Abstract

Laser-induced graphene (LIG) is conventionally produced from polyimide among thermosetting polymer substrates, but its flexible nature limits its tremendous potential in applications where flexibility of the substrate is not desired. Interestingly, polybenzoxazine has also been found to have potential as a substrate in LIG production. However, aside from being brittle, it has inferior char residue and thermal stability relative to polyimide, which could result in the production of LIG with inferior properties. Thus, exploring possible improvements in the properties of the polybenzoxazine-based substrate and LIG by alloying with polybenzoxazine and polyimide is the major motivation of this study. First, the improvement in the toughness, char residue and thermal stability of polybenzoxazine by alloying with polyimide was explored. Second, the properties of a LIG obtained from the polybenzoxazine/polyimide alloy were studied. The electrical sheet resistivity, Raman spectra indices, structural morphologies, and crystal size of the neat polybenzoxazine and polybenzoxazine/polyimide alloy substrates were compared. The results reveal significant improvements in the electrical resistivity, structural morphology, and crystal size of the LIG. In addition, the improved polybenzoxazine/polyimide alloy substrate was used to optimize the operational parameters of the laser machine for the production of the LIG. LIG with a minimum electrical sheet resistivity of 3.61 Ω sq−1, multi-layer crystals as confirmed by Raman spectroscopic analysis, and a sponge-like highly porous structure was achieved with the optimum operational conditions in an ambient environment. Last, a quadratic model was found and validated to suitably define the production process. The study demonstrated an improvement in the property of a rigid polybenzoxazine-based LIG by alloying polybenzoxazine with polyimide for the first time.

Alloying polybenzoxazine with polyimide have resulted in the production of a tougher substrate with higher thermal stability, char yield. These improvements have impacted positively on the properties of Laser-induced graphene (LIG).

Introduction

Nanomaterials are among the most versatile materials in the world, with applications cutting across various fields of human endeavour. Structurally, nanomaterials are grouped into four categories, namely carbon-based, organic, inorganic, and composite.1 Graphene is among carbon-based nanomaterials formed by a layer of sp2-hybridized carbon atoms arranged into a 2D-dimensional honeycomb-like lattice structure. It is applied in the field of energy storage, composite development, electronics, photonics, medical, and environmental management, for its high surface area and Young's modulus, excellent thermal stability, excellent electrical conductivity, and ultra-high electron mobility.2,3 Traditionally, graphene is synthesized using mechanical and liquid exfoliation, chemical vapour deposition, and flash joule heating. However, the aforementioned methods have been reported to be tedious, high-energy consuming and low productivity.3

In 2014, laser-induced graphene (LIG) production emerged, and since then the technique has been proved to be a versatile and efficient alternative method with very high precision and reduced capital expenditure.4 In addition, it has the advantages of producing high-surface-area graphene with a single production step with no chemical additives, agents, or solvents.5,6 Recently, Lawan et al.7 outlined major steps taken in the production of LIG using a thermosetting polymer substrate, namely, polymer substrate preparation, specification of laser machine parameters, application of the laser-induced irradiation on the prepared substrate, and characterization of the obtained LIG.

First, with regards to thermosetting polymer substrates, different polymers have been used as substrates in LIG production. Polyimide is conventionally used among different research groups, perhaps due to its high thermal stability and char residue characteristics.7 The high thermal stability and char residue characteristics are attributed to the stacked aromatic hydrocarbon in its structure.8–10 It is mostly used in the production of LIG for application in the areas of wearable and flexible electronics, where substrate flexibility is an advantage.11,12 However, the flexibility of the polyimide substrate will definitely limit the application of the polyimide-based LIG where rigidity is desired. Luong et al.13 corroborated this assertion where it was established that the type of substrate used could limit the applications of the resulting LIG. In addition, an independent research group hypothesized that flexible substrate-based LIG is susceptible to damage through mechanical abrasion and demonstrated a concept of laminating an LIG composite to avert damage.14 Moreover, polyimide substrate curing is very tricky as a curing agent is needed for appreciable low-temperature curing.15,16

Interestingly, new phenolic resins known as polybenzoxazines, which are obtained from the ring-opening polymerization of benzoxazine monomers, emerged. Apart from their rigidity and mechanical performance, polybenzoxazines have an easy and environmentally friendly polymerization reaction, molecular design flexibility, near-zero shrinkage upon curing, and low water absorption.17–19 However, aside from being brittle, polybenzoxazines have inferior thermal properties and char residue relative to polyimide and that could result in the production of a brittle substrate and LIG with inferior properties compared to LIG produced from a polyimide-based substrate. Thus, this presents a challenge of improving the polybenzoxazine substrate to have higher thermal stability and char residue, in addition to possible improvement in toughness for applications that require a tough and rigid substrate without extra support and protection. A study demonstrated blending polybenzoxazine with polyimide to produce a substrate with improved thermal stability and char residue. Therein, bisphenol-A polybenzoxazine with around 35% char residue was alloyed with polyimide and results showing some positive trends have been presented.17 However, the actual improvement of the thermal stability and char residue by alloying polybenzoxazine and polyimide and whether the magnitude of the improvements could positively influence the properties of the LIG, have not been reported.

Second, the laser machine used in the production of the LIG has parameters such as laser power, scanning speed, focus distance, and pulse per inch (PPI), which were found to have tremendous influence on the LIG production.20–22 Ming et al.21 mentioned laser power and scanning speed as the foremost parameters affecting LIG production, and several preliminary experimental runs conducted in this study confirmed that the laser power and engraving speed are the most significant factors affecting LIG production. Considering how numerous the aforementioned parameters are and the various levels in which each could be adjusted for efficient LIG production, the need for optimization of the parameters for the production of LIG with desirable properties for any interesting substrate cannot be over-emphasized. Unfortunately, according to literature reports, the optimization process is usually done by manual manipulation of the parameters and their levels. Interestingly, Wahab et al.23 and Pinheiro et al.24 recently demonstrated some improved methods of optimizing LIG production from substrates, namely Bayesian and pulse modulation operation optimization methods, for the production of LIG from graphene oxide/polyimide-based and paper-based substrates, respectively. Hitherto, optimization of LIG production from a polybenzoxazine/polyimide alloy substrate has not been reported, despite of its potential, to the best of our knowledge.

Therefore, this study focused on achieving the following objectives.: (i) to determine the improvements in toughness, thermal stability and char residue of polybenzoxazine by alloying with polyimide, (ii) to determine whether the improvements in thermal stability and char residue achieved in (i) could influence improvements in the properties of the LIG produced, and (iii) to optimize and model the alloy-based LIG production process using the central composite design (CCD) package of response surface methodology (RSM).

Experimental

Materials used

Analytical-grade phenol and paraformaldehyde were purchased from Loba Chemie Pvt. Ltd, India and Merck, Darmstadt, Germany, respectively, while 3,3,4,4-biphenyltetracarboxylic dianhydride (s-BPDA), 1,4,5,8-naphthalenetetracarboxylic dianhydride (NTDA), 4,4′-oxydianiline (ODA), and N-methyl-2-pyrrolidinone (NMP) were purchased from Tokyo Chemical Industry (TCI), Tokyo.

