Abstract

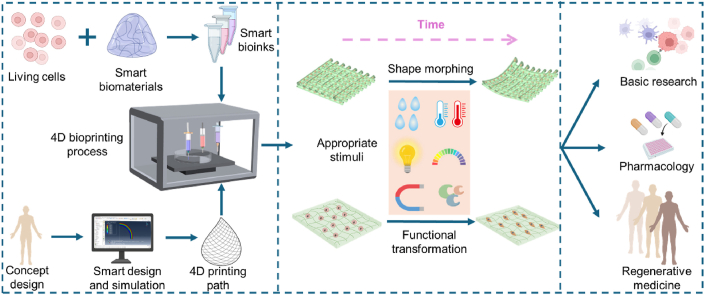

Setting time as the fourth dimension, 4D printing allows us to construct dynamic structures that can change their shape, property, or functionality over time under stimuli, leading to a wave of innovations in various fields. Recently, 4D printing of smart biomaterials, biological components, and living cells into dynamic living 3D constructs with 4D effects has led to an exciting field of 4D bioprinting. 4D bioprinting has gained increasing attention and is being applied to create programmed and dynamic cell-laden constructs such as bone, cartilage, and vasculature. This review presents an overview on 4D bioprinting for engineering dynamic tissues and organs, followed by a discussion on the approaches, bioprinting technologies, smart biomaterials and smart design, bioink requirements, and applications. While much progress has been achieved, 4D bioprinting as a complex process is facing challenges that need to be addressed by transdisciplinary strategies to unleash the full potential of this advanced biofabrication technology. Finally, we present future perspectives on the rapidly evolving field of 4D bioprinting, in view of its potential, increasingly important roles in the development of advanced dynamic tissues for basic research, pharmaceutics, and regenerative medicine.

Keywords: 4D bioprinting, Bioprinting technology, Smart material, Smart design, Programmed dynamic tissue

Graphical abstract

Highlights

-

•

A timely and thorough review of 4D bioprinting is presented, covering the concept, approaches, technologies, materials, and applications in creating dynamic tissues.

-

•

The major challenges facing 4D bioprinting, in terms of smart design, smart bioinks, bioprinting technologies, and post-bioprinting processing, are analyzed in depth.

-

•

Emerging applications of 4D bioprinting in different fields, including basic research, pharmaceutics, tissue engineering, and precision medicine are presented.

1. Introduction

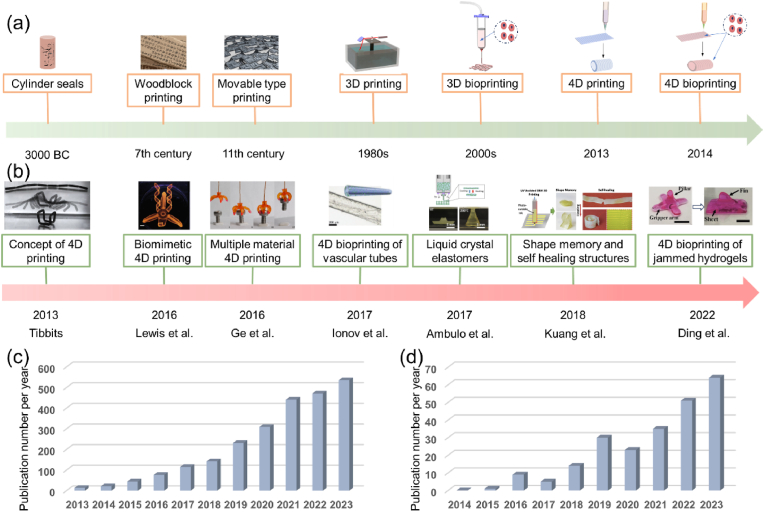

Printing technologies have a long history and have produced huge impacts on various aspects of human society (Fig. 1a). In the 1980s, additive manufacturing, alias 3D printing, emerged and resulted in rapid development that offers new opportunities for the applications in various areas, such as engineering, biology, and medicine [[1], [2], [3]]. 3D bioprinting emerged about two decades ago, which enables the processing of living cells, biomolecules and biomaterials into 3D living constructs that mimic the native tissues and organs [4]. Today, 3D bioprinting is widely applied to create diverse tissues and organs for basic research, high-throughput drug screening, and tissue regeneration [5,6]. While 3D printed constructs remain static after fabrication, native tissues and organs not only possess complex 3D hierarchical structures, but also exhibit dynamic features, such as conformational changes and functional transformations, to achieve unique functions. For example, the regular contraction of cardiac tissue enables the heart to pump blood throughout the body [7]. As another example, the size of blood vessels can be modulated by many factors such as nitric oxide (causing vasodilation) and caffeine (causing vasoconstriction) [8,9]. As such, in many cases, static products constructed by 3D printing/bioprinting may not meet the high demands of biomedical engineering.

Fig. 1.

Development of 4D printing and 4D bioprinting. (a) Evolution of printing technologies. (b) A timeline highlighting key milestones of 4D printing/bioprinting. Figures (from left to right) reproduced with permission from Ref. [11] (Copyright 2014, Wiley-VCH) [35], (Copyright 2016, Springer Nature) [36], (Licensed under a Creative Commons CC BY license) [37], (Copyright 2017, Wiley-VCH) [38], (Copyright 2017, American Chemical Society) [39], (Copyright 2018, American Chemical Society) [40], (Copyright 2022, Wiley-VCH). (c, d) Number of publications related to (c) 4D printing and (d) 4D bioprinting in the past decade. Statistics of the publication data are collected from Web of Science on March 9, 2024.

Over the last decade, 4D printing has emerged by incorporating time as the fourth dimension. The concept of 4D printing was first described in 2013 by Tibbitts of the Self-Assembly Lab at the Massachusetts Institute of Technology (MIT) [10,11]. At that time, 4D printing was simply defined as “3D printing + time” that allowed the fabrication of 4D objects with the ability to change their shape over time. In recent years, 4D printing is defined as a technology to fabricate 3D structures with desirable stimuli-responsive properties in response to external stimuli (i.e., water, heat, pH, light, and electric and magnetic fields) [12]. Smart materials and smart design are two key components for 4D printing to achieve the desirable 4D effect. Smart materials are materials that can change their shape or properties under external stimuli [13]. The aim of smart design is the programmable transformation by fully accounting for any time-dependent transformation of printed objects [14]. With the ability to produce dynamic features, 4D printing has gained increased research attention in recent years (Fig. 1b). As shown in Fig. 1c, the number of publications related to the topic of 4D printing grew rapidly. With dynamic shape, property, or functionality, 4D printed products can better meet the needs for use in medicine. Over the past few years, 4D printing has been increasingly used to fabricate dynamic products for biomedical applications [15,16], and this emerging technology is anticipated to drive the development of next-generation tissue regeneration and medical devices [17].

With the inception of 4D printing in 2013, the development of “4D bioprinting” was very soon perspective in some reviews [[18], [19], [20]], expecting that 4D printing would advance to process biocompatible smart materials, biochemicals, and living cells to generate dynamic 3D living constructs (i.e., 4D bioprinting) [21]. Compared to 3D bioprinting, 4D bioprinting enables the creation of dynamic living constructs, which can accurately recapitulate the intrinsic dynamic and conformation change of native tissues and potentially address the need for dynamic engineered tissues and organs. It should be noted that there is controversy over the concept of 4D printing in tissue engineering. It has been claimed that 3D bioprinting actually is one specific type of 4D printing, as the 3D bioprinted scaffolds are “active” and are often accompanied by dynamic changes over time [22]. It is because that the cells undergo reorganization to produce tissues and the degradable materials would break down over time when implanted in vivo. However, in some contexts, degradation is not considered as a 4D effect since the printed products serve as a carrier to account for the desired shape and function, and the degraded product no longer retains the intact construct [15,23]. For the cell-driven post-bioprinting changes, it has been claimed that the maturation of the printed microtissues derived from cell coating, cell organization, and/or matrix deposition belong to 4D bioprinting [22,24]. In such cases, 3D bioprinting is already “4D printing”, as the 3D bioprinted scaffolds can develop into functional tissues over time via cell (re)organization and matrix deposition. In response to this controversy, some researchers have re-defined 4D bioprinting as a strategy that combines 3D bioprinting with smart materials to create scaffolds capable of predictable and tunable structural remodeling in response to specific external stimuli [25]. 3D bioprinted products are typically static or undergo natural spontaneous changes without external stimuli. In contrast, 4D bioprinted products are expected to display programmable and controllable dynamic changes triggered by physical, chemical, and biological stimuli. In this review, in order to distinguish 4D bioprinting from 3D bioprinting, 4D bioprinting is defined as a group of technologies that can be used to deposit smart bioink (i.e., smart biocompatible materials, biochemicals, and living cells), in a layer-by-layer manner, based on smart pre-design patterns to create programmed dynamic structures with stimuli-responsive properties.

4D bioprinting has undergone rapid development in recent years, resulting in an increasing number of relevant publications (Fig. 1d). Although a number of recent reviews presented excellent discussions on 4D printing and bioprinting [17,[25], [26], [27], [28], [29], [30], [31], [32], [33], [34]], most of them only reviewed 4D bioprinting as a part of a broader topic and lacked an up-to-date and comprehensive presentation of this rapidly developing field. Besides, previously published related reviews rarely discussed the still debatable definition of 4D bioprinting. Thus, we address this issue by providing a historical overview and the conceptualization of 4D bioprinting. Further, this review provides a comprehensive discussion on 4D bioprinting and its recent advances in the biofabrication of dynamic tissues and organs. Firstly, the major approaches of creating dynamic tissue constructs via 4D bioprinting are discussed. The mainstream bioprinting technologies for 4D bioprinting are then presented by highlighting their key features and recent developments. Subsequently, smart materials and smart design for achieving the 4D effects of 4D bioprinted constructs are described, followed by a discussion of the requirements for developing and selecting smart bioinks. Finally, applications of 4D bioprinting in creating dynamic tissues and organs as well as related challenges and perspectives are discussed in depth. The goal of this review is to offer useful insights into the latest development of the 4D bioprinting technology and its wider future biomedical application in basic biomedical research, tissue engineering, and drug screening.

2. Approaches for 4D bioprinting

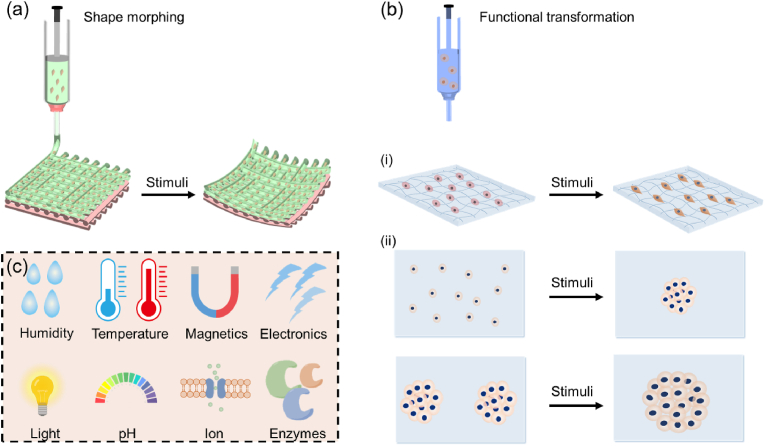

The two major approaches for 4D bioprinting are shape morphing and functional transformation (Fig. 2). Other approaches that have been proposed include biomimicry, self-assembly, and “in vivo” 4D bioprinting [21,41]. For instance, in vivo 4D bioprinting refers to the creation and implantation of polymer medical devices that can transform to accommodate tissue or organ growth by responding to the stimuli induced by tissue growth [21]. The two major approaches, shape morphing and functional transformation, will be the focus of this section.

Fig. 2.

Approaches to achieving 4D effects.(a) Shape morphing, (b) functional transformation, including (i) tissue maturation and (ii) cell pattern changes. (c) Common external stimuli employed to induce 4D effects in 4D bioprinting. OBB: organ building block.

2.1. Shape morphing

The shape morphing approach strictly follows the initial Tibbits's concept of 4D printing and has become the most common approach to achieve 4D bioprinting. For shape-morphing 4D bioprinting, the fabricated cell-laden constructs with living cells or tissue materials can change their shape from a 2D/3D morphology to a desirable 3D configuration (Fig. 2a). The programmed shape-shifting ability of a dynamic object can be achieved by strategically distributing different components within the object. Typically, controlling the distribution of different components (single or multiple materials) across its thickness, plane, or both thickness and plane can lead to different 3D deformations [[42], [43], [44]]. For example, a shape memory polymer with a gradient in the degree of molecular orientation across the thickness can self-fold when it was heated to its transition temperature [44]. Chitosan can be processed into a series of 2D patterns with a gradient in crosslinking degree across the thickness, resulting in different 3D morphologies (e.g., tube, helix, and flower) by responding to pH changes [45].

