Abstract

Around 8% of the global carbon dioxide emissions, are generated during cement manufacturing, which also involves significant use of raw materials, leading to adverse environmental effects. Consequently, extensive research is being conducted worldwide to explore the feasibility of utilizing different industrial waste by-products as alternatives to cement in concrete production. Fly ash (FA), Metakaolin (MK), Silica fume (SF), and ground granulated blast furnace slag (GGBS) are potential industrial materials that can serve as cement substitutes in pervious concrete. However, there exist conflicting findings in the literature regarding the impact of industrial supplementary cementitious materials (ISCMs) as partial cement replacements on the physical, mechanical, and durability properties of pervious concrete. The aim of this review is to investigate the feasibility and potential benefits of using ISCMs and compare them as partial cement replacements in the production of pervious concrete. The analysis primarily examines the effect of ISCMs as partial cement replacements on cementitious properties, including properties of ISMCs, mechanical properties, and durability of pervious concrete. The influence of ISCMs primarily stems from their pozzolanic reaction and filler characteristics. SF has the highest reactivity due to its high surface area and amorphous structure, resulting in a rapid pozzolanic reaction. GGBS and FA have moderate reactivity, while MK has relatively low reactivity due to its crystalline structure. Results from various studies indicate that the addition of FA, SF, and MK up to approximately 20% leads to a reduction in porosity and permeability while improving compressive strength and durability due to the filler effect of SF and MK. Incorporating GGBS increases permeability slightly while causing a slight decrease in compressive strength. The range of permeability and compressive strength for pervious concrete incorporating FA, SF, GGBS and MK were 0.17–1.46 cm/s and 4–35 MPa, 0.56–2.28 cm/s and 3.1–35 MPa, 0.19–0.64 cm/s and 8–42 MPa, 0.10–1.28 cm/s and 5.5–41 MPa, respectively, which are in the acceptable range for non-structural application of pervious concrete. In conclusion, it is possible to produce sustainable pervious concrete by substituting up to 20% of cement with FA, SF, GGBS, and MK, thereby reducing cement consumption, carbon footprint, energy usage, and air pollution associated with conventional cement production. However, further research is required to systematically assess the durability properties, long-term behavior, and, develop models for analyzing CO2 emissions and cost considerations of pervious concrete containing ISMCs.

Keywords: Pervious concrete, Industrial supplementary cementitious materials, Mechanical properties, Durability, Silica fume, Fly ash, Metakaolin, Slag, Waste management

Abbreviations

Abbreviation Description

- FA

Fly Ash

- MK

Metakaolin

- SF

Silica Fume

- GGBS

Ground Granulated Blast Furnace Slag

- SCMs

Supplementary Cementitious Materials

- ISCMs

Industrial Supplementary Cementitious Materials

- C–S–H

Hydrated Calcium Silicate

- SEM

Scanning Electron Microscope

- XRD

X-ray Diffraction

- FSD

Fine Sawdust

- CO2

Carbon Dioxide

- C3A

Tricalcium Aluminate

- Ca(OH)2

Calcium Hydroxide

- SP

Superplasticizer

- W/B

water-to-binder

- C/A

cement-to-aggregate ratio

- NS

nano-silica

1. Introduction

The advent of global industrialization and the progress of modern society have led to the creation of substantial amounts of waste, which has significantly increased in recent decades. Despite this, a significant portion of the waste continues to be disposed of in hazardous open landfills, posing a significant environmental risk [1]. The quantity and nature of industrial waste pose challenges in terms of safe disposal and recycling. Proper industrial waste disposal has become a significant global concern due to limited waste disposal sites and stringent environmental regulations. Sustainable waste management is a critical issue on a global scale, requiring efficient waste treatment and effective disposal services to be promptly implemented. On the other hand, the irresponsible use of natural resources will be harmful to future generations. Thus, efficient management of materials via improvement, recycling, the finding of substitutes, and efficient use of resources is required to decrease environmental problems.

The ongoing industrial and economic development worldwide has brought about a significant increase in waste production and has resulted in a surge in demand for construction activities. This, in turn, has necessitated a corresponding escalation in the manufacturing of building materials, with concrete emerging as the most ubiquitous and widely used material for construction purposes across the globe. As a result, cement production has reached a staggering volume of approximately 4.1 billion tons annually [2], with projected estimates anticipating a further increase to 5.8 billion tons by 2050 [3]. The construction industry utilizes more than 40% of the Earth's natural resources, encompassing water, fine and coarse aggregates, as well as wood [4]. Furthermore, the clinkering process utilized in cement production has a significant impact on diminishing reserves of raw materials [5]. As a result, there is mounting pressure to minimize the consumption of natural resources in the manufacturing of building materials. The components of concrete contribute substantially to both carbon dioxide emissions and energy usage, rendering cement production unsustainable [6]. The cement industry is responsible for approximately 8% of the world's annual carbon emissions resulting from fossil fuel combustion [[7], [8], [9], [10], [11]]. Hence, the reduction of cement content in concrete production is crucial and a matter of urgent global concern in the 21st-century concrete industry [12,13]. Embracing renewable and sustainable energy solutions is also vital to decrease carbon dioxide (CO2) emissions in the cement sector. Additionally, the depletion of natural resources and the accumulation of industrial waste have prompted extensive research on the feasibility of utilizing waste by-products in concrete production. The incorporation of these waste materials in construction processes is essential for environmental preservation, as it promotes sustainable resource management and helps reduce carbon dioxide emissions. Mitigating CO2 emissions, conserving energy, implementing sustainable waste disposal practices, and reducing reliance on natural resources are significant global challenges that must be addressed to achieve cleaner production and a more sustainable future [[14], [15], [16]]. Numerous approaches have been suggested to bolster the sustainability of concrete and cement manufacturing. Technological measures encompass the partial substitution of cement with supplementary cementitious materials (SCM) like ground granulated blast furnace slag (GGBS) or fly ash (FA), as well as the utilization of alternative additives with lower environmental impacts. Other strategies involve exploring alternative raw materials, enhancing the energy efficiency of kilns and pre-calciners, adopting renewable energy resources, improving grinding efficiency, and implementing carbon capture and storage techniques [[17], [18], [19], [20], [21]].

The growing utilization of SCMs or alternative materials as substitutes for clinker presents a significant opportunity to decrease global carbon dioxide emissions and to reduce the consumption of natural resources [[22], [23], [24], [25]]. In order to achieve an annual reduction of one billion tonnes of carbon emissions, approximately 50% of cement clinker must be replaced with alternative additives. This equates to incorporating around 1.6 billion tonnes of mineral additives annually in the production of cement [7,26]. To accomplish these reductions in CO2 emissions, it is crucial to implement comprehensive solutions that involve using less concrete in the construction of new structures, reducing the amount of cement in concrete mixtures, and minimizing the use of clinker in cement production [27]. According to reports, incorporating GGBS and pulverized FA into a concrete mix resulted in a significant reduction of approximately 49.6% and 28.9% in CO2 emissions, respectively, in comparison to using cement alone [28]. Further studies have demonstrated successful investigations into the replacement of cement up to 50% in the production of high-volume FA mixtures, particularly for constructing mass concrete structural members and pavement structures [29]. The challenge lies not only in mitigating the negative impacts of concrete production by maximizing the utilization of SCMs and other alternative waste materials but also in maintaining the comparable performance of cementitious composites [30,31]. Materials like FA, silica fume (SF), GGBS, and Metakaolin (MK) are extensively employed as partial substitutes for cement to enhance the properties of cement-based composites and promote the sustainability of concrete. However, due to the decarbonization policies, many governments worldwide have decided to phase out coal as an energy source for power plants in the upcoming years. This shift towards alternative renewable energy resources and the reduction in coal combustion significantly diminishes the availability of ash in the market. Consequently, the demand for SCMs surpasses the local supply, posing a challenge in meeting the required SCM quantities [32]. As a result, the concrete and cement industries have increasingly adopted the practice of sourcing local SCMs as partial replacements for cement. This approach aims to address the potential shortages of SCMs in specific regions and ensure the continued production of concrete without significant disruptions.

