Highlights

-

•

Cavitation erosion of different polymer coatings on mortar are investigated.

-

•

The water wedges and radial cracks led to the detaching of the epoxy polymer coating.

-

•

The introduction of intermediate epoxy mortar layer delays cavitation pits formation.

-

•

The elastic deformation of polyurea reduced the cavitation erosion probability.

Keywords: Epoxy coating, Polyurea coating, Cavitation erosion, Damage evolution

Abstract

This study focuses on unraveling the failure mechanisms of three distinct polymer-coating structures applied to mortar substrates: an epoxy coating (MEP1), an epoxy coating with an intermediate epoxy mortar layer (MEP2), and a polyurea coating with an intermediate epoxy mortar layer (MPU). Ultrasonic cavitation experiments are conducted to investigate the initial stages of cavitation erosion. The damaged surfaces of these three coating structures are meticulously investigated and characterized. An in-depth analysis is performed on the distribution characteristics of cavitation pits and the evolutionary patterns of these pits. The results indicate that the introduction of epoxy mortar as an intermediate layer significantly enhances the material’s cavitation resistance by improving its energy absorption capacity. This enhancement delays the formation of cavitation pits on the coating surface. Additionally, the superior adhesive properties of the intermediate epoxy mortar with the mortar substrate prevent direct cavitation erosion from forming on the substrate, even when brittleness failure occurs and coating erosion is observed on the surface epoxy polymer. The polyurea coatings demonstrate exceptional elastic–plastic deformation capabilities. When combined with the intermediate epoxy mortar layer, MPU can withstand prolonged and repetitive cavitation impacts, resulting in minimal coating erosion.

1. Introduction

High-speed flow frequently induces significant pressure drops in liquids [1], [2]. When local pressure falls below the saturated vapor pressure, gas nuclei expand rapidly, forming gas- or vapor-filled bubbles. Researchers [3], [4], [5] have shown that when bubbles form in low-pressure zones and travel to high-pressure areas, cavitation collapse occurs, accompanied with high-pressure, shockwaves, exothermic reactions, and microjets. Popinet and Zaleski [6] noted that initial cavitation damage can be attributed to shock waves and microjets directed toward the wall in the near-wall region. In natural phenomena and industrial applications, cavitation bubbles often exist in bubble clusters [7], implying that the aforementioned factors contributing to cavitation erosion continue to affect the wall, eventually leading to plastic deformation, fatigue cracking, and mass loss on the solid surface, a phenomenon known as cavitation erosion. Notably, significant cavitation damage has been observed in the Xiaolangdi spillway tunnel and the sand-flushing tunnel of the Zipingpu Dam [8]. Consequently, mitigating cavitation damage has become a focal point for numerous researchers [9], [10], [11].

In hydraulic engineering, aeration facilities are generally considered the most effective method to mitigate cavitation erosion. These facilities introduce air bubbles introduced into the water, acting as a shield at solid boundaries [12], [13]. However, in already constructed and operational hydraulic structures, the risk of cavitation damage may persist, possibly due to design inadequacies in the aeration facilities. In such cases, polymer coatings like epoxy and polyurea, known for their exceptional corrosion and impact resistance [14], [15], [16], have shown significant potential as surface protective materials against cavitation erosion. Abenojar et al. [17] incorporated nano-silica into epoxy resin, yielding a plasticizing effect and enhancing cavitation resistance. Shahi [18] applied a 0.5 mm polyurea coating to an aluminum substrate, observing no apparent surface damage after a 6-hour cavitation test. Hao et al. [19] reported that hydrofoils coated with epoxy exhibited the lowest cavitation number and shortest period in cloud cavitation, effectively suppressing cavitation onset and development.

Various researchers have also explored the mechanisms behind the alleviation of cavitation erosion by epoxy/polyurea polymer coatings. Cao et al. [20] combined bubble fluid dynamics with material mechanical response, discovering that when cavitation bubbles collapse on the surface of a viscoelastic material, like polyurea, the reflected wave, with a higher amplitude than the incident shock, impacts the bubble during its rebound. This reduces the velocity of rebound and the speed of the liquid jet. Similarly, Hattori and Itoh [21] investigated the relationship between the mechanical properties of polymers and their cavitation erosion resistance. The results indicate that polymers such as epoxy resin, due to their relatively small acoustic impedance, the impact loads upon the collapse of cavitation bubbles become very small. Marlin [22] showed that in short-duration cavitation processes, thinner polyurea coatings better resist bubble erosion. The temperature of polyurea coatings increases significantly due to cavitation effects, leading to heat accumulation and eventual coating failure. Unlike metals or ceramics, failed polyurea does not peel off but gets extruded at the edge under applied loads. Hibi et al. [23] studied cavitation damage behavior in epoxy resin specimens under uniaxial tensile loads, establishing a mathematical relationship between tensile stress and cavitation damage life, highlighting the significant impact of tensile stress on the initiation of damage. Chi et al. [24] compared the ultrasonic cavitation behavior of five coating materials used in the shipbuilding industry, finding that materials with better ductility and toughness, like urethane, exhibit superior erosion resistance compared to high-strength materials like epoxy resins. Correa et al. [25] found that during cavitation treatment of epoxy coatings on stainless steel and carbon steel plates, pores and cracks act as nucleation sites for cavitation, and the adhesive interaction between the coating and the substrate leads to the evolution of damage exhibiting two acceleration periods.

As previously mentioned, extensive research has been conducted on the cavitation resistance and failure mechanisms of polymers. However, most of these studies have focused on the cavitation erosion evolution process of the polymers themselves and their coatings on metals. To the best of the authors’ knowledge, the understanding of cavitation damage mechanisms for epoxy and polyurea coatings on concrete or mortar substrates remains limited. When polymer coatings bond with concrete or mortar substrates, previous researchers have primarily considered their protective role under explosive impact loads or in corrosive environments [26], [27], [28]. Epoxy coatings and polyurea coatings, as powerful green and environmentally friendly new materials, have been experimentally applied in the protection of overflow walls in hydraulic structures such as Xiaolangdi sand flushing tunnel and Xiaowan water cushion pond. However, the failure mechanisms of epoxy and polyurea coatings on concrete or mortar substrates in the face of cavitation damage caused by high-speed water flow have not been systematically studied. Wang et al. [29] subjected polyurea coatings on C60 concrete substrates to 8 h of intense cavitation treatment, clarifying the excellent cavitation resistance of polyurea elastomers, but only qualitatively described the roughening of the coating surface, the cavitation damage behavior on concrete or mortar substrates has not been adequately explained. The initial stage of cavitation erosion is crucial for understanding and explaining erosion behavior and mechanisms. During this phase, the formation and development of individual cavitation pits are distinct characteristics. The size, depth, and shape of these pits vary on different surfaces, providing rich information about the damage processes and influencing factors [30], [31], [32].

