Abstract

Awareness is growing that human health cannot be considered in isolation but is inextricably woven with the health of the environment in which we live. It is, however, under-recognized that the sustainability of human activities strongly relies on preserving the equilibrium of the microbial communities living in/on/around us. Microbial metabolic activities are instrumental for production, functionalization, processing, and preservation of food. For circular economy, microbial metabolism would be exploited to produce building blocks for the chemical industry, to achieve effective crop protection, agri-food waste revalorization, or biofuel production, as well as in bioremediation and bioaugmentation of contaminated areas. Low pH is undoubtedly a key physical–chemical parameter that needs to be considered for exploiting the powerful microbial metabolic arsenal. Deviation from optimal pH conditions has profound effects on shaping the microbial communities responsible for carrying out essential processes. Furthermore, novel strategies to combat contaminations and infections by pathogens rely on microbial-derived acidic molecules that suppress/inhibit their growth. Herein, we present the state-of-the-art of the knowledge on the impact of acidic pH in many applied areas and how this knowledge can guide us to use the immense arsenal of microbial metabolic activities for their more impactful exploitation in a Planetary Health perspective.

Keywords: antimicrobial, biohydrogen, phytopathogen, organic acids; food preservation, waste valorization

This review highlights how acidic pH, by impacting microbial metabolism, affects many areas of applied sciences, and how research can open avenues for an impactful exploitation of microbial activities at low pH in a Planetary Health perspective.

Abbreviations

- AMR

Antimicrobial resistance

- DF

Dark fermentations

- GAD

Glutamic acid decarboxylase

- GABA

γ-aminobutyric acid

- GRAS

Generally recognized as safe

- LAB

Lactic acid bacteria

- MEC

Microbial electrolysis cells

- PAW

Plasma activated water

- PHA

Polyhydroxyalkanoates

- ROS

Reactive oxygen species

- VFA

Volatile fatty acids

- VS

Volatile solids

Introduction

The extractive and polluting nature of the linear economy (take–make–consume–waste) has by far passed the limits of environmental sustainability (Despoudi et al. 2021). In the last two centuries, especially since the second industrial revolution, the anthropocentric perspective has prevailed over that of the planet and the environments in which we live (Baporikar 2020). Though Nature is resilient and has an incredible ability for self-renewal, the rate at which humankind pollute and the kind of waste generated has now reached a point of no return, i.e. by far exceeding that of Earth’s self-regeneration (Folke et al. 2021). A circular bioeconomy model (i.e. to stop waste accumulation and aiming at reduce–reuse–recycle) would be more sustainable, and the development of such an economy is now a stated target of governments and companies worldwide (Neves and Marques 2022). The circular bioeconomy model incorporates two important notions: generation of renewable energy and production of chemicals that are less-toxic and, most of all, recyclable (Tan and Lamers 2021). In a circular bioeconomy a fundamental role can be played by micro-organisms (archea, bacteria, and fungi), which are capable of colonizing the most disparate environments and niches on our planet and possess a very broad range of metabolic activities (Sauer 2022). Exploiting waste material is therefore a fundamental component of the circular bioeconomy and its main aim is to generate high-value products and bioenergy from waste streams (Priya et al. 2023). For its practical realization to large scale waste material refining, a considerable effort of interdisciplinary teams is needed. This also applies to bioremediation and bioaugmentation when it comes to polluted sites.

As we will discuss in this review, micro-organisms have the potential to be extremely valuable in regard to the above because of their very broad range of different metabolic activities, many of which have not yet been exploited (O’Connor 2021). Synthetic biology is paving the way to microbial cell factories that will meet human needs in a greener way than current processes do (Sauer 2022).

Key physical–chemical parameters that need to be understood and, when needed, manipulated for the full exploitation of the microbial metabolism include the presence/absence of molecular oxygen, the pH, the salinity, the osmotic pressure, and the temperature (Breznak and Costilow 2014). This is true regardless of whether single species and microbial community are being considered. In this review, we highlight the role and the importance of acidic pH (low pH) in many areas of applied sciences that can contribute to the circular bioeconomy.

Acidic pH greatly impacts foods shelf life and safety because it reduces spoilage and inhibits pathogens growth (Lund et al. 2020), Acidity can be imposed by the addition of acidic molecules (for the most part organic) during food processing or generated by the natural metabolic activities of beneficial micro-organisms that are present in food. As we will discuss in the following section, the substances produced by microbial processes at acidic pH, mostly driven by fermentation, play a vital role not only in food production, preservation, and shelf life, but also in increasing the final nutritional value, functional properties (i.e. benefits beyond basic nutrition) and sensory quality of the final food products. Fermented foods are “foods made through desired microbial growth and enzymatic conversions of food components” (Marco et al. 2021), most of which are intrinsically acidic. Fermented acid foods, including many traditional food and drinks (e.g. yogurt, cheese, sour krauts, pickled vegetables, kefir, and different types of fermented milks), are the result of the biotransformations performed by micro-organisms and provide additional health benefits for human and animal health.

However, the role and key importance of microbial activities at low pH go beyond food safety, and plant, animal, and human health and disease. The acidification of soil and oceans is for example a key parameter to monitor and ideally manage, because it shapes the microbial communities living in these environments and negatively impacts on the microbial biodiversity (Peixoto et al. 2022), with inevitable adverse consequences on food chains. Even in clouds acidic pH is a key parameter that, in combination with sunlight, may influence the survival of bacteria and affect their metabolism and ability to degrade organic acids in clouds (Liu et al. 2023).

On the other hand, weak organic acids, such as itaconic acid, lactic acid, and succinic acid, represent important building blocks with the potential for microbial production under low pH, as it will be discussed in one of the following sections. Itaconic acid, for example, is a platform chemical the microbial production of which can be improved by strain development and process optimization at low pH. Lactic acid, the most commonly used term for 2-hydroxypropionic acid, is mostly produced today by fermentation: its demand has increased significantly due to its utilization as a monomer for production of poly-lactides and poly-coglycolates. These polymers are thermostable, biocompatible, and biodegradable and also suitable for biomedical applications and food packaging with significant advantages over petroleum-based polymers for the mentioned applications (Djukić-Vuković et al. 2019, Magalhães Júnior et al. 2021). Bio-based production of succinic acid as a building block has the potential to replace monomers obtained from fossil oil in the production, for example, of polybutylene succinate, a biodegradable polymer of the polyesters family, suitable for the production of disposable items (Mancini et al. 2020). Routes for microbial production of succinic acid are still not sufficiently developed to make it competitive with the currently dominant petroleum-based production, however, initiatives are active in the European market (https://www.european-bioplastics.org/).

As the above examples show, understanding and ultimately enhancing the activity at low pH of neutralophilic micro-organisms and acidophilic micro-organisms, through appropriate biotechnological applications and strategies can be channeled into the needs of the circular bioeconomy. This review aims to provide an updated account of where we are in many applied science fields that exploit microbial responses to low pH to enhance both our and planet health.

Low pH as a key parameter in food preservation, processing, and protection: the impact of microbial acid stress responses on food safety, quality, and functionalization

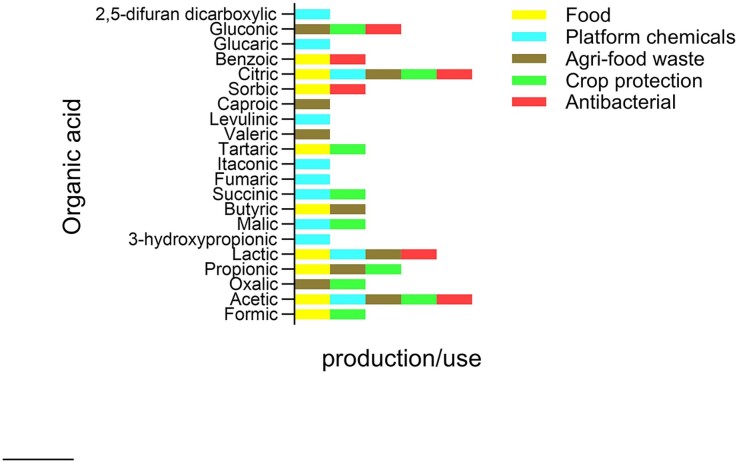

Acidity is an inherent property of some foods, such as citrus fruits and juices, and can be also caused by fermentation processes by autochthonous micro-organisms or intentionally added starter cultures (Pérez-Díaz et al. 2017). Acidophilic micro-organisms, like certain strains of lactic acid bacteria (LAB), generate organic acids that effectively inhibit the growth of pathogens and spoilage microbes. Hydrogen peroxide and bacteriocins are other antimicrobial substances produced by LAB and also greatly slow down the growth of organisms that cause food spoilage (Singh 2018). In addition, many ingredients and additives are added to food to reduce pH of the end product, which have beneficial effects on shelf life and hence safety. Among them, several organic acids, including acetic, citric, formic, lactic, propionic, sorbic, ascorbic, and benzoic acid, are routinely used in food products mainly as acidity regulators, but also (for some of them) as flavor enhancers, antioxidants or substances with direct antimicrobial activity (Coban 2020). Figure 1 summarizes the applied sectors in which the above, as well as other organic acids discussed in this review, are more prominently employed or produced.

