Abstract

"Aquafaba", defined as legume cooking water, has a feature that can be used in various formulations as an egg and milk alternative in vegan products and improves functional properties such as foaming, emulsifying and gelling. In this study, it was aimed to investigate the usability of aquafaba in ice cream type frozen desserts containing different fruit purees (strawberry, nectarine and banana) by using its foaming capacity. Rheological properties, microstructure, overrun, melting characteristics, color measurement, dry matter, and sensory properties were investigated in different fruit-based frozen dessert samples. The brix value, density, protein content, foaming capacity (FC) and foaming stability (FS), flow behavior index, consistency coefficient, and overrun of aquafaba were determined as 7.1 ± 0°Bx, 1.022 ± 0.011 g/ml, 1.51 ± 0.41%, 85 ± 0% FC and 81 ± 0.23% FS, between 0.28 and 0.64, between 8.68 and 41.30 Pa·sn, between 116.75 and 395.93%, respectively. The dry matter content of the strawberry, nectarine, and banana-based dessert samples ranged between 17 and 48%, 20–49%, 25–50%, and the first dropping times were determined between 348 and 1538 s, 369–1689 s and 435–1985 s, respectively. As a result, cooking liquid leftover aquafaba can be used as a suitable raw material in the production of an alternative ice cream type frozen dessert for individuals with milk allergy, lactose intolerance or who prefer a vegan diet.

Supplementary Information

The online version contains supplementary material available at 10.1007/s13197-023-05885-y.

Keywords: Aquafaba, Fruit puree, Ice-cream, Non-dairy, Vegan, Frozen dessert

Introduction

Ice cream is a food item that is widely consumed by people of all ages around the world and has dozens of varieties. Although it is very rich in nutritional components, many people who have a vegan diet and are lactose intolerant cannot consume these products due to the milk content. Apart from that, milk contains more than 20 proteins that can cause a clinically abnormal immunological allergic reaction for humans (El-Agamy 2007). In today's world, health-conscious consumers have increasingly shifted their focus towards foods that both fulfill the body's specific nutritional requirements and possess disease-fighting properties. For these reasons, non-dairy plant-based alternatives are being studied to increase the variety of products that can be consumed by people who follow a vegan diet and have special food needs (Marrone et al. 2021).

Food waste and loss occur at each stage of the food supply chain such as harvest, manufacturing, transportation, delivery, retail, and food service from the field to consumers. The Food and Agriculture Organization (FAO) has reported that about a third (approximately 1.3 billion tons) of the food produced for human consumption is lost or wasted per year. Over recent years, the global production of legumes has reached 90 million tons, with approximately 12 million tons of chickpeas, representing 14% of this total output (Ray et al. 2023). Among the diverse types of legumes in all around the world, chickpea (Cicer arietinum L.) is third, widely grown legume, especially for Afro-Asian countries (Glusac et al. 2020). The preferred method for cooking chickpeas, according to Damian et al. (2018), generally involves soaking them first, followed by cooking with a 1:1.75 ratio of dry matter to water. At the end of the cooking process, this large amount of water remains as waste water which is called as Aquafaba. Aquafaba combines two Latin words, aqua for water and faba for the family Fabaceae. The Aquafaba obtained from legume cooking water is often discarded without being used. Legume cooking water is rich in carbohydrates, proteins, phytochemicals, vitamins, and minerals. There is a growing awareness of this issue worldwide (Eren et al. 2021).

Soaking, boiling, steaming, and canning generally applied to legumes are the most common methods that result in the loss of most nutritional components. In terms of food processing technology, protein isolates and concentrates from legumes contribute to binding and thickening, partly due to their starch and fiber content (Meurer et al. 2020). These components are also effective in providing water binding ability, freeze–thaw stability, that is, crystallization control. When the literature information is examined, it shows that aquafaba is a valuable ingredient that can be used as an egg and milk alternative in various formulations of vegan products, providing functional properties such as foaming, emulsifying and gelling (Stantiall et al. 2018). In short, aquafaba obtained from chickpeas has technological properties such as water and oil holding capacity, emulsion stabilizer, foaming, gelling and thickening. Aquafaba could be used as a vegan, gluten-free, and cholesterol-free additive in a variety of food items such as egg-free mayonnaise, meringue, mousse, whipped cream, ice cream, emulsified dressings, cocktails, and baking products. Moreover, different commercial products have been produced, such as the instant form of aquafaba and vegan mayonnaises with aquafaba (He et al. 2021). Mustafa et al. (2018) used aquafaba as a replacer of egg white in sponge cake white in sponge cake production. According to the results, the physical and foaming properties of aquafaba are similar to the egg white in sponge cake showing that aquafaba can be used replacer of egg white in sponge cake formulation and other baked confectionaries. Stantiall et al. (2018) proposed that the proteins and saponins in pulse cooking waters (PCW) help to create foam and gel, they examined the physicochemical properties of PCW and their effects on product quality by using PCW in the meringue formulation.

Fruits are a source of dietary fibers, vitamins, and phenolic compounds linked to health outcomes such as a lower ratio of chronic diseases. In this study, fruit-based vegan ice cream-type frozen desserts were made with strawberry, banana, and nectarine fruits, resulting in a functional, non-dairy, and vegan ice cream substitute. This study investigated the usability of aquafaba in a new fruit-based ice cream type frozen dessert using its strong foaming property.

Materials and methods

Materials

Chickpea seeds of Kabuli type which are a large seeded type suitable to different climates, fresh banana and nectarine, frozen strawberries, and sugar were purchased from local growers (Istanbul, Turkey). The chemicals used were of analytical purity and all of these chemicals were obtained from Sigma Aldrich (St. Louis, MO, USA) or Merck (Darmstadt, Germany).

