Abstract

The effects of high pressure treatment were investigated on the physical properties and possible shelf-life extension of soy protein-based high moisture meat analog (S-HMMA) produced by the extrusion process. High pressure treatment was applied at 200, 400 and 600 MPa for 5, 10 and 15 min. Physical properties of S-HMMA including appearance, moisture content, color and texture were analyzed during storage at 4 °C for 8 weeks. Higher pressure and longer storage time significantly reduced moisture content by creating more air cells and increasing cavitation. L* value of S-HMMA products increased at higher levels of pressurization while increasing storage time tended to decrease lightness. The unpressurized control S-HMMA product showed increasing hardness and toughness, while S-HMMA products subjected to various pressures exhibited higher hardness and toughness over time compared to the control sample at 200–400 MPa. Products treated with high pressure (600 MPa) showed the highest reductions in microbial growth but the aroma of the beans became more pronounced.

Keywords: High pressure, High moisture meat analog, Extrusion process, Physical property, Shelf-life

Introduction

Nowadays, consumption trends are leaning toward plant-based materials and protein foods, with plant-based proteins replacing animal proteins as a result of the ethical impact of meat consumption. Cattle farming systems have high CO2 emissions that impact the environment, while adversely affecting the health of consumers from the use of chemicals/antibiotics in animal husbandry (Rubio et al. 2020). Animal fats also contain high cholesterol components. Plant protein nutrients now play a greater role in replacing meat in food with a similar flavor, texture and nutritional value to meat products but with different components (Rubio et al. 2020). Plant-based protein product sources are varied, with legumes popularly used as raw materials due to their high protein content. A variety of plant protein products have been developed with a taste and texture similar to meat.

Extrusion technology is an efficient food production process, with many useful features that are advantageous to other food processing methods such as a continuous production system, high production rate and low production cost. The food products are exposed to high temperature for a short period of time causing less nutritional loss (Forte and Young 2016), while nutrient molecules are in a more easily digested state, with reduced toxins, anti-nutritional agents, enzymes and microorganisms that cause food spoilage. Multiple product shapes can be selected, saving energy and reducing environmental pollution (Forte and Young 2016). A previous research study on the production of high moisture artificial meat found that the extrusion process produced good quality products (Zahari et al. 2020). The trend of plant-based protein alternatives is gaining momentum among health-conscious consumers because protein derived from plants has no cholesterol and contains dietary fiber.

High-pressure food processing and preservation have been studied and applied in food for more than a century, with many food products now produced commercially (Bolumar et al. 2021). This process does not change the original food quality and maintains nutritional value. The high-pressure process requires a relatively large initial investment but gives good returns as a clean technology with minimal environmental impact and does not generate heat, resulting in little change in food quality. The high pressure also destroys or inhibits pathogenic microorganisms and enzymes that cause food to deteriorate (Bolumar et al. 2021; Cava et al. 2021).

Nowadays, the trend towards health has become an important point for choosing food and the consumer turning to eat plant protein instead of meat. They are not only expecting for nutrition but also the texture to be similar like real meat. High moisture meat analog (HMMA) is considered to be an artificial meat that has fiber characteristics close to real meat. However, HMMA must be stored in the cold condition. It can be kept for 7–10 days in refrigerator. It can also be stored in a − 18 °C freezer for 6 months. However the freezing temperature may cause changes in product texture. Thus, the author tried to find the way to extend the shelf life of HMMA and the high pressure processing (HPP) is one of the most interesting methods because it can be process without using heat. HPP has also been studied in combination with other processing technologies to extend shelf-life and improve food quality. Results indicated the ability of high pressure processing to increase the water holding capacity of meat products as a physical property indicative of tenderness (Tintchev et al. 2013; Sikes & Tume 2014). However, the possibility to extending the HMMA’s shelf life using HPP has not been yet explored.

Bringing all of these into account, it was expected that the use of HPP could result in an effective extension of shelf life. Thus, this research aimed to investigate the effect of high pressure treatment on the physical properties and shelf-life of soy-based high moisture meat analog (S-HMMA). Results can be applied in the food industry to predict product characteristics and safety during storage. This research responds to the needs of today’s consumers.

Material and methods

Materials

Soy protein isolate (SPI) and non-GMO defatted soy flour (DFSF) (Baker Soy Flour of ADM, USA) were purchased from Win Chance Industries, Thailand. Wheat gluten (WG) was provided from a local bakery ingredient store (Bangkok, Thailand).

High moisture meat analog preparation

S-HMMA products were processed using an intermeshing co-rotating twin screw extruder (Hermann Berstorff Laboratory, ZE25 × 33D, Hannover, Germany) with length/diameter ratio 870:25. The extruder consisted of 7 barrel parts ending with a long square-shaped cooling die. The highest barrel temperature was operated at 130 °C for barrel No. 6. The feed moisture content was 55% and screw speed 350 rpm. The extrudates were cut and kept in sealed laminated plastic bags in a cold room (4 °C) until used (followed Thai Pretty Patent of Kantrong et al. Thailand Pretty Patent, 2021).

Sample preparation by high pressure treatment

S-HMMA products were treated under high pressure at 200, 400 and 600 MPa for 5, 10 and 15 min (Bolumar et al. 2021) by a high pressure machine (KFHPP model HPP600 MPa, chamber size 5 L, Bao Tou KeFa High Pressure Technology Co., Ltd., China). The pressurized products were kept at 4 °C for 8 weeks during the evaluation period.

Microstructure of S-HMMA

Scanning electron micrograph (SEM) images of S-HMMA samples were taken with a microscope (Hitachi Tabletop Microscope, model TM4000Plus, Japan) at magnitude × 25. The samples were prepared by cutting into small pieces, tearing along the fibrous structure, and then sticking to a carbon stub without a gold film coating (Limsangoun et al. 2020).

