Abstract

Assessing the quality of fuel is essential to comprehend its impact on the environment and human health. In this study, the evaluation of fuel quality standards at the consumer level was conducted by analyzing the motor fuels in Khulna, Bangladesh. A total of 32 samples of petrol (regular gasoline), and octane (premium gasoline) were collected from the fuel stations in the Khulna City Corporation area and analyzed with an FTIR-Fuel Analyzer. Fuel properties, such as research octane number (RON), motor octane number (MON), ethanol content, olefins content, and oxygen content were analyzed. For petrol, the average RON, MON, olefins, and oxygen content were 95.34, 85.70, 8.23 %v/v, and 0.78 %m/m, respectively, and for octane, they were 96.96, 85.39, 1.25 %v/v, and 0.09 %m/m, respectively. Almost all of these parameters complied with both Bangladesh standard and Euro 5 fuel specifications, and those that did not comply were very close to their standard values. However, benzene concentration, which was not specified in Bangladesh Standard, was the most alarming metric for octane since none of the samples matched the Euro 5 fuel specifications of the maximum concentration of 1 %v/v benzene; on average it was 3.70 %v/v. Although petrol benzene content (average 1.50 %v/v) was not as bad as it was for octane, it was still nowhere near good enough, with only 25% of the samples within the recommended level among the studied sample. This information holds significance in establishing the fuel profile and facilitating the identification of distinct samples linked to adulteration. Therefore, the analysis of motor fuel qualities is essential for maintaining the environment, human health, and the economy of a country.

Keywords: Environment, Fuel quality, Gasoline, Health, Octane, Petrol

1. Introduction

The quality and performance of various fuels: gasoline, diesel, biofuels, and jet fuel, directly impact energy production, transportation, industrial development, agricultural production, and other sectors. Oils account for approximately one-third of the total global energy production and 36% of the total global CO2 emission annually [1]. Among petroleum oils, gasoline is one of the most used fuels in motor vehicles. Properties such as volatility, ignition quality, viscosity, gravity, and stability are used to characterize these fuels. Fuel quality is necessary for determining how the chemical composition of motor fuel influences its physical properties and the pollutants produced by the engine by burning the fuel as a whole. Vehicle exhausts have long been a source of worry because of their negative impact on human health and vehicles emit toxic and harmful pollutants at a height that is within the breathing zone of humans [2]. The harmful emissions from vehicles can be controlled by controlling the composition and property of the fuel. Ensuring the fuel ignites fast and burns thoroughly can help increase engine performance and efficiency, and decreasing the quantity of sulfur and other toxic chemicals in gasoline may aid in lowering pollution and greenhouse gas emissions.

Any fuel must follow the quality standards set for local markets to satisfy engine specifications, and produce minimal environmental and health hazards. Before commercializing, some physicochemical properties of the motor fuel, including density, Research Octane Number (RON), Motor Octane Number (MON), Anti-Knock Index (AKI), oxygen content, and BTEX (benzene, toluene, ethylbenzene, and xylenes) content, must be analyzed. In the petroleum industry, standard test methods, specifications, and practices are developed under the jurisdiction of the ASTM D2 Committee on Petroleum and Petroleum Products, the ISO TC28 Technical Committee on Petroleum Products, and Euro 5. In Bangladesh, Bangladesh Standards and Testing Institution (BSTI) specifications [3,4] are solely followed.

The anti-knock quality or auto-ignition of fuel is a significant factor characterized by two parameters: RON and MON. Many researchers have studied the impact of RON, and it is generally accepted that a higher RON improves engine thermal efficiency [5,6]. Nonetheless, several studies have found that a fuel with a low MON has superior anti-knock properties, especially when auto-ignition is expected [6,7]. AKI is the simple mean or average of the RON and the MON.

Oxygenates are oxygen-containing organic fuel additives that enhance the performance of an Internal Combustion (IC) engine by increasing the octane number of petrol [[8], [9], [10]]. It is also used to reduce air pollution by enhancing fuel combustion and thereby reducing exhaust emissions of carbon monoxide (CO) [9]. Utilizing oxygenated fuel in SI engines can reduce environmental pollution, boost the agricultural economy, and reduce the need for gasoline [11]. Furthermore, oxygenates reduce the level of highly toxic aromatics like benzene, toluene, ethylbenzene, and xylenes in gasoline [9]. Oxygenates consist of compounds like ethanol, methanol, Methyl Tert-Butyl Ether (MTBE), Ethyl Tertiary-Butyl Ether (ETBE), Tertiary Butyl Alcohol (TBA), and Tertiary Amyl Methyl Ether (TAME), which contain oxygen in their structure [12]. Among these oxygenates, MTBE is currently the most widely used oxygenate and it could be carcinogenic if the concentration is high enough, e.g., for people working in refueling stations [8,9]. Furthermore, high solubility in water, hazardous effects, and breakdown products that have raised environmental concerns have restricted the use of MTBE [10,13]. Human exposure to methanol has been extensively studied in scientific literature [[14], [15], [16], [17], [18]]. Methanol poisoning from vehicle emissions and fuels results primarily from inhalation or dermal contact with methanol, which may cause metabolic acidosis, visual dysfunction (including permanent blindness), mental disorders, parkinsonism, and even death [[16], [17], [18], [19], [20], [21], [22]].

