Abstract

One of the greatest challenges to the automated production of goods is equipment malfunction. Ideally, machines should be able to automatically predict and detect operational faults in order to minimize downtime and plan for timely maintenance. While traditional condition-based maintenance (CBM) involves costly sensor additions and engineering, machine learning approaches offer the potential to learn from already existing sensors. Implementations of data-driven CBM typically use supervised and semi-supervised learning to classify faults. In addition to a large collection of operation data, records of faulty operation are also necessary, which are often costly to obtain. Instead of classifying faults, we use an approach to detect abnormal behaviour within the machine’s operation. This approach is analogous to semi-supervised anomaly detection in machine learning (ML), with important distinctions in experimental design and evaluation specific to the problem of industrial fault detection. We present a novel method of machine fault detection using temporal-difference learning and General Value Functions (GVFs). Using GVFs, we form a predictive model of sensor data to detect faulty behaviour. As sensor data from machines is not i.i.d. but closer to Markovian sampling, temporal-difference learning methods should be well suited for this data. We compare our GVF outlier detection (GVFOD) algorithm to a broad selection of multivariate and temporal outlier detection methods, using datasets collected from a tabletop robot emulating the movement of an industrial actuator. We find that not only does GVFOD achieve the same recall score as other multivariate OD algorithms, it attains significantly higher precision. Furthermore, GVFOD has intuitive hyperparameters which can be selected based upon expert knowledge of the application. Together, these findings allow for a more reliable detection of abnormal machine behaviour to allow ideal timing of maintenance; saving resources, time and cost.

Keywords: reinforcement learning, general value functions, outlier detection, fault detection, temporal difference (TD) learning

1 Introduction

Automation and robotics allow manufacturers to produce goods far more cheaply and consistently than hand-made products. With the advances in automated industrial production processes, the cost of downtime has grown proportionally. While machines can be designed for constant up-time, they will still degrade over time. As degradation is dependent on many variables, it is nearly impossible to accurately predict when the machine will break without actively monitoring its status. It is therefore imperative to shut machines down in a controlled way in order to maintain them before they break uncontrolled.

Deciding when to shut down machines for maintenance is still a field of ongoing research (Si et al., 2011; Lei et al., 2018). Performing maintenance only when the machine is in actual need is called condition-based maintenance (CBM) (Jardine et al., 2006). CBM therefore prevents unnecessary downtime and the replacement of parts that still have a long lifespan, ultimately saving on maintenance costs. This maintenance approach includes the tasks of fault detection and fault classification (called diagnostic problems), along with predicting the remaining useful life and the prediction of probability of failure (called prognostic problems). With these four values, it is possible to make informed decisions about when maintenance is necessary. In this paper, we focus on the task of fault detection.

The advantages of CBM come at the cost of needing data to access the state of the machine—the process of collecting data about the machine while it runs is called Condition Monitoring (CM). As the data are constantly collected while the machine is running, it is time series data. Examples of CM data include, but are not limited to: position, speed, force, vibration, and temperature. The need for data is an Achilles heel for CBM; to collect data, appropriate sensors are necessary. The performance of CBM is highly correlated with the availability and quality of data.

One way to ensure sufficient data for CBM is the installation of sensors. Sensors can be targeted towards a certain failure mode; e.g., a thermocouple can be installed and monitored for a process that is prone to overheat. While the installation of sensors ensures high quality data that caters to the exact need of CBM, it is also a costly solution. A solution that is more cost efficient is the use of existing sensors to gather data. Most industrial processes are already equipped with sensors that are necessary for their functioning; e.g., sensors for feedback control, machine calibration, or sensors that are installed to access the product quality. If these sensors can be used to infer machine degradation, they provide a cost efficient solution to CBM.

The use of existing sensors for anomaly detection is a field of active research and a review of supervised, semi-supervised, and unsupervised anomaly detection can be found in Hodge and Austin (2004) and Pimentel et al. (2014). Furthermore, Gupta et al. (2014) provided a review for (classical) outlier detection in time series data. More recently, Riazi et al. (2019) published a comprehensive study on data-driven outlier detection that compared different classical machine learning algorithms.

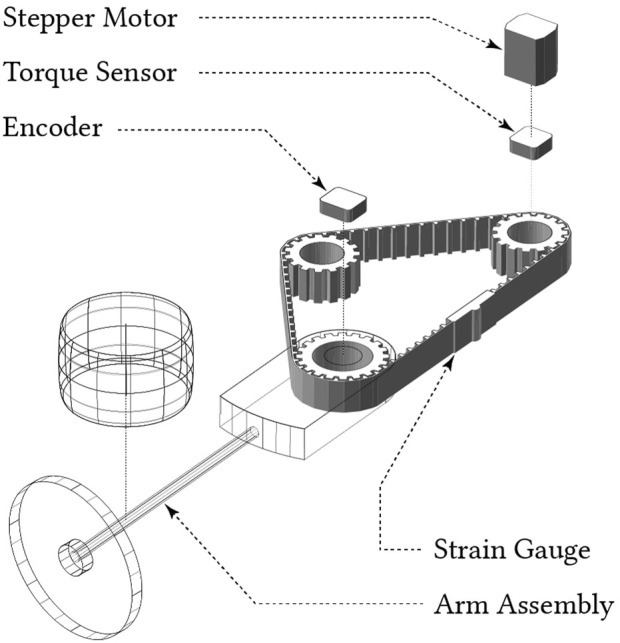

Riazi et al. (2019) also collected operating data from a lab-scale robotic arm, depicted in Figure 1. This data was labeled, indicating whether the arm was operating normally or if there was some fault in its operation. Within that study, machine fault detection was framed as a semi-supervised outlier detection problem. In the training phase, a multivariate semi-supervised outlier detection algorithm learns a boundary of normality from a random sample of normal operating data. In the testing phase, the algorithm evaluates whether new, unseen samples lie within or beyond the boundary, and classifies it as an inlier or outlier accordingly.

FIGURE 1.

A diagram showing the construction of the robot arm testbench, from which data arising from normal and faulty operation was collected.

