ABSTRACT

Traditional process monitoring control charts (CCs) focused on sampling methods using fixed sampling intervals ( s). The variable sampling intervals ( s) scheme is receiving increasing attention, in which the sampling interval ( ) length varies according to the process monitoring statistics. A shorter is considered when the process quality indicates the possibility of an out-of-control (OOC) situation; otherwise, a longer is preferred. The multivariate exponentially moving average for compositional data ( - ) CC based on a coordinate representation using isometric log-ratio ( ) transformation is proposed in this study. A methodology is proposed to obtain the optimal parameters by considering the zero-state ( ) average time to signal ( ) and the steady-state (SS) average time to signal ( ). The statistical performance of the proposed CC is evaluated based on a continuous-time Markov chain ( ) method for both cases, the and the SS using a fixed value of in-control (IC) . Simulation results demonstrate that the - CC has significantly decreased the OOC average time to signal ( ) than the CC. Moreover, it is found that the number of variables (d) has a negative impact on the of the - CC, and the subgroup size (n) has a mildly positive impact on the of the - CC. At the same time, the of the - CC is less than the of the - CC for all the values of n and d. The proposed - CC under steady-State performs effectively compared to its competitors, such as the - CC, the - CC and the - CC. An example of an industrial problem from a plant in Europe is also given to study the statistical significance of the - CC.

KEYWORDS: Average time to signal, compositional data, steady-state, variable sampling interval, zero-state

1. Introduction

Monitoring manufacturing processes has become increasingly difficult due to sophisticated consumer demands for quality products. Statistical process monitoring (SPM) is a commonly used statistical approach for quality control in the industrial scenario. Control charts (CCs) are the most widely used tool in SPM. W.A. Shewhart introduced the concept of CCs in 1924. Conventional CCs are simple and sensitive to large process variations but have poor sensitivity to small process variations. Several measurements are required to improve the detection speed for small process shift.

Aitchison defines Compositional data ( ) analysis as an adequate geometry model for the transformation of [1]. Since Karl Pearson first emphasized problems in the analysis of in 1897. has unique numerical characteristics that have significant implications for statistical analysis studied by many researchers (cf. [3,11,37]). Because represents parts of a larger whole, they have unique properties. The standard statistical techniques designed for probabilistic random variables that cannot analyze in raw form are studied (cf. [15]). In recent years, researchers have started focusing on CCs for . The First CC for was a Chi-square CC, assuming follows the properties of Dirichlet distribution. After the d = 3-part was analyzed using Hotelling CC to interpret the out-of-control (OOC) signals [59]. The Hotelling CC can also be applied on after deleting one component from the vector or after applying the isometric log-ratio (ilr) transformation, but the one with transformed values outperforms the other [58]. As these methods deal with d = 3-parts , a method to deal with high dimensional is introduced [60]. After the advancement of Hotelling CC for , multivariate exponentially moving average (MEWMA) CC using ilr transformation [56] and the effect of measurement error on Hotelling CC [62] and MEWMA [63] have been evaluated. The multivariate cumulative sum (MCUSUM) CC for has been studied with parameter estimation [17]. Recently, MEWMA CC for using variable sampling interval ( ) has been studied using zero-state ( ) average time to signal for ilr transformed d = 3-part using n = 1 subgroup size [35].

A strategy reduces the detecting time in CCs. A small sampling interval ( ) is used if there is any signal that the process has changed; if there is no signal, a longer is used. The fixed sampling interval ( ) CC is used when the length stays the same through all the samples (please see [64]). The multivariate CC to monitor the mean vector and variance-covariance matrix with was investigated by Reynolds and Cho [43]. The MEWMA and MEWMA-type CCs were combined to get the best performance of the CC. The variable sampling rate (VSR) scheme has been used to study the increase and decrease in process dispersion in inverse normal transformation [50]. Further, the CC to monitor the coefficient of variation has been introduced [7]. The CCs with double warning lines are faster at detecting small shifts in the mean vector [22]. The CC with and variable sample size (VSS) was used to monitor the variance-covariance matrix of a multivariate normally distributed process [23].

Many researchers [4,25,41,61] examined the and the features for univariate and multivariate CCs for process monitoring. Simulation is used to investigate the average run length ( ) properties of the exponentially weighted moving average (EWMA) CC to effectively detect the small changes in the process's desired value [52]. More recently, the performance of EWMA techniques based on the for the monitoring logistic profiles has been proposed [31]. The CUSUM CCs are found to be an effective method for monitoring changes in aquatic toxicity [16]. The robust measures of the location were applied to improve exponential-cum-ratio estimators [14]. The multivariate EWMA ( ) CCs using unequal sample sizes were studied [20]. Improving the multivariate CUSUM and EWMA CCs for monitoring purposes has focused most research on quality control proposed by Jarrett [18]. Further, MCUSUM CCs using were used to monitor the ratio when more than two mixture components were considered [33].

The performance of the CC was evaluated using a continuous-time Markov chain ( ) method [39]. Several researchers have attempted to improve the CC's efficiency in identifying shift patterns in the process mean vector through various methods. For example, the CC using sequential sampling [20] and the CC using unequal sample sizes [44]. Changing the value in response to process data is a frequently used technique for increasing the efficiency of CCs [57]. The scheme has been amalgamated to study the performance of CCs [9], the CUSUM CCs for monitoring process mean [42], double EWMA CCs [49], Hotelling CC for exponentially distributed random variables [12], multivariate Shewhart and -type CCs for simultaneously monitoring vectors of means and standard deviations matrix [13]. Further, two s were used for designing the optimal process for Taguchi's online monitor and control method with and without misclassification errors [5]. The performance of the CC was investigated using a proposed approach by Sabahno et al. [48]. To study the benefits of using scheme, the and the CC's performance has been compared [34].

In SPM literature, two different types of performance are typically considered: and steady-state (SS). The term ‘SS performance’ shows the time required for the CC to identify a process shift for control statistics to reach a static distribution. Some processes are initially uncontrollable; the procedure is initiated under control in most realistic scenarios and then changes randomly [40]. When the average number of samples is taken from the start of signal monitoring in an OOC situation, then the CC's performance is evaluated using (cf. [8,10]). The comparison between the zero-state average time to signal ( ) symmetric and asymmetric distributions to the steady-state average time to signal ( ) using the showed the performed better in terms of [19]. The method is also used to determine the of the CC [21]. To detect changes in the process mean, the SS properties of synthetic CCs have been examined [10]. The CCs give more significant results by using to create a CC with m-of-m run rules [24]. Numerous researchers have distinguished between the SS optimal and optimal schemes (cf. [53,54]). The CUSUM CC for two possible s and probability ratio tests were used to study the SS-optimized methods [55]. The -based CC scheme is superior to the -based CC scheme in terms of average time to signal ( ) performance [29].

As discussed earlier, many researchers are currently working on CC for , but all the above-mentioned studies deal with the Markov chain model with ATS to study the CC performance for . Also, most of the research on deals with d = 3-part . As far as the author knows, till now, the SS ATS performance has not been used for monitoring . The literature shows the SS ATS performs better than the ATS (cf. [6,30,51]). Hence to fill this gap, this paper makes an attempt to take SS ATS performance into account. The VSI-MEWMA CC has been proposed using ilr transformation to investigate the ATS using the different number of variables p (i.e. d = 3, 5), subgroup sizes n (i.e. n = 1, 3) and the (i.e. ). The ATS has also been computed to study the difference between and SS ATS performances.

The rest of this paper is as follows: Section 2 discusses brief details about how to model and manipulate the . In Section 3, the model for VSI-MEWMA CC for has been presented. Section 4 presents the for both and SS for the and the . Section 5 gives the CCs performance and compares the - and the - CC. Finally, an illustrative example and conclusions are presented in Sections 6 and 7.

