Abstract

The implementation of the head-only electrical stunning procedure in poultry processing has been aimed at enhancing eating, ethical, and religious quality. However, inconsistencies in voltage and frequency standardization, along with variations in previous research outcomes, have led to numerous cases of both under-stunned and over-stunned birds. Thus, this study aimed to comprehensively evaluate the effects of varying voltages and frequencies during electrical water bath stunning on carcass quality, meat attributes, and textural properties in broiler chickens. A cohort of 240 healthy female broilers (Cobb 500, 42-days-old, 2 kg ± 0.1 kg) was meticulously selected from a commercial farm. The birds underwent exposure to different stunning voltages (2.5, 10.5, 30, and 40 V) and frequencies (50 and 300 Hz). Subsequent analyses were conducted on meat samples to assess physicochemical properties, carcass quality, and textural attributes. The findings revealed a higher incidence of petechial hemorrhage (P < 0.05) in birds stunned at 10.5 V compared to other voltage. Notably, no broken bones were recorded in birds subjected to high voltages (30 and 40 V). Low frequency (50 Hz) significantly increased the occurrence of petechial hemorrhage and simultaneously resulted in pectoralis major muscle with decreased redness (a*). Birds subjected to the 10.5 V stunning treatment exhibited a lower cooking loss percentage. Significant interactions between voltage and ageing (V × A) were observed. Birds stunned at 30 V and aged for 7 d displayed highest drip loss compared to a one-day ageing period across different voltage levels. This interaction also impacted pH values, with birds subjected to 10.5 V showing significantly lower (P < 0.05) pH at d 7 of ageing. The meat hardness was influenced by the V × A interaction, wherein birds stunned at 10.5 V exhibited lower hardness after one day of ageing compared to other voltage levels. Red wing tips, lightness (L*), adhesiveness, and resilience were also significantly impacted (P < 0.05) by the interaction between frequency and voltage. A notable 3-way interaction was observed for gumminess and chewiness (F × V × A), where the 2-way interaction between frequency and voltage (F × V) affected both parameters differently at various ageing periods. Additionally, there was a significant interaction (P < 0.05) between frequency and voltage influencing shear strength and yellowness.

Key words: head-only electrical water bath stunning, voltage, frequency, meat quality, textural properties

INTRODUCTION

The quality of meat stands out as a paramount factor influencing consumer purchasing decisions. Animals subjected to stress, pain, and fear before and during the slaughtering process are notably more prone to the degradation of meat quality. A multitude of factors, both intrinsic and extrinsic, contribute to this phenomenon. In particular, environmental conditions such as heat (Humam et al., 2020), transportation (Abubakar et al., 2021), handling (Zulkifli et al., 2000), shackling (Zulkifli et al., 2019), stunning (Nakyinsige et al., 2014; Lambooij and Hindle, 2017; Hayat et al., 2023), slaughtering (Petracci et al., 2010; Addeen et al., 2014; Zulkifli et al., 2019), and subsequent processing, storage (Vieira et al., 2009; Aziz et al., 2020) and cold transportation (Hayat et al., 2021) exert detrimental effects on muscle metabolism, lactic acid deposition, and protein denaturation. As a result, there is a compelling need for rigorous adherence to effective animal handling and processing procedures throughout the entire processing chain to uphold optimal meat quality (Kumar et al., 2023b).

Electrical water bath stunning serves as a method to induce unconsciousness in birds, rendering them insensitive to pain (Humane Slaughter Association, 2016). Birds are acutely responsive to threats, danger, and pain, perceiving these stimuli through visual, auditory, and olfactory cues in their environment. Effective stunning is achieved when the animals' sensory attributes are neutralized, brought about by the generalized epileptiform state induced by sufficiently high electrical voltage and hypersynchronous brain cell activity (Sabow et al., 2017; Hayat et al., 2023). Conversely, inadequate electrical stunning can result in adverse consequences, including the deterioration of meat quality, heightened pain and distress, and a potential compromise of halal status (Sazili et al., 2023).

While high-voltage electrical stunning has been correlated with achieving a more effective state of unconsciousness in poultry (Lambooij and Hindle, 2017), the use of low-voltage electrical stunning persists in certain regions, particularly where the emphasis is on halal meat production (DOS, 2009). The primary rationale for continuing this practice is the concern for preventing bird mortality during stunning. However, the lack of induced unconsciousness manifests physically in varying carcass defects, encompassing broken bones, wings, hemorrhages, ecchymosis, and hematoma, ultimately leading to the condemnation of products and a reduction in the economic value of the final product (Novoa et al., 2019). Despite the reported benefits of electrical stunning, studies have indicated that high voltage and high frequency can result in reduced pH, increased glycolytic potential and improved tenderness (Xu et al., 2011). The incongruities in findings across previous research, coupled with the need to strike a balance between eating quality, ethical considerations, and religious/spiritual aspects, motivated the initiation of the present study. Thus, this study aimed to assess the impact of different voltages and frequencies in electrical water bath stunning on the carcass quality, meat quality, and textural properties of broiler chickens.

MATERIALS AND METHODS

Ethical Note

The present study was conducted following the animal ethics guidelines of the Research Policy of Universiti Putra Malaysia as per Institutional Animals Care and Use Committee (IACUC) approval No.: UPM/ IACUC/ AUP-R019/2020, dated 30th June 2020.

Animals

A cohort of 240 healthy female broiler chickens (Cobb 500, 42-days-old, 2 kg ± 0.1 kg) was systematically chosen from Merit Farm Marketing Sdn. Bhd., a commercial broiler farm located at Lot 1514, Jalan Batu-bata, Off Jalan Raja Abdullah, 45800 Jeram, Selangor, Malaysia (Latitude 3° 14′ 25.0218″ N and longitude 101° 19′ 24.5814″ E). The manually caught chickens were then placed in a plastic crate (75 × 55 × 33 cm) then promptly transported to the Research Slaughterhouse in the Department of Animal Science, Faculty of Agriculture, Universiti Putra Malaysia using a truck, within a period of one and a half hours. Upon arrival, the birds were distributed into eight treatment groups, each consisting of 30 chickens, and were subsequently exposed to various combinations of stunning voltages and frequencies. Prior to stunning and slaughtering, the birds were granted a 1-h resting period without feed and water. The treatment groups were configured as follows: (T1) 2.5 V × 50 Hz; (T2) 10.5 V × 50 Hz; (T3) 30 V × 50 Hz; (T4) 40 V × 50 Hz; (T5) 2.5 V × 300 Hz; (T6) 10.5 V × 300 Hz; (T7) 30 V × 300 Hz; (T8) 40 V × 300 Hz. The stunning procedures were conducted using a commercial head-only electrical poultry stunning system, employing alternate current (AC), where birds were invertedly restrained on a moving shackle and stunned individually, with 6 s stunning durations. This locally manufactured high-frequency stunner, boasts versatile capabilities, enabling the production of variable voltage up to 100 V and configurable frequency ranging from 50 to 2,000 Hz, catering to both low- and high-frequency operations. Rigorous adjustments, measurements, and calibrations of voltage and frequency were carried out before each treatment group initiation. This process was facilitated by a handheld digital multimeter (Agilent U1272A, with the capacity to measure voltage up to 1000 V and current up to 10 A) and an oscilloscope (Tektronix TBS1154, featuring a bandwidth of 150 MHz and a maximum sampling rate of 1 GS/s). Ensuring accuracy, a dedicated high-voltage differential probe (GW Instek GDP-025) was employed to establish a reliable connection between the high-frequency stunner source and the oscilloscope.

Immediately after stunning, the birds were slaughtered by a licensed slaughterman according to the halal slaughter procedure, by severing the trachea, esophagus, carotid artery and jugular vein, as indicated in the Malaysian Standard MS1500:2009 (Department of Standards Malaysia, 2009). The birds were subsequently left on a moving shackle to bleed for 4 min before taken for muscle sampling to ascertain death as per the halal protocol requirement. The right Pectoralis major muscle was removed from the carcass and portioned for meat quality analysis. Drip loss, cooking loss, shear force, color, pH and texture profile analysis (TPA) samples were subjected to 1 and 7 d of ageing at 4°C before stored in -80°C until subsequent analysis.

Carcass Quality

Carcass evaluation was executed using a modified method of Kranen et al. (1996). Upon completion of evisceration and dressing, pictures of each carcass (dorsal & ventral, with a black background) were taken to be evaluated for carcass evaluation parameters (Figure 1). Scores were given based on the level of severity of each incidence. Score 0: Absence of petechial hemorrhage/ ecchymosis/ hematoma/ broken bones/ bruised and reddish wing tips, score 1: 1–2 incidence, score 2: 3–7 incidence, score 3: 8–10 incidence, score 4: 11 Above incidence, Score 5: Fiery red areas (Figure 1).

Figure 1.

Carcass petechial hemorrhages, broken bones, red wing tips, hematoma, and ecchymosis/ blood splash.

Physico-Chemical Properties

pH Measurement

The pH of meat prerigor (less than 20 min or 0 h postmortem) and postrigor (1 d and 7 d postmortem) were determined using an indirect method using a portable pH meter (Mettler Toledo, AG 8603, Switzerland), according to the method described by Hayat et al. (2021). Prerigor samples were snap-freeze in liquid nitrogen and stored at -80°C until further analysis, whereas samples for d 1 and 7 were aged at 4°C before transferred to -80°C upon completion of each postmortem ageing duration. Prior to reading, the pH meter was calibrated at pH 4, pH 7, and pH 9. To prevent further glycolysis, approximately 0.5 g of Pectoralis major muscle was crushed using liquid nitrogen and homogenized (Wiggen Hauser D-500, Germany) for 20 s in 10 mL of ice-cold distilled water with the presence of 5 mM sodium iodoacetate (Merck Schuchardt OHG, Germany). pH of the mixture was measured using the handheld glass electrode connected to the pH meter.

