Abstract

The increase in the use of energy from forest biomass has increased the demand for knowledge about tree-chipping operations. Therefore, this study aimed to evaluate the effect of different drying times of wood logs and various combinations of knife and anvil configurations in the horizontal chipper on the quality of Eucalyptus dunnii chips produced for energy purposes. The study was conducted in a seven-year-old stand of E. dunnii. A horizontal chipper was used to chip whole trees and obtain nine types of chips, resulting from the interaction between the three drying times of the trees and three configurations of the horizontal chipper. The chips were characterized, followed by an evaluation of energy quality for comparison between the treatments. Among the outcomes discerned, it became evident that the employed wood exhibited a Basic Density (0.506 g.cm-³). The chip dimensions and bulk density presented notable disparities owing to the distinct chipper configurations and tree drying time. The extended drying period (150 days) conferred a lower average moisture content (34.20%) to the study materials. Moreover, the ash content was lower in the treatment with 150 drying days (0.52%). Both the useful calorific value and the Fuel Value Index were also greater in the treatment (150 drying days), measuring 2600.00 kcal kg−1 and 128.06 cal cm−3, respectively. In the analysis of the Fuel Value Index concerning chipper configurations, it was observed that for chips featuring a granulometry of 25 mm, the treatment involving 150 days of drying, four knives, and one shim proved the most efficient (Q = 0.979). Conversely, for chips with a granulometry of 16 mm, the treatment involving 150 days of drying, eight knives, and one shim emerged as the most efficient (Q = 0.970). Consequently, the proposed index is efficacious and underscores the necessity of adapting knife settings in response to moisture content changes to maintain the desired granulometry and apparent density standards.

Keywords: Bioenergy, Forest biomass, Granulometry, Chipping, Moisture content, Energy quality

1. Introduction

One of the main objectives proposed in the United Nations Framework Convention on Climate Change (COP 24) was the reduction of greenhouse gas (GHG) emissions in the atmosphere to mitigate global warming. Therefore, one of the strategies to ensure this reduction in emissions is the replacement of fossil fuels with renewable energy, such as forest biomass, primarily derived from planted trees, due to its sustainable management model that ensures carbon-neutrality during the burning process [[1], [2], [3]].

Brazil is one of the most promising countries in the renewable energy generation market, owing to favorable edaphoclimatic conditions and high investments. The nation stands as a global reference in the production of planted forests, covering an extensive area of 9 million hectares, with average productivity of 30 m³ per hectare per year in Pinus stands and 36 m³ per hectare per year in Eucalyptus stands [4]. Moreover, Brazil has excelled in the generation and utilization of renewable energy sources, constituting 46.1% of the national energy matrix, with 9% of this share derived from biomass [5].

Due to the escalating energy demands within the forestry sector for self-sustainability, the mining sector's efforts to substitute mineral coal with charcoal, and particularly the agricultural sector's needs for grain drying and steam generation in boilers, the utilization of energy derived from forest biomass has gained significant prominence in the Brazilian market in recent years [6]. This biomass can be sourced from various products generated in planted forests, such as firewood, charcoal, sawmill residues, briquettes, pellets, or wood harvesting waste chips [[6], [7], [8]].

The replacement of materials in the form of firewood with chips, defined as small pieces of wood with greater energy capacity than round wood [9], is a growing trend due to their increased contact surface and higher reactivity. As highlighted in Refs. [1,7], apart from improved energy utilization, this substitution is driven by optimized storage, transportation, and handling processes achieved through reducing particle size, homogenizing composition, enhancing apparent density, enabling mechanization, controlling humidity, and producing higher quality steam.

However, to effectively integrate chips into the global energy matrix, it is essential to adhere to technical, chemical, and physical quality specifications. The poor quality of wood chips leads to a range of technical and operational issues during the energy generation process, including decreased energy conversion efficiency, higher chemical costs, and a decrease in manufacturing process uniformity [10]. Consequently, the energetic quality of chips must be assessed based on parameters such as density, humidity, ash content, calorific value, and fine particle percentage [11].

Among the parameters mentioned [12], moisture is arguably the most sensitive. As emphasized by authors [1] in their research, efficient wood drying plays a vital role in controlling this variable, as it not only reduces the weight of the material but also increases the calorific value and energy efficiency, while minimizing emissions during energy conversion. The authors [13] highlighted in their research that wood logs with lower moisture content produce larger and thicker chips. This occurs because, according to Ref. [10], these woods are stiffer and less flexible than logs with higher moisture content.

Additionally, another crucial factor highlighted by Ref. [11] is the size and distribution of particles, as this directly impacts combustion efficiency, calorific value, material durability, and the energy required for converting forest biomass into liquid biofuels [14]. Consequently, the type of chipper (equipment used to convert wood into chips, employing blades and knives attached to a disk or drum) and the configuration and adjustment of the equipment's knives directly influence the size of the chips [15].

Many studies are showing the quality and viability of using wood chips [[16], [17], [18], [19], [20]]. Furthermore, it is known that the way horizontal chippers are configured [[21], [22], [23], [24], [25]] and the drying time of wood logs [10,23,26] affect the quality of the produced chips. However, there are still few records on the joint analysis of these factors and on understanding how they simultaneously impact the efficiency of wood chip production.

Thus, our objective is to answer the question: Do the configurations of the horizontal chipper affect the quality of chips produced from dried wood at different time intervals?

In this context, to address the raised question, we aimed to evaluate the effect of different drying times of wood logs and various combinations of knife and anvil configurations in the horizontal chipper on the quality of Eucalyptus dunnii chips produced for energy purposes. As a result, this study holds a unique significance in the decision-making process regarding wood chip production for renewable energy generation. It has the potential to optimize chip production, enhance burning efficiency, reduce production costs, promote environmental sustainability, and obtain higher quality chips with reduced drying time and more efficient adjustments in chipper configurations.

Thus, the hypotheses guiding this research were as follows: (A) Drying time will influence the energetic characteristics of the wood chips, and the chipper adjustment will affect the physical form of the chips; (B) Moisture below the fiber saturation point - the moisture level at which the cellulose fibers in the wood are fully saturated with water - will influence the mechanical strength of the wood, impacting the chipper's performance and resulting in wood chips of different granulometries, even for identical chipper settings; (C) Drying time and chipper adjustment will influence the apparent density of the wood chips.

2. Material and methods

2.1. Study area

The research was conducted at an agro-industrial cooperative situated in the municipality of Castro, state of Paraná, Brazil, precisely at south latitude 24°47′34.01″ and west longitude 49°56′28.64" (Figure A.1 of the supplementary material).