The primary objective of this study is to investigate the damage evolution of three different polymer-coating structures: epoxy coating (MEP1), epoxy coating with intermediate epoxy mortar (MEP2), and polyurea coating with intermediate epoxy mortar (MPU) on mortar substrates under cavitation effects. The early mechanisms of damage initiation and evolution, as well as the mechanisms leading to material removal, are explored. The surface morphology of polymer coatings after cavitation erosion is observed to assess the process of coating damage evolution. Furthermore, the microscopic impact of surface damage induced by cavitation on the failure of the mortar substrate is analyzed.

2. Materials preparation and experimental setup

2.1. Materials and samples preparation

Cubic cement mortar blocks measuring 70 × 70 × 70 mm3 were utilized as substrates in this study. Ordinary Portland cement with a strength grade of 42.5 was used for specimen preparation. The cement and sand were mixed in a mortar mixer at a mass ratio of 1:2. Water was then added to achieve a mortar consistency of 70–90 mm before casting. The specimens were demolded after a 24-hour curing period.

Epoxy coatings comprise two components, A and B. Component A primarily contains modified epoxy resin, flexible resin, and modified powdered fillers, while Component B includes toughening agents and specialized curing agents. Polyurea coatings, formulated with functional polyether polyols, aliphatic isocyanates, and latent curing agents as the primary materials, are combined with various additives and fillers. Table 1 presents the basic mechanical properties of cured epoxy and polyurea coatings. Epoxy coatings, characterized by high cross-linking density, are a typical thermosetting polymer [33]. Despite modification with toughening agents, their inherent brittleness and low fracture toughness result in a significantly lower elongation at break [34], [35] compared to the viscoelastic nature of polyurea coatings [36], [37].

Table 1.

Mechanical properties of epoxy and polyurea coatings.

| Coating | Tensile strength (MPa) |

Elongation at break (%) |

Adhesion to mortar (MPa) |

|---|---|---|---|

| Epoxy | 24 | 15 | 4 |

| Polyurea | 16.26 | 423 | 4 |

In this study, epoxy mortar was used as an intermediate layer between the substrate and polymer coatings. It consists of a mixture of epoxy resin, high-tech flexible resin, curing agent, and selected quartz sand. The density of epoxy mortar, according to the manufacturer’s specifications, is 1.9 g/cm3. After 28 days of curing, it exhibited a tensile strength of up to 14.2 MPa and a compressive strength of 64.3 MPa.

Ensuring robust adhesion between the coating and the mortar substrate is crucial. Before coating application, the surface of the mortar substrate underwent cleaning to remove excess mortar and loose, friable particles. An interface agent was then applied to the substrate surface to achieve optimal coating adhesion. The specimen design includes three types: single epoxy coating (MEP1), epoxy coating with intermediate epoxy mortar (MEP2), and polyurea coating with intermediate epoxy mortar (MPU) on the mortar substrate. The typical cross-sections of these three specimens, as shown in Fig. 1, exhibit relatively uniform coating thicknesses, with surface layer coatings controlled at approximately 350 μm. The thicknesses of coatings on mortar substrates for the three specimens and their average surface roughness are depicted in Table 2. Notably, to ensure good adhesion between the surface polyurea coating and the intermediate epoxy mortar coating while preparing the MPU samples, an interface agent was applied onto the surface of the epoxy mortar coating, resulting in a slightly greater total thickness of the MPU coating on the mortar substrate compared to the MEP2 specimen. Fig. 2 presents the surface morphology of three specimens before cavitation treatment. The polymer surface is smooth and flat, without the presence of any voids.

Fig. 1.

Typical cross-sectional morphology of three specimens: (a) epoxy coating applied on mortar substrate (MEP1); (b) epoxy coating with intermediate epoxy mortar coating on mortar substrate (MEP2); (c) polyurea coating with intermediate Epoxy mortar coating on mortar substrate (MPU). All interface boundaries are delineated using white dotted lines.

Table 2.

Surface characteristics of the three specimens: MEP1, MEP2, and MPU.

| Coating | coating thickness (μm) |

Average surface roughness (μm) |

|

|---|---|---|---|

| MEP1 | upper | 330.5 ∼ 362.6 | 2.755 |

| MEP2 | upper | 331.5 ∼ 377.4 | 2.820 |

| total | 779.2 ∼ 809.1 | ||

| MPU | upper | 374.9 ∼ 399.6 | 2.614 |

| total | 944.8 ∼ 989.2 | ||

Fig. 2.

Surface morphology of three specimens before cavitation treatment: (a) MEP1; (b) MEP2; (c) MPU.

2.2. Experimental setup

Fig. 3 illustrates the ultrasonic cavitation experimental setup. A 25-mm diameter probe, driven by a piezoelectric transducer, oscillated at a frequency of 20 kHz with an amplitude of 35 μm (Sonics, VX-1500). This generated ultrasonic waves that propagate through water, inducing significant cavitation phenomena beneath the probe. Specimens coated with polymer were fixed at the bottom of the water tank, positioned 5 mm away from the probe tip. Unlike earlier studies [38], [39], a greater distance was maintained to ensure lower cavitation intensity, preserving the independence of pit development. It is noteworthy that the probe’s center was coaxial with the sample’s center, ensuring consistent cavitation intensity in specific regions of the coated surface. Given the notable influence of temperature on erosion depth [40], the water temperature within the tank was maintained at 298 ± 1 K by circulating cooling water. The cavitation experiments lasted for 180 min. After each 30-minute ultrasonic treatment, the samples were removed, rinsed with tap water, and thoroughly air-dried at room temperature for surface morphology characterization.

Fig. 3.

(a) Schematic diagram; (b) experimental setup in present study.

2.3. Pit analysis

The square central region, measuring 30 × 30 mm on the coating surface and exhibiting the majority of cavitation pits, was selected for comprehensive analysis. The surface morphology of the specimens was meticulously measured using a three-dimensional optical scanning profilometer (Keyence, VR-5000) equipped with a 160 × objective lens capable of achieving a resolution of 0.1 μm. The typical surface map of cavitation damage, captured through optical scanning, is presented in Fig. 4. ImageJ, an open-source software, was then utilized for image processing to isolate individual cavitation pit areas [41], with cavitation pit edges marked in yellow. Assuming the cavitation pits were circular, the outlines of these pits were used to calculate the projected area of each pit, which was then converted into the diameter of an equivalent circle with the same area. In order to reduce the influence of initial surface defects on subsequent data analysis, a pre-cavitation examination of the sample surface was conducted. It revealed that most surface defects had diameters within 20 μm. Consequently, only cavitation pits with diameters exceeding 20 μm were considered for further analysis.

Fig. 4.

