Abstract

The aging population is now a global challenge, and impaired walking ability is a common feature in the elderly. In addition, some occupations such as military and relief workers require extra physical help to perform tasks efficiently. Robotic hip exoskeletons can support ambulatory functions in the elderly and augment human performance in healthy people during normal walking and loaded walking by providing assistive torque. In this review, the current development of robotic hip exoskeletons is presented. In addition, the framework of actuation joints and the high-level control strategy (including the sensors and data collection, the way to recognize gait phase, the algorithms to generate the assist torque) are described. The exoskeleton prototypes proposed by researchers in recent years are organized to benefit the related fields realizing the limitations of the available robotic hip exoskeletons, therefore, this work tends to be an influential factor with a better understanding of the development and state-of-the-art technology.

Key words: actuation joints, assist torque generation, gait phase estimation, robotic hip exoskeleton

Introduction

Robotic exoskeletons can be mainly divided into the medical type and nonmedical type according to their applications. Medical type exoskeleton is used for patients with upper (Yan and Yang, 2014; Chen et al., 2019; Gandolla et al., 2021) or lower body disabilities (Yang et al., 2016; Hwang et al., 2021; Zhu et al., 2021). With this kind of exoskeleton, some patients can regain the ability of locomotion (Farris et al., 2014), while some other patients can achieve therapeutic movement and speed up rehabilitation progress (Wang et al., 2019; Yang et al., 2020). Nowadays, the nonmedical type exoskeleton is widely researched for its potential in both industries (Chang et al., 2020; Iranzo et al., 2020; Lazzaroni et al., 2020) and the military (Hong et al., 2019). With this kind of exoskeleton, part of the human body’s limbs can be augmented. Thus, metabolic expenditure will be reduced during walking, running, lifting, or some other physical labor scenarios versus the cases without the exoskeleton. For further strength enhancement, various exoskeleton structures across different high-level control strategies are designed and tested, which arises great attention toward the research of energy economy in exoskeleton.

For walking assist, single, part or full of hip flexion/extension, knee flexion/extension, and ankle dorsi-flexion/plantar-flexion in the sagittal plane are selected as driven joints. Franks et al. (2021) carried out experiments using a hip–knee–ankle exoskeleton emulator paired with human-in-the-loop optimization to find assistance for different joints that maximally reduced the metabolic cost of walking. They found that hip-only and ankle-only assistance separately reduced the metabolic cost of walking by 26 and 30% relative to walking with the device unassisted while knee-only assistance reduced the metabolic cost of walking by 13%, which confirms that both hip joint and ankle joint are good targets for assistance. For their high energy efficiency, hip exoskeleton and ankle exoskeleton are mostly researched. In this review, we thoroughly summarize and organize walking-assist hip exoskeleton research for a better understanding of the development and state-of-the-art technology.

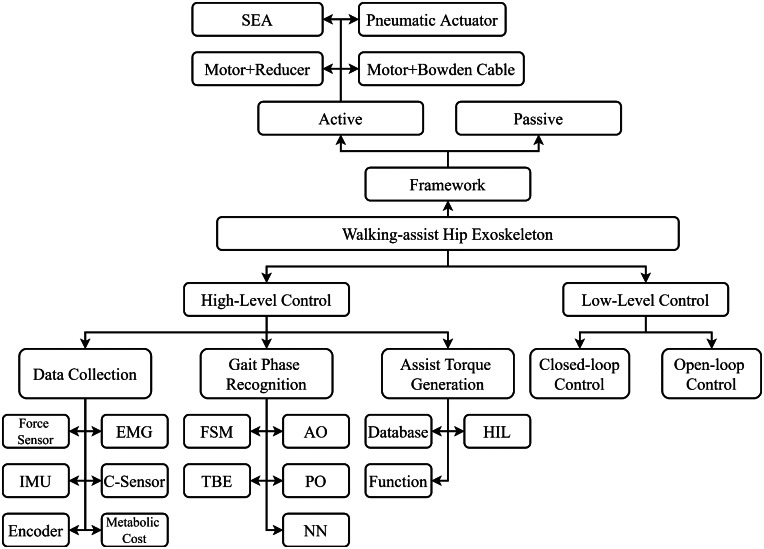

The frame of this review is shown in Figure 1. In our opinion, a walking-assist hip exoskeleton could be divided into mechanical structure, framework of the actuation joints, high-level control methods, and low-level control methods. Low-level control mainly refers to the output torque control, which is the solid basis for high-level decision-making blocks. Nevertheless, low-level control methods have been investigated with an enormous amount of work in the past time. In this review, the hip exoskeleton is thoroughly studied and discussed from two aspects, the framework of the actuation joints and the control strategies.

Figure 1.

Frame of this review. AO, adaptive oscillator; Electromyogram (EMG), electromyogram, FSM, finite state machine; HIL, human-in-the-loop optimization; IMU, inertial measurement unit; NN, neuro network-based gait phase estimation; PO, phase oscillator; SEA, series elastic actuator; TBE, time-based estimation.

The Framework of Actuation Joints

According to external power consumption, the hip exoskeleton can be divided into active exoskeleton and passive exoskeleton. The active one uses a wide variety of actuators, including motors, pneumatics, hydraulics, and so forth. The pneumatic actuator is usually connected directly to the exoskeleton thigh link and controls the movement of the exoskeleton hip joint through its expansion and contraction. The motor generally transfers the torque to the corresponding actuator through some transmission mechanics. For motor-driven actuators, the way of force/torque transmission has a great impact on the control of the hip exoskeleton. The transmission mechanics can be divided into rigid actuators and flexible actuators such as Bowden cable-based actuators, serial elastic actuators (SEAs), and so on. Passive exoskeletons generally recycle the negative mechanical energy generated during certain gait phases and use this energy to assist walking during another part of gait phases, thus improving the energy expenditure efficiency during walking. The typical prototypes of robotic hip exoskeletons with active or passive actuation joints are shown in Figure 2.

Figure 2.

Hip exoskeleton with different actuators. (a) Motor with gear reducer (Shimada et al., 2009; Yasuhara et al., 2009; Buesing et al., 2015; Yang et al., 2021). (b) SEA (Giovacchini et al., 2015; Kang et al., 2018; Zhang et al., 2019a). (c) Pneumatic actuator (Young et al., 2017b; Thakur et al., 2018). (d) Motor with Bowden cable (Kim et al., 2019; Tricomi et al., 2022). (e) Passive (Zhou et al., 2021a,b).

Active Hip Exoskeleton

Active hip exoskeletons can assist the wearer to break through some limitations and complete a wider variety of tasks with external energy. The biggest difference between the active exoskeleton ton and the passive exoskeleton is the existence of an external power source. For the active hip exoskeleton, the actuation joint is dominant since it determines mechanism architecture and corresponding functionality. In this review, actuation joints of the active hip exoskeleton are divided into four categories: motor with gear reducer, motor with Bowden cable, pneumatic actuator, and SEA. These alternative actuators and power transmission mechanisms are described in the following subsections.

Motor with gear reducer

Most hip exoskeletons actuation joints are designed with motors and reducers. Both left and right actuation joints are mounted near the wearer’s left and right hip joints and their rotation axes are in alignment with those of the wearer’s hip joints (Wu et al., 2015; Lee et al., 2017c, 2019; Sugar et al., 2017). With excellent performance of low-level motor position control or torque control, precise assist torque generation is guaranteed. Besides, the compact motor and reducer modular design makes the whole system lighter.

Seo et al. (2015) developed the device to assist the walking of the elderly with weak muscles. This exoskeleton driven by electrical motors could produce 10 Nm torque nominally. Lee et al. (2017c) designed the GEMS to deliver assistive torque to the hip joints for extension and flexion, which is generated by two BLDC motors and transmitted to the hip joint through a 75:1 multistage gear system. Sugar et al. (2017) designed HeSA driven by two motors with gear reducers to assist hip flexion and extension.

Most hip exoskeletons actuated by motors with reducers are rigid types. Some typical hip exoskeletons of this kind are shown in Figure 2a. However, it should be noted that due to the direct connection of motor and reducer actuation characteristics, compliance control needs to be considered to ensure safety and better human–machine interaction.

Motor with Bowden cable

To make the hip exoskeleton actuation joint soft or flexible, a new actuator is developed, which consists of a motor and Bowden cable. Bowden cable is covered with a cable sleeve and winded by a pulley, which is connected to the motor output shaft (Veneman et al., 2005). Thus, the rotation motion of the motor is converted to linear motion. Since the Bowden cable is flexible, it can be aligned with the human body better than rigid actuation joints. However, the hysteresis and nonlinearity characteristics of this flexible actuator make a low-level position or torque control with higher difficulty.

Most Bowden cable-driven exoskeletons are tethered type, with the motors and accessories mounted on the base. Veneman et al. (2006) developed a series elastic and Bowden cable-based actuation system, which is applied to a lower limb exoskeleton. A series elastic element is designed with low-level force feedback control. Totally, 11 and 20 Hz bandwidths for the full and small force ranges respectively are realized with this actuation system. Collins designed several prototypes with a tethered-type exoskeleton for walking assistance. With Bowden cables, not only single hip, knee, and ankle joints in the sagittal plane can be actuated (Galle et al., 2017; Zhang et al., 2017; Witte et al., 2020), but also full lower limbs in the sagittal plane (Bryan et al., 2021) or hip joint motions in both sagittal and frontal planes (Chiu et al., 2021) are driven with torque control. Each direction of actuation is designed with a closed-loop torque bandwidth of at least 18 Hz. To optimize real-time torque tracking performance, Zhang and Collins (2021) developed feed-forward iterative learning, which is applied to feedback control. Through theoretical analysis, an optimal iterative-learning gain is predicted as the inverse of the passive actuator stiffness, and walking experiments prove this hypothesis. Walsh reports their research on reducing the metabolic cost of running with a tethered soft exosuit which is also driven by a motor with Bowden cable (Lee et al., 2017b). Furthermore, they designed a portable exosuit to reduce the metabolic cost during walking and running (Kim et al., 2019). The compact motors are mounted on the backpack and Bodwen cables are attached through the human waist and lower limbs. Yu et al. (2019) proposed a soft exoskeleton composed of Bowden cable and quasi-direct drive (QDD) actuation, which produces high backdrivablity.