Moisture content of S-HMMA

S-HMMA samples were ground then evaluated for moisture content according to the method of the AOAC (2019).

Color of S-HMMA

The color of the S-HMMA products was measured using the CIELAB 1976 L*, a*, b* color scale using a spectrophotometer (Spectraflash 600 plus, Datacolor International, USA). The CIE color values were recorded as L* = lightness (0 = black, 100 = white), a* (− a* = greenness, + a* = redness) and b* (− b* = blueness, + b* = yellowness), with color difference (Limsangouan et al. 2020) determined as the following equation: .

Textural properties

The texture of S-HMMA samples was measured on the day of production and during storage. The measuring method was adapted from Zahari et al. (2020). Each sample was cut into 2 × 2 cm squares and kept in a laminated plastic bag at room temperature. At least 5 squares of each sample were cut using a knife blade set in a texture analyzer (model TA.XT plus, Stable Micro System, England) at cutting speed 2 mm/s transversal to the direction of the extrudate flow from the extruder. Maximum cutting force (g) and area (g.s) were recorded and interpreted as hardness and toughness.

Stability of S-HMMA

Total microbial count (aerobic plate count) was analyzed according to Maturin and Peeler (2001) for 8 weeks of storage in a refrigerator (4 °C). The S-HMMA samples were tested every week for the first 4 weeks and again at 8 weeks.

Volatile compound analysis of S-HMMA

Volatile compounds were extracted and analyzed by the Headspace-Solid Phase Microextraction (HS-SPME) technique combined with gas chromatography and mass spectrometry (GC–MS) (7890A; Agilent Technologies, USA) followed the method of Zhang et al. (2021) with some modification. Three grams of sample (textured vegetable protein) with 2-methyl-3-heptanone as the internal standard were placed in a headspace vial. The vial was equilibrated at 60 °C for 20 min. The SPME fiber was then inserted into the vial with headspace extraction for 20 min. The fiber was then desorbed in the GC inlet at 250 °C for 10 min using an HP-5MS capillary column (30 × 0.25 mm × 0.25 µm). Helium was used as the carrier gas at a flow rate of 1 mL/min. An initial column temperature of 40 °C was raised to 200 °C at a rate of 5 °C/min, with a final temperature increase up to 250 °C at a rate of 5 °C/min. Volatile compounds were identified by comparing mass spectra with the NIST Mass Spectral Library and retention indices (RI) were calculated from the alkane series C6-C30 and compared with the literature. Relative concentration was calculated using the internal standard.

Experimental design and statistical analysis

All experiments were performed using a completely randomized design, with data expressed as mean ± standard error (SE) and subjected to statistical analysis using SPSS/PC version 12.0 (SPSS Inc., Chicago, IL, USA). The data were analyzed by one-way analysis of variance (ANOVA), with mean separations performed using Duncan’s multiple-range test. Differences at p < 0.05 were considered to be significant.

Results and discussion

Physicochemical characteristics of initial S-HMMA products

The physicochemical characteristics of S-HMMA products were initial moisture content 55.67 ± 0.37% (w.b.), with L*, a*, b* values of 71.57 ± 0.65, 2.26. ± 0.19 and 23.84 ± 0.84, respectively. Texture was measured by cutting the artificial meat sample to a length of 2 cm and measuring the longitudinal and transverse cutting forces of the fibers with a texture meter blade probe, reported as hardness and toughness. The longitudinal and transverse cutting forces of the fibers had hardness values of 1826.53 ± 73.15 and 1597.57 ± 57.60 g, with toughness values of 14,937.03 ± 588.57 and 13,898.24 ± 760.84 g.s., respectively.

Microstructures of S-HMMA

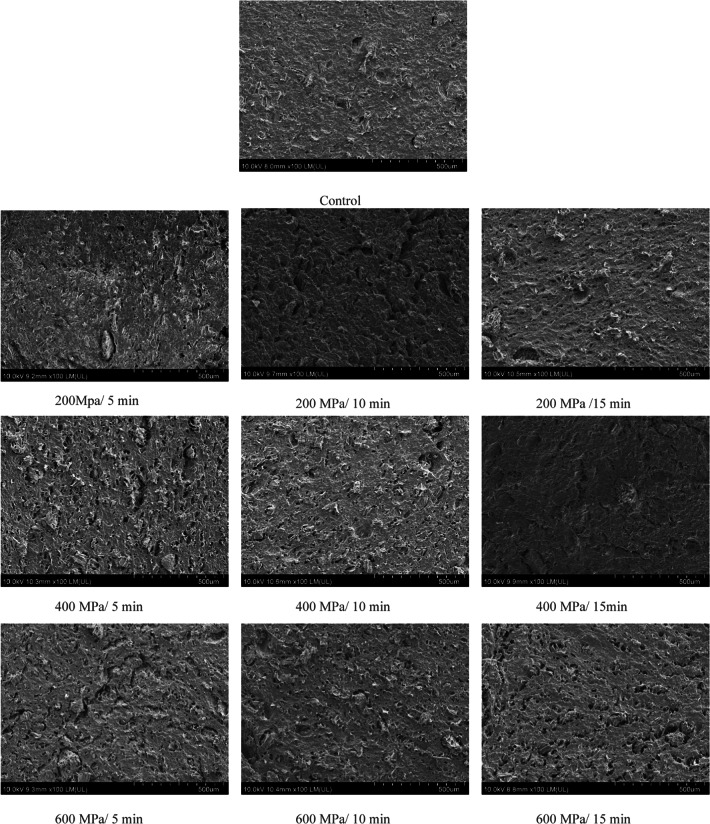

The surfaces and cross-sections of the products processed at different pressure levels were analyzed using a scanning electron microscope (Hitachi model SU8020, Japan), as shown in Fig. 1. Cross sections of artificial products subjected to higher pressure showed more cavitation compared to the unpressurized control. High pressure changed the binding structure of the proteins (Bolumar et al. 2021), thereby creating more air pockets. The fibers were more pronounced on the surface when subjected to pressure because structural changes in the proteins resulted in more fibrous characteristics (Beniwal et al. 2021), especially in artificial tissue products from the extrusion process.