Preparation of the polybenzoxazine/polyimide alloy substrate

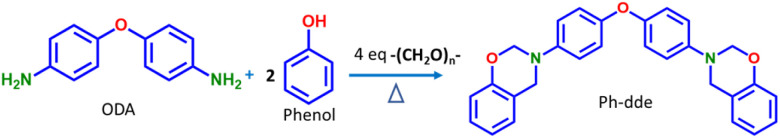

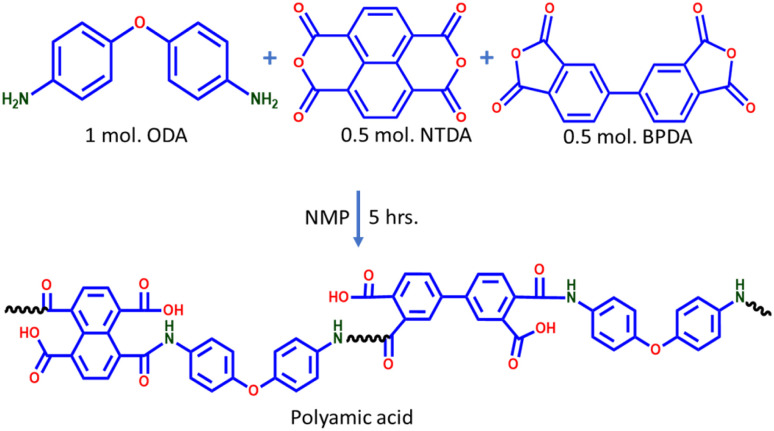

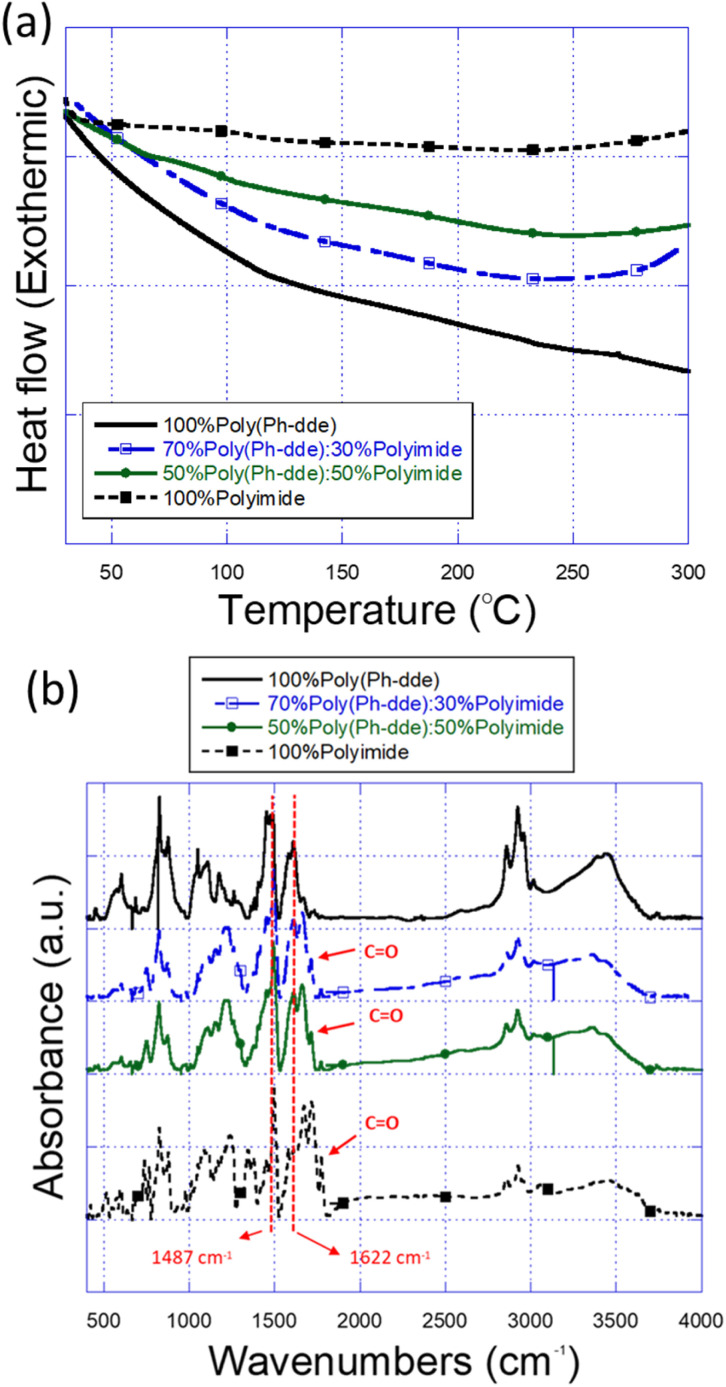

First, polybenzoxazine resin was synthesized by the solventless procedure by combining phenol, ODA, and paraformaldehyde in a 2 : 1 : 4 molar ratio, as depicted in Scheme 1. The reaction mixture was heated at 130 °C for 2 hours to obtain a deep yellow solid denoted as Ph-dde resin. Second, polyamic acid was synthesized by mixing ODA, NTDA, and BPDA in a 1 : 0.5 : 0.5 molar ratio with an NMP solvent of approximately four times weight of the formulation for 5 hours (Scheme 2). Last, prepared Ph-dde resin was ground to a fine powder. Then, it was slightly heated for liquefaction before diluting it with some quantity of NMP to aid mixing. The liquefied Ph-dde resin was mixed with synthesized polyamic acid in 70 : 30 and 50 : 50 weight ratios of Ph-dde and polyamic acid (Scheme 3), respectively. Then, 100 : 0, 70 : 30, 50 : 50, and 0 : 100 formulations were poured differently into silicon moulds. The silicon moulds containing the formulations were heated at; 80 °C for 12 hours to evaporate off the NMP solvent used in the formulations. This is followed by step curing as follows; 120 to 150 °C at 10 °C increment for 1 hour each and 160 to 240 °C at 20 °C increment for 2 hours each. Heating of the Ph-dde resin (100 : 0) was stopped at 200 °C, while the formulations (70 : 30 and 50 : 50) and the polyamic acid (0 : 100) were removed from silicon moulds to finish heating at 240 °C in aluminium foil cups to prevent damaging the silicon moulds. The samples obtained after the curing are denoted as 100%poly(Ph-dde),70%poly(Ph-dde) : 30%polyimide, 50%poly(Ph-dde) : 50%polyimide, and 100%polyimide.

Scheme 1.

Scheme 2.

Scheme 3.

The obtained substrates were characterized using Fourier-transform infrared spectroscopy (FTIR), differential scanning calorimeter (DSC) thermograms, thermogravimetry, and toughness (flexural stress and strain analysis, ASTM D79-M93) using a spectrometer (Spectrum GX, PerkinElmer), a DSC (DSC module 1, Mettler-Toledo), a thermogravimetric analyzer (GC10, Mettler-Toledo), and a universal testing machine (Instron 5567), respectively.

Production of graphene on the prepared substrate using a laser machine

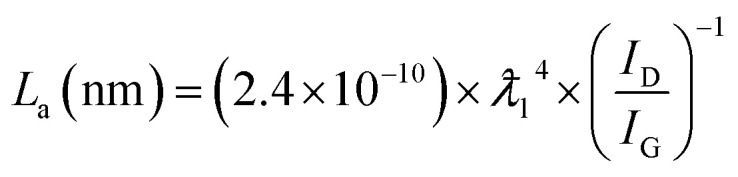

Laser-induced graphene (LIG) with dimensions of 5 mm by 5 mm was produced by single passage engrave using a Trotec Laser Machine (Speedy 100/R-C8063) on the 100%poly(Ph-dde) and 50%poly(Ph-dde) : 50%polyimide substrates. The machine was operated in ambient air with power, speed, pulse per inch (PPI), and focus parameters set at 4.5 W, 18 cm S−1., 1000 and 1.5 inches, respectively. The LIG produced from different substrates were characterized by measuring the sheet resistance and crystal size (eqn (1)) using four-point probe equipment (Jandel RM3) with a bias current of 1 mA and a Raman spectrometer, respectively.

|

1 |

where La = crystal size (nm),  ,

,  to be obtained from Raman spectra obtained from the Raman spectroscopic analysis.

to be obtained from Raman spectra obtained from the Raman spectroscopic analysis.

