Abstract

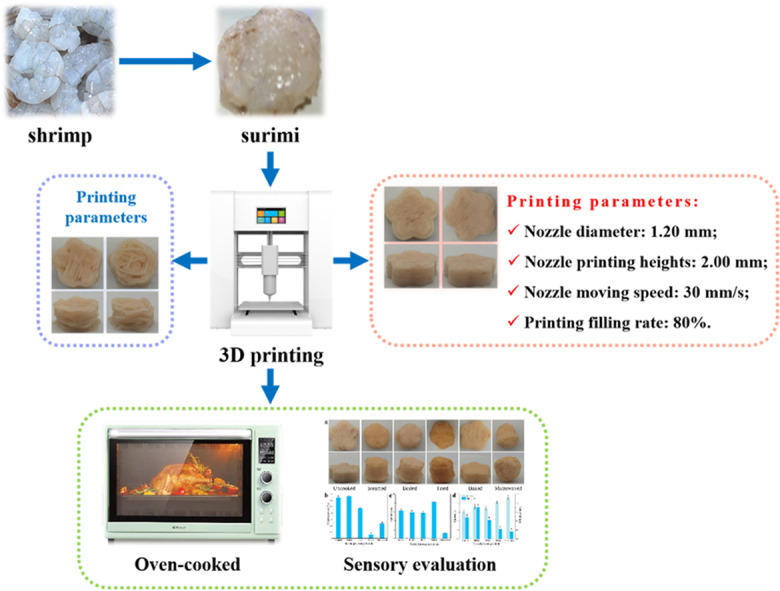

Improving the printing accuracy and stability of shrimp surimi and finding appropriate printing parameters and suitable thermal processing method can help to develop high value-added 3D printing products of shrimp surimi. It was found that in order to make the 3D printing products of shrimp surimi have higher printing adaptability (printing accuracy and printing stability reach more than 97%), by choosing nozzle diameter of 1.20 mm and setting the printing height of the nozzle to 2.00 mm, the layers of the printed products were better fused with each other, and the printing accuracy of the products could be greatly improved; there was no uneven discharge and filament breakage when the nozzle moved at the speed of 30 mm/s; and the products were internally compact and had good stability when the printing filling rate was 80%. In addition, the deformation rates of steamed, boiled and deep-fried shrimp surimi products were significantly higher than those of oven-baked and microwaved shrimp surimi products (P < 0.05). Microwave heating had a greater effect on the deformation and color of shrimp surimi products, and was not favored by the evaluators. In terms of deformation rate, sensory score, and textural characteristic, the oven-baked thermal processing method was selected to obtain higher sensory evaluation scores and lower deformation rates of shrimp surimi 3D printed products. In the future, DIY design can be carried out in 3D printing products of shrimp surimi to meet the needs of different groups of people for modern food.

Keywords: 3D printing, Shrimp surimi, Printing parameters, Thermal processing methods, Printing adaptability

Graphical abstract

Highlights

-

•

Printing parameters and cooking methods are key factors in food 3D printing.

-

•

Suitable printing parameters improved the 3D printability of shrimp surimi.

-

•

Oven-cooked had the least effect on deformation rate of 3D printing shrimp surimi.

1. Introduction

Litopenaeus vannamei, also known as South American white shrimp, is rich in amino acids, minerals, polyunsaturated fatty acids and other nutrients, and is favored by consumers for its rich nutrition and delicious meat (Jia et al., 2019). Currently, they are usually marketed in the forms of fresh shrimps, frozen shrimps and shrimp surimi products. Shrimp surimi product is one of the deep processing products of shrimp, but the existing shrimp surimi products in the market are relatively simple in shape, which can not meet the needs of consumers in personalized customization (Pan et al., 2021). Previous studies found that shrimp surimi, as a sol-gel with good plasticity and deformability, could be innovated into different shapes through 3D printing technology, greatly increasing its product innovation and product value, and alleviating the problems of single consumption and low cost performance of shrimp surimi to a certain extent (Pan et al., 2021, 2022, 2024).

3D printing, also known as additive layer manufacturing, is a three-dimensional printing method that obtains set models through layer-by-layer stacking. As a new technology that integrates digital software and processing equipment, 3D printing can fulfill personalized product design and production (Dankar et al., 2018). Nowadays, 3D printing technology has been applied in bioengineering, engineering manufacturing, medicine, and aerospace and other fields (Zheng et al., 2021) after continuous improvement and diversified development. Therefore, food 3D printing emerged at the historic moment and gradually developed into one of the hotspots of current research, with the more popular products of 3D printing cookies (Pulatsu et al., 2020), pizza (Lipton et al., 2015), cheese (Tohic et al., 2018), chocolate (Rando and Ramaioli, 2021) and so on. In the process of production and processing, printing parameters are considered as factors that directly affect the adaptability of 3D printing (Feng et al., 2019; Wang et al., 2021). In order to obtain 3D printing products with high printing accuracy and stability, it is necessary to find the most appropriate printing parameters for different printing materials. Yang et al. (2018) proposed the influence of printing parameters on product quality when studying the 3D printing of lemon juice gel system, and explored a new formula to explain the relationship between nozzle diameter, nozzle printing speed, and extrusion rate. Liu et al. (2019) found that by optimising the printing parameters, the printed dough could have the advantages of neat structure, clear texture contour, and smaller overall deformation. In addition, most materials for 3D printing products are not ready to be eaten and need to be cooked by thermal processing before they can be consumed (Ross et al., 2021). At the same time, the choice of thermal processing method has a decisive influence on the final shape of the printed product. Traditional thermal processing methods include: steaming, boiling, frying, baking and microwave, etc (Cao et al., 2022). The main difference lies in the heat conducting medium and the heating source (Chandra et al., 2021). In steaming, boiling and frying, steam, water and oil are respectively used as heat conducting medium for thermal processing of shrimp surimi products, while in baking and microwave heating, only air can be used as the heat conducting medium and non-open fire heat source for heating (Ni and Datta, 1999; Nekouei and Rezaei, 2023). Although each of these different thermal processing methods has its own characteristics, it is urgent to choose one that maximizes the retention of the printed shape (Yang et al., 2019).

The 3D printing parameters of shrimp surimi have a significant impact on the quality of the product, and an inappropriate selection of the cooking method will cause deformation of the 3D printing food to some extent. In order to solve the problems in the printing process and improve the molding effect of the printed products, it is essential to choose the appropriate printing parameters and thermal processing methods. Therefore, a single-factor experimental design was adopted in this study to explore the effects of the main printing parameters such as nozzle diameter size, nozzle printing height, nozzle moving speed, and printing filling rate on the accuracy and stability of 3D printing of shrimp surimi, and optimise the printing parameters. At the same time, the suitable thermal processing methods for 3D printing products of shrimp surimi were screened by comparing the effects of different thermal processing methods on 3D printing products of shrimp surimi in the sensory perception and the deformation rates, that is, evaluating the 3D printed products from the aspect of sensory perception, and analyzing the deformation rates and the textural characteristics of the products by using a comprehensive scoring method. In this study, explored the main parameters for 3D printing of shrimp surimi and different thermal processing methods to improve the adaptability of 3D printing surimi, to meet the needs of consumers’ personalized nutritional diet, to improve the added value of surimi products, and to provide a theoretical basis for 3D printing application of shrimp surimi and improving the quality of 3D printing products.

