Abstract

The use of microfluidics to make mechanical property measurements is increasingly common. Fabrication of microfluidic devices has enabled various types of flow control and sensor integration at micrometer length scales to interrogate biological materials. For rheological measurements of biofluids, the small length scales are well suited to reach high rates, and measurements can be made on droplet-sized samples. The control of flow fields, constrictions, and external fields can be used in microfluidics to make mechanical measurements of individual bioparticle properties, often at high sampling rates for high-throughput measurements. Microfluidics also enables the measurement of bio-surfaces, such as the elasticity and permeability properties of layers of cells cultured in microfluidic devices. Recent progress on these topics is reviewed, and future directions are discussed.

I. INTRODUCTION

Measurements of biological systems were one of the original motivations for the development of microfluidic technologies.1 These early "lab-on-a-chip" devices primarily focused on microreactors or for molecular analyses such as high-throughput DNA sequencing. The methodologies used in the fabrication and design of these devices have been adopted by many different fields for manipulating flow at micrometer length scales for a wide variety of purposes. The measurement of mechanical properties of biological material has been a particular area for a proliferation of new measurement techniques not feasible with macroscale instrumentation.

For instance, the use of microfluidics for rheological characterization has been of interest to characterize high shear rate viscosity, extensional flow behaviors, while requiring small sample sizes.2 Microfluidics is also frequently combined with microscopy imaging to characterize the dynamic behavior of suspended bio-particles.3 The application of these techniques is often well-suited for biological applications where many biofluids are suspensions with viscoelastic properties and sample volumes are often limited.4

The measurement of individual cell properties has been a long-standing purpose for microfluidics.5–8 The ultimate goal of many of these technologies is to produce platforms for testing medical treatments by comparing normal cell properties to cells in diseased states and then after treatment. Methods developed for manipulation and characterization of individual cells have also been increasingly used for assisted reproductive technologies, many of which require measurements of biomechanical properties.9–11 The controlled flow environment in microfluidics has also lead to new methods for studying the development of biofilms and developing mitigation technologies for biofouling.12

The small length scales used in microfluidic channel flows are a natural fit for in vitro models for studying the microcirculatory system, such as red blood cell (RBC) behavior and endothelium properties.13 Other examples of devices that mimic physiological systems, often referred to as "organ-on-a-chip" technologies, are produced by culturing cells in microfluidic chambers with applied flow.14 The flow in these devices is needed for transport of nutrients and waste products as well as applying stress, which is important for the function of many biological components. The response of cells to applied stress in microfluidics is increasingly used for mechanobiology research, which aims to understand the responses of biological systems to applied mechanical stress.15–19 The mechanical properties of cells and tissues are important aspects for cell functions. For instance, the application of stress to cells during culturing and the measurement of mechanical properties can both be accomplished through design and flow controls of microfluidic devices.

This review focuses on microfluidic techniques recently developed for making mechanical property measurements of biological materials. The emphasis is on the measurement of mechanical properties and mass transport, such as viscosity, elastic modulus, and permeability, of biological samples. Techniques that are intended for biological samples, but demonstrated with synthetic systems are highlighted as well. First, the use of microfluidic rheometers for the measurement of properties such as shear viscosity, extensional viscosity, and relaxation time are reviewed. The development of robust devices intended for high shear rates and point-of-care deployment are focused on due to their applications in pharmaceutical industry and medical testing. Section II focuses on the measurement of mechanical properties of soft biological particles, such as cells and vesicles. Various approaches are discussed including methods for deforming particles by flow stress, geometric confinement, and externally applied fields. Devices specifically intended for measuring mechanical properties of bacteria and forces exerted by nematodes are highlighted. Section III focuses on measurements of the properties of cell layers. This includes the response of biofilms to flow stress and the elasticity and permeability of cell layers, such as endothelial cells, in both planar and 3D geometries. In conclusion, challenges and future directions for biomechanical measurements in microfluidics are discussed. A summary of the types of devices, their working principles, main applications, and commonly studied samples covered in this review are shown in Table I.

TABLE I.

Summary of the device types, their working principle, main applications, and samples of interest covered in this review.

| Device type | Principle | Main applications | Common samples | |

|---|---|---|---|---|

| Viscoelastic fluids | Microelectromechanical (MEMS) viscometers | Resonator characteristics are used to measure viscosity and density. | Microliter volumes for single shear rate point-of-care measurements | Blood, saliva |

| Capillary viscometers | Capillary pressure-driven flow through microchannels or paper and measured flow is used to determine viscosity relative to reference | Small volume requirements and point-of-care applications | Blood, saliva | |

| Shear viscosity rheometers | Shear viscosity as a function of shear rate is determined using relationship between pressure drop and flow rate | Measurement of both Newtonian and non-Newtonian fluids often at high shear rates with to ml volumes | Blood, protein solutions | |

| On-chip particle tracking rheology | Relate diffusion of dispersed particles to material creep compliance | Measurements of viscoelastic properties during phase transitions without applied deformation | Hydrogels, protein solutions | |

| Extensional rheometers | Measure resistance to fluid due to the extensional components of microchannel flows | Extensional viscosity measurement of non-Newtonian fluids at high rates with small volumes | Saliva, synovial fluid | |

| Biological particles | Constrictions (flow deformation) | Measure modulus due to extensional flow stress in a fluidic constriction | Rapid measurement of modulus for flow cytometry | Red blood cells, DNA, actin |

| Cross-slot | Deformation from extensional flow in center of cross-slot is related to viscoelastic properties | Measurements of large strains, time-dependent deformation, and manipulation of individual cells | Red blood cells, cancer cells, DNA, vesicles | |

| Constrictions (confinement) | Particles are forced into narrow constrictions and resistance to applied force is used to determine viscoelastic properties | Large deformation, multiplexed, and high-throughput measurements | Red blood cells, cancer cells | |

| Electrical and optical | Electrical and optical fields generate stress on particles to induce deformation that is related to mechanical properties | Manipulation of particles, tunable stress, and cyclic loading for fatigue measurements | Red blood cells, vesicles | |

| Filament shape specific | Elongated cells are trapped in chambers and flow stress produces bending | Observation of the change in properties under different growth conditions | Escherichia coli | |

| Cell forces | Deformation of soft micropillars with known properties are used to measure forces exerted by organisms | Measure forces under different environmental conditions and organism mutations | Caenorhabditis elegans | |

| Cell layers | Biofilms | Measurements of the structure, growth, and internal flow of biofilms provide viscoelastic properties and critical shear stress | Testing impact of various chemical and stress conditions on growth and mechanical properties | Bacterial biofilms |

| Planar cell layers | The deformation of membranes with cultured cells is used to measure elastic modulus. Flow through cell layers on permeable membranes is used to measure permeability | Measures the effect of environment, including media type and flow stress, and exposure to drugs | Epithelial and endothelial cells | |

| 3D geometries | Cell layers or tissues are cultured in cylindrical or suspended geometries to observe their deformation and/or mass transport across them | The elasticity and permeability of cell layers exposed to flow conditions mimicking physiological environment | Collagen, endothelial cells |

II. MICROFLUIDIC RHEOLOGY OF BIOLOGICAL FLUIDS

Rheometry measures the viscoelastic properties of complex fluids under the flow. The mechanical properties of many biological and biocompatible materials are crucial for proper biological function. For instance, high concentration of biologic drug formulations can vary significantly in viscosity, which can affect injectability and processing. The stability of these high concentration formulations is also an important factor for therapeutic efficacy, where change in solution state and the loss of efficacy manifest as a change in rheological properties. Changes in the mechanical properties of biological fluids, such as blood and saliva, can also be indicators of disease. See previous reviews of microfluidic viscometers and rheometers for discussion on a range of device designs and applications.2,20

Biological fluids are also often high in value and available in small quantities, which has motivated the development of microfluidic rheometers that use smaller volumes than traditional rheologic techniques. Small form factor microfluidic devices are particularly well-suited for biological fluids that rapidly change properties outside of the physiological conditions, such as blood, which necessitates the point-of-care measurement. The rheology of blood is a challenge due to the complexity of the suspension and donor to donor variation. See a recent review by Beris et al. for more details on blood rheology.21 One particular challenge for blood rheology measurements is the rapid coagulation of RBCs, which occurs after collection and can have a significant effect on viscosity. Typically stabilization agents are added to the blood immediately after collection, but the measurement is best performed soon after collection. The deploy ability of a microfluidic device provides the possibility for screening through blood property measurements. See a review by Kang and Lee on the in vitro and ex vivo measurement of blood properties using microfluidics for more details.22

In this section, advancements in microfluidic viscometers and rheometers are discussed. Here, viscometers are referred to as devices that measure viscosity at a single shear rate, while rheometers measure it at multiple shear rates. The integration of rheometric measurements based on particle tracking into microfluidic devices is discussed. Finally, the methods for measuring extensional viscosity of complex fluids are discussed.

