Abstract

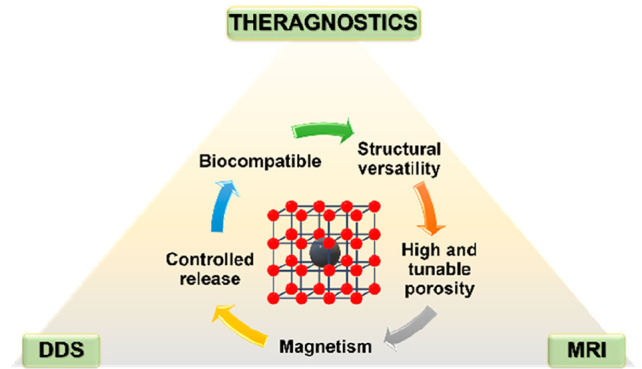

In the last two decades, metal–organic frameworks (MOFs) with highly tunable structure and porosity, have emerged as drug nanocarriers in the biomedical field. In particular, nanoscaled MOFs (nanoMOFs) have been widely investigated because of their potential biocompatibility, high drug loadings, and progressive release. To enhance their properties, MOFs have been combined with magnetic nanoparticles (MNPs) to form magnetic nanocomposites (MNP@MOF) with additional functionalities. Due to the magnetic properties of the MNPs, their presence in the nanosystems enables potential combinatorial magnetic targeted therapy and diagnosis. In this Review, we analyze the four main synthetic strategies currently employed for the fabrication of MNP@MOF nanocomposites, namely, mixing, in situ formation of MNPs in presynthesized MOF, in situ formation of MOFs in the presence of MNPs, and layer-by-layer methods. Additionally, we discuss the current progress in bioapplications, focusing on drug delivery systems (DDSs), magnetic resonance imaging (MRI), magnetic hyperthermia (MHT), and theragnostic systems. Overall, we provide a comprehensive overview of the recent advances in the development and bioapplications of MNP@MOF nanocomposites, highlighting their potential for future biomedical applications with a critical analysis of the challenges and limitations of these nanocomposites in terms of their synthesis, characterization, biocompatibility, and applicability.

Keywords: magnetic nanoparticles, metal−organic frameworks, magnetic MOF composites, MNP@MOF, nanomaterials, bioapplication, drug delivery systems, magnetic resonance imaging, theragnostic

1. Introduction

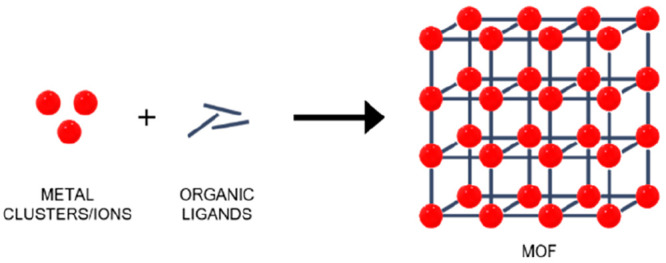

Since 2006, metal–organic frameworks (MOFs) have been exponentially investigated in the biomedical field,1−6 where they have been proposed as imaging agents7 and drug carriers.8 These materials are coordinative networks, based on metallic inorganic subunits (e.g., chains, clusters, atoms) and organic bridging ligands (Figure 1), with crystalline architectures, presenting a high and tunable porosity and structural versatility.9−11 In this sense, their properties make them promising candidates in several biomedical areas such as drug delivery systems (DDSs),5,12,13 biosensing,14,15 antimicrobial therapy,16,17 biomedical imaging,2 phototherapy,18,19 and theragnostics,20,21 among others.11,22

Figure 1.

Schematic representation of MOF structure.

An important consideration for the biomedical application of MOFs is their safety; it is crucial to ensure and evaluate the synthetic route and the final chemical composition taking into account that the solvents, metal ions, and organic ligand precursors could possess potential toxicity.23 Thus, the selection of safe and biocompatible metal and ligand precursors is very important.24 Furthermore, the size, morphology, and surface properties of the MOF are of pivotal relevance both for its biosafety and efficacy.20,24 Indeed, the main features in MOFs as DDSs are the biocompatibility, porosity available for drug loading, and controlled release at the targeted site, which are closely related to its physicochemical properties and dimensions. For instance, intravenous administration generally necessitates a size below 200 nm; therefore, the nanoscale design, encompassing factors such as size, shape, and surface functionalization, can influence the capacity for cell-specific targeting and subsequent cellular uptake.25 Furthermore, particles smaller than 250 nm have been reported to exhibit a higher likelihood of extravasation through leaky endothelium via the enhanced permeability and retention (EPR) effect, a characteristic fundamental for deposition in the tumor targeting site.25,26 Additionally, the clearance route is affected by the size: nanoparticles larger than 200 nm in diameter are preferentially cleared by the reticuloendothelial system, whereas those smaller than 10 nm are eliminated by renal filtration.25 In this context, nanoscaled MOFs (nanoMOFs) have attracted great attention in this matter because of their optimal size. Moreover, they can be tuned not only to target a particular administration route and safety but also the biodistribution.27−30

In addition to the advantageous properties of nanoMOFs, incorporating guest materials into MOFs, thereby forming MOF nanocomposites, presents a promising avenue for enhancing the performance of these structures in the realm of nanomedicine. Currently, there is a growing body of reviews that recognize the importance of improving MOF properties with the integration of organic polymers,31−33 enzymes,34,35 metals and metal oxides,36,37 silica,38 polyoxometalates,39 quantum dots,40,41 and carbons,42,43 among others.44 In this regard, MOF nanocomposites are becoming particularly promising as DDSs, by associating nanoMOFs with different nanometric (inorganic, organic) species44,45 that will provide them with additional relevant properties (targeting, furtivity, therapeutic effect, imaging, etc.).20,21

Of particular relevance are the composites based on nanoMOFs and magnetic nanoparticles (MNPs).46−48 In the biomedical field, MNPs are mainly represented by magnetite (Fe3O4), maghemite (γ-Fe2O3), and some ferrite colloids which typically have a hydrodynamic size below 100 nm.49 Given the enormous variability in their synthesis, their physicochemical properties (e.g., size, shape, structure, surface charge, magnetism) are tuned for a multitude of applications, such as magnetically guided nanoparticles for drug delivery,50,51 magnetofection (gene delivery),50,52 magnetic hyperthermia,53,54 magnetic resonance imaging (MRI)55−57 or magnetic particle imaging (MPI),58 and magnetic separation (cell separation, cell sensing, biosensing, etc.).59 Combining these relevant properties with those of MOFs (e.g., porosity, versatility) makes the resulting composites excellent candidates to be used in advanced drug delivery, nanothermometry, biosensing, bioimaging, and MRI contrast agents. A series of iron oxide nanoparticles with biocompatibility and nontoxicity are currently commercialized.60,61 Despite the noteworthy advancements in MNPs and their significant clinical implications,61−63 applying a nanocomposite system that harnesses the combined properties of MNPs and nanoMOFs introduces a compelling approach for augmenting the properties of both components while ensuring enhanced biocompatibility and potential efficacy for theragnostic applications.

Thus, here we will review the recent progress in the development of magnetic composites (MNP@MOF) based on MOFs and MNPs, specifically Fe-MNPs, discussing the main synthetic approaches and their challenging characterization with special attention to biomedical-related considerations, considering mainly nanocomposites (<500 nm) and the most significant submicron-sized composites (>500 nm). Further, the most relevant bioapplications of the MNP@MOF composites reported recently will be critically described, identifying their main advantages and limitations.

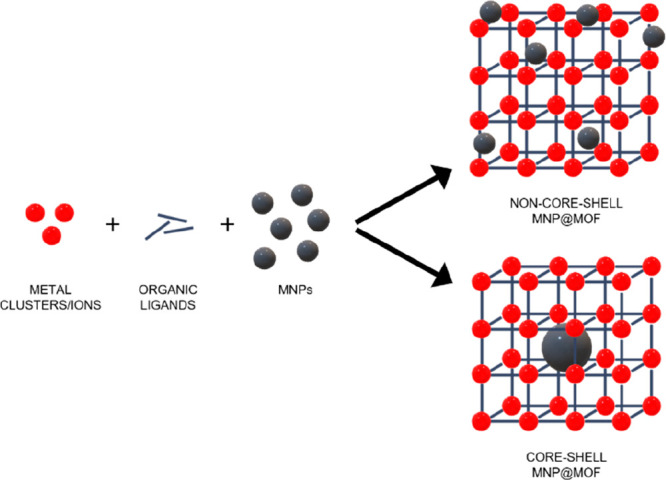

2. Synthetic Approaches for Magnetic Metal–Organic Framework Composites

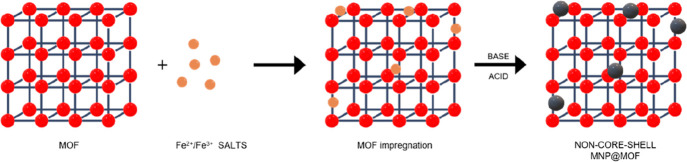

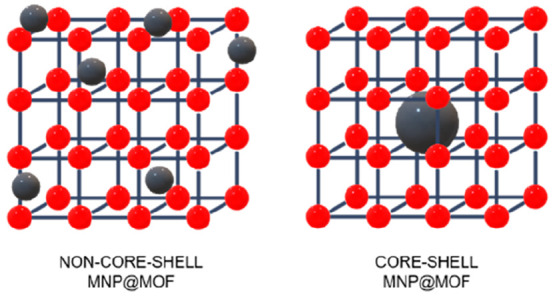

To combine MNPs with MOFs, four main strategies have been traditionally employed depending on the synthetic route of the final composite: (1) mixing, where the composite is formed by simply putting in contact previously synthesized magnetic particles and MOF crystals,64 (2) in situ formation of MNPs in the presence of preformed MOFs, (3) in situ synthesis of the MOF in the presence of magnetic particles, and (4) layer-by-layer, using functionalized nucleation sites to grow step-by-step the MOF by repeated cycles.65 Furthermore, it is important to highlight that different morphologies can be obtained such as core–shell and non-core–shell structures (Figure 2). In a core–shell composite, the MOF acts as the shell surrounding a single nanoparticle core material. Therefore, the core material in the case of MNP@MOF nanocomposites is the MNP and this configuration provides unique properties and synergistic effects between the core and shell components. In contrast, a non-core–shell MOF composite refers to a structure where the MNPs are randomly distributed, resulting in a heterogeneous composite with the MOF and the additional MNPs allocated throughout the composite structure, either within the framework and/or on the outer surface.

Figure 2.

Schematic representation of the non-core–shell and core–shell MNP@MOF composites.

Overall, in the following section, the synthetic procedures are illustrated following the above classification, considering their architectural configuration.