Previous work on using machine learning for outlier detection were predominantly based on supervised and unsupervised machine learning algorithms (Riazi et al., 2019). While these approaches demonstrated good performance, they fail to take the temporal structure of the data into account. Many approaches, especially those based on deep learning, assume the data to be i.i.d., which is not the case in this application. New data are highly correlated to previous data, resulting in a data distribution that can be seen as the result of Markovian sampling (Arnold, 1970). For this reason, we suggest the use of temporal-difference (Sutton, 1988) based methods, as predictions learned with these methods have already shown their potential in industrial processes (Günther et al., 2016) and they are a well-fitted approach to this domain.

Our paper extends the work of Riazi et al. (2019) in two major ways. First, we modify the random sampling and validation techniques from machine-learning practice to better represent real-world deployments of fault detection. Therefore, we ensure that normal training data occurs strictly prior to normal testing data. Second, we implement three state-space models for time-series data, including a new algorithm based on temporal-difference learning, named General Value Function Outlier Detection (GVFOD). GVFOD is a novel method of applying general value functions for fault detection. We investigate whether these strictly temporal methods can outperform general multivariate methods. To the best of our knowledge, this is the first example of using predictions which are learned by the methods of temporal-difference learning to detect faulty behaviour in data streams from machine data. It is also one of few studies that show how reinforcement learning methods can be leveraged in industrial processes.

Leveraging machine learning to use data from existing sensors promises to address one of the most important challenges for CBM. By applying reinforcement learning techniques to take the temporal structure of machine data into account, we extend the current state of the art and demonstrate how this approach successfully detects outliers in data. We therefore provide a cost-effective solution to fault detection in order to enable automated CBM in real-world applications.

2 Background and methods

This study considers outlier detection as a semi-supervised problem. In a real-world situation, these algorithms would be employed in situations where known-good (or known-mostly-good) operational data is available, and where it is tolerable for fault detection to be enabled only after a period of known-good operation. It is also permissive of applications where faulty data is not available (or mixed within the normal data).

In semi-supervised outlier detection, the training dataset consists only of normal records, while the testing dataset has a mix of normal and abnormal records. An algorithm will first learn a model of normality using the training data. The algorithm will then assign a numerical outlier score to each sample in the training dataset. Based on the empirical distribution of training outlier scores, a threshold of normality can be determined. When the model is used to calculate outlier scores on the testing data, the algorithm classifies each sample as either an inlier or an outlier. We use the convention where scores larger than the threshold are outliers, and scores smaller than the threshold are inliers.

The outlier threshold is dependent on a common hyperparameter across all algorithms, the contamination ratio, CR ∈ (0, 0.5]. The contamination ratio defines the probability that a future inlier will be incorrectly classified as an outlier; and equivalently, the proportion of training data that lies beyond the outlier threshold. In this study, all algorithms had contamination ratios of 5%; and thus, predicted outliers are those with outlier scores (OS) above the 95th percentile.

2.1 Multivariate outlier detection

We evaluate the best multivariate outlier detection techniques from Riazi et al. (2019) and Gupta et al. (2014). The methods in both papers have been applied successfully to similar data sets, validating this decision. They span multiple classes of anomaly detectors, including probabilistic, distance/density, reconstruction, and domain-based methods. The algorithms include.

• Isolation forest (IForest) (Liu et al., 2008)

• One-class support vector machine (OCSVM) (Schölkopf et al., 1999)

• Local outlier factor (LOF) (Breunig et al., 2000)

• Angle-based outlier detection (ABOD) (Kriegel et al., 2008)

• kth-nearest neighbour (KNN) (Ramaswamy et al., 2000)

• Histogram-based outlier score (HBOS) (Goldstein and Dengel, 2012)

• Minimum covariance discriminant (MCD) (Rousseeuw, 1984)

• Principal components analysis (PCA) (Shyu et al., 2003) and all are implemented in the PyOD (Zhao et al., 2019) package.

2.2 State-space models for temporal outlier detection

Furthermore, we include temporal algorithms to make our comparisons more meaningful. Two existing state-space models are used for outlier detection:

• Markov chain (MarkovChain) (Ye et al., 2000)

• Hidden Markov model (HMM) (Smyth, 1994; Schreiber, 2017)

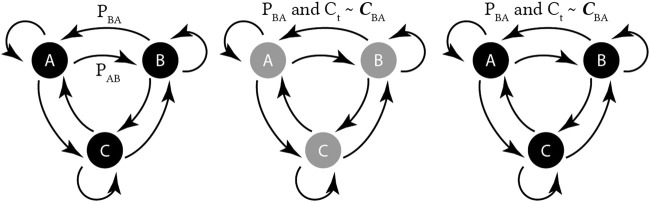

Examples of these are shown in Figure 2.

FIGURE 2.

Overview of state-space temporal outlier detection approaches. (left) a Markov chain with three observable states. (middle) A hidden Markov model, with three hidden (greyed-out) states, and observable cumulants. (right) An MDP with three observable states, and a cumulant is provided with each state-transition. Actions omitted for clarity.

In a Markov chain (Figure 2, left), the world is described sequentially, where at each time step t, transitions are made from state to state, with . These transitions are completed stochastically, following some transition probability , which is trivial to estimate from data.

In a hidden Markov model (HMM) (Figure 2, middle), the same transitions are made, except the underlying states x t cannot be observed. Instead, a finite number of the hidden states are inferred from the sensor observations. The Baum-Welch algorithm is used to estimate the states, state-transition probabilities P, and emission probabilities C. In general, HMM estimation is a computationally slow process (Gupta et al., 2014).

In a Markov decision process (MDP) (Figure 2, right), an agent takes an action , which causes a similar transition from the observed x t to x t+1. The transition probabilities in an MDP are action-dependent, with . The agent also receives a reward as feedback for its choice of action. The agent’s choice of action, A t , is determined by a probability function , known as a policy.

2.3 Prediction learning methods and general value functions

This paper uses a prediction learning method called General Value Functions (GVF) (White, 2015). GVFs learn to make predictions solely by interacting with the environment—they are based on observations.