2.2. Functional transformation

Another approach to introducing dynamic features into 4D bioprinted structures is function transformation (Fig. 2b). As living cells are already encapsulated within 4D bioprinted constructs, the engineered tissue constructs can undergo functional transformation and maturation, representing another dynamic feature of 4D bioprinting. The functionalities of a bioprinted tissue construct should be induced in a programmable and controllable manner under specific stimuli, such as magnetic field, mechanical force, enzymes, and biomolecules. As shown in Fig. 2b(i), the 4D bioprinted tissue constructs with living cells can directly grow into matured constructs during post-bioprinting culture via cell proliferation, differentiation and matrix deposition under appropriate stimuli such as physical factors, drug molecules, and growth factors. Moreover, as shown in Fig. 2b(ii), the cell patterns can be first stimulated to transform into another pattern, which can then change over time to obtain the programmed functions via self-organization and self-development. For instance, magnetic fields can be applied to assemble different cells patterns by labeling the cells with magnetic nanoparticles (e.g., gold/iron oxide nanoparticles, filamentous phages, etc.) [46,47] or by exploiting the innate diamagnetism of cells (i.e., the Magneto-Archimedes effect) [48]. In addition to individual cells, cell spheroids or organoids can fuse to generate organ building blocks (OBBs), and the differentiation, maturation, and 3D assembly of these OBBs can lead to the creation of functional organ-specific tissues [[49], [50], [51]]. A deep understanding of multiple disciplines such as cell biology, mechanobiology, and cell biophysics is required to achieve programmable and controllable functional transformation.

3. 4D bioprinting technologies

For 4D bioprinting, mild processing environments are needed to maintain cell viability and functionality. Currently, the main bioprinting technologies for processing living cells and smart biomaterials are micro extrusion-based bioprinting (MEB), inkjet bioprinting, stereolithography (SLA), digital light processing (DLP), and laser-assisted bioprinting (LAB). This section discusses the key features of these 4D bioprinting technologies (Table 1) and recent advances. Detailed descriptions of these bioprinting technologies are presented in several recent outstanding reviews [31,[52], [53], [54], [55]].

Table 1.

Comparison of different 4D bioprinting technologies.

| 4D bioprinting technologies |

|||||

|---|---|---|---|---|---|

| MEB | Inkjet | SLA | DLP | LAB | |

| Ink/bioink viscosity | 1 to > 107 mPa s [56,57] | 3–30 mPa s [52] | 3–300 mPa s [58,59] | 1–200 mPa s [60,61] | 1–300 mPa s [62,63] |

| Cell density | 108 cells/ml, cell spheroids, organoids [49,51,64,65] | 106 cells/ml [66,67] | > 106 cells/ml [68,69] | 106 to108 cells/ml [61,70] | 108 cells/ml [62] |

| Cell viability | 70–95% [37,71] | >85% [67,72,73] | >75% [68,69] | >75% [74] | >85% [63,75] |

| Nozzle diameter | 200 μm to mm scale | 20–150 μm | Nozzle free | Nozzle free | Nozzle free |

| Resolution | 200 μm to mm scale | 50–300 μm | 20–80 μm | <150 μm | <150 μm |

| Printing speed | Slow | Fast | Medium to fast | Fast | Slow |

| Typical materials | Shape memory polymers, hydrogels, and composites (e.g., AlgMA [37,40], MC/alginate [42,76], cellulose nanofiber/NIPAM [35]) | Hydrogels (e.g., GelMA [73]) | Photopolymers (e.g., soybean oil epoxidized acrylate [77]) | Photopolymers (e.g., silk fibroin [70], GelMA/PEGDA [74]) | Hydrogels (e.g., collagen [75]) |

| External stimuli | Humidity [37,40], heat [78,79], and light [80,81] | Humidity [82] | Humidity, temperature [77] | Humidity [70,74] | Patterned fibroblasts [75] |

Abbreviation: AlgMA, methacrylate alginate; MC, methylcellulose; NIPAM, N-isopropylacrylamide; GelMA, gelatin methacryloyl; PEGDA, poly(ethylene glycol) diacrylate.

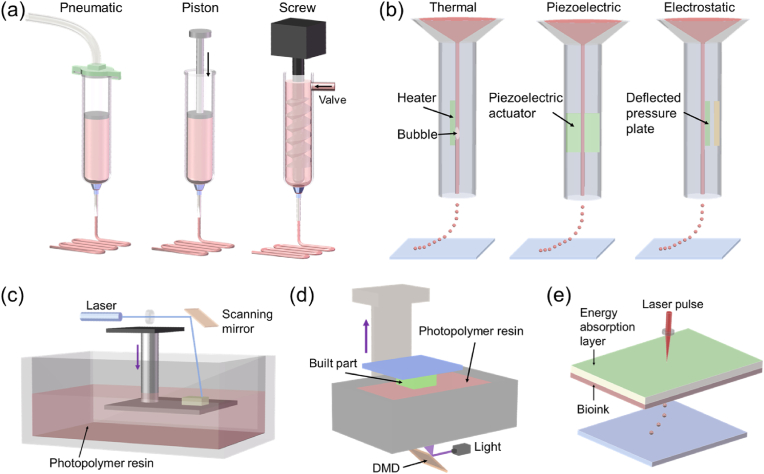

3.1. Micro extrusion-based bioprinting

MEB is a commonly used 4D bioprinting technique. For MEB bioprinting, inks with or without cells are loaded into syringes and extruded through a nozzle to form continuous filaments, which are then deposited in a layer-by-layer manner to form a 3D object. As shown in Fig. 3a, the inks/bioinks are extruded via a pneumatic or a mechanical dispensing system (using piston or screw). Pneumatic dispensing systems have a relatively simple air-driven component, while mechanical dispensing systems require more complex components. Mechanical dispensing systems enable more direct control over the materials flow, while there is a volumetric delay of compressed air in pneumatic dispensing systems. MEB is able to process a variety of materials with a wide viscosity range of 1 to >107 mPa s [56,57]. However, MEB faces challenges when processing low viscosity materials. In recent years, several strategies, such as in situ crosslinking [57] and FRESH bioprinting [83], have been developed to improve the capabilities of MEB in processing materials with ultra-low viscosity. Most of the shape memory polymers (SMPs), shape morphing hydrogels (SMHs) and their composites are printable by MEB. Besides, this type of bioprinting technology can be used to process cell spheroids or organoids into constructs with high cell density [49,64,65], which are challenging to achieve using other bioprinting technologies. The printing resolution of MEB is determined in part by the diameter of the used nozzle, where a smaller diameter of nozzle generally leads to higher printing resolution. However, nozzles with a small diameter can cause clogging issues, leading to decreased cell viability as increased shear stress is applied on the cells; cell viability for micro extrusion-bioprinting is also greatly affected by the shear stress exerted on the cells [71,84]. It is believed that cell viability decreases exponentially as shear stress increases, related to increased cell deformation and even significant cell damage/death [85]. In practice, different cell types also show distinct responses towards shear stress, leading to difference in cell viability. Therefore, the shear stress aspect of MEB should be carefully considered and controlled to avoid significant cell damage/death. Shear stress may be controlled by several factors, including material viscosity, pneumatic pressure (or piston/screw speed), and nozzle diameter. Some methods have been developed to improve cell viability of MEB-bioprinted cell-laden constructs. For instance, moderate shear stress before bioprinting was found to enhance the ability of cells to tolerate the bioprinting induced stress and improve their viability post-bioprinting [86]. Li and coworkers used a bioprinting method that applied bioink pairs of alginate/MC and trisodium citrate (or GelMA) and achieved a cell viability of above 93% after bioprinting [87,88]. MEB bioprinting has many advantages, including easy operation, ability to process a wide range of biomaterials, and capability of printing cell aggregates [49,87,89]. However, MEB faces the shortcomings of relatively slow printing speed and low printing resolution in comparison with other bioprinting technologies [2,33]. To improve the printing speed of MEB, a type of multi-material, multi-nozzle, extrusion-based 3D printer (MM3D) has been developed to simultaneously deposit multiple inks to form periodic structures with much higher fabrication speed [90]. However, this MM3D technology encounters several constraints such as limited available materials and fixed nozzle arrays. Besides, the feasibility of MM3D in processing 4D bioinks still needs to be further explored.

Fig. 3.

Schematic illustration of 4D bioprinting technologies. (a) Micro extrusion-based bioprinting using pneumatic, piston, or screw dispensing systems. (b) Inkjet bioprinting using thermal, piezoelectric, or electrostatic ejecting systems. (c) Stereolithography. (d) Digital light processing. (e) Laser-assisted bioprinting.

3.2. Inkjet bioprinting

Inkjet bioprinting has been one of the most commonly used technology for bioprinting applications [52]. It is a drop-on-demand (DOD) printing technology that ejects droplets only when an ejection signal arrives. Fig. 3b illustrates three mainstream inkjet bioprinting systems: thermal inkjet bioprinting, piezoelectric inkjet bioprinting, and electrostatic inkjet bioprinting. In thermal inkjet bioprinting, a heater is used to heat the surrounding liquid to about 250–350 °C in a very short time (∼2 μs), which causes the generation of a bubble. The bubble expands rapidly and produces a driving force to overcome the surface tension of the ink and eject it out of an orifice. In piezoelectric inkjet bioprinting, a piezoelectric actuator can change its shape when receiving a voltage pulse, leading to a sudden volumetric change of the ink chamber and hence ejection of a droplet. In electrostatic inkjet bioprinting, a defected pressure plate is attracted to the other plate under the action of static electricity, leading to chamber deformation and hence droplet ejection. The use of inkjet printing for 4D bioprinting has several advantages, including low cost, high printing speed, and high availability. However, inkjet bioprinting also has some shortcomings. Firstly, the materials used for inkjet bioprinting are restricted to a relatively narrow viscosity range of 3–30 mPa s [52]. Secondly, due to the low viscosity, it is hard to maintain the structures of the printed objects before solidification [91,92]. Thirdly, the orifice diameter of inkjet bioprinting is relatively small, which impairs the ability of inkjet bioprinting to process bioinks with high cell density [67,93]. Also, bioinks made of cell spheroids and organoids are not processable for inkjet bioprinting due to the small orifice. Finally, there are concerns over cell viability when inkjet bioprinting is used to process live cells. The transient high temperature for thermal inkjet bioprinting can cause cell death [72,93]; for piezoelectric and electromagnetic inkjet bioprinting, the high frequencies used may disrupt the cell membranes and cause cell lysis [94]. As inkjet bioprinting involves the use of an orifice for ejecting inks, shear stress should be carefully controlled and kept below 10 kPa to avoid significant cell death [84]. Although inkjet bioprinting can cause varying degrees of cell death, most of the cells remain viable after bioprinting. Generally, inkjet bioprinting can achieve a cell viability higher than 85%, which is larger than that of MEB [72,73].

3.3. Stereolithography

Stereolithography (SLA) has emerged for over 30 years since Hull patented the first SLA apparatus in 1986 [1]. As shown in Fig. 3c, SLA is mainly composed of a laser source, an X–Y scanning mirror, a build platform, and a vat containing photopolymer resin. In SLA, a laser is used to selectively cure and solidify the photopolymer resins point-by-point to generate one solidified layer. Afterwards, the build platform moves down one-layer thickness, and one layer of fresh resin is coated on the built part. As such, this process is repeated until the final layer is fabricated. In as early as 2004, SLA was used for fabricating tissue engineered cell-laden constructs by Dhariwala and coworkers [95]. Compared to MEB, SLA bioprinting has the advantages of faster building speed and higher printing resolution (about 20–80 μm). The high printing resolution of SLA is attributed to the small laser spots. Besides, SLA is a nozzle-free fabricating process, which avoids cells being exposed to shear stress that may compromise cell viability. However, there are some drawbacks when using SLA for bioprinting. First, in most cases, SLA bioprinting systems solidify the bioinks using UV-light or near-UV blue light, which may negatively affect cell viability, especially with long light exposure. To fabricate living constructs with improved cell viability and proliferation, visible light has often been used to replace UV light in SLA, thus requiring the development of new photoreactive groups [68]. Secondly, since the resin being polymerized is in direct contact with the air, oxygen-based inhibition occurs easily for SLA and causes incomplete crosslinking and overhanging. Thirdly, the resin-recoating step of SLA is time-consuming and significantly slows down the printing speed. To overcome this limitation, a microfluidic circulation has been used in SLA to achieve continuous replenishment of the liquid resin atop the built part and allow fabrication of multiscale solid hydrogels within minutes [96]. Fourthly, it is difficult to integrate multiple bioinks into one living construct using SLA due to the challenge in switching between different bioinks during the same manufacturing process. However, efforts are being made to address this issue. For example, Miller's group used an automated material selection process and a manual saline rinsing step to achieve multiple-material SLA bioprinting [97].