Aquafaba production

Before the cooking process, chickpea seeds were soaked with distilled water (1:2.5 dry matter:water) for 16 h (Haileslassie et al. 2019). Chickpea samples were washed and filtered with stainless steel laboratory strainer (mesh 4 mm, size: 25 cm diameter). Cooking in boiling water (1:3.5 dry matter:water) was continued for 1–2 h and the process was continued until the samples softened. The process was carried out in a 5L stainless steel pressure cooker. At the end of the cooking process, the grains are kept in the pot without opening the lid until they reach room temperature and the grains are filtered with stainless steel laboratory strainer (mesh 4 mm, size: 25 cm diameter). Then Aquafaba was separated by using a strainer. It was stored in a freezer at − 18 °C until the time of use (Arçelik 2031 MB, Turkey).

Quality analysis of aquafaba

Density, brix and protein concentration value of aquafaba

Quality analysis such as density, brix and protein content were made using chickpea cooking water. The density of aquafaba was obtained by dividing its mass by its volume (g/ml). The brix value of the Aquafaba sample was measured with the binoculars of the hand refractometer and the result was taken as brix value. Kjeldahl nitrogen determination method was used for determination of % protein content of aquafaba. Protein content was calculated as the nitrogen content (N) multiplied by a conversion factor of 6.25 (AOAC 2011.11) (Shim et al. 2018).

Foaming capacity and foaming stability

According to Mustafa et al. (2018) aquafaba (Vsample = 20 ml) was whipped for 6 min at the highest level of the mixer (Fakir Sierra 425 W, Turkey). The volume of foam obtained was measured at time 0 (VF0). After 30 min, the volume of foam was determined again (VF30) and both foaming capacity (FC) and foaming stability (FS) were calculated following Eqs. (1) and (2), respectively.

| 1 |

| 2 |

Fruit puree production

Banana, strawberry, and nectarine fruits were used to obtain fruit puree. After washing the banana and nectarine with water, they were frozen with their peels in the deep freezer. Frozen bananas were mashed after removing the skin, and nectarines were mashed without removing the skin. The frozen strawberries were mashed directly. Food mixer device (Philips Hr2291/41 3000, Holand) with a rotating blade was used for the crushing process.

Production of fruit-based ice cream-type frozen dessert with aquafaba

Fruit puree was added to the prepared Aquafaba ice cream-type frozen dessert according to Table 1. They were mixed with a hand mixer (Fakir Sierra 425 W, Turkey) until the whipped ice cream-type frozen dessert mix had a homogeneous appearance for nearly 2 min. Whipped dessert mix was placed in the plastic ice cream container with lid. Frozen-desserts were preserved at − 18 °C. The stages were repeated separately for 21 fruit-based frozen dessert samples (Attachment 1) belonging to 3 different fruit varieties. While the abbreviations S, N, B, C, A represent Strawberry, Nectarine, Banana, Powdered Sugar and Aquafaba, respectively, the numbers represent the percentages in the mixture.

Table 1.

Ingredient ratios used in fruit-based ice cream-type frozen dessert with Aquafaba

| Sample Codes according to fruit-based type | Percentage weight ratio in ice cream (%w/w) | ||||

|---|---|---|---|---|---|

| Strawberry (S) |

Nectarine (N) |

Banana (B) |

Fruit | Sugar (C) |

Aquafaba (A) |

| S0.33C0.33A0.33 | N0.33C0.33A0.33 | B0.33C0.33A0.33 | 33.33 | 33.33 | 33.33 |

| S0.36C0.27A0.36 | N0.36C0.27A0.36 | B0.36C0.27A0.36 | 36.36 | 27.27 | 36.36 |

| S0.40C0.20A0.40 | N0.40C0.20A0.40 | B0.40C0.20A0.40 | 40.00 | 20.00 | 40.00 |

| S0.44C0.11A0.44 | N0.44C0.11A0.44 | B0.44C0.11A0.44 | 44.44 | 11.11 | 44.44 |

| S0.27C0.36A0.36 | N0.27C0.36A0.36 | B0.27C0.36A0.36 | 27.27 | 36.36 | 36.36 |

| S0.20C0.40A0.40 | N0.20C0.40A0.40 | B0.20C0.40A0.40 | 20.00 | 40.00 | 40.00 |

| S0.11C0.44A0.44 | N0.11C0.44A0.44 | B0.11C0.44A0.44 | 11.11 | 44.44 | 44.44 |

Quality analysis of fruit based ice cream-type frozen dessert with aquafaba

Rheological properties of fruit based ice cream-type frozen dessert

Rheological measurements were performed by Anton Paar (MCR 302, Austria) rheometer (PP50, gap 2 mm). The flow behavior (shear stress and shear viscosity) was examined by steady shear test at shear rates ranging from 0.1 to 100 s−1. All samples were taken at + 4 °C and analysis were carried in triplicate (Rossa et al. 2012). Yield stress (τ0), consistency index (K), and behavior index (n) were determined and interpreted using the Herschel-Bulkley model (Chen et al. 2019).

Microstructure investigation of fruit-based ice cream-type frozen dessert

The microstructure of whipped ice cream-type frozen dessert mixes was investigated by polarized light microscopy (PLM, Zeiss Axio imager A2, Carl Zwiss, Germany). After whipping of ice cream-type frozen dessert mix according to the production method, the mix was applied to the depression slide, covered with the cover slip for observation at + 4 °C from a 40 × objective.

Overrun (%)

The overrun of the ice cream-type frozen dessert was measured depending on the foaming capacity of Aquafaba. The required ingredients for the samples were placed in the cylinder measure to determine the mix volume (Vmix). The volume of the whipped ice cream-type frozen dessert mix (Vice-cream) was determined in a volumetric beaker after the required ingredients for the mix were prepared in accordance with the ice cream-type frozen dessert samples production method. Overrun (%) was calculated according to the formula number (4).

| 3 |

Dry matter (%)

Ice cream-type frozen dessert samples were weighed between 1 and 2 g in a tared container which was kept in the oven with a fan at 100 °C for 3.5 h. Afterwards, the ice cream samples kept in the desiccator were allowed to cool, weighed, and the dry matter % was calculated by determining the weight differences. Dry matter content (%) was calculated from the following formulas (4) (where m and E are the dry weight of the test sample and the initial weight of the test sample, respectively, expressed in grams):

| 4 |

Melting characteristics

The frozen (− 18 °C) dessert sample (20 g) was placed on a wire filter fixed in a graduated glass cylinder. The time when the ice cream frozen dessert samples were first dropped (sec) was taken as the time when they were first dropped, and the time when they were completely melted (sec) was taken as the full melting time (Cottrell et al. 1979).