Gasoline is a highly flammable, volatile mixture containing paraffins, olefins, and aromatics. High olefin contents in gasoline enhance gum formation, which could be deposited on car filters and distribution lines and make the fuel less stable [23]. On the contrary, exposure to benzene can have carcinogenic health impacts like leukemia and a variety of non-carcinogenic health impacts linked to functioning abnormalities of key bodily systems like the immunological, neurological, endocrine, cardiovascular, and respiratory systems [24,25]. Studies show that exposure to toluene results in respiratory difficulties, including asthma and cardiovascular diseases [26,27]. Ethylbenzene exposure causes low birth weight and damages the immune systems of both adults and children [28]. Xylenes are another aromatic hydrocarbon that also causes developmental, immunological, and respiratory diseases with prolonged exposure [29,30]. The effect of BTEX results in hormonal imbalance, respiratory dysfunction, cardiovascular diseases, asthma, and many more irregularities in the human body [31]. Through gas-to-particle conversion mechanisms, BTEX pollutants can produce secondary pollutants such as ozone and secondary aerosol [32]. The toxic effects of benzene and other aromatic hydrocarbons are widely investigated in a broader range of literature [26,[33], [34], [35]].

Despite the risks different components of liquid fuels might pose, published work on quality analysis of motor fuels in Bangladesh was not found. However, there are many investigations on fuel quality on a global scale. In northern China, the sulfur level of market fuels has been examined to look into the quality of automobile gasoline [36]. It has been found that adding organic solvents (light, heavy, and aromatic hydrocarbons) to Brazilian petrol on a regular basis has a negative impact on the quality of the fuel [37]. The sulfur content was also analyzed for both diesel and gasoline fuel in different parts of India [38]. In the European Union region, nationwide fuel quality monitoring was conducted in the year 2020 to mitigate climate change and environmental pollution [39]. In addition, fuel testing was conducted in America, Japan, Pakistan, Ukraine, the UK, and many other countries to mitigate climate change and establish effective fuel compliance programs [[40], [41], [42], [43], [44]].

As no literature has been published at the time of writing this article on the quality of conventional motor fuels used in Bangladesh at consumer levels, this article aimed to test two conventional liquid motor fuels: petrol (regular gasoline), and octane (premium gasoline) in the Khulna City Corporation (KCC) area for the first time in Bangladesh, and to detect and measure different fuel parameters, and the presence of different components that can be potentially harmful to engines, the environment, and public health. Furthermore, the fuel parameters were analyzed and compared with the Bangladesh standard (BDS) specifications [3,4] and Euro 5 fuel specifications [45]. As the three dealers who distribute these fuels all over the country and in KCC are the same, these statistics are representative of the whole of Bangladesh's marketplace to some extent. This article may help the crude oil importers in deciding which type of crude oil is to be imported, the policymakers in making environmental policy considering the impact of different fuel parameters, and the consumers in deciding which fuel they should buy.

2. Materials and methods

The fuel analysis procedure consists of three steps. At first, motor fuel samples were collected from 16 fuel refilling stations (locally known as oil pumps) of KCC. Then, the collected samples were tested, and finally, the obtained results were analyzed and compared with the BDS and Euro 5 fuel specifications.

2.1. Fuel sample collection

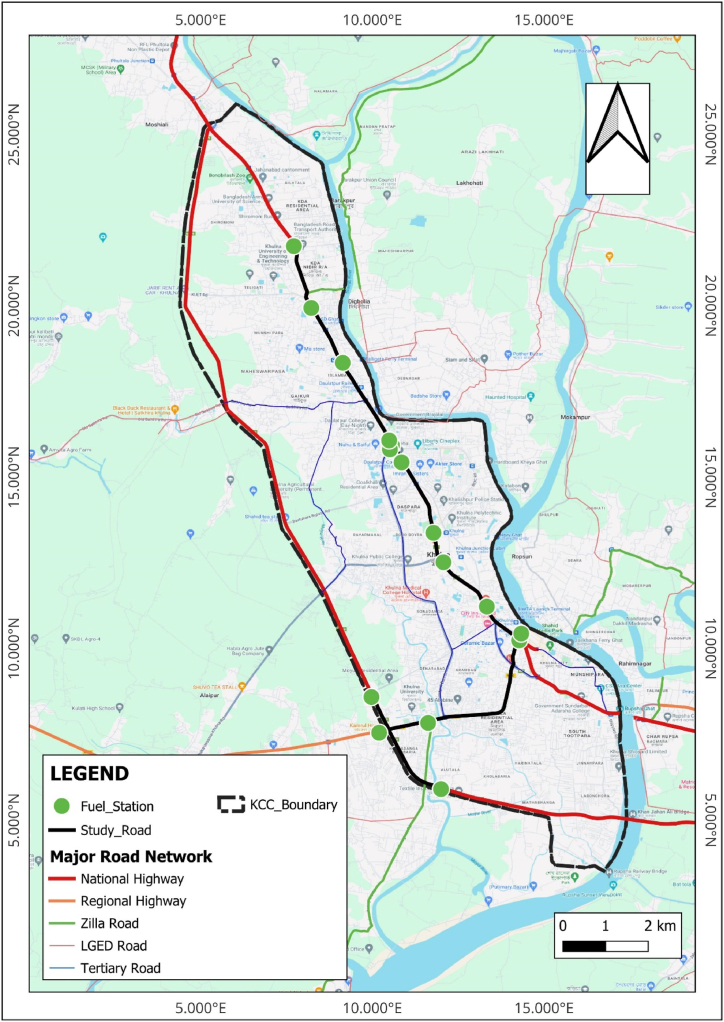

As the case study region was KCC, the fuel refilling stations of the KCC region were selected to collect the fuel samples. Samples were collected from 16 fuel stations. Among these fuel stations, fuel stations 1 to 5 collect their fuels from Distributor A, 6 to 12 from Distributor B, and the rest from Distributor C. The fuel samples included one petrol (regular gasoline) sample and one octane (premium gasoline) sample from each of the 16 fuel stations. The fuel samples number and their corresponding fuel station number are identical, i.e. sample 5 of petrol and sample 5 of octane were both collected from fuel station 5, and so on. The study area and locations of the samples collected are shown in Fig. 1.

Fig. 1.

Fuel sample collection points.