Many researchers investigated alternatives for cement substitution from waste materials to produce sustainable normal concrete [25,[33], [34], [35]]. Recently more researchers studied the effect of using waste materials as cement replacement on properties of pervious concrete due to the use of more cement. Moreover, the coating thickness of cementitious material has been discovered to be a very significant factor in evaluating the hydrological and structural behavior of pervious concrete [36,37]. It is obvious that with increasing the content of cement in pervious concrete, the paste thickness around the aggregate will increases, which can result in greater strength but decreases the void ratio of pervious concrete and leads to a reduction in permeability and serviceability of pervious concrete [38]. Pervious concrete has been utilized for over the past 30 years in many areas, especially in the US and Japan due to its various environmental advantages [[39], [40], [41], [42]]. Normally, the porosity of pervious concrete is around 15–25%, the water permeability is generally between 0.1 and 0.6 cm/s, and the compressive strength is about 2–10 MPa [[43], [44], [45]]. Therefore, considering the low strength of normal pervious concrete, its use is limited to being used as recreation squares, parking lots, sidewalks, and subbases for conventional pavement [43,46,47]. However, by utilizing smaller-size aggregate and some special admixtures, high-strength pervious concrete can be produced and it can be utilized in pavement shoulders and local roads [48,49]. Therefore, due to the various environmental disadvantages of using cement by producing pervious concrete, there is a strong interest among international researchers to investigate the possibility of using different industrial supplementary cementitious materials (ISCMs), such as FA, SF, GGBS, and MK as a partial replacement of cement in pervious concrete [[50], [51], [52], [53], [54], [55]]. As far as the authors are concerned, there has been no study to date that presents a thorough review of the effect of industrial waste materials as cement replacement on properties of pervious concrete. Furthermore, the use of ISCMs and their effects on the mechanical properties, durability, and microstructure of pervious concrete is an area that has been less explored, which is the major objective of this review article. Studies in the literature on the use of ISCMs in pervious concrete have often yielded conflicting results regarding their effects on the mechanical and physical properties and durability of pervious concrete. Therefore, the categorization presented here can help the readers select the most suitable ISCMs for their study.

Additionally, a thorough review was performed on studies of pervious concretes, and the optimal mix design of each study was collected in a table. This table helps the readers gain insights into the required mix proportioning for achieving a target permeability and compressive strength with different amounts of fine aggregate, coarse aggregate, cement, and ISCMs. The previous studies related to the utilization of ISCMs as cement replacement in the production of pervious concrete were discussed and reviewed by the current work.

This paper provides a comprehensive review and analysis of the scientific literature regarding the utilization of ISCMs in the production of pervious concrete. The characteristics of ISCMs and their effect on the properties of pervious concrete were investigated.

2. Source of obtaining ISCMs

2.1. Source of obtaining FA

FA is a by-product generated from the combustion of coal in thermal power plants. It is a finely powdered substance that is captured from the flue gases through electrostatic precipitators or bag filters. The composition of FA can vary depending on the type and source of coal burned, but it generally consists of different proportions of silica, alumina, iron oxide, and calcium oxide. The process of FA production begins with the combustion of pulverized coal in a power plant boiler. During the combustion process, the coal is burned at high temperatures, producing hot gases that contain FA. The FA is then captured by electrostatic precipitators or bag filters, which remove the particles from the flue gases. The collected FA is then transported to storage silos for further processing or disposal.

FA is widely used as a partial replacement for cement in the production of concrete and as a component in the manufacture of building materials such as bricks, blocks, and roofing tiles. Its use in these applications helps to reduce the environmental impact of coal-fired power plants by diverting waste materials from landfills and reducing the need for virgin materials.

2.2. Source of obtaining SF

SF is a by-product of silicon and ferrosilicon blend manufacturing industries [56,57]. The process involves heating a mixture of quartz, coke, and iron or other metals to high temperatures, causing a chemical reaction that produces silicon and carbon monoxide gas. SiO vapor is discharged upon the decrease of quartz in the mixture and is gathered at the bottom of the furnace. Simultaneously, the fume oxidizes and condenses in the higher segments of the furnace, manufacturing microspheres of amorphous silica which is called SF [56]. The particles are then collected in a baghouse or other filtration system, where they are cooled and stored. The resulting SF is a fine powder that is highly reactive due to its small particle size and high surface area. It is typically transported in bulk or in bags to concrete producers, where it is added to cementitious mixtures to improve their mechanical and durability properties.

2.3. Source of obtaining GGBS

GGBS) is a by-product made because of the oxidation of impurities in pig iron during steel-making, resulting in its final state as a very fine powder form. This is achieved by passing molten slag through multiple processes [58]. GGBS can yield various types based on the production method used, and these types exhibit similar characteristics to other slags [59]. The disposal of steel slag has become an expensive and problematic process as a result of the growing severity of environmental instructions and regulations [60]. From the production of iron and steel in the plant, around 400 kg of slag per is produced. GGBS makes up 300 kg of this content whereas the remaining 100 kg is steel slag [61]. According to data, 15.7 million tons of steel slag have been produced as industrial by-product waste in Europe alone, of which around 75% (11.5 million tons) are recycled [61]. Nowadays, the utilization of GGBS as a replacement for cement in the production of pervious and normal concrete brings lots of economic and environmental advantages.

2.4. Source of obtaining MK

MK is produced by calcining kaolin clay at temperatures ranging from 500 °C to 800 °C in a rotary kiln. During the calcination process, the kaolin clay undergoes a series of physical and chemical transformations, resulting in the formation of MK. MK is a highly reactive pozzolanic material that can be used as a partial replacement for cement in the production of concrete. The use of MK in concrete can lead to improved strength, durability, and workability of the concrete, as well as a reduction in the environmental impact of concrete production. MK is commonly used in high-performance concrete applications, such as bridge decks, high-rise buildings, and marine structures. MK is manufactured by calcination of high-quality kaolinite clay mineral at a temperature rate of around 700–850 °C [62].

3. Pozzolanic activity and chemical reaction of ISMCs

As illustrated in Fig. 1, FA, SF, GGBS, and MK are all pozzolanic materials that show a hydraulic and pozzolanic reaction. They react with existing water and free calcium hydroxide (Ca(OH)2) to create hydrated calcium silicate (C–S–H), which is comparable to that achieved in the process of cement hydration, resulting in improved strength and durability of cementitious materials [57,63]. Compared to other pozzolanic materials, SF has the highest reactivity due to its high surface area and amorphous structure, resulting in a rapid pozzolanic reaction. GGBS and FA have moderate reactivity, while MK has relatively low reactivity due to its crystalline structure. The pozzolanic activity of these materials also depends on their chemical composition, particle size distribution, and curing conditions. FA and GGBS typically contain higher amounts of alumina and silica, while SF and MK are mostly composed of silica. In general, the use of pozzolanic materials can improve the compressive strength, durability, and other properties of cementitious materials. However, the specific properties and effectiveness of each material depend on several factors, including the composition of the cementitious system, the type and amount of pozzolanic material used, and the curing conditions.

Fig. 1.

SCMs from industry used in sustainable cementitious composites [64].

4. Physical properties of ISMCs

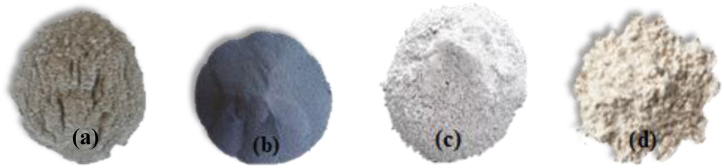

Fig. 2, Fig. 3, and Table 1 show the specific surface area and specific gravity of ISMCs. It can be seen that SF has the highest specific surface area and specific gravity, followed by MK, FA, and GGBS. FA has the lowest specific gravity but a relatively high specific surface area. The values of the specific surface area of these materials are higher than cement. GGBS has a relatively low specific surface area but a higher specific gravity compared to FA.

Fig. 2.

(a) FA, (b) SF, (c) GGBS and (d) MK

Fig. 3.

Table 1.

Physical properties of SMCs.

| References | SMCs | Specific gravity | Specific Surface area (m2/kg) |

|---|---|---|---|

| [67] | Cement | 3.14 | 367 |

| [68] | FA | 2.04 | – |

| [69] | FA | 2.47 | 4200 |

| [70] | FA | 2.45 | – |

| [71] | FA | 2.07 | 3290 |

| [72] | FA | 2.10 | 3500 |

| [73] | FA | 2.28 | 3097 |

| [74] | FA | 2.00 | – |

| [75,76] | SF | 2.15 | 17300 |

| [77] | SF | 2.2 | 20000 |

| [67] | GGBS | 2.90 | 455 |

| [78] | GGBS | 2.88 | 586 |

| [69] | MK | 2.60 | – |

| [79] | MK | 2.54 | – |

| [68] | MK | 2.41 | – |

Note: SF = Silica fume, MK = Metakaolin, GGBS = Ground granulated blast furnace slag.

FA is a fine powder that is predominantly gray or black (Fig. 2(a)) and has an average particle size ranging from 1 to 100 μm. It has a low specific gravity ranging from 2.1 to 2.8 g/cm3 and a high specific surface area ranging from 250 to 700 m2/kg [[52], [53], [54]].

SF, on the other hand, is a very fine powder that is usually gray in color [56] (Fig. 2(b)) and has an average particle size of less than 1 μm [56,97]. has a high specific gravity ranging from 2.2 to 2.3 g/cm3 and a very high specific surface area ranging from 15,000 to 30,000 m2/kg. The particles of normal cement are around 100 times bigger than the particles of SF. The smaller particle sizes of SF result in a higher rate of early hydration and increase the chance of pozzolanic reactions [98]. GGBS is a by-product of the iron and steel industry. It has a glassy appearance and a predominantly white color (Fig. 2(c)). Its particle size ranges from 1 to 100 μm, and it has a specific gravity ranging from 2.8 to 3.0 g/cm3. The specific surface area of GGBS is relatively high and ranges from 300 to 600 m2/kg [67,99]. MK is a white or off-white fine powder with an average particle size ranging from 1 to 10 μm (Fig. 2(d)). It has a high specific gravity ranging from 2.4 to 2.6 g/cm3 and a specific surface area ranging from 8000 to 20,000 m2/kg [97,100].

