Abstract

Nanobiochar is an advanced nanosized biochar with enhanced properties and wide applicability for a variety of modern-day applications. Nanobiochar can be developed easily from bulk biochar through top-down approaches including ball-milling, centrifugation, sonication, and hydrothermal synthesis. Nanobiochar can also be modified or engineered to obtain “engineered nanobiochar” or biochar nanocomposites with enhanced properties and applications. Nanobiochar provides many fold enhancements in surface area (0.4–97-times), pore size (0.1–5.3-times), total pore volume (0.5–48.5-times), and surface functionalities over bulk biochars. These enhancements have given increased contaminant sorption in both aqueous and soil media. Further, nanobiochar has also shown catalytic properties and applications in sensors, additive/fillers, targeted drug delivery, enzyme immobilization, polymer production, etc. The advantages and disadvantages of nanobiochar over bulk biochar are summarized herein, in detail. The processes and mechanisms involved in nanobiochar synthesis and contaminants sorption over nanobiochar are summarized. Finally, future directions and recommendations are suggested.

1. Introduction

Biochar has emerged as a sustainable contributing solution for a wide range of environmental issues, including water pollution, land degradation, accumulating waste, and climate change.1−9 Biochar is a carbonaceous product of biomass pyrolysis under limited oxygen supply.10 A wide range of biomass agricultural wastes,1,9,11,12 animal manures,1,12,13 municipal wastes,8,12,14,15 forest residues,16,12,13,17 and industrial byproducts12,13,18 can be, and have been, utilized for biochar production. Biochar was initially developed as a soil fertility enhancer and for carbon sequestration.19−22 Later, biochar was successfully applied for water treatments, photocatalysis, enzyme immobilization, electrodes, supercapacitors, sensor preparation, and as a filler material in construction.1,2,9,23−26 Still, large scale biochar application has been mainly focused toward agricultural practices and some adsorption applications due to limited or restricted surface functionalities1,2,19,20,27 needed for many applications. For example, biochar’s moderate catalytic performances are related to limited functionality, insufficient surface area, and porosity.28,29

Various chemical and morphological modifications can overcome some biochar limitations by enhancing porosity, specific surface area, introducing specific surface functionalities, and removing others, as well as improving selectivity, separability, and structural stability.30−37 One such approach is developing nanobiochars (particle sizes with at least one dimension <100 nm), which can provide enhanced properties and applicability.17,38−42 Nanobiochar can be synthesized using ball-milling, sonication, centrifugation, and other techniques.17,38,40−42 Nanobiochar can also be modified to develop what we call engineered nanobiochars in this review.39,42,43 Nanobiochar possesses higher specific surface area to mass ratios versus macro or pristine biochar. This property can assist in several applications, including use as an adsorbent, capacitor, reinforcing filler sensor, slow-release fertilizer, photocatalytic material, and fuel additive.17,38−40,42,43

Nanobiochar development and use have generated extensive recent interest in the scientific community as an emerging material. A few review articles summarizing nanobiochar development have appeared.17,38,39,42−46 Nevertheless, a systematic and well-researched review documenting all the dimensions of this topic is needed. Nanobiochar preparation techniques are less explored in the literature.17,38,39,44 This review covers the full scope of nanobiochar and engineered nanobiochar, while most available reviews only deal with nanobiochar. Insights into nanobiochar and engineered nanobiochar production techniques were compiled, describing their merits and demerits. Bulk biochar and nanobiochar’s physicochemical properties are compared. Agents to regenerate adsorbent biochar and their operational conditions are also explored. Nanobiochar applications other than environmental remediation are discussed, along with their economic feasibility, advantages over bulk biochar, possible toxic effects on flora and fauna, and future perspectives.

2. Bibliometric Analysis

2.1. Data Collection

The web of science core collection was utilized to collect all the data for bibliometric analysis in this study.47 Data with the keywords “Nanobiochar” OR “Nano-biochar” OR “Biochar nanoparticle” OR “Engineered nanobiochar” OR “Modified nanobiochar” OR “Treated nanobiochar” OR “Biochar nanorod” OR “Nanobiochar composite” OR “Ball milled biochar” OR “Biochar sonication” OR “Biochar centrifugation” OR “Biochar disc milling” OR “Hydrothermal biochar” OR “Biochar carbonization” appearing in the “All Fields” of the English documents were collected on December 5, 2023.

The initial application of biochar, separate from traditional charcoal or activated carbon, in the context of water remediation was documented in the Journal of Colloid and Interface Science in 2007.48 In this study, biochar was developed as a byproduct through fast pyrolysis of pine wood and oak wood in an auger-fed reactor during biooil production and used to extract heavy metals from water. Following the publication of this research, subsequent studies began exploring the utility of both slow and fast pyrolysis-derived biochars as an alternative to activated carbon for water purification. Prior to this development, biochar had primarily found use in enhancing soil quality and sequestering carbon.

Web of science database provided articles on the above searched keywords started in 2013, and that first article was titled as “Antagonistic Effects of Humic Acid and Iron Oxyhydroxide Grain-Coating on Biochar Nanoparticle Transport in Saturated Sand”.49

2.2. Analysis Tools

VOSviewer50 and RStudio’s bibliometrix package51 were employed for visualizing scientific landscapes and science mapping analyses, respectively. Also, data has been analyzed and plotted using OriginPro 2018. The data obtained were downloaded using the “Tab delimited file” and “BibTeX” options for VOSviewer and Rstudio’s bibliometrix package, respectively.

2.3. Outcome

A total of 221 documents were collected from 2013 to December 5, 2023, with a 41.42% annual growth rate over the decade, showing the nascent stage of nanobiochar research. A total of 881 authors worldwide contributed to nanobiochar related research within this time span. The data were classified based on the annual rate of article production (Figure 1A), average total citations per year (Figure 1B), journal-wise article distribution per decade (Figure 1C), document types (Figure 2A), distribution of articles by science category (Figure 2B), nanobiochar application areas (Figure 2C), nanobiochar preparation methods (Figure 2D), WordCloud (based on keywords plus) (Figure 2E), keyword co-occurrence (Figure 3A), bibliographic coupling among countries (Figure 3B), collaboration among countries with total scientific production (Figure 4), nanobiochar related trend topics (Figure 5), and historiography (Figure 6).

Figure 1.

Bibliometric analysis of nanobiochar studies: (A) annual article production, (B) average total citations per article, (C) journal-wise article distribution. Data were collected on December 5, 2023 from Web of Science and processed by bibliometrix package (RStudio).

Figure 2.

Bibliometric analysis of nanobiochar studies: (A) document types, (B) distribution of publications by science category, (C) nanobiochar application area, (D) nanobiochar preparation methods, and (E) WordCloud. Data were collected and processed on December 5, 2023 from Web of Science.

Figure 3.

VOSviewer’s (A) network visualization for co-occurrence of all keywords and (B) bibliographic coupling among countries from 221 peer-reviewed publications (2013–2023). Each frame represents a keyword, and the size of the frame represents the number of times a pair of keywords appears together in a publication.

Figure 4.

Collaboration among countries with total scientific production on nanobiochar research, prepared by bibliometrix package (RStudio).

Figure 5.

Trend topics related to nanobiochar research from 2016 to 2023, prepared by bibliometrix package (RStudio).

Figure 6.

Historiograph of nanobiochar recent research from 2017 to 2023, prepared by bibliometrix package (RStudio).

The number of nanobiochar publications has increased over the last 10 years (Figure 1A). The average total citations per article exhibit a higher number of citations for earlier publications (Figure 1B). Science of the Total Environment published the most nanobiochar articles, followed by Chemical Engineering Journal, Chemosphere, and then Biomass Conversion and Biorefinery (Figure 1C). Approximately 89.72% of the published manuscripts are original articles, followed by review articles (∼7%) and early access (∼3.27%) (Figure 2A). Nanobiochar publications have appeared in a wide variety of science categories. The category of “Environmental Science” was the most frequent, followed by the “Chemical Engineering” and “Chemistry” categories (Figure 2B). Nanobiochars made so far have mostly been applied for water/wastewater remediation (∼44%) and this category was followed by soil management/plant growth (20%), characterization (∼9%), sensors (∼6%), catalysts (∼6%), fuels (∼5%), and others (∼9%) (Figure 2C). Ball-milling is the most applied technique for nanobiochar synthesis (∼35%), followed by sonication (∼21%) and carbonization (∼21%) (Figure 2D). The WordCloud illustrates how the less frequent terms are smaller and less obvious, while the more frequent terms are larger and more prominent. The WordCloud is centered around the most frequently mentioned terms, including “Adsorption”, “Removal”, “Carbon”, “Sorption”, “Biochar”, “Nanoparticles”, and “Aqueous solution” each with a frequency of 56, 51, 46, 38, 31, 28, and 26, respectively. The terms with smaller frequencies are “Ball-milled biochar”, “Water”, “Heavy metals”, and “Pyrolysis temperature” (Figure 2E).

VOSviewer’s network visualization for co-occurrence of all keywords suggests “biochar”, “adsorption”, “nano-biochar” or “nanobiochar” and “sorption” are among the most frequently used keywords (Figure 3A). Bibliographic coupling among countries provides connectivity among objects, which is measured on the basis of the number of references they share.52 The strength of their relatedness (coupling) becomes greater when a document receives more citations.52 It provides the similarities between the two works’ subject matter in the form of documents, sources, authors, organizations, and countries.52 Here, China dominates and shows more coupling with other countries. India, USA, South Korea, Canada, and Australia were also well related to each other (Figure 3B). The highest percentage of documents were published from China (50%), followed by USA (20%), India (10%), and South Korea (6%) (Figure 4). China shows collaboration with most of the countries contributing literature on nanobiochar (Figure 4).

In a scatter diagram, the trend topic graph plots time on the x axis versus the topic on the y axis.51 The median of the distribution of occurrences during the time period under consideration is used to determine the reference year for each topic. Pyrolysis temperature (2016–2022) and optimization (2018–2021) were two most trending topics during the initial days of nanobiochar research (Figure 5). From 2020 onward, adsorption, removal, water, wastewater, aqueous solution, mechanism and carbon became trending topics. The chronological citation network is known as a historiograph.51Figure 6 represents a chronological map (2017–2023) of the most relevant citations for nanobiochar research, resulting from bibliographic collection from web of science. The articles present in Figure 6 are the most influential among the remaining published articles. Early stage articles published in 2017–2019 [Naghdi et al. (2017)53 and Naghdi et al. (2017),54 in 2018 Naghdi et al. (2018)55 and in 2019 Naghdi et al. (2019),56 Naghdi et al. (2019)57 and Nath et al. (2019)58] are the most cited. In 2020, two articles by Ramanayaka17,59 are influential, followed by Amusat et al. (2021),60 Zhang et al. (2021),61 and Mahmoud et al. (2021)62 in 2021. Most recently, articles by Rajput et al. (2022)44 in 2022 and Khaliq et al. (2023)63 in 2023 are gathering more citations.

