Abstract

Nanomaterials are structures with a wide range of applications in the medical, pharmaceutical, food, textile, and electronic industries, reaching more customers worldwide. As a relatively new technological field, the information about the associated risk of nanomaterials in environmental and human health must be addressed and consolidated to develop accurate legislations, frameworks, and guidelines to standardise their use in any field. This review aims to display and context the global applications of nanomaterials, their final disposal, as well as the perspective of the current efforts formulated by various countries (including Mexico and Latin American countries), international official departments and organisations directed to implement regulations on nanomaterials, nanotechnology, and nanoscience matters. In addition, the compiled information includes the tools, initiatives, and strategies to develop regulatory frameworks, such as life cycle assessments, risk assessments, technical tools, and biological models to evaluate their effects on living organisms. Finally, the authors point out the importance of implementing global regulations to promote nanotechnological research according to a precautionary principle focused on an environmental and health protection approach to ensure the use and application of nanotechnologies safely, and responsibly.

Nanotechnology is a relatively new technological field, therefore, the information about the associated risk of nanomaterials in environmental and human health must be addressed and consolidated to develop accurate legislations, frameworks, and guidelines to standardise a safe use in any field.

Introduction

Today, nanotechnology leads to numerous nano-based products available in the market, breakthroughs around technology, and synthesis methods. Thus, nanotechnology brings to the market high-tech characterisation equipment, and it has accelerated growth in various areas of science and industry.

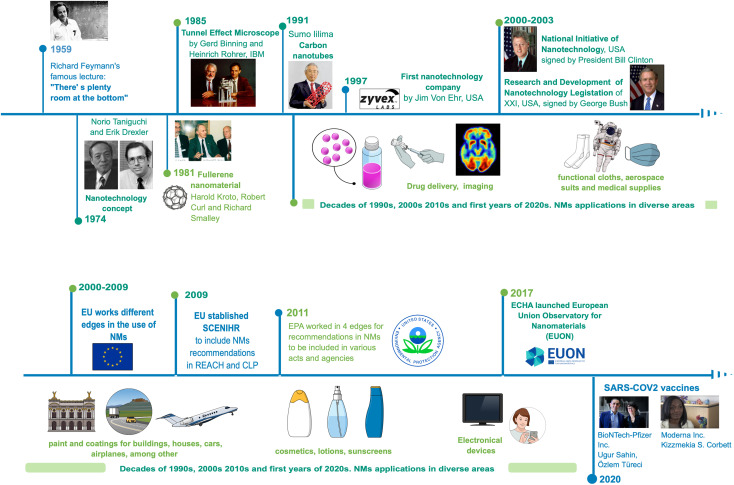

Historically, the visualisation of nanotechnology can be tracked to 1959, when physicist Richard Feynman proposed his famous lecture: “There's plenty of room at the bottom”,1 where he first stated direct manipulations of atoms to synthesise materials for the first time. Since then, fundamental advances in the development of nanotechnology have taken place; for example, the molecular beam epitaxy growth technique by Günther in 1968.2 Furthermore, Norio Taniguchi and Kim Erick Drexler in 1974 and 1986, respectively, used the term «nanotechnology» to describe materials at a nanoscale and their applications.3 Then, the first NMs were obtained, when a patented process for the synthesising fullerenes was granted to Robert Curl, Richard Smalley, and Harold Kroto in 1978,4 and Sumio Lijima made a breakthrough in describing the procedure to obtain carbon nanotubes (CNTs) in 1991.3 Later, Xu et al. (2004) discovered carbon dots with a size below 10 nm when they were developing an electrophoretic method for single-walled CNTs5 suitable for applications such as bioimaging, drug delivery, and catalysis due to their enhanced optical and electronic properties and low toxicity.6

The knowledge of the matter manipulation in a nanoscale, confers a great impact with economic relevance in different areas of industry and research. For the last 20 years, nanotechnology stands out with the registration of products and manufactured patents related to nanomaterials (NMs): cosmetics, toothpaste, filtration systems, photovoltaic cells, electronic devices, medical products, among others.7 In 2020, this impact reached a vaccine for the SARS CoV-2 virus, where two large pharmaceutical companies, Pfizer and Moderna, developed a vaccine using nanoliposomes (lipidic nanostructures) as a vehicle for the mRNA sequence needed for the antigenic spike protein of this virus,8 and in 2023, Alexey Ekimov, Moungi Bawendi, and Louis Eugene Brus won The Nobel Prize in Chemistry for obtaining and studying quantum dots of different elements for current electronical and optical applications9 (Fig. 1).

Fig. 1. The history and development of Nanotechnology (1959–2020). Original creation (using Mind the Graph program) based on information obtained from ref. 1–9, 106, 109, 133–137, 142–144.

According to the National Science Foundation workshop report “Nanotechnology Research Directions”, nanotechnology is defined as «the application of scientific knowledge to manipulate and control matter predominantly in the nanoscale to use size- and structure-dependent properties and phenomena distinct from those associated with individual atoms or molecules, or extrapolation from larger sizes of the same material».10 From this, crucial concepts emerge such as nanomaterial (NM), which is «a material with any external dimension in the nanoscale or having an internal structure or surface structure in the nanoscale»,11 and nanoparticles (NPs) defined as «nano-objects with all external dimensions in the nanoscale where the lengths of the longest and the shortest axes of the nano-object do not differ significantly».12 However, other definitions are suggested. The European Commission (EC) has worked on definitions, compiling information, and proposing regulations for about two decades and defines NM as «a natural, incidental or manufactured material consisting of solid particles that are present, either on their own or as identifiable constituent particles in aggregates or agglomerates, and where 50% or more of these particles in the number-based size distribution fulfil at least one of the following conditions: (a) one or more external dimensions of the particle are in the size range 1 nm to 100 nm; (b) the particle has an elongated shape, such as a rod, fibre or tube, where two external dimensions are smaller than 1 nm and the other dimension is larger than 100 nm; (c) the particle has a plate-like shape, where one external dimension is smaller than 1 nm and the other dimensions are larger than 100 nm».13

If the NM is synthesised, the process can be performed by “top down” or “bottom up” techniques. In the first group, a raw material in a micro or macro scale is breaking down to the nanoscale, while “bottom up” techniques refer to assembling atoms and molecules into nanoscale arrangements.14 Those synthesis are selected according with the chemical nature of the NM. In this respect, NMs are classified in (1) carbon-based NMs (e.g. graphene and carbon nanotubes); (2) metallic-based NMs (e.g. gold and silver NPs; (3) quantum dots (e.g. Cerium quantum dots); (4) dendrimers, which are polymeric branched nanostructures; and (5) composites, for a combination of inorganic and organic structures.15

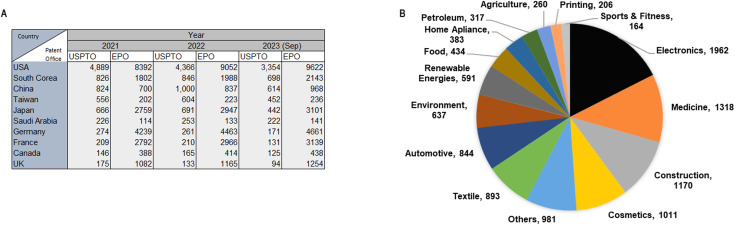

The development of new NM-derived products and applications are associated with increasing numbers of requested and approved patents. In 1991, 224 patents were registered worldwide while in 2008, the number of patents increased to 12 776.16 The data obtained from the United States Patent and Trademark Office (USPTO) until 2023 ranks the United States as the leading country in nanotechnology patenting, followed by South Korea, China, Japan, and Taiwan. Moreover, according to the European Patent Office (EPO), the United States is also the leading country in patenting, followed by Germany, France, Japan, and South Korea. The most recent update of nanotechnology Japan patenting dates to March 2023 and it shows that the United States still leads in nanotechnology patenting (Fig. 2A). Currently, the Statnano platform17 compiles information converging from nanotechnology, biotechnology, informatics, and cognitive science technologies. This platform states that 3910 companies in 68 countries offer 11 171 products using nanotechnology products and developments (Fig. 2B). Companies such as Intel Corporation have registered 189 products using nanotechnology, and Texas Instruments Inc. has registered 60 products that employ nanotechnologies.18

Fig. 2. (A) Top ten patenting countries (2019–2023) according with the United States Patent and Trademark Office and the European Patent Office; (B) nanotechnology products classified (2019–2023) according with industrial areas.18 Creation adapted and based on information obtained from http://www.statnano.com (accessed on December 14th, 2023).18.