5. Chemical properties of ISMCs

Overall, the chemical properties of these materials play a crucial role in their performance as pozzolans and affect the strength and durability of cement-based composites (see Table 2). SF has the highest reactivity among the four materials due to its small particle size and amorphous structure, which provides a large surface area for the pozzolanic reaction to occur. GGBS has a lower reactivity compared to SF but still provides good strength and durability due to its high calcium content. FA has a lower reactivity compared to the other materials due to its larger particle size and lower silica content. Finally, MK has moderate reactivity due to its amorphous structure and high silica content.

Table 2.

Chemical properties of ISMCs.

| References | Composition (% wt.) | CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | K2O | Na2O | LOI | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [80] | Cement | 61.60 | 22.40 | 5.20 | 3.76 | 2.36 | 1.70 | 0.66 | 0.48 | 1.44 | 0.40 |

| [80] | FA | 5.0 | 30.8 | 9.9 | 39.6 | 11.4 | 0.4 | 1.0 | 0.9 | 7.6 | 0.6 |

| [69] | FA | 11.3 | 47.5 | 21.7 | 8.2 | 1.7 | 2.5 | – | – | 2.5 | – |

| [72] | FA | 1.6 | 50.9 | 27.9 | 4.7 | – | 2.3 | – | – | 3.7 | – |

| [81] | FA | 10.7 | 51.3 | 22.8 | 6.9 | 1.9 | 2.8 | – | – | – | – |

| [70] | FA | 10.8 | 51.6 | 23.2 | 7.2 | 1.9 | 2.9 | – | – | 2.5 | – |

| [71] | FA | 11.1 | 41.7 | 24.2 | 13.2 | 2.8 | 2.2 | 2.6 | 0.7 | 0.4 | 0.7 |

| [82] | FA | 6.3 | 50.8 | 28.0 | 7.0 | 0.4 | 1.2 | 1.9 | 1.5 | – | 1.0 |

| [83] | FA | 11.7 | 42.1 | 29.1 | 6.8 | 1.9 | 1.9 | 0.9 | 2.2 | – | 1.2 |

| [84] | FA | 35.5 | 29.5 | 19.3 | 3.5 | 7.4 | 1.8 | – | – | – | 3.1 |

| [85] | FA | 0.3 | 57.4 | 40.0 | 1.1 | 0.0 | 0.3 | 0.9 | 0.1 | – | – |

| [86] | FA | 23.3 | 23.9 | 9.1 | 28.5 | 3.0 | 9.7 | 0.6 | – | 1.6 | 0.9 |

| [87] | FA | 3.8 | 56.2 | 26.7 | 4.4 | – | 0.1 | – | 1.3 | – | 0.1 |

| [88] | FA | 17.5 | 36.4 | 14.1 | 22.4 | 1.0 | 2.6 | 2.1 | 0.2 | 1.5 | – |

| [73] | FA | 8.40 | 46.0 | 17.8 | 18.2 | 2.59 | 0.95 | 2.16 | 0.6 | 1.5 | – |

| [38] | FA | 12.5 | 50.2 | 30.5 | 2.1 | 0.4 | 0.1 | – | 1.3 | 1.1 | 1.8 |

| [85] | SF | 0.25 | 99.41 | 0.21 | 0.14 | 0.0 | 0.13 | 0.06 | 0.02 | – | – |

| [89] | SF | 0.4 | 91.7 | 0.3 | 0.1 | 0.5 | 0.4 | – | – | – | 6.6 |

| [75] | SF | 0.87 | 90.12 | 0.94 | 1.62 | 0.29 | – | 1.21 | – | – | – |

| [76] | SF | 0.64 | 87.67 | 0.28 | 0.60 | 0.82 | 1.80 | – | – | 1.57 | – |

| [90] | SF | 0.87 | 90.12 | 0.94 | 1.62 | 0.29 | – | 1.21 | – | 2.87 | – |

| [91] | NS | – | 98.5 | – | – | 0.5 | 0.5 | – | – | 0.5 | – |

| [38] | GGBS | 47.5 | 30.7 | 9.8 | 2.1 | 4.4 | 3.8 | – | 1.07 | 0.63 | – |

| [84] | GGBS | 40.24 | 33.68 | 14.37 | 0.29 | 0.66 | 7.83 | – | – | – | 2.93 |

| [67] | GGBS | 42.1 | 35.4 | 10.6 | 0.4 | 0.3 | 8.1 | – | – | 3.1 | – |

| [92] | GGBS | 47.06 | 9.22 | 5.56 | 24.87 | 0.60 | 8.45 | – | – | – | – |

| [93] | GGBS | 58.6 | 27.8 | 8.1 | 1.3 | – | 6.0 | – | 0.2 | 0.9 | 0.3 |

| [94] | GGBS | 28.96 | 32.12 | 16.41 | 0.32 | 4.41 | 15.86 | 0.21 | 0.30 | 2.58 | 0.02 |

| [95] | GGBS | 38.7 | 35.5 | 14.8 | 0.27 | 2.2 | 6.7 | – | 0.26 | 0.88 | 0.79 |

| [96] | MK | 0.39 | 54.30 | 40.26 | 2.28 | – | 0.08 | 0.5 | 0.12 | – | 0.33 |

| [79] | MK | 8.1 | 52.9 | 30.5 | 5.5 | – | 0.6 | 0.6 | 0.7 | – | – |

| [76] | MK | 0.29 | 70 | 23 | 4.0 | 0.19 | 0.12 | – | – | 2.01 | – |

| [69] | MK | 3.2 | 50.85 | 40.15 | 0.8 | – | 0.26 | – | – | 2.07 | – |

| [68] | MK | 0.29 | 58.20 | 41.40 | 0.38 | – | 0.13 | 0.29 | 0.12 | – | – |

| [94] | MK | 0.11 | 51.35 | 46.17 | 0.77 | 0.14 | 0.06 | 0.07 | 0.01 | 2.89 | 0.02 |

Note: NS=Nano silica, GGBS = Ground granulated blast furnace slag, SF = Silica fume, MK = Metakaolin.

FA contains primarily silica, alumina, and calcium oxide. Its chemical composition can vary depending on the type of coal burned and the combustion conditions. SF, on the other hand, is composed mainly of silicon dioxide and small amounts of other oxides such as aluminum, calcium, and iron. GGBS is composed of primarily silica, alumina, and calcium oxide. Finally, MK is primarily composed of amorphous silica and alumina.

The chemical properties of these materials affect their ability to react with calcium hydroxide in the presence of water to form C–S–H gel, which is responsible for the strength and durability of cement-based composites. FA and GGBS are both rich in calcium oxide, which allows them to react with calcium hydroxide to form C–S–H gel. SF and MK, on the other hand, are primarily composed of amorphous silica, which provides a large surface area for the pozzolanic reaction to occur. This results in the formation of a denser C–S–H gel, which leads to higher strength and durability of the cement-based composite. Around 90% of MK was consist together of alumina and silica oxides, which create Al2O3·2SiO2 (AS2) crystalline. As mentioned, the produced AS2 reacts with Ca(OH)2 to create the secondary C–S–H gel [69].

6. Morphology of ISMCs

Overall, Scanning Electron Microscope (SEM) and X-ray Diffraction (XRD) analysis show that FA, SF, GGBFS, and MK have different morphologies and crystal structures, which can affect their physical and chemical properties and their performance as pozzolanic materials in cementitious composites.

As shown in Fig. 4, the SEM image of FA particles shows spherical and irregular shapes (Fig. 4(a)). SF particles have angular shapes that are mostly spherical with smooth surfaces due to their amorphous nature (Fig. 4(b)) [85]. MK particles are irregular in shape and have a smooth surface due to their amorphous nature (Fig. 4(c)). GGBS particles are irregular in shape and often have a glassy surface due to their rapid cooling during production (Fig. 4(d)). XRD analysis of FA shows a broad peak, indicating the presence of amorphous and crystalline phases (Fig. 5(a)). The crystalline phases present in FA include quartz, mullite, and magnetite. SF does not show any peaks in XRD analysis, indicating its amorphous nature (Fig. 5(b)). GGBS shows peaks corresponding to its crystalline phases, including calcium silicate hydrate, gehlenite, and merwinite (Fig. 5(a)) [9]. MK shows a peak at around 23°, corresponding to its amorphous phase, and a peak at around 35°, indicating the presence of a small amount of crystalline phase (Fig. 5(c)) [101]. From the SEM photo presented in Fig. 4, it can be observed that MK particles have irregular shapes similar to cement particles, and they are randomly distributed over the surface. MK incorporates active alumina and silica, which react with free Ca(OH)2 (created during the hydration process) to produce crystalline C–S–H [100,102].

