Abstract

Teff [Eragrostistef (Zucc.)] is one of the most important cereal crops in Ethiopia which is part of the traditional dish of the people in the form of Injera. Interest in Teff has increased noticeably due to its very attractive nutritional profile and the gluten-free nature of the grain. It is a gluten-free cereal, among the major cereal crops, Teff accounts for the largest average annual acreage in the country. It also accounts for the second-largest average annual production, next to maize. The study endeavored to review the harvest and postharvest losses, the causes of these losses, and possible solutions to reduce the postharvest losses of the Teff crop in Ethiopia. There are inadequate postharvest research works conducted in Ethiopia, and most of the limited studies are focused on cereals other than Teff. Teff farming in Ethiopia is dominated by traditional methods of harvesting and postharvest handling. The application of modernharvest and postharvest technologies during Teff production and handling is critically low. As a result, a considerable loss of Teffgrain (16–30 %) in the harvest and postharvest stages has been recorded. The largest share of this loss is observed during the harvesting stage due to shattering, scattering, animal feeding, and contamination with unwanted parts. Lack of awareness of postharvest losses, limited access and availability of postharvest technologies, and low attention given to postharvest research, extension, and infrastructure have also contributed their share to these losses. Transforming the traditional practice into mechanized farming, modern postharvest technologies, and supporting the system by further research works and pieces of training on loss prevention methods could potentially minimize the harvest and postharvest losses of Teff in the country.

Keywords: Teff grain, Postharvest loss assessment, Postharvest loss reduction, Postharvest loss causes, Conventional harvesting method

1. Introduction

Ethiopia has diverse agroecologies well-suited for cultivating various crops. Cereals reign supreme among these, dominating both in terms of land coverage and production volume. Notably, Teff holds the largest share of cereal cultivation in the country [1]. Ethiopia stands out not just as the biggest producer of Teff but also as the only nation to embrace Teff as a staple crop in its diet [2]. Teff [Eragrostistef (Zucc.)] is an indigenous crop to the country and part of the traditional and staple food of the people. It plays a significant role in the agriculture sector of the country to ensure food security [2]. According to data from the Central Statistical Agency of Ethiopia (CSA), in the 2020/21 production year, Teff covered approximately 22.56 % of the total agricultural land, encompassing around 2,928,206.26 ha. Furthermore, it contributed significantly to grain production, accounting for approximately 16.12 % of the total yield, totaling 55,099,615.14 quintals, with an average yield of 18.82 quintals per hectare. Table 1 provides a comparative overview of Teff's average area coverage, production, and yield alongside other cereal crops from 2017/18 to 2020/21.

Table 1.

The average Area, Production, and Yield of Teff as compared with other cereal crops from 2017/18 to 2020/21 cropping season (Compiled from CSA reports) [[3], [4], [5]].

| Crop | Number of Holders | Area Covered (Ha) | Distribution (%) | Production (Qt) | Distribution (%) | Yield (Qt/Ha) |

|---|---|---|---|---|---|---|

| Teff | 6,963,454 | 3,032,315.54 | 23.67 | 54,831,379.77 | 16.90 | 18.09 |

| Barley | 3,710,597 | 910,156.04 | 7.11 | 21,344,087.48 | 6.56 | 23.40 |

| Wheat | 4,546,225 | 1,782,905.91 | 13.91 | 51,441,101.82 | 15.82 | 28.80 |

| Maize | 11,024,717 | 2,324,316.15 | 18.13 | 95,203,715.43 | 29.29 | 40.92 |

| Sorghum | 5,205,097 | 1,808,377.81 | 14.12 | 49,941,377.22 | 15.44 | 27.61 |

Due to the normal and adequate rainfall in the season [6,7], population growth, and urbanization [[8], [9], [10]], the cropped land area and amount of production fluctuated across different cropping seasons. The demand for Teff in the country has also continuously increased over the years [8]. Table 2 shows the amount of cropped land area, production, and yield of Teff across various cropping seasons.

Table 2.

