Summary

Hydrogen generation from boron hydride is important for the development of hydrogen economy. Cobalt (Co) element has been widely used in the hydrolysis of boron hydride. Pyrolysis is a common method for materials synthesis in catalytic fields. Herein, Co-based nanocomposites derived from the pyrolysis of organic metal precursors and used for hydrolysis of boron hydride are summarized and discussed. The different precursors consisting of MOF, supported, metal, and metal phosphide precursors are summarized. The catalytic mechanism consisting of dissociation mechanism based on oxidative addition-reduction elimination, pre-activation mechanism, SN2 mechanism, four-membered ring mechanism, and acid-base mechanism is intensively discussed. Finally, conclusions and outlooks are conveyed from the design of high-efficiency catalysts, the characterization of catalyst structure, the enhancement of catalytic activities, the investigation of the catalytic mechanism, and the catalytic stability of active structure. This review can provide guidance for designing high-efficiency catalysts and boosting development of hydrogen economy.

Subject areas: Catalysis, Materials chemistry

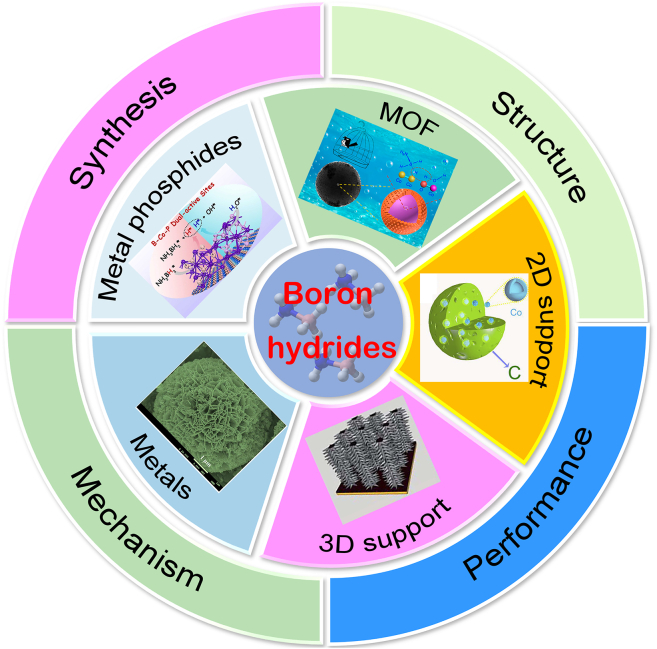

Graphical abstract

Catalysis; Materials chemistry

Introduction

The significance of hydrogen generation

With social development and the improvement in human lifestyle, the energy demand continuously increases and energy is regarded as the most important problem facing humanity. Hydrogen, as an attractive energy carrier and environmentally friendly fuel, is promising in the development of an energy economy because of its high energy density, sustainability, and socioeconomic/environmental advantages.1,2,3,4 Hydrogen is the lightest of all the elements with a density of 0.0899 g/L in standard state and the value is one ten-thousandth the density of water. Additionally, at −252.7°C, it can be liquid following a density of 70 g/L, and this value is only 1/15th of water. Thus, there remains a considerable challenge to create highly efficient technology for the storage of hydrogen. Conventional methods such as physical storage, the acceptable gravimetric and volumetric storage capacities only can be obtained at up to 800 bar high pressure or cryogenic temperature (−253°C). Such conditions require sophisticated technologies and pose safety problems.5 Recently, the development of sustainable technologies, such as solar water splitting6,7,8 and clean-zero carbon emission9,10,11 and so on are important for the hydrogen economy. Illustratively, the chemical hydride storage and release of hydrogen is a promising way of development in the field of hydrogen generation. The reasons are as follows: (1) The presence of a large amount of water increases stability by preventing combustion; (2) kinetically stable, it does not release hydrogen without appropriate catalysts; and (3) hydrogen generation is controllable according to practical needs. Thus, the catalytic hydrolytic dehydrogenation of chemical hydrides is a safe and efficient way to provide hydrogen fuel for new energy vehicles and portable electronic devices. Currently, cost-efficient and high-performance catalysts must be developed before the large-scale application of this hydrogen generation technology can proceed. Chemical hydrides, such as SB, AB, and N2H4BH3 with high densities of available hydrogen, are considered convenient hydrogen sources through hydrolysis or pyrolysis. The development of earth-abundant catalysts for efficient hydrolysis of boron hydride is of great importance in the conversion and utilization of hydrogen energy. Despite great progresses being made in recent years, all the reported heterogeneous catalysts up to now involve noble metals greatly limits their large-scale practical application because of their high cost and insufficient reserves in the Earth’s crust. Therefore, the development of a cost-effective noble-metal-free catalyst is imperative for hydrogen generation by boron hydride, possibly Fe, Ni, Cu, or Co. Cobalt is an efficient metal catalyst and has already proven to be a potential alternative to noble metals. Recently, Co-based catalysts have caused concern for hydrogen generation of boron hydride. The non-noble metal Co has the advantage of abundant coordination forms and adjustable redox ability. The existence of Co is found in a mixed valence state under AB reaction conditions and can provide a structural basis for the formation of multi-active sites. Illustratively, the elements Fe, Ni, and Cu present a single/stable valence state during the reaction of AB hydrolysis, thus, Co-based catalysts exhibit superiority compared to Fe, Ni, Cu, and their derived catalysts.12 However, the strong reducibility of the low-valent B and active H species produced during the reaction will decrease the catalytic activity of the Co-based catalyst. The Co nanoparticles NPs with the ferromagnetism would force the catalyst to be driven by its magnetism, which called self-stirring mode during the hydrolysis of AB. The self-stirring mode means that the reaction system was stirred by an external magnetic field through the ferromagnetic catalysts in the absence of magneton. Due to the existence of magnetism, magnetons are not necessary and this is wonderful for cyclic hydrogen generation, namely, the reaction products from the reactant circumstances can be smoothly separated and start the next activity testing of hydrogen generation. Additionally, from the literature, the catalytic activity of cobalt and cobalt oxides is significantly increased supported by related experimental results.13,14,15 When the catalyst is prepared through support on the foam nickel, carbon cloth, or other substrates, the obtained catalysts can be stopped at any time in catalytic hydrogen generation, which has more value for future industrial application. Additionally, on-demand hydrogen generation from the hydrolysis reactions of chemical hydrides has gained ever-increasing attention as a promising approach for providing mobile/portable hydrogen sources. Therefore, the design and synthesis of effective catalysts for releasing hydrogen is the decisive factor.

The importance of catalysts design

The design of heterogeneous catalysts relies on an understanding of the fundamental surface dynamics that govern the performance of catalysts. The rational design of the catalysts can expose more active sites and play an important role in the enhancement of the catalytic performance.16,17 The reaction of boron hydride hydrolysis involves a bimolecular reaction and the active ingredient in designed catalyst should has the ability to activate boron hydride and water molecules. Based on the catalytic activity and catalytic mechanism, the rational design of the catalysts has a significant role in conveying the design idea. The purpose of catalyst design is to select the most efficient catalyst for a reaction using established concepts and simultaneously determine the preparation method and use conditions of the catalyst. The main contents of the catalyst design include the reaction target, source of raw materials, comprehensive consideration of economic rationality, thermodynamic analysis, the design of the reaction process, the selection of active components, additives, supports types in the catalysts, the kinetic test inspection and determination of operating conditions and so on. The design strategy is suitable for the high-efficiency catalysts and many methods have been used in the preparation of precursors, such as deposition-precipitation method,18 one-step hydrothermal method,19,20 sol-gel method,21 leaching method,22 ion exchange method,23 thermal melting,24 and so on. The different methods have different advantages and disadvantages for the preparation of catalysts. The deposition-precipitation method can ensure all the active components are retained on the surface of the support, which improves the utilization rate of active components. However, some problems exist in this method: (1) The control of the sediment location; (2) the nucleation process is more likely to occur in solution than on a support; and (3) the generated metal particles have low uniformity. Although the one-step hydrothermal method is simple, short in process, and low in synthesis cost, it is not applicable for the synthesis of water-sensitive compounds, such as III–V semiconductors, novel phosphorus (or arsenic), or acid molecular sieve skeleton structure materials. The sol-gel method occurs under low temperature conditions and can produce small/uniform particle size. The sol-gel method incurs high cost because of the use of metal alkoxides as raw materials. The leaching method is simple, efficient, fast, and with a wide range of applications; however, it is difficult to control the leaching time and leaching agent concentration. The ion exchange method has the advantage of removing inorganic ions, but the exchange capacity is limited. From the above-mentioned methods, the different strategies have different effects on the construction of active structures and will lead to different influences on the performance of different reactions. Among the many metal-based preparation methods, metal ion pyrolysis is the most common method in synthesizing the corresponding materials. Pyrolysis has become a common method in materials synthesis in many aspects of catalytic fields because of the low demand for experimental equipment in metal ion pyrolysis. Therefore, the usage of pyrolysis technology to design catalysts or the catalyst structure is vital for the profound research in the field of heterogeneous catalysis. Based on the operation of pyrolysis, the discussion of scientific problems of catalyst design will have excellent significance on the enhancement of catalytic activity and the confirmation of the structure-activity relationship.