Typical data obtained from three-dimensional optical scanning (The edges of cavitation pits are marked with solid yellow lines).

3. Results and discussion

3.1. Evolution of cavitation erosion on the surface

Fig. 5 illustrates the surface morphology of the mortar substrate before and after the cavitation treatment without coatings. Before the cavitation test, excess mortar and loose particles were removed from the mortar surface, as shown in Fig. 5(a). Despite the presence of some small defects, the mortar surface was generally smooth. Previous studies [42], [43] have indicated that a stable conical bubble structure forms beneath the ultrasonic probe when the probe amplitude exceeds 30 μm. Concurrently, a thin layer of bubbles adheres to the probe’s surface, as evidenced in this experiment (Fig. 5(c)). An area significantly affected by the ultrasonic action on the coating surface, marked with a 25-mm diameter circular label directly under the ultrasonic probe, was identified as the primary affected zone (Fig. 5(a)). After an hour of ultrasonic treatment, material detachment became noticeable on the mortar surface (Fig. 5(b)). Within the primary affected zone, the intensity of cavitation attenuated radially due to the conical bubble structure beneath the probe. The central area showed the most significant damage, with almost no independently developed cavitation pits, and its maximum erosion depth surpassed 1900 μm.

Fig. 5.

The surface characteristics of mortar: (a) before cavitation erosion; (b) after 1 h of cavitation treatment; (c) conical bubble structure under the ultrasonic probe.

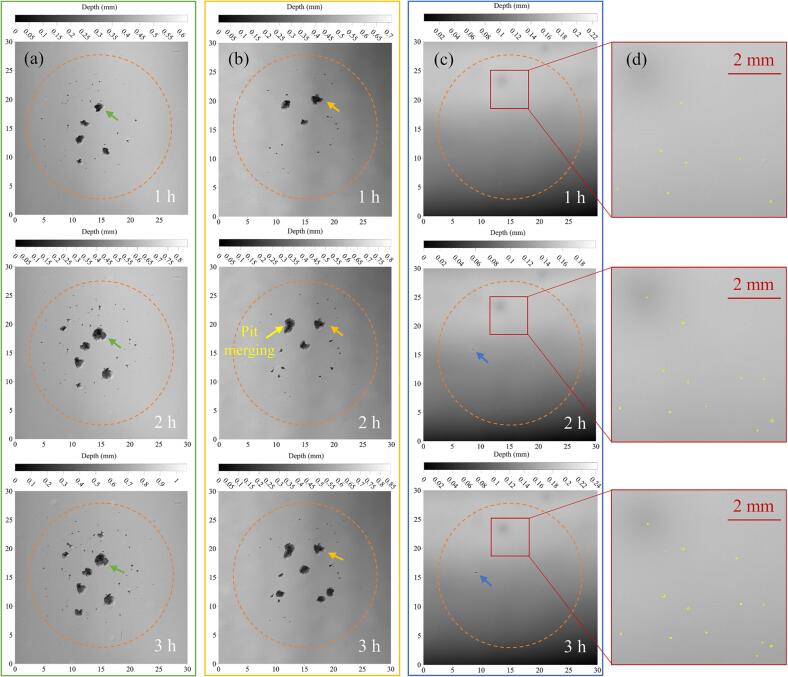

Fig. 6 compares the cavitation surface evolution of three different coating structures. The primary affected zones are outlined by orange dashed lines, and prominent independent cavitation pits on the coating surfaces are indicated with arrows. As the duration of ultrasonic treatment increased, more cavitation pits formed on the surfaces of all three polymer coatings. The development of cavitation pits in the center of the primary affected zone occurred before those on the periphery, owing to the conical bubble structures beneath the probe. The development of cavitation pits on the MEP1 coating surface remained isolated, with no merging observed among the pits during the cavitation process.

Fig. 6.

Cavitation characteristics on the surface with different cavitation treatment times for: (a) MEP1, (b) MEP2, (c) MPU, and (d) magnified micrograph of MPU (Individual maximum cavitation pits are marked with arrows. The cavitation pits in the magnified micrograph are delineated by solid yellow lines).

A similar number of larger-sized cavitation pits appeared on the MEP2 surface compared to MEP1 upon introducing epoxy mortar as an intermediate layer between the mortar substrate and the epoxy coating in MEP2. However, the quantity of smaller-sized cavitation pits within the primary affected zone significantly decreased. Notably, after 2 h of ultrasonic treatment (Fig. 6(b)), an unexpected merging behavior of cavitation pits was observed on the MEP2 coating surface. Nonetheless, for most cavitation pits on the coating under these experimental conditions, their evolution remained independent.

In the MPU coating case, numerous small, independent cavitation pits emerged at the center of the primary affected zone, as illustrated in Fig. 6(d). The largest observed cavitation pit on the MPU coating had an equivalent diameter of only 228.8 μm, markedly smaller, tenfold, than the maximum diameter of cavitation pits on MPE1 and MPE2 specimens. Following 3 h of ultrasonic cavitation treatment, the MPU coating exhibited the least amount of cavitation damage.

3.2. Cavitation pit distribution

In order to thoroughly examine the distribution patterns of cavitation pits on various polymer coatings under different durations of ultrasonic treatment, these pits were categorized, as recorded by a three-dimensional scanning profilometer, based on their diameters. Fig. 7 displays the correlation between the cumulative pitting rate and the diameters of cavitation pits across three distinct polymer-coating structures. The cumulative distribution function of the pitting rate is characterized as the count of pits exceeding a specific diameter, denoted as D, normalized by both time and area. Prior studies suggested that the distribution of the pitting rates closely aligns with the Weibull distribution [31], [44], as follows:

| (1) |

where N is the cumulative pitting rate; D is the diameter of pits; N* is the characteristic pitting rate; D* is the characteristic diameter of pits; k is the shape parameter. The Levenberg-Marquardt method is employed in this study to obtain the three parameters of the Weibull distribution.

Fig. 7.

Cumulative pitting rate, , as a function of pit diameter for different ultrasonic treatment durations on: (a) MEP1; (b) MEP2; (c) MPU (The curve fitting corresponds to a three-parameter Weibull distribution).

Due to the imperfect approximation of Weibull distribution for large diameter cavitation pits under semi-logarithmic coordinates [44], a separation diameter Ds can be obtained based on whether the cavitation pits develop into the mortar substrate or the intermediate epoxy mortar coating. Thus, cavitation pits of different diameters appearing on the surface of specimens under different ultrasonic treatment times are classified into two categories: large pits and small pits. Small pits continue to develop within the surface coating, and their pitting rate can be well approximated by the Weibull distribution. As shown in Fig. 7, the separation diameter of cavitation pits on the MEP1 coating on the mortar substrate is 466.9 µm. Fig. 7 further traces the evolution of the maximum pit diameter on the MEP1 surface, noting a marginal increase of only 10 µm in diameter as the ultrasonic treatment duration extends from 120 to 180 min. This observation implies a potential upper limit in the independent growth of cavitation pits on the plane.