Cultivated Area, Production and Yield of Teff crops for 2017/18 to 2021/22 cropping season (CSA reports, (2018–2022)) [[3], [4], [5]].

| Production year | Area Covered |

Production |

Yield [Qt/Ha] | ||

|---|---|---|---|---|---|

| [Hectares] | Distribution [%] | [Quintal] | Distribution [%] | ||

| 2017/18 | 3,023,283.50 | 23.85 | 52,834,011.56 | 17.26 | 17.48 |

| 2018/19 | 3,076,595.02 | 24.17 | 54,034,790.51 | 17.12 | 17.56 |

| 2019/20 | 3,101,177.38 | 24.11 | 57,357,101.87 | 17.11 | 18.50 |

| 2020/21 | 2,928,206.26 | 22.56 | 55,099,615.14 | 16.12 | 18.82 |

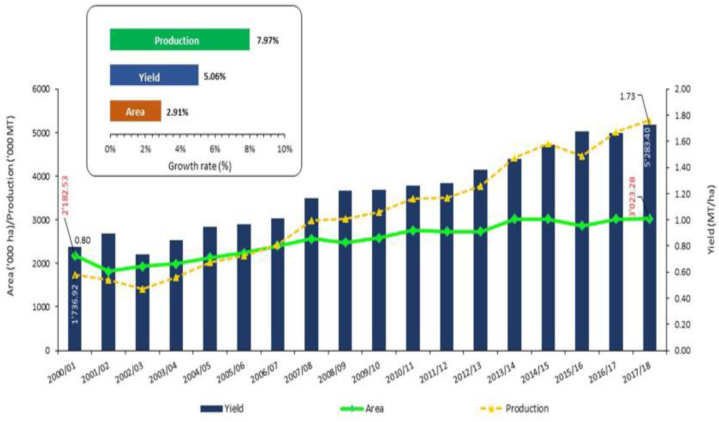

Even though there has been an increase in production for several consecutive years [6,7], Teff farming in Ethiopia remains below its potential. The study by Solomon Chanyalew et al. [6] computed the growth of production, yield, and cultivation area by using the statistical reports of the Ethiopian Central Statistical Agency for the years 2000/01–2017/18 (Fig. 1). According to this study, the production of Teff increased from 1.74 to 5.28 million metric tons in the specified period due to enhancement in productivity and expansion in the cultivation area. This is equivalent to the average production growth of 7.97 % per annum. Moreover, Teff's yield has been increased by 5.06 % per annum during the same period to reach the yield level of 1.73 metric tons/ha in 2017/18. On the other hand, the rate of its area expansion was estimated at 2.91 % per annum [6].

Fig. 1.

Trend of Teff cultivation and production in Ethiopia [6]; Computed from statistical reports of the Central Statistical Agency (CSA) of Ethiopia for the years 2000/01–2017/18.

In another study conducted by Roselle Barretto et al. [11], the production, yield, and cultivation area of Teff were compared with other known cereals cultivated in the area for Meher Season 2018/19 in Ethiopia. The study presented that Teff had the lowest yield (17.56 Qt/ha) among the known cereal grains (barley, wheat, maize, sorghum, finger millet, oats, and rice), despite covering the largest cultivation area. The reduced productivity of Teff can be attributed to various factors including inadequate agronomic practices, poor seedling establishment, limitations in nutrient and water availability, and lodging. The utilization of appropriate spacing, maintenance of optimal plant population, and the application of nutrients are critical for obtaining better yields.

Teff has broad agroecological adaptation under varied climatic and socio-economic conditions [12]. It grows under different moisture, temperature, altitude, and soil regimes. Its fitness for various cropping systems and crop rotation schemes is the other feature of the Teff crop [6]. Teff has little vulnerability to epidemics of pests and diseases and has excellent storage properties, as a result, it plays an important role in the food security of Ethiopia in combating global climate change [6,13]. Teff provides promising alternatives for new food uses as it has notably superior nutritional value compared to most other cereal grains [11]. In recent years, it has also become popular in the health-food markets of developed countries due to its gluten-free nature [[13], [14], [15]]. The absence of gluten allows flexibility in food utilization since it can be directly substituted for gluten-containing products [11].