The scope of the review

Currently, the investigation of Co-based materials derived from pyrolysis of organic metal precursors has drawn enormous attention and applied many physical and chemical fields. The pyrolysis operation has been applied in many fields of energy catalysis and storage. The pyrolysis operation can change the status and structure of the materials to obtain corresponding targeted catalysts. In this review, Co-based compounds refer to material containing the active ingredient of cobalt element during the hydrogen generation of boron hydride. Illustratively, the pyrolysis operation in this review refers to the catalysts whose last step is achieved through calcination at a certain temperature in air or an inert atmosphere in a tube furnace or other pyrolysis devices. The pyrolysis treatment is an important step in the preparation of metal catalysts that are effective for promoting the hydrolysis reaction of boron hydride. Thus, in this review, detailed information on the hydrogen generation of boron hydride is provided, including the hydrogen generation in the Batch/Slurry-Bed reactor. The preparation of Co-based compounds derived from pyrolysis of organic metal precursors based on metal organic frameworks (MOF), supported, metal, and metal phosphide types are discussed in detail. Additionally, the corresponding characterizations and performance tests are summarized. Furthermore, four universal catalytic mechanisms for AB hydrolysis consisting of dissociation mechanism based on oxidative addition-reduction elimination, pre-activation mechanism, SN2 mechanism, four-membered ring mechanism, and acid-base mechanism are also investigated (Figure 1). Finally, prospects with remaining challenges are suggested based on the correlative literature reports about 2010–2023 presented in this review and summarized further outlooks in Co-based compounds derived from pyrolysis of organic metal precursor.

Figure 1.

Schematic illustration of Co-based compounds derived from pyrolysis of organic metal precursors for hydrolysis of boron hydride

The summarization of boron hydride

The excessive consumption of fossil fuels and corresponding environmental deterioration has triggered demand for sustainable and green energy. Hydrogen, as an ideal energy, has been generally deemed a promising candidate to replace conventional fossil fuels.14 However, efficient and safe hydrogen storage and transportation technology are still one of the most restrictive challenges for improving the development of hydrogen economy.25 Boron hydride as a chemical-solid hydrogen storage material is regarded as an ideal hydrogen source material for fuel cells because of its high hydrogen storage density and stable storage at room temperature. Illustratively, the general formula of the metal borohydride is M(BH4)n (n refers to the valence status of metals). M(BH4)n is the research focus of solid-state hydrogen storage materials because of the extremely high hydrogen storage capacity.26,27 Currently, hydrogen carriers, such as AB,28 sodium borohydride (NaBH4),13 formic acid (FA),29 and hydrous hydrazine (N2H4BH3),30,31 have received intensive attention owing to their unique advantages. Among them, AB and NaBH4 have been certified to be a convenient and safe liquid hydrogen carrier for portable hydrogen storage technology and have many presented research.32

Ammonia borane (NH3BH3, AB)

AB is a colorless molecular crystal under ambient conditions with a density of 0.74 g cm−3 and is soluble in water and other relatively polar solvents. The hydrogen stored in AB can be released either by thermolysis in a solid state and nonaqueous medium or metal-catalyzed reactions in protic solvents (water and methanol). Thermal decomposition of AB usually requires high temperature and the reaction was relatively difficult to control. In contrast, catalytic hydrolysis or methanolysis can provide a more convenient strategy for hydrogen generation from AB. AB as the simplest borane-nitrogen (B−N) compound, is a stable and environmentally sustainable material with impressive gravimetric and volumetric hydrogen density (19.6 wt % and 0.145 kg H2 L−1) and low molecular weight (30.86 g mol−1).3 AB is well ahead of the 2015 target for U.S. Departments of Energy (DOE) (9.0 wt % and 0.082 kg H2 L−1), making it the most attractive storage medium of all chemical hydrides.33 More importantly, it can release high-purity hydrogen via an ambient temperature hydrolysis reaction in the presence of suitable catalysts. Three moles of hydrogen can be generated from one mole of AB through a complete hydrolysis reaction only in the presence of a suitable catalyst at ambient temperature. The hydrolytic cleavage of the AB complex is expounded as follows,34,35

| (Equation 1) |

| (Equation 2) |

Compared to AB hydrolysis, AB methanolysis has several benefits. First, ammonia gas will not be produced during the process of AB methanolysis, which is favorable for the hydrogen-oxygen fuel cell. Second, NH4B(OCH3)4 generated during AB methanolysis can be easily converted back to AB at room temperature by a chemical reaction, which makes AB renewable and can remarkably lower the overall cost of this technology. Third, due to the low freezing point of methanol (lower than −90°C), AB methanolysis technology can be applied to produce hydrogen at very low temperatures, which is extremely important in cold areas.34 However, the hydrolysis of AB has been researched extensively because of the ease of analyzing the catalytic mechanism. Thus, much work has been done in the field of hydrogen generation.

Sodium borohydride (NaBH4)

Sodium borohydride (NaBH4) is discovered by H. C. Brown and his boss Schlesinger at the university of Chicago in 1942. NaBH4 can remain stable at room temperature and atmospheric pressure. NaBH4 breaks down quickly in acidic conditions to release hydrogen, so it can not react in acidic conditions, however, NaBH4 can contact carboxylic acids in alkaline conditions to break down hydrogen quickly. NaBH4 has been given high expectations for its high hydrogen storage capacity (10.8 wt. %), purity of hydrogen product stream, and stability in alkaline solution. From the stoichiometry of this reaction, 1 mol NaBH4 can produce 4 mol H2 under ambient conditions, which is much more efficient than other reported hydrogen storage materials. Hydrogen can be released through the hydrolysis of NaBH4 according to the following equation,

| (Equation 3) |

The above reaction occurs at room temperature, but the reaction rate is slow and needs an appropriate catalyst to enhance and regulate the catalysts. The main choices for NaBH4 hydrolysis are acid and transition metal-based catalysts. When the acid medium is used as a catalyst, it is rather demanding for the reactor vessel during the reaction. Therefore, the transition metal-based catalysts have been considered more promising in enhancing the catalytic activity.

Evaluation parameters on hydrogen generation

The hydrogen generation reaction system is different because of various boron hydrides, such as in our recent study, NaOH as a cocatalyst is applied in AB hydrolysis, Coincidentally, NaOH acts as a hindrance in the hydrolysis of NaBH4. All the hydrogen generation materials have different approaches but equally satisfactory results. The hydrolysis of boron hydride was all performed through a water displacement method. The quality of the catalyst and the corresponding other value can increase or decrease according to the changes based on same magnitude. Each research group does something different when it comes to the hydrogen generation from boron hydride. Illustratively, through different measures, the reaction parameter and activity indicator can be achieved. Herein, AB is just an example to introduce in detail the producing hydrogen and provide some guidance for the scientific researcher.

Hydrogen generation in the batch reactor

The hydrogen generation in the batch reactor has many different test detailed operations for the water displacement method.13,14,36,37,38 Namely, (1) Catalyst (20 mg) was preloaded into a round-bottom flask (50 mL). Then NaOH solution (1 M, 10 mL) containing AB (84 mg) was rapidly injected into the flask using a gastight syringe. A gas burette (200 mL) filled with water connected to the other side of the reaction flask was employed to collect the gas. The experiment was conducted by using a constant-temperature magnetic stirring apparatus, and the stirring speed was kept at 500 rpm.

Furthermore, the hydrolytic dehydrogenation experiments were performed in a two-necked round-bottom flask, in which one neck was sealed with a rubber cap, while the other was connected to a gas burette. We used a constant-temperature bath to maintain the reaction temperature of system. Certain amounts of catalysts were placed in the two-necked round-bottomed flask, and then AB solution was quickly injected using a syringe. The generated hydrogen in the system was identified though a gas chromatograph. And then record the amount of gas.32

Hydrogen generation in the slurry bed reactor

The continuous hydrolysis of AB was also tested through a water displacement method. Catalyst (20 mg) and water (80 mL) were placed into a glass slurry-bed reactor (100 mL) fixed on a magnetic stirrer. The NaOH (1 M) aqueous solution of AB (0.136 or 0.272 M, 60 mL) was put into the reactor bottom through an entrance at a flow rate of 1.20 mL min−1 by an injector pump. The mixture exited from the reactor top through an export tube and the stirring rate was fixed at 500 rpm. Hydrogen left the reactor through a top tube and its volume was measured in the same inverted and water-filled gas burette in a water-filled vessel.

Illustratively, for the above-mentioned hydrolysis process, the operation of the existence of NaOH or not has the ability to interpret the role of NaOH. The amounts of various materials can change in an equal proportion to conduct the hydrolysis of borohydride. And the nature of the reaction has no change. We can change the parameter of the reaction to adjust and improve the process of hydrogen generation.

Hydrogen generation activity descriptor

In catalytic reactions, the hydrogen generation rate is an indicator to measure the catalytic activity of materials. The volume or mole of hydrogen produced per unit of time is based on the elemental content of the active substance. Herein, the active material element is used as an example to illustrate the calculation of hydrogen generation rate in detail. In this review, the Co as an example in the calculation of active substance was used to assess the catalytic activity. The whole calculation format is listed in the following and the practical implications have some similar in a sense.