Drip Loss Determination

The water holding capacity of Pectoralis major muscle was determined based on the percentage of drip loss and cooking loss after postmortem ageing of 1 d and 7 d. For drip loss, approximately 30 g of fresh Pectoralis major muscle was removed from the carcass, weighed and recorded as initial weight (Wa). The weighted muscle samples were then placed in polyethylene bags, properly labelled, vacuum packed and stored in a 4°C chiller for 1 d and 7 d (Hayat et al., 2021). Immediately after the completion of each postmortem storage duration, the muscle samples were taken out of from the bag, gently dapped with paper towels and reweighed. The weight after postmortem storage was recorded as the final weight (Wb). The following formula was used to determine the percentage of drip loss (Honikel, 1998):

Where Wa is the muscle sample weight before postmortem storage (g) and Wb is the sample weight after postmortem ageing (g).

Cooking Loss Determination

Cooking loss was determined after the completion of 1 d and 7 d of postmortem ageing. 50 g ± 1 g of Pectoralis major muscle was removed from the carcass, gently dapped with paper towels and weighed (Wx). The meat samples were then placed in a water-impermeable polyethylene bag and vacuum-packed. The samples were then cooked in a preheated water bath at 80°C for 20 min. After 20 min, when the internal temperature of the meat reached 78°C as shown by a stabbing probe thermometer (HI 145-00 thermometer, HANNA instruments), the meat was allowed to cooked for another 10 min to ensure that all the other meat samples had attained similar final internal temperature. The meat samples were then removed from the water bath, equilibrated to room temperature by placing them under running water, removed from the plastic bag, dapped dry gently using paper towels without squeezing, and reweighed (Wy) (Honikel, 1998). The cooking loss percentage was calculated using the following equation:

Where Wx is the muscle sample weight before cooking in the water bath (g) and Wy is the muscle sample weight after cooking in the water bath (g).

Shear Force Measurement

Shear force determination was carried out using samples from cooking loss analysis. For each sample, at least 3 replicate blocks (1 cm x 1 cm x 2 cm) were cut in parallel to the direction of muscle fibers and each block was sheared at the center and perpendicular to the longitudinal direction of the fibres (Sazili et al., 2005). Prior to shear force measurement, the equipment [(TA.HD plus Texture Analyzer (Stable Micro System, Surrey, UK)] was calibrated using 5 kg weight for force, whilst, return distance for height and return speed were set at 20 mm and 20 mm/s, respectively. The average peak positive force value for all blocks from each individual sample was used to determine shear force values (Hayat et al., 2021).

Color Values Determination

For color analysis, 30 ± 1 g of Pectoralis major muscles from each treatment was removed from the carcass, the skin was removed, vacuum packed, and divided into 2 ageing periods (1 d and 7 d) at 4°C. Meat color determination was carried out using ColorFlex EZ spectrophotometer (HunterLab Reston, VA) to obtain the International Commission on Illuminance Lab-values (L*: lightness, a*: redness, b*: yellowness, C*: Chroma, h: hue angle). D65 illuminant with 10° angle standard observer (aperture size 5 cm) was used during measurement (Hayat et al., 2021). The device was calibrated against black and white tiles prior to analysis. The frozen samples from the -80°C freezer were thawed overnight at 4°C. The thawed samples were unpacked and bloomed for 30 min, following which the bloomed surface was placed in contact with the bottom of the ColorFlex cup. For each sample, after the first measurement, the cup was rotated 90° for the second and third readings. The average for the 3 readings was used to represent the value of each color parameters (Hayat et al., 2021).

Texture Profile Analysis

Texture profile analysis (TPA) was conducted directly after the completion of each postmortem ageing period. Pectoralis major muscle (30 ± 1 g) was cooked in a preheated water bath (80°C) for 30 min, before cooled down and cut into chunks of 1.5 cm x 1.5 cm size with 1 cm thickness (Hayat et al., 2021). TPA measurements were conducted using TA.HD plus Texture Analyzer (Stable Micro System, Surrey, UK) equipped with P/75 compression probe. Prior to measurement, the instrument was calibrated with a 5 kg load cell (force calibration) and 20 mm return distance, 10 mm/s return speed, and 5 g contact force for probe height calibration. The instrument settings were preset and fixed at 1.0 mm/s (pre-test speed), 5.0 mm/s (test speed), and 5.0 mm/s (post-test speed). Samples were positioned in the middle of the platform before being double compressed, in which the second compression uses 50% strain (Asyrul-Izhar et al., 2021). The hardness (kg), adhesiveness (g.sec), springiness (mm), cohesiveness, gumminess (g), chewiness (g mm) and resilience of each sample were then recorded and calculated.

Experimental Design and Statistical Analysis

Data for physicochemical and textural properties were analyzed by 3-way Analysis of Variance (ANOVA) while data for carcass evaluation were analyzed by 2-way Analysis of Variance (ANOVA) using General Linear Model (GLM) procedure of Statistical Analysis System 9.4 (SAS Institute Inc., Cary, NC, USA). Duncan's Multiple Range Test was used to compare the significant difference between treatments (P < 0.05).

RESULTS AND DISCUSSIONS

Effect of Different Voltage and Frequency on Carcass Quality

The analysis of carcass defects holds the utmost significance for various reasons, encompassing the assurance of food safety, preservation of high-quality standards, fostering consumer confidence, and adherence to regulatory norms. These factors collectively contribute to the enhancement of the economic value of the final product. Differences in carcass quality parameters for birds stunned at different voltages and frequencies are shown in Table 1. Results indicate that no significant interactions (P > 0.05) were recorded for all carcass quality parameters except for red wing tips. The incidence of petechial hemorrhage was higher (P < 0.05) in birds subjected to 10.5 V and 50 Hz (low frequency) compared to 300 Hz with the same voltage. Petechial hemorrhage refers to the appearance of small, pinpoint-sized red spots on the skin (Kuttappan et al., 2017). These tiny hemorrhages occur when capillaries rupture, leading to leakage of blood to surrounding tissues (Kranen et al., 1996). Low voltage stunning had been associated with the inability to render birds’ unconscious (Bourassa et al., 2017). Conscious birds are highly prone to stress and pain, either during handling, shackling, slaughtering and especially during ineffective stunning. The build-up of stress and pain will lead to an increase in pressure in the blood vessels and capillaries, causing them to rupture (Gregory and Grandin, 1998; Sabow et al., 2017). The outcome of the studies agreed with the findings reported by Kuttappan et al. (2017), who reported a significant impact of the head-only electrical stunning procedure on the incidence of hemorrhage in breast muscle.

Table 1.

The effect of different electrical frequency and voltage combinations of water-bath stunning procedure on carcass quality of broiler meat.

| Parameters | Frequency (Hz) | Voltage (V) |

P-value (Voltage) | P-value (F x V) | |||

|---|---|---|---|---|---|---|---|

| 2.5 | 10.5 | 30 | 40 | ||||

| Petechial hemorrhage | 50 | 1.4 ± 0.22 a,x | 1.9 ± 0.23 a,x | 1.5 ± 0.22 a,x | 1.4 ± 0.16 a,x | 0.3029 | 0.5135 |

| 300 | 1.2 ± 0.13 a,x | 1.3 ± 0.15 a,y | 1.1 ± 0.10 a,x | 1.3 ± 0.21 a,x | 0.7685 | ||

| P-value (Freq.) | 0.4486 | 0.0453 | 0.1198 | 0.7142 | |||

| Ecchymosis | 50 | 0.5 ± 0.27 a,x | 0.3 ± 0.21 a,x | 0.5 ± 0.27 a,x | 1.0 ± 0.33 a,x | 0.3293 | 0.2454 |

| 300 | 0.6 ± 0.22 a,x | 0.9 ± 0.28 a,x | 0.6 ± 0.27 a,x | 0.5 ± 0.27 a,x | 0.7214 | ||

| P-value (Freq.) | 0.7771 | 0.1033 | 0.7947 | 0.2581 | |||

| Red wing tips | 50 | 0.6 ± 0.27 a,y | 1.2 ± 0.39 a,x | 1.2 ± 0.36 a,x | 1.5 ± 0.40 a,x | 0.3566 | 0.0114 |

| 300 | 1.5 ± 0.22 a,x | 1.9 ± 0.28 a,x | 0.7 ± 0.21 b,x | 0.7 ± 0.21 b,x | 0.0011 | ||

| P-value (Freq.) | 0.0186 | 0.1597 | 0.2468 | 0.0954 | |||

| Broken bones | 50 | 0.8 ± 0.42 ab,x | 1.4 ± 0.56 a,x | 0 ± 0 b,x | 0 ± 0 b,x | 0.0184 | 0.2967 |

| 300 | 0 ± 0 a,x | 0.6 ± 0.4 a,x | 0 ± 0 a,x | 0 ± 0 a,x | 0.0992 | ||

| P-value (Freq.) | 0.0706 | 0.2612 | 0.0000 | 0.0000 | |||

Means with different superscript letters within the same row differ significantly (P<0.05) between ageing voltages.

Means with different superscript letters within the same column differ significantly (P<0.05) across stunning frequencies. Means are presented as ±SEM (standard error of mean). V: volt; F: frequency.

