying capacity of RAC made with source concretes of grade 100 MPa and 80 MPa, respectively, were reduced in contrast to NAC. However, in the high strength concrete, the compressive load carrying capacity of concrete made with aggregates with 100 MPa and 80 MPa strengths was comparable to or some 3.9% larger than the concrete made with conventional aggregates. This could be due to the fact that RCA obtained from high strength parent concrete is of higher quality and the internal water curing process had an enhanced hydration process, because of the inclusion of recycled aggregates [30]. Similar increases in results were also observed by other authors with the application of high-strength parent concrete aggregates [[22], [23], [24],26,28,30]. The findings by Kou and Poon [43] showed that source concrete with higher strength (not less than 80 MPa) may be applied to manufacture high-strength concrete without using any additional natural aggregates.

Luisa Pani et al. [35] and Akbarnezhad et al. [18] investigated that the mechanical properties of source concrete do not influence the quality of RAC. They reasoned that the method used for crushing concrete substantially influences how much mortar is contained in RCA, not the parent concrete strength. Andreu and Miren [27] performed mechanical and durability tests to see how the efficiency of recycled concrete was impacted by the source concrete. They determined that for the highest degree of substitution, all mixes using RCAs from the 60 MPa compressive load carrying capacity and 100 MPa compressive load carrying capacity source concrete achieved compressive load carrying capacity values that were identical to those of the recycled concrete (around 100 MPa). Only 20% and 50% of the RCA from the 40 MPa parent concrete experienced this, though. For the 100% ratio, there was a 20% difference in strength inside the interval of the mixes Appling RCA with the 40 MPa parent concrete and that of the 100 MPa parent concrete. According to a review of works from different authors [[62], [63], [64]] by D. Pedro et al. [26], compressive strengths of RAC losses in the interval of 6%–25% were found for natural aggregate replacement with different parent strength recycled aggregates at 100%. Similarly, the strength level achieved for a particular goal decreases when the strength of the source concrete, from where the RCA is produced, increases [20]. This decrease in strength may be resulted from the existence of high quantity of adhered hardened cement paste in the high-load carrying capacity PC aggregates.

It is claimed that RCA concrete strength increases with increasing source concrete strength; but it begins to decrease once the source concrete strength reaches 45 MPa [21]. This binominal trend in the strength may be because of the different quality and quantity of the RAs used in their study. There is a third argument in the literature that says source concrete strength has no visible effect on the characteristics of RAC. According to microstructural investigations by Nagataki et al. [29], contrary to usual expectations, adherent mortar is not necessarily the primary factor influencing the quality of the RCA. Similarly, Akbarenezihad [18] also found that the compressive load carrying capacity of recycled aggregate concretes was not highly impacted by an increase in mortar content; it was believed to be due to the positive effects of increased load carrying capacity and mass to volume ratio of the hardened cement paste, and harder concretes with improved adherence to natural aggregates, partially outweighed the negative effects of the increase in adhered mortar.

Incorporation of RCAs from different sources, aiming to assess the capability of producing concrete with a predetermined level of performance (mechanical strength) using laboratory-produced concrete as well as precast industry rejected elements, demonstrated that, for the greatest levels of the required strength, there were no appreciable mechanical or durability variations comparing precast waste aggregates and those from monitored sources [26]. The invisible difference in results reported in the study findings [26] may indicate that the application of waste products from deconstruction in the manufacture of new concrete could not hinder the achievement of the new concrete if the samples taken were controlled and free of impurities. Furthermore, using medium- or high-strength source concrete significantly reduces the performance losses brought on by the integration of the RCAs [26]. These reductions induced by increases in parent concrete may be because the fact that a rise in the mass to volume ratio and the fall in porosity of RCA in high-strength parent concrete leads to the production of good-quality RAC.

The impact of the parent concrete quality, from where the coarse RCA particles were found, on the mechanical characteristics of three strengths of RAC were examined by Ahmad Bhat [28]. He used two phases of weight replenishment of NAs with recycled aggregates of 50% and 100%. The RCAs parent concretes were intended to withstand the cube compressive load at 28 days at nominal strengths of 20 MPa (normal load carrying capacity), 40 MPa (medium load carrying capacity), and 60 MPa (high load carrying capacity). The RACs were prepared at target strengths of 20 MPa (normal strength RAC), 40 MPa (medium load carrying capacity RAC), and 60 MPa (high load carrying capacity RAC). The findings showed that none of the mentioned strengths of recycled aggregate concrete's compressive load carrying capacity was significantly impacted by the grade of the original concrete. The aforementioned characteristics were not as good as the control concrete that included solely NA. However, the mechanical qualities of the resulting RAC generated with high-load carrying capacity of source concrete were higher than those created with normal and medium-strength parent concrete.