With soft and flexible actuators consisting of motors and Bowden cables, the walking assist exoskeleton is more like a suit rather than a rigid robot. The advantages of the actuators with Bowden cables are lightweight, high torque, and high degree controllability (Thalman and Artemiadis, 2020). This actuation joint architecture provides a new promising solution for compliant human–machine physical interaction.

Pneumatic actuator

The pneumatic actuator itself is compliant and lightweight. However, the pneumatic accessories such as air pumps are heavy, therefore, the pneumatic accessories are usually mounted on a fixed base to make the pneumatic actuated hip exoskeleton system lightweight. In this way, the portability of the pneumatic exoskeleton is limited. Similar to Bowden cable transmission actuators, another drawback of the pneumatic actuators is the nonlinearity characteristics. The relationship between the torque generated by pneumatic muscles and the pressure applied in the working process is always nonlinear, which increases the difficulty of low-level torque feedback control (Shiraishi and Watanabe, 1996; Sridar et al., 2020). Kawamura et al. (2013) made an orthosis for hip flexion assistance based on the application of the straight-fiber pneumatic artificial muscle and evaluated the performance of the orthosis by measuring the sEMG signal of the lower limb. Thakur et al. (2018) developed a lightweight (total weight is only 1.217 kg) and wearable Augment Walking Suit using pneumatic gel muscles and tested the assumption that the device can assist walking based on the sEMG signal. Young and Ferris (2017a) developed a pneumatic hip exoskeleton that assists with both flexion and extension during walking. Bidirectional piston-cylinder pneumatic actuators on each leg assist hip flexion and extension, and are tethered to an external air tank. Biological torque control is applied to the pneumatic hip exoskeleton based on proportional electromyography control, which is proved to have more advantages (metabolic cost and muscle activity reduction) compared to a controller that targeted a biological torque profile (Young et al., 2017b). In addition to assisting hip joints, several pneumatic actuator-driven exoskeletons have been developed to assist the ankle joints and knee joints during walking or running (Carberry et al., 2011; Park et al., 2014; Sridar et al., 2017).

The lightweight structure and high power density are the biggest advantages of the pneumatic actuator, on the condition that the pneumatic accessories are mounted on a fixed base. The primary disadvantage is that they are highly underdamped, which makes them the poor choices for position control tasks (Ferris and Lewis, 2009). Besides, the need for external drive accessories limits the use of pneumatic muscles.

Serial elastic actuator

Unlike rigid actuators, SEAs are designed by introducing an elastic element between the load and motor with reducers. With the serial elastic element, the inertia and nonlinear frictions of the motor and transmission are decoupled from the load. Meanwhile, external disturbances and shocks are also isolated from the gear transmission (Vallery et al., 2008). Pratt and Williamson, (1995) firstly reported the design of SEA, which consists of a motor, a reducer, linear springs, and a displacement sensor measuring the deflection of the spring. Based on Hook’s law, the SEA force output is calculated with sensored displacement. Li et al. (2018) developed adaptive human–robot interaction control by SEA, which provides either robot-in-charge or human-in-charge mode (Zelik et al., 2014). Zhang et al. (2017) designed an SEA-driven hip exoskeleton and proposed an admittance-based control method, which was experimentally verified to help patients with muscle weakness to walk normally. Kang et al. (2018) designed a hip exoskeleton driven by SEA with high-fidelity closed-loop torque control using ball screw transmissions and fiberglass leaf springs.

SEA provides a solution for physical compliance to ensure soft human–machine force interaction. However, the SEA restrains the devices with a narrow bandwidth and limited stiffness. Additionally, the bulkiness of SEA also limits its application. Thus, the selection of elastic elements with a certain stiffness to match human joints’ impedance is the core of SEA driven exoskeleton.

QDD actuator

QDD actuator composed of high torque motors and low gear ratio transmission is a promising solution for wearable robots actuation. On one hand, a portable hip exoskeleton is quite sensitive to its own weight. The compact QDD actuator design is relatively lightweight. On the other hand, the QDD design concept meets the underlying philosophy of “design for control,” namely meticulous robot design can simplify control algorithms while ensuring high performance (Yu et al., 2020). Lv et al. (2018) presented the design philosophy of a highly backdrivable exoskeleton with torque-dense motors (7.2 Nm peak torque) and low-ratio transmissions (24:1). To balance the joint output torque and velocity requirements, the QDD actuator was designed to provide 30 Nm continuous torque output with peak velocity at 80 RPM. The backdrive torque during static and dynamic conditions are 1.5 and 3 Nm, respectively, and the torque bandwidth is 10 Hz, which exceeds the required bandwidth for human walking (4–8 Hz). Nesler et al. (2022) introduced the design of a Modular Backdrivable Lower-limb Unloading Exoskeleton (M-BLUE), which implements high torque, and low mechanical impedance actuators. The AK80-9 actuator was selected for its high torque density and low gear ratio (9:1). The static and dynamic backdrive torques were measured under 0.5 and 2 Nm, respectively. The benchtop tests verified the low mechanical impedance of the QDD actuator and the accuracy of open-loop current control. Yu et al. (2020) designed a high-performance QDD actuator-based hip exoskeleton that demonstrates mechanical versatility for being highly backdrivable (0.4 Nm backdrive torque) with high rated torque (17.5 Nm) and high control bandwidth (62.4 Hz). This customized QDD actuator has the potential to ensure fluid human motion, handle rapid or unexpected human movements, and enhance the metabolic expenditure.

QDD actuators use high-torque motors to achieve high output torques with low gear ratios (and thus low friction/inertia). They are promising hip exoskeleton joint actuation solutions to perform dynamic walking, running, and squatting assistance with high control bandwidth, precise current-based torque control, compliance to impacts, and reduced acoustic noise.

Passive Hip Exoskeleton

The passive exoskeleton collects and stores the energy of the human body during periodic walking through the elastic elements, and releases the energy at a certain stage to help the human body complete the next stage of action and realize the power of the whole moving process. Since level walking with steady speed requires no power input, in theory, unpowered walking assistance is practicable, which is validated by simulation models with spring-loaded legs (Zelik et al., 2014). Initially, most researchers focused on the ankle joint (Collins et al., 2015; Li et al., 2018), for its relatively small range of motion which benefits elastic element mounting and makes energy acquisition and release simpler.

In recent years, the passive exoskeleton acting on the hip joint has been gradually developed. Haufe et al. (2020) studied the influence of the spring installed in front of the hip joint on human movement when walking at the speed of 0.5–2.1 m/s and concluded that the spring releases energy to help the bending of the hip joint. But there is a corresponding increase in muscle activity associated with ankle plantar flexion before and after the bend. Chen et al. (2019) from Xiong’s group fabricated a passive elastic exoskeleton called peEXO that can provide torques to assist hip flexors during walking. They find peEXO of a minor stiffness is beneficial to reduce the muscle activation of hip flexors, especially the iliopsoas. Subsequently, their colleagues, Zhou et al. (2021a) designed an unpowered hip exoskeleton that can reduce the metabolic cost of walking and running by adjusting the metabolizable energy of hip flexion, and can reduce the metabolic cost of walking and running by 7.2 and 6.8%, respectively after selecting the appropriate spring stiffness. In the same year, Zhou et al. (2021b) proposed a passive exoskeleton acting on the hip joint and ankle joint. By recovering the energy of the knee joint at the end of the leg swing to do positive work on the hip joint at the stage of standing posture, energy consumption could be reduced by 8.6% compared with that without wearing the exoskeleton. In 2021, Li’s group developed a passive exoskeleton that strategically removes kinetic energy during the swing phase, leading to a reduction of the metabolic cost of walking by 2.5 ± 0.8% for a healthy male. Meanwhile, the removed energy can be converted into 0.25 ± 0.02 watts of electrical power through the portable exoskeleton system (Shepertycky et al., 2021).

Summary of Actuation Joints

The summary of the actuators of the hip exoskeleton is shown in Figure 2. As a traditional drive mode, a motor with gear reducer has some advantages such as higher torque density that flexible actuators do not have. Therefore, a rigid hip exoskeleton driven by a motor with gear reducer occupies a lot of proportion. QDD actuator is a promising exoskeleton joint actuation solution since it leverages high torque-dense motors with low-ratio transmissions. Its backdrivability and low mechanical impedance simplify the low-level control. Because of the better human-exoskeleton interaction, flexible exoskeletons have attracted the attention of researchers. The flexibility of the SEA is achieved through the structure. Pneumatic muscles have high power density and have many applications in hip exoskeletons. Motor with Bowden cable can more easily transfer toque to where it is needed, which makes it possible to design a soft exosuit.

Control Strategy of Robotic Hip Exoskeleton

During the development of the robotic hip exoskeleton, the control strategy is one of the most fundamental issues (Chen et al., 2020). With suitable control approaches, robotic hip exoskeletons can generate the assistive torques as needed for the wearers, and the comfort and safety of the human-exoskeleton system can be guaranteed. In this article, the whole control flow is divided into two stages, the high-level control stage and the low-level control. High-level control is the strategy for how desired assistive torque is generated according to the human–machine-environmental state. At the high level, the robotic hip exoskeleton estimates the gait phase and then generates the desired torque by the data collected by the sensor system to deal with the question of when and how to provide assist torque to human body. The low-level controller mainly ensures the desired torque received from the high-level controller is accurately output.