Fig. 4.

Microscopic images of ISCMs: (a) FA [103], (b) SF [103], (c) MK [104], and (d) GBBS [9].

Fig. 5.

7. Influence of ISMCs on mechanical properties of previous concrete

The summary of mix designs and properties of pervious concrete incorporating various amounts of ISMCs is presented in Table 3, Table 4.

Table 3.

Pervious concrete mixtures incorporating industrial ISMCs.

| References | ISMCs (%) | Cement (kg/m3) | W/B | Coarse aggregate (kg/m3) | Fine aggregate (%) | SP (%) | |

|---|---|---|---|---|---|---|---|

| [82] | FA | 5–20 | 435–517 | 0.3–0.45 | 1360 | – | – |

| [68] | FA | 5–20 | 323–383 | 0.38 | 2117 | – | – |

| [107] | FA | 30–50 | 150–210 | 0.45 | 1530–1800 | ||

| [70] | FA | 10–20 | 200–225 | 0.34 | 1640 | – | – |

| [72] | FA | 5–20 | 272–340 | 0.34 | 1395 | 10 | 2–5 |

| [73] | FA | 15 | 320 | 0.32 | 1448 | 9 | – |

| [76] | SF | 5–10 | 315–332 | 0.28 | 1504 | 5 | 1.25 |

| [75] | SF | 4–16 | 402–459 | 0.34 | 1588 | 9 | – |

| [85] | SF | 5–20 | 322–403 | 0.38 | 2116 | – | – |

| [108] | SF | 5–25 | 380 | 0.44 | 1520 | 5 | – |

| [90] | SF | 5–10 | 345–363 | 0.33 | 1490 | 8 | – |

| [91] | NS | 3–6 | 300 | 0.26 | 1500 | – | – |

| [38] | GGBS | 20–30 | 196–280 | 0.35 | 1450 | – | – |

| [67] | GGBS | 50 | 192.6 | 0.3 | 1834 | – | – |

| [109] | GGBS | 20 | 320–400 | 0.35 | 1200 | – | – |

| [78] | GGBS | 30–50 | – | 0.35 | 1619 | – | 5–6 |

| FA | |||||||

| [40] | GGBS | 10–15 | 330–458 | 0.43 | 1167 | – | – |

| FA | 5–20 | ||||||

| [79] | MK | 5–25 | 247–313 | 0.36 | 1550 | – | – |

| [68] | MK | 5–20 | 323–383 | 0.38 | 2117 | – | – |

| [76] | MK | 5–10 | 315–332 | 0.28 | 1504 | 5 | 1.25 |

| [69] | MK | 2 | 251–314 | 0.33 | 1568 | – | 1 |

| FA | 5–20 | ||||||

Note: NS=Nano silica, SF = Silica fume, GGBS = Ground granulated blast furnace slag, FA=Fly ash, MK = Metakaolin, SP = Superplasticizer, W/B= Water to binder ratio.

Table 4.

Properties of pervious incorporating ISMCs.

| References | SMCs | Void (%) | Permeability (cm/s) | Compressive strength (MPa) 28d |

Tensile strength (MPa) 28d |

Flexural strength (MPa) 28d |

|---|---|---|---|---|---|---|

| [82] | FA | 17–23 | 0.17–0.88 | 13–32 | – | – |

| [68] | FA | 17–18 | 0.40–0.55 | 14–18 | 1.5–1.8 | 2.5–2.8 |

| [107] | FA | 27–33 | – | 5–8 | – | – |

| [110] | FA | 13–14 | 0.38–0.40 | 15–20 | – | – |

| [69] | FA | 27–31 | – | 4–10 | – | – |

| [111] | FA | 21–23 | 0.61–0.69 | 20–35 | – | – |

| [38] | FA | 27–28 | 0.55–0.70 | 7–9 | – | – |

| [112] | FA | 21–35 | 0.84–1.46 | 15–25 | 1.23–1.29 | – |

| [70] | FA | 25–27 | 0.8–0.9 | 8–9 | 1.8–2.2 | 1.6–1.7 |

| [113] | FA | – | 0.55–0.76 | 21–23 | – | – |

| [73] | FA | 27 | 0.25 | 14 | – | – |

| [72] | FA | 20–24 | 0.18–0.24 | 18–26 | 2.3–2.5 | 2.7–3.6 |

| [76] | SF | – | 0.60–0.65 | 33–35 | 2–2.4 | 6–6.6 |

| [114] | MS | 8.5–29.04 | 0.56–2.28 | 21–46 | 2.33–4.03 | 3.45–5.25 |

| [90] | SF | 18.5–21 | 1.48–1.60 | 13–20 | – | – |

| [108] | SF | – | 1.16–1.41 | 15–34 | – | – |

| [91] | NS | 23.1–23.2 | 1.40–1.46 | 3.1–3.3 | – | – |

| [85] | SF | 16–17 | 0.3–0.43 | 12–15 | 1.00–2.00 | 2.75–3.50 |

| [75] | SF | – | – | 12–19 | 1.4–2.1 | 1.14–2.40 |

| [38] | GGBS | 27.9–27.2 | 0.56–0.64 | 8–8.2 | – | – |

| [67] | GGBS | 10 | 0.19 | 42 | 3 | – |

| [109] | GGBS | – | 0.66–0.85 | 32–34 | – | – |

| [78] | GGBS,FA | – | 0.05–0.23 | 2–12 | 0.4–2 | – |

| [40] | GGBS,FA | – | – | 26–30 | 2.97–3.74 | – |

| [79] | MK | 31–36 | 0.09–0.1 | 10–12 | – | – |

| [68] | MK | 16–18 | 0.3–0.4 | 12–17 | 2–3 | 2.7–3.4 |

| [76] | MK | – | 0.4–0.5 | 33–36 | 2.1–2.6 | 5–9 |

| [69] | MK,FA | 21–28 | – | 5.5–10 | – | – |

| [96] | MK | 15.9–21.6 | 0.64–1.28 | 30–41 | 3.74–4.31 | 3.90–4.57 |

Note: SF = Silica fume, FA=Fly ash, MS = Micro silica, NS=Nano silica, GGBS = Ground granulated blast furnace slag, SP = Superplasticizer, MK = Metakaolin.

7.1. Influence of FA on mechanical properties of previous concrete

The findings demonstrated that as the percentage of FA increased, the void ratio and permeability of pervious concrete reduced. This can be attributed to the filler influence of FA and its pozzolanic activity, which led to the formation of secondary C–S–H gels. These gels contributed to cohesive activity, resulting in a reduction in voids and permeability. The research results varied within the range of 13–35% for void content and 0.03–1.3 cm/s for permeability. Deepika et al. [115] indicated that the utilization of class F FA up to 20% led to a decrease in the permeability of pervious concrete. These findings align with similar observations reported by several other researchers [72,107,109,[116], [117], [118], [119]]. Muthaiyan and Thirumalai [70] observed that replacing 10–20% of cement with class C FA led to a reduction of approximately 12–16% in total voids compared to the normal mixture. This reduction could be attributed to the micro-filler effect of FA. They also found that the permeability of FA pervious concrete decreased with an increase in the content of FA, ranging from 1.19 cm/s to 0.641 cm/s endorsed these findings, reporting a 42.15% reduction in the coefficient of permeability after replacing 10% of cement with FA. Singh et al. [68], revealed that pervious concrete with a maximum of 20% FA demonstrated water permeability rates ranging from 0.44 to 0.55 cm/s and void content levels between 17.5% and 18.5%. These findings align with the recommended range of void content (15–35%) as stated by ACI 552R-10 [120], indicating that the results are within acceptable limits.

Rasiah [121] and Aoki et al. [102], found that the use of low calcium FA up to 50% insignificantly reduced water permeability and void content. In the study conducted by Aoki et al. [102], it was noted that the average permeability and void ratio of pervious concrete samples were approximately 1.3 cm/s and 33%, respectively. The researchers reported that there was no significant influence on the permeability, void content, and density of pervious concrete. Liu et al. [110], supported these findings and reported that the dosage of FA did not affect the permeability and porosity. This could be attributed to the fact that FA partially substituted cement using an equal volume method.