A. Microfluidic MEMS viscometers

Many methods exist for measuring fluid viscosity where viscosity is independent of the shear rate, i.e., Newtonian fluids, or only one shear rate is of interest, such as the 0 s−1 shear rate limit. The advantage of many viscometers is that they often require very small sample sizes on the order of (10 to 100) µL. Measurements can also be made without the application of flow but with other sensors integrated into microelectronic mechanical systems (MEMS). For more details on microfluidic viscometers, see a recent review by Puneeth et al.23 Another recent review from Singh et al. focuses on MEMS-based viscometers.24 Here, we highlight approaches related to biological fluids.

A popular approach for measuring fluid viscosity and density uses the resonant characteristics of MEMS resonators.27,28 This approach is well-suited for biological fluids and point-of-care applications because it requires small volumes and can be incorporated into established electronic sensing technologies. Improvements to the designs for the MEMS sensors have focused on increasing sensitivity and reducing complexity and cost.

For example, a MEMS resonator was developed by Cakman et al. to measure the viscosity of samples as small as 150 µL.29 The device worked by actuating Ni cantilevers using a magnetic field and their response, measured using a phase lock loop control circuit, and detected changes by the reflection of a laser off the cantilever. A model to relate the phase change to the viscosity was calibrated with glycerol solutions. The device capabilities were demonstrated with viscosity measurements in the range of (1 to 14) mPa s and tested on various bovine serum albumin (BSA) solutions and blood plasma.30 The cantilever technique was later incorporated into a device with multiple channels and mounted on a temperature control stage, and the required sample size was decreased to 10 µL.31 Solutions with different viscosities and densities were used to calibrate the device. The samples were combined with different coagulation activators used in clinical settings, and the coagulation is measured by the viscosity over time to distinguish between normal and abnormal samples. The device was further developed to measure both density and viscosity using multiple cantilevers with different dimensions.32

The use of cantilever resonators for measuring blood coagulation was pursued by Padovani et al. with the motivation to reduce issues with adsorption onto the cantilevers and analyze the rate of RBC aggregation in addition to the density and viscosity measurements.33 A calibration process using glycerol-water mixtures was used to determine density and viscosity measurements. Various surface functionalization on the cantilevers were evaluated by measuring the mass adsorption using thrombin and fibrinogen protein solutions, and a polyethylene-glycol (PEG) surface coating was determined to be the most effective at reducing adsorption. The sensitivity of the device was used to measure human plasma coagulation kinetics through the change in viscosity. The device was used in another study to measure coagulation kinetics in response to various activated coagulation tests used in clinical settings.34

Similar to the cantilever design, magnetically actuated microposts were used by Judith et al. to measure the viscoelasticity of blood clots.35 The microposts were fabricated from polydimethylsiloxane (PDMS) with a magnetic nickel shell on top of the posts. The microposts were actuated by an oscillatory magnetic field, and the response was observed through microscopy and a photodiode detector. The device was used to measure the stiffness of blood clots over time and after a sequence of dilutions. Modeling of the micropost response was developed to include hydrodynamic interactions of the actuated microposts to measure viscosity.26 Measurements of the viscosity of sucrose and corn syrup solutions were compared to reference measurements, and the capability for measuring biofluids such as mucus, synovial fluid, and blood was discussed.

Rather than using posts or cantilevers, a MEMS resonating microplate design was developed by Manzaneque et al. that works by sensing the response of the resonator to an applied actuation.36 A model was developed to describe the relationship between the oscillations, the density, and viscosity of the fluid surrounding the plate. The device was tested on a set of fluids in the (1 to 10) mPa s range and showed good agreement with reference measurements. Another film-based design by Ahumada et al. used a quartz crystal microbalance (QCM) to measure viscosity of hyaluronic acid (HA) as a method for detecting arthritis.37 The quartz crystal resonator works by stimulation with an alternating current (AC) voltage that vibrates the crystal at a resonant frequency. By conducting a frequency sweep near the resonant frequency, the response of the crystal to the fluid surrounding liquid can be related to the viscoelastic properties of the fluid. A sample holder that used about 50 µL of solution was connected to an Arduino card for applying and analyzing the electrical signals. The results were compared to reference measurements, and an error between 9 % and 56 % was determined for different HA solution concentrations.

The QCM approach was later used by Yao et al. to measure blood coagulation by tracking the dissipation factor measured by the sensor and related the changes to blood viscoelasticity.38 The testing portion of the device was integrated with electronics to connect to a smartphone for analysis. The results showed high correlation with coagulation times made from reference measurements. A different approach for measuring the aggregation kinetics of blood was taken by Chen et al. using a film bulk acoustic resonator (FBAR), a MEMS sensor that works at gigahertz frequencies and has higher sensitivities than other MEMS sensors, see Fig. 1(a).25 The viscosity was measured through a calibration procedure with glycerol–water solutions. Microliter-scale drops were placed on the sensor surface, and the change in viscosity over time is used to determine the coagulation response to various additives. For instance, the effect of added heparin to blood samples was studied to measure the effect of the concentration on coagulation. A different surface-based device by Chen et al. measured changes in the viscoelastic properties of blood during coagulation using a surface acoustic wave sensor (SAW).39 The device was designed to be disposable and used 1 µL of sample. The shift in the maximum frequency of the SAW was used to determine the change in viscosity over time. The large frequency shift with viscosity changes produced more sensitivity compared to other resonator-based measurements. Coagulation kinetics of blood samples are measured and compared to standard thromboelastography measurements.

FIG. 1.

(a) A film bulk acoustic resonator using a ZnO film designed by Chen et al. for blood viscosity measurements.25 Reproduced with permission from Chen et al., Sensors 17, 1015 (2017). Copyright 2017 authors, licensed under a Creative Commons Attribution (CC BY) License. (b) Magnetically actuated flexible microposts were used by Judith et al. to measure the viscosity through hydrodynamic interactions.26 Reproduced with permission from Judith et al., PLoS One 13, e0200345 (2018). Copyright 2018 authors, licensed under a Creative Commons Attribution (CC BY) License.

The deformation of materials that can be excited by resonators in microfluidic device has also been used as viscometers. For example, a magnetoelastic material that resonates in an AC magnetic field was incorporating into a microfluidic device by Chen et al.40 The resonance spectra of the sensor were measured to calibrate the device for different glycerol–water solutions in the range of (1 to 1420) mPa s. The device was used to measure plasma solutions in the range of (1 to 3) mPa s with uncertainty around 1 . A membrane transducer made from silicon nitride was used by Oliva et al. to measure density and viscosity of polymerizing F-actin solutions placed in a 1 µL microwell.41 The setup consisted of excitation and detection lasers, which were used to excite the membrane resonator through photothermal actuation and then measure the response from a separate detection laser optical path. The glycerol–water calibration approach was used to extract the density and viscosity from the eigenfrequency and quality factor. One main advantage of the membrane resonator is the rapid measurement time, about 3 min for each sample, which could be further reduced using faster readout systems.