Low-Level Control

Most of the low-level control methods are not limited to an exoskeleton but rather shared between many robotic applications. Besides, where those methods are used will not affect the desired behaviors such as tracking of reference input accurately and stably. Therefore, there are only a few papers that focused mostly on low-level control for exoskeletons. In this review, according to whether there is feedback, the low-level control is divided into open-loop control and closed-loop control, and both are outlined separately.

Open-loop control

For open-loop control, the actual torque received by the human body is not measured through force or torque sensors as feedback signals. Instead, stable and accurate torque output is achieved through friction, damping force, and inertia force compensation, which are identificated and modeled offline (Ikeuchi, 2007). Seo et al. (2016) compensate the friction and the inertial force in order to deliver the assist torque as intended without measuring the force delivered to the users. In our previous work, a parameter was added to the motor controller for friction compensation to make sure that the output torque and the target torque are as consistent as possible (Yang et al., 2021).

The reason why researchers chose open-loop control is that it requires no extra sensors and structures, which makes the hardware simpler (Baud et al., 2021). However, it is difficult to compensate for the friction completely because of its complex modeling.

Closed-loop control

Unlike the open loop control, closed-loop control requires a torque sensor or force sensor for feedback signal measurement. For low-level closed-loop control, how to achieve stable and accurate control performance attracts researchers’ attention.

Yu et al. (2020) proposed a simplified low-level feedback torque control thanks to the design of QDD actuator. The control architecture is composed of an inner-loop current control and outer-loop torque control. The feedback signal of the outer-loop is from motors, load cells, and IMU-based gait detection. Experiments indicate that the low-level control is able to produce high bandwidth (62.4 Hz) and high control accuracy (1.09 Nm RMS tracking error, 5.4% of the desired peak torque). Xue et al. (2019) proposed a direct force controller to achieve ideal force tracking performance and further guarantee flexible and natural walking assistance. The feedback signal of the direct force controller comes from the torque sensor. The bandwidth is calculated as 61.4 Hz from the bodegraph, which is sufficient for gait assistance. The fact that the actual torque is capable to track a desired reference with a maximum tracking error of 1.5 Nm has been proved by experiments. Oh and Kong (2017) proposed that the force control performance of the SEA can be improved by exploiting the dynamic model of the SEA. And then an SEA trajectory-tracking control method was used to control the exoskeleton (Zhang et al., 2019a). Subsequently, they proposed a new torque control, based on the singular perturbation integrated with flexibility compensation for SEA to better control the designed SEA with a clutch for the hip exoskeleton. It can effectively control actuation timing and allow precise assistive torque control (Zhang and Xia, 2019b). Zhang et al. (2015) identified a model-free, integral-action-free feedback control compensated by iterative learning as the most effective controller for lower-limb exoskeletons torque tracking during walking. With time-based desired torque, root-mean-squared errors were 0.6 Nm (1.3% of peak desired torque) step by step, and 0.1 Nm (0.2%) on average. They designed, developed, and compared the torque-tracking performance of nine control methods and then tested each control method with four high-level controllers that generate desired torque.

Compared with the open-loop control, the close-loop control is a more classical way for accurate torque tracking, which requires a torque sensor or force sensor for feedback signal measurement. In the meantime, closed-loop control also requires better algorithms and compact mechanical design.

High-Level Control Strategy

A high-level control strategy can firstly be divided into three parts: data collection, gait phase estimation, and assistive torque generation. For the data collection part, gait information is sampled by sensors installed on the hip exoskeleton during walking. With the gait information, the gait phase is estimated which divides continuous walking into several gait cycles and quantifies the period of current state during each gait cycle, thus the gait phase ratio is obtained. Assistive torque is finally generated based on the gait phase ratio during each gait cycle and human–machine interaction performance as well.

Data collection

According to the type of data sources, sensors can be divided into physiological sensors and physical sensors. Physical sensors are mainly used for detecting the body’s physical data, such as inertial measurement unit (IMU) used to detect the joint angular velocity (Ding et al., 2016; Lee et al., 2017c; Seo et al., 2018; Steijlen et al., 2021), force-sensitive resistor (FSR) used to measure human plantar pressure or human–machine interaction force (Pappas et al., 2001; Kong and Tomizuka, 2009; Sanz-Merodio et al., 2014). Physiological sensors mainly collect human body physiological signals to achieve no time-delay control, such as surface electromyogram (sEMG) sensor to collect weak electrical signal of muscle surface that represents muscle strength (He and Kiguchi, 2007; Zhang et al., 2017), capacitive sensor to measure muscle strength (Zheng et al., 2014, 2017; Zheng and Wang 2017), metabolic consumption detection equipment that used to measure the energy expenditure of the human body (Panizzolo et al., 2019), and so on. In this section, we will introduce these sensors and their applications in the hip exoskeleton.

Physical signal

Force sensors: The force sensor mounted at the heel detects the contact between the heel and the ground to recognize the heel strike gait event. Thus the continuous walking gaits can be divided into repeated gait cycles. Force sensors can also be applied to measure plantar force distributions (Yang et al., 2020) and calculate the stability margin of the human–machine system during walking. In this application, several FSR sensors are distributed in the shoes.

Pappas et al. (2001) designed a real-time gait stages detecting system that recognizes standing, heel leaving, swinging, and heel strike, using three FSRs in the soles and a gyroscope on the foot. In their experiments, the gait phase detection delay is less than 90 ms, and the accuracy of the walking state recognition (upstairs and downstairs) is over 96%. Kong and Tomizuka (2009) used an air force sensor to measure ground contact forces and designed an algorithm that can detect the gait phase smoothly and continuously. A high-level algorithm for detecting the abnormal gait phase is also proposed, which applies a fuzzy logic algorithm to detect the gait phase of each foot to achieve abnormal gait detection. Kang et al. (2018) placed a force-sensitive resistor at each heel to detect the beginning of a gait cycle. Yan et al. (2017) divided the gait by sensitive plantar pressure insoles. Song and Collins (2021) used a force sensor placed at the heel to detect heel-strike events. We developed an 8 × 8 FSR array-based shoes for gait event detection and children’s pathological gait identification as well (Xu et al., 2021). The advantage of using the plantar pressure sensor to detect the segmentation point of gait is that it is simple and accurate. Nevertheless, during multimodal walking scenarios, it is difficult to perform continuous gait estimation using plantar pressure sensors, in which case, plantar pressure sensors are usually used as data inputs for the time-based gait partitioning method. The force sensor is usually composed of a load sensor and a force-sensitive resistor, and its service life is limited due to repeated loads (Menguc et al., 2013). The limited service life reduces the reliability of the system in long-term use.

Inertial measurement unit: IMU can measure the acceleration of the lower limbs during exercise, the swing angular velocity and angle of the foot, and other stable and repeatable gait information during exercise. Compared with the force sensor, the gait information of IMU is more continuous and smooth. At the same time, compared with the EMG signal, IMU, as a physical signal, is not directly connected with the user’s skin or flesh and is not affected by the user’s physiological state. IMU is usually used in combination with force sensors to improve the accuracy of detection. At the same time, due to the small size of the IMU, it can be easily embedded in various devices.

The compact and portable IMU sensor can be embedded in the waist, thigh, shank, or foot of either the human body or exoskeleton to measure the kinematic information of each part. Seo et al. (2018) obtained the posture of the lower limb exoskeleton with IMU sensors installed on the backpack, shank, and foot. Thus the hip flexion/extension angle, abduction/adduction angle, and knee flexion/extension angle could be calculated. With the kinematic data, they innovatively divide the walking scenarios into the flat ground, upstairs/downstairs, and up/down slopes. The experiments show a classification accuracy of 100% (Weigand et al., 2020). Hu et al. (2018) presented a use of IMU and depth sensors fixed on the thigh to detect gait data and perform gait segmentation with accuracy approaching that of a setup with bilateral thigh and shank IMUs. Ding et al. (2016) proposed an iterative hip joint torque controller based on an IMU sensor, which can provide a predefined auxiliary contour to assist hip joint extension. The controller is implemented on a single-joint soft jacket coupled with a multijoint driving platform. The platform can quickly reconfigure different sensors and implement control strategies to generate assist torque. However, the shortcomings of IMU are also obvious. The sampled data drift will affect the consistency of the measured results. To compensate for data drift, additional calculations and more sensors must be used, which increases the complexity of the entire system, and the performance of the system will also be affected by violent movement (Tucker et al., 2015).

Encoder: The encoder is one of the most applied sensors in the exoskeleton. In a large number of researches, the encoder is integrated into the motor to measure the rotation angle of the motor so that the motor can be controlled more accurately.

Some researchers also use the encoder to measure the joint angle of the exoskeleton. Bryan et al. (2021) use an encoder to measure the joint angle of the hip, knee, and ankle of the exoskeleton. Giovacchini et al. (2015) set up two encoders in each actuation unit. An incremental encoder was built into the motor to measure the angle of the motor to control the motor. An absolute encoder was mounted on the axis collocated with the human hip flexion–extension axis to indirectly measure the absolute hip joint angle. Quinlivan et al. (2017) used a motor encoder to collect the Bowden cable position.

The advantage of the encoder is that it can measure the angle precisely. Nevertheless, encoders have high requirements for installation accuracy, it is difficult to completely align the human body with external joints. Therefore, encoders are usually used to measure the angle of the exoskeleton for feedback or to measure the rotation angle of the motor for low-level control rather than measure the angle of human joints.

Physiological signal

EMG sensors: EMG signals are important information for the robot system to understand how the user intends to move (Kiguchi et al., 2004, 2005; Kiguchi, 2007). Compared with other sensors, the EMG sensor can detect the muscle electrical signal which directly reflects the user’s movement intention. He and Kiguchi (2007) proposed an EMG-based control for the exoskeleton. They installed six electrodes on the front of the thigh and two electrodes on the back of the thigh to detect the EMG signal as the input of the controller using a fuzzy neural control method. Meanwhile, EMG sensors are used to show that the user’s muscle activation decreased with the help of the exoskeleton. Grazi et al. (2018) proposed a new EMG-based assistive control strategy for lower-limb exoskeletons. They experimentally demonstrated that the assistive method based on the integration of a gait phase estimator and an EMG proportional controller can reduce the activation peak of the muscles involved in the forward movement.