Fig. 6 illustrates the results obtained by various researchers regarding the strength of pervious concrete incorporating FA. All of the results, ranging from 4 to 35 MPa, fall within the normal compressive strength range for pervious concrete as reported by ACI 552R-10 [120] (3–20 MPa). Moreover, several of these studies also documented a reduction in the early strength of pervious concrete when FA was added. The possible reason for this could be a reduction in cement content resulting from a decrease in the cement binder used to coat the aggregate particles. This decline in cement content contributes to a weakened bonding strength between the coarse aggregates. On the other hand, the increased water absorption of FA reduces the amount of water available for cement hydration, leading to incomplete cement hydration and a weakened connection between the coarse aggregates. Consequently, this combination of factors results in a decrease in the strength of the pervious concrete. In a study by Joyal et al. [122], the utilization of FA as a replacement for pervious concrete was found to lead to a decrease in both tensile and compressive strength of pervious concrete samples by up to 20%. This result was confirmed by Ong et al. [73], who reported a 6% reduction in compressive strength when class F FA was added at a rate of 15%. Hamdulay and John [123], observed a decrease in flexural and compressive strengths of pervious concrete when FA was used at a rate of up to 35%, attributing it to the quality and category of the FA. Joyal et al. [122] also confirmed these findings by utilizing FA up to 20%. Muthaiyan and Thirumalai [70], examined the impact of replacing a portion of cement with 10% and 20% class C FA on the properties of pervious concrete. The results indicated that the compressive strength varied between 5.70 and 8.83 MPa after 28 days, with binder contents ranging from 250 to 400 kg/m3, including FA concentrations of up to 20%. The researchers observed a minor decrease in compressive, tensile, and flexural strength when cement was substituted with FA up to 20%. Aoki et al. [102], reported that substituting 20% and 40% of cement with FA led to an approximate 9% and 65% decrease in compressive strength, respectively (at 28 days). Furthermore, several studies have examined the long-term impact of FA on the strength of pervious concrete. It was observed that the pace of strength gain in FA pervious concrete was initially lower compared to conventional pervious concrete but increased as the age of the concrete increased. This occurrence can be attributed to the progression of the pozzolanic activity and cement hydration of FA, which interacts with the free lime produced during cement hydration. The slow activation of pozzolanic properties leads to a slower rate of strength enhancement in pervious concrete containing FA. Generally, notable strength enhancement in FA pervious concrete is observed between 28 and 90 days of curing. According to Rasiah [121], when 50% of cement is replaced with FA by mass, the 28-day compressive strength of pervious concrete can decrease by approximately 4%. However, it was observed that the pervious concrete with 50% FA exhibited a significant increase of 50% in strength between 7 days and 28 days of the curing time. Singh et al. [68]; investigated the impact of incorporating FA up to 20% as a substitution of cement in a pervious concrete mixture, it was found that the compressive strength decreased at different substitution levels. The compressive strength reduction percentages, compared to the normal mixture at 28 days (12.43 MPa), were 9.41%, 4.86%, 1.52%, and 0.92% for substitution levels of 20%, 15%, 10%, and 5% FA, respectively. The findings of Dewoolkar [124], and Sata et al. [125], support the previously mentioned results. This can be related to the delayed pozzolanic activity of FA compared to cement [[126], [127], [128]]. According to Fig. 7, after 90 days of curing, the compressive strength demonstrated an increase of up to 3.09%, 2.34%, 2.06%, and 1.07% for substitution levels of 20%, 15%, 10%, and 5% FA, respectively, compared to the control pervious concrete mix with a strength of 12.62 MPa. A similar pattern was found for indirect tensile strength. This enhancement in strength can be attributed to the pozzolanic action of FA, along with the fine particles of FA that contribute to overall improvements in the properties of the cement binder and the microstructure of the transition zone between the aggregate and the binder material (Fig. 8(a–c)).

Fig. 6.

Influence of different percentages of FA on compressive strength of pervious concrete.

Fig. 7.

Compressive strength of pervious concrete incorporation FA [68].

Fig. 8.

SEM images of pervious concrete containing (a) 0%FA, (b) 5%FA, (c) 20%FA [68].

In the study conducted by Liu et al. [110], the properties of pervious concrete containing various percentages of FA (3%, 6%, 9%, and 12%) were investigated. The results revealed that the inclusion of FA decreased the strengths during the early stages of the curing time. Specifically, it was indicated that raising the FA content to 12% led to a 34% reduction in compressive strength. However, with the passage of time and an extended curing time (up to 150 days), the strength of the pervious concrete containing FA improved. This can be attributed to the progressive enhancement of hydration as the curing time increased, resulting in stronger bonding between the coarse aggregates. The researchers reported that although the addition of FA may have a negative impact on the characteristics of pervious concrete initially, it is still feasible to use FA as a partial replacement for cement in pervious concrete. Furthermore, they observed that the pace of strength gain escalated as the curing time extended.

Unlike the studies mentioned earlier, certain research has indicated that FA can have a positive impact on the engineering properties of pervious concrete when utilized in conjunction with other admixtures or pozzolanic materials. Scientists have investigated various approaches to enhance the quality of FA and improve its pozzolanic characteristics, including processes like burning or grinding. In a study by Carmichael et al. [129], an investigation was carried out to determine the optimal mix design for pervious concrete. The results showed that incorporating 40% Nano FA particles with a water-to-binder (W/B) ratio of 0.34 yielded the highest tensile strength of 3.89 MPa and compressive strength of 20.93 MPa after 28 days. However, growing the amount of nano FA beyond 40% slightly diminished the strength, possibly because of an excessive amount of filler and pozzolanic materials present in the mixture. In a study conducted by Shafabakhsh and Ahmadi [72], the impact of FA on the strength of pervious concrete was examined at substitution rates of 5%, 10%, 15%, and 20%. The researchers utilized a burning process to reduce the content of unburned carbon and improve the pozzolanic compounds present in FA. It was reported that initially, the substitution of cement with FA led to an increase in both compressive and tensile strength. The researchers reported that initially, the compressive and tensile strength increased with an increase in the substitution rate of cement with FA. However, beyond a certain point, the strength began to decrease. The sample with a 10% FA content exhibited the highest tensile and compressive strength. This can be attributed to the formation of secondary C–S–H gel by FA, which fills and strengthens the cement paste, as well as the crystallization of new materials within the transition area's pores. However, with further increases in amount of FA, the strengths decreased due to reduced performance and inadequate water availability. These findings highlight the potential for FA to positively impact the engineering properties of pervious concrete when utilized in combination with other materials or with proper treatment to enhance its pozzolanic characteristics.

Conversely, many studies employed superplasticizer (SP) to mitigate the adverse effects of increased water absorption caused by FA and enhance the characteristics of pervious concrete. Swe, Jongvivatsakul, and Pansuk [71] conducted tests where cement was replaced with FA (ranging from 20% to 60%) while incorporating SP. The samples containing FA exhibited better compressive strength compared to the normal mixture design, primarily due to the pozzolanic activity of FA, which become more active after 28 days. Wang et al. [111], evaluated the performance of pervious concrete with FA content up to 40% by incorporating both superplasticizer and superfine SF. They noted that the compressive strength increased from 25.7 MPa to 34.5 MPa with the incorporation of FA, with the strength enhancement being observed as the FA content rose from 0% to 20%. They identified the mix design with a cement-to-aggregate ratio (C/A) of 0.20–0.24 and 20% FA content as the optimal combination for producing pervious concrete with a compressive strength exceeding 30 MPa and adequate void content. Usha K N and B K Smitha [74], studied the effects of class F FA up to 30% on the characteristics of pervious concrete using SP. They reported that pervious concrete with a 20% replacement of cement by FA exhibited better tensile and compressive strength compared to pervious concrete without FA. In contrast, the samples with 10% and 30% substitution demonstrated reduced strength compared to the normal mixture design. Overall, these studies demonstrate that the incorporation of superplasticizer, along with FA, can enhance the compressive strength of pervious concrete and improve its properties. The optimal FA content and mix design may vary depending on the specific requirements and desired performance characteristics of the pervious concrete mixture. Al-sallami et al. [107], conducted a study to investigate the impact of Class F FA on the characteristics and performance of pervious concrete when substituted for cement at ratios ranging from 30% to 50% by weight. They found that a 30% substitution of FA resulted in significant improvements in flexural strength (38.34%) and compressive strength (40%) after 90 days of curing. These improvements can be attributed to the micro-filler influence of FA and its pozzolanic action, which led to the formation of secondary C–S–H gels, enhancing cohesion, reducing voids, and enhancing the elastic modulus and strength of the pervious concrete.