2. Compositional data

A row vector is defined as a vector if it belongs to simplex space ,

| (1) |

where κ is a constant sum of the vector. Because of the constraint of constant sum, Euclidean geometry is unsuitable for . To overcome this problem, J. Aitchison proposed a specific geometry known as Aitchison's geometry [2]. In which advanced operators for sum and multiplications have been defined,

- the perturbation operator for the sum of vectors,

(2) - the powering operator for multiplication of vector with a constant,

(3)

To overcome the constant sum constraints, can be transformed from simplex sample space to real space using the predefined transformations,

- Centered log-ratio transformation,

where is the component-wise geometric mean of , i.e.(4) (5) - Isometric log-ratio

where(6)

To transform the vector from real space to simplex space, we use inverse isometric log-ratio,(7)

There are two ways to deal with , one is to use as it is by using powering and perturbation operator, and the second way is to transform into real space by using the above-mentioned log-ratio transformations so that the classical methods can be applied to after making some important amendments. For more details about , the readers can refer to [17].

3. The VSI-MEWMA CoDa chart

Let us assume that there are have n measures of the quality characteristic at the time . when the process is IC, where is the IC mean vector and when the process is OOC, where is the OOC mean vector and remain unchanged in both cases. Let and , where and . According to [36], x follows a multivariate normal distribution on if the vector of random orthonormal coordinates, , follows a multivariate normal distribution on . This paper is an extension of [35] CC, considering the SS ATS performance analysis. The - CC statistic is,

| (8) |

with

| (9) |

where and are smoothing parameters. The - CC shows a signal when

| (10) |

where H is the upper control limit ( ), and is the variance-covariance matrix of . Here the author used the asymptotic variance-covariance matrix proposed by Lowry et al. [27], i.e.

| (11) |

Due to the directional invariant property, the CC's depend on the non-centrality parameter δ [26]. Where the value of δ is,

| (12) |

When the is fixed, the of - CC is denoted by . But for - CC, the selection of is based on the charting statistics . The time interval between the sample and can vary. Using two sampling intervals is reasonable to limit the - CC's complexity and achieve the proposed chart's efficacy [46]. Hence following [46], two s are used in this paper, and , where denotes the small and denotes the long one. For the - CC, the is the same as that of - CC. A warning limit (L) is introduced such that 0<L<H and . The switch between the small and the long depends on the value of the CC parameter . If the CC parameter lies within the L, a long will be used, and if the value of lies between the L and the H, then the small should be used.

4. The average time to signal

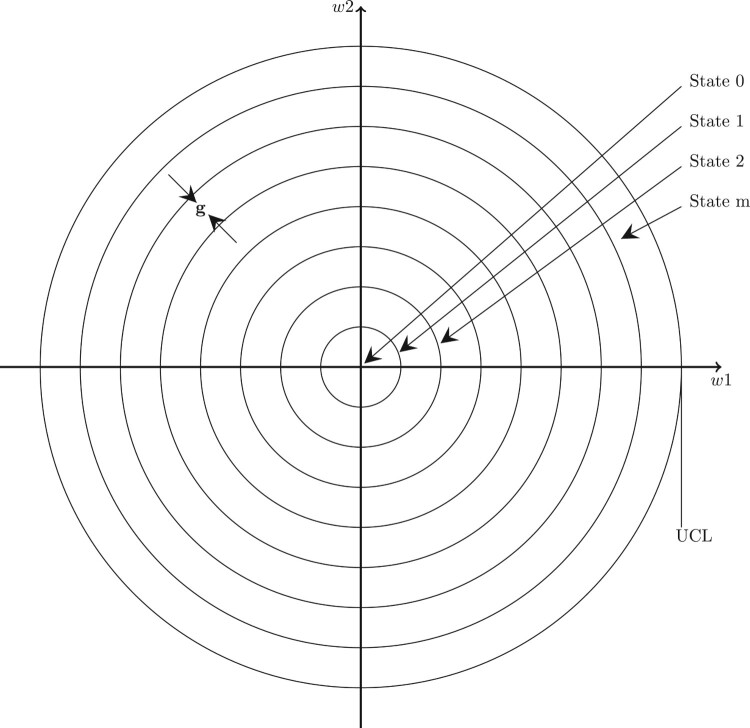

Prabhu and Runger [47] suggested calculating the statistics as the standardized form of with to determine the IC and OOC of the CC using models. For the IC case, one-dimensional (i.e. ) is used to approximate the of , where have m + 1 sub-interval with the length of the first sub-interval g/2 and others g and the width of sub-interval . Concerning the - CCs is also added to the one-dimensional (i.e. ). The IC one-dimensional is also shown in Figure 1.

Figure 1.

IC Distribution for the VSI MEWMA CoDa CC.

The probability of transition for i to j state is,

| (13) |

where follows a non-central chi-square distribution with a non-centrality parameter having d−1 degree of freedom.

The of the VSI- CCs for IC case is as follows,

| (14) |

with is the identity matrix of size m + 1 and is the initial probability vector and is vector of . The average for the proposed CC can be written as

| (15) |

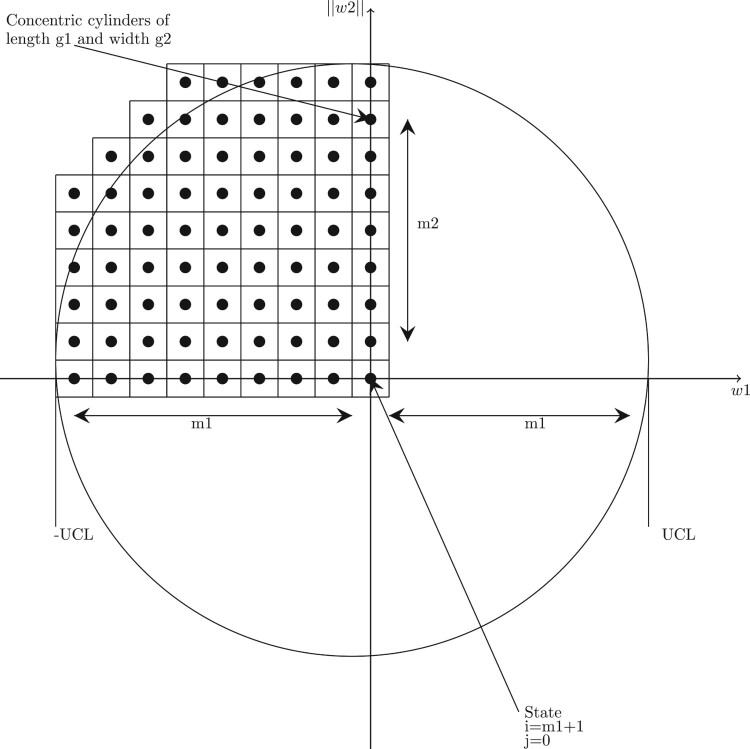

For the OOC case, two-dimensional is used to approximate the of with the partition of into and with δ and zero mean, respectively and . A two-dimensional can also be used for the CC. The approach used to approximate the component , and for is given in [28]; the same method for IC is used where d−1 is replaced by d−2. For , the OOC component is analyzed using the transition probability from state to state with states,i.e.

| (16) |

where Φ is the cumulative standard normal distribution function with being the midpoint of the state i and be the width of each state. The OOC two-dimensional is also shown in Figure 2.

Figure 2.

OOC Distribution for the VSI MEWMA CoDa CC.

For , the IC component is analyzed using the transition probability from state to state with states. i.e.

| (17) |

where with width of states . All the transient states of can be summarized in a transition probability matrix . Then,

| (18) |

where the symbol ⊛ is used for element-wise matrices multiplication, is the dimensional matrix defined as

| (19) |

and denotes the transition probability matrix of two-dimensional , , where and are the transitional probability matrices of and respectively and ⊗ is the Kronecker's matrices product. The OOC of the - CC is defined as,

| (20) |

with is the identity matrix of size m + 1, and is the initial probability vector with all components equal to zero except the component corresponding to the state which is equal to one and is the vector of .

The SS OOC of the - CC is defined as,

| (21) |

where is a vector with and is vector of with elements if , if and zero when the process is OOC. Where b is a SS probability vector obtained by solving the following equation: subject to . Where is the transition probability matrix when the process is IC, i.e. .