The region has an average altitude of 998 m and is predominantly characterized by a Cfb climate (with a temperate summer) according to the Köppen and Geiger climate classification [27], with an average annual temperature of 17.7 °C and precipitation of 1589 mm [28]. The soil type in the study area is the Mesic Organosol (OY) [29]. Table 1 displays the meteorological data for the municipality of Castro from March to August 2018.

Table 1.

Meteorological data for the municipality of Castro from March to August 2018.

| Average meteorological data | Months |

|||||

|---|---|---|---|---|---|---|

| March | April | May | June | July | August | |

| Rainfall (mm) | 216.0 | 10.2 | 34.0 | 88.6 | 21.4 | 44.8 |

| Relative humidity (%) | 89.7 | 84.0 | 83.3 | 88.1 | 79.9 | 85.0 |

| Solar radiation (MJ.m−2.dia−1) | 14.7 | 16.3 | 12.9 | 8.4 | 12.2 | 13.4 |

| Air temperature (°C) | 20.4 | 18.2 | 15.5 | 13.9 | 14.1 | 12.9 |

| Wind velocity (m.s−1) | 1.6 | 2.0 | 2.4 | 1.8 | 1.6 | 2.5 |

Source: Adapted from Ref. [30].

The region has an average altitude of 998 m and is predominantly characterized by a Cfb climate (with a temperate summer) according to the Köppen and Geiger climate classification.

2.2. Characterization of forest activities and stands

The cooperative produces wood chips for energy purposes, with a portion being used in its own meat processing line, while the remainder is sold for grain drying.

The company's energy forest stands consist of Eucalyptus dunnii stands established from seeds and are clear-cut at seven years of age. The harvesting system adopted involves whole tree harvesting, using track Feller-Buncher equipment, model 903 M, manufactured by John Deere, and Clambunk Skidder extraction equipment, model C640H, manufactured by TigerCat. According to Ref. [31], the whole tree harvesting system entails felling and extracting the entire tree (stem, branches, and bark) from inside the stand to the intermediate yard or roadside for processing.

2.3. Drying time

The wood drying time adopted is usually around 150 days, or until the material reaches the humidity standards established by the interested parties (≤40%). For this study, tree cutting and extraction occurred between March and May 2018, and the processing of stems for chip production took place in the first half of August 2018. In Brazil, this period corresponds to autumn and early winter, which poses a critical situation for drying the material in the open air due to the low temperatures.

2.4. Characterization of the horizontal chipper

The processing was conducted at the edges of the stands using a Vermeer chipper, model WC2500TX, specifically designed for whole trees, in conjunction with a crane attached to a Caterpillar excavator. The equipment possesses a power of 600 hp and produces chips ranging from 3 to 32 mm [32]. It is equipped with remote control capabilities, enabling the operator to maintain a safe distance of 90 m from the machine. Additionally, if necessary, the chipper can be operated by the same operator as the loader responsible for depositing the biomass on its horizontal table. The chips were directly deposited into trucks with a mobile floor during the processing, facilitating transportation of the product to its final destination (Fig. 1).

Fig. 1.

The chipper processes the wood by depositing the chips directly onto the cart and is fed by a loader.

2.5. Horizontal chipper settings

Two aspects of the horizontal chipper can be altered during the production process: knife adjustment and feed speed. Knife adjustment can vary based on the number of knives (4 or 8) and the utilization of shims, while the feed speed is controlled through the machine controls. The knife configuration, known as the “horizontal chipper configuration,” was adjusted based on the prescribed treatments. These adjustments covered all feasible configurations within the cooperative's operational conditions. Throughout the study, the feed speed remained constant at 1169 rpm to ensure no interference with chip quality and chipper performance.

2.6. Treatments

Nine (9) treatments were established, varying the tree drying time (150, 120, and 90 days) and chipper knife settings (K), including 4 knives, 4 knives plus a shim, and 8 knives plus a shim. Treatment 1 represents the standard utilized by the cooperative and, thus, serves as the control (Fig. 2).

Fig. 2.

Treatment matrix of the research, containing the nine treatments, varying between drying times and adjustment of the chopping knives.

2.7. Chip sampling

For each drying time, roadside treatment piles were assembled. Subsequently, from each of these piles, three random trees with an average diameter of 20 cm were selected from the central points of the piles to avoid the edge effect. This process was repeated for each of the chipper adjustment treatments, resulting in a total of 27 samples. The trees corresponding to each of the nine treatments were processed individually, leading to the formation of nine chip piles (Figure A2 of the supplementary material). Following the application of each treatment, the horizontal chipper was cleaned, and the knives were sharpened.

The sampling of the material in the chip piles followed the procedures outlined in the Brazilian Regulatory Standard (NBR) 10,007/2004, established by the Brazilian Association of Technical Standards [33], for sampling solid residues. A collection of 40 kg of chips was obtained from each treatment for subsequent analysis.

2.8. Physical and energetic characterization of chips

First, the moisture content (MC) in the wet base was determined following the guidelines of NBR 14929/2017 [34], with triplicate measurements conducted for each drying time.

To determine the Basic Density (BSD), the chips were subjected to the maximum MC method [35]. The chips were immersed in water for 30 days and received daily vacuum treatment to expedite complete fiber saturation. Subsequently, the wet chips were weighed and then dried in an oven at a temperature of 103 °C (±2 °C) until the weight variation was below 0.5 g between two successive weightings.

For the analysis of Higher Calorific Value (HCV) and Ash Content (AC), the material was ground in a Wiley mill, following the Technical Association of the Pulp and Paper Industry T257 om–92 standard [36], and then sorted using sieves. The analysis was performed only on the fraction that passed through a 40-mesh sieve (0.42 mm opening) and was retained in a 60-mesh sieve (0.25 mm). Once the material was shredded, the “chipper adjustment” factor no longer influenced these tests, and only the “drying time” (DT) factor was studied, leading to the establishment of three treatments: 90, 120, and 150 drying times.

HCV was determined by NBR 8633 [37]. The test was performed in duplicate, using 0.5 g of anhydrous material and an adiabatic calorimeter. Lower calorific value (LCV) and useful calorific value (UCV) were calculated according to Ref. [38].

The AC was determined following the M11/77 standard [39]. The test was conducted in triplicate, using 1 g of anhydrous material, which was placed in porcelain crucibles and subjected to a muffle furnace at 600 °C for 6 h. After this period, the samples were removed from the muffle and placed in a desiccator for cooling, then they were weighed to determine the ash content.