Fig. 5(a) demonstrated that for normal strength recycled aggregates with replacement threshold of 50%, the RAC's compressive strength produced from the 60 MPa (N-50, 60) parent concrete had 4.5% greater strength as compared to ordinary concrete (OC-20). This showed that, in some cases, recycled aggregate concrete can have a better quality than natural aggregate concrete at specified optimum replacement levels.

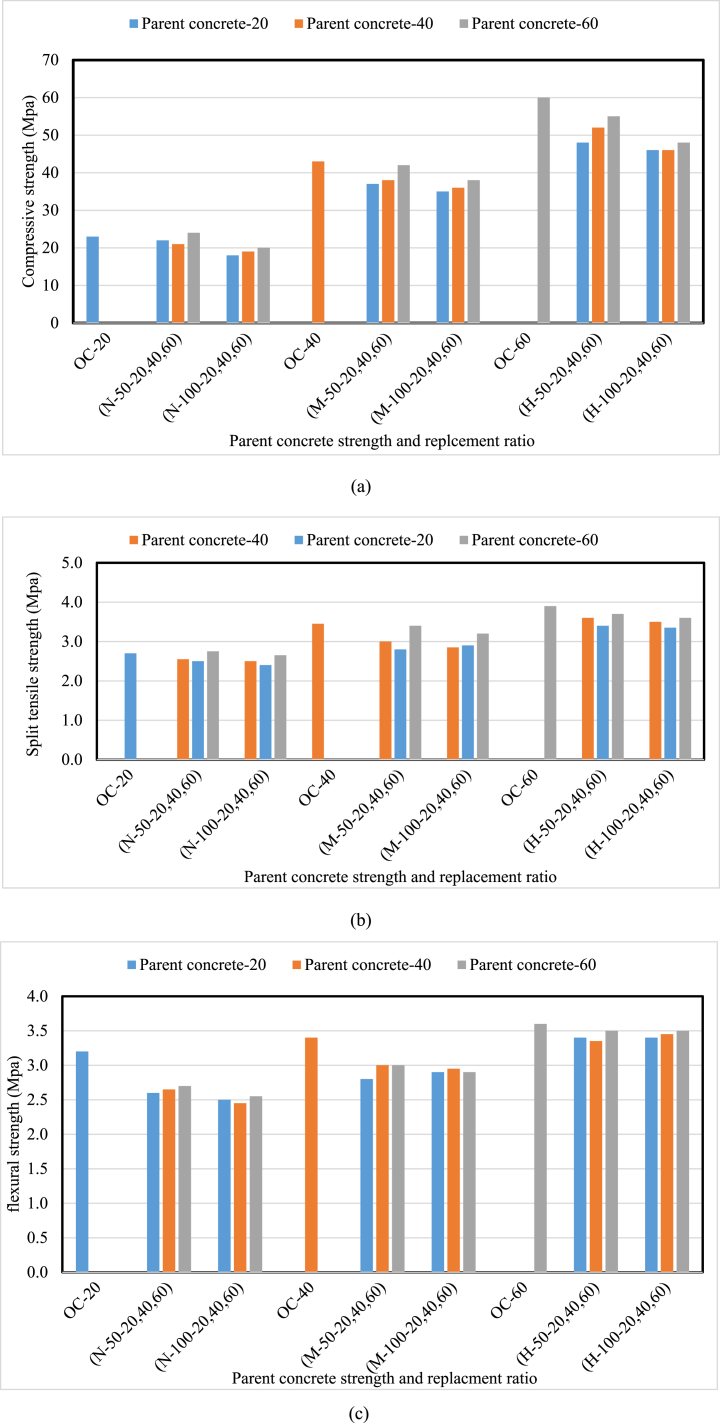

Fig. 5.

(a) Variation of the recycled aggregate concrete's compressive load carrying capacity of the (low, medium and high-strength concrete) with source concrete compressive strength. (b) Disparity of tensile load carrying capacity of RAC concrete (normal, medium, and high-strength) with compressive strength of the source concrete. (c) Variation of RAC concrete's flexural strength (normal, medium, and high-strength) with source concrete compressive strength. Notes: OC-20, 40, 60: Original concrete strengths of 20, 40, 60 MPa. RACs (N, M, H-50,100–20, 40, 60): Concrete grades (Normal, Medium, High) with 50% or 100% RCA substitution, from source concrete strengths of 20, 40, 60 MPa [Reprinted with some arrangements from Ref. [28] with permission from Elsevier].