Though Teff farming is mainly attributed to the socio-economic, cultural, and agronomic benefits [10,13,14,16], it has a series of highly labor-intensive operations such as land preparation, seeding, weeding, harvesting, and threshing. These drudgery operations with limited availability of suitable mechanized technology result in no large-scale Teff farms in the country [1,5,17].

In Ethiopia, Teff is primarily consumed in the form of Injera which constitutes the major component of the favorite staple national dish of most Ethiopians. Urban households, as well as those led by older, educated individuals, tend to consume a greater quantity of Teff compared to other demographics. The recent findings that Teff is gluten-free have sparked research interest in the world by nutritionists and food scientists [18]. As a result, research on the nutritional value of Teff and its processing characteristics has increased, and the creation of new Teff-based products has accelerated through time.

Teff is superior to other grains in terms of nutritional values and composition [19]. It has comparable to or better fiber and nutrient content than that of the major world cereals (Table 3) [6,18,20]. High levels of dietary fiber, calcium, iron, magnesium, and phosphorus are present in Teff [21]. The mineral content of Teff varies according to the variety: red Teff contains more iron and calcium than mixed or white Teff, while white Teff contains more copper than any of the other varieties [14]. Moreover, Teff has a balanced amino acid composition and is a good source of unsaturated fatty acids [19,20]. Because of these properties, teff serves as a functional grain for creating healthy and appropriate food products [19]. It accounts for approximately 15 % of all calories consumed and provides 66 % of daily protein intake in Ethiopia [21]. Its widespread usage is attributed to its resilience against disease epidemics and its ability to be stored for extended periods without being susceptible to weevil infestations [22].

Table 3.

| Cereals | Teff | Barley | Maize | Wheat | Sorghum |

|---|---|---|---|---|---|

| Energy (cal.) | 362.1 | 355.9 | 368.2 | 351.9 | 359.6 |

| Moisture (%) | 10.0 | 11.3 | 12.4 | 11.8 | 12.1 |

| Protein (%) | 11.0 | 9.3 | 8.3 | 11.2 | 7.1 |

| Fat (%) | 2.7 | 1.9 | 4.6 | 1.9 | 2.8 |

| Carbohydrate (%) | 71.0 | 72.4 | 71.2 | 70.6 | 74.1 |

| Fiber (%) | 3.0 | 3.1 | 2.2 | 3.0 | 2.3 |

| Ash (%) | 2.3 | 2.0 | 1.3 | 1.5 | 1.6 |

| Ca (mg/100g) | 165.2 | 47.0 | 6.0 | 49.0 | 30.0 |

| P (mg/100g) | 366.0 | 325.0 | 276.0 | 276.0 | 282.0 |

| Fe (mg/100g) | 18.9 | 10.2 | 4.2 | 7.5 | 7.8 |

Teff is gluten-free cereal and can readily be tolerated by patients with celiac disease. Its high iron content is important in preventing pregnancy-related anemia in people consuming Teff as a staple food [11,19,20,23]. Additionally, recent research has shown that Teff has the potential to be used as a raw material in the production of gluten-free foods and malting for beverage manufacturing, alongside its traditional use in injera [24]. These applications encompass a wide range of food items such as pasta, bread, sourdough, cookies, extrudate, fat replacer, weaning food, malt, and lactic acid beverages. Particularly, these Teff-based food products often exhibit desirable nutritional qualities, including being gluten-free, enhanced dietary fiber contents, and having a lower glycemic index [19].

While the global use of Teff for human consumption has been limited, partly due to insufficient knowledge about its nutritional benefits and the challenges faced in processing Teff-based food items, the revelation that Teff does not contain gluten has raised global interest [19]. Teff serves as an excellent alternative for individuals with celiac disease or those opting for gluten-free diets. The increasing awareness of celiac disease and gluten intolerance has led to a growing demand for gluten-free products in many parts of the developed nations. Celiac disease is an autoimmune disorder triggered by the consumption of gluten, a protein found in wheat and related grains like barley and rye. Consequently, teff has gained traction as a nutritious and versatile gluten-free option, finding its way into various recipes and food products [12].

