Abstract

In current years, natural pigments are facing a fast-growing global market due to the increase of people’s awareness of health and the discovery of novel pharmacological effects of various natural pigments, e.g., carotenoids, flavonoids, and curcuminoids. However, the traditional production approaches are source-dependent and generally subject to the low contents of target pigment compounds. In order to scale-up industrial production, many efforts have been devoted to increasing pigment production from natural producers, via development of both in vitro plant cell/tissue culture systems, as well as optimization of microbial cultivation approaches. Moreover, synthetic biology has opened the door for heterologous biosynthesis of pigments via design and re-construction of novel biological modules as well as biological systems in bio-platforms. In this review, the innovative methods and strategies for optimization and engineering of both native and heterologous producers of natural pigments are comprehensively summarized. Current progress in the production of several representative high-value natural pigments is also presented; and the remaining challenges and future perspectives are discussed.

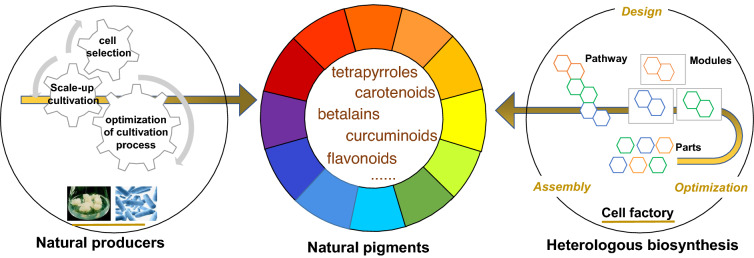

Graphical Abstract

Keywords: Natural pigments, Plant cell/tissue culture, Microbial cultivation, Heterologous biosynthesis, Metabolic engineering

Introduction

Pigments are defined as finely divided and usually water-insoluble colorants, absorbing and reflecting the visible light to show different colors (Rapp 2009). They are of larger molecular weight, less water-soluble, and less transparent than dyes. The usage of pigments has a long history, dating back to the beginning of ancient civilizations (ancient China, India, and Egypt), whereby natural plants, insects, and minerals were used to dye textiles, color foods, paint, color the body in religious ceremonies, and more. In 1856, English chemist William Henry Perkin discovered the first synthesized organic dye from coal tar distillate (Chandler 2001), which triggered the commercial flourishing of synthetic pigments. However, they are derived from chemical reactions, causing heavy environment stress. More notably, many serious health hazards such as toxicity, oncogenicity, and teratogenicity were found associated with synthetic pigments (Li and Tian 2017).

With the increase in public health awareness, replacement of synthetic pigments with safer and more ecofriendly natural pigments has become the current marketing trend. According to the report by GRAND VIEW RESEARCH, the global market for natural pigments in food industry alone is estimated to reach 2.5 billion USD by 2025 (https://www.grandviewresearch.com/industry-analysis/food-colorants-market). Besides usage as colorants, many of natural pigments show great potential in pharmaceutical, nutrition, and skincare industries, due to their health benefits (Amalraj et al. 2017; Chen and Zhong 2015; Yamagata et al. 2015). For instance, as one of the most bioactive xanthophyll pigments that mainly presents in higher plants and microalgae, lutein can prevent and treat retinal damage, including age-related macular degeneration, glaucoma and diabetic retinopathy (Krinsky et al. 2003; Seddon et al. 1994; Sun et al. 2011; Zhang et al. 2016a). It has also been shown to prevent cardiovascular diseases, atherosclerosis and cancers (Astorg 1997; James et al. 2001). The global market for lutein is fast growing, which is expected to reach 357.7 million USD and 2121.2 tons by 2022 (Markets 2017).

According to their structural characteristics, natural pigments can be classified into tetrapyrroles, carotenoids, flavonoids, curcuminoids, betalains, quinones, and others. They are widely distributed across all the natural kingdoms, e.g., plants, animals, and microorganisms. However, each natural source has its own limitations and currently cannot compete economically with synthetic counterparts. Taking astaxanthin (a typical carotenoid compound) as an example, its extraction from green microalga is subject to the lengthy autotrophic cultivation in open freshwater ponds (10–15 days) and the requirement of cell wall disruption to release the carotenoids (Mota et al. 2021); the frequently reported astaxanthin contents from crustaceans, salmon, and trout sources are less than 1 mg/g (Ahmadkelayeh and Hawboldt 2020); the yield of astaxanthin in most wild strains of the microorganism Phaffia rhodozyma can only reach 0.3–0.9% while in bioreactor high cell density and production titers can be achieved in much shorter times (Wan et al. 2021). Therefore, improving biotechnological productivity towards achieving large-scale production is presently an important challenge.

To date, great efforts have been devoted to in vitro production of natural pigments via plant cell/tissue culture and optimization of microbial cultivation. Moreover, rational engineering via pathway mining and genetic engineering has been proposed and applied to improve the yield of various natural pigments. Although considerable achievements have been obtained from biotechnological modification of natural producers, in most cases their productivity still cannot meet the requirements for industrial-scale production.

At the beginning of the twenty-first century, the emergence of “omics” techniques greatly improved our understanding of natural biological systems. Based on these knowledge treasures, synthetic biology came into the forefront, whereby engineering principles were employed to design and reconstruct novel biological modules as well as biological systems (Osbourn et al. 2012). By constructing artificial metabolic pathways using designed parts in well-known biological systems, unlimited supply of previously expensive or unfeasible products could be realized. Currently, model microorganisms like Escherichia coli and Saccharomyces cerevisiae are regarded as the ideal chassis for engineering, owing to their genetic tractability, short cycle of life, and mature technology of high-density fermentation. One classic example is the production of crocins (Fangyu et al. 2018; Liu et al. 2020), which demonstrates the potential of synthetic biology in realizing large-scale production of rare and high-value natural pigments. The simultaneous blooming of genome sequencing, genetic editing, and computer modeling techniques further accelerated progress in heterologous biosynthesis, ushering in the dawn of industrial production of natural pigments.

During the past two decades, several reviews (Begum et al. 2016; Lagashetti et al. 2019; Manivasagan et al. 2018; Rodriguez-Amaya 2016; Sigurdson et al. 2017) have been published on the topic of natural pigments. These articles mainly focused on the characteristics, biosynthesis, regulation, functions and applications of pigments, while comparatively little information on the biotechnological progresses in their production was given. More recently, certain pigments (mainly carotenoids) have been well reviewed, covering their potential use, chemistry and biosynthesis, economic importance, and strategies to enhance production (Heider et al. 2014; Hu et al. 2018; Mussagy et al. 2019b; Saini et al. 2020; Saini and Keum 2019; Venil et al. 2013; Wang et al. 2021a). However, readers cannot get a full picture of the progresses and challenges in industrial application of natural pigments due to the limited categories of pigments and producers (like microalgae) covered in those reviews. Furthermore, the biotechnological engineering methods and strategies are rarely systematically analyzed and summarized. In this review, we present a systematic introduction on the progresses in biosynthesis of natural pigments with the aim to provide a more complete picture of natural pigments development. Specifically, part 2 introduces the current progresses in improving pigment production from natural producers; part 3 summarizes the technical developments towards efficient heterologous biosynthesis of pigments in non-pigment producing organisms; part 4 focuses on representative high-value products among natural pigments, and comprehensively reviews the efforts made in promoting their biosynthesis; lastly, part 5 discusses the challenges and future perspectives in industrial application of natural pigments.

Biosynthesis of pigments from natural producers

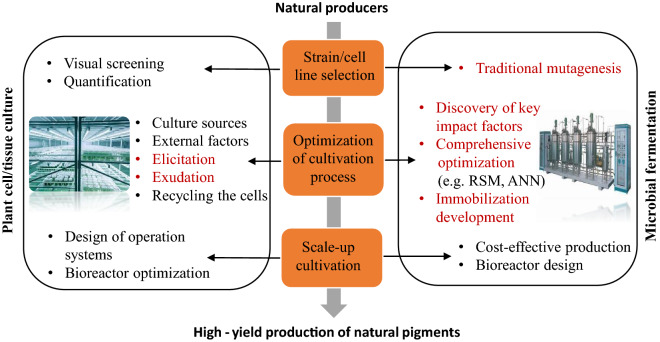

Plant cell culture and tissue culture

Plants are the most abundant source of natural pigments, including chlorophyll, anthocyanin, carotenoids, betalains, etc. Traditionally, most of the commercial pigments are derived from natural sources, either foraging or large-scale plant field cultivation. Due to the low accumulated contents of desired biochemicals in the whole plant, this approach leads to heavy consumption of farmlands and damage to precious natural plants. Taking crocetin—the most important active ingredient and pigment mainly distributed in the stigmas of Crocus sativus, as an example, it is estimated that 20 g of crocetin (in 1 kg of dry Crocus sativus stigma) requires 110,000–170,000 flowers and over 400 h of hand-labor (Frusciante et al. 2014). Besides, Crocus sativus grows slowly and only propagates by vegetative production. Plant cell culture is a technique which can enable plant cells to produce the full spectrum of characteristic second metabolites as mother plants under strictly controlled environmental conditions (Georgiev et al. 2018). In vitro plant production approach is independent of geographical and seasonal limitations, providing an alternative approach to increase the productivity of plant metabolites of interests. Selection and development of high-yielding cell lines as well as optimization of cell cultivation process, including optimization of culture conditions, recycling the cells via immobilization, and bioreactor redesign for scale-up cultivation, are the most commonly used strategies for improving metabolite accumulation (Fig. 1) (Bhojwani and Dantu 2013). As these traditional strategies in pigment production have been summarized in previous reviews (Murthy et al. 2014; Steingroewer et al. 2013), herein, we will mainly focus on two extension techniques for triggering the biosynthesis of secondary metabolites based on bionic innovation (elicitation) and continuous release of desired bioactive compounds (exudation).

Fig. 1.