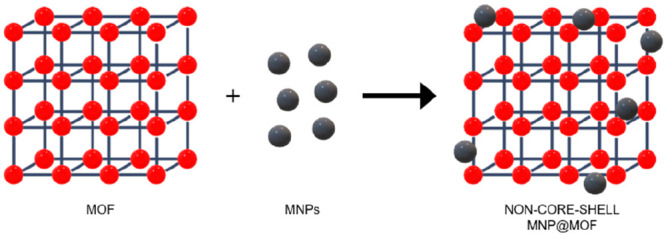

2.1. Mixing

The simplest approach is the mixing method, which involves the interaction of both presynthesized MNPs and MOFs (Figure 3). The final composite is thus exclusively based on the stability of the interactions between the two components.64

Figure 3.

Schematic representation of the mixing strategy.

Only a few examples are reported so far, mainly involving mesoporous iron(III) trimesate MIL-100(Fe)66 or chromium(III) terephthalate MIL-101(Cr)67 (MIL, Material Institut Lavoisier) as MOF, selected by their high porosity (up to SBET ∼ 3000 m2·g–1) and chemical robustness. Despite the in vivo proven biosafe character of MIL-100(Fe),68 chromium-based materials (even if based on Cr(III)) are considered potentially toxic,66 ruling out its interest in the biomedical field. However, MIL-101(Cr) is a benchmarked MOF widely proposed as a model in many fields due to its exceptional chemical stability. Indeed, the first synthesis of a magnetic MIL-101(Cr) composite by the mixing approach was reported in 2012, when Huo et al. described the formation of a Fe3O4@SiO2-MIL-101(Cr) composite.69 For the synthesis, silica-coated iron oxide microparticles (Fe3O4@SiO2, ∼ 600 nm with about 30 nm of silica shell) and MIL-101(Cr) submicrometric crystals (∼650 nm) were dispersed in an aqueous solution under ultrasonication for 20 min. The negatively charged silica-coated Fe3O4 favored the electrostatic interactions with the positively charged MIL-101(Cr), leading to a microsized Fe3O4@SiO2 assembled onto the external surface of the MIL-101(Cr) crystals. The silica coating, with an average thickness of about 30 nm, is required not only for preventing iron oxide corrosion and oxidation but also to favor the static electric interactions with the MOF. The saturation magnetization (MS) value for Fe3O4@SiO2-MIL-101(Cr) was 21 emu·g–1 (vs 76 and 38 emu·g–1 for Fe3O4 and Fe3O4@SiO2, respectively), keeping the magnetic property for the desired magnetic solid-phase extraction aim. Critically, in this first work, the composite has unsteady characteristics based on too weak interactions between two enormous components attracted to each other in an insufficiently stable structure. In consideration of the pore size and the substantial dimensions of the MNPs, it is evident that these entities are predominantly located on the surface. The concept behind this work was further improved by reducing the size of the MNPs, which will interact more effectively with the MOF surface. Thus, Qian and co-workers70 promoted the interaction between the here biocompatible iron version of MIL-101(Fe) (∼700 nm) and Fe3O4 in deionized water by increasing the pH up to 8 with a NaOH solution, which switches the ζ-potential of the MNPs from positive to negative. Even if the Fe3O4 nanoparticles presented an average size of ∼10–30 nm, through this method, the MNPs were restricted to the outermost layer. The resulting magnetic composite (MS ∼ 26 vs 46 emu·g–1 for Fe3O4) exhibited a powder X-ray diffraction (PXRD) pattern matching well with the indexed peaks of the Fe3O4, and some other peaks consistent with the MIL-101(Fe) structure. However, the majority of the diffraction peaks of the MOF were indistinguishable from the background. This result was attributed to the cover effect of the MNPs, but one could also consider a potential degradation of the Fe carboxylate MOF under basic pH (pKa carboxylic acids ∼3–5 vs pH = 7.4), as previously reported for MIL-100(Fe).71

Similarly, magnetic composites γ-Fe3O4@MIL-100(Fe) and cit-γ-Fe3O4@MIL-100(Fe) with maghemite (γ-Fe3O4, ∼7–10 nm) and citrate-functionalized maghemite (cit-γ-Fe3O4, ∼15–20 nm) were synthesized with a mean hydrodynamic diameter of about 160 nm from dynamic light scattering (DLS) analysis.72 The nanocomposite, showing PXRD peaks of the MIL-100(Fe) and the maghemite, was achieved by mixing the previously microwave (MW)-synthesized MIL-100(Fe) nanoparticles73 with γ-Fe3O4 or cit-γ-Fe3O4 at pH 4.2 and 3.5, respectively. The high-resolution transmission electron microscopy (HR-TEM) images revealed MIL-100(Fe) nanoparticles (∼130 nm) with a decoration on the outer surface of small aggregates of MNPs. The magnetometry experiments showed a superparamagnetic behavior. Among all the samples the cit-γ-Fe3O4@MIL-100(Fe) presented the highest magnetic moment with Brunauer–Emmett–Teller surface areas (SBET) about 1180–1310 m2·g–1, not significantly reduced compared to SBET ∼ 1330 m2·g–1 of the initial MIL-100(Fe).

In conclusion, the mixing synthetic method is however underdeveloped because, in spite of its simplicity, it has poor control over the final properties of the composite and the association is exclusively based on the formation of weak interactions (mainly electrostatic attraction). Therefore, it results in a lack of preference for MNPs on their directionality within pores or the outer surface of MOFs. Even if the crucial size of the MNPs may be compatible with the pore dimensions of the MOF, then this would be not sufficient to avoid the partial or total presence of the MNPs on the outer surface of the MOF, leading to less stable composites with MNPs’ leaching.

2.2. In Situ Formation of MNPs in the Presence of the MOF

Another notable pathway to obtain MNP@MOF composites is the “ship in a bottle” strategy, which consists of the in situ formation of the MNPs in the presence of the preformed MOF.74 The magnetic composite is obtained by first incorporating iron ions or precursors of the MNPs in the MOF (mainly via chemical vapor infiltration, solution impregnation, and incipient wetness infiltration75) and then, forming the MNPs through a transformation (e.g., phase and/or topotactic transformations, dehydration, reduction)76 to iron oxide nanoparticles formation (see Figure 4). The MNPs are usually located on the MOF external surface or within the porosity, partially destroying the structure (creating defects) in case of particle size larger than the accessible pore dimension. However, this insertion of defect points in the framework is a hard equilibrium to control, in order to avoid the structure collapse. Otherwise, in the optimiztic and more desired case, the MNPs are well-dispersed inside the MOF,75 being advantageously protected from degradation or leaching.

Figure 4.

Schematic representation of the in situ formation of the MNPs in the presence of presynthesized MOF for non-core–shell MNP@MOF composites.

In this sense, Wu et al.77 originally proposed this “ship in a bottle” method to prepare γ-Fe2O3@ZIF-8 and γ-Fe2O3@MIL-53(Al) composites using rigid microporous zinc(II) 2-methylimidazolate ZIF-8 (ZIF = Zeolite Imidazolate Framework; ∼200 nm and SBET ∼ 1800 m2·g–1)78 and flexible microporous aluminum(III) terephthalate MIL-53(Al) (SBET ∼ 1500 m2·g–1 in the open form structure).79 The Fe(acac)3 metal precursor was infiltrated in the MOF by the incipient wetness method, and γ-Fe2O3 MNPs were formed by pyrolysis (300 °C under N2 for 1 h). Then, a reduction treatment was performed to form Fe0 (CO atmosphere at 550 °C for 1 h) and proved the formation of MNPs. The crystallinity of MOFs was retained, as shown by PXRD, and then, the magnetic composites were further investigated for drug encapsulation with the anti-inflammatory and analgesic ibuprofen. Under these conditions, the MNPs conferred a significantly lower MS than that of pure γ-Fe2O3 (33.5 vs 1.8 and 6.1 emu·g–1 for γ-Fe2O3@ZIF-8 and γ-Fe2O3@MIL-53(Al), respectively). The γ-Fe2O3 particles were mainly located on the outer surface of the ZIF-8 as large agglomerates; instead, ultrafine MNPs and clusters were observed within the crystalline structure, creating a hollow structure with defects during the pyrolysis process. This fact highlights that the location of the MNPs depends on the method to insert the precursor and its motion under the pyrolysis process, which is challenging to control. In addition, the pyrolysis process could be limited by the MOF thermal stability.

The in situ formation of MNPs has also been employed for the preparation of Fe3O4@MIL-101(Cr) composite by partial reduction.80,81 MIL-101(Cr) micrometric crystals were dispersed and sonicated for 30 min at room temperature into a FeCl3 solution to favor the impregnation. The in situ formation of MNPs (∼10–20 nm) occurred, first, with the addition of Na2SO3 solution dropwise. Then, NH4OH solution was slowly added under an inert atmosphere, leading to the formation of Fe3O4 nanoparticles, as supported by PXRD. The final magnetic composite (MS ∼ 15.6 emu g–1), with a particle size of 600–700 nm, was successfully applied in magnetic solid phase extraction (MSPE) combined with ultrahigh performance liquid chromatography-tandem mass spectrometry (UPLC-MS/MS) for the quantitation of eight nonsteroidal anti-inflammatory drugs (NSAIDs) in wastewater and environmental water samples.80

As reflected in the examples shown above, the difficulties of this method lay in the homogeneous diffusion of the metal precursors into the MOF and the challenging control of the in situ process. Moreover, the MOF stability under the in situ conditions is fundamental for the successful formation of the nanocomposite, being this procedure limited to high thermally and chemically robust MOFs.

2.3. In Situ Formation of MOF in the Presence of MNPs

One of the main approaches followed for the synthesis of magnetic nanocomposites, known as “bottle around ship”, consists of the in situ formation of the MOF in the presence of preformed MNPs (Figure 5).74 The MNPs could be coated with different functional groups, polymers, or capping agents.74 In the following sections, the synthetic methods will be distinguished considering the final architecture (non-core–shell or core–shell) of the composite as well as the MNPs functionalization (uncoated MNP, amine or acidic-coating, etc.).

Figure 5.

Schematic representation of the in situ formation of the MOF in the presence of presynthesized MNPs for non-core–shell and core–shell MNP@MOF composites.

2.3.1. Non-core–Shell Magnetic Composites

In the non-core–shell magnetic architecture, the MOF grows in the presence of preformed MNPs, leading to a composite where MNPs are often randomly distributed in/on the MOF.