2. Materials and methods

2.1. Materials

Salt (Guangdong Salt Industry Group Co., Ltd., Guangzhou, Guangdong, China), cross-linked starch (Meruo Industry Co., Ltd., Zhengzhou, Henan, China), soybean isolate protein powder (Pine Biological Co., Ltd., Linyi, Shandong, China), and lard oil (Gaojin Food Co., Ltd., Suining, Sichuan, China) were purchased from Wal-Mart Stores (Zhanjiang, China).

2.2. Preparation of shrimp surimi

Fresh Litopenaeus vannamei (30–40 individuals/kg) were purchased from the Happy Ocean Aquatic Market (Zhanjiang, China), and immediately transported to the laboratory in seawater tanks. The shrimps were then stunned in an ice bath, and after removing the heads, shells, and intestinal glands, they were placed in a blender (GZB20, Machinery Department Shanbao Food Factory, Guangzhou, China) and blended for 5 min. The minced shrimps were rinsed three times in ice water. After that, the shrimp surimi was wrapped in three layers of gauze for manual dehydration and added with 3% salt to blend for 2 min. Then, 4.5% cross-linked starch, 4.5% soybean protein isolate powder, and 3% lard oil were added to the shrimp surimi successively and beat together for 2 min. The whole preparation process was kept at the temperature of 2∼5 °C.

2.3. Printing parameter settings

A syringe-type fused deposition modelling 3D food printer (FOODBOT E1, Shinnove, Zhejiang, China) was used. The 3D printing model designed for this experiment is a three-dimensional petal, with the diameter of 30 mm, and the height of 10 mm. Firstly, a single-factor experimental design was used to study the effects of nozzle diameter sizes, nozzle printing heights, nozzle moving speeds, and printing filling rates on the adaptability of 3D printing of shrimp surimi. The factors and levels were set as follows.

-

(1)

Effect of nozzle diameter on the adaptability of 3D printing of shrimp surimi

The cylinder temperature of the 3D printer was set as 25 °C; the nozzle moving speed was 30 mm/s; the nozzle printing height was 2.00 mm; the printing filling rate was 80%, and the nozzle diameter of the 3D printer were selected as 0.40, 0.60, 0.84, and 1.20 mm, respectively.

-

(2)

Effect of nozzle printing heights on the adaptability of 3D printing of shrimp surimi

The cylinder temperature of the 3D printer was set as 25 °C; the nozzle diameter of the 3D printer was 1.20 mm; the nozzle moving speed was 30 mm/s; the printing filling rate was 80%; and the nozzle printing heights were set as 1.00, 2.00, 4.00, 6.00, 8.00, and 10.00 mm, respectively.

-

(3)

Effect of nozzle moving speeds on the adaptability of 3D printing of shrimp surimi

The cylinder temperature of the 3D printer was set as 25 °C; the nozzle diameter of the 3D printer was 1.20 mm; the nozzle printing height was 2.00 mm; the printing filling rate was 80%; and the nozzle moving speeds were set as 20, 25, 30, 35, and 40 mm/s, respectively.

-

(4)

Effect of printing filling rates on the adaptability of 3D printing of shrimp surimi

The cylinder temperature of the 3D printer was set as 25 °C; the nozzle diameter of the 3D printer was 1.20 mm; the nozzle moving speed was 30 mm/s; the nozzle printing height was 2.00 mm; and the printing filling rates were set as 0, 20, 40, 60, 80 and 100%, respectively.

2.4. Calculation of 3D printing accuracy and stability

The printing accuracy and stability were analyzed by referring to the methods of Pan et al. (2021). After printing, the plane diameter (Ds, mm) and height (H0, mm) of 3D printing products were measured by vernier calipers. At the same time, the 3D printing products were evaluated in terms of appearance. The printing accuracy (%) was calculated through Equation (1). The printed product was placed at room temperature (25 °C) for 60 min, and then the height of the printed product was measured (H60, mm). The printing stability (%) was calculated through Equation (2). The printing accuracy and stability were calculated as follows:

| (1) |

| (2) |

where Ds represents the diameter of the finished product (the mean value of the diameter of the bottom layer and the top layer), mm; Dm stands for preset diameter, mm; H0 is the height of the sample when it stands for 0 min after printing, mm; H60 is the height of the sample when it stands for 60 min after printing, mm.

2.5. Product thermal processing method

The 3D printing model designed for this experiment is a three-dimensional petal, with the diameter of 30 mm, and the height of 10 mm. The cylinder temperature of the 3D printer was set as 25 °C, and the parameters of the 3D printer were set according to the results of the single-factor test of optimized printing parameters in the early stage. After printing, the 3D printed shrimp surimi was processed by different thermal processing methods. The effects of the different thermal processing methods on the deformation rate of 3D printed products of shrimp surimi were studied, and the sensory evaluation of the products was carried out. Meanwhile, the 3D printed products were photographed by digital camera in the LED light box and the effects were evaluated from the appearance. The specific settings for different thermal processing method are as follows.

-

(1)

Steaming: Place the printed shrimp surimi in a steamer, and steam for 5 min.

-

(2)

Boiling: Place the printed shrimp surimi directly in the boiling water, and boil for 5 min.

-

(3)

Frying: Place the printed shrimp surimi in 200 mL of hot oil, and fry for 30 s.

-

(4)

Baking: Place the printed shrimp surimi in the oven with the upper and lower tube temperature at 100 °C, and bake for 5 min.

-

(5)

Microwaving: Place the printed shrimp surimi into 600 W microwave oven, and microwave for 30 s.

2.6. Calculation of product deformation rate

The volumes of the uncooked 3D printed shrimp surimi and the cooked products were measured by using the millet exclusion method (Al-Mashikiii and Nakai, 1987). The volume of each sample was calculated using Equation (3), and the deformation rate of the 3D printed products of shrimp surimi with different thermal processing and cooking methods were calculated using Equation (4).

| (3) |

| (4) |

where V1 is the volume of millet, cm3; V2 is the volume of millet plus sample, cm3; Vq is the volume of uncooked 3D printed sample of shrimp surimi, cm3; Vh is the volume of 3D printed sample of shrimp surimi cooked by different thermal processing methods, cm3.

2.7. Sensory evaluation of product

The sensory evaluation on the quality characteristics of 3D printed products of shrimp surimi were carried out by using a comprehensive scoring method, and the sensory evaluation method referred to Farahani et al. (2021, 2022a) were slightly modified. The sensory evaluation team consisted of 10 trained sensory evaluators. The sensory evaluators firstly evaluated the appearance of the 3D printed products of shrimp surimi with different thermal processing methods, and conducted sensory evaluation according to the criteria in Table 1. Evaluation indicators are appearance, texture, taste and color. The score of each item ranges from 0 to 10 points, with the weight ratio of 50% for appearance, 20% for texture, 20% for taste, and 10% for color, respectively. The higher the score, the better the quality. The overall score is calculated by the following Equation:

| (5) |

where a is the evaluation index; b is the evaluation weight; i = 1, 2, 3 …... n; and the scoring results were expressed as the mean ± standard deviation of the data obtained by 10 sensory evaluators.

Table 1.