2.2. Fuel testing

The fuel properties were tested using the Eraspec FTIR fuel analyzer. Before starting any sample test, rinsing was done. At first, the fuel analyzer was rinsed by air, followed by rinsing with the sample, which consumed approximately 10 mL of the sample. To test the sample, 12 mL of the sample was needed. The fuel analyzer used the latest ASTM standards to determine various fuel parameters. For octane and petrol sample analysis, the analyzer used the ASTM D5845 methods. The analyzer was calibrated from time to time during the experiment. It used FTIR to determine different parameters of the fuel samples. In addition, it used cluster analysis (CA) and multilinear regression (MLR) analysis methods to determine various properties of the fuel.

3. Results and discussion

The densities of the samples varied between 0.723 and 0.779 g/cm3 for petrol and 0.760–0.795 g/cm3 for octane (Table 1). In this study, all tested properties of petrol and octane complied with their respective BDS Specifications [3,4], except for one sample of octane when it was tested for RON. By contrast, when the tested values were compared with a more stringent regulation − Euro 5 fuel specifications, which is in effect in the European Union zone, the test results of many samples did not meet the standard.

Table 1.

Different properties of petrol and octane.

| Properties | Petrol (Gasoline – Regular) |

Octane (Gasoline – Premium) |

Euro 5 |

|||||

|---|---|---|---|---|---|---|---|---|

| Mina | Maxa | Mean ± SDa | Mina | Maxa | Mean ± SDa | Mina | Maxa | |

| Density at 15 °C (g/cm3) | 0.723 | 0.779 | 0.744 ± 0.013 | 0.760 | 0.795 | 0.783 ± 0.008 | – | – |

| RONb | 90.50 | 96.40 | 95.34 ± 1.34 | 94.70 | 98.20 | 96.96 ± 0.86 | 95 | – |

| MONb | 85.20 | 86.60 | 85.70 ± 0.33 | 84.10 | 87 | 85.39 ± 0.79 | 85 | – |

| AKI | 90.10 | 91.50 | 90.68 ± 0.34 | 89.40 | 92.60 | 91.17 ± 0.81 | 90 | – |

| Ethanol (%v/v) | 0 | 0.36 | 0.07 ± 0.13 | 0 | 0.47 | 0.07 ± 0.14 | – | 5 |

| Benzene (%v/v) | 0.83 | 2.95 | 1.50 ± 0.66 | 2.88 | 4.64 | 3.70 ± 0.45 | – | 1 |

| BTEX (%v/v) | 12.50 | 29.70 | 20.21 ± 5.82 | 31.50 | 52 | 42.89 ± 5.02 | – | – |

| Olefins (%v/v)2 | 2.90 | 14 | 8.23 ± 3.49 | 0.70 | 2.40 | 1.25 ± 0.51 | – | 18 |

| Oxygenates (%v/v) | 1.53 | 6.56 | 4.22 ± 1.83 | 0 | 2.03 | 0.38 ± 0.60 | – | – |

| Oxygen (%m/m) | 0.33 | 1.20 | 0.78 ± 0.32 | 0 | 0.35 | 0.09 ± 0.13 | – | 2.7 |

| MTBE (%v/v) | 1.25 | 6.56 | 4.15 ± 1.92 | 0 | 2.03 | 0.87 ± 0.73 | – | – |

Total number of samples = 32.

Max = Maximum, Min = Minimum, SD = Standard Deviation.

These values were calculated by implementing MLR.

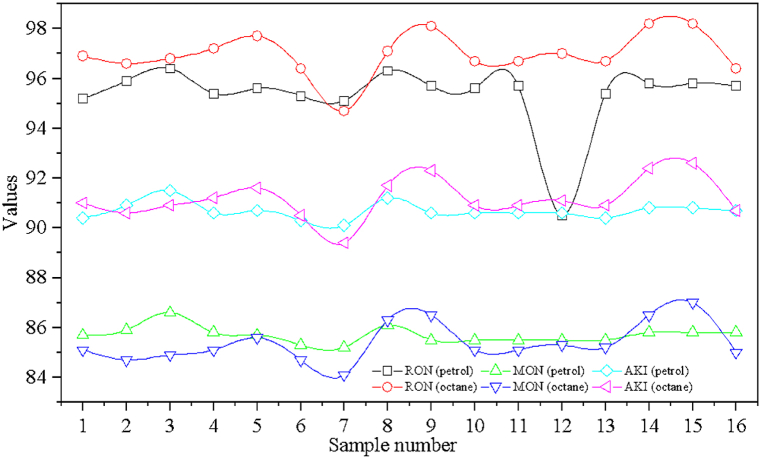

The average value of RON was 95.34 for petrol, and a slightly higher value of 96.84 was obtained for octane. On the other hand, the average MON was 85.70 for petrol and 85.26 for octane, as shown in Table 1. The highest RON (96.40) and MON (86.60) were found in sample 3 for petrol, whereas for octane, the highest RON (98.20) was in samples 14 and 15, and MON (87) was in sample 15. In all samples but sample 4, RON was higher for octane than for petrol (Fig. 2). Since octane is the premium version of gasoline with a higher price, it should have better efficiency and knock resistance than petrol, the regular version of gasoline. Hence, higher RON values for octane than regular petrol are to be expected since it is generally accepted that higher RON enhances the thermal efficiency of an engine and its anti-knock properties [5,6,46,47]. In addition, of the few parameters that are specified in Bangladesh Standard, RON is one, with a minimum of 89 for petrol, and 95 for octane. However, the result was the opposite for MON; in 81.25% of samples, petrol had a higher MON compared to octane. This might be due to the fact that both higher RON and increased fuel sensitivity (RON – MON) can lead to decreased fuel consumption and enhanced thermal efficiency of the engine [48]. Therefore, a lower MON and a higher RON are better considering the fuel consumption and engine efficiency. This may be the reason why octane, the premium version of gasoline, usually had higher RON but lower MON than petrol (regular gasoline). Another reason for lower MON in octane samples could be that when autoignition is expected, low MON shows superior anti-knock properties [6,7]. Therefore, a lower MON value in octane than in petrol improves the auto-ignition engine's anti-knocking performance. Moreover, the significance of MON in contemporary gasoline engines has been called into question over the past decades, and some investigators even found that higher MON is detrimental to modern engines [[49], [50], [51], [52]]. Additionally, the BDS [3,4] does not have any specified MON value, which is why fuel refilling stations and refineries might be ignoring MON and solely focusing on RON. As for AKI, three-quarters of the octane samples showed a greater AKI value than petrol's (Fig. 2). Around 93% of samples of both petrol and octane complied with the standard RON of Euro 5 fuel specifications. All petrol samples had MON values higher than the Euro 5 fuel specifications minimum standard value of 85, whereas only 75% of octane samples had MON of at least 85.