2.3.1.1. Synthesis of Magnetic Composites with Nonfunctionalized MNPs

The complex structure of a magnetic nanocomposite can be obtained from the simplest uncoated MNPs, by interacting with the MOF precursors or being incorporated into the porosity that arises as the MOF grows.82,83

In this matter, Lohe and collaborators84 explored the benchmarked microporous copper(II) trimesate HKUST-1 (HKUST = Hong Kong University of Science and Technology; SBET ∼ 600–1600 m2·g–1)85,86 together with other two MOFs, aluminum(III) 2,6-naphthalenedicarboxylate (DUT-4; DUT = Dresden University of Technolog; SBET ∼ 1000–1300 m2·g–1) and aluminum(III) biphenyl-4,4′-dicarboxylate (DUT-5; SBET ∼ 1200–1700 m2·g–1),87−89 as an efficient method for magnetically controlled catalyst separation. In this work, the magnetic composites were also studied as model systems for heating-trigger desorption of drug molecules by an external alternating magnetic field (AMF). In the synthesis, MNPs (spherical, ∼ 10–20 nm) were added to the organic ligand solution in N,N-dimethylformamide (DMF). Then, to obtain DUT-4 and DUT-5, an aluminum precursor (Al(NO3)3·9H2O) was added also in DMF and the mixtures were heated at 180 °C for 24 h in an autoclave. For the preparation of magnetic HKUST-1, Cu(OAc)2·H2O was mixed with the previous MNP/ligand solution and altogether refluxed for 12 h under stirring. The composites exhibited high surface areas within the range of reported values (1394, 1346, and 1248 m2·g–1 for the HKUST-1, DUT-4, and DUT-5 composites, respectively). Remarkably, all the composites showed magnetic properties, since they were collected through an external magnet. In the case of the magnetic HKUST-1 composite, it was characterized under a magnetic field of 1.7 kA·m–1 at a frequency of 183 kHz, presenting a specific absorption rate (SAR) of 11.1 W·g–1. Despite the relatively low SAR value, the magnetic HKUST-1 composite showed an accelerated release rate of ibuprofen as the temperature increased under the AMF, representing the first proof of concept of a MOF magnetic nanocomposite demonstrating improved drug release under heating by AMF.

Another example of catalytic application was recently reported by Zamani and colleagues,90 developing a magnetic porphyrin-loaded MOF. The Fe3O4@CoTHPP@UiO-66 composite, based on the robust microporous zirconium(IV) terephthalate UiO-66 (UiO = University of Oslo; CoTHPP(OAC) = meso-tetrakis(4-hydroxyphenylporphyrinato) cobalt(II)).91 The resulting nanocomposite (∼400 nm) was prepared by a one-step solvothermal route, first dispersing the MNPs in DMF, then the MOF precursors (ZrCl4 and terephthalic acid) and the desired porphyrin (CoTHPP), for finally carrying out the solvothermal reaction at 120 °C for 24 h in the presence of glacial acetic acid as the modulator. The magnetic nanocomposite formation was confirmed by PXRD and by the magnetization curve (10 emu·g–1), presenting a surface area reduced from for the parent UiO-66 (SBET 732 vs 1380 m2·g–1). The MNPs permitted an easy, low energy and short-time consumption recovery magnetic separation of the composite that improved its reusability as a catalyst, using it for the epoxidation of olefins and allylic alcohols with a yield of the reaction up to 95% and 5 cycles-reusability.

As shown in these examples, the non-core–shell structures based on uncoated MNPs present a priori an absence of specific MNPs-MOF interactions, leading to some associated issues. For instance, it could lead to the segregation of the MOF formation, obtaining mixtures of pure components and not composites. Also, the uncoated MNPs usually tend to aggregate in the reaction mixture, leading to the formation of heterogeneous composites. In this sense, solvothermal reactions are usually carried out without stirring, generally preventing a good MNPs dispersion. Finally, the reaction conditions for the preparation of the MOFs should be compatible with the MNPs’ stability, limiting the number of suitable MOF structures (generally synthesized under acidic conditions and highly complexant species that could dissolve the MNPs).92

2.3.1.2. Synthesis of Magnetic Composites Using with Acid-Functionalized MNPs

An interesting approach to prevent MNPs aggregation and promote specific MNPs-MOF interactions is the MNPs’ surface functionalization with acidic or other groups, which can be also regulated in terms of the length of the hydrocarbon chain.

In this sense, Schejn et al.93 proposed the addition of citrate-capped Fe3O4 nanoparticles to form Fe3O4@ZIF-8. The citrate-capped Fe3O4 nanoparticles and the 2-methyl-1H-imidazole ligand (HmIM) were dispersed in water. Then, an aqueous solution of the Zn(NO3)2 was added, forming the composite at room temperature after only 10 min with a particle size of ∼250 nm. The specific surface area and the pore volume (SBET ∼ 1856 vs 871 m2·g–1; 0.71 vs 0.35 m3·g–1)78 decreased for the Fe3O4@ZIF-8 with respect to ZIF-8, and was justified by the TEM-based location of the MNPs (∼10 nm) at the MOF surface, blocking the cavities. The PXRD analysis confirmed the formation of the ZIF-8 and the presence of the Fe3O4 nanoparticles. The formation of the composite was favored by the presence of carboxylate groups, which can interact weakly with the MOF precursors (imidazolate and metal ions). Additionally, a more complex composite based on ZIF-8 and ZIF 67 (>450 nm) was synthesized based on citrate-capped Fe3O4.94 The authors introduced the MNPs in the solution of HmIM, adding then the Zn2+ solution. After 6 h, HmIM solution was added again. In this way, first, the MOF shell of ZIF-8 was produced, then with Co(NO3)2·6H2O, HmIM, and folic acid (FA) was obtained a second MOF shell (ZIF-67) functionalized with FA (Fe3O4@ZIF-8@ZIF-67/FA). TEM images showed that MNPs (∼6 nm) were dispersed in the ZIF-8 structure (∼400 nm), and the ZIF-67 shell (∼50 nm) maintained the same morphology. In the final composite Fe3O4@ZIF-8@ZIF-67/FA, the FA produced agglomerated flower-like structures, desired for the DD purpose. The observed PXRD diffraction peaks for the composites were attributed to the MNPs, ZIF-8, and ZIF-67. However, after the drug encapsulation of a model antitumoral drug (quercetin, Q), the PXRD pattern of Fe3O4@ZIF-8@ZIF-67/FA/Q was broadened. The surface areas varied from 42 m2·g–1 for Fe3O4 to 1994, 1203, and 259 m2·g–1 for Fe3O4@ZIF-8, Fe3O4@ZIF-8@ZIF-67/FA, and Fe3O4@ZIF-8@ZIF-67/FA/Q, respectively, indicating first the MOF porosity contribution, then, the presence of the FA functionalization, and, finally, the drug loading.

Certainly, these examples evidence the challenging control of the MNPs position (e.g., core–shell) in the MOF. Indeed, the functionalization over the MNPs surface may not only establish bonds with the MOF precursors but also the MNPs have to promote the growth of the MOF over them as nucleation seeds.

2.3.1.3. Synthesis of Magnetic Composites Using Polymer-Functionalized MNPs

Another interesting approach to accomplish the composite formation is using surface-engineered MNPs in order to avoid their aggregation, favoring their easy dispersion in solution. The surface functionalization has been mostly based on polymers, such as polyvinylpyrrolidone (PVP) or polystyrenesulfonate (PSS), among others, which could present additional functionalities (e.g., −COOH, poly(dopamine)-PDA) that might help the MOF formation.

On this matter, Fang and colleagues95 synthesized magnetic MOF nanoparticles based on the ZIF-90 structure, based on zinc and the imidazolate-2-carboxyaldehyde (2-ICA) ligand (SBET ∼ 1103–1297 m2·g–1).96 The composite was prepared by mixing polyvinylpyrrolidone (PVP)-coated MNPs (Fe3O4@PVP, 12 nm) with 2-ICA,= and then immediately pouring the Zn(NO3)2 into the solution for finally heating at 90 °C for 18 h. The dried MNP@MOF nanocomposite (∼64 nm) was attracted by an external magnet, determining a decrease in saturation magnetization from 32 to 7 emu·g–1 in the magnetic nanocomposite due to the MOF presence. Interestingly, the nanocomposites indexed ZIF-90 and Fe3O4 peaks in the PXRD pattern and presented a kind of core–shell structure, being several MNPs located in the center of the ZIF-90 particles, as evidenced by TEM.

Another non-core–shell structure was also developed using ZIF-90 and (PDA)-coated MNPs (Fe3O4@PDA@ZIF-90).97 Briefly, an ethanolic Zn(NO3)2 solution was put in contact first with an aqueous solution of Fe3O4@PDA nanoparticles, recovering magnetically the MNPs, to then, add the 2-ICA solution. Then, Zn(NO3), trioctylamine, and 2-ICA solutions were poured in regular intervals until all the precursors’ solutions were added and continuously reacted. Trioctylamine, a tertiary amine with large alkyl substituents, can act as both a deprotonating agent and a surfactant, facilitating the nucleation and growth of the MOFs.96 The product was recovered magnetically, having a saturation magnetization of 9.3 emu·g–1 (vs 22.5 and 17.3 emu·g–1 for Fe3O4 and Fe3O4@PDA, respectively). Fe3O4@PDA@ZIF-90 exhibited the characteristic peaks of ZIF-90 in PXRD, with however almost no visible peaks corresponding to the MNPs, probably due to the small proportion within the composite. The TEM images clearly showed a non-core–shell structure of about 200 nm, with narrow size distribution and well-dispersion evidenced by DLS, with an agglomeration of the PDA-coated MNPs (∼170 nm) and about 20–30 nm of ZIF-90 growth.

ZIF-8 was also extensively studied here because of its simple and versatile synthesis which allows a fine-tuning of its properties.78,98 In this regard, Pang and co-workers99 proposed a Fe3O4@ZIF-8 composite (∼150 nm) based on poly(acrylic acid) (PAA) grafted MNPs (Fe3O4@PAA, ∼10 nm). The reaction at room temperature involved an aqueous solution of HmIM and Fe3O4@PAA nanoparticles, bearing carboxylate groups on their outer surface to prevent aggregation. Then, Zn2+ was added, coordinating with these carboxylate groups and subsequently forming the desired MOF composite, with a saturation magnetization in the range of 0.56–4.35 emu·g–1, depending on the Fe3O4 content. While the high purity of the resulting magnetite-based nanocomposite was supported by PXRD, the TEM images showed the presence of several MNPs grafted at the surface and also embedded into the MOF.

A noteworthy alternative approach based on ZIF-8 was developed by Zhong et al.,100 presenting a composite called Void nFe3O4@Pd@ZIF-8@ZIF-8, featuring an empty internal cavity. In the multistep synthesis, MNPs were initially combined with polystyrene-co-acrylic acid (PS-co-AA) nanospheres to produce Fe3O4/PS nanospheres. Then, these nanospheres were dispersed in a MeOH solution containing ZIF-8 precursors at room temperature for 3 h. Subsequently, Pd nanoparticles were encapsulated within Fe3O4/PS@ZIF-8 using an impregnation method, resulting in Fe3O4/PS@Pd@ZIF-8. An additional shell of ZIF-8 was created using a similar procedure. Finally, the PS core was removed from Fe3O4/PS@Pd@ZIF-8@ZIF-8 through DMF treatment to create the internal cavity, leading to the final nanocomposite, Void nFe3O4@Pd@ZIF-8@ZIF-8. The crystal structure of the composite was confirmed through PXRD. TEM and SEM images revealed a non-core–shell structure with multiple MNPs homogeneously dispersed within the MOF internal surface rather than forming a single core. Notably, the synthesis method facilitated the controlled distribution of MNPs and subsequent Pd nanoparticles. The sizes of Fe3O4/PS, Fe3O4/PS@Pd, and Void nFe3O4@Pd@ZIF-8@ZIF-8 were approximately 410, 450, and 520 nm, respectively. The porous nature of the material exhibited variations in SBET, with values of 192, 62, 306, and 523 m2·g–1 for Fe3O4/PS@ZIF-8, Fe3O4/PS@Pd@ZIF-8, Fe3O4/PS@Pd@ZIF-8@ZIF-8, and Void nFe3O4@Pd@ZIF-8@ZIF-8. Indeed, the presence of Pd nanoparticles in the final 30 nm layer affected its porosity, which is partially restored by reducing the solid phase contribution of PS nanospheres. This example represents a novel approach, utilizing a removable template that does not compromise the nanocomposite porosity. The advantage of this template lies in the controlled positioning of MNPs, a feature often absents in other cases, making it an interesting solution.