Sensory scoring table of 3D printing products of shrimp surimi with different thermal processing methods.

| Description | 10 | 9–6 | 5–3 | 2–0 |

|---|---|---|---|---|

| Appearance(50%) | Nice integrity; beautiful shape | Better integrity; better shape | Poor integrity; slight deformation | Bad integrity; serious deformation |

| Texture(20%) | Tight tissue; good elasticity; good tenderness; moderate soft and hard | Tight tissue; good elasticity; better tenderness; better soft and hard | Slightly tight tissue; better elasticity; poor tenderness | Loose tissue; poor elasticity; bad tenderness; slightly soft meat |

| Taste (20%) |

Delicious flavour; pure fragrance with unique mellow fragrance | Good flavour; normal meat taste good fragrance | Poor flavour; unapparent fragrance | Bad flavour, discomfort taste; bad fragrance |

| Color(10%) | Glossy surface; uniform color | Glossy surface; basically uniform color | Slightly glossy surface; basically uniform color | Poor surface gloss; uneven color |

2.8. Determination of product texture characteristics

TMS-Pro texture tester (FTC, USA) was used to conduct the texture profile analysis of shrimp surimi products, referring to the method of Farahani et al. (2022b), Farahani and Mousavi (2023a), and Farahani et al. (2023b). The 3D printed products of shrimp surimi with different thermal processing methods were placed on the operating table to measure the hardness and springiness.

2.9. Diversity display of 3D printed products of shrimp surimi

In order to reflect the diversity of 3D printed products of shrimp surimi, different models were designed for 3D printing. The printed samples were cooked using pre-screened thermal processing, while the uncooked and the cooked 3D printed samples were photographed with a digital camera (M200 15–45, Canon Co., Ltd., Tokyo, Japan) in the LED light box to evaluate the effects of printing and thermal processing in terms of appearance.

2.10. Statistical processing

In this experiment, three batches of shrimp surimi were processed by 3D printing. For each batch of samples, the texture test was repeated 5 times in parallel, and other tests were repeated 3 times in parallel. The measured data were expressed in the form of mean ± standard deviation. JMP Pro 16 statistical software (Version Pro 16, SAS Institute Inc., Cary, NC, USA) was used to conduct variance analysis, and Tukey's multiple comparison of the data, with a confidence level of 95% (P < 0.05).