Modeling and optimization of the LIG production

Response surface methodology (RSM) has the advantage of using fewer experimental runs to reliably understand the effects of factors and their interactions on the response.25 Therefore, that was the basis for the selection of the central composite design (CCD), which is a sub-set of the RSM, for the modeling and optimization of the LIG production using the polybenzoxazine/polyimide alloy substrate. After a series of preliminary experimental runs with the alloy substrate, 1.5 and 12 W laser power, and 9 and 36 cm s−1 laser engraving speed, extreme operating conditions (lowest and highest values, respectively) were established and inputted into the Design Expert Software (Version 12). The PPI and focus were maintained as 1000 and 1.5 inches, respectively. The laser machine was operated under ambient environmental conditions throughout. Table 1 presents the experimental runs required to achieve the objective, and each run was repeated three times, and the average values of responses were inputted into the software for analysis. The respective response (sheet resistance (Ω sq−1)) of each LIG sample was measured using four-point probe equipment (Jandel, RM3) with a bias current of 1 mA.

Experimental design and values of response.

| Experimental run | Factor A: power (W) | Factor B: speed (cm s−1) | Response: sheet resistance (Ω sq−1) |

|---|---|---|---|

| 1 | 3.0 | 22.5 | 30.4 |

| 2 | 13.9 | 22.5 | 22.0 |

| 3 | 3.0 | 9.0 | 26.8 |

| 4 | 12.0 | 9.0 | 8.0 |

| 5 | 12.0 | 36.0 | 14.0 |

| 6 | 7.5 | 3.4 | 6.0 |

| 7 | 3.0 | 36.0 | 14.0 |

| 8 | 7.5 | 41.6 | 4.1 |

| 9 | 7.5 | 22.5 | 5.5 |

| 10 | 7.5 | 22.5 | 4.0 |

| 11 | 7.5 | 22.5 | 3.9 |

| 12 | 7.5 | 22.5 | 3.8 |

| 13 | 7.5 | 22.5 | 3.7 |

Results and discussion

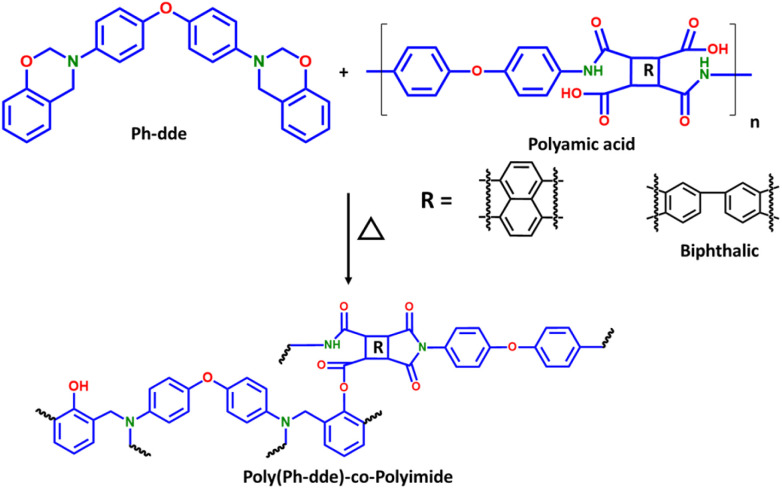

Prepared polybenzoxazine/polyimide alloy substrate

Fig. 1(a) depicts the DSC thermograms of substrate samples; as it can be observed, no exothermic peak appeared in any of the samples, indicating that the step curing within the temperature range used has appreciably cured the substrates. Fig. 1(b) presents the FTIR spectra of the samples; noticeable absorption peaks due to the tetra-substituted benzene ring and hydrogen linked to the phenol OH can be seen at 1487 and 1622 cm−1, indicating that the linking due to Mannich bridging by ring-opening polymerization has occurred. Furthermore, absorption at 1778 cm−1, which is due to the C O vibration of polyimide, could be observed with the 100%polyimide, 50%poly(Ph-dde) : 50%polyimide, and 30%poly(Ph-dde) : 70%polyimide substrates, which confirms imization of the substrates. These findings are comparable with the findings reported for a similar system.17 Thus, appreciably cured polybenzoxazine/polyimide alloy substrate and the neat (100%poly(Ph-dde) and 100%polyimide) samples have been achieved.

Fig. 1. Characteristics of cured substrates: DSC thermograms (a) and FTIR (b).

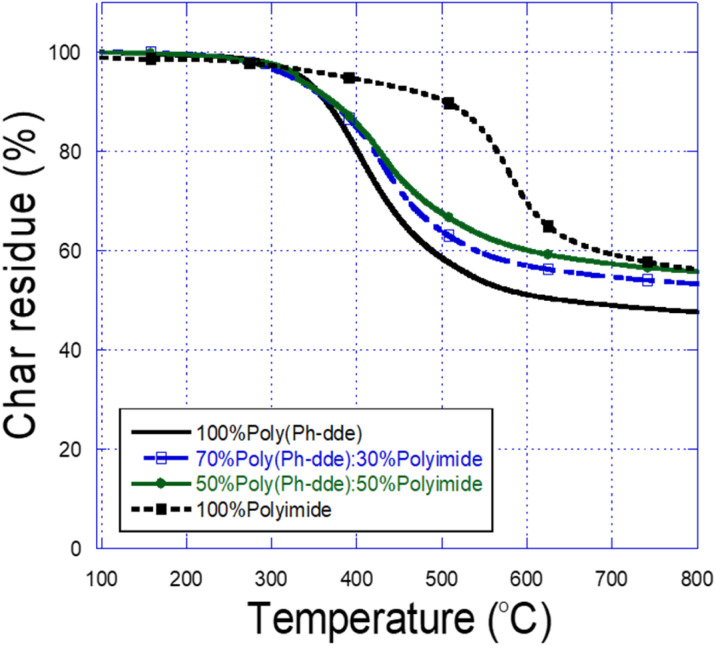

Fig. 2 depicts the thermal stability and char residue results recorded from the TGA of cured substrates. The 100%poly(Ph-dde) substrate exhibited the lowest thermal stability and char residue, while the 100%polyimide substrate exhibited the highest thermal stability and char residue. An obvious increase in thermal stability and char residue is achieved with the increase in the amount of polyimide in the polybenzoxazine/polyimide alloy system.

Fig. 2. Thermogravimetric analysis of the substrates.

Table 2 presents the thermal degradation temperatures (Td5 and Tdmax) and char residue (CR) of substrate samples. With 50 wt% polyimide in the alloy, a slight increase in the Td5 and a substantial increase in the Tdmax (+23 °C) was achieved. Similarly, a significant increase in the CR (∼17% increase) was achieved, giving the 50%poly(Ph-dde) : 50%polyimide alloy substrate a CR that almost matches that of the 100%polyimide substrate. These improvements could be directly linked to the high thermal stability and CR of polyimide, which are attributed to its rich aryl hydrocarbon structure. The 50%poly(Ph-dde) : 50%polyimide, with the highest thermal stability and char residue that almost match those of the 100%polyimide, represents the best polybenzoxazine/polyimide alloy substrate for LIG production.