On the other hand, funding for nanotechnology research increased from 432 million dollars to 4100 million dollars between 1997 and 2005.16 NM-related products have attracted more investments, and between 2007 and 2011, only the European Union reported 970 million dollars as an investment in NMs research. That approximation is about a quarter of a trillion dollars worldwide, and it is expected to exceed 125 billion dollars by 2024.19 The Statnano database has registered 2 040 200 research papers about NMs, 229 774 patents and 4326 products.18 The United States alone had registered 2300 products containing NMs during the first decade of the 21st century.20 The Woodrow Wilson International Centre for Scholars, a non-partisan organisation forum, conducted independent research, and registered 54 nanoproducts in 2005; by 2009 this number increased to 1015 products.21 By 2020, the Woodrow Wilson Database reported 1833 nanotechnological products worldwide.22 Nanowerk Nanomaterial Database Inventory, the global leading portal database of nanosciences and nanotechnology products, news, links with nanotechnologies industries/laboratories, industrial reports, magazines, and journals, registered an increase in the number of manufactured nanoproducts from 1917 in 2008 up to 2238 products in 2009, and a total of 3600 products in 2018.2,21

On the other hand, the technology consultancy Future Markets Inc. projected in 2012 a total worldwide production of 250 000 to 300 000 metric tons of NPs obtained by chemical synthesis. Meanwhile, the EC reported in the same year 1 500 000 tons worldwide;23 among them, the most produced NMs (2010–2012) were NPs of titanium dioxide (TiO2), silicon dioxide (SiO2), aluminium oxides (AlxOx), zinc oxide (ZnO), iron oxides (FexOy), cerium oxides (CexOy), silver (AgNPs), and CNTs.20

Nowadays, nanotechnology has a significant participation in global markets; the sustained increase and past and future growth clearly show its importance. For example, the valued of nanotechnology was up to 2 trillion USD in 2015 (ref. 24); meanwhile, other projections assessed 2020 a value in the global economy of up to 3 trillion USD.25 Inkwood Research projected that the NM market would reach an approximate value of up to 13 billion USD, and Mordor Intelligence forecasted a value in markets of NMs up to 11.3 billion USD in 2020.2 This economic data was before 2020; therefore, the current monetary yields could be far more today, and the impact of the SARS-CoV2 global pandemic must be considered.

By the immediate antecedents related to the accelerated increase in products containing NMs, this review explores and make an analysis of the current applications and uses of a series of products based on NMs. At the same time, the authors contextualise aspects related to the disposal, regulations, legislations, and worldwide advances of these materials in the nano scale within the last years. Some publications have recognised the importance of the regulation of NMs in fields such as cosmetics or nanomedicine26–28 or address them in a broader approach,29,30 analysing aspects such as funding, patenting, economic participation of NMs in global markets, but also the impact that confer the release of NMs in the environment and health risks. In addition, this review emphasises the current situation in which countries from different continents face the situation of NMs regulation, including countries that have designed initiatives with different degrees to contribute to the good use of nanotechnologies, which gives a broader view to the reader of the importance of developing regulations on NMs. It is also stablished the importance of the development of these regulations and how they should be strongly related with the Sustainable Development Goals (SDG).

Global applications of NMs

The United Nations (UN) has developed actions to contribute to NMs-related environmental safety. In 2015, all the countries that belong to the UN approved the 17 Sustainable Development Goals (SDG), part of the Sustainable Development Agenda 2030 that included objectives related to human health and environmental safety.31 To the date, uses and application with NMs are diverse as Fig. 1 represents. Those applications may cover relevant targets in the SDG. For instance, objective 3 good health and well being, considers reducing by one third premature mortality from non-communicable diseases through prevention and treatment and promote mental health and well-being. NMs are being applied for the improvement of diagnosis, drug delivery and vaccines (communicable and non-communicable diseases). NMs are also considered for the removal and degradation of water pollutants to enhance water quality, which is part of the targets in objective 6 clean water and sanitation. Interestingly, a recent use of NMs is as nano pesticides to replace hazardous chemical currently applied in crops, and this is also a target in the objective 6 for reducing water contamination. Moreover, the use and applications of NMs in solar cells and other devices for renewal energies may reduce the costs of those systems, as considered in objective 7 affordable and clean energy. On the other hand, the commercial use of NMs for painting and coating impact in the development of quality, reliable, sustainable, and resilient infrastructure as set in objective 9 industry innovation and infrastructure.

Regarding objective 3 good health and well being, most of the NMs applications are lipid-based NMs. Previously, it has been mentioned the BioNTech-Pfizer and Moderna SARS-CoV2 vaccines were a breakthrough in 2020 when the COVID-19 pandemic stroked. Those vaccines contain a nucleoside-modified mRNA encoding for SARS-CoV-2 spike protein encapsulated in liposomes assembly with polymer-phospholipids, allowing the mRNA protection and enhancing the immune response.8 However, this vaccine has not been the first biomedical NMs applications. In 1995, the FDA approved the use of Doxil®, a liposomal doxorubicin drug for Kaposi's sarcoma, ovarian cancer, and myeloid melanoma. Later, in 1997, AmBisome®, a liposomal amphotericin B against opportunistic fungal pathogens, was released to the market, reducing the toxicity of the drug in patients.32 That was the starting point for several liposomal formulations for drug delivery.33 Moreover, in 2013, MagForce Nanotechnologies AG started the commercialisation of NanoTherm® AS1 (12 nm Fe2O3 with a lipidic shell), for thermal therapy in patients with brain tumours. The Fe2O3 NPs are activated by a magnetic field that changes its polarity 100 000 times per second and release heat into the tumour (intracranial administration of NanoTherm® is required).34,35

Another application of NMs is in the food industry. ZnONPs, SiO2 NPs, and TiO2 NPs are used in the food industry as thickeners, dyes, clarifying agents, and dust fluidity controllers. In contrast, AgNPs and ZnONPs enhance the shelf time of several products due to their bacteriostatic properties; FeONPs are used to fortify foods.36,37 Organic polymeric NPs such as pectin have also been used to elaborate films in food packages containing aqueous and alcoholic food extracts, and their synthesis is carried out from polymers obtained from natural sources and biodegradable synthetic polymers such as starch, pectin wheat proteins, zein, sunflower seeds proteins, among others.38 Polymeric NPs have been employed in the nanoencapsulation of functional foods (nutraceuticals) to protect them from the gastrointestinal tract,39 or as drug delivery vehicles to produce nanoemulsions of omega-3 fatty acids,40,41 and oil-in-water nanoemulsions (such as triglycerides with either vitamin D, astaxanthin, or β-carotene).42–44

Relevant mention is the use of NMs in cosmetics since the definition of cosmetics is typically wide in many countries. Cosmetics are interpreted as beauty products such as lipsticks and eyeliners, but according to The European Union Cosmetics Directive (EUCD) a cosmetic is “any substance or preparation intended to be placed in contact with various external parts of the human body (epidermis, hair, nails, lips, teeth…changing their appearance and/or correcting body odours and/or protecting them in good condition”.45 Thus, since cosmetics are not aimed at first to be drug formulations, less legislations applied in their production and commercialisation; hence, more NMs can be found in cosmetic formulations, including TiO2 as sunscreen (e.g. Phytorx UV defense46), nano-hydroxyapatite for dental desensitiser and polish remineralisation of teeth (e.g. Kinder Karex47), AuNPs as antimicrobial activity in facemask (e.g. gold radiance peel off mask48). However, the long-term use of NMs in cosmetics has not been studied and toxic effects could be found in evaluations. Furthermore, the released of NMs in the environment can alter the trophic chain.