Fig. 2.

RON, MON, and AKI for petrol and octane samples.

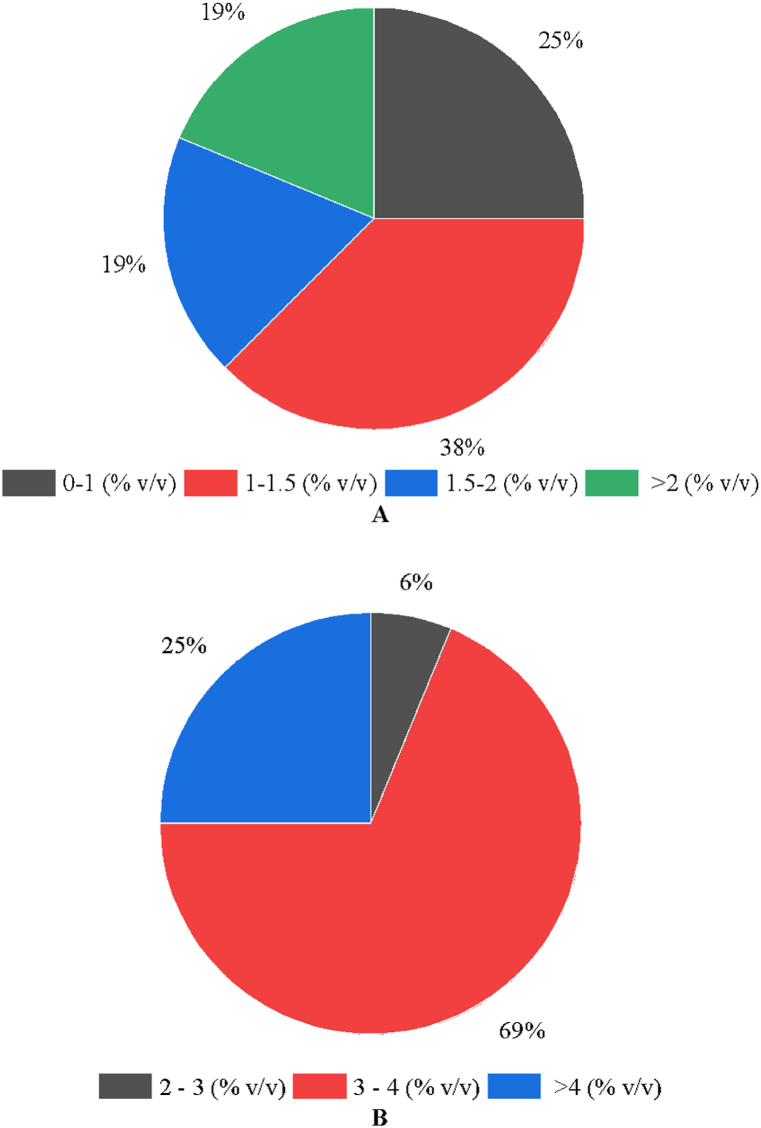

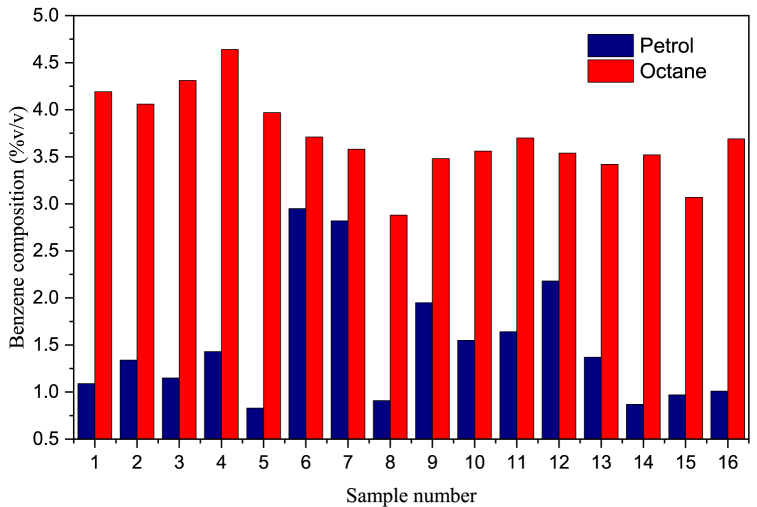

According to Fig. 3(A), the benzene content of 75% of the petrol samples and according to Fig. 3(B), all of the octane samples exceeded the standard 1 %v/v according to the Euro 5 fuel specifications. However, there was no specified value for benzene content in Bangladesh standards [3,4]. The average benzene composition in petrol was 1.50 % v/v, whereas it was 3.70 % for octane (Table 1). The maximum benzene content of 4.64 %v/v was found in sample 4 of octane, and the highest benzene concentration in petrol at 2.95 %v/v was found in sample 6 of petrol (Fig. 4). As depicted in Fig. 4, benzene concentration was greater in octane than in gasoline in every sample. As benzene increases the RON of gasoline, maybe that was why octane samples were rich in benzene compared to petrol. However, benzene is harmful to both the environment and human health. It may cause carcinogenic health issues like leukemia, and noncarcinogenic abnormalities in the immunological, neurological, endocrine, cardiovascular, and respiratory systems [24,25]. Therefore, this high benzene content may pose significant carcinogenic and noncarcinogenic health risks to the population of Bangladesh, specifically the consumers, and the fuel station workers.