Figure 1.

Organic acids of microbial origin that find important applications and/or are produced in different fields. The graph mainly reflects the molecules discussed in this review. Created with GraphPad Prism 10.0.

Acidic pH and food safety

Acidification is one of the most important pretreatments in some food industries, such as the canning industry, where it is commonly applied before the thermal treatment to reduce the heat resistance and inhibit the germination of bacterial spores, therefore allowing the reduction of the intensity of the thermal treatments applied (Derossi et al. 2011). Acidification by the food industry in such cases can be applied through blanching or immersion of the food ingredients in acidified aqueous solutions, direct batch acidification, or addition of acid raw materials to low-acid foods in controlled proportion to conform with specific formulations (Derossi et al. 2011).

Acidic pH also plays an important role contributing to the antimicrobial effect of some recent technological interventions developed to improve food safety. An example of such novel technology is plasma-activated water (PAW), generated through the direct exposure of water to the action of nonthermal atmospheric plasma. During its production PAW is rapidly acidified, reaching values close to pH 3.0. This is mainly due to the dissociation of water caused by the plasma treatment, and to the formation of nitric acid and nitrous acid, if nitrogen is present, either from ambient air or from the gas used in the process (Oliveira et al. 2022). Recent studies have shown that the microbial responses to PAW are quite similar to those triggered by acid pH (Fernández-Gómez et al. 2023). Several reactive species with strong antimicrobial activity are present in PAW. These include ozone, atomic oxygen, reactive oxygen species (ROS, such as singlet oxygen, hydrogen peroxide, hydroperoxide, hydroxyl, and superoxide anion radicals), nitrogen oxides (NO2, N2O3, N2O5, and N2O4), and nitric oxide derivatives, such as nitrates, nitrites, and peroxynitrites (Tian et al. 2015, Risa Vaka et al. 2019, Xu et al. 2020, Hou et al. 2021). Although acidification is not the primary cause of microbial inactivation by PAW, it has been suggested that its low pH could contribute to (i) the stabilization of some reactive chemical species present in PAW, (ii) the formation of new antimicrobial compounds, and/or (iii) the penetration of the reactive species through the cell wall, thus enhancing the antimicrobial effects attained (Naïtali et al. 2010, Oehmigen et al. 2010, Julák et al. 2012). Considering the strong bactericidal properties of PAW, it is being currently proposed as an attractive alternative for the pretreatment or washing of foods, or food-contact surfaces, taking also into account its potential for sustainable production with low energy input, offsite generation, and storability under refrigeration (Herianto et al. 2021).

The micro-organisms that occur in acidic foods or that are exposed to acidic environments in the food industry are endowed with mechanisms to respond to low pH conditions. When acid stress responses are activated in spoilage and pathogenic microbes, food quality and safety can be compromised, because the long-term survival/growth of these microbes during food processing and storage can lead to increased food waste and outbreaks of disease, even in high income countries (European Centre for Disease and Control 2023, Lakicevic et al. 2022, Yang et al. 2017). On the other hand, the enhanced growth and/or survival abilities provided by low pH responses are considered desirable attributes in the case of beneficial microbes (micro-organisms added to food for technological, sensorial, or functionalization purposes) (Lund et al. 2020). Indeed, high acid tolerance or an ability to respond to acidic pH is indispensable for industrial strains that are intentionally added to food and has become one of the most important standards for strain screening (Ko et al. 2022). Considering the competence provided by enhanced acid tolerance, engineering strategies have also been applied to improve the survival and metabolic activity of beneficial microbes under acid stress. Some of these engineering approaches involve random mutation evolution in the presence of the stressor (i.e. acid pH), where parental strains are repeatedly exposed to acidic pH while the pH is lowered gradually, and then selecting for strains with enhanced capabilities under acidity relative to the parental strain (Zhu et al. 2010).

Acidic pH and food quality

Preadaptation to acid stress has been proposed as a valuable strategy to improve the survival of beneficial microbes, such as LAB, under low pH conditions, where microbial cultures are pretreated (preculturing) at a sublethal acid stress condition prior to exposure to a harsher or more lethal acid environment (Upadrasta et al. 2011). In bifidobacteria, the enhanced survival of acid-adapted cultures has been described to be mediated by a physiological acid tolerance response which can include, analogously to other bacterial species (Lund et al. 2014): (i) pH homeostasis by proton-translocating F1FO-ATPase, (ii) the alteration of cell membrane properties by modifications in the fatty acid composition, (iii) an increase in the alkalinity of the cytoplasm by the activity of amino acid decarboxylase systems, and (iv) the production of several stress proteins (Ruiz et al. 2011). As an example, Settachaimongkon et al. (2015) demonstrated that the adaptation of the probiotic strains Lactobacillus rhamnosus GG and Bifidobacterium animalis subsp. lactis BB12 to sublethal acid pH conditions (pH 4.5 or pH 5.0) improved their viability in yogurt during refrigerated storage. Likewise, the exploitation of acid stress responses, through strain engineering or acid stress adaptation of cultures, can increase the robustness in the acidic environment of the stomach upon ingestion of probiotics (Sánchez et al. 2012).

Apart from having an impact on the survival of microbes in food and the gastrointestinal tract upon ingestion, microbial acid stress responses also involve important alterations in the metabolic activity of the microbial cells, which can lead to substantial changes in their technological and functional potential, and even in the biochemical and organoleptic characteristics of fermented foods (Serrazanetti et al. 2009). As an example, Settachaimongkon et al. (2015), in the aforementioned study, showed how culturing the probiotic strains L. rhamnosus GG and B. animalis subsp. lactis BB12 under sublethal acid stress conditions changed the relative abundance of various aroma compounds, mainly of volatiles derived from the catabolism of branched-chain amino acids and sulfur-containing amino acids in yogurt. These compounds included 1-methoxy-2-propanol (Val), 2-methyl-1-butanol (Ile/Leu), 3-methyl-2-butenal (Ile/Leu), 3-methyl-butanoic acid (Leu), 2-methyl-propanoic acid (Val), and sulfur-containing compounds (Cys/Met), which can considerably influence the organoleptic quality of the product (Settachaimongkon et al. 2015).

A paradigmatic case of both the negative and positive impacts that the metabolic changes induced by acid stress responses may have on human health outcomes is exemplified by the various amino acid decarboxylases that are induced by cell exposure to acid pH. Decarboxylation pathways are activated in acid conditions as they catalyze the conversion of an amino acid into a biogenic amine, generating carbon dioxide and consuming a proton, thus contributing to the maintenance of the intracellular pH and improved survival at low pH (Pennacchietti et al. 2016, Lund et al. 2020). On the negative side, some biogenic amines produced by micro-organisms through the action of decarboxylases, such as histamine (from His), tyramine (from Tyr), 2-phenylethylamine (from Phe), tryptamine (from Trp), putrescine (from ornithine or through the agmatine deiminase pathway, which follows the decarboxylation of arginine to agmatine), and cadaverine (from Lys), can cause several adverse reactions to consumers, such as tingling tongue, rash, vomiting, diarrhea, burning sensation, headache and dizziness, nausea, palpitations, or breathing difficulties. Thus, while on one hand the acid stress causes a beneficial growth delay, it can also increase the contents of putrescine, histamine, and cadaverine. Indeed, it has been extensively demonstrated that the transcription of genes of many decarboxylase clusters involved in biogenic amine synthesis are induced by low pH (Gardini et al. 2016). On the positive side, in some micro-organisms under acidic conditions, including several LAB strains, the glutamate decarboxylase (GAD) system catalyzes a reaction producing GABA (γ-aminobutyric acid), a metabolite associated with several physiological functions in humans, such as strengthening of blood vessels, insulin secretion modulation, increased blood cholesterol prevention, or mitigation of emotional unrest, among others (Rashmi et al. 2018, Strandwitz et al. 2018). Various research initiatives are currently exploring the possibility of exploiting strains of LAB with capability to produce GABA to obtain GABA-enriched dairy products with health promoting properties. In this respect pH is an important factor influencing the yield of GABA in the fermented foods, given that the GAD enzyme of LAB is only active under acidic conditions and sharply loses activity at pH values higher than 5.0 (Yang et al. 2008, Li et al. 2010, Renes et al. 2017, 2019). The recent studies on GAD in LAB confirm that some biochemical features are shared with GAD from Escherichia coli, which is the most extensively characterized GAD at the biochemical level (De Biase and Pennacchietti 2012). Detailed characterization of decarboxylase systems is important for the selection of appropriate live cultures for food industry applications, to counteract the accumulation of biogenic amines in foods or to identify strains with desired functionalities. Moreover, modulation of their activity through exogenous addition of their substrates (e.g. glutamate in the case of the GAD system) or the strict control of the culture environment (pH, temperature, salinity, and so on) can facilitate the production of safer fermented foods with improved functional attributes.