The Fuel Value Index (FVI) was calculated according to the methodology proposed by Ref. [39] (Eq. (1)).

| (1) |

Where the FVI is the fuel value index (cal.cm−3), the HCV is the higher calorific value (kcal.kg−1), the BSD is the Basic Density of wood (g.cm−3), AC is the ash content (%), and the MC is the moisture content of the wood, on a wet basis (%).

The chips from each treatment underwent an adapted granulometric separation test, as described by Ref. [40]. The material was poured into a particle separator with six granulometric sieves, featuring mesh sizes of 63 mm, 45 mm, 25 mm, 16 mm, 8 mm, and 5 mm. The material was sieved for 10 min to ensure the movement of the particles. Subsequently, the chips retained in each sieve were weighed, with 6 repetitions per treatment.

Following this procedure, percentage calculations relative to the total weight of material in each repetition were carried out. Using the percentage values of the sieved material, granulometric classification was conducted based on the methodology proposed by Ref. [41], as detailed in Table A1 of the supplementary material.

The aim was to produce homogeneous and high-quality chips, with the main granulometry representing a fraction greater than 80% of the total weight. The fraction of fines (very fine particles) was not to exceed 5%, and the fraction of oversize chips (chips larger than planned) should not surpass 1% [41]. The results were compared with the European BS EN 14961–1 [42] and Canadian CAN/CSA ISO 17225 [43] standards.

Bulk density (BD) was obtained following the guidelines of NBR 6922 [44]. However, the material moisture was not standardized according to the norm due to the purpose of studying the effect of different humidity.

2.9. Chip quality analysis

To establish a comparative parameter for the chips, a chip energy quality index (Q) was proposed by summing and correlating the variables that influence chip quality, including moisture, basic density, higher calorific value, ash content, granulometry, and bulk density. Weights were assigned to each variable in the equation.

The methodology was based on the principles of Fuzzy logic, according to Ref. [45], is a mathematical method that transforms qualitative variables into numerical values ranging from 0 to 1. The closer the value is to 1, the higher its representativeness within the proposed model. To apply the parameters in the equation, the values of each parameter were divided by the highest value within its set, resulting in dimensionless numbers from 0 to 1 under the Fuzzy concept. As a result, all values for Q are also dimensionless.

For the chip energy quality index (Q), 50% was assigned to the FVI for its comprehensiveness regarding the correlated properties, and the other 50% was allocated to the physical properties. Within the physical properties, 30% was attributed to the homogeneity of the material's granulometry, while 20% was assigned to BD, considering its significance in transport (Eq. (2)).

| (2) |

Where Q is the chip energy quality index, FVI is the fuel value index, MP is the percentage of the main granulometric fraction, and BD is the bulk density.

2.10. Statistical analysis

Statistical analyses were conducted to examine the parameters of MC, AC, UCV, and FVI by applying an analysis of variance (α ≤ 0.05). The objective was to determine whether the different drying times in the field exhibited any significant differences. In cases where significance was observed, regression analysis was employed.

For BSD, HCV and LCV, Student's t tests (α ≤ 0.05) were applied to confirm the homogeneity of the material. This method was chosen due to the homogeneity of the data provided by the analysis of a single material, from the same stand, and of the same age, regardless of the drying time and processing methods of the trees. Subsequently, descriptive statistical analysis was applied.

For the analysis of BD data, a completely randomized design was used in a 3 (drying time) × 3 (chipper adjustment) factorial scheme, to identify the influence of the relationship between treatments. For granulometry, descriptive statistics were applied.

3. Results

The DBS was 0.506 g.cm−³ (coefficient of variation = 0.032 g.cm−³), which indicates that it is a medium-density wood, according to the classification by Ref. [43].

The values of MC, AC, HCV and FVI showed a significant difference between the drying times (Table 2).

Table 2.

Energy characterization of Eucalyptus dunnii chips at different tree drying times.

| Variables | Drying time (days) |

CV | ||

|---|---|---|---|---|

| 90 | 120 | 150 | ||

| MC (%) | 47.03 a | 39.09 b | 34.20 c | 0.007 |

| AC (%) | 0.76 b | 0.83 a | 0.52 c | 0.037 |

| UCV (kcal.kg−1) | 1923.95 c | 2342.12 b | 2600.00 a | 0.007 |

| FVI (cal.cm−3) | 64.36 c | 71.03 b | 128.06 a | 0.006 |

Where CV is the coefficient of variation. Means followed by the same letter on the line do not statistically differ from each other by Tukey's at 5% significance.

Regarding the MC, it was observed that there was a decrease in the drying time, with higher values for a drying time of 90 days and lower values for 150 days. This suggests that longer drying time results in reduced MC of the wood, making it more favorable for its energy potential.

For the ash content (AC) values, higher values were noted for a drying time of 150 days and lower values for 120 days, demonstrating that drying time influences the amount of mineral residues present in the wood.

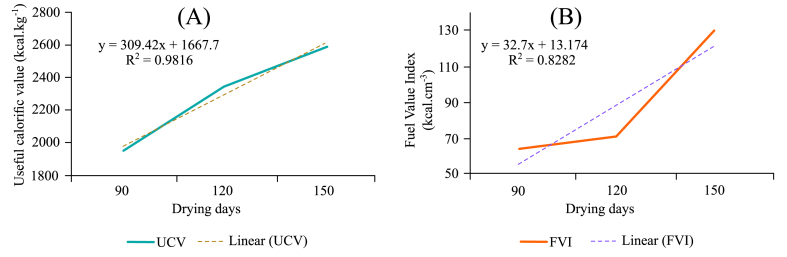

As for the Useful Calorific Value (UCV) and Fuel Value Index (FVI), there is a growth in these values as the drying time increases, indicating that these variables are influenced by the drying time.

Despite the small variations, the coefficient of determination of the linear regression of MC is 0.9816, indicating the model's high capacity to explain the drying time × MC relationship, Fig. 3. In 3A, the relationship between moisture content (MC) in relation to drying days is found, and in 3B, the same relationship is shown for ash content.

Fig. 3.

Relation of moisture content (MC) in (A) and ash content (AC) in (B) with drying time.

For the UCV and the FVI, the behavior pattern is evident: the values increase as the drying time progresses and the humidity decreases, Fig. 4. In 4 A, the relationship of useful colorific values in relation to drying days is demonstrated, and in 4B, the same relationship for fuel values index.

Fig. 4.

Relation of useful calorific value (UCV) in (A) and fuel value index (FVI) in (B) with drying time.

Fig. 5 shows the types of particles retained in each of the particle separator sieves.

Fig. 5.

Types of chips retained in each particle separator screen.

Table 3 presents the mean percentages of material retained on each sieve for each treatment studied.

Table 3.