Recently, the use of nanotechnology in water treatment systems (objective 6 clean water and sanitation) has been explored to improve the quality of treated water, using metallic and oxide metallic NPs due to their catalytic and/or antimicrobial activity and non-metallic NMs such as CNTs due to properties, such as high absorption surface area, layered structure and hollowness.49 In this sense, CNTs employed for wastewater treatments have demonstrated to remove heavy metals (lead or cadmium)50 and decreased microbial pollution.21 Fe2O3 NPs in batch systems have removed heavy metals such as arsenic (As III), copper (Cu II), aluminium (Al III), cadmium (Cd II), cobalt (Cd II) and nickel (Ni II).51 On the other hand, fullerenes (C60) have showed antimicrobial activity in a Bacillus subtilis demonstrating that fullerenes could be effective antimicrobial agents.52

Nano pesticides also represent an emerging research area in agriculture and environmental protection science and technology. They are chemicals used to control pests, diseases, or harmful microorganisms in agriculture and crop protection that can offer substantial benefits, such as increased effectiveness in controlling pests and diseases, reducing the use of conventional chemicals, controlled release of active ingredients, and minimizing environmental impact. There are two types of nano pesticides, the first one elaborated with Ag, Ti, and Cu as active ingredients, and the second one elaborated based on nanocarriers like nano-polymer and nano-clay to house as the active ingredients. These products act through various mechanisms, such as the controlled release of active ingredients, the inhibition of specific biological processes in pests or microorganisms, or through the modification of the surfaces properties to prevent the adhesion of microorganisms.53,54

Moreover, NMs can contribute to objective 7 affordable and clean energy by reducing environmental pollution, as they have improved the usage of renewable energy in solar cells, hydrogen production, batteries, and supercapacitors.55 Potential candidates are semiconductor materials such as silicon or gallium arsenide, which at the nanoscale present a decreased electronic and thermal conductivity and can be used in solar cells with high photoelectric conversion efficiency by catalysing the decomposition of inorganic and organic substances by solar energy.56 On the other hand, graphite and graphite-containing NMs has also been incorporated to solar panels due to their high charge and discharge rates.57 Due to the reduced scale, and therefore a faster ion and electron transport, NMs can improve the power of rechargeable batteries. Graphene and metallic-based nanocomposites have been proposed as an alternative to lithium in rechargeable batteries;58 these materials have also been used for the fabrication of electrodes in supercapacitors.59 The increased active surface area of NPs has also been exploited in catalysis and energy-conversion systems.60

The industry of paintings and coatings have applied NMs in recent years, looking for the improvement of various properties such as anticorrosion, durability, biodegradability, antimicrobial properties,61 and waterproofing in textiles62 addressing the objective 9 industry innovation and infrastructure. NMs have been used for coatings on sealed porous surfaces with a thinner layer, and various companies have applied those and other properties to commercial products. The company Niasol has products for car, furniture, and shoe protection, repelling dirt, and water from surfaces.63 Aculon sells about 100 hydrophobic nanocoating products with over 35 patents, finding applications in medical devices and electronics.64 Nanocar, which additional to the nanocoatings for car protection, it produces antimicrobial sprays for surfaces.65 Importantly, none of the recent nanotechnological companies selling paintings and coatings disclosure the use NMs in their formulations, they only state the functionality.

In contrast, NMs in commercial products and their potential applications in several fields highlights their relevance in human history, as the SDG in the Agenda 2030 stablishes. However, due to the NMs small size is crucial to consider their implications in human health and environment, faced critical challenges including the safety and toxicity of NPs, risk assessment for human health and the environment, stability and controlled release of active ingredients, regulatory concerns, in addition to the public agreement, topics that will be discuss in the following sections.

Where NMs are going after their shelf-life?

Nanotechnology-derived products are imminently incorporated in products and services under a global market that increases daily.

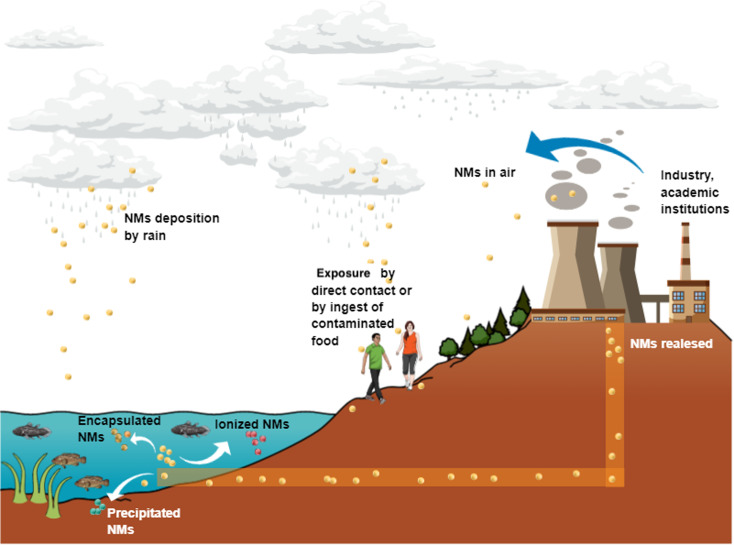

Due to their extended production and distribution, NMs may be released to air, soil, and water. Rains can also deposit NMs to water bodies and soils, and changes in temperature, pH or either interaction with other NMs can form aggregates or ionised NMs with the subsequent uptake by different animal and vegetable species through the trophic chain (Fig. 3).

Fig. 3. Nanoparticles released in water bodies can be taken up by aquatic fauna and enter the human body by trophic transfer. Air pollution by nanoparticles is also a concern due to nanoparticles could be deposited in water bodies through rainfall. Original creation (using Mind the Graph program) based on information obtained from ref. 23, 66–74.

Thus, contact with NMs by air, water, soil, or food may activate different cellular pathways in living organisms, including humans, and this topic is worthy of being studied in detail.66 Even with the benefits that NMs provide due to their novel properties, the other side of the coin is how the waste is treated for disposal to avoid environmental pollution and diseases. Particular attention is required for products containing NMs, in which ions or individual NPs can be released from the whole matrix or from some matrix fragments. For instance, painting and coating containing NPs and applied in outdoor buildings and monuments for stone's consolidation can be altered when exposing to different weather conditions.67 Zuin et al. (2014) and Zhang et al. (2017) tested nano-based paints containing TiO2 and Ag NPs according to Standard ISO 2812-2:2007 for paints and varnishes finding the release of NPs as free forms and ionic forms.68 Other evidence of NPs and ion release is reported by Pantano et al. (2018), who analysed wood preservatives containing CuO NPs by European Standard EN84:1997, which specifies a method for the leaching of compounds (durability in rainwater).69

Hence, NMs are now grouped in a new pollutant classification known as «emerging pollutants», which can be defined as «those compounds from different origins and chemical nature whose presence in the environment is not considered significant in terms of distribution or concentration»,70 and their «concentration ranges are parts per million (ppm) to parts per trillion (ppt)»71 Some reports alert that the concentrations of several NMs such as TiO2 NPs, AgNPs, CNTs, and fullerenes in freshwater and wastewater treatment plants and effluents have reached worrying levels ranging from 0.0005–0.0008 μg L−1 (or ppb) of CNTs, 0.03–0.08, 0.04–0.34 μg L−1, both ranges valued for AgNPs, 0.0005–19 μg L−1 for fullerenes and 0.7–16 μg L−1 for TiO2 NPs.72

Furthermore, other concepts around this topic emerge that are also relevant and have their implications, such as «nanopollutants» for referring to «those NMs that are directly released in the environment», or «nanowaste», which englobes «those nanomaterials that were collected as waste coming from production activities, disposal due to end of its useful life of solid waste containing nanomaterials».23 Nanopollutants suspended in the air, for example, composed mainly of heavy metals and produced by industrial facilities, waste incinerating plants, and fossil fuel burning, can reach different environments by spreading over long distances to enter terrestrial and aquatic ecosystems. Nanopollutants have also been spread indirectly by the surface runoff from soil to waterbodies with their subsequent use of biosolids on the ground. It has been reported that NPs can permeate soil when fertilisers or plant protection products are applied and into aquatic environments through effluent discharge from wastewater plants.73 Thus, using NMs faces complex challenges before they become safe to use and prevent contributing to the problem of pollution.

Using NMs in water treatment systems is a helpful tool that increases water quality. Nevertheless, the regulatory gaps and the subsequent lack of acceptable concentration limits for NMs cannot guarantee their biosafety, including when they are released to water bodies. AgNPs could lead to possible toxic effects starting with bioaccumulation, causing cytotoxicity, tissue damage, oxidative stress, and genotoxicity in aquatic species.74 Carbon-based NPs could be a safer alternative to metallic NPs for wastewater treatment, with less harmful effects on humans and the environment; however, side effects must be further studied in the short, medium, and long term.