Fig. 1.

Microstructure of S-HMMA under high pressure treatment (200–600 MPa for 5–15 min) at 100×

Moisture content of S-HMMA

The moisture content did not show any noticeable differences between high pressure treated and control samples at initial week gave results similar to those of dry-cured Iberian “Chorizo” that treated by high pressure at 600 MPa for 8 min (Cava et al. 2021). The moisture content of S-HMMA increased compared to the control sample when the artificial meat products were subjected to pressure treatment at different intervals (data not shown). Treatment time and pressure greatly impacted the moisture content of artificial meat products. With increasing time, product moisture content increased, while higher pressure significantly decreased the moisture content. Longer storage time resulted in reduced moisture content of the artificial meat products as well as the unpressurized control samples. Higher pressures increase water holding capacity by affecting the protein bonds (Sukmanov et al. 2019). Protein denaturing also increased water holding capacity (Li et al. 2021), with moisture content of the post-pressure products higher than the control sample.

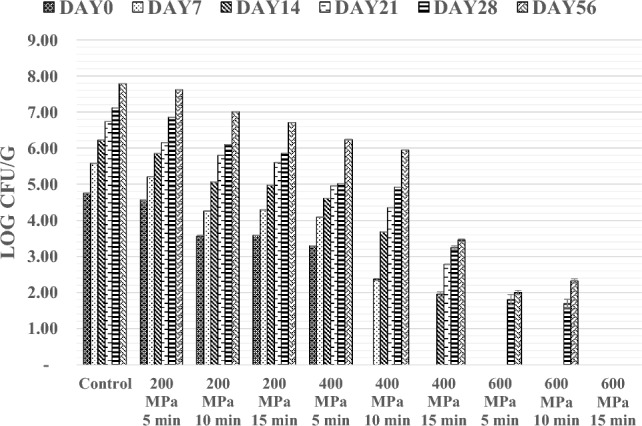

Color of S-HMMA

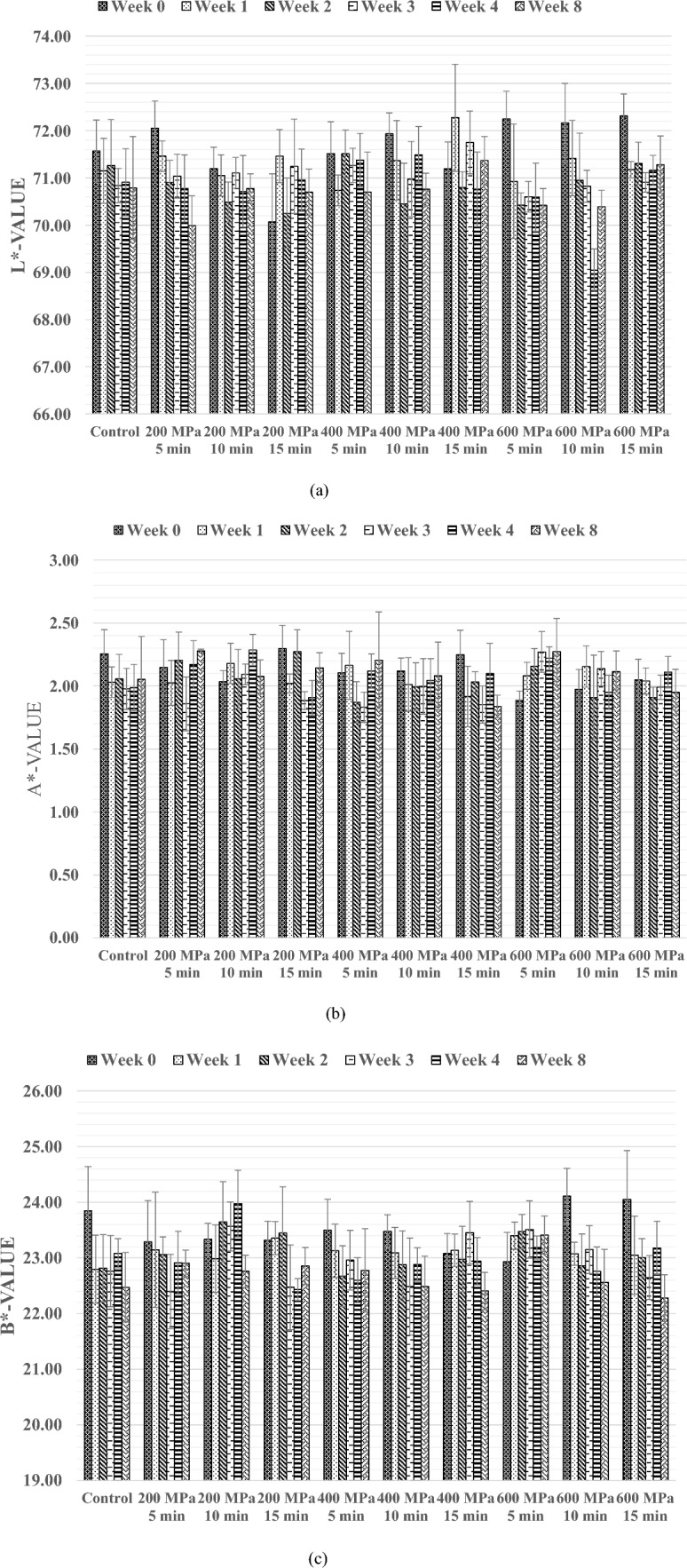

Color values in the CIE system (L*, a*, b*) of artificial meat products treated at various pressures and durations after 56 days (8 weeks) of storage at 4 °C are shown in Fig. 2. The untreated control artificial meat product at 56 days of storage slightly decreased in brightness, while pressurized artificial meat products had higher brightness than the control sample in agreement with the report of Janardhanan et al. (2023) that demonstrated the initial enhanced L* after pressure treatment at 350–600 MPa for 5–15 min of plant-based patties at week 0. Factors most affecting the brightness of the artificial meat products were pressure and duration of pressure. Higher pressure led to higher brightness. As pressure duration increased, the brightness decreased. However, at longer storage times, the brightness of pressurized artificial meat products decreased but was still higher than the unpressurized samples. The unpressurized control artificial meat product after 56 days of storage showed a slight but not significant decrease in a*, while the redness value of the pressurized product decreased compared to the control sample. Factors that most affected the redness of artificial meat products were amounts of pressure used and duration of pressure. The higher the pressure, the lower the redness. As the pressure duration increased, the redness value also increased. At longer storage periods, the pressurized artificial meat product showed reduced redness value lower than the unpressurized artificial meat product, corresponding to the brightness of artificial meat products.

Fig. 2.

Color of S-HMMA under high pressure treatment (200–600 MPa for 5–15 min) during 8 weeks, (a) lightness, (b) redness, (c) yellowness and (d) color difference