Hydrogen generation specific rate

The hydrogen generation-specific rate was calculated using the information from the stabilizing stages. The stabilizing stages refer to the stable phase of the hydrogen generation. Such as, the stabilizing stages present as follows, namely, 80 mL of hydrogen generated refers to the amount volume of hydrogen in a stable phase toward hydrogen generation and this principle helps to determine the volume of the calculation rate perfectly according to the following formula,13,38

| (Equation 4) |

Here, rB is the hydrogen generation specific rate; t140 and t60 represents the time of hydrogen generation for 140 mL and 60 mL, respectively; Wc is the weight of active substance of Co in the catalysts. Illustratively, the hydrogen volume will change with the change of the stability period during the catalytic reaction.

Turn over frequency

Another common method of rate calculation is the turn over frequency (TOF) value in this dehydrogenation reaction, TOF refers to the number of moles of hydrogen produced per mole of active material per unit time, h−1 and min−1 are the most common units. TOF (h−1) was calculated through the following formula,3,39

| (Equation 5) |

Herein, nH2 is the moles of generated hydrogen during the stability period of hydrogen generation process, while nCo is the total moles of active Co in the sample, t is the reaction time in units of hours during the stability period. The unit of TOF is h−1.

The different research has different calculation formats. The TOF also reported was based on the total amount of active metals. The equation of TOF calculation is given below,15

| (Equation 6) |

Here, VH2 was the total volume of hydrogen generated, Vs was the volume of solution (10 mL in this report), Cca was the concentration of active metals in the catalyst, and t was the time for the completion of the reaction. Additionally, the TOF value reported also can be calculated using the following Equation 7,36

| (Equation 7) |

The TOF value reported in Equation 7 could be calculated from three parallel tests. (Caution, the err bar<2%).

Durability test

The durability plays a key role in the development of heterogeneous catalysis and the excellent stability is beneficial to realize the industrial applications. The measurement of the stability during the process of hydrogen generation is narrated as follows: The catalyst was collected after reacting one cycle following an operation of dry. According to the experimental operation of the hydrogen generation, the same producers repeated many cycles (at least 5 cycles for non-noble metal-based catalysts and 10 cycles for noble metal-based catalysts). Additionally, the other method is that after the completion of first cycle reaction, another AB solution was directly injected into the reaction system for the next run. This operation was repeated many cycles to assess the stability of the prepared catalysts.15

Catalysts derived from different precursors

The precursor selection is important for the preparation and activity enhancement of targeted catalysts. The morphology, particle sizes, specific surface area and so on of precursors is the main physical and chemical indicators. The calcination temperature and calcination time are important factors affecting the properties of targeted materials. For the Co-based materials, different precursors can generate different structures and influence the catalytic activity. Thus, the Co-based compounds derived from pyrolysis of different organic metal precursor are classified in this review according to the different types.

MOFs precursors

MOFs are attracting increasing attention as a kind of material composed of metal ions and organic ligands with porous crystalline structures. MOFs possess adjustable and diverse ordered skeletal structures with modifiable surfaces. Moreover, MOFs can be used as adsorbents in gas adsorption and separation and as supports for metal NPs in heterogeneous catalysis. In recent years, MOFs have been used to prepare some porous carbon materials with a high specific surface area through metal-catalyzed thermal pyrolysis. The generated confining effect of organic ligands because of their highly porous ordered structure can be tentatively applied into energy conversion and storage areas. Some new nanostructures composed of metal or metal oxide and carbon matrix or carbon shells can be prepared from MOFs after thermal treatments. Additionally, MOFs with controllable shapes and high carbon contents can be used to make core-shell structures through thermal pyrolysis and these synthesized core-shell structures consisting of shells derived from organic ligands and metal or metal oxide cores can improve performances. Generally, the metals or metal oxides NPs generated from metal ions will be covered with closed or open carbon layer shells from organic ligands in thermal pyrolysis and the existence of core-shell will prevent the NPs from growing indefinitely and aggregation, which have a significant influence on catalytic activity.

The direct pyrolysis of MOF to obtain carbon-modified catalyst and the carbon can prevent the agglomeration of the NPs, thus endowing excellent catalytic activity. Carbon-coated cobalt nanosheets (Co@C) catalyst was designed using Co-MOF as the self-sacrificing template and starting a pyrolysis treatment of MOF precursor. The Co NPs are highly dispersed and encapsulated in porous carbon. At the pyrolysis temperature of 700°C, the obtained Co@C-700 catalyst exhibits optimal activity among the Co@C catalysts compared to the other prepared catalysts at different carbonization temperatures and retains 93.1% of its initial catalytic activity after five cycles in NaBH4 hydrolysis40 (Figure 2A). Porous magnetic cobalt/carbon composite (MCCC) via one-step carbonization of cobalt-based zeolitic imidazolate framework (ZIF-67) was synthesized and shows a superior catalytic capability with significantly low activation energy (25.8 kJ mol−1) in NaBH4 hydrolysis41 (Figure 2B). Illustratively, through changing the carbonization temperatures during the pyrolysis under inert or others to optimize the catalytic activity without changing the composition. The use of different ligands has different effects on the chemical composition and can adjust the active structure in the catalyst. Noteworthily, during the preparation of the MOF precursors using the 2-methylimidazole and other organic ligands containing the N element, the N-modified carbon can be achieved in the process of the MOF pyrolysis. Based on this, nitrogen-doped porous carbon nanowires (NPCNW) were synthesized, and synchronously the generation of cobalt NPs was supported on the nitrogen-doped porous carbon (Co/NPCNW) via the one-step carbonization of Co-MOF. The N element is derived from the organic ligand of 1,3,5-benzene tricarboxylic acid and 4,4′-bipyridine. The prepared catalyst Co/NPCNW presents a hydrogen generation rate of 2638 mL min−1 g−1 and a relatively low activation energy of 25.4 kJ mol−1 in hydrolysis of AB42 (Figure 2C). In conclusion, the rational design of catalyst precursors, such as the addition of some non-metal elements, can provide the research basis for AB hydrolysis in hydrogen storage applications.

Figure 2.

The analysis of structure and catalytic activity of Co-based catalysts on different MOFs

The analysis of structure and catalytic activity of (A) Co@C catalyst. Reproduced with permission,40 Copyright 2016, Elsevier.

(B) Porous magnetic cobalt/carbon composite (MCCC). Reproduced with permission,41 Copyright 2016, Elsevier.

(C) Co/NPCNW. Reproduced with permission,42 Copyright 2017, Royal Society of Chemistry.

(D) ZnxCo1-x@NC. Reproduced with permission,43 Copyright 2019, Elsevier.

(E) SiO2-encompassed Co@N-doped porous carbon. Reproduced with permission,44 Copyright 2019, American Chemical Society.

(F) Co-Co3O4@C-n series catalyst. Reproduced with permission,13 Copyright 2017, Springer.

(G) Co-CoOx@NCS-II series catalyst.38 Copyright 2019, American Chemical Society.

The introduction of the second metal into the MOFs can change the chemical features and environments after the treatment of pyrolysis. Gao et al.43 successfully prepared the bimetallic ZnCo-MOFs using the 2-methylimidazole as the ligands, cobalt nanoparticles packaged into N-doped porous carbon derived from the pyrolysis of MOFs. The catalyst showed excellent catalytic activity with a hydrogen generation rate of 1807 mLH2 min−1 gCo−1 and lower activation energy (20 kJ mol−1) in the hydrolysis of NaBH4 because of the contribution of highly dispersed Co nanoparticles and confinement effect. Additionally, the stability test confirmed that the deactivation of the catalyst was due to the deposition of borate species at the surface of the catalyst. The addition of Zn in MOFs as a “fence” expanded the distance of adjacent Co atoms in space and simultaneously the leaving Zn2+ sites generated free N sites during pyrolysis. The modification method allows the cobalt nanoparticles have a uniform and fine confinement within the porous carbon. This observation may provide an idea to modify and upgrade the stability of the catalyst (Figure 2D). Moreover, the Zn ion as a sacrificial agent can be removed from the catalyst when the temperature is as high as 800°C and is beneficial to reduce the sizes of NPs and enhance the dispersity of active sites. The above-mentioned strategies can apply to the other field for the construction of active structure.

Some modification of the other coating layer into the MOF precursor is essential for the improvement of activity and stability. Chen et al.44 reported the synthesis of SiO2-encompassed Co@N-doped porous carbon assemblies as a new type of recyclable catalyst for the calcination of ZIF-67@SiO2 microtubes at high temperatures under an N2 atmosphere. The surface layer of SiO2 in the precursor microtubes is essential for the production of efficient catalysts by supplying an additional surface for Co nanoparticle to reduce their size. In addition, the SiO2 layer renders a highly ordered arrangement of Co@N-doped porous carbon within the catalysts, possibly allowing the ease of mass transfer of AB within the catalysts. The optimized catalysts obtained via calcination at 800°C show remarkable catalytic benefits, including a high hydrogen generation rate of 8.4 mol min−1 molCo−1, a relatively low activation energy of 36.1 kJ mol−1, and remarkable reusability (at least 10 times). The results can provide new insight into the design and synthesis of highly ordered SiO2-supported catalysts for different reactions (Figure 2E).