However, surface electromyography electrodes must be firmly attached to the skin around the target muscle. The displacement of electrodes and the presence of sweaty skin have a negative impact on the performance of motion recognition (Sawicki et al., 2005). The EMG signal is weak and susceptible to external noise, so a dedicated onboard circuit is required for signal preprocessing. Due to the weakness of the electrical sensor signal, using sEMG signal as a control parameter directly has high requirements on the hardware system and control algorithm.

Another issue we need to focus on about EMG sensors is the selection of muscle. Researchers have focused on the muscles of the lower extremities used for walking, among which the rectus femoris and gastrocnemius are believed to play a major role in walking. Both two muscles have been selected in many studies, while some other muscles have been selected as example.

As a physiological signal, EMG can show the state of the user wearing the exoskeleton more intuitively than physical sensors. Therefore, EMG signals are increasingly used in the evaluation and control of exoskeleton, even though there are some disadvantages as mentioned above. Some other feature extraction methods of EMG signals have also been concerned by researchers.

Capacitive sensor: A capacitive sensing system is a noncontact wearable sensor. The capacitive sensor (C-Sens) is designed with two sensing cuffs to measure the muscle shape change during walking. The capacitance electrodes adhered to the inner surface of the sensing cuff form the equivalent capacitor with the human body. The contraction and extension of muscles during walking will cause a change of capacitance. By analyzing the change in capacitance, the user’s current motion intention and walking state can be detected (Zheng et al., 2014). Zheng et al. (2017) proposed a noncontact capacitive sensor system for amputees, which can judge the user’s motion mode with high precision. In subsequent studies, Zheng and Wang (2017) placed capacitors on the thigh and calf, and continuous gait phase estimation with good real-time performance is obtained through adaptive oscillators (AOs), and the stability of the phase estimation system based on wearable capacitive sensors is also proved. In their experiment, a single-channel capacitance signal was used to achieve accurate and consistent gait phase estimation. Crea et al. (2019) presented a hip exoskeleton that was controlled using capacitive sensors placed in orthopedic cuffs on the shanks. Experiments show that the controller can estimate the gait phase with an average error of 4%.

Metabolic consumption sensors: The ultimate goal of most walking-assist exoskeletons is to improve the effort of a human during walking. In this case, energy expenditure, as an objective measure of effort that can be detected, is a gold standard for evaluating the walking-assist exoskeleton (Beneke and Meyer, 1997; Sawicki et al., 2020). In addition, the metabolic cost is related to overall performance in a given mode (Hoogkamer et al., 2016).

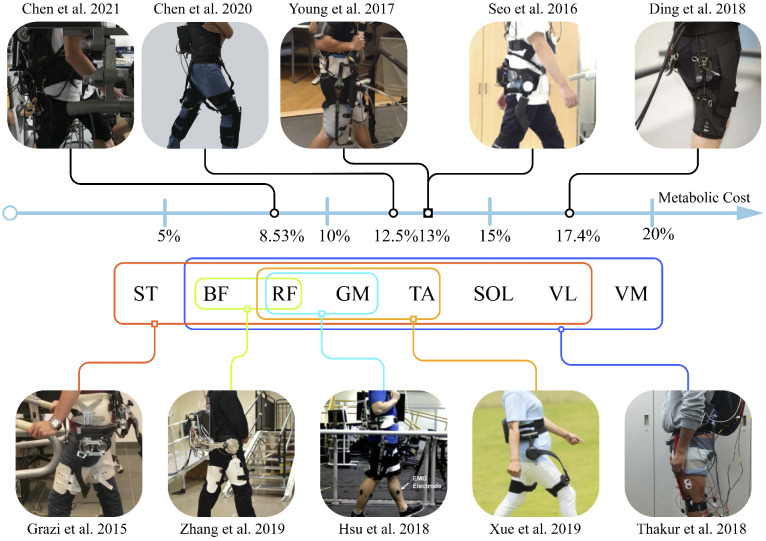

Many researchers use metabolic cost to characterize the performance of designed hip exoskeletons, as shown in Figure 3. Seo et al. (2016) designed a hip exoskeleton GEMS which showed a 13% reduction in energy consumption compared to no exoskeleton. On this basis, Lim et al. (2019) updated the structure of GEMS to make it lighter and used a new algorithm that significantly reduced the subjects’ energy consumption from 16.6 to 24% through metabolic cost tests, and proved that the performance of the exoskeleton was optimized. Ding et al. (2018) tested the effect of their exosuit by metabolic rate and found that with the assistance of the exosuit, the metabolic rate was reduced by 17.4 ± 3.2% compared with normal walking.

Figure 3.

Robotic hip exoskeleton with the index of metabolic cost reduction and selection of muscles for sEMG detection. BF, biceps femoris; GM, gluteus maximus; RF, rectus femoris; ST, semitendinosus; SOL, soleus; TA, tibialis anterior; VL, vastus lateralis; VM, vastus medialis.

Measuring energy consumption requires specialized and complex equipment and takes a long time to collect results, which means that it is difficult to use the metabolic cost as a feedback control signal for the exoskeleton. In most cases, the metabolic cost is used as an indicator to determine whether the exoskeleton can assist the user. Some researchers pay attention to generating superior assistance torque profiles by metabolic cost.

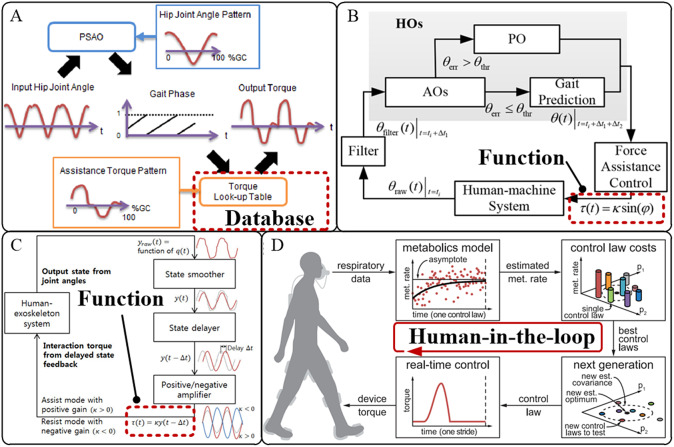

Gait phase estimation

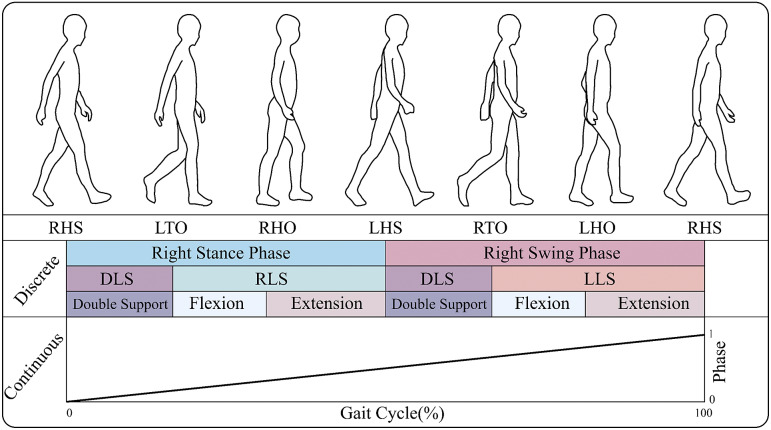

Gait is the key kinematic characteristic for describing how a person walks. A human individual varies in anatomical structure, physiological function, motion control ability, and mental state, thus varies in their gaits. In general, the gait changes periodically in the process of walking. Dividing the gait into different stages in each gait cycle can help us extract the features of each stage, and achieve a better gait stage-based exoskeleton control. Gait phase estimation can be divided into discrete gait event classification and continuous gait phase estimation, as shown in Figure 4. Discrete gait event consists of several characterized stages such as heel strike, toe off, support phase, swing phase, and so forth. The finite state machine (FSM) based gait event classification is one of the classical discrete gait event classification methods. Continuous gait phase estimation divides the gait into each cycle and counts the gait phase of each cycle from 0 to 100% continuously. Phase oscillator (PO), adaptive oscillator (AO), time-based estimation (TBE), and neural network based gait phase estimation (NN) are all state-of-the-art continuous gait phase estimation methods.

Figure 4.

Gait phase division during walking, which can be divided into discrete one and continuous one. DLS, double leg support; LHR, left heel rise; LHS, left heel strike; LLS, left leg support; LTO, left toe-off; RHR, right heel rise; RHS, right heel strike; RLS, right leg support; RTO, right toe-off.

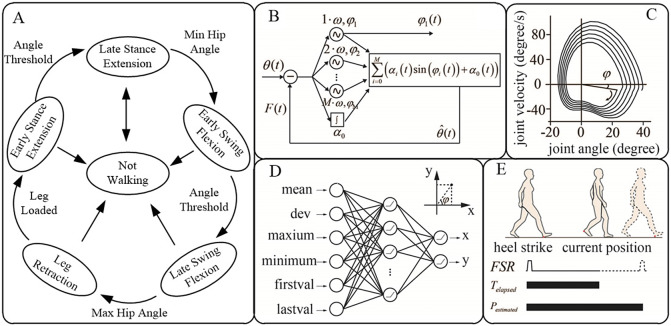

Finite state machine

In a Gait-Phase Detection Sensor (GPDS) and a programmable Functional Electrical Stimulation (FES) system, the gait phase is extracted by a knowledge-based FSM algorithm, which is used in a finite state control scheme to time the electrical stimulation sequences leading to an improvement in gait-kinematics of the affected leg (Pappas et al., 2004; Wang et al., 2013). Similarly, Pappas et al. (2001) designed a GPDS that consisted of three FSRs in the shoe insole and a gyroscope in the shoe. The GPDS detected accurately and reliably in real-time the four gait events: stance, heel-off, swing, and heel-strike. Walsh et al. (2006) applied the FSM based on the hip angle and the force in the exoskeleton leg to divide each gait cycle into six discrete gait events, which were used for exoskeleton hip joint control (Figure 5a).