Percentages of Eucalyptus dunnii chips retained in the different meshes of the particle separator.

| Treatments |

Percentage of chips retained in the mesh (%) |

Sum | |||||||

|---|---|---|---|---|---|---|---|---|---|

| CAT | DT | 63 | 45 | 25 | 16 | 8 | 5 | 5 > | |

| 4 Knives + 1 Shim | 150 | 0.27 | 2.58 | 17.82 | 40.59 | 34.40 | 1.63 | 2.71 | 100 |

| 120 | 0.00 | 0.90 | 7.66 | 24.46 | 52.12 | 10.07 | 4.79 | 100 | |

| 90 | 0.00 | 0.23 | 9.35 | 28.00 | 52.90 | 6.33 | 3.19 | 100 | |

| 4 Knives | 150 | 1.58 | 3.32 | 16.41 | 38.88 | 35.91 | 1.74 | 2.16 | 100 |

| 120 | 1.13 | 0.85 | 29.00 | 37.27 | 26.65 | 2.02 | 3.08 | 100 | |

| 90 | 2.68 | 3.41 | 8.33 | 25.35 | 50.90 | 5.67 | 3.66 | 100 | |

| 8 Knives + 1 Shim | 150 | 0.00 | 0.98 | 5.68 | 30.08 | 54.92 | 5.09 | 3.25 | 100 |

| 120 | 0.00 | 0.52 | 2.47 | 15.32 | 61.64 | 16.76 | 3.29 | 100 | |

| 90 | 0.00 | 2.38 | 9.37 | 34.74 | 47.23 | 3.23 | 3.05 | 100 | |

Where CAT refers to chipper adjustment treatments and DT to drying time treatments in days.

The different CAT provided different particle sizes between the chips with the same DT. Considering the same CAT, granulometry was equal for the different DT, since the humidity was the same below the fiber saturation point, except for the treatment 150 days of drying and chipper with 4 Knives +1 shim (150 4K + 1) (Table 4).

Table 4.

Dimensions of the main chip granulometry (mm) resulting from the DT × CAT.

| CAT | Drying time (days) |

||

|---|---|---|---|

| 150 | 120 | 90 | |

| 4 Knives + 1 Shim | 25 | 16 | 16 |

| 4 Knives | 25 | 25 | 25 |

| 8 Knives + 1 Shim | 16 | 16 | 16 |

It can be observed that when the chipper is adjusted to 4 knives + 1 shim, the chip size is 25 mm for a drying time of 150 days. However, for drying times of 120 and 90 days, the chip size decreases to 16 mm. This suggests that a shorter drying time results in a smaller chip size when using this specific chipper adjustment.

On the other hand, when the chipper is adjusted to 4 knives and also to 8 knives +1 shim, regardless of the drying time, the chip size remains constant at 25 mm and 16 mm, respectively. This indicates that, even with different drying times, the chip size is not affected.

Fig. 6 shows all fractions for each treatment (fine, main, and over). In 6A, the distributions of the main and fine chip fractions for each treatment are presented. In 6B, the distributions of fractions for each treatment, with details of the main fraction. The treatment of 120 days of drying and chopping with 4 Knives (120 4K) presented the highest main fraction and the lowest fractions of over and fines.

Fig. 6.

A) Distributions of the over, main and fine fractions of the chips in each treatment, and B) Distributions of the over, main and fine fractions of the chips in each treatment, with details of the main fraction.

Although the study of particle size provides more efficient applications for chips, analyzing the energy characteristics of the material is also important. Thus, similarly, observing that the high performance of treatment in one analysis does not guarantee the same result in another is possible (Fig. 7).

Fig. 7.

Bulk density, percentage of chips in the main fraction and fuel value index of the treatments.

Regarding the results, it is evident that the chipper adjustments influence the dimensions of the main chip's granulometry. Specifically, the “8 Knives +1 Shim” adjustment leads to larger dimensions compared to the other settings. The drying time also plays a significant role in chip dimensions. For the “4 Knives +1 Shim” adjustment, chips from a drying time of 90 days exhibit larger dimensions compared to those from 150 days. This suggests that a shorter drying time may result in increased fragmentation of the chips during the milling process (Table 5).

Table 5.

Dimensions of the main chip granulometry (mm) resulting from the tree DT × CAT.

| CAT | Drying time (days) |

||

|---|---|---|---|

| 150 | 120 | 90 | |

| 4 Knives + 1 Shim | 0.339 Bb | 0.294 Aa | 0.346 Ba |

| 4 Knives | 0.310 Aa | 0.304 Aa | 0.342 Ba |

| 8 Knives + 1 Shim | 0.348 Ab | 0.354 Ab | 0.376 Bb |

Means followed by the same uppercase letter in a row and lowercase in a column, are not differentiated by the Tukey test at 5% significance.

Fig. 8 shows BD behavior is different when the factors are evaluated separately, where 8A shows bulk density in relation to wood chipper adjustment, while in 8B, bulk density is shown in relation to drying time.

Fig. 8.

Bulk density behavior for (A) the same drying times and varying the chopper setting and (B) the same chopper Knives settings and varying the drying time.

Fig. 9 shows the values resulting from the chip energy quality index equation (Q) proposed to establish a comparison parameter.

Fig. 9.

Energy quality index of Eucalyptus dunnii chips. Where BD is Bulk Density, MP is Percentage of chips retained in the main granulometric fraction, FVI is Fuel Value Index and Q is Chip Energy Quality Index.

Table A.2 of the supplementary material shows the general ranking of treatments.

In the 25 mm granulometry category, the “150 4K + 1″ treatment achieved the highest chip energy quality index (Q = 0.979) and secured the first position in the ranking. This suggests that this treatment produced Eucalyptus dunii chips with 25 mm granulometry of high energy quality. The “150 4K″ treatment also obtained a high chip energy quality index (Q = 0.959) and ranked second. These results indicate that the use of four cutting knives and one adjustment shim in the chipper, combined with a tree drying time of 150 days, resulted in chips with favorable granulometry for energy purposes (Table 6).

Table 6.

Ranking of the energetic quality of Eucalyptus dunii chips: Granulometry Ranking by main fraction.

| Granulometry with 25 mm | ||

|---|---|---|

| Treatment | Q | Placing |

| 150 4K + 1 | 0.979 | 1st |

| 150 4K | 0.959 | 2nd |

| 120 4K | 0.737 | 3rd |

| 90 4K | 0.704 | 4th |

| Granulometry with 16 mm | ||

| 150 8K + 1 | 0.970 | 1st |

| 120 8K + 1 | 0.759 | 2nd |

| 90 8K + 1 | 0.724 | 3rd |

| 120 4K + 1 | 0.705 | 4th |

| 90 4K + 1 | 0.698 | 5th |

Where Q is the energy quality index of the chips in dimensionless values from 0 to 1.