We learn predictions by forming predictive questions (Sutton et al., 2011) about our sensor signals, which we phrase as GVFs—predictions about a signal of interest, or cumulant, C, from the environment over some time-scale or horizon defined by γ ∈ [0, 1), and a behaviour policy π. The discounted future sum of the cumulant is known as the return, . A GVF is the expected return of this cumulant: , which can be estimated using incremental online learning methods, such as TD learning (Sutton and Barto, 2018). The learning algorithm, TD(λ), and the TD-error, δ, are shown in Algorithm 1, lines 3–8. TD(λ) uses a step-size α and a trace-decay parameter λ. The step-size, along with the TD-error, determine the magnitude of GVF updates. The trace-decay parameter, λ, determines how much the current TD-error will update GVF estimates in previously visited states.

Like in Markov chains, GVFs use sensory observations as state. Features are constructed from observations using tile coding. Tile coding , maps observations from a bounded continuous space into a sparse binary feature vector, and is a common technique from Sutton and Barto (2018) Tile coding has two hyperparameters. divs_per_dim defines how many divisions are made in each dimension—resulting in a grid of tiles. The size of a tile limits the extent to which learning on one state can generalize to neighboring states. n_tilings determines the number of offset tilings to use. It also determines the number of ones in the feature vector. Combined, divs_per_dim and n_tilings determine the specificity of the features.

In this paper, we leverage a signal, called Unexpected Demon Error (UDE) (White, 2015). This signal is a measure for unexpected changes in the TD-error due to changes in the environment. The UDE can be thought of as surprise (Günther et al., 2018) and is potentially a useful measure for outlier detection. Mathematically, the UDE for a sensor is calculated as

| (1) |

where β is a sliding window width that defines the timescale of recent TD-errors; σ δ ,[t] is the standard deviation of TD-errors prior to t; and ϵ is a small constant to prevent division by zero. Intuitively, the UDE learns the recent distribution of TD-errors and will therefore only spike if the environment provides the learning agent with signals that are new.

We use linear function approximation in conjunction with tile coding to approximate the true value function. The form of the GVF estimate is , where w are the weights to be learned, x are the sensor values, and ϕ is the tile coder which creates the linear basis functions of . When combined with linear function approximation, temporal-difference learning scales linearly with the number of features, making it an excellent candidate for real-world tasks (Sutton and Barto, 2018).

3 General value function outlier detection (GVFOD)

Given a training dataset , GVFOD requires that the time series are ordered chronologically, so they can be unrolled into a single time series . For each of the k sensors, a GVF is learned, which combined serve as a model of normality. The learning phase then proceeds as in Algorithm 1. Evaluation of test data can be seen in Algorithm 2.

Algorithm 1

General Value Function Outlier Detection (Training).

1: Using training data

2: Initialize weights w = 0 d×k , traces z = 0 d×k , TD-errors δ = 0(nT)×k , scalar step size α, surprise , outlier scores , and scalar outlier threshold OS*

3: Repeat for each sensor j ∈ [k]:

4: Observe x t = x 0 := X 0,:

5: For each subsequent observation x t+1 in X

6:

7: z j ← γλ z j + ϕ ( x t )

8: w j ← w j + αδ z j

9: Repeat for each sensor j ∈ [k]:

10: Observe x t = x 0 := X 0,:

11: For each subsequent observation x t+1 in X

12:

13: UDE tj ← UDE(t, δ [t],j ) # See Eq. 1

14: Repeat for each period i ∈ [n]:

15: OS i ← OS GVFOD (i, UDE ) # See Eq. 2

16: OS* ← quantile( OS , (1 − α))

17: return w , OS*

Algorithm 2

General Value Function Outlier Detection (Inference).

1: Using weights w , an outlier threshold OS*, and testing data

2: Initialize TD-errors δ ∈ 0(nT)×k , surprise , outlier scores , and outlier classifications y ∈ {0,1} n

3: Repeat for each sensor j ∈ [k]:

4: Observe x t = x 0 := X 0,:

5: For each subsequent observation x t+1 in X

6:

7: UDE tj ← UDE(t, δ [t],j ) # See Eq. 1

8: Repeat for each period i ∈ [n]:

9: OS i ← OS GVFOD (i, UDE ) # See Eq. 2

10: y i ← [OS i > OS*]

11: return OS , y i

Compared to a typical application of TD(λ) and UDE, GVFOD is now an offline learning algorithm, requiring two passes through the training data. The first pass (lines 3–8) learn the weights in order to make accurate predictions about the data. In the second pass through the data (lines 9–13), the weights are fixed, and no model updates occur. The computational complexity, like TD(λ), scales linearly with the number of features (d), the experience (nT) and the number of sensors (k).

The outlier scores for a single period are calculated as the average surprise (UDE) over the k sensors and T time steps. For a multivariate time series X i , the scalar outlier score is

| (2) |

when the model encounters surprising data, the outlier score will increase, indicating anomalous behaviour. Because weights are fixed during inference—no learning is occurring, and the UDE and corresponding OS GVFOD remain elevated during the entire duration of abnormal behavior. This contrasts with the original online implemention of UDE (Günther et al., 2018), where UDE eventually dies down as the learners adapt to new operating conditions.

There are many hyperparameters for GVFOD. divs_per_dim and n_tilings were previously discussed for tile coding. The discount rate γ ∈ [0, 1), step-size α ∈ (0, n_tilings −1], and trace-decay parameter, λ ∈ [0, 1), are part of the original TD(λ) algorithm. determines the sliding window width for UDE calculation. Notice also that λ and α are used only in the training phase, and all other hyperparameters are used in both training and testing. Albeit numerous, selection of these hyperparameters is straightforward and demonstrated in Section 5.

A Python implementation of GVFOD is provided on GitHub.