Particularly, the rational construction of heterogeneous interfaces is an effective way to adjust the electron distribution with rich active sites, and to optimize the chemisorption capacity of the catalyst, thus resulting in excellent catalytic efficiency. The combination of MOFs pyrolysis and controllable oxidation to generate the synergistic effect is important for the enhancement of hydrogen generation. Liu et al. reported a core-shell heterostructure of Co-Co3O4@C-n prepared via pyrolysis of Co-MOFs@glucose polymer and partial oxidation in the air (Figure 2F). During NaBH4 hydrolysis, as-fabricated Co-Co3O4@C-n exhibited higher catalytic activity (5360 mL min−1 gCo−1) because of the synergistic interactions between Co and Co3O4 NPs.13 The assembly-pyrolysis-oxidation strategy provides theoretical guidance in the design of novel nanocomposites. Xing et al.45 reported Co-MOFs used as pyrolysis precursors to synthesize multilayer core-shell composites loaded on reduced graphene oxide (rGO) sheets and then used in NaBH4 hydrolysis. Due to the encapsulation of multilayer core-shell structure, the shell plays a limiting effect on the core, prevent active components of catalysts aggregation, making the catalyst more stable. The core-shell structure features the multifunctionality in the regulation of surface structure and electronic properties, thus, increasing the catalytic activity. The controllable oxidation of Co to CoOx anchored onto the surface of rGO sheets makes a high hydrogen generation specific rate of 5560 mL min−1 gCo−1. Coincidentally, Co-N-doped carbon spherical catalysts (Co@NCS) were synthesized via the composition of Co-metal-organic frameworks and resorcinol-formaldehyde resin (CMRF) following precursor pyrolysis by Zhang et al.38 Similarly, controllable oxidation of Co@NCS-n was also processed to obtain Co-CoOx@NCS-II. The optimal catalyst demonstrated a superior specific hydrogen generation rate of 5562 mL min−1 gCo−1 in AB hydrolysis because of the synergistic effect between Co and CoOx (Figure 2G). Illustratively, the generation of core-shell structures was obtained by the formation of cores from metal ions and carbon shells from carbonization of ligands during the pyrolysis of MOFs precursors. The core-shell structure can prevent the agglomeration of metal NPs. The formation of the hetero-structure derived from the pyrolysis of MOF-based precursors adjusts the electronic character and thus enhance the catalytic activity. And the construction of the hetero-structure derived from MOFs can be used in the other transition metals according to the rational design of the active sites based on the catalysis reaction. These synthetic strategies may improve the development and application of noble-metal-free catalysts in the sustainable catalysis field.

In a nutshell, the catalysts derived from the MOFs, the magnetism, porosity, and suitable size of cobalt-based active structure make MOFs became a promising synthesis method for the preparation of the catalysts and used for hydrogen generation. The MOFs also can be used in other catalysis fields. The carbon derived from the pyrolysis of MOFs is responsible for the stability during the hydrolysis of boron hydride. Furthermore, some modifications on MOFs precursors can be operated to enhance the improvement of the activity and stability. After the operation of the pyrolysis treatment on MOFs, some other operations such as introducing other metal or non-metal elements into catalysts to regulate the electronic structure are central to the design of the high-efficiency catalysts.

Supported precursors

Metal NPs are fundamental components of various catalysts because of their unique controllable size, morphology, and composition. The suitable NPs feature the advantages of small size, high surface atomic ratio, coordination unsaturation, and exposure a large number of active sites, thus expressing outstanding performance in heterogeneous catalysis and significantly increasing the effective utilization and scope of use. However, the problems of agglomeration and difficult separation of NPs after the reaction severely impede their practical application. Based on this, supported metal catalysts are an important class of multiphase catalysts and have widespread applications in the field of chemical industry. When the catalytic metal species are deposited on the support or modified on the support, the two-dimensional (2D) metal-support interface will naturally form. The generated interface holds the promise of effectively regulating the adsorption behavior of reactant intermediates or products on different chemical components, thus providing an opportunity to break the linear scaling relationship and improve the catalytic performance. The presence of suitable supports can avoid the agglomeration of NPs and make them disperse evenly. The metal-support interfaces between metals and supports have been studied in catalytic applications because of their significance in structural stability and efficient catalytic activity.46,47,48 The construction of such a new interfacial structure for molecule activation holds great promise in many catalytic systems.47 Through the process of pyrolysis, the supported catalysts present excellent catalytic activity in expediting the hydrogen generation of boron hydride.

Two-dimensional supports precursors

Two-dimensional (2D) supports such as rGO, carbon, and others present excellent characteristics in designing catalysts with high-efficiency active sites.49 2D materials have received extensive attention in various fields because of their 2D morphology and unique physical and chemical properties.50 In detail, the rGO nanosheet as support was operated to design Co@g-C3N4-rGO catalyst through hydrothermal and pyrolysis strategy51 (Figure 3A). In the process of catalyst preparation, g-C3N4 shells protect Co NPs cores from aggregating or growing. The connection between Co NPs and rGO was strengthened by the g-C3N4 shells to prevent them from leaching or flowing away. For hydrogen generation from the hydrolysis of NaBH4 or AB, the catalyst presents the highest rB of 3560 mL min−1 g−1 at room temperature. The magnetism of Co NPs and the shape of rGO nanosheets convey effective momentum transfer in the external magnetic field. This idea of composite design and magnetic momentum transfer will be useful for the development of both hydrogen generation and multifunctional composite materials. The functionalized graphene is of significance for the application of graphene in solving current energy and environmental problems. Graphene-based hybrid materials including porous graphene (PG) and carbon nanofibers anchored graphene oxide (GCNFs) through a controllable solid-phase reaction strategy were designed52 (Figure 3B). The PG and GCNFs were formed through red-ox reaction between graphene and Co3O4 during the process of calcination. During the NaBH4 hydrolysis, CoOx NCs anchored onto PG and GCNFs provided hydrogen generation specific rates of 1472 mL min−1 gCo−1 and 2696 mL min−1 gCo−1, respectively. These outstanding catalytic activities are attributed to the synergistic effect of CoOx NCs and PG/GCNFs. A Pitaya pulp structural cobalt-based carbon nanocatalyst through pyrolysis of the phenolic resin was obtained53 (Figure 3C). The phenolic resin gradually decomposes into a carbon texture framework, while the metal complex turns into Co NPs. During hydrogen generation from the alkaline NaBH4 and AB solutions, efficient catalytic performance of 3998 mL min−1 gCo−1 for NaBH4 and 4677 mL min−1 gCo−1 for AB was achieved. Co nanoparticles fixed in the carbon matrix effectively prevent particles from aggregation and loss. The unique structure, its synergistic effects, and its self-stirring mode enable effective catalytic performance and good stability. Zhang et al.54 used peanut shell as carbon precursor to synthesize porous sheet-like activated carbon in a fluidized bed and following a calcined in an N2 flow at 450°C for 4 h (Zr/Co/C). This novel carbon-supported Zr/Co exhibits superior catalytic activity for the hydrolysis of NaBH4 in alkaline medium (1708 mL min−1 g−1) and following an activation energy of 34.84 kJ mol−1. Zhu et al.55 prepared colloidal carbon spheres (CCS) as a support to obtain cobalt catalysts (CCS/Co) for the first time through impregnation-chemical reduction method and following calcination in a tubular furnace under N2 atmosphere at 673 K for 2 h. In particular, an average hydrogen generation rate of 10.4 L min−1 gmet−1 is achieved at 20°C for CCS/Co with a Co loading content of 18.38 wt %. Zou et al.56 synthesized highly dispersed Co-Ce-B nanoparticles supported on chitosan-derived carbon (Co-Ce-B/Chi-C) through chemical reduction and carbonization. A remarkably high hydrogen generation rate of 4760 mL min−1 g−1 at 30°C was achieved and followed by a low activation energy of 33.1 kJ mol−1 in NaBH4 hydrolysis (Figure 3D). Co NPs embedded in porous N-doped carbon (Co@N-C) were fabricated through one-step thermolysis of Co(salen) at selected temperatures (600°C, 700°C, 800°C) under an Ar atmosphere.57 The Co@N-C catalyst obtained at 700°C (Co@N-C-700) shows superior catalytic activity (TOF = 5.6 molH2 molCo−1 min−1) and high sustainability with a 97.2% of its initial catalytic activity after 10 cycles during the hydrolysis of AB. Mahmood et al.58 reported a 2D nitrogenated network polymer encapsulated cobalt-oxide (Co@C2N) catalyst fabricated via an in situ solvothermal synthesis and following an annealing at 450°C under argon atmosphere for 2 h. Co@C2N exhibits outstanding catalytic activities for hydrogen generation of 8903 mL min−1 g−1 at 303 K in hydrolysis of alkaline NaBH4 (Figure 3E). Huang et al.59 developed multiwalled carbon nanotubes supported cobalt-boron catalysts (Co–B/MWCNT) via the chemical reduction and pyrolysis in Ar atmosphere. The Co–B/MWCNT has a high rate of 5.1 L min−1 g−1 compared to 3.1 L min−1 g−1 on Co–B/C catalyst under the same conditions in hydrolysis of NaBH4. Xu et al.60 reported that mono-disperse cobalt NPs decorated on multi-walled carbon nanotubes (MWCNTs) were synthesized by an impregnation-reduction method and calcination of precursors and also used in the hydrolysis of AB. Zhang et al.61 reported Co and nitrogen co-doped mesoporous carbon catalysts (Co@NMC-T-0.5, T represents the carbonization temperature (600°C–900°C), 0.5 indicates the weight ratio between cobalt phthalocyanine (CoPc) and SiO2) synthesized via a facile and effective in situ mosaic strategy and annealing treatment (Figure 3F). Experimental results indicate that Co@NMC-800-0.5 exhibits the highest catalytic activity for the hydrolysis of AB among all the synthesized catalysts, which can be attributed to the superhigh surface area, pore volume, and large pore size of the support, as well as the modified electronic structure and chemical microenvironment of the metallic Co NPs. Fan et al.62 successfully synthesized non-noble bimetallic CoNi NPs encapsulated within h-BN (CoNi@h-BN) via annealing freshly prepared metal ammine boride complexes [Co0.5Ni0.5(NH3)6]Cl3)/NH4BO2 and KBH4 under flowing nitrogen gas at 900°C for 2 h. The result showed that CoNi NPs with a general size of 17 nm were completely encapsulated by h-BN shells, and the h-BN shells on the CoNi NPs are 10–20 layers. The obtained CoNi@h-BN demonstrated high sustainability, good stability (92% retained activity at reuse even recycled 5 times) and outstanding catalytic activity (176.19 mL min−1 g−1 at 293 K) on hydrolysis of AB and a lower activation energy (Ea) of 28 kJ mol−1. Additionally, the mesoporous silica, including beta zeolite seeded MCM-type was as the support to synthesize the corresponding catalysts. Zeolite-supported metal nanocatalysts have emerged as an indispensable class of industrial catalysts because of their superior catalytic activity and excellent stability, which are widely used in diverse catalytic conversions, such as hydrogenations, dehydrogenations, and reforming reactions.63 Co catalysts supported on MCM41 (Co/MCM41) via simple pyrolysis at 550°C was obtained.64 The effect of cobalt loading and weight percent of MCM41 on the catalytic activity was also investigated. The catalyst with the Co loading of 0.5 wt % (Co/MCM41-0.5w) exhibited the highest catalytic activity (915.2 mLH2 min−1 gcat−1) over all investigated catalysts in NaBH4 hydrolysis. Moreover, the different pyrolysis temperatures of 350°C and 650°C were also studied and the results indicated that the 550°C presented excellent performance. Just like discussed in the above results, the different pyrolysis temperatures can influence the micro-chemical structure and thus regulate the catalytic activity of catalysts. Luo et al.65 reported cobalt boride catalysts are supported on modified MCM-41 (Co@M41S) via chemical adsorption and then pyrolyzed at 540°C for 3 h. The Co@M41S presented excellent activity (258 L min−1 molCo−1) in AB hydrolysis reactions, which is better than traditional Co@M41T (73.4 L min−1 molCo−1). Illustratively, the supports of metal oxides were also investigated to prepare the Co-based catalysts for enhancing the catalytic activity of hydrogen generation. Al2O3 as the support to obtain Co/Al2O3 catalyst was successfully designed through impregnation-chemical reduction method and calcination treatment under nitrogen atmosphere at different temperatures. The catalyst was used to catalyze the methanolysis of NaBH4 for hydrogen generation.66 A novel catalyst Ti-supported nanostructured MnCo2O4 film was developed through hydrothermal reaction and calcination at 400°C for 3 h. In hydrolysis of AB, the catalyst conveyed a TOF of 24.3 min−1 and with an excellent stability of 96% even after long-time usage.67