The unpressurized control artificial meat product showed significant reduction in yellowness (b*) after 56 days of storage that differed from the pressure treated product. For artificial meat products pressurized at different periods of time, the yellowness value increased compared to the control sample. Factors most affecting the yellowness of artificial meat products were interaction between the amounts of pressure used and the duration of pressure. The higher the pressure, the higher the yellowness value obtained, while the duration did not affect change in the yellowness value. At longer storage periods, the pressurized artificial meat product showed more yellow color but was still higher than the unpressurized artificial meat product, corresponding to the brightness of artificial meat products.

Increased pressure induced protein transformation in the studied products, thus affecting color change. At high pressure, proteins undergo changes in properties such as water absorption, solubility and 3D structure, thereby affecting the absorption and refraction of light, and increasing the brightness, redness and yellowness values of the product (Bolumar et al. 2021; Bak et al. 2012).

From the reviews of Bolumar et al. (2021), types of meat containing a high level of Mb (red meat) are more affected by HPP than those with a low level of Mb (white meat). This occurs because the change of meat color induced by pressure due to the denaturation of Mb and other meat proteins, alteration or disruption of the porphyrin ring, and changes in the redox chemistry of Mb. But, in this research the HMMA made from soy protein which does not contain MB therefore, the HPP did not show any significant effect on the color of the sample. There is only a very slight color change in comparison to unpressurized meat.

However, when comparing the sample color in terms of color difference (ΔE) as shown in Fig. 2(d), it was found that the pressure and treatment time were not significantly different according to the Dunnet’s comparison test.

Textural properties of S-HMMA

The textural properties of artificial meat products subjected to various pressures and treatment periods were assessed after storage for 56 days (8 weeks) at 4 °C. Hardness and toughness values along the transverse cutting forces of the fiber are shown in Tables 1 and 2. The initial transverse cutting strength was 1597.57 g, while the initial transverse direction was 13,898.24 g s.

Table 1.

Hardness (g) of S-HMMA under high pressure treatment (200–600 MPa for 5–15 min) during 8 weeks

| Treatment | Condition | Day* | ||||||

|---|---|---|---|---|---|---|---|---|

| Pressure (MPa) | Time (min) | 0 | 7 | 14 | 21 | 28 | 56 | |

| 0 | Control | 1826.53BC,ab ± 73.15 | 1945.36E,cd ± 89.32 | 1782.77A,a ± 104.79 | 1924.85E,c ± 98.23 | 2017.19E,d ± 104.80 | 1884.69B,bc ± 74.47 | |

| 1 | 200 | 5 | 1986.34D,c ± 72.05 | 1887.37BCDE,b ± 70.31 | 1784.20A,a ± 122.69 | 1878.88DE,b ± 62.79 | 1980.19DE,c ± 57.86 | 1978.43CDE,c ± 105.07 |

| 2 | 200 | 10 | 1857.81C,ab ± 108.62 | 1799.51AB,a ± 73.46 | 1865.47ABC,ab ± 50.31 | 1843.59CD,ab ± 88.31 | 1876.88BC,ab ± 73.82 | 1919.88BC,b ± 92.33 |

| 3 | 200 | 15 | 1776.88ABC,a ± 95.43 | 2052.69F,b ± 153.90 | 1812.04AB,a ± 66.05 | 1761.64AB,a ± 104.88 | 1838.35B,a ± 90.98 | 2046.57EF,b ± 103.86 |

| 4 | 400 | 5 | 1970.68D,c ± 112.31 | 1851.13BCD,ab ± 101.08 | 1904.29C,bc ± 54.74 | 1802.53BC,a ± 72.09 | 1925.33CD,bc ± 74.94 | 2057.76F,d ± 70.63 |

| 5 | 400 | 10 | 1854.87C,a ± 86.63 | 1823.42ABC,a ± 93.06 | 1843.74ABC,a ± 43.06 | 1884.10DE,a ± 83.74 | 1881.15BC,a ± 63.51 | 2017.31DEF,b ± 77.37 |