Considering the relatively superficial depth of smaller pits, they predominantly appear on the surface of epoxy polymers. For MEP2 specimens, which incorporate an intermediate epoxy mortar layer, the separation diameter Ds closely mirrors that of MEP1 specimens, recorded at 467.2 µm. It is important to note that the large pits develop only up to the intermediate epoxy mortar layer. As illustrated in Fig. 7(b), the cumulative pitting rate on MEP2 also adheres to the Weibull distribution within the diameter range of small pits. The introduction of an intermediate epoxy mortar layer between the mortar substrate and the epoxy coating significantly influences the maximum pitting rate on MEP2, reducing it to approximately one-third of that on the MEP1 surface under identical ultrasonic treatment conditions. However, the dimensions and numbers of large pits on the eroded surface remain largely consistent with those on MEP1. This observation suggests that the primary role of the intermediate epoxy mortar layer in resisting cavitation erosion lies in the initial stages of pit formation, diminishing the formation likelihood. The layer’s ability to absorb and dissipate cavitation impact energy effectively prolongs the epoxy coating’s resistance to cavitation, thereby delaying pit formation on the coating surface. As cavitation pits develop on the surface of the epoxy mortar coating, the intermediate layer’s role is evident only in its bonding with the surface epoxy polymer, similar to the bonding between the mortar substrate and epoxy coating in MEP1 specimens. Consequently, this leads to the emergence of similar sizes and quantities of large pits on the surfaces of both MEP1 and MEP2 specimens. After 120 min of ultrasonic treatment, MEP2 exhibits no substantial increase in the maximum pit diameter, closely paralleling MEP1’s upper limit of individual pit development at approximately 2300 μm.

Polyurea polymers have attracted considerable attention among various polymer materials for their outstanding resistance to explosions and impact loads [14], [37], [45]. Replacing the topmost epoxy polymer layer in MEP2 specimens with a polyurea polymer layer resulted in an absence of cavitation pits extending to the interface between polyurea and epoxy mortar, categorizing all observed pits as small. As depicted in Fig. 7(c), the Weibull distribution encompasses nearly the entire spectrum of cavitation pit sizes, except for the largest pit. Despite no significant decrease in the maximum pitting rate of MPU coatings after 180 min of ultrasonic treatment, the maximum diameter of cavitation pits on its surface was only a tenth of that in MEP2 specimens, showing consistent planar growth. Notably, the use of semi-logarithmic scales accentuates the differences in maximum pitting rate under various ultrasonic treatment durations, with the increase in pitting rate for the MPU specimen being lower than that observed in the other two samples.

Fig. 8 shows the evolution process of the characteristic pitting rate N* and characteristic diameter D* for three specimens in relation to cavitation treatment time, approximated using power functions. It is evident that N* increases with the duration of cavitation treatment for all specimens, indicating more severe damage from prolonged ultrasonic exposure. D* effectively represents the growth of pit clusters. As shown in Fig. 8(b), MEP1 and MPU display a decreasing trend in D*, suggesting that pit cluster development primarily involves forming smaller pits. In contrast, MEP2’s pit clusters predominantly enlarge existing pits. Fig. 6 also clearly demonstrates the variation trend of the characteristic diameter D* of cavitation pits on the surfaces of the three specimens. With ultrasonic treatment extended from 2 h to 3 h, significant changes in the occurrence of large pits on the surface of the MEP1 specimen are almost absent. The evolution of the eroded surface is mainly attributed to the introduction of small pits, leading to a decreasing trend in the characteristic diameter D* of the MEP1 specimen. Similarly, due to the continuous generation of small pits, the characteristic diameter D* of the MPU specimen also exhibits a decreasing trend. However, as depicted in Fig. 6(b), with the extension of ultrasonic treatment duration, further development on the plane of already formed large pits can be clearly observed. As mentioned earlier, epoxy mortar, as an intermediate layer, absorbs more energy generated by cavitation bubble collapse, delaying the occurrence of cavitation pits on the surface of the MEP2 coating. This results in a different trend in the characteristic diameter D* of the MEP2 specimen compared to MEP1 and MPU. It is important to note that excluding large pits from the Weibull distribution fitting may underestimate the damage to MEP1 and MEP2 coatings. However, this does not hinder understanding the development of pit clusters on these coatings.

Fig. 8.

Comparison of the characteristic parameters for different ultrasonic treatment durations of three specimens: MEP1, MEP2, and MPU: (a) characteristic pitting rate; (b) characteristic diameter.

3.3. Evolution of single pit

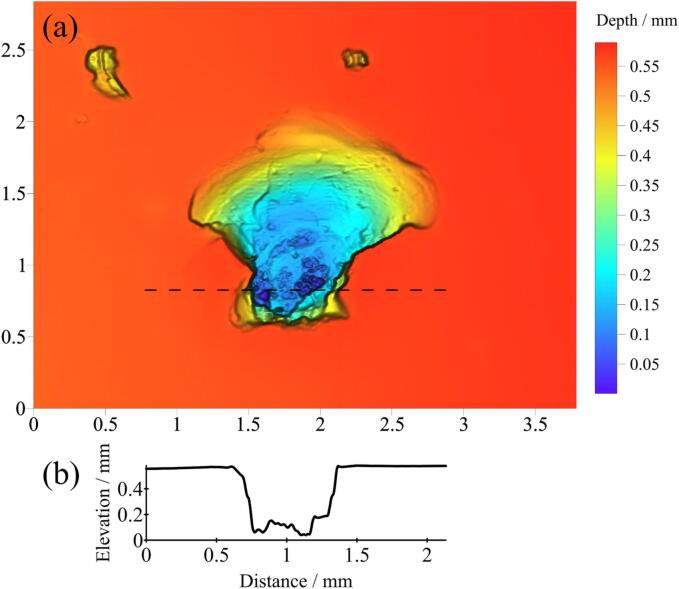

Fig. 9 illustrates the evolution of a typical pit on MEP1’s surface. In early cavitation erosion stages, noticeable cracks appear at the edges of the pit. However, these radial cracks generally do not directly cause coating detachment due to their limited interconnection. As depicted in Fig. 10, after 60 min of ultrasonic treatment, the pit’s development alters the boundary conditions for cavitation bubble collapse. The cavitation pit, reaching a maximum depth of approximately 530 μm due to material removal of the epoxy polymer on the mortar substrate, resembles a combination of two nearly perpendicular rigid walls when cavitation bubbles of around 300 μm collapse [46], [47]. Microjets directed toward the corners during bubble collapse [48], [49] form a water wedge that detaches material from the mortar substrate. Fig. 9(c) vividly shows this detachment process. Under radial cracks’ synergistic action, the coating detaches from the mortar substrate, forming larger pit as seen in Fig. 9(d). After 120 min of treatment, no further detachment occurs, exposing a large mortar substrate area. Consequently, some cavitation bubbles collapse unaffected by the coating, initiating direct erosion on the mortar substrate (Fig. 9(e)). Notably, the edges of cavitation pits remain smooth and sharp throughout. The presence of distinct radial cracks and fatigue streaks indicates MEP1’s predominantly brittle failure mode [50].