Many substances of interest for food industries, as well as novel foods, are or will be soon industrially produced through microbial synthesis processes in bioreactors or fermenters, where organic acids accumulate as either products or by-products of fermentation, negatively affecting the productivity and yield along the process (Yáñez et al. 2008, Wang and Yang 2013, Ghaffar et al. 2014, Jiang et al. 2015). In the food industry, some of these organic acids, like propionic acid or lactic acid, are used for acidifying or regulating the pH of food, reducing its water activity and enhancing the effect of some antioxidants such as ascorbic acid (Sun et al. 2020a). In addition, organic acids can be added to food for their direct antimicrobial activity in fresh or semiprocessed products, or used for the decontamination of carcasses or meat cuts (BIOHAZ 2011). As it will be discussed in more detail in the section "Relevance of low pH in the production of valuable organic acids as building blocks for the chemical industry", acid-resistant strains can be regarded as potential cell factories for these biotechnological processes.

Acidic pH and food properties

With regard to flavor development, pH conditions can influence the production of volatile compounds during microbial fermentation processes, leading to the development of unique flavors and aromas in foods (Sharma et al. 2020b). Acidophilic micro-organisms, such as certain LAB strains and yeasts, produce specific flavors that enhance the taste profile of fermented foods and beverages (Hu et al. 2022). In addition to improving the digestibility and taste of the food, metabolic activities by these organisms may also add pharmacological and nutritional benefits to food (Xiang et al. 2019, Han et al. 2022). A wide range of micro-organisms that are derived from the raw material, starter cultures, machinery, and processing environments participate in fermentation (Tamang et al. 2016, Maicas 2020). In fermented foods, the principal role of LAB is the fermentation of carbohydrates into lactic acid, which, in addition to acidifying the food matrix increasing shelf life and thereby microbiological safety (Wang et al. 2022), also contributes in developing their flavors (Anal 2019). Volatile compounds including alcohols, organic acids, aldehydes, heterocycles, esters, ketones, terpenes, sulfur, and nitrogen compounds, have been detected in fermented foods (Dai et al. 2018, Tian et al. 2022).

During the fermentation of meat products, a large number of beneficial micro-organisms are produced that control growth of pathogenic and spoilage bacteria while also lowering the amount of toxic compounds like nitrite. Zhong et al. (2021) investigated the relationship between microbial communities and flavor in conventionally fermented sour meat. Lactobacillus, Weissella, Staphylococcus, Kodamaea, Hyphopichia, and Yarrowia were the core micro-organisms in fermented sour meat. These dominant micro-organisms correlated with flavor substances. Similar results identifying potential links between microorganism and flavor were also reported for dry sausages (Hu et al. 2020), dry-cured grass carp (Zhao et al. 2022), and Suan zuo rou, a fermented meat from China (Wang et al. 2021). Thus, besides increasing the safety of meat products, these beneficial bacteria can also enhance the flavor.

As for texture modification, the role of acidophilic micro-organisms in food is widely exploited in the food industry. The best examples are yogurt and cheese production. Yogurt, for example, is made from milk fermented typically with Lactobacillus delbrueckii subsp. bulgaricus, Lactococcus lactis, and Streptococcus thermophilus. These bacteria are generally used as starter cultures of yogurt (Chang et al. 2021) because they ensure consistency, product quality and safety (Ibrahim et al. 2021). The fermentation of lactose, the natural sugar present in milk, into lactic acid by lowering the pH causes proteins to coagulate and form a gel-like structure. This acid-induced coagulation contributes to the characteristic thick and creamy texture of yogurt (Nagaoka 2019, Kamal-Eldin et al. 2020, Wang et al. 2022).

Acidophilic bacteria, along with yeasts, are also responsible for the fermentation process in sourdough bread. In a recent study Sevgili et al. (2023) investigated LAB and yeast of 36 home-made traditional sourdoughs. They reported that sourdough containing Lactobacillus brevis, Leuconostoc mesenteroides subsp. mesenteroides, Pedicoccus acidilactici, Lactiplantibacillus plantarum, Saccharomyces cerevisiae, and Kluyveromyces marxianus gave the most preferred bread. The sour taste, high volume, easy swallowing and chewiness, minimal hardness and moisture content were all attributed to the activity of the micro-organisms involved.

In addition to the above processes, acidophilic bacteria are involved in the fermentation of vegetables and fruits such as sauerkraut and kimchi (Ashaolu and Reale 2020). The increased acidity not only enhances the flavor but also affects the texture of the vegetables, resulting in a crispy and crunchy texture as well as enhancing the bioavailability of amino acids, vitamins, bioactive peptides, and phytochemicals.

Thus, acidic fermentation is an important biotechnological tool for enhancing the safety, and health-promoting properties of bread, different kind of fermented meat, dairy and vegetable products (Melini et al. 2019).

Acidic pH and probiotics activities

There is also a strong link between low pH and the enhancement of functional properties when it comes to the addition of probiotics in food. Probiotics are defined as “live micro-organisms which when administered in adequate amounts confer a health benefit on the host” (Hill et al. 2014). They can be present in the food matrix, but also in some beverages or supplements or even medical food, and have the potential to greatly benefit human health. Resistance to low pH is particularly important for probiotics. In fact, in order to exert positive effects, they should be capable of preserving viability during storage and of colonizing gut, oral cavity or vaginal mucosae after oral administration. Indeed, the criteria for the selection of probiotic strains include in vitro tests for resistance of strains to pH of 2.5, typically encountered in the stomach, as well as in the presence of bile salts (Hill et al. 2014). These in vitro conditions therefore mimic gastric passage and allow to select strains suitable to colonize the gut. However, anaerobic conditions, prevailing in the distal gut, in contrast with the aerobic ones of the proximal gut as well as in food production and processing, present additional obstacles to selection, cultivation, and application of many probiotic candidates. This limits research on applications of strains naturally present in the gut but not cultivable in the lab yet. Therefore, micro-organisms capable of producing and tolerating organic acids and oxygen like LAB, yeasts and some Bifidobacterium spp. are currently among those most represented in both functional food and probiotic formulations in supplements (De Filippis et al. 2020). Due to the acidic pH-induced activity of GAD mentioned above, GABA-producing strains are also interesting for the functional upgrading of food, such as GABA-enriched Bifidobacterium adolescentis fermented milk (Tames et al. 2023). In addition to this probiotic, industrially relevant and food-related probiotic strains belonging to former Lactobacillus spp. (i.e, L. rhamnosus, L. plantarum, L. casei, and L. sakei) have been reported as good GABA producers (Diez-Gutiérrez et al. 2020).

Recently, the tremendous expansion in the research on gut microbiota and the decrease in the pricing for metagenomics sequencing (a valuable culture-independent technique) allowed to discover very promising new probiotic strains from species like Akkermansia muciniphila, Roseburia intestinalis, Faecalibacterium prausnitzii, and different Eubacterium spp. or Bacteroides spp. (De Filippis et al. 2020, Cunningham et al. 2021). Metabolomic data from fecal samples helped to gain insight into the mechanisms of probiotic’s action. In this respect, the composition of the microbial communities along the gastrointestinal tract and their effects on host cells, has been shown to be strongly dependent on pH, which is known to change significantly along the gastrointestinal tract (Fallingborg 1999, De Biase and Lund 2015). Probiotics able to hydrolyzing bile acids into deconjugated bile acids are also receiving attention. Primary bile acids released into the proximal gut lumen by the bile duct are digestive surfactants that cause a stress to transiting bacteria. Probiotics belonging to the Lactobacillus and Bifidobacterium genera possess the enzyme bile salt hydrolase, which catalyzes hydrolysis of the amide bond between the steroid nucleus and the glycine/taurine moiety (Prete et al. 2020, Hernandez-Gomez et al. 2021, Ruiz et al. 2021). Bile salt hydrolase is maximally active at acidic pH and its activity offers a survival advantage in the small intestine, a prerequisite to persistence in the gut. The composition of the gut microbiota and the amount of one or other type of bile acids metabolites changes insulin signaling, lipid metabolism in the liver and energy management in the organism (Winston and Theriot 2020). Also, the composition of bile acids shapes the intestinal microbiota favoring some cohorts, which can be linked to the occurrence of diabetes and obesity-related pathologies in the population (Fiorucci and Distrutti 2015, Cunningham et al. 2021).