3. Result and discussion

3.1. Effect of nozzle diameter sizes on 3D printing of shrimp surimi

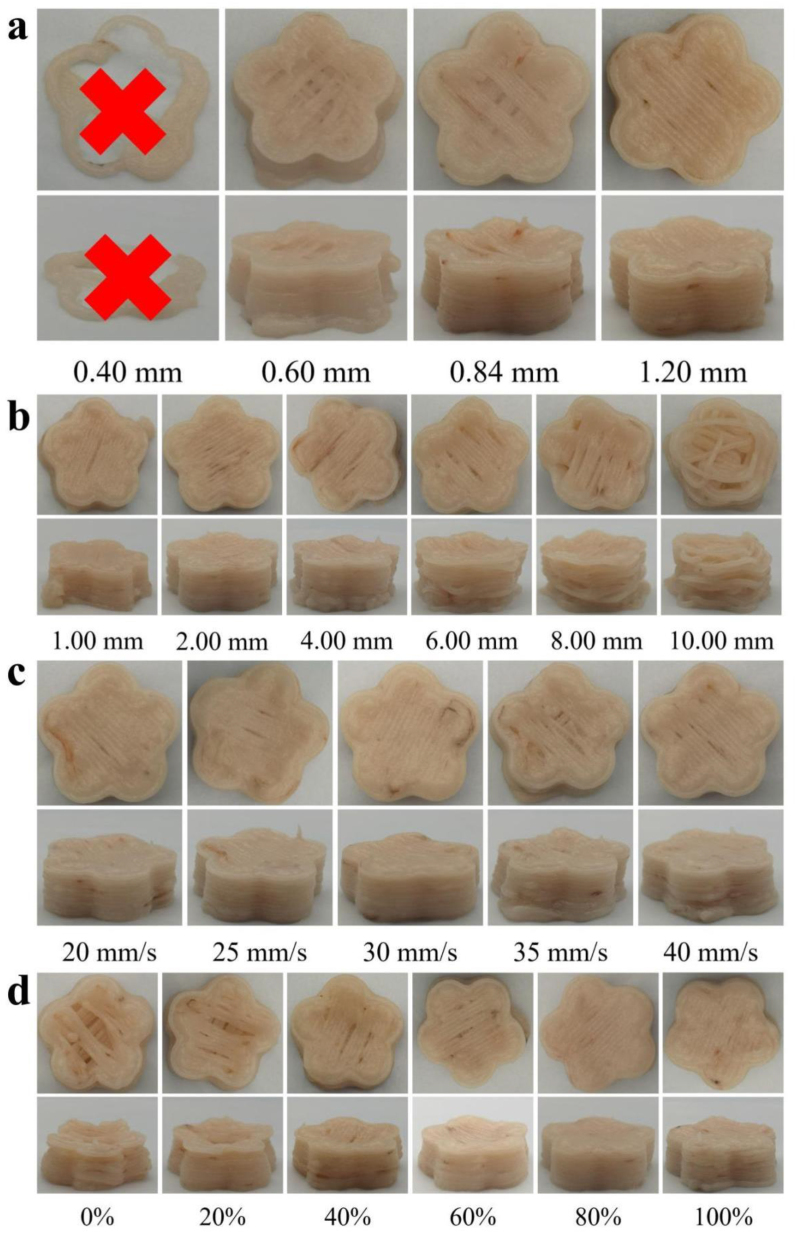

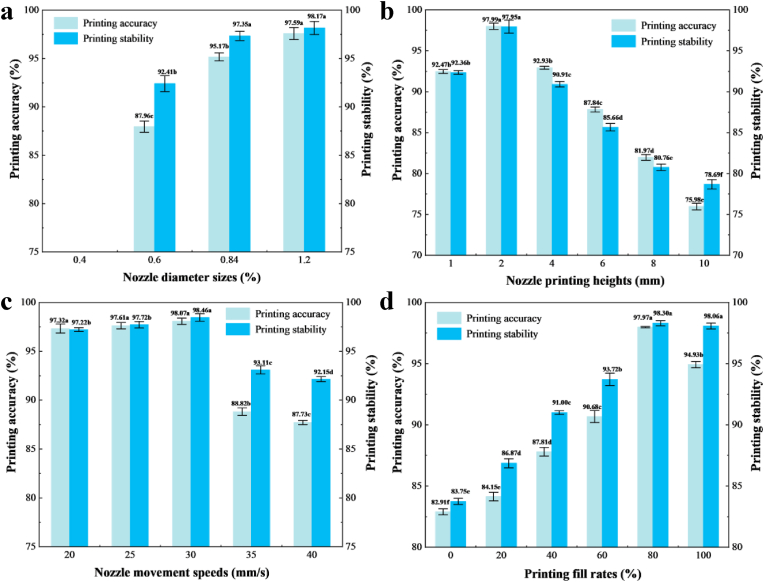

The nozzle diameter has a direct impact on the printing accuracy of 3D printing products and the smoothness of the product surface. Selecting an appropriate nozzle diameter can greatly improve the printing accuracy of the product (Yang et al., 2018). The smaller the diameter of the nozzle, the higher the printing accuracy of the printed product, but when the diameter of the nozzle is too small, the material extrusion will be affected. That is, the nozzle tends to be blocked due to the lack of delicacy of the material, resulting in the discharge difficulty. At the same time, too small diameter of the nozzle will also increase printing time and extrusion force, which can make the 3D printer overloaded, and even cause machine loss, if the extrusion force is too high for a long time (Wang et al., 2022). If the nozzle diameter is too large, the printed products will be relatively rough, with less clear print lines and patterns and it may even be impossible to recognize the appearance of the printed products (Liu et al., 2020; Yang et al., 2018). The top view and front view of the products printed with different nozzle diameters are shown in Fig. 1a, from which it can be seen that when the nozzle diameter was 0.40 mm, the material couldn't pass through the nozzle due to the small diameter of the nozzle, resulting in printing failure. When the nozzle diameter was 0.60 mm, uneven discharge and deposition collapse occurred at the bottom of the printed product, which may be because the diameter of the nozzle was small, and the materials could not be extruded from the nozzle smoothly, resulting in the stacking of materials, sudden extrusion, deposition collapse, and other phenomena (Fahmy et al., 2020) of the product. When the nozzle diameter is 0.84 mm, the printing effect of the product is improved, but the uneven discharge of the product may also be caused by the blockage of the nozzle, which is probably due to the fact that the binding chitin in the upper carapace on the surface of the shrimp surimi tends to stick together in the process of blending and block the nozzle due to its dense tissue structure (Nikoo et al., 2016). The best printing results with shrimp surimi were achieved when the nozzle diameter was 1.20 mm, without uneven discharge caused by blocking the nozzle. The study of Wang et al. (2018) showed that when the nozzle with a diameter of 2.00 mm was used to print silver carp surimi, the sample quality was the best. If the diameter of the printing nozzle was too small, the material is easy to block the nozzle and the printing effect was not good. In addition, the research results of Yang et al. (2019) showed that the dough printed by the nozzle with a diameter of 2.00 mm still had a good appearance and high printing stability after standing for 20 min. In short, it can be clearly seen from these studies that the size of the nozzle diameter has a significant impact on printing accuracy and the smoothness of the product surface, and that the optimal printing nozzle diameter varies for different materials. As can be seen from Fig. 2, Fig. 3, 3D printing accuracy and stability of shrimp surimi showed a gradually increasing trend with the increase of printing nozzle diameter (P < 0.05). There was a slight difference in 3D printing accuracy between 0.84 mm nozzle diameter and 1.20 mm nozzle diameter (P < 0.05), while there was no significant difference in 3D printing stability between them (P > 0.05), which is generally consistent with the appearance analysis of 3D printing products in Fig. 1a. Therefore, the nozzle diameter of 1.20 mm was adopted to achieve the optimal printing accuracy and stability of 3D printing products of shrimp surimi.

Fig. 1.

Photos of 3D printing products of shrimp surimi with different printing parameters: (a) nozzle diameter sizes; (b) nozzle printing heights; (c) nozzle moving speeds; (d) printing filling rates.

Fig. 2.

Effects of different printing parameters on the printing accuracy and printing stability of three-dimensional shrimp surimi: (a) nozzle diameter sizes; (b) nozzle printing heights; (c) nozzle moving speeds; (d) printing filling rates. (Mean (n = 3) values (±SD) with different superscripts indicate significant differences (P˂0.05).).

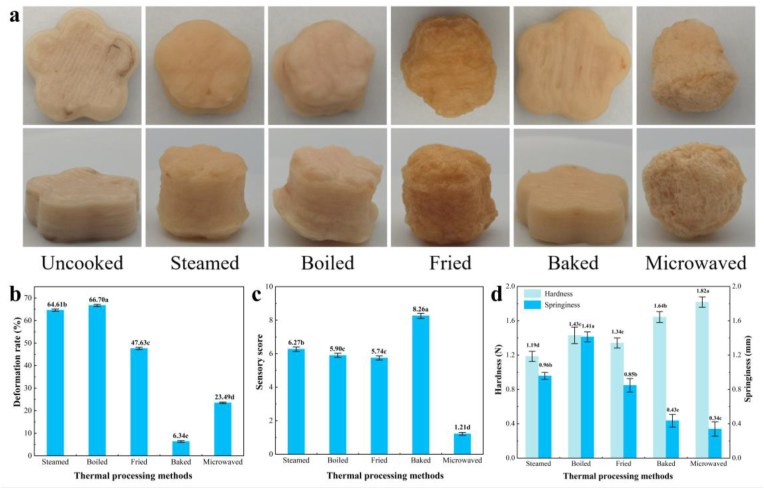

Fig. 3.

Effects of different thermal processing methods on 3D printed products of shrimp surimi: (a) appearance evaluation; (b) deformation rate; (c) sensory evaluation; (d) hardness and springiness. (Mean (n = 3) values (±SD) with different superscripts indicate significant differences (P˂0.05).).

3.2. Effect of nozzle printing heights on 3D printing of shrimp surimi

The nozzle printing height is the distance from the tip of the nozzle to the 3D printing platform. In the printing process, the nozzle printing height plays a decisive role in determining whether the material can be smoothly deposited on the printing platform, but also determines the effect of the initial layer of the printed product and affects the final molding effect of the printed product (Guénard-Lampron et al., 2021; Yang et al., 2018). The top view and front view of the products printed under different nozzle printing heights are shown in Fig. 1b, from which it can be seen, when the nozzle printing height is 1.00 mm,which is too small, the nozzle diameter (1.20 mm) of the material is larger than the nozzle printing height, the friction between the nozzle and the extruded material increases, and the material extrusion is not smooth, which would result in printing blockage. In addition, the shrimp surimi has high viscoelasticity. In the printing process, the tip of the nozzle is immerged in the freshly extruded shrimp surimi, and part of the shrimp surimi is glued to the tip of the nozzle, resulting in poor effect of the initial layer, which couldn't make the extruded material better deposit on the printing platform, and resulting in rough lines at the bottom of the printed product. The smaller the nozzle printing height, the more accurate the printed product will be. However, when the nozzle printing height is too small, the distance between the nozzle and print platform will be so short that the friction between the nozzle, the print platform and the material increases. When the nozzle moves to the second or higher level, the too small gap between the nozzle and the material will make the nozzle immersed in the extruded material, increasing the friction between the nozzle and the material, and affecting the product printing (Pérez et al., 2019). When the printing height of the nozzle is 2.00 mm, the optimal printing effect of the product can be achieved, with better fusion between the layers of the printed product and without deposit collapse and rough lines at the bottom. When the printing height of the nozzle is 4.00 mm, the bottom line of the printed product is not well merged with the printing platform, resulting in poor printing effect at the bottom of the product. When the nozzle printing height increases to 6.00 mm, 8.00 mm, and 10.00 mm respectively, the product printing effect deteriorates with increases of the nozzle printing height. Especially the bottom of the product is increasingly rough, which may be due to the printing principle of "layered manufacturing, layer by layer superposition", with the molding effect of the previous printing layer affecting the molding effect of the following printing layer (Kalsoom et al., 2016). In addition, it may be because the nozzle printing height is too large. At the beginning of printing, the initial layer of shrimp mince printing is printed on the printing platform, and then the extruded shrimp mince is still suspended between the printing platform and the nozzle. With the nozzle moving over the printing platform, the shrimp surimi will be pulled off, resulting in discontinuous discharge and decreased fusion between the printing layers, and the printing effect will become worse. Moreover, sharp edges and corners will be printed in a shape similar to an arc, resulting in printing effect distortion (Nijdam et al., 2021). Wang et al. (2018) studied 3D printing products of surimi and found that selecting the optimal printing parameters could improve the resolution of 3D printing products, which was better matching with the target geometry, with fewer point defects and no compressed deformation. The research results of Yang et al. (2019) showed that the printed dough with the printing height of 2.40 mm still had good appearance and maintained high printing stability after standing for 20 min. The research results of Zeng et al. (2021) showed that the rice starch gel printed with the nozzle height of 1.00 mm had higher printing stability and better appearance. As can be seen in Fig. 2b, with the increase of the nozzle printing height, 3D printing accuracy and stability of shrimp surimi both showed a trend of first increasing and then decreasing (P < 0.05). The 3D printing accuracy and stability of the nozzle printing height of 2.00 mm were significantly higher than those of other experimental groups (P < 0.05), which was basically consistent with the appearance analysis of 3D printing products in Fig. 1b. Therefore, the nozzle printing height of 2.00 mm was adopted to achieve the optimal printing accuracy and stability of 3D printing product of shrimp surimi.