3.4. Digital light processing

Digital light process (DLP) is a manufacturing process similar to SLA. However, unlike the point-by-point solidification of rein in SLA, DLP can solidify a layer of photopolymer resin at one exposure, resulting in a significant increase in building speed (Fig. 3d). Such a printing speed improvement in DLP is achieved by using a critical component, digital micromirror device (DMD). DMD is made of an array of micromirrors, which can rotate independently to guide the light to cure one layer of photopolymer resin all at once. In addition, DLP light cures the resin in the bottom of the vat and moves upwards, which avoids oxygen inhibition during printing. Like SLA, DLP is a nozzle-free manufacturing process with fast printing speed, high printing resolution, and good cell viability. Nevertheless, the printing speed of DLP can be further improved by using an O2-permeable membrane in the bottom of the vat, which induces the formation of a “dead zone” that allows the continuous flow of the liquid resin without a recoating step, hence the name continuous liquid interface production (CLIP) [98]. However, CLIP still faces challenges in processing high viscosity materials. To mitigate this issue, microfluidic channels have been applied in CLIP to positively inject high viscous materials into the built part without interruption [99]. It was reported that as compared to CLIP, the microfluidic channel-integrated CLIP technique could cure resins that are an order of magnitude more viscous and achieve a 5- to 10-fold increase in the printing speed [99]. It is worth noting that DLP faces difficulty in integrating multiple materials into one single object. Several strategies have been developed to address this issue. For example, Han and coworkers developed a dynamic fluidic control unit consisting of a cylindrical printing chamber with integrated microfluidic inlets and outlets, enabling material exchange to achieve multi-material printing of DLP [100]. However, this fluid flow method has drawbacks of small building size, limited available materials, and significant material contamination. To solve these issues, Ge's group proposed a DLP-based centrifugal multimaterial (CM) 3D printing method [101]. In their method, a glass plate was used to support two or more polymer resin containers and could move horizontally to deliver a specific resin for the corresponding slice. During the material switching, a rotating motor was applied to spin the printing platform to remove residual resin on the printed part. As such, the DLP-based CM 3D printing system could print multi-material 3D structures in an area of up to 180 mm × 130 mm without material contamination [101]. SLA, DLP, and CLIP belong to the category of vat polymerization 3D printing technologies. Currently, there are many biocompatible and shape memory polymers or resins (e.g., polyurethane-based polymers and polyester-based polymers), and digital multimaterials (i.e., variable and automatic mixtures of at least two resins) have been developed for these vat polymerization technologies [102]. It is worth paying caution when UV light is used to cure bioinks, as UV exposure can cause damage to cells. Increased UV exposure time has been reported to decrease cell viability [103]. For instance, when the irradiation dose of UV (365 nm) was increased from 1350 mJ cm−2 to 5400 mJ cm−2 for printing cell-laden GelMA hydrogel, the viability of Hep-G2 cells was significantly reduced from 90% to 56% [104]. Besides, in DLP and SLA, a cell density of higher than 2 × 107 cells/ml causes a light scattering effect, which may reduce the printing resolution and may also affect photopolymerization. To mitigate this scattering-induced decrease in resolution, iodixanol was added to the bioinks as iodixanol could greatly reduce light scattering and achieve a resolution of 50 μm with a bioink of a high cell density of 108 cells/ml [61].

3.5. Laser-assisted bioprinting

Laser-assisted bioprinting (LAB) is a nozzle-free manufacturing process that uses a laser pulse to eject the bioink layer to generate droplets containing a specific number of cells (Fig. 3e). Due to the use of laser pulses, LAB can achieve a high printing resolution at microscale (<10 pL droplets). As a nozzle-free approach, living cells processed via LAB is not subjected to shear stress, leading to high cell viability of >85% [63,75]. However, the cell viability of LAB decreases with increasing energy of laser source [63]. LAB is able to process bioinks with a cell density up to 108 cells/ml [62]. With high printing resolution, high cell viability and density, LAB has been commonly used for bioprinting to process different biomaterials (e.g., RNA, and protein) and living cells [e.g., human osteosarcoma cells and mesenchymal stem cells (MSCs)] into customized cell patterns [54]. However, the wider bioprinting applications of LAB are limited by several drawbacks. Firstly, the biomaterials that can be printed via LAB are relatively limited. Secondly, the speed of printing (or droplet generation) for LAB is lower than other bioprinting technologies. Thirdly, the high cost of LAB equipment further limits its applications in academic and commercial research.

4. Smart biomaterials and smart designs for 4D bioprinting

Smart biomaterials and designs are two key elements for 4D bioprinting to achieve programmable dynamic behaviors. Smart biomaterials currently used for 4D bioprinting include shape memory polymers, shape morphing hydrogels, and their composites. According to the specific smart design, these smart biomaterials are strategically deposited via 4D bioprinting to generate dynamic structures that can change their shape and functionality by responding to appropriate stimuli.

4.1. Shape memory polymers

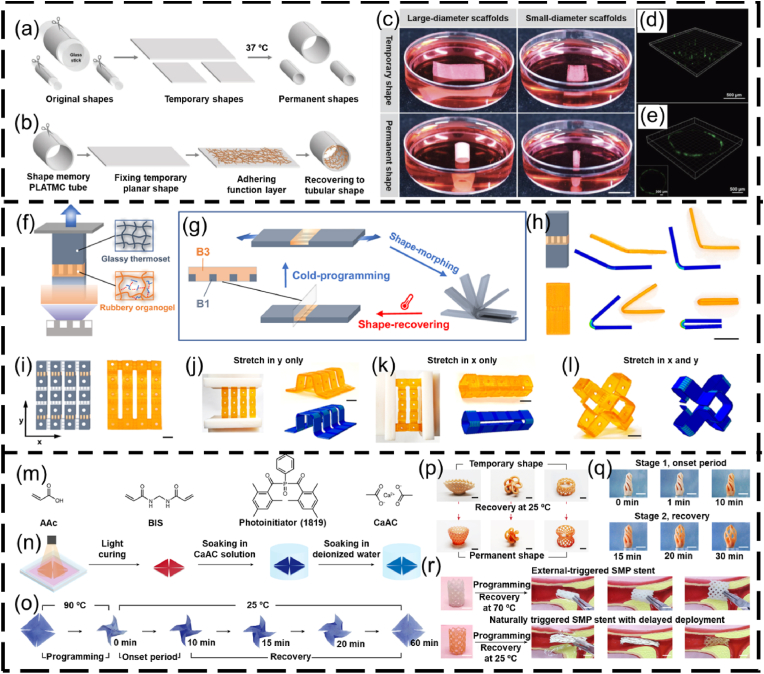

Shape memory polymers (SMPs) are smart polymeric materials with the ability to maintain a temporary shape and return to their permanent shape when exposed to external stimuli, such as heat, magnetic field, stress and light (Fig. 2c). SMPs-based structures can retain (or fix) the permanent shape via different programmable (or reshaping) strategies. The most commonly used reshaping strategy for SMPs is heat programming, which is strictly related to their transition temperature (Tt). Tt is the melting temperature (Tm) for a semicrystalline polymer, or the glass transition temperature (Tg) for an amorphous polymer. Typically, an SMP-based structure is deformed to the “permanent” shape at a temperature higher than Tt for a specific time period. The reshaped SMP-based structure is then cooled down below Tt and unloaded to remember the deformed shape. At a temperature below Tt, the SMP-based structure can be arbitrarily deformed to any temporary shape. Upon direct or indirect heating (e.g., photothermal effect and Joule heating) to a temperature above Tt, the SMP-based structure can undergo shape-transition and recover to its permanent shape. For example, poly(D, l-lactide-co-trimethylene carbonate) (PDLLA-co-TMC) is a temperature-responsive, amorphous SMP, and its Tg is determined by the ratio of DLLA and TMC monomers [105]. The PDLLA-co-TMC with a 9:1 ratio of DLLA:TMC exhibits a Tg close to the human body temperature [106]. In a representative application of this SMP, PDLLA-co-TMC was initially processed as 2D membranes [78]. The membranes were shaped into a tube structure using a glass rod, followed by incubation in an 80 °C oven to fix the reshaped structure. After cooling down to ∼25 °C, the reshaped structure could flatten as a 2D shape (Fig. 4a–c). Upon heating to 37 °C, the temporary 2D shape automatically folded into a permanent tubular shape within 1 min (Fig. 4c–e) [44,78]. However, heat programming faces some limitations such as whole energy waste and local shape programming. Efforts have been made to develop new mechanisms for programming SMPs. For example, Qi's group presented a cold-programming strategy by using the principle that the relaxation of SMP is a function of stress rather than temperature [107]. By using the grayscale-DLP (g-DLP, Fig. 4f) [108], a photocurable resin was 4D printed into multi-material objects with strategically designed hinges, which exhibited different 3D deformations by applying stretching force (Fig. 4g–l). In addition, Ni and coworkers proposed a phase-separation strategy for programming SMPs into specific shape-morphing structures, in which the onset of 3D deformation took place at a natural ambient temperature of 25 °C via internal mass diffusion instead of heat transport, which can be employed to lower the difficulty in deploying medical devices (Fig. 4m–r) [109].

Fig. 4.

SMPs reshaping using heat programming, cold programming, and phase separation programming. (a–e) Heat programming of PDLLA-co-TMC: (a) reshaping PDLLA-co-TMC membranes into tubular structures, (b) attachment of a fibrous membrane with the PDLLA-co-TMC to form bilayer scaffolds, (c) photograph showing the self-tubing of bi-layer scaffolds (scale bar = 1 cm), (d, e) confocal images showing the cell distribution (d) before and (e) after deformation. Reproduced with permission [44]. Copyright 2018, Wiley-VCH. (f–l) Cold programming of shape-shifting structures via g-DLP: (f) schematic illustration of g-DLP to create multi-material objects combining B1 glassy thermoset and B3 rubbery organogel (B1 and B3 refer to two different photocuring resins), (g) schematic of the heterogeneous hinge module design and morphing, (h) bending degrees of the hinge under different strain forces, (i) g-DLP 4D-printed structures with the hinges, and (j–l) corresponding different deformed morphologies by applying (j) y-directional force, (k) x-directional force, and (l) dual x-y directional forces (scale bar = 1 cm). Reproduced with permission [107]. Licensed under a Creative Commons CC BY license. (m–r) Programming SMPs via phase separation: (m) monomer precursors of a 4D photocurable ink, (n) DLP-4D printing process of a windmill, (o) a shape-shifting process of the windmill under 25 °C including a programming step of the shape-morphing onset time at 90 °C, an onset period, and a shape recovery period at 25 °C, (p) different shape-morphing structures, (q) shape morphing with a controlled onset of 10 min at the ambient temperature of 25 °C, (r) a comparison of the deployment of SMP stents made of heat programming and phase separation (scale bar = 1 cm). BIS, N,N′-methylenebisacrylamide; AAc, acrylic acid; CaAc, calcium acetate [109]. Reproduced with permission [109]. Copyright 2023, Springer Nature.