Color measurement

For color measurements, Hunter Lab (Color Quest XE, UK) device with D65/10 standard light source according to the CIE system was used. The L* (lightness: 0 = black, 100 = white), a* (greenness (−), redness ( +)), and b* (blueness (−), yellowness ( +)) values of the samples were measured for each sample from 3 points.

Sensory properties

Sensory analysis was carried out with 9 panelists trained and experienced in sensory evaluation consisting of undergraduate and graduate students in Food Engineering. Sensory analysis of frozen dessert samples was performed using a hedonic scale (5: best, 1: worst score). The purpose of the study was explained to the panelists in an informative article. Sensory evaluation parameters were determined as intensity of coldness, firmness, icy texture, homogeneous structure, general appearance, crystallization, aroma, bitterness, sourness, melting in the mouth, and last taste in the mouth.

Statistical analysis

ANOVA and Tukey tests were performed using the SPSS 16.0 statistical package for Windows (SPSS Inc., USA). The relationships between desserts belonging to each fruit type were shown in lowercase letters as the relationships between frozen dessert samples prepared at the same rate but using different fruit types were shown in uppercase letters.

Result and discussion

Physicochemical properties of aquafaba

As a result of cooking legumes, water-soluble carbohydrates are dispersed into Aquafaba. The brix value of aquafaba was determined as 7.1 ± 0°Bx. Mustafa and Reaney (2020) reported that dry matter is 5.13%. In the study, the density of chickpea aquafaba was found to be 1.022 ± 0.011 g/ml. In similar study, the aquafaba density of chickpea was reported as 1.020 g/ml (Stantiall et al. 2018) and 1.01 g/ml (Mustafa et al. 2018). The protein content of aquafaba was determined to be 1.51 ± 0.41%. This result was similar to Stantiall et al. (2018), and Buhl et al. (2019) reporting protein concentration in aquafaba as 0.95% and 1.3%, respectively. Aslan and Ertas (2020) reported that the protein amount of aquafaba produced for cake making was 9.98%. The results obtained may vary according to the dry legume/water ratio. Proteins are the main component of foaming ability as they are amphiphilic consisting of hydrophilic and hydrophobic parts. These amphiphilic properties create a correlation between foaming ability and protein content. In addition, these proteins are heat stable and can be frozen, thawed, heated, or refrigerated for repeated use (Mustafa et al. 2018).

The foaming capacity was determined as 85 ± 0% at 0 min after whipping and the foam has a stable and homogeneous appearance. The foaming stability after 30 min was calculated as 81 ± 0.23% and a partial decrease in volume was observed. Mustafa et al. (2018), in a study examining the foaming capacity of aquafaba recovered from canned chickpeas of different brands, reported that the foaming capacity ranged from 182.22 to 480.01%, and the foaming stability ranged from 77.21 to 91.61%. In another study, the addition of additives such as citric acid and salt to Aquafaba and experiments were made at different dry matter/water ratios. The foaming capacity was between 504.71 and 510.01%, and the foaming stability was between 81.17 and 82.10% (Nguyet et al. 2021). In another study, the foaming capacity of Aquafaba obtained from Garbanzo chickpeas was 58 (Stantiall et al. 2018). Differences in results may be due to differences in chickpea variety, processing conditions, canning process conditions, and additives.

Rheological properties of ice cream-type frozen desserts

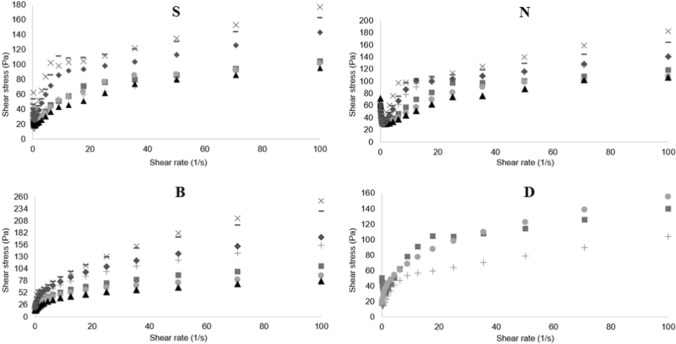

The shear stress versus shear rates of the ice cream-type frozen dessert mixes were shown in Fig. 1. Rheological properties indicate the flow character of a fluid and are essential because of their influence on the sensory quality of ice cream. Most of the ice cream mixes showed non-Newtonian pseudoplastic flow behavior (Bahramparvar and Tehrani 2011). The flow behaviors (n value) of all mixes of dessert samples were less than 1 (Table 2), thus they showed a pseudoplastic flow behavior. The flow behavior index varied from 0.28 to 0.64, meanwhile the consistency coefficient varied from 8.68 to 41.30 Pa·sn. In accordance with the consistency coefficient (K), the samples (B0.44C0.11A0.44, S0.44C0.11A0.44 and N0.44C0.11A0.44) with the lowest sugar content and the highest fruit ratio showed the lowest values, in accord with the lower value of the viscosity. The consistency index was significantly affected by the variety and ratio of the fruit, so even small differences in the fruit ratio affected this value. The reason for the increase in consistency index may be due to compounds that can interact with water, such as fiber, pectin, and starch in the fruit content.

Fig. 1.