In general, many novel probiotics strains and gut microbiota produce conventional volatile fatty acids (VFAs; which include acetic, propionic, and butyric acid) and unconventional branched short chain fatty acids in mM concentration, mainly in the colon. Being important modulators of immune response, they affect differentiation of regulatory T cells and IgA levels with numerous effects on host metabolism and health (Guo et al. 2019).

Altogether the abovementioned examples indicate an important role for low pH tolerating bacteria in improving food nutritional, sensory, and health promoting properties.

Exploiting low pH in waste management and in the revalorization of agricultural/food waste

Valorization of waste material is a fundamental component of the circular economy, i.e. getting significant support from governments and companies worldwide. This concept aims to generate high-value products and bioenergy from waste streams (Priya et al. 2023). A considerable effort of many scientists representing interdisciplinary teams is needed for the practical realization of this vision and of the current ideas for waste material refining.

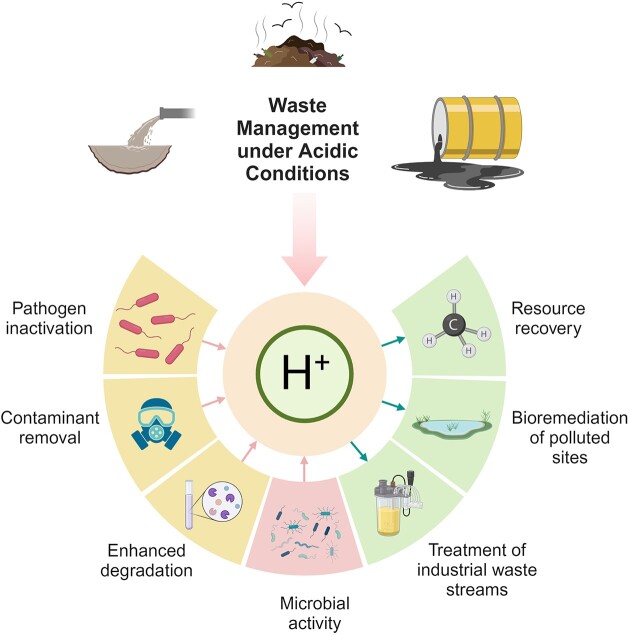

Harnessing the benefits of acidic conditions, the exploitation of acidophiles in waste management, and the revalorization of agricultural/food waste offer an innovative approach that holds great potential for effective waste treatment and resource recovery. Acidic pH environments provide unique opportunities for various waste management applications, including the degradation of organic matter, removal of contaminants, and the transformation of waste materials into valuable products (Mallick and Das 2023, Razia et al. 2023). This approach not only offers sustainable waste management solutions but also holds an enormous potential to the circular economy by reconsidering agricultural and food waste into valuable resources as illustrated in Fig. 2.

Figure 2.

Overview of the main benefits of exploiting low pH in waste management and revalorization of waste streams. Pink arrows signify areas where input issues exist, which can be effectively addressed through the application of low pH. Conversely, the blue arrows represent the outcomes that can be obtained as a result of these treatments. Created with BioRender.com.

In the previous section, how the adaptation in acidic environments allows micro-organisms’ exploitation in the food sector was discussed, while in the following section, the biotransformations for the production of valuable chemicals are discussed. As for the main molecular mechanisms that allow growth and/or survival at low pH, it is possible to refer to excellent reviews previously published (Krulwich et al. 2011, Kanjee and Houry 2013, Lund et al. 2014, Schwarz et al. 2022). In this section of the review, the acid stress response of micro-organisms is viewed in the perspective of how it can be harnessed in waste management.

Organic waste materials are in different aggregate states, which represents a first factor to take into consideration when selecting appropriate waste refining strategies. Liquid waste streams are more suitable for conducting various types of fermentations, as for example for biopolymer production. Solid waste material can be used in anaerobic processes for biogas production (see the section “Production of fuels under low pH conditions”) and can also be preprocessed using physical or enzymatic treatment to extract macro- and micro-elements for further revalorization (Fisgativa et al. 2016).

Food and agricultural waste from households, restaurants, schools, markets, and farms represent a source of different organic compounds which can be used per se or after pretreatment for valuable chemicals and materials production. However, the main challenge in refining food and agricultural waste material is their heterogeneous chemical composition, which varies depending on source, region, and seasons and ability to support the growth of specific microbial groups (Ren et al. 2018, Sindhu et al. 2019, Mengqi et al. 2023). In addition, food and agricultural waste has often low pH (< 4.0) possibly caused by anaerobic fermentation during storage and transport but also during controlled bioprocess development (Zhan et al. 2022). Starter cultures can direct the bioprocess into the desired metabolic conversion, but the substrate must be usually pretreated using high temperature, UV or chemicals, to inhibit or suppress the natural microbiota, a step that represents a cost burden in waste material valorization (Sharma et al. 2020a).

Low pH in the management of agriculture and food waste material

In this section, the management of agricultural and food waste will be considered from three perspectives: (i) microbial management of low pH waste material of food and agricultural origin, (ii) management of food and agricultural waste material that become acidified during fermentation, and (iii) low pH medium caused by chemical pretreatment of food/agricultural waste material for final microbial revalorization.

As for microbial management of low pH waste material of food and agricultural origin, bioethanol production from food waste, and feedstock is certainly one of the best-established biotechnological processes, of which the global market is still under an increase in trend. Since a large part of the product cost depends on the substrate, a low-value nonsterile organic waste material enables more cost-effective ethanol fermentation. The high-yield ethanol-producing microbial communities must first be selected from complex native microbial consortia. The ethanol producers, belonging to the Zymomonas genus and different yeasts species, compete for carbohydrates with VFA and lactic acid-producing LAB. In this environment, the pH < 5 enables the establishment of an effective consortium of LAB and homo-ethanol producers, leading to robust and competitive ethanol yields (Moscoviz et al. 2021).

A fungal fermentation was used to valorize cheese whey permeate into oil-rich fungal biomass as a potential feedstock for biofuel production and nutraceutical applications (Chan et al. 2018). Triacylglycerides were the major lipid class (92%), containing predominantly oleic (41%), palmitic (23%), linoleic (11%), and γ-linolenic acid (9%). The pH 4.5 in combination with a temperature of 33.6°C, yielded the highest biomass content of the oleaginous fungal strain Mucor circinelloides f. lusitanicus. Another example of cheese whey valorization is the production of polyhydroxyalkanoates (PHA) as a sustainable and promising alternatives to petrochemical plastics. PHA are secondary products of the microbial metabolism of some heterotrophic and photosynthetic bacteria or mixed microbial cultures. The composition of PHA can vary by controlling the pH in the acidic phase of the anaerobic bioprocess working with a microbial consortium originating from a waste treatment plant. At pH 4 the LAB prevailed, with Lactococcus being dominant over Lactobacillus, while the opposite occurred at pH 4.5 and 5.0. The microbial consortium was very robust, meaning that by varying the pH, without restarting the bioprocess, the fermentation profile necessary for particular PHA composition can be easily manipulated (Gouveia et al. 2017). This provides an excellent example of how low pH can be used to fine modulate the community composition for different purposes.

The high amount of soluble and insoluble carbohydrates in the citrus peel makes it also an attractive bioprocessing substrate. It can be utilized directly to produce hydrolytic enzymes (El-Sheekh et al. 2009). A straightforward and cost-effective medium was prepared for exopolygalacturonase production by Aspergillus sojae (Buyukkileci et al. 2015). The medium comprised orange peel, an industrial food by-product, and an inorganic nitrogen source. The submerged process, under uncontrolled pH, successfully ran at pH from 4.3 down to 2.5. The low pH was also advantageous to decrease the risk of bacterial contamination (Buyukkileci et al. 2015), which is indeed a general feature of the low pH over the many applications described in this review.

Notably, diverse organic food and agricultural waste material become acidified during fermentation and this is instrumental for the process. The following are some interesting examples.