A different approach using suspended magnetic particles as resonators was demonstrated by Wu et al.42 The paramagnetic particles were actuated by a mixed high and low frequency signal. A detection coil was used to measure the phase lag, determined by a voltage drop, between the particles response and the applied field. The phase lag was used to determine the viscosity by calibration with various glycerol–water mixtures over the range of (1 to 1000) mPa s. The technique was used to measure the viscosity of serum samples in the range of (1 to 8) mPa s.

An indirect approach for viscosity measurement was developed by Zarrin et al. through relating changes in dielectric properties to viscosity of saliva of patients with Chronic Obstructive Pulmonary Disease (COPD).43 The saliva in COPD patients was approximately 10 % more viscous due to a lower water content, which was measured by a decrease in electrical conductivity compared to healthy controls. The measurement is challenging due to the small changes in conductivity and viscosity, but the simplicity of the measurement makes it advantageous for point-of-care measurements.

B. Capillary driven viscometers and rheometers

Capillary driven flows are well-suited for microfluidic viscometry because microfluidic geometries easily generate sufficient force to drive flow. One main advantage of the technique is that flow can be produced without the need for syringe pumps or pneumatics. They also often require small amounts of sample. Capillary driven viscometers generally fall under two categories, either using small microchannels or paper based devices.

An example of a small volume capillary driven flow method for measuring fluid viscosity was developed by Srivastava et al.44 A reference fluid was used to calibrate the capillary pressure and then the velocity of the meniscus was used to determine the viscosity relative to the calibration fluid viscosity. The approach could measure fluid viscosities in the range of (1 to 5) mPa s and was used to measure blood plasma samples while using less than 1 µL of sample. Further development integrated electronic sensing, rather than optical methods, to determine the velocity of the meniscus.45 The same capillary driven flow method was used to measure non-Newtonian fluids by tracking the variation in velocity over time as the sample loads into the device.46 Recently, the capillary driven flow concept was used by Lee et al. to measure the viscosity of zebrafish blood at high shear rates, see Fig. 2(d).47 The device required a sample of 3 µL and was calibrated using water. The viscosity of the zebrafish blood was shown to be Newtonian in the shear rate range of approximately ( to ) s−1. The viscosity as a function of hematocrit levels was measured in both adult and embryonic zebrafish. Another recent method by Puneeth et al. used a fused deposition fabrication to make devices from polycaprolactone and used meniscus tracking to measure capillary driven flow rate.48 The device integrates into a single-board computer with an integrated camera, and image processing is automated to determine the flow rate by tracking the change in position of the liquid meniscus in the microfluidic channel.

FIG. 2.

(a) A paper based device developed by Li et al. for measuring the coagulation of blood by related the travel time of the fluid front to the viscosity. The device was later tested as a point-of-care diagnostic device by Hegener et al.49,50,52 Reproduced from Li et al., Biomicrofluidics 12, 014110 (2018) with the permission of AIP Publishing LLC. (b) A paper based device by Jang et al. used two paper strips for faster capillary driven flow to measure fluid viscosity without requiring a separate surface tension measurement.55 Reproduced with permission from Jang et al., Sens. Actuators, B 319, 128240 (2020). Copyright 2020 Elsevier B.V. (c) A paper-based device developed by Kang et al. uses the color of two mixed streams to measure the relative flow rates of the stream and determine viscosity.56 Reproduced with permission from Kang et al., Anal. Chem. 91, 4868 (2019). Copyright 2019 American Chemical Society. (d) A capillary-driven flow device designed by Lee et al. was used to measure zebrafish blood viscosity by tracking the interface velocity.47 Reproduced with permission from Lee et al., Sci. Rep. 7, 1980 (2017). Copyright 2017 authors, licensed under a Creative Commons Attribution (CC BY) License.

Paper based devices are often useful as disposable point-of-care devices. A paper based device by Li et al. was designed to measure the coagulation of blood through changes in viscosity, see Fig. 2(a).49 The device consists of three sections, a sample pad for sample collection, analytical membrane where the blood interface is tracked and wicking pad for continuous capillary force. The transport of both plasma and RBCs was both tracked on the membrane portion of the device. The travel time is related to the viscosity using reference values from glycerin–water solutions. The effect of CaCl2 on clotting was studied by measuring the travel distance at a fixed time for different concentrations of CaCl2. The device was used by Hegener et al. to obtain clinical results for blood coagulation measurements using 30 µL of whole blood.50 In this device, the travel distance was shown to vary with both hematocrit level and international normalized ratio (INR), a measure of prothrombin (blood clotting) time. The devices were designed to provide rapid and low-cost measurement to determine if a patient was within a normal range or if further tests were needed. A calibration method was developed to correct for the effect of the hematocrit level and improved the measurement of INR.51 The device was also demonstrated for measurements of blood clotting in animal blood.52 The effect of hematocrit on the lateral flow velocity was exploited by Frantz et al. by using a smartphone to automate tracking of the RBC front.53 Hematocrit levels between 28 % and 45 were measured within about (1 to 3) difference from the nominal values after about 20 s.

A device to measure biofluid viscosity was developed by Rayaprolu et al. by using the transit time between two marks on a paper strip.54 The sample viscosity was determined relative to the viscosity of water by comparing the sample's transit time and density relative to water results. The measured viscosity with the addition of either glycerol or sucrose was shown to have high correlation with measurements with an Ostwald viscometer between 1 mPa s and 40 mPa s. The device used less than 20 µL and the total time required was between 20 s and 1000 s, about four times faster than using the Ostwald viscometer. The device was used to measure the viscosity of saliva, protein solutions, and dextran solutions.

A different type of paper device was developed by Jang et al., based on a theoretical analysis by Shaumburg and Berli, that had a gap between two paper strips such that capillary driven flow would be increased compared to flow through paper, see Fig. 2(b).55,57 The effect of the gap dimension on the rate of meniscus travel was studied, and a maximum rate was observed for a 195 µm gap. One feature of the two layer design was the liquid was drawn up in the gap in the early flow stage but later only within the paper. The equilibrium height of the liquid in the gap and curve fitting of the meniscus velocity was used to determine the viscosity and diffusivity of the solution. Only one calibration parameter was required, the effective radius, but that parameter only depended on the device geometry. The device was validated by comparing PEG solutions and artificial saliva with reference measurements. Measurement errors less than 4 were shown for samples with viscosity in the range of (1 to 6) mPa s.

Another paper based viscometer used a "colorimetric" method by coflowing two fluids of two colors together into a T-junction, see Fig. 2(c).56 The reference fluid was dyed blue, and the sample fluid was dyed yellow. The color in the main channel was then used to measure the relative flow rates of the two fluids, which is inversely related to the relative viscosities. The device was constructed from multiple paper layers to create a loading, mixing, and measurement portions of the device. The viscosity can be determined by a single image, rather than a video, which makes measurement by a mobile phone simpler. Various biofluids such as blood plasma and bovine-serum-albumin solution were tested and compared to reference measurements within a few percent. While this method does not measure multiple shear rates, the device used as little as 20 µL of sample.