Effects of aquafaba on shear stress-shear rate rheograms of fruit-based dessert mixes. While the abbreviations S, N, B, C, A represent Strawberry, Nectarine, Banana, Sugar and Aquafaba, respectively, the numbers represent the percentages in the mixture. (S) Strawberry (×S0.11C0.44A0.44; — S0.20C0.40A0.40; ☐ S0.27C0.36A0.36; + S0.33C0.33A0.33; ◼ S0.36C0.27A0.36;● S0.40C0.20A0.40;▲ S0.44C0.11A0.44), (N) Nectarine (N0.11C0.44A0.44; —N0.20C0.40A0.40; ☐ N0.27C0.36A0.36; + N0.33C0.33A0.33; ◼N0.36C0.27A0.36;● N0.40C0.20A0.40; ☐ N0.44C0.11A0.44), (B) Banana (×B0.11C0.44A0.44; — B0.20C0.40A0.40; ◆ B0.27C0.36A0.36; + B0.33C0.33A0.33; ◼ B0.36C0.27A0.36;● B0.40C0.20A0.40; ▲ B0.44C0.11A0.44), D equal proportions of ingredients (● B0.33C0.33A0.33; + S0.33C0.33A0.33; ◼ N0.33C0.33A0.33)

Table 2.

Herschel-Bulkley model parameters of fruit-based ice cream-type frozen dessert with Aquafaba

| Samples | τ0 (Pa) | K (Pa·sn) | n | R2 |

|---|---|---|---|---|

| S0.33C0.33A0.33 | 1.05 ± 1.82cA | 22.52 ± 4.66bA | 0.33 ± 0.02cdA | 0.983 |

| S0.36C0.27A0.36 | 7.62 ± 1.31bcB | 18.80 ± 1.27bcA | 0.37 ± 0.01cC | 0.967 |

| S0.40C0.20A0.40 | 16.11 ± 0.01abB | 12.48 ± 2.39cdA | 0.44 ± 0.02bB | 0.942 |

| S0.44C0.11A0.44 | 15.21 ± 2.32abB | 8.68 ± 0.30dA | 0.50 ± 0.01aB | 0.967 |

| S0.27C0.36A0.36 | 7.43 ± 7.46bcAB | 32.54 ± 4.31a1B | 0.31 ± 0.03dA | 0.954 |

| S0.20C0.40A0.40 | 14.57 ± 4.44abA | 34.03 ± 4.17a1B | 0.33 ± 0.00cdC | 0.908 |

| S0.11C0.44A0.44 | 19.10 ± 6.04aA | 31.57 ± 2.86aB | 0.35 ± 0.02cdA | 0.917 |

| N0.33C0.33A0.33 | 17.93 ± 6.29abB | 21.24 ± 8.24bA | 0.39 ± 0.05abA | 0.926 |

| N0.36C0.27A0.36 | 5.40 ± 2.33bB | 41.30 ± 4.86aC | 0.33 ± 0.01cB | 0.935 |

| N0.40C0.20A0.40 | 20.65 ± 2.33aB | 23.59 ± 4.86bB | 0.46 ± 0.01bB | 0.929 |

| N0.44C0.11A0.44 | 30.21 ± 4.22aC | 10.55 ± 0.51cA | 0.64 ± 0.02aC | 0.923 |

| N0.27C0.36A0.36 | 16.41 ± 7.68abB | 26.37 ± 3.18bA | 0.35 ± 0.05cA | 0.901 |

| N0.20C0.40A0.40 | 20.77 ± 6.75aA | 24.90 ± 0.71bA | 0.38 ± 0.02abB | 0.918 |

| N0.11C0.44A0.44 | 19.60 ± 2.14aA | 28.11 ± 2.30bB | 0.38 ± 0.00abB | 0.944 |

| B0.33C0.33A0.33 | 4.15 ± 3.93cA | 30.06 ± 0.50bA | 0.35 ± 0.02cA | 0.999 |

| B0.36C0.27A0.36 | 0.03 ± 0.05cA | 27.21 ± 2.95bcB | 0.30 ± 0.01dA | 0.999 |

| B0.40C0.20A0.40 | 0.00 ± 0.00cA | 25.48 ± 1.51cA | 0.28 ± 0.01dA | 0.994 |

| B0.44C0.11A0.44 | 1.35 ± 1.31cA | 19.93 ± 1.76dB | 0.29 ± 0.02dA | 0.996 |

| B0.27C0.36A0.36 | 0.36 ± 0.62cA | 36.79 ± 2.52aB | 0.33 ± 0.01cA | 0.999 |

| B0.20C0.40A0.40 | 12.89 ± 3.14bA | 29.21 ± 0.58bcAB | 0.43 ± 0.00bC | 0.997 |

| B0.11C0.44A0.44 | 22.33 ± 5.09aA | 20.20 ± 0.41dA | 0.53 ± 0.01aC | 0.995 |

*τ0: yield stress; K: consistency index; n: flow behavior index

Different lowercase letters indicate that the difference between samples of the same fruit variety statistically significant. Those shown with uppercase letters show that the samples prepared with different fruit types but containing the same amount of fruit, sugar and aquafaba are different from each other (p < 0.05). While the abbreviations S, N, B, C, A represent Strawberry, Nectarine, Banana, Sugar and Aquafaba, respectively, the numbers represent the percentages in the mixture

Intermolecular associations and reduction in particle size increased yield stress (Kurt and Atalar 2018). According to the yield stress, the samples (S0.11C0.44A0.44 and B0.11C0.44A0.44) with the highest sugar content and the lowest fruit ratio showed the highest values, in harmony with the lower particle size. However, for dessert mix samples containing nectarine, the product with the highest fruit content (N0.44C0.11A0.44) had the highest yield stress. This situation may be caused by the stabilizing and thickening properties due to the fiber structure and pectin substances in the peel of the nectarine puree.

Microstructure properties of frozen-dessert mix

The foam structure of the ice cream-type frozen dessert mixes were seen in the form of intertwined rings (Attachment 2). The fact that the image clarity of the banana-based samples was lower than the strawberry and nectarine-based samples could be due to the starch and fibrous structure found in bananas. It appeared that the foam distribution and size was not completely homogeneous in mixes. However, others were more homogeneous than other samples of the same fruit type. The most homogeneous appearance in strawberry-based mix was formed in the S0.27C0.36A0.36, and this was the most admired sample among other strawberry-based dessert in terms of firmness, homogeneous structure and general appearance. Similarly, the most homogeneous appearance in nectarine based mix was formed in the N0.27C0.36A0.36, and this was the most admired sample among other nectarine-based dessert in terms of firmness and general appearance. The most homogeneous appearance in banana-based mix was formed in the B0.20C0.40A0.40, and this was the most admired sample among other banana -based dessert in terms of homogeneous structure and general appearance. It was stated that larger air bubbles were related to greater foam stability (da Silva et al. 2020). Therefore, S0.44C0.11A0.44, N0.44C0.11A0.44, and B0.44C0.11A0.44 which had larger bubbles, lower dry matter, and partially higher overrun could show more stable foam properties.