Figure 3.

The analysis of structure and catalytic activity of Co-based catalysts on different 2D supports

(A) Co@g-C3N4-rGO catalyst. Reproduced with permission,51 Copyright 2016, American Chemical Society.

(B) CoOx-PG and CoOx-GCNFs. Reproduced with permission,52 Copyright 2018, American Chemical Society.

(C) PF-based catalysts. Reproduced with permission,53 Copyright 2019, Elsevier.

(D) Co-Ce-B/Chi-C. Reproduced with permission,56 Copyright 2018, Elsevier.

(E) Co@N-C. Reproduced with permission,58 Copyright 2016, Royal Society of Chemistry.

(F) Co@NMC-800-0.5. Reproduced with permission,61 Copyright 2016, Royal Society of Chemistry.

In a nutshell, the 2D supports such as carbon-based or other elemental modifications hold promise in designing the supported catalysts with high-efficiency active sites to enhance the activity of hydrogen generation. However, challenges such as the construction of supported catalysts with high-efficiency catalytic active sites still exist in heterogeneous catalysis. Based on this, the monolithic catalysts play a crucial role in gas-solid phase reactions such as cracking/reforming, and catalytic oxidation/hydrogenation.68,69,70

Three-dimensional supports precursors

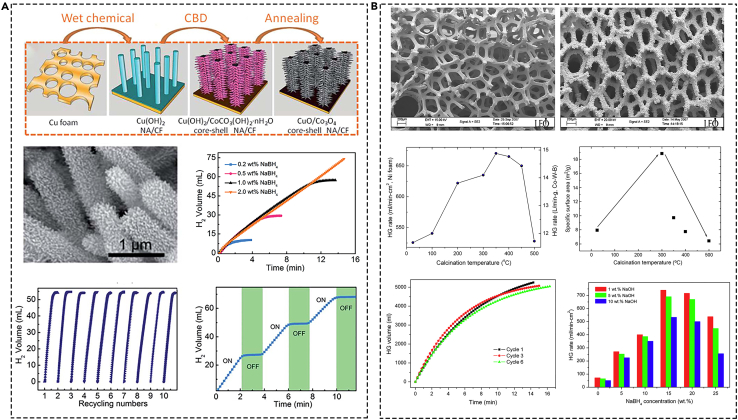

Copper foam, Ni foam, Ti mesh, carbon cloth, and so on have the advantages of special three-dimensional (3D) channels and good heat conduction performance have been widely considered in various catalyst carriers.71 The 3D supports are also conducted to prepare Co-based catalysts through the pyrolysis treatment. Xie et al. reported cobalt oxide nanosheet array on carbon cloth (CoO/CC) and CuO/Co3O4 core-shell nanowires array on copper foam (CuO/Co3O4 core-shell NA/CF) catalysts obtained through pyrolysis of corresponding precursors.72,73 The obtained catalysts presented excellent catalytic activity during the process of NaBH4 hydrolysis (Figure 4A). Cui et al.74 used the Ti mesh as the support to prepared cobalt carbonate hydroxide nanowire array on Ti mesh (CHNA/Ti) through hydrothermal and calcination in an Ar flow at 250°C for 2 h. Self-supported cobalt oxide nanorod array on a Ti sheet (Co3O4 NA/Ti) was obtained through calcination in air at 400°C for 2 h of Co(OH)F precursor.75 The synthesized catalysts showed excellent activity with an activity of 1940 mL min−1 gCo3O4−1 in the dehydrogenation of NaBH4. Dai et al.76 prepared a Co-W-B amorphous catalyst supported on Ni foam (Co-W-B/Ni foam catalyst) using a modified electroless plating method. Subsequently, the Co-W-B/Ni foam catalysts were pyrolyzed at a temperature ranging from 100°C to 500°C for 2 h under pure Ar atmosphere and present highly effective for catalyzing hydrogen generation from alkaline NaBH4 solution. The effect of different pyrolysis temperature on the hydrogen generation and the specific surface area was studied. The optimal catalyst presented excellent activity of 15 L min−1 g(Co–W–B) and with a lower activation energy of 29 kJ mol−1 (Figure 4B).

Figure 4.

The analysis of structure and catalytic activity of Co-based monolithic catalysts on different 3D supports

(A) CuO/Co3O4 core-shell nanowires array on copper foam. Reproduced with permission,73 Copyright 2016, Royal Society of Chemistry.

(B) Co–W–B/Ni foam. Reproduced with permission,76 Copyright 2008, Elsevier.

Generally, the catalysts can be prepared through facile one-pot solution reaction, pyrolysis at high temperatures, and oxidation in air. The various valence states of Co can be observed by utilizing various characterization methods. In a nutshell, the interface between active metal and support plays a key role in catalyzing various reactions. The design of efficient supported catalysts has been frontier research in catalysis field.77 However, the catalytic properties of interfacial structures can be influenced by many factors, such as the size of active metals, the type of supports, and the strength of metal-support interactions, making targeted creation of active interfaces with specific structures a challenge.78,79 Therefore, the construction of active interface is essential for the design of efficient supported catalysts. How to construct an efficient catalytic interface between metal and support has attracted widespread attention from researchers. It is generally believed that the interaction between metal and support is conducive to improving the dispersion of active metals, but there will also be cases of excessive coating, resulting in a large loss of active sites. Therefore, it is essential to properly design and control metal-support interactions to create rich and efficient interface sites for molecular transformation.47 Additionally, supported metal catalysts are typical heterogeneous catalysts, and most supported metal catalysts have metal particle sizes at the nanoscale. Because of their special geometric structure and electronic properties of supported catalysts, the catalyst exhibits excellent catalytic properties. The problem is that when the metal particles are reduced to the sub-nanometer scale, their specific surface area increases sharply, resulting in a dramatical increase in the free energy of the metal surface. Additionally, the generated high surface energy in the process of catalyst preparation and reaction will make metal particles to agglomerate to form large clusters, resulting in catalyst inactivation. Therefore, excavating the single-atom catalysts have hails as a research hotspot thanks to their extremely high atomic utilization rate and relatively uniform active center.