3.3. Effect of nozzle moving speeds on 3D printing of shrimp surimi

The printing speed of nozzle refers to the moving speed of nozzle over the printing platform, and the printing speed of nozzle has an impact on the quality of the printed product (Yang et al., 2019). With the acceleration of nozzle moving speeds, the printing time of the product will be shortened, which can greatly improve the production efficiency (Žarko et al., 2017). The top view and front view of products printed at different nozzle moving speeds are shown in Fig. 1c, from which it can be seen that when the nozzle moving speed is 20 mm/s, the printing effect is poor, probably because the nozzle moves too slowly, which makes it easy to cause blockage at the nozzle, resulting in uneven discharge and line thickening, etc. When the nozzle moving speed is 25 mm/s, the printing effect is improved, but there still exists a slight uneven discharge on the surface of the product. When the nozzle moving speed is too slow, the lines of the printed product will be thickened due to the accumulation of materials at the nozzle, resulting in the interruption of the printing process and uneven discharge of the material (Geng et al., 2019). When the nozzle moving speed is 30 mm/s, the printing effect is the best, without uneven discharge and filament breaking. When the nozzle moving speeds is 35 mm/s and 40 mm/s respectively, the molding effect of the printed products is poor, which may be because the nozzle moving speed is so fast that the material extrusion is not sufficient to keep up with the nozzle moving speed, resulting in the phenomenon of filament breaking. It is also possible that the nozzle moving speed is so fast that the freshly extruded shrimp surimi will be moved to the place not set by the model by the printing nozzle before merging with the previous printing layer, which causes the gap between the lines of the printed product to become larger, and even causes the distortion of the molding effect of the printed product (Farashi and Vafaee, 2022). Meanwhile, the tension generated by the dragging of material lines during the printing process makes the lines stretch and become thinner, or even broken. With the printed lines severely distorted, the molding effect of the printed products couldn't be guaranteed (Liu and Ciftci, 2021). The research results of Wang et al. (2018) showed that the best printing moldability of silver carp surimi was achieved when the nozzle moving speed was 28 mm/s, and that too fast or too slow speeds could affect the results of 3D printing products. Yang et al. (2018) studied the effect of 3D printing parameters on the molding effect of lemon gel and showed that when the nozzle moving speed was 30 mm/s, the printed product had a higher matching degree with the set target geometry model, with a smooth surface and without filament breaking. Therefore, the appropriate nozzle moving speed has a certain influence on the printing molding effect. As can be seen from Fig. 2c, with the increase of the nozzle moving speed, the 3D printing accuracy and stability of shrimp surimi both showed a trend of first increasing and then decreasing (P < 0.05). There is no significant difference in 3D printing accuracy between nozzle moving speeds of 20 mm/s, 25 mm/s, and 30 mm/s (P > 0.05) and no significant difference in 3D printing stability between nozzle moving speeds of 20 mm/s and 25 mm/s (P > 0.05), which is generally consistent with the appearance analysis of the 3D printing products in Fig. 1c. In addition, the slower the nozzle moving speed, the longer the printing time of product will be, and the longer the product will be exposed to air, which may lead to moisture loss and affect the quality of shrimp surimi products (Wang et al., 2018). In conclusion, the nozzle moving speed of 30 mm/s was adopted to achieve the optimal printing accuracy and stability of 3D printing product of shrimp surimi.

3.4. Effect of printing filling rates on 3D printing of shrimp surimi

The printing filling rate refers to the filling density of material inside 3D printing product, namely the percentage of materials inside the 3D printing product (Ma and Zhang, 2022), and its size directly determines whether the 3D printing products can maintain stability and sustain their own structure (Pulatsu et al., 2022; Guénard-Lampron et al., 2021). The larger the printing filling rate, the smaller the gap between the printing lines, the more compact the internal structure, and the better the support, and vice versa (Huang et al., 2022). The top view and front view of the printed products with different printing filling rates are shown in Fig. 1d. As can be seen from the figure, when the printing filling rate was 0%, the printing effect of the product was the worst, because the printing filling rate was too small and the internal structure was unsupported, resulting in the deposition collapse of the top layer of the printed product due to gravity. Meanwhile, the outer wall of the printed product was concave inward due to the small support area, ultimately resulting in the failure of printing. When the printing filling rate increased to 20%, the printing effect of the product was slightly improved, but there still existed serious deposition collapse and large gaps between lines were clearly visible. When the printing filling rate increased to 40% and 60%, the printed results were significantly improved with the increase of the printing filling rate, but there still existed partially deposition collapse, probably due to poor fusion between layers and inadequate support strength of the product. When the printing filling rate was 80%, the best molding effect of the shrimp surimi printing product was achieved, for there was no obvious gap between the lines inside the product and the internal structure was compact with good stability. When the printing filling rate was 100%, the internal structure of the product was more compact with a certain degree of support, due to sufficient filling materials. However, the extruded shrimp surimi would swell, making the product slightly more swollen than the designed model and affecting the printing effect. The research results of Guénard-Lampron et al. (2021) showed that setting the printing filling rate as 71% in making 3D printing appetizer cake of carrot could make the product have better sensory and visual effects. The research results of Yang et al. (2018) showed that the printing filling rate of 100% was not suitable for 3D printing due to the swelling property of the material, and the molding effect of lemon juice gel was the best when the printing filling rate was 90%. It can be seen from Fig. 2d that with the increase of printing filling rate, the 3D printing accuracy and stability of shrimp surimi both presented a trend of first increasing and then decreasing (P < 0.05). There was a small difference in 3D printing accuracy between 80% and 100% printing filling rate (P < 0.05), while there was no significant difference between them in 3D printing stability (P > 0.05), which is generally consistent with the appearance analysis of 3D printing products in Fig. 1d. In addition, the high printing filling rates require not only longer printing time but also more material consumption. To sum up, the printing filling rate of 80% was adopted to achieve the optimal printing accuracy and stability of 3D printing product of shrimp surimi.