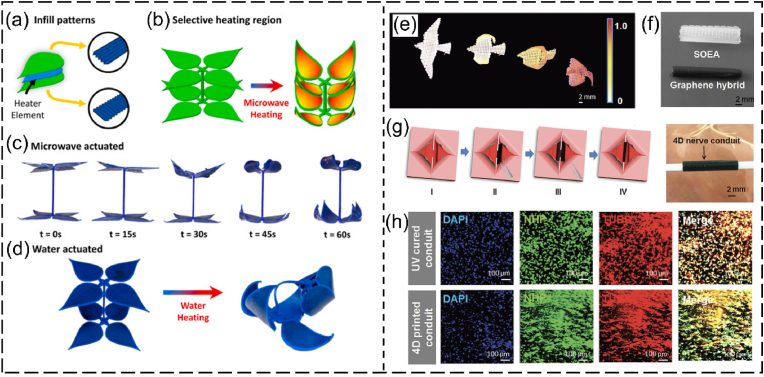

A variety of SMPs have been applied to produce different tissue engineering products via 4D printing [15,16,110]. The SMPs available for 4D printing of tissue engineering scaffolds are summarized in Table 2. These SMPs exhibit good biocompatibility and shape memory properties, making them appealing for fabricating different 4D structures with programmable shape-morphing behaviors. For instance, Manen and colleagues processed polylactic acid (PLA) into a series of 2D shape-shifting patterns using fused deposition modeling (FDM, a type of extrusion-based 3D printing that melts and extrudes polymer filaments to form 3D structures) [111]. In their method, PLA was melted above its transition temperature and extruded as stretched filaments, which were “memorized” after cooling them down. By strategically designing the porosity and thickness of the structures, the 2D patterns were programmed and could be deformed into a series of simple or complex 3D morphologies upon heating [111]. Using the same principle, Koh and Sutradhar printed a ferromagnetic PLA layer between each PLA patterns, which enabled selectively heating and actuation by microwave radiation (Fig. 5a–d) [112]. Although the biomedical applications of 4D printed PLA structures were not demonstrated in these studies, PLA is biocompatible and has been 4D printed into shape-morphing structures for tissue engineering [79,113]. Miao and coworkers developed a SMP using soybean oil epoxidized acrylate (SOEA), which could be 4D printed into tissue engineering scaffolds with programmable shape-morphing behaviors via SLA [77,114]. As shown in Fig. 5e–h, SOEA incorporated with GO was produced via SLA as dynamic scaffolds, that could self-fold into tubular structures for repairing damaged nerves, demonstrating promising potential for neural regeneration [77]. These SMPs hold significant potential for use in 4D bioprinting to fabricate living constructs with shape memory effects. In addition to these SMPs, other smart biopolymers, such as polynucleotides (RNA and DNA) and polypeptides, are also promising candidates for 4D bioprinting applications [115,116]. These smart biopolymers are sensitive to several external stimuli like temperature, humidity, and pH. Most importantly, they are derived from living (plant) materials and thus provide excellent biocompatibility and a favorable microenvironment for cell survival and growth during and after bioprinting.

Table 2.

SMPs for 4D printing.

| SMP | Printer type | External stimuli | Activation temperature | Application | Reference |

|---|---|---|---|---|---|

| Polylactic acid (PLA) | FDM | Heat | About 80 °C | __ | [111] |

| PLA and ferromagnetic PLA | FDM | Microwave | 28 °C to 130 °C | __ | [112] |

| Soybean oil epoxidized acrylate | SLA | Heat or water | 37 °C | Tissue engineering scaffolds | [77,114] |

| Methacrylated polycaprolactone | SLA | Heat | 40 °C to 50 °C | Airway stent | [117] |

| Black phosphorus nanosheets/TCP/PDLLA-co-TMC | MEB | Light | 45 °C | Bone tissue engineering scaffolds | [80] |

| Polycarbonates | SLA | Heat | 37 °C | Scaffolds for soft tissue repair | [118] |

| SMPs combined with two PCL-diacrylates with different molecular weights | __ | Heat | 30 °C to 55 °C | Bone tissue engineering scaffolds | [119] |

| MDI/PEG/PU | __ | Heat | 37 °C | Cartilage tissue engineering scaffolds | [120] |

| Poly(glycerol dodecanoate) acrylate | MEB | Heat | 20 °C to 37 °C | Vascular grafts | [121] |

| Poly(glycerol sebacate) acrylate-co-hydroxyethyl methacrylate | DLP | Heat | 37.8 °C | Inferior vena cava filters | [122] |

Abbreviation: MDI, andmethylene diphenyl 4,4-diisocyanate; PEG, poly (ethylene glycol); PU, polyurethane.

Fig. 5.

4D printing of SMPs. (a–f) 4D printing of PLA-based shape-changing leaves. (a) Schematic tri-layer configuration of a leaf showing two layers of PLA patterns (green) and one layer of ferromagnetic PLA (heater element). (b) Selective heating region of the leaves by microwave heating without heating the PLA stem. (c, d) Comparison of the shape-shifting process of the blooming leaves under (c) microwave selective heating of the leaves and (d) water heating of the whole structure. Reproduced with permission [112]. Copyright 2022, Elsevier B.V. (e–h) 4D printing of graphene/SOEA shape-morphing structures. (e) A series of structures mimicking flying actions of birds fabricated with SOEA with different graphene contents. (f) SLA-manufactured nerve guidance conduits without and with 0.8% GO. (g) A demonstration of the self-folding of a 4D structure to connect the broken nerve. (h) Immunofluorescence images of neurogenic differentiation of MSCs for UV cured conduit and 4D printed conduit. Reproduced with permission [77]. Copyright 2018, Wiley-VCH.

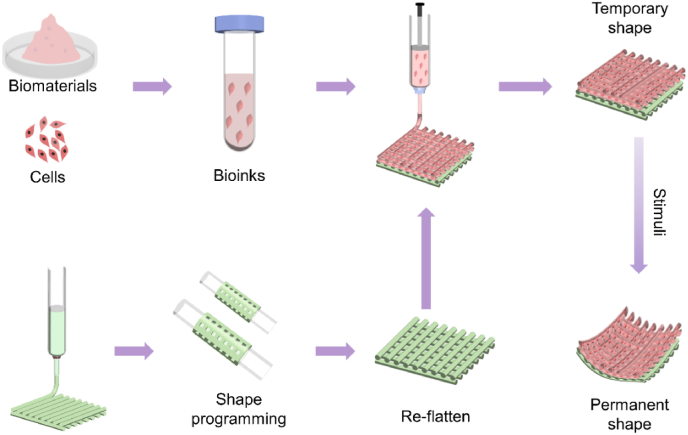

Most SMPs are synthetic, and their printing process often involves hazardous environments involving high temperatures and organic solvents, which can damage cells. As a result, it is often not feasible to directly incorporate living cells within these SMPs during 4D bioprinting. To make these SMPs available for 4D bioprinting, one feasible strategy is to produce cell-laden constructs with multiple layers, as illustrated in Fig. 6. In the multiple-layer configuration, the SMP is printed as the first layer that provides the shape memory behavior. Subsequently, the other bioinks with living cells are bioprinted onto the SMP layer to provide biological functions. By programming the SMPs, these multi-layer cell-laden structures can achieve the desired shape-shifting process in response to external stimuli, enabling the use of SMPs in 4D bioprinting. Several points are worth noting for 4D bioprinting of multiple-layer cell-laden dynamic structures using SMPs and bioinks. Firstly, although some SMPs can provide good shape memory behavior, their activation temperature is often much higher than the physiological temperature, potentially compromising cell viability and hampering their use in 4D bioprinting. Secondly, re-flattened 2D SMP membranes often do not have a perfectly flat surface, and deposition of bioinks onto the uneven SMP layer can be very difficult. Some strategies can be applied to address this issue. For MEB and inkjet bioprinting, distance sensing components can be equipped on printheads to enable real-time sensing of the distance between the printhead and printed surface during the printing process. Besides, some researchers have developed adaptive multi-degree-of-freedom bioprinters [123,124], which can achieve stereotactic deposition of bioinks onto skin defects with irregular geometry and satisfy the requirements of depositing bioinks onto an uneven SMP layer. For SLA and DLP, the fabrication of the second layer onto a SMP layer has been achieved, where the flattened SMP layer is placed on the bottom of build platform and coated with the bioink resin. Selective exposure of light on the bioink resin is then performed to generate a cell-laden layer on the SMP layer. Also noteworthy is that the interface between the cell-laden layer and the SMP layer should be tightly bonded to avoid their separation during in vitro and in vivo development. This 4D bioprinting approach for SMPs has been demonstrated for producing multi-layer shape-morphing living constructs. For instance, You and colleagues firstly cast out a SMP layer, followed by DLP-curing of a second hydrogel layer onto the SMP layer to form a bilayer scaffold, which could achieve self-bending upon immersion in water and microstructure transformation upon heating, showing potential for bone regeneration [119]. However, in their work, the second hydrogel layer was not laden with cells during the DLP printing. In another study, Luo and coworkers used alginate/polydopamine to form a self-folding layer, while alginate/GelMA was used to encapsulate living cells and bioprinted onto the SMP layer. Such bilayer scaffolds exhibited near-infrared irradiation (NIR)-triggered shape change and high cell viability after 1, 7 and 14 days of culture following NIR irradiation [81]. Wang's group used MEB to deposit a MSC-laden gelatin/GelMA bioink onto a shape-memory, highly stretchable layer of PDLLA-co-TMC/poly(lactic acid-co-glycolic acid) to obtain bilayer cell-laden scaffolds. The constructs could automatically fold into tubular structures when heated to ∼37 °C, showing high potential for regenerating uterine tissues [125].

Fig. 6.

Schematic illustration of 4D bioprinting for fabricating cell-laden biphasic constructs using SMPs and bioinks.

4.2. Shape morphing hydrogels

Hydrogels are water-containing polymeric networks stabilized via physical or chemical mechanisms. Most hydrogels possess largely reversible volumetric swelling or shrinking properties. Making use of this feature, some schemes have been proposed for developing shape morphing hydrogels (SMHs) by introducing uneven swelling or shrinking into different parts of the hydrogels, leading to nonuniform internal stress and shape-morphing process for the hydrogels. While most SMHs respond to water, however, their shape morphing behavior can also be triggered by other stimuli, such as temperature [126], ions [43,127], pH [45], and charge interactions [128,129]. SMHs are appealing candidates for 4D bioprinting due to their unique advantages, such as excellent biocompatibility, good biodegradability, similarity to extracellular matrix (ECM), ability to support cell survival and growth, and crosslinking ability [20,33,130]. Many SMHs can be directly mixed with living cells to obtain bioinks for 4D bioprinting of dynamic constructs that can change their shape over time. Various SMHs have been used for 4D bioprinting and are summarized in Table 3. Most of these 4D-bioprinted constructs achieved shape morphing (e.g., bending) properties and formed desired architectures, such as tubing and flowers, by responding to water (Fig. 7).

Table 3.

SMHs currently used for 4D bioprinting.

| SMH | 4D bioprinter | Mechanism for 4D effect | External stimuli | Cells | Cell viability | Structural stability | Application | Reference |

|---|---|---|---|---|---|---|---|---|

| AlgMA or HAMA | MEB | Crosslinking degree gradient across the thickness of the hydrogel | Water | Mouse bone marrow stromal cells | >95% | Self-folded tubes remained stable for at least 7 days but showed cracks on the wall of the tubules | Vasculature | [37] |

| GelMA and Gel–COOH–MA | Inkjet | Swelling difference between GelMA layer and Gel–COOH–MA layer | Water | Human umbilical vein endothelial cells | >90% on day 3 | Self-folded microtubes could remain stable while experiencing the contraction force of the cells during 3 days of in vitro culture | Vasculature | [73] |

| Silk | DLP | Crosslinking difference between the first and second layer | Water | Chondrocytes and turbinate-derived mesenchymal stem cells | __ | Transformed bending structure kept stable during 4-week in vitro culture | Cartilage | [70] |

| PEGDA | __ | Swelling difference between the first and second layer | Water | Fibroblasts | __ | Self-folded microtubes maintained their shape for 66 days | Vasculature | [131] |

| Oxidized AlgMA and GelMA | MEB | Swelling difference between oxidized AlgMA layer and GelMA layer | Water | NIH3T3 | __ | Bilayer structures with a low cell density (≤5 × 107 cell/ml) could not keep maximum curved structure over 21 days, while those with a high cell density (1 × 108 cell/ml) showed steady, increased curvature during 21 days of in vitro culture | Bone | [132] |

| Jammed micro flake hydrogel made of oxidized AlgMA | MEB | Crosslinking degree gradient across the thickness of hydrogel | Water or pH | Human MSC | __ | Bending structures remained stable during 21 days of in vitro culture | Cartilage | [40] |

| Oxidized AlgMA, GelMA, or 8-arm PEG-acrylate | MEB | Crosslinking degree gradient across the thickness of hydrogel | Water, pH, or chemicals | Human MSC | 86%–89% after 3 days of culture | Deformed structures retained similar bending degrees during 21 days of in vitro culture | Bone | [133] |

| Oxidized AlgMA and GelMA | MEB | Swelling difference between oxidized AlgMA layer and GelMA layer | Water | Human MSC | __ | Bilayer structures underwent tunable deformation due to unstable structure | Cartilage | [134] |

| Tyramine-functionalized hyaluronan (HAT) and alginate/HAT | MEB | Swelling difference between the first and second layer | Water | MSC | ∼75% | Curvature of the bilayer scaffolds gradually decreased during four weeks of in vitro culture | Cartilage | [135] |

| Ferromagnetic NdFeB microparticles, HAMA, and Alg/polyacrylamide | __ | Magnetic actuation | Magnetic field | Fibroblasts, epithelial cells | ∼90% for 3% (w/v) HAMA, and ∼70% for 5% (w/v) HAMA | Bilayer constructs retained regular folding under a magnetic field for 2 days with 3 h of stimulation each day | Bronchi | [136] |

| GelMA, poly-l-lysine (PLL) | MEB | Induction of membrane contraction by immersing anionic GelMA in cationic PLL solution | Opposite charge interactions | MSCs | <40% | Contracted thin membranes remained stable for at least two days | Membranous tissues | [128] |

| PEGDA/GelMA | DLP | Crosslinking degree gradient across the thickness of hydrogel | Water | NIH3T3 | 73% on day 1 and 90% on day 4 | Folded constructs kept stable for up to 14 days | __ | [74] |