Fig. 9.

Typical pit evolution on MEP1 surface. After 90 min of cavitation erosion, the mortar substrate is completely exposed at the bottom of the pit.

Fig. 10.

Surface morphology of typical pit on MEP1 after 60 min of cavitation erosion: (a) 2D view; (b) depth profiles.

Fig. 11 illustrates the morphology of a typical pit on MEP2’s surface after 180 min of ultrasonic treatment. Extended cavitation erosion resulted in brittle failure of the surface epoxy coating, leaving dense fatigue striations on the pit’s inner side (Fig. 11(a)). Unlike MEP1, the material delamination at MEP2’s pit bottom occurred within the intermediate epoxy mortar layer, as highlighted in the red-lined region of Fig. 11(a). The maximum erosion depth of this typical pit reached 574 μm after 180 min, less than MEP2’s total coating thickness of 784.6 μm. The mortar substrate remained shielded beneath the polymer coating. Due to the intermediate epoxy mortar layer, the pit’s development showed distinct stratification (Fig. 11(b)), with most areas at the pit bottom still retained a certain thickness of flat polymer coating, slightly lighter in color than the epoxy, as indicated by the yellow-lined region in Fig. 11(a). Despite the typical pit’s equivalent diameter exceeding 2000 μm (green-lined region in Fig. 11(a)), nearing MEP1 surface’s maximum pit size (Fig. 9(f)), the epoxy mortar coating’s introduction between the epoxy coating and mortar substrate impeded crack formation directly reaching the mortar during cavitation erosion. After the surface epoxy polymer delaminated, the intermediate coating’s presence prevented the mortar substrate’s direct exposure to cavitation, effectively protecting it.

Fig. 11.

The typical pit morphology on the surface of MEP2 after 180 min of ultrasonic treatment: (a) optical image; (b) three-dimensional morphology above the black dashed line.

Fig. 12 elucidates MEP2’s hierarchical pit development, showing erosion area variations within the pit. The line colors correspond to Fig. 11(a)’s erosion region contours. As Fig. 12 indicates, during erosion, the exposed intermediate epoxy mortar coating area positively correlates with total pit area. From 30 to 60 min of treatment, the total pit area increases by 53.9 %, while the bottom area grows by 82.9 %. After 60 min of ultrasonic treatment, the equivalent diameter of cavitation pits exceeded 1800 μm, as shown in Fig. 11(b). The profile shape of the cavitation pits resembled a concave surface. The microjets generated upon the collapse of cavitation bubbles with a diameter of around 300 μm no longer primarily developed towards the corners but propagated radially outward along the concave surface after impacting the inner wall of the cavitation pit, with reduced jet velocity [51]. In the case of weakened water wedge action, the total area of cavitation pit entered a stage of slow increase. Moreover, secondary pit development on the intermediate coating is not significant throughout the process. Pit evolution mainly manifests as planar expansion due to surface material detachment. Unlike MEP1, the detachment of the epoxy coating occurs on the intermediate epoxy mortar coating. The exposed intermediate coating at the pit bottom adheres to the substrate effectively, providing substantial protection.

Fig. 12.

Hierarchical development of typical pit on the damaged surface of MEP2.

Fig. 13 presents the morphological evolution of MPU’s largest equivalent-diameter pit, beginning from 90 min of cavitation erosion. The coating’s elastic deformation primarily absorbed the impact energy from cavitation bubble collapses and shock waves [52]. Polyurea, a viscoelastic material, has a fracture elongation approximately 28 times that of epoxy polymers. Unlike MEP1 and MEP2, which exhibited sharp edges and fatigue stripes from brittle fracture, MPU’s cavitation pit edges showed distinct white plastic zones. The pit’s inner sidewalls were rough, and no chunk detachment of polymer material occurred during cavitation erosion. After 180 min of ultrasonic treatment, the cavitation pits did not expose bare epoxy mortar at their bottoms.

Fig. 13.

Typical pit evolution on MPU surface under cavitation erosion.

3.4. Comparison of cavitation characteristics

Fig. 14 compares the evolution of maximum erosion depths on the surfaces of MEP1, MEP2, and MPU. After 30 min of ultrasonic treatment, a cavitation pit on MEP1’s surface had penetrated the mortar substrate, reaching a maximum depth of 456.7 μm, surpassing the epoxy coating’s thickness of 349.7 µm on the MEP1 specimen. This detachment of the epoxy polymer occurred beneath the interface on the mortar substrate, suggesting that the bond strength between the epoxy and the mortar substrate exceeds the mortar’s tensile strength. Following 120 min of ultrasonic treatment, MEP1’s maximum surface erosion depth extended to 773.4 μm, representing a 15.5 % increase in distance from the ultrasonic probe’s surface. As the cavitation intensity diminished, prolonged ultrasonic treatment resulted in negligible changes in maximum erosion depth. In the case of MEP2, the topmost epoxy polymer’s detachment similarly occurred beneath the first interface. However, due to decreasing cavitation activity, the rate of increase in maximum erosion depth gradually reduced. A notable distinction is that the development of cavitation pits remained within the thickness of MEP2’s intermediate epoxy mortar coating. After 180 min of ultrasonic treatment, at the maximum erosion depth on MEP2’s surface, an intermediate coating layer with a thickness of 135.2 μm still adhered to the mortar substrate, indicating that the cavitation pits did not fully penetrate through to the mortar substrate. Remarkably, although the MPU specimen’s cavitation pit depth continued to increase linearly, the maximum erosion depth reached only 192.3 μm by the test’s conclusion. The cavitation pits’ development consistently stayed within the thickness of the surface polyurea coating, demonstrating its superior resistance to cavitation.

Fig. 14.

Evolution of the maximum erosion depths on the surfaces of specimens MEP1, MEP2, and MPU.