Quality characteristics of fruit based ice cream-type frozen dessert

Overrun

Overrun results of the samples were shown in Table 3. The overrun value is an important matter that affects the quality parameters of frozen desserts, such as color, texture, melting parameters and sensory properties. The overrun values varied from 116.75 to 395.93%. The highest overrun value was found in B0.11C0.44A0.44, S0.40C0.20A0.40, N0.44C0.11A0.44. The effect of the fruit type on the overrun value was found to be statistically significant (p < 0.05). Similarly, it was reported in a study that the addition of durian puree increased the overflow of ice cream (the ability to bind water and form fruit gels), while the addition of jackfruit, melon, and pumpkin puree reduced the overflow of ice cream (Rawendra and Dwi 2020). The characteristics of the fruit variety also affect the overrun value of the ice cream.

Table 3.

Overrun (%), dry matter (%), L*, a*, and b* results of fruit-based ice cream-type frozen dessert with aquafaba

| Samples | Overrun (%) | Dry matter (%) | L* | a* | b* |

|---|---|---|---|---|---|

| S0.33C0.33A0.33 | 168.40 ± 6.55eB | 37.68 ± 0.07dA | 73.09 ± 2.17bc | 6.55 ± 2.20bc | 9.80 ± 1.44a |

| S0.36C0.27A0.36 | 286.66 ± 10.34bcC | 32.15 ± 0.21eA | 72.80 ± 2.76bc | 8.58 ± 2.54ab | 10.22 ± 1.22a |

| S0.40C0.20A0.40 | 395.93 ± 7.04aC | 25.01 ± 0.05fA | 73.36 ± 4.52bc | 10.04 ± 4.24ab | 10.81 ± 1.42a |

| S0.44C0.11A0.44 | 273.20 ± 8.80cdB | 16.74 ± 0.03gA | 67.47 ± 6.27c | 13.25 ± 3.05a | 11.62 ± 1.46a |

| S0.27C0.36A0.36 | 294.01 ± 10.40bB | 40.47 ± 0.39cA | 79.76 ± 2.59ab | 4.21 ± 1.69bcd | 9.63 ± 0.65a |

| S0.20C0.40A0.40 | 276.01 ± 8.14bcdC | 44.11 ± 0.05bA | 80.59 ± 1.35ab | 1.89 ± 0.96cd | 9.42 ± 0.60a |

| S0.11C0.44A0.44 | 263.55 ± 4.22dB | 48.35 ± 1.12aA | 86.01 ± 1.85a | − 1.84 ± 0.27d | 8.91 ± 0.31a |

| N0.33C0.33A0.33 | 238.89 ± 9.62bC | 39.74 ± 0.73cB | 83.45 ± 4.49a | − 2.83 ± 1.00ab | 19.11 ± 1.50ab |

| N0.36C0.27A0.36 | 169.46 ± 10.91cdA | 34.28 ± 0.35dB | 81.60 ± 0.23a | − 3.37 ± 0.18b | 19.30 ± 3.40ab |

| N0.40C0.20A0.40 | 272.81 ± 3.80aB | 27.73 ± 0.24eA | 80.69 ± 2.07a | − 2.97 ± 0.06ab | 19.93 ± 1.61ab |

| N0.44C0.11A0.44 | 278.97 ± 3.44aB | 19.62 ± 0.78fB | 76.42 ± 1.28a | − 1.86 ± 0.32a | 20.74 ± 1.76a |

| N0.27C0.36A0.36 | 139.62 ± 9.71eA | 41.99 ± 0.32cA | 81.65 ± 4.20a | − 3.81 ± 0.19bc | 18.66 ± 1.10ab |

| N0.20C0.40A0.40 | 185.58 ± 6.75cB | 45.02 ± 1.35bA | 81.94 ± 0.66a | − 3.40 ± 0.27b | 17.83 ± 1.94ab |

| N0.11C0.44A0.44 | 159.80 ± 8.49dA | 48.86 ± 1.15aA | 83.83 ± 2.85a | − 4.55 ± 0.43c | 14.82 ± 1.04b |

| B0.33C0.33A0.33 | 116.75 ± 9.53dA | 44.07 ± 0.16cC | 81.80 ± 2.80ab | − 4.38 ± 0.31bc | 14.07 ± 0.81bc |

| B0.36C0.27A0.36 | 212.41 ± 5.00cB | 39.22 ± 0.03dC | 80.66 ± 1.89bc | − 3.74 ± 0.33ab | 14.28 ± 0.41bc |

| B0.40C0.20A0.40 | 248.96 ± 8.12bA | 32.45 ± 1.41eB | 78.90 ± 1.17bc | − 3.86 ± 0.18ab | 14.78 ± 0.82b |

| B0.44C0.11A0.44 | 220.82 ± 4.56cA | 24.98 ± 0.20fC | 74.90 ± 1.12c | − 3.18 ± 0.09a | 16.19 ± 0.28a |

| B0.27C0.36A0.36 | 128.95 ± 6.84dA | 46.07 ± 0.98bcB | 78.82 ± 3.35bc | − 4.05 ± 0.49b | 13.34 ± 0.59cd |

| B0.20C0.40A0.40 | 132.89 ± 6.84dA | 47.50 ± 0.39bA | 87.32 ± 4.17a | − 4.40 ± 0.15bc | 12.36 ± 0.11de |

| B0.11C0.44A0.44 | 268.43 ± 5.88aB | 50.24 ± 0.30aA | 84.36 ± 0.79ab | − 4.81 ± 0.24c | 11.95 ± 0.31e |