Routes and strategies for improving production of pigments from natural producers, by optimization of traditional methods including plant cell/tissue culture (left) and microbial cultivation (right)

Elicitation

The biosynthesis of secondary metabolites in plants is activated in response to pathogens (or insects) attack or various abiotic stresses (e.g., radiation, heavy metal and mineral, temperature, salinity) (Ramirez-Estrada et al. 2016). These stress signaling compounds are designated as “elicitors”, the majority of which are perceived by membrane receptors first and entail various sequential reactions (including phosphorylation or dephosphorylation of plasma membrane proteins, [Ca2+] enhancement, Cl−and K+ efflux/H + influx, NADPH oxidase activation, defense gene expression, and secondary metabolite biosynthesis) to trigger the biosynthesis of secondary metabolites (Ramirez-Estrada et al. 2016; Zhang et al. 2012). According to the studies on production of the pigments—betalain, shikonins, carotenoids and flavonoids (Georgiev et al. 2008; Malik et al. 2016; Rizzello et al. 2014; Savitha et al. 2006), biotic elicitors can be divided to four classes: (1) exogenous compounds secreted by microorganisms and insects when attacking plants (Warhade and Badere 2018); (2) exogenous compounds formed from the degradation of microbial cells by plant enzymes, such as fungal and bacterial lysates and polysaccharides of the microbial cell walls (e.g., chitin, glucans) (Bahabadi et al. 2014; Tang et al. 2019); (3) plant cell wall fragments degraded by pathogens; (4) the intracellular proteins or compounds synthesized by plants in response to pathogen attack or abiotic stress (e.g., plant hormones). On the other hand, many abiotic elicitors (like heavy metals, UV irradiation, and inorganic salts) also play important roles in activating plant secondary product biosynthesis.

Exudation

Plant pigments are usually stored in different tissues, making their isolation difficult. A considerable number of studies have been executed to export pigment compounds, which can be summarized into three methods: (1) membrane permeabilization using chemical agents (e.g., Tween 20, DMSO, isopropanol, Triton X-100, polysaccharides like chitosan, and high ionic strength) or physical approaches (e.g., ultrasonication, pulsed electric fields, and high hydrostatic pressure) (Saw et al. 2012); (2) in situ extraction (e.g., usage of n-hexadecane and liquid paraffin in liquid–liquid system) (Zare et al. 2010); (3) introduction of specific transport mechanisms, including vesicle trafficking, membrane transporters, and glutathione S-transferase (GST) (Zhao 2015). However, the specific transporters as well as the mechanisms are still poorly understood, which may be a future research focus.

Microbial cultivation

Traditional mutagenesis

Typical pigment-producing microorganisms include Phaffia rhodozyma (yeast, producing red pigments—carotenoids), Monascus sp (fungus, producing monascus red pigments), Blakeslea trispora (fungus, producing orange pigments like beta-carotene), Streptomyces cyaneus (fungus, producing black pigment—melanin), and Serratia sp (bacteria, producing red pigment—prodigiosin) (Chao et al. 2018; El-Batal et al. 2017; Kim and Ku 2018; Mussagy et al. 2021; Sun et al. 2021). Traditional random mutagenesis using ultraviolet (UV), 1-methyl-3-nitro-1-nitrosoguanidine (NTG) and ethyl methane sulfonate (EMS) have greatly improved microbial pigment production (Yolmeh and Khomeiri 2016; Yolmeh et al. 2017). Nevertheless, these methods suffer from severe drawbacks such as long searching time and low success rate.

Discovery of key impact factors and comprehensive optimization

The accumulation of pigments is generally related to cell growth and affected by nutrient factors (carbon source, nitrogen source, C/N ratio), microbiological parameters (spores age, seed age, inoculum age) and environmental conditions. In terms of environmental conditions, several essential aspects should be evaluated and optimized for the solid-state fermentation (SSF)—the processes performed on non-soluble materials. These aspects include the humidity of medium, physical and structural properties of substrates, temperature, pH and agitation (de Castro and Sato 2015). The low moisture content indicates that this cultivation process can only be carried out by a limited number of microorganisms, mainly yeasts and fungi. The other cultivation process is submerged fermentation (SmF) which based on liquid culture for most microorganisms, and is highly influenced by factors including temperature, pH, and agitation (Morales-Oyervides et al. 2020). Furthermore, it was revealed that production of some pigments is induced by certain stress conditions. For instance, Velmurugan et al. demonstrated that total darkness stimulated accumulation of pigments in Monascus purpureus, Isaria farinosa, Emericella nidulans, Fusarium verticillioides and Penicillium purpurogenum (Velmurugan et al. 2010). For photosynthetic microorganisms, light sources, light intensity, and light photoperiod were illustrated to be the key factors affecting pigment production (Cheirsilp and Torpee 2012; Kuo et al. 2012; Liu et al. 2019b; Zhou et al. 2015b).

Based on discovery of the key impact factors, comprehensive optimization is required to obtain high-yield production of desired pigments. Response surface method (RSM) can solve multivariate data from appropriately designed experiments, and help improve pigment production by optimization of culture medium (Seyedin et al. 2015), process parameters (Sehrawat et al. 2017), and extraction conditions (Zhong et al. 2019). The recently emerged artificial neural networks (ANN) is more flexible and accurate in comparison to RSM (Shafi et al. 2018), having proved effective in improving the production of red pigment in M. purpureus MTCC 369 (Singh et al. 2015).

Development and application of novel immobilization methods

Immobilization technology provides a feasible approach to improve the stability and reusability of the cells, facilitating easier downstream cell separation and continuous operation. Immobilization of bacteria and yeast has been applied for production of carotenoids (Alipour et al. 2017). For molds, SSF is deemed to be superior to liquid-state fermentation (LSF) in pigment production. Extensive studies showed that immobilization cultivation by using cell entrapment and adsorption methods can mimic the solid-state environment of SSF and effectively improve pigment production from molds (Liu et al. 2010). To eliminate nutrient mass transfer limitation from traditional immobilization, membrane-surface liquid culture (MSLC) and modified system-self-immobilization biomembrane-surface liquid culture were developed, whereby the molds could grow on the upper side of the membrane and the other side contacts with liquid medium for supplementation of nutrition (Wang et al. 2012). On the other hand, cultivation of phototrophic dinoflagellates, which can produce pigments like carotenoids and xanthophyll peridinin, is hindered by their sensitivity to hydrodynamic stress. Immobilization of microalgae in a biofilm on sheet-like surfaces could circumvent this problem (Olivieri et al. 2014). Employment of biofilm photobioreactors for cultivation of marine dinoflagellate Symbiodinium led to significantly higher biomass yield and peridinin productivity over suspension culture (Benstein et al. 2014).

Rational engineering of natural producers

Mining of natural pathways

Pre-omics

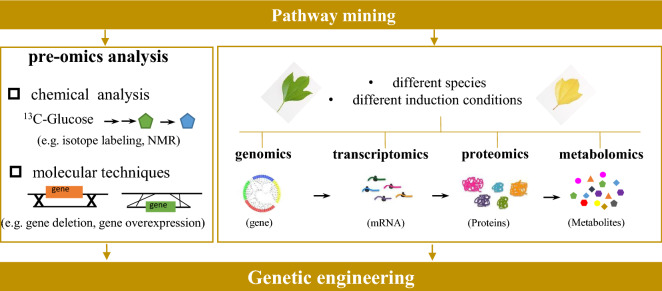

Isotope labeling (1H, 3H, 13C and 15 N) and nuclear magnetic resonance spectroscopy (NMR) analyses can give clues on the biosynthetic pathways via direct observation of isotopic shifts. In the study by Dong et al. (2021), a dual stable isotope labeling approach named DLEMMA was employed to identify and track phenylpropanoid pathway in Arabidopsis thaliana. It was found that PAP1 was a key enzyme for accumulation of cyanidin-type anthocyanins and quercetin-type flavonols. In addition to chemical analysis, a variety of molecular techniques have been employed to identify genes and gene clusters responsible for production of the target metabolites (Fig. 2). The most common strategies can be summarized as: (1) gene deletion and complementation (Bitok et al. 2017); (2) amplification of target gene based on conserved sequences of known enzymes from other organisms and other methods derived thereof (Jones et al. 2008); (3) sequencing the DNA fragments flanking both sides of the known functional enzymes by genome walking (Shapter and Waters 2014); and (4) using a known gene as the bait to reveal unknown regulators or related genes (Lu et al. 2018).

Fig. 2.

Overview of strategies for exploration of metabolic pathways in nature producers. Pre-omics analysis methods consist of chemical analysis (e.g., isotope labeling, NMR analysis) and molecular techniques (e.g., gene deletion, gene expression, DNA sequencing by genome walking); omics technologies include genomics, transcriptomics, proteomics and metabolomics. Both of them offer powerful tools to discover new genes, gene clusters, transcription factors as well as pathways for synthesis of bioactive compounds

Omics

In recent years, combined applications of “omics” techniques—via comparative systematic analysis among different species or the same species under different cultivation/induction conditions—offer powerful tools to discover new genes, gene clusters, transcription factors as well as pathways for synthesis of bioactive compounds (Fig. 2). Via transcriptome analysis of purplish-red leaf and green leaf of Paeonia qiui, several new candidate genes influencing anthocyanin accumulation were discovered, including MYB1, MYB2, bHLH1 and WD40-1 (Luo et al. 2017). Integrated transcriptomics and metabolomics in tomato revealed 38 candidate carotenoid-correlated genes and demonstrated the important role of the ethylene response factor SIERF6 in ripening and carotenoid production (Lee et al. 2012).

Omics-based information on gene distribution and expression regulation can also be used to guide the discovery of unknown genes or clusters (Medema and Osbourn 2016). As demonstrated by Shimura et al., new metabolic pathways or unknown genes can be discovered based on the identification of physically clustered groups (Shimura et al. 2007). Another typical rule is “co-expression”: specialized metabolites are synthesized in certain cell types, growth phases, or in response to environmental induction, for which the corresponding genes usually co-ordinate transcripts activated by specific transcription factors. Therefore, if the gene encoding one of the pathway enzymes has been identified, the other functional enzymes in the same pathway might be elucidated by co-expression analysis using transcriptomics and by metabolites analysis via metabolomics (Geu-Flores et al. 2012).