For the 16 mm granulometry category, the “150 8K + 1″ treatment obtained the highest chip energy quality index (Q = 0.970) and ranked first. This suggests that the use of eight cutting knives and one adjustment shim resulted in Eucalyptus dunii chips with 16 mm granulometry of high energy quality. The “120 8K + 1″ treatment ranked second in the ranking, with a considerable chip energy quality index (Q = 0.759). These results indicate that the chipper adjustment with eight cutting knives and one adjustment shim is effective in obtaining chips with the desired granulometry for energy purposes.

Overall, the results indicate that the chipper adjustment type (CAT) and drying time (DT) have a significant impact on the granulometry of Eucalyptus dunii chips. Different combinations of CAT and DT result in variations in chip dimensions, affecting their energy quality. The study emphasizes the importance of selecting the appropriate CAT, considering the number of cutting knives and the presence of adjustments, as well as a well-defined DT to achieve the desired granulometry for energy applications.

4. Discussion

Evaluating the effect of different drying times of wood logs and different configurations of knives and spacers in the horizontal chipper revealed significant results regarding the quality of Eucalyptus dunnii wood chips for energy purposes. Initially, it was observed that Eucalyptus dunnii wood has a medium density, which is relevant for determining its energy potential, as evidenced by Ref. [13].

Additionally, this result indicates that this characteristic provides favorable conditions for workability and favorable conditions for the chip production process, given that medium-density woods [46] have lower levels of tool resistance but are not flexible enough to break with minimal applied force, resulting in undesirable particle sizes [47].

Due to this fact [45], makes it clear that a basic wood density between 0.4 g cm−3 and 0.550 g cm−3, as is the case with the studied wood, is ideal for the efficiency of log cutting in chippers. Woods with densities below 0.400 g cm−3 are prone to breakage during processing, reducing industrial yield and productivity. On the other hand, values above 0.550 g cm−3 complicate the process, increasing chipper knife wear and generating larger chips than desired sizes, hindering the impregnation of reactants.

The authors [48], when analyzing the influence of density on the energy quality of chips from five eucalyptus genetic materials, observed that samples with lower basic density (449.47 kg m−3) exhibited lower ash content (0.39%), and consequently, samples with higher density (544.34 kg m−3) resulted in higher ash content (0.54%). Furthermore, the authors noted that the higher heating value was strongly affected by the basic density of the samples, with the treatment having the lowest density (449.47 kg m−3) showing the lowest higher heating value (10.40 MJ kg−1). Conversely, the sample with the highest density (544.34 kg m−3) exhibited the highest higher heating value (13.41 MJ kg−1) among those studied.

Regarding DT, it was observed that each treatment affected MC, AC, HCV, and FVI of the chips in different ways. Table 2 shows that MC decreased over the DT, being highest for the 90 days and lowest for 150 days. Furthermore, it was noticed that the longer the DT and thus the lower the MC, the higher the UCV (150 days = 2600.00 kcal kg−1; 120 days = 2342.12 kcal kg−1; 90 days = 1923.95 kcal kg−1), the higher the FVI (150 days = 128.06 cal cm−3; 120 days = 71.03 cal cm−3; 90 days = 64.36 cal cm−3), and the lower the AC (150 days = 0.52%; 90 days = 0.76%). This indicates that longer DT results in reduced MC, making it more favorable for its energy potential and more efficient energy conversion. During the energy generation process, part of the released energy is used to evaporate MC, thus reducing energy efficiency, achieving HCV, and consequently the higher FVI [49].

However, despite the significant difference found among the means, none of the treatments resulted in ash content above 3%, which according to Ref. [50], negatively influences the heating value and combustion efficiency [51] and increases the demand for boiler maintenance.

Wood quality, especially the MC of the chips, is one of the factors that most influence efficient chip combustion [12]. Similarly, to the present study, other authors highlight that high MC levels require higher energy consumption for material drying, making the process less efficient [7]. Therefore, it emphasizes the importance of improving the drying process, as it reduces material weight, increases heating value [52], improves boiler efficiency [53], and also reduces emissions during energy conversion, which is exactly what was done in this study.

From 90 to 120 days of drying, moisture decreased by 16.90% and the FVI increased by 10.30%. However, from 120 to 150 days, although the MC decreased by only 12.52%, the FVI increased by 80.30%. The explanation lies in the fact that in the first case, the total carbon (TC) increased by 8.83%, and in the second case, it decreased by 36.80%. Although the higher UCV is one of the most commonly used parameters to compare wood chips in the market, the FVI proves to be more efficient as it correlates with other factors that influence the energy efficiency of lignocellulosic fuel.

The initial general assumption is to associate the energy potential of biomass with its heating value, as it demonstrates the burning potential of the material, but the FVI allows for a more detailed evaluation. However, the FVI should not be used as the sole parameter to assess the energy quality of biomass, as the equation is highly sensitive to low MC and AC values, making the index imprecise in studies with a high coefficient of variation. The coefficient of determination for linear regression of the FVI is 0.8282, a value that also represents the high applicability of the model but is lower than the model for UCV. This occurs because, in addition to moisture, the FVI is also influenced by ash content, as BD and HCV are the same for all treatments.

The analysis of the particles retained on each sieve of the particle separator revealed that the chip size varied according to the mesh size. Sieves with larger meshes (63 mm and 45 mm) resulted in larger chips, represented entirely by bark or large bark-covered wood particles that passed through the chipper's retention sieve (Fig. 5). On the other hand, the 25 mm and 16 mm sieves presented bark and wood that appeared as poorly crushed material (Fig. 5), formed by the lack of contact between the knives during rotation and the wood. At certain moments, the wood remained trapped between the chipper wall and the Knives. In the 8 mm and 5 mm sieves, 100% of the retained material was wood (Fig. 5). Regarding the shape of the chips, the 25 mm sieve presented more homogeneous materials, while the 5 mm sieve showed more heterogeneous materials (Fig. 5).

The chip granulometry was influenced by both the CAT and the DT. However, the granulometry was the same for different DT as long as the moisture was below the fiber saturation point, except for the 150-day drying treatment with the configuration of 4 knives +1 spacer. This factor can be corrected by reducing the retention sieve mesh size and/or increasing preventive and corrective maintenance, as the constant impact force of particles in this part of the chipper can wear out or break the sieve.