*Different lowercase letters indicate that the difference between samples of the same fruit variety statistically significant. Those shown with uppercase letters show that the samples prepared with different fruit types but containing the same amount of fruit, sugar and aquafaba are different from each other (p < 0.05). While the abbreviations S, N, B, C, A represent Strawberry, Nectarine, Banana, Sugar and Aquafaba, respectively, the numbers represent the percentages in the mixture

Dry matter amounts of fruit-based ice cream-type frozen dessert

Dry matter analysis result of the samples was given in Table 3. The dry matter content of the strawberry, nectarine, and banana-based dessert samples ranged between 17 and 48%, 20–49%, and 25–50%, respectively. Similarly, Çakmakçi et al. (2016) found the amount of dry matter in ice cream between 37.29 and 41.38%. The changing the amount of fruit content in banana and nectarine-based ice cream samples affected the dry matter amount less than strawberry-based dessert. It is seen that the use of different fruits in the samples with high fruit ratio creates a significant difference on the dry matter percentage (p < 0.05). Sugar makes the function of a dense sweetener and a source of dry matter in ice cream (Polischuk et al. 2013). As a result that phenomenon, the highest dry matter content was found in ice cream samples with the highest sugar and the lowest fruit ratio S0.11C0.44A0.44, N0.11C0.44A0.44, and B0.11C0.44A0.44. The least dry matter content was found to be the lowest in sugar and the highest fruit ratio S0.44C0.11A0.44, N0.44C0.11A0.44, and B0.44C0.11A0.44 samples were found.

The first dripping time and complete melting time of fruit-based ice cream-type frozen dessert

The melting feature of ice cream is important in terms of melting in the mouth during consumption and having an idea about how it should be stored at certain temperatures. The change of first drip and melting time of dessert during storage was shown in Fig. 2. During 2 months of storage, the first dropping times of strawberry, nectarine, and banana-based dessert samples varied between 348 and 1538 s, 369–1689 s, and435–1985 s, respectively. In addition, during 2 months of storage, the complete melting time of strawberry, nectarine and banana-based dessert samples was between 1234 and 3403 s, 1260–3705 s, and 1007–3362 s, respectively. While strawberry-based and banana-based desserts melted late in the 15th day, nectarine-based desserts melted late in the 60th day. The first drop and complete melting time of samples with high sugar content (S0.11C0.44A0.44, N0.11C0.44A0.44, and B0.11C0.44A0.44), were found to have the lowest values. Alamprese et al. (2002) indicated that there was an inverse correlation between sugar concentration and melting time. This can be explained by the fact that the increase in sugar content negatively affects the freezing point of the ice cream mix. As a result of the decreasing of the freezing point, the solid fraction decreased, thus melting occurred faster, and the melting time was shortened (Kirmaci et al. 2014). The first drop and complete melting time of samples with high fruit pure content (B0.44C0.11A0.44, S0.44C0.11A0.44, N0.44C0.11A0.44), were found to have the highest melting time values. Similarly, the addition of ginger paste to ice cream significantly increased the first dripping time (Gabbi et al. 2018).

Fig. 2.

Change in first dripping and completely melting time of ice cream-type frozen dessert during storage. While the abbreviations S, N, B, C, A represent Strawberry, Nectarine, Banana, Sugar and Aquafaba, respectively, the numbers represent the percentages in the mixture. (S) Strawberry (×S0.11C0.44A0.44; — S0.20C0.40A0.40; ☐ S0.27C0.36A0.36; + S0.33C0.33A0.33; ◼S0.36C0.27A0.36;● S0.40C0.20A0.40;▲ S0.44C0.11A0.44), (N) Nectarine (× N0.11C0.44A0.44; — N0.20C0.40A0.40; ☐ N0.27C0.36A0.36; + N0.33C0.33A0.33; ◼ N0.36C0.27A0.36;● N0.40C0.20A0.40;▲ N0.44C0.11A0.44), (B) Banana (×B0.11C0.44A0.44; — B0.20C0.40A0.40; ☐ B0.27C0.36A0.36; + B0.33C0.33A0.33; ◼B0.36C0.27A0.36;● B0.40C0.20A0.40;▲ B0.44C0.11A0.44)

Color properties of fruit-based ice cream-type frozen dessert

Color properties of the desserts were shown in Table 3. It was seen that the sugar, Aquafaba, and fruit puree differences of the banana-based dessert samples were important for the L* (lightness), a* (redness), and b* (yellowness) values (p < 0.05). The highest b* value was obtained in the (B0.44C0.11A0.44) banana sample with the highest fruit ratio. The highest b* and a* values were observed in the (S0.44C0.11A0.44) strawberry samples with the highest fruit ratio. In the nectarine samples (N0.44C0.11A0.44) with the highest fruit ratio, the b* value is the highest. This was shown that as the fruit ratio increased, the natural fruit color was linked to the final product. Color changes were linked to the color of the added ingredients. The highest L* values were observed in ice cream samples with the highest sugar content and the lowest fruit ratio. The increase in sugar ratio positively affected the L* value of all dessert samples. In a study, the L* value of fruit dessert samples decreased as the fruit ratio increased, and the b* value increased in parallel with the fruit ratio (Çakmakçi et al. 2016). In another study, it was determined that the highest b* value was seen in the dessert containing the most fruit puree (Aloglu et al. 2018).

Sensory analysis

The sensory results obtained by evaluating the sensory properties of frozen dessert samples according to 11 different criteria were given in Fig. 3. Only the cold intensity was found to be statistically different in the banana-based dessert samples (p < 0.05). The cold intensity value of the banana-based dessert sample (B0.11C0.44A0.44) with high sugar content was scored low by the panelists. Since the high sugar content negatively affected the melting time of the ice cream samples, this situation negatively affected the intensity of coldness. Aroma and melting in mouth criteria were found to be statistically significant in strawberry-based samples (p < 0.05). While the dessert with low sugar content (S0.44C0.11A0.44) got the lowest score in all ice creams, the sample (S0.36C0.27A0.36) scored the highest. Increasing the volatility of the aroma components of sugar may be effective in achieving these results (Selli and Kilic Buyukkurt 2020). In nectarine-based dessert samples, the increase in the sugar content (36–44% w/w) and the decrease in fruit content (27–11% w/w) had a negative effect on the sensory properties. In the nectarine-based ice cream samples, those with a low fruit ratio scored low on the last taste in the mouth. In the nectarine-based dessert samples, those with a low fruit ratio scored low on the last taste by the panelists. The same result was observed with the banana-based sample. It was rated by the panelists that Aquafaba did not cause bitterness and sourness in the ice cream samples. The overall acceptability of Strawberry and Nectarine samples received higher scores than the samples containing Banana. Sugar content also affected overall acceptability. Low sugar content is rated low. In general, samples with a balanced sugar-fruit ratio were given higher scores.