Genetic engineering of natural producers

The rapid development of bioinformatics, sequencing technology, and genetic engineering has enabled gene manipulation of natural producers to improve pigment production. Herein, we take the progress of Monascus azaphilone pigments (MonAzPs) as an example for illustration. MonAzPs have been used as food colorants and food preservatives in East Asian countries for more than a millennium, while the genetic background of Monascus sp. for producing red pigments remained unclear until recently. In 2013, the key gene cluster (the PKS-FAS gene cluster) involved in the biosynthesis of azaphilone pigments was identified by T-DNA random mutagenesis in M. purpureus (Balakrishnan et al. 2013), whereby MppR1 and MpPKS5 were confirmed as the key enzymes. The complete genome information of M. purpureus YY-1 was obtained by next-generation sequencing and optical mapping techniques, which together with transcriptomic analyses revealed the potential biosynthesis pathway and the regulatory mechanism of pigment production (Yang et al. 2015). On this basis, the individual steps of MonAzPs pathway of M. ruber M7 were elucidated by a systematic functional investigation (Chen et al. 2017b). These advances in elucidating genetic background of natural pigment producers give a roadmap towards improved synthesis of desired products. Downregulation of the citrinin biosynthesis, a competing metabolic branch to MonAzPs biosynthesis, improved the production of pigments by 60% (Liang et al. 2018). Disruption of the ergosterol biosynthetic pathway increased membrane permeability and led to the secretion of Monascus pigments, resulting in 2.06-fold increase in pigment production (Liu et al. 2019a). In short, upregulation of the MonAzPs biosynthetic pathway, complemented with downregulation of competing metabolic branches and improvement of product secretion, offers effective approaches for enhancing Monascus pigments in the native producers. Apart from MonAzPs, genetic engineering is being performed in natural producers of other pigments, such as carotenoids (Ganapathy et al. 2016). For further improvement, the difficulty lies in the lack of understanding on the regulation of pigment synthesis.

Efforts towards heterologous biosynthesis of pigments

Despite the great progress achieved thus far in pigment production by natural biosynthesis, the yield of target compounds remains limited due to low productivity and incomplete understanding of the genetic background of natural producers. Over the past two decades, metabolic engineering has emerged as a powerful tool to develop heterologous cell factories for producing natural pigments. Herein, the efforts towards heterologous biosynthesis of pigments, in the aspects of pathway design, pathway construction and pathway optimization are summarized.

Pathway design

The first critical step for heterologous biosynthesis of pigments is the identification of functional genes and responsible pathways. Natural synthetic pathways usually suffer from metabolic bottlenecks caused by the presence of rate-limiting enzymes and feedback inhibition. Synthetic biology provides an approach to design novel pathways via assembly of catalytic elements and pathway modules from diverse organisms so as to circumvent low-activity enzymes and avoid feedback regulation. For example, insufficient isopentenyl diphosphate (IPP) and dimethylallyl diphosphate (DMAPP) supply is a common bottleneck for accumulation of carotenoids. Introduction of a recombinant mevalonate pathway (MVA pathway) consisting of the bottom portion from Streptococcus pneumonia and the top portion from Enterococcus faecalis led to increased β-carotene production in E. coli (Yoon et al. 2009). For production of anthocyanins and flavonoids, shikimate pathway (SK) is crucial for providing the key precursor coumaric acid. In SK, the conversion of 2-dehydro-3-deoxyarabinoheptulosonate-7-phosphate (DAHP) into the important intermediate EP3P was catalyzed by only Aro1 in yeast systems. In contrast, this catalysis requires the cooperation of seven distinct enzymes—AroB, AroD, AroE, YdiB, AroL, AroK, and AroA, in E. coli. The addition of aroL from E. coli into the native SK in yeast displayed a positive effect on p-coumaric acid production (Rodriguez et al. 2015).

Pathway construction

The long biosynthetic pathway of complex natural pigments, such as carotenoids, flavonoids and quinones, raises the issue of pathway assembly in heterologous hosts. Construction of multiple plasmids using the traditional approach involving multiple cloning steps such as PCR, endonuclease digestion and ligation, is time-consuming, inefficient, and limited by the availability of restriction sites in the plasmids. In recent years, novel DNA assembly methods and multi-locus integration methods have been developed and adopted for pigment production (Fig. 3).

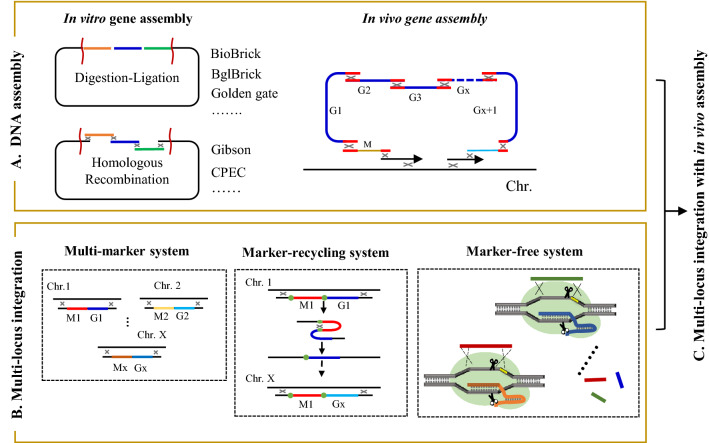

Fig. 3.

Overview of innovative methods for pathway assembly. A Assembly of multiple genes into one large plasmid or one genomic locus. Restriction digestion/ligation-based methods with usage of type II and type IIs restriction enzymes are employed for in vitro gene assembly. Sequence homology-based methods are adopted to join multiple DNA fragments within one step in vivo or in vitro via short overlap. B Multi-locus integration of long pathway by splitting the whole pathway into several segments and then inserting them into multiple sites within one step or by multi-round integration, utilizing multiple markers, recycling markers or adopting marker-free systems. C Combination of multi-locus integration approach and in vivo assembly method to facilitate long-pathway construction

DNA assembly

Restriction digestion/ligation-based methods using type II and type IIs restriction enzymes such as BioBrick (Shetty et al. 2008), BglBrick (Lee et al. 2011) and Golden gate (Engler et al. 2009), are the typical in vitro gene assembly method for large plasmid construction. The other type of in vitro gene assembly method is the sequence homology-based methods like Gibson (Gibson et al. 2009) and CPEC (Quan and Tian 2009), whereby multiple DNA fragments can be easily joined together within one step via short overlaps (Fig. 3A). Apart from in vitro gene assembly methods, in vivo HR-based methods like E. coli RecET/Red system (Fu et al. 2012) and B. subtilis DNA assembly (Itaya et al. 2008) have been developed and employed for pathway construction and even chromosome creation. In in vivo DNA assembler, each DNA cassette is designed with > 40 bp homologous arms. Based on simple operation plus the high efficiency of the native HR mechanism within yeast, several DNA fragments could be assembled and inserted into the designated sites in the chromosome. By employment of an in vivo DNA assembler, a xylose-utilizing zeaxanthin biosynthetic pathway consisting of eight genes (~ 19 kb) was assembled within one-step transformation in yeast (Shao et al. 2009). As compared to in vitro gene assembly, the in vivo gene assembly via employment of the intracellular HR mechanism may omit the addition of cloning enzymes which may lower cloning efficiencies.

Multi-locus integration

Although DNA assembly provides an effective approach for rapid construction of long pathways, successful rate could be affected depending on whether all bioparts are assembled in a single designated site. As an alternative strategy, multi-locus integration splits the pathway into several segments and inserts them into multiple sites via one-step manipulation or multi-round integration (Fig. 3B). The conventional way is to integrate target genes in different loci using different markers, but this strategy is limited by the low available number of selection markers. Cre-loxp-based system and URA-FOA negative selection were then developed for removal and reuse of selection marker (Aguiar et al. 2014). Inspired by these designs, we developed a marker recyclable integrative toolbox for pathway assembly in S. cerevisiae, with the “loxp-kanMX-loxp” cassette conferring resistance against the antibiotic G418 and meanwhile facilitating marker recycling (Ye et al. 2017). By combining this with the decentralized assembly strategy, a total of 11 genes encoding the carotenoid biosynthetic pathway, with length of ~ 22 kb, was integrated into the genome of yeast within 5 rounds of reiterative recombination, leading to successful heterologous production of 16.3 mg∙g−1 dcw carotenoids.

In order to improve the efficiency of HR and achieve marker-free genomic engineering in the multi-locus integration method, several CRISPR–Cas9-facilitated multiplexed integration strategies, such as delta integration CRISPR–Cas (Shi et al. 2016), “Wicket” (Hou et al. 2018), co-transformation of multiple gRNA and donor DNA cassettes (Horwitz et al. 2015), have been developed for assembly of long pathways or modulating the copy numbers of integrated genes. Taking “wicket” design as an example, a short DNA harboring two 50 bp HAs and a 23 bp CRISPR–Cas9 target sequence were designed as docks for integration of exogenous DNA fragments (Hou et al. 2018). Using this approach, multicopies of β-carotene synthetic genes crtE, crtYB and crtI were integrated into the yeast genome, without needing any selective marker.

Multi-locus integration with in vivo assembly

As mentioned previously, both DNA assembly and multi-locus integration can significantly facilitate long-pathway construction. In 2015, the Jay Keasling group developed a new method, named CasEMBLR, for multi-DNA assembly via a combination of multi-locus genomic integration method and in vivo DNA assembly with the usage of CRISPR/Cas9 system. To validate its applicability, 15 DNA parts for carotenoid biosynthesis were successfully assembled and integrated into three targeted genomic loci (URA3, HIS3 and ADE2) of yeast (Jakociunas et al. 2015).

Pathway optimization

Introduction of a heterologous pathway can endow the cell factory with the capacity to produce desired compounds, however the productivity is generally low due to the complexity of metabolic networks in all living systems. For instance, rate-limiting steps may result from undesirable biological characteristics of bio-parts (e.g., promoter, enzyme, cofactor, transporter); metabolic flux to the target compound may be limited by feedback regulation, diverse competing branches or insufficient precursor supply; moreover, overexpression of proteins may lead to heavy metabolic burden, resulting in significant biomass decrease. Therefore, pathway optimization is essential to overcome these bottlenecks for achieving high-efficiency bioproduction. Herein, pathway optimization strategies and their applications in pigment biosynthesis are illustrated, classified into three levels: engineering of rate-limiting bio-parts/factors (“Engineering of rate-limiting bio-parts/factors” Section , Fig. 4), engineering of the metabolic network (“Engineering of the metabolic network” Section, Fig. 5), and engineering of cellular systems (“Engineering of cellular systems” Section, Fig. 6).