3. Nanobiochar Preparation

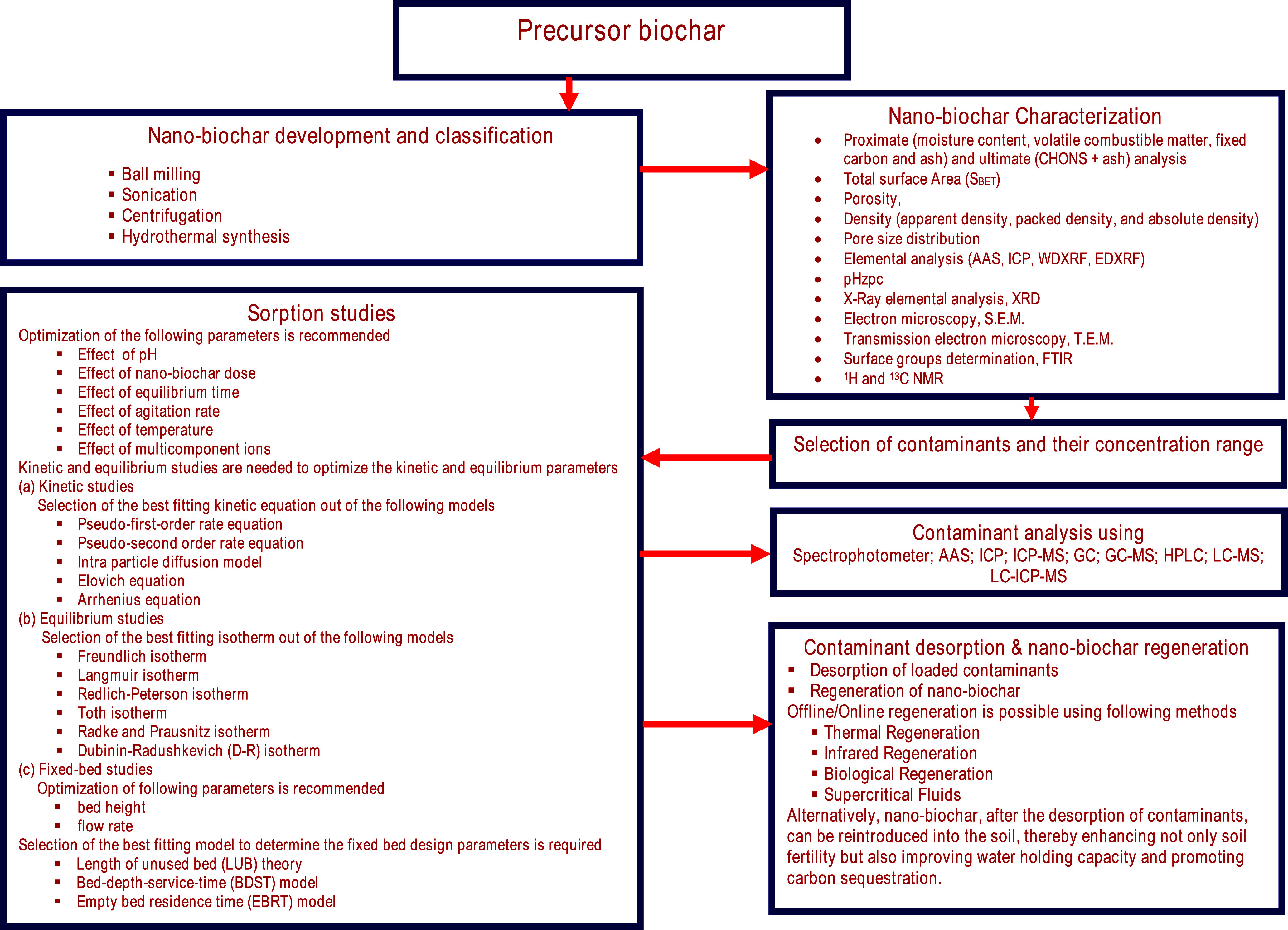

The preparation of nanobiochar is summarized in two subsections. The first covers pristine nanobiochar without any special modifications. The second discusses engineered nanobiochar where specific modifications during preparation are introduced to enhance one or more specific properties. Nanobiochar modifications introduce crucial characteristic properties that enhance effectiveness for target applications. Always under consideration are environmentally friendly methods that save energy and enhance yields during nanobiochar preparation.17

3.1. Pristine Nanobiochar

Pristine nanobiochar preparation is possible using ball milling,41,53,64 sonication,41,64−66 centrifugation,67,68 and acidic hydrothermal synthesis.69−71 These are the most widely used approaches. Other methods have also been reported, including disc milling59 and thermal flash pyrolysis.72,73 Ball milling has been the most commonly used technique for preparing nanobiochar. A summary of the nanobiochar and engineered nanobiochar preparation methods appears in Table 1. The most frequently used nanobiochar synthetic methods following ball milling include sonication, centrifugation, and carbonization in that order (Table 1).

Table 1. Detailed Information on Different Nanobiochar and Engineered Nanobiochar Preparation Methodsa.

| Ball milling | ||||||||

|---|---|---|---|---|---|---|---|---|

| Feedstock precursor | Pyrolysis temp.(°C)/applied gas | Modification of precursor biochar | Amount of Biochar used (g) | Milling time (h) | Milling speed (rpm) | Milling environment | Ball dia.(mm) /weight (g) | Ball to biochar ratio (weight) |

| Bamboo102 | 300/N2 | NA | 1.8 | 12 | 300 | Ambient air | NA/180 | 100:1 |

| 450/N2 | ||||||||

| 600/N2 | ||||||||

| Cow bone meal103 | 300/N2 | NA | 3.30 | 12 | 300 | Deionized water | NA/330 | 100:1 |

| 450/N2 | ||||||||

| 600/N2 | ||||||||

| Coconut shell77 | 500/N2 | Biochar (coconut, pinenut, and walnut shells) and iron powder (Fe) or iron oxides (α-Fe2O3 or Fe3O4) were mixed at a mass ratio of 3:1 and then ball milled | NA | 6 | 550 | Ambient air | 5.6/120 | 40:1 |

| Pinenut shell77 | ||||||||

| Walnut shells77 | ||||||||

| Corn straw75 | 500/NA | NA | 4.5 | 2.5 | 600 | NA | 5/NA | NA |

| Hickory wood chip76 | 300/N2 | NA | 1.8 | 12 | 300 | Ambient air | NA/180 | 100:1 |

| 450/N2 | 3.6 | 50:1 | ||||||

| 600/N2 | 9 | 20:1 | ||||||

| Wheat stalk14 | 300, 450, 600/N2 | NA | 12 | 300 | Ambient air | NA | 100:1 | |

| Poplar woodchips78 | 300 | 3 g biochar was added to 120 mL solution of 3.6 mL water, 114 mL ethanol, and 2.4 mL 3-mercaptopropyltrimethoxysilane (3-MPTS) and then ball milled | 3 | 12 | 300 | Water, ethanol, and 3-MPTS | 15–5–3/300 | 100:1 |

| Pinewood53 | 525/N2 | NA | 5–15 | 1.6–8.4 | 575 | NA | 2.4/NA | 4.5:1 |

| Pinewood54 | 525/N2 | NA | 10 | 1.64 | 575 | Ambient air | 2.4/45 | 4.5:1 |

| Pinewood57 | 525/N2 | NA | 10 | 1.6 | 575 | Ambient air | 2.4/45 | 4.5:1 |

| Rice husk75 | 500 | NA | 4.5 | 2.5 | 600 | NA | 5/NA | NA |

| Rice husk104 | 300/limited oxygen | NA | NA | 24 | 300 | Ambient air | 5/NA | 100:1 |

| 500/limited oxygen | ||||||||

| 700/limited oxygen | ||||||||

| Sawdust89 | 600/N2 | NA | NA | 2–12 | NA | Ambient/water | 6–10/NA | NA |

| Sugar cane bagasse102 | 300/N2 | NA | 1.8 | 12 | 300 | Ambient air | NA/180 | 100:1 |

| 450/N2 | ||||||||

| 600/N2 | ||||||||

| Wheat straw104 | 300/limited oxygen | NA | 24 | NA | 300 | Ambient air | 5/NA | 100:1 |

| 500/limited oxygen | ||||||||

| 700/limited oxygen | ||||||||

| Hickory wood13 | 300/N2 | NA | NA | 12 | 300 | Ambient air | NA | 100:1 |

| 450/N2 | ||||||||

| 600/N2 | ||||||||

| Wheat straw105 | 600/N2 | NA | 8 | NA | Ambient air | 6–10/800 | 100:1 | |

| Wood106 | 650/Argon | NA | NA | 6 | 500 | Argon | 15/10 | 10:1 |

| Wood saw dust107 | 350/limited oxygen | NA | NA | NA | NA | NA | NA | NA |

| Pinewood108 | 300–500 | NA | NA | 4 | 320 | NA | 5/NA | 30:1 |

| Corn stalk108 | ||||||||

| Lignin109 | 800/N2 | Nanobiochar mixed with styrene–butadiene rubber (vulcanized at 160 °C) | NA | 4 | NA | NA | NA | NA |

| Hickory woodchips16 | 600/N2 | Copper oxide was mixed with biochar and placed inside ball mill | 1.8 | 9 | 400 | Ambient air | NA/90 | 50:1 |

| Rice husk58 | NA | Ferrous sulfate heptahydrate (0.3 mol) and urea (1 mol) were ground and added to aqueous paste containing ∼15 g of nanoscale rice husk powder. Slurry was pyrolyzed at 600 °C under reducing conditions. | 15.0 | NA | 500 | Ambient air | 5/30 | NA |

| Bagasse110 | 450–600/N2 | 1.8 g of biochar mixed with 18 mL ammonium hydroxide (29%) and placed inside ball milling | 1.8 | 12 | 300 | NA | 6/180 | 100:1 |