Standard [41] defines fines fraction as particles smaller than 3.15 mm, and it should not exceed 5% of the total weight. Although for this study, it was adopted that the fines fraction would be represented by particles smaller than 5 mm, expanding the margin of this fraction, none of the treatments exceeded 5% fines. These values are also in line with the maximum fines established by European standards (12%) and Canadian standards (10–15%), indicating a stricter classification by Ref. [41].

Regardless of the actual particle sizes of the studied chips, their particle sizes may be related to an ideal use, as classified by Ref. [54]: in general terms, all treatments meet the needs of medium-sized burners, with power input ranging from 250 kW to 1 MW. However, chips with a particle size of 16 mm are more efficient when used in small burners, requiring up to 250 kW of power unless there is a high percentage of oversized particles, as in the case of the 120-day drying treatment with 8 knives +1 shims (120 8F + 1). Chips with a particle size of 25 mm are more efficient in large burners that require over 1 MW, as the majority of their chips are 25 mm in size, which is not the case in any of the treatments.

The different CAT also affected the BD of the chips. It was observed that the configuration with 8 knives and 1 spacer resulted in higher bulk density for the 90-day drying time (0.38 g cm−3).

The proposal of a chip energy quality index (Q) allowed for an evaluation of the quality of wood chips for energy purposes. The results indicated that the treatment with 150 days of DT and the configuration of 4 knives +1 spacer achieved the highest Q value (0.979), indicating high energy quality. The proposed quality index proved to be useful for assessing the energy quality of the studied wood chips, but it is important to develop a more comprehensive index for evaluating wood chips for energy use in general. This would be valuable for both the commercial wood chip sector and the scientific community.

In summary, the study demonstrated the importance of DT, CAT, and MC in the quality of Eucalyptus dunnii chips for energy purposes. The results contribute to understanding the factors that influence the energy quality of wood chips and provide relevant information for the production and efficient utilization of biomass as an energy source.

5. Conclusions

Chip grading and bulk density are affected by both chipper adjustment and material MC. The influence of the chipper adjustment is in the number of Knives, the greater the number, the smaller the particles generated and, consequently, the smaller the granulometry. Since different granulometries occupy different spaces in the cargo, this variable also influences the bulk density.

Higher humidity increases the weight of the load without changing the occupied volume, increasing the bulk density value but decreasing the energy efficiency of the material. The variations in the particle size of the chips due to the MC revealed the need for a more in-depth study on the water-wood ratio, SFP, and interferences in the mechanical strength of wood.

The proposed quality index helped to understand how different factors need to be evaluated together in determining the ideal quality of wood chips for energy production, despite being specific to the chips studied in this research. A new study to develop a more complete index capable of evaluating wood chips for energy use in a general scope would be interesting for the commercial chip sector and science.

It can be concluded that the basic density of the wood directly influences the quality of eucalyptus chips. Furthermore, variations in chipper configurations and drying times significantly impact the dimensions and density of the produced chips. The 150-day drying period is most effective in reducing moisture content to 34.20% and ash content to 0.52%. The longer drying time also positively affects the useful calorific value and Fuel Value Index, measuring 2600.00 kcal kg−1 and 128.06 cal cm−3, respectively.

Regarding the chipper configuration, the analysis of the Fuel Value Index highlights that the configuration with four knives and a shim demonstrates maximum efficiency for 25 mm chips (Q = 0.979), while the 150-day drying, eight knives, and one shim configuration is ideal for 16 mm chips (Q = 0.970). These findings underscore the importance of optimizing chipper configurations and drying times for the efficient production of high-quality wood chips, aiming to meet the growing demands for renewable and sustainable energy.

Data availability statement

All data may be made available by the authors upon request from interested readers.

CRediT authorship contribution statement

Dâmaris Figueiredo Billo Nogueira: Conceptualization, Formal analysis, Investigation, Methodology, Project administration, Software, Supervision, Writing – original draft, Writing – review & editing. Nilton Cesar Fiedler: Formal analysis, Project administration, Supervision, Writing – original draft, Writing – review & editing. Graziela Baptista Vidaurre: Formal analysis, Supervision, Writing – original draft, Writing – review & editing. Eduardo da Silva Lopes: Conceptualization, Data curation, Formal analysis, Validation, Visualization, Writing – review & editing. Carla Krulikowski Rodrigues Pelissari: Conceptualization, Formal analysis, Writing – original draft, Writing – review & editing. Antonio Henrique Cordeiro Ramalho: Conceptualization, Formal analysis, Investigation, Writing – original draft, Writing – review & editing. Renato Cesar Gonçalves Robert: Conceptualization, Investigation, Methodology, Writing – original draft, Writing – review & editing. Fernanda Dalfior Maffioletti: Investigation, Software, Supervision, Visualization, Writing – original draft.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The authors thank the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) Financing Code 001, b) Fundação de Amparo à Pesquisa e Inovação do Espírito Santo (FAPES) and c) Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq).

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.heliyon.2024.e25991.

Contributor Information

Dâmaris Figueiredo Billo Nogueira, Email: damaris_billo@hotmail.com.

Nilton Cesar Fiedler, Email: niltoncesarfiedler@yahoo.com.br.

Graziela Baptista Vidaurre, Email: grazividaurre@gmail.com.

Eduardo da Silva Lopes, Email: eslopes@unicentro.br.

Carla Krulikowski Rodrigues Pelissari, Email: carlakr@gmail.com.

Antonio Henrique Cordeiro Ramalho, Email: henriqueramalho14@gmail.com, henriquecr2012@hotmail.com.

Renato Cesar Gonçalves Robert, Email: renatorobert@ufpr.br.

Fernanda Dalfior Maffioletti, Email: Fernandamaffioletti123@hotmail.com.

Appendix A. Supplementary data

The following is/are the supplementary data to this article.

References

- 1.Bianchini D.C., Simioni F.J. vol. 44. Sustainable Energy Technologies and Assessments; 2021. (Economic and Risk Assessment of Industrial Wood Chip Drying). [DOI] [Google Scholar]

- 2.Birdsey R., Duffy P., Smyth C., Kurz W.A., Dugan A.J., Houghton R. Climate, economic, and environmental impacts of producing wood for bioenergy. Environ. Res. Lett. 2018;13 doi: 10.1088/1748-9326/aab9d5. [DOI] [Google Scholar]

- 3.Nunes L.J.R., Matias J.C.O. Biomass torrefaction as a key driver for the sustainable development and decarbonization of energy production. Sustainability. 2020:12. doi: 10.3390/su12030922. [DOI] [Google Scholar]

- 4.IBÁ . Brasília, DF; 2020. Brazilian Tree Industry Annual Report - Base Year 2019.http://abpa-br.org/relatorios/ [Google Scholar]