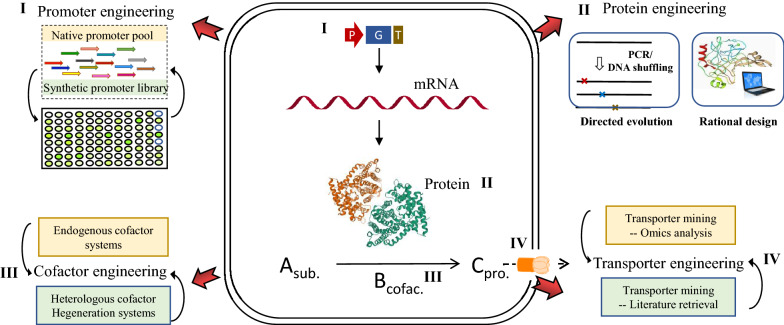

Fig. 4.

Overview of strategies for engineering of rate-limiting bio-parts in heterologous biosynthesis. I Promoter engineering is used for fine-tuning of gene expression via screening and characterization of native promoter pool as well as construction of synthetic promoter library. II Protein engineering is employed to optimize enzymatic properties via directed evolution and rational design. III Cofactor engineering is adopted to improve the supply of reducing forces by regulation of endogenous cofactor system or introduction of heterologous cofactor regeneration systems. IV Transporter mining is applied to eliminate the transportation bottlenecks via omics analysis and literature retrieval

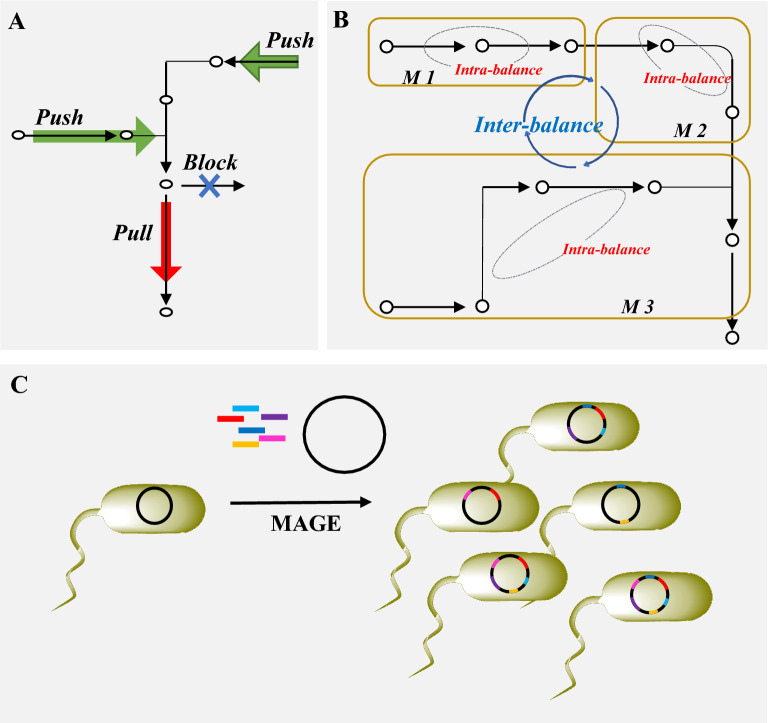

Fig. 5.

Overview of strategies for engineering of metabolic network in heterologous biosynthesis. A “Push–pull–block” strategy is used to direct more metabolic flux to the target compounds, in which “push” indicates enhancing the precursor supply towards target products, “pull” means strengthening the formation ability of the target products, and “block” represents downregulation of the competing pathways. B Inter- and intra-modular pathway engineering strategy is proposed to regulate metabolic balance among multiple modules as well as individual genes within each module. C Multiplex genome engineering like multiplex automated genome engineering (MAGE) is applied for large-scale programming of cell factory. In MAGE, synthetic ssDNA pools (color lines) are transformed into engineered hosts for generation of a diverse set of genomic modifications

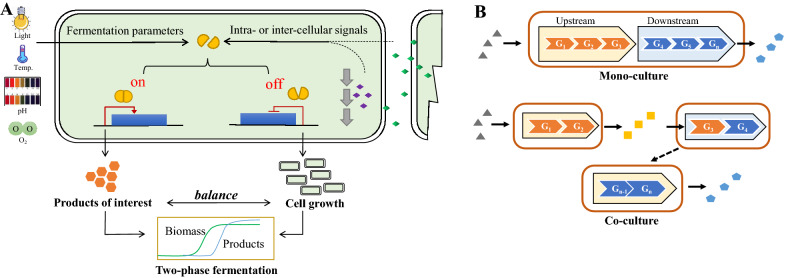

Fig. 6.

Overview of strategies for engineering of cellular systems in heterologous biosynthesis. A Two-stage cultivation is employed to maintain normal cell growth while maximizing pigment production, in which environmental signals (like temperature, light, pH and oxygen) and intra-/inter-cellular signals (like QS system) are used as inducers to trigger the switch-on and switch-off of gene expression. B Co-culture engineering provides an alternative approach for efficient pathway engineering via dividing the complex long pathways into several pathway sections in different strains

Engineering of rate-limiting bio-parts/factors

Promoter engineering

Precise regulation of gene expression is critical to improve product formation and cell growth, as excessive gene expression will generate metabolic burden while insufficient expression may cause accumulation of metabolic intermediates. Promoter optimization is the most direct way to modulate gene expression via controlling the transcription level of specific genes. However, its application is dependent on the availability of endogenous promoters with proper feature. To enrich promoter sources, the native promoter pools in microorganisms and plants are screened via omics and characterized using reporters, and synthetic promoter libraries have been constructed by means of error-prone PCR, site-directed mutagenesis, saturation mutagenesis, and hybrid-promoter design (Fig. 4I). As these above methods have been previously reviewed (Xu et al. 2019; Zhou et al. 2017c), they shall not be described in detail here.

Protein engineering

Enzymes are the basic catalytic elements for biosynthesis of natural products. Innate enzymatic properties, including catalytic activity, substrate specificity and allosteric regulation characteristics, are often incompatible with the engineering hosts. Poor performance of enzymes may generate bottlenecks, unwanted by-products and feedback inhibition, resulting in low synthetic efficiency and productivity.

Directed evolution can mimic Darwinian evolution to achieve functional changes by altering the enzyme structure, and the process typically comprises library construction and artificial selection (Fig. 4II). Random mutations can be introduced into the protein via either error-prone PCR or DNA shuffling. In terms of pigments biosynthesis, colorimetric assays are used as the most intuitive and effective high-throughput screening method. For production of high-purity lycopene, we have created a CrtYB variant with solely phytoene synthase activity via directed evolution, which eliminated the metabolic flux loss towards β-carotene and dramatically improved lycopene yield (Xie et al. 2015a). Apart from altering substrate specificity, the catalytic activity of the pathway enzymes such as OBKT (β-carotene ketolase) and GGPPS (geranylgeranyl diphosphate synthase) was also improved by directed evolution, leading to improved biosynthesis of astaxanthin (Zhou et al. 2017b).

With the growing number of structural data and increasing availability of mechanistic information, rational design is playing a more important role in protein engineering (Fig. 4II). In this approach, engineering targets can be identified via homologous modeling followed by molecular docking or molecular dynamics simulations or via sequence conservatism analysis, followed by site-specific mutagenesis, which significantly reduces the onerous task of screening that is required for directed evolution. For instances, isopentenyl phosphate kinase (IPK) can catalyze the conversion of dimethylallyl alcohol into the fundamental building block of isoprenoids, IPP and DMAPP. Rational design based on protein coevolution analysis generated a positive IPK mutant with eightfold activity improvement, leading to 97% higher β-carotene production (Liu et al. 2016b).

Cofactor engineering

Biosynthetic pathways of pigments commonly comprise multiple redox reactions driven by the reducing forces provided by cofactors, NAD(P)H. Although native cofactor systems exist in microorganisms and plants, they are often insufficient to support heterologous biosynthesis.

Regulation of endogenous cofactor systems, via strengthening cofactor generation or restraining cofactor consumption, provides a feasible strategy to maintain cellular redox balance (Fig. 4 III). In S. cerevisiae, enhancement of NADPH supply by overexpression of POS5 (a mitochondrial NADH kinase) and ZWF1 (glucose-6-phosphate dehydrogenase involved in the pentose phosphate pathway) led to 59.9% and 81.4% increase of lycopene and β-carotene production, respectively (Zhao et al. 2015). In addition to regulation of endogenous cofactor systems, NADPH generation can also be enhanced via introduction of heterologous cofactor regeneration systems (Fig. 4 III). By introducing a heterologous Entner–Doudoroff (ED) pathway from Zymomonas mobilis into E. coli, the NADPH regeneration rate was increased by up to 25-fold, achieving 97% improvement of carotenoid production (Ng et al. 2015). Comprehensive regulation of NADH supply in Monascus purpureus by addition of exogenous cofactor compounds and disturbing nuoI (encoding NADH-quinone oxidoreductase) significantly increased Monascus pigment production (Liu et al. 2021a).

Transporter engineering

In metabolic engineering, extracellular export of natural compounds like fat-soluble compounds (e.g., carotenoids) is a big challenge. In recent years, based on transcriptomic analysis and literature mining (Fig. 4 IV), many novel transporters have been revealed for specific pigments and then applied to eliminate the transport bottlenecks.

Depending on the mechanism, transporters can be divided into the ATP-binding cassette (ABC) transporters (driven by ATP hydrolysis) and facilitator superfamily (making use of electric gradients). When microorganisms or plants are exposed to noxious environment or engineered to produce heterologous biochemicals, efflux pumps will be activated to export harmful substances for cell survival. Based on this mechanism, the transcriptomes of two engineered S. cerevisiae strains with different carotenoids production capacities were comparatively analyzed, suggesting induction of genes involved in pleiotropic drug resistance including the ABC transporter-pdr10 in the strain with high carotenoids production (Verwaal et al. 2010). To confirm its effects on secretion of carotenoids, pdr10 from S. cerevisiae was introduced into Rhodosporidium toruloides in our previous study, leading to production improvement of total carotenoids from 1.9 μg/mg to 2.9 μg/mg in a bi-phasic culture (Lee et al. 2016). In addition to omics analysis, literature retrieval has also been used for transporter mining. For example, an array of efflux pumps reportedly responsible for secondary metabolite transports were introduced in anthocyanins-producing E. coli, and an anthocyanin-associated transporter yadH was identified, overexpression of which resulted in 15% increase of anthocyanin production (Lim et al. 2015).