Since NMs are tiny and have unique properties, the same elimination approach used for other conventional materials cannot simply be applied. Then some general considerations and strategies being studied are listed: (1) recycling and reuse: depending on the type of NM and its application, it may be possible to recover and recycle them for reuse in other processes or products. This requires proper management and effective separation of NMs during the recycling process;75,76 (2) waste treatment: Sometimes, NMs can end in solid or liquid waste. For appropriate direction, it is essential to consider waste treatment methods that are safe and effective in eliminating NMs without causing negative impacts on the environment or human health;76,77 (3) research on degradability: the degradability of NMs is being investigated to determine whether they can naturally decompose into more uncomplicated and less harmful components over time.78 These approaches will help us understand NMs persistence and long-term effects on the environment and contribute to consolidate regulations and guidelines or elaborate new ones that include specific protocols and procedures directed to eliminate the NMs, reducing the damage to the environment and health.

International regulatory framework for NMs

If the incorporation of NMs to the environment and biological systems is possible, due to the accelerated increase of nanotechnology, it is necessary an adequate regulatory framework and adapting regulations that consider the particularities that emerge in the production of NMs and the industries in which they are applied.

Accordingly, in 2017, the World Health Organisation (WHO) published the “WHO guidelines on protecting workers from potential risks of manufactured nanomaterials” aimed to establish guidelines for policymakers in the occupational field,79 and to address goals such as good health and well-being, decent work and economic growth, responsible consumption and production, life below water and life on land. Nowadays, the SDGs are a major axis in the development of new policies, such as environmental legislations (including NMs), and are being approached in universities and educational centres. Importantly, regulations regarding the production, use, application, and disposal of NMs impact on objective 12 responsible consumption and production of SDG, since it targets to promote public procurement practices that are sustainable, ensure that people have the relevant information and awareness for sustainable development and lifestyles in harmony with nature.

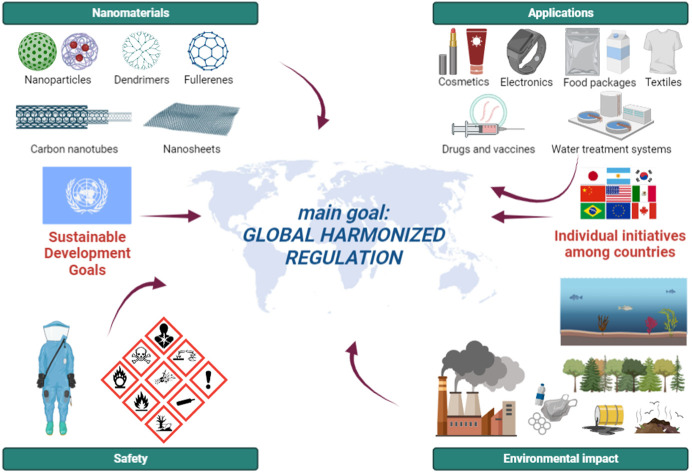

Institutions such as the United Nations for Training and Research (UNITAR) provide solutions through developing human resources with knowledge and skills in environmental matters. On the other hand, the United Nations Environmental Program (UNEP) is the foremost environmental authority in the world that promotes, overlooks, and qualifies nations for the sustainable development of the countries. To date, UNEP offers more than 15 000 documents related to environmental issues, including nanopollutants, in various areas, such as biosafety, energy, technology, water, etc.,80,81 (Fig. 4). So far, UNITAR's achievements can be quantified as follows: since 2010, UNITAR has organised 7172 courses and learning events and reached 780 534 beneficiaries.81

Fig. 4. National and international authorities, agencies and initiatives developing frameworks, legislations, and guidelines for nanomaterials. UN, United Nations; WHO, World Health Organisation; UNEP, United Nations Environment Program; UNITAR, United Nations Institute for Training and Research; OECD, Organisation for Economic Cooperation and Development; WPMN, Working Party on Manufactured Nanomaterials; ISO, International Organisation for Standardisation; ISO-TC229, International Organisation for Standardisation Technical Committee 229; USA, United States of America; FDA, Food and Drug Administration; EPA, Environmental Protection Agency; SINANOTOX, National Nanotoxicological Evaluation System Initiative; CONAHCyT, National Council of Humanities, Sciences and Technologies; CENAM, National Centre of Metrology; CENAT, National Centre of High Technology; LANOTEC, National Laboratory of Nanotechnology; ICONTEC, Colombian Institute of Technical Norms; ABNT, Brazilian Association of Technical Norms; IRAM, Argentinian Institute of Normalisation and Certification; REACH, Registration, Evaluation, Authorisation, and Restriction Chemicals; ECHA, European Chemical Agency; EUON, European Union Observatory for Nanomaterials. Original creation (using Excel and Biorender programs) based on information obtained from ref. 12, 31, 79–81, 94, 98, 115, 124–137, 143, 144,159, 180, 189, 202–204, 269.

In 2004, the international organisation erosion technology and concentration group pointed out the non-legal development of nanotechnology due to the considerable number of manufactured products.82 In this respect, the reports regarding the impact of NMs on health and the environment have increased at least during the last 20 years,83–92 showing the harmful effects in organs of different species (rats, fish, humans) due to the exposure and intake of NMs that could lead to a physiological misfunction and a lowered life quality. Consequently, today, the issue of regulation on emerging NMs through socio-economical politics is an aspect that has been evolving, perfecting, and advancing gradually during the last few years. However, many actions must be taken to reach the legal order and global harmonisation.

The momentum of nanotechnology development, establishment, and consolidation paths varies and differs between different countries. In some cases, there are no points of comparison regarding the aspects to be regulated or the standard type. The United States and Europe are the ones who have leadership in the establishment of both mandatory and soft regulations with specific considerations, where government agencies, public and private organisations have joined through initiatives, proposals, and generation of documents that contribute to the proper governance of nanotechnologies that include the regulation of NMs and even more, to achieve harmonisation at a global level, with the expectative to reach a delicate balance between the flexibility and control in the use and application of the regulatory measured to be beneficial in the aspects in where the social sectors are moving, such as the economic level in matters of exportation and importation products made with a nanotechnology base, but at the same time protect and safeguard the living beings and the environment.

Most of the topics discussed in turn to future regulations include: the common language related to the nomenclature, terminology, and classification, the standardised forms in its measurement, characterisation, traceability, aging of the NM, types, and levels of toxicological evaluation in the short, medium, and long term, the forms, and protocols for the disposition of them, as well as their impact on health and the environment. In addition to the products and processes generated based on NMs, their possible and potential combinations, risks, labelling for consumer awareness, work exposure, and the openness to dialogue on social and ethical aspects, several controversial points are being addressed at the national and international levels, which have promoted and motivated various sectors to propose and generate documents that lead their regulation.

To date, several countries have generated regulations on nanotechnology. The USA and Europe are actively working in the elaboration of different documents through their corresponding instruments. Considering that there are two forms of regulation: (a) mandatory and (b) voluntary or soft, the second one is mainly used while the obligatory frameworks develop,93–96 applying them as an essential reference in emerging technologies, such as nanotechnologies, where more information is necessary in specific areas that permit conduce to the generation of mandatory frameworks.94 Regulation can also be classified as horizontal and vertical. The horizontal one is defined as that regulation which affects two or more sectors, in contrast to the vertical regulation (or specific), in where dispositions affect a particular sector.95

USA and Europe have tried to include and cover several aspects of the NMs and their derivatives by applying horizontal regulation (or primary) forms. Even though the horizontal mandatory regulations cover the NMs, in this concern, it is essential to mention that the USA and Europe have different points of view on generating specific regulations for NMs. For instance, in Europe, the creation of a “NanoAct” could be elaborated from the previous instruments and regulations or the proposal of a particular and detailed regulatory framework named REACT NOW, whose acronym is Registration, Evaluation, Authorisation, Categorisation, and Tools to Evaluate Nanomaterials-Opportunities and Weaknesses.94,97,98

On the other hand, the USA regulation in the matter of NMs is conducted to ensure that products are safe for use and consumption, it focuses on occupational safety and health, establishing regulations to protect workers who handle NMs in work environments, and monitoring their exposure to the environment.94,99,100 Related to the voluntary or soft regulations of NMs, they are more flexible, and autoregulatory, represent an alternative to the laws and traditional regulatory politics, are complementary at the normative, and in several times and cases they become mandatory.94,95,101,102

Due to the controversy that NMs and their derivatives display in terms of commercialisation and the impact on health and the environment, soft regulation represents an essential and viable alternative for the industries to display to the consumer the degree of compromise and responsibility in the use of products based on NMs and prevented for new regulations.103 In this concern, there are four types of soft regulation by the nanotechnologies,93–95,104 which are described briefly:

(1) Registers; (2) labelled; (3) codes of conduct; (4) risk management systems; (5) guidelines; (6) technical standards.