- 5.Mme Balanço. Rio de Janeiro; 2020. Energético Nacional 2020 - Relatório Síntese/Ano Base 2019. [Google Scholar]

- 6.Simioni F.J., Buschinelli C.C. de A., Deboni T.L., dos Passos B.M. Cadeia produtiva de energia de biomassa florestal: O caso da lenha de eucalipto no polo produtivo de Itapeva - SP. Ciência Florest. 2018;28:310–323. doi: 10.5902/1980509831602. [DOI] [Google Scholar]

- 7.Sahoo K., Bilek E.M., Mani S. Techno-economic and environmental assessments of storing woodchips and pellets for bioenergy applications. Renew. Sustain. Energy Rev. 2018;98:27–39. doi: 10.1016/j.rser.2018.08.055. [DOI] [Google Scholar]

- 8.Pedroso L. de A.L., Freitas da Silva F., Freitas da Silva F., Morais Melo Á., Erthal Junior M., Shimoya A., Matias Í. de O., de Souza C.L.M. Demandas atuais e futuras da biomassa e da energia renovável no Brasil e no mundo/Current and future demands for biomass and renewable energy in Brazil and worldwide. Brazilian Journal of Development. 2018;4:1980–1996. [Google Scholar]

- 9.Pereira M.P.D.C.F., Costa E.V.S., Corradi Pereira B.L., Carvalho A.M.M.L., Oliveira Carneiro A. de C., Costa A. Torrefação de cavacos de eucalipto para fins energéticos. Pesquisa Florestal Brasileira. 2016;36:269. doi: 10.4336/2016.pfb.36.87.1093. [DOI] [Google Scholar]

- 10.Silveira D.J., Durigan A., Monteiro T., Sgarbiero I.M., Silva D.A. Influence of storage time and log length on the distribution of wood chip size. Bioresources. 2023;18:4510–4518. doi: 10.15376/biores.18.3.4510-4518. [DOI] [Google Scholar]

- 11.Mancini M., Toscano G., Feliciangeli G., Leoni E., Duca D. Investigation on woodchip quality with respect to ISO standards and relationship among quality parameters. Fuel. 2020:279. doi: 10.1016/j.fuel.2020.118559. [DOI] [Google Scholar]

- 12.Lopes G. de A., Brito J.O., de Moura L.F. Energy use of wood residues in production of ceramics in the state of Sao Paulo. Ciência Florest. 2016;26:679–686. doi: 10.5902/1980509822767. [DOI] [Google Scholar]

- 13.Elloumi I., Hernández R.E., Cáceres C.B., Blais C. Effects of temperature and moisture content of logs on size distribution of black spruce chips produced by a chipper-canter at two cutting widths. Bioresources. 2021;16:6684–6704. [Google Scholar]

- 14.Nati C., Spinelli R., Fabbri P. Wood chips size distribution in relation to blade wear and screen use. Biomass Bioenergy. 2010;34:583–587. doi: 10.1016/j.biombioe.2010.01.005. [DOI] [Google Scholar]

- 15.Moskalik T., Gendek A. Production of chips from logging residues and their quality for energy: a review of European literature. Forests. 2019;10:262. doi: 10.3390/f10030262. [DOI] [Google Scholar]

- 16.Hernández U.F., Jaeger D., Samperio J.I. Evaluating economic alternatives for wood energy supply based on stochastic simulation. Sustainability. 2018;10:1–19. doi: 10.3390/su10041161. [DOI] [Google Scholar]

- 17.Paolotti L., Martino G., Marchini A., Boggia A. Economic and environmental assessment of agro-energy wood biomass supply chains. Biomass Bioenergy. 2017;97:172–185. doi: 10.1016/j.biombioe.2016.12.020. [DOI] [Google Scholar]

- 18.Anerud E., Jirjis R., Larsson G., Eliasson L. Fuel quality of stored wood chips – influence of semi-permeable covering material. Appl. Energy. 2018;231:628–634. doi: 10.1016/j.apenergy.2018.09.157. [DOI] [Google Scholar]

- 19.Miranda M.A. da S., Ribeiro G.B. de D., Valverde S.R., Isbaex C. Eucalyptus sp. Woodchip potential for industrial thermal energy production. Rev. Árvore. 2017;41 doi: 10.1590/1806-90882017000600004. [DOI] [Google Scholar]

- 20.Dessbesell L., Welter C.A., de Farias J.A. vol. 26. 2019. (Economic and Environmental Analysis of Pellets' Production in Rio Pardo Watershed, Brazil, Floresta e Ambiente). [DOI] [Google Scholar]

- 21.Kuptz D., Hartmann H. The effect of raw material and machine setting on chipping performance and fuel quality – a German case study. Int. J. For. Eng. 2015;26:60–70. doi: 10.1080/14942119.2015.1021529. [DOI] [Google Scholar]

- 22.Kuptz D., Hartmann H. Influence of tree species and machine settings on chip quality and specific energy consumption of a stationary drum chipper. Biomass Bioenergy. 2021;155 doi: 10.1016/J.BIOMBIOE.2021.106305. [DOI] [Google Scholar]

- 23.Eliasson L., Von Hofsten H., Johannesson T., Spinelli R., Thierfelder T. Effects of sieve size on chipper productivity. Fuel Consumption and Chip Size Distribution for Open Drum Chippers, CROJFE. 2015;36:11–17. [Google Scholar]

- 24.Spinelli R., Cavallo E., Eliasson L., Facello A., Magagnotti N. The effect of drum design on chipper performance. Renew. Energy. 2015;81:57–61. doi: 10.1016/J.RENENE.2015.03.008. [DOI] [Google Scholar]

- 25.Spinelli R., Eliasson L., Magagnotti N. Increasing wood fuel processing efficiency by fine-tuning chipper settings. Fuel Process. Technol. 2016;151:126–130. doi: 10.1016/J.FUPROC.2016.05.026. [DOI] [Google Scholar]

- 26.Van Der Merwe J.-P., Ackerman P., Pulkki R., Längin D. The impact of log moisture content on chip size distribution when processing Eucalyptus pulpwood. Croat. J. For. Eng. 2016;37 https://www.researchgate.net/publication/307019020 [Google Scholar]

- 27.Alvares C.A., Stape J.L., Sentelhas P.C., De Moraes Gonçalves J.L., Sparovek G. Köppen’s climate classification map for Brazil. Meteorol. Z. 2013;22:711–728. doi: 10.1127/0941-2948/2013/0507. [DOI] [Google Scholar]

- 28.Climate Data, Castro Clima (BRASIL), CLIMATE-DATA. ORG.; 2021. https://pt.climate-data.org/america-do-sul/brasil/parana/castro-43746/ [Google Scholar]