Metal precursors

The Co-based catalysts obtained from pyrolysis of metal precursors were also reported and used in the hydrogen generation of boron hydride. Tomboc et al.80 reported a synthesis of Co3O4 with porous macrocube structure through hydrothermal treatment of chitosan/urea/Co(NO3)2 6H2O mixtures at 180°C for 8 h and then calcined at different temperatures (500°C, 600°C, 700°C and 800°C) for 4 h. The catalyst showed a high hydrogen generation rate of 1497.55 mlH2 min−1 gcat−1 at 25°C. Durano et al.81 developed a simple precipitation method to prepare Co3O4 nanorods using cobalt chloride and urea in aqueous solution and then following a calcined at 600°C, 700°C, 800°C for 4 h and used in NaBH4 hydrolysis, which present an activity of 1776 mlH2 min−1 gcat−1. Figen et al.82 reported a novel perspective Co-B catalysts prepared through sol-gel reaction of boron oxide (B2O3) with cobalt (II) chloride hexahydrate (CoCl2 6H2O) in the presence of citric acid (C6H8O7) and then calcined at 500°C and 700°C. The maximum hydrogen generation rate is observed with an amorphous Co-B catalyst (9157.20 mL min−1 gcat−1) in hydrogen generation from AB and the corresponding activation energy (Ea) is only 47.50 kJ mol−1. The Co or CoOx as the active sites provide the responsibility for the absorption and dissociation of reactants thus expediting the catalytic activity. However, the single Co-based catalysts have the disadvantages of easy agglomeration and low activity, which dramatically decreases the activity of catalysts. Therefore, the investigation of the introduction of other metal or non-metal elements is beneficial for the enhancement of the catalytic activity.

Precise regulation of metallic NPs structure is essential to understand structure-activity relationships in catalytic reactions and improve catalytic performance. The introduction of other metal or non-metal elements can adjust the electronic structure and modify the chemical environment and thus construct new active sites to boost the catalytic reaction.83 Zhang et al.84 fabricated porous single-crystal CoO nanorods (PS CoO NRs) through gas phase cation exchange using ZnO NRs as a template. Additionally, the cation exchange was verified to proceed gradually from the outer surface to the inner core of ZnO NRs, and CoO NRs can be achieved at the exchange temperature of 600°C. The single-crystal structure of the ZnO template is well-preserved after the cation exchange, and numerous nanopores form in the PS CoO NRs because of the volume shrinkage. As-synthesized PS CoO NRs exhibited outstanding catalytic activities for NaBH4 hydrolysis in alkaline solutions with hydrogen generation rates of 20.3 L min−1 g−1 (Figure 5A). Wu et al.85 synthesized a series of Ni-Co-B catalysts by a two-step technique, namely, chemical reduction (5% NaBH4+1% NaOH) to prepare the precursors, and heat-treatment (573 K, 673 K, 773 K, 973 K) to adjust the crystal structures under the protection of an Ar atmosphere. The sample treated at 673 K achieves an average hydrogen generation rate of 708 mL min−1 g−1 in NaBH4 hydrolysis, which can give successive hydrogen supply for a 115 W portable proton-exchange membrane fuel cell (PEMFC). Zhao et al.86 reported various metal elements (M = Ni, Co, NiCo) dispersed on graphene oxide (GO) to form the M-GO hybrids through a facile method. The samples were heated to 300°C in H2 (100 sccm) atmosphere at the rate of 8 °C min−1 and held at 300°C for 2 h. The hybrids showed good catalytic activities in the hydrolytic dehydrogenation of AB, which presented superior activity compared to the metal NPs or GO alone. NiCo-GO shown the optimal TOF value of 6.78 min−1 and catalytic activity decreases but still has a value of about 65% after circulation. Barakat et al.87 synthesized MnO-doped Co nanofibers using electrospinning technology. Briefly, electrospun nanofibers composed of poly(vinyl alcohol), cobalt acetate, and manganese acetate were vacuously dried and calcined in an Ar atmosphere at 850°C for 5 h, which was introduced as an effective catalysts for AB hydrolysis. Qian et al.88 reported Co-Zn-S nano-porous microspheres catalyst synthesized through a solvothermal method and following an annealing treatment. The catalyst also showed good catalytic performance toward the hydrolysis of AB and produced around 70 mL of hydrogen. Liao et al.89 prepared a series of CoxCu1−xMoO4 microspheres through an annealing treatment at 500°C for 2 h. Especially, Co0.8Cu0.2MoO4 exhibited excellent catalytic activity with a TOF of 55.0 min−1 toward AB hydrolysis (Figure 5B). Illustratively, the introduction of noble-metal holds the promise of improving catalytic activity due to its special d band center. For example, the introduction of Pd-doped Co-based catalysts synthesized through a calcination of precursors and used in the catalytic hydrolysis of AB.66,90 However, the rare resource and prohibitive cost severely hampered their widespread application.

Figure 5.

The analysis of the structure and catalytic activity of Co-based catalysts derived from the pyrolysis of metal precursors

(A) CoO NRs. Reproduced with permission,84 Copyright 2017, American Chemical Society.

(B) Co0.8Cu0.2MoO4. Reproduced with permission,89 Copyright 2018, American Chemical Society.