3.5. Effect of thermal processing on 3D printing products of shrimp surimi

The thermal processing of 3D printing products is the last step that affects the molding effect before the product is completed (Wang et al., 2022). Especially for printing non-instant products such as shrimp surimi, which require thermal processing before becoming edible, the thermal processing method will inevitably have a different impact on the 3D printing products, for the printed product will have different degrees of deformation after different thermal processing and cooking methods. Therefore, it is very necessary to choose a thermal processing method that has the least influence on the deformation rate of printed products. The top view and front view of the 3D printed products of shrimp surimi cooked by different thermal processing methods are shown in Fig. 3a. As can be seen from the figure, the height of the 3D printed products of shrimp surimi steamed in the steamer, boiled in boiling water, and deep-fried at high temperature expanded more than that of the uncooked shrimp surimi, which may be because the proteins denature during the heating process of the shrimp surimi and intertwine to form a new protein network structure, or it may be due to the expansion of the protein powder and the starch particles in shrimp surimi by absorbing water after heating (Yang and Park, 1998), which makes the shrimp surimi 3D printed products expand and increase in height, affecting the final molding effect of printed products. Microwave heating had the most serious impact on 3D printed products of shrimp surimi, with severe deformation in appearance, which may be because microwave heating is an integral heating and cooking method based on the heat generated by friction of water molecules, which can cause expansion effect by making the water inside the food rapidly and evenly heated, and cause shrinkage of the product by making the surface moisture decreased rapidly, resulting in a large deformation of the original printed shape (Jiang et al., 2019). As can be seen from the figure, the appearance of oven-baked shrimp surimi was not much different from that of uncooked printed products of shrimp surimi, which may be because the heat from the oven is transferred from the outside to the inside and the surface of the shrimp surimi products can easily form a dry film caused by evaporation of water, resulting in less effect on deformation. As can be seen in Fig. 3b, the deformation rate of oven-baked shrimp surimi products was significantly better than that of shrimp surimi products cooked by other thermal processing methods (P < 0.05), while the deformation rate of steamed, boiled, and deep-fried shrimp surimi products was significantly higher than that of oven-baked and microwaved shrimp surimi products (P < 0.05). This may be because oven-baking and microwave heating are processing methods that only take air as a heat conduction medium and use non-open fire heat source for heating, while steaming, boiling, and frying are traditional thermal processing and cooking methods that take water steam, water and oil as heat conduction medium respectively (Ni and Datta, 1999). With the introduction of the media, increasing temperature also has adverse effects on the deformation of shrimp surimi products (Jiang et al., 2019), which is generally consistent with the appearance analysis of 3D printing products in Fig. 3a. Sensory evaluation aims to measure sensory perception and its influence on the acceptance of food and taste, which can determine the value and acceptability of 3D printed shrimp surimi products, and help determine the best and most reasonable thermal processing and cooking methods, which then can obtain a better commercial promotion. For the sensory evaluation of 3D printed shrimp surimi products, the acceptability of appearance is primarily considered, followed by texture, taste, and color. As can be seen from Fig. 3c, the sensory score of oven-baking was significantly better than that of other thermal processing and cooking methods (P < 0.05), while the microwaved shrimp surimi products was not preferred by the evaluators, mainly because microwaving had greater impacts on shrimp surimi products in deformation and color, resulting in a low score. Diamante (2021) found in their study that the shrimp heated by steam was reddish in color, while the shrimp fried by high temperature was yellow in color and their texture and taste were preferred by evaluators, which is consistent with the findings in this study and could account for the relatively high sensory scores of fried shrimp surimi products. As can be seen from Fig. 3d, shrimp surimi products cooked by different thermal processing methods had different hardness and springiness, which may be due to the different heat transduction methods in shrimp surimi products and the different denaturation effects on myofibrillar protein, resulting in different texture properties (Wang et al., 2022). In addition, oven-baked shrimp surimi products can be found to have comparatively suitable hardness and springiness. Therefore, from the aspects of the deformation rate, sensory score and texture characteristics, the oven-baked thermal processing method was selected for the optimal final molding effect of 3D printing products of shrimp surimi.

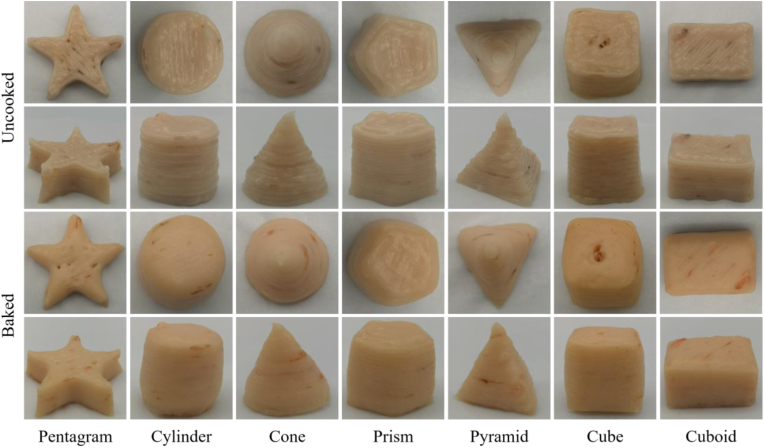

Fig. 4 shows 3D printing products of shrimp surimi with different dioramas baked in the oven. As the name implies, 3D printing is three-dimensional printing, along with a wide variety of shapes to meet the needs of consumers. The top view and front view of uncooked shrimp surimi products as well as the baked shrimp surimi products, which were printed with different dioramas, such as pentagram, cylinder, cone, prism, pyramid, cube, and cuboid are shown in Fig. 4. As can be seen from the pictures of uncooked shrimp surimi products, the optimization of printing parameters effectively improved the adaptability of 3D printing of shrimp surimi, resulting in high printing accuracy and printing stability, which further verified the reliability of the preliminary test results. In addition, as can be seen from the pictures of oven-baked shrimp surimi products, the final molding effect of 3D printing products was better, which further proved that oven-baking is a thermal processing and cooking method suitable for 3D printing shrimp surimi products. In addition, different decorations according to different printed products can further enrich the types of shrimp surimi products, which makes it possible to carry out DIY design in 3D printing products of shrimp surimi.

Fig. 4.

Photos of 3D printing products of shrimp surimi with different shapes.

4. Conclusion

The setting of printing parameters has certain influence on the adaptability of 3D printing of shrimp surimi, and different thermal processing and cooking methods have different degrees of influence on the final molding effect of 3D printing product of shrimp surimi. In order to make the 3D printing products of shrimp surimi have higher printing adaptability (printing accuracy and printing stability reach more than 97%), select the nozzle with the diameter of 1.20 mm for printing, setting the nozzle printing height as 2.00 mm, the nozzle moving speed as 30 mm/s, and the printing filling rate as 80%. From the perspectives of high sensory evaluation, low deformation rate, and texture characteristics, the oven-baking is selected as the optimal thermal processing and cooking method for 3D printing products of shrimp surimi. In the future, it possible to carry out DIY design in 3D printing products of shrimp surimi in order to cater for consumers, and further promotes the commercialization of 3D printing products of shrimp surimi to meet the needs of different people for modern food.