- 29.IBGE, Mapa de Solos do Brasil - EMBRAPA Solos 1:5.000.000 | solos – 1:5 000 000. 2006. https://www.ibge.gov.br/geociencias/informacoes-ambientais/pedologia/15829-solos.html?=&t=downloads

- 30.Fundação abc, monitoramento - estações agrometeorológicas - mensal, sistema de Monitoramento agrometeorológico. 2018. http://sma.fundacaoabc.org/monitoramento/grafico/mensal

- 31.Bessaad A., Terreaux J.-P., Korboulewsky N. Assessing the land expectation value of even-aged vs coppice-with-standards stand management and long-term effects of whole-tree harvesting on forest productivity and profitability. Ann. For. Sci. 2021;78:1–15. doi: 10.1007/s13595-021-01071-2/Published. [DOI] [Google Scholar]

- 32.Vermeer, Picador de árvores inteiras WC2500TX, Vermeer (2021). Available on <https://www.vermeer.com/em/whole-tree-chippers/wc2500tx?hl=pt-BR>. (Accessed 2 May 2021).

- 33.Abnt . Rio de Janeiro, RJ; 2004. NBR 10007/2004 - Amostragem de resíduos sólidos.http://wp.ufpel.edu.br/residuos/files/2014/04/nbr-10007-amostragem-de-resc3adduos-sc3b3lidos.pdf [Google Scholar]

- 34.ABNT - Brazilian Association of Technical Standards. Wood - Determination of moisture content of chips - Oven-drying method. NBR. 2017;14929 [Google Scholar]

- 35.Zhang Y., Fang S., Tian Y., Wang L., Lv Y. Responses of radial growth, wood density and fiber traits to planting space in poplar plantations at a lowland site. J. Res. 2022;33:963–976. doi: 10.1007/s11676-021-01382-0. [DOI] [Google Scholar]

- 36.Tappi . Atlanta; 2012. T257 Om-92 - Sampling and Preparing Wood for Analysis. [Google Scholar]

- 37.ABNT - Brazilian Association of Technical Standards. Charcoal - Determination of Calorific Value. NBR. 1984;8633 [Google Scholar]

- 38.Cardenas-Rodriguez H. de N., Martins R., Oliveira L.E.L., Bonaldi E.L., Assuncao F. de O., Lambert-Torres G., Villa-Nova H.F., Sant’ana W.C., Borges-Da-silva L.E., Bomfin C.B., Haddad J. Analysis on the use of briquettes as an alternative to improve the generation of thermal energy in the locality of Aripuana-Brazil. Energies. 2021;14 doi: 10.3390/en14196355. [DOI] [Google Scholar]

- 39.Purohit A.N., Nautiyal A.R. Fuelwood value index of indian mountain tree species. Int. Tree Crops J. 1987;4:177–182. doi: 10.1080/01435698.1987.9752821. [DOI] [Google Scholar]

- 40.Guerra S.P.S., Oguri G., Ceragioli N.S., Spinelli R. Trade-offs between fuel chip quality and harvesting efficiency in energy plantations. Fuel. 2016;183:272–277. doi: 10.1016/j.fuel.2016.06.079. [DOI] [Google Scholar]

- 41.LIPPEL . 2023. Qualidade dos cavacos, LIPPEL downloads - qualidade dos cavacos.https://www.lippel.com.br/Assets/Downloads/05-05-2014-10-36qualidade-dos-cavacos-para-combustao.pdf 1–1. [Google Scholar]

- 42.European Committee for Standardization, EN 1496. Brussels, Belgium; 2010. [Google Scholar]

- 43.CSA . 2015. CAN/CSA-ISO 17225-2. [Google Scholar]

- 44.Abnt . 1983. NBR 6922 - Carvão vegetal - ensaios físicos – determinação da massa específica - densidade a granel. [Google Scholar]

- 45.Ramalho A.H.C., Neder E. de C., Fiedler N.C., Moreira T.R., Silva J.P.M. Geotechnology applied to predict the risk of occurrence of fire in the Atlantic Forest. Revista Ibero-Americana de Ciências Ambientais. 2021;12:707–720. doi: 10.6008/CBPC2179-6858.2021.001.0057. [DOI] [Google Scholar]

- 46.Foelkel C. 2021. Pergunte ao euca expert, Eucalyptus online book & newsletter.https://www.eucalyptus.com.br/eucaexpert/1037_Classificacao madeiras eucalipto pela densidade.pdf 3. [Google Scholar]

- 47.Zine O., El bouardi A., Taoukil D., Kadri E.H., El abbassi I. E3S Web of Conferences. EDP Sciences; 2021. Influence of density and water content on the thermal diffusivity of wood chips. [DOI] [Google Scholar]

- 48.Ribeiro G.B. de D., de Magalhães M.A., Batista F.R.S., Miranda M.A. da S., Valverde S.R., A. de C. de O. Carneiro Evaluation of Eucalyptus woodchip utilization as fuel for thermal power plants. Maderas Cienc. Tecnol. 2021;23:1–12. doi: 10.4067/s0718-221x2021000100429. [DOI] [Google Scholar]

- 49.Zarzycki R., Panowski M. Increase of thermal efficiency of cogeneration plant by waste heat utilisation with absorption heat pump. Therm. Sci. 2019;23:1101–1112. doi: 10.2298/TSCI19S4101Z. [DOI] [Google Scholar]

- 50.Lieskovský M., Jankovský M., Trenčiansky M., Merganič J., Dvořák J. Ash content vs. the economics of using wood chips for energy: model based on data from central europe. Bioresources. 2017;12:1579–1592. [Google Scholar]

- 51.Simetti R., Bonduelle G.M., da Silva D.A., Mayer S.L.S., Souza H.P., de Muniz G.I.B. Production of biomass and energy stock for five Eucalyptus species. Revista Ciência Da Madeira - RCM. 2018;9:30–36. doi: 10.12953/2177-6830/rcm.v9n1p30-36. [DOI] [Google Scholar]

- 52.Heidenreich S., Müller M., Foscolo P.U. 2016. Biomass Pretreatment, Advanced Biomass Gasification; pp. 11–17. [DOI] [Google Scholar]

- 53.Li H., Chen Q., Zhang X., Finney K.N., Sharifi V.N., Swithenbank J. Evaluation of a biomass drying process using waste heat from process industries: a case study. Appl. Therm. Eng. 2012;35:71–80. doi: 10.1016/J.APPLTHERMALENG.2011.10.009. [DOI] [Google Scholar]

- 54.Kofman P.D. 2006. Quality Wood Chip Fuel. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

All data may be made available by the authors upon request from interested readers.