However, the study also revealed that a 50% replacement of cement with FA led to a reduction in pervious concrete strength. This decline can be attributed to the fact that at this level of replacement, some FA particles remain inactive and do not involve in the hydration process. As a result, extra C–S–H gel formation does not occur, and the FA particles act as fillers, which improves density but does not enhance strength. Additionally, this higher level of substitution may contribute to a decrease in void content. Overall, the study suggests that an optimal level of FA substitution in pervious concrete exists to achieve improved strength and performance, while exceeding this level may have diminishing returns and potentially lead to reduced strength. Other investigations examined the impact of incorporating FA in combination with additional pozzolanic admixtures and materials, aiming to enhance hydration and develop the overall effect of FA on the behavior of pervious concrete. Opiso et al. [86], conducted a study on the behavior of mixed pervious concrete by containing class C FA as a partial replacement for cement and fine sawdust (FSD) as an internal filler and curing agent admixture, the researchers attained a compressive strength of 10.8 MPa after 28 days of curing for the blended pervious concrete. This value was slightly lower than the compressive strength of 13.5 MPa attained by pervious concrete containing FA and Fe2O3 nanoparticles after the same duration of curing [130]. According to De Weerdt et al. [131], the adequate strength enhancement observed in pervious concrete with FA and FSD could be related to the gradual reaction of FA in the creation of calcium aluminate precipitates. In terms of flexural strength, the pervious concrete containing FA and FSD attained a strength of 4.167 MPa after 28 days of curing, surpassing the minimum requirement for parking lots (3.5–4.5 MPa) according to ACI 552R-10, [120]. This flexural strength was notably better than the outcomes reported by Muthaiyan and Thirumalai [70], for mixed pervious concrete with a 10% FA replacement rate, which could be attributed to their lower cement-to-aggregate ratio of 1:6.7. In another study, Peng et al. [38], evaluated the effect of FA and GGBS on the physical and engineering properties of pervious concrete. They found that both BFS and FA initially reduced the compressive strength of pervious concrete up to 28 days of curing due to the quicker hydration rate of cement compared to BFS and FA. However, pervious concrete containing BFS and/or FA exhibited comparable strengths at longer curing periods (60 days). FA had a more significant impact on strength at early curing stages compared to BFS, likely due to the different chemical compositions of FA and BFS. BFS contained a higher amount of CaO, creating a more favorable alkaline environment for pozzolanic action. Hence, FA exerted a stronger effect on early-age strength compared to BFS. Likewise, Babu et al. [40], reported that the combination of BFS and FA can enhance the strengths of pervious concrete. They found that the best tensile and compressive strengths were attained with 15% BFS and 20% FA, resulting in approximately 3.74 MPa and 29.48 MPa, respectively. Saboo et al. [69], investigated the influence of class-F FA and MK (up to 2%) as partial substitutions for cement in pervious concrete, along with the use of a superplasticizer as an admixture. They observed that the strength of pervious concrete raised with a growth in the amount of FA and MK. Overall, these studies demonstrate that the addition of FA, in combination with other materials or admixtures, can positively impact the engineering performance and strength of pervious concrete, although the specific effects may vary depending on factors such as curing time, substitution rates, and chemical compositions.

7.2. Influence of SF on mechanical properties of previous concrete

Several studies investigated the influence of SF on normal concrete. SF is utilized in normal concrete to enhance its performance. The addition of SF increases the speed and the rate of cement hydration at all stages of the curing time. Previous studies reported that SF increases compressive and durability performance, whereas reduces permeability [56,97]. They also found that by utilizing SF as a partial substitute for cement and due to its ultra-fine particles, the requirement of water increases, hence, they had to use superplasticizers to achieve the required workability. Moreover, they reported that the higher pozzolanic reaction and filling effect of SF resulted in lower porosity and permeability while increasing density and improving the strength of concrete. Because of the existence of extremely reactive amorphous silica, it can bond with CH to create C–S–H, which is the most significant hydration product that assures binding and strength performance in cementitious materials. In addition, with the substitution of cement for SF crack resistance of concrete improved due to decreasing permeability and porosity of concrete [132]. Despite several benefits, the main problem with the utilization of SF as a partial replacement for cement is its ultra-fine particles which could cause health risks as ultra-fine particles can easily get through the skin, lungs, and digestive tract [[133], [134], [135]]. On the other hand, by utilizing SF slurry using 50% weight of solid content, this problem is someway solved. Utilization of SF slurry reduces the difficulties confronted by workers to a specified limit from using it in the format of dry powder [136]. Thus, studies on normal concrete proved that SF can have an important role in the enhancement of the engineering performance of normal concrete by producing a denser interfacial transition area or by making a stronger cement paste component [97].

However, several researchers investigated the influence of adding SF in producing pervious concrete (Table 3, Table 4). Some of them indicated that using SF as a partial substitution for cement showed no impact on the mechanical properties of pervious concrete while making it denser [137]. Similar results were found by M.J. Chinchillas [138] in which the utilization of 10% SF resulted in the production of denser pervious concrete but no enhancement in strength properties. This might be due to the fact that CH was dissolved because of underwater curing and was unreachable for reactions with SF for enhancement of the compressive strength and improvement of mechanical properties [139].

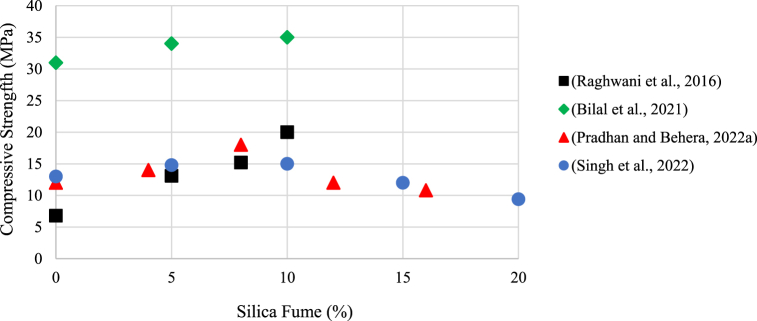

As can be seen from Fig. 9, some other works demonstrated that using SF up to 10% positively influenced the mechanical and durability performance of pervious concrete [76,85,90]. Yang and Jiang [140] and Bilal et al. [76], achieved the highest compressive strength (Fig. 5). Yang and Jiang [140] found that by utilizing 6% SF, 0.8% SP, and 20% fine aggregate in the production of pervious concrete, the compressive strength of 35 MPa (157% greater than the control mixture) and flexural strength of 6 MPa can be achieved. Bilal et al. [76], investigated the effects of adding SF on the properties and durability of pervious concrete. They reached the compressive strength of 35 MPa (16% greater than the normal mixture) by pervious concrete with 10% SF, 1.25% SP, and 5% fine aggregate. With increasing content of SF from 5% to 10% as cement replacement, the permeability was reduced by around 50% compared to the normal mixture. It might be due to the filler effect and pozzolanic activities of SF and MK. Liu et al. [141], conducted an experimental study on the mechanical and physical performance of pervious concrete and concluded that the optimum amount of SF is 5% with 0.5% SP and 0.26–0.3 water to binder ratio. Similar trends were reported by Raghwani et al., [90]. They investigated the influence of 5–10% of SF as cement replacement with constant water-to-binder ratio of 0.33 and fixed porosity of 20% on the mechanical properties of pervious concrete. They concluded that partial substitution of SF did not have a negative effect on permeability while increasing the compressive strength and abrasion resistance of pervious concrete. In this regard, the Compressive strength of 10% SF replaced pervious concrete increased by around 30%.

Fig. 9.

Influence of different percentages of SF on compressive strength of pervious concrete.

Some of the researchers tried to increase the amount of SF beyond 10% and investigated the behavior of pervious concrete. Pradhan and Behera [75], used cement 43 grade, SF which substitutes the cement by 4%–16%, with 9% sand and a fixed W/C ratio of 0.34. They found that 4–12% replacement of SF showed better strength compared to that of the control mix design. Haji et al. [108], evaluated the effect of 0–25% SF on the properties of pervious concrete. They indicated that with 5% replacement of cement by SF the permeability decreased while the compressive strength increased by 24% higher than that of control pervious concrete. However, with an increasing amount of SF up to 25% the compressive strength decreased by 44% compared to normal pervious concrete Singh et al. [85], evaluated the behavior of pervious concrete by substitution of 5, 10, 15, and 20% of cement by SF. They reported that permeability was reduced by replacing 5% SF and then increased with growing substitution levels. At the optimum level of 10% substitution, water permeability reduced from around 0.44 cm/s (normal mix) to 0.41 cm/s at 28 days of curing time which is completely proper for drainage [[142], [143], [144]]. In addition, it was reported that by using 5% and 10% of SF the compressive strength of pervious concrete increased by 16 and 18%, respectively at 28 days (Fig. 10). Similar trends were reported at 7 and 90 days. SEM images visibly displayed the creation of C–S–H gel, Ca(OH)2, CaCO3, and Ca6Al2(SO4)3(OH)12.26H2O in all mixtures (Fig. 8(a–c). The denser microstructure at a 10% substitution rate of cement with SF can be observed in Fig. 7 because of the creation of C–S–H gel compared with the normal mixture. It could be due to the exceedingly amorphous and extremely ultra-fine characteristic of silica, which boosts the pozzolanic activity by reacting with Ca(OH)2 resulting from the initial hydration process and increases the strength performance of the pervious concrete [136,145]. While by increasing the content of SF higher than 10%, the compressive strength of the pervious concrete decreased. At a 20% substitution rate with SF, poor spreading of excess SF particles occurred in the concrete mixtures (Fig. 11(d)). It could be due to the smaller size of the SF than cement, which makes the cement particles move apart, indicating to discharging of the system and resulting in the poor spreading of SF particles in the concrete mixtures. Leftover precipitated SF particles that did not take part in the chemical activity of the hydration process, leads to a decrease in the compressive strength Fig. 11(a–d).

Fig. 10.

Influence of different amounts of SF on compressive strength of pervious concrete [85].

Fig. 11.

SEM images of different pervious concrete mixtures at 28 days (a) 0% SF, (b) 5% SF, (c) 10% SF, (d) 20% SF [85].