Birds stunned at high frequency (300 Hz) coupled with 2.5 V had higher red wing tip scores, in comparison with birds stunned at low frequency (50 Hz). As stated previously, low voltage had a low tendency to render birds’ unconscious, thus leading to excessive and violent wing flapping throughout the process (Bourassa et al., 2017). More recently, Huang et al. (2017) revealed that low voltage (5, 15, and 25 V) had a more detrimental impact on Pectoralis major muscle damage compared to high voltage (35 and 45 V). On the contrary, Bourassa et al. (2017) reported that there was no significant impact of different voltage of direct current (DC-15 V and 25 V) and alternate current (AC-0 V, 100 V, and 120 V) on red wing tips score. Excessive flapping can result in wing bruising and damage, which may lead to a higher incidence of red wing tips.

In the industry, broken bones are the main factor for carcass downgrading. Broken bone incidence was not detected in birds subjected to high voltage (30 V and 40 V) for both low and high frequencies, which indicates an efficient stunning procedure. With sufficient voltage, an electrical current is passed through the brain, which disrupts its normal functions and leads to unconsciousness (Sabow et al., 2017). The birds become unresponsive to external stimuli, thus indirectly minimizing struggling and wing flapping, the leading cause of broken bones (Sabow et al., 2017). The results obtained in this study were in contrary to the findings by Bourassa et al. (2017) which reported no significant impact of different voltages and flow of current (AC or DC).

Effect of Different Voltages, Frequencies, and Postmortem Ageing Days on Meat Quality Parameters

Meat quality parameters as affected by the voltage, frequency, and postmortem ageing are presented in Table 2.

Table 2.

The effect of different frequencies (50 Hz & 300 Hz) and voltages (2.5 V, 10.5 V, 30 V & 40 V) of electrical water-bath stunning procedure on pH, drip loss, cooking loss and shear force of Pectoralis major muscle at prerigor (0 h) and postrigor (1 d and 7 d).

| ANOVA (P-value) | Ph | Drip loss | Cooking loss | Shear Force |

|---|---|---|---|---|

| Main effects: | ||||

| Frequency (F) | 0.2029 | 0.0290* | 0.1895 | 0.1064 |

| Voltage (V) | 0.0387* | 0.0887 | 0.0003⁎⁎ | 0.6413 |

| Postmortem ageing (A) | <0.0001⁎⁎⁎ | <0.0001⁎⁎⁎ | <0.0001⁎⁎⁎ | 0.1876 |

| 2-way interactions: | ||||

| F x V | 0.2188 | 0.1652 | 0.3459 | 0.7372 |

| F x A | 0.1307 | 0.4307 | 0.0575 | 0.0062⁎⁎ |

| V x A | 0.0115* | 0.0085⁎⁎ | 0.6603 | 0.0779 |

| 3-way interactions: | ||||

| F x V x A | 0.7237 | 0.4967 | 0.6443 | 0.7782 |

N = 240, n = 30. ANOVA, analysis of variance.

P < 0.05.

P < 0.01.

P < 0.001.

pH Value

The pH level of meat plays an important role in determining final meat quality. pH can affect other meat quality parameters, particularly regarding tenderness, color, flavor, and shelf life. In this study, there was a significant 2-way interaction (P < 0.05) between voltage and ageing days (Table 2). The changes in pH throughout the ageing days depended on the voltage used during stunning. Using 2.5 and 10.5 V during stunning significantly reduced meat pH after 1 and 7 d of postmortem ageing, while a significant drop in pH for birds stunned using 30 and 40 V was only seen on d 1. On the final ageing day (d 7), the pH value of meat for birds stunned at 2.5 and 10.5 V was significantly lower (P < 0.05) than the other voltages (Table 4). Based on Table 3, the main effects of voltage and ageing have a significant (P < 0.05) effect on pH, while frequency does not significantly affect pH level in meat (Table 2).

Table 4.

The effect of different electrical voltage of electrical water-bath stunning procedure and ageing duration on drip loss percentage (%) of broiler meat.

| Voltage (V) | Postmortem ageing (Days) |

P-value (A) | P-value (V x A) | |

|---|---|---|---|---|

| 1 | 7 | |||

| Mean (SEM) | Mean (SEM) | |||

| 2.5 | 2.79 ± 0.48 b,x | 4.04 ± 0.27 a,y | 0.0305 | |

| 10.5 | 2.71 ± 0.22 b,x | 4.22 ± 0.22 a,y | <0.0001 | 0.0085 |

| 30 | 2.49 ± 0.20 b,x | 5.53 ± 0.39 a,x | <0.0001 | |

| 40 | 2.48 ± 0.18 b,x | 4.28 ± 0.22 a,y | <0.0001 | |

| P-value (V) | 0.8334 | 0.0011 | ||

Means with different superscript letters within the same row differ significantly (P < 0.05) between ageing duration.

Means with different superscript letters within the same column differ significantly (P < 0.05) across stunning voltages. Means are presented as ± SEM (standard error of mean). V: volt; A: ageing days.

Table 3.

The effect of different electrical voltages of electrical water-bath stunning procedure and ageing duration on the pH value of broiler meat.

| Voltage (V) | Postmortem ageing (Days) |

P-value (A) | P-value (V x A) | ||

|---|---|---|---|---|---|

| 0 | 1 | 7 | |||

| Mean (SEM) | Mean (SEM) | Mean (SEM) | |||

| 2.5 | 6.25 ± 0.05 a,x | 5.91 ± 0.02 b,x | 5.68 ± 0.02 c,xy | 0.0054 | |

| 10.5 | 6.21 ± 0.02 a,x | 5.92 ± 0.02 b,x | 5.62 ± 0.05 c,y | 0.0068 | 0.0046 |

| 30 | 6.15 ± 0.03 a,x | 5.88 ± 0.09 b,x | 5.79 ± 0.02 b,x | 0.0321 | |

| 40 | 6.24 ± 0.04 a,x | 5.87 ± 0.05 b,x | 5.84 ± 0.01 b,x | 0.0544 | |

| P-value (V) | 0.4655 | 0.5622 | 0.0115 | ||

Means with different superscript letters within the same row differ significantly (P < 0.05) between ageing duration.

Means with different superscript letters within the same column differ significantly (P < 0.05) across stunning voltages. Means are presented as ±SEM (standard error of mean). V: volt; A: ageing days.

Postmortem changes, particularly the intricate processes of glycolysis within muscle tissue following slaughter, wield a crucial role in determining the ultimate pH of meat. After exsanguination, birds are deprived of oxygen; thus, to maintain normal cell metabolism and attain energy, the body opts for anaerobic respiration process called glycolysis that converts glycogen into lactic acid (Mir et al., 2017). The rate and amount of lactic acid accumulation in meat will determine the final pH of meat. Preslaughter handling and processing efficiency significantly influence the rate and extent of glycolytic changes. Stress and pain induced by unsuccessful stunning inflict suffering upon birds during shackling, electrocution, neck cutting, and the bleeding period. Each painful episode accumulates stress, manifesting in heightened physical responses like wing flapping, jerking, and an increased heart rate, necessitating glycogen consumption (Kumar et al., 2023a). The study's outcome indicated that low voltage stunning has been associated with reduced meat pH levels, indicative of a predisposition to PSE (pale, soft, exudative) meat incidence. Fear, stress, anxiety, and pain contribute to glycogen depletion in the muscle before slaughter. The reduction of glycogen reserves causes acceleration of postmortem glycolysis and causes a rapid pH decline (Salwani et al., 2015). Previous studies have documented mixed results regarding the impact of electrical stunning on meat pH. Sirri et al. (2017) reported that there was no significant impact of increasing the electrical amperage during high frequency stunning (400 Hz) from 90 mA/bird to 150 mA/bird. However, our findings were in agreement with Huang et al. (2017), in which a decrease in pH was observed after 24 h of ageing, with no significant difference among the different voltages after 24 h. Kissel et al. (2015) also reported that the 24-h meat pH for birds subjected to no stunning was significantly lower than for stunned birds.

In our study, birds subjected to low voltage stunning procedures (2.5 V and 10.5 V) exhibited a continued drop in pH even after d 1 and d 7 of ageing. Beyond postmortem glycolysis, the prolonged decline in pH during storage may be linked to protein breakdown. Enzymes in the muscle tissue engage in proteolysis, breaking down proteins and releasing amino acids that influence pH regulation and overall meat acidity. Notably, the evidence indicates that high voltage stunning (30 and 40 V) resulted in early glycogen depletion, with no significant drop in meat pH observed after d 1 of ageing.

Drip Loss Percentage

The water holding capacity of meat is the ability of meat to retain water throughout different processing and cooking methods. Meat's ability to retain water will be reflected in their juiciness, tenderness, and overall eating experience. Table 4 present the impact of different voltages on drip loss percentage between two postmortem ageing periods. Based on the results, a significant (P < 0.05) 2-way interaction between voltage and ageing on drip loss percentage was detected. Stunning birds using 30 V led to a higher drip loss percentage after 7 d of ageing. However, regardless of any voltages used, the drip loss percentage on d 7 was significantly (P < 0.05) higher than on d 1. The main effects of frequency and ageing have significantly (P < 0.05) affected drip loss (Table 2).

Drip loss in meat signifies the release of moisture or liquid during the various processing, handling, and storage stages (Mir et al., 2017). The moisture or liquid contributing to drip loss originates from free water, water not bound to or associated with proteins or other structures within the meat (Ertbjerg and Puolanne, 2017). However, the variation of electrical voltages used during stunning and the extent of postmortem ageing can contribute to changes in drip loss percentage. Our findings reveal a positive correlation between drip loss and ageing time, indicating an increase in the former with extended ageing. This aligns with the pH results, demonstrating a proportional decrease in drip loss with declining pH. As meat pH decreases during prolonged storage due to the conversion of glycogen to lactic acid, protein denaturation occurs, particularly within myofibrillar proteins, altering their native structure. Myofibrillar proteins, initially exhibiting an affinity for water (Bekhit et al., 2016), unfold as the native structure is disrupted by the decreasing meat pH. This unfolding of protein exposes hydrophobic regions of the proteins, ultimately reducing their water-binding capacity. Huang et al. (2017) reported no significant difference in drip loss between broilers subjected to different voltages (5, 15, 25, 35, 45 V).