Registers

As Saldívar Tanaka L., 2020 describes, the registers are systems that collect helpful information for public authorities to act more appropriately in risk management associated with protecting workers, consumers, and the environment. The information compiled in these systems is related to the potential hazard and possible exposure to humans and the environment.95 The United Kingdom, through the Department for Environment, Food and Rural Affairs (DEFRA), implemented this voluntary register to understand the properties of the NMs contained in products of importation.105 Through the EPA, the USA implemented the Nanoscale Materials Stewardship Program (NMSP), which was designed for those companies to voluntarily report information on the NMs related to the development, manufacturing, transportation, and risk management practices.106 In contrast, other European countries, such as France, Belgium, Norway, Denmark, and Sweden, have established obligatory registers for the NMs that cover aspects of the collection of information related to the production, distribution, and importation of the nanoscale substances (France, through the French Agency for Food, Environmental and Occupational Health & Safety-ANSES);107 or the registration of products based on NM in the Swedish Chemical Agency for Chemicals-KEMI implemented by Sweden. KEMI is a central supervisory authority of the Ministry of the Environment. It is responsible for “a non-toxic environment”108 to generate databases such as Nano DataBase through Danish Enviroment Pretction Agency (DEPA) or the RiskCat as a tool for understanding the risk of products based on NMs and the correspondent risk management (created by Denmark).

Labelled

Product labelling is an essential tool to provide complete and accurate information to consumers related to ensuring safety and health, compliance with regulations, and enabling informed decision-making. In the case of nanotechnology-based products, several countries have implemented regulations; some examples of these countries include essential aspects: (1) European Union (EU): The EU has established labelling requirements for NM products. Manufacturers must indicate on labelling whether a product contains NMs and provide additional information on their use. The voluntary tool is the EU Ecolabel for detergents and cleaning products.109 However, in Europe, there are also mandatory mechanisms for this purpose, such as regulations No. 1223/2009 110 by cosmetics to ensure the safety of this kind of products and protect consumers' health. It establishes specific requirements in terms of allowed ingredients, labelling, product notification, safety testing, and market oversight No. 1169/2011,111 which contains essential considerations related to food information; the primary purpose is protect the interests of consumers by providing them with clear and complete information about the food they consume. This allows them to make informed decisions, especially regarding food safety, allergies, and nutritional information; (2) Australia: the Therapeutic Goods Regulatory Authority of Australia (TGA) has established guidelines for labelling medicines containing NMs;112 (3) Canada: Health Canada is the agency responsible for health that has developed guidelines for labelling consumer products based on NMs. These guidelines guide how manufacturers can label and communicate the presence of NMs in their products;113 (4) South Korea: The Korean Ministry of Food and Product Safety (MFDS) has established regulations for labelling products containing NMs. These regulations require manufacturers to indicate the presence of NMs in products;114 (5) Mexico: It applies the Mexican technical standard non-mandatory NMX-R13830-SCFI-2014, which is equal to the ISO/TS1383 guide for voluntary labelling of consumer products containing nanoobjects.115

Even with these labelling initiatives, several concerns arise, such as industrial secrecy, which is another controversial point116 and a limitation for the total reliability and transparency to the user.

Codes of conduct

The codes of conduct in NM regulation are sets of principles and guidelines related to ethical and practical standards for their responsible use and management. They have been developed by different organisations, such as government agencies, academic institutions, and industry associations, to point out the ethics, safety, responsibility, and sustainability related to the use and development of NMs and their derivatives, covering essential topics associated with:10,12,23,24,93,95,117

(1) Occupational safety and health, related to the safety in workplaces.

(2) The manufacturing practices of NMs, which ensure that safety processes protecting the workers, environment, and consumers, are minimised.

(3) Promoting adequate transparency and communication about the presence of NMs in products allows consumers and end users to make informed decisions.

(4) The identification of possible risks of NMs, like potential hazards and implementation of mitigation measures.

(5) The impulse at the responsible and open research in the field of nanotechnologies.

It is important to note that codes of conduct regulating NMs are generally voluntary and do not have mandatory legal force. However, organisations in the different sectors must implement and follow these codes to manifest their commitment, responsability and safe practices.

Risk management systems

They are processes constituted to identify, evaluate, and control the possible risks associated with these technologies and apply them for the use and application of nanotechnologies and NMS.

These systematic processes are designed to help identify, manage, and reduce the potential risks to the health and environment to ensure that NMs are safe, during their life cycle, in addition to the responsible use during and after their development, through the appropriate continuous monitoring and, if it is the case, by taking precautionary measures, through the precautionary principle, based on taking preventive measures to protect human health and the environment, even in the absence of complete scientific certainty, to avoid possible risks and promote safe and sustainable use of NMs.

This involves identifying and evaluating potential risks, implementing appropriate control measures, and using continuous monitoring to ensure that established security standards are met. These systems are important because NMs and nanotechnologies are constantly growing in various fields, such as medicine, electronics, and energy, among others.

Some initiatives that have proposed and developed risk management systems on this topic we can mention: nano risk framework;118 Certifiable Nanospecific Risk Management and Monitoring System (CENARIOS);119 precautionary matrix for synthetic nanomaterials.10,95,120

Guidelines

They are documents that provide recommendations about the use of NMs in a responsible and safe way in the different sectors and applications. These documents are elaborated and developed by different instances like government agencies, experts in the development of NMs and nanotechnologies, and international organisations.

Examples of guidelines are:

Foresight guidelines for responsible nanotechnology development, elaborated by the Foresight Institute;121 guidance on the risk assessment of the application of nanoscience and nanotechnologies in the food and feed chain revised by the European Food Safety Authority (EFSA);95,122 guidance on the safety assessment on nanomaterials in cosmetics with the Scientific Committee on Consumer Safety (SCCS) and published by the European Commission;123 guidelines of the testing programme of WPMN124 by the OECD. In addition, a compilation of “the current status of projects (aimed) to develop or adapt OECD Test Guideline (TGs) and Guidance Documents (GDs) for nanomaterials”, has elaborated in collaboration to the Federal Institute for Occupational Safety and Health (BAuA), Germany, The National Institute for Public Health, and the Environment (RIVM), Netherlands and Organisation for Economic Co-operation and Development (OECD). In a status report in July 2022, the authors included a list of OECD documents completed and OECD projects under development applicable for nanomaterials, including since documents related to the physicochemical properties of the NMs to toxicity tests, for instance some listed guidelines included in the development or revisions of oecd Test Guideline (TG) and Guidance Documents (GD) applicable for nanomaterials, 2022,125 which literally mentions:

“Related to the physicochemical properties of the NMs (OECD documents completed):

(a) Test guideline No. 124 on determination of the volume specific surface area of manufactured nanomaterials.

(b) Test guideline No. 125 on particle size and size distribution of manufactured nanomaterials.

(c) Test guideline No. 318: dispersion stability in simulated environmental media.

(d) Guidance document 318 for testing of dissolution and dispersion stability of nanomaterials and the use of the data for further environmental testing and assessment strategies.

Related to the toxicity of the NMs (OECD documents completed):

(a) Test guideline No. 412: subacute inhalation toxicity: 28-day study.

(b) Test guideline No. 413: subchronic inhalation toxicity: 90 days study.

(c) Guidance document No. 39 on inhalation toxicity studies

(d) Study report and preliminary guidance on the adaptation of in vitro mammalian cell based genotoxicity TGs for testing of NMs.”

This document is very important compilations that also summarise those documents that are in development, as well as other activities related to the evaluation of the NMs. Then this list of guidelines and guidance's can be updated constantly or adapted since the use and application of the NMs in different sectors is increasing every day, which importance may help in minimise the possible risks associated with them in aspects related to the risk assessment, safe selection, and handling of nanomaterials, safe work practices, health, and environmental protection, labelling and risk communication.