4 Experimental setup

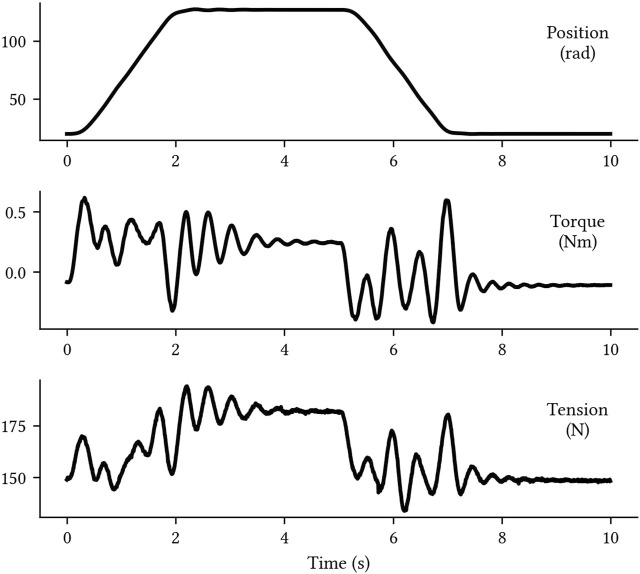

A full description of the robotic arm testbench in Figure 1 can be found in Lipsett et al. (2019). The robot arm is mounted on a stable platform, with the arm assembly rolling horizontally on a steel plate. The assembly moves between two angular positions with a period of 10s. There are a total of three sensors: for arm position, motor torque, and belt tension; sampling data at 200Hz.

A summary of the available data are presented in Table 1, and a sample of normal data can be seen in Figure 3. Each sample, , is a multivariate time series containing the observations from each sensor for the entire period. Three sensors are installed - an encoder for arm position, a strain gauge on the motor output shaft to measure torque, and a strain gauge on the rubber belt to measure tension. To collect normal operating data, the arm was allowed to operate undisturbed for roughly 22 h, creating a total of 7193 samples. The machine was then stopped, and modified, to create a faulty operating condition. Five of these abnormal datasets were collected: three contain data from varying the belt tension level; one contains data from a sandy rolling surface; and one contains data from both high belt tension and high operating temperature 1 . The data was cleaned by removing the startup and shutdown data, including the first and last periods if they were incomplete. In all subsequent experiments, we use Loose L1 data as the sole source of abnormal data, since its operation is most similar to normal data, and demonstrates the worst-case performance on this collection of data (Riazi et al., 2019).

TABLE 1.

Robot arm datasets.

| Case | Samples | Belt tension (N) | Description |

|---|---|---|---|

| Normal | 7193 | 160 | Normal operation. |

| Loose L2 | 180 | 120 | Varying belt tension levels. |

| Loose L1 | 182 | 140 | |

| Tight | 194 | 180 | |

| Sandy | 183 | 160 | Sand on rolling surface. |

| HighT | 210 | 180 | Tight belt and heated with two incandescent floodlights. |

Bolded values indicate the subset of data that was used in this experiment.

FIGURE 3.

A sample of normal robot arm data.

Furthermore, we have split each normal and abnormal dataset into two parts. The first part—the tuning dataset(s)—contains roughly the first half of available data: 4197 samples of normal data, and the first half of each of the abnormal classes. The tuning dataset is used for hyperparameter selection 2 using the Tree of Parzen Estimators (TPE) algorithm (Bergstra et al., 2011). The second part—the evaluation dataset(s)—consists roughly of the latter half of data: 4196 samples of normal data, and the last half of each of the abnormal classes. It is used solely for evaluation. In this way, there is minimal overlap in normal data between the tuning and evaluation datasets, and no overlap for the abnormal data. We reiterate that this does not follow the typical train-validate-test splitting of typical machine learning problems, due to restriction that training data consists only of normal data, and must precede the normal data in the test set. We instead choose train-validate-test datasets that minimize the amount of data overlap between folds, while ensuring data is contiguous within folds (Wong, 2021).

The values that were found by TPE for GVFOD are shown in Table 2. The default and TPE search values for all other algorithms are shown in Table 3. The TPE algorithm evaluated 400 candidate parameter combinations and picked the best, using the tuning dataset. With the exception of the HMM model, this heuristic search was completed in a similar manner for all other outlier detection algorithms, and all were limited to the same number of trials. Expert selection of the only HMM hyperparameter—the number of hidden states—was used in all experiments due to computational constraints.

TABLE 2.

GVFOD hyperparameters.

| Name | Symbol | Value (search) | Value (expert) |

|---|---|---|---|

| divs_per_dim | (7,7,2) | (10,10,10) | |

| n_tilings | m | 2 | 10 |

| discount_rate | γ | 0.96 | 0.90 |

| step_size | α | 0.052 | 0.001 |

| lambda | λ | 0.209 | 0.1 |

| beta | β | 888 | 250 |

TABLE 3.

Algorithms and hyperparameters used.

| Algorithm | Hyperparameter | Value (default) | Value (search) |

|---|---|---|---|

| IForest | n_estimators | 100 | 14 |

| max_features | 1.0 | 0.88 | |

| bootstrap | False | True | |

| OCSVM | kernel | rbf | sigmoid |

| nu | 0.5 | 0.996 | |

| gamma | 0.05 | 4.280e-05 | |

| coef0 | N/A | 0.103 | |

| LOF | n_neighbors | 20 | 500 |

| metric | Euclidean | Chebyshev | |

| ABOD | n_neighbors | 5 | 92 |

| kNN | n_neighbors | 5 | 500 |

| metric | Euclidean | Chebyshev | |

| HBOS | n_bins | 10 | 10 |

| alpha | 0.1 | 0.827 | |

| tol | 0.5 | 0.754 | |

| MCD | support_fraction | 0.5 | 0.714 |

| PCA | n_components | All | 3 |

| weighted | True | False | |

| whiten | False | True | |

| Markov Chain | divisions | N/A | 8 |

| HMM | n_states | N/A | 8 |

| GVFOD | divs_per_dim | N/A | [7, 7, 2] |

| numtilings | 2 | ||

| discount_rate | 0.96 | ||

| step_size | 0.052 | ||

| lambda | 0.209 | ||

| beta | 888 |

In order to realistically evaluate the performance of the multivariate and temporal outlier detection methods for machine fault detection, we design our experimental training and testing data to emulate a real CBM implementation. Samples in a single dataset are always ordered consecutively. Data in the training set consists only of normal samples, collected immediately prior to normal samples in the testing set. The size of the training set is variable to see how algorithms react to varying training data availability. The testing set contains both normal samples and ones from a single fault class. In the testing set, the abnormal data are appended to the end of the normal data, as a machine would typically enter a faulty condition after it has been operating normally. Lastly, the quantity of normal and abnormal samples in the testing set are fixed, unlike the sample size in the training set.