C. Shear viscosity measurements and capillary rheometers

Microfluidic rheology is often designed for high shear rate measurements due to the small channel dimensions.58 A common microfluidic measurement is to determine the shear viscosity. The velocity gradient at the wall, defined as , is used to determine the viscous resistance, , where is the shear stress component of the stress tensor. For Newtonian fluids, the viscosity is independent of shear rate and the viscosity at the wall of a rectangular channel is determined by the ratio of wall shear stress, , to the wall shear rate, , using the equations,

| (1) |

where Q is the flow rate and h is the channel height and w is the channel width. Flow is generated either by applying a known flow rate from a syringe pump and measuring the pressure drop along the channel or by applying a known pressure drop and measuring the flow rate. Additional analysis is needed to measure the non-Newtonian viscosity, see Pipe and McKinley for details.59

For pressure driven flow microfluidic rheometers, limitations include the range of pressure regulators and the maximum pressure a device can withstand before deforming or bursting. The accuracy and operating range of flow sensors is another limitation. For syringe pump driven flow, which typically has a wide operating range, the accuracy of pressure or stress sensors are often the limiting factor. The accuracy of the channel dimensions, particularly the channel height or radius, is important since the viscosity scales as for rectangular channels. Wall slip can also lead to error in the measurement of viscosity in microfluidics. The effects of wall slip can be investigated by changing channel dimensions or through particle tracking methods.60

For biological fluids, many of the technological improvements in shear viscosity measurement have focused on novel shear stress measurements and flow rate measurements using meniscus tracking to limit sample volume. A small volume microfluidic rheometer using pressure driven flow was developed by Hudson et al. that used a drawn glass capillary to measure the viscosity of protein solutions.61 Using water as a working fluid, water was brought in contact with the sample in a reservoir and then through pneumatic controls the sample liquid was drawn up into the microcapillary section. A calibrated flow sensor in-line with the water tubing measured the flow rate. The viscosity was calculated using by accounting for the resistances of the various flow components and determining the pressure drop associated with the microcapillary section. The device was used to measure the viscosity of protein solutions at different concentrations and temperature. The advantage of the approach was the ability to measure up to three decades in shear rate using a single capillary setup between 10 s−1 to over s−1. The small volume rheometer was used by Dharmaraj et al. to measure the viscosity of lysozyme solutions at different concentrations and temperatures.62 Non-Newtonian behavior was observed and the structural relaxation time was related to the relaxation time determined by dynamic light scattering as a function of temperature.

Another method well-suited for flow rate measurements but without using a working fluid is meniscus tracking. The velocity of the meniscus can be converted to flow rate through multiplication with the cross sectional area of the channel.63 This method was adapted by Solomon et al. to track the meniscus through a PDMS channels using a phone camera, see Fig. 3(b).64 The device was used to measure viscosity over about two decades in the shear rate for a given fluid within the range of (10 to 104) s−1. A straight channel geometry allowed for multiple channels to be fabricated in parallel on the same chip and "multiplexed" measurements of different samples was performed. The viscosity of shear-thinning biocompatible polymer solutions and bovine serum albumin (BSA) protein solutions was measured using the device.

FIG. 3.

(a) A "smart" pipette designed by Oh et al. with an air chamber to deliver pneumatic pressure to microcapillary channels in a 3D-printed microfluidic for viscosity measurement at different flow rates.67 Reproduced with permission from S. Oh and S. Choi, Micromachines 9, 314 (2018). Copyright 2018 Authors, licensed under a Creative Commons Attribution (CC BY) License. (b) A meniscus method for viscosity measurements by Solomon et al. to measure flow rate through a microchannel using a smartphone camera.64 Reproduced with permission from Solomon et al., Rheol. Acta 55, 727 (2016). Copyright 2016 Springer-Verlag Berlin Heidelberg. (c) A microfluidic rheometer fabricated by Mendez-Mora et al. with gold electrodes across a microfluidic channel used to track the fluid meniscus for flow rate measurements.65 Reproduced with permission from Méndez-Mora et al., Micromachines 12, 726 (2021). Copyright 2021 authors, licensed under a Creative Commons Attribution (CC BY) License. (d) A small volume rheometer designed by Salipante et al. uses real-time mesniscus tracking using a linear image sensor and a pneumatic valve to reversibly drive flow through a microcapillary.66 Reproduced with permission from Salipante et al., Rheol. Acta 61, 309 (2022). Copyright 2022. This is a U.S. government work and not under copyright protection in the U.S.; foreign copyright protection may apply.

Another example of a small volume rheometer using interface tracking was designed by Mendez-Mora et al. as a point-of-care device, see Fig. 3(c).65 Channels in PDMS were bonded to a glass substrate with gold electrodes along a surface. The change in electrical signals of the electrode array was used to track the fluid meniscus. A portable pneumatic pressure pump was used for point-of-care purposes. The device was validated with reference fluids and then used to measure blood samples at different hematocrit levels as a function of shear rate. The volume of fluid used in the experiments was 0.5 mL, but the interface tracking approach can use less than 0.1 mL of volume with different device geometries.

A device that utilized the interface tracking approach was recently developed by Salipante et al. for small volume high shear rate measurements.66 The device used pneumatically driven flow through a silica microcapillary connected to larger glass capillary where the meniscus is tracked with a linear image sensor, see Fig. 3(d). A pneumatic valve is used to switch the direction of the applied pressure and automatic controls were used to sample multiple transits at different applied pressures. The viscosity over the range of approximately (1 to 1000) mPa was measured between 10 s−1 and 105 s−1 shear rate range using a single capillary device. A minimum volume of approximately 50 µL was demonstrated.

A slightly different approach based on interface tracking was taken by Oh and Choi for a “smart" pipette rheometer, see Fig. 3(a).67 The device used an air chamber as a pressure buffer to deliver the same pneumatic pressure to different microcapillary channels in a 3D-printed microfluidic device. The compressed air volume was used to calculate the pressure relative to atmosphere, which eliminated the need for either a syringe pump or a pressure controller. The displacement of fluid volume by the air was small relative chamber size, which limited the change in applied pressure during operation. The flow rates are determined by tracking the transit of the meniscus using a phone camera in each of the fluidic chambers. The viscosity at different shear rates can be obtained by changing the resistance of the microcapillaries, which is performed by changing the capillary geometry. Glycerol and xanthan gum solutions, examples of Newtonian and non-Newtonian fluids respectively with comparable viscosity to blood, were used to test the device in the shear rate range of about (10 to 100) s−1.

Rather than track a meniscus inside a channel, a design by Tammaro et al. measured flow rate by tracking the free surface of the liquid as it exits a microcapillary.68 Multiple microcapillaries machined in stainless steel are used for measurements at different shear rates. The assembled parts integrated temperature control, pressure sensors, inlets for gas and sample, and a window for observing the sample outlet. The multiple microcapillaries resulted in a wide shear rate range of about (0.01 to ) s−1 for high viscosity polymer melts. The volume requirements for polymer melts was shown to be about 10 ml, and the device geometry could be modified for measurements of biofluids with lower viscosities.

A different type of interface tracking based methods was recently developed by Shih et al. using a centrifugal platform to deform the interface of the sample liquid.69 The deflection angle of the meniscus is obtained visually or through image analysis. A theoretical model was developed to describe the relationship between interface deformation and the sample viscosity. The device was shown to use approximately 25 µL of samples and was designed for portability and ease of operation.

These examples of microfluidic rheometers utilized pneumatic controls and interface tracking for shear viscosity measurements over wider range of shear rates than previously demonstrated and using microliter-scale volumes. Future developments of this technology have multiple directions. For instance, point-of-care measurements require reducing the need for extensive lab equipment while maintaining accuracy. Further reducing the required fluid volume to less than 100 µL is particular important for pharmaceutical applications where early stage manufacture of samples is expensive and viscosity is important for therapeutic efficacy. Improvements to device robustness and scalability are required for both small volume and point-of-care applications, particularly for the commercial development of these types of rheometers.

Another method for measuring shear viscosity involves tracking the position of an interface between two co-flowing streams in a rectangular microchannel. The method was developed by Galambos and Forster and was later extended to measure complex fluids by Guillot et al.70,71 Sample fluid was flowed through one inlet port while a reference fluid was flowed through the other, creating an interface between the two fluids in the main channel. The position of the interface and relative flow rates of the two fluids were used to determine the viscosity contrast, which was used to determine the unknown viscosity of the sample. The device was used to measure the shear thinning behavior of various fluids in the range of (10 to 1000) s−1 and compared to reference measurements. Using a slightly different coaxial flow approach, Lan et al. measured viscosity by tracking the diameter of the co-flowing stream.72 Similar to the rectangular geometry, the flow rate of the two streams, the viscosity of the reference fluid, and the measured stream diameter was used to determine the sample viscosity.

