Abstract

This work investigates the effect of varying the knitting structure and stitch length (SL) on various thermo-physiological and ergonomic comfort properties of the occupational graduated compression socks. Thermo-physiological comfort, ergonomic comfort and dimensional stability of theses stockings were analysed in a comparative manner. Obtained results were evaluated statistically using the technique of analysis of variance (ANOVA). A Fisher's multiple comparison test was commissioned to analyze the relationship between the alteration of stitch length (SL) on various utility functions and properties desired in the occupational compression socks. In order to examine whether the difference of stitch length is significant, p values were determined. Further the influence of knitting structures e.g., plain, 2 × 2 Rib and 1 × 3 Rib was analysed on the selected properties. The interactive effect of both stitch length (SL) and knitting structure was studied using statistical techniques. It was concluded that knitting structure has a stronger impact on thermo-physiological and ergonomic comfort properties. Results showed a significant variation in thermo-physiological and ergonomic comfort by altering stitch length by means of the statistical analysis. An innovative approach for the manufacturers has been developed for optimizing performance in compression stockings. The construction of the compression socks can thus be optimized in terms of constructional parameters to provide optimum comfort to the users.

Keywords: Compression stockings (CS), Stitch length (SL), Knitting structure, Ergonomic comfort, Porosity, Thermo-physiological comfort

1. Introduction

Compression garments are specially designed clothing, containing elastomeric yarns which are used to apply significant amount of pressure on the selected body zones, where required. There are different compression garments available e.g., stockings, elastic bandages, pneumatic pumps and specialized garments [1]. Our modern lifestyle is causing many health issues in people. Persons involved in a standing or sitting position during day-to-day activities e.g., hairdressers, shop assistants, telephone operators etc. experience blood flow related problems in their lower limbs, causing venous diseases [2]. This occurs due to extravasation of fluid from the venules because of a steadily increasing venous pressure in the lower limbs of the body, owing to gravity [3]. Occupational postures adopted for longer time over a working day leads to symptoms such as pain, fatigue, tiredness and in later stages it is associated with venous diseases [4]. This results in reduction of productivity, increased work absenteeism and poor quality of life. In such cases, many people start using compression garments without consultations with doctors or specialists to make their work life easier [5]. These venous ulcers in legs may negatively impact the quality of life and their treatment is costly [6]. Using bandages requires a great deal of experience to achieve the required compression level. Also, there are chances of slippage of bandages which can cause adverse effects. The use of compression stockings/socks seems to be the best option in this regard. Graduated compression stocking commonly uses mechanical antithrombotic agents. They have proven efficacy in general application for activities related to occupation [[7], [8], [9], [10]]. These stockings enable professionals to perform their job diligently and without pain. Such stockings are called compression/preventive compression stockings. During long flights (prolonged sedentary time) also it has been suggested that wearing compression stockings might reduce the deep vein thrombosis (DVT) risk [11]. The compression stockings are made of Lycra-Polyamide blended knitted fabrics. Usually plain and Rib knitted structures are widely used as per available literature [[11], [12], [13], [14], [15]]. Industrial scale production of compression garments is done worldwide, and they need to be certified by the medical authorities [16,17]. It has been concluded that the compression stockings should have a smaller circumference than the body size. Pressure at the ankle region is always higher which gradually decreases along the direction of the leg to regulate the blood flow [[18], [19], [20], [21], [22]]. For the compression stocking a pressure higher than 20 mmHg is needed to improve the velocity of blood flow and the optimum pressure values at ankle is 18 mmHg. At the calf region, it should be14 mmHg, and at the knee region, the pressure should be 10 mmHg. For the lower and upper thigh regions it should be 8 mmHg [23,24]. The graduated compression stockings are classified into different types as circular knit stockings, flat bed knit stocking, net stocking, one way stretch stockings and their styles e.g., thigh length and below knee length [25]. Uneven or excessive pressure distribution of compression stockings can damage the skin especially in case of elderly people.

The physiological effect of compression stockings imparting variable pressures at different regions of the lower limbs was studied. It was concluded that compression stocking with mild pressure proved to be much more effective and sufficient for those who inactively stand and sit for long term during their daily activities [[26], [27], [28], [29]]. Researchers suggested that compression of tubular knitted compression socks decreases significantly as stitch length increases [30]. The influence of inlay yarn fineness, main yarn type, stitch length and fabric structure on extensibility and bursting strength of developed compression stocking was investigated [31]. The effect of construction parameters like type of inlay yarn, tension during yarn feeding, thickness, stitch density and areal density on the compression behaviour of medical grade stockings is also investigated [32].

It has become a bigger challenge for compression garment products to be more comfortable and acceptable to consumers. The side effects of compression stockings like skin irritations and discomfort are major factors limiting their usage. The literature reveals that different studies regarding compression properties were conducted, but comfort characteristics were not considered which need to be investigated for performance and functional needs of the end users. The wearing comfort in garments can be assessed subjectively (using human experts) or objectively (using devices in the laboratory). Subjective assessment of comfort is not reliable due to variability in opinion of the experts while objective assessment is based on scientific principles. Thermal as well as moisture management properties are essential for wearing comfort in knitted garments including compression stockings [[33], [34], [35], [36], [37], [38]]. Based on the available literature, the current study aims to explore the effect of different knitting structures and stitch length on thermo-physiological comfort, ergonomic comfort and dimensional stability of compression garments. This study investigates the comfort performance of compression stockings by relating the properties with the interaction the structure and stitch length. The significance of the influence is determined by using statistical analysis based on ANOVA. It aims to improve the comfort properties of compression stockings by integrating experimental and statistical analysis. This will help to fill the knowledge gap regarding the effect of varying knitting structure and stitch length on the functional performance of compression garments.

2. Materials and methods

2.1. Materials

In the current research, three types of yarns as shown in Fig. 1(a) were used. Main yarn or the ground yarn was made of 100% polyamide (PA) fibre. The plaiting yarn was a single covered yarn (SC) made of elastane (Lycra) and polyamide fibres. The double covered yarn (DC) made of elastane yarn and two coverings of PA yarns was used as the inlay yarn as shown in Fig. 1(b). In the present work, main yarn consisted of 48 multifilament of 100 % polyamide (PA6.6) fibers and the plaiting yarn was a single covered (SC) yarn where polyurethane (PU, Lycra®, Dupont, Wilmington, Delaware, USA) was used in the core and covered by polyamide multifilament (24 filaments). The double covered inlay yarn used Lycra® in the core and was covered by two layers of polyamide yarns as mentioned in Table 1. Linear densities of elastane PU (Lycra®) in core yarn of plaiting and inlay yarn are 20 Denier and 160 Denier respectively. The yarns were imported from USA.

Fig. 1.

Yarn descriptions (a) Yarn types, (b) Schematic yarn diagram.

Table 1.

Specifications of the yarns used.

| Parameters of the yarns | Plaiting yarn (Single covered) | Inlay yarn (Double covered) | The main/ground yarn |

|---|---|---|---|

| Overall yarn linear density (Denier) | 90 ± 2 | 322 ± 2 | 152 ± 2 |

| Linear density of top covering (Denier) | 72 ± 2 | 22 ± 2 | – |

| Linear density of bottom covering (Denier) | – | 22 ± 2 | – |

| Linear density of Elastane/Lycra (Denier) | 22 ± 2 | 162 ± 2 | – |

| Elastane/Lycra (%) | 7.79 | 55.84 | 0 |

| Nylon (%) | 92.21 | 44.16 | 100 |

| No. of filaments | 24 | 40 | 48 |

| Cross section | Round | Round | Textured |

| Orientation | POY | POY | POY |

| Colour | Raw white | Raw white | Raw white |

The yarn linear density was determined according to ASTM D1059-17 [39]. Microscope (Beck London 35288, Model 47) was used to count the number of mono-filaments, as per standard method. Yarn details are given in Table 1. Commercial samples of a compression stocking (Sockeye®, Shanghai, China) was used to check the stitch length. The commercial samples are also made of nylon and Lycra® and the structures were found to be plain, 2 × 2 Rib and 1 × 3 Rib knit.

2.2. Methods

2.2.1. Design of experiment

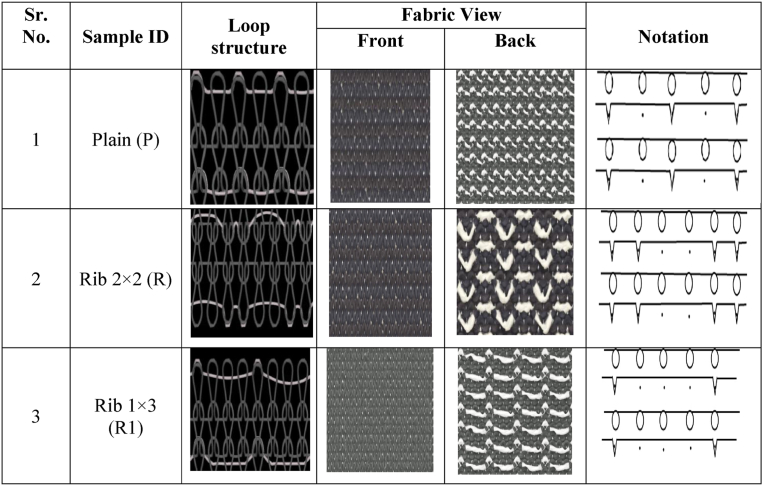

Samples of compression stockings (CS) were collected from (Sockeye®, Shanghai, China). The stitch length was analysed and was marked as standard stitch length (SL). The stitch length was varied to different levels to obtain tight, standard and slack structures as detailed in Table 2. Samples were made by following the standard stitch length (SL = 0.30 cm) which was measured from the available market sample. Then, 3 different knitting structures were made by increasing the stitch length by 0.02 cm (SL = 0.28 cm) higher than standard SL and then 3 samples were made by reducing the SL by 0.02 cm (SL = 0.32 cm). Compression stocking samples were prepared by using plain and rib structures (with long inlay yarns floating on the technical backside, to form a visual effect like rib structure). Table 3 shows the full-factorial design of experiment prepared by Minitab-21 (Minitab version-21, Pennsylvania, USA). The experimental design was made by using two factors, each at three levels. Two-level factorial design including 2000 experiment is the most widely used first order design [38]. In 32 full-factorial design, there are 9 (3 × 3) runs. 9 different samples were prepared by using the three types of structures e.g., Plain, 2 × 2 Rib and 1 × 3 Rib as mentioned in Table 3. The knitting structures were manufactured by using the alternate inlay yarn, as shown in Table 4 [39]. Samples codes are given in Table 3. The configurations/structures and the simulations of the fabrics were visualized by SDS-ONE, APEX vision platform (from Shima Seiki, Wakayama, Japan).