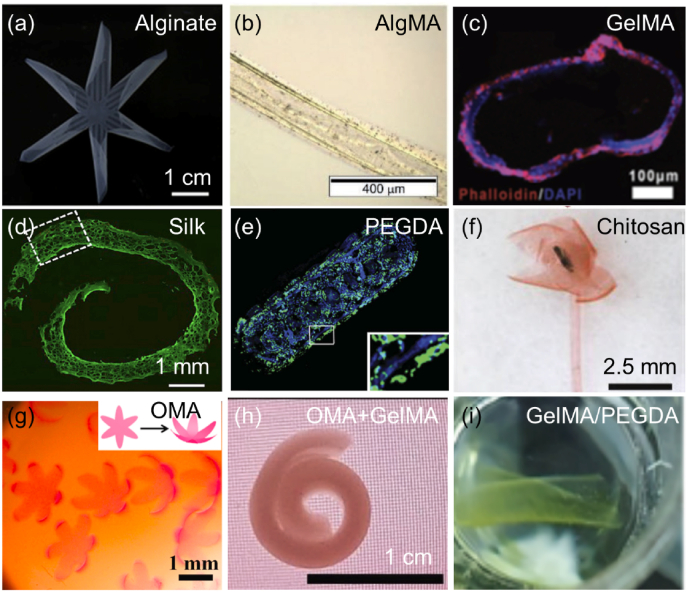

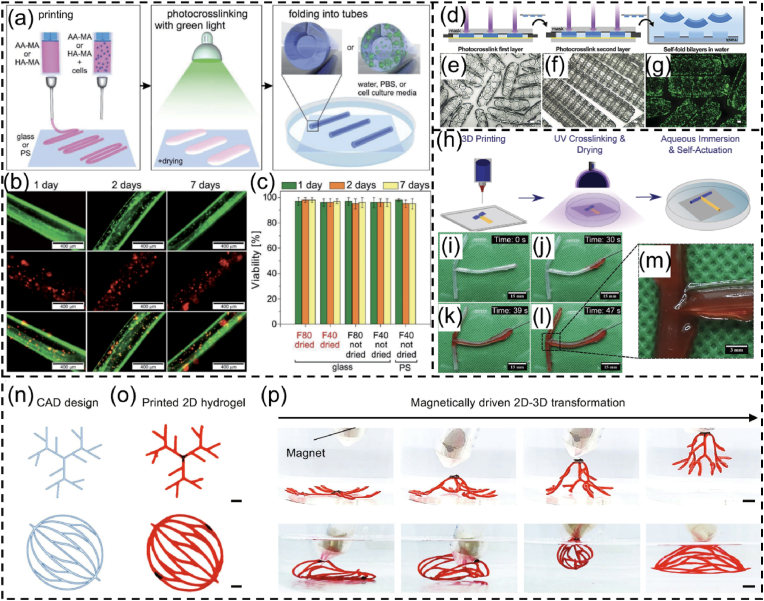

Fig. 7.

Shape morphing hydrogels. (a) A 6-petal flower made of alginate. Reproduced with permission [43]. Licensed under a Creative Commons CC BY license. (b) 4D-bioprinted self-folding AlgMA tube. Reproduced with permission [37]. Copyright 2017, Wiley-VCH. (c) Cross section of GelMA tubes seeded with human umbilical vein endothelial cells (HUVECs). Reproduced with permission [137]. Licensed under a Creative Commons CC BY license. (d) PKH dye-labeled cells in 4D-bioprinted silk after two-week culture in vitro. Reproduced with permission [70]. Copyright 2020, Elsevier B.V. (e) PEGDA bilayer tubes containing Hoechst-stained fibroblasts (blue) in the inner hydrogel layer and calcein AM-stained fibroblasts (green) in the outer hydrogel layer. Reproduced with permission [131]. Copyright 2013, Wiley-VCH. (f) An artificial flower changed from a chitosan sheet. Reproduced with permission [45]. Licensed under a Creative Commons CC BY license. (g) Human MSC-laden 6-petal blossoms made of oxidase AlgMA (OMA). Reproduced with permission [133]. Licensed under a Creative Commons CC BY license. (h) Cell-laden bilayer tubes composed of an OMA layer and a GelMA layer. Reproduced with permission [132]. Copyright 2021, Wiley-VCH. (i) DLP-produced GelMA/PEGDA self-folding scaffolds containing NIH/3T3 cells. Reproduced with permission [74]. Copyright 2023, American Chemical Society.

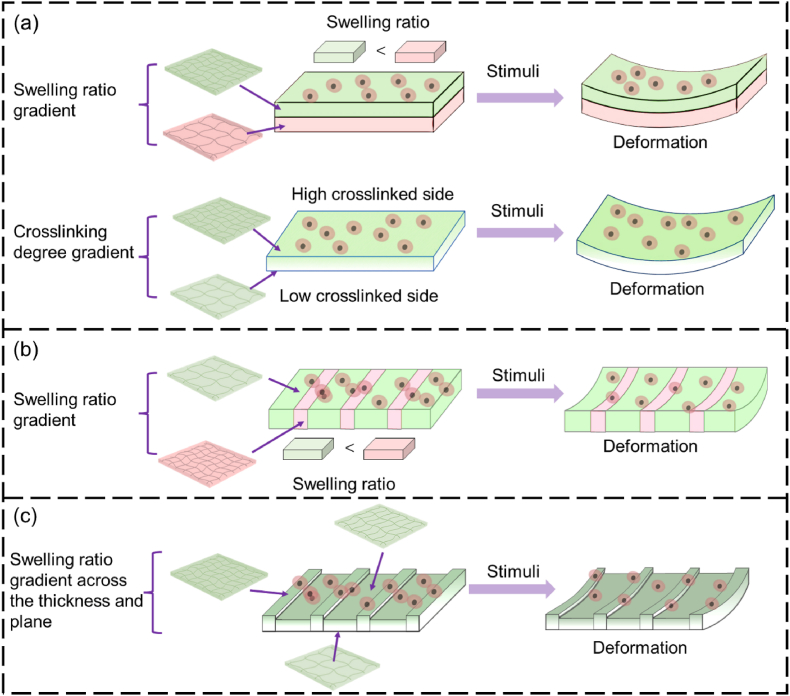

As shown in Table 3, a number of SMHs have been used for 4D bioprinting to produce shape-changing living constructs by strategic allocation of the bioinks. Currently, most of the 4D-bioprinted cell-laden SMHs can change shapes by responding to water. The water-triggered 2D-to-3D or 3D-to-3D shape transformation of 4D bioprinted SMH constructs has been achieved via several strategies, primarily by controlling the crosslinking degree gradient (or swelling ratio gradient) (i) across the thickness of the hydrogels (i.e., out-of-plane), (ii) across the hydrogel plane (i.e., in-plane), or (iii) across both the thickness and plane of the hydrogel (inside-out-plane), as illustrated in Fig. 8.

Fig. 8.

Strategies for 4D bioprinting of SMHs.(a) Out-of-plane SMHs. (b) In-plane SMHs. (c) Inside-out plane SMHs.

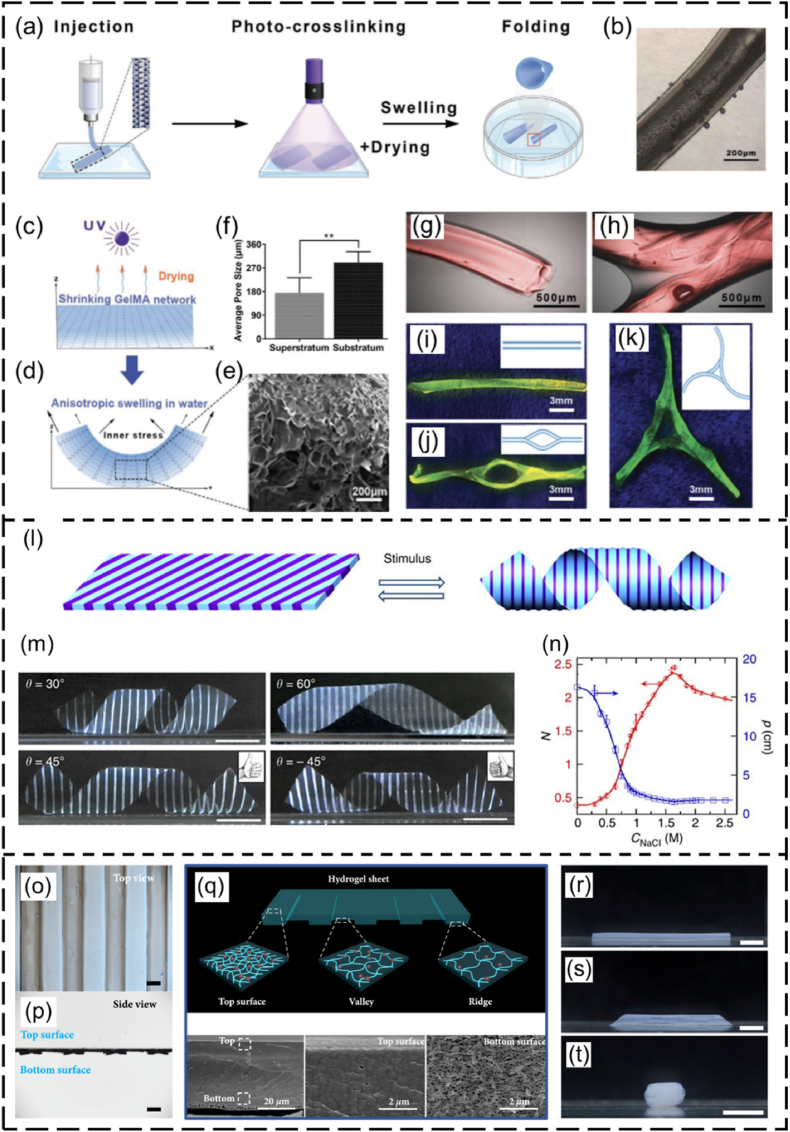

In the out-of-plane strategy, 4D-bioprinted SMHs exhibit a gradient of swelling ratio along the thickness (i.e., vertical direction) of the hydrogels, resulting in self-bending or folding structures upon immersion on water (Fig. 8a). This strategy has been commonly applied in 4D bioprinting of dynamic cell-laden hydrogels. To achieve the out-of-plane force, one major approach is to use a single SMH to fabricate structures with a gradient in crosslinking degrees from the top to the bottom surface of a hydrogel structure, by modulating the physical or chemical crosslinking process. This results in different contractility and swelling ratio between the upper and lower layers, leading to self-bending or folding of the hydrogel. Fig. 9a–k shows one typical example related to the fabrication of a series of self-folding GelMA micro-tubes [137]. Another major approach is to fabricate bilayer structures using two types of SMHs with different volume expansion properties. For example, bilayer hydrogel scaffolds were fabricated by combining a cell-laden GelMA layer and a cell-laden OMA layer. The differential swelling of the two layers led to the self-folding of the scaffolds in aqueous solution [132].

Fig. 9.

SMHs engineered using different strategies. (a–k) Self-forming GelMA tubes with crosslinking gradient across the thickness: (a) the 4D printing process, (b) optical image of a GelMA tube, (c, d) schematic illustration of the difference in crosslinking degree between the upper and lower layers and (e) corresponding SEM image and (f) pore sizes, (g–k) different GelMA microtubes fabricated by 4D printing. Reproduced with permission [137]. Licensed under a Creative Commons CC BY license. (l–n) In-plane force triggered helical structures formation: (l) planar sheet of the composite gel patterned with PNIPAm strips (dark blue) and PAMPS/PNIPAm strips (light blue), (m) different helical structures governed by the patterned angles (θ) (scale bar: 1 cm); (n) variation in the pitch (p) and number of turns (N) of the left-handed helix (θ = 45 °C), plotted as a function of the concentration of NaCl solution. Reproduced with permission [138]. Copyright 2013, Springer Nature. (o–t) Inside-out shape-morphing alginate: (o, p) top view and side view of an alginate pattern, (q) illustration of the hydrogel pattern with different crosslinking gradient across the thickness and plane of alginate (upper image) and SEM images of top and bottom parts of the alginate pattern (bottom images). (r–t) Tube formation (r), twisting (s), and curving (t) of the inside-out alginate after immersing it in Ca2+ solution (scale bar: 0.5 cm). Reproduced with permission [43]. Licensed under a Creative Commons CC BY license.