The co-flow method was used by Kang et al. to study the non-Newtonian properties of blood by using an array of channels downstream of a Y-junction to determine the relative viscosity from the relative flow rates and the number of downstream channels occupied by each fluid.73 The device was validated by comparing viscosity measurements of the shear-thinning behavior of blood to rotational rheometry. Further developments based on the co-flowing approach have focused on measuring blood viscoelasticity by tracking both steady and transient flow. This was performed by Jun Kang and Lee using a device where sample transfers through a bridging channel, an analogue to a Wheatstone-bridge, to a second channel flowing a reference fluid, see Fig. 4(a).74,75 The steady flow in the bridge channel was used to determine the viscosity, while the time for the bridge channel flow to change after a change in sample flow was used to determine a characteristic elastic timescale. The device was used to measure blood properties with different hematocrit levels, temperature treatments, and shear history. The device was capable of measuring non-Newtonian flow between about 100 s−1 and 1000 s−1 by changing the flow rates and compared the change in viscosity of blood in plasma and buffer solution. While this method used high precision syringe pumps and high speed cameras, the approach was useful for modifying the blood constituents through mixing before being flowed into the channel. This was tested by adding dextran and glutaraldehyde to the blood and measuring the effect of the concentration of these additives on blood properties.76 A study by Yeom et al. used the device to simultaneously measure platelet adhesion and blood viscosity in samples with different hematocrit levels and was able to measure changes over time.77

FIG. 4.

(a) A co-flowing device made continuous measurement of blood viscosity by tracking the position of the interface between the sample and reference fluid.77 Reproduced with permission from Yeom et al., Sci. Rep. 6, 24994 (2016). Copyright 2016Authors, licensed under a Creative Commons Attribution (CC BY) License. (b) A co-flowing device by Kim et al. used a smartphone camera to track the interface position to determined the viscosity of blood and plasma samples.80 Reproduced with permission from Kim et al., Opt. Lasers Eng. 104, 237 (2018). Copyright 2018 Elsevier Ltd. (c) A suspended micro-membrane with folded beams by Liu et al. measured viscosity by relating deflection of the membrane to the fluid stress.81 Reproduced with permission from Liu et al., Micromachines 11, 934 (2020). Copyright 2020 authors, licensed under a Creative Commons Attribution (CC BY) License. (d) A co-flowing viscometer by Mehri et al. tracked aggregation of RBC at different flow rates.82 Reproduced with permission from Mehri et al., PLoS ONE 13, 7 (2018). Copyright 2018 authors, licensed under a Creative Commons Attribution (CC BY) License.

The device was altered to create an array of outlet channels where the number filled with the sample fluid was used to determine the position of the reference-sample interface.78 A theoretical model based on the circuit approach was developed to calculate the viscosity from the flow rates and fluidic resistances of the channels. The viscosity of rat blood at different hematocrit levels was measured with this method. Recently, the change of blood properties over time was measured by tracking the aggregation of RBCs in a closed loop microfluidic channel.79 The same liquid is continuously flowed using a peristaltic pump through the parallel flow device where the blood viscosity and RBC aggregation is measured periodically. The effect of hematocrit and dextran over long durations and on-off cycles was investigated. One potential application cited for this work is for extracorporeal bypass loops, a similar closed loop systems, that would not require periodic collection for off-line analysis.

A recent method for measuring viscosity using the co-flowing approach in a single channel was developed by Kim et al. using imaging from a smartphone camera, see Fig. 4(b).80 The device was constructed with a 3 mm wide channel so that the interface between two optically distinct fluids can be tracked using a low-magnification camera. Experiments with phosphate buffer solutions were used to determine a relationship between the position of the interface and the pressure ratio. The approach was used to measure the viscosity of blood and plasma in the range of approximately (40 to 5000) s−1.

A different approach using the co-flowing method was taken by Mehri et al. to study RBC aggregation at low shear rates.82 A dual-camera setup was used to perform microparticle image velocimetry to determine shear rates and a high speed camera to measure RBC aggregate size, see Fig. 4(d). The viscosity measurements showed shear-thinning behavior in the range of (5 to 50) s−1. The shear-thinning was related to the average aggregate size, which was observed to decrease with increasing shear rate. The device demonstrated connections between blood microstructure and viscosity by utilizing particle tracking to perform microfluidic rheometry at low shear rates.

A droplet-based method for measuring blood viscosity was demonstrated in the study by Mena et al. by relating the size of blood droplets formed at a T-junction to the relative viscosity of the surrounding fluid.83 The device was used to measure the change in viscosity over time of swine blood as an indicator of coagulation. The effect of coagulant activators and inhibitors were tested and compared to thromboelastography (TEG), the clinical method for testing coagulation. The change in viscosity was shown to have a more rapid response than the measurements of clots with TEG. The device was demonstrated to operate at different shear rates, making it capable of measuring shear rate dependent behavior.

A commercial instrument (Formulaction) utilizes the co-flowing method in a single channel rheometry measurements. The flow rate can be adjusted to reach a range of shear rates, typically (102 to 105) s−1. The device was used by Sepulveda et al. to measure the viscosity xanthan gum solutions in combination with rotation rheometry over a range of shear rates from ( to ) s−1. The effect of adding whey protein isolate to the viscosity of the xanthum gum solutions was also investigated.84 The rheometer was used to measure the viscosity of HA solutions, used as artificial tears, in comparison with the viscosity of natural tears.85 The results showed both natural and artificial tears were shear-thinning and a low molecular weight HA based formulation most closely matched the natural tears.

Methods for making shear viscosity measurements with a fixed flow rate from syringe pumps often rely on pressure sensors integrated into microfluidic channels. Advancement in materials and fabrication methods also provide opportunities for improved pressure sensors. For instance, liquid metal filled into a pressure sensing channel with a thin film of PDMS between the sensing and fluidic channel was used by Jung et al.86 The change in electric resistance through the liquid metal channel was calibrated to the applied pressure from the sample liquid channel. The device was shown to measure viscosity of fluids similar to blood viscosity over a range of shear rates from about (30 to 1000) s−1. A different type of pressure sensor was developed by Doshi and Thostenson using nanotube-based piezoresistive sensors. The thin film was less than a micrometer thick and had a sensing range between 10 kPa and 50 MPa, which makes these types of sensors appealing for integration into microfluidic rheometers.87

In contrast to measuring pressure, a method for measuring shear stress was demonstrated by Mustafa et al. that used the deflection of PDMS micropillars.88 The nonlinear relationship between viscosity, shear rate, and the deflection of the micropillar was used to create a calibration curve based on reference fluids. The deflection of the pillars was then used to measure both Newtonian and non-Newtonian fluids with viscosity similar to blood over a range of shear rates about (60 to 400) s−1. A different deflection-based technique was used by Liu et al. to measure viscosity by tracking the deformation of a suspended micro membrane as a function of flow rate, see Fig. 4(c).81 The membrane was made from SU-8 epoxy and consisted of a plate connected by folded cantilever beams to the surrounding film. The membrane was surrounded by PDMS layers that made up the microfluidic channel. The spring constant of the beam was determined by the geometry and elasticity of the beams. The viscosity was determined through a relationship including this spring constant and the other geometric parameters of the channel and membrane. The device capabilities were demonstrated by measuring bovine blood samples at different hematocrit levels.

A commercial microfluidic rheometer (mVROC) with pressure sensors integrated into microfluidic channels has frequently been used for high shear rate measurements of protein solution viscosity. A syringe pump drive flow through the device and the range of shear rates can be adjusted by using channels with different heights. The device has typically been used to measure the constant viscosity plateau present in protein solutions at high shear rates and in combination with rheometry measurements better suited for lower shear rate.89–100 The rheometer has also been used to measure shear-thinning behavior in protein solutions.101–103 Other studies have used the device to determine the intrinsic viscosity of marine oligosaccharides and polyelectrolyte matrices.104,105

D. On-chip particle tracking based methods

Particle tracking methods are useful for rheological characterization without applying large deformations to the material, making them well-suited for many biological materials. An established method called passive microrheology uses the tracks of diffusive microparticles to make measurements in viscoelastic fluids. The method utilizes the relationship between the mean squared displacement of the particle, , to the creep compliance, of the suspending material by the generalized Stokes–Einstein relation,

| (2) |

where is the lag time, is thermal energy, and a is the particle radius.106,107 While this method is accurate and uses very small material quantities, measurements using microscopes can be labor intensive and low throughput. The measured viscosity can be accurate as long as the particles remain dispersed, which can be a problem for some systems that introduce attractive interactions. For example, dissolved proteins can produce attractive depletion interaction between the particles, so that they aggregate. Recent efforts have used microfluidic approaches to improve throughput and control the microenvironment to observe phase changes through changes in pH or temperature.108

A high-throughput approach developed by Schultz and Furst used a T-junction drop generator to adjust drop composition through changes in relative flow rates of the fluid components.109 The flow was stopped and particles included in the fluids were tracked to make microrheology measurements. This approach can measure changes in viscosity with fluid of different composition as well as measure gelation processes in hydrogels.110 A recent device by Yang et al. used traps in microfluidic channels to capture concentrated droplets of protein solutions for microrheology characterization.111 The water in the drops slowly partitioned into the surrounding mineral oil, increasing the concentration of the protein filled droplets. Microrheology measurements over time were then used to characterize the change in viscosity with concentration.