Several studies tested the behavior of pervious concrete by using nano-silica (NS) or using several SCMs combined to improve the properties of pervious concrete. Mohammed et al. [88], assessed the effects of adding NS up to 3% on the behavior of pervious concrete incorporating FA up to 70% as a partial replacement for cement. Authors reported that by adding NS the strength performance of FA pervious concrete was enhanced without negatively affecting its permeability, porosity, and void ratio. It could be due to the fact that NS modifies the microstructure of the hardened cementitious paste and activates the reaction of FA. Alighardashi et al. [91], investigated the effectiveness of adding NS in pervious concrete on the subtraction of nitrate from polluted water. They found that with the substitution of NS up to 6% of cement weight the nitrate removal increased by around 35% compared to that of control pervious concrete. Liu et al. [110], investigated the effect of replacing 6% ground tire rubber and 12% SF as partial cement replacement on the various properties of pervious concrete. They indicated that using ground tire rubber and SF not only enhanced the deformability, strength, and fatigue life of pervious concrete but also created an appropriate pathway to increase the utilization of waste, environmental protection, and sustainable development. Arun and Chekravarty [114], tried to enhance the strength performance of pervious concrete by using micro-silica up to 20%. They found that with increasing the content of micro-silica the permeability and porosity of pervious concrete decreased. While it was reported that by using 10 and 20% of micro-silica the compressive strength of pervious concrete improved by 38 and 96%, respectively at 28 days.

7.3. Influence of GGBS on mechanical properties of previous concrete

Various studies investigated the influence of GGBS on the properties of normal concrete. They found that BFS mostly has an adverse impact on the early strength of concrete, while it could slightly increase the long-term strength [146] due to the slow hydration speed of GGBS. However, GGBS improved the resistance to chloride penetration. It could be due to that GGBS formed more C–S–H gels and enhanced the pore size distribution to adsorb more chloride ions and block distributing route [147,148].

Limited studies investigated the effect of GGBS on the performance of pervious concrete. Deepa Shri et al. [109], examined the properties of pervious concrete after replacing 20% of cement with GGBS. They showed that permeability and compressive strength decreased by 55% and 3.4% compared to the control specimen. Peng et al. [38], studied the effect of 20–30% GGBS as partial cement replacement on the properties of pervious concrete. It was observed that void content and permeability decreased with the incorporating of GGBS. Using 20 and 30% GGBS decreased the compressive strength of the pervious concrete slightly by 2.3% and 4.7% respectively compared to the control mixture. El-Hassan and Kianmehr [67], evaluated the properties of pervious concrete incorporating 50% GGBS. They found that adding 50% GGBS decreased the permeability due to the lower cementitious material content. It was observed that by replacing 50% of cement with GGBS the compressive strength and tensile strength decreased by 8.4% and 28% respectively at 28 days. They concluded that pervious concrete containing GGBS is more sustainable that improves heat island influence, decreases cost, and reduces carbon emissions by 54% compared to normal concrete.

Babu et al. [40], and Ho et al. [78], investigated the influence of using a combination of GGBS and FA as cement replacement on the properties of pervious concrete. Babu et al. [40], found that the compressive strength increased from 22.5 MPa for the control specimen to 29.5 for the specimen containing 15% GGBS and 20% FA. Ho et al. [78], investigated the effect of total substitution of cement with GGBS and co-fired FA on the properties of pervious concrete to reach the cementless pervious concrete. They indicated that the permeability of cementless pervious concrete was higher than that of control pervious concrete with 100% cement. Substitution of cement with GGBS and FA reduced the compressive strength by 10–20% compared to that of the control mixture. However, all cementless pervious concrete samples met the requirement of compressive strength and permeability for normal engineering applications, which are 1.5 MPa–14 MPa and higher than 0.01 cm/s respectively. They concluded that producing sustainable pervious concrete is possible by replacing cement with FA and GGBS to reduce carbon footprint, energy consumption, and air pollution.

7.4. Influence of MK on mechanical properties of previous concrete

Several researchers investigated the influence of MK on the performance of normal concrete [149,150]. They concluded that utilizing MK as partial cement replacement up to 10% in normal concrete increased density and strength while reducing void content. In addition, the carbonation resistance of concrete can be improved by adding MK due to the filler character of MK.

Various studies suggested to use of MK for enhancing the properties of pervious concrete and all of them achieved a similar trend that the addition of MK as a partial substitution of cement up to 15–20% improved the performance of pervious concrete (Fig. 12). Saboo et al. [69], investigated the effect of replacing cement with 2% MK on properties of pervious concrete incorporating FA. They reported that the porosity (by 10%) and permeability decreased while density increased with adding 2% MK compared to control specimens without MK. It could be because of the greater fineness of MK when compared to cement. It was found that adding MK increased the compressive strength of FA pervious concrete. Azad et al. [151], evaluated the effect of weather conditions and 5–25% MK on the properties of pervious concrete. It was shown that by adding 5–25% MK the void content increased by 0.3–0.36 for specimens that were cured in winter. It could be due to the cold climate that causes the freezing of MK. However, for specimens that were cured in spring the values of void content were like the control mixture. It was reported that when the amount of MK increased, the permeability of pervious concrete reduced slightly. They indicated that by adding 5 and 20% MK, the compressive strength of the pervious concrete raised from 10.7 MPa in the normal mix specimen to 11.1 MPa (4%) and 12.2 (14%) MPa, respectively. This might be because of the amorphous structure of MK that leads to a strong bond between cement and MK [152]. It was reported that adding MK had a negative influence on the compressive strength of the pervious concrete specimens which were cured in winter. while, for specimens cured in spring, with adding MK the compressive strength of the pervious concrete increased by 15% when compared to the control mixture. The compressive strength of specimens cured in winter containing 5, 10, 15, 20, and 25% MK was reduced by 12, 23, 28, 47, and 36% compared to the specimens cured in spring, respectively. It could be due to the reduction of pozzolanic and hydration activity of MK in low temperatures. The results from the study of Singh et al. [68], compressive strength of pervious concrete improved with using MK (Fig. 13). They indicated that by adding 20% of MK compressive, tensile, and flexural strength raised to 46, 67, and 25% respectively at 90 days. It could be due to the existence of a higher amount of SiO2 that causes the higher reaction of MK. With the increasing content of MK, the permeability of pervious concrete specimens decreased. It can be explained from SEM images of pervious concrete incorporating MK that illustrated greater forming of C–S–H gel, calcium carbonate, Ca(OH)2, and ettringites causing denser microstructure and better strengths by increasing the amount of MK. Moreover, the XRD images indicated similar observations that extra peaks of C–S–H gel are illustrated (Fig. 14(a–d)).

Fig. 12.

Effect of various percentages of SF on compressive strength of pervious concrete.

Fig. 13.

Compressive strength of specimens incorporating various amounts of MK [68].

Fig. 14.

SEM micrographs of various specimens (a) 0% MK, (b) 5%MK, (c) 20%MK, and (d) XRD -20%MK at 90 days [68].

Bilal et al. [76], examined the effect of 5% and 10% MK on the performance of pervious concrete. They found that with the increase in the amount of MK from 5% to 10%, the permeability of pervious concrete decreased by approximately 50% compared to that of the control specimen. However, the results also showed that the compressive strength of the pervious concrete increased from 33 MPa to 36 MPa with the increasing amount of MK from 5% to 10%, compared to the normal specimen strength of 30 MPa at 28 days. This improvement could be attributed to the higher pozzolanic reaction and filler influence of MK.

In addition, similar trends were reported by S. Bright Singh and Murugan, [96]. They found that the optimum mix design was the specimens incorporating 15% MK, which showed the highest increase in mechanical performance and enhanced the behavior of pervious concrete subjected to cyclic, impact, and static loads. It was observed that with an increase in the amount of MK from 5% to 20%, the density of pervious concrete increased, while void content and permeability decreased because of the filler effect of MK. The flexural, split tensile, and compressive strength of the optimum mix were found to be 18.70%, 15.26%, and 39.25% greater, respectively, than those of the control specimen. They indicated that using 15% MK, the ultimate load increased by 15.70% compared to the control mix. Moreover, adding 15% MK led to an 84.18% increase in total cumulative energy dissipation compared to that of the control specimen. Similar trends were observed for cyclic loading tests and crack resistance, which could be attributed to the strong bonding formation in the cement matrix. It can be concluded that the utilization of around 10%–15% of MK in pervious concrete improves the mechanical performance and durability behavior of pervious concrete and also helps in decreasing the utilization of cement.