Thermogravimetric data for the substrates.

| Sample | T d5 (°C) | T dmax (°C) | Char residue (%) |

|---|---|---|---|

| 100%poly(Ph-dde) | 327 | 408 | 47.8 |

| 70%poly(Ph-dde) : 30%polyimide | 328 | 422 | 53.4 |

| 50%poly(Ph-dde) : 50%polyimide | 329 | 431 | 56.0 |

| 100%polyimide | 389 | 580 | 56.3 |

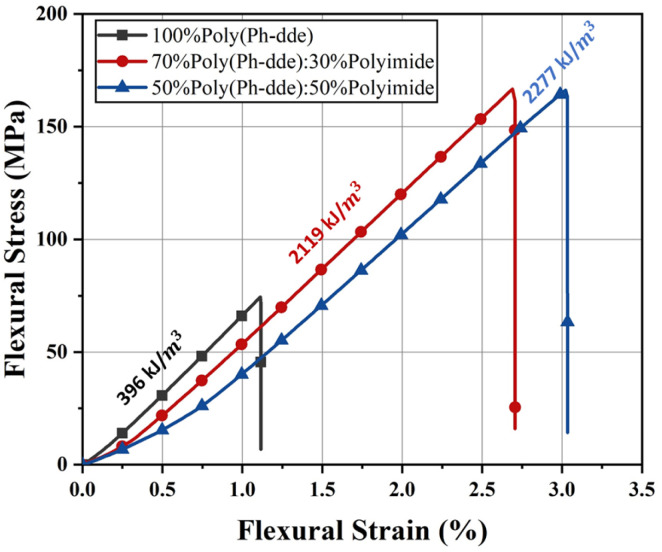

Fig. 3 presents flexural stress versus strain plots and toughness of the 100%poly(Ph-dde),70%poly(Ph-dde) : 30%polyimide and 50%poly(Ph-dde) : 50%polyimide substrates. The toughness of the 100%polyimide could not be established because its flexibility made it unsuitable for the flexural test used. It could be observed that significant improvement in the toughness of the polybenzoxazine/polyimide alloy compared to neat polybenzoxazine substrate was achieved. Improvement in toughness by about four times was achieved with the 50%poly(Ph-dde) : 50%polyimide substrate.

Fig. 3. Flexural stress–strain plots and toughness of the substrates.

Produced LIG on the prepared substrate

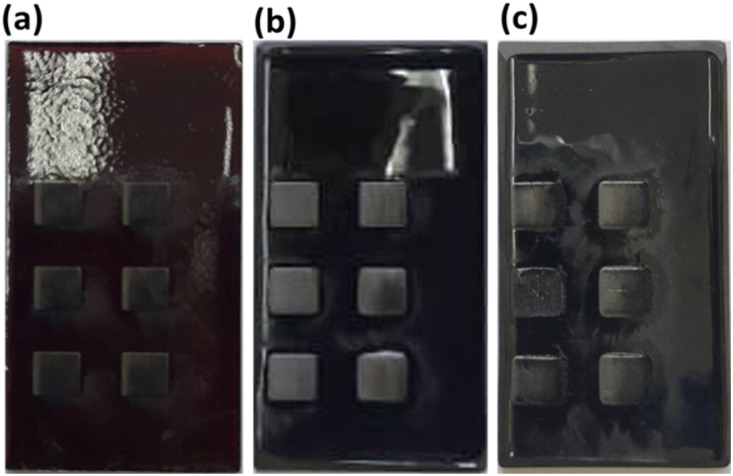

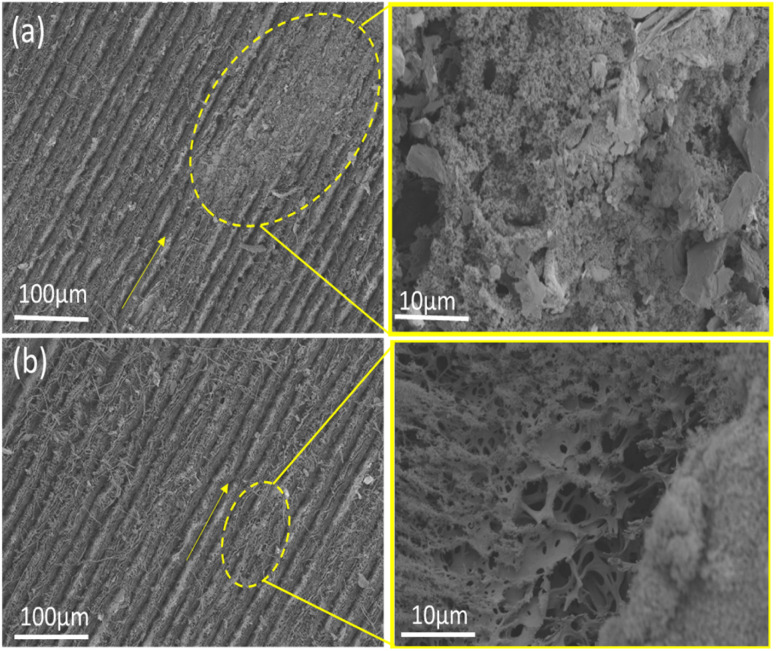

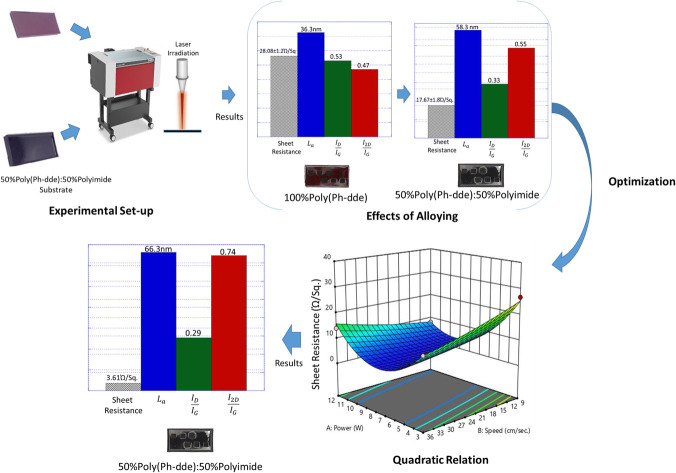

Fig. 4 presents images of the produced 5 mm by 5 mm LIG samples engraved on the 100%poly(Ph-dde) (Fig. 4(a)) and 50%poly(Ph-dde) : 50%polyimide (Fig. 4(b)).

Fig. 4. Images of the LIG: 100%poly(Ph-dde)-LIG (a), 50%poly(Ph-dde) : 50%polyimide-LIG (b), and 50%poly(Ph-dde) : 50%polyimide-LIG produced using the optimum conditions (c).