Chinese cabbage is the most widely produced vegetable in China. However, about 30% of its yield represents waste for which anaerobic fermentation by LAB has been established for organic acid production, primarily lactic and acetic acids (Li et al. 2023b). The acids cause pH to decrease to values around 4.0. The study showed that fructose and molasses addition enriched the acid-tolerant bacteria Lactobacillus paralimentarius and Lactobacillus heilongjiangensis, promoting fiber degradation and inhibiting undesired bacteria, such as pathogenic and biofilm-forming strains. The selected strains are thus directing the cabbage waste revalorization into efficient acid production in a safe microbiological bioprocess (Li et al. 2023a). Another example is that of biohydrogen fermentation liquor produced from rice-straw, with pH 4 (due to the presence of acetate, propionate, butyrate, and valerate) successfully used by Bacillus fusiformis, Bacillus subtilis, and Bacillus flexis for polysaccharides production with flocculation capacities of kaolin suspension (Siddeeg et al. 2020). Citric acid is another acid, widely used in beverages, detergents, foods, and cosmetics. The choice of the substrate for its production plays an important role in reducing costs. Different food and agricultural waste material, such as coffee husk, rice bran, wheat bran, carrot waste, cassava bagasse, banana peel, vegetable wastes, brewery wastes, decaying fruits pineapple peel, or pomaces of grapes, among others can be used by citric acid-producing micro-organisms. The filamentous fungi Aspergillus niger is the workhorse for its production. The acidic pH in these processes is important for inhibiting oxalic and gluconic acids production and to prevent contamination by other micro-organisms (Behera et al. 2021). In recent years, a product named “Agricultural Jiaosu,” with high enzymatic activity was produced from one or more food wastes (Gao et al. 2022). The product has biocatalytic and antimicrobial activities and has been used, for example, in wastewater treatment, soil remediation, compost quality improvement, and so on. The product has low pH (∼3), high content of beneficial organisms, and of different organic acids, besides other metabolites (Gao et al. 2023).

A low pH medium can also be the result of a chemical pretreatment of food/agricultural waste material. It is the case of the production of β-carotene, used as a nutrition supplement and in medicine due to its antioxidant and pro-vitamin A activities, and to its anticancer effect, respectively. In order to enhance its yield and reduce the cost of its production by microbial fermentation, food wastes containing significant amounts of sugars can be used as a medium for microbial growth (Cheng and Yang 2016). However, the sugars must be first extracted by water or acid hydrolysis. A recent study presented an efficient sequential two-step process for β-carotene production with yeast Rhodotorula glutinis in a growth medium obtained from orange and grape wastes (Uğurlu et al. 2023). Both steps resulted in acidic pH: water extraction at pH 5.5–6.0, and acid hydrolysis with H2SO4 at pH 5.5. The β-carotenes in these media are produced very efficiently, i.e. without using any additional nutrients, which is extremely positive for the economic feasibility of the process and waste management perspective. In another study, the yeast Sporobolomyces roseus was used for the coproduction of lipids and carotenoids using pasta processing waste. The sugars were released from wastes after enzymatic treatment using Aspergillus luchuensis. After centrifugation and filtration, the substrate was adjusted to pH 5.0, supplemented with selected salts and successfully used for simultaneous lipids and carotenoid production (Villegas-Méndez et al. 2023). A highly demanded product in medicine, cosmetology, and pharmacy is bacterial cellulose membrane. The acid and thermal hydrolysate of grape pomace was successfully used for bacterial cellulose production by Komagataeibacter melomenusus solely in a grape pomace extract at pH 4.5 (Gorgieva et al. 2023).

During the degradation of organic waste through fermentation by acidogenic micro-organisms, organic waste streams are converted into carboxylic acids such as VFA and lactic acid (Kim et al. 2015, Kibler et al. 2018). As said, these carboxylic acids can be used in many different ways, such as the production of bio-based materials like biogas, bioplastics, medium-chain fatty acids, and microbial proteins (as discussed in the following sections). Furthermore, these carboxylic acids can also be recovered as raw materials for several industries, such as the chemical industry, personal care, medical, and animal feed (Strazzera et al. 2018). Importantly, the acidic environment during fermentation plays a crucial role in increasing the hydrolysis rate of waste, resulting in higher end product yields, and also influences the product profile based on the intended application (Zhou et al. 2018, Luo et al. 2021). However, as mentioned before, the production of carboxylic acids during the fermentation process leads to a further decrease in pH, requiring the addition of alkali to maintain pH stability, and therefore avoid halting of the metabolic activities (Chen et al. 2015). Approximately 15% of the operational costs are imputable to this practice (Joglekar et al. 2006). On the other hand, acidic conditions can facilitate the separation and purification of target products, as precipitation or separation of specific compounds are favored (Tang et al. 2016).

The benefits of acidic conditions for carboxylic acid production is exemplified by the study of Pau et al. (2022) who investigated the effects of hydraulic retention time and organic loading rate on lactic acid production from food waste. They found that an acidic pH < 3.5 favored lactic acid production by inhibiting the production of VFAs and enhancing the performance of Lactobacillus strains. The highest lactic acid production (8.72 g l−1), with an 82% conversion rate, was attained at pH 3.11, at 14 days hydraulic retention time and 2.14 g volatile solids (VS) l−1 day−1 (Pau et al. 2022).

Low pH and the ability to manipulate product profiles

In the process of anaerobic digestion for organic waste streams, the breakdown of the carbon source into methane typically occurs within a pH range of 6.5–8.2. However, the acidic pH inhibits the activity of methanogens, which are responsible for the production of methane. Qui et al. (2023) demonstrated a complete suppression of methanogenesis at pH 4.0, in contrast to neutral pH conditions (pH 7.0), and attributed to the acidic environment the observed reduction in abundance of acetoclastic methanogens. This strategy can be employed to inhibit methanogenesis and increase the production yield of carboxylic acids.

Atasoy and Cetecioglu (2022) demonstrated that acidic conditions (pH 5.0) enhanced VFA (also known as short chain fatty acids) production by 4.4-fold compared to neutral pH (pH 7) conditions using cheese production wastewater. Moreover, adjusting the pH of the system toward acidic conditions not only influences the product spectrum, but also drives the selection of the predominant acid type. In a study by Candry et al. (2020), it was observed that when the pH level increased from below pH 6 to above it, the product distribution distinctly switched from a medium chain fatty acids mixture (primarily composed of butyric, valeric, and caproic acids) to a mixture dominated by acetic and propionic acids.Thus, by understanding and utilizing the acid stress response of micro-organisms, the waste management processes can be optimized for improved efficiency and the production of valuable products. For this, it is crucial to consider the specific requirements of the fermentation pathways and microbial communities involved to achieve the desired outcomes. Moreover, as already mentioned, an acidic environment creates unfavorable conditions for the survival and proliferation of pathogenic micro-organisms (Lund et al. 2014, Li et al. 2022) and this is extremely important because acid-tolerant micro-organisms present in waste can outcompete and suppress the growth of pathogens, leading to a reduction in their overall abundance and activity (Mokoena et al. 2021). This strategy can be used for microbial protein production from waste streams. Microbial protein, also known as single-cell protein, holds great promise as a sustainable and protein-rich source, offering versatility in terms of feedstock selection. Its unique advantages, including independence from climate, soil characteristics, and weather conditions, as well as reduced greenhouse gas emissions and nitrogen losses, rapid production with a small ecological footprint, and abundant protein, carbohydrate, vitamin, mineral, and nucleic acid contents (Anupama and Ravindra 2000, Matassa et al. 2016), make it an attractive option. However, the cost of substrates remains a significant limitation for achieving sustainable and profitable microbial protein production. To address this challenge, waste streams have emerged as appealing substrate sources for microbial protein production. Nevertheless, the presence of pathogens poses a major concern (Lee et al. 2015, Khoshnevisan et al. 2019, Zhou et al. 2019). In this regard, the fermentation of food waste under acidic conditions offers a 2-fold solution: (i) it provides a rich substrate source for microbial protein production, thereby contributing to enhanced productivity and (ii) the inherent acidity of the environment acts as a protective barrier, reducing to a significant extent pathogen contamination during the fermentation process. By utilizing food waste as a substrate and creating acidic conditions, microbial protein production can effectively capitalize on waste resources while mitigating the risk of pathogen-related issues. This approach not only maximizes the economic viability of microbial protein production but also aligns with sustainability goals by reducing waste and ensuring the safety and quality of the final product (Anupama and Ravindra 2000, Raziq 2020). However, it is important to note that the effectiveness of acidic environments for pathogen inactivation varies, depending on factors such as the specific pathogen types, their tolerance to acidic conditions, and the intricacies of the waste management process (Li et al. 2022). Consideration of parameters like pH levels, contact time, and the nature of the waste materials being treated is, therefore crucial to ensure optimal pathogen inactivation while minimizing any potential adverse effects on the environment or beneficial micro-organisms.