8. Influence of ISMCs on the durability of pervious concrete

Limited studies have focused on examining the durability of pervious concrete incorporating industrial by-products or ISMCs. Singh et al. [68], evaluated the abrasion resistance of pervious concrete containing up to 20% FA based on mass loss. They found that as the content of FA increased, the abrasion resistance improved, resulting in a decrease in the percentage mass reduction. Similar findings were reported by Refs. [125,153]. These improvements in abrasion resistance can be attributed to the filler and pozzolanic properties of FA, as noted by Siddique, [128]. Furthermore, Rasiah [121], reported a 21% reduction in drying shrinkage after 56 days for pervious concrete specimens containing 50% FA. This decrease in shrinkage can be attributed to the substitution of cement with FA, which enhances the dimensional stability of pervious concrete. Aoki et al. [102], supported these findings. Nevertheless, Liu et al. [110], investigated the impact of FA on the freeze-thaw behavior of pervious concrete. They observed that pervious concrete incorporating 12% FA exhibited a 27.2% decrease in compressive strength after undergoing 50 freeze-thaw cycles. This decrease can be attributed to the reduction in aggregate bonding caused by the addition of FA. In summary, the limited studies available indicate that the integration of FA in pervious concrete can positively influence abrasion resistance, dimensional stability, and shrinkage. However, its impact on freeze-thaw performance may have adverse effects on the compressive strength due to reduced aggregate bonding. Further research is needed to explore the full extent of ISMCs' effect on the durability of pervious concrete. Bilal et al. [76], conducted a study on the effects of incorporating SF on the performance and durability of pervious concrete. The results revealed that increasing the SF content from 5% to 10% considerably enhanced the resistance to rapid freeze-thaw cycling and the mutual attack of calcium leaching and freeze-thaw cycling. They determined that the optimal amount of SCMs for achieving favorable durability behavior and engineering performance in pervious concrete was 10%. This improvement in durability can be attributed to the filler effect and pozzolanic activity of SF. Similarly, Raghwani et al. [90], reported a 40% increase in abrasion resistance by incorporating 8% SF. Pradhan and Behera [75], utilized cement grade 43, substituting 4%–16% of cement with SF, along with 9% sand and a fixed water-to-cement ratio of 0.34. They concluded that the addition of SF improved the freeze-thaw resistance of pervious concrete. Singh et al. [85], also observed that the abrasion resistance of pervious concrete was comparable to that of the normal mixture up to a 10% replacement with SF. However, beyond 10% replacement, the abrasion resistance was negatively affected, resulting in a significant increase in percentage mass loss. In summary, the incorporation of SF in pervious concrete can enhance durability by improving resistance to freeze-thaw cycling, abrasion, and the mutual attack of calcium leaching and freeze-thaw cycling. The optimal SF content and its impact on specific properties may vary, and careful consideration is required to balance the desired performance characteristics in pervious concrete.

Ho et al. [78], conducted a study on the durability of pervious concrete by completely substituting cement with GGBS and co-fired FA. The results showed that pervious concrete incorporating GGBS and FA exhibited higher resistance against chloride penetration and sulfate attack compared to the control mixture. The optimum mix design was determined to have a GGBS to FA ratio of 7:3. By replacing 100% of the cement with a combination of GGBS and FA, the content of C3A (tricalcium aluminate) in the concrete significantly decreased. Furthermore, the samples containing GGBS and FA experienced an increase in weight due to the formation of ettringite crystals when exposed to sulfate solution. This indicates that the incorporation of GGBS and FA can improve the durability of pervious concrete by reducing the susceptibility to chloride penetration and sulfate attack, and by promoting the formation of ettringite crystals. Singh et al. [68], indicated that the abrasion resistance of pervious concrete increased with an increasing content of MK. This observation can be explained by examining SEM images of the pervious concrete incorporating MK, which showed a greater formation of C–S–H gel, calcium carbonate, Ca(OH)2, and ettringites. These formations contribute to a denser microstructure, resulting in improved durability. The incorporation of MK up to 20% led to a denser microstructure and enhanced durability of the pervious concrete. In another study conducted by Bilal et al. [76], the effect of 5% and 10% MK on the durability performance of pervious concrete was examined. It was concluded that an increasing percentage of MK from 5% to 10% improved the freeze-thaw resistance of the pervious concrete. This improvement can be attributed to the filler effect of MK and the denser microstructure it creates in the concrete. Overall, the addition of MK contributes to the durability enhancement of pervious concrete by improving its resistance to abrasion and freeze-thaw cycles.

9. Priority recommendations for selecting ISMCs

When selecting ISMCs as cement replacements for pervious concrete with different strength grades, the choice should be based on several factors, including reactivity, particle size, chemical composition, and pozzolanic properties. Some priority recommendations for selecting these four ISMCs are shown at Table 5.

Table 5.

Priority recommendations for selecting ISMCs.

| ISMCs | Priority Recommendation | Reasons |

|---|---|---|

| SF | High |

|

| FA | High |

|

| MK | Medium |

|

| GGBS | Medium |

|

In summary, for pervious concrete with different strength grades, priority recommendations for selecting cement replacements are SF and FA due to their high reactivity and positive impact on strength and durability. MK and GGBS can also be considered but may require careful optimization and combination with other materials to achieve desired performance characteristics. Additionally, conducting further tests and research can help in making more informed decisions about the optimal replacement levels of these materials in pervious concrete mixtures.

10. Conclusions

This paper has attempted to cover a wide range of information so that the reader can better understand the effect of ISMCs on the properties of pervious concrete. Considering the characteristics of ISMCs and their behavior in the structure of pervious concrete will help decrease waste problems and cement consumption, promoting the utilization of waste materials in construction and reducing environmental pollution. The following conclusions can be derived based on the current review work.

-

●

FA is a byproduct of coal combustion, SF is a byproduct of the production of silicon and ferrosilicon alloys, GGBS is a byproduct of iron production, and MK is produced by calcining kaolin clay.

-

●

FA, SF, GGBS, and MK are all pozzolanic materials that show a hydraulic and pozzolanic reaction, which reacts with existing water and free calcium hydroxide (Ca(OH)2) to create C–S–H, similar to the process of cement hydration. This results in improved strength and durability of cementitious materials. SF has the highest reactivity among the four materials due to its small particle size and amorphous structure, leading to a rapid pozzolanic reaction. GGBS and FA have moderate reactivity, while MK has relatively low reactivity due to its crystalline structure. The pozzolanic activity of these materials also depends on their chemical composition, particle size distribution, and curing conditions. FA and GGBS typically contain higher amounts of alumina and silica, while SF and MK are mostly composed of silica.

-

●

The addition of FA to pervious concrete decreases the water permeability and void ratio of the concrete. The void content ranges from 13% to 35%, and the permeability varies from 0.03 cm/s to 1.3 cm/s for different FA content mixes. This can be attributed to the filler properties of FA and its pozzolanic action, which contributes to the creation of extra C–S–H gels. These gels help to reduce the total void content and permeability of the concrete. However, the utilization of FA as a partial substitution for cement results in a decrease in the early-age strength of the concrete due to reduced cement paste available to coat the coarse aggregates, leading to a weaker bond between the aggregates. Additionally, FA has higher water absorption, reducing the water available for cement hydration, resulting in incomplete cement hydration and lower final strength of the concrete.

-

●

The pace of strength gains in FA-modified concrete increases with curing age. The compressive strength of pervious concrete with FA falls within the acceptable range of 4 MPa–35 MPa, as recommended by ACI 552R-10. Some studies report an initial reduction in strength of up to 65% with a 40% FA replacement, but the strength increases with curing time. This can be explained by the presence of silica in FA, which helps in the formation of C–S–H gel and enhances the bond between the paste and aggregate. The optimum level of cement replacement with FA is found to be between 10% and 30%. However, when the level of replacement exceeds this optimum range (30–50%), the hydration process is negatively affected, resulting in slower strength gain and reduced strength.

-

●

The complex relationship between compressive strength and FA content opens new possibilities for engineering durable and resilient pervious concrete structures. Researchers have explored the use of superplasticizers and other admixtures to enhance the strength and performance of pervious concrete with FA. This innovative combination approach not only improves the early-age compressive strength but also provides the potential for optimizing long-term strength gain, making pervious concrete with FA suitable for various structural applications.

-

●

Moreover, the incorporation of other pozzolanic materials, such as fine sawdust or ground granulated blast furnace slag, in conjunction with FA offers an inductive approach to further enhance the engineering properties of pervious concrete. These blended materials create a synergistic effect, promoting better cement hydration, denser microstructure, and improved bonding between the aggregates and cementitious matrix. By exploring novel combinations of fly ash with other materials, researchers and engineers can unlock the full potential of pervious concrete as a sustainable, durable, and high-performance construction material.

-

●

SF's ultra-fine particles accelerate cement hydration and pozzolanic reactions, leading to reduced porosity, permeability, and improved density in both normal and pervious concrete. This contributes to improved compressive strength, crack resistance, and durability properties in pervious concrete.

-

●

According to the studies, the range of permeability and compressive strength for pervious concrete incorporating SF was found to be 0.56–2.28 cm/s and 3.1–35 MPa, respectively, which falls within the acceptable range for non-structural applications of pervious concrete. The addition of SF up to 10–12% reduced water permeability and porosity while enhancing the durability performance of pervious concrete. This improvement can be attributed to the filler effect of SF and its pozzolanic action, which contributes to the formation of C–S–H gel, leading to a denser microstructure and improved durability.

-

●