Another high-throughput microrheology method developed by Josephson et al. measured protein solutions in multiple channels on a single temperature controlled microfluidic device.112 The device was fabricated using a microfluidic stickers technique, which used a PDMS mold to imprint channels in a UV curable resin to make thin sheets that were then sealed between glass and a polyethylene substrate. The device was mounted in a temperature control stage mounted onto a microscope for particle tracking. Combined with bulk rheology, the temperature dependence on the viscosity provided a calculation of the apparent activation as a function of concentration and indicated when protein-protein interactions begin to dominate the activation energy.

A device by Wehrman et al. utilized microfluidic techniques to control the concentration of components in a fluid chamber, which induced a gel to sol transition that was measured by microrheology, see Fig. 5(a).113,114 The device created a fluid exchange through vertical channels separating materials of different density that can be driven by gravity or through suction into the other chamber. The effect of pH on covalently adaptable hydrogels was studied, which have a wide variety of applications including cell culturing, tissue regeneration, and drug delivery due to their ability to change properties with external stimuli.115 The microfluidic device was also used to probe the change in structure as a function of time after a change in pH, similar to what would occur in the gastrointestinal (GI) tract. A sequence of different pH conditions based on the expected pH and duration in the GI tract was developed.116 The device was used to measure gel properties and kinetic transitions through repeated gelation and degradation cycles induced by pH changes.117

FIG. 5.

(a) A multilayer microfluidic device by Wehrman et al. to control release of components into a chambers where phase transitions between gel and sol transition are measured with microrheology tracking114 Reproduced with permission from Wehrman et al., J. Rheol. 62, 437 (2018). Copyright 2018 The Society of Rheology. (b) Mean-squared-displacement measurements from microparticle tracking by Wehrman et al. in covalently adaptable hydrogels during phase changes.113 Reproduced with permission from Wehrman et al., Lab Chip 17, 2085–2094 (2017). Copyright 2017 Royal Society of Chemistry.

Particle tracking methods have also been integrated with microfluidics to study cell properties. The effects of pressure on the intracellular environment of E. coli cells was studied by Yu et al. using a multilayer microfluidic device combined with particle tracking methods.118 The device was used to compress the cells by pressurizing an upper channel and deforming the PDMS membrane separating the channel with E. coli. The mean squared displacement (MSD) from microparticle tracking of cytoplasmic particles and DNA loci with and without compression were compared. The rate of change of the MSD with lag-time was used to show changes in subdiffusive behavior, an indication of a viscoelastic medium. The results showed a decrease in the diffusivity and more subdiffusive behavior when pressure was applied.

Microrheology is often used in combination with other microfluidic techniques for thorough characterization of material properties. An example of a multimodal characterization study was performed by Del Giudice et al. on hydroxyethyl cellulose using various techniques including microrheology, bulk rheology, microfluidic rheology.119 Microfluidic rheology was used for high shear rate viscosity measurements and included with bulk rheology to measure viscosity over a range of ( to ) s−1. A technique for determining the longest relaxation time by tracking the cross stream motion of the microparticles in a microfluidic channel.120 The microfluidic technique is well-suited for shorter relaxation times and characterized the relaxation time at low collagen concentrations while higher concentrations were measured using bulk rheology, dynamic light scattering, and optical tweezers.

E. Extensional viscosity on a chip

The composition of many biological fluids, especially fluids containing biopolymers, results in a high resistance to extensional flow. Often this is an important characteristic for the biological function of the fluids. For instance, saliva has a high extensional viscosity relative to shear viscosity due to the composition of high molecular weight mucin molecules.121,122 Extensional viscosity is the resistance to the stretching of a fluid element by the strain rate, , where is the velocity in the flow direction. The extensional viscosity is therefore defined by the stress due this stretching flow, defined by , where and are the normal components of the stress tensor.123,124 Many flows in biological systems are mixed, containing both shear and extension components. If the extensional viscosity changes significantly with extension rate, the flow behavior can be altered.

Extensional viscosity measurements are commonly performed using a capillary breakup extensional rheometer (CABER) device. The device works by pulling apart two posts with the sample fluid bridging the posts. The breakup of the liquid capillary thread connecting the two posts is tracked with a high speed camera. The thinning and breakup of the capillary thread is predominantly an extensional flow field and, therefore, the dynamics are sensitive to the extensional viscosity. The CABER approach was integrated into microfluidics by Nelson and Kavehpour, but instead of mechanical actuation, electrowetting was used to retract fluid between two electrodes.125 The capillary thinning analysis was tracked similarly from a high speed camera. The use of electric fields was shown not to influence the measured rheology. The device is well-suited for biological samples since it requires microliter scale sample volumes.

Most microfluidic devices designed to measure extensional viscosity do so by creating geometries where large portions of the fluid experience extensional flow. The resistance to flow can then be related the extensional viscosity similarly to how flow rate and pressure drop are used to measure shear viscosity described in Sec. II C. One main difficulty in using microfluidic channels for extensional viscosity measurements is that the flow at the wall is dominated by shear, making the overall fluid flow field a mixture of both extensional and shear components. One method for creating a large region of extensional flow is a cross-slot geometry, a perpendicular intersection of two straight channels. Haward et al. used oscillatory flow in a cross-slot to measure extensional viscosity of saliva by subtracting off the pressure drop due to shear in the microchannel.121 The remaining pressure drop and the geometry of the channels were then used to calculate the extensional viscosity microliter volumes. The rheology of saliva before and after centrifugation is compared to separate large mucin proteins. The results shows that non-Newtonian behavior remained even after centrifugation. The device was also used with birefringence measurements, a method of relating the change in optical properties of the fluid to the alignment and stretching of molecules, which was used to estimate the relaxation time of mucin and measure its birefringence. A subsequent study by Haward et al. used a cross-slot geometry with a shape optimized with computational fluid dynamics (CFD) for measuring extensional viscosity, see Fig. 6(b).126 The device was used to measure the extensional viscosity of hyaluronic acid solutions, a main component in synovial (joint) fluid. The Trouton ratio, the ratio of extensional viscosity to shear viscosity, was measured as a function of Weissenberg number, which compares the magnitude of elastic stress to viscous stress in a viscoelastic fluid.

FIG. 6.

(a) A two-channel device by Kim et al. with a differential pressure sensor to measure the extra pressure drop from a converging channel used to measure extensional viscosity.129 Reproduced with permission from S. G. Kim and H. S. Lee, Macromolecules 52, 9585 (2019). Copyright 2019 American Chemical Society. (b) An optimized cross-slot device by Haward et al. to create a larger region of extensional flow for extensional rheology measurements.126 Reproduced from Haward et al., Biomicrofluidics 7, 044108 (2013) with the permission of AIP Publishing LLC. (c) A microfluidic flow focusing device by Metaxas et al. used to measure extensional rheology by tracking the thinning of the fluid filament.130 Reproduced with permission from Metaxas et al., Phys. Rev. Fluids 5, 113302 (2020). Copyright 2020 American Physical Society.