Fig. 3.

Benzene composition distribution in Petrol (A), and Octane (B).

Fig. 4.

Benzene composition in petrol and octane.

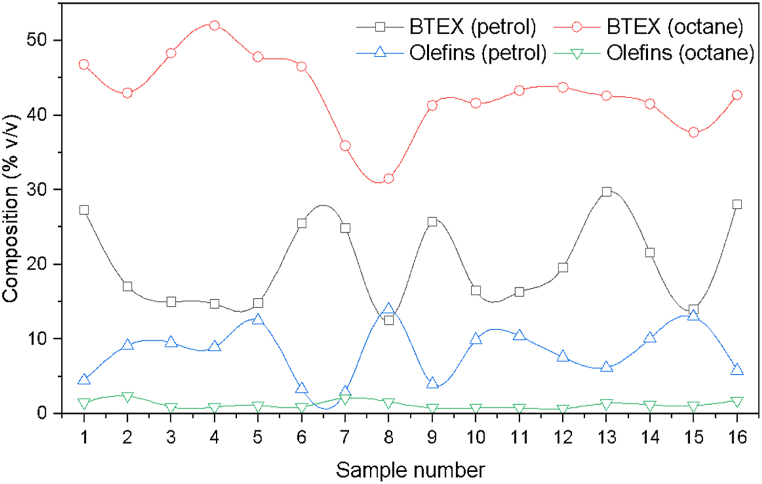

Fig. 5 and Table 1 demonstrate that the olefin concentrations for petrol and octane were within the standard value of 18 %v/v (maximum) according to the Euro 5 fuel specifications. BDS, on the other hand, does not have any specified olefins content. In octane, BTEX content was between 31.5 and 52 %v/v; in petrol, it was much leaner (12.5–29.7 %v/v). The average BTEX content was more than double in octane samples (mean 42.89 %v/v), compared to petrol's (mean 20.21 %v/v). Instead of considering the whole aromatics contents, if only BTEX is taken into consideration, 93.75% of the octane samples violated the Euro 5 fuel specifications' standard for aromatics (35 %v/v aromatics, max). The only sample whose BTEX content did not violate the aromatics limit had a BTEX content of 31.5 %v/v. However, this sample could violate the standard value if other aromatics' (aromatics other than BTEX) content were greater than 3.5 %v/v. The high aromatics content, perhaps, was used to increase the octane numbers of the octane (premium gasoline). Albeit BTEX contents in petrol samples were lower than 35 %v/v, it was not impossible to violate the Euro 5 standard for aromatics if other aromatics contributed significantly to increase the value to over 35 %v/v. In all samples, BTEX content was considerably higher in octane than in petrol, and it might be due to the fact that aromatics increase the RON of fuels. By contrast, the scenario for olefin was the opposite, where in all samples olefin quantities in petrol were consistently greater than in octane. As olefins are not good for fuel stability and also enhance the probability of gum formation [23], perhaps for these the olefin content in octane was kept lower. A minor amount of naphthalene was also present in some of the petrol (0.17–0.35 %v/v) and octane samples (0–0.23 %v/v).

Fig. 5.

Composition of BTEX and olefins in petrol and octane.

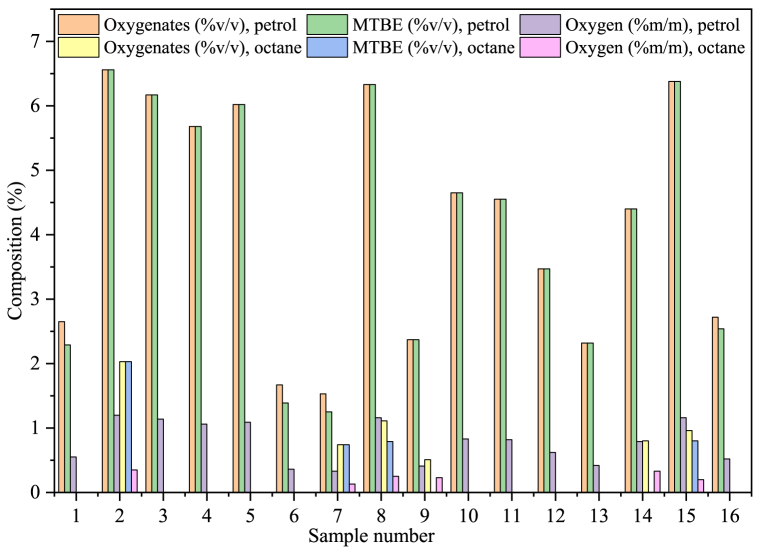

Oxygenates and oxygen contents were considerably higher in petrol than in octane, which is evident in Fig. 6. No samples exceeded the Euro 5 standard value of 2.7 %m/m (maximum) oxygen content. However, there was no specified oxygen or oxygenate content in Bangladesh standards [3,4]. In most octane samples, there was no oxygen content in them (Fig. 6). The average oxygen content was 0.78 %m/m for petrol and 0.09 %m/m for octane (Table 1). Although oxygenates reduce harmful emissions, oxygenates differ from gasoline; generally, their heating values are lower than gasoline [11], eventually decreasing fuel mileage. Perhaps, that is why the refineries and fuel stations are disinclined to add oxygenates in their premium gasoline, combined with the fact that Bangladesh has no standard for oxygen or oxygenate content in gasoline. The oxygenate present in the fuel was primarily MTBE and a minor amount of ethanol in a few samples. In two samples of octane, a trace amount of methanol (0.33 %v/v) was detected in both samples. However, in petrol samples, there was no detectable methanol.

Fig. 6.