| 6 | 400 | 15 | 1740.56A,a ± 63.19 | 1872.62BCDE,b ± 58.62 | 1814.58AB,b ± 90.43 | 1709.63A,a ± 57.53 | 1831.84B,b ± 71.04 | 1935.93BC,c ± 43.34 |

| 7 | 600 | 5 | 1758.75AB,a ± 107.27 | 1908.55CDE,bc ± 116.34 | 1894.92BC,bc ± 94.84 | 1883.84DE,bc ± 68.20 | 1819.10B,ab ± 92.89 | 1971.81CDE,c ± 80.18 |

| 8 | 600 | 10 | 1711.02A,a ± 76.15 | 1920.52DE,cd ± 84.41 | 1891.03BC,c ± 90.90 | 1791.11BC,b ± 64.74 | 1694.40A,a ± 41.14 | 1965.51CD,d ± 74.69 |

| 9 | 600 | 15 | 1828.67BC,b ± 81.24 | 1746.85A,a ± 46.39 | 1901.31C,c ± 74.51 | 1774.07ABC,ab ± 87.21 | 1828.72B,b ± 61.85 | 1796.43A,ab ± 44.09 |

*Different letters in each row and column indicate significant difference, p < 0.05

Table 2.

Toughness (g.s) of S-HMMA under high pressure treatment (200–600 MPa for 5–15 min) during 8 weeks

| Treatment | Condition | Day* | ||||||

|---|---|---|---|---|---|---|---|---|

| Pressure (MPa) | Time (min) | 0 | 7 | 14 | 21 | 28 | 56 | |

| 0 | Control | 14,937.50BC,a ± 588.57 | 14,664.21BC,a ± 592.14 | 14,723.38BCD,a ± 521.41 | 14,896.12D,a ± 1,032.52 | 15,911.71E,b ± 713.99 | 14,972.18BCD,a ± 579.95 | |

| 1 | 200 | 5 | 16,182.43D,d ± 712.51 | 15,362.27D,c ± 567.95 | 14,426.47ABC,ab ± 833.14 | 14,263.96BC,a ± 694.27 | 15,157.41CD,c ± 744.60 | 15,024.12BCD,bc ± 562.09 |

| 2 | 200 | 10 | 14,938.66BC,c ± 755.32 | 14,146.94AB,a ± 392.15 | 14,861.74BCD,bc ± 626.62 | 14,274.91BC,ab ± 386.72 | 14,382.64B,abc ± 710.89 | 14,690.48ABC,abc ± 752.44 |

| 3 | 200 | 15 | 14,772.79B,a ± 772.66 | 16,136.95E,b ± 1,015.75 | 14,270.35AB,a ± 642.68 | 14,208.41BC,a ± 883.63 | 14,495.57BC,a ± 645.94 | 15,650.76D,b ± 412.12 |

| 4 | 400 | 5 | 15,523.96C,b ± 790.82 | 14,627.40BC,a ± 572.53 | 15,122.79D,ab ± 763.85 | 14,802.43CD,ab ± 542.88 | 15,456.51DE,b ± 703.72 | 15,208.37CD,ab ± 973.10 |

| 5 | 400 | 10 | 15,290.74BC,bc ± 810.28 | 14,100.75AB,a ± 694.25 | 14,592.97ABCD,ab ± 631.07 | 14,952.38D,b ± 449.80 | 15,146.75CD,bc ± 711.33 | 15,714.55DE,c ± 1,113.47 |

| 6 | 400 | 15 | 13,874.16A,b ± 846.92 | 15,008.99CD,c ± 1,030.35 | 14,048.49A,b ± 644.62 | 12,883.24A,a ± 525.12 | 14,932.28BCD,c ± 1,073.46 | 14,436.08AB,bc ± 560.20 |

| 7 | 600 | 5 | 14,691.85B,ab ± 618.28 | 15,529.09DE,c ± 1,114.21 | 15,081.25CD,bc ± 510.02 | 14,234.24BC,a ± 724.70 | 15,246.43DE,bc ± 652.32 | 16,363.80E,d ± 618.77 |

| 8 | 600 | 10 | 13,774.77A,ab ± 379.71 | 15,462.96DE,c ± 451.53 | 15,171.54D,c ± 869.26 | 14,019.48B,b ± 393.42 | 13,299.56A,a ± 548.08 | 15,562.57D,c ± 948.07 |

| 9 | 600 | 15 | 15,405.96BC,c ± 988.81 | 13,781.05A,a ± 382.08 | 14,755.90BCD,b ± 628.31 | 14,090.26B,a ± 488.55 | 14,245.85B,ab ± 694.45 | 14,096.72A,a ± 691.53 |

*Different letters in each row and column indicate significant difference, p < 0.05

The unpressurized control artificial meat product after 56 days of storage showed increase in fiber cross-sectional strength (corresponding to a decrease in moisture content with longer storage) but the cross-sectional strength of the fibers differed from the pressurized products. When artificial meat products were subjected to various pressures, the cross-sectional strength of the fibers increased compared to the control sample at 200–400 MPa but decreased at 600 MPa, with a significant reduction in the cross-sectional strength of the fibers. Factors that most affected fiber cross-sectional strength of artificial meat products were the amount of pressure used and the duration of pressure. However, when the artificial meat product was subjected to higher pressure and storage, a slight increase in fiber cross-sectional strength was observed compared to the control sample (Table 1).