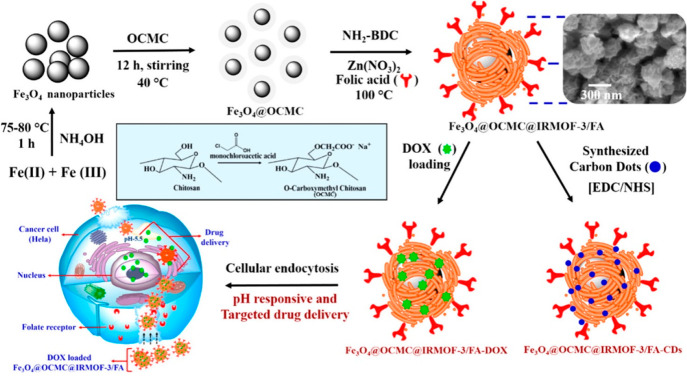

Another example based on a non-core–shell morphology was reported by Chowdhuri and co-workers,101,102 developing the Fe3O4@IRMOF-3 nanocomposite. The highly porous (SBET = 1568 m2·g–1 and pore volume = 1.07 cm3·g–1)103 zinc aminoterephthalate IRMOF-3 (Iso Reticular MOF)104 was solvothermally formed on MNPs. Briefly, Fe3O4 nanoparticles (∼10 nm) were well dispersed in a PVP solution (1:1, DMF and absolute ethanol). Then, Zn(NO3)2 and 2-aminobenzene-1,4-dicarboxylic acid (NH2–H2BDC) dissolved in DMF were added to the previous Fe3O4 solution, heating at 100 °C for 4 h. Nanoparticles of Fe3O4@IRMOF-3 (∼65 nm) were observed through field emission scanning electron microscopy (FESEM), although the average particle size in DLS was around 200 nm, probably associated with slight aggregation in solution.101 Furthermore, the normalized saturation magnetization values of the synthesized bare Fe3O4 and the nanocomposites were observed to be ∼80 and ∼50 emu·g–1, respectively.101,102 More recently, Taghavi et al.105 reported a similar non-core–shell Fe3O4@IRMOF-3 (∼150 nm with MNPs below 50 nm) with a saturation magnetization of about 60 emu·g–1, making this composite highly promising.

2.3.2. Core–Shell Magnetic Composites

So far, this Review has shown the formation of the MNP@MOF nanocomposites where the particle location is not controlled. However, it is now necessary to explain the great interest in a well-defined core–shell architecture (Figure 2), since locating a single MNP inside (core) a single MOF nanoparticle (shell) is a nice chemical challenge to guarantee the homogeneity of the system, porosity, and intimate interaction between MNPs and MOFs, avoiding the MNPs–MNPs ones.106 Therefore, it would be ideal for the manipulation of the nanoparticles insertion and the ratio between the MNPs and the MOF precursors content to systematically tune the properties for a precise control over the size, shape, and composition of the nanocomposites.106 In this section, the more recent examples of core–shell composites will be discussed classifying them as a function of the magnetic core nature (e.g., uncoated, acidic functionalized, amino functionalized, polymer functionalized).

2.3.2.1. Synthesis of Magnetic Composite with Nonfunctionalized MNPs

Despite the issues related to the uncoated MNPs, their use is still considered for the synthesis of core–shell nanocomposites. The reason is evident in the following examples, where the choice of the uncoated-MNPs is related to their easy fabrication via a simple, and low-cost coprecipitation method. The central objective of the forthcoming analysis centers around the optimization of MOF growth surrounding a magnetic core. To this end, two recent examples have been selected, both adhering to a size criterion of approximately 300 nm because it is significant for biomedical applications.

In this regard, a magnetic nanocomposite based on uncoated-Fe3O4 nanoparticles (∼260 nm) and magnesium 2,5-dihydroxyterephthalate Mg-MOF-74 was reported.107 The nanocomposite was solvothermally (125 °C for 5 h) prepared from a suspension of Fe3O4 nanoparticles and Mg(NO3)2 in a mixture of DMF-ethanol-H2O (15:1:1), adding then the ligand. The final nanocomposite (∼320 nm) was magnetically collected, identifying both the MOF and the Fe3O4 structures by PXRD. However, the BET surface area was much lower than the expected one (265 vs 1250 m2·g–1 for Mg-MOF-74), which could be related to the presence of dense MNPs and the low shell thickness of the MOF.

On the other hand, a more complex structure, Fe3O4@UiO-66@UiO-67/CTAB, was achieved with the cationic surfactant hexadecyltrimethylammonium bromide (CTAB) surface modification.108 In the first step, ZrCl4, 1,4-benzene dicarboxylic acid (H2BDC), and DMF were mixed with uncoated-Fe3O4 nanoparticles, adding then acid modulators (HCl and acetic acid) and heated at 120 °C for 24 h. Second, after the recovery, UiO-67 was formed over the Fe3O4@UiO-66 composite following the same procedure but with the biphenyl-4-4′-dicarboxylic acid (H2BPDC) as the organic linker. Finally, the Fe3O4@UiO-66@UiO-67/CTAB composite was obtained by introducing it in a CTAB solution. The final material exhibited an irregular morphology that differs from UiO-66 and UiO-67, presenting a dimension of about 60–130 nm. The magnetization loops indicated a superparamagnetic feature and a high saturation magnetization of about 36 emu·g–1 for Fe3O4@UiO-66@UiO-67/CTAB, considering the values of saturation magnetization at room temperature of bulk magnetite (92 emu·g–1) and maghemite (76 emu·g–1).109,110

As was pointed out in the introduction to this subsection, the limited number of reported works of core–shell nanocomposites emphasizes the difficulties for nanoparticles to be the seed for MOF formation. However, with nanoparticles of suitable size, even if uncoated, a synthesis protocol of a small nanoMOF can lead to a single shell of MOF around a single MNP.

2.3.2.2. Synthesis of Magnetic Composite with Acid- or Amino-Functionalized MNPs

As previously explained, carboxylic groups on the surface of nanoparticles are employed to stabilize them in a well-dispersed solution and to increase the affinity of the MOF in order to grow the crystal on the MNP surface. Another alternative, improving stabilization and preventing agglomeration, is the use of amino groups to increase again the chance of a core–shell architecture. In the following subchapter, some examples are reported with both functionalization over MNPs.

In this matter, Chen et al.111 prepared magnetic core–shell Fe3O4@HKUST-1 (∼50–100 nm) with carboxyl functionalized Fe3O4 cores (∼20 nm). The MNPs were dispersed in a mixed solution of DMF/EtOH/H2O (1:1:1), and PVP was then added as a surface capping agent to promote the core–shell growth together with Cu(OAc)2·H2O. Finally, with further metal precursor and trimesic acid, the reaction proceeded for 12 h. The BET surface area of the Fe3O4 core (SBET ∼ 10 m2·g–1) increased up to 738 m2·g–1 in the Fe3O4@HKUST-1 nanostructure, within the range of the MOF itself (SBET = 600–1600 m2·g–1).86 Furthermore, they achieved a magnetic fluid composite with high particle content (25.0–45.4 wt %) by introducing Fe3O4@HKUST-1 core–shell nanoparticles into a carboxymethylcellulose (CMC) solution.112 According to the literature,111,112 other Fe3O4@HKUST-1 composites were proposed for their good catalytic activities.113,114 In all the cases, PXRD patterns demonstrated that both phases of Fe3O4 and HKUST-1 were present in the composites. The same synthetic protocol, with carboxyl functionalized Fe3O4 cores and PVP as a surface capping agent, guaranteed the core–shell Fe3O4@HKUST-1 nanocomposite formation, being later further improved with a DMF-free modified version.113,114

Notably, for the synthesis of several MNP@ZIF-8 nanocomposites, citric acid (CA) has garnered significant interest. For instance, Hou et al.115 prepared a core–shell magnetic ZIF-8 via a solvothermal method with glucose oxidase (GOx) embedded into the composite (Fe3O4@ZIF-8@GOx). For the synthesis, CA-modified Fe3O4 nanoparticles (CA-Fe3O4, ∼100 nm) were suspended and sonicated in an EtOH/H2O (1:1) solution containing Zn(NO3)2 and HCl. Lastly, an EtOH/H2O (1:1) solution containing HmIM and PVP was added and stirred. The magnetic Fe3O4@ZIF-8 (MS ∼ 48.2 vs 82.2 emu·g–1 for Fe3O4) was easily collected with a magnet, exhibiting a core–shell spherical morphology. Additionally, in the PXRD pattern, the diffraction peaks were consistent with the Fe3O4 and ZIF-8 patterns.

Slightly different, Lin and colleagues116 proposed the synthesis of Fe3O4@ZIF-8 (∼120 nm) using MNPs (∼6 nm) coated with 3,4-dihydroxyhydrocinnamic acid (DHCA). Prior to the synthesis of the nanocomposite, the MNPs underwent a ligand exchange procedure to substitute oleylamine ligands with DHCA molecules. In this way, their solubility in H2O was improved, providing also terminal −COOH on the surface of MNPs for coordinating the Zn2+ ions. Afterward, in a solution of HmIM, PVP, and Fe3O4 nanoparticles, the Zn(NO3)2·6H2O aqueous solution was rapidly poured to afford the final composite. Both FTIR and PXRD determined the presence of Fe3O4 and ZIF-8 in the magnetic nanocomposite (MS ∼ 18.9 vs 44.3 emu·g–1 for Fe3O4). The hydrothermal method maintains the aforementioned advantages; however, the ligand exchange introduced a slighter modification which permitted the synthesis without ethanol.