Figure 5.

Graphical diagrams of five gait estimation methods. (a) Finite state machine (Walsh et al., 2006), (b) Adaptive oscillator (Lenzi et al., 2013), (c) Phase oscillator (Sugar et al., 2015), (d) Neural network (Kang et al., 2021), and (e) Time-based estimation (Kang et al., 2018).

Although everyone’s walking style is not identical, FSM can achieve high detection reliability in tasks involving walking on different terrains and is insensitive to interference caused by nonwalking activities.

Time-based estimation

TBE estimates the gait cycle using FSR mounted under the heel. The current phase inside each gait cycle expressed as a percent of the stride period is acquired as the ratio between the time elapsed from the start of the current cycle and the expected duration of the cycle (Lewis and Ferris, 2011; Lenzi et al., 2013). Figure 5e is a graphical diagram of TBE.

TBE is suitable for highly periodic gaits. In this method, the time of each step is collected to predict the time of subsequent gait cycles. Lewis and Ferris (2011) used the mean time of the first 10 strides to predict the time of the next cycle. Thus the assist torque applied in each gait phase is determined. Kang et al. (2018) obtained the time of each gait cycle by FSR and averaged it over the last five strides. The time after the current heel impact is then normalized to the average stride time to estimate the current gait stage. For TBE, the most important parameter is the number of cycles used to estimate the next cycle. The more cycles used to estimate the next cycle, the better the overall estimation effect will be, but the ability to change the response speed will be weak.

TBE can be used to correctly estimate the gait phase for the simple system since the algorithm is quite simple. The disadvantage of this method is that it cannot adapt to rapid changes in speed. It would take several gait cycles to fit the current speed after the change. If there are conscious rapid changes, TBE will not be able to estimate the gait cycle accurately.

Phase oscillator

A phase-based oscillator could help humans perform periodic or repetitive tasks. Kerestes et al. (2015) added a bounded amount of energy to their wearable robots to assist body motion. They take advantage of an anti-phase angle to subtract energy from body motion. De La Fuente et al. (2020) applied the Lyapunov redesign method to construct a robust controller using a bounding function and produced a bounded control signal to modify the amplitude and frequency of the resulting second-order oscillator, this can modulate stiffness and damping properties

Notice that utilizing resonant energy pumping and adding a tiny amount of energy at an appropriate time can result in an amplified response. Sugar et al decided to add energy at resonance so the system attains the limit cycle based on a PO (Figure 5c). It handles the problem of not clearly defined resonant boundaries (Sugar et al., 2015). To optimize oscillator behavior, De la Fuente et al. (2017) applied a nonlinear oscillator, using a forcing function-based on the sine and cosine of the system’s phase angle, which can modulate the amplitude and frequency of oscillation. The phase oscillator assumes the thigh angle profile and its integral to be sinusoids. However, the angle profile and its integral do not fit the assumption at lower walking speeds. In terms of this issue, Hong et al. (2021) proposed a phase-shifted variable using the user’s thigh information, which can improve linearity and heel-strike detection in the resulting phase variable and enable more accurate gait detection.

With an extra integral signal, the phase oscillator performs well in the mode transition such as changes in walking speed. However, this extra signal causes the phase oscillator to be susceptible to noise, so good filtering is essential for phase oscillators.

Adaptive oscillator

An AO is a system that can lock on to a time-varying input signal, synchronizing its output to both the frequency and phase of the input. It is a mathematical primitive being able to learn the high-level features of a quasi-sinusoidal signal. Given the cycle feature of gait analysis, AO is a natural way of modeling or generating periodic behavior (Buchli et al., 2004; Ronsse et al., 2011a; Yan et al., 2017; Xue et al., 2019).

Ronsse et al. (2011b, 2012) first applied AO to estimate the user’s intended movement while performing a cyclical motion task such as walking. As shown in Figure 5b, Lenzi et al. (2013) proposed an assistive controller which can compute the current stride percent by combining the left foot heel strike detection with the gait cycle estimated through an adaptive frequency oscillator. Seo et al. (2015) proposed a new adaptive frequency oscillator called a particularly shaped adaptive oscillator (PSAO) which can estimate the gait cycle without foot contact sensors. The results of the simulation showed that the PSAO-based gait assistance system reduced the metabolic cost in some assistance patterns. In subsequent studies, Seo et al. (2016, 2018) continuously optimized the PSAO to make it converge faster. Besides, Yan et al. (2017) came up with an AO-based gait phase estimator that could provide consistent and finely tuned assistance for an exoskeleton device to augment the mobility of participants. Grazi et al. (2018) estimated the current gait phase in real-time using a pool of AOs. The pressure signals from the shoe insoles help detect the heel strike gait event and reset the gait phase from AOs. The assistive torque of the active pelvis orthosis is then calculated based on the gait phase. Later, Xue et al. (2019) proposed a novel gait synchronizer driven by only hip angular velocity.

Optimization of the AO method is progressing continuously. Traditional AO does not always converge or converge slowly when the gait task is switching. Wu et al. (2019) adjusted to fine-tuning the AO network. They devised a new gait phase estimator architecture, including a gait tasks classifier, an AO reset, a peak detector, and a transition gait phase estimator. Also, some other researchers presented a two-layered system for learning and encoding a periodic signal without any knowledge of its frequency and waveform, and modulating the learned periodic trajectory in response to external events on a humanoid HOAP-2 robot (Gams et al., 2009). In our previous work, a hybrid oscillator is designed consisting of PO and AO. During cyclic or quasi-cyclic walking, AO is selected for precise gait phase estimation while during noncyclic walking, PO is selected for gait phase estimation (Yang et al., 2021).

Neuro network

Due to the rising popularity in the neural networking field, lots of scholars start to apply the NN method in gait analysis and boost recognition performance by a large margin. Figure 5d shows a graphical diagram of this method. Susanto et al. (2016) used data from an experiment with staircases to train artificial neural networks and use the k-Nearest-Neighbor method in a continuous gait phase estimation. This model achieves a mean absolute error of less than 6%, and results in three cases, namely level walking, stair ascent, and stair descent. Seo et al. (2019) developed a neural network model based on sensor fusion to estimate the gait phase adaptable to dynamic speed in real-time and verified the feasibility of using a machine learning model to accurately estimate the gait phase and improve the controllability of the lower limb exoskeleton. In recent years, Young and his colleagues made remarkable progress in NN-based gait phase estimation for multimodal locomotion (Camargo et al., 2021; Kang et al., 2021), which is applied to hip exoskeleton (Kang et al., 2020, 2021), knee exoskeleton (Lee et al., 2021), and ankle exoskeleton (Shafer et al., 2021). For hip exoskeleton control, they developed a sensor fusion-based NN model to estimate the continuous gait phase in real-time, which can adapt to variable walking speeds ranging from 0.6 to 1.1 m/s (Kang et al., 2021).

The NN method does not require a phase prediction part, the algorithm processing is simple, and it is promising regarding performance and processing speed for implementation on the hip exoskeleton. However, inside the NN is a black box, which is difficult for experts to debug, or further optimize the effect of the algorithm.

Assist torque generation algorithms

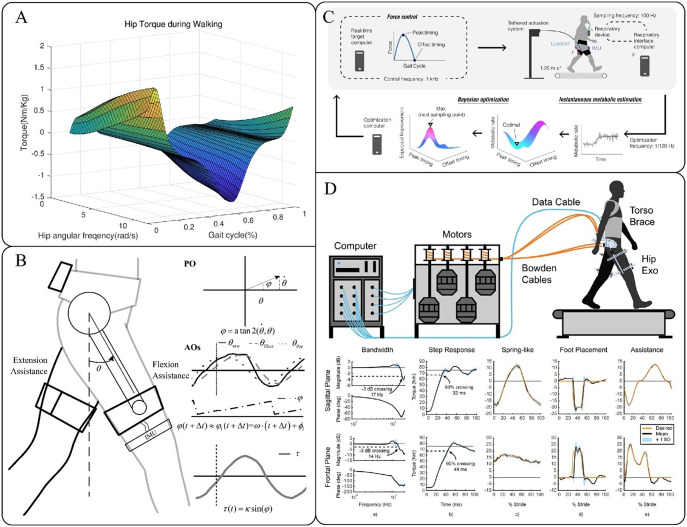

Another important part of the exoskeleton high-level control is the generation of desired assist torque, which determines how much force to output at each gait phase to assist the subject’s hip joint. Much effort has been made to determine the optimal assist torque for better walking assistance. The torque profile generation methods can be divided into the database, function with adjustable parameters, and Human-in-the-loop optimization as shown in Figure 6.

Figure 6.

Typical assist torque generation methods. (a) Database with a look-up table (Xue et al., 2019). (b) Function-based on gait phase and assist torque factor (Yang et al., 2021). (c,d) Human-in-the-loop optimization (Ding et al., 2018; Chiu et al., 2021).

Database

There are many ready-made databases from biomechanical simulations and experiments on human normal walking. Scaling the biomechanical joint torque profiles, the assist torque database is generated (Figure 7a). Database-based torque generation algorithm is simple and feasible.

Figure 7.

Diagrams for various assist torque generation algorithms. (a) Database (Seo et al., 2016). (b,c) Function with adjustable parameters (Lim et al., 2019; Yang et al., 2021). (d) Human-in-the-loop optimization (Zhang et al., 2017).