The average of for the - CC can be written as,

| (22) |

where is the proportion of time to signal. If the CC will be the standard CC. The number of states greatly impacts the of the CC. (see [32]), but due to limited resources and time, the author cannot use a large number of m. Following literature reviews, hence will be used. (see [32] or [56]).

5. Comparative analysis of the VSI-MEWMA CoDa chart

This section presents an optimization approach for statistical designing the - CC. An optimal CC can be achieved using two different s, with the small taken as small as possible and the long dependent on δ and , where the CC is best for tracking shifts δ. Similar to [38,45], the practitioners need to set the fixed for the minimum interval hmin. The - CC is designed by determining the CC parameters (i.e. r, , W, and H) that minimize the OOC aspect to the target value specified for constraints h, = hmin, and , for the provided values of n, d, and δ. The value of H will be the same for the and the - - CCs for given values of r, n, h, and . The following is the optimized statistical layout process for the - CC:

Specify n, , d, , and δ.

Initialize r as 0.05.

Initialize as . Set , then find the value of H for the fixed value of IC , where . Given δ is calculated, the OOC and . Increasing r with a step size of 0.005, iterate Steps 3 to 5.

The r, , W, and H values are used to determine the minimum OOC and for the optimal - CC parameters.

For comparison of the with the CC, the average of the - CC is assumed to be the same as the of the - CC, i.e. when the process is IC when . In other words, for the - CC is chosen to have a similar IC as the - CC; in the specific context, the - CC's false alarm rate (i.e. ) is the same as the - CC.

5.1. ZATS of the VSI-MEWMA CoDa control chart

The values of optimal couples of the and the CCs under are presented in Table 1. The OOC values of the and the CCs for are given in Table 2 when and . The OOC values of the and the CCs for the are also given in Table 2.

Table 1.

optimum charting parameters for - and - CC.

| n = 1 | n = 3 | ||||

|---|---|---|---|---|---|

| - | - | - | - | ||

| δ | p | ||||

| 0.25 | 3 | (0.05, 7.35, 1.74, 1.62, 0.10) | (0.05, 7.35) | (0.05, 7.35, 0.82, 2.70, 0.10) | (0.05, 7.35) |

| 5 | (0.05, 9.46, 2.27, 2.10, 0.10) | (0.05, 9.46) | (0.05, 9.46, 2.30, 2.10, 0.10) | (0.05, 9.46) | |

| 0.50 | 3 | (0.05, 7.50, 1.72, 1.65, 0.10) | (0.06, 7.50) | (0.05, 7.50, 1.24, 2.50, 0.10) | (0.06, 7.50) |

| 5 | (0.05, 9.50, 1.73, 2.28, 0.10) | (0.06, 9.50) | (0.05, 9.50, 1.78, 2.28, 0.10) | (0.06, 9.50) | |

| 0.75 | 3 | (0.09, 8.51, 1.64, 1.73, 0.10) | (0.09, 8.51) | (0.10, 8.51, 1.48, 2.20, 0.10) | (0.10, 8.51) |

| 5 | (0.08, 10.27, 1.69, 2.09, 0.10) | (0.08, 10.27) | (0.09, 10.27, 1.76, 2.08, 0.10) | (0.08, 10.27) | |

| 1.00 | 3 | (0.14, 9.19, 2.90, 1.32, 0.10) | (0.14, 9.19) | (0.15, 9.41, 1.88, 1.89, 0.10) | (0.15, 9.41) |

| 5 | (0.13, 10.71, 1.95, 1.83, 0.10) | (0.13, 10.71) | (0.14, 10.93, 2.05, 1.82, 0.10) | (0.13, 10.93) | |

| 1.25 | 3 | (0.19, 9.61, 1.65, 1.82, 0.10) | (0.20, 9.61) | (0.21, 9.77, 2.45, 1.69, 0.10) | (0.20, 9.77) |

| 5 | (0.18, 10.97, 2.45, 1.65, 0.10) | (0.19, 10.97) | (0.20, 11.13, 2.58, 1.64, 0.10) | (0.19, 11.13) | |

| 1.50 | 3 | (0.25, 9.91, 3.51, 1.22, 0.10) | (0.25, 9.91) | (0.27, 10.05, 2.86, 1.49, 0.10) | (0.25, 10.05) |

| 5 | (0.24, 11.11, 2.81, 1.46, 0.10) | (0.25, 11.11) | (0.26, 11.25, 2.96, 1.45, 0.10) | (0.25, 11.25) | |

| 1.75 | 3 | (0.31, 10.12, 3.72, 1.24, 0.10) | (0.31, 10.12) | (0.34, 10.23, 4.01, 1.28, 0.10) | (0.31, 10.23) |

| 5 | (0.31, 11.16, 3.92, 1.26, 0.10) | (0.31, 11.16) | (0.33, 11.27, 4.09, 1.25, 0.10) | (0.31, 11.27) | |

| 2.00 | 3 | (0.37, 10.26, 3.62, 1.25, 0.10) | (0.38, 10.26) | (0.41, 10.36, 4.70, 1.10, 0.10) | (0.38, 10.36) |

| 5 | (0.37, 11.14, 4.57, 1.10, 0.10) | (0.37, 11.14) | (0.40, 11.24, 4.77, 1.10, 0.10) | (0.37, 11.24) | |

Table 2.

OOC of the - CC.

| n = 1 | n = 3 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| δ | p | ||||||||

| 0.25 | 3 | 56.842 | 64.6 | 115.528 | 88.553 | 48.346 | 53.980 | 112.877 | 85.902 |

| 5 | 64.362 | 70.27 | 120.928 | 99.909 | 53.746 | 59.654 | 118.277 | 97.258 | |

| 0.50 | 3 | 19.935 | 26.4 | 76.86 | 51.885 | 17.731 | 22.440 | 75.900 | 50.925 |

| 5 | 26.695 | 31.65 | 81.86 | 59.076 | 22.731 | 27.686 | 80.900 | 58.116 | |

| 0.75 | 3 | 10.441 | 15.1 | 55.323 | 33.367 | 9.095 | 12.900 | 54.784 | 32.828 |

| 5 | 15.69 | 19.72 | 59.723 | 38.901 | 13.495 | 17.525 | 59.184 | 38.362 | |

| 1.00 | 3 | 6.913 | 9.9 | 41.916 | 22.986 | 5.489 | 8.440 | 41.559 | 22.629 |

| 5 | 10.748 | 13.89 | 45.716 | 27.482 | 9.289 | 12.431 | 45.359 | 27.125 | |

| 1.25 | 3 | 4.934 | 7.1 | 32.942 | 16.039 | 3.885 | 6.050 | 32.687 | 15.784 |

| 5 | 8.333 | 10.67 | 36.342 | 19.932 | 7.285 | 9.623 | 36.087 | 19.677 | |

| 1.50 | 3 | 3.728 | 5.4 | 26.618 | 11.744 | 3.185 | 4.610 | 26.425 | 11.551 |

| 5 | 6.978 | 8.55 | 29.618 | 15.142 | 6.185 | 7.757 | 29.425 | 14.948 | |

| 1.75 | 3 | 3.008 | 4.3 | 21.984 | 9.14 | 2.852 | 3.680 | 21.832 | 8.989 |

| 5 | 6.075 | 7.03 | 24.584 | 12.088 | 5.452 | 6.407 | 24.432 | 11.936 | |

| 2.00 | 3 | 2.419 | 3.5 | 18.484 | 7.484 | 2.246 | 3.000 | 18.362 | 7.362 |

| 5 | 4.95 | 5.81 | 20.684 | 9.684 | 4.446 | 5.306 | 20.562 | 9.562 | |

5.1.1. Impact of sampling interval h

Based on Table 2, it can be seen that the of the CC is less than the of the CC. When , n = 1, d = 3, , and W = 1.78, the for the - CC is , while for the - CC is . Similarly, when , n = 1, d = 3, , , r = 0.14, H = 9.19 and W = 1.78, the for the - CC is , while for the - CC is . Hence it is summarized that the CCs have a greater degree of efficacy than the CCs for .