| Hickory chips110 | ||||||||

| Wheat straw6 | 400/N2 | Impregnation of 100 g wheat straw into 1 L solution of 3.4 g FeCl2 and 8.5 g FeCl3 for 24 h. Further, pyrolyzed and ball milled | 1.0 | 12 | NA | Ambient air | 5/100 | NA |

| 550/N2 | ||||||||

| 700/N2 | ||||||||

| Hickory chips87 | 600/N2 | Magnetite addition in 3:1 ratio of biochar | NA | 12 | 500 | Ambient air | 6/180 | 100:1 |

| Hickory chips111 | 600 | Hickory chips were mixed with FeCl3·6H2O in 0, 0.5, 1, 2, 5, and 10 (w/w) ratio before pyrolysis | 1.8 | 12 | 300 | Ambient air | NA | 100:1 |

| Pine saw dust112 | 300–700 | 2 g ball milled biochar, 200 agate ball, 2.4 mL water and 76 mL ethanol were mixed in 500 mL agate jar. Further, along with N2 purging, 1.6 mL 3-MPTS added and 10 pH was maintained using NH4OH | 2 | 30 h with direction alteration every 6 h | 400 | Ambient air | 15:5:3/200 | 100:1 |

| Digitalis purpurea(113) | 400/N2 | NA | NA | 50 h with alteration of direction every 2 h | 400 | Ambient air | NA/90 | 50:1 |

| Farmyard manure114 | 500 | NA | NA | 24 | 300 | NA | 3/NA | NA |

| Wheat straw115 | 550 | Obtained biochar were pretreated at −80 °C to improve its grindability | NA | 4 h and ball mill machine was rested every 5 min to prevent agglomeration | NA | NA | NA | NA |

| Wheat straw116 | 350 and 650 | Reduction in H2 | NA | 12 | 350 | Ethanol | NA | 15:1 |

| Rice straw116 | ||||||||

| Corn straw116 | ||||||||

| Hickory chips117 | NA | NA | 1.0 | 12 | 300 | Deionized water | 6/100 | 100:1 |

| Sulfuric acid | ||||||||

| Sonication | ||||||||

|---|---|---|---|---|---|---|---|---|

| Biomass/Feedstock precursor | Pyrolysis temp.(°C)/applied gas | Modification | Biochar used (g) | Dispersion media (pH) | Time (min) | Temperature (°C) | Power | Process repetition (times) |

| Wheat straw118 | 350–550/anaerobic condition | NA | 15 | Deionized water (6.8) | 30 | NA | 100W | No |

| Pine needle118 | ||||||||

| Peanut shell41 | 300–600/Nitrogen flow | NA | 0.7 | Deionized water (6.8) | 15 | 25 | 120W | Yes (5) |

| Cotton straw41 | ||||||||

| Chinese medicine residues41 | ||||||||

| Furfural residues41 | ||||||||

| Elephant grass64 | 350–700 | NA | 3.0 | Water | NA | <20 | 60 kJ | Yes |

| Wicker64 | ||||||||

| Wheat straw64 | ||||||||

| Pinewood65 | 550–600/limited oxygen | Acid/alkaline and amine functionalization | 3.0 | Deionized water | 30 s | Ambient | 20 kHz/700W | No |

| Corn stalks119 | 450 | 10 g biochar in 100 mL 1.25 mol/L MgCl2 oscillated for 30 min. 100 mL 2.5 mg/L NaOH were mixed and magnetic stirred for 12 h at 120 rpm at 25 °C and left for 24 h | 150 | Deionized water | 120 | Ambient | 20 kHz/2000 W | No |

| Cotton straw66 | 600/Nitrogen | NA | NA | Deionized water | 40 | 40 | NA | NA |

| Hardwood and softwood residues120 | 400/anerobic | Heated with nitric acid at 90 °C for 3 h | 0.01 | Various solvents | 15 | 3 | 20W | No |

| Eucalyptus scrap chips121 | 1200/argon | Particle size reduction using ball mill (300 rpm for 24 h) | 0.05 | Sodium cholate water | 60 | 10 | 30% amplitude | No |

| Acid treated hydrothermal synthesis | ||||||||

|---|---|---|---|---|---|---|---|---|

| Hydrothermal

conditions |

||||||||

| Biomass/Feedstock precursor | Pyrolysis temp.(°C)/applied gas | Modification | Biochar used (g) | Sonication (time) | Time (h) | Temp. (°C) | Media | Cooling agent (mL) |

| Soybean straw69 | 500/Nitrogen | 15 mL conc. HNO3 and 45 mL conc. H2SO4 | 1.0 | No | 2 | Room temperature | Acidic | Deionized Water (1000 mL) |

| Cattle manure69 | ||||||||

| Biochar70 | 75 mL conc. H2SO4 and 25 mL conc. HNO3 | 2.0 | Yes (3h) | 24 | 100 | Acidic | Double distilled water (300 mL) | |

| Corn residues and wood71 | 400/Nitrogen | 15 mL conc. HNO3 and 45 mL conc. H2SO4 | 5.0 | No | 24 | 25 | Acidic | Deionized Water (1000 mL) |

| 700/Nitrogen | ||||||||

| Centrifugation | ||||||||

|---|---|---|---|---|---|---|---|---|

| Biomass/Feedstock precursor | Pyrolysis temp.(°C)/applied gas | Modification | Biochar used (g) | Dispersion media (volume) | Time (h) | Temperature (°C) | Power | Centrifugation conditions |

| Rice straw68 | 400 and 700/anaerobic condition | NA | 50 | Deionized water (1L) | 24 | Room temperature | 120W | 10000 rpm for 30 min |

| Wood Chips67 | 500/N2 | NA | 15 | Deionized water | 24 | NA | 100W | 3500 × g for 30 min |

| Pine wood67 | ||||||||

| Wheat straws67 | ||||||||

| Barley grasses67 | ||||||||

| Peanuts shells67 | ||||||||

| Rice husks67 | ||||||||

| Dairy manures67 | ||||||||

| Pig manures67 | ||||||||

| Sewage sludge67 | ||||||||

| Tobacco stems95 | 500/N2 | NA | NA | Double distilled water | NA | NA | NA | 3500 × g |

| Rice straw122 | 400 and 700/anoxic condition | NA | NA | Deionized water | 2 | Room temperature | NA | 10000 rpm for 30 min |

| Sugar cane123 | 900/N2 | 1 g/L biochar was dispersed in double distilled water and ultrasound for 30 min | NA | Double distilled water | 12 | NA | NA | 12000 rpm for 5 min |

| Wood shreds124 | 550/limited oxygen | NA | NA | Deionized water | 2 | NA | NA | 10000 for 30 min |

| Carbonization | ||||||||

|---|---|---|---|---|---|---|---|---|

| Additional

treatment |

||||||||

| Biomass/Feedstock precursor | Pyrolysis temp.(°C)/applied gas | Modification | Biochar used (g) | Temperature (°C) | Time (min) | pH | Process | Conditions |

| Microcrystalline cellulose125 | 550/N2 | ZnO | 1.76 | 120 | 60 | 7 | Centrifuge | 5 min at 4000 rpm |

| Corncob126 | 400/limited oxygen | Triethylenetetramine | 12.0 | 60 | 120 | NA | H2SO4 | Stirred for 1 h at 1 pH |

| Artichoke leaves127 | 350 | NA | 5.0 | 50–60 | 60 | NA | NaOH | 150 mL NaOH (2.0 mol/L) |

NA = not available.

3.1.1. Ball Milling

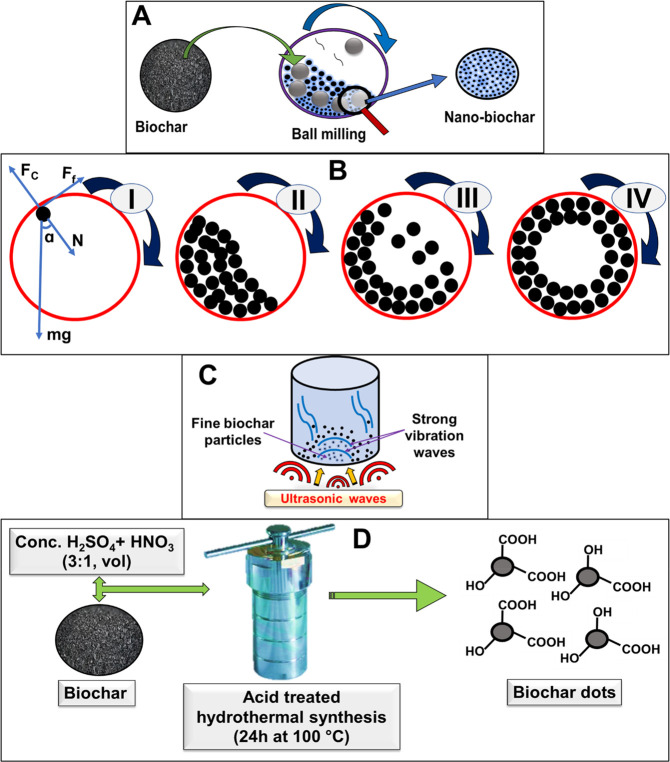

Nanobiochar production by ball milling is an emerging, inexpensive, sustainable, and reproducible method.74 Several studies used ball milling for the preparation of nanobiochar with enhanced functional characteristics.13,53,54,75−78 Increase in specific surface area,79 particle size reduction,54 enhancement in oxygen-containing surface functional groups,76 adsorption, and catalytic efficiency proliferations80 are improved through ball milling as compared to their pristine biochar precursors. The progress in this new area of research is still in development and rising rapidly, along with challenges and opportunities.38,74 The diagrammatic representation of ball milling procedure and functioning is shown in Figure 7A and B.

Figure 7.

(A) Typical ball milling, (B) ball milling functioning, (I) impact of forces and the types of motion of grinding balls in a ball mill: (II) rolling over; (III) falling; (IV) rolling. Reprinted with permission from ref (60). Copyright 2021 Elsevier. (C) Sonication and (D) acid treated hydrothermal method. Reprinted with permission from ref (70). Copyright 2017 American Chemical Society.