Fig. 5(a) also shows that RAC constructed with RCAs from high-load carrying capacity source concrete has greater compressive capacity than recycled aggregates produced with RCAs from normal- and medium-strength parent concrete. It could also be observed from Fig. 4(a) that the replacement of RCA in high-strength recycled aggregate concretes has greater variation in compressive strength (H-100, 20, 40 had 23% less strength than OC-60) than the normal (N-100, 20, had 21% less strength than OC-20) and medium-strength (M − 100, 20, had 18.5% less strength than the OC-40) RACs. Additionally, Fig. 5 showed that, at a 100% RCA substitution limit, the corresponding compressive load carrying capacity of RAC produced from RCAs obtained from high-load carrying capacity source concrete (N, M, H-50-60) has a reduction of 12%, 11.6%, and 20% of the ordinary concrete-20, ordinary concrete −40, and ordinary concrete −60 strengths, respectively. These findings suggest that RACs of lower grades should be made with high-strength parent concrete aggregate so that RACs with better quality than NAC are produced.

Generally, even though there are contradicting results, most of the test results from the published papers stated that RAC's compressive strength manufactured from RCA produced with relatively higher-load carrying capacity source concrete was slightly higher compared to regular concrete. However, RAC constructed using RCA produced from similar strength of source concrete consistently had a lower compressive strength compared to the source concrete throughout the entire curing time. This means that recycled aggregate concrete created from parent concrete aggregate that has a substantially higher strength may yield a strength that is comparable to natural aggregate concrete of equal strength. Similarly, higher-strength source concrete yields RAC of greater strength. The rise in compressive load carrying capacity may be attributable to the cement mortar relative strength (bond) with the aggregates.

The majority of the study findings suggest that, at high performance levels, parent concrete aggregates produce comparable or better compressive strength with RAC than NAC. This finding is very interesting for making sustainable structural concrete with 100% RAs. Despite the fact that many Research has been done to improve the recycled aggregate and recycled aggregate concrete characteristics, they have been more general in nature, focusing on the enhancement of all RCA types without taking into account the parent concrete strength effects. Therefore, enhancement methods targeting the parent concrete quality to increase the compressive load carrying capacity of low-strength source concrete aggregates could be the target of future research.

4.2.3. Tensile load carrying capacity of RAC

One of the methods to measure the tensile load carrying capacity of concrete is the splitting tensile strength (STS). In this test, a normal cylindrical sample is laid out horizontally, and force is applied radially along its surface until a vertical crack develops along the specimen's diameter. The STS of RAC is influenced by numerous parameters, encompassing the kind of cement used, the amount of RA used, the process of blending, the source concrete grade, and the age of the RAC [33]. Research has been done to investigate the impact of source concrete strength on the STS of RAC. A tensile load carrying capacity of two distinct recycled aggregates mixed concretes, Concrete mix design 1 with an expected load carrying capacity of 30 MPa and design mix of concrete 2 with 50 Mpa expected strength, was studied by Tabsh and Abdelfatah [65]. The STS test outputs for concrete from Mix 1 demonstrates that concrete manufactured with coarse recycled aggregates from the 50 MPa parent concrete has similar STS as equivalent concrete produced from conventional coarse aggregates. Nevertheless, the tensile strength of concrete produced with RCA—which came from concrete with a goal strength defined by Mix 1 (30 MPa)—or coarse aggregate made from crushed concrete from unidentified sources decreased by 25–30%.

The experimental outputs from the second Mix exhibited a pattern that is comparable to that of Mix 1 except for a lesser decline in strength. The concrete produced with RCAs from the 50 MPa source concrete exhibited about similar STS as concrete produced with conventional aggregate. The tensile strength of RAC was shown to be dependent on the load carrying capacity of the concrete accustomed to create the recycled aggregate and to have a greater significance when it comes to concrete with a lower strength. It is clear from the findings of the article [66] that the usage of high-strength parent concrete aggregates in the production of concrete by replacing natural aggregates is useful in the manufacture of better-quality RAC.

Ahmed Bhat [28] illustrated the connection among the STS and the parent concrete compressive load carrying capacity. Tensile strength was found to be reduced by 2%–25% throughout the RACs where RCA substitution is 100% in contrast to the source concrete. Looking at Fig. 4(b), It is evident that the three grades of STS for RCA concrete with 50% RCA replacement level were very slightly impacted by the quality of original concrete. Additionally, it ought to be pointed out that (Fig. 5(b)) RACs produced from recycled aggregates of high-strength parent concrete have stronger tensile-strength properties than RACs manufactured with RCAs from normal- and medium-load carrying capacity source concrete. Fig. 5(b) demonstrated that for normal strength concrete with 50% substitution level, the STS of the RAC produced from the 60 MPa (N-50, 60) parent concrete had 1.85% greater strength compared to the ordinary concrete (OC-20). The reason for the increased tensile strength achieved by the application of high load carrying capacity parent concrete may be due to a reduction in porosity.