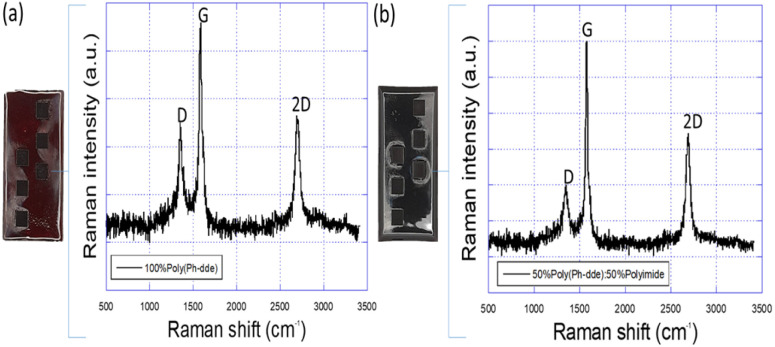

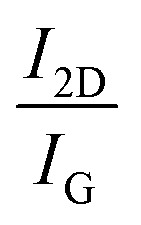

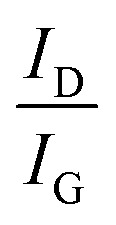

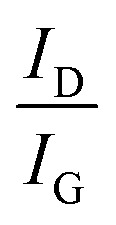

Fig. 5(a) and (b) show Raman spectra of the LIG samples the three characteristics peaks, D, G, and 2D at 1350 cm−1, 1580 cm−1, and 2680 cm−1, respectively are shown on the Raman spectra, which confirms the production of graphene on both the substrates. The D peak is linked to disorders and defects in the graphene structure, while G and 2D peaks are due to carbon atom vibration because of the sp2 hybridization in the hexagonal lattice and stacking and phonon of the graphene structure, respectively.26–29 It could be observed that the D peak intensity in the 100%poly(Ph-dde)-LIG spectrum (Fig. 5(a)) is much more pronounced relative to the D peak intensity in the 50%poly(Ph-dde) : 50%polyimide-LIG spectrum (Fig. 5(b)). Consequently, higher  was recorded with the 100%poly(Ph-dde)-LIG (Table 3), suggesting that the 50%poly(Ph-dde) : 50%polyimide-LIG has less disorders and defects compared to the 100%poly(Ph-dde)-LIG. Additionally, the 50%poly(Ph-dde) : 50%polyimide-LIG had a higher

was recorded with the 100%poly(Ph-dde)-LIG (Table 3), suggesting that the 50%poly(Ph-dde) : 50%polyimide-LIG has less disorders and defects compared to the 100%poly(Ph-dde)-LIG. Additionally, the 50%poly(Ph-dde) : 50%polyimide-LIG had a higher  (Table 3), which suggests a higher stacking order of the graphene structure.

(Table 3), which suggests a higher stacking order of the graphene structure.

Fig. 5. Raman spectra of the LIG: 100%poly(Ph-dde)-LIG (a) and 50%poly(Ph-dde) : 50%polyimide-LIG (b).

Properties of the LIG.

| Sample | Sheet resistance (Ω sq−1) | Raman spectra indices | L a (nm) | |

|---|---|---|---|---|

|

|

|||

| 100%poly(Ph-dde)-LIG | 28.08 ± 1.2 | 0.53 | 0.47 | 36.3 |

| 50%poly(Ph-dde) : 50%polyimide-LIG | 17.67 ± 1.8 | 0.33 | 0.55 | 58.3 |

Similarly, the La of the 50%poly(Ph-dde) : 50%polyimide-LIG was found to be significantly higher than that of the 100%poly(Ph-dde)-LIG (Table 3), where an increase of about 61% was achieved. This is owing to the fact that La is inversely related to the  . This improvement also implies that the 50%poly(Ph-dde) : 50%polyimide-LIG has a more porous structure, as it has been established that graphene structures with larger La possess more porous structures.29 Moreover, a significantly lower electrical resistivity was recorded with the 50%poly(Ph-dde) : 50%polyimide-LIG (Table 3), compared to that of the 100%poly(Ph-dde)-LIG, with a reduction in electrical resistivity of about 37% being achieved. This finding further corroborates the improvement in porosity, as it has been established that higher porosity in LIG structures leads to lower electrical resistivity, as electrical resistivity arises from hopping of carriers between crystals.29

. This improvement also implies that the 50%poly(Ph-dde) : 50%polyimide-LIG has a more porous structure, as it has been established that graphene structures with larger La possess more porous structures.29 Moreover, a significantly lower electrical resistivity was recorded with the 50%poly(Ph-dde) : 50%polyimide-LIG (Table 3), compared to that of the 100%poly(Ph-dde)-LIG, with a reduction in electrical resistivity of about 37% being achieved. This finding further corroborates the improvement in porosity, as it has been established that higher porosity in LIG structures leads to lower electrical resistivity, as electrical resistivity arises from hopping of carriers between crystals.29

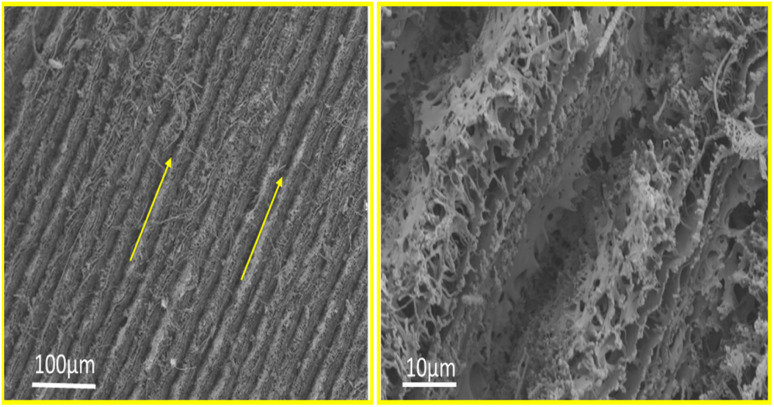

Observation of the surface morphology of the LIG samples (100 μm scale images in Fig. 6) reveals a ridge-like route indicating laser engraving passages, with the 50%poly(Ph-dde) : 50%polyimide-LIG exhibiting a much more pronounced ridge-like route, which could be attributed to the higher stability and char yield of the substrate. Thermosetting polymer substrate-based LIG has been reported to have similar engraving passages route.30,31 Moreover, spots believed to be structural disorder and defects were observed in both the LIG samples. However, more and bigger spots were observed with the 100%poly(Ph-dde)-LIG (Fig. 6(a)), and a zoomed-in image (10 μm per scale) of the spots shows structural collapse in the graphene structures, which is contrary to the case of the 50%poly(Ph-dde) : 50%polyimide-LIG (Fig. 6(b). This observation is in agreement with the trend of results presented in Table 3.

Fig. 6. SEM Images of the LIG: 100%poly(Ph-dde)-LIG (a) and 50%poly(Ph-dde) : 50%polyimide-LIG (b).

Therefore, it can be summarized that the less disorders and defects in the lattice structure, the larger La, larger porosity, and lower electrical resistance achieved with the 50%poly(Ph-dde) : 50%polyimide-LIG can be attributed to the relatively higher thermal stability and char yield of the polybenzoxazine/polyimide alloy substrate.