For all multivariate techniques, the 6000 features were scaled to have zero mean and unit variance. Certain multivariate outlier detection techniques perform poorly with high-dimensional data. For OCSVN, LOF, ABOD, kNN, and MCD, principal components analysis was used to decompose the input space into the 20 covariates, which cumulatively represent 96.2% of the total variance in the original data.

5 Results and discussion

For every experiment, 20 runs were completed; the runs are not fully independent, but we minimized the amount of overlapping data between runs. The measures of performance include precision, recall, and F1-score. All results reported include 95% confidence intervals of the mean response. To ensure statistical relevance of our results, we also performed paired-sample t-tests. In all cases, GVFOD had statistically significantly better F1 score as compared to each competing algorithm, at the 5% significance level, when presented with 2000 training data samples.

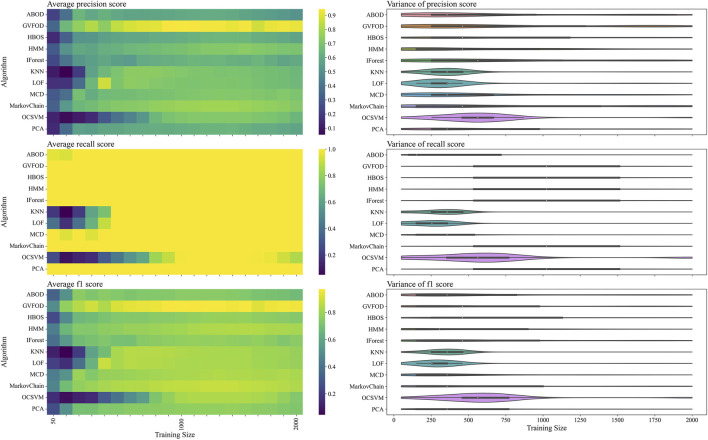

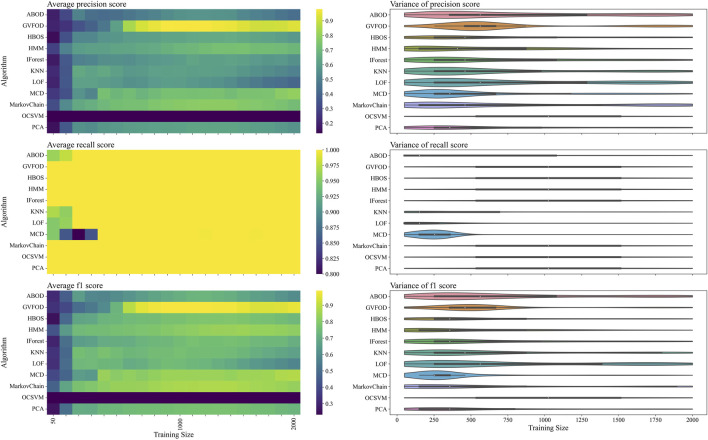

The performance of GVFOD relative to other outlier detection methods on the tuning data is shown in Figure 4. Since this data was also used for hyperparameter tuning, the results are not indicative of true model performance. However, there are several notable peculiarities in the results.

FIGURE 4.

The presented figure depicts the performance of models on tuning data, as evaluated by three distinct metrics. The three rows of the figure illustrate the average and variance of the precision score, recall score, and f1-score, respectively, across different sizes of the training data. A heat-map is used to represent the average performance, while a violin plot is employed to visualize the variance. In the violin plot, a significant deviation from the horizontal line for each algorithm indicates a high level of variance.

In a machine fault detection context, precision is poor when normal operation is improperly classified as faulty, whereas recall is poor when faulty operation is improperly classified as normal.

From the recall heat-map in the second row of Figure 4, we can interpret that the vast majority of algorithms will successfully detect true machine faults. However, the precision heat-map in the first row of Figure 4 shows that it was difficult to achieve accurate classification of normal behavior. In production, a CBM system constantly reporting faults erroneously will result in excessive maintenance activity, and reduce user trust in the fault detection system (Kay et al., 2015).

Furthermore, with limited training data, model performance is degraded as expected. However, the precision heat-map in Figure 4 shows that increasing the available training data beyond 1300 periods results in reduced precision for multivariate techniques. There are two plausible explanations for this. Firstly, the hyperparameters were optimized for F1-score at a training data size of 1000. The hyperparameters could be overfit for this training size. Secondly, the normal training data could be non-stationary. Non-stationarity is defined as a shift in the sampling distribution of the robot arm data—as more training data accumulates, the subsequent normal testing data is sampled from a distribution more distant than the distribution of the initial training data.