Table 2.

Factors and levels.

| No. | Factors | Levels | Level details | ||

|---|---|---|---|---|---|

| 1 | Structure | 3 | Plain knit (P) | 2 × 2 Rib (R1) | 1 × 3 Rib (R2) |

| 2 | Stitch length (cm) | 3 | Lower (0.28) | Standard (0.30) | Higher (0.32) |

Table 3.

Details of experiments/experimental layout.

| Experiment # | Sample code | Sample/name |

|---|---|---|

| 1 | PL | Plain (Stitch length lower) |

| 2 | RL | Rib 2 × 2 (Stitch length lower) |

| 3 | RL1 | Rib 1 × 3 (Stitch length lower) |

| 4 | PS | Plain (Stitch length standard) |

| 5 | RS | Mock Rib 2 × 2 (Stitch length standard) |

| 6 | RS1 | Mock Rib 1 × 3 (Stitch length standard) |

| 7 | PH | Plain (Stitch length higher) |

| 8 | RH | Mock Rib 2 × 2 (Stitch length higher) |

| 9 | RH1 | Rib 1 × 3 (Stitch length higher) |

Table 4.

Structure representation.

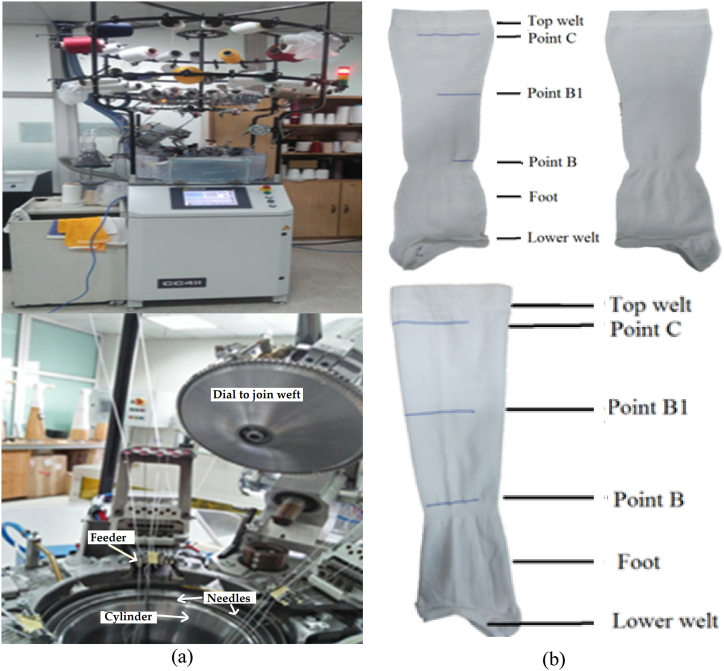

2.2.2. Stockings production

Compression stocking samples were prepared on Merz CC 411 (Merz Maschinenfabrik GmbH, Hechingen, Germany) knitting machine, with 24 gauge(E), 360 needles, 12 cm diameter and 4 feeder's machines including two furnishers. This machine is shown in Fig. 2(a). In the beginning, the machine forms 2–3 courses and then the graduated pressure region starts to manufacture as per programming. The formation of portions C, B and B1 shown in Fig. 2(b)–is completed according to the set parameters in the program. After completion of graduated compression parts, the foot region is knitted. Labelling of different parts in the samples were done as shown in Fig. 2(b). For production of Rib knitted samples, different machine of the same make (Merz Maschinenfabrik GmbH, Hechingen, Germany) was used with 180 cylinder needles and 180 dial needles, 24 gauge(E),12 cm diameter and 4 feeders. This research emphasizes on the stitch length variation to develop the compression stockings. The samples were developed by keeping stitch length (SL) 2.8 mm at point B, 3.0 mm at point B1 and 3.2 mm at the compression point C in all the three selected structures like plain, 2 × 2 Rib and 1 × 3 Rib. These levels were considered as a lower, standard, and higher SL respectively with the difference of ±0.2 mm. To maintain the compression for all developed stockings, the feeding tension for insertion of inlay yarn was adjusted accordingly.

Fig. 2.

Machine descriptions (a) Compression stocking machine, (b) Labelled samples.

The stocking samples were dipped in a detergent solution for 5 min. They were left in the solution for about 5 min and then washed with running water. After that the samples were squeezed to remove extra water. Finally, the samples were dried for 24 h in open air. The washing and drying process was carried out at temperature 22 ± 2 °C, and 65 ± 2% relative humidity.

2.2.3. Compression measurement

All the stockings samples were verified as class 1 (18–23 mm.Hg, as per German standard (RAL GZ 387) [40]. The apparatus used for the test is MST MK V, SWL, Medical Stocking Tester (from Swisslastic Ag., St. Gallen, Switzerland). Pressure at points B, B1 and C were measured after placing the stocking on dummy leg as shown in Fig. 3(a). The pressure values were noted in mm.Hg. The reduction of compression was under the gradual compression rule in a graduated compression stocking for a steady upward flow of blood. The effective pressure of stockings is evaluated at ankle position (B).

Fig. 3.

Measurement of compression stockings (a) Pressure measurement, (b) Graduated compression pressure at point B (1 mm.Hg = 133.3 Pa).

At ankle (B) required pressure in percentage should be 100%, and it gradually decreases from the ankle towards thigh, at point B1, where the pressure range should be 70–100%, at C it should be 50–80% [39]. Each sample was tested thrice, and their mean and standard deviation was calculated. The pressure value at point B was analysed to check the visual trend. The compression for all the samples was measured under standard conditions e.g., temperature 22 ± 2 °C, and 65 ± 2% relative humidity. Fig. 3(b) shows pressure values for the different samples at point B. All the compression values for the samples were found to be within compression class 1 (i.e., 18–23 mm.Hg as per German standard, RAL GZ 387). With lower stitch length, maximum compression was observed in case of 1 × 3 Rib structures. For standard stitch length, 2 × 2 Rib structures exert maximum compression due to tighter construction as compared to other structures. Further with higher stitch length, 1 × 3 Rib structures showed maximum compression. The compression performance is a combined effect of stitch length and knit structure which must be optimized to achieve tighter construction.

2.2.4. Testing physical and physiological attributes

Fabric thickness, weight/area, dimensional stability, thermo-physiological and ergonomic comfort performance were tested for all stocking samples.

2.2.5. Physical properties

Physical attributes of all stocking samples e.g., thickness and areal density (mass/unit area) were measured. Thickness was checked by a thickness tester (of model 99–0697), from Framincham, MA, USA as per standard ASTM D 1777 [41]. Areal density was measured by using a GSM cutter (of model JH-10-36) from Jenhaur Co. Ltd., Taipei, Taiwan) according to ASTM D 3776 [40]. Each of the parameters was measured ten times and the mean values are reported.

2.2.6. Dimensional stability

Dimensional changes in percentage were calculated as per standard AATCC 150 [42]. All the stocking samples (after washing) were tested in the circumferential/transversal direction. The stretch% and recovery% are important characteristics for required compression and fit. Fabric stretch is very important property relating to comfort. Extra stretch will lead to irritation and skin rashes. Clothing ergonomics other than subjective assessment can be investigated objectively by considering clothing elasticity. Most important requirement of ergonomic wear comfort is to allow freedom of body movement and to maintaining the shape of the body. An optimum stretch level is required in compression stockings for supporting optimum blood flow. The stretchability is the extension under a pre-determined load, while elasticity is the ability to recover after removal of the load. Both these parameters determine dimensional stability in compression stockings. Fabric stretch was checked as per ASTM D 2594 standard using CETME stretch tester (of model VIA A MORO 17) from Attrezzature Per Calzific Reggio EM, Italy, [43].

2.3. Physiological attributes

2.3.1. Air permeability

SDL Atlas air permeability tester (M 021A), from South Carolina, USA was used for this measurement according to international standard ISO-9237 [44] by setting 100 Pa pressure at 20 cm2. AP was measured for ten specimens of each fabric category and the mean was reported.

2.3.2. Thermal resistance

The thermal resistance (TR) of stocking samples was determined on Alambeta apparatus (from Sensora, Liberec, Czechia) by following standard ISO-11092 [45]. This instrument is widely used for measurement of thermo-physical properties (e.g., thermal conductivity and thermal insulation). Thickness is also measured by this device. The sample is placed between two plates connected to thermocouples and temperature sensors. Both measuring heads are equipped with thermocouples and so-called heat flow sensors. Lower plate is at room temperature while the upper plate can be set at variable temperatures. It measures a time-dependent transient heat flow through the thickness of the sample. Each of the parameters was measured ten times and the mean values are reported.

2.3.3. (OMMC)- overall moisture management capacity

The ability of the material to absorb moisture and transform in it into vapor is termed as Overall Moisture management capacity (OMMC). This test was carried out by following international standard AATCC – 195–2009 [46] using the MMT (Moisture Management Tester) from SDL Atlas, South Carolina, USA. The results were expressed in terms of overall moisture management capability (OMMC). The moisture management tests were conducted under standard conditions e.g., temperature 22 ± 2 °C, and 65 ± 2% relative humidity. The mean value of 10 measurements was reported.

2.3.4. Vertical wicking (VW)

Vertical wicking in wale and course directions were measured using AATCC 197–2013 test method from American Association of Textile Chemists & Colourists [47]. The fabric samples were conditioned at temperature 22 ± 2 °C, and 65 ± 2% relative humidity before the wicking tests were conducted. Rectangular samples of the stockings were cut in wale and course directions with dimensions (200 mm × 25 mm). The fabric samples were vertically hung into a bath of distilled water with one of the ends dipping up to 20 mm. A weight of 4 g was applied by using clips to the end of sample dipping inside water. The capillary rise of water in the stocking samples was measured after 5 min. The mean value of 10 measurements each in wale and course direction was reported.