Recently, further ZIF-8-based nanocomposites were produced, incorporating Fe3O4-nanorods (NRs) as the core material and subsequent decoration with Pt for catalytic purposes (Fe3O4-NR@ZIF-8/Pt).117 During the synthesis process, oleylamine-functionalized Fe3O4-NRs were mixed with ZIF-8 precursors in a MeOH solution at room temperature. The resulting nanocomposite was characterized through the analysis of PXRD and FTIR, confirming the successful growth of the MOF and the presence of the Fe3O4-NRs. TEM images provided further insights, revealing the length of the Fe3O4-NRs to be approximately 700 nm with a width of around 50 nm. Additionally, the synthesis of ZIF-8 led to the formation of a 30 nm MOF shell surrounding the NRs. Instead, Pt content was determined using Energy-dispersive X-ray spectroscopy (EDS), and the surface area as measured by the BET method decreased from 620 (Fe3O4-NR@ZIF-8) to 265 m2·g–1 (Fe3O4-NR@ZIF-8/Pt), as a consequence of the Pt decoration. Notably, this fascinating material, primarily synthesized for catalytic purposes, also exhibited magnetic characteristics, with MS of 73.9, 58.9, and 50.2 emu·g–1 for Fe3O4-NR, Fe3O4-NR@ZIF-8, and Fe3O4-NR@ZIF-8/Pt, respectively. Thus, this example once again emphasizes the remarkable versatility of ZIF-8 synthesis, even when there are variations in the composition of the magnetic core. Despite the ZIF-8 advantageous synthetic properties (fast, simple, and versatile), its utilization for bioapplications is accompanied by several limitations. Specifically, it demonstrates low to medium stability in aqueous environments. To enhance its long-term performance, stability, and biocompatibility, as well as to improve its targeting capabilities, additional modifications such as functionalization and surface engineering steps (e.g., GOx) become imperative to address these challenges to fully exploit the potential of ZIF-8 for bioapplications. For the simplicity of the synthesis, in the same way, other magnetic core–shell Fe3O4@ZIF-8 composites with size ranges from 180 to 400 nm were synthesized with minor modifications but finalized for different applications, such as water treatment,118 protein separations,119 bioimaging,120 drug delivery,121 and potential theragnostic agents.122

Similarly, an Au@Pt nanoparticle-decorated magnetic Fe3O4@UiO-66 composite123 (∼100–300 nm) was constructed. PXRD and FTIR of the Fe3O4@UiO-66 confirmed the formation of the composite, exhibiting Fe3O4 nanoparticles (∼90 nm) interacting with the MOF in the SEM and TEM images. Recently, in a similar manner, the same composites were also synthesized, reaching particle size of the final product about 200 nm,124 smaller than 100 nm,125 or even about 16–17 nm.126 The focus is on achieving a size below 200 nm, targeting suitable sizes for intravenous nanocarriers.127

In another study, core–shell Fe3O4@MIL-100(Fe) spheres (∼350 nm) were fabricated using citrate-capped Fe3O4 magnetic particles.128 The citrate-functionalized Fe3O4 particles (∼250 nm) were dispersed in an ethanol solution, first of FeCl3•6H2O and then, of H3BTC at 70 °C for 15 and 30 min, respectively. This mixture acted as a precursor of Fe3O4@MIL-100(Fe), which was dispersed into a solution of FeCl3•6H2O and H3BTC under stirring and heated at 70 °C for 24 h for the MOF growing. The magnetic composite exhibited a size of 350 nm, with PXRD and FTIR analyses establishing the presence of both Fe3O4 and MIL-100(Fe) phases. In a reduced particle size range, Tregubov et al.129 prepared as well Fe3O4@MIL-100(Fe) nanocomposite (∼100 nm) just increasing the temperature to 95 °C and keeping it for 12 h. In these cases, the solvothermal synthesis was anticipated with a short step, which created a precursor for the next step. The precursor acted as a seed for the MOF growth, and the MNPs (∼80 nm) were in contact with the metal ions and the organic linkers for 30 min to create the first interactions for the further shell framework growth in the solvothermal procedure. The reasoning behind this is to facilitate the interaction of the MNPs with the precursors of the MOF under stirring, enhancing the dispersion of the Fe3O4 nanoparticles. Therefore, MNPs in the static condition of the solvothermal reaction were less encouraged to aggregate.

Instead, Li and co-workers130 used Fe3O4-NH2 nanoparticles (∼158 nm) to MW-assisted synthesize Fe3O4-NH2@MIL-101(Fe)-NH2 core–shell nanocomposites (∼268 nm) since the amino group of MNPs could improve the interaction with the carboxylic groups of the organic linker. The obtained magnetic MOFs were recovered by a magnet (MS ∼ 20–21 emu·g–1 vs Twenty-seven emu·g–1 for Fe3O4-NH2). The efficient MW heating gave rise to a highly homogeneous Fe3O4-NH2@MIL-101(Fe)-NH2 nanocomposite. Actually, this strategy has been employed in MOFs synthesis in the past decade not only for the short reaction times but also because the high yield and the properties (tuning crystal size) are affected by the specific and almost instantaneous and homogeneous heating.131 The microwave-assisted method is almost unexplored for the synthesis of MNP@MOF nanocomposites; however, in the near future, we expect an improvement in this method. One of the issues around this approach is the temperature, and consequently, the pressure, in the microwave vessels, because generally fast reactions are correlated to higher temperature with respect to the solvothermal synthesis. Currently, there is a dearth of evidence concerning the influence of radiation on MNPs. Nevertheless, it is worth noting that certain studies have reported evidence of a decrystallization effect in powder magnetite when exposed to microwave radiation for a brief duration of only 5 min near its Curie temperature.132 Although this finding does not provide insights into the behavior of MNPs under specific conditions, it could suggest potential limitations for the synthesis of nanocomposites involving MOFs.

2.3.2.3. Synthesis of Magnetic Composite with Polymer-Functionalized MNPs

As previously stated, the core–shell architecture does certainly offer superior control over the shape, morphology, and size of the nanocomposites.133 However, it depends on the addition of a mediator between the magnetic core and the shell growth.133 Examples of these capping agents are once again polymers, facilitating the MOF overgrowth134 and also affecting the magnetic properties of the final magnetic nanocomposite.

Based on PVP-coated iron oxide particles, Zhuang et al.135 synthesized a 70 nm core–shell composite with a PVP-Fe3O4 core (∼50 nm) and a ZIF-8 shell with encapsulated fluorescein. Zhang et al.136 also prepared Fe3O4@ZIF-8 magnetic core–shell composites, but as microspheres (∼800 nm, MS = 54.6 vs 63.2 emu·g–1 of Fe3O4) starting from poly(styrenesulfonate, sodium salt) (PSS) functionalized Fe3O4 microspheres (∼600 nm) mixed with methanol, Zn(NO3)2·6H2O, and HmIM. Upon heating (50 °C/3h), the resulting composite showed diffraction peaks corresponding to both components, and the core–shell structure was clearly evidenced by microscopy. The aforementioned examples depict two opposing extremities regarding their dimensions. The former exemplifies dimensions that hold greater relevance to biomedical applications, albeit the study fails to thoroughly investigate the material’s magnetic properties and its potential application in biomedical contexts. Conversely, the latter serves as an illustration of a scenario wherein the magnetic core is employed merely as a means of material retrieval in catalytic applications. In addition, the variability in the selection of polymer to facilitate the growth of MOF shell is noteworthy. Specifically, in the former instance, the commonly employed amphiphilic and nonionic PVP was utilized and, in the latter case, the anionic PSS was opted for due to its established efficacy in reducing the surface charge to increasingly negative values (up to −26.9 mV from an initial value of −7.56 mV for unmodified MNPs). This reduction might promote interaction between the metal cation for deposition and subsequent MOF nucleation.

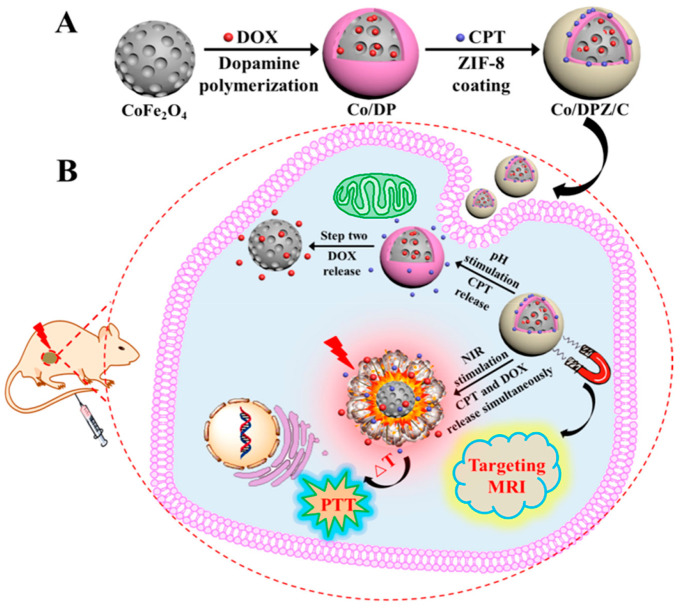

An alternative approach for forming polymer coatings over the MNPs is the use of PDA. For instance, the CoFe2O4@PDA@ZIF-8 nanocomposite137 evidenced the chelating effect of the PDA. Moreover, a different CoFe2O4magnetic core (∼70 nm) was employed, which exhibited a mesoporous structure. The magnetic nanocomposite (36.4 vs 68.5 and 50.3 emu·g–1 for CoFe2O4 and CoFe2O4@PDA, respectively) was obtained at room temperature after 30 min, starting from CoFe2O4@PDA (∼100 nm) dispersed in a Zn(NO3)2 methanol solution and, subsequently, with the continuous dripping of HmIM solution. In the PXRD patterns, the characteristic peaks of the cubic spinel phase of CoFe2O4 and the crystalline ZIF-8 could be found. Furthermore, the porosity of the magnetic core increased with respect to the MNPs from SBET ∼164 to 349.6 m2·g–1 due to the presence of the MOF. Finally, the architecture and morphology of the composite in TEM revealed a core–shell structure of around 150 nm. The PDA presence was proved to be essential for the formation of the ZIF-8 because, in the absence of the polymer, the interactions between the MNPs and the ZIF-8 do not form a core–shell architecture. Moreover, the negatively charged magnetic core advantageously presents hydrophilic open voids, which has extended the encapsulation capability of the hydrophobic ZIF-8 positively charged shell presented in the other nanocomposites.

A further example is the production of spheres consisting of Fe3O4@PDA@Cu3 (BTC)2 (∼300–500 nm; SBET ∼ 161 m2·g–1).138 Specifically, Fe3O4@PDA (∼280 nm) were dispersed in an ethanol solution of Cu(OAc)2·H2O and trimesic acid and altogether was heated at 70 °C. The composite formation was proved by PXRD. In this interesting work, the interface between the magnetic core and the MOF overgrowth was evidenced by TEM. The PDA was a homogeneous coating over the Fe3O4 surface, which stimulate the crystallization of the Cu3 (BTC)2 because the metal ions could be coordinated by the phenolic hydroxyl and amino groups of the PDA.138 From polydopamine-modified Fe3O4 particles, also Deng and colleagues139 described a solvothermal method for synthesizing a magnetic MIL-101(Fe) composite. A solution of FeCl3·6H2O and H2BDC in DMF was added to the magnetic Fe3O4@PDA particles (∼270 nm), then, and heated at 110 °C for 24 h. The TEM images clearly exhibited a core–shell structure with about 30 nm-thick shell of MIL-101(Fe) on the Fe3O4@PDA core. The thin coating of PDA once again acted as an interface between the MNPs and the framework structure.