Kou and Poon [30] developed two series of recycled aggregate concrete: high-strength RAC (Series II), and normal-strength (Series I), using RA derived from parent concretes with strengths of 30, 45, 60, 80, and 100 MPa. In high-performance RAC, the STS of RCA-concrete produced from source concretes with load carrying capacity ranging from 30 to 100 MPa was found to be 11.1–26.0% higher compared to equivalent conventional aggregate concrete, respectively. Whereas in normal-capacity RAC, it was discovered that RAC produced with RA obtained from source concrete strengths varying from 30 to 100 MPa had split tensile strengths that were, correspondingly, 2.1–12.2% greater than the comparable concrete made with conventional aggregates. The rougher and permeable surface of RCAs may have strengthened the interfacial transition zone (ITZ) among the RCAs and hardened cement paste, increasing the STS of RAC. This gives a clue to use recycled aggregates rather than natural aggregates in areas highly stressed by tensile forces; however, further research into practical applications is required.

Another significant element that influences how concrete behaves structurally is its flexural load carrying capacity, or the rupture modulus. Regardless of any of the factors, the compressive and STS load carrying capacity of the recycled concretes were often inferior to those of the original concrete [28]. Bhat [28] on his study has implemented to determine the interaction among the RAC modulus of rupture and the compressive load carrying capacity of the original concrete. (Fig. 5(c)) demonstrated that the source concrete grade had less discernible impact on the flexural strength of the three grades of the RCA concrete at either the 50% or 100% RCA substitution levels. Conversely, the modulus of rupture was found to be reduced by 7%–23% in the aggregates with a 100% RCA substitution level in contrast to the conventional aggregate concrete. The reduction in modulus of rupture may be due to the inability of RACs to withstand moment loads. Slip and bonding behavior of reinforced recycled aggregate concrete under tensile and flexural loading is an important characteristics of recycled aggregate concrete that is not investigated so far.

4.2.4. Static elastic modulus

An additional crucial mechanical characteristics that defines concrete's resilience is its static modulus of elasticity. Numerous factors, including the density of the aggregate, grade of parent concrete, and characteristics of the ITZ, impacts the concrete modulus of elasticity. This is so because the porosity and density of the aggregate dictate the bulk matrix stiffness. The substitution of RCA for natural aggregate has an influence on the static elastic modulus. However, the modulus of elasticity is more significantly impacted by RCA porosity [67]. The elasticity of the concrete formed using RCA was inferior to the conventional concrete because of the weaker modulus of the previous hardened mortar that was glued to the RCAs.

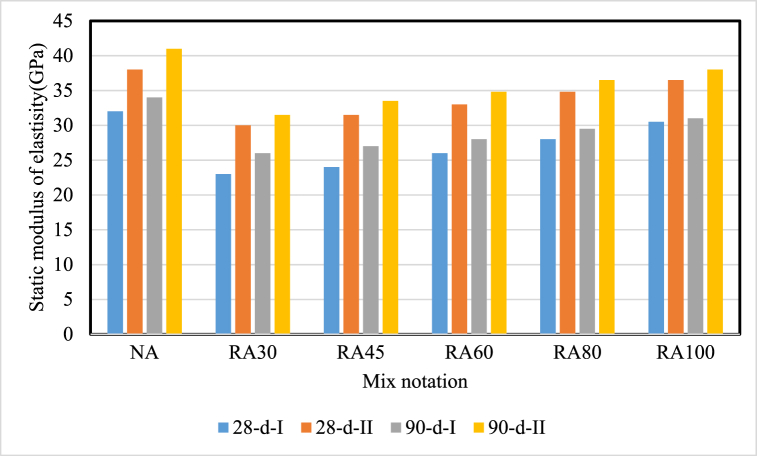

The largest change in loss of modulus of elasticity resulted from variable source concrete strength and was shown to be between 11% and 80% [25,48,68,69]. Kou and Poon [30] determined the impact of source concrete strength on RACs static elastic modulus (Fig. 6). It was discovered that the RAC with RCAs had a lower elastic modulus compared to ordinary concrete; this is regardless of the parent concrete's load carrying capacity. However, the drop in static modulus was lessened by the source concrete's increased strength, from which the RCA was produced. For instance, considering Series II concrete of Kou and Poon [30], the static elastic modulus of the RACs cured for 90 days at 100 MPa and 30 MPa parent concrete strengths have a drop of 6% and 23%, correspondingly, in contrast with the corresponding natural aggregate concrete (Fig. 6). Considering similar parent concrete strength, RAC produced with RCA having higher amounts of attached mortar had a lower 28 and 90 days elastic modulus compared to those produced with RCA with lower amounts of adhered mortar and conventional aggregates [30]. According to Kou et al. [61], RAC produced using low-grade RCA has a considerably lower elastic modulus than regular concrete.