Overall, exploiting the low pH conditions in waste management and harnessing the potential of acidophilic micro-organisms present a promising pathway toward sustainable waste treatment and resource recovery. This approach offers innovative solutions for efficient waste management and for the generation of valuable products from waste materials, fully in line with circular bioeconomy model.

Relevance of low pH in the production of valuable organic acids as building blocks for the chemical industry

Production of building blocks, i.e. organic compounds that are used for the synthesis of more complex molecules, from renewable substrates by microbial biotransformation is an alternative to petroleum-based chemicals. Currently, bio-based chemicals represent around 3% of the global market for chemical compounds (Spekreijse et al. 2019). Support of policymakers for transition toward bio-based chemicals, including through microbial production, grew in recent decades in the framework of Sustainable Development Goals. Recent legislation in the EU-identified bio-based products as a key enabling technology and a priority area for development (Spekreijse et al. 2019). Many microbial bio-based building blocks are still not economically competitive with the chemical synthesis processes using hydrocarbons, which are fossil fuel-based, but significant growth is expected. Among bio-based chemicals lactic acid production is already economically competitive, i.e. 1.17 EUR kg−1 for bio-based versus 1.75 EUR kg−1 for fossil-based (Spekreijse et al. 2021). Spekreijse et al. (2019) from the European Joint Research Centre analyzed the current status of the market and projected the annual growth rate for platform chemicals in the EU at 10%. A similar annual growth rate of 9%–10% is predicted globally for the next 5 years (Fortune 2021, Estimates 2022). It is expected that the demand from the chemical industry for biomass will grow until 2050 with a staggering rate of 327% for wheat only (Nong et al. 2020), which could have a huge effect on ecosystems globally and could question the sustainability of the transition to bio-based chemicals if it is not implemented responsibly, i.e. considering the planet health. This emphasizes the role of efficient biocatalysts, robust micro-organisms capable to convert substrates with high efficiency and minimal wasting of resources.

Bio-based chemicals are produced either by direct fermentation with the final product obtained by microbial transformation using whole cell-based process from renewable substrate or part of the synthesis is done by fermentation and derivatives are obtained by different routes (Bozell and Petersen 2010). Although whole-cell microbial production of many bio-based chemicals is modest in scale, microbial products have significant potential for derivatization into commercially important chemicals that are currently petroleum-based. Microbial production of chemicals also has the advantage of being stereospecific, while chemical synthesis results in racemic mixtures, which require additional separation of isomers for downstream applications. This is particularly important when microbial products are used for polymerization, since the ratio of isomers defines the physical–chemical properties of polymers (Abdel-Rahman et al. 2013).

Organic acids, which could be produced by micro-organisms, are recognized as being among the most promising bio-based chemicals obtained from biomasses. They included: dicarboxylic acids (fumaric, 2,5 furan, glucaric, itaconic, malic, and succinic acid), 3-hydroxy propionic, levulinic, glutamic, and aspartic acids (Werpy and Petersen 2004). A later revised list addressed advances in microbial and biochemical production of building blocks and included, by similar criteria, among the top ten promising bio-based chemicals, five organic acids, i.e. lactic, succinic, 3-hydroxy propionic, 2,5 furan dicarboxylic, and levulinic acid (Bozell and Petersen 2010). In the 28-members EU market, acetic and lactic acid are the most represented organic acids among bio-based platform chemicals (Spekreijse et al. 2019).

The main reasons for the low market share of bio-based chemicals lay in low process productivity on second and third generation substrates and the high costs related to substrate pretreatment and final product extraction and purification (Magalhães Júnior et al. 2021). Cheaper biomass substrates like by-products and wastes from the agri-food industry and lignocellulose are very complex and often contain many inhibitory substances, such as metals in molasses. Inhibitors are also generated during substrate pretreatment, hydrolysis, and sterilization. End-products induce media acidification during the process and affect the productivity, viability, and recovery of produced organic acids. Thus, robust micro-organisms capable of achieving high yields in the presence of multiple stressors, including low pH, are needed.

To keep costs lower for extraction of organic acids from fermentation media, it is preferable to run the process at low pH, as this avoids neutralization and production of excessive amounts of salts during purification steps. The use of micro-organisms that are natural producers of acids, like wildtype strains of LAB for lactic acid, Aspergillus terreus for itaconic acid and other Aspergillus spp. for malic and citric acid or Rhizopus strains for fumaric acid (Lee et al. 2011) is a clear advantage because they already possess several mechanisms to cope with low pH and other stresses, as previously explained. However, yields and profiles of biotransformation in media are still greatly affected by deviations in pH and concentrations of acids in media (Djukić-Vuković et al. 2012, Burgé et al. 2015a, Asunis et al. 2019). For example, Lactobacillus reuteri produces 3-hydroxypropionic acid naturally and tolerates concentrations of up to 2.5 g l−1 of a by-product, 3-hydroxypropionic aldehyde, when grown on glycerol and at pH above 5.0; in contrast below pH 5.0, this compound is toxic (Burgé et al. 2015b). In general, neutral or mildly acidic conditions favor a dissociated form of acids and make it more difficult for the acid to enter microbial cells and hinder viability and productivity (Guan and Liu 2020, Lund et al. 2020). The pKa of the carboxylic groups in lactic acid (3.8), itaconic acid (3.8 and 5.5), fumaric acid (3.1 and 4.4), and similar pKa values for other microbial organic acids, require that the majority of industrial fermentations for organic acid production is carried out at pH values between 5.0 and 7.0, with pH control, so as to avoid affecting cell viability and productivity. Neutralization of media, usually with the addition of CaCO3, NaOH, or Ca(OH)2 during fermentation, leads to the generation of large quantities of side streams of salts like gypsum, thus adding a negative environmental footprint of the process (Salek et al. 2015, Shi et al. 2015).

To overcome this problem heterologous and nonconventional strains, engineered by adaptive evolution and genetic manipulation to tolerate low pH, can be used (Thorwall et al. 2020). These genetic manipulations can be coupled with alternatives in process design like different substrate feeding strategies (Hosseinpour Tehrani et al. 2019a), reactive extraction of organic acids or electrochemical pH swings, which can be well coupled with engineering of strains for high yield of specific products (Becker et al. 2020, Gausmann et al. 2021).

Itaconic acid production

Itaconic acid is an unsaturated dicarboxylic acid that can be used as a building block for polymers production (in alternative to acrylate), following its transformation into esters. Itaconic acid-derived polymers can be used in corrosion prevention but also in dental and drug delivery applications (Robert and Friebel 2016). The advances in strain and process engineering have been studied in detail for the production of itaconic acid, because this acid is an important precursor for applications in the pharmaceutical industry (Steiger et al. 2013, 2016, Hosseinpour Tehrani et al. 2019a, b, c, Trivedi et al. 2020). Aspergillus terreus is the dominant industrial microorganism for itaconic acid production because it provides high yields, and we have a good know-how in process development with this microorganism (Steiger et al. 2016). A techno-economic assessment estimated costs for itaconic acid fermentation by A. terreus at 1.13 US$ kg−1 and compared costs of different downstream processing strategies. Costs were estimated at 0.63 US$ kg−1 for adsorption, at 0.88 US$ kg−1 for reactive extraction, while electrodialysis-based process adds 1.50 US$ kg−1 (Magalhães et al. 2019). Downstream processing significantly affects process profitability and Magalhães et al. (2019) identified cheap carbon sources and fermentation with high itaconic acid titres as critical steps to make the process financially viable, emphasizing the importance of resilient production micro-organisms. Additionally, changes in the morphology of micro-organisms, and the solubility of end product, plus its interaction with other compounds present in media, particularly in the case of cheaper waste substrates, depend on pH during production and processing and affect upscaling, due to technical difficulties like clogging, mixing, mass transfer and aeration during the process (Alonso et al. 2015, Trivedi et al. 2020). Although highly productive, A. terreus is susceptible to impurities which are present in cheaper substrates used for itaconic acid production (Steiger et al. 2013, 2016). To overcome this limitation, Becker et al. (2020) optimized nonconventional Ustillago maydis strain MB215 to produce itaconic acid at theoretical maximum levels, at pH 4.0, in shaken culture by cutting off carbon flux into the side product pathways, favoring yeast-like morphology and enabling transport of metabolites within basidiospore compartments to prevent bottlenecks in the main metabolic pathway.