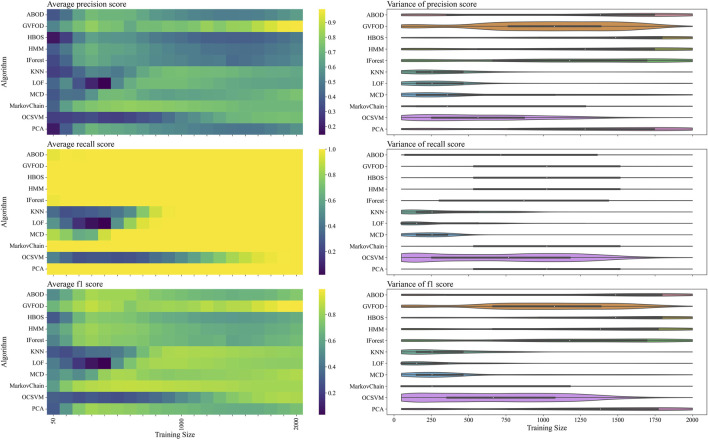

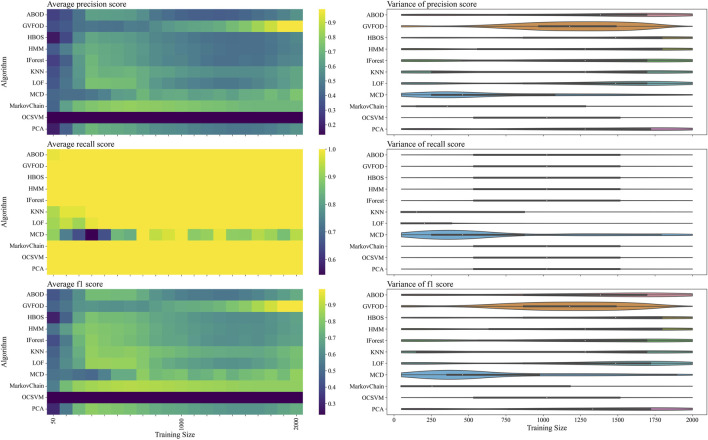

To determine which of the two proposed factors more likely caused the observed drop in performance at larger training sizes, the model is evaluated on the evaluation half of the dataset in Figure 5. Again, we see that most algorithms exhibit similar recall (heat-map on the second row of Figure 5) and are better differentiated by their precision (heat-map on the first row of Figure 5). For multivariate outlier techniques, there is a reduction in precision as training data increases from 500 periods to 1500 periods. By visual inspection, it is clear that the performance of all algorithms changes significantly between Figures 4, 5. The first suspicion when observing this discrepancy is hyperparameter overfitting. However, because of unusual variation in performance as training data quantity changes (within both tuning and evaluation datasets), we suspect that there is significant non-stationary behavior in the normal operation of the robot arm.

FIGURE 5.

The presented figure depicts the performance of models on evaluation data, as evaluated by three distinct metrics. For more information about each figure, please refer to the caption of Figure 4.

To further investigate this claim, we completed experiments using default hyperparameters for the multivariate outlier detection algorithms. These default values are provided by PyOD (Zhao et al., 2019), and represent a real-world deployment of machine fault detection where no fault data is available. For GVFOD, no default parameters are provided in this paper. However, we propose some guidelines to select these parameters based upon knowledge of the machine and of reinforcement learning. To the best of our ability, we selected the hyperparameters based on these guidelines, with no manual tuning based on model performance.

• divs_per_dim: the number of tiles (or bins) to have for each dimension (sensor). The chosen value is (10, 10, 10), which corresponds to the number of tiles for position, torque, and tension respectively. This determines the amount of generalization: learning on one state can at most affect value function estimates of states of the sensor range in either direction.

• n_tilings (m): the number of offset tilings to use. It also determines the number of ones in the feature vector. The chosen value is 10. Combined with the previous choice of divs_per_dim, there is resolution in each dimension.

• discount_rate (γ): The chosen value is 0.9. This yields a pseudo-horizon of the GVF predictions of time-steps, and the discounted sum (and the value function) will be roughly ten times the scale of the sensor value (cumulant).

• step_size (α): the amount of correction with each visit to a state. The chosen value is 0.001. If there is no noise, and the true value function is fully representable with the feature mapping, the ideal value is always m −1. With a step_size of , the error would decay to zero in 100 visits to that state if the initial magnitude of value estimate updates are maintained.

• lambda (λ): the trace-decay parameter. The chosen value was 0.1. This value is typically fairly arbitrary - larger values pass more information backwards in time to update previously visited states, but have higher variance.

• beta (β): the “window width” for UDE. The chosen value was 250. This should be set to a value representative of how many time steps it would take to recognize an outlier. Since the period of the robot arm is 2000 steps, a choice of 250 is reasonable.

The Markov chain and HMM models also do not have default hyperparameters. For Markov Chain, divs_per_dim, was kept the same as its optimized value of (8, 8, 8). This results in 83 = 512 states. By our judgment, this is a reasonable expert-selected value for our robot-arm application. Likewise, the hyperparameter for HMM was kept the same (8 internal states), due to computational constraints. This is supported by the algorithm runtimes in Table 4. The computations were performed using a system with an AMD Ryzen 7 4800H CPU with a 2.90 GHz clock rate, 8 MB of shared L3 cache and 16 GB DDR4-3200 RAM.

TABLE 4.

Algorithm runtime. The median time is reported, using tuned hyperparameters.

| Algorithm | Training data (samples) | Testing data (samples) 700 | |

|---|---|---|---|

| 700 | 1400 | ||

| Time (s) | |||

| IForest | 2.26 | 5.44 | 0.89 |

| OCSVM | 0.03 | 0.13 | 0.01 |

| LOF | 0.05 | 0.12 | 0.04 |

| ABOD | 38.51 | 76.93 | 38.15 |

| KNN | 0.04 | 0.11 | 0.11 |

| HBOS | 1.45 | 1.82 | 0.11 |

| MCD | 0.69 | 0.84 | 0.00 |

| PCA | 0.35 | 0.75 | 0.04 |

| MarkovChain | 5.98 | 11.84 | 4.08 |

| HMM | 980.09 | 1959.79 | 7.99 |

| GVFOD | 2.14 | 4.35 | 0.95 |

The same comparisons between algorithms on the two datasets are shown in Figures 6, 7. Again, we see that there is a significant difference in performance between the two datasets. Since no parameter fitting was done, we can confidently conclude that there is a significant shift in the sampling distribution of normal data over time.

FIGURE 6.

The presented figure depicts the performance of models with default hyperparameters on tuning data, as evaluated by three distinct metrics. For more information about each figure, please refer to the caption of Figure 4.

FIGURE 7.

The presented figure depicts the performance of models with default hyperparameters on evaluation data, as evaluated by three distinct metrics. For more information about each figure, please refer to the caption of Figure 4.

In general, multivariate outlier detection algorithms behaved as expected when comparing optimized and default parameters. LOF, kNN, OCSVM, and MCD exceed mean F1 of 80% at a training data size of 1000 periods using optimized parameters, but do not exceed 80% at any training size using default parameters.

Interestingly, the expert-selected parameters for GVFOD were better than the optimized values. Due to computational constraints, GVFOD hyperparameter tuning was only allocated 400 evaluations of the objective function. The objective is the mean F1-score with a training data size of 1000 periods, on the tuning dataset. The optimized parameters reached mean F1 of 96.8%, while the expert selected parameters yielded a mean F1 of 98.8% 3 . Because of the intuitive nature of GVFOD hyperparameters, they can be well-matched to a machine given machine knowledge (such as sampling frequency, number of sensors, period, etc.), outperforming optimization algorithms, even though the optimization algorithm is given access to fault data.