The in-plane force of 4D-bioprinted SMHs can also lead to the self-bending or folding process in aqueous environment by introducing a swelling ratio gradient across the plane (or in the horizontal direction) of the hydrogels (Fig. 8b). The in-plane SMHs can be fabricated using single materials or multiple materials with different swelling ratios. For example, a single smart hydrogel composed of methylcellulose and alginate has been 4D printed into a series of in-plane 2D patterns, which could transform into different simple or complex 3D morphologies in CaCl2 solution [42]. Wu and coworkers produced a series of hydrogel sheets composed of alternate strips of poly(N-isopropylacrylamide) (PNIPAm) and poly(2-acrylamido-2-methylpropane sulphonic acid) (PAMPS/PNIPAm) (Fig. 9l) [138]. Temperature-responsive structures could be fabricated through using these two hydrogels as they had different swelling ratios under the same temperature in water (Fig. 9m–n).

Although out-of-plane and in-plane SMHs can be used to achieve different 3D shape-morphing processes, in some cases, only out-of-plane or in-plane forces are not sufficient to achieve a desired shape-shifting process. To address this issue, swelling ratio gradients across both the thickness and plane (i.e., inside-out plane) of hydrogels have been developed, which enables the production of structures with improved shape-morphing ability (Fig. 8c). For instance, single out-of-plane GelMA hydrogels could self-fold into microtubes with a diameter ranging from 50 to 500 μm [137], but they do not have sufficient internal force to achieve a large tube with a diameter comparable to that of large blood vessels, such as veins with a diameter of 7–14 mm. Zhao and coworkers introduced a photocrosslinking gradient across the thickness and the plane of GelMA by constructing a second layer of strips onto the first solid membrane [139]. The inside-out GelMA hydrogels could fold into tubes with increased diameters of up to 6 mm. In another study, Du's group developed inside-out reversible alginate hydrogels by introducing different periodic patterns onto a solid membrane layer, leading to various 3D morphologies such as twist, tube, and plant-inspired architectures by responding to Ca2+ solution (Fig. 9o–t) [43].

4.3. Smart composite biomaterials

The applications of single SMPs or SMHs in 4D bioprinting are often hampered by their limited shape morphing ability, insufficient mechanical properties, poor printability, and low biocompatibility. To overcome the limitations of a single biomaterial, a typical solution is to develop smart composite biomaterials (SCBs) by incorporating suitable reinforcements (e.g., micro particles, nanofibers, and sheets) into the matrix [140]. Leveraging the advantages of different types of biomaterials, SCBs can achieve properties that cannot be obtained by a single biomaterial. The properties of SCBs can be influenced by the matrix, the reinforcement, and the interface between the matrix and reinforcement.

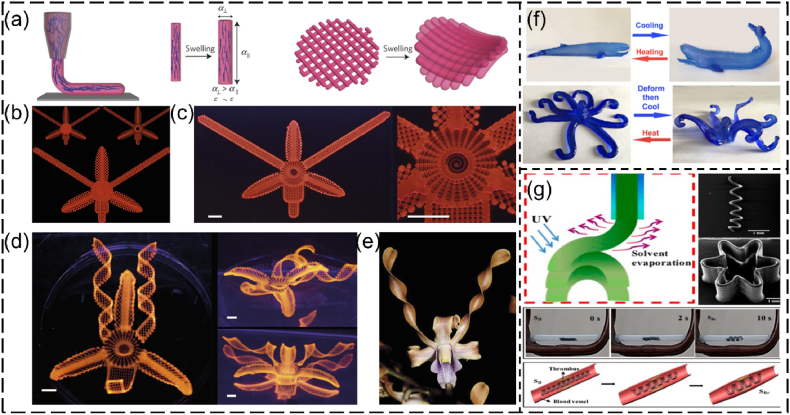

Various SCBs (Table 4) have been developed for 4D printing (Table 4). The incorporation of reinforcements into the base polymers can improve their performance such as printability, mechanical properties, and shape memory properties [25,141,142]. SMHs often have low printability and weak mechanical properties. This can make it challenging to print them as 2D/3D structures with high precision. Laponite nanoclay, a commonly used rheology modifier, is often added to hydrogel-based bioinks to improve their rheological properties and printability [[143], [144], [145]]. Laponite nanoclay is a sodium lithium magnesium silicate and these nanoscale disks have a thickness of ∼1 nm and a diameter of ∼25 nm. It can be dispersed in hydrogels and interact with them to form nanoclay/hydrogel composites with improved performances [143]. For instance, in the work by Lewis's group, Laponite nanoclay and nanofibrillated cellulose (NFC) were added to the NIPPAm SMH to form a composite ink, in which nanoclay offered good extrudability and printability and NFC was aligned during extrusion to induce the in-plane force (i.e., anisotropic swelling ratio) [35]. This composite ink was 4D printed into different accurate, complex plant-inspired architectures that could undergo 3D deformation upon immersion in water (Fig. 10a–e). In another study by Guo and colleagues, Laponite nanoclay was incorporated into agarose and polyacrylamide (PAM) hydrogels to enhance their shear viscosity and extrudability. This allowed the composite to be 4D printed into temperature-responsive dynamic structures resembling fish and whales, as depicted in Fig. 10f [146]. In addition to nanoclay, magnetic nanoparticles have been incorporated into SMPs or SMHs to endow them with remote and/or cyclic actuation capability in response to magnetic fields [142,147]. For example, Fe3O4 nanoparticles incorporated in SMPs can be heated by alternating magnetic fields and hence allow us to trigger shape-shifting of SMPs remotely [[148], [149], [150]]. Fe3O4/PLA composites have been 4D printed to generate different magnetic field-responsive structures including line- and flower-like shapes and vascular stents (Fig. 10g) [148]. Other reinforcements have also been applied for developing SMP or SMH-based composites. For instance, hydroxyapatite, a bioactive ceramic, was incorporated into collagen to improve the osteogenic activities of 4D-printed bone scaffolds [151]. In another study, Wang and coworkers developed a SCB by combining black phosphorus nanosheets (BPN), tricalcium phosphate (TCP), and PDLLA-co-TMC, in which PDLLA-co-TMC provided shape memory property, TCP enhanced the bone regeneration efficacy, and BPN could be heated by NIR to drive the shape-morphing process of the 4D-printed scaffolds [80].

Table 4.

Smart composite biomaterials for 4D printing.

| Composite | Printer type | Mechanism for 4D effect | External stimuli | Application | Reference |

|---|---|---|---|---|---|

| NIPPAm + Laponite nanoclay + NFC + glucose + glucose oxidase | MEB | In-plane force induced by the alignment of NFC | Water or heat | Biomimetic structures | [35] |

| Agarose + polyacrylamide + Laponite nanoclay | MEB | Sol-gel transition of agarose | Temperature | Tissue engineering | [146] |

| Fe3O4 + PLA | MEB | Shape memory effect of PLA | Magnetic field | Vascular stents | [113,148] |

| Fe3O4 + PLA + thermoplastic polyurethane (TPU) | FDM | Shape memory polymers | Magnetic field | Biomimetic structures | [150] |

| Poly-hydroxybutyrate/PCL + Fe3O4 + cellulose nanofiber | FDM | Shape memory polymer | Magnetic field | __ | [149] |

| Black phosphorus nanosheets/TCP/PDLLA-co-TMC | MEB | Shape memory polymer | NIR-irradiation | Bone tissue engineering | [80] |

| Hydroxyapatite + collagen | MEB | Leaching of the constituent components from printed structs to form fibrous bindles | Solvent leaching | Bone tissue engineering | [151] |

Fig. 10.

4D printing of SCBs. (a–e) 4D printing of Laponite/NFC/NIPPAm: (a) schematic illustration of the shear-induced alignment of cellulose fibrils during extrusion and subsequent effects on anisotropic stiffness E and swelling strain α, (b) printing path of an orchid, (c) printed structure, (d) shape-morphing orchid from different views, (e) a native orchid (scale bar: 5 mm). Reproduced with permission [35]. Copyright 2016, Springer Nature. (f) Temperature-triggered shape change of 4D printed whale-like and octopus-like structures made of Laponite/agarose/PAM. Reproduced with permission [146]. Copyright 2018, American Chemical Society. (g) 4D printing of shape memory structures (line, flower, vascular stents) using Fe3O4/PLA. Reproduced with permission [148]. Copyright 2017, American Chemical Society.

4.4. Smart design

While smart materials are a key element for the shape and functional transformation of dynamic structures, smart design is also essential in regulating these changes in a controllable manner. The smart design of 4D bioprinted structures should be conducted by taking into account the anticipated time-dependent transformation of objects [14]. A successful 4D bioprinting design requires a holistic consideration of shape memory property and mechanisms of the smart materials, patterns of the smart materials, type of 4D printer, and target tissues. Different smart materials exhibit distinct shape memory mechanisms and thus should be programmed using different 4D strategies to achieve controllable shape change. The properties of printed patterns of the smart materials are significantly influenced by the printing parameters (e.g., angle, position, and layer thickness), which affect the shape-morphing behavior (e.g., orientation, bending degree, and spiral angle) and thus should be controlled carefully. Based on the designed printing path, the 4D printer type should be carefully selected as certain printing technologies may not be able to achieve the desired smart design. For example, inkjet bioprinting or LAB may struggle to process smart designs for building complex 3D constructs with high precision. The target tissues also need to be considered when designing the dynamic scaffolds. For instance, to (re)generate vasculature requires structures with good self-folding capabilities to conform to the native tubular shape of vessels, while bone regeneration requires structures with good shape transformation abilities to fit irregular bone defects.

The complexity of intended shape-shifting behavior greatly affects the smart design procedure. Smart design for simple 2D-to-3D deformations, such as bending, twisting, and forming tubular structures, is relatively straightforward. For instance, self-folding can be achieved in SMHs by designing a 2D rectangular membrane with different crosslinking degrees between the upper and lower surfaces. As the complexity of 3D deformation increases, the design process becomes more complicated and challenging. For intricate 3D deformation, such as plant-inspired architectures and 3D-to-3D shape transformation, a holistic consideration of many factors is necessary during the smart design process, such as the spatial distribution of different components, the integration of multiple simple 3D deformations, the connection of distinct shape-morphing components, and the properties of connection points.