In this context, is important to mention that the first initiative was the “special session of the potential implications of manufactured nanomaterials for human health and environmental safety” held by OECD's Chemicals Committee in 2005 126 which intended to identify human health and environment safety issues associated with manufactured NMs. Its significant achievement was the establishment of the WPMN in 2006, which is responsible for coordinating methods and developments that allow the elaboration of the appropriate NMs regulatory frameworks or the applicability of test guidelines. The efforts of countries and international and non-governmental organisations are conducted by the Steering Groups of Priority Area 9, which belongs to a nine-priority strategic area plan for regulatory science, establishing the test guidelines that involve the participation of the OECD.127,128 Also, OECD-WPMN has developed the “OECD Series on the safety of manufactured nanomaterials” in its open access series ENV/JM/MONO (Environmental Directorate. Joint Meeting of The Chemicals Committee and The Working Party on Chemicals, Pesticides and Biotechnology), a valuable tool for the development of standards, including ISO.129 These series consist of numerous reports about NMs guidance documents, health and environmental reports, risk and life cycle analysis, chemical, and physical properties, etc., aiming to develop future NMs regulations and legislations.

Standards

The OECD defines standard as legal instruments and other sets of policy principles that are committed to stablish the fundamentals of how certain processes must be done;130 ISO also defines standard, describing it as “a formula that describes the best way of doing something”.131 Both organisations agreed that these standards are elaborated in accordance with the opinion and consultancy of group of experts in the topics of different areas. In Latin America, standards on NMs are elaborated in accordance with the ISO standards, such as the NMX in Mexico, that are the first approach of regulating NMs based on an international document emitted by a regulatory authority such as ISO.94

In 2005, ISO established the Technical Committee 229 (ISO/TC 229) of nanotechnologies composed of 33 permanent countries and 16 observing countries. This committee has established four working groups headed by the United States, Canada, Japan, and China. Furthermore, ISO's primary goal is to contribute to the fundaments for the management, RA, and standardisation of nanotechnologies worldwide. Nowadays, ISO/TC 229 is composed of 39 permanent members, including all the countries with the most remarkable advances in nanotechnology and nanoscience's and 17 observing countries.132 The standards developed by ISO/TC 229 are focused on issues such as vocabulary, characterisation, specifications, and methodology guidance of NMs. Nowadays, to reach a more accurate regulation on NMs, ISO/TC 229 is developing a new ISO framework, “ISO/WD TS 12901-2: occupational risk management applied to engineered nanomaterials-part 2: use of the control banding approach” that is going to replace the previous framework “ISO/TS 12901-2:2014, nanotechnologies-occupational risk management applied to engineered nanomaterials-part 2:Use of the control banding approach”, for controlling the risks associated with occupational exposures to nano-objects, and their aggregates and agglomerates greater than 100 nm (NOAA)”,132 which means that previous solutions developed for control chemical occupational exposures can be suggested to be applied in other cases with similar exposure situations.

Other authors have suggested a nanotechnology regulation with at least two approaches: (1) modifying the current regulations and (2) considering NMs as a separate category of potential pollutants.133 Both proposals are closely related to the points made by Handy & Shaw (2007) about the assignment of unique numbers for existing chemicals such as CAS numbers (Chemicals Abstracts Service).134 For new materials without CAS numbers, it will be required to carry out tests considering that some NMs have the same chemical formula as the other bulk materials; thus, NMs must be considered “new substances.” In this situation, the Royal Society and The Royal Academy of Engineering in the United Kingdom favoured treating chemicals in nanoforms as new substances under the Registration, Evaluation, Authorisation, and Restriction Chemicals (REACH) criteria. Similarly, The Danish Board of Technology (2006) proposed classifying NMs separately from existing chemicals.135

The United States, Australia, and the United Kingdom have been at the forefront of generating information, leading to the development of regulatory frameworks for nanotechnology. Additionally, some other countries have made valuable contributions to this matter. According to the Statnano database, the top ten countries with nanotechnology standards are China, the United Kingdom, Iran, the Netherlands, the United States, Denmark, Sweden, Taiwan, Bulgaria, and France18 (Fig. 5).

Fig. 5. Top ten countries with nanotechnology standards to date.17,18 Original creation (using Excel and Biorender programs) based on information obtained from http://www.statnano.com (accessed on December 6th and 14th, 2023).17,18.

For the above, the development of international regulations around NMs would provide the tools for controlling environmental spoilage, keeping the integrity of terrestrial and aquatic ecosystems, and preventing or reducing their effects on animal, plant, and human health. Future regulations must focus on a progressive decrease in NM waste and the rational use of resources in the synthesis without affecting technological progress and improving life quality (Fig. 3).

Regulatory frameworks by regions

Europe

The European Chemical Agency (ECHA) is the EC regulation committee for the registration of manufactured or imported substances in ranges above one ton per year that includes carcinogenic, mutagenic, reproductive, persistent, bioaccumulative, and toxic NMs136,137 which aligns previous European Union legislation with the Globally Harmonised System (GHS).137 Other databases and systems for reporting and tracking NMs in Europe include the European Association for Coordination of Consumer Representation in Standardisation, the Bureau Europeén des Unions de Consommateurs, the German Environmental NGO Bund für Umwelt und Naturschutz Deutschland, the Grenelle II Act (by France), and the Nanotechnology Action Plan for the Safety of NMs (by Austria).136,138

The EC has published some guidelines and approaches to arrange scientific committees to address the regulatory problem of NMs. For example, in 2005, the EC published recommendations in the document “action plan for Europe 2005–2009” that aimed to reinforce the leading position of Europe in nanoscience's and nanotechnology but also highlighted the importance of environmental, health, social, and safety issues139,140 and a review of the European legislation recapping the risks involved with the production and use of NMs including aspects such as health, safety, and environment of any product containing NMs.138 By 2007, the EC included an approach that took advantage of existing laws and legislative structures to carry out a series of actions, including studies, recommendations, commissions, trials, and interventions to lead a regulatory framework.135 These actions preceded the creation of organisations such as ECHA.

In 2009, the EC recommended all users related to nanotechnological research, including funding organisations, industrial, academic, and research groups. Those recommendations emphasise the limitations and suggest solutions for better study and work-related practices following the precautionary principle, avoiding contact, and including NMs if safety risk information is unavailable. The recommendations include implementing safety, environmental, and hygiene measures for students, researchers, and workers.7

Also, the EC created the Scientific Committee on Emerging and Newly Identified Health Risk (SCENIHR) to assess the associated risk of working, using, or conducting research with NMs. In 2008, The SCENIHR set up an advisor structure of Scientific Committees and experts in different areas advising consumer safety, public health, environmental risk, and emerging and newly identified health risk based on risk assessments according to their area of experience.138 The SCENIHR considers that using NMs in medical devices is an area of potential risk, especially when those materials will be incorporated into cell therapy, tissue engineering, or blood products; adverse effects may include fertility reduction, and cancer, among others.134 In 2014, the SCENIHR released an expert public opinion on using AgNPs regarding safety, health, and environmental effects and their role in antimicrobial resistance.141 This document suggests scientific evidence cannot elucidate the mechanisms of action regarding microorganisms' AgNPs resistance,142 therefore, using AgNPs in several products should be further evaluated regarding human and environmental health towards broader regulations.

Later in 2011, the EC recommended that NMs be considered in the European regulations, including REACH and the European Classification, Labelling, and Packaging of Substances and Mixtures (CLP), which have been in force since 2009. CLP regulation aligns the previous European Union legislation with GHS and relates to the REACH legislation.141 Meanwhile, the ECHA and the European Union permanent members made public some documents that could ease the registration of NMs in REACH.137

In 2017, the EC, through ECHA, launched the European Union Observatory for Nanomaterials (EUON), providing information about NMs used in the European Union markets. This initiative also conducts research and innovation on NMs, includes information for new regulation, and serves as an ECHA collaborative tool jointly with REACH and the Organisation for Economic Cooperation and Development (OECD) test guidelines and alternative methods. Besides, EUON's platform describes the importance of learning the risks of NMs to human health and their potential environmental damage. It also considers the risk of exposure in working places and for workers as a primary subject.143,144 To provide valuable and complete information about NMs, EUON looks beyond the recommendations emitted in 2009 by the EC and proposes actions that are addressed to the public, students, researchers, workers, and industry, emphasising the importance of issues such as visual content targeted at the public, promote communication networks and the social, environmental, and economic implications of NMs.145