Notably, the process of ageing meat contributes to an elevation in drip loss. Prolonged chill storage impacts drip loss through interconnected factors linked to postmortem changes (Aziz et al., 2020). One such factor is protein denaturation, a consequence of biochemical transformations in meat. The denaturation of proteins diminishes the water-binding capacity of the meat (Leygonie et al., 2012). Additionally, given that the meat ages at a chilled temperature, residual enzymatic activity persists. Proteolytic enzymes breaking down proteins can result in structural dismantling, influencing the meat's ability to retain water.

Cooking Loss Percentage

The effect of frequency, voltage, ageing and their interactions are recorded in Table 2. All possible interactions between the factors in this study have shown no significant (P > 0.05) effect on cooking loss. Based on the results, cooking loss percentages were significantly affected by the main factors, which are voltage and ageing. Cooking loss percentage significantly (P < 0.05) increases in samples subjected to stunning at 30 and 40 V. The highest cooking loss was found in birds subjected to 30 V of stunning (Table 5).

Table 5.

The effect of different electrical voltage of electrical water-bath stunning procedure on cooking loss percentage (%) of broiler meat.

| Voltage (V) | Cooking loss (%) | P-value |

|---|---|---|

| 2.5 | 19.20 ± 0.58 ab | |

| 10.5 | 18.12 ± 0.46 b | 0.0003 |

| 30 | 20.72 ± 0.80 a | |

| 40 | 20.55 ± 0.43 a |

Means with different superscript letters differ significantly (P < 0.05) between across stunning voltages. Means are presented as ±SEM (standard error of mean).

Cooking loss is an essential indicator of water-holding capacity, representing the weight or moisture lost during cooking. Several factors, including cooking method, temperature, cooking time, and the initial characteristics of the meat, influence this natural occurrence. Our findings reveal a correlation between stunning voltage and cooking loss percentage in birds. Those stunned at higher voltages exhibited a more significant cooking loss, potentially attributable to the more intense and rapid electric shock they experienced. This heightened stress response, characterized by the release of hormones like cortisol, has implications for postmortem metabolism. The accelerated glycolysis induced by stress leads to a reduction in meat pH. Similar to drip loss, the decreased pH may contribute to the denaturation of myofibrillar proteins, compromising the meat's ability to retain water during cooking. However, the outcome of our study differs from the results obtained by Sirri et al. (2017), who observed no significant differences in cooking loss between broilers subjected to 90 mA of electrical current with 150 mA.

Shear Force

Shear force is one of the most well-known means to assess the tenderness of meat. The force required to shear or cut a meat sample will be quantified and considered as a measurement of meat texture. A significant (P < 0.05) 2-way interaction between frequency and ageing was observed in this study (Table 2). The force required to shear meat samples on d 1 of ageing depended on the stunning frequency. On d 1, meat samples from birds stunned using 300 Hz required significantly (P < 0.05) lower force to shear than 50 Hz. However, with an increase in ageing time, meat samples from the 300 Hz group significantly (P = 0.0085) fluctuated in shear force value (Table 6). Aside from the interaction between frequency and ageing, other paramount factors and possible interactions had no significant (P > 0.05) impact on shear force.

Table 6.

The effect of different electrical frequencies of electrical water-bath stunning procedure and ageing duration on shear force value (kg) of broiler meat.

| Frequency (Hz) | Postmortem ageing (Days) |

P-value (A) | P-value (F x A) | |

|---|---|---|---|---|

| 1 | 7 | |||

| Mean (SEM) | Mean (SEM) | |||

| 50 | 1.07 ± 0.06 a,x | 1.00 ± 0.043 a,x | 0.3447 | 0.0085 |

| 300 | 0.86 ± 0.04 b,y | 1.05 ± 0.042 a,x | 0.0025 | |

| P-value (F) | 0.0055 | 0.3786 | ||

Means with different superscript letters within the same row differ significantly (P < 0.05) between ageing duration.

Means with different superscript letters within the same column differ significantly (P < 0.05) across stunning frequencies. Means are presented as ±SEM (standard error of mean). F: frequency; A: ageing days.

While the shear force of meat may not be directly influenced by electrical frequency during stunning, the chosen frequency profoundly affects the overall success of the stunning procedure, thereby impacting meat quality. Our findings indicate that stunning birds at a higher frequency result in a decreased shear force value, signifying better meat tenderness. High-frequency stunning has been associated with faster and more effective stunning compared to low-frequency methods. A successful and efficient stunning process can reduce preslaughter stress experienced by the birds. Calmer birds expend less energy during slaughter and bleeding periods, slowing the rate of glycolysis and glycogen conversion to lactic acid. Maintaining a normal glycolysis rate minimizes protein denaturation effects, allowing myofibrillar proteins to retain their structure better. With the native structure preserved, myofibrillar proteins maintain their ability to bind with water, yielding more desirable textural properties (Ertbjerg and Puolanne, 2017). Huang et al. (2014) observed that the use of high frequency (750 Hz, 15 V, DC) led to lower shear force compared to un-stunned birds, low frequency (50 Hz, 50 V, AC). However, our results contradict Sirri et al. (2017), who reported no significant difference in shear force value in chicken breast meat with different electrical currents (T1: 90 mA and T2: 150 mA).

Effect of Different Voltages, Frequencies and Postmortem Ageing Days on Meat Color Coordinates

Meat color is one of the most critical organoleptic characteristics of meat products. The color of meat during display on supermarket shelves and at the point of purchase reflects the sensory quality and product safety in the eyes of the consumers. The statistical significance of the main effects (frequency, voltage, ageing), 2-way interaction and 3-way interaction for each meat colour coordinates are presented in Table 7.

Table 7.

The effect of different frequencies (50 Hz and 300 Hz) and voltages (2.5 V, 10.5 V, 30 V and 40 V) of electrical water-bath stunning procedure on color coordinates of Pectoralis major muscle at prerigor (0 h) and postrigor (24 h amd 7 d).

| ANOVA (P-value) | Lightness (L*) | Redness (a*) | Yellowness (b*) | Chroma (C*) | Hue (h*) |

|---|---|---|---|---|---|

| Main effects: | |||||

| Frequency (F) | 0.166 | 0.0065⁎⁎ | <0.0001⁎⁎⁎ | <0.0001⁎⁎⁎ | 0.7496 |

| Voltage (V) | 0.001⁎⁎ | 0.3286 | 0.0009⁎⁎ | 0.0024⁎⁎ | 0.0758 |

| Postmortem ageing (A) | 0.165 | 0.0311* | 0.2277 | 0.1287 | 0.0561 |

| 2-way interactions: | |||||

| F x V | 0.020* | 0.9737 | 0.9885 | 0.9901 | 0.9097 |

| F x A | 0.075 | 0.3320 | 0.0404* | 0.0474* | 0.8614 |

| V x A | 0.939 | 0.5826 | 0.8626 | 0.798 | 0.7178 |

| 3-way interactions: | |||||

| F x V x A | 0.626 | 0.1511 | 0.9798 | 0.9301 | 0.0702 |

N = 240, n = 30. (ANOVA) Analysis of Variance.

P < 0.05.

p < 0.01.

p < 0.001.

Lightness Value

Lightness (L*) represents the perceived brightness of the color and ranges from 0 (black) to 100 (white). In meat color, a higher L* value indicates a lighter or brighter color, while a low L* value indicates a darker color. The outcome of the study suggested that there is a significant 2-way interaction (P < 0.01) between frequency and voltage on lightness value. The effect of frequency depended on the voltage used during stunning. Birds stunned using 10.5 V exhibited lowest lightness value (P < 0.05) at 50 Hz frequency (Table 8). On the other hand, the meat lightness of birds subjected to 30 V decreases (P < 0.01) with an increase in stunning frequency. Aside from the interaction between frequency and voltage, the main effects of voltage had shown a significant impact on the L* value. In contrast, the rest of the factors and interactions were not significant.

Table 8.

The effect of electrical frequencies and voltages of electrical water-bath stunning procedure on lightness (L*) value of broiler meat.

| Voltage (V) | Frequency (Hz) |

P-value (F) | P-value (F x V) | |

|---|---|---|---|---|

| 50 | 300 | |||

| Mean (SEM) | Mean (SEM) | |||

| 2.5 | 47.87 ± 0.65 a,x | 47.24 ± 0.65 a,x | 0.5019 | |

| 10.5 | 45.57 ± 0.55 a,y | 47.01 ± 0.46 a,x | 0.0529 | 0.020 |

| 30 | 49.67 ± 0.65 a,x | 47.36 ± 0.54 b,x | 0.0092 | |

| 40 | 48.65 ± 0.61 a,x | 47.83 ± 0.53 a,x | 0.3171 | |

| P-value (V) | 0.0001 | 0.7526 | ||

Means with different superscript letters within the same row differ significantly (P < 0.05) between frequencies.

Means with different superscript letters within the same column differ significantly (P < 0.05) across stunning voltages. Means are presented as ±SEM (standard error of mean). F: frequency; V: voltage.