Fig. 15 illustrates the erosion processes in MEP1, MEP2, and MPU specimens. Throughout the ultrasonic treatment, introducing an intermediate epoxy mortar layer between the epoxy coating and the mortar substrate slightly reduced the surface erosion area of the epoxy polymer. Notably, the count of pits on the coating surface decreased by approximately two-thirds. This reduction predominantly involved pits with equivalent diameters less than 467.2 μm, signifying a decrease in defects on the coating surface and a lower probability of cavitation damage. In contrast, for the MPU specimen, the progression of the cavitation process manifested primarily in an increased count of small-sized pits on the polyurea coating’s surface. As shown in Fig. 7(c), the equivalent diameters of these cavitation pits are merely 1/10 or smaller when compared to those on the other two specimens. Consequently, the erosive area on the MPU surface consistently remained at comparatively lower levels. Under identical experimental conditions, the MPU specimen demonstrated enhanced cavitation resistance relative to MEP1 and MEP2. This superior resistance can be attributed not only to the intermediate layer’s ability to absorb and dissipate the impact energy from the collapse of the cavitation bubble but also to the high elastic deformation capacity of the polyurea polymer. This elasticity enables the polymer to endure repeated energy impacts, effectively preventing the polymer’s extensive detachment during the development of cavitation pits. Such resilience results in smaller cavitation pit sizes and depths, thereby decelerating the advancement of cavitation damage.

Fig. 15.

Comparison of total erosion area and cavitation pit quantity on the surfaces of MEP1, MEP2, and MPU.

4. Conclusions

In this study, three distinct polymer-coating structures were applied to a mortar substrate: MEP1, consisting of an epoxy coating; MEP2, featuring an epoxy coating with an intermediate epoxy mortar layer; and MPU, comprising a polyurea coating with an intermediate epoxy mortar layer. Numerous cavitation pits were formed on the surface of these coatings following 180 min of ultrasonic treatment.

The emergence of conical bubble structures led to a more extensive formation of cavitation pits in the central area of the primary affected zone compared to the peripheral regions. However, the development of cavitation pits on the surfaces of the three specimens was essentially independent, each exhibiting unique evolutionary patterns.

The MEP1 specimen, with only a single epoxy layer on the mortar substrate, showed the most significant damage. During cavitation erosion, MEP1 demonstrated a typical brittle failure mode, characterized by cavitation pits with smooth, sharp edges and visible fatigue striations on their inner walls. After 30 min of ultrasonic treatment, the maximum erosion depth of a cavitation pit surpassed the epoxy coating’s thickness, suggesting that cavitation erosion had already begun on the mortar substrate before the pits merged. The combined effect of water wedges formed by collapsing cavitation bubbles and radial cracks around the cavitation pits led to the detachment of epoxy polymer in blocks from the mortar substrate, resulting in the development of cavitation pits on the plane.

Introducing an intermediate epoxy mortar layer between the mortar substrate and the epoxy coating enhanced the MEP2 specimen’s resistance to cavitation. This epoxy coating gained an improved ability to absorb the impact energy from collapsing cavitation bubbles. While there was no notable change in the size and number of large pits on the coating surface, the number of small pits decreased significantly by nearly two-thirds. Material detachment, caused by water wedges and radial cracks, occurred below the interface between the epoxy coating and the intermediate epoxy mortar layer, indicating a stronger bond at the interface than the tensile strength of the epoxy mortar. Additionally, the intermediate coating prevented radial cracks from reaching the mortar substrate. The bottoms of large pits remained coated with a layer of epoxy mortar, thereby protecting the mortar substrate from direct cavitation erosion damage.

For the MPU specimen, no significant cavitation damage was observed on the surface throughout the experiment, and the total erosion area remained exceptionally low. Despite the increase in the number of cavitation pits, their planar dimensions were about 1/10th the size of those on MEP1 and MEP2, or even smaller. The intermediate layer’s introduction enhanced energy absorption, while the polyurea’s excellent elastic deformation capability reduced the likelihood of material chunk detachment. The inner sidewalls of the cavitation pits showed pronounced plastic failure with noticeable roughness. Even after 180 min of ultrasonic treatment, the development of cavitation pits remained confined to the polyurea coating’s thickness, effectively shielding the mortar substrate and demonstrating superior cavitation resistance.

The results clearly illustrate that the introduction of an intermediate coating and the enhancement of a polymer’s elastic deformation ability are both critical in protecting the mortar substrate. These findings offer promising directions for future design and manufacturing of cavitation-resistant coatings. Nevertheless, further research is crucial to understand the underlying mechanisms, such as the potential impact of the development of secondary cavitation pits on the intermediate coating on the progression of the primary cavitation pit.

CRediT authorship contribution statement

Caisheng Huang: Writing – original draft, Methodology, Conceptualization. Xiaolong He: Writing – review & editing, Supervision, Investigation. Jianmin Zhang: Writing – review & editing, Supervision, Funding acquisition.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant numbers: U22A20236). In addition, the authors especially thank Mingyang Yu for his support and help in the preparation of specimens.

Contributor Information

Xiaolong He, Email: xiaolonghescu1990@gmail.com.

Jianmin Zhang, Email: zhangjianmin@scu.edu.cn.

Data availability

Data will be made available on request.

References

- 1.Falvey H.T. Cavitation in chutes and spillways. Eng. Monogr. 1990;42 [Google Scholar]

- 2.Hohermuth B., Schmocker L., Boes R.M. Air demand of low-level outlets for large dams. J. Hydraul. Eng. 2020;146:04020055. doi: 10.1061/(ASCE)HY.1943-7900.0001775. [DOI] [Google Scholar]

- 3.Brujan E.A., Ikeda T., Matsumoto Y. On the pressure of cavitation bubbles. Exp. Therm. Fluid Sci. 2008;32:1188–1191. doi: 10.1016/j.expthermflusci.2008.01.006. [DOI] [Google Scholar]

- 4.Gonzalez Avila S.R., Song C., Ohl C.-D. Fast transient microjets induced by hemispherical cavitation bubbles. J. Fluid Mech. 2015;767:31–51. doi: 10.1017/jfm.2015.33. [DOI] [Google Scholar]

- 5.He X., Peng H. Modeling inception and evolution of near-wall vapor thermo-cavitation bubbles via a lattice Boltzmann method. Int. J. Hydrog. Energy. 2024;49:828–849. doi: 10.1016/j.ijhydene.2023.09.092. (S036031992304658X) [DOI] [Google Scholar]

- 6.Popinet S., Zaleski S. Bubble collapse near a solid boundary: A numerical study of the influence of viscosity. J. Fluid Mech. 2002;464:137–163. doi: 10.1017/S002211200200856X. [DOI] [Google Scholar]

- 7.He X., Peng H., Zhang J., Yuan H. Multiple vapor cavitation bubble interactions with a thermal lattice Boltzmann method. Ocean Eng. 2022;266 doi: 10.1016/j.oceaneng.2022.113058. [DOI] [Google Scholar]

- 8.Xu W. Mesoscale Analysis of Hydraulics. Springer; Singapore, Singapore: 2021. [DOI] [Google Scholar]