Oxygenates, MTBE, and oxygen concentration in petrol and octane.

4. Conclusion

In this research work, the quality of vehicle fuels (petrol and octane) was analyzed. All of the analyzed fuel parameters complied with Bangladesh standards, except one octane sample, whose RON value was 94.70, slightly below the recommended minimum RON of 95. For petrol, the average RON and MON were 95.34 and 85.70, respectively, and for octane, they were 96.96 and 85.39, respectively. Moreover, all of the tested samples' olefins content, ethanol content, and oxygen content for both petrol and octane complied with the Euro 5. However, the benzene content of all of the octane samples (2.88 − 4.64 %v/v) and 75% of the petrol samples (0.83 − 2.95 %v/v) exceeded the Euro 5 standard benzene content of 1 %v/v (max). Also, a higher concentration of benzene was found in all of the octane samples than in petrol's. This high benzene content may damage the environment and cause different health issues. Compared to petrol, octane was also very rich in aromatic compounds, BTEX. It varied from 12.50 to 29.70 %v/v in petrol, and 31.50 to 52 %v/v in octane.

It is surprising that even when the distributor was the same, the test results were not the same, rather it varied greatly. It could be due to the different sources of crude oil and their refining process. However, there are no standard values for many parameters in Bangladesh standards, such as aromatics or benzene. Therefore, the Bangladesh government should adopt standards like Euro 5 fuel specifications at least for the aromatic and benzene content in Bangladesh, considering the detrimental impact these fuel components may have on the environment and human health, and ensure that the standards are being followed.

In this study, 32 samples were analyzed and only the KCC region was the study area. More samples from all over the country are required for a better representation of the overall scenario. Also, the fuel composition variation from time to time needs to be considered. In future work, these things can be considered and other fuel types can also be added for study.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

All data required to support this study is already mentioned in the manuscript.

CRediT authorship contribution statement

Shuvashish Mondal: Writing – review & editing, Writing – original draft, Validation, Methodology, Investigation, Conceptualization. Md Hafijur Rahman Sabbir: Writing – original draft, Investigation. Md Rashedul Islam: Investigation, Writing – original draft. Md Faisal Ferdous: Writing – original draft, Methodology, Conceptualization. Md Mahmudul Hassan Mondol: Writing – review & editing, Writing – original draft, Supervision. Md Jahangir Hossain: Writing – original draft.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

The authors are grateful to the KUET authority for their technical support to conduct the research properly.

References

- 1.Maliha A., Abu-Hijleh B. A review on the current status and post-pandemic prospects of third-generation biofuels. Energy Systems. 2022:1–32. doi: 10.1007/S12667-022-00514-7/FIGURES/13. [DOI] [Google Scholar]

- 2.Liu X., Wang Y., Zhu R., Wei Y., Hu J. Complex temperature dependence of vehicular emissions: Evidence from a global meta-analysis. Environ. Res. 2023;237 doi: 10.1016/j.envres.2023.116890. [DOI] [PubMed] [Google Scholar]

- 3.BSTI, Bangladesh . BSTI; Dhaka: 2019. Standard-Specification for Unleaded Motor Gasoline-Regular (Fifth Revision) [Google Scholar]

- 4.BSTI, Bangladesh . BSTI; Dhaka: 2010. Standard-Specification for Unleaded Motor Gasoline-Premium (Fourth Revision) [Google Scholar]

- 5.Binjuwair S., Mohamad T.I., Almaleki A., Alkudsi A., Alshunaifi I. The effects of research octane number and fuel systems on the performance and emissions of a spark ignition engine: a study on Saudi Arabian RON91 and RON95 with port injection and direct injection systems. Fuel. 2015;158:351–360. doi: 10.1016/j.fuel.2015.05.041. [DOI] [Google Scholar]

- 6.Nakata K., Uchida D., Ota A., Utsumi S., Kawatake K. JSAE/SAE International Fuels & Lubricants Meeting. 2007. The impact of RON on SI engine thermal efficiency. 2007-01–2007. [DOI] [Google Scholar]

- 7.Prakash A., Cracknell R., Natarajan V., Doyle D., Jones A., Jo Y.S., Hinojosa M., Lobato P. Understanding the octane appetite of modern vehicles. SAE International Journal of Fuels and Lubricants. 2016;9:345–357. doi: 10.4271/2016-01-0834. [DOI] [Google Scholar]

- 8.Li D., Han X. Methyl tert-butyl ether. Reproductive and Developmental Toxicology. 2011:617–621. doi: 10.1016/B978-0-12-382032-7.10046-3. [DOI] [Google Scholar]

- 9.Lim C.-S., Lim J.-H., Cha J.-S., Lim J.-Y. Comparative effects of oxygenates-gasoline blended fuels on the exhaust emissions in gasoline-powered vehicles. J. Environ. Manag. 2019;239:103–113. doi: 10.1016/j.jenvman.2019.03.039. [DOI] [PubMed] [Google Scholar]

- 10.Yee K.F., Mohamed A.R., Tan S.H. A review on the evolution of ethyl tert-butyl ether (ETBE) and its future prospects. Renew. Sustain. Energy Rev. 2013;22:604–620. doi: 10.1016/j.rser.2013.02.016. [DOI] [Google Scholar]

- 11.Awad O.I., Mamat R., Ibrahim T.K., Hammid A.T., Yusri I.M., Hamidi M.A., Humada A.M., Yusop A.F. Overview of the oxygenated fuels in spark ignition engine: environmental and performance. Renew. Sustain. Energy Rev. 2018;91:394–408. doi: 10.1016/j.rser.2018.03.107. [DOI] [Google Scholar]

- 12.Magnusson R., Nilsson C. The influence of oxygenated fuels on emissions of aldehydes and ketones from a two-stroke spark ignition engine. Fuel. 2011;90:1145–1154. doi: 10.1016/J.FUEL.2010.10.026. [DOI] [Google Scholar]