The lightness (L*) of meat stands out as the crucial indicator for detecting PSE (pale, soft, exudative) characteristics. Elevated lightness, stemming from compromised water-holding capacity, notably through increased drip loss, poses a significant threat to meat quality and consumer preferences. Lightness exhibits a notable sensitivity to voltage fluctuations in low-frequency stunning, with higher voltages (30 V and 40 V) correlating with elevated L* values. The application of high voltage potentially induces acute stress in birds, prompting the release of stress-related hormones like adrenaline, noradrenaline, and corticosterone. In an oxygen-deprived environment, gluconeogenesis is interrupted. Instead, these hormones drive glycogenolysis, converting muscle glycogen into lactic acid for energy, subsequently lowering pH and diminishing water-holding capacity. The poor water-holding capacity results in increased liquid and moisture on the meat surface, amplifying light reflection when measured by the machine (Hayat et al., 2021).

Aside from light refraction caused by excessive surface moisture, protein denaturation introduces an additional way to how light traverses through the meat tissue. The denaturation process, characterized by protein unfolding, changes how light scattering actions occur compared to the normal refractive behavior of proteins. The results obtained do not align with the findings by Huang et al. (2017) and Sirri et al. (2017), in which no significant difference in lightness value was observed between different stunning voltage and electrical amperage. However, regarding the stunning procedure, Riggs et al. (2023) reported that the lightness value of the electrically stunned meat was significantly lower than that of the controlled atmosphere stunning.

Redness Value

In meat, a higher positive redness (a*) value is associated with a more pronounced red color. Redness value varies among species, and it is affected by cooking and ageing processes. Results obtained had shown that there is no significant interaction between frequency, voltage and ageing. Only the main effects of frequency and ageing have a significant effect on the redness of meat samples. Birds stunned using 300 Hz frequency registered significantly higher (P < 0.01) redness values compared to those stunned at 50 Hz (Table 9).

Table 9.

The effect of electrical frequencies of electrical water-bath stunning procedure on redness (a*) value of broiler meat.

Means with different superscript letters differ significantly (P < 0.05) between frequencies. Means are presented as ±SEM (standard error of mean).

Redness of meat is a significant attribute in certain meat products and is usually associated with myoglobin pigment (Lawrie, 2006; Wideman et al., 2016; Mir et al., 2017). The distribution and state of myoglobin, whether it is in an oxygenated or deoxygenated state, will influence the redness depth in meat. Oxymyoglobin is a bright red pigment, whereas metmyoglobin will appear brown. The results suggest that low frequency leads to lower redness value. Low-frequency stunning has been associated with being less effective in rendering animals unconscious quickly and efficiently compared to high frequencies. Inefficient stunning will lead to heightened stress and pain during stunning, slaughtering and bleeding. Myoglobin structure can be denatured due to low pH due to rapid glycogen depletion from excessive movement and stress. Denatured myoglobin will have a significantly decreased ability to bind with oxygen. The drop in pH will also influence the activity of some enzymatic systems, including those responsible for metmyoglobin-reducing activity (MRA). Metmyoglobin-reducing activity is in charge of regulating the conversion of metmyoglobin to myoglobin. The study on the impact of electrical frequency on meat quality is scarce and primarily focuses on voltage and amperage. Previous studies have reported the significant impact of different voltages (Huang et al., 2014,2017) and amperage (Sirri et al., 2017) on the redness of broiler chicken breasts.

Yellowness Value

For the industry, measuring yellowness (b*) is an essential step to enunciate freshness, especially in poultry meat, which will alter consumer perception of the meat product. In this study, there is a significant 2-way interaction between frequency and ageing, where the response to different ageing durations on b* depended on the stunning frequency used to desensitize the birds. Birds stunned using 50 Hz have significantly (P < 0.05) lower b* value than 300 Hz. Additionally, an increase in postmortem ageing duration leads to a decrease (P < 0.05) in the b* value for groups subjected to 300 Hz stunning frequency (Table 10). Aside from interaction, the main effects of frequency and voltage had a significant effect on b* values (Table 7).

Table 10.

The effect of electrical frequencies of electrical water-bath stunning procedure and ageing duration on yellowness (b*) value of broiler meat.

| Postmortem ageing (Day) | Frequency (Hz) |

P-value (F) | P-value (F x A) | |

|---|---|---|---|---|

| 50 | 300 | |||

| Mean (SEM) | Mean (SEM) | |||

| 1 | 17.79 ± 0.52 b,x | 21.34 ± 0.48 a,x | <.0001 | 0.0404 |

| 7 | 18.19 ± 0.39 b,x | 19.82 ± 0.48 a,y | 0.0103 | |

| P-value (A) | 0.5396 | 0.0282 | ||

Means with different superscript letters within the same row differ significantly (P < 0.05) between frequencies.

Means with different superscript letters within the same column differ significantly (P < 0.05) across ageing duration. Means are presented as ±SEM (standard error of mean). F: frequency; A: ageing.

Yellowness in poultry is as crucial as redness in ruminants-derived meat. In this study, the frequency significantly influenced yellowness. As mentioned in the previous sub-chapters, the high frequency had a higher affinity to render animals unconscious, thus resulting in lower glycogen usage due to reduced wing flapping and struggling movement during slaughtering and while bleeding. The meat pH slowly went down to achieve the optimal pH. Less denaturation of myoglobin pigments leads to a higher distribution of functional myoglobin in meat. With the absence of oxygen during ageing, a high abundance of functional myoglobin pigment is present in the meat, where some of them cannot bind with oxygen and remain in the state of deoxymyoglobin or metmyoglobin. Aside from myoglobin denaturation, lipid oxidation, which involves the reaction of fats with oxygen, will produce various volatile compounds that can influence the color, flavor, and aroma of meat. It is also reported that prolonged storage may lead to the growth of Pseudomonas-associated spoilage bacteria, producing a slime layer capable of reducing metmyoglobin to deoxymyoglobin, thus resulting in a lower yellowness value (Leygonie et al., 2011; Hayat et al., 2021). Previous studies reported have shown that there was no significant impact of different electrical frequencies (Lafuente and López, 2014), different electrical stunning methods (Huang et al., 2014; Riggs et al., 2023), different electrical voltages (Huang et al., 2017), different electrical amperage (Sirri et al., 2017). However, the outcome of this study was in agreement with a study conducted by Siqueira et al. (2017), which showed that broilers stunned at a higher frequency (650 Hz) resulted in higher yellowness value compared to broilers subjected to low frequency (300 Hz).

Chroma Value

Chroma (C*) refers to the intensity or vividness of a color. In the context of meat color, chroma (C*) is usually used to represent the intensity of redness in red meats or the intensity of yellow in poultry. In light of the outcomes from this study, there is a significant (P < 0.05) 2-way interaction between frequency and ageing. The impact of frequency on C* changes depended on the duration of ageing. Birds stunned at 300 Hz were seen to have their C* value decreases with an increase in ageing time (Table 11). Furthermore, stunning birds using 300 Hz resulted in a significantly (P < 0.05) higher C* value compared to 50 Hz for both ageing durations. Additionally, per the results obtained, the C* value was also significantly affected by the main effects of frequency and voltage (Table 8).

Table 11.

The effect of electrical frequencies of electrical water-bath stunning procedure and ageing duration on chroma (C*) value of broiler meat.

| Postmortem ageing (Day) | Frequency (Hz) |

P-value (F) | P-value (F x A) | |

|---|---|---|---|---|

| 50 | 300 | |||

| Mean (SEM) | Mean (SEM) | |||

| 1 | 19.14 ± 0.56b,x | 22.85 ± 0.50 a,x | <.0001 | 0.0474 |

| 7 | 19.38 ± 0.42b,x | 21.09 ± 0.51 a,y | 0.0117 | |

| P-value (A) | 0.7373 | 0.0168 | ||

Means with different superscript letters within the same row differ significantly (P < 0.05) between frequencies.

Means with different superscript letters within the same column differ significantly (P < 0.05) across ageing duration. Means are presented as ±SEM (standard error of mean). F: frequency; A: ageing.

The intensity of color, whether it is redness or yellowness, is very influential in the determination of overall color parameters and also in convincing consumers about the meat's overall palatability. The chroma value is derived from the value of redness (a*) and yellowness (b*); therefore, a deterioration in the pigment responsible for redness and yellowness value will be influenced by chroma. As mentioned in previous chapters, the rate and amount of myoglobin denaturation depended on the pH level postmortem. Low pH level due to rapid glycogenolysis, caused by excessive movement from ineffective stunning that was carried out using low frequency, will lead to changes in the intensity of redness and yellowness in meat. The results of this study were in agreement with Siqueira et al. (2017), who reported a positive correlation between electrical stunning frequency and chroma, where an increase in frequency led to an increase in chroma value. On the other hand, a study carried out by Sabow et al. (2017) revealed that different stunning procedure (low-frequency head-only, high-frequency head-to-back) does not affect chroma.

Hue Angle

Hue angle (h*) is a measurement of attributes that distinguishes different colors from one another. In meat, h* can be used to pinpoint the most dominant color of the meat, such as red for fresh beef or poultry. According to our findings, the main effects of frequency, voltage, ageing, and all possible interactions were not significant (P > 0.05) for hue angle (Table 7). The results suggested that there is no dominant color between redness and yellowness.

Effect of Different Voltages, Frequencies, and Postmortem Ageing Days on Textural Properties

The texture of meat is a predominant organoleptic characteristic as it significantly influences the overall eating experience and consumer satisfaction. Whether via tenderness, juiciness, or chewiness, the texture contributes to the sensory experience and can influence consumer perception of a certain product. Table 12 summarizes the statistical significance for each textural property's main effects, 2-way interaction, and 3-way interaction.

Table 12.