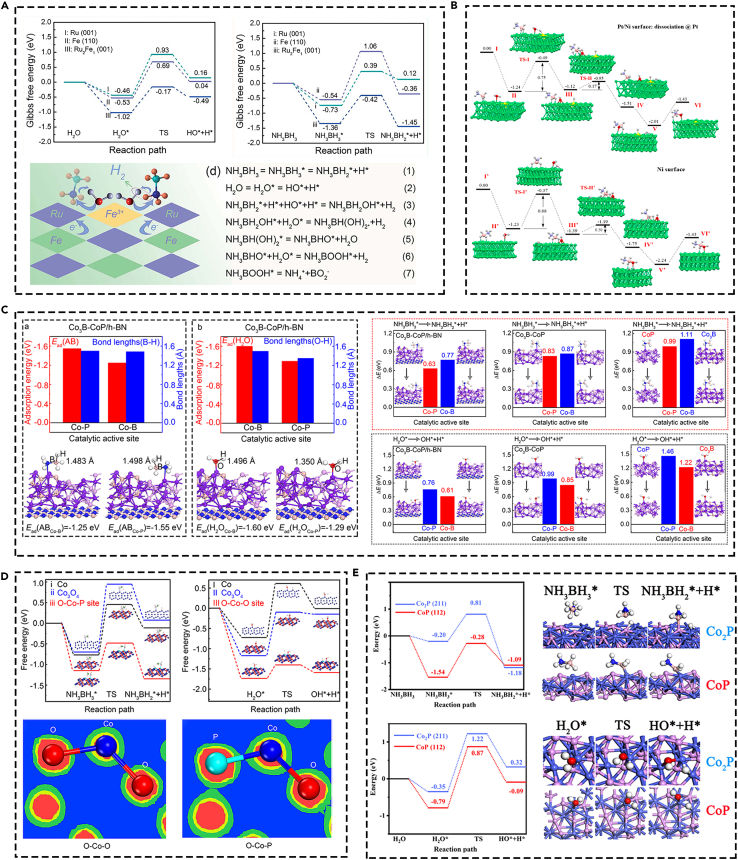

Metal phosphides precursors

Metal phosphides (MPs) have adjustable composition, excellent electrical conductivity, rich phase structure, and good redox performance have been used in catalysis field.91,92,93,94,95 For the hydrolysis of boron hydride, the introduction of phosphorus (P) element can regulate the electronic structure and coordination environment, thus presenting great application potential in the fields of energy storage and heterogeneous catalysis.96,97 The P regulation strategy is referred to introducing P atoms into the metal-based catalytic active center/active phase and forming an efficient active structure.98,99 The incorporation of P atom can regulate the electronic structure, valence state, and existence form of the metal through the coordination strategy, thus helping to improve the catalytic reactivity of metal sites.100 Although MPs have great potential, there are still many great challenges, such as, the lattice stress release caused by the replacement of P atoms leads to aggregation and sintering of catalysts in the process of P-inducing, thus destroying the original structure and reducing the catalytic activity of catalysts. Based on this, the construction of high-efficiency accessible active sites through rational regulation strategy of P atoms, and to understand the correlation between the active sites, the catalytic performance and catalytic mechanism of the catalysts are of great significance in the field of heterogeneous catalysis. Based on this, more research on MPs to improve the hydrogen generation of boron hydride is investigated. The atomic-bridge structure in B-Co-P dual-active sites on boron nitride nanosheet was rationally design through simple NaBH4 reduction and P-inducing strategy, which present excellent activity during the catalytic hydrogen generation of AB.2 The introduction of P atom regulates the chemical environment of Co and generates new active sites of Co-B and Co-P. The existence of the dual-active sites is responsible for the absorption and dissociation of the AB and H2O molecule (Figure 6A). Additionally, CoBP nanoparticles supported on 3D nitrogen-doped graphene hydrogel was synthesized and conveyed superior catalytic activity for hydrogen generation from hydrolysis of AB.101 Through the MOFs pyrolysis to obtain the corresponding MPs is the common method. Polar O-Co-P surface was prepared through the pyrolysis of compound precursors of Co-MOF and resorcinol-formaldehyde, the introduction of P atom changes the existence valence of Co and boosts the bimolecular activation in AB hydrolysis.102 CoP nanoparticles encapsulated in carbonaceous nanorods (CoP@CNR),103 hierarchical porous carbon (HPC)104 derived from Co-MOF-74 and the corresponding phosphorization treatment under different treatment methods was obtained and convey excellent performance on the dehydrogenization of AB. Cobalt phosphide carbon-based nano-frameworks (CoP@CNFs) was obtained through Zn/Co-ZIF as the template combined with the pyrolysis treatment. Zn in the MOF precursor plays the dual crucial role of separating the Co ions and maintaining the framework during pyrolysis. The hierarchical porous structure, well-exposed active sites, and hydrophilic channels make the catalyst exhibited extraordinary TOF of 165.5 min−1 for hydrogen generation of AB105 (Figure 6B). The Co-based bimetallic phosphides, especially NiCo-based phosphides were also studied and presented high activity. Through one-pot chemical reduction approach to synthesize ultrafine Ni0.13Co0.87P nanoparticles on halloysite nanotubes and the catalyst presented a TOF of 47.5 min−1 in the hydrogen evolution from AB. The synergistic effect among Ni, Co, and P in Ni0.13Co0.87P effectively enhances their interaction with AB and thus boost the activity106 (Figure 6C). Additionally, CoNiP nanoboxes on graphene oxide (CoNiP/GO) were synthesized through pyrolysis and P-inducing strategy, which achieved a remarkable TOF value of 134.6 min−1 because of the slightly modulated chemical state of Co107 (Figure 6D). Boron nitride–supported NiCoP nanoparticles were harvested via the hydrothermal-phosphorization strategy and presented a TOF of 86.5 min−1 in the hydrogen generation from AB, the synergistic effect between Ni, Co, and P, as well as the strong metal-support interaction between NiCoP and h-BN.108 Uniformly dispersed Co@Co2P core-shell nanoparticles (NPs) embedded in N-doped carbon nanotube polyhedron (Co@Co2P/N-CNP) were achieved through a carbonization-phosphidation strategy and afforded a high TOF value of 18.4 min−1 for hydrogen generation from AB. Benefiting from the electronic effect of P doping, high dispersibility and strong interfacial interaction between NPs and support endows the excellent activity109 (Figure 6E). Moreover, the monolithic catalysts based on MPs were also fabricated. The self-supporting NiCoP supported on nickel foam was synthesized and presented excellent activity for hydrogen generation via hydrolysis of AB.110 Cobalt phosphide nanowall arrays supported on carbon cloth presented a hydrogen generation rate of 5960 mL min−1 gCoP−1 during the hydrolytic dehydrogenation of NaBH4.111 Self-supported CoP nanosheet arrays on Ti mesh (CoP/Ti mesh) were obtained and followed with a hydrogen generation rate of 6100 mL min−1 gCoP−1 in alkaline NaBH4 solution.112 The introduction of low noble metal into Co-based catalysts can adjust the active structure of metal and thus boost the hydrogen generation. Pd@Co@P NPs with orange-like supported on rGO was designed through one-pot co-reduction synthesis. The synthesized catalyst presented excellent TOF of 127.57 min−1 for catalytic hydrolysis of AB because of the existence of an orange-like structure, good dispersion of Pd@Co@P/rGO NPs, and the synergistic electron interactions between palladium, cobalt, and phosphorus113 (Figure 6F). The comparison of Co-based catalysts contain the typical catalysts are listed in Table 1.

Figure 6.

The analyses on the structure and catalytic activity of Co-based phosphides

(A) B-Co-P atomic structure. Reproduced with permission,2 Copyright 2022, Elsevier.

(B) CoP@CNF. Reproduced with permission,105 Copyright 2019, Royal Society of Chemistry.

(C) NixCo1-xP/Hal. Reproduced with permission,106 Copyright 2021, Elsevier.

(D) CoNiP/GO. Reproduced with permission,107 Copyright 2022, Elsevier.

(E) Co@Co2P/N-CNP. Reproduced with permission,109 Copyright 2021, Elsevier.

(F) Pd@Co@P/rGO. Reproduced with permission,113 Copyright 2021, Elsevier.

Table 1.

The comparison of Co-based catalysts contain the typical catalysts included in this review

| Catalysts | Catalyst mass | Reactant | NaOH | Catalytic activity | Ea (kJ/mol) | Year | Reference |