Fig. 3.

Sensory analysis results of ice cream-type frozen dessert with aquafaba. While the abbreviations S, N, B, C, A represent Strawberry, Nectarine, Banana, Sugar and Aquafaba, respectively, the numbers represent the percentages in the mixture. (S) Strawberry (×S0.11C0.44A0.44; — S0.20C0.40A0.40; ☐ S0.27C0.36A0.36; + S0.33C0.33A0.33; ◼S0.36C0.27A0.36; ●S0.40C0.20A0.40; ▲S0.44C0.11A0.44), (N) Nectarine (×N0.11C0.44A0.44; — N0.20C0.40A0.40; ☐ N0.27C0.36A0.36; + N0.33C0.33A0.33; ◼N0.36C0.27A0.36; ●N0.40C0.20A0.40; ▲N0.44C0.11A0.44), (B) Banana (×B0.11C0.44A0.44; — B0.20C0.40A0.40; ☐ B0.27C0.36A0.36; + B0.33C0.33A0.33; ◼B0.36C0.27A0.36; ●B0.40C0.20A0.40; ▲B0.44C0.11A0.44)

Conclusion

Aquafaba's improvement in parameters such as foaming capacity, foam stability, and gelling provide important gains for ice cream-type products. With all benefits of Aquafaba, it has the potential to lift the limitations of ice cream consumption and those who prefer a vegan diet, those who are lactose intolerant and allergic to certain proteins in milk. Moreover, the high foaming capacity (1250%) and stability (100%) of aquafaba make it possible for the aeration process, which is the most important feature for ice cream production. The consistency coefficient (K) showed a low value for the samples with the lowest sugar content and the highest fruit ratio (B0.44C0.11A0.44, S0.44C0.11A0.44and N0.44C0.11A0.44) and the fruit variety statistically affected this value. Those samples also had larger bubble microstructure, lower dry matter, and partially higher overrun could show more stable foam properties. The high amount of fruit increased the overrun value, and the effect of the fruit type on the overrun value was found to be statistically significant (p < 0.05). The samples with the longest melting time belong to the B0.44C0.11A0.44, S0.44C0.11A0.44 and N0.44C0.11A0.44 with the lowest sugar content and the highest fruit ratio, and it was found that the amount of fruit puree had a positive effect on the melting rate and increased the resistance of frozen dessert to melting. Aquafaba did not cause bitterness or sourness in dessert samples and did not affect the taste of the products. As a result, chickpea cooking water, which is economically worthless, is a suitable raw material for obtaining alternative products which could be an option for individuals who have allergies of dairy proteins, lactose intolerance or prefer a vegan diet. Further research can be conducted for people on a special food diet based on the assumptions that emerge from the findings.

Supplementary Information

Below is the link to the electronic supplementary material.

Author contributions

EE: Investigation, Validation; EA: Investigation, Validation; MC: Investigation, Validation; NCI: Writing- Reviewing and Editing, Visualization, Formal analysis; OST: Writing- Reviewing and Editing, Project administration, Supervision.

Funding

This work was funded by the Scientific and Technological Research Council of Turkey (TUBITAK), Project No: 1919B012000716.

Availability of data and material

It is open to sharing with appropriate request.

Declarations

Conflict of interest

The author declare that they have conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Alamprese C, Foschino R, Rossi M, et al. Survival of Lactobacillus johnsonii La1 and influence of its addition in retail-manufactured ice cream produced with different sugar and fat concentrations. Int Dairy J. 2002;12:201–208. doi: 10.1016/S0958-6946(01)00159-5. [DOI] [Google Scholar]

- Aloglu HS, Gokgoz Y, Bayraktar M. Kocayemiş (Dağ Çileği-Arbutus Unedo L.) Meyveli Dondurma Üretimi, Fiziksel, Kimyasal ve Duyusal Parametreler Açısından İrdelenmesi. Gida/J Food. 2018;43:1030–1039. doi: 10.15237/gida.gd18098. [DOI] [Google Scholar]

- Aslan M, Ertas N. Possibility of using “chickpea aquafaba” as egg replacer in traditional cake formulation. Harran Tarım ve Gıda Bilim Derg. 2020;24:1–8. doi: 10.29050/harranziraat.569397. [DOI] [Google Scholar]

- Bahramparvar M, Tehrani MM. Application and functions of stabilizers in ice cream. Food Rev Int. 2011;27:389–407. doi: 10.1080/87559129.2011.563399. [DOI] [Google Scholar]

- Buhl TF, Christensen CH, Hammershøj M. Aquafaba as an egg white substitute in food foams and emulsions: Protein composition and functional behavior. Food Hydrocoll. 2019;96:354–364. doi: 10.1016/j.foodhyd.2019.05.041. [DOI] [Google Scholar]

- Çakmakçi S, Topdaş EF, Çakir Y, Kalin P. Functionality of kumquat (Fortunella margarita) in the production of fruity ice cream. J Sci Food Agric. 2016;96:1451–1458. doi: 10.1002/jsfa.7241. [DOI] [PubMed] [Google Scholar]

- Chen W, Liang G, Li X, et al. Effects of soy proteins and hydrolysates on fat globule coalescence and meltdown properties of ice cream. Food Hydrocoll. 2019;94:279–286. doi: 10.1016/j.foodhyd.2019.02.045. [DOI] [Google Scholar]