- 9.Gonzalez-Avila S.R., Nguyen D.M., Arunachalam S., Domingues E.M., Mishra H., Ohl C.D. Mitigating cavitation erosion using biomimetic gas-entrapping microtextured surfaces (GEMS) Sci. Adv. 2020;6:eaax6192. doi: 10.1126/sciadv.aax6192. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Singh R., Tiwari S.K., Mishra S.K. Cavitation erosion in hydraulic turbine components and mitigation by coatings: Current status and future needs. J. Mater. Eng. Perform. 2012;21:1539–1551. doi: 10.1007/s11665-011-0051-9. [DOI] [Google Scholar]

- 11.Dular M., Ohl C.D. Bulk material influence on the aggressiveness of cavitation – Questioning the microjet impact influence and suggesting a possible way to erosion mitigation. Wear. 2023;530–531 doi: 10.1016/j.wear.2023.205061. [DOI] [Google Scholar]

- 12.Wei W., Deng J. Wedge aerator at the bottom outlet in flat tunnels. J. Hydraul. Eng. 2023;149:04022037. doi: 10.1061/(ASCE)HY.1943-7900.0002010. [DOI] [Google Scholar]

- 13.Li J., Xu W., Zhai Y.-W., Luo J., Wu H., Deng J. Influence of multiple air bubbles on the collapse strength of a cavitation bubble. Exp. Therm. Fluid Sci. 2021;123 doi: 10.1016/j.expthermflusci.2020.110328. [DOI] [Google Scholar]

- 14.Rijensky O., Rittel D. Polyurea coated aluminum plates under hydrodynamic loading: Does side matter? Int. J. Impact Eng. 2016;98:1–12. doi: 10.1016/j.ijimpeng.2016.07.006. [DOI] [Google Scholar]

- 15.Guo L., Chen Z., Han H., Liu G., Luo M., Cui N., Dong H., Li M.-Z. Advances and outlook in modified graphene oxide (GO)/epoxy composites for mechanical applications. Appl. Nanosci. 2023;13:3273–3287. doi: 10.1007/s13204-022-02653-w. [DOI] [Google Scholar]

- 16.Gu M., Ling X., Yu A., Chen G., Wang H., Wang H. Experimental study of polyurea-coated fiber-reinforced cement boards under gas explosions. Def. Technol. 2023;23:201–213. doi: 10.1016/j.dt.2021.12.011. [DOI] [Google Scholar]

- 17.Abenojar J., Tutor J., Ballesteros Y., del Real J.C., Martínez M.A. Erosion-wear, mechanical and thermal properties of silica filled epoxy nanocomposites. Compos. B Eng. 2017;120:42–53. doi: 10.1016/j.compositesb.2017.03.047. [DOI] [Google Scholar]

- 18.V.K. Shahi, A study of cavitation erosion on Polyurea coatings, M.S., University of Massachusetts Lowell, 2017. https://www.proquest.com/docview/1927182267/abstract/1C01C06687994829PQ/1 (accessed July 25, 2023).

- 19.Hao J., Zhang M., Huang X. Experimental study on influences of surface materials on cavitation flow around hydrofoils. Chin. J. Mech. Eng. 2019;32:45. doi: 10.1186/s10033-019-0355-5. [DOI] [Google Scholar]

- 20.Cao S., Wang G., Coutier-Delgosha O., Wang K. Shock-induced bubble collapse near solid materials: Effect of acoustic impedance. J. Fluid Mech. 2021;907:A17. doi: 10.1017/jfm.2020.810. [DOI] [Google Scholar]

- 21.Hattori S., Itoh T. Cavitation erosion resistance of plastics. Wear. 2011;271:1103–1108. doi: 10.1016/j.wear.2011.05.012. [DOI] [Google Scholar]

- 22.Marlin P., Chahine G.L. Erosion and heating of polyurea under cavitating jets. Wear. 2018;414–415:262–274. doi: 10.1016/j.wear.2018.08.019. [DOI] [Google Scholar]

- 23.Hibi M., Triawan F., Inaba K., Takahashi K., Kishimoto K., Hayabusa K., Nakamoto H. Cavitation damage of epoxy resin subjected to uniaxial tensile loading. Mech. Eng. J. 2018;5:17–151. doi: 10.1299/mej.17-00151. 17-00151-17-00151. [DOI] [Google Scholar]

- 24.Chi S., Park J., Shon M. Study on cavitation erosion resistance and surface topologies of various coating materials used in shipbuilding industry. J. Ind. Eng. Chem. 2015;26:384–389. doi: 10.1016/j.jiec.2014.12.013. [DOI] [Google Scholar]

- 25.Correa C.E., García G.L., García A.N., Bejarano W., Guzmán A.A., Toro A. Wear mechanisms of epoxy-based composite coatings submitted to cavitation. Wear. 2011;271:2274–2279. doi: 10.1016/j.wear.2011.01.088. [DOI] [Google Scholar]

- 26.Dorado F., Toledo L., de la Osa A.R., Esteban-Arranz A., Sacristan J., Pellegrin B., Steck J., Sanchez-Silva L. Adhesion enhancement and protection of concrete against aggressive environment using graphite-Fe2O3 modified epoxy coating. Constr. Build. Mater. 2023;379 doi: 10.1016/j.conbuildmat.2023.131179. [DOI] [Google Scholar]

- 27.Guo H., Du C., Chen Y., Li D., Hu W., Lv X. Study on protective performance of impact-resistant polyurea and its coated concrete under impact loading. Constr. Build. Mater. 2022;340 doi: 10.1016/j.conbuildmat.2022.127749. [DOI] [Google Scholar]

- 28.Wang H., Feng P., Lv Y., Geng Z., Liu Q., Liu X. A comparative study on UV degradation of organic coatings for concrete: Structure, adhesion, and protection performance. Prog. Org. Coat. 2020;149 doi: 10.1016/j.porgcoat.2020.105892. [DOI] [Google Scholar]

- 29.Wang X., Liu G.-S., Luo S.-Z., Tian F.-L., Bai Y. Experimental study of abrasion and cavitation resistance performance of polyurea materials for hydraulic discharge structure protection. J. Hydroelectr. Eng. 2013;32:222–227. https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CJFD&dbname=CJFDHIS2&filename=SFXB201306037&uniplatform=NZKPT&v=qLViItnjIfUDr1GE55C0jLgfldVka5Ai0fTHiWU-WXyXtwI6QkeqNlg9YBryvxKW [Google Scholar]

- 30.Kühlmann J., Lopez de Arcaute y Lozano C., Hanke S., Kaiser S.A. Correlation of laser-induced single bubbles with cavitation damage via in-situ imaging. Wear. 2023;522 doi: 10.1016/j.wear.2023.204723. [DOI] [Google Scholar]