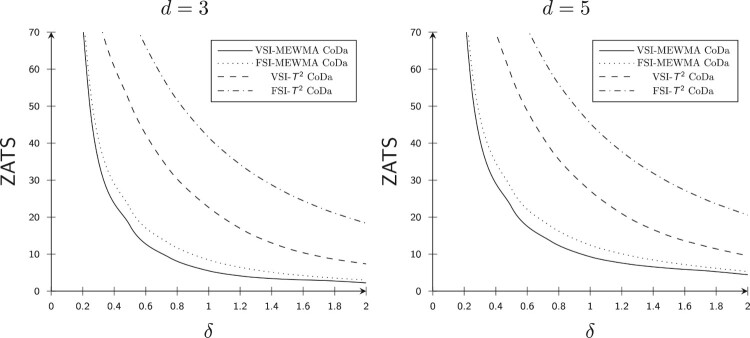

5.1.2. Impact of number of the variables d

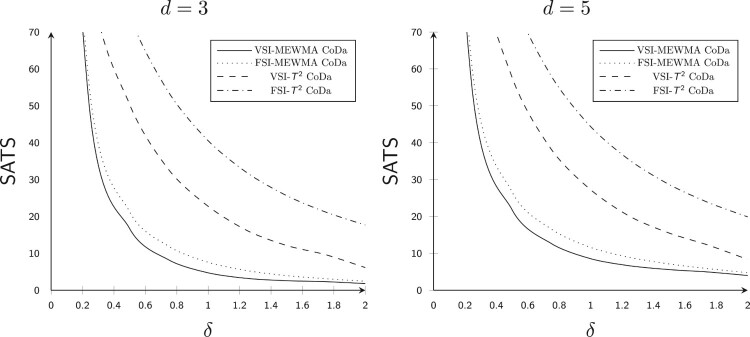

Based on Table 2 and Figure 3, it can be seen that d has a negative effect on the of the CC for ; that is, the OOC values increase with an increase in the value of d.

Figure 3.

Curves for n = 3 and .

When , n = 1, d = 3, , and W = 1.78, the for the - CC is and for the - CC is . But when the value of d increases to d = 5, the for the - CC increases to and the - CC increases to .

Similarly, when , n = 1, d = 3, , , r = 0.14, H = 9.19 and W = 1.78, the for the - CC is , and for the - CC is . But, when the value of d increases to d = 5, the for the - CC increases to and the - CC increases to . Figure 3 also shows the impact of the number of variables d on of the and the CC for both the and the situations.

Where a solid black line shows the of the - CC, the of the - CC is shown by the dotted line, and the dashed line shows the of the - CC, the dashed-dotted line shows the of the - CC. From Figure 3, it is also clearly visible that d has a negative effect on the of the and the CC for .

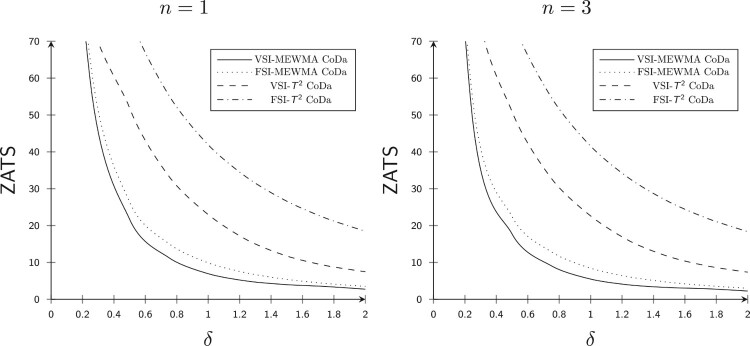

5.1.3. Impact of subgroup size n

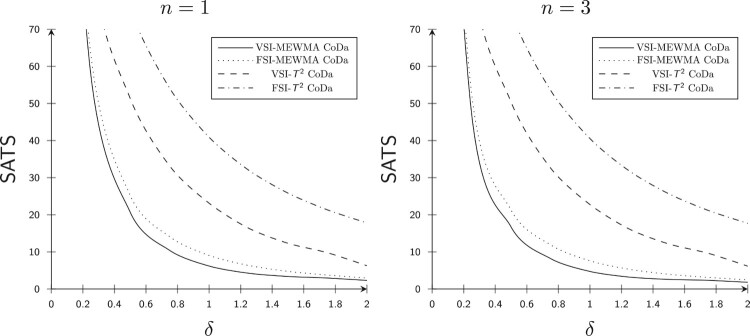

Based on Table 2, it can be seen that n has a mild positive effect on the of the CC for ; that is, the OOC values decrease with an increase in the value of n.

When , n = 1, d = 3, , and W = 1.78, the for the - CC is , and for the - CC is . But when the value of n increases to n = 3, the for the - CC decreases to , and the - CC decreases to .

Similarly, when , n = 1, d = 3, , , r = 0.14, H = 9.19 and W = 1.78, the for the - CC is and for the - CC is . But when the value of n increases to n = 3, the for the - CC decreases to , and the - CC decreases to . Figure 4 also shows the impact of the subgroup size n on of the Hotelling and the CC for both the and the situations. From Figure 4, it is also clearly visible that n has a positive effect on the of the and the CC for .

Figure 4.

Curves for d = 3 and .

5.2. SATS of the VSI-MEWMA CoDa control chart

The values of optimal couples of the and the CCs under SS are presented in Table 3. The OOC values of the and the CCs for are given in Table 4 when and . The OOC values of the and the CCs for the SS are also given in Table 4.

Table 3.

SS optimum charting parameters for - and - CC.

| n = 1 | n = 3 | ||||

|---|---|---|---|---|---|

| - | - | - | - | ||

| δ | p | ||||

| 0.25 | 3 | (0.05, 7.38, 0.80, 2.50, 0.10) | (0.05, 7.38) | (0.05, 7.38, 0.83, 2.50, 0.10) | (0.05, 7.38) |

| 5 | (0.05, 9.33, 2.25, 1.92, 0.10) | (0.05, 9.33) | (0.05, 9.33, 2.30, 1.91, 0.10) | (0.05, 9.33) | |

| 0.50 | 3 | (0.05, 7.53, 1.19, 2.30, 0.10) | (0.05, 7.53) | (0.05, 7.53, 1.24, 2.30, 0.10) | (0.05, 7.53) |

| 5 | (0.05, 9.37, 1.71, 2.09, 0.10) | (0.05, 9.37) | (0.05, 9.37, 1.78, 2.09, 0.10) | (0.05, 9.37) | |

| 0.75 | 3 | (0.09, 8.54, 1.42, 2.00, 0.10) | (0.10, 8.54) | (0.10, 8.54, 1.49, 2.00, 0.10) | (0.10, 8.54) |

| 5 | (0.08, 10.14, 1.68, 1.89, 0.10) | (0.09, 10.14) | (0.09, 10.14, 1.77, 1.89, 0.10) | (0.08, 10.14) | |

| 1.00 | 3 | (0.14, 9.22, 1.80, 1.70, 0.10) | (0.15, 9.22) | (0.15, 9.44, 1.90, 1.69, 0.10) | (0.15, 9.44) |

| 5 | (0.13, 10.58, 1.95, 1.64, 0.10) | (0.14, 10.58) | (0.14, 10.80, 2.07, 1.63, 0.10) | (0.14, 10.80) | |

| 1.25 | 3 | (0.19, 9.64, 2.35, 1.50, 0.10) | (0.20, 9.64) | (0.21, 9.80, 2.47, 1.49, 0.10) | (0.20, 9.80) |

| 5 | (0.19, 10.84, 2.45, 1.46, 0.10) | (0.19, 10.84) | (0.20, 11.00, 2.59, 1.45, 0.10) | (0.19, 11.00) | |

| 1.50 | 3 | (0.25, 9.94, 2.74, 1.30, 0.10) | (0.26, 9.94) | (0.27, 10.08, 2.89, 1.29, 0.10) | (0.26, 10.08) |

| 5 | (0.25, 10.98, 2.82, 1.27, 0.10) | (0.25, 10.98) | (0.27, 11.12, 2.99, 1.25, 0.10) | (0.25, 11.12) | |

| 1.75 | 3 | (0.31, 10.15, 3.86, 1.10, 0.10) | (0.32, 10.15) | (0.34, 10.26, 4.04, 1.10, 0.10) | (0.32, 10.26) |

| 5 | (0.31, 11.03, 3.94, 1.07, 0.10) | (0.31, 11.03) | (0.33, 11.14, 4.12, 1.10, 0.10) | (0.31, 11.14) | |

| 2.00 | 3 | (0.38, 10.29, 4.54, 1.10, 0.10) | (0.38, 10.29) | (0.41, 10.39, 4.74, 1.10, 0.10) | (0.38, 10.39) |

| 5 | (0.37, 11.17, 4.60, 1.08, 0.10) | (0.37, 11.17) | (0.40, 11.27, 4.81, 1.10, 0.10) | (0.37, 11.27) | |

Table 4.