|---|---|---|---|---|---|---|---|

| Co@C-700 | 10 mg | NaBH4 | yes | – | 56.9 | 2019 | Zhang et al. 40 |

| Co/C | – | NaBH4 | yes | 1738a | 25.8 | 2016 | Lin et al.41 |

| Co/NPCNW | 10 mg | NaBH4 | no | 2638a | 25.4 | 2017 | Zhou et al.42 |

| Zn1Co1-Co@NC | 10 mg | NaBH4 | yes | 1807a | 20 | 2019 | Gao et al.43 |

| Co@N−C@SiO2 | 10 mg | AB | no | 8.4a | 36.1 | 2019 | Chen et al.44 |

| Co-Co3O4@C-n | 20 mg | NaBH4 | yes | 5360a | 37.12 | 2016 | Liu et al.13 |

| Co@CoOx@N-CG | 20 mg | NaBH4 | yes | 5560a | 36.6 | 2016 | Liu et al.13 |

| Co-CoOx@NCS-II | 20 mg | AB | yes | 5562a | 46.37 | 2019 | Zhang et al.38 |

| Co@g-C3N4-rGO | 20 mg | NaBH4 | yes | 3560a | 35.42 | 2016 | Duan et al.51 |

| CoOx/GCNFs | 20 mg | NaBH4 | no | 2696a | 28.3 | 2018 | Wu et al.52 |

| Co-CoOx/C | 20 mg | AB | yes | 4677a | 30.84 | 2019 | Wang et al.53 |

| Zr/Co/C | – | NaBH4 | yes | 1708a | 34.84 | 2013 | Zhang et al.54 |

| CCS/Co | 20 mg | NaBH4 | yes | 10400a | 24.04 | 2012 | Zhu et al.55 |

| Co-Ce-B/Chi-C | 150 mg | NaBH4 | yes | 4760a | 33.1 | 2018 | Zou et al.56 |

| Co@N-C-700 | 20 mg | AB | no | 5.6a | 31.0 | 2016 | Wang et al.57 |

| Co@C2N | 10 mg | NaBH4 | yes | 8903a | 66.17 | 2015 | Mahmood et al.58 |

| Co–B/MWCNT | 10 mg | NaBH4 | yes | 5100a | 40.4 | 2008 | Huang et al.59 |

| Co/CNT | 20 mg | NaBH4 | yes | – | 33.8 | 2012 | Xu et al.60 |

| Co@NMC-T-0.5 | 30 mg | AB | no | – | 41.6 | 2018 | Zhang et al.61 |

| CoNi@h-BN | – | AB | – | 176.19a | 28 | 2017 | Fan et al.62 |

| Co/MCM41–0.5w | – | NaBH4 | yes | 915.2a | 108.7 | 2019 | Shu et al.64 |

| Co@M41S | – | NaBH4 | no | 258a | 54.6 | 2013 | Luo et al.65 |

| MnCo2O4 film | – | AB | yes | 24.3b | 17.5 | 2017 | Liu et al.67 |

| CHNA/Ti | – | NaBH4 | yes | 4000a | 39.78 | 2016 | Cui et al.74 |

| Co3O4 NA/Ti | – | NaBH4 | yes | 1940a | 59.84 | 2016 | Huang et al.75 |

| Co–W–B/Ni foam | – | NaBH4 | yes | 15000a | 29 | 2008 | Dai et al.76 |

| Co3O4 | 20 mg | NaBH4 | yes | 1497.55a | 47.97 | 2017 | Tomboc et al.80 |

| Co3O4 nanorods | – | NaBH4 | no | 1776a | 49.52 | 2017 | Durano et al.81 |

| Co-B | – | AB | – | 9157.20a | 47.5 | 2013 | Kantürk et al.82 |

| PS CoO NRs | 10 mg | NaBH4 | yes | 20333a | 45.94 | 2015 | Zhang et al.84 |

| Ni–Co–B | 100 mg | NaBH4 | yes | 708a | – | 2011 | Wu et al.85 |

| NiCo-GO | 10 mg | AB | no | 6.78b | – | 2016 | Zhao et al.86 |

| CoxCu1−xMoO4 | 10 mg | AB | yes | 55.0b | 39.6 | 2018 | Liao et al.89 |

| B-Co-P | 10 mg | AB | yes | 37b | 51.8 | 2022 | Zhang et al.2 |

| Co0.79B0.15P0.06/NGH | – | AB | no | 32.8b | 39.42 | 2018 | Men et al.101 |

| O-Co-P | 20 mg | AB | yes | 37b | 41.0 | 2023 | Zhang et al.102 |

| CoP@CNR | 10 mg | AB | yes | 10014a | – | 2021 | Jiang et al.103 |

| CoP@HPC | – | AB | – | 27.7b | 42.55 | 2020 | Ma et al.104 |

| CoP@CNFs | – | AB | yes | 165.5b | – | 2019 | Hou et al.105 |

| Ni0.13Co0.87P/Hal | – | AB | yes | 47.5b | 41.8 | 2021 | Xiong et al.106 |

| CoNiP/GO | 5 mg | AB | yes | 134.6b | 44.12 | 2022 | Chen et al.107 |

| Ni0.8Co1.2P@h-BN | 10 mg | AB | yes | 86.5b | 40.26 | 2019 | Zhou et al.108 |

| Co@Co2P/N-CNP | – | AB | – | 18.4b | 32.1 | 2021 | Wang et al.109 |

| Co2P nanosheets | – | AB | – | 44.9b | 32.03 | 2022 | Wan et al.128 |

| CoP NAs/CC | – | AB | yes | 5960a | 42.1 | 2016 | Yang et al.111 |

| CoP/Ti mesh | 0.6 mg | AB | yes | 6100a | 42.01 | 2016 | Liu et al.112 |

| Pd@Co@P/rGO | – | AB | – | 127.57b | 39.05 | 2021 | Qu et al.113 |

Summarily, the enhancement of catalytic activity, stability, and the clearness of catalytic mechanism always are the key science problem during the construction of non-noble metal-based catalysts. The P atom regulation strategy plays a paramount role in synthesizing catalyst with high-efficiency active sites. Additionally, we can change the temperature of P-inducing, different types of phosphorus sources to design the catalysts with precise and controllable structures. At the same time, the introduction of special supports into the metal phosphide NPs and the migration of metal phosphide NPs on the supports through the activation of P atoms can accelerate the electron transfer. In addition, the regulation of P elements can regulate the chemical composition and electronic structure of the active phase of active structure, change the intrinsic characteristics of the catalysts, and then promote the catalytic reaction. Illustratively, through in situ spectrometric characterization and theoretical calculation can provide theoretical guidance for the design of highly active catalysts.

The interaction between cobalt and other components

From the above-mentioned types derived from different precursors, we can infer that different precursors have different effects on the structure formation of catalysts, thus influencing the activity of catalysts. Illustratively, the investigation of the interaction between cobalt and other components is important for understanding the nature of catalysts and thus revealing the catalytic mechanism. From the above-mentioned discussion, we can conclude that the introduction of other components can change the structure of catalysts, adjust the chemical valence and thus generate new active structures. The effect of other components on the catalytic activity of boron hydride can be divided into two types of effects: (1) The direct action, namely, the presence of the other components can generate a synergistic effect. The Co substance and the other components have the ability to activate the boron hydride and water molecules. The enhanced activity is contributed by the synergistic effect of them. (2) The indirect action. This refers to the introduction of other components that can affect the chemical coordination environment of Co through electronic promoter or structural promoter and so on. This operation can regulate the surface structure and electronic properties of Co, thus promoting the reaction activity. How the Co and the other components contribute to enhancing the activity still have vast space for research. Additionally, for the different detailed active substances, the activity and mechanism are different. The core research content for us is to construct high-efficiency active sites, clarify the origin of the improvement of catalytic activity and thus reveal the structure-activity relationship.

The comparison of other methods for obtaining catalysts

Besides the mentioned pyrolysis method, other methods are also used to synthesize catalysts and present excellent performance during the process of hydrogen generation. In this part, we will select representative research to present other methods for catalyst preparation. The other methods may provide guidance for the design and synthesis of catalysts for hydrogen generation. For example, the simple impregnation reduction method was applied to synthesize Ru/N-RHC (N-RHC: nitrogen-doped rice husk activated carbon support) catalysts, and present a TOF of 83.71 min−1.114 The existence of support can evenly disperse nanoparticles and the metal-support interaction can boost hydrogen generation. A step-by-step reduction method was used to prepare Pt0.25%Co3%/TiO2; the TOF was up to 2250 min−1 during AB hydrolysis. The introduction of CoO species leads to the formation of electron defects in the interface region of Pt species, which significantly promotes the chemical adsorption and dissociation of water molecules, and accelerates the hydrolysis of AB.9 Highly dispersed Ru-Cu alloy nanoparticles loaded on nitrogen-doped carbon-coated TiO2 were successfully prepared by the organic pyrolysis of solid surfaces. The synthesized catalyst exhibits a TOF of 626 min−1; the ensemble-boosting effect significantly promotes the hydrogen generation.115 Atomic layer deposition strategy was used to treat the Pt-Ni interface and a TOF of 751.6 min−1 was obtained. The high activity is attributed to the construction of a specific interface structure.116 The α-MoC supported Co/Ni catalysts were synthesized using the impregnation method. The TOF was reached 321.1 min−1; the strong metal support interaction (SMSI) effect is responsible for the improvement in activity.15 From the above-mentioned research, the other methods also have a positive impact on hydrogen generation. Although different strategies have different effects on structure construction, the common emphasis is the rational design of catalysts based on different active structures to enhance catalytic activity. Research on other methods to obtain catalysts may be a direction for future review writing to present the types of catalysts derived from those methods.

Catalytic mechanism: A universal voew for boron hydrolysis

The process of heterogeneous catalytic reaction is the combination of a series of physical and chemical processes. The determination and understanding of catalytic mechanism have always been a key and difficult point in the field of heterogeneous catalysis. For the hydrolysis reaction of boron hydride, the possible forms or pathways of Co substances exist in the hydrolysis reaction. During the hydrolysis reaction, the valence state of Co may exist in the zero or another valence state and then become an acid site; Co also exists in the form of a redox site. For example, zero-valent Co exists as a coordination center. Zero-valent and divalent Co can form an ionic redox cycle and serve as a redox site. For the hydrogen generation of boron hydride, there are four types of possible mechanisms depending on the microstructure and properties of catalysts. Although the mechanism is suitable for heterogeneous catalysis, it is also appropriate for Co-based catalysts. Illustratively, Co as an active substance has an induction period during the hydrogen generation of boron hydride. The surface reconstruction of Co will occur, and it is still necessary to investigate in depth what happened to the Co substance. Due to the lack of detailed and profound experimental characterization, the understanding of surface reconstruction is not deep enough, and maybe Operando technology can provide help to monitor the mechanism in the future. Currently, the catalytic mechanism of hydrogen generation of AB hydrolysis presents a dissociation mechanism based on oxidative addition-reduction elimination, pre-activation mechanism, SN2 mechanism, four-membered ring mechanism, and acid-base mechanism. In this review, the five catalytic mechanisms are analyzed in detail.

Dissociation mechanism based on oxidative addition-reduction elimination

Oxidative addition and reductive elimination mechanism as a fundamental processes was observed and have always been a concern of transition metal chemistry in various heterogeneous fields, such as the redox-neutral electrochemical conversion of CO2,117 photosensitization, and C−H carbometallation.118 Based on this, a plausible catalytic mechanism for the oxidation addition of O−H and reductive elimination of hydrogen during AB hydrolysis is investigated. Namely, [H3NBH2H]···H−OH hydrogen bonding resulting from the hydridic property of the B−H bond is suggested here to play a key role. A hydridic B−H is proposed to transfer the H atom to the surface of NPs, this is called the oxidative addition of the B−H bond on the surface. The hydridic surface has the beneficial to close the acidic H atom in H2O through electrostatic interaction. The dissociation of O–H bond in H2O and B–H bond in AB forms the intermediates of M−H bonds on the surface of catalyst through oxidative addition. Then, the generation of hydrogen releases from the surface of the catalysts through reductive elimination. This hypothesis provides further theoretical direction for the catalytic mechanism of AB hydrolysis.

Illustratively, the oxidative addition of the O−H bond in H2O was the rate-determining step (RDS) during the reaction. The effect of favorable OH− for monometallic or bimetallic NPs of the electronic structure of the NPs on the oxidative addition of H2O119 (Figure 7A). AuNi@ZIF-8 alloys are synthesized through NaBH4 reduction and convey excellent performance for hydrogen generation upon AB hydrolysis and the catalytic mechanism was also dissected. The first hydridic surface ligand formed upon hydride transfer from AB and the second hydridic ligand formed upon H2O activation, eventually after “walking” near each other on the surface via successive bridging (μ2) hydride bonds reductively eliminate to form hydrogen. The cleavage of O–H bonds from H2O is the RDS, B–H bonds from AB forming the intermediates M–H bonds and further reductive elimination is boosted by visible light irradiation to release hydrogen28 (Figure 7B). Ni2Pt@ZIF-8 was prepared through simple one-step NaBH4 reduction and express excellent hydrogen generation from AB hydrolysis. During the mechanism of catalytic reaction, the H2O molecule forms a hydrogen bond [NH3BH2H]···H−OH because of the hydridic character of B−H bond. The oxidative addition of the O−H bond of H2O occurs in the RDS and is validated by the results of the large KIE obtained with D2O120 (Figure 7C).

Figure 7.

The oxidative addition and reductive elimination mechanism for hydrogen generation catalyzed by

(A) Pt1Co1/1. Reproduced with permission,119 Copyright 2019, American Chemical Society.

(B) AuNi@ZIF-8. Reproduced with permission,28 Copyright 2023, Elsevier.

(C) NiPt@ZIF-8 NPs. Reproduced with permission,120 Copyright 2018, American Chemical Society.