Another nonconventional strain, Ustilago cynodontis has a low-pH resistance and after engineering and deletion of the fuz7 gene, it achieved 82.9 g l−1 concentration of itaconic acid at pH 3.6 while keeping the yeast-like morphology (Hosseinpour Tehrani et al. 2019b) proving the applicability of the proposed strategy on a different strain. Engineered strains achieved itaconic acid concentrations of up to 220 g l−1 with process engineering and optimization, showing that there is great potential for commercial implementation and scaling up of the production (Hosseinpour Tehrani et al. 2019a). These significant advancements in production of itaconic acid will probably soon increase the share of microbial itaconic acid in the market.

Lactic acid production

Lactic acid is a very good example of a bio-based platform chemical already produced by fermentation on large scale today. Over 90% of all available lactic acid on the market today is produced by fermentation and it is widely used in bulk, as an acidulant, to enhance flavor, and as preservative in the food, beverage and cosmetic industry or even as a descaling agent in the marine industry or as a platform chemical for the production of poly-lactides (Abdel-Rahman et al. 2013, Djukić-Vuković et al. 2019, Sauer and Han 2021). Innovations in lactic acid production and the development of very productive processes have been driven by the expanding range of applications of lactic acid polymers in medicine and packaging (Castro-Aguirre et al. 2016, Murariu and Dubois 2016).

Competition of lactic acid polymers with petroleum-based polymers on the market set maximal costs for lactic acid production and pushed research efforts into the development of novel, more productive strains. A number of natural lactic acid producing bacteria use the homofermentative route for the conversion of glucose into l- or d-lactic acid with yields of over 95%. However, pH control is still required and lactic acid concentrations in batch fermentation are most often below 90 g l−1 when natural lactic acid producing bacteria are used (Chen and Nielsen 2016, Djukić-Vuković et al. 2019). The potential of LAB as cell factories is huge and was extensively reviewed (Upadhyaya et al. 2014, Sauer et al. 2017, Börner et al. 2019, Sauer and Han 2021) including the benefits of the systems biology approach (Liu et al. 2019). Other than LAB, Rhizopus oryzae ranks among the top natural lactic acid producing strains, with concentrations of up to 230 g l−1 but also at a medium pH above 4.5 (Yamane and Tanaka 2013).

The robustness of yeasts to survive at very low pH qualified them as potentially very good hosts for lactic acid production. Some yeasts, like Kluyveromyces thermotolerans, have genes for lactic acid production at low pH, although productivity is low,. As in the case of other organic acids, lactic acid yields are higher at neutral pH, but extraction and purification are much more expensive when neutralizing agents are used, with the generation of salts and consumption of acids used later to release free lactic acid. This is not financially viable and production of free lactic acid at low pH is preferred.

Adaptive laboratory evolution has been widely used to improve acid resistance among both natural lactic acid producers and engineered strains (Singhvi et al. 2015, 2018, Liang et al. 2018, Börner et al. 2019, Cubas-Cano et al. 2019), and it is also a convenient strategy for adaptation to nonconventional carbon sources, like xylose, which are present in cheaper lignocellulose or waste substrates (Cubas-Cano et al. 2019, Mladenović et al. 2019). Adaptive evolution was combined with genome shuffling in S. cerevisiae for lactic acid production (Wang et al. 2018), while error-prone whole genome amplification was used in the case of a Lactobacillus pentosus stain, enabling its growth at pH 3.6 and the production of lactic acid with 95% yield during 25 subcultures (Ye et al. 2013). Bacillus spp. were also reported as good and robust lactic acid producing micro-organisms. They are, suitable for low-pH lactic acid production on very complex substrates with mixed carbon sources to avoid catabolic repression or even in open fermentations, with Bacillus coagulans being the most promising candidate (Ma et al. 2014, 2016, Zhang et al. 2014a, Glaser and Venus 2018, Wang et al. 2018, 2019, Alexandri et al. 2020).

Industrial lactic acid production processes are mostly performed by engineered strains. Cargill, one of the largest lactic acid producers globally, reported that the engineered yeast strain CB1 is capable to produce over 135 g l−1 of lactic acid at pH 3, with 90% of free lactic acid, decreasing extraction and purification costs significantly. Screening of promising strains was first performed based on the resistance of over 1200 yeast isolates to low pH and temperature. Following the screening, the nine most promising candidates were engineered by deleting pyruvate decarboxylase and introducing lactate dehydrogenase genes, together with introducing random and targeted mutations for further optimization (Miller et al. 2011).

The potential of natural LAB strains as probiotics, their status of generally recognized as safe (GRAS) micro-organisms and their wide utilization in the food industry were considered positively in some processes for lactic acid production because the microbial biomass after the fermentation can be used as added value feed product (Mladenović et al. 2018, Sadiq et al. 2019) or for silage to improve the cost-effectiveness of the process (Hatti-Kaul et al. 2018). However, the need for valorizations of the remaining microbial biomass in feed production is accompanied by aversion toward genetically modified micro-organisms in food and feed chains. This has affected to some extent the development of engineering tools for LAB and has limited commercial genome manipulation of LAB even for the production of lactic acid as a chemical (Börner et al. 2019).

Succinic acid production

Succinic acid is an organic acid mostly produced chemically from glucose and is very important as a platform chemical for the production of oil-based polymers. Its natural producers are very limited. Biosuccinic acid can be produced by fermentation from second-generation feedstocks by Acinobacillus succinogenes or by engineered E. coli with yields of around 30 g l−1 (Mancini et al. 2020, Putri et al. 2020, Magalhães Júnior et al. 2021). The limited availability of suitable micro-organisms in terms of productivity is currently a key factor that limits a wider adoption of biosuccinic acid production. However, the importance of succinic acid for the production of a large number of chemicals makes it an attractive candidate for the development of microbial producers of biosuccinic acid.

Costs in all phases of fermentative production of platform chemicals vary significantly and depend on the number of parameters. Techno-economic analyses were done for some processes (Kwan et al. 2015, Gezae Daful and Görgens 2017, Magalhães et al. 2019) and should be performed more often for the assessment of improvements in industrial micro-organisms and process engineering. The majority of these studies considered fermentative production on renewable biomass as a more sustainable option, however, critical assessment reveals that the substitution of synthetic chemicals with bio-based ones at the estimated increase in demand requires huge consumption of biomass as substrates. This would cause deforestation, arable land deterioration and possibly loss of biodiversity and it argues against the overall sustainability and improved CO2 footprint of bio-based chemicals production. (Morone and D’Amato 2019, Nong et al. 2020). However, significant transition toward circular economy approach, as emphasized earlier, considers utilization of waste streams of one industry as raw materials for other. The metabolic potential and role of micro-organisms in this respect is unprecedented and still not fully exploited. Diversity, versatility, and adaptability of micro-organisms, as well as additional spectra of biotransformation, which can become available through metabolic and genetic engineering of strains are among the most powerful tools on our planet for resource recovery. Even highly polluting fossil-based polymers, which are not biodegradable in reasonable time, could be degraded, under the specific conditions, by Aspergillus spp., Pseudomonas spp., Brevibacillus spp., Mucor spp., and so on (Ru et al. 2020). A circular design concept, that involves the design of new polymers based on the knowledge on metabolic capabilities of micro-organisms and suitability of specific bonds for microbial cleavage in order to enable degradation and resource recovery (Schink et al. 1992), could indeed play an important role for really circular and sustainable solutions in the future.

Harnessing microbial activity in contaminated acidic environments: biotechnological approaches and strategies

The application of biotechnological methods that harness the benefits of acidic environments in microbial communities holds significant potential for optimizing resource recovery, pollutant remediation, and ecosystem restoration. Various techniques have been employed to leverage the acid stress response of microbial communities, as well as benefit of the metabolic activity of acidophile. These techniques include bioremediation, bioaugmentation, bioleaching, chemotaxis, synthetic biology, and genetic engineering, depending on the aim of the study (Zhang et al. 2018, Calero and Nikel 2019, Muter 2023).

Enhancing metabolic capabilities could significantly improve bioremediation, a widely employed technique, which offers immense potential to combat environmental contaminations. Bioremediation harnesses the power of micro-organisms or their metabolic processes to degrade contaminants or convert them into less detrimental/toxic substances (Calero and Nikel 2019). Bioremediation strategies can be employed to stimulate indigenous acidophilic micro-organisms naturally present in contaminated sites, thereby amplifying their activity and effectiveness. This approach encompasses various methods such as bioaugmentation, biostimulation, bioattenuation, and biosparging, tailored to in situ and ex situ applications (Vishwakarma et al. 2020, Shweta et al. 2021).