Xue et al. (2019)established a database using the human hip joint torque for the power assist of a flexible hip exoskeleton. By measuring the hip angular velocity, the commanded torque profile is modulated with estimated walking states and speed. Lee et al. (2017c) mapped the assist torque with the gait cycle according to the biomechanical hip joint torque database. Meanwhile, the subject’s body weight and assist factor will be multiplied as the coefficient, thus the final actuator torque command is acquired.

The database is a simple and intuitive way to generate assist torque, but it also has many shortcomings. The database is generally targeted at the situation of uniform walking, however, the subject will face more complex and diverse scenarios in daily hip exoskeleton assisted walking. It may be difficult to generate assist torque by the database to adapt to changeable external conditions. The other problem with the database-based torque generation algorithm is that the scaled biomechanical joint torque profiles may not be the optimal assist torque.

Function with adjustable parameters

To achieve more optimized control, some researchers proposed the torque generation algorithms determined by function with adjustable parameters. The parameters can be adjusted offline or online to determine the relatively optimal parameters and achieve discrete optimization. Figure 7b,c shows two types of functions to generate assist torque profiles.

The relatively simple parameters are the timing to start the assist torque, the timing to apply the peak torque, and the peak torque value. Ding et al. (2016) optimized these parameters and conducted experiments on the following four cases depending on the different parameters, early-start-early-peak, early-start-late-peak, late-start-early-peak, and late-start-late-peak. The highest positive mechanical power delivered by the soft exosuit was reported in the early-start-late-peak condition, which also showed a significant reduction in both biological hip and knee joint power. In addition, relatively complex optimization can also be carried out. Chen et al. (2021) added parameters to the torque control function. The parameters of the assistive profiles were estimated based on an analysis of biological hip power and then optimized in real-time using the hip angles. The peak and offset timings were determined using the parameters of the previous gait, while the start and stop points were determined from those of the current gait. Finally, it was determined through experiments that with adjustable parameters, the maximum hip joint assist torque could be generated and the relatively optimal walking assist effect could be obtained.

The torque generation algorithm based on function with adjustable parameters is more flexible. The parameters can be tuned to make the exoskeleton adapt to a variety of situations, and the discrete optimal walking assist can also be obtained. The number of parameters should be limited. If there are too many parameters, the workload of determining the optimal parameters will be increased geometrically. The value of the available parameter is also limited, so we can only choose a relatively better one in the experiment, which is a discrete optimization method.

Human-in-the-loop optimization

Researchers put forward the method of determining the parameters by adding the real-time biological signals of the wearer into the control system, which is called human-in-the-loop control. At present, the most commonly used biological signals are metabolic cost and EMG signals, which are mostly used to characterize the reduction of the subject’s effects during exoskeleton-assisted walking.

Zhang et al. (2017) used metabolic cost as a feedback signal (Figure 7d) to optimize the assist torque profile of the exoskeleton and used the rise time, fall time, peak time, and peak torque to generate a cubic spline curve. Combined with the energy consumption acquisition device, they carried out online continuous optimization and finally reduced the energy consumption by 24.2 ± 7.4% compared to no torque. To solve the delay and noise of the sensor, and to shorten the optimization, many researchers have proposed improved schemes for the human-in-the-loop algorithm. Felt et al. (2015) demonstrated Instantaneous Cost Gradient Search method to automatically identify parameters of assistive devices via the optimization of a desired physiological objective. This method enables considerable time savings and readily extends to multidimensional parameter spaces. The subjects’ walking time could be reduced from over an hour to less than 10 min. Based on improving the experimental device designed by Ding et al. (2018) and Felt et al. (2015) proposed a new global parameter optimization algorithm with high noise tolerance, adopted the optimization method of Gaussian process regression to fit the distribution of metabolic expenditure, and optimized the metabolism through Bayesian optimization. Experiments show that the proposed Bayesian optimization algorithm can double the convergence rate of the traditional gradient descent method. In a follow-up study, Ding et al. (2018) found optimal peak and offset times in an average time of 21.4 ± 1.0 min, resulting in a 17.4 ± 3.2% reduction in metabolic costs compared to walking without instruments.

Human-in-the-loop is an iterative optimization scheme. The parameters of assist torque can be tuned automatically according to the wear’s biological signals. However, some problems still need to be overcome. Since it is impractical to wear the mask all the time for metabolic expenditure measurement, the assist torque profile parameters must be optimized separately before use. Therefore, individual differences will affect the application of human-in-the-loop optimization methods for assist torque generation. In 2021, Walsh’s group developed a muscle-based assistance strategy. The exosuit assistance was derived from direct measurements of wearers’ muscle dynamics using ultrasonographic imaging in real-time. This novel approach enables a relatively rapid (about 10 s) generation of individualized low-force assistance profiles that provide metabolic benefits (Nuckols et al., 2021). This approach provides an alternative solution for human-in-the-loop control.

Conclusions

The typical hip exoskeletons reported in the literature are summarized and listed in Table 1. They are classified through the framework of actuation joints (such as active/passive, rigid/flexible) and high-level control strategies (including the selection of sensors, gait recognition algorithms, and assistive torque generation algorithms) as mentioned above.

Table 1.

Walking assist hip exoskeletons

| Exoskeleton | Summary of actuator features | Sensor | Gait phase | Torque generation | Device weight (kg) | References |

|---|---|---|---|---|---|---|

| SAS | Rigid actuator with motor and reducer | Foot switch | TBE | Database | 2.4 | Shimada et al., 2009 |

| XPED2 | The leaf spring at the foot will tighten the cable during hip extension and loosen the cable during hip flexion | NA | Threshold | NA | 6.91 | van Dijk and Van der Kooij, 2014 |

| SMA | Rigid actuator with motor and reducer | IMU | AO | Function | 2.8 | Buesing et al., 2015 |

| PH-EXOS | The force of the driving motors mounted behind the backpack is delivered to the joints of the exoskeleton | FSR Encoder | NA | Function | 3.5 | Wu et al., 2015 |

| APO | Actuation units employ an SEA architecture to achieve closed-loop control and flexibility | FSR | AO | NA | 4.2 | Giovacchini et al., 2015 |

| Harvard hip exosuit | Flexible actuator with motor and Bowden cable | IMU Force | TBE | Function | 6.5 | Asbeck et al., 2015 |

| GEMS | Rigid actuator with motor and reducer | Encoder IMU | AO | Function | 2.8 | Lee et al., 2017d |

| HeSA | Rigid actuator with motor and reducer | IMU | PO | NA | 2.95 | Sugar et al., 2017 |

| NREL-Exo | SEA-driven hip exoskeleton with powered hip flexion/extension and hip abduction/adduction | IMU FSR | FSM | Admittance shaping | 9.2 | Zhang et al., 2017 |

| Michigan exoskeleton | Pneumatic actuators around the hip joint provide hip flexion and extension assistance | Foot switch | FSM | Function | 6.8 | Young et al., 2017a |

| Michigan exoskeleton | Pneumatic actuators around the hip joint provide hip flexion and extension assistance | Electromyogram (EMG) | FSM | Function | 6.8 | Young et al., 2017b |

| Harvard exosuit | Flexible Bowden cable apply forces across joints in parallel with human muscles | IMU | TBE | Function | 5 | Lee et al., 2017a; Ding et al., 2018 |

| AWS | Pneumatic gel muscle (PGM) along the rectus femoris assist hip flexion | FSR | FSM | Function | 1.127 | Thakur et al., 2018 |

| Gatech exoskeleton | Flexible actuator with SEAs | IMU Encoder Force | TBE | Function | 7 | Kang et al., 2018, 2019 |

| APO | Actuation units employ an SEA architecture to achieve closed-loop control and flexibility | C-sens FSR | AO | NA | 4.2 | Crea et al., 2019 |

| FHAE | Flexible actuator with SEAs | IMU | AO | Database | 4.47 | Xue et al., 2019 |

| SIAT | Flexible exoskeleton with Bowden cable | IMU Encoder | CNN | Database | 4.6 | Chen et al., 2020 |

| QDD exoskeleton | Rigid exoskeleton using a compact direct-drive actuator | IMU Encoder | NN | Database | 3.4 | Yu et al., 2020 |

| HUST hip exoskeleton | The spring stores energy with the hip extension to its maximum extension position and releases the stored energy to assist hip flexion | NA | Threshold | NA | 1.305 | Zhou et al., 2021a |

| SUDA exosuit | Flexible actuator with SEAs and the series-wedge-structure is driven by Bowden cable | IMU Foot switch | FSM | Function | 1.4 | Zhang et al., 2021 |

| HUST hip-knee exoskeleton | The spring absorbs negative mechanical energy of the knee joint and then transfer the stored energy to assist hip musculature | NA | Threshold | NA | 1.86 | Zhou et al., 2021b |

| SIAT exosuit | Flexible actuator with Bowden cable | IMU force | NA | NA | 2.2 | Fang et al., 2021 |

| WEI | Rigid actuator with motor and reducer | IMU FSR | AOPO | Function | 4.8 | Yang et al., 2021 |

| HEBUT exosuit | Flexible actuator generate extension moment to hip by Bowden cable and assist hip flexion by the pulling belts | Force | FSM | Function | 7.5 | Chen et al., 2021 |

| XJTU exoskeleton | Rigid actuator with motor and reducer | IMU FSR | AO | Function | NA | Zhang et al., 2021 |

| UNC exoskeleton | Rigid actuator with motor and reducer | NA | FSM | HIL | NA | Tu et al., 2021 |

| SSSUP exosuit | A motor wraps up the left and right leg tendons | IMU | AO | NA | 2.2 | Tricomi et al., 2022 |

| U of U exoskeleton | A high-torque actuator. An electric motor located on the user’s legs transfers torque to the hip joint by gear stage, ball screw and nut, and spring. | IMU Encoder | FSM AO | Function | 2.7 | Ishmael et al., 2021, 2022 |

Abbreviations: AO, adaptive oscillators; AOPO, Adaptive Oscillator & Phase Oscillator; APO, Active Pelvis Orthosis; AWS, Augmented Walking Suit; CNN, Convolutional neural network; EMG, Electromyogram; FHAE, Flexible Hip Assistive Exoskeleton; FSM, finite state machine; FSR, force-sensitive resistor; GEMS, Gait Enhancing Mechatronic System; HIL, Human In the Loop; IMU, inertial measurement unit; NREL, “Not provided in references”; PGM, pneumatic gel muscle; QDD, quasi-direct drive; SAS, Stride Assistance System; SEA, serial elastic actuators; SIAT, Shenzhen Institute of Advanced Technology; SSSUP, Scuola Superiore di Studi Universitari e di Perfezionamento Sant’Anna; SMA, Stride Management Assist system; TBE, time-based estimation; WEI, Wearable Xian Jiao Tong University exoskeleton; XPED2, Not provided in references Exoskeleton Instrument; XJTU, Xian Jiao Tong University exoskeleton.