In the precision heat-maps of Figures 5, 7, we see that the mean precision of GVFOD increases when the availability of training data increases. Other algorithms do not always exhibit this behavior. One hypothesis to explain this behavior lies within the design of the TD(λ) learning algorithm. TD(λ) has a constant step-size parameter. Because of this, it will tend to overwrite previously learned state-value estimates as it learns, effectively assigning larger weights to data later in the training process. This tracking behavior allows it to better adapt to non-stationary operating data. It also results in an algorithm that better classifies normal data in the testing phase, since the normal testing data is collected immediately after the training data. Moreover, because the distribution of GVFOD outlier scores are calculated using the biased model, GVFOD learns not only normal behavior - but the range of non-stationarity that is acceptable in normal behavior. This conclusively explains why GVFOD achieves better precision (with no penalty to recall) compared to multivariate outlier detection methods on this dataset, when allocated large amounts of training data.

We see that GVFOD has higher variance in precision compared to most other algorithms through Figures 5, 7. This is especially apparent comparing the performance of Markov Chain outlier detection to GVFOD—both are state-space time series models, while Markov Chain is significantly more consistent, both in variation within a training data quantity, and between training data quantities. This can be a significant problem for GVFOD in practice, since high variance can manifest as inconsistent fault detection performance. However, given sufficient training data for our robot-arm (e.g. beyond 1500 training samples), we observe consistently better precision than other algorithms, which we believe to be an acceptable compromise for less consistent behavior with less training data.

6 Future work

GVFOD is presented here as a batch algorithm, as it requires two passes over the training data in order to learn the GVFs. A preliminary online and incremental version of GVFOD has been derived, but it is currently inapplicable to all but the smallest datasets due to computational constraints. As presented in this paper, GVFOD can only be applied used in situations where a machine starts operating in known-good conditions. An online implementation of GVFOD could be applied more broadly to situations where fault detection is required from system startup - but this would not alleviate concerns of large data requirements before reaching acceptable levels of precision and recall.

GVFOD is a general algorithm and not specifically tailored to the data in this paper. As it learns shifts in the data distribution, we expect it to generalize well to other applications and data sets, including aperiodic time series data. This intuition needs to be validated in future work by using data from other domains. Furthermore, we are applying GVFOD to simulated environments where failure can be controlled precisely, in order to evaluate how the algorithm performs in gradual-failure scenarios.

7 Conclusion

In this paper we used General Value Functions (GVFs) as a means to detect outliers in robotic data. The data is collected from a robot that emulates an industrial actuator—a machine that is widespread over various applications in daily life as well as in industry. We compared our new algorithm, called General Value Function Outlier Detection (GVFOD), to existing methods for outlier detection in multivariate data. As GVFOD uses reinforcement learning methods, we expect it to be better suited for time-series data than traditional methods. GVFOD exhibits higher precision paired with a comparable recall as existing methods, making it a more suited approach. While GVFOD has a high variance when only trained on a small data set, its performance significantly improves with more data. Overall, GVFOD outperforms the traditional outlier detection algorithms. As the hyperparameters are intuitive to select based on knowledge about the application, this algorithm is a viable solution to allow for condition-based maintenance in industrial applications. The results in this paper demonstrate how predictions, learned via reinforcement learning methods, can be used in real-world applications. To the best of our knowledge, this paper is the first demonstration of General Value Functions to be used for outlier detection in an industrial setting. With its improved performance when compared to traditional outlier detection methods GVFOD allows for better predictive maintenance, saving resources and cost in the process.

Funding Statement

The funding for this project was provided by Mitsubishi Electric Co. and Alberta Machine Intelligence Institute.

Footnotes

The complete dataset and results of hyperparameter search can be found at https://figshare.com/s/4db1bbe92998aaf34323. The code to use GVFOD (including software requirements) to reproduce these experiments is on GitHub.

Due to its complex tree structure, the search space is described in the code on GitHub.

Reported on the tuning data, due to the confounding nature of non-stationarity on the evaluation data.

Data availability statement

The complete dataset and results of hyperparameter search can be found at https://figshare.com/s/4db1bbe92998aaf34323. The code to use GVFOD and to reproduce these experiments is at https://github.com/andywong36/GVFOD.

Author contributions

AW implemented the algorithms and wrote the draft of the paper. MT analyzed the experimental results and turn them into understandable formats, and revised the paper. JG and OZ were supervisors of the project and TT was the industrial supervisor. All authors contributed to the article and approved the submitted version.

Conflict of interest

Author TT was employed by Mitsubishi Electric Co.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

- Arnold J. (1970). A Markovian sampling policy applied to water quality monitoring of streams. Biometrics 26, 739–747. 10.2307/2528720 [DOI] [Google Scholar]

- Bergstra J. S., Bardenet R., Bengio Y., Kégl B. (2011). “Algorithms for hyper-parameter optimization,” in Advances in neural information processing systems 24 Editors Shawe-Taylor J., Zemel R. S., Bartlett P. L., Pereira F., Weinberger K. Q. (Red Hook, NY, United States: Curran Associates, Inc.), 2546–2554. [Google Scholar]

- Breunig M. M., Kriegel H.-P., Ng R. T., Sander J. (2000). “LOF: identifying density-based local outliers,” in Proceedings of the 2000 ACM SIGMOD International Conference on Management of Data (New York, NY, USA: Association for Computing Machinery), SIGMOD ’00, New York; NY; United States, May 15 - 18, 2000, 93–104. 10.1145/342009.335388 [DOI] [Google Scholar]

- Goldstein M., Dengel A. (2012). Histogram-based outlier score (hbos): a fast unsupervised anomaly detection algorithm. KI-2012 poster demo track 1, 59–63. [Google Scholar]

- Günther J., Kearney A., Dawson M. R., Sherstan C., Pilarski P. M. (2018). “Predictions, surprise, and predictions of surprise in general value function architectures,” in Proceedings of the AAAI Fall Symposium on Reasoning and Learning in Real-World Systems for Long-Term Autonomy. 22–29, Arlington, VA, 18–19 October 2018. [Google Scholar]

- Günther J., Pilarski P. M., Helfrich G., Shen H., Diepold K. (2016). Intelligent laser welding through representation, prediction, and control learning: an architecture with deep neural networks and reinforcement learning. Mechatronics 34, 1–11. 10.1016/j.mechatronics.2015.09.004 [DOI] [Google Scholar]