Under nonequilibrium conditions, ball milling mechanically reduces the biochar’s particle size to an ultrafine or nanoscale level.79,81 It has been an effective, efficient, and environmentally friendly technique for synthesizing advanced nanomaterials such as nanobiochar.76,82 The mechanisms of ball milling process include diffusion improvement, strain generation, structural, electronic, and ionic defects, and interactions among the substrates. The kinetic energy needed to rupture or stretch the chemical bonds of large molecules is provided by the movement of milling media and substrates. As a result, solid materials are broken up, elements are produced, glycosidic linkages are broken, and charge transfer occurs.83,84

The disintegration of biochar particles to nano level is assisted by the collision between metallic balls inside ball milling chamber.38,60 The desirable particle size, i.e., up to a grinding limit, can be attained by reducing the agglomeration and varying the ball milling conditions (balls to biochar ratio and milling speed/time).38,74 The grinding in ball milling is facilitated by colliding particles, where aggregations of particles are a possibility and may contribute toward the enhancement of the apparent particle size.59,85 Ball milling does not use toxic/hazardous chemicals, provides high atom economy, prevents waste formation from biodegradable products, and consumes only renewable resources.6,38,54,74,80,86−88

Biochar ball milling can be performed in two different ways, i.e., dry and wet milling.38,74,150 Operational convenience and techno-economic analysis are two deciding factors for selecting the milling method.74 In general, dry ball milling is preferred for materials that are difficult to subsequently filter.89,90 Wet milling has shown advantages including higher dispersion of smaller particles, more surface functional group formation, labor-savings, and it is a greener technology.89 Dry and wet ball milling can prepare biochar with similar yet different properties.89 In a comparative study, sawdust biochar was ball milled using wet and dry methods.89 Both wet and dry ball milling produced similar BET surface areas but different structural properties.89

The properties of ball-milled biochars derived from different preparation parameters are compared in Table 1. Preparation variables in Table 1 include precursor type, pyrolysis temperature (°C), the gas applied, various modifications used to engineer the nanobiochar (if given), biochar weight (g), milling time (h), milling speed (rpm), milling environment, ball diameter (mm)/weight (g), and ball-to-biochar weight ratio. A wide variety of feedstocks have been converted to biochar and then ball-milled to reduce particle size. Feedstocks include bamboo, coconut shell, pine nutshell, walnut shells, corn straw, hickory woodchips, poplar woodchips, pinewood, rice husk, sawdust, sugar cane bagasse, wheat straw, wood feedstock, wood sawdust, and lignin (Table 1).

3.1.2. Sonication

The physical modification of biochar using ultrasound irradiation is an efficacious route to enhance its adsorption capacity for various contaminants (Figure 7C).38 Fine particles adhering to the surface or embedded in the pores of the biochar are exfoliated by sonication to produce nanobiochar.26 To produce a desired particle size distribution, sonication of biochar can be repeated several times to generate a nanobiochar.41,64 Sonication utilizes high-energy ultrasound waves to disintegrate a biochar’s particles present in a suspension.41,91,92 The solvent media carries the ultrasound, which impinges on particle surfaces via microcavitation that produces short-lived, very high temperatures and shockwaves. A typical sonication method involves dispersion of prepared biochar in a solvent, which is subjected to sonication using an ultrasonic transducer. After sonication, the suspension’s larger particles can be gravity-settled, filtered, or centrifuged to obtain a supernatant containing biochar nanoparticles.40,64,67,93

The shockwaves caused by ultrasound irradiation increase the microporous area of biochar via mechanical damage, which opens blocked pores and enhances carbon structural exfoliation. The fine fragments, either embedded in pores or adhered to the surface of biochars, are also exfoliated during sonication.41 This damage causes mineral matter exposure at the surface and distribution from pores, leading to the improved sorption efficacy.65 Nanobiochar yield rises with increased sonication time and depends on the amount of heterogeneous carbon in bulk biochar.41 Sonication of biochar facilitates uniform surfaces and unclogs pores.66,94 Nanobiochar properties may be altered with changes in sonication temperature, power, amplitude, and probe size.38,64 Previous sonication studies have employed biochars made from wheat straw, pine needles, peanut shells, cotton straw, furfural residues, elephant grass, wicker, and pinewood at 300 to 700 °C with variations in sonication power (Table 1). The dearth of literature in the field of biochar sonication has not permitted general conclusions to be drawn about the optimization of process parameters.38

3.1.3. Centrifugation

In addition to ball milling and sonication, centrifugation is often used during nanobiochar preparation.40,67,68,93,95 Carbonization and centrifugation are commonly discussed separately, but one literature analysis describes the involvement of both in combination to produce nanobiochar.38 Centrifugation in a solvent is a straightforward method for separating highly dispersed nanoparticles.96 To obtain desired nanoparticle size ranges, several rounds of centrifugation are required. Centrifugation is employed up to an enhanced gravity effect of 100,000 rpm (roughly 800,000 × g). This is suitable for sedimentation of micron-sized species down to the smallest nanoparticles.97 The mechanism of nanobiochar preparation depends on the intrinsic particle properties of different biochars, such as size, density, surface functions, and shape. These cause varied sedimentation velocities.97

Typically, grinding is performed followed by centrifugation to obtain nanobiochar fractions. One study used two major feedstock classes, i.e., plant-based wastes and municipal wastes, to make biochars at 500 °C under nitrogen for 2 h. Plant-based wastes included pine wood, wood chips, barley grasses, wheat straws, peanut shells, and rice husks, while municipal wastes employed were dairy manures, pig manures, and sewage sludge.67 To prepare micron-sized biochar particles, 15 g of biochar was added to a beaker (500 mL) containing deionized (DI) water in a 3% (wt./wt.) ratio. It was stirred for 1 min; then ultrasonicated for 30 min, followed by stirring for 10 min. The particles obtained was allowed to settle for 24 h to separate <1 μm particle sizes according to Stokes Law. After the particles in solution settle, these are called micron-size biochar particles. The nano sized biochar particle suspensions prepared were then further centrifuged for 30 min at 3500 × g to separate 1 μm to 100 nm particles, leaving a supernatant that contains particle size fractions <100 nm. All these micron and nano sized biochar particle suspensions were freeze-dried to provide respective biochar powders, which were then stored in a desiccator.67 A clear demarcation of the size distribution was observed. Micron-sized biochar particles had hydrodynamic diameters dominantly <1000 nm with a wide range of size distributions from 70 to 1000 nm, and nano sized biochar particles were <100 nm. The varied size distribution of micron- and nanosized biochar fractions resulted from the use of different feedstocks because of their nonuniform compositions and densities.67 In another study, rice straw biomass was powdered (2.0 mm mesh) and pyrolyzed under an oxygen deficiency at 400 and 700 °C for 2 h. The resulting biochar particles were further ground and sieved (150 μm mesh). A mixture of biochar particles and deionized water was held for 2 h to settle the particles based on Stoke’s law. Then, the topmost suspension layer was taken from the mixture, centrifuged (at 10,000 rpm) for 30 min, and a 100–350 nm biochar fraction size was obtained.68

3.1.4. Hydrothermal Synthesis

Acid-treated hydrothermal synthesis is another path to synthesize smaller biochar nanoparticles (average particle size ∼3–6 nm).69−71 The acid-treated hydrothermal biochars are often termed “biochar dots”, “biochar nanodots”, or “biochar nanoparticles”.69−71 At present, only a handful of studies report synthesizing nanobiochar using acid-treated hydrothermal synthesis.69−71 The obtained biochar nanodots can be used for various environmental applications. Compared to grinding and sonication, hydrothermal synthesis does not require a high energy input and produces relatively smaller biochar particles.69 Hydrothermal synthesis is also useful to optimize nanobiochar synthesis conditions by systematically changing the time, temperature, and aqueous environments used during hydrolysis.69 A typical acid-treated hydrothermal synthesis procedure is shown in Figure 7D. Biochar, prepared at 500 °C from cattle manure and soybean straw at 500 °C under nitrogen, was ground and passed through a 60-mesh sieve. This biochar (1 g, homogenized) was immersed in 15 mL conc. HNO3 and 45 mL conc. H2SO4 for 2 h at room temperature in a hydrothermal reactor. Then, this mixture was added to 1000 mL deionized water.69 The suspension was filtered through a 0.22 μm membrane filter and oven-dried for 48 h at 65 °C.69 The process yielded biochar nanodots of 2–10 nm in size. This drastic reduction in size is due to the oxidative hydrolysis during acid digestion, which is determined by the nitric and sulfuric acid concentrations used to alter the biochar microstructure by oxidation.69

A comparative study of the physicochemical properties of biochar nanoparticles produced by sonication/centrifugation versus acid-treated hydrothermal synthesis was evaluated.71 For hydrothermal synthesis, biochar (∼5 g) was weighed and passed through fine sieves of 270-mesh (53 μm). Then, this biochar was treated with conc. H2SO4 (45 mL) and conc. HNO3 (15 mL) in a 3:1 ratio to carry out the oxidation at 25 °C for 24 h. The acid-biochar mixture was diluted to 1000 mL using deionized water, stirred for 1 min and left for 2 h. The suspension formed was filtered through a 0.22 μm membrane filter, and the filtrate was washed several times with deionized water to pH 6.71 The sonication/centrifugation method employed 3 g of biochar with the same starting particle size as the hydrothermally made sample (<53 μm). This sample was mixed with deionized water in a 3% (wt./wt.) ratio, sonicated for 30 min, stirred for 1 min, and then held for 2 h. This suspension was centrifuged (8500 rpm) for 30 min, and the supernatant was oven-dried at 80 °C.71 Biochar nanoparticle production yield was ∼10-times higher in hydrothermal method (0.365–0.589%) vs sonication/centrifugation (0.035–0.075%). These two methods exhibited different particle size distributions. The sonication/centrifugation sample gave 91.53 to 172.6 nm hydrodynamic sized biochar nanoparticles.71 Centrifugation created nanoparticles with variable sizes due to fragmentation98 but the acid-treated hydrothermal method provided relatively uniform particles with a “rather lower size” range (hydrodynamic size of 89.71 to 152.9 nm).71 The biochar nanoparticles produced from the hydrothermal method had higher surface polarity, stability, more surface functional groups, and the highest surface area (51.2 to 167.7 m2/g).71 Biochar nanoparticles produced using sonication/centrifugation had lower surface areas from 19.1 to 34.3 m2/g. The ash content was higher for biochar nanoparticles prepared via sonication/centrifugation vs the hydrothermal route.71 Increasing ash content, in sonication/centrifugation, probably results from salt build-up during the extraction of biochar nanoparticles. Acid treatment, in contrast, removes inorganic materials and reduces the amount of ash found in the biochar nanoparticles.71,99 The hydrothermal method proved to be a cost-effective, simple, and quick biochar nanoparticle-producing method.69 To develop biochar nanoparticles on a large scale, substantial study is needed, and special consideration must be given to the creation of novel strategies.69

3.1.5. Other Preparation Methods

Other nanobiochar preparation methods include thermal flash heating,72,73 disc milling,59 and conventional grinding.100 Only limited reports of nanobiochar syntheses using these methods exist in the literature. For example, the application of double-disc milling process to produce nanobiochar is very limited, primarily due to its high operations cost.