Engineering of the metabolic network

Push–pull–block strategy

In heterologous biosynthesis, the efficiency of cell factories is often limited by the insufficient precursor supply and strong competitive metabolic branches. To direct more metabolic flux to the target compound, “push–pull–block” strategies have been developed and employed for biosynthesis of diverse chemicals and biofuels (Li et al. 2016): “push” indicates pushing more precursor supply towards target products, “pull” means strengthening the target biosynthetic pathway, and “block” or “restrain” represents downregulation of the competing pathways (Fig. 5A).

Isoprene is the monomeric building block of carotenoids. In our previous study, a rational push–pull–block strategy was employed for enhancement of isoprene biosynthesis in S. cerevisiae via engineering of the native acetyl-CoA and MVA pathways. This strategy was decomposed into upregulation of precursor supply in the acetyl-CoA and MVA pathway (by overexpression of ACS2/ERG10 and tHMG1, respectively), increasing the isoprene branch flux (via overexpression of IDI1 and ISPS), and downregulation of the competitive pathway (through decreasing the promoter strength of ERG20). With this combined regulation strategy, a total of 782-fold improvement of isoprene production was achieved in the engineered strain (Lv et al. 2014). Similar strategies have also enhanced the synthesis of pigments like flavonoids (Lyu et al. 2019b).

Inter- and intra-modular pathway engineering

In heterologous biosynthesis of complex pigments, overexpression of a large set of pathway genes often results in severe imbalance in pathway flux. Multivariate modular metabolic engineering partitions the complicated pathway of natural compounds into multiple modules, and the carbon flux of each individual module will be maximized and balanced to enable global fine-tuning of the whole metabolic network. The metabolic levels of different modules can be adjusted via altering plasmid copy number, promoter strength, RBS variety and enzyme properties (Fig. 5B). For example, the eight-step pinocembrin biosynthetic pathway was divided into four modules and optimized via altering the copy number of plasmids, leading to more than tenfold increase in pinocembrin production (Wu et al. 2013).

In addition to inter-module engineering, intra-module engineering is also viral to reduce the accumulation of intermediates (Fig. 5B). As illustrated in our previous study (Lv et al. 2016), a combinatorial strategy of protein engineering and modular pathway engineering was applied to simultaneously improve the intra- and inter-pathway balance for biosynthesis of isoprene in E. coli. Specifically, the whole biosynthetic pathway of isoprene was partitioned into the upstream module consisting of the native MEP pathway, and the downstream module containing isoprene synthase. The intra-module engineering within the upstream module via directed coevolution of DXS/DXR/IDI resulted in 60% improvement of isoprene production. Inter-module engineering between the upstream and downstream module via promoter manipulation further increased isoprene production by 4.7-fold. In a more recent study, a multidimensional heuristic process (MHP) was developed to co-ordinate intra-module activities and inter-module balance for biosynthesis of astaxanthin. A total of 15 genes were distributed in four modules and balanced by varying promoter strength, and intra-module balance was coordinated via RBS and enzyme variants, resulting in 320 mg/L of astaxanthin (Zhang et al. 2018a).

Multiplex genome engineering

Due to the complexity of biological systems, it is often hard to meet industrial demand on titers of desired compounds by solely engineering the target pathways. To date, a series of multiplex genome engineering methods have been developed for large-scale programming of cell factories, which can be classified into three types: (1) RNA interference-based (RNAi) method, for which a large RNAi library was coupled with high-throughput screening to generate accumulated beneficial modifications (Si et al. 2015). (2) Recombinase-based method, e.g., multiplex automated genome engineering (MAGE) (Wang et al. 2009) and trackable multiplex recombineering (TRAR) (Warner et al. 2010). (3) Multiplex CRISPR-based technologies, in which numerous gRNA or Cas enzymes are expressed simultaneously (McCarty et al. 2020). Herein, we will take MAGE (Fig. 5C) as an example to briefly introduce its application in metabolic engineering of E. coli for pigment production (Wang et al. 2009). MAGE depends on single-stranded DNA (ssDNA)-based genetic modification. Directed by λ-Red ssDNA-binding protein β, the sodas are loaded to the lagging strand of the replication fork for subsequent incorporation. Transformation of synthetic oligo pools enable generation of a diverse set of genetic modifications. Targeting 24 targeting genomic sites related to the 1-deoxy-D-xylulose-5-phosphate (DXP) biosynthesis pathway, fivefold increase of lycopene production was obtained with employment of MAGE method in E. coli.

Engineering of cellular systems

Dynamic control for cell growth–metabolism balance

Static pathway engineering, e.g., constitutive overexpression of pathway genes and deletion of competing pathways, has been proven as a powerful strategy to improve the yield of valuable products. However, it often results in decreased biomass due to severe metabolic burden and accumulation of toxic intermediates.

Two-phase cultivation has been widely recognized as a powerful strategy to circumvent the trade-offs between product accumulation and cell growth. Unlike traditional inducible expression systems, the newly developed environmental signal-responsive systems use cultivation parameters (like temperature, light, pH and oxygen) as inducers to trigger the switch-on and switch-off of gene expression, eliminating the requirement of adding expensive inducers (like isopropyl-β-D-thiogalactoside and galactose) (Fig. 6A). In our previous study, a glucose-responsive dynamic control system with PGAL promoters has been developed by deletion of GAL80, which has been successfully applied for β-carotene production (Xie et al. 2014). By employment of a lycopene-indicated high-throughput screening method, a temperature-sensitive Gal4 mutant was screened out from directed evolution library and introduced into the GAL80-knockout yeast strain. With this design, target genes under PGAL can be precisely switched on by altering the culture temperature, which resulted in 44% higher biomass and 177% increased lycopene production (Zhou et al. 2018), and facilitated high-density fermentation of astaxanthin (Zhou et al. 2019).

A further extension of dynamic control is autonomous regulation systems, in which target enzymes can be activated by intracellular intermediates or intercellular signals (Fig. 6A). For example, quorum-sensing circuits offer a powerful strategy to autonomously regulate cell metabolism. At high cell densities, quorum-sensing microbes can secrete sufficient molecular signals to alter the expression of endogenous genes. LuxI-LuxR and AHL-EsaR are two of the best-studied QS systems. A bifunctional QS circuit combining both LuxR and EsaR systems was developed using 3-oxohexanoyl homoserine lactone as the signal to dynamically regulate the expression of genes under Plux and PesaR in a cell density-dependent manner, and successfully improved flavonoid titer (Dinh and Prather 2019).

Co-culture engineering

Despite the progress in engineering single strains, introduction and regulation of the whole target biosynthetic pathway often raises overwhelming metabolic burden and encounter the intrinsic limitation of monocellular environment. Recently, co-culture engineering has emerged as an alternative approach for pathway engineering via division of the complex and long biosynthetic pathways into different host strains. As compared to mono-culture engineering, co-culture systems display notable advantages: (1) reducing metabolic burden by division of labor to different strains; (2) improving flexibility for balancing pathway modules via optimizing the population ratio of engineered strains; (3) providing diversified intracellular environments for functional overexpression of a large variety of enzymes involved; (4) reducing negative cross-interference among pathway modules; (5) enabling utilization of different carbon sources (Fig. 6B).

In recent years, considerable progress has been achieved in employment of modular co-culture system for biosynthesis of complex natural colored compounds (e.g., flavonoids and curcuminoids). One typical example is the biosynthesis of anthocyanins by E. coli polycultures, in which 15 exogenous enzymes were divided into 4 modules across four E. coli strains (Jones et al. 2017). Similar E. coli co-culture systems have also been adopted for biosynthesis of other flavonoids like sakuranetin (Wang et al. 2020), naringenin (Ganesan et al. 2017), resveratrol (Hong et al. 2020), and flavan-3-ols (Jones et al. 2016). In addition, efforts have also been made to employ cross-species co-culture systems for biosynthesis of complex compounds. For example, a synergistic E. coli-S. cerevisiae culture system was developed for naringenin production from D-xylose, generating 21.16 mg/L of the target product (Zhang et al. 2017). Although co-culture engineering exhibited significant advantages over mono-culture engineering, it is not suitable for all biosynthetic systems. For instance, many pathway intermediates cannot easily traverse cellular membranes, and different specifies may not be compatible in the same environment due to differing requirements of nutrients, temperature and pH.

Major natural pigments and advances in biotechnological production

Depending on their structural characteristics, natural pigments may be classified into five major classes: tetrapyrroles, carotenoids, flavonoids, curcuminoids, and betalains. The general introduction of each class of pigments, including structure, classification, function and biosynthetic pathway, as well as the advances in biotechnological production of the typical products from each group are individually summarized in this section.

Tetrapyrroles

Structure, classification and function

Tetrapyrroles, also called ‘pigments of life’, represent a small group of complex pigments which are the most abundant in living organisms. Structurally, tetrapyrroles are composed of four pyrrole-derived rings, joined together by methine bridges to form linear bile pigments or cyclic porphyrins (Solymosi and Mysliwa-Kurdziel 2017). Cyclic tetrapyrroles may differ in the oxidation state of pyrrole rings, peripheral substitutions, and the centrally chelated metal ions. They can be further subdivided into several groups—chlorophylls, hemes, cytochrome C, vitamin B12, and coenzyme F430, all of which contribute to the wide color range of natural pigments, from red, yellow to green, blue, and purple (Velisek et al. 2007). Moreover, degradation of cyclic tetrapyrroles generates linear tetrapyrroles like bilins, which loses one bridge carbon.

The most famous representatives of these ‘pigments of life’ are chlorophyll (‘plant blood’, in charge of the green color in plants) and heme (giving red color in animal blood). In natural producers, tetrapyrroles play important roles in a series of key metabolic processes, such as photosynthesis (e.g., chlorophyll) and electron transfer (e.g., cytochrome c) in plants, as well as transportation of oxygen (e.g., heme) in animals. More importantly, they have been proven to possess good antioxidant, anticancer, antimutagenic and anticlastogenic activities, showing great potential for applications in food and pharmaceutical industries (Beata and Solymosi 2016).