- 31.Lim Y., Murugesan P., Jung S., Lee H. Evaluation of residual stress from ultrasonic cavitation peening using cavitation pit analysis and FEA. Int. J. Mech. Sci. 2021;198 doi: 10.1016/j.ijmecsci.2021.106352. [DOI] [Google Scholar]

- 32.Dular M., Požar T., Zevnik J., Petkovšek R. High speed observation of damage created by a collapse of a single cavitation bubble. Wear. 2019;418–419:13–23. doi: 10.1016/j.wear.2018.11.004. [DOI] [Google Scholar]

- 33.Domun N., Hadavinia H., Zhang T., Sainsbury T., Liaghat G.H., Vahid S. Improving the fracture toughness and the strength of epoxy using nanomaterials – A review of the current status. Nanoscale. 2015;7:10294–10329. doi: 10.1039/C5NR01354B. [DOI] [PubMed] [Google Scholar]

- 34.Mashouf Roudsari G., Mohanty A.K., Misra M. Green approaches to engineer tough biobased epoxies: A review. ACS Sustain. Chem. Eng. 2017;5:9528–9541. doi: 10.1021/acssuschemeng.7b01422. [DOI] [Google Scholar]

- 35.Vijayan P.P., Puglia D., Al-Maadeed M.A.S.A., Kenny J.M., Thomas S. Elastomer/thermoplastic modified epoxy nanocomposites: The hybrid effect of ‘micro’ and ‘nano’ scale. Mater. Sci. Eng. R Rep. 2017;116:1–29. doi: 10.1016/j.mser.2017.03.001. [DOI] [Google Scholar]

- 36.Wang H., Deng X., Wu H., Pi A., Li J., Huang F. Investigating the dynamic mechanical behaviors of polyurea through experimentation and modeling. Def. Technol. 2019;15:875–884. doi: 10.1016/j.dt.2019.04.016. [DOI] [Google Scholar]

- 37.Zhang L., Wang X., Ji C., Wang Y., Yang G., Zhao C., Tao C. Effect of polyurea coating with different mechanical properties on blast resistance of aluminum alloy circular tube structures: Experiments vs numerical simulations. Thin Walled Struct. 2023;183 doi: 10.1016/j.tws.2022.110361. [DOI] [Google Scholar]

- 38.Liao X.-J., Luo X.-T., Zhang L., Chen X., Sun Y.-Q., Li C.-X., Yang G.-J., Li C.-J. Mo-alloyed stainless steel coating with improved cavitation erosion resistance by plasma spraying a specially designed core-shell-structured powder. Wear. 2023;528–529 doi: 10.1016/j.wear.2023.204961. [DOI] [Google Scholar]

- 39.Martinović S., Alil A., Milićević S., Živojinović D., Volkov Husović T. Morphological assessment of cavitation caused damage of cordierite and zircon based materials using principal component analysis. Eng. Fail. Anal. 2023;148 doi: 10.1016/j.engfailanal.2023.107224. [DOI] [Google Scholar]

- 40.Ahmed S.M. Investigation of the temperature effects on induced impact pressure and cavitation erosion. Wear. 1998;218:119–127. doi: 10.1016/S0043-1648(97)00290-1. [DOI] [Google Scholar]

- 41.Arganda-Carreras I., Kaynig V., Rueden C., Eliceiri K.W., Schindelin J., Cardona A., Sebastian Seung H.S. Trainable Weka Segmentation: A machine learning tool for microscopy pixel classification. Bioinformatics. 2017;33:2424–2426. doi: 10.1093/bioinformatics/btx180. [DOI] [PubMed] [Google Scholar]

- 42.Bai L., Xu W., Deng J., Li C., Xu D., Gao Y. Generation and control of acoustic cavitation structure. Ultrason. Sonochem. 2014;21:1696–1706. doi: 10.1016/j.ultsonch.2014.02.027. [DOI] [PubMed] [Google Scholar]

- 43.Tan K.L., Yeo S.H. Bubble dynamics and cavitation intensity in milli-scale channels under an ultrasonic horn. Ultrason. Sonochem. 2019;58 doi: 10.1016/j.ultsonch.2019.104666. [DOI] [PubMed] [Google Scholar]

- 44.Jayaprakash A., Choi J.-K., Chahine G.L., Martin F., Donnelly M., Franc J.-P., Karimi A. Scaling study of cavitation pitting from cavitating jets and ultrasonic horns. Wear. 2012;296:619–629. doi: 10.1016/j.wear.2012.07.025. [DOI] [Google Scholar]

- 45.Iqbal N., Sharma P.K., Kumar D., Roy P.K. Protective polyurea coatings for enhanced blast survivability of concrete. Constr. Build. Mater. 2018;175:682–690. doi: 10.1016/j.conbuildmat.2018.04.204. [DOI] [Google Scholar]

- 46.Lu X., Chen C., Dong K., Li Z., Chen J. An equivalent method of jet impact loading from collapsing near-wall acoustic bubbles: A preliminary study. Ultrason. Sonochem. 2021;79 doi: 10.1016/j.ultsonch.2021.105760. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.L. Bai, W. Xu, Y. Zhang, Y. Li, D. Huang, Experimental investigations on the collapse of cavity cluster in high power ultrasound fields, 2008, in: IEEE Ultrason. Symp., IEEE, Beijing, China, 2008: pp. 942–945. https://doi.org/10.1109/ULTSYM.2008.0227.

- 48.Li S.-M., Zhang A.-M., Wang Q.X., Zhang S. The jet characteristics of bubbles near mixed boundaries. Phys. Fluids. 2019;31 doi: 10.1063/1.5112049. [DOI] [Google Scholar]

- 49.Trummler T., Bryngelson S.H., Schmidmayer K., Schmidt S.J., Colonius T., Adams N.A. Near-surface dynamics of a gas bubble collapsing above a crevice. J. Fluid Mech. 2020;899:A16. doi: 10.1017/jfm.2020.432. [DOI] [Google Scholar]

- 50.Olowojoba G.B., Eslava S., Gutierrez E.S., Kinloch A.J., Mattevi C., Rocha V.G., Taylor A.C. In situ thermally reduced graphene oxide/epoxy composites: Thermal and mechanical properties. Appl. Nanosci. 2016;6:1015–1022. doi: 10.1007/s13204-016-0518-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Cui R.-N., Li S., Wang S.-P., Zhang A.-M. Pulsating bubbles dynamics near a concave surface. Ocean Eng. 2022;250 doi: 10.1016/j.oceaneng.2022.110989. [DOI] [Google Scholar]

- 52.Qiao X., Chen R., Zhang H., Liu J., Liu Q., Yu J., Liu P., Wang J. Outstanding cavitation erosion resistance of hydrophobic polydimethylsiloxane-based polyurethane coatings. J. Appl. Polym. Sci. 2019;136:47668. doi: 10.1002/app.47668. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.