Optimized conditions and model of the LIG engraving on the prepared substrate

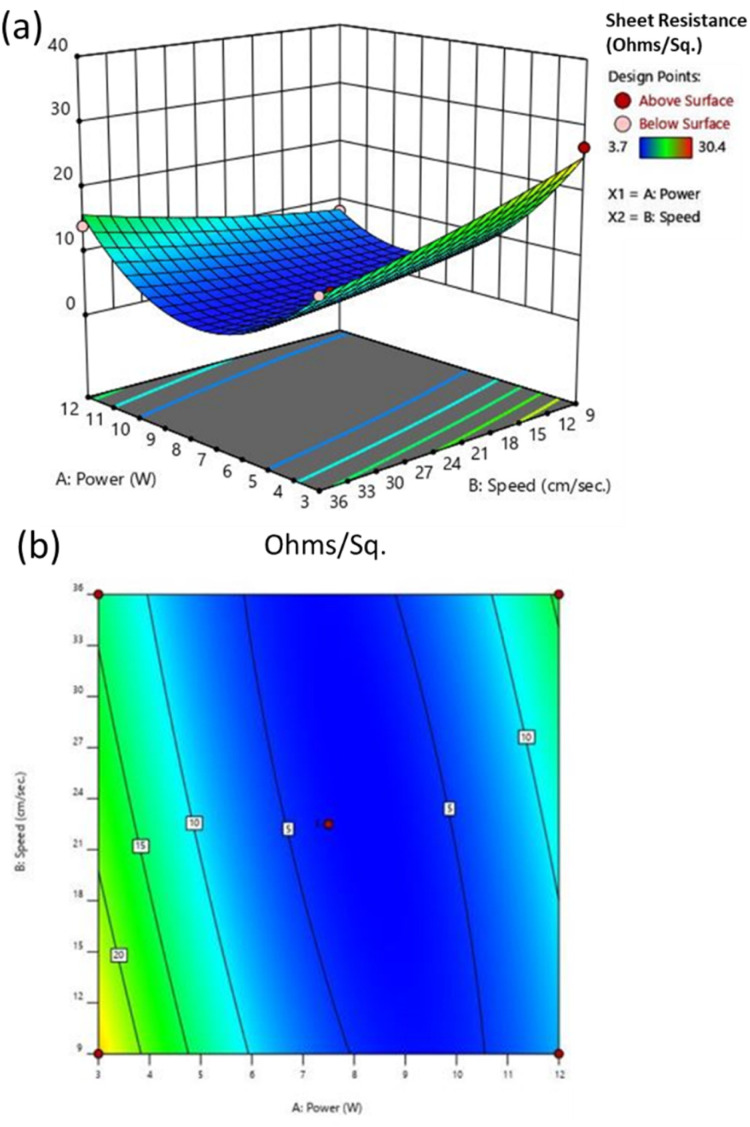

Table 1 presents various responses (sheet resistance (Ω sq−1)) recorded for each experimental run designed using the 50%poly(Ph-dde) : 50%polyimide substrate. The values ranged from 3.7 to 30.4 Ω sq−1, and further analyses generated plots showing the effects of power (W) and speed (cm s−1) on the sheet resistance (Ω sq−1). Fig. 7(a) and (b) present 3D and contour plots, where the effects of laser power from 3 to 12 W and engraving speed from 9 to 36 cm s−1 on the sheet resistance (Ω sq−1) are simultaneously shown. Three distinctive regions could be observed: 3 to 4.6 W versus 9 to 16 cm s−1, 5 to 11 W versus 18 to 33 cm s−1, and >11 W versus >33 cm s−1, marked by orange/green, blue, and green colored regions, were found to have the highest, least, and medium electrical resistance, respectively.

Fig. 7. Plots of the 50%poly(Ph-dde) : 50%polyimide-LIG resistance against power and speed: 3D plot (a) and contour plot (b).

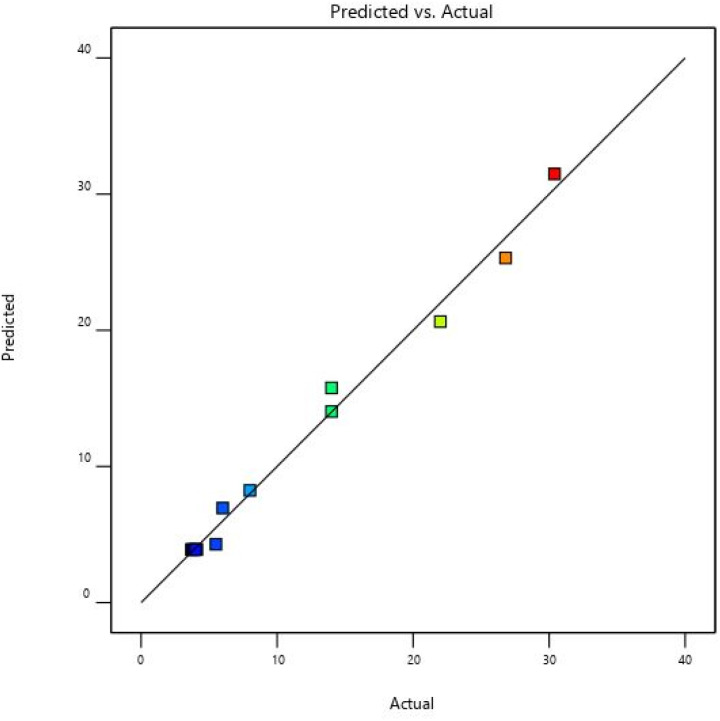

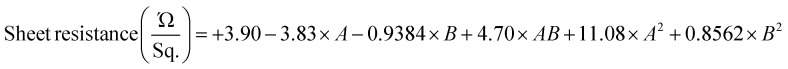

Table 4 presents four relationship templates, and a quadratic model was fitted to the scenario based on the responses recorded from the experimental runs. The quadratic model was found to have adjusted and predicted R2 values to be closest to 1, and the difference between the adjusted and predicted R2 is less than 0.2. The model defining the quadratic relationship is presented in eqn (2).

|

2 |

Fit summary.

| Source | Sequential P-value | Lack of fit P-value | Adjusted R2 | Predicted R2 | Remark |

|---|---|---|---|---|---|

| Linear | 0.5417 | <0.0001 | −0.0615 | −0.6944 | |

| 2FI | 0.3634 | <0.0001 | −0.0704 | −0.7787 | |

| Quadratic | <0.0001 | 0.0002 | 0.9827 | 0.9289 | Suggested |

| Cubic | <0.0001 | 0.0697 | 0.9994 | 0.9909 | Aliased |

Table 5 presents the ANOVA of the quadratic model, where it can be seen that the quadratic model suggested is significant. The laser power was found to be a significant factor, while engraving speed is not significant. In contrast, all model coefficients (AB, A2 and B2) were found to be significant. The lack of fit is also significant; however, there is only a 0.02% chance that a lack of fit F-value this large could occur due to noise. These findings show that the quadratic model adequately defines the scenario.

ANOVA for quadratic model.

| Source | Sum of squares | df | Mean square | F-value | P-value | Remarks |

|---|---|---|---|---|---|---|

| Model | 1069.73 | 5 | 213.95 | 137.67 | <0.0001 | Significant |

| A-power | 117.65 | 1 | 117.65 | 75.71 | <0.0001 | Significant |

| B-speed | 7.04 | 1 | 7.04 | 4.53 | 0.0708 | Not significant |

| AB | 88.36 | 1 | 88.36 | 56.86 | 0.0001 | Significant |

| A 2 | 854.22 | 1 | 854.22 | 549.66 | <0.0001 | Significant |

| B 2 | 5.10 | 1 | 5.10 | 3.28 | 0.1130 | Significant |

| Residual | 10.88 | 7 | 1.55 | |||

| Lack of fit | 10.78 | 3 | 3.59 | 143.71 | 0.0002 | Significant |

| Pure error | 0.1000 | 4 | 0.0250 | |||

| Cor total | 1080.61 | 12 |

Fig. 8 presents a plot of predicted versus actual responses, and an obvious linear positive correlation that validates the model is presented as eqn (2).

Fig. 8. Quadratic model validation plot.

The software suggests optimum conditions for the production of the 50%poly(Ph-dde) : 50%polyimide-LIG (Fig. 4(c)) to be 8.4 W and 25.2 cm s−1 to achieve an electrical sheet resistance of 3.61 Ω sq−1. Findings from the analysis done to validate the optimum conditions revealed a very negligible percentage error between the theoretically suggested optimum sheet resistance and average resistance obtained from repeated experimental runs. Thus, the overall optimum conditions for LIG production using the 50%poly(Ph-dde) : 50%polyimide have been established as 8.4 W, 25.2 cm s−1, 1000 PPI, and 1.5 inches.