2.3.5. Relative water vapor permeability (RWVP)

PERMETEST equipment (from Sensora, Liberec, Czechia) was used to measure relative water vapor permeability of the samples by following standard ISO 11092:1993 [48]. The device is based on heat flux sensing principle. The samples are kept on the measuring head which is covered by a semi-permeable foil. Air is blown at a speed of 1 m/s, parallel to the sample. Isothermal condition (room temperature of 22 ± 2 °C) is maintained for the measuring head. Heat loss is caused by the flow of water through the measuring head. The heat loss is calculated both when the measuring head is empty and when it is covered with the sample. Relative water vapor permeability (RWVP) was determined by calculating the percentage of heat loss when measuring head is covered by fabric (qs) with respect to heat loss when it is empty (qo). The calculation is shown in Eqn. (1).

| (1) |

The mean value of 10 measurements was reported.

2.3.6. Statistical analysis of data

Minitab-21 statistical software (developed by Minitab, Pennsylvania, USA) was used to conduct analysis of variance (ANOVA) in order to determine the significance of identified variables.

In the current research, first the influence of stitch length (SL) and knit structure on different responses like physical, thermo-phycological, extensibility and dimensional stability was quantified and analysed by ANOVA technique along with comparative Fisher's method. If a p-value of less than 0.05 (or p < 0.05) was obtained, then it was regarded to be statistically significant. Further, interval plots were used to compare the groups of samples. The interval plots display 95% confidence interval for the mean result in each group of stocking samples. The interactive effects of knitting structure and stitch length were also plotted to understand the combined effect of these construction parameters on the comfort and performance of compression stockings.

3. Results & discussions

ANOVA Fisher's response table of all the parameters were prepared for analysing the effect of stitch length. For a specific parameter, p-value of less than 0.05 implies a statistically significant influence on the output performance within 95% confidence interval.

3.1. Physical properties

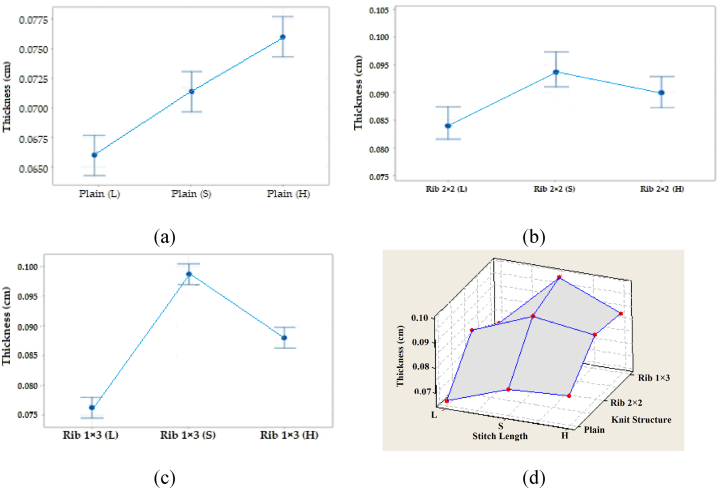

3.1.1. Influence of construction parameters on thickness

All the developed structures have different thickness owing to differences in the shape of loops. Thickness of 2 × 2 Rib is highest among all structures followed by 1 × 3 Rib because of yarn accumulation at tuck positions. In the same manner, in 1 × 3 Rib fabrics, the thickness increased due to longer float of yarn, on reverse side of the fabric. In Rib knitted structures, it was observed that samples with standards SL have highest thickness followed by higher SL and lower SL respectively. However, it is not the case in plain knitted structures. Table 5 shows that SL has a highly significant effect on thickness of 1 × 3 Rib structure (F-value = 248.49, p-value = 0.000). Fisher's comparison results also show that the mean responses of standard, higher and lower SL are significantly different. 1 × 3 Rib with standard SL had the largest effect followed by higher and the lower SL which had the least effect on thickness. In 2 × 2 Rib structure, SL showed insignificant effect on thickness (F-value = 2.07, p-value = 0.207). This can be due to a balanced and self-compensating structure in Rib 2 × 2. The lower, standard, and the higher SL have similar responses that are shown by assigning the same grouping/letter A to each sample. Within a variation of 0.25 mm in stitch length, there is no significant change in thickness. SL in plain structure has a significant effect on thickness (F-value = 61.23, p-value = 0.000). Fisher's comparison shows that mean response of standard and higher SL are insignificantly different (A), while plain structure with lower SL shows medium difference (B).

Table 5.

Result summary & ANOVA table for thickness (cm).

| Variable | Type | Factor | Mean | Grouping | Source | Degrees of freedom | Adjusted Sum of Squares | Adjusted Mean Sum of Squares | F Value | P Value | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness (cm) | Plain | Lower | 0.0660 | B | Error | 6 | 0.000009 | 0.000001 | |||||

| Plain | Standard | 0.0747 | A | Factor | 2 | 0.000177 | 0.000088 | 61.23 | 0.000 | S** | |||

| Plain | Higher | 0.0760 | A | Total | 8 | 0.000186 | |||||||

| Rib 2 × 2 | Lower | 0.0840 | A | Error | 6 | 0.000207 | 0.000034 | ||||||

| Rib 2 × 2 | Standard | 0.0937 | A | Factor | 2 | 0.000143 | 0.000071 | 2.07 | 0.207 | ||||

| Rib 2 × 2 | Higher | 0.0900 | A | Total | 8 | 0.000350 | |||||||

| Rib 1 × 3 | Lower | 0.0762 | C | Error | 6 | 0.000009 | 0.000002 | ||||||

| Rib 1 × 3 | Standard | 0.0987 | A | Factor | 2 | 0.000345 | 0.000377 | 248.49 | 0.000 | S** | |||

| Rib 1 × 3 | Higher | 0.0880 | B | Total | 8 | 0.000354 | |||||||

S**(Significant).

This situation is also visible from interval plots shown in Fig. 4(a–c). The interval plots and 95% confidence interval of thickness are shown in Fig. 4 (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3. Fig. 4(d) presents the interactive plot.

Fig. 4.

Interval plot of fabric thickness (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3 and (d) Interactive plot.

When the SL was reduced, thickness reduced due to more compact structure. While in case of increasing SL, the overlapping of the loop also increased and thus increasing the thickness. Thickness is increased due to contraction of the loops by the Lycra based yarn [49].

In case of plain knitted fabrics, there is an increase of thickness with increase in stitch length and there is decrease in compactness. However, in Rib knitted structures the thickness is highest for the standard stitch length. With increase and decrease of stitch length, the fabric becomes compact and the thickness decreases. The interactive plot in Fig. 4(d) also shows the combined effect of knitting structure & stitch length on thickness. It shows that the combination of standard stitch length with 1 × 3 Rib knitted structure results in maximum thickness.

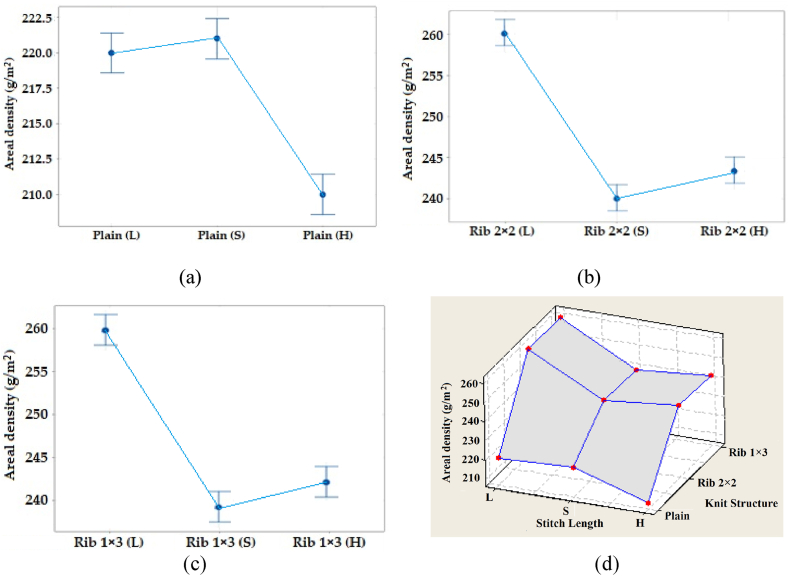

3.1.2. Influence of construction parameters on areal density (g/m2)

Table 6 shows that areal density (weight per unit area) has the highly significant effect in 1 × 3 Rib (F-value = 504.14, p-value = 0.000). Fisher's comparison results also show that the mean responses of lower, standard, and higher SL are significantly different. Lower SL has the largest effect followed by higher SL and the standard SL has the least effect on areal density. In plain knitted structure, Fisher's comparison shows that mean response of standard and lower SL are similar as shown by assigning same letter A to each of the cases.

Table 6.

Result summary & ANOVA table for areal density (g/m2).

| Variable | Type | Factor | Mean | Grouping | Source | Degrees of freedom | Adjusted Sum of Squares | Adjusted Mean Sum of Squares | F Value | P Value | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Areal density (g/m2) | Plain | Lower | 220 | A | Error | 6 | 6 | 1 | |||||

| Plain | Standard | 221 | A | Factor | 2 | 222.000 | 111.00 | 111 | 0.000 | S** | |||

| Plain | Higher | 209 | B | Total | 8 | 228 | |||||||

| Rib 2 × 2 | Lower | 260 | A | Error | 6 | 6.67 | 1.111 | ||||||

| Rib 2 × 2 | Standard | 240 | C | Factor | 2 | 688.889 | 344.444 | 310.00 | 0.000 | S** | |||

| Rib 2 × 2 | Higher | 243 | B | Total | 8 | 695.556 | |||||||

| Rib 1 × 3 | Lower | 260 | A | Error | 6 | 4.667 | 0.778 | ||||||

| Rib 1 × 3 | Standard | 239 | C | Factor | 2 | 784.22 | 392.11 | 504.14 | 0.000 | S** | |||

| Rib 1 × 3 | Higher | 242 | B | Total | 8 | 788.889 | |||||||

S**(Significant).

With increase in tuck stitches, there is yarn accumulation at tuck positions and thus an increase in fabric weight. For plain knitted samples, the inlay yarn is tucked in alternate wales. For the 2 × 2 Rib knitted samples, tucking of inlay yarn occurs in two successive wales and there is a float in the next two successive loops. For 1 × 3 Rib samples, there is tucking of the inlay yarn in a wale and there is a continuous float for the next three successive loops. Due to thicker dimensions, the tuck stitched fabric is heavier while miss stitched fabric has lower weight [50].