The unpressurized control artificial meat product after 56 days of storage showed an increase in fiber cross-sectional toughness that differed from pressurized products. Artificial meat products subjected to 200–400 MPa pressure showed higher fiber cross-sectional toughness compared to the control sample. However, at 600 MPa and longer duration of pressure application there was a significant reduction in the cross-sectional toughness of the fibers. Factors most affecting fiber cross-sectional toughness of artificial meat products were the amount of pressure used and duration. However, when artificial meat products were subjected to higher pressure for longer, there was only a slight increase in fiber cross-sectional toughness compared to the control sample (Table 2).

Artificial meat products are composed of protein as the main component, therefore pressure has a significant effect on product properties, especially the texture resulting from protein transformation. Changing the 3D structure altered the water holding capacity, solubility, and agglomeration (Lawrie 1998; Kim et al. 2007; Marcos et al. 2010). The contact surface decreases, thereby increasing the hardness and toughness of the product (Bolumar et al. 2021).

Janardhanan et al. (2023) was investigated the texture (hardness) of plant-based patty (made from soy, rice and bean) under pressure from 350 to 600 MPa for 5–15 min. The result exhibited a linear trend with pressure that gave the same as this study at lower pressure that might be attributed to the lower cooking loss observed in the sample (Zhou et al. 2022).

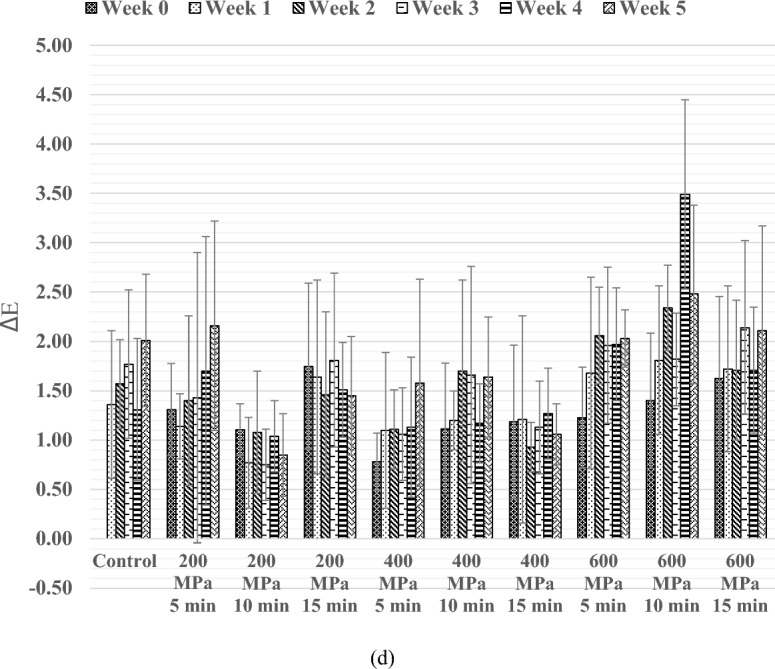

Storage stability of S-HMMA

Figure 3 shows that the unpressurized control artificial meat product had significant increase in the number of microorganisms after 56 days of storage. However, the amount of microorganisms differed from products treated with pressure. Artificial meat products pressurized for different periods of time had lower microbial count compared to the control sample. Factors that most affected the number of microorganisms in artificial meat products were the amount of pressure used and pressure duration. When the pressure and duration time increased, the number of microorganisms reduced. After longer storage time, the pressurized artificial meat product had significantly reduced microorganisms compared to the unpressurized artificial meat product. Several studies have examined the effect of pressure on microbial reduction in meat products (Bajovic et al. 2012; Hygreeva and Pandey 2016; Simonin et al. 2012) at the log CFU/g level. At pressure range 400–600 MPa with duration of 3–7 min, reduction of microbial count was up to 5 logs because of pressure damages the microbial cell wall and inhibits growth. In this study, the efficacy of pressure reduction was up to 6 log, similar to that of previous studies. In a recent paper, Cava et al. (2021) reported that treatment by high pressure at 600 MPa for 8 min reduced the count on dry-cured Iberian “Chorizo” inoculated with Listeria monocytogenes by 3.2 log after 60 d. The results of this work also agree with Jayathilakan et al. (2019) who reported that HPP application results in protein denaturation, which can inhibit some microorganisms in fish and fish products. It can be successfully implemented in the meat industry for achieving a product’s shelf stability.

Fig. 3.

Total microbial count of S-HMMA under high pressure treatment (200–600 MPa for 5–15 min) during 8 weeks

Odor characteristics of S-HMMA

The odor characteristics of 10 samples of S-HMMA products subjected to different pressure and time treatments by SPME–GC–MS were analyzed, with 16 volatile compounds found, as shown in Table 3. Bean flavors detected were hexanal, heptanone, heptanal, 2-pentyl-furan, 1-octen-3-ol, 3-octen-2-one, 2-octenal and 3,5-octadien-2-one. Pressure ranges between 100 and 1000 MPa are used as preservation methods to inactivate microorganisms and enzymes in both liquids and solids. Pressure has little effect on nutrients and volatile compounds in food. Volatile matter such as aldehydes, ketones, and terpenes at pressures ranging 100–600 MPa, tended to increase, while volatile compounds such as alcohols, esters, lactones and phenols at pressures ranging 100–600 MPa tended to decrease. When analyzing the odor of 10 samples treated with different pressure and time by the SPME–GC–MS method, total volatile compounds were mostly found as heptanone, heptanal, 2-pentyl-furan, 1-octen-3-ol, 3-octen-2-one, 2-octenal, and 3,5-octadien-2-one. The nutty flavor can be characterized by various odors including green, grassy and rancid. Our results concurred with Friedeck et al. (2006) who studied the use of soy protein in low-fat ice cream. Volatile hexanal was the main substance that gave the bean flavor. Samples exposed to higher pressure for a longer time yielded higher concentrations of bean-flavored volatile compounds, particularly 2-pentyl furan that was found in soybean protein isolate subjected to 600 MPa for 15 min with highest content of 1240 ppm. In contrast, with the work of Rajan et al. (2023) who studied the pasteurization of whole soy milk using HPP, we found that the beany and grassy flavors were reduced effectively after HPP treatment. However, the result of the effects of HPP on HMMA has not been report yet.