Disc milling has an advantage of providing an enhanced nanobiochar quality via shear and attrition stress and a more uniform nanobiochar size and shape.59 In ball milling, particles collide and grind. As they aggregate, the apparent particle size increases. The nanobiochar produced by double-disc milling was evaluated to remove a wide range of contaminants.59 These included antibiotics, herbicides, and potentially toxic elements.59 Biochar (< 3 mm) obtained as a gasification byproduct of Gliricidia sepium was preconditioned at −80 °C for 3 days and then mechanically ground dry with a disc mill.53,59 Disc mill was again used to grind both dried biochar and a biochar ethanol suspension for 2 min at a speed of 1000 rpm.59,101 Next, the colloidal biochar obtained (5 g) was dispersed in ethanol (100 mL) and centrifuged at 2000 rpm for 10 min. After removing the separated solids, the supernatant containing biochar nano fractions was further sonicated for 30 min (at 50 kHz) and vacuum-dried at 50 °C. These nanobiochar particles had a BET surface area, diameter, and length of 28 m2/g, 50–150 nm, and <1 μm, respectively.59 Surface area is approximately ten-times lower than original macro-scale biochar, which may be the combined effect of fracturing macro, meso, and micropores boundaries during size reduction. The graphitic particle character, the existence of nanopores, and the method used to make the nanoparticles determine the surface area.59 This nanobiochar gave enhanced adsorption capacities for all the adsorbates tested, including oxytetracycline (520 mg/g), glyphosate (83 mg/g), Cr(VI) (7.46 mg/g), and Cd(II) (922 mg/g) from aqueous media.59 The adsorption capacities per unit area (mg/m2) for oxytetracycline, glyphosate, Cr(VI), and Cd(II) were 18.6, 2.96, 0.27, and 32.9, respectively.59

The lignin coating on wheat straw was partially oxidized along with cellulose prior to pyrolysis to biochar (Figure 8). Then thermal-flash heating was conducted, which provided exfoliated biochar nanosheets (Figure 8). These types of synthesis methods are less explored.72,73 The first step of thermal-flash heating is the pretreatment of wheat straw biomass (particle size, 2 mm) with 1 M HNO3 (50 mL) at 70 °C for 6 h. The pretreated wheat straw biomass was filtered and dried at 80 °C for 24 h and then pyrolyzed at 450 °C for 2 h under a N2 environment (200 mL/min).73 In the second step, 2–3 g of pretreated biochar was oxidized with 20 mL 65–68% conc. HNO3 for 2 h, suction filtered, and then flash-treated using a muffle furnace at 900 °C without N2 gas to cause structural exfoliation.73 Exfoliated nanobiochar exhibits a higher BET surface area (421.24 m2/g) and pore size (3.98 nm) than pristine biochar, which had a 3.81 m2/g BET surface area and a 2.05 nm pore size.73 The thallium adsorption capacity was 9-times greater on exfoliated nanobiochar than pristine biochar.73

Figure 8.

Schematic illustration of the synthesis technique for the functionalization of exfoliated wheat straw biochar nanosheets by a thermal flash pyrolysis method. Reprinted with permission from ref (73). Copyright 2022 Elsevier.

The conventional grinding process to prepare micro/nano biochar powder is a simple technique utilizing grinding and sieving.100 Small pieces of biomass (pitch pine) waste were dried at 90 °C for 3 h to remove moisture and ground to a fine powder using a universal high-speed smashing machine. This powder was pyrolyzed for 2 h at 600 °C inside a sealed steel pot with limited oxygen and cooled to room temperature.100 To obtain ultrafine biochar powders, a planetary type grinding mill (with variable frequency) was used for 2 h. Finally, 200-mesh screen (stainless steel) with a mesh size of 74 μm was used to obtain biochar micro/nanopowders.100 This powdered micro/nano biochar was used to prepare electrodes, sensors, fuel briquettes (pellets), biofertilizers, and adsorbents.

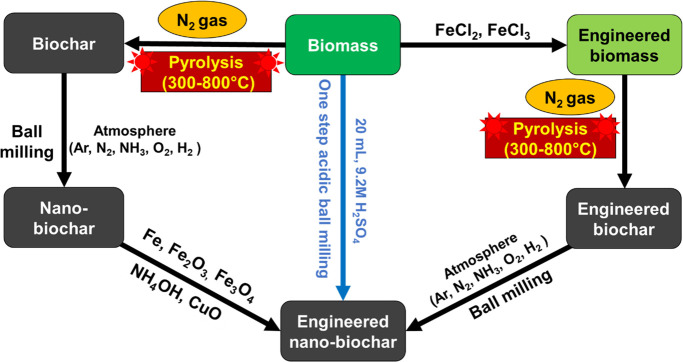

3.2. Engineered Nanobiochar

Engineered nanobiochar can be prepared by either pre- or post-treatment methods.39,42,43 To further enhance the selectivity and diverse applicability, nanobiochars were engineered/modified with different chemicals such as hematite,77 magnetite,6,77,87 zerovalent iron,77 ammonium hydroxide (nitrogen),110 copper oxide,16 acids (sulfuric, nitric, and hydrochloric acid),53,57 thiol,78 and styrene–butadiene rubber (Figure 9).109 Modifications can add new material surfaces to the existing nanobiochar. These may adsorb impurities that biochar does not, or they may release nutrients or other chemicals into soils. Modification may cause reactions on the biochar’s surfaces, which generate new functional groups, which modify surface behavior, influencing adsorption uptake, dispersion of nanoparticles, or reactions in the media to which they are added. Until now, very few studies have reported the production and application of engineered nanobiochar (Table 1). Ball milling has also been selected frequently for preparing engineered nanobiochar.6,16,54,56,77,78,87,110,128 Ball milling to modify nano-BC could be done simultaneously with the biochar to nanobiochar size reduction or after this process as a separate additional milling step with an additive. For example, 3 g of poplar wood chip-based biochar was ball milled with a mixture of 3.6 mL water, 114 mL ethanol, and 2.4 mL 3-MPTS (3-mercaptopropyltrimethoxysilane) to produce engineered nanobiochar in a single step.74

Figure 9.

Example ball mill-assisted syntheses of nanobiochar and engineered nanobiochar.

3.2.1. Nitrogen Doping

Nitrogen doping has provided enhancements in the amount of active surface sorption sites, basicity, and provided excess positive surface charges onto engineered nanobiochar, which resulted in enhanced contaminants sorption.110,129,130 In particular, heavy metals sorption was improved by (a) creating active N-functional group sites to which the metals could undergo complexation; (b) enhancing basicity of biochar due to N-doping increases adsorption of acidic pollutants e.g., CO2 and SO2; and (c) forming positive biochar surface charges by N-doping to promote sorption of negatively charged contaminants (such as reactive red dye) via electrostatic interactions.110 N-doped biochar has also been employed as a catalyst in various chemical reactions to degrade sulfamethoxazole, orange G, phenol, and bisphenol A.131 For example, ethanol (50 mL) and 1 g of reed biomass (0.2 mm) were mixed, agitated (0.5 h), and sonicated (1 h). Then, 1 g of NH4NO3 was added to the above suspension. It was heated at 85 °C for 4 h while being stirred. The NH4NO3 and reed biomass mixture was pyrolyzed, at a rate of 15 °C per min, for 90 min in N2 at different constant temperatures between 400–1000 °C.131 N-doped biochar at 900 °C produced a 6.5-fold and 39-fold faster sulfamethoxazole degradation rate than pristine biochar and N-doped biochar pyrolyzed at 400 °C, respectively.131

Ball milling is often done under N2 to avoid air (O2) oxidation of the biochar surface. Conversely, purposeful nitrogen doping can be achieved by adding chemicals such as ammonium hydroxide and ammonium nitrate. In one study, N-doped carbon nanoparticles were synthesized using graphite powders and N2 gas in a high-energy rolling ball mill (300 kPa) at room temp.132 In brief, four hardened steel balls (2 cm) were added to a milling jar (300 mL) containing 2 g of the graphite powders in a ratio of 1:132 (graphite to ball mass ratio). This mixture was milled at 150 rpm for 24 h. After that, milled samples were pyrolyzed for 3 h at 700 °C in a horizontal tube furnace with 25 °C/min ramp rate. The atmosphere of horizontal tube furnace was maintained by a 0.05 L/min gas flow rate of 85% N2/15% H2 mixture.132 The N-doped carbon nanoparticles obtained were utilized as an electro-catalyst for oxygen reduction reactions.132

Nitrogen doping of ball milled bagasse and hickory chip biochars was performed to improve the sorption of reactive red dye and carbon dioxide.110 Initially, both biomasses were oven-dried (80 °C), ground to 0.5–1 mm, and pyrolyzed under nitrogen at 450 or 600 °C for 2 h.110 Biochars (1.8 g each) were milled in a planetary ball mill inside agate jars (500 mL) with 180 g agate balls (6 mm dia.) for 12 h at 300 rpm. The rotation direction was alternated every 3 h. Nitrogen doping of the biochars was facilitated by ball milling 1.8 g of already ball milled biochar mixed with 18 mL ammonium hydroxide (29%) under the same conditions.110 After this milling, the N-doped ball milled biochars were washed with deionized water in vacuum filtration units until the filtrate was almost neutral and dried for 48 h at 80 °C.110 Biochars originally pyrolyzed at 450 °C achieved higher surface N-doping (2.41–2.65%) than those pyrolyzed at 600 °C (1.18–1.82%). This was due to the lower amount of O-containing functional groups present in biochar pyrolyzed at 600 °C versus that present when pyrolysis temperature was 450 °C.110 Oxygenated surfaces function from the start of most pathways leading to nitrogen introduction. Example pathways to N-doped biochar by ball milling are provided in eqs 1–6.110,133