The effect of different frequencies (50 Hz and 300 Hz) and voltages (2.5 V, 10.5 V, 30 V and 40 V) of electrical water-bath stunning procedure on rheological properties of Pectoralis major muscle at prerigor (0 h) and postrigor (24 h and 7 d).

| ANOVA (P-value) | Hardness (kg) | Adhesiveness (g.sec) | Springiness (mm) | Cohesiveness | Gumminess (kg) | Chewiness (kg.mm) | Resilience |

|---|---|---|---|---|---|---|---|

| Main effects: | |||||||

| Frequency (F) | 0.5801 | 0.5129 | 0.7935 | 0.2321 | 0.7215 | 0.98 | 0.2548 |

| Voltage (V) | 0.0263* | 0.0978 | 0.1683 | 0.2556 | 0.1788 | 0.061 | 0.295 |

| ageing (A) | 0.3086 | 0.7217 | 0.0035⁎⁎ | 0.0595 | 0.5771 | 0.8841 | 0.0379* |

| 2-way interactions: | |||||||

| F x V | 0.9809 | 0.0483* | 0.6787 | 0.2699 | 0.8739 | 0.9154 | 0.045* |

| F x A | 0.0196* | 0.5133 | 0.0089⁎⁎ | 0.6185 | 0.1061 | 0.6321 | 0.9535 |

| V x A | 0.002⁎⁎ | 0.9059 | 0.1802 | 0.3677 | 0.012* | 0.0046⁎⁎ | 0.6223 |

| 3-way interactions | |||||||

| F x V x A | 0.0629 | 0.4397 | 0.0863 | 0.3977 | 0.0033⁎⁎ | 0.0032⁎⁎ | 0.8792 |

N = 240, n = 30. (ANOVA) Analysis of Variance.

P < 0.05.

P < 0.01.

***P < 0.001.

Hardness

Meat hardness can be interpreted as the force required for the meat to reach the first major deformation. It is a reflection of the initial resistance encountered during chewing using our molars teeth. As indicated by the outcomes of the study, a significant (P < 0.01) 2-way interaction was observed between voltage and ageing on hardness value (Table 12). The effect of postmortem ageing on meat hardness depended on the voltage used during stunning. The use of 30 V and 40 V during stunning significantly (P < 0.05) decreased meat hardness, whereas stunning birds at 10.5 V increased meat hardness. Furthermore, meat hardness after 1 d of ageing was significantly (P < 0.01) affected by voltage, whereas birds stunned at 40 V had a significantly higher hardness value compared to the other voltages (Table 13).

Table 13.

The effect of electrical voltages of electrical water-bath stunning procedure and ageing duration on hardness (kg) value of broiler meat.

| Voltage (V) | Postmortem ageing (Days) |

P-value (A) | P-value (V x A) | |

|---|---|---|---|---|

| 1 | 7 | |||

| Mean (SEM) | Mean (SEM) | |||

| 2.5 | 5.71 ± 0.37 a,y | 6.08 ± 0.26 a,x | 0.4108 | |

| 10.5 | 5.05 ± 0.34 b,y | 5.96 ± 0.29 a,xy | 0.0433 | 0.0020 |

| 30 | 6.08 ± 0.38 a,y | 5.21 ± 0.25 b,y | 0.0471 | |

| 40 | 7.33 ± 0.52 a,x | 5.69 ± 0.28 b,xy | 0.0042 | |

| P-value (V) | 0.0013 | 0.1074 | ||

Means with different superscript letters within the same row differ significantly (P < 0.05) between ageing periods.

Means with different superscript letters within the same column differ significantly (P < 0.05) across voltages. Means are presented as ±SEM (standard error of mean). V: voltage; A: ageing.

High voltage (30 V and 40 V) decreases hardness after prolonged postmortem ageing, indicating a better chewing sensation. However, the hardness of meat samples was found to be higher on d 1 of ageing. Meat at this stage may still be in the resolution phase in which critically low levels of adenine triphosphate (ATP) have limited the ability of the actomyosin crosslink bridges to return to their relaxed state. Therefore, the crosslink between actin and myosin is permanently present (Ertbjerg and Puolanne, 2017). However, with an increase in postmortem duration, proteolysis will start to intervene, thus causing the actomyosin crosslink to be broken, leading to a decrease in hardness at d 7. The rate at which energy (ATP) is used may be influenced by voltage, where high voltage during stunning renders the animal to a higher stress level, leading to the release of stress hormones and the fluctuation in energy usage. Gezgin and Karakaya (2016) reported that electrically stunned broilers were tougher than non-stunned broilers.

Adhesiveness

Adhesiveness is a measurement of the force required to overcome the attractive forces between the food surface and the surface of the teeth or in this study, refers to the compression plate. Understanding adhesiveness could provide insights into how the meat behaves when chewed or bitten. In this study, a significant 2-way interaction was observed between frequency and voltage, in which the hardness of birds stunned using 40 V of voltage was affected by the frequency used. Birds subjected to 300 Hz had a higher adhesiveness than 50 Hz (Table 14). No significant impact (P > 0.05) was observed from the main effects and the other possible interactions aside from the 2-way interaction between frequency and voltage (F × V) (Table 12).

Table 14.

The effect of electrical voltages and frequencies of electrical water-bath stunning procedure on adhesiveness (g.sec) of broiler meat.

| Voltage (V) | Frequency (Hz) |

P-value (F) | P-value (F x V) | |

|---|---|---|---|---|

| 50 | 300 | |||

| Mean (SEM) | Mean (SEM) | |||

| 2.5 | −2.48 ± 0.66 a,x | −4.77 ± 1.18 a,yz | 0.0759 | |

| 10.5 | −3.66 ± 0.98 a,x | −1.46 ± 0.44 a,x | 0.0724 | 0.020 |

| 30 | −4.59 ± 1.07 a,x | −5.48 ± 1.48 a,z | 0.6207 | |

| 40 | −4.35 ± 0.99 a,x | −2.33 ± 0.54 a,xy | 0.0172 | |

| P-value (V) | 0.3741 | 0.7526 | ||

Means with different superscript letters within the same row differ significantly (P < 0.05) between frequencies.

Means with different superscript letters within the same column differ significantly (P < 0.05) across voltages. Means are presented as ±SEM (standard error of mean). F: frequency; A: ageing.

The surface of the meat is an integral part of determining adhesiveness in meat products. High voltage (40 V) has led to stress in birds during stunning, thus draining the energy in the form of glycogen in muscle. As a result, it leads to a low pH and higher susceptibility of protein to denature, reducing their ability to retain water (Mir et al., 2017). With water secreted out onto the surface of the meat due to its low water retention ability, the surface of the meat tends to be covered with moisture, thus associating the meat with higher stickiness and tackiness.

Springiness

Springiness is one of the texture parameters that measures the ability of meat to return to its original shape after deformation. Understanding springiness is important in assessing the resilience or bounce-back properties of meat during chewing or biting. Meats with higher springiness values may be perceived as more resilient and elastic in the mouth, contributing to the overall textural experience. The results suggested that there was a significant 2-way interaction between frequency and ageing. The response to different electrical frequencies depended on the duration of ageing. If the meat samples were aged for 7 d, the springiness value increased (P < 0.05) when a higher frequency (300 Hz) was used. It is also observed that for birds stunned at 300 Hz, ageing meat for only 1 d resulted in a lower (P < 0.01) springiness value (Table 15).

Table 15.

The effect of electrical voltages and frequencies of electrical water-bath stunning procedure on springiness (mm) of broiler meat.

| Postmortem ageing (Day) | Frequency (Hz) |

P-value (F) | P-value (F x A) | |

|---|---|---|---|---|

| 50 | 300 | |||

| Mean (SEM) | Mean (SEM) | |||

| 1 | 0.671 ± 0.01 a,x | 0.643 ± 0.02 a,y | 0.1301 | 0.0089 |

| 7 | 0.674 ± 0.01 b,x | 0.699 ± 0.01 a,x | 0.0182 | |

| P-value (A) | 0.7122 | 0.0011 | ||

Means with different superscript letters within the same row differ significantly (P < 0.05) between frequencies.

Means with different superscript letters within the same column differ significantly (P < 0.05) across ageing duration. Means are presented as ±SEM (standard error of mean). F: frequency; A: ageing.

Meat springiness can be influenced by a multitude of factors, including both physical and biological aspects. The results suggested that the use of high frequency (300 Hz) combined with extended ageing duration (7 d) had increased springiness. The breakdown of collagen into gelatine through enzymatic activity during ageing may lead to changes in the structure of meat (Gasto´n Torrescano et al., 2003; El-Senousey et al., 2013). The breakdown leads to a decrease in the amount of collagen, increases tenderness, and ultimately influences the springiness of meat. High frequency may contribute to a better stunning efficiency, thus leading to normal biochemical changes postmortem. With less susceptibility toward rapid glycolytic cycle, protein denaturation will be minimized, and more water can be retained inside the muscle. The distribution and amount of water inside the meat will influence the texture.

Cohesiveness

In texture profile analysis, cohesiveness can be defined as the ability of meat to maintain its structure and stick together during multiple compression cycles. A higher cohesiveness value suggests that the meat maintains its structure and does not easily fall apart. In this study, cohesiveness was not significantly affected (P > 0.05) by the main factors (frequency, voltage, ageing) nor their combination (Table 12).

Changes in water holding capacity would influence the cohesiveness of meat (Mir et al., 2017). Excessive water loss may lead to reduce ability for meat to retain its structure. Besides that, protein denaturation especially the one attributed to the structure of muscle fiber, such as actin and myosin, will lead to a lower cohesiveness score.

Gumminess

Gumminess is a texture parameter that describes the chewiness or resistance to swallowing a food sample based on the force required to disintegrate the food during mastication. Given the observed outcome, the main effects did not affect gumminess (P > 0.05). However, the gumminess of meat was affected by 2-way interactions between voltage (V) and ageing (A) (P < 0.05) (Table 12).