Table 3.

Odor characteristic of S-HMMA under high pressure treatment (200–600 MPa for 5–15 min)

| No | Compound | Odor properties | Concentration (ppm)* | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | 200/5 | 200/10 | 200/15 | 400/5 | 400/10 | 400/15 | 600/5 | 600/10 | 600/15 | |||

| 1 | Hexanal | Green, cut-grass, oil odor | 183 | 140 | 145 | 221 | 299 | 231 | 274 | 307 | 80 | 270 |

| 2 | Heptanone | Soap | 95 | 16 | 125 | 94 | 90 | 57 | 49 | 81 | 23 | 84 |

| 3 | Heptanal | Fat, citrus, rancid | nd | nd | 32 | 63 | 51 | 33 | 21 | 36 | 7 | 53 |

| 4 | 1-Octen-3-ol | Mushroom | 82 | 95 | 106 | 99 | 215 | 104 | 245 | 239 | 96 | 351 |

| 5 | 2,5-Octanedione | – | 15 | 17 | 21 | 19 | 36 | 18 | 47 | 36 | 16 | 40 |

| 6 | 2-Pentyl furan | Soybean, oil | 476 | 474 | 507 | 508 | 1255 | 538 | 1193 | 1194 | 560 | 1240 |

| 7 | 5-methyl-3-hepten-2-one | – | nd | 98 | 107 | 107 | 352 | 126 | 88 | nd | nd | nd |

| 8 | Heptanoic acid | Fatty | nd | nd | 22 | 41 | 96 | 36 | 24 | 24 | nd | 28 |

| 9 | 3-Octen-2-one | Nut, crushed bug | 39 | 55 | 89 | 34 | 119 | 42 | 75 | 75 | 49 | 85 |

| 10 | Hexanoic acid | Fatty | 51 | 56 | 61 | 57 | 0 | 61 | 108 | 109 | 58 | 134 |

| 11 | 2-Octenal | Green, nut, fat | nd | 40 | 50 | 48 | 167 | 49 | 164 | 128 | 56 | 139 |

| 12 | 3,5-Octadienone | Fruit, fat, mushroom | 20 | 92 | 27 | 23 | 47 | 21 | 48 | 47 | 21 | 35 |

| 13 | 3,5-Octadien-2-one | – | 135 | 93 | 180 | 165 | 390 | 163 | 368 | 390 | 145 | 368 |

| 14 | 2-Nonenal | Fat | nd | 30 | 35 | 32 | 80 | 32 | 71 | 99 | 30 | 83 |

| 15 | 2-Butyl-2-heptenal | – | 50 | 34 | 36 | 32 | 68 | 32 | 54 | 63 | 22 | 64 |

| 16 | 2-Butyl-2-octenal | – | 100 | 111 | 114 | 108 | 287 | 116 | 259 | 241 | 94 | 262 |

*Pressure (MPa)/time (min); nd = not detected

Conclusions

The physicochemical, microbial and volatile compound odor characteristics of soy-based high moisture meat analog products were analyzed under different pressure conditions (200, 400 and 600 MPa at 5, 10 and 15 min) after storage at 4 °C for 8 weeks (56 days). The color of the product became brighter than the control sample due to the inhibition of browning. Over time, the brightness decreased. Textural characteristics, especially the hardness and toughness of the pressurized products were higher than the control sample, with good characteristics similar to meat, especially toughness. When analyzing the microbial content throughout the storage period, products treated at high pressure (600 MPa) gave the highest reductions in microbial growth.

Acknowledgements

This work was supported by Kasetsart University Research and Development Institute (Granted number: FF(KU) 8.64).

Funding

Kasetsart University Research and Development Institute (Granted number: FF(KU) 8.64).

Declarations

Conflict of interest

The authors declare no conflicts of interest related to this study.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AOAC (2019) Official methods of analysis of the association of official analytical chemists: official methods of analysis of AOAC international (21st edn). AOAC, Washington, DC

- Bajovic B, Bolumar T, Heinz V. Quality considerations with high pressure processing of fresh and value added meat products. Meat Sci. 2012;92(3):280–289. doi: 10.1016/j.meatsci.2012.04.024. [DOI] [PubMed] [Google Scholar]

- Bak KH, Lindahl G, Karlsson AH, Orlien V. Effect of high pressure, temperature, and storage on the color of porcine longissimus dorsi. Meat Sci. 2012;92(4):374–381. doi: 10.1016/j.meatsci.2012.02.002. [DOI] [PubMed] [Google Scholar]

- Beniwal AS, Singh J, Kaur L, Hardacre A, Singh H. Meat analogs: protein restructuring during thermomechanical processing. Compr Rev Food Sci Food Saf. 2021;20(2):1221–1249. doi: 10.1111/1541-4337.12721. [DOI] [PubMed] [Google Scholar]

- Bolumar T, Orlien V, Sikes A, Aganovic K, Bak KH, Guyon C, Stubler A, Lamballerie M, Hertel C, Bruggemann DA. High-pressure processing of meat: Molecular impacts and industrial applications. Compr Rev Food Sci Food Saf. 2021;20(1):332–368. doi: 10.1111/1541-4337.12670. [DOI] [PubMed] [Google Scholar]