From Table 6 as well as Fig. 5(a–c), it is apparent that, for stitch length lower than standard SL, the weight of the 2 × 2 and 1 × 3 Rib structured fabrics are relatively higher due to a higher stitch density (no. of loops/unit area). In case of higher SL than standard, the fabric weight slightly increased, instead of decreasing similar to the reported literature [51]. This is because of the Lycra component which helps in compacting of the loops in the fabric. The results show that there is more significant influence of Lycra yarn in case of knitted structures as compared to the influence of SL.

Fig. 5.

Interval plot for areal density (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3 and (d) Interactive plot.

The interval plots and 95% confidence interval of areal density are shown in Fig. 5 (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3. Fig. 5(d) presents the interactive plot.

In case of plain knitted structure, the maximum areal density was observed for standard stitch length. Increase or decrease in stitch length causes decrease in areal density due to looseness of the structure. It is more prominent in case of longer stitch length. However, in case of Rib knitted structures, the highest areal density was observed with minimum stitch length owing to compactness of the fabric. The interactive plot in Fig. 5(d) also shows the combined effect of knitting structure & stitch length on areal density. It shows that the combination of lower stitch length with 2 × 2 & 1 × 3 Rib knitted structures results in maximum areal density.

3.2. Dimensional stability

3.2.1. Influence of construction parameters on shrinkage%

Dimensional stability (DS) in textile structures refers to the ability to retain the original dimensions through the fabric manufacturing process as well as during use by the customer. It is a very important parameter with respect to shape stability, especially after washing. The fabric shrinks or expands during washing, based on the change in the loop length. However, magnitude of change in dimensions depends on shape of the loops. All the three types of structures were susceptible to shrinkage which is visible from Table 7. Lycra yarn causes significant shrinkage in the width direction of the fabric. The shrinkage of less than +5% is not considered to be significant [52]. So, the shrinkage in all the developed structures is within acceptable limit, which implies that compression stockings can sustain the dimensional stability during use.

Table 7.

Result summary & ANOVA table for shrinkage%.

| Variable | Type | Factor | Mean | Grouping | Source | Degrees of freedom | Adjusted Sum of Squares | Adjusted Mean Sum of Squares | F Value | P Value | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Shrinkage% | Plain | Lower | 2.22 | A | Error | 6 | 118.60 | 19.76 | ||||

| Plain | Standard | −2.50 | A | Factor | 2 | 118.70 | 59.36 | 3 | 0.125 | |||

| Plain | Higher | −6.66 | B | Total | 8 | 237.30 | ||||||

| Rib 2 × 2 | Lower | −28.10 | A | Error | 6 | 2633.00 | 438.90 | |||||

| Rib 2 × 2 | Standard | −1.31 | A | Factor | 2 | 1206.00 | 603.10 | 1.37 | 0.323 | |||

| Rib 2 × 2 | Higher | −6.66 | A | Total | 8 | 3840.00 | ||||||

| Rib 1 × 3 | Lower | −7.14 | B | Error | 6 | 0.00 | 0.00 | |||||

| Rib 1 × 3 | Standard | 0.00 | A | Factor | 2 | 101.96 | 50.98 | 1529388 | 0.000 | S** | ||

| Rib 1 × 3 | Higher | 0.00 | A | Total | 8 | 101.96 | ||||||

S**(Significant).

1 × 3 Rib structured stockings have better DS, as compared to other two structure. Due to longer float length, shape of the loops after washing has not changed much. Consequently, the samples show high DS. Shrinkage of fabric varies with the change of SL. More compact structure in case of standard SL due to overlapping of loops restricts the movement, leading to lower extensibility. Due to lower extensibility, changes in dimensions of the stockings are lower [53].

Table 7 and Fig. 6(a–c) show that SL has a highly significant effect on shrinkage of 1 × 3 Rib (F-value = 1529388, p-value = 0.000).

Fig. 6.

Interval plot of Shrinkage% (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3 and (d) Interactive plot.

Fisher's comparison results also show that the mean response of lower SL is different from standard and higher SL. Plain knitted structure shows insignificant effect on shrinkage (F-value = 3, p-value = 0.125). The 2 × 2 Rib structure shows (F-value = 1.37, p-value = 0.323), which also indicates an insignificant effect. Rib 2 × 2 with lower, standard and the higher SL have similar responses that are shown by assigning the same letter A to each. Fisher's comparison shows that mean response of standard and lower SL are insignificantly different (A), while higher SL shows medium difference (B).

The interval plots and 95% confidence interval of shrinkage% are shown in Fig. 6 (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3. Fig. 6(d) presents the interactive plot.

For plain knitted structures, shrinkage% decreases linearly with the increase in stitch length. As yarn length in each loop is increased, the fabric becomes more stable dimensionally. Rib knitted structures are more balanced and lower stitch length results in lower shrinkage. The interactive plot in Fig. 6(d) also shows the combined effect of stitch length and knit structure on shrinkage%. It shows that the combination of standard stitch length with 2 × 2 & 1 × 3 Rib knitted structures result in zero shrinkage indicating better stability.

Influence of construction parameters on stretch%

Stretch/extensibility is important for ergonomic comfort. From Table 8, it can be seen that 2 × 2 Rib structure exhibits highest stretch% followed by Plain structured stockings. As compared to miss stitches, the tuck stitches make the fabric more stretchable. Therefore, 1 × 3 Rib structure shows minimum stretch due to yarn floats connecting the wales in a compact manner and thus reduces extensibility. It makes the overall structure stable which can be seen from recovery% of samples [54]. The behaviour is depicted in Table 8 and Fig. 7(a–c). There is increase in stretch% as SL increases. Lycra yarn always enables the knitted fabrics to be more extensible.

Table 8.

Result summary & ANOVA table for stretch%.

| Variable | Type | Factor | Mean | Grouping | Source | Degrees of freedom | Adjusted Sum of Squares | Adjusted Mean Sum of Squares | F Value | P Value | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stretch% | Plain | Lower | 180.00 | B | Error | 6 | 2.6 | 0.40 | |||||

| Plain | Standard | 63.73 | C | Factor | 2 | 28590.3 | 14295.10 | 32398.95 | 0.00 | S** | |||

| Plain | Higher | 186.33 | A | Total | 8 | 28592.9 | |||||||

| Rib 2 × 2 | Lower | 185.71 | B | Error | 6 | 2.9 | 0.50 | ||||||

| Rib 2 × 2 | Standard | 65.03 | C | Factor | 2 | 32986.5 | 16493.20 | 34191.53 | 0.00 | S** | |||

| Rib 2 × 2 | Higher | 200.00 | A | Total | 8 | 32989.4 | |||||||

| Rib 1 × 3 | Lower | 169.0 | B | Error | 6 | 1.5 | 0.30 | ||||||

| Rib 1 × 3 | Standard | 62.50 | C | Factor | 2 | 23374.6 | 11687.32 | 45283.91 | 0.00 | S** | |||

| Rib 1 × 3 | Higher | 172.00 | A | Total | 8 | 23376.1 | |||||||

S**(Significant).

Fig. 7.

Interval plot of stretch % (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3 and (d) Interactive plot.

Table 8 shows that SL has the highest significant effect on stretch% of 1 × 3 Rib (F-value = 41931.87, p-value = 0.000). Fisher's comparison results also show that the mean responses of lower, standard and higher SL are significantly different. Fisher's comparison shows that for all the knitted structures, the responses of lower, standard and higher SL are significantly different. The differences are shown by assigning different letters to each. The interval plots and 95% confidence interval of stretch% are shown in Fig. 7 (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3. Fig. 7(d) presents the interactive plot.

In all the structures, minimum stretch was observed for the standard stitch length owing to a stable structure. The interactive plot in Fig. 7(d) also shows the combined effect of knitting structure & stitch length on stretch%. It shows that the standard stitch length results in minimum stretch% in all knitted structures. With increase or decrease in stitch length, the stretch% increases in all the structures due to loose construction and a decrease in inter-yarn friction.

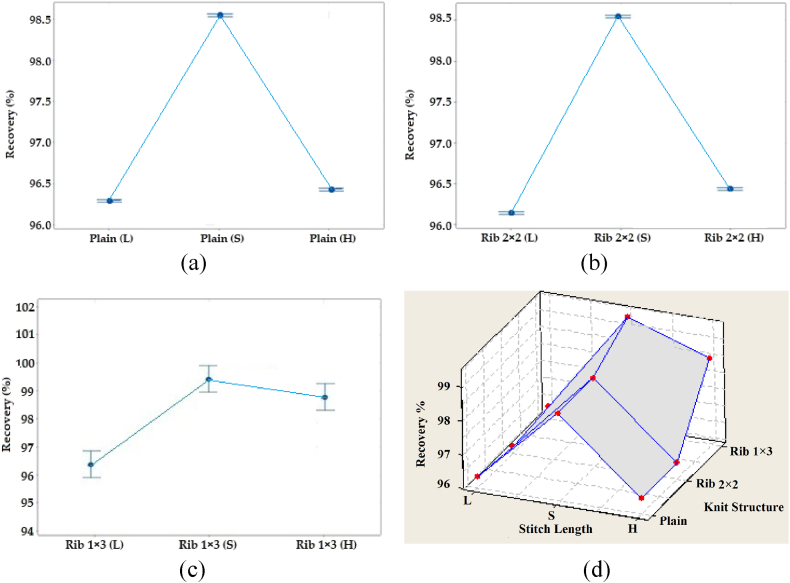

3.2.2. Influence of construction parameters on recovery%

It can be observed from Table 9 that Rib 1 × 3 structure has maximum recovery% as mentioned before. It can be ascertained that the recovery% in the knitted fabrics is improved by Lycra yarn. This happens because of the Lycra yarn holding the loops tightly which ultimately increases the compactness [55].

Table 9.