- Cottrell JIL, Pass G, Phillips GO. Assessment of polysaccharides as ice cream stabilisers. J Sci Food Agric. 1979;30:1085–1088. doi: 10.1002/JSFA.2740301111. [DOI] [Google Scholar]

- da Silva JM, Klososki SJ, Silva R, et al. Passion fruit-flavored ice cream processed with water-soluble extract of rice by-product: What is the impact of the addition of different prebiotic components? Lwt. 2020;128:109472. doi: 10.1016/j.lwt.2020.109472. [DOI] [Google Scholar]

- Damian JJ, Huo S, Serventi L. Phytochemical content and emulsifying ability of pulses cooking water. Eur Food Res Technol. 2018;244:1647–1655. doi: 10.1007/s00217-018-3077-5. [DOI] [Google Scholar]

- El-Agamy EI. The challenge of cow milk protein allergy. Small Rumin Res. 2007;68:64–72. doi: 10.1016/j.smallrumres.2006.09.016. [DOI] [Google Scholar]

- Eren E, Icyer NC, Tatlisu NB, et al. A new trend among plant-based food ingredients in food processing technology: Aquafaba. Crit Rev Food Sci Nutr. 2021 doi: 10.1080/10408398.2021.2002259. [DOI] [PubMed] [Google Scholar]

- Gabbi DK, Bajwa U, Goraya RK. Physicochemical, melting and sensory properties of ice cream incorporating processed ginger (Zingiber officinale) Int J Dairy Technol. 2018;71:190–197. doi: 10.1111/1471-0307.12430. [DOI] [Google Scholar]

- Glusac J, Isaschar-Ovdat S, Fishman A. Transglutaminase modifies the physical stability and digestibility of chickpea protein-stabilized oil-in-water emulsions. Food Chem. 2020;315:126301. doi: 10.1016/j.foodchem.2020.126301. [DOI] [PubMed] [Google Scholar]

- Haileslassie HA, Henry CJ, Tyler RT. Impact of pre-treatment (soaking or germination) on nutrient and anti-nutrient contents, cooking time and acceptability of cooked red dry bean (Phaseolus vulgaris L.) and chickpea (Cicer arietinum L.) grown in Ethiopia. Int J Food Sci Technol. 2019;54:2540–2552. doi: 10.1111/ijfs.14165. [DOI] [Google Scholar]

- He Y, Meda V, Reaney MJT, Mustafa R. Aquafaba, a new plant-based rheological additive for food applications. Trends Food Sci Technol. 2021;111:27–42. doi: 10.1016/j.tifs.2021.02.035. [DOI] [Google Scholar]

- Kirmaci HA, Kuscu A, Atasoy F. The effect of stevia extract containing different proportions of prebiotic fiber on quality characteristics of probiotic ice cream. Harran J Agric Food Sci. 2014;18:48–59. [Google Scholar]

- Kurt A, Atalar I. Effects of quince seed on the rheological, structural and sensory characteristics of ice cream. Food Hydrocoll. 2018;82:186–195. doi: 10.1016/j.foodhyd.2018.04.011. [DOI] [Google Scholar]

- Marrone G, Guerriero C, Palazzetti D, et al. Vegan diet health benefits in metabolic syndrome. Nutrients. 2021;13:1–24. doi: 10.3390/nu13030817. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Meurer MC, de Souza D, Ferreira Marczak LD. Effects of ultrasound on technological properties of chickpea cooking water (aquafaba) J Food Eng. 2020 doi: 10.1016/j.jfoodeng.2019.109688. [DOI] [Google Scholar]

- Mustafa R, He Y, Shim YY, Reaney MJT. Aquafaba, wastewater from chickpea canning, functions as an egg replacer in sponge cake. Int J Food Sci Technol. 2018;53:2247–2255. doi: 10.1111/ijfs.13813. [DOI] [Google Scholar]

- Mustafa R, Reaney MJT (2020) Aquafaba, from food waste to a value-added product, pp. 93–126. Doi: 10.1002/9781119534167.ch4

- Nguyet NTM, Quoc LPT, Buu TG. Evaluation of textural and microstructural properties of vegan aquafaba whipped cream from chickpeas. Chem Eng Trans. 2021;83:421–426. doi: 10.3303/CET2183071. [DOI] [Google Scholar]

- Polischuk G, Bass O, Osmak T, Breus N. Cryoprotective ability of starch syrup in the composition of aromatic and fruit-berry ice cream. Ukr Food J. 2013;2:1–148. doi: 10.24263/2304-974x-2019-8-2-4. [DOI] [Google Scholar]

- Rawendra RDS, Dwi GN (2020) enrichment of soft ıce cream with different fibrous fruit puree: physicochemical, textural characteristics and sensory properties. In: IOP Conference series: earth and environmental science, vol. 426. 10.1088/1755-1315/426/1/012178

- Ray LIP, Swetha K, Singh AK, Singh NJ. Water productivity of major pulses—a review. Agric Water Manag. 2023;281:108249. doi: 10.1016/J.AGWAT.2023.108249. [DOI] [Google Scholar]

- Rossa PN, Burin VM, Bordignon-Luiz MT. Effect of microbial transglutaminase on functional and rheological properties of ice cream with different fat contents. LWT Food Sci Technol. 2012;48:224–230. doi: 10.1016/j.lwt.2012.03.017. [DOI] [Google Scholar]

- Selli S, Kilic Buyukkurt O (2020) Aroma Maddeleri̇ni̇n Saliniminda Etki̇li̇ Faktörler. Gida J Food 45: 204–216. 10.15237/gida.gd19122

- Shim YY, Mustafa R, Shen J, et al. Composition and properties of aquafaba: water recovered from commercially canned chickpeas. J Vis Exp. 2018;2018:14. doi: 10.3791/56305. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stantiall SE, Dale KJ, Calizo FS, Serventi L. Application of pulses cooking water as functional ingredients: the foaming and gelling abilities. Eur Food Res Technol. 2018;244:97–104. doi: 10.1007/s00217-017-2943-x. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

It is open to sharing with appropriate request.