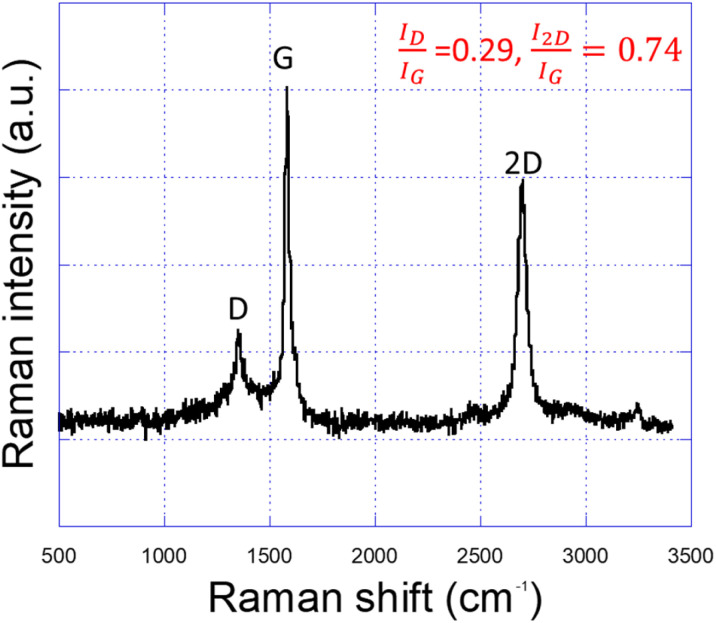

Fig. 9 depicts the peaks intensity in the Raman spectrum of the 50%poly(Ph-dde) : 50%polyimide-LIG obtained under the optimum conditions. The D peak is seen to have relatively lower intensity compared to the G and 2D peaks. Consequently, an  as low as 0.29 was recorded, whereas an

as low as 0.29 was recorded, whereas an  as high as 0.74 was recorded. This finding suggests that the graphene produced under the optimum conditions has less disorders and defects.

as high as 0.74 was recorded. This finding suggests that the graphene produced under the optimum conditions has less disorders and defects.

Fig. 9. Raman spectrum of 50%poly(Ph-dde) : 50%polyimide-LIG produced under the optimum conditions.

Conversely, Yu et al.32 stipulated that an  value in the range of 0.72–0.91 indicate the formation of a multi-layered graphene. Thus, this shows that the 50%poly(Ph-dde) : 50%polyimide-LIG produced using the optimum conditions has a multi-layered stacked structure. The values of

value in the range of 0.72–0.91 indicate the formation of a multi-layered graphene. Thus, this shows that the 50%poly(Ph-dde) : 50%polyimide-LIG produced using the optimum conditions has a multi-layered stacked structure. The values of  and

and  recorded with the 50%poly(Ph-dde) : 50%polyimide-LIG produced under the optimum conditions compares favourably with the values recorded with LIG produced on a polyimide-based substrate.33–36 Furthermore, an La of 66.3 nm was recorded for the optimum conditions, which shows that the 50%poly(Ph-dde) : 50%polyimide-LIG produced has larger pore spaces compared to the pore spaces of the 50%poly(Ph-dde) : 50%polyimide-LIG (Table 3) produced with power, speed, pulse per inch (PPI), and focus parameters set at 4.5 W, 18 cm s−1, 1000 and 1.5 inches, respectively. Interestingly, the zoomed-in SEM image of the 50%poly(Ph-dde) : 50%polyimide-LIG produced under the optimum conditions (Fig. 10) shows a sponge-like porous structure, which corroborates the findings of low resistance

recorded with the 50%poly(Ph-dde) : 50%polyimide-LIG produced under the optimum conditions compares favourably with the values recorded with LIG produced on a polyimide-based substrate.33–36 Furthermore, an La of 66.3 nm was recorded for the optimum conditions, which shows that the 50%poly(Ph-dde) : 50%polyimide-LIG produced has larger pore spaces compared to the pore spaces of the 50%poly(Ph-dde) : 50%polyimide-LIG (Table 3) produced with power, speed, pulse per inch (PPI), and focus parameters set at 4.5 W, 18 cm s−1, 1000 and 1.5 inches, respectively. Interestingly, the zoomed-in SEM image of the 50%poly(Ph-dde) : 50%polyimide-LIG produced under the optimum conditions (Fig. 10) shows a sponge-like porous structure, which corroborates the findings of low resistance  and high

and high  and La achieved with the 50%poly(Ph-dde) : 50%polyimide-LIG.

and La achieved with the 50%poly(Ph-dde) : 50%polyimide-LIG.

Fig. 10. SEM Images of 50%poly(Ph-dde) : 50%polyimide-LIG produced under the optimum conditions.

Conclusion

Based on data recorded, analysis, and discussion presented, the following conclusions could be drawn:

(i) Alloying polybenzoxazine with polyimide has produced a polybenzoxazine-based substrate with significant improvements in toughness, thermal stability, and char residue. For instance, there was a fourfold increase in toughness and increases in thermal degradation and char residue of 23 °C and 17% were achieved, respectively, by alloying with 50 wt% polyimide.

(ii) The aforementioned magnitude of improvements in the substrate has influenced the properties of the LIG produced. A significant reduction in electrical sheet resistance of 37% and a dramatic increase in crystal size of 61% were achieved.

(iii) Laser power and the interaction between laser power and engraving speed were found to significantly affect the properties of the LIG produced.

(iv) A quadratic model was established to adequately define LIG production with the polybenzoxazine/polyimide alloy substrate for the first time. Laser power of 8.4 W and engraving speed of 25.2 cm s−1 were established and validated to be optimum parameters to achieve LIG with the lowest electrical resistance of 3.61 Ω sq−1, multi-layer crystals, and a sponge-like highly porous structure.

(v) Overall, the concept of alloying polybenzoxazine with polyimide has produced an improved tough and rigid polybenzoxazine-based substrate for the production of high-performing LIG for applications where a flexible neat polyimide substrate is not desired.

Author contributions

Ibrahim Lawan; conceptualizing, methodology; formal analysis; writing & editing. Panuwat Luengrojanakul; conceptualization; validation. Krittapas Charoensuk; methodology of substrate production. Hariharan Argunam; chemical schemes validation. Cheol-Hee Ahn; supervision and result validation. Sarawut Rimdusit; supervision, resources, validation, review and editing.

Conflicts of interest

There are no conflicts to declare.

Supplementary Material

Acknowledgments

The authors would like to acknowledge and appreciate the support provided by the Second Century Fund (C2F) of Chulalongkorn University, Thailand. The authors would like to also express their sincere appreciation to the National Research Council of Thailand (NRCT) fund (No. 42A660910) and the Thailand Science Research and Innovation fund Chulalongkorn University (6641/2566).