Result summary & ANOVA table for recovery%.

| Variable | Type | Factor | Mean | Grouping | Source | Degrees of freedom | Adjusted Sum of Squares | Adjusted Mean Sum of Squares | F Value | P Value | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Recovery% | Plain | Lower | 96.29 | C | Error | 6 | 0.00087 | 0.00014 | |||||

| Plain | Standard | 98.55 | A | Factor | 2 | 9.63216 | 4.81608 | 33342.08 | 0.00 | S** | |||

| Plain | Higher | 96.42 | B | Total | 8 | 9.63302 | |||||||

| Rib 2 × 2 | Lower | 96.15 | C | Error | 6 | 0.0009 | 0.00014 | ||||||

| Rib 2 × 2 | Standard | 98.55 | A | Factor | 2 | 10.3396 | 5.16981 | 35791.00 | 0.00 | S** | |||

| Rib 2 × 2 | Higher | 96.42 | B | Total | 8 | 10.3405 | |||||||

| Rib 1 × 3 | Lower | 96.29 | B | Error | 6 | 10 | 1.667 | ||||||

| Rib 1 × 3 | Standard | 99.35 | A | Factor | 2 | 27.53 | 13.764 | 8.26 | 0.02 | S** | |||

| Rib 1 × 3 | Higher | 98.51 | A | Total | 8 | 37.53 | |||||||

S**(Significant).

The Fisher's test results demonstrate that all samples have significantly different recovery % with the exception of 1 × 3 Rib standard and higher SL samples. The interval plots and 95% confidence interval of recovery% are shown in Fig. 8 (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3. Fig. 8(d) presents the interactive plot.

Fig. 8.

Interval plot of recovery % (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3 and (d) Interactive plot.

In all the structures, maximum stretch recovery was observed for the standard stitch length owing to a stable structure. Recovery is reduced due to inadequate length of yarn available in case of a shorter/longer loop and an imbalanced knit pattern is obtained. The interactive plot in Fig. 8(d) also shows the combined effect of knitting structure & stitch length on recovery%. It shows that the recovery is about 99% for standard stitch length in case of all knitted structures. For lower stitch length there is a decrease in recovery due to rigidity of loop structure.

3.3. Thermo-physiological comfort

3.3.1. Influence of construction parameters on air permeability (AP)

Air permeability significantly affects the wearing comfort of compression stockings. Air flow through fabric is affected by various factors including porosity. It is well known that overall porosity consists of two main components, one is void/space between fibers of the yarn and other is space between yarns of the fabrics. In the present study, as all samples are made from same type of fiber and yarn with different SL and structure, so difference of air flow is mainly because of void/spaces between yarns of the fabric. This type of structure ultimately affects the AP because the spaces in loops differ in different knitted structures. The structures were different from each other by different patterns of inlay yarn. From Table 10, it can be seen that the samples made with 2 × 2 Rib structure showed the highest value of AP followed by 1 × 3 Rib structure. Samples made from plain structure showed the least values of AP. The number of tuck stitches equals the number of miss stitches of inlay yarn in samples of plain and 2 × 2 Rib structure. However, the arrangement of such stitches in the structures ultimately affects the AP results. More tuck stitches in a course make the fabric more porous. The pore volume and pore size significantly affect the passage of air through knitted structures. 1 × 3 Rib structure includes one loop of inlay yarn and then a long float over three successive loops. Therefore, the freely floating yarn on the fabric can bring consecutive groups of wales closer which in turn reduces the AP [56].

Table 10.

Result summary & ANOVA table for air permeability (cm3/s/cm2).

| Variable | Type | Factor | Mean | Grouping | Source | Degrees of freedom | Adjusted Sum of Squares | Adjusted Mean Sum of Squares | F Value | P Value | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Air permeability (cm3/s/cm2) | Plain | Lower | 540.00 | B | Error | 6 | 12.17 | 2.03 | |||||

| Plain | Standard | 534.00 | C | Factor | 2 | 3700.48 | 1850.45 | 911.94 | 0.00 | S** | |||

| Plain | Higher | 580.00 | A | Total | 8 | 3713.07 | |||||||

| Rib 2 × 2 | Lower | 626.67 | C | Error | 6 | 7.33 | 1.22 | ||||||

| Rib 2 × 2 | Standard | 629.00 | B | Factor | 2 | 8494.89 | 4247.44 | 3475.18 | 0.00 | S** | |||

| Rib 2 × 2 | Higher | 687.00 | A | Total | 8 | 8502.22 | |||||||

| Rib 1 × 3 | Lower | 577.00 | C | Error | 6 | 4.7 | 0.7 | ||||||

| Rib 1 × 3 | Standard | 589.00 | B | Factor | 2 | 19554.9 | 9777.44 | 12571.5 | 0.00 | S** | |||

| Rib 1 × 3 | Higher | 682.00 | A | Total | 8 | 19559.6 | |||||||

S**(Significant).

With respect to SL, samples with higher SL exhibit higher AP values, while sample with standard and lower SL show lower AP value as given in Table 10. Increasing SL reduces the stitch density and compactness and thus the AP is increased. As the SL increases, it increases the spaces between adjacent loops and the structure becomes loose. This allows air to pass easily through the knitted compression stocking structure [57].

Table 10 shows that SL had a highly significant effect on AP of 1 × 3 Rib (F-value = 12571.5, p-value = 0.000 followed by 2 × 2 Rib (F-value = 3475.18, p-value = 0.000). Fisher's comparison results also show that the mean response of the Standard SL is significantly different from higher & lower SL in all samples. The interval plots and 95% confidence interval of air permeability are shown in Fig. 9 (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3. Fig. 9(d) presents the interactive plot.

Fig. 9.

Interval plot of AP (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3 and (d) Interactive plot.

With increase in the stitch length, there is an increasing trend in the air permeability of all the knitted structures due to more openness of the geometry. The interactive plot in Fig. 9(d) also shows the combined effect of knitting structure & stitch length on air permeability. Furthermore, the Rib constructions allow more airflow as compared to plain knitted structures due to more openness of structure.

3.3.2. Influence of construction parameters on OMMC

Overall moisture management capability (OMMC) is important for wearing comfort characteristics of consumer textiles e.g., occupational compression stockings. The flow of moisture through knitted fabrics is governed by wetting and wicking phenomena. When the fabric gets wet, the capillary channels between fibers help in wicking of water. Wetting, wicking and later on drying or vapor transmission are critical aspects for assessing moisture management properties [58]. Since compression stockings are worn for longer period over the body, so moisture from sweat would be present at skin level. Overall moisture management capability of the stockings under investigation are rated Fair to good 0.2–0.4, 0.4–0.6 [59]. Among three types of structures, 1 × 3 Rib has highest OMMC value for all types of stockings followed by plain and 2 × 2 Rib structure. For the moisture management, wicking of moisture by capillary action is very important. As tuck stitches increase in the structure, they restrict the capillary action due to more accumulation of yarn as mentioned by other researchers [60]. Samples with standard SL show highest OMMC values followed by higher SL and lower SL. For capillary action, tortuous path is important. In case of smaller SL, the path becomes less complicated for water outflow to be transferred out and evaporated effectively [59,60]. This may be attributed to areal density. As areal density increases, the time for spreading, wetting also increases. This ultimately leads to lower OMMC value. Results are given in Table 11. The interval plots and 95% confidence interval of OMMC are shown in Fig. 10(a–c).

Table 11.

Result summary & ANOVA table for OMMC.

| Variable | Type | Factor | Mean | Grouping | Source | Degrees of freedom | Adjusted Sum of Squares | Adjusted Mean Sum of Squares | F Value | P Value | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OMMC | Plain | Lower | 0.480 | C | Error | 6 | 0.00120 | 0.000200 | |||||

| Plain | Standard | 0.680 | A | Factor | 2 | 0.06980 | 0.03490 | 174.50 | 0.000 | S** | |||

| Plain | Higher | 0.650 | B | Total | 8 | 0.07100 | |||||||

| Rib 2 × 2 | Lower | 0.284 | B | Error | 6 | 0.08816 | 0.01476 | ||||||

| Rib 2 × 2 | Standard | 0.586 | A | Factor | 2 | 0.19164 | 0.09572 | 6.51 | 0.031 | S** | |||

| Rib 2 × 2 | Higher | 0.590 | A | Total | 8 | 0.27960 | |||||||

| Rib 1 × 3 | Lower | 0.520 | C | Error | 6 | 0.0012 | 0.0002 | ||||||

| Rib 1 × 3 | Standard | 0.850 | A | Factor | 2 | 0.1134 | 0.0567 | 283.5 | 0.000 | S** | |||

| Rib 1 × 3 | Higher | 0.610 | B | Total | 8 | 0.1146 | |||||||

S**(Significant).

Fig. 10.

Interval plot of OMMC (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3 and (d) Interactive plot.

Rib 1 × 3 structure shows a highly significant effect of SL on OMMC (F-value = 283.5, p-value = 0.000). Fisher's comparison results also show that the mean responses of lower, standard and higher SL are significantly different. 2 × 2 Rib structures with standard SL had the highest effect, followed by Rib 1 × 3 with higher SL and the least effect was observed for lower SL (Table 11). Similar results were observed for plain structure (F-value = 6.51, p-value = 0.00). For Rib 2 × 2 with Standard and the Higher SL, similar responses are shown by assigning the same letter A to each.

The interval plots and 95% confidence interval of OMMC are shown in Fig. 10 (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3. Fig. 10(d) presents the interactive plot.

The OMMC values were observed to be the highest in case of standard stitch length in 1 × 3 Rib structure. It means the standard stitch length generates optimum capillary action. Only in Rib 2 × 2 structure, the OMMC increased as the stitch length further increased. The interactive plot in Fig. 10(d) also shows the combined effect of knitting structure & stitch length on OMMC. It shows that the maximum OMMC was achieved for the standard stitch length. In case of 2 × 2 Rib structure the OMMC increases when the stitch length increases. However, in plain and 1 × 3 Rib structures, when the stitch length increases from standard length, the OMMC value decreases due to inadequate capillarity hindering moisture transport in the fabric [[58], [59], [60]].