Fig. 6.

Static elastic modulus of concrete combinations in normal strength RAC (Series I) and high performance RAC (series II). [Reprinted from Ref. [30] with permission from Elsevier].

This output was anticipated since low-grade RCAs have a reduced elastic modulus than conventional and industrially manufactured RCAs, because it is widely recognized that aggregate elastic modulus has a greater influence on the elastic modulus of concrete [48]. Generally, it can be seen from earlier works that the static elastic modulus is negatively impacted by the load carrying capacity of the source concrete if the aggregates are manufactured from low-strength source concrete. However, at an increased capacity of parent material, its effect on the elastic modulus is low. Future research should focus on the use of recycled aggregate concrete with varied source concrete strength considering dynamic elastic modulus, as it was not taken into account in the all previous literature studies.

4.3. Effects of parent concrete strength on long term and durability properties of recycled aggregate concrete

The durability of concrete can be expressed in terms of its capacity to withstand abrasion, harsh environmental attack, chloride penetration, carbonation, frost resistance and weathering while retaining the desired engineering qualities [70]. All concrete projects must fulfill their intended purposes and maintain appropriate strength and serviceability requirements throughout their service period. Concrete should, therefore, possess the ability to withstand the deteriorating degree to which it will likely be subjected [70]. RACs are more vulnerable to abrasion, chemical attack, chloride penetration, carbonation, frost action and weathering attacks because of the existence of attached porous mortar. It is obvious that the capacity of the parent concrete has a visible impact on the durability characteristics of RAC. The effects of the source concrete's strength on the durability and long-term behavior of RAC are addressed in the following sub-sections.

4.3.1. Drying shrinkage

One of the notable characteristics of a RAC is shrinkage of the material upon drying. This is the reduction in cubic volume of the concrete caused by the concrete's reduction in capillary water which, in turn, promotes the growth of cracks in osmotic stress inside the cement mortar's structure of the mesopores [69]. The residual mortar quality, which is mostly defined by the life time and load carrying capacity of the source concrete, may affect the drying induced shrinkage of RAC. Pedro et al. [26] and Geng et al. [36] stated that the source concrete strength showed no noticeable effect on the drying induced shrinkage of the final concrete. They reasoned out that the crushing procedure is the key parameter that removes the porous mortar attached to the natural aggregates; their finding is that the amount of attached mortar has negative enfluence on the shrinkage resistance of the RAC more than the grade of the source concrete.

Kou and Poon [30], Gonzalez-Corominas and Etxeberria [38], and Gholampour and Ozbakkaloglu [22] discovered that concrete products made with recycled aggregates derived from higher strength source concrete experienced less drying induced shrinkage than concrete mixtures produced with recycled aggregates derived from reduced strength source concrete. It is because the less porous nature of good strength source concrete in contrast to low grade source concrete, that sucks less capillary water and losses less water during drying causing less shrinkage in the RAC was their reason for their conclusion [22,30,38]. In cases of normal to medium-load carrying capacity source concrete aggregates, to increase the shrinkage resistance of RAC to a level that is similar to that of regular concrete, it may be necessary to incorporate additional crushing steps into the RCA process, which reduces the amount of deformable older mortar and effectively controls concrete shrinkage.

The amount of adhered mortar gives a clue on the detrimental effect on the ability of RAC to withstand shrinkage. The best crushing technique for removing the adhered mortar and minimizing drying shrinkage can be determined by comparing several crushing techniques. Admixtures can also be used to modify concrete's drying shrinkage and other properties. The development of new admixtures specifically designed to reduce drying shrinkage can lead to the production of more durable recycled aggregate. Therefore, future studies should focus on minimizing the drying induced shrinkage of RAC through the application of different crushing techniques and admixtures.

4.3.2. Freezing and thawing

Frequent exposure to moisture, high relative humidity, and low ambient temperature can lead to concrete elements degrading due to cyclic frost and thaw. The corrosion of the rebar begins as a result of this damage, which makes it possible for hostile external agents (such as sulphates and chlorides) to penetrate [35,61,71,72]. In the case of RCAs, the connected mortar's porous character worsens the freezing-thawing effect. Parent concrete strength variations may also introduce variability in the capacity of the recycled concrete to resist the freeze and thaw effects.