OOC of the - CC.

| n = 1 | n = 3 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| δ | p | ||||||||

| 0.25 | 3 | 57.882 | 63.350 | 114.028 | 87.804 | 47.267 | 52.740 | 111.378 | 85.155 |

| 5 | 62.882 | 68.600 | 119.028 | 99.900 | 52.905 | 58.698 | 117.129 | 97.044 | |

| 0.50 | 3 | 20.695 | 25.250 | 75.480 | 51.356 | 16.732 | 21.290 | 74.521 | 50.398 |

| 5 | 25.295 | 30.080 | 80.080 | 59.195 | 21.819 | 26.642 | 79.647 | 57.718 | |

| 0.75 | 3 | 10.410 | 14.100 | 54.123 | 33.169 | 8.216 | 11.910 | 53.586 | 32.633 |

| 5 | 14.410 | 18.300 | 58.123 | 39.213 | 12.662 | 16.579 | 58.049 | 38.194 | |

| 1.00 | 3 | 6.188 | 9.050 | 40.896 | 23.119 | 4.732 | 7.590 | 40.543 | 22.766 |

| 5 | 9.588 | 12.620 | 44.296 | 27.986 | 8.560 | 11.616 | 44.380 | 27.255 | |

| 1.25 | 3 | 4.253 | 6.350 | 32.042 | 16.394 | 3.209 | 5.310 | 31.792 | 16.144 |

| 5 | 7.253 | 9.500 | 35.042 | 20.564 | 6.629 | 8.899 | 35.218 | 20.016 | |

| 1.50 | 3 | 3.378 | 4.750 | 25.838 | 12.320 | 2.590 | 3.960 | 25.652 | 12.135 |

| 5 | 5.978 | 7.480 | 28.438 | 15.901 | 5.606 | 7.131 | 28.672 | 15.509 | |

| 1.75 | 3 | 2.955 | 3.750 | 21.324 | 9.774 | 2.338 | 3.130 | 21.172 | 9.622 |

| 5 | 5.155 | 6.060 | 23.524 | 12.524 | 4.952 | 5.857 | 23.772 | 12.222 | |

| 2.00 | 3 | 2.310 | 2.950 | 17.824 | 6.274 | 1.806 | 2.450 | 17.702 | 6.152 |

| 5 | 4.510 | 5.260 | 20.024 | 9.024 | 4.006 | 4.756 | 19.902 | 8.352 | |

5.2.1. Impact of sampling interval h

Based on Table 4, it can be seen that the of the CC is less than the of the CC. When , n = 1, d = 3, , and W = 1.80, the for the - CC is , while for the - CC is . Similarly, when , n = 1, d = 3, , , r = 0.14, H = 9.22 and W = 1.80, the for the CC is , while for the - CC is . Hence it is summarized that the CCs have a greater degree of efficacy than the CCs for .

5.2.2. Impact of number of the variables d

Based on Table 4, it can be seen that d has a negative effect on the of the CC for ; that is, the OOC values increase with an increase in the value of d.

When , n = 1, d = 3, , and W = 1.80, the for the - CC is and for the - CC is . But when the value of d increases to d = 5, the for the - CC increases to and the - CC increases to .

Similarly, when , n = 1, d = 3, , , r = 0.14, H = 9.22 and W = 1.80, the for the - CC is and for the - CC is . But when the value of d increases to d = 5, the for the - CC increases to , and the - CC increases to . Figure 5 also shows the impact of the number of variables d on of the CC. From Figure 5, it is also clearly visible that d has a negative effect on the of the and the CC for .

Figure 5.

Curves for n = 3 and .

5.2.3. Impact of subgroup size n

Based on Table 4, it can be seen that n has a mild positive effect on the of the CC for ; that is, the OOC values decrease with an increase in the value of n.

When , n = 1, d = 3, , and W = 1.80, the for the - CC is and for the - CC is . But when the value of n increases to n = 3, the for the - CC decreases to , and the - CC decreases to .

Similarly, when , n = 1, d = 3, , , r = 0.14, H = 9.22 and W = 1.80, the for the - CC is and for the - CC is . But when the value of n increases to n = 3, the for the - CC decreases to , and the - CC decreases to . Figure 5 also shows the impact of the subgroup size n on the of the CC. From Figure 6, it is also clearly visible that n has a positive effect on the of the and CC for .

Figure 6.

Curves for d = 3 and .

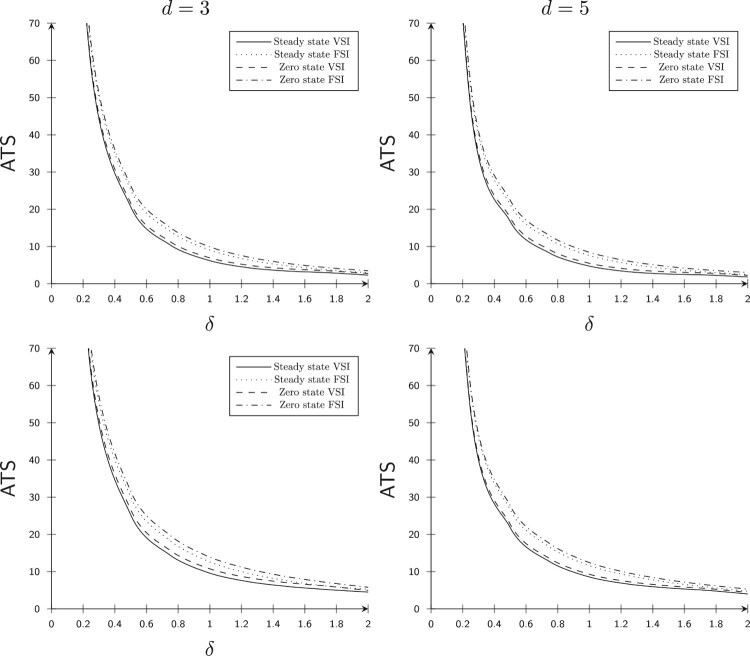

5.3. Comparison of ZATS and SATS of the VSI-MEWMA CoDa control chart

To compare the and the SS performance of the VSI-MEWMA CoDa CC, all the and the values for different combinations of the involved variables are given in Table 5. It can be seen from Table 5 that the for both the and the CC are less than the of both the and the CC.

Table 5.