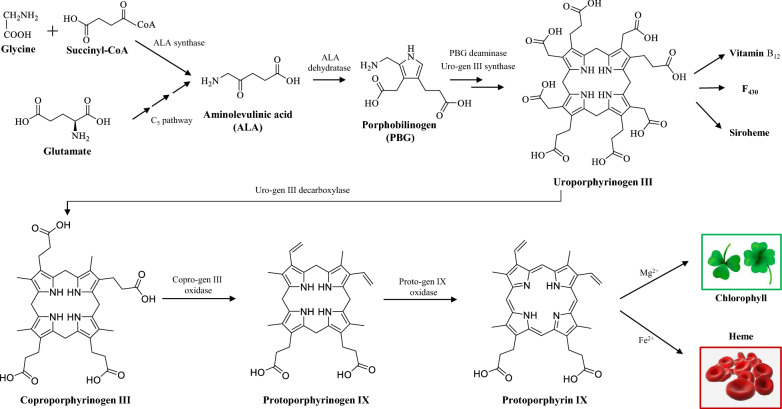

Biosynthetic pathway

The biosynthetic pathway of tetrapyrroles can be sectioned into six stages (Kobayashi and Masuda 2016) (Fig. 7): (1) biosynthesis of the common precursor- 5-aminolevulinic acid (ALA); (2) formation of the pyrrole unit porphobilinogen (PBG); (3) formation of uroporphyrinogen III, the carbon skeleton of porphyrins; (4) decarboxylation of uroporphyrinogen III to generate coproporphyrinogen III via uroporphyrinogen decarboxylase; (5) conversion of coproporphyrinogen III to protoporphyrinogen IX under the catalysis of coproporphyrinogen oxidase; (6) generation of protoporphyrin IX, the completely conjugated ring system to show color, by losing six hydrogen atoms under the action of protoporphyrinogen oxidase.

Fig. 7.

Schematic for the biosynthetic pathways of tetrapyrroles. Tetrapyrroles, including vitamin B12, F430, siroheme, chlorophyll and heme, are initiated from condensation of glycine and succinyl-CoA or synthesized through C5 pathway from the C5-skeleton of glutamate

Typical product—heme

Heme is the most famous representative of tetrapyrroles, which gives red color in animal blood and serves critical biological functions in transporting O2 and electrons, modulating gene expression, as well as regulating protein stability and cell differentiation. Due to its natural red color displayed in blood, it has a long history of use as a meat additive. Nowadays, it is widely used as an iron supplement in the healthcare industry, owing to its high bioavailability (Hoppe et al. 2013), and is drawing increasing attention in production of plant-based meat alternatives by increasing the meat-like color and flavor (Gerhard 2020; Simsa et al. 2019).

Free heme sources are traditionally isolated from biological samples, typically animal blood, with obvious issues of this production mode being low-yielding and ethical animal welfare concerns. Bioproduction of heme on a large scale is therefore greatly preferred. The biosynthetic pathway of heme starts with the formation of 5-aminolevulinate (ALA) via the C4 pathway (in humans, animals, fungi and few bacteria) and the C5 pathway (in plant and most bacteria), followed by cyclization, modification of the side chains, and incorporation of reduced iron. In 2003, an entire heme biosynthetic pathway including hemA (encoding ALA synthase of the C4 pathway) from Rhodobacter capsulatus, hemB, hemC, hemD and hemF genes from E. coli, hemE from Synechocystis, and hemY, hemH from B. subtilis was assembled in E. coli, leading to accumulation of 3.3 μmol/L of heme (Kwon et al. 2003). In another study, co-expression of ALA synthase (hemA), NADP-dependent malic enzyme (MaeB) and dicarboxylic acid transporter (DctA) in E. coli resulted in 6.4 mg/L of heme (Kwon et al. 2009), and additional overexpression of pantothenate kinase (coaA) led to 0.49 μmol/g DCW of heme (Lee et al. 2013). In a more recent study, comprehensive regulation of heme synthesis and secretion was conducted to improve heme production. Respective expression of the C4 and C5 pathways in E. coli revealed the superior capacity of the C5 pathway for producing ALA. Downstream pathways for heme biosynthesis were subsequently optimized by elimination of the limiting steps and balancing enzyme expression. In addition, three competing pathways including acetate and lactate synthesis, and heme degradation pathway, were blocked via knocking out pta (encoding phosphate acetyl transferase), ldhA (encoding lactate dehydrogenase) and yfeX (encoding a heme dechelatase). The resulting E. coli strain produced 7.88 mg/L of heme. Further overexpression of a heme exporter cmABC led to total heme production of 239.2 mg/L, among which 151.4 mg/L was secreted (Zhao et al. 2018). These studies demonstrated that microbial metabolic engineering by enhancement of the upstream C4/C5 pathway, together with downregulation with the heme degradation pathway and improvement of heme secretion, provides a highly promising option for enhancing the production of free heme.

Carotenoids

Structure, classification and function

Carotenoids are a family of lipophilic isoprenoid pigments produced by numerous bacteria (e.g., Corynebacterium michiganense, Micrococcus roseus, Brevibacterium spp., Bradyrhizobium spp., Gordonia jacobaea and Dietzia natronolimnaea), fungi (e.g., Blakeslea trispora, Phycomyces blakesleeanus, Rhodotorula spp., Xanthophyllomyces dendrorhous), and microalgae (e.g., the genus of Chlorella, Dunaliella, Coelastrella and Haematococcus). (Carlos Mata-Gomez et al. 2014; Mannazzu et al. 2015; Mussagy et al. 2019a). Recent studies have demonstrated that some multicellular organisms like aphids, adelgids, phylloxerids, and gall midges, possess the capability for de novo synthesis of carotenoids (Cobbs et al. 2013; Moran and Jarvik 2010; Novakova and Moran 2012; Zhao and Nabity 2017); in contrast, most higher animals (including humans) can only take carotenoids from their diet (Rodriguez-Concepcion et al. 2018). Structurally, carotenoids originate from the condensation of C5 isoprenoid units to generate a vast class of over 600 carotenoid structures, among which C40 carotenoids are the most abundant in nature (Kiokias et al. 2016). These pigments are mainly classified into two subgroups: (1) hydrocarbons-carotenes (e.g., lycopene, α-carotene, and β-carotene); and (2) xanthophylls, the oxygenated derivatives of carotenes (e.g., lutein, zeaxanthin, astaxanthin, canthaxanthin). They display in yellow, orange, red or even colorless, and possess excellent antioxidant, anticancer, and anti-inflammation activities. According to the reports from Allied Market Research, the global carotenoid market value was $1.5 billion in 2017, and is estimated to reach nearly $2.1 billion by 2025 (Dawande 2018). Structurally, carotenoids originate from the condensation of C5 isoprenoid units to generate a vast class of over 600 carotenoid structures, among which C40 carotenoids are the most abundant in nature.

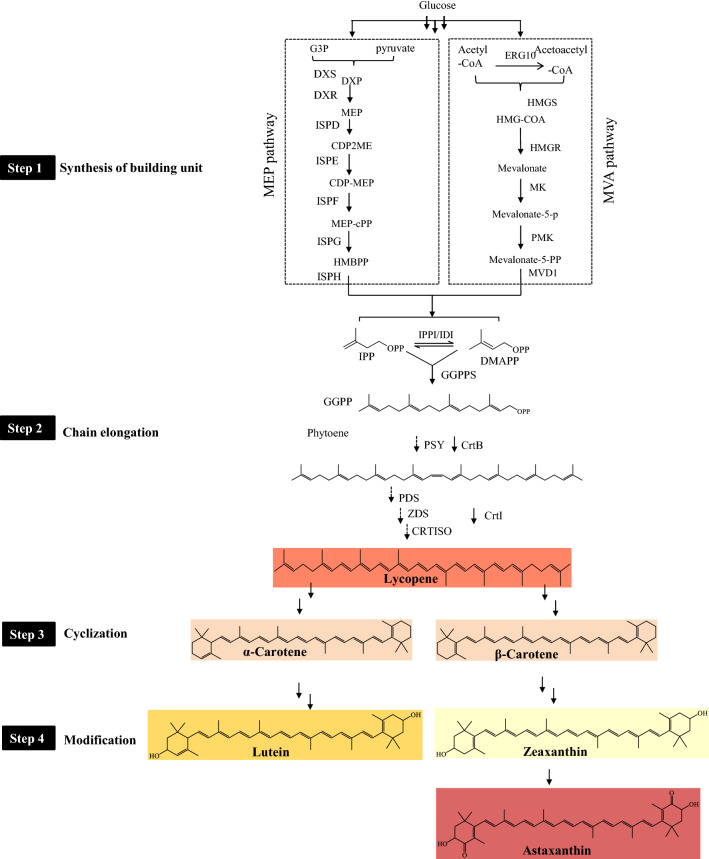

Biosynthetic pathway

The biosynthetic process of carotenoids can be summarized as four steps, as shown in Fig. 8: (1) synthesis of the building units—isopentenyl diphosphate (IPP) and dimethylallyl diphosphate (DMAPP); (2) chain elongation by successive condensation reaction of IPP to DMAPP generating the growing polyprenyl diphosphate chain; (3)cyclization of linear isopentenyl pyrophosphate precursors to form the carotenoid carbon skeleton; (4) modification of the carotenoid carbon skeleton to generate diverse carotenoids. Among numerous carotenoids, β-Carotene and astaxanthin are the most commercially valuable products.

Fig. 8.