Liu et al. [17] clarified how the source concrete and the technique of mixing affected the resilience of concrete with air-entrained RCA to thawing and freezing conditions. The qualities of the RAC were heavily dependent on the source concrete. The frost resistance of the air-entrained concrete and regular RAC were comparable because the recycled aggregates used in the sample was derived from frost-resistant parent concrete. The air-entrained RAC sample showed high freeze and thaw resistivity in addition to almost similar freeze and thaw durability as natural air-contained concrete. However, the second air-entrained RAC sample, on the other hand, was manufactured with RCA derived from non-air-contained concrete and low-strength concrete, and it had a low resistance to frost. The development of strategies to improve the freeze and thaw resistance of RAC needs further study. This will enable RAC to be used more widely in a variety of climates and applications.

4.3.3. Creep

Numerous studies [33,73,74] have demonstrated that, because of the existence of weak adhered mortar, employing RCA in concrete causes greater shrinkage and creep than NAC. Additionally, it has been found that the volume, composition, and qualities of the previous adhering mortar have a substantial impact on the RAC creep [32]. Lower strength recycled concrete aggregate mixes have poorer mechanical characteristics and exhibit greater shrinkage strain and creep deformation than higher strength recycled concrete aggregate mixes. This is resulted from the low strength source concrete aggregates, less dense and more permeable behavior compared to stronger parent concrete aggregates, allowing them to drain and lose water during temperature variations.

Because the characteristics of the low-strength source concrete RAC are more vulnerable to variation due to environmental factors, the RAC produced from them wears and degrades over time. Additionally, it has been demonstrated that high-strength RACs, which are made by completely substituting conventional aggregates with RCAs of higher source concrete strength, have either a long-term and time-varying mechanical qualities that are comparable to or superior to those of associated NAC [34]. The increased durability due to increased parent concrete strength could be due to the presence of less capillary pores with less moisture intake, making the RAC resistant to weathering degradations.

Future research could concentrate on the Establishment of models in mathematics that estimate the creep behavior of RAC based on the load carrying capacity of the source concrete. This can help in understanding the relationship between the long-term deformation characteristics of recycled concrete and the load carrying capacity of the parent concrete without experimental studies.

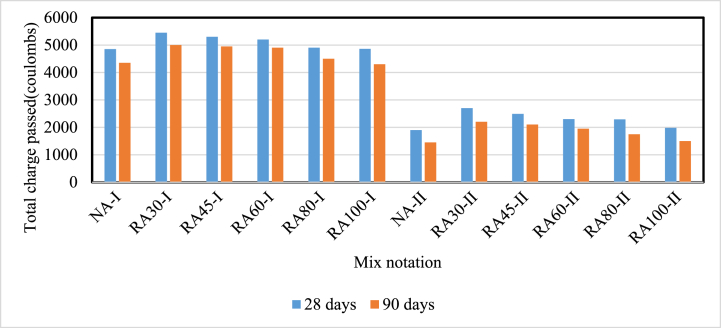

4.3.4. Resistance to chloride ion infiltration and carbonation

Carbonation resistance and resistance to chloride ion penetrations of RAC were influenced by the quality of the source concrete in a similar manner with other properties of RAC. As described by Rao et al. [75], the outcomes of two RAC mixes' defense against penetration of chloride ions (w/c proportions of 0.5 and 0.35) made with recycled aggregates and gained various strengths ranging from 30 to 100 MPa of parent concrete were reported by Kou and Poon [30] and are shown in Fig. 7. The results showed that adding RCA, which is made from a mix of various strengths of parent concrete, increases chloride penetrability in comparison to the NAC mixture. However, compared to concrete manufactured with RCA that was collected from parent concrete with inferior strength, the chloride penetrability of mixtures produced with RA from source concrete with greater strength was lower due to the denser attached mortar in the high-strength parent concrete. Carbonation resistance levels ranged widely, from a 3% increase [56] to a 67% decrease [52], and resistance to chloride penetration decreased by 10%–32% [25,33,34] due to parent concrete strength variations. This variation could be caused by the uncontrolled parallel effects of other variables such as the crushing procedure and size of aggregates. The draw backs of using different parent concrete strength recycled aggregates in RAC's opposition to carbonation and chloride ion infiltration could be the subject of future studies.

Fig. 7.

Penetrability potential of concrete by chloride ions (w/c proportions of 0.5) and (w/c proportions of 0.35) [Reprinted from Ref. [30], with permission from Elsevier].