Recent work for optimizing extensional flows in the cross-slot geometry was performed by Zografos et al. using CFDsimulations.127 The optimization process updated the geometry based on CFD simulation results for both Newtonian and viscoelastic fluids to create a homogeneous extensional flow region in the device. The CFD results were also used to investigate theoretical limits of operation based on viscoelastic and inertial instabilities. A subsequent paper investigated a commercial microfluidic extensional rheometer using CFD simulations of non-Newtonian viscoelastic fluids.128 The results showed that the flow field through a contraction-expansion geometry is dominated by shear flow. They also analyzed how it changed with flow rate for non-Newtonian fluids compared to Newtonian fluids and the effect of normal stresses on the extensional viscosity measurement. The authors argued for improvements to the geometry based on optimization method modification of the geometry based on whether the fluid is Newtonian or non-Newtonian.

The concept of subtracting the stress contribution from shear flow in a contraction flow was developed by Lee and Muller and later implemented by Kim and Lee.129,131,132 The microfluidic device consisted of two channels, one with a constriction and another with a straight channel with length that provided the same resistance due to shear, see Fig. 6(a). A differential pressure sensor between the two channels at the inlet provided the pressure drop due to the extensional flow. The microfluidic extensional rheometer was used to measure the average normal stress and extensional viscosity of polyethylene oxide (PEO) solutions over an extension rate between 1 s−1 and 1000 s−1 using different constriction geometries. The extensional relaxation time determined using the rheometer agreed with reference measurements from other CABER measurements. Another constriction-based device was used by Suteria et al. to measure extensional viscosity.133 Meniscus tracking using a phone camera was used to determine the flow rate. The pressure drop due to the shear viscosity was determined by 3D CFD simulations of the flow field. The experimental 3D flow field was measured using in-line holographic particle tracking to determine velocity gradients for shear and extension, which confirmed the need for the pressure drop correction calculated using CFD. Particle tracking was also used to assess when instabilities occur, which can produce an additional pressure drop leading to errors. Extensional viscosities of polymer solutions were tested and agree with previous microfluidic extensional rheometers and dripping on a substrate measurements.

An example of a fluid used in medical applications where extensional viscosity characterization is important for function is methylcellulose, often used as a biocompatible rheological modifier used for applications such as cell culture media, artificial tears, and saliva.134 Recent measurements of methylcellulose have used a microfluidic contraction–expansion geometry to measure extensional viscosity as a function of strain rate for different salt conditions.135 As discussed above, the shear viscosity was measured in a straight channel and the corresponding pressure drop from these measurements were used to determine the pressure drop due to the extensional flow in the contraction-expansion channel. The results of the measurements showed thinning in the extensional viscosity, which was attributed to the loss of entanglements between the molecules as they align with the flow. The effect of salt on the extensional viscosity was observed to be largest at low strain rates (below 100 s−1) with more salt resulting in higher extensional viscosity. The contraction-expansion geometry was used by Lin et al. for characterizing the extensional viscosity of a particle-loaded biocompatible sprayable gel.136 The fluid was composed of polyethylene particles embedded in a solution of associating polysaccharides, xanthan, and konjac glucomannan. The extensional viscosity was needed to determined appropriate values of yield stress and spray ability. Here, the shear-thinning shear viscosity of the fluid was fit with a power-law curve to calculate the pressure drop contribution. The results showed strain-thinning for the polysaccharide solutions and the extensional viscosity could be adjusted through the addition of salt that modifies the molecular interactions. The results were contrasted with PEO solutions, which exhibited extensional thickening, demonstrating that these solutions were well-suited for spraying applications.

A different method is based on flow-focusing tracks the thinning of a liquid filament downstream of a microfluidic junction. This method was used by Steinhaus et al., and Arratia et al. to measure extensional rheology of polymer solutions.137,138 The method was subsequently employed by Juarez and Arratia to measure the effect of DNA molecular weight and concentration on extensional rheology.122 More recently, Metaxas et al. used this method to measure methylcellulose solution properties.130 The sample fluid was surrounded by an immiscible continuous phase of 50 mPa s silicone oil, and the diameter of methylcellulose stream thins after the junction with the surrounding oil, see Fig. 6(c). Images were recorded on a microscope using a high speed camera and analyzed to measure the thinning of the filament diameter as a function of time. Similar to analysis used with CABER, the rate of thinning was used to determine the extensional viscosity while also considering the contribution of the viscosity of the surrounding oil. The extensional viscosity for different salt concentrations was determined from the early time thinning behavior where the extensional flow dominates the dynamics.

Microfluidic extensional viscometers are increasingly being used to characterized biofluid and fluids used in medical applications. The inherent challenge in these devices is reducing uncertainties from the shear flow components of the flow. Developments in optimizing geometries enhance the pressure drop from extensional flow compared to shear flow and therefore improve the accuracy of these measurements. While there are a few examples of point-of-care extensional rheometer devices, the principles used toward deployment of microfluidic shear rheometers can also be applied to future deployment of microfluidic extensional rheometers.

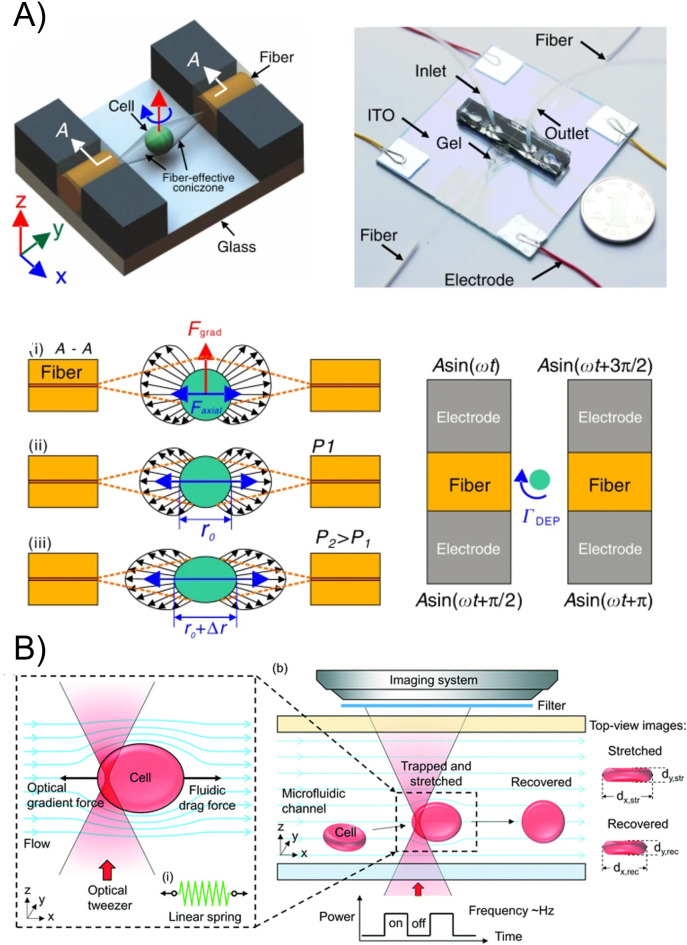

III. ELASTICITY OF SOFT BIOLOGICAL PARTICLES

Many soft biological materials are characterized as viscoelastic solids that exhibit both nonlinear and time-dependent response to loading, see a recent review by Efremov et al. for more details.139 Many of these materials constitute biological cells or lipid vesicle membranes or may compose bulk materials such as collagen. Methods for measuring mechanical properties of individual cells in microfluidics are typically done by imposing deformation through applied flow or a geometric constriction. First these methods are reviewed, specifically flow through a constriction, flow in a cross-slot geometry, and confinement through capillary constrictions. Alternative methods by integrating electrical or optical forces are discussed, followed by approaches for mechanical measurements on filament shaped systems. Finally, measurements of forces generated by cells are discussed.