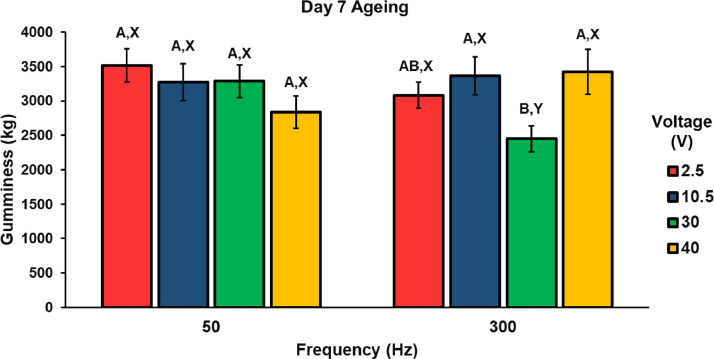

Also, the 3-way interactions of all the factors (Table 12) were significant, which indicates that the 2-way interaction between frequency and voltage (F × V) affected gumminess differently at one of the ageing periods (Table 12). A significant interaction between F × V was only observed on d 7 of ageing (P = 0.0090), whereas for d 1, the P-value for the interaction between F × V was only 0.2280. Thus, the F × V interaction can only be explained for d 7 of ageing. For meat samples aged for 7 d, the gumminess value depends on the voltage (V) and the frequency used during stunning (F). For samples aged for 7 d, meat samples stunned using the combination of 300 Hz and 30 V resulted in significantly lower gumminess scores compared to other electrical stunning combinations (Figure 2).

Figure 2.

The interaction effect between voltage and frequency (F × V) on gumminess of meat for d 7 of ageing. ABMeans with different letters differ significantly (P < 0.05) between frequencies. XY means with different letters differ significantly (P < 0.05) across voltages.

Stunning voltage and frequency may influence meat's gumminess, especially after prolonged storage. The changes in meat gumminess had often been related to the distribution and amount of water available in meat. As reported previously in the drip loss section, prolonged ageing had increased moisture loss. Excessive moisture loss may be due to the denaturation of proteins and the breakdown of collagen to gelatine (Gasto´n Torrescano et al., 2003; El-Senousey et al., 2013). As a result, the meat will tend to be less juicy but gummier. Based on the study carried out by Gezgin and Karakaya (2016) revealed that the firmness of stunned broiler was significantly higher than un-stunned.

Chewiness

Gumminess and chewiness are two related but distinct texture parameters that describe different aspects of the mechanical properties of a food sample, such as meat, during the chewing process. Gumminess specifically focuses on the energy required to disintegrate the sample, reflecting its cohesive nature. Conversely, chewiness is a broader measure considering the mechanical effort needed to masticate the sample before swallowing. In this study, gumminess was affected (P < 0.05) by 2-way interactions between voltage and ageing (V × A) and also by the 3-way interactions.

In the case of 3-way interaction, it could be described as the interaction between (V × F) at each duration of ageing (A) (Table 12). A significant interaction between F × V was only observed on d 7 of ageing (P = 0.0402), whereas for d 1, the P-value for the interaction between V × F was 0.1236. Thus, the F × V interaction can only be explained for d 1 of ageing. For meat samples aged for one day, the interaction between F × V significantly affected the chewiness of the meat. Like gumminess, the combination between 300 Hz and 30 V significantly decreased chewiness on d 7 (Figure 3).

Figure 3.

The interaction effect between voltage and frequency (F × V) on chewiness of meat for d 7 of ageing. ABMeans with different letters differ significantly (P < 0.05) between frequencies. XY means with different letters differ significantly (P < 0.05) across voltages.

The biochemical changes of the meat postmortem depend on its handling before slaughter. Stress and struggle during slaughter and bleeding may lead to higher energy consumption, which impacts the postmortem pH level (Sabow et al., 2017a). Protein denaturation due to low pH levels in meat will influence water retention and, ultimately, the chewiness of meat (Ertbjerg and Puolanne, 2017). Furthermore, storage conditions may lead to collagen breakdown into gelatine, which may also influence chewiness.

Resilience

Resilience is a texture parameter that measures the ability of a food sample to recover its original shape after deformation during the first compression cycle. While both resilience and springiness describe the recovery of a sample after deformation, resilience is calculated based on the area under the force-distance curve during successive compressions, emphasizing the overall recovery pattern. Springiness, on the other hand, focuses specifically on the distance the sample recoils after the initial compression, providing a more direct measure of the rebounding behavior.

Based on the outcome of the study, resilience was significantly affected (P < 0.05) by the 2-way interactions between frequency and voltage of electrical stunning. The impact of frequency depended on the voltage used during stunning. The effect of increased frequency from 50 Hz to 300 Hz on resilience was only visible on birds stunned at 10.5 V (Table 16).

Table 16.

The effect of electrical voltages and frequencies of electrical water-bath stunning procedure on resilience of broiler meat.

| Voltage (V) | Frequency (Hz) |

P-value (F) | P-value (F x V) | |

|---|---|---|---|---|

| 50 | 300 | |||

| Mean (SEM) | Mean (SEM) | |||

| 2.5 | 0.23 ± 0.01 a,x | 0.22 ± 0.01 a,y | 0.1384 | |

| 10.5 | 0.22 ± 0.01 b,x | 0.25 ± 0.01 a,x | 0.0219 | 0.045 |

| 30 | 0.23 ± 0.01 a,x | 0.23 ± 0.01 a,xy | 0.7877 | |

| 40 | 0.23 ± 0.01 a,x | 0.24 ± 0.01 a,xy | 0.3701 | |

| P-value (V) | 0.2966 | 0.1060 | ||

Means with different superscript letters within the same row differ significantly (P < 0.05) between frequencies.

Means with different superscript letters within the same column differ significantly (P < 0.05) across voltages. Means are presented as ±SEM (standard error of mean). F: frequency, V: voltages.

Stunning birds using low voltage have been associated with low unconsciousness incidence. In addition to poor stunning efficiency, they also suffered more stress due to shackling and electrocution. The accumulative stress will lead to a decrease in pH thus promoting the rate of protein denaturation, which is an important determinant of water holding capacity (WHC) (Hayat et al., 2023). The integrity of the muscle fiber will be disrupted due to lack of ability to bind water thus affecting the resilience of the meat.

CONCLUSIONS

The results of the current study reveal a diminished occurrence of broken bones following exposure to high electrical stunning frequencies. Except for red wing tips, the impacts of electrical frequency and voltage on the carcass characteristics of broiler chickens were independent. However, regarding physicochemical properties, the interaction between voltage and ageing influenced pH and drip loss. Conversely, the interaction between frequency and ageing affected shear force, yellowness, and chroma. Notably, the pectoralis major muscle, aged for a longer duration (7 d), exhibited a higher drip loss percentage than a 1-d ageing period across different voltages.

DISCLOSURES

The authors declare no conflicts of interest.

REFERENCES

- Abubakar A.A., Zulkifli I., Goh Y.M., Kaka U., Sabow A.B., Imlan J.C., Awad E.A., Othman A.H., Raghazli R., Mitin H., Sazili A.Q. Effects of stocking and transport conditions on physicochemical properties of meat and acute-phase proteins in cattle. Foods. 2021;10:252. doi: 10.3390/foods10020252. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Addeen A., Benjakul S., Wattanachant S., Maqsood S. Effect of Islamic slaughtering on chemical compositions and post-mortem quality changes of broiler chicken meat. Int. Food Res. J. 2014;21:897–907. [Google Scholar]

- Asyrul-Izhar A.B., Sarbon N.M., Ismail-Fitry M.R. Effects of mixing duration and raw materials on the physicochemical, microstructural and sensorial properties of sausages prepared from red tilapia (Oreochromis sp.) Asian Fish. Sci. 2021;34:355–364. [Google Scholar]

- Aziz M.F.A., Hayat M.N., Kaka U., Kamarulzaman N.H., Sazili A.Q. Physico-chemical characteristics and microbiological quality of broiler chicken Pectoralis major muscle subjected to different storage temperature and duration. Foods. 2020;9 doi: 10.3390/foods9060741. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bekhit A.E.D.A., Suwandy V., Carne A., van de Ven R., Hopkins D.L. Effect of repeated pulsed electric field treatment on the quality of hot-boned beef loins and topsides. Meat Sci. 2016;111:139–146. doi: 10.1016/j.meatsci.2015.09.001. [DOI] [PubMed] [Google Scholar]

- Bourassa D.V., Bowker B.C., Zhuang H., Wilson K.M., Harris C.E., Buhr R.J. Impact of alternative electrical stunning parameters on the ability of broilers to recover consciousness and meat quality. Poult. Sci. 2017;96:3495–3501. doi: 10.3382/ps/pex120. [DOI] [PubMed] [Google Scholar]

- Department of Standards Malaysia. (2009). Malaysian Standard MS1500:2009; Halal Food Production, Preparation, Handling and Storage-General Guidelines (Second Revision).