Similarly, this strategy has been exploited also for Zr-MOF composites.140,141 In a solvothermal synthesis, Fe3O4@PDA particles (∼250–300 nm) were dissolved in a DMF solution containing ZrCl4 and the different dicarboxylate organic linkers (H2BDC,140,141 H2BPDC,141 and [2,2′-bipyridine]-5,5′-dicarboxylic acid (H2BPYDC)141). The functional groups (−OH, −NH2) of PDA can chelate to Zr4+, enabling MOF growth onto the MNP surface.141 In the H2BDC case,140 upon heating at 140 °C for 20 min, a porous core–shell nanocomposite (∼400 nm and SBET ∼ 216.14 m2·g–1) with an increase in the thickness of the PDA shell from 40 nm on the MNPs to an additional 47 nm of MOF was observed. The nanocomposite exhibited diffraction peaks consistent with the MOF growth and the MNPs presence. In the other study,141 the mixture solution of Fe3O4@PDA and Zr-MOF precursors was heated to 140 °C under stirring for 8 h. The PXRD patterns of all the nanocomposites exhibited peaks for Fe3O4 and the MOF’s crystalline structure, confirming the synthesis of Fe3O4@UiO-66, Fe3O4@UiO-66-PYDC, Fe3O4@UiO-67 and Fe3O4@UiO-67-BPYDC. The TEM images of all magnetic nanocomposites showed a core–shell composite with a shell thickness of the MOF of about 40–75 nm, and an average size of about 280–300 nm for the nanoparticles.141

As shown in the described studies, PDA coating of MNPs has provided functional groups (−OH, −NH2) as anchoring points for Cu-, Fe-, and Zr-MOFs. However, the polymer coating also affects the Fe3O4 core’s magnetic properties together with the MOF shell. Indeed, in general, the bare MNPs have a saturation magnetization which decreases with the surface coating and, even more, with the MOF shell. Nevertheless, the magnetic properties are tunable with an optimized synthesis. In fact, the in situ core–shell method relies on control of the size, as well as the shape and morphology control. Therefore, a control of the thickness of the MOF shell as well as the starting magnetic nanocore can tune the nanocomposites’ properties.

In recent years, other researchers proposed the synthesis of Fe3O4@UiO-66 or Fe3O4@UiO-66-NH2 nanocomposites employing PAA. Zhao and colleagues142 directly dispersed Fe3O4 nanoparticles (treated with PAA and urea, with a diameter size of ∼150 nm) into a DMF solution of the synthetic precursors of UiO-66 (ZrCl4, NH2-H2BDC). The core–shell Fe3O4@UiO-66 showed a UiO-66 shell of about 25 nm thickness, while the composite size was about 240 nm.142 The MS of both Fe3O4@UiO-67-BPYDC141 and Fe3O4@UiO-66142 exhibited similar values within the range of approximately ∼50 emu·g–1 (vs ∼70–75 emu·g–1 for Fe3O4). However, it was noteworthy that only the latter has undergone adequate dimension to facilitate its investigation as a theragnostic system, as elaborated on subsequently (see section 3.3: Theragnostics).

2.3.2.4. Synthesis of Magnetic Composite with Carbon- or SiO2-Functionalized MNPs

In addition to the aforementioned methods, there are two other possibilities. In the first case, MNP@MOFs can be synthesized employing Fe3O4@carbon (Fe3O4@C) nanoparticles. Besides the role in the stabilization of the magnetic core in the reaction mixture, the porous carbon shell can improve the imaging properties of the nanocomposites due to the carbon dots fluorescence. On this matter, He and co-workers143 synthesized ZIF-8 nanocomposites using Fe3O4@C nanospheres as the core. The nanocomposite (∼220 nm) was simply synthesized at 60 °C for 1 h by adding Fe3O4@C nanospheres (∼190 nm) in a methanol solution containing Zn(NO3)2·6H2O and HmIM.

In the second strategy, silica-capped MNPs (Fe3O4@SiO2) are employed, with the SiO2 capping conferring lower cytotoxicity to the MNPs.144 Moreover, the thickness of the silica surface over the Fe3O4 core can be easily tuned,145 and then, the magnetic responsivity varied as well as the porosity properties related to the mesoporous silica.144 Additionally, through different silanization agents, different functionalities can be included to promote the interactions with the MOF precursors. In the field of MNP@MOF nanocomposites, core–shell structures of Fe3O4@SiO2@MIL-100(Fe) were fabricated146−148 by the reaction mixture of Fe3O4@SiO2 (∼360,146 50,147 20148 nm) with the MIL-100(Fe) precursors under reflux at 100 °C for 8 h. In all these composites (∼440,146 50,147 50148 nm), the PXRD patterns confirmed the MIL-100(Fe) structure and the Fe3O4 phase.146 In this case, the detection of the magnetic component into MIL-100(Fe) could be recognized. It was observed a magnetic saturation decrease from 82.5 emu·g–1 for the MNPs to 30 emu·g–1 in the nanocomposite due to the SiO2 and MIL-100(Fe) shells, permitting an easy magnetic separation. However, the identification of the iron content by EDS did not allow to discriminate between the Fe3O4 and the MIL-100(Fe), distinguishing the Fe3O4 core from the MOF shell only by TEM.146

Instead, Jia et al.149 presented a thermoresponsive polymer, poly(N-isopropylacrylamide) (PNIPAM), tethered to Fe3O4@SiO2@MOF core–shell magnetic nanospheres. The magnetic composite Fe3O4@SiO2@UiO-66-NH2 was fabricated from Fe3O4@SiO2 nanospheres (∼200–300 nm) obtained by carboxylate-terminated reaction with succinic anhydride and (3-aminopropyl)triethoxysilane (APTES). The magnetic nanosphere were ultrasonically mixed with a DMF solution containing the UiO-66-NH2 precursors (ZrCl4, NH2-H2BDC and acetic acid). Fe3O4@SiO2@UiO-66-NH2 (MOF shell ∼ 30–50 nm) was obtained at 130 °C for 4 h under stirring, and after drying, the composite underwent to a subsequent reaction in chloroform using PNIPAM-NHS at 60 °C for 24 h. The Fe3O4@SiO2@UiO-66-NH2–PNIPAM nanospheres reached dimensions around 350–450 nm, presenting magnetic properties (MS ∼ 45.60 emu·g–1) with SBET ∼ 262 m2·g–1 and indexing the PXRD pattern to UiO-66-NH2 and Fe3O4. In the same manner, Yang et al.150 fabricated Fe3O4@SiO2@UiO-67 by dispersing Fe3O4@SiO2 in a ZrCl4 solution for the complexation of Zr4+ and adding then H2BDC and glacial acetic acid (heating at 120 °C for 24 h). The resulting Fe3O4@SiO2@UiO-67 nanocomposites (224–258 nm; MOF shell thickness ∼ 20 nm) were characterized by SEM and TEM, and compared with Fe3O4 (∼170 nm) and Fe3O4@SiO2 (∼208–232 nm). The composite exhibited a saturated magnetization lower than that of Fe3O4 (61.0 emu·g–1) and Fe3O4@SiO2 (47.3 emu·g–1), specifically 20.9 emu·g–1. Although, as expected, the shell reduced the magnetic properties, the MOF presence was there to influence its positive features, such as the porosity and biocompatibility.

The most evident “bottle around ship” strategy was reported by Huang and colleagues,151 Fe3O4@SiO2@Cu(OH)2, where the self-template shell of Cu(OH)2 over Fe3O4@SiO2 nanoparticles (∼15 nm) promoted the conversion of Cu(OH)2 into HKUST-1. Briefly, Fe3O4@SiO2@Cu(OH)2 in a water–ethanol solution of the organic linker (H3BTC) gave rise to core–shell nanostructures (MOF shell ∼ 5–10 nm) of Fe3O4@SiO2@HKUST-1 at room temperature after stirring for 12 h. This method was not so different from what was previously reported, the Cu ions being able to interact with the magnetic core before the MOF growth. The Fe3O4@SiO2@Cu(OH)2 precursor acted as a seed for the crystallization of the MOF, favoring a core–shell architecture.

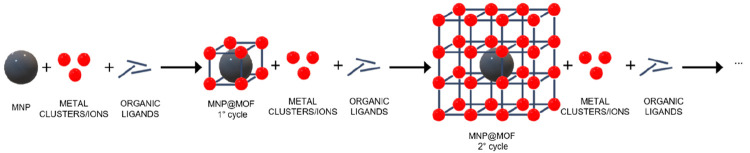

2.4. Layer-by-Layer Strategy

The layer-by-layer (LbL) strategy has the purpose to control the crystal growth of the MOF over the MNPs. The synthetic strategy is a step-by-step sequential repeated cycle of immersion in solutions of the metal precursor and solutions of organic ligand152 or MOF precursors solutions, first proposed in 2007 for HKUST-1.65 The protocol proposed by Shekhah was et al. extended to different MOF structures.153 Herein, we will present the extension of this strategy for the synthesis of magnetic composites, where the first layer of the MOF is over a MNP and the thickness of the MOF shell is controlled by the number of repeating cycles performed, as represented in Figure 6.

Figure 6.

Schematic representation of the layer-by-layer (LbL) strategy.

2.4.1. Synthesis of Magnetic Composites with Acid- Or Thiol-Functionalized MNPs

As was pointed out earlier, MNP functionalization has been employed for several advantages. In the LbL method, Ke and co-workers154 proposed magnetic core–shell spheres of Fe3O4@HKUST-1 or Fe3O4@MIL-100(Fe), subsequently, numerous works155−169 followed the same synthetic protocol with mainly a carboxylic functionalization over the magnetic core or thiol groups. In general, COOH-functionalized Fe3O4 MNPs ranging from 20 to 500 nm were dispersed in solutions of Cu(CH3COO)2.·H2O or FeCl3·6H2O precursors, respectively for Fe3O4@HKUST-1 or Fe3O4@MIL-100(Fe) composites. After 15–30 min and a magnetic recovery of the Fe3O4 nanoparticles, the organic linker solution (H3BTC) was mixed with the MNPs for 30 min at 25, 40, or 70 °C. These two steps formed a cycle to coat Fe3O4 with a layer of MOFs and each cycle was subsequently repeated several times. Generally, the diffraction peaks for the samples Fe3O4@HKUST-1 in the PXRD pattern matched well with those of both Fe3O4 and crystalline HKUST-1.154−156,162 In the case of SEM and TEM investigation for Fe3O4@HKUST-1, the images showed a spherical-shaped morphology with a core–shell structure with narrow size distribution and uniform dispersion (ranging from 210 nm to 1.5 μm depending on the number of assembling layers).154−156,162 The magnetic Fe3O4@HKUST-1 composites exhibited BET surface area variable depending on the number of cycles employed, with values from 57 to 668 m2·g–1; as expected the surface area increases with a larger number of MOF layers.154−156,162 Moreover, the magnetic properties and separability were also tested. For instance, the core–shell microspheres desired in the selective removal of Hg2+ and Pb2+ were separated in a few seconds in an aqueous solution by placing a permanent magnet near the glass bottle.162 The saturation magnetization varied from ∼14 to 43 emu·g–1 and all core–shell MNPs exhibited superparamagnetic behavior at room temperature, which also depicted the strong magnetic response to an AMF.