- 13.Da Silva R., Cataluña R., De Menezes E.W., Samios D., Piatnicki C.M.S. Effect of additives on the antiknock properties and Reid vapor pressure of gasoline. Fuel. 2005;84:951–959. doi: 10.1016/J.FUEL.2005.01.008. [DOI] [Google Scholar]

- 14.Souza F.G.T., Nogueira V.V.E., Maynart L.I., de Oliveira R.L., Mendonça T.C. dos S., Oliveira P.D. Optic neuropathy toxic after methanol inhalation. Rev. Bras. Oftalmol. 2018;77:47–49. [Google Scholar]

- 15.Zhen X., Wang Y. An overview of methanol as an internal combustion engine fuel. Renew. Sustain. Energy Rev. 2015;52:477–493. doi: 10.1016/j.rser.2015.07.083. [DOI] [Google Scholar]

- 16.Nekoukar Z., Zakariaei Z., Taghizadeh F., Musavi F., Banimostafavi E.S., Sharifpour A., Ebrahim Ghuchi N., Fakhar M., Tabaripour R., Safanavaei S. Methanol poisoning as a new world challenge: a review. Annals of Medicine and Surgery. 2021;66 doi: 10.1016/J.AMSU.2021.102445. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Ma Z., Jiang H., Wang J. Clinical analysis of severe visual loss caused by inhalational methanol poisoning in a chronic process with acute onset: a retrospective clinical analysis. BMC Ophthalmol. 2019;19:124. doi: 10.1186/s12886-019-1127-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Mojica C.V., Pasol E.A., Dizon M.L., Kiat W.A., Lim T.R.U., Dominguez J.C., Valencia V.V., Tuaño B.J.P. Chronic methanol toxicity through topical and inhalational routes presenting as vision loss and restricted diffusion of the optic nerves on MRI: a case report and literature review. ENeurologicalSci. 2020;20 doi: 10.1016/j.ensci.2020.100258. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Choi J.-H., Lee S.K., Gil Y.-E., Ryu J., Jung-Choi K., Kim H., Choi J.Y., Park S.A., Lee H.W., Yun J.Y. Neurological complications resulting from non-oral occupational methanol poisoning. J. Kor. Med. Sci. 2016;32:371–376. doi: 10.3346/jkms.2017.32.2.371. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Kumar P., Gogia A., Kakar A., Miglani P. An interesting case of characteristic methanol toxicity through inhalational exposure. J. Fam. Med. Prim. Care. 2015;4:470. doi: 10.4103/2249-4863.161359. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Mohammed W.B., Tarabzouni S., Bohlega S. Methanol-induced parkinsonism and cerebral vasculopathy due to perfume inhalation. BMJ Neurol Open. 2022;4 doi: 10.1136/bmjno-2021-000221. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Shen H., Zhong L.X., Fu Y., Shao W., Yang Y., Wang Z., Yang H. Factors affecting the severity and prognosis of visual damage in inhalational methanol poisoning. Front. Med. 2023;10 doi: 10.3389/fmed.2023.1098138. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Pereira R.C.C., Pasa V.M.D. Effect of mono-olefins and diolefins on the stability of automotive gasoline. Fuel. 2006;85:1860–1865. [Google Scholar]

- 24.Bahadar H., Mostafalou S., Abdollahi M. Current understandings and perspectives on non-cancer health effects of benzene: a global concern. Toxicol. Appl. Pharmacol. 2014;276:83–94. doi: 10.1016/j.taap.2014.02.012. [DOI] [PubMed] [Google Scholar]

- 25.Weisel C.P. Benzene exposure: an overview of monitoring methods and their findings. Chem. Biol. Interact. 2010;184:58–66. doi: 10.1016/j.cbi.2009.12.030. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Xu X., Freeman N.C., Dailey A.B., Ilacqua V.A., Kearney G.D., Talbott E.O. Association between exposure to alkylbenzenes and cardiovascular disease among national health and nutrition examination survey (NHANES) participants. Int. J. Occup. Environ. Health. 2009;15:385–391. doi: 10.1179/oeh.2009.15.4.385. [DOI] [PubMed] [Google Scholar]

- 27.Rumchev K. Association of domestic exposure to volatile organic compounds with asthma in young children. Thorax. 2004;59:746–751. doi: 10.1136/thx.2003.013680. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Ghosh J.K.C., Wilhelm M., Su J., Goldberg D., Cockburn M., Jerrett M., Ritz B. Assessing the influence of traffic-related air pollution on risk of term low birth weight on the basis of land-use-based regression models and measures of air toxics. Am. J. Epidemiol. 2012;175:1262–1274. doi: 10.1093/aje/kwr469. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Rolle-Kampczyk U.E., Rehwagen M., Diez U., Richter M., Herbarth O., Borte M. Passive smoking, excretion of metabolites, and health effects: results of the Leipzig's Allergy risk study (LARS) Arch. Environ. Health. 2002;57:326–331. doi: 10.1080/00039890209601416. [DOI] [PubMed] [Google Scholar]

- 30.Saijo Y., Kishi R., Sata F., Katakura Y., Urashima Y., Hatakeyama A., Kobayashi S., Jin K., Kurahashi N., Kondo T., Gong Y.Y., Umemura T. Symptoms in relation to chemicals and dampness in newly built dwellings. Int. Arch. Occup. Environ. Health. 2004;77:461–470. doi: 10.1007/s00420-004-0535-0. [DOI] [PubMed] [Google Scholar]

- 31.Bolden A.L., Kwiatkowski C.F., Colborn T. New look at BTEX: are ambient levels a problem? Environmental Science & Technology. 2015;49:5261–5276. doi: 10.1021/es505316f. [DOI] [PubMed] [Google Scholar]