A. Deformation through flow constrictions

Extensional flow is useful for mechanical measurements on cells, particles, and molecules because the applied flow stress can be related to the measured strain. Similar to Sec. II E, the difficulty in microfluidic channel flows is creating either homogeneous regions of strain or flow trajectories of cells where the extensional flow stress is well described. A microfluidics-based method to quantify mechanical properties of deformable objects through a constriction was developed by Cabral and Hudson using fluid drops to determine interfacial tension.140 Similar approaches were used to study the dynamics of adenosine triphosphate release from RBCs due to the hydrodynamic stress as the cells flow through a constriction.141

More recent work has focused on the properties of cells, which are stiffer than drops and therefore require higher strain rates to deform. Improvement in high speed camera technology, notably complementary metal-oxide semiconductor (CMOS) cameras, enabled Otto et al. to develop a real-time deformability cytometry method capable of measured deformation of 100 cells/s.142 The cytometry technique was able to identify different cell populations by analyzing size vs deformability. In contrast to other cytometry techniques, deformability is appealing because it is label free and therefore can be combined with other cytometry techniques. This approach was extended to produce dynamic real-time measurements by simultaneously characterizing size and shape of cells passing through the constriction.143 The recorded cell shapes were analyzed by fitting the shapes to models that considered the balance between hydrodynamic stresses on cell surface and elastic stresses of the cell. Various models for the cells, including an elastic sphere, and elastic shell, were used to determine values for Young's modulus and surface tension. The quantitative method was compared to atomic force microscopy (AFM) measurements and for agar particles with known stiffness.

Cells can adopt non-ellipsoidal shapes in flow contractions due to complex viscoelastic dynamics. An approach for analyzing the cell shape based on Fourier analysis was taken by Fregin et al. for the analysis of the time-dependent shape, see Fig. 7(a).144 The measurement of Young's modulus was obtained using the modeling from Mietke et al. and the time dependent information was used to determined viscosity from a viscoelastic Kelvin–Voigt model. The method was shown to precisely discriminate between cell components based on their rate of deformation, including different types of leukocytes. A high-throughput shape analysis of RBCs through a channel was used to investigate the different types of flow behaviors such as tumbling, tank-treading, or adopting a parachute shape.145 A mix of behaviors was observed within a sample and the probability of each behavior for different flow conditions was measured. Through comparisons between simulations and experiments, the variability in the shear elasticity was analyzed to explain variations in flow states observed in experiments. The study showed how characterization of variability inherent to RBCs can provide a framework for detection of diseased states. A different approach based on the flow of cells through a constriction was demonstrated by Dannhauser et al. using non-Newtonian polymer solutions as the suspending fluid.146 By tuning the polymer concentration and flow rate the viscoelastic forces on the cells could be tuned. The method was used to determine the phenotype breast cell lines that differ in mechanical properties by flow observing different flow behavior.

FIG. 7.

(a) The time-dependent shape deformation and shear stress used of cells flowed through a constriction by Fregin et al for high-throughput cytometry to measure viscoelastic properties.144 Reproduced with permission from Fregin et al., Nat. Commun. 10, 415 (2019). Copyright 2019 Authors, licensed under a Creative Commons Attribution (CC BY) License. (b) A microfluidic nozzle by Rubio et al. formed by melt-shaping a glass capillary used to measure elastic properties of RBCs by tracking deformation in the nozzle.153 Reproduced with permission from Rubio et al., Polymers 14, 2784 (2022). Copyright 2022 Authors, licensed under a Creative Commons Attribution (CC BY) License. (c) An optimized constriction geometry developed by Liu et al. to create a region of uniform extension used for measurements of DNA and actin filaments under extension.151 Reproduced with permission from Liu et al., Soft Matter 16, 9844–9856 (2020). Copyright 2020 Royal Society of Chemistry.

The extensional flow in contractions can also be used to measure properties of DNA molecules. For instance, Hirano et al. tracked fluorescently labeled DNA strands elongated by the flow through a constriction.147 The change in length observed was compared against the difference in flow velocity between the two ends of the DNA. The nonlinear elastic behavior of the DNA strand was then analyzed compared by stretch against strain rate.

While abrupt contractions provide strong extensional forces, the extension rate changes rapidly along the path lines that particles and cells follow. The extension rate can be adjusted by changing the geometry of the entrance.148 For instance, Faghih and Sharp used a hyperbolic shaped contraction with a constant extension rate along the channel centerline for studying the deformation of RBCs.149 The stress on the cells was modified by changing the flow rate and viscosity of the suspending solution and compared to measured aspect ratio. The deformation under shear flow was observed to be lower than the extensional flow at comparable stress due to the different flow kinematics. The deformation was compared to previous work using rabbit blood cells and significant discrepancies were observed, which demonstrated that animal models are not always well-suited for extrapolating to human cells. A hyperbolic contraction was also used by Faustino et al. to compare the RBC deformability between patients with end-stage kidney disease and samples from healthy individuals as controls.150 The samples from the diseased patients were shown to have less deformability than the samples from the control group and the deformability decreased further for patients with diabetes. The study demonstrated that the method may lead to new diagnostic tools and blood pathologies.

While the constant strain rate along the centerline of a hyperbolic contraction is theoretically well-suited for deformation measurements, the implementation in a microfluidic channel can lead to deviations from the constant strain rate due to finite size effects. To overcome this limitation, a microfluidic device was designed using CFD optimization methods to create a large region of uniform strain rate, see Fig. 7(c).151 The millimeter scale length of device necessitated tracking particles on a microscope with a motorized stage to capture the deformation of bio-particles. The strain rate was verified using particle tracking velocimetry and then the measured extension of DNA and actin filaments was used to characterize their elastic properties.152

The mix of extensional and shear flow that exists for most particle trajectories through constriction geometries was studied by Piergiovanni et al. using CFD to determine the flow field experience by leukemia particles.154 Different types of flow behaviors were evaluated by analyzing trajectories with different mixes of extensional and shear flow. The study showed that CFD simulations can be used to evaluate viscoelastic properties of cells and also provide a process for evaluating whether a microfluidic geometry produces a flow type that can differentiate cell lines based on viscoelastic properties.

Most studies using microfluidic constrictions are made from PDMS. While these devices are well-suited for research, the difficulty of mass production, limited ability to withstand high pressures, and a lack of general robustness make them ill-suited for commercialized devices. To address these limitations, Rubio et al. developed a microfluidic nozzle created by melt-shaping a glass capillary in a capillary puller, see Fig. 7(b).153,155 The nozzle was submerged in glycerol to reduce the distortion effects of the curved glass surface for optical imaging. The flow was characterized by comparing CFD simulations with particle tracking velocimetry. This resulted in identification of a region with small variations in strain rate where the most accurate deformation measurements could be made. The nozzle device was used to measure the deformation of two RBC populations in the near constant strain rate region, one healthy and another treated with glutaraldehyde to increase rigidity. The difference in deformation between the two populations was studied in nozzles of different size and shapes. The relative simplicity of fabrication and robust glass construction makes it attractive for scaling up production, cleaning, and clinical applications.

The use of constrictions in microfluidics is a useful technique for observing differences in cell properties by deformation and flow behavior in the channels. Access to CFD simulations has enabled more detailed analysis of the flow field in these microfluidic geometries. Connections to measuring material properties is difficult due to the complex flow fields the particles experience in the entrances. Work toward optimizing geometries to create large regions of constant strain-rates provide opportunities for more accurate measurement of viscoelastic properties of cells. The development of more robust microfluidic fabrication techniques will also promote high-throughput and automated measurements for clinical applications.

B. Cross-slot devices

The cross-slot geometry is a common microfluidic design for generating extensional flow. Microfluidic cross-slots and four-roll mill designs have been used commonly as rheological tools.156–158 These devices have also been used for characterizing deformable particles, such as the dynamics of giant vesicles in flow.159,160 One challenge with using a cross-slot for mechanical measurements of cells and other bio-particles is controlling the flow field experienced by the particle. Some approaches, such as that used by Marie et al., have used confining channels to trap DNA and then apply extensional flow to measure properties of the DNA161 More recent approaches have developed real-time feedback over the flow to maintain the position and deformation, or have used CFD to model the flow experienced by the particles.