CRediT authorship contribution statement

Yanmo Pan: Conceptualization, Methodology, Software, Validation, Formal analysis, Data curation, Writing – original draft, preparation, Writing – review & editing. Qinxiu Sun: Conceptualization, Methodology, Software, Validation, Formal analysis, Resources, Data curation, Writing – review & editing, Project administration. Yang Liu: Methodology. Shuai Wei: Formal analysis, Project administration. Zongyuan Han: Supervision. Ouyang Zheng: Supervision. Hongwu Ji: Formal analysis, Supervision, Project administration. Bin Zhang: Project administration. Shucheng Liu: Conceptualization, Methodology, Validation, Formal analysis, Resources, Writing – review & editing, Supervision, Project administration, Funding acquisition.

Declaration of competing interest

The authors declare that we have no competing financial interests or personal relationships that would affect the research reported in this paper.

Acknowledgements

This work was financially supported by China Agriculture Research System (CARS-48), Scientific and Technological Innovation Strategy of Guangdong Province (2022A05036), Guangdong General Universities Young Innovative Talents Project (2020KQNCX028), Guangdong Innovation Team of Seafood Green Processing Technology (2019KCXTD 011), and the Postgraduate Education Innovation Project of Guangdong Ocean University (202243).

Handling Editor: Xing Chen

Data availability

Data will be made available on request.

References

- Al-Mashikiii S.A., Nakai S. Separation of ovotransferrin from egg white by immobilized metal affinity chromatography. Agric. Biol. Chem. 1987;51(11):2881–2887. doi: 10.1080/00021369.1987.10868499. [DOI] [Google Scholar]

- Cao J., Feng A., He Y., Wang J., Liu Z., Xia G., Lin X., Shen X., Zhou D., Li C. The effect and mechanism of four drying methods on the quality of tilapia fillet products. Food Frontiers. 2022;3(2):316–327. doi: 10.1002/fft2.124. [DOI] [Google Scholar]

- Chandra R.D., Prihastyanti M.N.U., Lukitasari D.M. Effects of pH, high pressure processing, and ultraviolet light on carotenoids, chlorophylls, and anthocyanins of fresh fruit and vegetable juices. eFood. 2021;2(3):113–124. doi: 10.2991/efood.k.210630.001. [DOI] [Google Scholar]

- Dankar I., Haddarah A., Omar F.E., Sepulcre F., Pujolà M. 3D printing technology: the new era for food customization and elaboration. Trends Food Sci. Technol. 2018;75:231–242. doi: 10.1016/j.tifs.2018.03.018. [DOI] [Google Scholar]

- Diamante L. Vacuum frying of selected shellfish products. Eurasian. J. Food Sci. Technol. 2021;5(1):11–24. doi: 10.1016/ejfst/issue/63044/865099. [DOI] [Google Scholar]

- Fahmy A.R., Becker T., Jekle M. 3D printing and additive manufacturing of cereal-based materials: quality analysis of starch-based systems using a camera-based morphological approach. Innov Food Sci Emerg. 2020;63 doi: 10.1016/j.ifset.2020.102384. [DOI] [Google Scholar]

- Farahani Z.K., Mousavi M.A.E. Impact of drying methods on textural/rheological attributes of insoluble fraction of Persian gum. Food Chem Adv. 2023;3 doi: 10.1016/j.focha.2023.100479. [DOI] [Google Scholar]

- Farahani Z.K., Mousavi M., Ardebili M.S., Bakhoda H. The effects of Ziziphus jujuba extract-based sodium alginate and proteins (whey and pea) beads on characteristics of functional beverage. J. Food Meas. Char. 2022;16(4):2782–2788. doi: 10.1007/s11694-022-01353-x. [DOI] [Google Scholar]

- Farahani Z.K., Mousavi M., Ardebili M.S., Bakhoda H. Production and characterization of Ziziphus jujuba extract‐loaded composite whey protein and pea protein beads based on sodium alginate-IFPG (insoluble fraction of Persian gum. J. Sci. Food Agric. 2023;103(7):3674–3684. doi: 10.1002/jsfa.12509. [DOI] [PubMed] [Google Scholar]

- Farahani Z.K., Mousavi M., Ardebili S.M.S., Bakhoda H. Modification of sodium alginate by octenyl succinic anhydride to fabricate beads for encapsulating jujube extract. Curr. Res. Food Sci. 2022;5:157–166. doi: 10.1016/j.crfs.2021.11.014. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Farahani Z.K., Mousavi S.M.A.E., Ardebili S.M.S., Bakhoda H. Functional beverage based on alginate/insoluble fraction of Persian gum, WPI and PPC beads loaded with jujube extract: physicochemical, rheometry and sensory properties. Int J. Food SCI Tech. 2021;57(1):499–505. doi: 10.1111/ijfs.15423. [DOI] [Google Scholar]

- Farashi S., Vafaee F. Effect of extruder temperature and printing speed on the tensile strength of fused deposition modeling (FDM) 3D printed samples: a meta-analysis study. Int. J. Interact. Des. Manuf. 2022;16(1):305–316. doi: 10.1007/s12008-021-00827-4. [DOI] [Google Scholar]

- Feng C., Zhang M., Bhandari B. Materials properties of printable edible inks and printing parameters optimization during 3D printing: a review. Crit Rev Food Sci. 2019;59(19):3074–3081. doi: 10.1080/10408398.2018.1481823. [DOI] [PubMed] [Google Scholar]

- Geng P., Zhao J., Wu W., Ye W., Wang Y., Wang S., Zhang S. Effects of extrusion speed and printing speed on the 3D printing stability of extruded PEEK filament. J. Manuf. Process. 2019;37:266–273. doi: 10.1016/j.jmapro.2018.11.023. [DOI] [Google Scholar]

- Guénard-Lampron V., Masson M., Leichtnam O., Blumenthal D. Impact of 3D printing and post-processing parameters on shape, texture and microstructure of carrot appetizer cake. Innov Food Sci Emerg. 2021;72 doi: 10.1016/j.ifset.2021.102738. [DOI] [Google Scholar]

- Huang Y., Zhang M., Pattarapon P. Reducing freeze-thaw drip loss of mixed vegetable gel by 3D printing porosity. Innov Food Sci Emerg. 2022;75 doi: 10.1016/j.ifset.2021.102893. [DOI] [Google Scholar]

- Jia S., Liu Y., Zhuang S., Sun X., Li Y., Hong H., Lv Y., Luo Y. Effect of ε-polylysine and ice storage on microbiota composition and quality of Pacific white shrimp (Litopenaeus vannamei) stored at 0 C. Food Microbiol. 2019;83:27–35. doi: 10.1016/j.fm.2019.04.007. [DOI] [PubMed] [Google Scholar]

- Jiang H., Zheng L., Zou Y., Tong Z., Han S., Wang S. 3D food printing: main components selection by considering rheological properties. Crit Rev Food Sci. 2019;59(14):2335–2347. doi: 10.1080/10408398.2018.1514363. [DOI] [PubMed] [Google Scholar]

- Kalsoom U., Nesterenko P.N., Paull B. Recent developments in 3D printable composite materials. RSC Adv. 2016;6(65):60355–60371. doi: 10.1039/C6RA11334F. [DOI] [Google Scholar]

- Lipton J.I., Cutler M., Nigl F., Cohen D., Lipson H. Additive manufacturing for the food industry. Trends Food Sci. Technol. 2015;43(1):114–123. doi: 10.1016/j.tifs.2015.02.004. [DOI] [Google Scholar]