Schematic of carotenoids biosynthesis. Most carotenoids go through four synthetic steps consisting generation of building unit, chain elongation, cyclization, and modification. DXS, 1-deoxy-d-xylulose-5-phosphate synthase; DXR, 1-deoxy-d-xylulose-5-phosphate reductoisomerase; ISPD, 4-diphosphocytidyl-2C-methyl-D-erythritol synthase; IspE, 4-diphosphocytidyl-2-C-methyl-D-erythritol kinase; IspF, 2C-methyl-D-erythritol-2,4-cyclodiphosphate synthase; IspG, 1-hydroxy-2-methyl-2-(E)-butenyl-4-diphosphate synthase; IspH, 1-hydroxy-3-methyl-2-(E)-butenyl-4-diphosphate reductase; HMGS, HMG-CoA synthase; HMGR, HMG-CoA reductase; MK, mevalonate kinase; PMK, phosphomevalonate kinase; MVD1, mevalonate diphosphate decarboxylase; IPPI/IDI1, isopentenyl-diphosphate isomerase; GGPPS, GGPP synthase; PSY, phytoene synthase; PDS, phytoene desaturase; ZDS, ζ‐carotene desaturase; CRTISO, carotenoid isomerase; CrtB, phytoene synthase; CrtI, phytoene desaturase; DXP, 1-deoxy-D-xylulose-5-phosphate; MEP, 2-C-methyl-D-erythrito-l4-phosphate; CDP2ME, 4-diphosphocytidyl-2-C-methylerythritol; MEP-cPP, 2-C-methyl-D-erythritol-2,4-cyclo-diphosphate; HMBPP, (E)-4-hydroxy-3-methylbut-2-enyl-diphosphate; IPP, isopentenyl diphosphate; DMAPP, dimethylallyl diphosphate; GGPP, geranylgeranyl diphosphate

Scrutinizing the first step, IPP and DMAPP may generated from one of two distinct pathways, the mevalonate (MVA) pathway and the 2-C-methyl-D-erythritol 4-phosphate (MEP) pathway (Lange et al. 2000; Rohdich et al. 2003; Rohmer et al. 1993; Wölwer-Rieck et al. 2014). The MVA pathway is ubiquitous in bacteria, most fungi, and plants (in the cytoplasm), which initiates from acetyl-CoA and ends up with the production of DMAPP under the catalysis of acetoacetyl-CoA thiolase (ERG10), HMG synthase (HMGS), 3-hydroxy-3-methylglutaryl-CoA reductase (HMGR), MVA kinase (MK) and phosphor-MVA kinase (PMK), diphospho-MVA decarboxylase (MVD1), and IPP isomerase (IDI) (Allen et al. 1967; Vranova et al. 2013). In the MVA pathway, HMGR is identified as the rate-limiting enzyme. The MEP pathway is present in most bacteria, green algae, and plants (in the chloroplast) (Rohdich et al. 2003). It starts from the condensation of glyceraldehyde-3-phosphate (G3P) and pyruvate to generate 1-deoxy-D-xylulose 5-phosphate (DXP), which is further catalyzed by 1-deoxy-D-xylulose 5-phosphate synthase (DXS), DXP reductoisomerase (DXR), 2-C-methyl-D-erythritol 4-phosphate cytidylyltransferase (ISPD), 4-(cytidine 5′-diphospho)-2-C-methyl-D-erythritol kinase (ISPE), 2-C-methyl-D-erythritol 2,4-cyclodiphosphate synthase (ISPF), 4-hydroxy-3-methylbut-2-enyldiphosphate (HMBPP) synthase (ISPG), HMBPP reductase (ISPH), and IPP isomerase (IPPI), to yield IPP/DMAPP (the end product in the first step). The processes catalyzed by DXS (Lv et al. 2013a; Ramos et al. 2014; Xue and Ahring 2011), DXR (Lv et al. 2013a; Zhao et al. 2011) and IPPI (Lv et al. 2013b; Ramos et al. 2014) are identified to be the rate-limiting steps involved in the MEP pathway. In the second step, lycopene is the typical product from IPP/DMAPP, under catalysis of geranylgeranyl diphosphate synthase (GGPPS), phytoene synthase (PSY), phytoene desaturase (PDS), ZISO f-carotene isomerase (ZDS), and carotenoid isomerase CRTISO in plants, or under the catalysis of GGPP synthase (CRTE), phytoene synthase (CRTB), and phytoene desaturase/isomerase (CRTI) in non-photosynthetic bacteria. In the next step, α/β-carotene can be generated from lycopene under the catalysis of lycopene β-cyclase (LCYB) and/or lycopene ε-cyclase (LCYE). Further modification of carbon skeleton in the last step will result in other active carotenoids, e.g., lutein, zeaxanthin, and astaxanthin.

Typical product—β-carotene

β-Carotene is the most extensively studied carotenoid, abundant in leafy vegetables and is sold as a dietary supplement due to its well-known pro-vitamin A characteristic and excellent antioxidant activity. As the precursor of Vitamin A, β-carotene can help accelerate human growth, maintain a healthy immune system and good vision (Chen and Zhong 2015).

At present, the natural source-based production methods of β-carotene are either extraction from plants, silkworm excrement or algae, or cultivation of yeast and fungi. The extraction process of β-carotene from carrot, palm, seabuckthorn and other raw materials is complex. Moreover, its efficiency is limited by the long growth cycle of plants and the impact of climate and geography on their growth. Algae have proven to be more advantageous than plants in terms of productivity and production cycle. However, due to the harsh cultivation conditions and degradation issues, large-scale cultivation remains difficult. Microbial cultivation is a promising alternative with the advantage of continuous production, and has achieved stellar progress in the last decade (Table 1). Blakeslea trispora and Rhodotorula glutinis are the best-explored natural producers for β-carotene. The improvement in biosynthetic ability of these two strains have stemmed from the optimization of cultivation equipment133 and the culture medium (Chang-he et al. 2020; Tkáčová et al. 2017), random mutagenesis and addition of exogenous stimulants (Hu et al. 2013; Jing et al. 2016; Luo et al. 2021). The incomplete host genetic information and the lack of tools for genetic-level operation have thus far prevented more precise rational engineering of these strains. Researchers turned to engineering of E. coli and S. cerevisiae, the two model for prokaryotic and eukaryotic organisms, respectively. Herein we mainly focus on such studies reported in the last decade.

Table 1.

Progresses of β-carotene biosynthesis in the last decade

| Strain | Strategy | Yield | Year | Refs. |

|---|---|---|---|---|

| Native producers | ||||

| Blakeslea trispora | Development of new cultivation equipment | 44.56 mg/g DCW, 8 days (bubble column reactor) | 2012 | Nanou et al. (2012) |

| Blakeslea trispora | Increase of oxygen concentration and induced high oxidative stress via addition of 3% (v/v) liquid paraffin |

715 mg/L 84 h (shake flask) |

2013 | Hu et al. (2013) |

| Mucor circinelloides | Strain mutagenesis with UV and NTG | 4 mg/g DCW (shake flask) | 2016 | Zhang et al. (2016b) |

| Blakeslea trispora | Addition of sodium acetate (NaAC) in mated B. trispora |

59.91 mg/g DCW 2130 mg/L, 8 days (shake flask) |

2016 | Jing et al. (2016) |

| Blakeslea trispora | Optimization of cultivation by single factor and response surface test | 523.8 mg/L (shake flask) | 2020 | Chang-he et al. (2020) |

| Blakeslea trispora | Protoplast fusion between ATCC 14,272( +) and ATCC 14,272(−) | 36.93 mg/gDW (shake flask) | 2021 | Wang et al. (2021b) |

| Blakeslea trispora | Regulation of light and active oxygen | 5.0 mg·g DW (shake flask) | 2021 | Luo et al. (2021) |

| Rhodotorula glutinis | Optimization of carbon:nitrogen (C/N) ratios (20:1, 50:1, 70:1, and 100:1) to analyze carotenoid and lipid biosynthesis | N.A | 2017 | Tkáčová et al. (2017) |

| Rhodotorula glutinis | Supplementation of vegetable oils as carbon source and optimization of bioreactor |

0.36 mg/L 156 h (agitator bioreactor) |

2019 | Yen et al. (2019) |

| Heterologous hosts | ||||

| S. cerevisiae | Overexpressing HMG-CoA reductase gene and adding ergosterol synthesis inhibitor ketoconazole | 6.29 mg/g DCW | 2012 | Yan et al. (2012) |

| S. cerevisiae | Deletion of gene rox1, yjl064w and ypl062w | ~ 2.1 mg/g DCW | 2013 | Ozaydin et al. (2013) |

| S. cerevisiae | Design of a set of marker recyclable integrative plasmids (pMRI) for decentralized assembly of reconstructing controllable multi-gene pathways by employing the GAL regulatory system |

7.41 mg/g DCW (shake flask culture) |

2013 | Xie et al. (2014) |

| S. cerevisiae | Introduction of crtE, crtYB and crtI from Phaffia rhodozyma into S. cerevisiae INVSc1; Additional expression of the catalytic domain of 3-hydroxy-3-methylglutaryl coenzyme A reductase (cHMG1) |

528.8 ± 13.3 μg/g DCW (shake flask culture) |

2014 | Shi et al. (2014) |

| S. cerevisiae | Increasing the gene transcription of MVA pathway, by reducing temperature from 30℃ to 4℃;supplementation of 30 mg/L triclosan, an inhibitor of fatty acid synthesis |

4.94 mg/g DCW (shake flask culture) |

2015 | Sun et al. (2015) |

| S. cerevisiae | Enriching unsaturated fatty acids (UFAs) contents by exogenous supplementation or strengthening their biosynthesis | 2.83 mg/g DCW | 2016 | Sun et al. (2016) |

| S. cerevisiae | Discovery the relationship between carotenoid biosynthesis and cell membrane (CM) fluidity via genome-wide transcriptional analysis as well as optimization of CM fluidity by supplying linoleic acid |

4.65 mg/g DCW (shake flask culture) |

2016 | Liu et al. (2016a) |

| S. cerevisiae | Development of an inducer/repressor-free sequential control strategy regulated by glucose concentration for two-phase cultivation of engineering strains |

20.79 mg/g DCW (fed-batch fermentation) |

2016 | Xie et al. (2015a) |

| S. cerevisiae | Identification and overexpression of novel gene targets outside the isoprenoid pathway, including genes encoding 14–3-3 protein (Bmh1), class E protein of the vacuolar protein-sorting pathway (Did2), translation initiation factor (Tif5), and vacuolar H( +)-ATPase subunit 1 (Voa1) | 5.9 ± 0.1 mg/g DCW | 2017 | Li et al. (2017) |

| S. cerevisiae | Introduction of a beta-carotene biosynthetic pathway containing crtYB, crtI, and crtE from Xanthophyllomyces dendrorhous in a xylose-fermenting S. cerevisiae | 772.8 mg/L | 2020 | Sun et al. (2020) |

| S. cerevisiae | Expression of lipases of LIP2, LIP7, LIP8, and introduction of beta-carotene biosynthetic pathway from Xanthophyllomyces dendrorhous | 46.5 mg/g DCW | 2021 | Fathi et al. (2021) |

| E. coli | Engineering MEP module and β-carotene synthesis module; engineering of ATP synthesis, pentose phosphate pathway (PPP) and TCA modules; |