O-containing surface functional groups (e.g., lactones, pyrones (ether-type), and carbonyls) can react with ammonia to form the other N species that have been reported in carbon materials.133 Temperature is a key factor for the formation of other functional groups (eqs 1–6). Nitriles are formed at 180 °C by amide dehydration, for example. Amine groups are formed at initial carboxyl and hydroxyl sites on biochar at temperatures below 300 °C. Pyridinic-type nitrogens are generated from ether functions in the medium temperature range between 300 and 500 °C.133 Increasing the ball milling velocity (≥500 rpm) or raising pressure have resulted in the formation of various N species.133 Four types of nitrogen-containing functions (pyridinic, pyrrolic, graphitic N, and N-oxides) were generated in carbon nanoparticles after ball milling nitrogen with graphite powders at 300 kPa, followed by pyrolysis for 3 h at 700 °C.132 Another report suggests three nitrogen functions (pyridinic N, pyrrolic N, and graphitic N) were formed on nitrogen-doped graphene, which was made by ball milling melamine with graphene for 48 h at 500 rpm.134 Therefore, adjusting the ball milling operating parameters can lead to formation of various N species in N-doped biochars.110Eqs 1–6 provide example nitrogen-containing surface functional group generation by reacting ammonia with various oxygen functional groups as a function of temperature.110,133

Carboxylic acids can react at room temperature with NH3 to form ammonium salts, which dehydrate thermally to amides and nitriles at about 180 °C (eq 1):133

|

1 |

Lactones can generate lactams with NH3 and then decarbonylate to a pyrrole at high temperatures (450 °C), as given in eq 2. Lactams can also dehydrate after protonation to form pyridinic groups. In eq 3, HCN is formed by thermolysis of an amide to a nitrile by loss of water. The subsequent loss of HCN provides the proton needed for the lactam to pyridine conversion (at 615 °C):133

|

2 |

|

3 |

Furthermore, temperatures above 150 °C can dehydrate adjacent carboxyl groups into carboxylic anhydrides, which then form an imide after reacting with NH3. Decarboxylation of the imide groups produces pyridines at around 395 °C, with CO2 evolution as shown in eq 4:133

|

4 |

Phenolic compounds can form anilines, as shown in eq 5, at temperatures below 300 °C:133

|

5 |

Elevated temperatures facilitate reactions between NH3 and ethers via dehydration. Further, pyridine-like nitrogen can be seen on the periphery of the carbon layers after dehydrogenation, as shown in eq 6:133

|

6 |

Ammonia decomposition to N2 + H2 begins above 500 °C. Also, a very small amount of HCN forms above 450 °C.133

3.2.2. Thiol Functionalization

3-Mercaptopropyltrimethoxysilane (3-MPTS) is commonly used to add thiol functions to modified adsorbents.78,135,136 It releases methanol in exchange for surface bound hydroxyl groups of adsorbents including smectite, metal oxides, and SiO2.135,137−139 It can also react with water to release methanol and form oligomeric siloxanes, which are also bound to surfaces. Either way, strong surface adhesion bonds −CH2CH2CH2S–H functions onto surfaces.140 The sorption of Hg was assisted via ligand exchange and complexation on engineered biochar because the thiol groups provide surplus adsorption sites, creating strong sulfur binding to mercury. Also, biochar surfaces become more net negatively charged by the acidic thiol functions. This supports electrostatically induced sorption of cationic contaminants or heavy metals.135

Chemical impregnation and ball milling were used to prepare thiol-modified adsorbents.78 3-MPTS solutions were used to provide the surface thiol functionalization.78 Poplar wood chip biochar was prepared at 300 °C. A ball mill agate jar was charged with 3g biochar suspended in a 120 mL solution of water, ethanol, and 3-MPTS (3.6 mL water, 114 mL ethanol, and 2.4 mL 3-MPTS). Alternatively, dropwise addition of 3-MPTS provides better mixing with biochar.78 Agate balls (300 g) with diameters of 15–3 mm were added into this mixture in a mass ratio of 2:5:3. After placing the agate jar inside the ball mill, it was operated for 12 h at 300 rpm, with its rotation direction altered after every 6 h.78 Biochar-to-ball mass ratios (1:100, 1:50, and 1:20), ball milling duration (3, 6, 12, 30, and 48 h), and various biochar amounts (3, 6, and 15 g) were evaluated. Rotation speeds of 300, 400, and 600 rpm were also investigated for biochar (3 g) mixed with agate balls (300 g) for 12 h. Finally, product biochars were washed with deionized water and ethanol 3 times and freeze-dried for 48 h.78 Biochar that was modified with thiol after ball milling showed greater removal capacities (320.1 mg/g and 104.9 mg/g) than chemical treatments before ball milling with 3-MPTS (175.6 mg/g and 58.0 mg/g) for Hg2+ and CH3Hg+, respectively.78

3.2.3. Metal Impregnation

Metal dispersion on nanobiochar can be performed through pretreatment of the biomass precursor or post-treatment after nanobiochar preparation.39,45,46,58,141,142 The pretreatment method involves immersing the biomass feedstock in a metal ion solution. Conversely, post-treating applies metal impregnation after nanobiochar preparation.39 Metal, metal oxide, and metal hydroxide impregnated nanobiochar composites were developed via these routes for enhanced contaminants removal and other applications.39,45,46,58,141,142 For example, iron oxide impregnated biochar nanocomposites showed both magnetic properties and enhanced removal of contaminants such as arsenic.143−145 Porous biochar facilitates dispersion and strong adherence of iron oxide particles, which expands the iron oxide surface area.145 A promising As(V) removal capacity of 6.80 mg/g was achieved by corn straw biochar impregnated with iron.146

A post-treatment preparation of iron oxide-permeated rice husk nanobiochar employed ∼15 g of dried rice husks that were ball milled (50 mL container) with 30 g of 5 mm diameter stainless-steel balls at 500 rpm to form nanoscale rice husk powders.58 These nanoscale rice husks (15 g) were mixed with 0.3 mol Fe3(SO4)2·7H2O and 1 mol urea paste and pyrolyzed at 600 °C under reducing conditions via a one-pot pyrolytic technique at different residence times.58 The Fe3O4-impregnated engineered nanobiochar prepared using a 5 h residence time showed better arsenic removal capacity. TEM images revealed nano-Fe3O4 clusters present in the nanobiochar matrices and the Fe3O4 nanoparticles were surrounded by graphite layers.58 The reactions involved in the formation of different iron oxide and hydroxide species on the biochar surfaces are given below in eqs 7–10:

| 7 |

| 8 |

| 9 |

| 10 |

3.3. Advantages and Disadvantages of Different Preparation Methods

Nanobiochar preparation is most often accomplished by a top-down approach, where biochar particle sizes are reduced progressively to the nanoscale. This is most commonly carried out by ball milling in recent studies.17 Surface modification to engineer different properties has been explored. Surface tailoring has been performed by oxidization, chemical impregnation, and coating functional nanoparticles.38 Each method described here has its own unique merits as well as demerits. To quickly summarize the advantages and disadvantages of nanobiochar preparation methods, including ball milling, sonication, centrifugation, carbonization, and chemical treatment-based modifications, see Table 2.

Table 2. Pros and Cons of Different Nanobiochar Preparation Methods.

| Preparation methods | Advantages | Disadvantages |

|---|---|---|

| Ball milling17,38,54,74,104 | - No harmful chemicals required | - Possibilities of particle’s aggregation |

| - Large scale applicability | - Issues of purity and homogeneity | |

| - Requires low energy | - Mostly confined to laboratory only | |

| - Low-cost production | - Little data available on financial viability and environmental concerns | |

| - Does not damage microcrystalline biochar structure | ||

| - Easy to change ball milling environment | ||

| - Reproducible | ||

| - High efficiency | ||

| - No waste generation | ||

| Centrifugation38 | - Simple method | - Multiple centrifugations required to get desired nanoparticle |

| - Enhances zeta potential/dispersibility of nano- biochar | - Costly | |

| - Lower nanobiochar yields reported | ||

| Sonication38 | - Provides uniform surfaces | - Excessive ultrasound exposure may damage tissue |

| - No clogging of pores | - Large scale production may increase the manufacturing cost | |

| - Requires shorter reaction times | ||

| - High purity | ||

| Carbonization38 | - Easy surface modification | - High energy consumption due to high temperature requirement (activation) |

| - Generates hazardous gases | ||

| - Additional treatment needed to get nanosize particles | ||

| Modification with chemical treatments38 | - Provides engineered nanobiochar with desired surface properties | - Acidic treatment can corrode walls of nano- biochar micropores lowering surface area |

| - Improves affinity toward selected contaminants | - Additional chemical cost required | |

| - Use of hazardous chemicals sometimes reported |

As mentioned above, ball milling is generally the preferred method for nanobiochar preparation because it seldom needs to use harmful chemicals. It can be scaled up, and has high atom and mass efficiency. Aggregation of particles at certain conditions and presence of some impurities and heterogeneities are possible ball milling drawbacks. Centrifugation is a straightforward and simple method to separate different biochar particle sizes by sedimentation. It must be used with some other method that gives size reduction of particles. Thus, grinding, sonication, ball milling or other methods can form a particle size range, and nanosized particle fractions can be separated by centrifugation. Centrifugation is a solvent-assisted method for nanobiochar preparation since sedimentation proceeds through a liquid medium. It provides highly dispersed nanoparticles with improved zeta potentials.38,96 To get the desired biochar particle sized fractions, multiple rounds of centrifugation are required, making this process costly. It is hard to scale up to large nanobiochar weights. Nanobiochar yields obtained by centrifugation are lower compared to those fractions obtained from direct ball milling.38,42 Sonication is frequently used because it provides uniform surfaces, less pore clogging, and high purity nanobiochar in less reaction time compared to other methods.38 The disadvantages of sonication include difficulty in upscaling to mass production, which further adds to production cost. Excess exposure to ultrasound may be dangerous to health.38 An increase in tissue temperatures upon exposure to ultrasound occurs at intensities above 3 W/cm2 resulting in tissue injury. Usually, the surface of the bones is where this happens most often.147

Engineered nanobiochar preparation usually requires using chemicals to develop specific desired surface properties and improved affinity toward selected contaminants (Table 2). Chemical application is associated with disadvantages, including the possible exposure to hazardous chemicals and wall corrosion in nanobiochar micropores. This further enhances the overall cost of engineered nanobiochar production.38

4. Characteristic Nanobiochar Properties

Biochar with different characteristic properties has been applied in diverse fields such as adsorbents, sensors, soil conditioners, and carbon sequestration.1−5,8,9,20,148 Feedstock used and preparation conditions, play key roles in the successful production of desired biochar properties.1−3,9 As expected, nanobiochar will have characteristics derived from the precursor macro-biochar from which they were derived by particle size reduction. However, several of the nanobiochar properties will differ, including surface area, pore volume, pore size, and zeta potentials.17,40,93 These changes arise during particle size reduction as well as specific influences of the nanobiochar preparation techniques. For example, changing the biomass feedstock can influence the resulting biochar particle sizes and the nanobiochar composition (e.g., carbon (%), minerals, surface functional groups, aromatic clusters, zeta potential, colloidal stability, and ash content). Feedstock changes cause key changes in % carbon, mineral contents, functional groups available, aromatic cluster content, zeta potential, and colloidal stability based on particle sizes (bulk, micron, and nano).67

This section deals with the characteristic nanobiochar properties versus those of its macro counterpart’s properties based on the method of the nanobiochar’s preparation by ball milling (Figure 10), sonication (Figure 11), and centrifugation (Figure 12). All data related to the characteristic properties of nanobiochar prepared via these three methods are summarized in Table 3. In addition, Table 3 also has information on the x-axis (sample numbers) for Figures 10, 11, and 12. Surface area, total pore volume, pore size, O/C ratio, H/C ratio, zeta potential, ash content, and pH are given for ball milled nanobiochars and their pristine precursors (Figure 10a–h). Surface area, O/C ratio, H/C ratio, zeta potential, pH, and ash content of each nanobiochar versus its pristine biochar precursor were also compared for nanobiochar synthesis by sonication (Figure 11a–f) and centrifugation (Figure 12a–f).