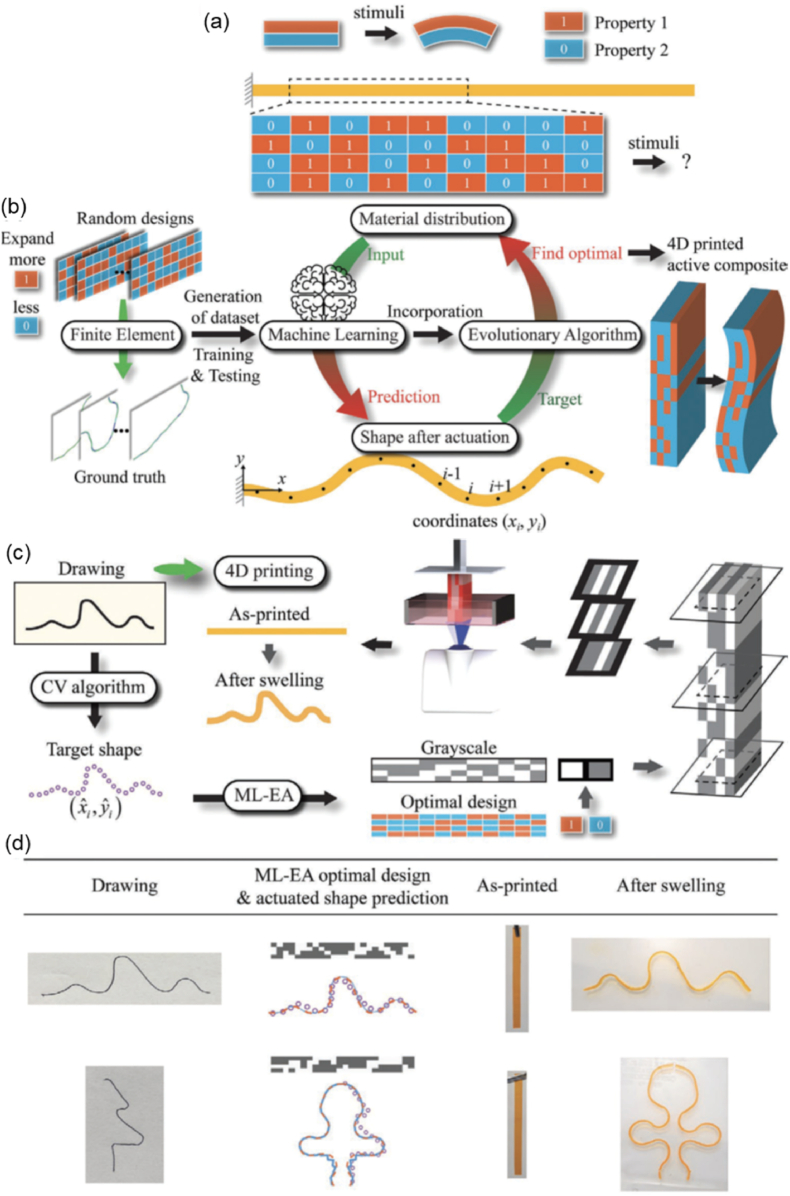

To assist the design of shape transformations, mathematical models and simulations have been developed to investigate the shape memory or shape morphing behaviors of smart materials. These models and simulations can enhance the users' understanding of shape-shifting mechanisms, thereby facilitating the improvement and optimization of 4D bioprinting paths. SMPs are primarily mathematically modeled based on the standard linear viscoelasticity approach or the thermodynamics behavior approach [152]. The former models SMP by combining elastic and viscous units with temperature-dependent parameters, while the latter models SMP as a mixture of active and frozen phases, in which the conversion of the active phase to the frozen phase causes the shape recovery behavior of SMPs. Many mathematical models have been developed for SMPs based on these two approaches [[152], [153], [154]]. The shape-morphing behavior of SMHs can be modeled based on the Timoshenko bimetal model [35,155]. The Timoshenko bimetal model was initially used for bi-layer metallic thermostat, and has been used, with or without modification, to describe and predict the deformation (or curvature) of SMHs based on the printing path [35,73]. Besides, finite element analysis (FEA) has been commonly used to simulate the shape transformation process of 4D bioprinted structures. The FEA can be performed using commercially available software (e.g., Abaqus) by modeling the 4D structure and selecting/designing a suitable constitutive model. This allows us to explore the influence of structural, chemical, or environmental factors on shape transformations, which in turn helps users optimize their smart design and 4D systems. Furthermore, machine learning (ML), a subset of artificial intelligence (AI), and neural network algorithms are developing rapidly in recent years and provide a highly efficient tool for optimizing the smart design of 4D bioprinted dynamic constructs through combining with the mathematic models [156,157]. For example, Qi's group developed an AI-strategy for 4D printing by combining FEA, ML, and EA (an AI algorithm inspired by biological evolution) [[158], [159], [160], [161]]. As shown in Fig. 11, two shape memory materials were encoded as “0” and “1” and their distribution in the structures was optimized using the ML-EA approach (Fig. 11a and b). After optimization, the material distribution was converted to grayscale slices, which were then transferred to a DLP printer for processing the two active materials into 4D structures (Fig. 11c). The 4D active composite structures could undergo 3D deformation upon swelling to achieve the target shapes of drawn profiles (Fig. 11d) [159].

Fig. 11.

A machine learning-evolutionary algorithm (ML-EA) to assist the design of 4D printed active composites with desired shape transformation. (a) Property mismatch-induced actuation and distribution of two materials with different shape memory properties (property “1” and property “2” are encoded as “1” and “0” for the algorithm, respectively). (b) A complete design for designing and optimizing the 4D printing path, including generation of the dataset by FEA simulations of random designs, prediction of shape changes by ML, optimization of material distribution by EA, and 4D printing of active composite using the optimized design. (c) 4D printing process based on the ML-EA design, including identification of drawn profiles as target shapes, ML-EA design, conversion of the obtained optimal design to the grayscale slices, 4D printing by DLP, and actuation of the printed structure. (d) Experimental results showing DLP-produced structures with target shape transformation to mimic drawn profiles. Reproduced with permission [159]. Copyright 2021, Wiley-VCH.

5. Requirements for bioinks in 4D bioprinting

Smart bioinks for 4D bioprinting can be made of cell-laden smart biomaterials or solely living cells. As 4D bioprinting is still in its early development stage, limited smart biomaterials are available for 4D bioprinting. Currently, one of the major challenges for 4D bioprinting is to develop suitable smart biomaterials that not only have excellent printability and biological functionalities, but also robust responsiveness to stimuli. The fundamental bioink traits in 4D bioprinting include printability, biocompatibility, stimuli-responsiveness, biodegradability, mechanical properties, and cells (Table 5). Except for stimuli-responsiveness, the other traits are also vital for 3D bioprinting and have been discussed in several well-written reviews [2,22,162,163]. However, compared to 3D bioprinting, 4D bioprinting poses more stringent requirements on these features, which will be discussed in this section.

Table 5.

Desired properties for smart bioinks for 4D bioprinting.

| Properties | Requirements |

|---|---|

| Printability | Processable and compatible with different types of bioprinting technologies Production of dynamic constructs with accurate patterns according to the smart design |

| Biocompatibility and bioactivity | Supporting cell growth and functionality during in vitro and in vivo development Absence of side effects in the host Facilitating desirable host responses after in vivo deployment |

| Stimuli-responsiveness | Robust stimuli-responsiveness Enabling fabrication of dynamic constructs with preprogrammed changes in shape, property, and function under stimuli Multiple stimuli-responsive, reversible shape changes, remote and cyclic actuation Enabling multi-step 3D deformation Adaptation to the complex human physiological environments |

| Biodegradability | Achieving a preprogrammed multi-step shape-shifting process by controlling the degradation rates Matching the growth of neo-tissues after deployment in vivo by designing appropriate degradation kinetics |

| Mechanical properties | Supporting structural integrity and shape transformation during evolvement of the 4D bioprinted constructs Matching the mechanical properties of target tissues |

| Cells | Cell sources with high availability High cell viability Comparable cell density to native tissues Excellent cellular functionalities (e.g., proliferation and differentiation) Generation of cell traction force to induce the shape transformation of microstructures |

5.1. Printability

Printability is the foremost requisite for bioinks in 4D bioprinting. A bioink with good printability enables the accurate deposition of the materials, enabling the precise fabrication of intricate 4D structures with specific component distributions for achieving desired shape/function transformations. The specific requirements on the printability of bioink materials vary depending on the type of bioprinting technology utilized. For MEB, the bioink materials should have good rheological properties, including a high viscosity, shear thinning behavior, and thixotropic property. The printability of a material for MEB is affected by many parameters such as nozzle size, printing speed, and layer thickness. Some mathematical models have been used to describe the ink flow behavior in MEB [[164], [165], [166]]. Based on these models, a number of approaches have been developed to evaluate the printability of a material for MEB according to the extruded filament size, the printed grid circularity, and the obtained stackability [56,144,167]. As inkjet bioprinting and LAB are DOD-based bioprinting technologies, the printability of a bioink material is mainly affected by its physical parameters such as viscosity, density, and surface tension, which determine the formation and size of a droplet [168]. Besides, fast crosslinking is required for DOD bioprinting as rapid stabilization of the deposited low-viscosity droplets can avoid collapse. SLA and DLP require a bioink material to be photocrosslinkable and have suitable viscosity, thus permitting fresh bioink to flow and re-coat the construct after one layer is printed. The processing parameters should also be optimized to obtain a precise 3D structure with good shape fidelity, such as light intensity, scanning speed, and light exposure time [53].

5.2. Biocompatibility

Biocompatibility refers to the ability of a material to accommodate and permit appropriate biological response in a specific biological application [169,170]. Therefore, a biocompatible material not only can co-exist with the host without producing side effects or toxicity, but also is expected to produce positive responses to and by the host. Like 3D bioprinting, 4D bioprinted constructs involve living components and undergo a broad range of biological interactions with a living system. As a result, a bioink material for 4D bioprinting must be biocompatible to support the in vitro and in vivo development of the fabricated constructs. A material with excellent biocompatibility can support cell growth, maintain high cell viability, facilitate the transfer of molecular or mechanical signals, and interact positively with both endogenous tissues and the immune system, all of which are essential for successful transplantation and function. The SMPs and SMHs listed in section 4 are representative biocompatible materials for 4D bioprinting, and most SMHs are natural polymers and thus provide a comfortable microenvironment for cell survival and growth.

5.3. Stimuli-responsiveness

Robust stimuli-responsiveness is critical for 4D bioprinted constructs as they need to change their shape and/or functionality in response to appropriate stimuli. The human body has intricate microenvironments which are maintained by multiple mechanisms, such as humoral, ionic, and neural regulation. To accommodate such complex conditions, an ideal responsive material should have the capability to self-transform in response to multiple physiological signals, rather than being limited to a single type of stimulus. Currently, stimuli-responsive materials that can be 4D bioprinted are primarily SMPs or SMHs. However, most of them respond to only a single stimulus, such as temperature or humidity. Additionally, it is necessary for stimuli-responsive materials to maintain their shape fidelity and functional stability, even when exposed to disturbance. In certain applications (e.g., recapitulating the regular contraction of native tissues), reversible shape transformation and cyclic reversible shape transformation are needed for 4D bioprinted dynamic structures. In such cases, the 4D bioprinted structure should exhibit robust shape memory behavior with minimal decline in its performance at increased cycles [39,44].

5.4. Biodegradability

Biodegradation is a common property for most biomaterials and scaffolds in vitro and in vivo. It should be noted that the degradation process per se is not generally regarded as a 4D effect for 4D bioprinting [15,23]. However, in some cases, degradation rate is programmed to trigger the specific deformation at specific time point during in vitro incubation. For example, Alsberg's group produced shape-morphing trilayer hydrogels composed of two layers of different OMA hydrogels and one layer of GelMA hydrogel [171]. Due to the swelling and degradation discrepancies of these layers, the trilayer hydrogels underwent multiple-shape (five-phase) transformations during in vitro culture [171]. In tissue regeneration, the scaffolds gradually degrade while the embedded cells produce new ECM to replace the degraded materials, ultimately forming new tissues [172]. As such, it is ideal that a material's degradation rate matches the rate of new tissue growth. However, it is still challenging since the new tissue growth rate is dynamic and difficult to control. Besides, the degradation byproducts should be biocompatible (i.e., producing no side effects in the host). The degradation products should also be able to be cleared from the human body via cell metabolism or the urinary system. Most SMPs are synthetic polymers and thus generally exhibit a slower degradation rate compared to SMHs. The degradation rate of SMHs depends on various factors, such as hydrogel type, crosslinking degree, concentration, temperature, and in vitro and in vivo conditions.

5.5. Mechanical properties

Mechanical properties of a material are a key consideration for bioinks in 4D bioprinting. Firstly, sufficient mechanical strength is needed to support the structural integrity and prevent the bioprinted structures from collapsing during and after bioprinting. Secondly, a 4D bioprinted structure with good mechanical strength and structural stability can effectively support 2D-to-3D and 3D-to-3D shape transformation. Currently used SMHs are mostly natural hydrogels with relatively low mechanical strength. Thus, it is often challenging to print stable structures with designed structural anisotropy, making it difficult to achieve effective 3D shape transformation for biocompatible hydrogels laden with cells [40]. Although a number of studies have reported that simple self-bended and cell-laden hydrogel structures could remain stable over several days of in vitro culture [40,70,133], the structural stability of 4D bioprinted constructs still faces many crucial issues. For example, it is often observed that self-tubed cell-laden constructs form loose or leaky tubular structures and cracks on the tubule wall, which are undesirable when using the constructs for vascular regeneration [37,125]. In some studies, the bending degree of self-folded scaffolds would gradually change during days or weeks of in vitro incubation [132,135], which may be caused by the structures’ degradation and unstable swelling ratio of upper and bottom layers. In addition, cell-laden 4D constructs, especially for micro-constructs, experience cell contraction forces during incubation, which may lead to undesired deformation for the already shape-morphing constructs [73]. In such cases, smart biomaterials must have sufficient mechanical strength to prevent the undesired deformation caused by the cell contraction force. Thirdly, although native tissues and organs show diverse mechanical properties, the implanted constructs should ideally have mechanical properties comparable to those of the target native tissues to avoid mechanical mismatches or transplant failure. At the early stage of tissue regeneration, cells embedded in the hydrogels do not produce sufficient new ECM to support themselves. Therefore, the bioprinted structures should have a certain mechanical strength to support cell growth and functions until the cells are capable of secreting enough of their own ECM.