4.4. Impact of strength of source concrete on the microstructure of RAC

There are a total of three phases in the microstructure of concrete: the aggregate phase, the bulk hardened mortar phase, and the interfacial transition zone [76]. Because of RACs have increased number of interface zones than conventional concrete, studying the interface of attached mortar and aggregate is especially important in this type of concrete. Contrary to conventional concrete, which has single ITZ; located between the aggregate and cement paste, there is additional interface zone in recycled aggregate concretes: ITZ between the adherent hardened cement paste and the new cement paste matrix (the new ITZ) and between the natural aggregate and the old connected mortar (the old ITZ) [75].

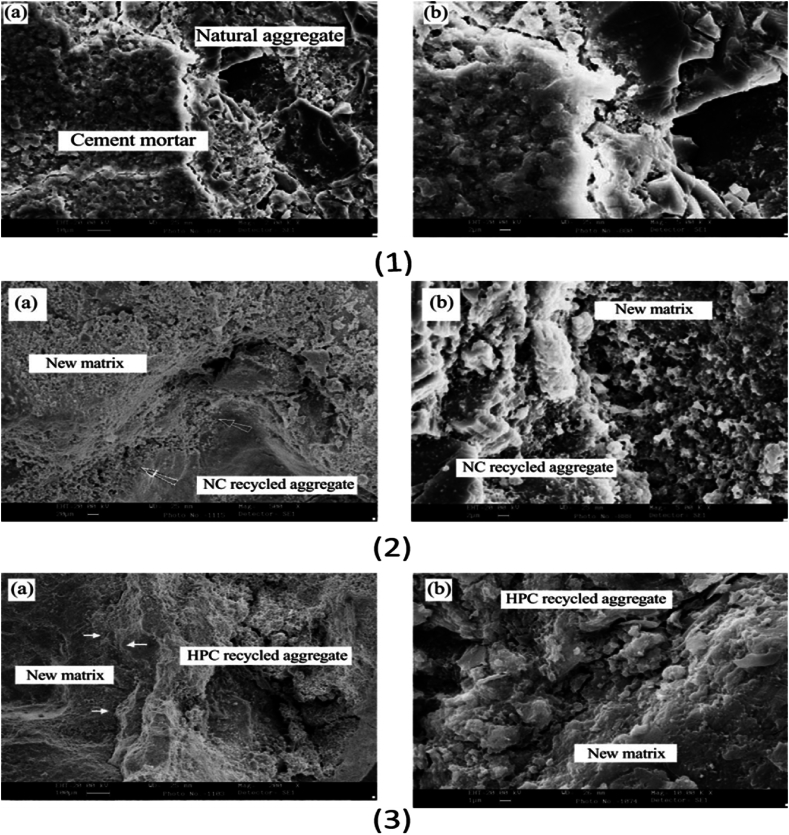

Poon et al. [77] produced concrete specimens using a recycled high-strength concrete aggregates, a recycled normal-strength concrete (NC) aggregates (compressive strength between 20 and 40 MPa), and a conventional aggregate (NA) as a control and, subsequently investigated the effect of those particles on the micro-scale organization of the resulting concrete. Generally, the scanning electron microscope (SEM) findings revealed that the normal-strength RCA and cement matrix had a weak and permeable interfacial layer, whereas the high strength RCAs and cement matrix had stronger interfaces (Fig. 8(3(a and b))). The increased porosity and absorption capacity of RCAs are the causes for the inferior ITZ in RAC with regular strength concrete aggregate, and under higher magnification, the ITZ extreme porosity could be detected [77] (Fig. 8(2(b))). Additionally, from Fig. 8((1(a)) and (1(b)), the dimension of the ITZ ranged over the aggregate surface, as can be seen obviously, and the interface between the granite aggregate and mortar was rather loose. It was found that the ITZ between the mortar matrix and the aggregates made from regular load carrying capacity concrete was approximately 45 μm wide and mostly comprised loose particles [77]. Under higher magnification, the ITZ extreme porosity could also be detected (Fig. 8(2(a)) and Fig. 8 (2(b)) [77].

Fig. 8.

Microstructure of recycled aggregate concrete: (1) RCA concrete made of crushed raw granite, (2) RCA concrete made with recycled ordinary-strength parent concrete aggregates. (3) RCA concrete made with recycled high-strength parent concrete). [Reprinted from Ref. [77] with permission from Elsevier].