Figure 10.

Comparison between bulk and nanobiochar (synthesized using ball milling) properties i.e., (a) surface area, (b) total pore volume, (c) pore size, (d) O/C ratio, (e) H/C ratio, (f) zeta potential, (g) ash content and (h) pH. All information related to the feedstock, precursor pyrolysis temperature, nanobiochar preparation conditions, and sample numbers on x-axis are given in Table 3. Data obtained (Table 3) with permission from refs (103, 77, 87, 105, 284, 14, 78, 104, 76, 6, 110, 13). Copyright 2020, 2016, 2020, 2019, 2020, 2020, 2020, 2019, 2018, 2020, 2019, 2020 Elsevier, respectively. Data obtained (Table 3) with permission from ref (89). Copyright 2019 Taylor and Francis.

Figure 11.

Comparison between precursor bulk and product nanobiochars (synthesized using sonication) properties i.e., (a) surface area, (b) O/C ratio, (c) H/C ratio, (d) zeta potential, (e) pH, and (f) ash content. All information related to the feedstock, precursor pyrolysis temperature, nanobiochar preparation conditions, and sample numbers on x-axis are given in Table 3. Data obtained (Table 3) with permission from refs (118, 151). Copyright 2013 and 2018 American Chemical Society, respectively. Data obtained (Table 3) with permission from ref (152). Copyright 2016 Elsevier.

Figure 12.

Comparison of the properties of bulk versus nanobiochar (synthesized by centrifugation fractions of bulk samples) i.e., (a) surface area, (b) O/C ratio, (c) H/C ratio, (d) zeta potential, (e) pH, and (f) ash content. All information related to the feedstock, precursor pyrolysis temperature, nanobiochar preparation conditions, and sample numbers on x-axis are given in Table 3. Data obtained (Table 3) with permission from refs (67, 153). Copyright 2019 and 2019 Elsevier, respectively. Data obtained (Table 3) with permission from ref (68). Copyright 2020 American Chemical Society.

Table 3. Comparison between Pristine and Nanobiochar Physicochemical Propertiesa.

| Precursor biomass | Pyrolysis conditions | Ball milling conditions | Surface area (m2/g)

|

Folds increase in surface area | Total pore

volume (cm3/g)

|

Pore size

(nm)

|

O/C Ratios

|

H/C Ratio

|

Zeta value

(mV)

|

pH

|

Ash content

|

Sample no. on X axis | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball milling | ||||||||||||||||||||

| Cow bone meal103 | Pyrolyzed under N2 flow of 200 mL/min at 300 °C | Wet milling (ball to biochar ratio 100:1) at 300 rpm for 12 h, then ball milled biochar was 5 min centrifugated at 9000 rpm | 12.8 | NA | NA | 1a | ||||||||||||||

| 450 °C | 8.7 | 1b | ||||||||||||||||||

| 600 °C | 5.9 | 1c | ||||||||||||||||||

| Coconut shell77 | 500 °C for 1.5 h under nitrogen flow | 40:1 (ball to biochar ratio) milled for 6h at 550 rpm | 11.8 | NA | NA | NA | NA | NA | 2 | |||||||||||

| Hickory chips87 | 600 °C for 6 h (nitrogen flow) | Planetary ball mill with 6 mm agate balls (100:1) | 1.15 | 3 | ||||||||||||||||

| Sawdust89 | 600 °C for 2 h at 10 °C/min ramp rate in N2 | Ball milled with 6–10 mm ball diameter for 2 h | 2.13 | NA | NA | NA | NA | 4a | ||||||||||||

| 12 h | 2.34 | NA | NA | NA | 4b | |||||||||||||||

| Wet ball milled (1 g BC:3 mL water) for 2 h | 2.11 | NA | NA | NA | 4c | |||||||||||||||

| 12 h | 2.17 | NA | NA | NA | 4d | |||||||||||||||

| Corn straw75 | 500 °C for 2 h at 5 °C/min rate | Planetary ball milling (diameter 5 mm at 600 rpm for 150 min | 1.97 | NA | 5a | |||||||||||||||

| Rice husk75 | 3.11 | NA | 5b | |||||||||||||||||

| Wheat straw105 | 600 °C for 1 h under 100 mL/min N2 flow rate | Milling of 8 g biochar and 800 g ZrO2 ball (6–10 mm dia.) for 5 min. | 18.89 | NA | NA | NA | 6 | |||||||||||||

| Poplar woodchips284 | Ambient atmosphere at 300 °C | 200 rpm for 24 h for 1 g biochar with 100 g agate ball (3–15 mm dia.) | 6.55 | NA | NA | 7a | ||||||||||||||

| 500 °C | 0.90 | NA | NA | 7b | ||||||||||||||||

| 700 °C | 0.38 | NA | NA | 7c | ||||||||||||||||

| Wheat stalk14 | Pyrolyzed in N2 at 300 °C | Ball to biochar ratio 100:1 with 300 rpm for 12 h | 3.46 | NA | NA | NA | NA | NA | 8a | |||||||||||

| 450 °C | 4.15 | NA | NA | 8b | ||||||||||||||||

| 600 °C | 1.22 | NA | NA | 8c | ||||||||||||||||

| Poplar wood chips(78) | Pyrolyzed at 300 °C for 3 h | 3 g biochar was mixed with 2.4 mL 3-MPTS and milled at 300 rpm for 12 h | 33.52 | NA | NA | NA | 9 | |||||||||||||

| Wheat straw104 | At 300 °C for 2 h | Planetary ball milling, ball to biochar powder ratio (1:100) Stainless steel balls of size 5 mm, operational speed 300 rpm for 24 h | 8.64 | NA | NA | NA | 10a | |||||||||||||

| At 500 °C for 2 h | 96.98 | NA | NA | 10b | ||||||||||||||||

| At 700 °C for 2 h | 1.22 | NA | NA | 10c | ||||||||||||||||

| Rice husk104 | At 300 °C for 2 h | 5.16 | NA | NA | 10d | |||||||||||||||

| At 500 °C for 2 h | 17.59 | NA | NA | 10e | ||||||||||||||||

| At 700 °C for 2 h | 1.12 | NA | NA | 10f | ||||||||||||||||

| Sugar cane bagasse76 | For 2 h at 300 °C | Planetary ball milling, Ball diameter 6 mm, Operational speed of 300 rpm in ambient air with rotation and direction altered every 0.5 h | 10.8 | NA | NA | NA | NA | 11a | ||||||||||||

| 450 °C | 6.5 | NA | NA | NA | NA | 11b | ||||||||||||||

| 600 °C | 1.01 | NA | NA | NA | 11c | |||||||||||||||

| Bamboo76 | 300 °C | 4.15 | NA | NA | NA | NA | 11d | |||||||||||||

| 450 °C | 63.62 | NA | NA | NA | NA | 11e | ||||||||||||||

| 600 °C | 4.68 | NA | NA | NA | NA | 11f | ||||||||||||||

| Hickory chips76 | 300 °C | 7 | NA | NA | NA | NA | 11g | |||||||||||||

| 450 °C | 31.53 | NA | 11h | |||||||||||||||||

| 600 °C | 1.22 | NA | 11i | |||||||||||||||||

| Wheat straw6 | Engineered biomass pyrolyzed in N2 at 400 °C for 2 h | Magnetic wheat straw biochar was ball milled (5 mm ball dia.) with 100:1 ball to biochar ratio | 16.1 | NA | NA | NA | NA | 12a | ||||||||||||

| 550 °C | 10.7 | NA | NA | 12b | ||||||||||||||||

| 700 °C | 1.5 | 12c | ||||||||||||||||||

| Hickory chips110 | At 450 °C for 2 h | Planetary ball milling, 6 mm ball dia, Ball to mass ratio 10:1, operated at 300 rpm for 12 h | 46.5 | NA | NA | 13a | ||||||||||||||

| 600 °C | 1.16 | NA | NA | 13b | ||||||||||||||||

| Bagasse110 | At 450 °C for 2 h | 3.44 | NA | NA | 13c | |||||||||||||||

| 600 °C | 2.04 | NA | NA | 13d | ||||||||||||||||

| Hickory wood13 | For 2 h in nitrogen atmosphere at 300 °C | Planetary ball milling, Ball to mass ratio (1:100) operated at 300 rpm | 7 | NA | NA | 14a | ||||||||||||||

| 450 °C | 29 | NA | 14b | |||||||||||||||||

| 600 °C | 1.4 | NA | 14c | |||||||||||||||||

| Precursor biomass | Pyrolysis conditions | Nanobiochar preparation conditions | Surface area (m2/g)

|

Folds increase in specific surface area | Total pore

volume (cm3/g)

|

Molar O/C

ratio

|

H/C ratio

|

Zeta potential

(mV)

|

pH

|

Ash Content

|

Sample no. on X axis | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sonication | ||||||||||||||||||

| Peanut shell151 | For 2 h under N2 flow in a tube furnace at 300 °C | 0.7 g bulk biochar with 35 mL deionized water dispersed for 15 min at 25 °C under sonication at 120 W | 17.3 | NA | NA | 15a | ||||||||||||