OOC and of the and - CC.

| d = 3 | d = 5 | |||||||

|---|---|---|---|---|---|---|---|---|

| n = 1 | n = 3 | n = 1 | n = 3 | |||||

| δ | VSI | FSI | VSI | FSI | VSI | FSI | VSI | FSI |

| 0.25 | 56.842 | 64.6 | 48.346 | 53.98 | 64.362 | 70.27 | 53.746 | 59.654 |

| 0.5 | 19.935 | 26.4 | 17.731 | 22.44 | 26.695 | 31.65 | 22.731 | 27.686 |

| 0.75 | 10.441 | 15.1 | 9.095 | 12.9 | 15.69 | 19.72 | 13.495 | 17.525 |

| 1 | 6.913 | 9.9 | 5.489 | 8.44 | 10.748 | 13.89 | 9.289 | 12.431 |

| 1.25 | 4.934 | 7.1 | 3.885 | 6.05 | 8.333 | 10.67 | 7.285 | 9.623 |

| 1.5 | 3.728 | 5.4 | 3.185 | 4.61 | 6.978 | 8.55 | 6.185 | 7.757 |

| 1.75 | 3.008 | 4.3 | 2.852 | 3.68 | 6.075 | 7.03 | 5.452 | 6.407 |

| 2 | 2.419 | 3.5 | 2.246 | 3 | 4.95 | 5.81 | 4.446 | 5.306 |

| 0.25 | 55.762 | 63.35 | 47.267 | 52.74 | 62.882 | 68.6 | 52.905 | 58.698 |

| 0.5 | 18.935 | 25.25 | 16.732 | 21.29 | 25.295 | 30.08 | 21.819 | 26.642 |

| 0.75 | 9.561 | 14.1 | 8.216 | 11.91 | 14.41 | 18.3 | 12.662 | 16.579 |

| 1 | 6.153 | 9.05 | 4.732 | 7.59 | 9.588 | 12.62 | 8.56 | 11.616 |

| 1.25 | 4.254 | 6.35 | 3.209 | 5.31 | 7.253 | 9.5 | 6.629 | 8.899 |

| 1.5 | 3.128 | 4.75 | 2.59 | 3.96 | 5.978 | 7.48 | 5.606 | 7.131 |

| 1.75 | 2.488 | 3.75 | 2.338 | 3.13 | 5.155 | 6.06 | 4.952 | 5.857 |

| 2 | 1.979 | 2.95 | 1.806 | 2.45 | 4.51 | 5.26 | 4.006 | 4.756 |

When , n = 1, d = 3, the for the and the CC are and respectively. While the for the and the CC are and , respectively, are less than for both the and the CC.

Figure 7 also shows the and the curves for both the and the CCs. A solid line shows the of in all the figures, the of the is shown by a dotted line in all the figures, the of the is shown by a dashed line in all the figures, while a dashed-dotted line shows the of the in all the figures. From Figure 7, we can see that the for both the and the CC are less than the of both the and the CC.

Figure 7.

and Curves.

Also the out-of-control performances of CC under and SS can be compared using percentage improvement indicator as,

Table 6 presents the percentage improvement in terms of out-of-control s under the and SS of the - CC for n = 1 and p = 3. The SATS of - CC is always smaller than the ZATS of the - CC.

Table 6.

Comparison in terms of out-of-control s under the and SS of the - CC for n = 1 and p = 3.

| δ | Δ | ||

|---|---|---|---|

| 0.25 | 56.842 | 55.762 | 1.90 |

| 0.50 | 19.935 | 18.935 | 5.02 |

| 0.75 | 10.441 | 9.561 | 8.43 |

| 1.00 | 6.913 | 6.153 | 10.99 |

| 1.25 | 4.934 | 4.254 | 13.78 |

| 1.50 | 3.728 | 3.128 | 16.09 |

| 1.75 | 3.008 | 2.488 | 17.29 |

| 2.00 | 2.419 | 1.979 | 18.19 |

In terms of their percentage improvement indicators it can be seen that, depending on the level of shift δ, when n = 1 and p = 3, the - CC under SS proposed in this paper is between 2% to 18% more efficient than the - CC under presented in [35].

6. Illustrative example

Similar to [56,58], the example of the particle-size distribution for a plant in Europe is used in this study. According to [58], there were four OOC points in the data (i.e. ). Following [56], the author removed all the four OOC points described by Vives et al. [58] to get the IC phase I data set. Assume that the author would like to use the - CC with r = 0.05 and H = 7.35 to control a process of d = 3-part . After removing the OOC point, the IC phase-I dataset is given in Table 7. The estimates for the parameters of the multivariate normal distribution of the transformed mean vector and variance-covariance matrix are given by

and

while the mean of original can be written as

Table 7.

The Phase I dataset from [56].

| i | M | L | S | i | M | L | S | i | M | L | S | i | M | L | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 92.6 | 3.2 | 4.2 | 14 | 94.5 | 2.6 | 2.9 | 27 | 83.6 | 7.4 | 9 | 40 | 84.5 | 6.9 | 8.6 |

| 2 | 91.7 | 5.2 | 3.1 | 15 | 94.5 | 2.7 | 2.8 | 28 | 84.8 | 6.8 | 8.4 | 41 | 84.4 | 7.4 | 8.2 |

| 3 | 86.9 | 3.5 | 9.6 | 16 | 88.7 | 7.9 | 3.4 | 29 | 87.1 | 6.3 | 6.6 | 42 | 84.3 | 8.9 | 6.8 |

| 4 | 90.4 | 2.9 | 6.7 | 17 | 84.6 | 6.6 | 8.8 | 30 | 87.2 | 6.1 | 6.7 | 43 | 89.8 | 8.2 | 2 |

| 5 | 92.1 | 4.6 | 3.3 | 18 | 90.7 | 4 | 5.3 | 31 | 87.3 | 6.6 | 6.1 | 44 | 90.4 | 6.7 | 2.9 |

| 6 | 91.5 | 4.4 | 4.1 | 19 | 90.2 | 2.5 | 7.3 | 32 | 84.8 | 6.2 | 9 | 45 | 90.1 | 5.9 | 4 |

| 7 | 90.3 | 5 | 4.7 | 20 | 92.7 | 3.8 | 3.5 | 33 | 87.4 | 6.5 | 6.1 | 46 | 83.6 | 8.7 | 7.7 |

| 8 | 85.1 | 8.4 | 6.5 | 21 | 91.5 | 2.8 | 5.7 | 34 | 86.8 | 6 | 7.2 | 47 | 88 | 6.4 | 5.6 |

| 9 | 89.7 | 4.2 | 6.1 | 22 | 91.8 | 2.9 | 5.3 | 35 | 88.8 | 4.8 | 6.4 | 48 | 84.7 | 8.4 | 6.9 |

| 10 | 92.5 | 3.8 | 3.7 | 23 | 90.6 | 3.3 | 6.1 | 36 | 89.8 | 4.9 | 5.3 | 49 | 93 | 5.1 | 1.9 |

| 11 | 91.8 | 4.3 | 3.9 | 24 | 87.3 | 7.2 | 5.5 | 37 | 86.9 | 5.8 | 7.3 | 50 | 91.4 | 5 | 3.6 |

| 12 | 91.7 | 3.7 | 4.6 | 25 | 82.6 | 7 | 10.4 | 38 | 83.8 | 7.2 | 9 | 51 | 86.2 | 5 | 8.8 |

| 13 | 90.3 | 3.8 | 5.9 | 26 | 83.5 | 6 | 10.5 | 39 | 89.2 | 5.6 | 5.2 | 52 | 87.2 | 5.9 | 6.9 |

For the phase II dataset, using simulation, 20 samples of size n = 3 have been generated using . The process is IC up to sample 10, after sample 10, a shift with the assignable cause in the mean vector has been introduced, and the next 10 samples are generated using . Hence the mean vector shifted from

to

or it can be written in original as

Where the shift from to equals . But here, the author has used a shift of size in the mean vector. is considered enough to detect the shift in quickly, as it is interpreted as a signal that something is not right in the process. For this reason, is used to implement the - CC. For n = 1 and , the optimal parameters for the - CC are r = 0.05 and H = 7.35 (see Table 2).

Here the author has taken the subgroup of size n = 3 and the IC . Using and , the author gets a WL of the - CC W = 0.8 with the SS OOC SATS = 57.882. The next depends on the position of the - CC; if the CC lies below W, the will be , while if the CC lies between W and H, the will be . The - CC has a greater degree of efficacy than the - CC; as for the same values of r, H, d and n, the - CC have the SS OOC SATS = 63.35. For the sake of comparison, the author has used a percentage improvement indicator,

The percentage improvement indicator shows that the - CC has almost greater degree of efficacy than the - CC in terms of SS OOC SATS. The same is the case with OOC , and the - CC have an almost greater degree of efficacy than the - CC in terms of ZATS.