Though it is an important crop to the economy and food security of the country, knowledge of efficient farming, harvesting, and processing practices of teff still lags behind other cereal crops in Ethiopia [8]. The research and innovation system to afford the increasing demand of Teff in the country is affected by limited infrastructure, interactions and partnerships among actors, the capacity of actors, technology and market development, resource mobilization, and entrepreneurial participation [25]. Even the limited research on Teff crops has focused more on breeding and Genetic diversity in Teff [[26], [27], [28], [29], [30]], the influence of environmental factors on teff production [[31], [32], [33]], the nutritional composition of Teff [12,13,20,[34], [35], [36]], potential benefits of Teff [10,19,[37], [38], [39]], Productivity of Teff [8,[40], [41], [42]], food items from Teff grain [24,[43], [44], [45], [46], [47], [48]].

Furthermore, the application of modern harvesting and postharvest technologies in Teff production and handling is critically low. Therefore, reviewing this article on the subject is warranted to raise awareness among researchers and relevant stakeholders about the seriousness of postharvest losses in Teff grain.

The main aim of this study is to review the available knowledge concerning postharvest losses of Teff, assess the extent of postharvest loss in Teff, and analyze methodologies for loss assessment. Additionally, the study aims to provide recommendations for reducing postharvest losses and to outline future research directions for improving postharvest management practices of Teff.

A comprehensive review was conducted on published and unpublished empirical literature concerning theories and application of the findings to Teff production, supply chain, demand, food items, postharvest studies of Teff, and its loss reduction methods in the post-production system. The technologies and production status of the Teff farming system, harvest and postharvest operations of Teff crop in the supply chain, the level of postharvest losses of Teff at different stages, the causes, and the potential solutions of these losses have been discussed.

The literature searches mainly emphasized the postharvest management and utilization of Teff production issues focused on Ethiopia. Google was used to access information from various published documents, including journal articles, books, reports, periodicals, and proceedings. Main search keywords and basic terms such as “Teff,” “Teff production in Ethiopia,” “Teff supply chain in Ethiopia,” “nutritional value of Teff,” “postharvest management of Teff,” “postharvest loss of Teff,” etc. were employed. About 65 academic journals, books, proceedings, and thesis works, along with international agencies and national statistical reports related to the topic, were reviewed. The quantitative data from the literature was taken to assess the level of postharvest losses of Teff grain within the country.

2. Postharvest handling and supply chain of teff

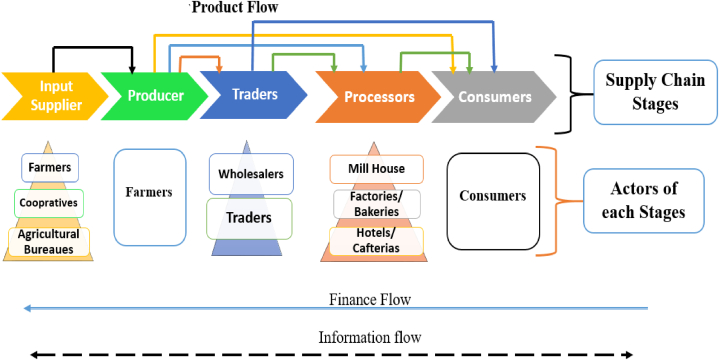

2.1. Flow of teff products in the supply chain

The simplified flow chart indicating the supply chain of Teff, information, and finance in this supply chain can be represented by the chart in Fig. 2. The chart shows how Teff distributes from producers to consumers and how the inputs reach from the supplier to the producers. The supply chain also indicates the role of the players at each stage. The flow of materials, finance, and information throughout the supply chain is pointed out.

Fig. 2.

Simplified flow chart of Teff in the supply chains [6].