In the case of Fe3O4@MIL-100(Fe),154,157−161,163−169 the diffraction peaks for the samples were consistent with the crystalline phases of Fe3O4 and MIL-100(Fe). However, the intensities of MIL-100(Fe) patterns in some diffractograms were very weak, which was correlated to the low thickness of the MOF shell.158,161,166 By SEM and TEM, the magnetic composites reported a core–shell structure, with an average size dependent on the diameter of the MNP core and also on the number of layers, varying from 150 nm up to 1 μm.154,157−161,163−169 The BET surface areas of Fe3O4@MIL-100(Fe) increased with increasing assembly cycles, ranging from ∼36 to 899 m2·g–1 in the different composites reported.154,158−161,164−169 This general trend was due to the decreasing contribution of nonporous Fe3O4 MNPs to the total mass of the magnetic core–shell nanoparticles.158 Furthermore, the majority of these Fe3O4@MIL-100(Fe) presented magnetization saturation values in the range of ∼20–56 emu·g–1.154,158,160,163−169 It was observed either the presence of a magnetic hysteresis loop or no obvious remanence or coercivity at 25 °C. Therefore, the magnetic composites possessed ferromagnetic or superparamagnetic features and, for the majority of them, it was observed a simple magnetic separation in the solution media through a magnet in a few seconds. The great number of studies on MIL-100(Fe) based composite was related to the versatility of MIL-100(Fe), which had good in vitro and in vivo biocompatibility as well as important drug loadings for biomedical applications, and, moreover, a potential application for separations through strong coordination with guest molecules.160

Furthermore, the LbL strategy has also been proposed for other composites. For instance, Zheng et al.170 developed a Fe3O4@ZIF-8 core–shell structure (∼530 nm). The synthetic protocol consisted of citrate-Fe3O4 (∼390 nm) solution mixed with Zn(NO3)2·6H2O and HmIM, heating later at 70 °C for 20 min and, separating the product with a magnet. The thickness of the ZIF-8 shell was increased by repeating the above process several times. Likewise, also Liu et al.171 reported the fabrication of core–shell Fe3O4@ZIF-8. Both studies confirmed the Fe3O4@ZIF-8 formation by PXRD, indexing the diffraction peaks of Fe3O4 and crystalline ZIF-8. The specific surface areas were about 1075 m2·g–1, lower than that of the isolated ZIF-8 (SBET ∼ 1709 m2·g–1)171 as an effect of the Fe3O4 core on the formation of ordered microporous. On the other hand, the effect of the shell on the magnetic core was translated into a saturation magnetization value of 14.38 emu·g–1.170 A similar procedure was followed also for the complex multifunctional system, Fe3O4@PAA/AuNCs/ZIF-8 (∼130 nm).172 In this case, oleic acid (OA)-capped MNPs (∼20 nm) underwent, first, a polymer coating process with PAA, and then the gold nanoclusters (AuNCs) were integrated into the synthetic step for the MOF growth to obtain a theragnostic agent that combines multiple capabilities for cancer treatment.

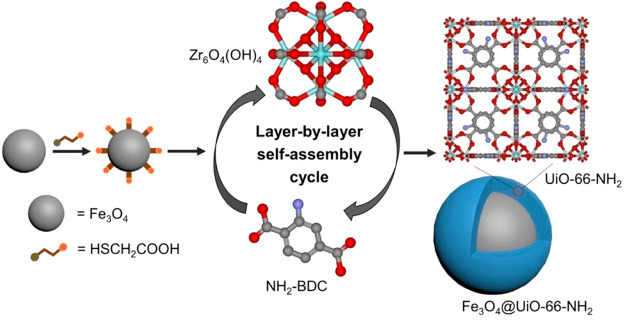

Another MOF widely used for this strategy was UiO-66-NH2. In this sense, Chen and co-workers173 reported a core–shell Fe3O4@UiO-66-NH2. During the synthesis, Fe3O4 nanoparticles (∼200–300 nm) functionalized with carboxylic moieties were immersed, first, in the metal node [Zr6O4 (OH)4]12+ precursor solution, and then, in the organic linkers (NH2–H2BDC) solution, respectively for 15 and 20 min (Figure 7). Before each subsequent immersion step, MNPs were recovered with a magnet and washed. After 20 cycles, the MOF shell was only around 13 nm, leading to a composite size of about 300–350 nm. The surface area increased for the magnetic Fe3O4 core with the MOF shell (SBET ∼ 11 vs 76 m2·g–1, respectively), far from the high value of the isolated UiO-66-NH2 (SBET ∼ 735 m2·g–1). The crystal growth was however not uniform throughout the magnetic iron oxide core. Therefore, the final morphology and structure may not justify the enormous effort and highly time-consuming of the method.

Figure 7.

Schematic illustration for the layer-by-layer fabrication of core–shell Fe3O4@UiO-66-NH2. Reproduced from ref (173). Copyright 2019 American Chemical Society.

Thus, the synthesis of materials using the LbL technique offers significant advantages in terms of adaptability in the final structure and consequent properties; therefore, in the optimization of the nanocomposite performance in diverse fields, offering a highly customizable approach to achieve desired applications. This versatility arises from the control of the number of synthetic cycles, directly correlated to the thickness of the resulting MOF, enabling adjustments to the porosity and magnetization characteristics. However, in contrast to the core–shell in situ formation of the MOF in the presence of MNPs, the LbL method is a more time-consuming procedure, with complex scalability.

2.4.2. Synthesis of Magnetic Composites with Polymer-Functionalized MNPs

In the LbL approach, for instance, Li et al.174 presented a core–shell Fe3O4@IRMOF-3, through the growth promotion of the MOF modifying the surface of the MNPs with PVP. In brief, the synthesis included the mixture of a dissolution of Zn(NO3)2 and NH2–H2BDC in DMF, with PVP in DMF:EtOH (3:2) and Fe3O4 nanoparticles, heating then at 100 °C for 4 h under vigorous stirring. All the previous steps were repeated several times. The PXRD patterns possessed diffraction peaks assigned to both Fe3O4 and the MOF. Also, it was demonstrated that a certain dosage of the polymer not only stabilized the MNP but also favored the crystalline growth of the MOF. In TEM images, after three cycles, the spherically shaped Fe3O4 nanoparticles (∼200–500 nm) were embedded in micrometric IRMOF-3 crystals, with a BET surface area and pore volume of 238 m2·g–1 and 0.31 cm3·g–1. The saturation magnetization values of Fe3O4 decreased from 78.5 to 13.5 emu·g–1, in the case of the composite formation due to the presence of the MOF layer. In this example, the synthesis involved uncoated-MNPs, where the presence of a polymer was necessary to favor the dispersion of the magnetic core and the consequent MOF growth.

Instead, Miao and colleagues175 synthesized a core–shell magnetic Fe3O4@P4VP(poly(4-vinylpyridine))@MIL-100(Fe) composite. In this example, the PAA-functionalized Fe3O4 where involved in a polymer-shell formation, Fe3O4@P4VP, to favor the interactions between pyridine and Fe3+. Then, Fe3O4@P4VP nanospheres (magnetic core ∼200 nm and polymer shell ∼38 nm) were dispersed in an ethanol solution, first, of FeCl3·6H2O for 15 min and collected with a magnet; subsequently, they were dispersed in an H3BTC ethanolic solution and stirred at 70 °C for 30 min. These steps were repeated, giving a composite confirmed in the PXRD pattern. In the HR-TEM, the images clearly showed a 200 nm-diameter magnetic core with a shell thickness of the polymer of 38 nm and the outer MIL-100(Fe) thickness ranging between 15 and 90 nm, depending on the number of assembling cycles (from 5 to 20 cycles). The magnetization saturation values decreased from 73.90 emu·g–1 for Fe3O4-(PAA) to 47.35 and 28.21 emu·g–1, respectively for Fe3O4@P4VP and Fe3O4@P4VP@MIL-100(Fe). These results indicated that the materials exhibited a strong magnetic response.

2.4.3. Synthesis of Magnetic Composites with SiO2-Functionalized MNPs

The versatility of the SiO2-functionalized MNPs to obtain a core–shell structure via the LbL method was only proposed in the work conducted by Jiang et al.176 A sophisticated nanocomposite consisting of two distinct 3D MOF structures based on the same ligand, namely, SiO2@Fe3O4@Yb-MOF@Nd-MOF, was proposed, involving the SiO2@Fe3O4 as a core template for the successive synthesis of multiple MOF layers. In the first synthetic step, the SiO2-functionalized MNPs were added to a solution containing ytterbium(III) acetate at 80 °C for 5 min in a DMF/H2O mixture. Subsequently, the resulting mixture was centrifuged to separate the precipitate from the supernatant. In the second step, the separated precipitate was once again suspended in a solution containing terphenyl-3,4″,5-tricarboxylic acid (H3L) ligand. This step followed a similar procedure to that of the first step. Moving on to the third step, a solution of neodymium(III) trichloride was employed, following the same sequence as in step 1. Finally, in the fourth step, the process from step 2 was repeated. All these complex steps were then cyclically repeated 14 times. Based on TEM images, the MNPs’ core could be identified, enveloped by a silica layer with a thickness < 6.5 nm. Additionally, sequential layering of MOFs ranging from 9.86 to 21.63 nm was observed, resulting in a total nanocomposite size of approximately 150–200 nm. This innovative example introduces in the LbL method the alternating arrangement of two MOFs that share the same ligand. The resulting structure appears to be relatively complex and warrants further investigation, particularly concerning the magnetic properties of the core and the surface area characteristics, as well as the variability of the properties increasing the cycle number.

3. Applications of Magnetic Metal–Organic Framework Composites in the Biomedical Field

As mentioned in the Introduction, combining MOFs as promising nanocarriers and MNPs to provide potential imaging, targeted release, and hyperthermia, makes the MNP@MOF nanocomposites particularly interesting in diagnosis, therapy, and theragnostics. The most recent developments will be covered in this section, categorized in therapy, MRI, and theragnostics, comprising nanocomposites with sizes below 500 nm, and analyzing the potential of these systems for their real application.

3.1. Therapy

The administration of therapeutic agents by nanocarriers has been developed to minimize toxicity and side effects, increase the efficacy avoiding early clearance, and ensuring a progressive and located drug release within the active sites.177,178 Since 2006 and 2010, when micrometric8 and nanoscaled6 MOFs were originally proposed as DDSs, great advances have been achieved in this exciting topic.179,180 In particular, this section will describe in detail the use of MNP@MOF nanocomposites as DDS, providing representative examples. Finally, as far as we know, the only work describing magnetic nanocomposite as magnetic hyperthermia (MHT) agents will be presented, as a nice combination of MHT and DDS to further improve the therapeutic efficacy.