Bioaugmentation and biostimulation represent essential subgroups within the field of bioremediation. Biostimulation focuses on the enhancement of indigenous micro-organisms already present in the environment, harnessing their existing metabolic capabilities to achieve remediation objectives via the addition of one or more limiting nutrients or other specific compounds to the system (Kouzuma and Watanabe 2011, Yagnik et al. 2023). Bioaugmentation on the other hand entails the deliberate introduction of specific micro-organisms or microbial groups into a system to enhance targeted applications such as pollutant degradation or transformation, as well as the amplification of desired metabolites production (Herrero and Stuckey 2015, Butler and Hung 2016, Nzila et al. 2016, Raper et al. 2018). Bioaugmentation can be delivered via several methods including direct injection of micro-organisms, construction of biogranulation (i.e. microbial aggregation), biocurtains (biobarriers), or gene-mediated methods (Gough and Nielsen 2016). By utilizing the natural adaptability and abilities of acidophiles to survive in acidic environments, bioaugmentation can be designed for remediation of acidic mine drainage (Anekwe and Isa 2023), removal of metal contaminants from acidic sites (Ayangbenro et al. 2018), treatment of acidic industrial wastewater (e.g. acidic food processing, acidic metal planting, and acidic petrochemical wastewater treatment) (Nzila et al. 2016, Anh et al. 2021), remediation and restoration of acidic soil/sediment and water bodies (Kumar et al. 2018, Adetunji and Anani 2021), and recovery of valuable products from waste streams under acidic conditions (Zhang et al. 2022b).

Zhang et al. (2022b) developed a bioaugmentation approach aimed at enriching autochthonous acid-tolerant LAB, enhancing the production of lactic acid from source-sorted organic household waste at pH 4. The findings revealed that bioaugmentation with a specific acid-tolerant strain (L. reuteri DTUAT 04) resulted in a 29% increase in lactic acid production at pH 4 compared to the non-bioaugmented control group (Zhang et al. 2022b).

Additionally, Sánchez-Andrea et al. (2012) devised a bioremediation approach to address the treatment of acid mine drainage in conjunction with domestic wastewater at bioreactors under pH 5. The study employed sediments sourced from the Tinto River in Spain, characterized by an exceedingly acidic environment and a high concentration of metals, as the inoculum. Through this strategy, the researchers accomplished the successful removal of dissolved metals exceeding 99% (with the exception of Mn), sulfate removal by over 75%, and iron removal surpassing 85% (Sánchez-Andrea et al. 2012).

Similarly, Anekwe and Isa (2022) implemented an innovative bioremediation strategy to address acid mine drainage-contaminated soils. Their approach involved the combination of biostimulation, bioventing (i.e. injection of air or molecular oxygen into the system), and bioattenuation (i.e. utilization of native micro-organisms) techniques. In a microcosm experiment utilizing 1 kg of polluted soil, the researchers employed domestic and brewery wastewaters for biostimulation to enhance the microbial community through nutrient and carbon source enrichment. For bioventing, atmospheric air was introduced alongside wastewater as a form of biostimulation, while for bioattenuation, the researchers focused on monitoring the growth rate of the microbial communities without additional interventions. The results demonstrated that the highest efficiency in metal removal was achieved through the synergistic combination of bioventing and biostimulation, yielding a removal rate of 56%–70%. Biostimulation alone resulted in a removal rate of 50%–66%, while bioattenuation achieved a removal rate of 12%–31%. This study highlights the significance of employing multiple approaches in tandem, as their combined effects can lead to enhanced degradation efficiency (Anekwe and Isa 2022).

In addition to the growing interest in the development of synthetic cultures for targeted pollutant degradation, several studies have successfully patented bioaugmentation strategies employing micro-organisms. Notably, BioTigerTM, a consortium of 12 aerobic bacteria isolated from an oil refinery in Poland, has demonstrated promising results in the bioremediation of hexanoic acid and phenanthrene present in oil sands. It is important here to recall that hexanoic acid, a naphthenic acid, and phenanthrene, a polycyclic aromatic hydrocarbon, are recognized as the principal toxic compounds found in oil refinery wastewater. Within a 24-hour timeframe, BioTigerTM exhibited significant degradation capabilities, with ~55% degradation of hexanoic acid and ~80% degradation of phenanthrene (Reddy et al. 2020).

Bioaugmentation strategies are commonly applied in resource recovery approaches, facilitated by the controllable environment of bioreactors and for ex situ applications targeting the degradation of pollutant sites. Nonetheless, despite its inherent complexity, bioaugmentation can also be effectively implemented in situ within ecosystems. Dybas et al. (2002) conducted a study in Schoolcraft, MI, USA, focusing on the remediation of a carbon tetrachloride and nitrate-impacted aquifer. They implemented a combined approach of bioaugmentation and biostimulation, utilizing a biocurtain. In this method, they introduced Pseudomonas stutzeri KC strain, a denitrifying bacterium capable of cometabolically degrading carbon tetrachloride without generating chloroform, for bioaugmentation. Additionally, the wells were stimulated through the external addition of an electron donor (acetate), phosphorus, and pH adjustment using a base. Over a span of 4 years, their findings demonstrated that the biocurtain achieved a carbon tetrachloride removal rate exceeding 99% and successful colonization of the bioaugmented species, i.e. P. stutzeri KC (Dybas et al. 2002). Although in this specific case the developed solution did not involve the application of acidic conditions, it paves the way to the implementation of a bioaugmentation strategy for remediating in situ acid mine drainage or rehabilitating acidic soil, sediments, and aquatic ecosystems.

In situ applications of bioremediation strategies have demonstrated success on contaminated sites; however, the complexities inherent in in situ ecosystems present significant challenges. These challenges include complex environmental factors, contamination heterogeneity, limited nutrient availability, the presence of inhibitory substances, and long-term monitoring requirements. Such complexities make the application of bioremediation more challenging compared to controlled laboratory or ex situ environments. To overcome these difficulties, the integration of modeling approaches into bioremediation strategies can provide valuable insights into the long-term effects of bioaugmentation or biostimulation. Genome-scale models have emerged as powerful tools for understanding microbial interactions and metabolic networks, primarily in bioreactor settings. By utilizing genome-scale models, researchers can gain valuable insights into the interactions of microbial communities and ecosystem processes. As suggested by Wang et al. (2023a), the combination of mathematical models with the construction of synthetic microbial communities offers a quantitative approach to validate theoretical studies of microbial ecology. These modeling approaches have the potential to ease the difficulties associated with in situ bioremediation, providing a foundation for predicting and optimizing the outcomes of bioaugmentation or biostimulation strategies when dealing with complex environmental settings (Wang et al. 2023b).

Based on all the above, it is possible to conclude that the application of acidic environments in microbial communities through various approaches, such as bioremediation, bioaugmentation, bioleaching, and more, has been used effectively for pollutant remediation, ecosystem restoration, and resource recovery. These strategies are being further enhanced through the continued development and application of synthetic biology, along with the integration of diverse modeling methods, including metabolic and microbial community models.

Production of fuels under low pH conditions

The transition to a low-emission economy will strongly depend on green fuels, the production of which is both sustainable and economically viable. Among these, a leading role is expected to be played by “green hydrogen,” as hydrogen is a precursor of most synthetic fuels. The global demand for hydrogen is expected to nearly double between 2021 and 2030. In 2021, worldwide demand for hydrogen stood at 94.3 million metric tons per year (https://www.statista.com/statistics/1121206/global-hydrogen-demand). Most hydrogen is consumed in the chemicals and refining sectors and still largely derived from fossil fuels, in the process called natural gas reforming. The US Department of Energy has proposed the goal of producing green hydrogen at a cost of below 2$ kg−1 by 2025 and 1$ kg−1 by 2030. In the near- and mid-term these goals are expected to be fulfilled by electrolysis, however, in a slightly longer perspective waste-to-hydrogen technologies should be included. This expectation gave a strong impulse to new research studies on biohydrogen production in dark fermentation (DF) and also microbial electrolysis cells (MEC) and photofermentation. The number of new research papers related to DF has grown substantially in the last few years (from 3562 articles in 2020 to already 3451 as of July 2023) (source: ScienceDirect.com). When referring to biohydrogen, it is meant hydrogen produced through biological process (e.g. DF process and algae photobiological water splitting).