- 32.Dehghani M., Fazlzadeh M., Sorooshian A., Tabatabaee H.R., Miri M., Baghani A.N., Delikhoon M., Mahvi A.H., Rashidi M. Characteristics and health effects of BTEX in a hot spot for urban pollution. Ecotoxicol. Environ. Saf. 2018;155:133–143. doi: 10.1016/j.ecoenv.2018.02.065. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Aguilera I., Garcia-Esteban R., Iñiguez C., Nieuwenhuijsen M.J., Rodríguez À., Paez M., Ballester F., Sunyer J. Prenatal exposure to traffic-related air pollution and ultrasound measures of fetal growth in the INMA sabadell cohort. Environmental Health Perspectives. 2010;118:705–711. doi: 10.1289/ehp.0901228. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Gluckman P.D., Pinal C.S. Regulation of fetal growth by the somatotrophic Axis. J. Nutr. 2003;133:1741S–1746S. doi: 10.1093/jn/133.5.1741S. [DOI] [PubMed] [Google Scholar]

- 35.Triggiani M., Loffredo S., Granata F., Staiano R.I., Marone G. Modulation of mast cell and Basophil functions by benzene metabolites. Curr. Pharmaceut. Des. 2011;17:3830–3835. doi: 10.2174/138161211798357863. [DOI] [PubMed] [Google Scholar]

- 36.Zhang K., Hu J., Gao S., Liu Y., Huang X., Bao X. Sulfur content of gasoline and diesel fuels in northern China. Energy Pol. 2010;38:2934–2940. doi: 10.1016/j.enpol.2010.01.030. [DOI] [Google Scholar]

- 37.Kaiser C.R., Borges J.L., dos Santos A.R., Azevedo D.A., D′Avila L.A. Quality control of gasoline by 1H NMR: aromatics, olefinics, paraffinics, and oxygenated and benzene contents. Fuel. 2010;89:99–104. doi: 10.1016/j.fuel.2009.06.023. [DOI] [Google Scholar]

- 38.Sathiamoorthy B., Bandivadekar A. Working Paper; 2020. Gasoline and Diesel Fuel Quality Survey for India: Part 2. [Google Scholar]

- 39.Mellios G., Gouliarou E. 2022. ETC/CME Report 11/2021: Fuel Quality Monitoring in the EU in 2020. [Google Scholar]

- 40.Fung F. 2011. Best Practices for Fuel Quality Inspection Programs, San Francisco. [Google Scholar]

- 41.Iqbal Khan Z., Ahmad Taimoor A., Rabbani J., Nawaz F. Effect of fuel quality, vehicle maintenance and advanced emission control technology on Pakistan in -use light vehicle emissions. J. King Abdulaziz Univ. Eng. Sci. 2023;33:95–112. doi: 10.4197/ENG. [DOI] [Google Scholar]

- 42.Kramer U., Ferrera M. 2015. Natural Gas/Methane Fuels : European Automotive Fuel Quality and Standardization Requirements Erdgas/Methankraftstoffe : Europäische Kraftstoffqualitäts-und Normungsanforderungen für Kraftfahrahrzeuge. [Google Scholar]

- 43.Zadorsky W. In: Medical Treatment of Intoxications and Decontamination of Chemical Agent in the Area of Terrorist Attack. Dishovsky C., Pivovarov A., Benschop H., editors. Springer Netherlands; Dordrecht: 2006. Non-ruled market economy as a source of chemical terrorism. Automotive fuel: quality and environmental safety; pp. 27–48. [Google Scholar]

- 44.Hirota K., Kashima S. How are automobile fuel quality standards guaranteed? Evidence from Indonesia, Malaysia and Vietnam. Transp. Res. Interdiscip. Perspect. 2020;4 doi: 10.1016/J.TRIP.2019.100089. [DOI] [Google Scholar]

- 45.Parliament E. The council of the European union, directive 2003/17/EC of the European parliament and of the council of 3 March 2003 amending directive 98/70/EC relating to the quality of petrol and diesel fuels. Official Journal of the European Union L Series. 2003;76:10–19. [Google Scholar]

- 46.Daniel R., Xu H., Wang C., Richardson D., Shuai S. Combustion performance of 2,5-dimethylfuran blends using dual-injection compared to direct-injection in a SI engine. Appl. Energy. 2012;98:59–68. doi: 10.1016/J.APENERGY.2012.02.073. [DOI] [Google Scholar]

- 47.Wang C., Xu H., Daniel R., Ghafourian A., Herreros J.M., Shuai S., Ma X. Combustion characteristics and emissions of 2-methylfuran compared to 2,5-dimethylfuran, gasoline and ethanol in a DISI engine. Fuel. 2013;103:200–211. doi: 10.1016/J.FUEL.2012.05.043. [DOI] [Google Scholar]

- 48.Prakash A., Wang C., Janssen A., Aradi A., Cracknell R. Impact of fuel sensitivity (RON-Mon) on engine efficiency. SAE International Journal of Fuels and Lubricants. 2017;10 doi: 10.4271/2017-01-0799. 2017-01–0799. [DOI] [Google Scholar]

- 49.Davies T., Cracknell R., Lovett G., Cruff L., Fowler J. Fuel effects in a boosted DISI engine. SAE Technical Papers. 2011 doi: 10.4271/2011-01-1985. [DOI] [Google Scholar]

- 50.Kalghatgi G.T. SAE Transactions; 2001. Fuel Anti-knock Quality-Part I. Engine Studies; pp. 1993–2004. [Google Scholar]

- 51.Kalghatgi G.T., Nakata K., Mogi K. Octane Appetite studies in direct injection spark ignition (DISI) engines. SAE Technical Papers. 2005 doi: 10.4271/2005-01-0244. [DOI] [Google Scholar]

- 52.Risberg P., Kalghatgi G., Ångstrom H.E. Auto-ignition quality of gasoline-like fuels in HCCI engines. SAE Technical Papers. 2003 doi: 10.4271/2003-01-3215. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

All data required to support this study is already mentioned in the manuscript.