Based on one of the most used families of MOFs for bio applications, as a proof of concept, the anti-inflammatory drug ibuprofen (IBU) was successfully encapsulated in a γ-Fe2O3@MIL-53(Al) nanocomposite, reaching a drug loading of 110 mg·g–1 with a long progressive release in PBS at 37 °C (7 days).77 Considering the potential toxicity of this Al-based MOF, the IBU was successively loaded in a magnetic LbL composite (MS ∼ 50.69 and 20.42 emu·g–1, after 40 and 20 cycles, respectively) based on the biocompatible MIL-100(Fe) (Fe3O4@MIL-100(Fe)),158 achieving higher IBU loadings (310 mg·g–1) associated with a greater porosity. In this exploratory research, the IBU release under simulated physiological conditions (PBS, pH 7.4) took place for about 35% in the first 2 h, then it slowed down and was completed in 70 h. These works evidenced the possibility to encapsulate drugs into magnetic nanocomposites. However, these preliminary studies only tested the drug encapsulation and the release without further practical considerations (e.g. biocompatibility, in vitro and in vivo therapies).

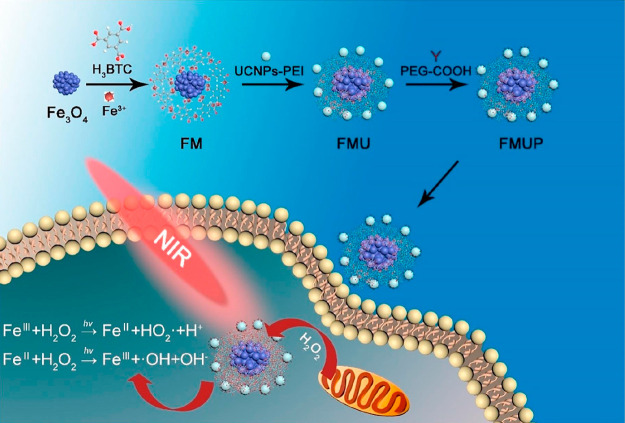

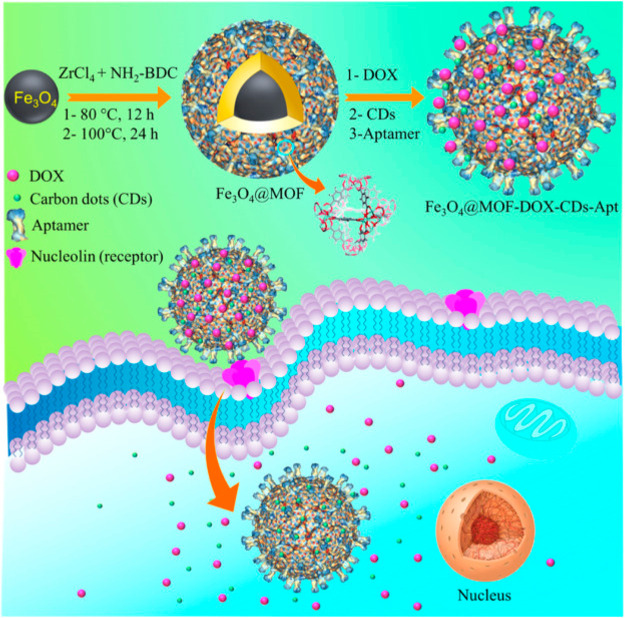

In recent times, significant effort has been predominantly placed on the encapsulation of more challenging antitumoral drugs. As far as cancer therapy is concerned, a large number of studies have reported the use of the convenient fluorescent antitumoral drug doxorubicin (DOX), widely used in clinics to treat a variety of human diseases, including Hodgkin’s lymphoma, leukemia, multiple myeloma, breast cancer, osteosarcoma, ovarian cancer, and lung cancer.181 This chemotherapeutic product was granted FDA approval as the first nanodrug in 1995 and, at present, is known under the brand name Doxil, a liposomal formulation.182 Even if the DOX hydrochloride salt formulations on the market have a high therapeutic index and high efficacy against a variety of solid tumors, they are also associated with significant side effects including heart damage, typhlitis, cardiac arrhythmias, nausea, and vomiting.181 Thus, DOX delivery through nanocarriers has garnered considerable interest. Within the magnetic MOF-based nanocomposites, DOX was encapsulated in Fe3O4-NH2@MIL-101(Fe)-NH2 (∼140–330 nm; MS ∼ 20.47–21.32 emu·g–1 vs 27.67 emu·g–1 for Fe3O4-NH2).130 Its DOX loading capacity was optimized by using different MNP:MOF ratios, reaching the highest loading (360 mg·g–1) at 1:1 molar ratio due to the improved porosity (SBET = 96 m2·g–1 vs 12–88 m2·g–1). The relative amount of dense MNPs in comparison to the pure MOF elucidates the significantly diminished porosity of the nanocomposite (pure MOF reaching 1800 m2·g–1).183 The drug release, dependent on pH, was faster under acidic media due to MOF degradation, simplifying targeted DOX release in acidic cancer cells. Nevertheless, 37–61% of DOX release from the composite in simulated body fluid (SBF) at pH 7.4 occurred in 48 h, more gradually than pristine MIL-101(Fe)-NH2. Furthermore, cytotoxicity tests pointed out the biocompatibility of the nanocomposite and the applicability of the DOX-loaded composite as a DDS. In this sense, the biocompatibility and controlled DOX release in an acidic environment were further guaranteed by coating a Fe3O4@Fe-MOF composite with hydroxyapatite (HAp),184 although HAp is present in the body at the hard tissue level. In this case, the DOX capacity was 53 and 75 mg·g–1 in Fe3O4@Fe-MOF and Fe3O4@Fe-MOF@HAp, respectively. Indeed, the HAp-coating not only increased the drug cargo but also contributed to a more gradual release (at pH 7.4, 25 vs 46% after around 11.7 h from the HAp-coated and noncoated systems, respectively). Finally, cytotoxic assays confirmed the biocompatibility of both composites and the selective DOX effect on HeLa cells.

Another nanocomposite that was employed for DOX release was based on ZIF-8. In this study, DOX was encapsulated in the Fe3O4@ZIF-8 nanocomposite (∼70–100 nm) with a content of about 120 mg·g–1 and a loading efficiency of 12%.185 The release was proven to be controlled over time without a burst effect, and its in vitro biosafety was demonstrated on the hepatocarcinoma cell line (MHCC97H). Similarly, in the biocompatible Fe3O4@ZIF-8 nanocomposite (∼180 nm, MS ∼ 18.6–37.2 vs 48.1 emu·g–1 for Fe3O4), developed by Chen and co-workers,121 the DOX encapsulation was enhanced (330 mg·g–1, 76.6% of loading efficiency). In this latest example, an elevated concentration of DOX during encapsulation may have increased loading efficiency. Plausibly, it is due to a surplus of DOX adsorbed in the outer surface due to the electrostatic interaction between the negatively charged carboxylate groups and positively charged DOX molecules.186 Additionally, the strong coordinative affinity of the C–O and C=O groups may contribute to the formation of coordination bonding of Zn2+-DOX in aqueous solutions.187 The drug release in PBS after 48 h was higher at pH 5.5 (63%) than at pH 7.4 (33%), showing again a pH dependence that was in line with the acidic environment in the cancer cell. Moreover, the resulting Fe3O4@ZIF-8 nanocomposite evidenced photothermal effects under laser irradiation (808 nm), showing a selective cancer cell death for the Fe3O4@ZIF-8-enriched area. This study investigated the magnet-targeted photothermal effect of the composites in a preliminary manner. Prior studies indicated that Fe3O4 nanoparticles exhibit an outstanding photothermal effect,188 hence, this work showed that the formation of composites does not impede cancer treatment under these laser conditions. Furthermore, the possibility of evaluating promising combined antitumoral therapies, considering DOX-encapsulated Fe3O4@ZIF-8, warrants further investigation.

Likewise, a magnetic composite based on the UiO-66-NH2 material was studied as DDS for the anticancer DOX, proposing Fe3O4@UiO-66-NH2 (∼150 nm) with hybridization over a layered 2D material, the graphdiyne (GDY).189 In the resulting complex nanocomposite (∼250 nm; Fe3O4@UiO-66-NH2/GDY), the macroporous structure of the GDY offered an ulterior surface for drug uptake, resulting in a high DOX loading content of 438 mg·g–1. Once more, the composite demonstrated a pH-dependent DOX release (after 36 h, 49 vs 34% released at pH 5 and pH 7.4, respectively), negligible cytotoxicity, and efficient endocytosis-mediated drug carrier uptake in HeLa cells. Notably, the antitumor activity of the DOX-loaded Fe3O4@UiO-66-NH2/GDY nanocomposite was evaluated in vivo in BALB/c-nu mice, displaying no obvious toxicity with promising tumor-targeting and -inhibition when compared with the free DOX (77.8 vs 27.7%).

As anticipated in the introduction of this section, magnetic nanocomposites present also a strong potential in the development of MHT oncological therapy. MHT consists of increasing the temperature (42–46 °C) in a target tumoral tissue by using nanoheating probes (i.e., MNPs) under an AMF in the kHz radiofrequency range.190,191 In clinical use, for patient safety, a frequency of 100 kHz and a magnetic field amplitude of 15 kA·m–1 is generally employed.190,191 In this regard, the only reported example so far was Fe3O4@PDA@ZIF-90 with an average particle size of about 200 nm, originally reported for combined MHT and chemotherapy.97 This magnetic nanocomposite (MS ∼ 9.2 vs 22.5 and 17.3 emu·g–1 for Fe3O4 and Fe3O4@PDA, respectively) exhibited a good increase of temperature from 30 to 45.6 °C under an AMF at 409 kHz and 14.3 kA·m–1 for 20 min. In this experiment, the frequency of the AMF is 4-fold greater than the value for clinical use. For comparison, under the same conditions, Fe3O4 and Fe3O4@PDA controls led to a temperature increase up to 77.5 and 49.4 °C, not adapted to safe physiological values. Furthermore, the DOX-loaded Fe3O4@PDA@ZIF-90 composite (160 mg·g–1, with a loading efficiency of 80%) demonstrated a faster release as the acidity increases (PBS pH 7.4, 6.0, and 4.5). This fact, together with the magnetic heating, could favor the DOX release at the tumor level, combining chemotherapy and MHT. In fact, for DOX-loaded Fe3O4@PDA@ZIF-90, cell death was enhanced under an AMF, demonstrating a hyperthermia therapy in combination with chemotherapy for only the drug-loaded nanocomposites (i.e., cell viability without AMF, with AMF once and twice, respectively, for the composite = 110, 60 and 40% and DOX-loaded composite = 80, 30 and 10%).