Leite and Monteiro [78] examined the RAC morphology utilizing sophisticated light source synchrotron microtomography (μCT) and scanning electron microscopy analysis. In their research, the authors used compressive strengths of the parent concrete of 40 MPa and 80 MPa with the initial water content conditions of saturated surface dry (SSD) and oven dry states of the RCAs. Based on the microstructural findings, they suggested that it would be possible to produce recycled concrete by using RCA from high-load carrying capacity source concrete (greater than 80 MPa) that was employed in the SSD condition and whose mechanical, physical, and microstructural qualities could be comparable to those of the standard concrete used as a reference. Because there is less porosity in the RAC at higher levels of source concrete strength, the standard of the RAC improves. There are few microstructural studies in the literature considering parent concrete effects; accordingly further studies on the microstructural attribute of RAC incorporating various strengths of parent concrete is needed to strengthen the current findings.

Another crucial area of study was the analysis of the bond attribute of reinforced RACs and geopolymer RACs that contained aggregates from various parent concrete strengths. The effects of source concrete calibre on RAC characteristics such as durability and steel concrete bondage were examined by Joseph et al. [79]. The test findings demonstrated that the PC grade has a visible impact on the ultimate bonding strength and stress transmission to inserted rebars. Similarly the workability of geopolymer concrete can be significantly enhanced by the application of good quality RCAs, according to a study by Blessen et al. [80]. A further review and investigation on the impact of source concrete grade on bond to steel reinforcement, on geopolymer and engineered cementitious composts should be the areas of future studies.

5. Conclusions and future remarks

A number of researches on the impact of source concrete strength on RCAs and concrete have been carried out so far, producing informative findings that can add value to the recycling world. However, there are inconsistencies in the findings from these studies in terms of the influence of source concrete quality on RCA characteristics. The objective of the study reported in this paper has been to review the investigations carried out to date on the potential effects of source concrete properties on RAC qualities in order to identify the possible causes of variability and inconsistency in those findings.

Based on the reviewed findings, it is not fully and conclusively clear yet in what manner parent concrete load carrying capacity affects the behavior of RCAs and RAC. But, the porosity of the source concrete, and the crushing methodology of the source concrete aggregate were the two primary causes of variabilities in the results of the literary works on recycled aggregate concrete. In view of these developments, it is found that more in-depth experimental work and research are required, including developing norms and standards for parent concrete strength effects while taking into account the constraints and competing claims in the studies, in order to arrive at a dependable conclusion regarding the core issue of the subject matter.

The key specific findings and recommendations from this review are as follows:

-

•

Several factors contribute to the heterogeneity in recycled aggregate concrete properties of literature outcomes. Firstly, the qualities of RAC are significantly impacted by the parent concrete's porosity. Porosity is affected by shape and texture, with angular and rough surfaces encouraging a stronger connection with cement pastes. Second, different researchers used different natural aggregate types in parent concrete, which results in diverse qualities of RCAs. The method of crushing also has an impact on how much mortar is adhered to recycled aggregates. Different crushing methods result in variable quantity of mortar. On top of that, the porosity of attached mortar might vary based on the compaction of the RAC and the type of cement, among other factors. For comprehensive studies in this subject, researchers must take these elements into account.

-

•

After reviewing the research carried out on the effects of source concrete strength on RAC characteristics, it has been found that, contrary to the popular belief that “RACs in general have lower quality than natural aggregate concrete”, RACs produced using high-strength source concrete (not less than 80 MPa) can have equivalent or better strength properties than NAC. Therefore, aggregates produced from parent concrete with higher strength could be applied to produce good-physical and mechanical property concrete without using any additional natural aggregates. But, with the addition of the high-strength source concrete aggregates, it was seen that the long term behavior of the RAC began to deteriorate after 50% replacement level. Therefore, consideration of approaches for durability enhancement should be the subject of further research.

-

•

The findings of the tensile load carrying capacity of RAC studies in the literature showed that, at higher strengths of the parent concrete, RAC has better tensile capacity than NAC. This could be because of the rough and porous nature of the RCA, which creates an interlocking bond in the weak ITZ that makes the tensile strength of the RAC better. Similarly, a rise in the strength of the source concrete produces RAC with better tensile strength than low-quality parent concrete because the attached mortar in the high strength RAC is dense and resistant to tension.

-

•

Employing high-strength parent concrete as the source material for RAC can demonstrably enhance its structural integrity, with potential strength gains exceeding 20% relative to RACs produced from weaker parent concrete.

-

•

It has been seen from the literature that the rise in the aggregates' source concrete strength clearly enhanced the durability properties of RAC. Upcoming studies should concentrate on the efficacy of various RCA property improvement techniques and their impact on the durability performance of RA and RAC made from low-strength parent concrete. Similarly, enhancement methods for the microstructure of RCAs and RACs at new and old ITZs of the low strength parent concretes should be considered because the characteristics of RCA and the micro-scale organization of concrete are what generally determine the durability capacity of RAC.

-

•