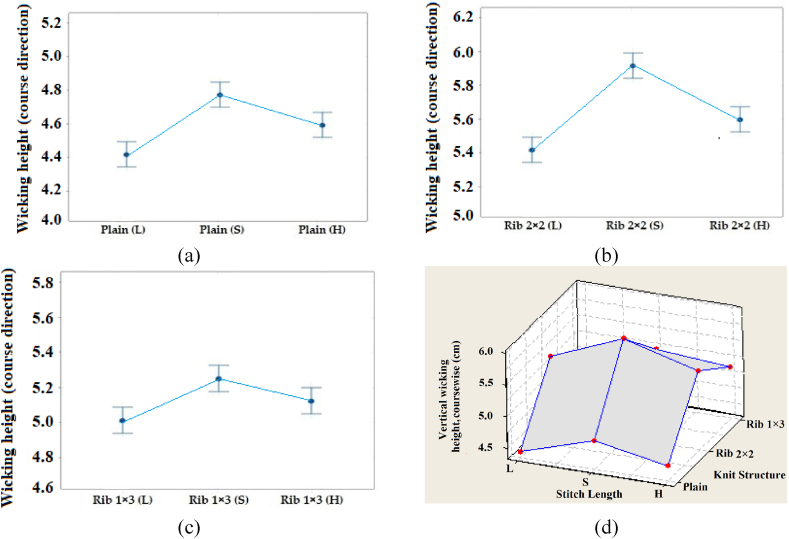

3.3.3. Influence of construction parameters on vertical wicking (VW)

The vertical wicking was measured for the samples in wale and course direction. Among the three types of structures, 1 × 3 Rib showed highest wicking height in the wale direction followed by 2 × 2 Rib and plain structures. In the course direction, highest wicking height was observed for 2 × 2 Rib structure followed by 1 × 3 Rib and plain. Overall, the wicking behaviour was better in Rib structures as compared to plain knitted structure due to capillary action. Samples with standard SL showed highest wicking height followed by higher SL and lower SL along the wale as well as course direction. In all the knitted structures, course wise wicking height was higher than the height in wale direction. For capillary action, tortuous path is important, and this was achieved with standard SL. In case of smaller SL, the path becomes less complicated for water flow [[60], [61], [62]]. As areal density increases, the time for wicking also increases. This ultimately leads to lower wicking height. Results of vertical wicking in wale direction are given in Table 12 & Fig. 11(a–d). The interval plots and 95% confidence interval of vertical wicking in wale direction are shown in Fig. 11 (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3. Fig. 11(d) presents the interactive plot.

Table 12.

Result summary & ANOVA table for vertical wicking in wale direction (cm).

| Variable | Type | Factor | Mean | Grouping | Source | Degrees of freedom | Adjusted Sum of Squares | Adjusted Mean Sum of Squares | F Value | P Value | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vertical wicking height, walewise (cm) | Plain | Lower | 3.12 | C | Error | 6 | 0.00220 | 0.000210 | |||||

| Plain | Standard | 3.89 | A | Factor | 2 | 0.04420 | 0.04270 | 142.30 | 0.000 | S** | |||

| Plain | Higher | 3.41 | B | Total | 8 | 0.04200 | |||||||

| Rib 2 × 2 | Lower | 4.02 | B | Error | 6 | 0.02816 | 0.04217 | ||||||

| Rib 2 × 2 | Standard | 4.57 | A | Factor | 2 | 0.14764 | 0.07465 | 4.22 | 0.021 | S** | |||

| Rib 2 × 2 | Higher | 4.25 | A | Total | 8 | 0.25230 | |||||||

| Rib 1 × 3 | Lower | 4.47 | C | Error | 6 | 0.0013 | 0.0001 | ||||||

| Rib 1 × 3 | Standard | 5.04 | A | Factor | 2 | 0.1144 | 0.0427 | 125.5 | 0.000 | S** | |||

| Rib 1 × 3 | Higher | 4.74 | B | Total | 8 | 0.1412 | |||||||

S**(Significant).

Fig. 11.

Interval plot for vertical wicking in wale direction (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3 and (d) Interactive plot.

The results of vertical wicking in course direction are given in Table 13 & Fig. 12 respectively.

Table 13.

Result summary & ANOVA table for vertical wicking in course direction (cm).

| Variable | Type | Factor | Mean | Grouping | Source | Degrees of freedom | Adjusted Sum of Squares | Adjusted Mean Sum of Squares | F Value | P Value | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vertical wicking height, coursewise (cm) | Plain | Lower | 4.41 | C | Error | 6 | 0.00120 | 0.000220 | |||||

| Plain | Standard | 4.77 | A | Factor | 2 | 0.04430 | 0.05230 | 125.20 | 0.000 | S** | |||

| Plain | Higher | 4.56 | B | Total | 8 | 0.04100 | |||||||

| Rib 2 × 2 | Lower | 5.42 | B | Error | 6 | 0.04253 | 0.04741 | ||||||

| Rib 2 × 2 | Standard | 5.88 | A | Factor | 2 | 0.14425 | 0.07362 | 2.45 | 0.011 | S** | |||

| Rib 2 × 2 | Higher | 5.55 | A | Total | 8 | 0.14520 | |||||||

| Rib 1 × 3 | Lower | 5.01 | C | Error | 6 | 0.0011 | 0.0001 | ||||||

| Rib 1 × 3 | Standard | 5.22 | A | Factor | 2 | 0.1142 | 0.0475 | 145.2 | 0.000 | S** | |||

| Rib 1 × 3 | Higher | 5.12 | B | Total | 8 | 0.1742 | |||||||

S**(Significant).

Fig. 12.

Interval plot for vertical wicking in course direction (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3 and (d) Interactive plot.

The interval plots and 95% confidence interval of vertical wicking in course direction are shown in Fig. 12 (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3. Fig. 12(d) presents the interactive plot.

The vertical wicking height values in wale and course directions were observed to be the highest in case of standard stitch length. It means the standard stitch length generates optimum capillary action [[60], [61], [62]]. The interactive plots in Fig.s 11(d) & 12(d) also showed the combined effect of knitting structure & stitch length on vertical wicking heights. Maximum wicking height in wale direction was achieved for the standard stitch length and 1 × 3 Rib structure. However, in the course direction, the maximum wicking height was achieved for the standard stitch length and 2 × 2 Rib structure.

Rib 1 × 3 and 2 × 2 structures showed a highly significant effect of SL on vertical wicking heights. Fisher's comparison results also showed that the mean responses of standard, higher and lower SL are significantly different. 2 × 2 Rib structures with standard SL had the highest effect, followed by Rib 1 × 3 with higher SL and the least effect was observed for lower SL. For Rib 2 × 2 with Standard and the Higher SL, similar responses were shown by assigning the same letter A to each.

3.3.4. Influence of construction parameters on thermal resistance (TR)

Thermal resistance (TR) is governed by volume and size of air pores, which act like a dead pockets and do not allow heat to pass through. Effect of knitting structure is significant in this regard. From Table 14, TR of 1 × 3 Rib structured stockings is highest followed by 2 × 2 Rib and plain structures due to more tuck stitches which make the fabric more porous. In case of 1 × 3 Rib structure, due to longer floats, the wales are drawn closer. Also, due to presence of Lycra yarn, which in turn leads to increase in stitch density and increase the microporosity. Presence of air in pores leads to increase in TR, as the thermal conductivity of stagnant air (approximately 0. 025 W/m.K) is much lower than most of the fibers [[58], [59], [60]]. Still air is a good heat insulator. When smaller SL was used, the TR value increased for all stockings samples as per previous literature [61,62]. As SL increased, TR value of all stockings decreased. With increase in SL, fabric porosity should have increased but it is reversed by the Lycra yarn embedded in the knitted structures. The Lycra-based yarn makes the structure more compact and reduces micro-porosity. The results for thermal resistance of the samples are given in Table 14.

Table 14.

Result summary & ANOVA table for thermal resistance (K/W).

| Variable | Type | Factor | Mean | Grouping | Source | Degrees of freedom | Adjusted Sum of Squares | Adjusted Mean Sum of Squares | F Value | P Value | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thermal resistance (K/W) | Plain | Lower | 0.026 | A | Error | 6 | 0.000002 | 0.00000 | |||||

| Plain | Standard | 0.012 | C | Factor | 2 | 0.000302 | 0.00015 | 453.00 | 0.000 | S** | |||

| Plain | Higher | 0.016 | B | Total | 8 | 0.000304 | |||||||

| Rib 2 × 2 | Lower | 0.039 | A | Error | 6 | 0.000001 | 0.00001 | ||||||

| Rib 2 × 2 | Standard | 0.018 | C | Factor | 2 | 0.000437 | 0.00028 | 874.11 | 0.000 | S** | |||

| Rib 2 × 2 | Higher | 0.025 | B | Total | 8 | 0.000463 | |||||||

| Rib 1 × 3 | Lower | 0.039 | A | Error | 6 | 0.000001 | 0.00000 | ||||||

| Rib 1 × 3 | Standard | 0.013 | C | Factor | 2 | 0.000790 | 0.00040 | 3556.00 | 0.000 | S** | |||

| Rib 1 × 3 | Higher | 0.030 | B | Total | 8 | 0.000791 | |||||||

S**(Significant).

From Table 14 Fisher's comparison results, it can be seen that the mean response of all variations in SL was significantly different for the structures. Rib 1 × 3 showed a highly significant effect of SL on TR (F-value = 3556.00, p-value = 00.000), Rib 1 × 3 with lower SL had the highest main effect, second largest mean effect was observed for Rib 1 × 3 with highest SL and the least mean effect was for the type of standard SL (Table 14). Similar trends can be observed for other structures and SL. The interval plots and 95% confidence interval of TR are shown in Fig. 13 (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3. Fig. 13(d) presents the interactive plot.

Fig. 13.

Interval plot of TR (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3 and (d) Interactive plot.

The minimum thermal resistance was observed for all the knitted structures prepared with standard stitch length. It means that the standard length enables the fabric to have optimum number of micro pores necessary for heat transfer required for compression stockings used in hot climates. The interactive plot in Fig. 13(d) also shows the combined effect of knitting structure & stitch length on thermal resistance. It shows that the standard stitch length is optimum for minimum thermal resistance in all the knitted structures for compression stockings to be used in hot climates.

3.3.5. Influence of construction parameters on relative water vapor permeability % (RWVP)

RWVP was measured for the samples of knitted compression stockings and the results are given in Table 15.

Table 15.