| 400 °C | 16.5 | NA | 15b | |||||||||||||||

| 500 °C | 31.4 | NA | 15c | |||||||||||||||

| 600 °C | 29.9 | NA | 15d | |||||||||||||||

| Wheat straw152 | 350–700 °C in an oxygen poor atmosphere (<1% O2) | 3 g biochar was added to 80 mL water and ultrasonic vibrator was used to disperse the biochar | 1.1 | 16a | ||||||||||||||

| Wicker152 | 1.6 | 16b | ||||||||||||||||

| Miscanthus152 | 47.9 | 16c | ||||||||||||||||

| Wheat straw118 | Under anaerobic conditions at 350 °C | 15 g biochars were sonicated in 500 mL deionized water for 30 min to prepare nanobiochar suspension | 65 | NA | NA | NA | 1.289 | NA | 17a | |||||||||

| 550 °C | 205 | NA | NA | NA | 1.478 | 17b | ||||||||||||

| Pine needle118 | 350 °C | 30 | NA | NA | NA | 1.20 | 17c | |||||||||||

| 550 °C | 83 | NA | NA | NA | 0.721 | 17d | ||||||||||||

| Centrifugation | ||||||||||||||||||

| Rice straw68 | At 400 °C | Nano biochar was separated by centrifugation method | 0.66 | NA | NA | NA | 18a | |||||||||||

| 700 °C | 1.6 | 18b | ||||||||||||||||

| Wood chips67 | At 500 °C | Nanoparticles were separated using centrifugation | NA | NA | NA | 19a | ||||||||||||

| Pine wood67 | 19b | |||||||||||||||||

| Wheat straw67 | 19c | |||||||||||||||||

| Barley grass67 | 19d | |||||||||||||||||

| Peanut shell67 | 19e | |||||||||||||||||

| Rice husk67 | 19f | |||||||||||||||||

| Dairy manure67 | 19g | |||||||||||||||||

| Pig manure67 | 19h | |||||||||||||||||

| Sewage sludge67 | 19i | |||||||||||||||||

| Tobacco stem95 | Pyrolyzed at 500 °C with a N2 carrier | Centrifugation at 3500 g | NA | NA | NA | 20 | ||||||||||||

| Rice hull153 | Carbonized at 600 °C in limited oxygen | Centrifuged at a rate of 10,000 rpm for 30 min | 4.5 | NA | NA | NA | NA | 21 | ||||||||||

P = Pristine biochar, N = Nanobiochar, NA = Not available.

4.1. Surface Area

Nanobiochar pore properties can be a deciding factor for the extent of its different applications. The pore properties (surface area, pore volume, and pore size) of bulk and nanobiochars have been widely explored after preparation by ball milling, but less explored for other preparation methods like sonication and centrifugation. Figure 10a summarizes changes in surface areas of different bulk biochars and their corresponding nanobiochars prepared by ball milling of those bulk samples. Large increases in surface area were reported (up to 97-fold) after ball milling compared to the pristine biochar (Figure 10a).104 For example, the surface area of cow bone biochar increased from 2.76, 22.90, and 52.78 m2/g in three pristine samples to 35.49, 199.5, 313 m2/g after ball milling. These biochars were originally prepared at 300, 450, and 600 °C and ball milling increased surface areas by 12.9-, 8.7-, and 5.9-fold, respectively.103 Raising pyrolysis temperature and applying ball-milling enhanced both the external as well as internal surface areas of the resulting nanobiochar. Raising pyrolysis temperatures (from 300 to 600 °C) releases more volatiles and exposes hidden biochar matrix pores to increase surface area.103,149 The surface area of hickory wood biochar also increased from 1.4 to 29.1 fold after ball milling.13

A change in milling time and a wet vs dry milling environment can affect nanobiochar’s surface properties.89 Mechanical ball milling produced a ∼ 200% increase in the surface area for sawdust ball milled biochar. The “before ball milling” surface area (154 m2/g) rose to 325 m2/g after mechanical ball-milling (at 2 h wet milling), 334 m2/g (at 12 h wet milling), 328 m2/g (at 2 h dry milling), and 360 m2/g (at 12 h dry milling).89 Different biomass feedstocks give biochars that respond differently to ball milling. Pristine corn straw biochar (185 m2/g) and rice husk biochar (96 m2/g) were ball milled at 600 rpm for 2.5 h to generate nanoscale biochars with 100–600 nm particle sizes and surface areas of 364 m2/g and 298 m2/g, respectively.75 The surface area of coconut shell biochar increased from 30.9 m2/g to 365 m2/g after ball milling.77 A rare decline in a biochar’s surface area after ball milling has also been reported.103 Poplar woodchips biochar prepared at 500 and 700 °C, with surface areas of 167 and 415 m2/g, lost surface after ball milling to 151 and 156 m2/g, respectively. This might be due to destruction of part of the original pore structure by ball milling.103

Surface area variations of different bulk biochars and their corresponding nanobiochars prepared using sonication are plotted in Figure 11a. Nanobiochars exhibited from 1.13- to ∼48-fold surface area increases versus their precursor macro-biochars. Biochars prepared using wheat straw, wicker, and miscanthus had surface areas of 26.27, 11.38, and 0.76 m2/g, respectively. These rose to 29.56, 18.25, and 36.39 m2/g, respectively, after sonication (60 kJ energy output with 80% amplitude).64 In this sonication, 3 g biochar was dispersed in 80 mL water using a probe-type ultrasonic vibrator.64

Nanobiochar was generated via sonication of previously made peanut shell biochar that had been pyrolyzed at 300, 400, 500, and 600 °C. These nanobiochars had large enhancements in their surface areas exhibiting 17.3-, 16.6-, 31.3-, and 29.9-fold rises as their particle sizes dropped into the nano level during sonication.41 BET surface areas of peanut shell nanobiochar also increased with a rise in the pyrolysis temperature of their precursor biochars.41

A clear trend for the isolation of nanobiochar fractions with larger surface areas is achieved after centrifugation (Figure 12a). After centrifugation, a maximum 4.55-fold increase in surface area of nanobiochar is reported as compared to bulk biochar (Figure 12a). For instance (sample no. 18b), the BET surface area increased from 155.31 m2/g to 253.90 m2/g for bulk biochar and nanobiochar prepared at 700 °C, respectively.68 However, a reduction in the BET surface area, from 141.25 m2/g to 93.18 m2/g, of nanobiochar occurred after centrifugation of the rice husk biochar prepared at 400 °C.68 The reduction in the BET surface area indicates the role of pyrolysis temperature.68

4.2. Total Pore Volume and Pore Size

The total pore volumes of bulk and nanobiochars were also compared (Figure 10b). Higher total pore volumes were observed for ball milled biochars than their pristine counterparts (Figure 10b). Increases in the pyrolysis temperatures to make the pristine biochars increase pore volumes for both pristine and ball milled biochars (Figure 10b). For example, the total pore volumes of pristine and ball milled cow bone meal biochars were 0.017/0.163, 0.074/0.367, and 0.097/0.453 cm3/g in the samples pyrolyzed at 300, 450, and 600 °C, respectively.103 Ball-milling increases the biochar’s external surface area by decreasing the grain size and also increases its internal surface area by exposing the pore networks.76,103 For example, a remarkable increase in total pore volume was reported going from unmilled (0.042 cm3/g) to ball milled biochar/Fe3O4 (0.54 cm3/g).77

Similarly, total pore volumes also increased from 0.089 and 0.101 cm3/g for pristine biochar prepared from rice straw at 400 and 700 °C, respectively, to 0.356 and 0.575 cm3/g for its nanobiochar prepared by centrifugation.68 Similarly, rice hull nanobiochar prepared by ball milling its biochar pyrolyzed at 600 °C has an enhanced BET surface area (27.1 to 123.2 m2/g). This nanobiochar’s total pore volume increased to 0.062 from 0.036 cm3/g.153 On rare occasions, a reduction in total pore volume after ball milling is reported in literature.13 The total pore volumes of 0.096, 0.436, and 0.471 cm3/g of the hickory wood biochars prepared under nitrogen gas at 300, 450, and 600 °C all declined after ball milling to 0.079, 0.304, and 0.307 cm3/g, respectively.13

The comparison of pore sizes of bulk biochars with their corresponding nanobiochars made using ball milling is illustrated in Figure 10c. No clear trend was reported for pore sizes, as a few studies revealed an increase in pore size after ball milling, while other studies showed a decline in pore size. Only limited studies exist on pore properties (surface area, pore volume, and pore size) of nanobiochar prepared using centrifugation or other methods.

4.3. O/C Ratio and H/C Ratio

Molar elemental ratios are useful to estimate the aromaticity (H/C ratio) and polarity (O/C ratio) of biochars and nanobiochars.40,64 Lower H/C ratios imply higher aromaticity and more advanced carbonization of the bulk and nanobiochars. Lower O/C ratios reflect a less-polar nature of the biochar/nanobiochar.89 Raising biochar pyrolysis temperature increases aromaticity but lowers the polar characteristics. Macro- and nanobiochar H/C and O/C ratios of less than 1 indicate less availability of organic residues.64 These characteristics further help improve sorption capacity of many aqueous contaminants.5 How the O/C ratios of bulk versus their corresponding ball milled nanobiochars compare is shown in Figure 10d. O/C ratios for bulk biochar range from 0.04 to 0.55 versus 0.06 to 0.75 for ball milled biochar (see Figure 10d). Most nanobiochars have higher O/C ratios after ball milling their precursors, but not always (see example 14a in Figure 10(C). O/C ratios of cow bone meal biochar pyrolyzed at 300, 450, and 600 °C increased from 0.32, 0.39, and 0.46 before to 0.36, 0.43, and 0.46, respectively, after ball milling.103 A decrease in C (wt %) content increases O/C ratios, resulting in forming more oxygen-containing surface functional groups. A slight decrease of C (wt %), during wet ball milling, might be associated with the structures of oxygen-containing groups (C = O, in ester and carboxyl groups, etc.) that were disrupted. Small fused-ring aromatics, aliphatic carbon, and carboxyl carbon in the biochar- dissolved organic carbon (DOC) or the tar particles could be released into aqueous solutions from biochar pores.79,103,110,154 H/C ratios of different biochars and their counterpart nanobiochars prepared using ball-milling are compared in Figure 10e. No clear trends appeared. A few studies showed distinct rise in the H/C ratio (sample 10a, Figure 10e) after ball-milling, but most H/C ratios remained almost constant with a few showing small drops. Bulk biochar H/C ratios ranged from 0.11 to 1.22, while ball-milled biochar showed H/C ratios of 0.22 to 1.40 (Figure 10e).