- El-Senousey H.K., Fouad A.M., Yao J.H., Zhang Z.G., Shen Q.W. Dietary alpha lipoic acid improves body composition, meat quality and decreases collagen content in muscle of broiler chickens. Asian-Australas. J. Anim. Sci. 2013;26:394–400. doi: 10.5713/ajas.2012.12430. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ertbjerg P., Puolanne E. Muscle structure, sarcomere length and influences on meat quality: a review. Meat Sci. 2017;132:139–152. doi: 10.1016/j.meatsci.2017.04.261. [DOI] [PubMed] [Google Scholar]

- Gasto´n Torrescano G., Sa´nchezsa´nchez-Escalante A., Gime´nezgime´nez B., Roncale´s P.R., Jose´antonio J., Beltra´n B. Shear values of raw samples of 14 bovine muscles and their relation to muscle collagen characteristics. Meat Sci. 2003;64:85–91. doi: 10.1016/s0309-1740(02)00165-1. www.elsevier.com/locate/meatsci accessed: November 25, 2023. [DOI] [PubMed] [Google Scholar]

- Gezgin T., Karakaya M. The Effects of electrical water bath stunning on meat quality of broiler produced in accordance with Turkish slaughter procedures # Türk Kesim Usullerine Uygun Olarak Üretilen Broyler Et Kalitesi Üzerine Su Banyosunda Elektrikle Bayıltma İşleminin Etkisi. J. of Poult. Res. 2016;13 www.turkishpoultryscience.com accessed November 26, 2023. [Google Scholar]

- Gregory N.G., Grandin T. CAB International; Wallingford, UK: 1998. Animal Welfare and Meat Science: Vol. Chapter 4. [Google Scholar]

- Hayat M.N., Kaka U., Sazili A.Q. Assessment of physicochemical characteristics and microbiological quality in broiler chicken breast muscle (Pectoralis major) subjected to different temperatures and lengths of cold transportation. Foods. 2021;10 doi: 10.3390/foods10040874. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hayat M.N., Kumar P., Sazili A.Q. Are spiritual, ethical, and eating qualities of poultry meat influenced by current and frequency during electrical water bath stunning? Poult. Sci. 2023;102 doi: 10.1016/j.psj.2023.102838. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Honike l, K.0. Reference methods for the assessment of physical characteristics of meat. Meat Sci. 1998;49 doi: 10.1016/s0309-1740(98)00034-5. [DOI] [PubMed] [Google Scholar]

- Huang J.C., Huang M., Yang J., Wang P., Xu X.L., Zhou G.H. The effects of electrical stunning methods on broiler meat quality: effect on stress, glycolysis, water distribution, and myofibrillar ultrastructures. Poult. Sci. 2014;93:2087–2095. doi: 10.3382/ps.2013-03248. [DOI] [PubMed] [Google Scholar]

- Huang J.C., Yang J., Huang M., Chen K.J., Xu X.L., Zhou G.H. The effects of electrical stunning voltage on meat quality, plasma parameters, and protein solubility of broiler breast meat. Poult. Sci. 2017;96:764–769. doi: 10.3382/ps/pew335. [DOI] [PubMed] [Google Scholar]

- Humam A.M., Loh T.C., Foo H.L., Izuddin W.I., Awad E.A., Idrus Z., Samsudin A.A., Mustapha N.M. Dietary supplementation of postbiotics mitigates adverse impacts of heat stress on antioxidant enzyme activity, total antioxidant, lipid peroxidation, physiological stress indicators, lipid profile and meat quality in broilers. Animals. 2020;10:1–21. doi: 10.3390/ani10060982. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Humane Slaughter Association. (2016). HSA online guide-electrical waterbath stunning of poultry.

- Kissel C., Soares A.L., Oba A., Shimokomaki M. Electrical water bath stunning of broilers: effects on breast meat quality. J. Poult. Sci. 2015;52:74–80. [Google Scholar]

- Kranen R.W., Veerkamp C.H., Lambooy E., Van Kuppevelt T.H., Veerkamp J.H. Processing and products hemorrhages in muscles of broiler chickens: the relationships among blood variables at various rearing temperature regimens. Poult. Sci. 1996;75:570–576. doi: 10.3382/ps.0750570. [DOI] [PubMed] [Google Scholar]

- Kumar P., Abubakar A.A., Ahmed M.A., Hayat M.N., Kaka U., Pateiro M., Sazili A.Q., Hoffman L.C., Lorenzo J.M. Pre-slaughter stress mitigation in goats: prospects and challenges. Meat Sci. 2023;195 doi: 10.1016/j.meatsci.2022.109010. [DOI] [PubMed] [Google Scholar]

- Kumar P., Ahmed M.A., Abubakar A.A., Hayat M.N., Kaka U., Ajat M., Goh Y.M., Sazili A.Q. Improving animal welfare status and meat quality through assessment of stress biomarkers: a critical review. Meat Sci. 2023;197 doi: 10.1016/j.meatsci.2022.109048. [DOI] [PubMed] [Google Scholar]

- Kuttappan V.A., Owens C.M., Coon C., Hargis B.M., Vazquez-A Non M. Research Note Incidence of broiler breast myopathies at 2 different ages and its impact on selected raw meat quality parameters. Poult. Sci. 2017;96:3005–3009. doi: 10.3382/ps/pex072. [DOI] [PubMed] [Google Scholar]

- Lafuente R., López M. Effect of electrical and mechanical stunning on bleeding, instrumental properties and sensory meat quality in rabbits. Meat Sci. 2014;98:247–254. doi: 10.1016/j.meatsci.2014.05.031. [DOI] [PubMed] [Google Scholar]

- Lambooij B., Hindle V. Pages 77–98 in Advances in Poultry Welfare. Elsevier Science Limited; Oxford, United Kingdom: 2017. Electrical stunning of poultry. [Google Scholar]

- Lawrie R.A. Meat Science. 7th ed. Woodhead Publishing Limited; Abingdon Cambridge, England: 2006. Lawrie’s meat science. [Google Scholar]

- Leygonie C., Britz T.J., Hoffman L.C. Oxidative stability of previously frozen ostrich Muscularis iliofibularis packaged under different modified atmospheric conditions. Int. J. Food Sci. Technol. 2011;46:1171–1178. [Google Scholar]

- Leygonie C., Britz T.J., Hoffman L.C. Impact of freezing and thawing on the quality of meat: review. Meat Sci. 2012;91:93–98. doi: 10.1016/j.meatsci.2012.01.013. [DOI] [PubMed] [Google Scholar]

- Mir N.A., Rafiq A., Kumar F., Singh V., Shukla V. Determinants of broiler chicken meat quality and factors affecting them: a review. Int. J. Food Sci. Technol. 2017;54:2997–3009. doi: 10.1007/s13197-017-2789-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nakyinsige K., Sazili A.Q., Zulkifli I., Goh Y.M., Abu Bakar F., Sabow A.B. Influence of gas stunning and halal slaughter (no stunning) on rabbits welfare indicators and meat quality. Meat Sci. 2014;98:701–708. doi: 10.1016/j.meatsci.2014.05.017. [DOI] [PubMed] [Google Scholar]

- Novoa M., Vázquez L., Lage A., González-Torres I., Pérez-García L.F., Cobas N., Lorenzo J.M. Water-bath stunning process in broiler chickens: effects of voltage and intensity. Span. J. Agric. Res. 2019;17 [Google Scholar]

- Petracci M., Bianchi M., Cavani C. Pre-slaughter handling and slaughtering factors influencing poultry product quality. Worlds Poult. Sci. J. 2010;66:17–26. [Google Scholar]

- Riggs M.R., Hauck R., Baker-Cook B.I., Osborne R.C., Pal A., Terra M.T.B., Sims G., Urrutia A., Orellana-Galindo L., Reina M., DeVillena J.F., Bourassa D.V. Meat quality of broiler chickens processed using electrical and controlled atmosphere stunning systems. Poult. Sci. 2023;102 doi: 10.1016/j.psj.2022.102422. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sabow A.B., Adeyemi K.D., Idrus Z., Meng G.Y., Ab Kadir M.Z.A., Kaka U., Aghwan Z.A., Abubakar A.A., Sazili A.Q. Carcase characteristics and meat quality assessments in goats subjected to slaughter without stunning and slaughter following different methods of electrical stunning. Ital. J. Anim. Sci. 2017;16:416–430. [Google Scholar]

- Sabow A.B., Nakyinsige K., Adeyemi K.D., Sazili A.Q., Johnson C.B., Webster J., Farouk M.M. High frequency pre-slaughter electrical stunning in ruminants and poultry for halal meat production: a review. Livest. Sci. 2017;202:124–134. [Google Scholar]

- Salwani M.S., Adeyemi K.D., Sarah S.a., Vejayan J., Zulkifli I., Sazili a.Q. Skeletal muscle proteome and meat quality of broiler chickens subjected to gas stunning prior slaughter or slaughtered without stunning. CYTA J. Food. 2015;16:1–7. [Google Scholar]

- Sazili A.Q., Kumar P., Hayat M.N. Vol. 13. Multidisciplinary Digital Publishing Institute (MDPI); 2023. Stunning compliance in halal slaughter: a review of current scientific knowledge. (Animals). [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sazili A.Q., Parr T., Sensky P.L., Jones S.W., Bardsley R.G., Buttery P.J. The relationship between slow and fast myosin heavy chain content, calpastatin and meat tenderness in different ovine skeletal muscles. Meat Sci. 2005;69:17–25. doi: 10.1016/j.meatsci.2004.06.021. [DOI] [PubMed] [Google Scholar]

- Siqueira T.S., Borges T.D., Rocha R.M.M., Figueira P.T., Luciano F.B., Macedo R.E.F. Effect of electrical stunning frequency and current waveform in poultry welfare and meat quality. Poult. Sci. 2017;96:2956–2964. doi: 10.3382/ps/pex046. [DOI] [PubMed] [Google Scholar]

- Sirri F., Petracci M., Zampiga M., Meluzzi A. Research note: effect of EU electrical stunning conditions on breast meat quality of broiler chickens. Poult. Sci. 2017;96:3000–3004. doi: 10.3382/ps/pex048. [DOI] [PubMed] [Google Scholar]

- Vieira C., Diaz M.T., Martínez B., García-Cachán M.D. Effect of frozen storage conditions (temperature and length of storage) on microbiological and sensory quality of rustic crossbred beef at different states of ageing. Meat Sci. 2009;83:398–404. doi: 10.1016/j.meatsci.2009.06.013. [DOI] [PubMed] [Google Scholar]