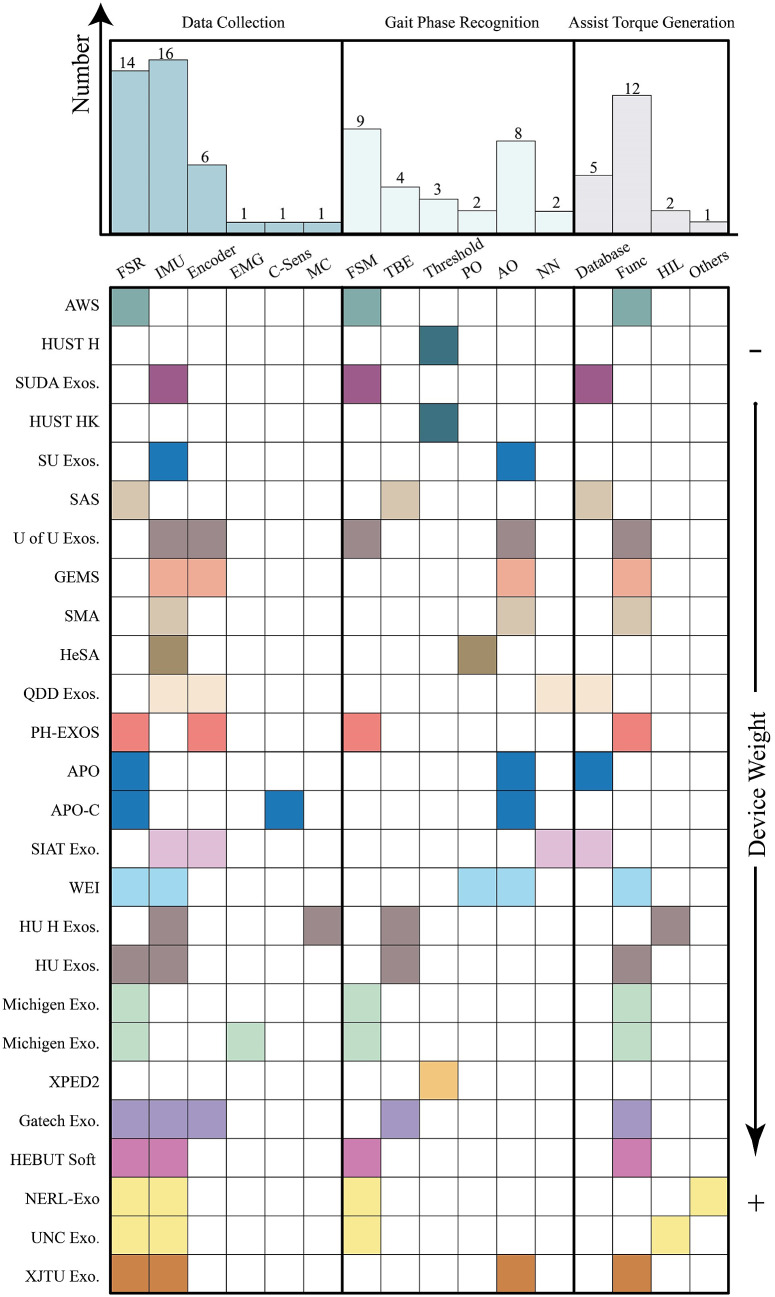

The developments of walking assist hip exoskeleton, especially focusing on the framework of actuation joint and high-level control strategy, have been demonstrated in this review. The active hip exoskeleton joints are mostly driven by a motor with gear reducer, motor with Bowden cable, pneumatic actuator, and SEA, while the passive hip exoskeleton restores and releases the energy of the human body during certain gait phases through the elastic elements. A high-level control strategy mainly consists of three steps: data collection, Gait Phase Estimation, and assist torque generation. For data collection, one part of data sensing is for gait phase estimation, such as physical signals including ground reaction forces, joint angles, and human–machine interaction forces. While another part is for assist torque generation, such as physiological signals including sEMG and metabolic cost. Gait phase estimation consists of discrete gait event classification and continuous gait phase estimation. The latter one is more promising for the walking-assist hip exoskeleton since it contains more information. Assist torque can be either predefined offline referring to the biomechanical database or tuned online based on the states of the human, robot, or both.

For intuitive understanding, each part of the high-level control strategy for related hip exoskeleton prototypes is summarized in Figure 8. Each colored square stands for use of corresponding sensors, gait phase recognition methods, and assist torque generation methods as listed at the top of each column. The same color in the squares for each row stands for the hip exoskeleton prototypes from the same research group. IMU and FSR are mostly used by each hip exoskeleton prototype for gait phase estimation and the encoder is mainly mounted into an actuator modular to realize high-performance low-level position or torque control. The major researchers select AO for continuous gait phase estimation for its outstanding performance of gait phase estimation accuracy and gait trajectory prediction which is applicable for both periodic and quasi-periodic gaits. Besides, various simple and efficient parameters-based torque generation algorithms can be adopted with gait phase and predicted gait trajectory obtained from AO. Although database and function-based torque generation algorithms seem more popular at the moment, human-in-the-loop optimization is more promising for torque generation since it directly optimizes the desired evaluation indicators such as muscle activation and metabolic cost.

Figure 8.

Detailed comparison of robotic hip exoskeletons from the aspect of data-collection, gait phase estimation, and assist torque generation. The same color in the squares for each row stands for the hip exoskeleton prototypes from the same research group.

This review presents the design and control of the hip exoskeleton for walking assist. Although remarkable breakthroughs have been made, some technical barriers still need to be overcome. The future R&D direction should be (but not limited to): (a) development of soft actuators with large torque density and high torque tracking control bandwidth; (b) integrated design of the untethered and portable system with high computational power and the weight is designed to be as light as possible; and (c) modeling of multiple scenarios recognition algorithms and accurate gait phase estimation/switch algorithms for the unstructured environment. We believe that wearable robotics technology will benefit humans and become an indispensable external organ for a better life once the aforementioned technology barriers are overcome and human–machine integration is realized.

Funding Statement

This work was supported by Natural Science Foundation of Zhejiang Province (Grant number LY21E050020), and by Ningbo Science and Technology Innovation 2025 Project (Grant number 2020Z022, 2020Z082, and 2021Z108).

Competing Interests

The authors declare no competing interests exist.

Authorship Contributions

Conceptualization: C.Y., W.Y.; Data curation: L.Y., L.X., Z.Y., D.H.; Data visualization: L.Y., W.Y.; Manuscript writing: C.Y., S.Z., W.Y. All authors approved the final submitted draft.

References

- Asbeck AT, Schmidt K, Galiana I, Wagner D and Walsh CJ (2015) Multi-joint soft exosuit for gait assistance. In 2015 IEEE International Conference on Robotics and Automation (ICRA). Seattle, USA: IEEE, pp. 6197–6204. [Google Scholar]

- Baud R, Manzoori AR, Ijspeert A and Bouri M (2021) Review of control strategies for lower-limb exoskeletons to assist gait. Journal of Neuroengineering and Rehabilitation 18(1), 119. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Beneke R and Meyer K (1997) Walking performance and economy in chronic heart failure patients pre and post exercise training. European Journal of Applied Physiology and Occupational Physiology 75(3), 246–251. [DOI] [PubMed] [Google Scholar]

- Bryan GM, Franks PW, Klein SC, Peuchen RJ and Collins SH (2021) A hip–knee–ankle exoskeleton emulator for studying gait assistance. The International Journal of Robotics Research 40(4–5), 722–746. [Google Scholar]

- Buchli J, Ijspeert AJ, Schaal S, Billard A, Vijayakumar S, Hallam J and Meyer J-A (2004) A simple, adaptive locomotion toy-system. A simple, adaptive locomotion toy-system. In From Animals to Animats. Cambridge, MA: MIT Press. [Google Scholar]

- Buesing C, Fisch G, O’Donnell M, Shahidi I, Thomas L, Mummidisetty CK, Williams KJ, Takahashi H, Rymer WZ and Jayaraman A (2015) Effects of a wearable exoskeleton stride management assist system (SMA®) on spatiotemporal gait characteristics in individuals after stroke: A randomized controlled trial. Journal of Neuroengineering and Rehabilitation 12(1), 69. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Camargo J, Ramanathan A, Flanagan W and Young A (2021) A comprehensive, open-source dataset of lower limb biomechanics in multiple conditions of stairs, ramps, and level-ground ambulation and transitions. Journal of Biomechanics 119, 110320. [DOI] [PubMed] [Google Scholar]

- Carberry J, Hinchly G, Buckerfield J, Tayler E, Burton T, Madgwick S and Vaidyanathan R (2011) Parametric design of an active ankle foot orthosis with passive compliance. In 2011 24th International Symposium on Computer-Based Medical Systems (CBMS). Bristol: IEEE, pp. 1–6. [Google Scholar]