Some existing regulatory frameworks and legislation that include NMs can be applied to regulate their use, such as the guidelines of the Health & Safety Executive, e.g., (1) the Approved Code of Practice (ACOP) under the Control of Substances Hazardous to Health Regulations (COSHH), 2) the risk assessment guideline of the COSHH, and 3) the ACOP of the dangerous substances and explosive atmosphere regulations.146 In addition, other European agencies are responsible for the regulation of cosmetic products, such as the European Union Cosmetic Products Notification Portal and the REACH Scientific Committee on Consumers Safety, which has emitted opinions regarding the use of silica, hydrated silica, and silica surface modified with alkyl silicates (nanoform) in cosmetic products, commenting that evidence by far point out there is still not sufficient evidence in the safe use of those materials.147

Other approaches for developing regulatory frameworks include risk and NMs exposure assessments. In this respect, the REACH system aims to ensure that “new” chemical substances will not be marketed without convincing safety information under the premise «no information, no market».146 However, it is essential to address that due to the lack of a mandatory regulation on NMs, the information about the risk and exposure of NMs cannot be assured. On the other hand, the European Food Safety Authority stated the possibility of applying food regulations to use NMs and nanotechnologies (including guidelines for food products with NMs).138 In 2013, the group assessing already registered nanomaterials, -belonging to ECHA-focused on studying the exposure of NMs and their risks, recognised the usefulness of the manuals of the International Uniform Chemical Information Database for evaluating NMs.127

Until 2007, it was considered impractical to regulate nanotechnology in a European context due to the challenge of legislation for clear and specific regulatory processes.135 One of the clearest examples can be found in the pharmaceutical industry, where current legislation is insufficient for nano pharmaceuticals due to the particularity of their properties (morphology, composition, and surface properties), production methods, quality measurement, and good manufacturing practices (including quality control).148 Another industry in the European context that has also been subject to regulations is the cosmetic industry. In 2013, the European Union cosmetic regulation 1223/2001 was replaced by directive 76/768/EEC,136 generating a renewed concern about how NMs used in cosmetic products could impact human and environmental health, unlike directive 76/768/EEC, which only regulated cosmetics in a human health approach based on composition, labelling, packaging, and economic and technological requirements but not attending environmental issues.149

Other institutions that have published guidelines for the safe management of NMs include the Health & Safety Executive in the United Kingdom, which published an approach for the management of CNTs used in electronic devices, sensors, batteries, medical applications, etc.,150 since exposure levels to multi-walled CNTs were considered a serious concern due to their effects in lungs such as injuries, epithelioid granulomas, mechanical blockage of upper airways, inflammation, and fibrosis.134 On the other hand, the British Standard Institute published in 2009 a guideline for the safe management of NMs in terms of risk management, information needs, hazard assessments, exposure measurement, disposal, and control methods.7 Furthermore, the European Centre for Ecotoxicology of Chemical Task Force on Nanomaterials made significant progress on functional conceptualisation by grouping NMs according to their environmental prevalence. This is a decision-making framework for NMs classification and testing (DF4 nano grouping), which is a risk assessment (RA) tool consisting of three levels to assign four significant groups abbreviated as MGs (main groups), including soluble NMs (MG1's), persistent high aspect ratio NMs (MG2's), passive NMs (MG3's) and active NMs (MG4's).73

All these efforts and actions aimed at better and most effective management of NMs have impacted how NMs are used and treated. The frameworks, guidelines, committees, and organisations created over the last 20 years have led to the sustainable and responsible management of NMs; nevertheless, it is essential to establish mandatory enforcement of the proposed actions and plans. The regulatory gaps and the lack of information about the risks of NMs allow environmental and health issues to persist. Nonetheless, it is still necessary to compile all the information to generate global and unified criteria for regulations on NMs, which all industries or research groups related could use as a guideline for a responsible and sustainable standard. Thus, the European Union has come with strong efforts to face the challenges in the production, use, and disposal of NMs; however, the regulations have yet to reach a level of law. This may be related to regulatory gaps, in other words, the heterogeneous definition of NMs, and to the authors' perspective, there are still isolated efforts and committees of different organisations and governments that need to agree and join the information.

In the United Kingdom (UK) there are some regulatory authorities that participates in the nanotechnology regulation in different areas such as cosmetic, food, agroindustry's, etc. The UK Office for Product Safety and Standards (OPSS) regulates consumer products except food, medicine, and vehicles, participating in regulation of nanomaterials applied on cosmetic products.151 The Department of Environment, Food & Rural Affairs (DEFRA) is the governmental organisation in charge of the improvement and environmental conservation that has emitted documents about the labelling of food containing nanomaterials and the potential risk of NMs in the environment.105 The Health and Safety Executive (HSE) is the British national regulator for laboral safety in workplaces that in 2013 emitted a guidance document about the control of exposure to manufactured nanomaterials and has published other documents. Other organisations in UK responsible for NMs regulations are the Health Security Agency (HSA) and the Food Standard Agency (FSA).152,153

In Germany, organism such as the German Federal Institute for Risk Assessment, the Federal Ministry for Food and Agriculture, The German Chemical Industry Association and The German Environment Agency have developed recommendations and legislations about NMs used in food, cosmetics, etc.,154–157 while in Spain, the only known regulatory authority on NM Superiore di Sanità is the institution that has published research and document about risk assessments, characterisation and toxicological assays of NMs.158

The United States of America

As mentioned previously, the United States is the leading country in nanotechnology research and one of the countries where a wide variety of consumer products comprise many NMs and NPs. Through national institutions and initiatives, the United States authorities have been responsible for developing regulatory frameworks and legislations that address the use and necessary restrictions of NMs and nanotechnology in different industries. In this respect, the most critical regulatory authorities are the Food & Drug Administration (FDA), the Environmental Protection Agency (EPA), the National Institute of Occupational and Safety Health (NIOSH), and the Institute for Food and Agricultural Standards (IFAS). These organisations have been responsible for developing protocols in the United States about the risks of NMs and nanoproducts.136,159

The EPA classifies NMs according to their chemical properties under the Toxic Substances Control Act (TSCA) jurisdiction that prompts them to collect, publish, and review the tests made on chemical substances. In 2011, EPA worked in a 4-edge regulatory approach that included: (1) pre-manufacturing notifications, (2) a significant new use rule, (3) an information collection rule, and (4) a test rule.133 Also, manufacturers must provide detailed information about NMs, a provision previously voluntary through the Nanoscale Materials Stewardship Program.137 Under this approach, EPA gives a 90 days deadline for manufacturers to submit information about their NMs.127 By 2015, EPA had revised more than 160 new “nanoscale” chemical substances issuing actions aimed at the use and limitations of NMs in terms of limiting emissions to the environment and, with it, the use of protective equipment and the test applications to generate information about environmental and health effects.137

The FDA regulatory approaches, however, are restricted and only address terminology or classification issues around handling nanoproducts but not nanotechnology, which means that the processes to produce NMs are not included in the FDA regulatory initiatives. Furthermore, regulations emitted by this governmental agency only reach a limited class of products, regulating only those the sponsor requests.146,160 In June 2001, the FDA published the guidelines for NMs identification that are valid in all industries that use NMs in food, medical devices, drugs, cosmetics, and other products entitled “draft guidance for industry considering whether an FDA-regulated products involves the application of nanotechnology”.133 Among the actions undertaken by the FDA include the creation in 2006 of the FDA Nanotechnology Task Force to determine the regulatory approaches for the development of new products that incorporate NPs, as well as cooperation programs with the National Institute of Health/National Institute of Environmental Health Sciences.133,146 In addition, by 2013, the FDA launched the “nanotechnology regulatory science research plan”, which addresses the execution and management of various NPs and nanoproducts.148 With this plan, the FDA increases collaboration with external and international stakeholders to contribute to the solution of emerging challenges, regulatory science knowledge, facilitate innovation and coordination of policy to fulfil FDA's mission.161

Other regulatory organisations that endeavour to develop frameworks, regulations, and standardisations on NMs used in different areas aiming for their safe and responsible use are the IFAS,71 the National Cancer Institute through the Nanotechnology Characterisation Laboratory,73 the American Society for Testing and Materials, the Institute of Electrical and Electronics Engineers,133 and the NIOSH.159 In addition, in 2000, during Bill Clinton's administration, the National Nanotechnology Initiative (NNI) was created to span around 20 agencies and departments (including EPA) to work on the research and development (R&D) of NMs, and their impact on the environment, health, and safety;127,146,161–165 and in 2003, President George W. Bush signed the Nanotechnology Research and Development Act.6 Since its creation, NNI has strengthened nanotechnology development, increasing research capacity by supporting postdoctoral researchers, graduate students from a broad range of scientific areas, imparting courses, and investing in the technician training,166 boosting the development of high training human resources.