7. Conclusions

This article has investigated the performance of the function in the CCs using a normal random vector described as the inverse log-ratio of a d-part to monitor the mean vector. This article focuses on the s instead of using the -based charting schemes to monitor the shift in the process mean vector. In the CC, the length of the depends on the charting statistic. A WL was introduced, and the length was divided into two values, for the large and for the small . By fixing the small to 0.1, the author can find the values of optimal parameters considering a fixed value of the IC for a wide range of shifts in the process mean. If the monitored statistics lie below the WL, then a large has been used. But, when the monitored statistics lie between the warning and the , the small has been used. The proposed study has investigated the CC's performance under zero-state and steady-state properties of the run length using the method. The process mean and the variance-covariance matrix is supposed to be known for the comparative study. Different values of the number of variables d and subgroup size n have been used to investigate the OOC using a fixed value of IC . The main conclusions of this article are (i). The and the of the - CC are greater than the and the of the - CC; (ii). The of the - CC increases with an increase in the d; (iii). The of the - CC decreases with an increase in the n; (iv). The of the proposed CC is less than the for all the different combinations of n and d. A comparison of the - CC with the - CC, the and the Hotelling CC has also been made to study the statistical sensitivity of the proposed CC. For future research, MCUSUM- , Hotelling , for the location mean vector and dispersion matrix, can be designed using .

Funding Statement

This work was supported by National Natural Science Foundation of China [Grant number: 71802110]; Foundation of Nanjing University of Posts and Telecommunications [Grant number: NY222176]; The Excellent Innovation Teams of Philosophy and Social Science in Jiangsu Province [Grant number: 2017ZSTD022]; Key Research Base of Philosophy and Social Sciences in jiangsu Information Industry Integration Innovation and Emergency Management Research Center [Grant number: None]; Humanity and Social Science Foundation of the Ministry of Education of China [Grant number: 19YJA630061].

Disclosure statement

No potential conflict of interest was reported by the author(s).

References

- 1.Aitchison J., The Statistical Analysis of Compositional Data, Monographs on Statistics and Applied Probability, Reprinted 2003 with additional material by Blackburn Press. Chapman and Hall Ltd., London, 1986. [Google Scholar]

- 2.Aitchison J., The Statistical Analysis of Compositional Data, Monographs on Statistics and Applied Probability. Springer Dordrecht Netherlands, 1986. [Google Scholar]

- 3.Aitchison J. and Egozcue J.J., Compositional data analysis: Where are we and where should we be heading?, Math. Geol. 37 (2005), pp. 829–850. [Google Scholar]

- 4.Asghar S., Alireza F., Cédric H., Erwin S., and Moghadam M.B., A modified economic-statistical design of the control chart with variable sample sizes and control limits, J. Appl. Stat. 38 (2011), pp. 2459–2469. [Google Scholar]

- 5.Bessegato L., Quinino R., Ho L.L., and Duczmal L., Variable interval sampling in economical designs for online process control of attributes with misclassification errors, J. Oper. Res. Soc. 62 (2011), pp. 1365–1375. [Google Scholar]

- 6.Bourke P.D., The geometric CUSUM chart with sampling inspection for monitoring fraction defective, J. Appl. Stat. 28 (2001), pp. 951–972. [Google Scholar]

- 7.Castagliola P., Achouri A., Taleb H., Celano G., and Psarakis S., Monitoring the coefficient of variation using a variable sampling interval control chart, Qual. Reliab. Eng. Int. 29 (2013), pp. 1135–1149. [Google Scholar]

- 8.Champ C.W., Steady-state run length analysis of a shewhart quality control chart with supplementary runs rules, Commun. Stat. Theory Methods 21 (1992), pp. 765–777. [Google Scholar]

- 9.Cui R.Q. and Reynolds Jr M.R., Chart with runs and variable sampling intervals, Commun. Stat. Simul. Comput. 17 (1988), pp. 1073–1093. [Google Scholar]

- 10.Davis R.B. and Woodall W.H., Evaluating and improving the synthetic control chart, J. Qual. Technol. 34 (2002), pp. 200–208. [Google Scholar]

- 11.Egozcue J.J. and Pawlowsky-Glahn V., Compositional data: The sample space and its structure, Test Off. J. Span. Soc. Stat. Oper. Res. 28 (2019), pp. 599–638. 10.1007/s11749-019-00670-6. [DOI] [Google Scholar]

- 12.Faraz A.R. and Saniga E., Economic statistical design of A T2 control chart with double warning lines, Qual. Reliab. Eng. Int. 27 (2011), pp. 125–139. [Google Scholar]

- 13.Ghanaatiyan R., Amiri A., and Sogandi F., Multi-Objective economic-Statistical design of VSSI-MEWMA-DWL control chart with multiple assignable causes, J. Ind. Syst. Eng. 10 (2017), pp. 34–58. [Google Scholar]

- 14.Gulzar M.A., Latif W., Abid M., Nazir H.Z., and Riaz M., On enhanced exponential-cum-ratio estimators using robust measures of location, Concurr. Comput. Pract. Exp. 34 (2022), Article ID e6763. e6763 CPE-21-1421.R1. [Google Scholar]

- 15.Hron K., Templ M., and Filzmoser P., Imputation of missing values for compositional data using classical and robust methods, Comput. Stat. Data Anal. 54 (2010), pp. 3095–3107. [Google Scholar]

- 16.Hussain S., Sun M., Mahmood T., Riaz M., and Abid M., IQR CUSUM charts: An efficient approach for monitoring variations in aquatic toxicity, J. Chemom. 35 (2021), Article ID e3336. [Google Scholar]

- 17.Imran M., Sun J.S., Zaidi F.S., Abbas Z., and Nazir H.Z., Multivariate cumulative sum control chart for compositional data with known and estimated process parameters, Qual. Reliab. Eng. Int. 38 (2022), pp. 2691–2714. [Google Scholar]

- 18.Jarrett J.E., Total quality management (TQM) movement in public health, Int. J. Qual. Reliab. Manag. 33 (2015), pp. 25–41. 10.1108/IJQRM-12-2013-0193. [DOI] [Google Scholar]

- 19.Khilare S.K. and Shirke D.T., Nonparametric synthetic control charts for process variation, Qual. Reliab. Eng. Int. 28 (2012), pp. 193–202. [Google Scholar]

- 20.Kim K., Marion R., and Reynolds J., Multivariate monitoring using an MEWMA control chart with unequal sample sizes, J. Qual. Technol. 37 (2005), pp. 267–281. [Google Scholar]

- 21.Knoth S., Steady-state average run length(s): Methodology, formulas, and numerics, Seq. Anal. 40 (2021), pp. 405–426. [Google Scholar]

- 22.Lee M.H., Variable sampling rate multivariate exponentially weighted moving average control chart with double warning lines, Qual. Technol. Quant. Manag. 10 (2013), pp. 353–368. [Google Scholar]

- 23.Lee M.H. and Khoo M.B.C., Double sampling control chart with variable sample size and variable sampling interval, Commun. Stat. Simul. Comput. 47 (2018), pp. 615–628. [Google Scholar]

- 24.Lim T.J. and Cho M., Design of control charts with M-of-M runs rules, Qual. Reliab. Eng. Int. 25 (2009), pp. 1085–1101. [Google Scholar]

- 25.Lin Y.C. and Chou C.Y., Robustness of the EWMA and the combined -EWMA control charts with variable sampling intervals to non-normality, J. Appl. Stat. 38 (2011), pp. 553–570. [Google Scholar]

- 26.Linna K.W., Woodall W.H., and Busby K.L., The performance of multivariate control charts in the presence of measurement error, J. Qual. Technol. 33 (2001), pp. 349–355. [Google Scholar]

- 27.Lowry C.A., Woodall W.H., Champ C.W., and Rigdon S.E., A multivariate exponentially weighted moving average control chart, Technometrics 34 (1992), pp. 46–53. [Google Scholar]

- 28.Lucas J.M. and Saccucci M.S., Exponentially weighted moving average control schemes: Properties and enhancements, Technometrics 32 (1990), pp. 1–12. [Google Scholar]