- Chang SE, Pesek T, Pote TR, Hull J, Geissinger J, Simon AA, Alemi MM and Asbeck AT (2020) Design and preliminary evaluation of a flexible exoskeleton to assist with lifting. Wearable Technologies 1, E10. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chen T, Casas R and Lum PS (2019) An elbow exoskeleton for upper limb rehabilitation with series elastic actuator and cable-driven differential. IEEE Transactions on Robotics 35(6), 1464–1474. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chen Q, Guo S, Sun L, Liu Q and Jin S (2021) Inertial measurement unit-based optimization control of a soft exosuit for hip extension and flexion assistance. Journal of Mechanisms and Robotics 13(2), 021016. [Google Scholar]

- Chen W, Wu S, Zhou T and Xiong C (2019) On the biological mechanics and energetics of the hip joint muscle-tendon system assisted by passive hip exoskeleton. Bioinspiration & Biomimetics 14(1), 016012. [DOI] [PubMed] [Google Scholar]

- Chen C, Zhang Y, Li Y, Wang Z, Liu Y, Cao W and Wu X (2020) Iterative learning control for a soft exoskeleton with hip and knee joint assistance. Sensors 20(15), 4333. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chen B, Zi B, Qin L and Pan Q (2020) State-of-the-art research in robotic hip exoskeletons: A general review. Journal of Orthopaedic Translation 20, 4–13. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chiu VL, Raitor M and Collins SH (2021) Design of a hip exoskeleton with actuation in frontal and sagittal planes. IEEE Transactions on Medical Robotics and Bionics 3(3), 773–782. [Google Scholar]

- Collins S, Wiggin M and Sawicki G (2015) Reducing the energy cost of human walking using an unpowered exoskeleton. Nature 522, 212–215. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Crea S, Manca S, Parri A, Zheng E, Mai J, Lova RM, Vitiello N and Wang Q (2019) Controlling a robotic hip exoskeleton with noncontact capacitive sensors. IEEE/ASME Transactions on Mechatronics 24(5), 2227–2235. [Google Scholar]

- De La Fuente J, Subramanian SC, Sugar TG and Redkar S (2020) A robust phase oscillator design for wearable robotic systems. Robotics and Autonomous Systems 128, 103514. [Google Scholar]

- De la Fuente J, Sugar TG and Redkar S (2017) Nonlinear, phase-based oscillator to generate and assist periodic motions. Journal of Mechanisms and Robotics 9(2), 024502. [Google Scholar]

- Ding Y, Galiana I, Siviy C, Panizzolo F A and Walsh C (2016) IMU-based iterative control for hip extension assistance with a soft exosuit. In 2016 IEEE International Conference on Robotics and Automation (ICRA). Stockholm, Sweden: IEEE, pp. 3501–3508. [Google Scholar]

- Ding Y, Kim Myunghee, Kuindersma S and Walsh C (2018) Human-in-the-loop optimization of hip assistance with a soft exosuit during walking. Science Robotics 3, eaar5438. [DOI] [PubMed] [Google Scholar]

- Ding Y, Panizzolo FA, Siviy C, Malcolm P, Galiana I, Holt KG and Walsh CJ (2016) Effect of timing of hip extension assistance during loaded walking with a soft exosuit. Journal of Neuroengineering and Rehabilitation 13(1), 87. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fang T, Cao W, Chen C, Zhang Y, Wang Z and Wu X (2021) A soft exosuit for hip extension assistance of the elderly. Technology and Health Care 29(4), 837–841. [DOI] [PubMed] [Google Scholar]

- Farris RJ, Quintero HA, Murray SA, Ha KH, Hartigan C and Goldfarb M (2014) A preliminary assessment of legged mobility provided by a lower limb exoskeleton for persons with paraplegia. IEEE Transactions on Neural Systems and Rehabilitation Engineering 22(3), 482–490. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Felt W, Selinger J, Donelan M and Remy C (2015) “Body-in-the-loop”: Optimizing device parameters using measures of instantaneous energetic cost. PLoS One 10, e0135342. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ferris DP and Lewis CL (2009) Robotic lower limb exoskeletons using proportional myoelectric control. In 2009 Annual International Conference of the IEEE Engineering in Medicine and Biology Society. Minneapolis, MN: IEEE, pp. 2119–2124. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Franks PW, Bryan GM, Martin RM, Reyes R, Lakmazaheri AC and Collins SH (2021) Comparing optimized exoskeleton assistance of the hip, knee, and ankle in single and multi-joint configurations. Wearable Technologies 2, E16. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Galle S, Malcolm P, Collins SH and De Clercq D (2017) Reducing the metabolic cost of walking with an ankle exoskeleton: Interaction between actuation timing and power. Journal of Neuroengineering and Rehabilitation 14(1), 35. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gams A, Ijspeert AJ, Schaal S and Lenarcic J (2009) On-line learning and modulation of periodic movements with nonlinear dynamical systems. Autonomous Robots 27, 3–23. [Google Scholar]

- Gandolla M, Dalla Gasperina S, Longatelli V, Manti A, Aquilante L, D’Angelo MG, Biffi E, Diella E, Molteni F, Rossini M, Gfohler M, Puchinger M, Bocciolone M, Braghin F and Pedrocchi A (2021) An assistive upper-limb exoskeleton controlled by multi-modal interfaces for severely impaired patients: Development and experimental assessment. Robotics and Autonomous Systems 143, 103822. [Google Scholar]

- Giovacchini F, Vannetti F, Fantozzi M, Cempini M, Cortese M, Parri A, Yan T, Lefeber D and Vitiello N (2015) A light-weight active orthosis for hip movement assistance. Robotics and Autonomous Systems 73, 123–134. [Google Scholar]

- Grazi L, Crea S, Parri A, Lova RM, Micera S and Vitiello N (2018) Gastrocnemius myoelectric control of a robotic hip exoskeleton can reduce the user’s lower-limb muscle activities at push off. Frontiers in Neuroscience 12, 71. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Haufe FL, Wolf P, Riener R and Grimmer M (2020) Biomechanical effects of passive hip springs during walking. Journal of Biomechanics 98, 109432. [DOI] [PubMed] [Google Scholar]

- He H and Kiguchi K. (2007) A study on EMG-based control of exoskeleton robots for human lower-limb motion assist. In 2007 6th International Special Topic Conference on Information Technology Applications in Biomedicine. Tokyo: IEEE, pp. 292–295. [Google Scholar]

- Hong W, Anil Kumar N and Hur P (2021) A phase-shifting based human gait phase estimation for powered transfemoral prostheses. IEEE Robotics and Automation Letters 6(3), 5113–5120. [Google Scholar]

- Hong MB, Kim GT and Yoon YH (2019) ACE-ankle: A novel sensorized RCM (remote-center-of-motion) ankle mechanism for military purpose exoskeleton. Robotica 37(12), 2209–2228. [Google Scholar]

- Hoogkamer W, Kipp S, Spiering BA and Kram R (2016) Altered running economy directly translates to altered distance-running performance. Medicine & Science in Sports & Exercise 48(11), 2175–2180. [DOI] [PubMed] [Google Scholar]

- Hu BH, Krausz NE and Hargrove LJ (2018) A novel method for bilateral gait segmentation using a single thigh-mounted depth sensor and IMU. In 2018 7th IEEE International Conference on Biomedical Robotics and Biomechatronics (Biorob). Enschede, Netherland: IEEE, pp. 807–812. [Google Scholar]

- Hwang SH, Sun DI, Han J and Wan-Soo K (2021) Gait pattern generation algorithm for lower-extremity rehabilitation–exoskeleton robot considering wearer’s condition. Intelligent Service Robotics 14(3), 345–355. [Google Scholar]

- Ikeuchi Y (2007) Development of moment assist and system weight compensation control for wearable walking assist system. Honda R&D Technical Review 19(2), 154. [Google Scholar]

- Iranzo S, Piedrabuena A, Iordanov D, Martinez-Iranzo U and Belda-Lois J-M (2020) Ergonomics assessment of passive upper-limb exoskeletons in an automotive assembly plant. Applied Ergonomics 87, 103120. [DOI] [PubMed] [Google Scholar]

- Ishmael MK, Archangeli D and Lenzi T (2021) Powered hip exoskeleton improves walking economy in individuals with above-knee amputation. Nature Medicine 27(10), 1783–1788. [DOI] [PubMed] [Google Scholar]

- Ishmael MK, Archangeli D and Lenzi T (2022) A powered hip exoskeleton with high torque density for walking, running, and stair ascent. IEEE/ASME Transactions on Mechatronics, 1–12. [Google Scholar]

- Kang I, Hsu H and Young AJ (2018) Design and validation of a torque controllable hip exoskeleton for walking assistance. In Proceedings of the Asme 11th Annual Dynamic Systems and Control Conference, Vol 1. New York: American Society of Mechanical Engineers, p. V001T12A002. [Google Scholar]

- Kang I, Hsu H and Young A (2019) The effect of hip assistance levels on human energetic cost using robotic hip exoskeletons. IEEE Robotics and Automation Letters 4(2), 430–437. [Google Scholar]

- Kang I, Molinaro DD, Choi G and Young AJ (2020) Continuous locomotion mode classification using a robotic hip exoskeleton. In 2020 8th IEEE RAS/EMBS International Conference for Biomedical Robotics and Biomechatronics (Biorob). New York: IEEE, pp. 376–381. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kang I, Molinaro DD, Duggal S, Chen Y, Kunapuli P and Young AJ (2021) Real-time gait phase estimation for robotic hip exoskeleton control during multimodal locomotion. IEEE Robotics and Automation Letters 6(2), 3491–3497. [DOI] [PMC free article] [PubMed] [Google Scholar]