2.1 g/L 60 mg/g DCW (fed-batch fermentation) |

2013 | Zhao et al. (2013) |

| E. coli | Overexpression of the complete β-carotene synthetic pathway (including dxs, ipiHP1, crtE, crtB, crtI, and crtY genes) and the entire MVA pathway (namely, mvaE, mvaS, mvaK1, mvaK2, mvaD, and idi genes), |

2.47 g/L 72 mg/g DCW (fed-batch culture) |

2013 | Nam et al. (2013) |

| E. coli | Improving the supply of precursor-IPP and GPP by optimization of MEP pathway and introduction of hybrid MVA pathway | 256.8 mg/L in flask culture and 3.2 g/L in fed-batch fermentation | 2014 | Yang and Guo (2014) |

| E. coli | Engineering the cell membrane in both morphological and biosynthetic aspects by overexpressing membrane-bending proteins and engineering the membrane synthesis pathway | 44.2 mg/g DCW (shake flask culture) | 2017 | Wu et al. (2017) |

| E. coli | Knockout of a few proteins related to the formation mechanism of outer membrane vesicles like tolR and nlpI were to promote the excretion of β-carotene; overexpression of both AccABCD and PlsBC to supplement the loss of membrane components | 44.8 mg/g DCW (shake flask cultivation) | 2019 | Wu et al. (2019a) |

| E. coli | Regulation of central carbon metabolism by knockout of zwf and pts genes and improving NADPH supply by overexpression of nadk gene | 266.4 mg/L in flask culture and 2579.1 mg/L in bioreactor fermentation | 2020 | Wu et al. (2020b) |

| E. coli | Integration of systems metabolic engineering, cell morphology engineering, inner- and outer-membrane vesicle formation, and cultivation optimization | 343 mg/L | 2021 | Yang et al. (2021) |

| Yarrowia lipolytica | Optimization of promoter strength and gene copy number |

4 g/L (fed-batch fermentation) |

2017 | Gao et al.( 2017) |

| Yarrowia lipolytica | Development of a combinatorial synthetic biology approach based on Golden Gate DNA assembly to screen the optimum promoter–gene pairs for each transcriptional step |

6.5 g/L 90 mg/g DCW (fed-batch fermentation) |

2018 | Larroude et al. (2018) |

| Yarrowia lipolytica | Promoting the synthesis of precursor substrates by overexpression of hexokinase (Hxk) and hydroxymethylglutaryl-CoA synthase (Erg13) | 2.4 g/L (fed-batch fermentation) | 2020 | Qiang et al. (2020) |

| Yarrowia lipolytica | Construction of codon-adapted CarRA and CarRB and maintaining metabolic balance by regulation of the expression level of enzymes involved in rate-limiting steps | 1.7 g/L and 21.6 mg/g DCW (fed-batch fermentation) | 2021 | Liu et al. (2021b) |

Via multiple strategies such as coordinating the inherent MEP pathway (Yuan et al. 2006) and β-carotene pathway (Zhao et al. 2013), introducing exogenous MVA pathway to increase the supply of precursors (Yang and Guo 2014; Yoon et al. 2009), cofactor engineering (Wu et al. 2020b), increasing membrane biosynthesis (Wu et al. 2017) and changing membrane morphology (Wu et al. 2019a) as well regulation of inner- and outer-membrane vesicle formation (Yang et al. 2021) to alleviate the burden caused by accumulation of hydrophobic macromolecule products on cell membrane, the β-carotene production of E.coli reached as high as 44.8 mg/g DCW. However, concerns such as the food safety of E. coli, the requirement of expensive inducers, and its susceptibility to phage infection, have thus far prevented the commercialization of β-carotene produced by engineered E. coli.

As a generally recognized as safe (GRAS) microorganism, S. cerevisiae has been widely used to produce carotenoids as well as other isoprenoids. In the early stage, the main research focuses were on improving the genetic stability of β-carotene synthetic genes in engineered strains and optimizing culture temperature (Shi et al. 2014; Sun et al. 2015). Overexpression of the rate-limiting enzyme in the MVA pathway and several novel genes outside the isoprenoid pathway and adjustment of the copy number of downstream pathway genes were then employed to balance the synthetic pathway and improve β-carotene production (Li et al. 2017; Yan et al. 2012). Deleting genes in bypassing pathways including lipid, amino acid and ergosterol syntheses, genes encoding transcription factors (e.g., Rox1) that represses many enzymes in the MVA and ergosterol synthesis pathways, as well as some genes involved in the stability of mRNA and protein (Ozaydin et al. 2013) also resulted in increased the accumulation of precursors and further increased final production of β-carotene. In addition, dynamic regulation of the synthetic pathway to separate β-carotene accumulation from cell growth greatly improved β-carotene production (Xie et al. 2015b). Recently, it was found that the synthesis and addition of unsaturated fatty acids also had a significant influence on β-carotene synthesis (Liu et al. 2016a; Sun et al. 2016).

The oleaginous yeast Yarrowia lipolytica has emerged as a promising microbial cell factory, due to its biochemical characteristics such as intrinsic high flux of acetyl-CoA and therefore a native high capacity to accumulate lipid-based chemicals. By strengthening and balancing the biosynthetic pathway (Gao et al. 2017; Larroude et al. 2018; Liu et al. 2021b; Qiang et al. 2020), production of up to 6.5 g/L β-carotene was achieved in Y. lipolytica.

Typical product—astaxanthin

Astaxanthin (3, 3′-dihydroxy-β,β-carotene-4,4′-dione), a red ketocarotenoid belonging to the terpene family, has received intensive attention worldwide due to its strong antioxidant activity and in particular, widespread use as feed additive for farmed salmon. The global market for astaxanthin was valued at USD 1,371.24 million in 2020 and is estimated to increase at an annual growth rate of 16.8% by 2028 (https://www.grandviewresearch.com/industry-analysis/global-astaxanthin-market). In recent years, microbial biosynthesis has emerged as a promising alternative astaxanthin production route to alga extraction and chemical synthesis. As summarized in Table 2, heterologous production of astaxanthin in microorganisms has been achieved in E. coli, S. cerevisiae, Y. lipolytica and Corynebacterium glutamicum 158.

Table 2.

Engineering microorganisms for astaxanthin production

| Strain | Strategy | Cultivation mode | Astaxanthin yield | Refs. |

|---|---|---|---|---|

| E. coli | Gene screening (four CrtZ and twelve CrtW genes) and gene combination | Shake flask |

1.99 mg/g DCW |

Scaife et al. (2012) |

| E. coli | Genomic integration (crtE, crtB, crtI, crtY and crtZ genes from P. ananatis as well as crtW148 gene from N. punctiforme PCC 73102) and promoter engineering | Shake flask |

1.4 mg/g DCW |

Lemuth et al. (2011) |

| E. coli | Optimization of gene expression via ribosome-binding site combinatorics | Shake flask |

5.8 mg/g DCW |

Zelcbuch et al. (2013) |

| E. coli | Gene mining of CrtE and CrtZ genes from Sphingomonas sp. ATCC 55669 | Shake flask |

6.6 mg/g DCW |

Ma et al. (2016) |

| E. coli | Combinatorial expression of different β-carotene ketolase and ketolases | Shake flask |

7.4 ± 0.3 mg/g DCW |

Lu et al. (2017) |

| E. coli | Pathway engineering- metabolic engineering of DXP pathway by introduction of genes from Kocuria gwangalliensis, as well as introduction of astaxanthin downstream biosynthetic pathway from Paracoccus haeundaensis | Shake flask |

1100 μg/g DCW |

Jeong et al. (2018) |

| E. coli | Optimization of gene codon, promoters, strain species and culture media | Shake flask |

4.30 ± 0.23 mg/g DCW 24.16 ± 2.03 mg/L |

Li and Huang (2018) |

| E. coli | Comprehensive metabolic engineering, consisting of optimization of β-carotene biosynthetic pathway, introduction of CrtZ from Pantoea ananatis and CrBKT from Chlamydomonas reinhardtii, truncation of CrBKT, culture condition optimization, strengthening of DXP pathway and uptake of glycerol, introduction of hok/sok system for improving the stability of hereditary stability | Fed-batch fermentation |

432.82 mg/L |

Park et al. (2018) |

| E. coli | Optimization of the localization of CrtZ and CrtW enzymes; a total of 215.4% improved production of astaxanthin was achieved by combining CrtZ and CrtW together with a linker and locating them on the cell membrane | Shake flask | No clear data | Ye et al. (2018) |

| E. coli | Multidimensional heuristic process was proposed to optimization of the long astaxanthin biosynthetic pathway, via inter-module balance by varying promoter strength and intra-module balance by using different RBSs | Shake flask |

15.1 mg/g DCW 320 mg/L |

Zhang et al. (2018b) |

| E. coli | Optimization of gene expression by using different inducible and constitutive promoters | Shake flask | 8.3 mg/g DCW | Chou et al. (2019) |

| E. coli | Optimization of cell morphology and oxidative stress for increasing astaxanthin yield, via gene mining and gene deletion. A complementary temperature-sensitive plasmid was introduced to further balance cell growth and production accumulation | Fed-batch fermentation | 432.82 mg/L | Lu and Liu (2019) |

| E. coli | Gene fusion of CrtW and CrtZ | Shake flask | 576.4 μg/g DCW | Nogueira et al. (2019) |

| E. coli | Assembly of the key enzymes in the MVA pathway (ACAT, HMGS, HMGR) into multi-enzyme complexes via orthogonal protein reactions (SpyCatcher/SpyTag and SnoopCatcher/SnoopTag pairs) | Shake flask | 1 mg/g DCW | Qu et al. (2019) |

| E. coli | Gene screening and enzyme fusion of CrtZ and CrtW, replacement of different linkers, carbon source optimization | Shake flask |

26.16 mg/L (5.18 mg/g DCW) |

Wu et al. (2019b) |