Agencies in charge of NM regulatory framework development are ruled under federal laws. As previously mentioned, EPA is governed under TSCA, and the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA).137 Other federal laws that can be useful for regulatory framework development include the Clean Air Act, the Comprehensive Environmental Recovery Compensation and Liability Act, the Resource Conservation and Recovery Act,133 the Federal Food, Drug, and Cosmetic Act, the Personal Care Products Council, and the Voluntary Cosmetic Registration Program.136 Although these regulatory agencies can settle a starting point for broader regulations, some of them, such as FIFRA have limitations on NMs, therefore, research about NM effects is needed for developing regulatory frameworks that can be applied according to the needs of the products using NMs.

It can be pointed out some parallelism between the United States and the European Union efforts to regulate NMs; both have legislation for the registration and management of chemical substances, including NMs, REACH in the case of the European Union and TSCA in the United States, besides, in both cases, frameworks and guidelines have been developed, not only for NMs but for products containing NMs such as food, pharmaceutics, and cosmetics that are consumed by humans and could be dangerous for human health and environmentally risky. Despite this, definitions of NMs are still different, so a homologated purpose and legislation are still off the table.

Nevertheless, with the many initiatives and agencies in charge of developing frameworks and guidelines for the safe management and use of NMs, the non-mandatory application is still an issue that needs to be solved due to the vast fields of applications of NMs. Therefore, governmental, and non-governmental agencies should coordinate among themselves to develop mandatory frameworks, considering the urgency of the significant number of products using NMs and the waste generated that could lead NMs to natural environments.

Other countries in the world

Other countries with outstanding R&D of nanotechnologies and NMs have developed or started developing projects, guidelines, RA, and/or regulatory frameworks that allow the responsible and controlled application of NMs, such as the Asian countries. Japan, in the last 20 years has focused its efforts on creating research platforms, testing methods of standardisation, data collection, and RA of NMs supported by governmental agencies such as the Ministry of Education, Culture, Sports, Science and Technology, the Ministry of Economy, Trade, and Industry, the Ministry of Health, Labour and Welfare, the Ministry of Environment, the National Institute of Material Science and the National Institute of Advanced Industrial Science and Technology Council for Science, Technology, and Innovation.26,127,137,146 China and South Korea have also worked in the development of regulatory policies for NMs using regulatory frameworks such as the Act of Registration and Evaluation of Chemicals or the Development Promotion Act, the involvement of some government departments as well as cooperation with international organisations (in the case of Korea)127 or the creation of agencies, such as the Chinese Academy of Sciences, or the National Centre for Nanoscience and Technology in China.146 These organisations/initiatives address guidance and regulatory issues such as terminology, safety requirements, and trade regulations useful for nanotechnology development and boosting China and Korea as technological leaders in this field.

In Canada, regulations are led by the Canadian Environmental Protection Act, the Pest Control Product Act, and the Fertiliser, Feeds, Food, and Drug Act;137 however, these legislations are not specific to NMs. NMs are regulated by different government organisations and frameworks; for cosmetics, the Cosmetic Regulation Act (1977) and Food and Drug Act (1985) regulates nanomaterials in cosmetic products;167 NMs in food products are regulated by the Canadian Food Inspection Agency (CFIA) and the Public Health Agency of Canada (PHAC)168 and the nanotechnology-based agri-products are regulated by the Canada Environmental Protection Act 1999 (CEPA), the Food and Drug Act, The Pest Control Product Act (PCPA)and the Canada Agricultural Products Act (CAPA).169 In Australia, there are at least four national chemical schemes that are relevant for NM regulation: Food Standards Australia-New Zealand, the National Industrial Chemicals Assessment Scheme, Therapeutic Good Administration, and the Australian Pesticides and Veterinarian Medicines Authority,159 all these legislations are applicable for food products containing NMs, particularly nanosilver. It is worth mentioning that Canadian and Australian regulatory initiatives are non-specific for NMs and were designed to regulate a wide range of products, which consider NMs or products containing NMs, so the importance of designing and developing specific regulations for NMs cannot be ignored.

Those regulatory initiatives and policies are based on other international or foreign frameworks; their criteria or at least some regulations have coincident points that encompass each country's needs and environmental or health goals. Therefore, the cooperation between countries, governmental institutions, private companies, and non-governmental plays a key role due to the synergic that can be accomplished (Table 1).

Some examples of regulatory frameworks on nanomaterials in different countries.

| Country | Framework |

|---|---|

| United States | Toxic substances control act |

| Draft guidance for industry considering whether an FDA-regulated products involves the applications of nanotechnology | |

| Nanotechnology regulatory science research plan | |

| National nanotechnology initiative | |

| Nanotechnology research and development act | |

| Federal insecticide, fungicide and rodenticide act | |

| Clean air act | |

| Comprehensive environmental recovery, compensation and liability act | |

| Resource conservation and recovery act | |

| Federal food, drug, and cosmetic act | |

| Voluntary cosmetic registration program | |

| European countries | Globally harmonised system |

| Action plan for Europe 2005–2009 | |

| Scientific committee on emerging and newly identified risk | |

| European classification, labelling and packaging of substances and mixtures | |

| Approved code of practice | |

| Risk assessment guideline of the control of substances, hazardous to health regulations | |

| ACOP of the dangerous, substances and explosive atmosphere regulation | |

| EU cosmetic regulation 1223/2001 | |

| Directive 76/768/EEC | |

| China | Act of registration and evaluation of chemicals |

| Development promotion act | |

| Canada | Canadian environmental protection act |

| Pest control product act | |

| Fertiliser, feeds, food and drug act | |

| Australia | Food standards Australia-New Zealand |

| National industrial chemical assessment scheme | |

| Therapeutic good administration | |

| Australian pesticides and veterinarian medicines authority | |

| Korea | Act of registration and evaluation of chemicals |

| Development promotion act |

In the race for nanotechnology development leadership, Mexico and other Latin American countries recently started to develop this area through the newest economic and technological tendencies that would allow them to create their technologies. Unlike the leading countries in nanotechnology, the development of NMs in Mexico is not considered an emerging area. In terms of funding, the public amounts invested in nanotechnology research in Mexico are minimal compared to the investment in countries such as the United States, China, and Germany. In perspective, Camarillo et al. (2019) estimated that nanotechnology investment in Mexico was only US60 million in the period 2005–2010,170 while in the United States, only in 2005, the funding from the NNI was USD 982 million.171 This valuation contrasts with Anzaldo et al. (2014), who pointed out that public investment in México until 2009 amounted to USD 128 million.172 Nevertheless, these are not isolated facts since the estimate for 2011 in public investment in Mexico for science and technology was equivalent to 0.43% Gross Domestic Product (GDP). Meanwhile, in many OECD country members, the investment amount is around 2% GDP.173 Furthermore, regarding public funding distribution to nanotechnologies, 37% was captured by private companies, followed by the National Council of Humanities Sciences and Technologies (CONAHCyT) research centres (17%) and public universities (16%).172

The balance recorded from 1994 to 2020 by the country is that 559 Mexican nanotechnological patents were registered in the World Intellectual Property Organisation (WIPO) Pantescope.174 By 2012, 86 companies used nanotechnology in their products175 and by 2014 the number of companies went up to 188,170 including Investigación y Desarrollo de Nanomaterials SA de CV, Nanomaterial SA de CV and Nanobio, Tronics SA de CV, Nano AZT, Nanomat S.A de CV19 and Nanoquem176 in Apodaca, Nuevo León as examples.

Since the early 21st century, Mexico has considered nanotechnology a strategic area in the “National Development Plan 2001–2006”.177 Thus, the nanotechnology area should be developed, boosted, and managed mainly by decentralised public organisms for being considered as a matter of “national security interest” or a social benefit. The first nanotechnological initiative was the National Technical Committee for Standardisation of Nanotechnologies which is jointly coordinated by the Ministry of Economy and the National Centre of Metrology, in charge of issuing Mexican non-mandatory regulations in nanotechnology and validating existing norms that have their equivalents in ISO standards;170,177–179 however, this committee does not have official attributions for the development of mandatory guidelines or regulations.