Result summary & ANOVA table for relative water vapor permeability % (RWVP).

| Variable | Type | Factor | Mean | Grouping | Source | Degrees of freedom | Adjusted Sum of Squares | Adjusted Mean Sum of Squares | F Value | P Value | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RWVP% | Plain | Lower | 10.12 | A | Error | 6 | 0.000004 | 0.00000 | |||||

| Plain | Standard | 11.41 | C | Factor | 2 | 0.000403 | 0.00014 | 742.04 | 0.000 | S** | |||

| Plain | Higher | 11.82 | B | Total | 8 | 0.000742 | |||||||

| Rib 2 × 2 | Lower | 11.78 | A | Error | 6 | 0.000002 | 0.00003 | ||||||

| Rib 2 × 2 | Standard | 12.42 | C | Factor | 2 | 0.000486 | 0.00025 | 735.71 | 0.000 | S** | |||

| Rib 2 × 2 | Higher | 12.53 | B | Total | 8 | 0.000753 | |||||||

| Rib 1 × 3 | Lower | 12.04 | A | Error | 6 | 0.000002 | 0.00000 | ||||||

| Rib 1 × 3 | Standard | 12.21 | C | Factor | 2 | 0.000730 | 0.00070 | 4526.24 | 0.000 | S** | |||

| Rib 1 × 3 | Higher | 12.56 | B | Total | 8 | 0.000723 | |||||||

S**(Significant).

Among the three types of structures, 1 × 3 Rib showed highest RWVP followed by 2 × 2 Rib and plain structures. This is attributed to the openness of structure which facilitates easier evaporation. Samples with higher SL showed maximum RWVP followed by standard SL and lower SL. Further the looser construction in Rib knitted fabrics is favourable for easier transmission of water vapor [[57], [58], [59], [60], [61], [62]]. The interval plots and 95% confidence interval of RWVP are shown in Fig. 14 (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3. Fig. 14(d) presents the interactive plot.

Fig. 14.

Interval plot of RWVP (a) Plain, (b) Rib 2 × 2, (c) Rib 1 × 3 and (d) Interactive plot.

The minimum evaporative resistance was observed for all the knitted structures prepared with higher stitch length. It means that the higher stitch length enables the fabric to allow better vapor transfer required for compression stockings used in hot and humid climates. The interactive plot in Fig. 14(d) also shows the combined effect of knitting structure & stitch length on RWVP. It shows that the higher stitch length and 1 × 3 Rib construction allows maximum permeability to water vapor. The lower stitch length and plain construction allows maximum evaporative resistance.

4. Conclusions

In the present research, occupational graduated compression stockings were designed and developed for routine healthcare. Compression stockings with pressure class 1 have been developed to reduce the chances of occupational venous health issues. The present work emphasizes on ergonomic as well as thermo-physiological comfort characteristics of occupational graduated compression stockings/socks for tasks performed while standing or sitting for a prolonged period of time. These are also essential in case of pregnant women. The studies were performed by changing stitch length and knitting structures in the fabrics. From the results it was concluded that by varying stitch length (SL) in the knitting structure the thermo-physiological and ergonomic comfort properties can be significantly influenced. 1 × 3 Rib structure showed maximum OMMC and AP which are important for breathability. Vertical wicking and relative water vapor permeability were found to be optimum in case of standard stitch length. Beside this, these socks have better stretch and recovery% as compared to other structures. Therefore, such compression stockings can be recommended for summer weather with better comfort characteristic. Effect of stitch length variation was influenced by presence of Lycra yarn. Fisher's comparison results also show that the mean responses of standard, higher and lower stitch length (SL) are significantly different for all the properties except dimensional stability. This study can be helpful for manufacturers of compression stockings, to understand the effect of SL and knitting structure on different comfort aspects especially when Lycra yarn is used. Variation in construction parameters with different knitted structures provides an optimization of functionality, serviceability, comfort, and cost. The study has developed a practical approach for the manufacturers in order to optimize the performance in compression stockings. The construction of the compression socks can thus be optimized in terms of constructional parameters to provide optimum comfort to the users. Nonetheless, this study is limited to only stitch length and knitting structures of plain, 2 × 2 Rib and 1 × 3 Rib only. In future studies, other structural factors such as yarn linear density and effect of material composition can be considered.

Data availability statement

Data are included in article/supp. material.

CRediT authorship contribution statement

Hafsa Jamshaid: Writing – review & editing, Writing – original draft, Visualization, Validation, Supervision, Software, Resources, Project administration, Methodology, Investigation, Funding acquisition, Formal analysis, Data curation, Conceptualization. Rajesh Kumar Mishra: Writing – review & editing, Writing – original draft, Visualization, Validation, Supervision, Software, Resources, Project administration, Methodology, Investigation, Funding acquisition, Formal analysis, Data curation, Conceptualization. Naseer Ahamad: Writing – review & editing, Writing – original draft, Methodology, Investigation, Formal analysis, Data curation. Vijay Chandan: Writing – review & editing, Writing – original draft, Visualization, Methodology, Investigation, Formal analysis, Data curation, Conceptualization. Muhammad Nadeem: Writing – review & editing, Writing – original draft, Project administration, Investigation, Funding acquisition, Formal analysis, Data curation, Conceptualization. Viktor Kolář: Writing – review & editing. Petr Jirků: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Writing – original draft, Writing – review & editing. Miroslav Müller: Writing – review & editing, Writing – original draft, Supervision, Project administration, Methodology, Investigation, Funding acquisition, Formal analysis, Data curation, Conceptualization. Tegginamath Akshat: Writing – review & editing, Writing – original draft, Resources, Methodology, Investigation, Formal analysis, Data curation, Conceptualization. Shabnam Nazari: Writing – review & editing, Writing – original draft, Software, Methodology, Investigation, Formal analysis, Data curation, Conceptualization. Tatiana Alexiou Ivanova: Writing – review & editing, Writing – original draft, Supervision, Resources, Project administration, Methodology, Funding acquisition, Formal analysis, Data curation, Conceptualization.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was supported by the Internal Grant Agency (IGA) of the Faculty of Engineering, Czech University of Life Sciences Prague, project “Numerical and experimental analysis of hybrid composites partially reinforced with bio-fibers and fillers”, (no. 2023:31140/1312/3111) and by the Integral Grant Agency of the Faculty of Tropical AgriSciences, Czech University of Life Sciences Prague, project “Appropriate technologies in waste and water management” [no. 51130/1312/3110, 2022–2023].

References

- 1.Alavi A., Maibach H.I. Springer Nature; Berlin, Germany: 2020. Local Wound Care for Dermatologists; pp. 83–94. [Google Scholar]

- 2.Siddique H.F., Mazari A.A., Havelka A., Kus Z. Performance characterization and pressure prediction of compression socks. Fibers Polym. 2020;21:657–670. [Google Scholar]

- 3.Shingler S., Robertson L., Boghossian S., Stewart M. Compression stockings for the initial treatment of varicose veins in patients without venous ulceration. Cochrane Database Syst. Rev. 2011;9:CD008819. doi: 10.1002/14651858.CD008819.pub2. [DOI] [PubMed] [Google Scholar]

- 4.Ananthapadmanabhan A., Nair A.A., Koshi D.A., Kishore G., Johnson A.K. Good vibe-a device for early detection and prevention of varicose vein. Int. Res. J. Eng. Technol. 2020;7:5142–5146. [Google Scholar]

- 5.https://www.healthline.com/health/compression-stockings-for-varicose-veins#how-compression-stockings-work. Assessed on [29 August 2023].

- 6.https://my.clevelandclinic.org/health/diseases/4722-varicose-veins. Assessed on [29 August 2023].

- 7.https://www.womenshealth.gov/a-z-topics/varicose-veins-and-spider-veins. Assessed on [29 August 2023].

- 8.Siddique H.F. Assessment of mechanical properties of compression socks using cut-strip method. J. Text. Eng. Fash. Technol. 2019;5:228–233. [Google Scholar]

- 9.Bochmann R.P., Seibel W., Haase E., Hietschold V., Rodel H., Deussen A. External compression increases forearm perfusion. J. Appl. Physiol. 2005;99:2337–2344. doi: 10.1152/japplphysiol.00965.2004. [DOI] [PubMed] [Google Scholar]

- 10.Mirakhmedova S., Amirkhanov A., Seliverstov E., Efremova O., Zolotukhin I. Daily duration of compression treatment in chronic venous disease patients: a systematic review. J. Personalized Med. 2023;13:1316. doi: 10.3390/jpm13091316. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Li Y., Mükke A., Rother U., Janka R., Uder M., Lang W., Heiss R. Effect of flat-knitted medical compression stockings on venous malformations. J. Clin. Med. 2023;12:2723. doi: 10.3390/jcm12072723. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Chen Y., Bruniaux P., Sun Y., Hong Y. Modelization and identification of medical compression stocking: Part 2–3D interface pressure modelization. Textil. Res. J. 2020;90:2184–2197. [Google Scholar]

- 13.Johnson S. Compression hosiery in the prevention and treatment of venous leg ulcers. J. Tissue Viability. 2002;12:72–74. doi: 10.1016/s0965-206x(02)80016-x. [DOI] [PubMed] [Google Scholar]

- 14.Muller M., Choteborsky R., Valasek P., Hloch S. Unusual possibility of wear resistance increase research in the sphere of soil cultivation. Tehniki Vjesnik-Technical Gazzette. 2013;20:641–646. [Google Scholar]

- 15.Moni S.P. Daffodil international University; Dhaka, Bangladesh: 2020. Study on the Effect of Physical Properties of Different Knit Fabrics on Shrinkage% after Normal Wash.http://dspace.daffodilvarsity.edu.bd:8080/handle/123456789/5490 [Google Scholar]

- 16.Sampath M.B., Senthilkumar M. Effect of moisture management finish on comfort characteristics of microdenier polyester knitted fabrics. J. Ind. Text. 2009;39:163–173. [Google Scholar]