- 29.Mahadik S.B. and Shirke D.T., On the superiority of a variable sampling interval control chart, J. Appl. Stat. 34 (2007), pp. 443–458. [Google Scholar]

- 30.Mahmoud M.A., Woodall W.H., and Davis R.E., Performance comparison of some likelihood ratio-based statistical surveillance methods, J. Appl. Stat. 35 (2008), pp. 783–798. [Google Scholar]

- 31.Mohammadzadeh M., Yeganeh A., and Shadman A.R., Monitoring logistic profiles using variable sample interval approach, Comput. Ind. Eng. 158 (2021), Article ID 107438. [Google Scholar]

- 32.Molnau W.E., Runger G.C., Montgomery D.C., Skinner K.R., Loredo E.N., and Prabhu S.S., A program of ARL calculation for multivariate EWMA charts, J. Qual. Technol. 33 (2001), pp. 515–521. [Google Scholar]

- 33.Nguyen H.D., Tran K.P., and Heuchenne H.L., Cusum control charts with variable sampling interval for monitoring the ratio of two normal variables, Qual. Reliab. Eng. Int. 36 (2020), pp. 474–497. [Google Scholar]

- 34.Nguyen Q.T., Giner-Bosch V., Tran K.D., Heuchenne C., and Tran K.P., One-sided variable sampling interval EWMA control charts for monitoring the multivariate coefficient of variation in the presence of measurement errors, Int. J. Adv. Manuf. Technol. 115 (2021), pp. 1821–1851. [Google Scholar]

- 35.Nguyen T.V., Heuchenne C., and Tran K.P., Anomaly detection for compositional data using VSI MEWMA control chart, in Scientific Congresses and Symposiums, Elsevier, June 2022

- 36.Pawlowsky-Glahn V., Egozcue J.J., and Tolosana-Delgado R., Modeling and Analysis of Compositional Data, John Wiley & Sons, Hoboken, New Jersey, US, 2015. [Google Scholar]

- 37.Pawlowsky-Glahn V. and Egozcue J.J., Compositional data in geostatistics: A log-ratio based framework to analyze regionalized compositions, Math. Geosci. 52 (2020), pp. 1067–1084. [Google Scholar]

- 38.Prabhu S.S., Montgomery D.C., and Runger G.C., A combined adaptive sample size and sampling interval control scheme, J. Qual. Technol. 26 (1994), pp. 164–176. [Google Scholar]

- 39.Prabhu S.S. and Runger G.C., Designing a multivariate EWMA control chart, J. Qual. Technol. 29 (1997), pp. 8–15. [Google Scholar]

- 40.Qiu P. and Hawkins D., A rank-based multivariate CUSUM procedure, Technometrics 43 (2001), pp. 120–132. [Google Scholar]

- 41.Ramalhoto M.F. and Morais M., Shewhart control charts for the scale parameter of a weibull control variable with fixed and variable sampling intervals, J. Appl. Stat. 26 (1999), pp. 129–160. [Google Scholar]

- 42.Reynolds M.R., Amin R.W., and Arnold J.C., CUSUM charts with variable sampling intervals, Technometrics 32 (1990), pp. 371–384. [Google Scholar]

- 43.Reynolds M.R. and Cho G.Y., Multivariate control charts for monitoring the mean vector and covariance matrix with variable sampling intervals, Seq. Anal. 30 (2011), pp. 1–40. [Google Scholar]

- 44.Reynolds M. R. and Kim K., Multivariate control charts for monitoring the process mean and variability using sequential sampling, Seq. Anal. 26 (2007), pp. 283–315. [Google Scholar]

- 45.Runger G.C. and Montgomery D.C., Adaptive sampling enhancements for shewhart control charts, IIE Trans. 25 (1993), pp. 41–51. [Google Scholar]

- 46.Runger G.C. and Pignatiello J.J., Adaptive sampling for process control, J. Qual. Technol. 23 (1991), pp. 135–155. [Google Scholar]

- 47.Runger G.C. and Prabhu S.S., A Markov chain model for the multivariate exponentially weighted moving averages control chart, J. Am. Stat. Assoc. 91 (1996), pp. 1701–1706. [Google Scholar]

- 48.Sabahno H., Amiri A., and Castagliola P., A new adaptive control chart for the simultaneous monitoring of the mean and variability of multivariate normal processes, Comput. Ind. Eng. 151 (2021), Article ID 106524. [Google Scholar]

- 49.Shamma S.E., Amin R.W., and Shamma A.K., A double exponentially weigiited moving average control procedure with variable sampling intervals, Commun. Stat. Simul. Comput. 20 (1991), pp. 511–528. [Google Scholar]

- 50.Shi L., Zou C., Wang Z., and Kapur K.C., A new variable sampling control scheme at fixed times for monitoring the process dispersion, Qual. Reliab. Eng. Int. 25 (2009), pp. 961–972. [Google Scholar]

- 51.Shongwe S.C., Malela-Majika J., and Castagliola P., A combined mixed-s-skip sampling strategy to reduce the effect of autocorrelation on the scheme with and without measurement errors, J. Appl. Stat. 48 (2021), pp. 1243–1268. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 52.Srivastava M.S. and Wu Y., Comparison of EWMA, CUSUM and Shiryayev–Roberts procedures for detecting a shift in the mean, Ann. Stat. 21 (1993), pp. 645–670. 10.1214/aos/1176349142. [DOI] [Google Scholar]

- 53.Stoumbos Z.G., Reynolds M.R., Ryan T.P., and Woodall W.H., The state of statistical process control as we proceed into the 21st century, J. Am. Stat. Assoc. 95 (2000), pp. 992–998. [Google Scholar]

- 54.Stoumbos Z.G., Mittenthal J., and Runger G.C., Steady-state-optimal adaptive control charts based on variable sampling intervals, Stoch. Anal. Appl. 19 (2001), pp. 1025–1057. [Google Scholar]

- 55.Stoumbos Z.G. and Reynolds M.R., Control charts applying a general sequential test at each sampling point, Seq. Anal. 15 (1996), pp. 159–183. [Google Scholar]

- 56.Tran K.P., Castagliola P., Celano G., and Khoo M.B.C., Monitoring compositional data using multivariate exponentially weighted moving average scheme, Qual. Reliab. Eng. Int. 34 (2018), pp. 391–402. [Google Scholar]

- 57.Tran P.H. and Heuchenne C., Monitoring the coefficient of variation using variable sampling interval CUSUM control charts, J. Stat. Comput. Simul. 91 (2021), pp. 501–521. [Google Scholar]

- 58.Vives-Mestres M., Daunis-I-Estadella J., and Martin-Fernandez J.A., Individual control chart for compositional data, J. Qual. Technol. 46 (2014), pp. 127–139. [Google Scholar]

- 59.Vives-Mestres M., Daunis-I-Estadella J., and Martín-Fernández J.A., Out-of-control signals in three-part compositional control chart, Qual. Reliab. Eng. Int. 30 (2014), pp. 337–346. [Google Scholar]

- 60.Vives-Mestres M., Daunis i Estadella J., and Martín-Fernández J., Signal interpretation in hotelling's control chart for compositional data, IIE Trans. 48 (2016), pp. 661–672. [Google Scholar]

- 61.Wu Z., Tian Y., and Zhang S., Adjusted-loss-function charts with variable sample sizes and sampling intervals, J. Appl. Stat. 32 (2005), pp. 221–242. [Google Scholar]

- 62.Zaidi F.S., Castagliola P., Tran K.P., and Khoo M.B.C., Performance of the hotelling control chart for compositional data in the presence of measurement errors, J. Appl. Stat. 46 (2019), pp. 2583–2602. [Google Scholar]

- 63.Zaidi F.S., Castagliola P., Tran K.P., and Khoo M.B.C., Performance of the MEWMA-CoDa control chart in the presence of measurement errors, Qual. Reliab. Eng. Int. 36 (2020), pp. 2411–2440. [Google Scholar]

- 64.Zou C., Tsung F., and Wang Z., Monitoring general linear profiles using multivariate exponentially weighted moving average schemes, Technometrics 49 (2007), pp. 395–408. [Google Scholar]