Notes and references

- Mekuye B. Abera B. Nanomaterials: An overview of synthesis, classification, characterization, and applications. Nano Sel. 2023;4:486–501. doi: 10.1002/nano.202300038. [DOI] [Google Scholar]

- Scardaci V. Laser synthesized graphene and its applications. Appl. Sci. 2021;11(14):6304. doi: 10.3390/app11146304. [DOI] [Google Scholar]

- Chakraborty M. & Hashmi M. S. J., Graphene as a Material – An Overview of Its Properties and Characteristics and Development Potential for Practical Applications, Reference Module in Materials Science and Materials Engineering, Elsevier Ltd, 2018, 10.1016/b978-0-12-803581-8.10319-4 [DOI] [Google Scholar]

- Lin J. et al., commercial polymers. Nat. Commun. 2014;5:12. doi: 10.1038/ncomms6714. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang Z. et al., A review of laser-induced graphene: From experimental and theoretical fabrication processes to emerging applications. Carbon. 2023;214:118356. doi: 10.1016/j.carbon.2023.118356. [DOI] [Google Scholar]

- Cao L. et al., Stable and durable laser-induced graphene patterns embedded in polymer substrates. Carbon. 2020;163:85–94. doi: 10.1016/j.carbon.2020.03.015. [DOI] [Google Scholar]

- Lawan I. Luengrojanakul P. Charoensuk K. Argunam H. Laser-Induced Graphitization of Thermosetting Polymer Substrate and its Application—A Review. Eng. J. 2023;27(10):11–20. doi: 10.4186/ej.2023.27.10.11. [DOI] [Google Scholar]

- Torlon A. P., 6 Polyimides, 2012, 10.1016/B978-1-4557-2598-4.00006-X [DOI] [Google Scholar]

- Hu J. et al., Preparation and characterization of luminescent polyimide/glass composite fiber. J. Mater. Res. Technol. 2022;18:4329–4339. doi: 10.1016/j.jmrt.2022.04.101. [DOI] [Google Scholar]

- Constantin C. P., Aflori M., Damian R. F. & Rusu R. D.Constantin 2019.Pdf. 2019 [Google Scholar]

- Usman M. Jafry A. T. Abbas A. Hussain G. Abbas N. A high strength and flexible multilayered thin film laser induced graphene heater for thermal applications. Thin Solid Films. 2023;780:139979. doi: 10.1016/j.tsf.2023.139979. [DOI] [Google Scholar]

- Shah S. A. A. Idrees R. Saeed S. A critical review on polyimide derived carbon materials for high-performance supercapacitor electrodes. J. Energy Storage. 2022;55:105667. doi: 10.1016/j.est.2022.105667. [DOI] [Google Scholar]

- Luong D. X. et al., Laser-Induced Graphene Composites as Multifunctional Surfaces. ACS Nano. 2019;13(2):2579–2586. doi: 10.1021/acsnano.8b09626. [DOI] [PubMed] [Google Scholar]

- Li J. T. Stanford M. G. Chen W. Presutti S. E. Tour J. M. Laminated Laser-Induced Graphene Composites. ACS Nano. 2020;14:7911–7919. doi: 10.1021/acsnano.0c02835. [DOI] [PubMed] [Google Scholar]

- Sui Y. et al., Low temperature curing polyimides with covalent-boned 5-aminobenzimidazole. Polyme. 2021;218:123514. doi: 10.1016/j.polymer.2021.123514. [DOI] [Google Scholar]

- Huang C. et al., Comprehensive properties study of low-temperature imidized polyimide with curing accelerators. J. Mater. Chem. C. 2020;8:14886–14894. doi: 10.1039/D0TC03770B. [DOI] [Google Scholar]

- Takeichi T. Guo Y. Rimdusit S. Performance improvement of polybenzoxazine by alloying with polyimide: Effect of preparation method on the properties. Polymer. 2005;46:4909–4916. doi: 10.1016/j.polymer.2005.03.096. [DOI] [Google Scholar]

- Santhosh Kumar K. S. & Reghunadhan Nair C. P., Polybenzoxazine-new generation phenolics, Handb. Thermoset Plast, 2014, pp. 45–73, 10.1016/B978-1-4557-3107-7.00003-8 [DOI] [Google Scholar]

- Rimdusit S., Jubsilp C. & Tiptipakorn S., Alloys and Composites of Polybenzoxazines:Properties and Applications, Springer, 2013, vol. 13 [Google Scholar]

- Misra U., Dixit N. & Singh S. P., Effect of Laser Parameters on Laser-Induced Graphene Filter Fabrication and its Performance for Desalination and Water Purification, 2023, 10.1021/acsami.2c17106 [DOI] [PubMed] [Google Scholar]

- Ming L. I. U. Effects of laser processing parameters on properties of laser- induced graphene by irradiating CO2 laser on polyimide. Sci. China: Technol. Sci. 2022;65:41–52. doi: 10.1007/s11431-021-1918-8. [DOI] [Google Scholar]

- Bai S. et al. , Investigation into the Influence of Interdigital Parameters on Electrochemical Performance for In-Plane Supercapacitors via Mathematical Modeling and Conformal Mapping Techniques, 2023, vol. 65 [Google Scholar]

- Wahab H. et al., Machine-learning-assisted fabrication : Bayesian optimization of laser- induced graphene patterning using in-situ Raman analysis. Carbon. 2020;167:609–619. doi: 10.1016/j.carbon.2020.05.087. [DOI] [Google Scholar]

- Pinheiro T. Influence of CO2 laser beam modelling on electronic and electrochemical properties of paper-based laser-induced graphene for disposable pH electrochemical sensors. Carbon Trends. 2023;11:100271. doi: 10.1016/j.cartre.2023.100271. [DOI] [Google Scholar]

- Lamidi S., Olaleye N., Bankole Y., Obalola A., Aribike E. and Adigun I., Applications of Response Surface Methodology (RSM) in Product Design, Development, John Wiley & Sons, 2005 [Google Scholar]

- Younis A. A. Evaluation of the flammability and thermal properties of a new flame retardant coating applied on polyester fabric. Egypt. J. Pet. 2016;25:161–169. doi: 10.1016/j.ejpe.2015.04.001. [DOI] [Google Scholar]

- Velasco A. et al., Laser-Induced Graphene Microsupercapacitors: Structure, Quality, and Performance. Nanomaterials. 2023;13(5):788. doi: 10.3390/nano13050788. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Akintola T. M. Kumar B. K. Dickens T. Combined Additive and Laser-Induced Processing of Functional Structures for Monitoring under Deformation. Polymers. 2023;15(2):443. doi: 10.3390/polym15020443. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang Y. et al., Laser direct writing of graphene photodetector with a wide spectral detection from the visible to the infrared. Carbon Trends. 2023;11:100255. doi: 10.1016/j.cartre.2023.100255. [DOI] [Google Scholar]

- Yen Y. et al. , Laser-Induced Graphene Stretchable Strain Sensor with Vertical and Parallel Patterns, 2022, vol. 1–14 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cao L. et al., Stable and durable laser-induced graphene patterns embedded in polymer substrates. Carbon. 2020;163:85–94. doi: 10.1016/j.carbon.2020.03.015. [DOI] [Google Scholar]

- Yu Z. et al., Upcycling of Polybenzoxazine to Magnetic Metal Nanoparticle-Doped Laser-Induced Graphene for Electromagnetic Interference Shielding. ACS Appl. Nano Mater. 2022;5:13158–13170. doi: 10.1021/acsanm.2c02912. [DOI] [Google Scholar]

- Report B., Ragulis P., Ratautas K. & Trusovas R., Laser-Induced Graphene in Polyimide for Antenna Applications, 2023 [Google Scholar]

- Rodrigues J. et al. , Nanoscale Advances by Direct Laser Scribing, 2019, pp. 3252–3268, 10.1039/c8na00391b [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hristovski I. R. et al. , Manifestations of Laser-Induced Graphene under Ultraviolet Irradiation of Polyimide with Varied Optical Fluence, 2022 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Laser D. Sakarya Univ. J. Sci. 2023;27:1105–1111. [Google Scholar]