- 17.Lozo M., Penava Ž., Lovričević I., Vrljičak Z. The structure and compression of medical compression stockings. Materials. 2022;15:353. doi: 10.3390/ma15010353. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Candan C., Nergis B., Cimilli Duru S., Koyuncu B. Development of a care labelling process for compression stockings based on natural (cotton) fibers. Polymers. 2021;13:2107. doi: 10.3390/polym13132107. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Lee Y., Kim K., Kang S., Kim J.Y., Kim S.G., Kim T., Jung J. Compression stocking length effects on oedema, pain, and satisfaction in nursing students: a pilot randomized trial. Healthcare. 2020;8:149. doi: 10.3390/healthcare8020149. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Rodríguez-Sanz D., Becerro-de-Bengoa-Vallejo R., Losa-Iglesias M.E., Martínez-Jiménez E.M., Muñoz-García D., Pérez-Boal E., Calvo-Lobo C., López-López D. Effects of compressive stockings and standard stockings in skin temperature and pressure pain threshold in runners with functional ankle equinus condition. J. Clin. Med. 2018;7:454. doi: 10.3390/jcm7110454. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Horiuchi M., Takiguchi C., Kirihara Y., Horiuchi Y. Impact of wearing graduated compression stockings on psychological and physiological responses during prolonged sitting. Int. J. Environ. Res. Publ. Health. 2018;15:1710. doi: 10.3390/ijerph15081710. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Gun A.D. Dimensional, physical and thermal comfort properties of plain knitted fabrics made from modal viscose yarns having microfibers and conventional fibers. Fibers Polym. 2011;12:258–267. [Google Scholar]

- 23.Ichetaonye S.I., Ichetaonye D.N., Adeakin O.A., Tenebe O.G., Yibowei M.E. Effect of stitch length on the physical properties of both plain and 1×1 Rib knitted fabrics. J. Textil. Sci. Eng. 2014;4 [Google Scholar]

- 24.Ghosh A., Mal P., Majumdar A., Banerjee D. Analysis of knitting process variables and yarn count influencing the thermo-physiological comfort properties of single Jersey and rib fabrics. J. Inst. Eng. (India) Series E. 2016;97:89–98. [Google Scholar]

- 25.https://comprogear.com/washing-compression-stockings. Accessed on [August 31, 2023].

- 26.Quality assurance RALGZ 387/1, medical compression hosiery, deutsches institut Fur gutesicherung und kennzeichnung E.V. Fränkische Str. 2008;7 Bonn, Germany. [Google Scholar]

- 27.Liu R., Lao T.T., Wang S.X. Technical knitting and ergonomical design of 3D seamless compression hosiery and pressure performances in vivo and in vitro. Fibers Polym. 2013;14:1391–1399. [Google Scholar]

- 28.Safa Y., Bhatti H.N. Adsorptive removal of direct textile dyes by low cost agricultural waste: application of factorial design analysis. J. Chem. Eng. 2011;167:35–41. [Google Scholar]

- 29.Stansal A., Lazareth I., Pasturel U.M., Ghaffari P., Boursier V., Bonhomme S., Sfeir D., Priollet P. Compression therapy in 100 consecutive patients with venous leg ulcers. J. Des. Mal. Vascul. 2013;38:252–258. doi: 10.1016/j.jmv.2013.05.006. [DOI] [PubMed] [Google Scholar]

- 30.Jamshaid H., Mishra R.K., Ahmad N., Nadeem M., Muller M., Kolar V. Exploration of effects of graduated compression stocking structures on performance properties using principal component analysis: a promising method for simultaneous optimization of properties. Polymers. 2022;14:2045. doi: 10.3390/polym14102045. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Yesmin S., Hasan M., Miah M.S., Momotaz F., Idris M.A., Hasan M.R. Effect of stitch length and fabric constructions on dimensional and mechanical properties of knitted fabrics. World Appl. Sci. J. 2014;32:1991–1995. [Google Scholar]

- 32.Mizera C., Herak D., Hrabe P., Muller M., Kabutey A. Mechanical behavior of Ensete ventricosum fiber under tension loading. J. Nat. Fibers. 2017;14:287–296. [Google Scholar]

- 33.Senthil Kumar C.B., Senthil Kumar B. Study on thermal comfort properties of eri silk knitted fabrics for sportswear application. J. Nat. Fibers. 2022;19:9052–9063. [Google Scholar]

- 34.Soundri G.M., Kumar B.S. Dimensional, moisture, and thermal properties of bi-layered knitted fabric for sportswear application. Res. J. Text. Apparel. 2023;27:543–559. [Google Scholar]

- 35.Kumar S., Boominathan S.K. Comparative analysis on thermo-physiological behavior of Eri silk, wool and bamboo knitted fabrics toward sportswear. J. Nat. Fibers. 2021;19:7702–7713. [Google Scholar]

- 36.Soundri G.M., Senthilkumar B., Vijay Raj D., Patchiyappan K.M. Comparative moisture management studies of single Jersey knitted soya bean fabrics. J. Nat. Fibers. 2022;19:12462–12472. [Google Scholar]

- 37.Sentil Kumar C.B., Sivagnanam J., Senthil Kumar B. Effect of inlay yarn in moisture and thermal transmission properties of plaited double knit fabric structures. Int. J. Res. Appl. Sci. Eng. Technol. 2020;8:770–774. [Google Scholar]

- 38.Kumar B.S. Thermal property analysis of tri layer composite fabric towards the utility of sleeping bag. Res. J. Text. Apparel. 2022;26:124–137. [Google Scholar]

- 39.ASTM D1059-17: Standard Test Method for Yarn Number Based on Short-Length Specimens. ASTM International; West Conshohocken, PA, USA: 2022. [Google Scholar]

- 40.ASTM D 3776: Standard Test Methods for Mass Per Unit Area. ASTM International; West Conshohocken, PA, USA: 2022. [Google Scholar]

- 41.ASTM D 1777: Standard Test Methods for Thickness of Textile Materials. ASTM International; West Conshohocken, PA, USA: 2022. [Google Scholar]

- 42.AATCC 150, Revision 18T . 2022. 2018 - Test Method for Dimensional Changes of Garments after Home Laundering. PO Box 12215, Research Triangle Park, NC; p. 27709. 2215, USA. [Google Scholar]

- 43.ASTM D2594 . ASTM International; West Conshohocken, PA, USA: 2022. Standard Test Method for Stretch Properties of Knitted Fabrics. [Google Scholar]

- 44.ISO 9237 . International Organization for Standardization ISO Central Secretariat, Chemin de Blandonnet 8, CP 401 - 1214 Vernier; Geneva, Switzerland: 1995. Determination of the Permeability of Fabrics to Air. [Google Scholar]

- 45.ISO 11092:2014 . International Organization for Standardization ISO Central Secretariat, Chemin de Blandonnet 8, CP 401 - 1214 Vernier; Geneva, Switzerland: 2014. Specifies Methods for the Measurement of the Thermal Resistance and Water-Vapour Resistance, under Steady-State. [Google Scholar]

- 46.AATCC 195 . 2017. 2017 Edition - Test Method for Liquid Moisture Management Properties of Textile Fabrics; p. 27709. PO Box 12215, Research Triangle Park, NC. 2215, USA. [Google Scholar]

- 47.AATCC 197 . 2022. 2022 Edition- Test Method for Vertical Wicking Rate of Textiles: to Specified Distances; p. 27709. PO Box 12215, Research Triangle Park, NC. 2215, USA. [Google Scholar]

- 48.ISO 11092:1993 . International Organization for Standardization ISO Central Secretariat, Chemin de Blandonnet 8, CP 401 - 1214 Vernier; Geneva, Switzerland: 2014. Physiological Effects — Measurement of Thermal and Water-Vapour Resistance under Steady-State Conditions (Sweating Guarded-Hotplate Test) [Google Scholar]

- 49.Xiong X., Yang T., Mishra R., Militky J. Transport properties of aerogel-based nanofibrous nonwoven fabrics. Fibers Polym. 2016;17:1709–1714. [Google Scholar]

- 50.Behera B.K., Pattanayak A.K., Mishra R. Prediction of fabric drape behavior using finite element method. J. Textil. Eng. 2008;54:103–110. [Google Scholar]

- 51.Yang T., Hu L., Petrů M., Wang X., Xiong X., Yu D., Mishra R. Determination of the permeability coefficient and airflow resistivity of nonwoven materials. Textil. Res. J. 2022;92:126–142. [Google Scholar]

- 52.Eltahan E. Effect of lycra percentages and loop length on the physical and mechanical properties of single Jersey knitted fabrics. JEC Compos. 2016;2016 [Google Scholar]

- 53.Venkataraman M., Mishra R., Wiener J., et al. Novel techniques to analyse thermal performance of aerogel-treated blankets under extreme temperatures. J. Text. Inst. 2015;106:736–747. [Google Scholar]

- 54.Assefa A., Govindan N. Physical properties of single Jersey derivative knitted cotton fabric with tuck and miss stitches. J. Eng. Fibers Fabr. 2020;15:1–10. [Google Scholar]

- 55.Behera B.K., Mishra R.K. Artificial neural network-based prediction of aesthetic and functional properties of worsted suiting fabrics. Int. J. Cloth. Sci. Technol. 2007;19:259–276. [Google Scholar]

- 56.Tugrul O.R., Mavruz M.S. Optimization of air permeability of knitted fabrics with the Taguchi approach. J. Text. Inst. 2011;102:395–404. [Google Scholar]

- 57.Venkataraman M., Mishra R., Xiong X., Yao J., Zhu G. Electrospun nanofibrous membranes embedded with aerogel for advanced thermal and transport properties. Polym. Adv. Technol. 2018;29:2583–2592. [Google Scholar]

- 58.Hu J., Li Y., Yeung K.W., Wong A.S., Xu W. Moisture management tester: a method to characterize fabric liquid moisture management properties, Text. Res. J. 2005;75:57–62. [Google Scholar]

- 59.Crina B., Blaga M., Luminita V., Mishra R. Comfort properties of functional weft knitted spacer fabrics. Tekst. Konfeksiyon. 2013;23:220–227. [Google Scholar]

- 60.Oner E., Atasağun H.G., Okur A.Y., Beden A.R., Durur G. Evaluation of moisture management properties on knitted fabrics. J. Text. Inst. 2013;104:699–707. [Google Scholar]

- 61.Baltusnikaite J., Abraitiene A., Stygiene L., Krauledas S., et al. Investigation of moisture transport properties of knitted materials intended for warm underwear, Fibres Text. East. Eur. 2014;106:93–100. [Google Scholar]

- 62.Cubric I.S., Skenderi Z., Mihelic-Bogdanić A., Andrassy M. Experimental study of thermal resistance of knitted fabrics. Exp. Therm. Fluid Sci. 2012;38:223–228. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data are included in article/supp. material.