- Liu L., Ciftci O.N. Effects of high oil compositions and printing parameters on food paste properties and printability in a 3D printing food processing model. J. Food Eng. 2021;288 doi: 10.1016/j.jfoodeng.2020.110135. [DOI] [Google Scholar]

- Liu Y., Liang X., Saeed A., Lan W., Qin W. Properties of 3D printed dough and optimization of printing parameters. Innov Food Sci Emerg. 2019;54:9–18. doi: 10.1016/j.ifset.2019.03.008. [DOI] [Google Scholar]

- Liu Z., Bhandari B., Zhang M. Incorporation of probiotics (Bifidobacterium animalis subsp. Lactis) into 3D printed mashed potatoes: effects of variables on the viability. Food Res. Int. 2020;128 doi: 10.1016/j.foodres.2019.108795. [DOI] [PubMed] [Google Scholar]

- Ma Y., Zhang L. Formulated food inks for extrusion-based 3D printing of personalized foods: a mini review. Curr. Opin. Food Sci. 2022;44 doi: 10.1016/j.cofs.2021.12.012. [DOI] [Google Scholar]

- Nekouei N., Rezaei K. Introducing degummed water-extracted wild almond oil as a safe vegetable oil through the quality evaluation of par-fried potato sticks and oil thermo-oxidative stability during a continuous prolonged deep-fat frying process. Food Saf Health. 2023;1(2):202–213. doi: 10.1002/fsh3.12019. [DOI] [Google Scholar]

- Ni H., Datta A.K. Moisture, oil and energy transport during deep-fat frying of food materials. Food Bioprod. Process. 1999;77(3):194–204. doi: 10.1205/096030899532475. [DOI] [Google Scholar]

- Nijdam J.J., Agarwal D., Schon B.S. Assessment of a novel window of dimensional stability for screening food inks for 3D printing. J. Food Eng. 2021;292 doi: 10.1016/j.jfoodeng.2020.110349. [DOI] [Google Scholar]

- Nikoo M., Benjakul S., Rahmanifarah K. Hydrolysates from marine sources as cryoprotective substances in seafoods and seafood products. Trends Food Sci. Technol. 2016;57:40–51. doi: 10.1016/j.tifs.2016.09.001. [DOI] [Google Scholar]

- Pan Y., Huang Y., Liu Y., Huang D., Sun Q., Wei S., Han Z., Wang Z., Xia Q., Liu S. Effects of protein powder on 3D printing properties of shrimp surimi. J. Guangdong Ocean University. 2022;42(4):129–137. doi: 10.3969/j.issn.1673-9159.2022.04.015. [DOI] [Google Scholar]

- Pan Y., Sun Q., Liu Y., Wei S., Han Z., Zheng O., Ji H., Zhang B., Liu S. Investigation on 3D printing of shrimp surimi adding three edible oils. Foods. 2024;13:429. doi: 10.3390/foods13030429. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pan Y., Sun Q., Liu Y., Wei S., Xia Q., Zheng O., Liu S., Ji H., Deng C., Hao J. The relationship between rheological and textural properties of shrimp surimi adding starch and 3D printability based on principal component analysis. Food Sci. Nutr. 2021;9(6):2985–2999. doi: 10.1002/fsn3.2257. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pérez B., Nykvist H., Brøgger A.F., Larsen M.B., Falkeborg M.F. Impact of macronutrients printability and 3D-printer parameters on 3D-food printing: a review. Food Chem. 2019;287:249–257. doi: 10.1016/j.foodchem.2019.02.090. [DOI] [PubMed] [Google Scholar]

- Pulatsu E., Su J.W., Kenderes S.M., Lin J., Vardhanabhuti B., Lin M. Restructuring cookie dough with 3D printing: relationships between the mechanical properties, baking conditions, and structural changes. J. Food Eng. 2022;319 doi: 10.1016/j.jfoodeng.2021.110911. [DOI] [Google Scholar]

- Pulatsu E., Su J.W., Lin J., Lin M. Factors affecting 3D printing and post-processing capacity of cookie dough. Innov Food Sci Emerg. 2020;61 doi: 10.1016/j.ifset.2020.102316. [DOI] [Google Scholar]

- Rando P., Ramaioli M. Food 3D printing: effect of heat transfer on print stability of chocolate. J. Food Eng. 2021;294 doi: 10.1016/j.jfoodeng.2020.110415. [DOI] [Google Scholar]

- Ross M.M., Crowley S.V., Crotty S., Oliveira J., Morrison A.P., Kelly A.L. Parameters affecting the printability of 3D-printed processed cheese. Innov Food Sci Emerg. 2021;72 doi: 10.1016/j.ifset.2021.102730. [DOI] [Google Scholar]

- Tohic C.L., O'Sullivan J.J., Drapala K.P., Chartrin V., Chan T., Morrison A.P., Kerry J.P., Kelly A.L. Effect of 3D printing on the structure and textural properties of processed cheese. J. Food Eng. 2018;220:56–64. doi: 10.1016/j.jfoodeng.2017.02.003. [DOI] [Google Scholar]

- Wang L., Zhang M., Bhandari B., Yang C. Investigation on fish surimi gel as promising food material for 3D printing. J. Food Eng. 2018;220:101–108. doi: 10.1016/j.jfoodeng.2017.02.029. [DOI] [Google Scholar]

- Wang P., Zou B., Ding S., Li L., Huang C. Effects of FDM-3D printing parameters on mechanical properties and microstructure of CF/PEEK and GF/PEEK. Chin. J. Aeronaut. 2021;34(9):236–246. doi: 10.1016/j.cja.2020.05.040. [DOI] [Google Scholar]

- Wang T., Kaur L., Furuhata Y., Aoyama H., Singh J. 3D printing of textured soft hybrid meat analogues. Foods. 2022;11(3):478. doi: 10.3390/foods11030478. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yang F., Zhang M., Bhandari B., Liu Y. Investigation on lemon juice gel as food material for 3D printing and optimization of printing parameters. LWT--Food Sci. Technol. 2018;87:67–76. doi: 10.1016/j.lwt.2017.08.054. [DOI] [Google Scholar]

- Yang F., Zhang M., Fang Z., Liu Y. Impact of processing parameters and post‐treatment on the shape accuracy of 3D‐printed baking dough. Int. J. Food Sci. Technol. 2019;54(1):68–74. doi: 10.1111/ijfs.13904. [DOI] [Google Scholar]

- Yang H., Park J.W. Effects of starch properties and thermal-processing conditions on surimi-starch gels. LWT--Food Sci. Technol. 1998;31(4):344–353. doi: 10.1006/fstl.1997.0366. [DOI] [Google Scholar]

- Žarko J., Vladić G., Pál M., Dedijer S. Influence of printing speed on production of embossing tools using FDM 3D printing technology. J. Graph. Eng. Des. 2017;8(1):19–27. doi: 10.24867/JGED-2017-1-019. [DOI] [Google Scholar]

- Zeng X., Li T., Zhu J., Chen L., Zheng B. Printability improvement of rice starch gel via catechin and procyanidin in hot extrusion 3D printing. Food Hydrocolloids. 2021;121 doi: 10.1016/j.foodhyd.2021.106997. [DOI] [Google Scholar]

- Zheng L., Liu J., Liu R., Xing Y., Jiang H. 3D printing performance of gels from wheat starch, flour and whole meal. Food Chem. 2021;356 doi: 10.1016/j.foodchem.2021.129546. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.