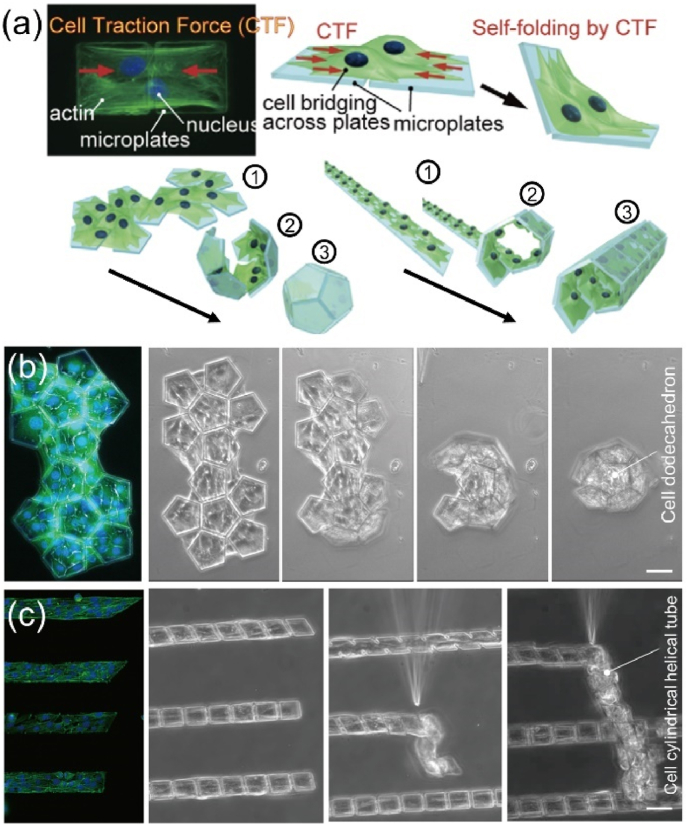

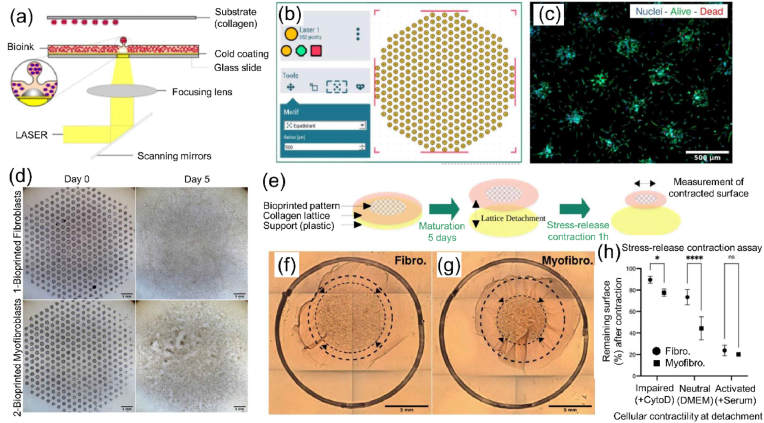

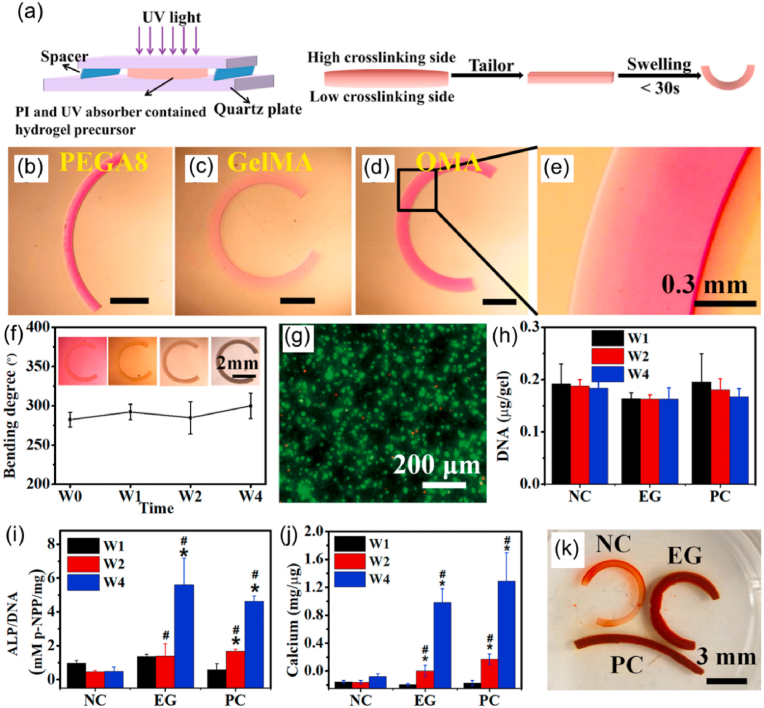

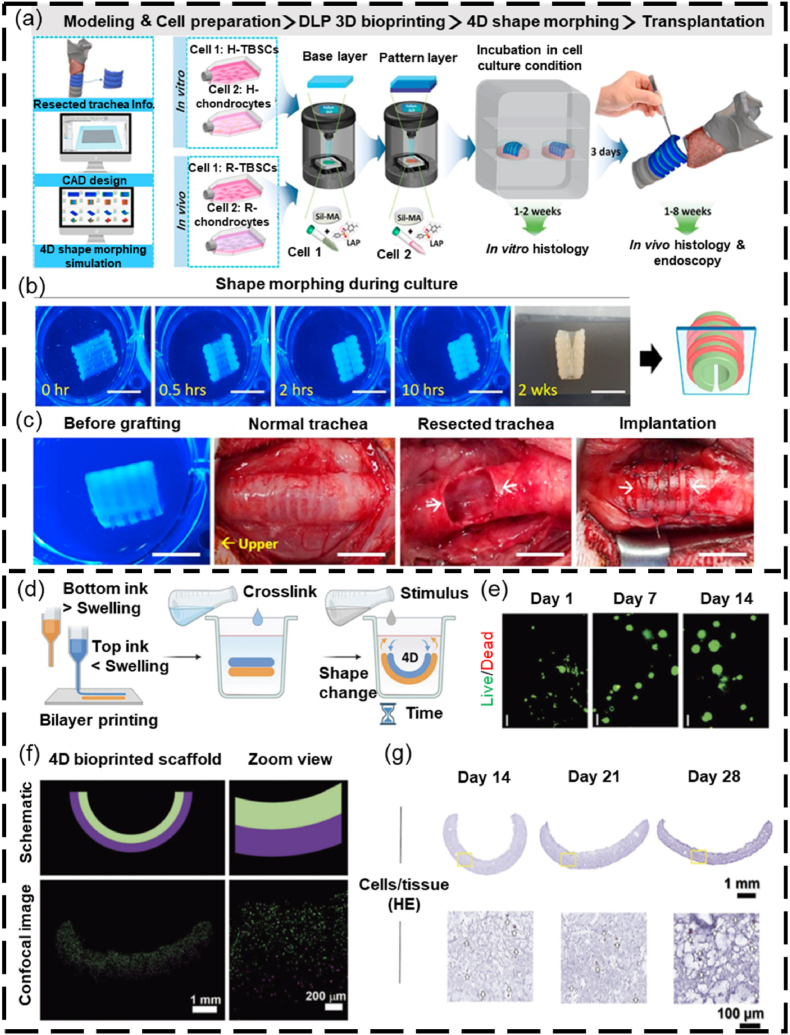

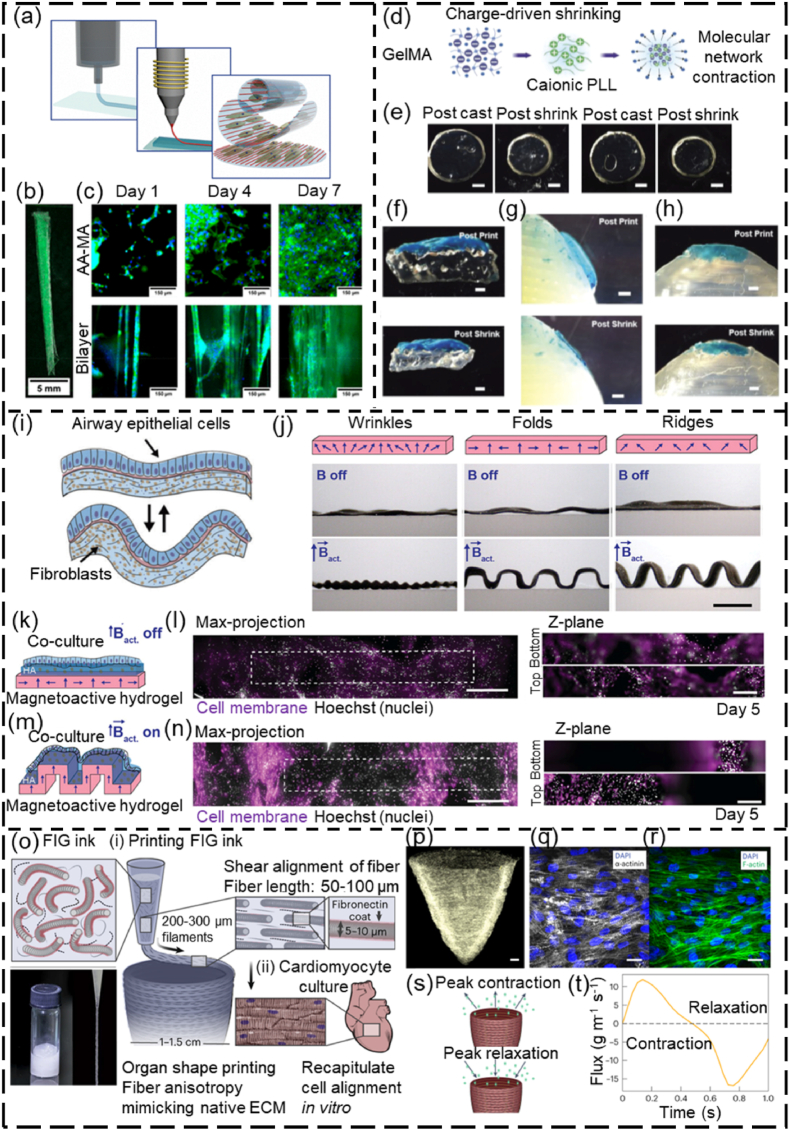

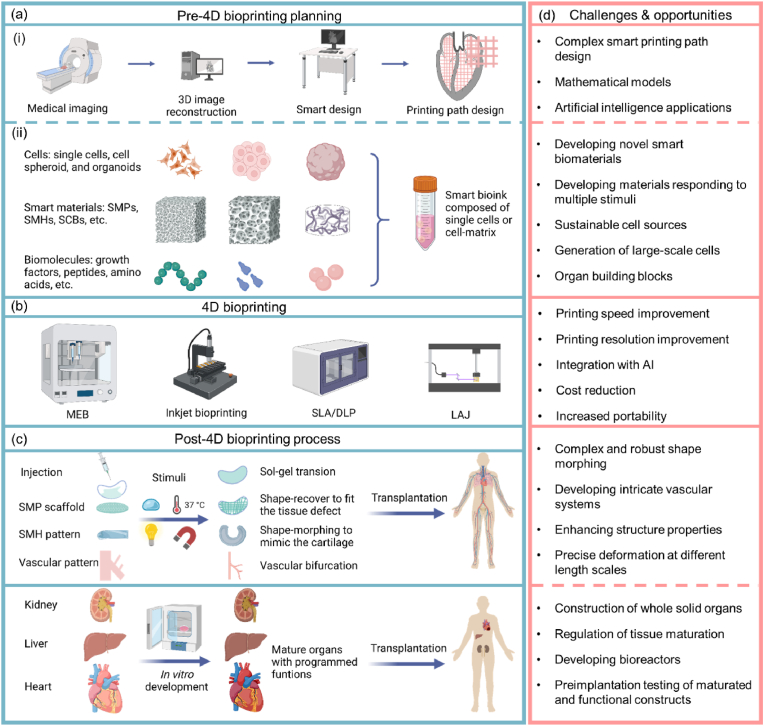

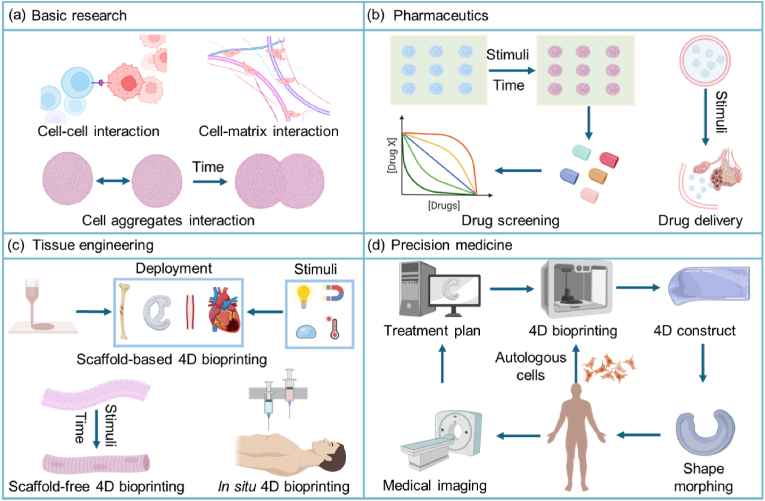

5.6. Cells