- Gupta M., Gao J., Aggarwal C. C., Han J. (2014). Outlier detection for temporal data: a survey. IEEE Trans. Knowl. Data Eng. 26, 2250–2267. 10.1109/TKDE.2013.184 [DOI] [Google Scholar]

- Hodge V., Austin J. (2004). A survey of outlier detection methodologies. Artif. Intell. Rev. 22, 85–126. 10.1023/B:AIRE.0000045502.10941.a9 [DOI] [Google Scholar]

- Jardine A. K., Lin D., Banjevic D. (2006). A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. signal Process. 20, 1483–1510. 10.1016/j.ymssp.2005.09.012 [DOI] [Google Scholar]

- Kay M., Patel S. N., Kientz J. A. (2015). “How good is 85%? a survey tool to connect classifier evaluation to acceptability of accuracy,” in Proceedings of the 33rd annual ACM conference on human factors in computing systems, Seoul, Republic of Korea, April 18-23, 2015, 347–356. [Google Scholar]

- Kriegel H.-P., Schubert M., Zimek A. (2008). “Angle-based outlier detection in high-dimensional data,” in Proceedings of the 14th ACM SIGKDD international conference on Knowledge discovery and data mining, Las Vegas, Nevada, USA, August 24-27, 2008, 444–452. [Google Scholar]

- Lei Y., Li N., Guo L., Li N., Yan T., Lin J. (2018). Machinery health prognostics: a systematic review from data acquisition to rul prediction. Mech. Syst. signal Process. 104, 799–834. 10.1016/j.ymssp.2017.11.016 [DOI] [Google Scholar]

- Lipsett M., Maltais A., Riazi M., Olmedo N., Zaiane O. (2019). “Robot manipulator drive fault diagnostics using data-driven and analytical modelling,” in Proc machinery failure prevention tech (MFPT) (king of prussia, PA), 12. [Google Scholar]

- Liu F. T., Ting K. M., Zhou Z.-H. (2008). “Isolation forest,” in 2008 eighth ieee international conference on data mining (IEEE), Pisa, Italy, 15-19 December 2008, 413–422. [Google Scholar]

- Pimentel M. A., Clifton D. A., Clifton L., Tarassenko L. (2014). A review of novelty detection. Signal Process. 99, 215–249. 10.1016/j.sigpro.2013.12.026 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ramaswamy S., Rastogi R., Shim K. (2000). “Efficient algorithms for mining outliers from large data sets,” in Proceedings of the 2000 ACM SIGMOD international conference on Management of data, Dallas, Texas, May 16-18, 2000, 427–438. [Google Scholar]

- Riazi M., Zaiane O., Takeuchi T., Maltais A., Günther J., Lipsett M. (2019). “Detecting the onset of machine failure using anomaly detection methods,” in International Conference on Big Data Analytics and Knowledge Discovery (Springer), Linz, Austria, 26-29 August 2019, 3–12. [Google Scholar]

- Rousseeuw P. J. (1984). Least median of squares regression. J. Am. Stat. Assoc. 79, 871–880. 10.1080/01621459.1984.10477105 [DOI] [Google Scholar]

- Schölkopf B., Williamson R., Smola A., Shawe-Taylor J., Platt J. (1999). “Support vector method for novelty detection,” in Proceedings of the 12th International Conference on Neural Information Processing Systems (Cambridge, MA, USA: MIT Press), NIPS’99, Denver, Colorado, USA, November 29 - December 4, 1999, 582–588. [Google Scholar]

- Schreiber J. (2017). Pomegranate: fast and flexible probabilistic modeling in python. J. Mach. Learn. Res. 18, 5992–5997. 10.48550/arXiv.1711.00137 [DOI] [Google Scholar]

- Shyu M.-L., Chen S.-C., Sarinnapakorn K., Chang L. (2003). A novel anomaly detection scheme based on principal component classifier. Philadelphia, PA, United States: Miami Univ Coral Gables Fl Dept of Electrical and Computer Engineering. Tech. rep. [Google Scholar]

- Si X.-S., Wang W., Hu C.-H., Zhou D.-H. (2011). Remaining useful life estimation–a review on the statistical data driven approaches. Eur. J. operational Res. 213, 1–14. 10.1016/j.ejor.2010.11.018 [DOI] [Google Scholar]

- Smyth P. (1994). Hidden markov models for fault detection in dynamic systems. Pattern Recognit. 27, 149–164. 10.1016/0031-3203(94)90024-8 [DOI] [Google Scholar]

- Sutton R. S. (1988). Learning to predict by the methods of temporal differences. Mach. Learn. 3, 9–44. 10.1007/bf00115009 [DOI] [Google Scholar]

- Sutton R. S., Barto A. G. (2018). Reinforcement learning: an introduction. Massachusetts, United States: MIT press. [Google Scholar]

- Sutton R. S., Modayil J., Delp M., Degris T., Pilarski P. M., White A., et al. (2011). “Horde: a scalable real-time architecture for learning knowledge from unsupervised sensorimotor interaction,” in Proceedings of the International Conference on Autonomous Agents and Multiagent Systems-Volume 2 (AAMAS), Taipei, Taiwan, May 2-6, 2011, 761–768. [Google Scholar]

- White A. (2015). Developing a predictive approach to knowledge. Edmonton, AB, Canada: University of Alberta. Ph.D. thesis. [Google Scholar]

- Wong A. (2021). Intelligent machine reliability with general value functions. Edmonton, AB, Canada: University of Alberta. Master’s thesis. [Google Scholar]

- Ye N. (2000). “A Markov chain model of temporal behavior for anomaly detection,” in Proceedings of the 2000 IEEE Systems, Man, and Cybernetics Information Assurance and Security Workshop (Citeseer), vol. 166, West Point, NY, June 2006, 169. [Google Scholar]

- Zhao Y., Nasrullah Z., Li Z. (2019). PyOD: a python toolbox for scalable outlier detection. J. Mach. Learn. Res. 20, 1–7. 10.48550/arXiv.1901.01588 [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The complete dataset and results of hyperparameter search can be found at https://figshare.com/s/4db1bbe92998aaf34323. The code to use GVFOD and to reproduce these experiments is at https://github.com/andywong36/GVFOD.