- Cava R, Higuero N, Ladero L. High-pressure processing and storage temperature on Listeria monocytogenes, microbial counts and oxidative changes of two traditional dry-cured meat products. Meat Sci. 2021;171:1–11. doi: 10.1016/j.meatsci.2020.108273. [DOI] [PubMed] [Google Scholar]

- Forte D, Young G (2016) Food and feed technology, 1st edn. Food Industry Engineering, Australia

- Friedeck KG, Aragul-Yuceer YK, Drake MA. Soy protein fortification of a low-fat dairy-based ice cream. J Food Sci. 2006;68(9):2651–2657. doi: 10.1111/j.1365-2621.2003.tb05784.x. [DOI] [Google Scholar]

- Hygreeva D, Pandey MC. Novel approaches in improving the quality and safety aspects of processed meat products through high pressure processing technology—a review. Trends Food Sci Technol. 2016;54:175–185. doi: 10.1016/j.tifs.2016.06.002. [DOI] [Google Scholar]

- Janardhanan R, Leidenz NH, Ibaňez FC, Beriain MJ. High-pressure processing and sous-vide cooking effects on physicochemical properties of meat-based, plant-based and hybrid patties. LWT. 2023;173:114273. doi: 10.1016/j.lwt.2022.114273. [DOI] [Google Scholar]

- Jayathilakan K, Sultana K, Pandey MC (2019) High-pressure processing of meat, fish, and poultry products. In: Non-thermal processing of foods, 1st edn. CRC Press

- Kantrong H, Charunuch C, Pengpinit W, Limsanuoun N, Prasert W (2021) High moisture meat analog by extrusion technology and its processing. In: Thailand pretty patent no. 17250. Department of Intellectual Property

- Kim YJ, Lee EJ, Lee NH, Kim YH, Yamamoto K. Effects of hydrostatic pressure treatment on the physicochemical, morphological, and textural properties of bovine Semitendinosus muscle. Food Sci Biotechnol. 2007;16(1):49–54. [Google Scholar]

- Lawrie RA. Meat science. 6. London: Woodhead Publishing Ltd.; 1998. [Google Scholar]

- Li YP, Kang ZL, Sukmanov V, Ma HJ. Effects of soy protein isolate on gel properties and water holding capacity of low-salt pork myofibrillar protein under high pressure processing. Meat Sci. 2021;176:1–6. doi: 10.1016/j.meatsci.2021.108471. [DOI] [PubMed] [Google Scholar]

- Limsangouan N, Charunuch C, Sastry SK, Srichamnong W, Jittanit W. High pressure processing of tamarind (Tamarindus indica) seed for xyloglucan extraction. LWT. 2020;134:1–10. doi: 10.1016/j.lwt.2020.110112. [DOI] [Google Scholar]

- Marcos B, Kerry JP, Mullen AM. High pressure induced changes on sarcoplasmic protein fraction and quality indicators. Meat Sci. 2010;85(1):115–120. doi: 10.1016/j.meatsci.2009.12.014. [DOI] [PubMed] [Google Scholar]

- Maturin L, Peeler JT (2001) Chapter 3. Aerobic plate count. In: Food and drug administration (FDA), bacteriological analytical manual online, 8th edn. Silver Spring, Berlin

- Rajan A, Velusamy M, Baskaran K, Rangarajan J, Natarajan V, Radhakrishnan M. High pressure processing of whole soymilk: effect on allergenicity, anti-nutritional factor, lipoxygenase activity and E-nose-aroma characteristics. Food Chem Adv. 2023;3:100427. doi: 10.1016/j.focha.2023.100427. [DOI] [Google Scholar]

- Rubio NR, Xiang N, Kaplan DL. Plant-based and cell-based approaches to meat production. Nat Commun. 2020;11:1–11. doi: 10.1038/s41467-020-20061-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sikes AL, Tume RK. Effect of processing temperature on tenderness, colour and yield of beef steaks subjected to high-hydrostatic pressure. Meat Sci. 2014;97(2):244–248. doi: 10.1016/j.meatsci.2013.12.007. [DOI] [PubMed] [Google Scholar]

- Simonin H, Duranton F, De Lamballerie M. New insights into the high-pressure processing of meat and meat products. Compr Rev Food Sci Food Saf. 2012;11(3):285–306. doi: 10.1111/j.1541-4337.2012.00184.x. [DOI] [Google Scholar]

- Sukmanov V, Hanjun M, Li YP. Effect of high pressure processing on meat and meat products. A review. Ukr Food J. 2019;8(3):448–469. doi: 10.24263/2304-974X-2019-8-3-4. [DOI] [Google Scholar]

- Tintchev F, Bindrich U, Toepfl S, Strijowski U, Heinz V, Knorr D. High hydrostatic pressure/temperature modeling of frankfurter batters. Meat Sci. 2013;94(3):376–387. doi: 10.1016/j.meatsci.2013.02.012. [DOI] [PubMed] [Google Scholar]

- Zahari I, Ferawati F, Helstad A, Ahlstrom C, Ostbring K, Rayner M, Purhagen JK. Development of high-moisture meat analogues with hemp and soy protein using extrusion cooking. Foods. 2020;9(6):772. doi: 10.3390/foods9060772. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang Y, Sun Y, Song H. Variation in volatile flavor compounds of cooked mutton meatballs during storage. Foods. 2021;10:2430. doi: 10.3390/foods10102430. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhou H, Vu G, Gong X, McClements DJ. Comparison of the cooking behaviors of meat and plant-based meat analogues: appearance, texture, and fluid holding properties. ACS Food Sci Technol. 2022;2:844–851. doi: 10.1021/acsfoodscitech.2c00016. [DOI] [Google Scholar]