2.2. Postharvest operations of teff crop

The main stages within the agricultural supply chain during which losses occur in Teff crops include harvesting, threshing, winnowing, transport (farm to market), storage (at farm and market level), and processing. Some basic activities in the Teff supply chain are discussed here.

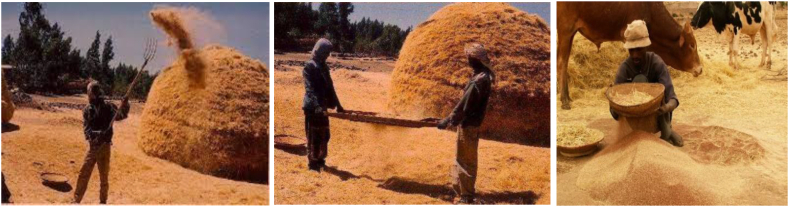

2.2.1. Harvesting

In Ethiopia, Teff production is dominated by smallholder farmers who use traditional technologies to produce the crop. Harvesting is the act of cutting off matured Teff at the bottom part of its straw and collecting it. In Ethiopia, it is carried out traditionally by grasping the Teff plants in one hand and mowing them with sickles near the base after the crops are matured and dried in the field (Fig. 3) [49,50]. Both genders of the family are responsible for harvesting. The average growing period of Teff is about 17 weeks. In Ethiopia, the harvesting season usually extends from early October to the end of January, varying according to factors such as regional distinctions, rainfall patterns, altitude, and other local features [50]. The time of harvesting is determined by the degree of maturity of the Teff crop when the grain reaches physiological maturity. The maturity of straw and seeds affects the output from the successive operations, particularly threshing, winnowing, storage, and processing.

Fig. 3.

Harvesting operation of Teff farm [51].

Harvesting too early or too late has its own consequences. Late harvesting results in extended pre-harvest field drying, which may ensure good preservation, but increases the risk of loss due to shattering before harvest, incomplete harvesting of straws, unseasonal rain, and attack by animals (birds). On the other hand, harvesting before the maturity stage has the risk of low-quality Teff grain and loss through mold development leading to the decay of the product.

Farmers determine the right time of harvesting based on their practical experience that is based on the crop calendar, color change of leaves (straws), texture of the seed, etc. Teff is harvested when its vegetative parts turn yellowish color [49].

2.2.2. Stacking/piling

After harvesting, the Teff crop is left on the farm field for three to five days for drying purposes. Then, it is transported to near the threshing area where a large stack or pile, called Kimir, is formed for further drying by protecting it from animals and unconditional rain (Fig. 4). The crop remains in the stack until it is completely dry and the farmer is ready to thresh. The grain and the straw may further dry in the staking period [49]. Teff typically undergoes a drying period lasting approximately 40 days between the time of harvesting and threshing [50].

Fig. 4.

Pile/Stack (Kimir) of Teff around the threshing ground; [Photograph: Sunshine Seeds and Julio Etchart/Alamy Stock photo].

2.2.3. Threshing

In Ethiopia, Teff threshing is done either traditionally in the case of small-scale farmers or by using mechanized threshing machines when the farm size is large (mechanized threshing is very rare). The traditional Teff threshing process is tedious, laborious, time-consuming, produces high losses, and frequently prevents children from attending school while threshing. Animal trampling is the most typical traditional threshing practice [49,50]. The threshing ground called ‘Awdemma’ is prepared first by carefully leveling, smoothing, and smearing the ground with fresh cattle dung to minimize soil contamination of Teff grains (Fig. 5 a). In preparation for animal trampling threshing (Fig. 5 b), dried Teff crops are placed across the Awdemma. To retain Teff grains on the threshing floor/Awdemma, the farmers constantly push Teff straws towards the center of the threshing ground. In the traditional threshing practice, Teff grain is mixed with dirt, stones, and animal feces, making it unclean and unhealthy, and much grain is left on the stalk [52].

Fig. 5.

Threshing activity: a) preparation of threshing ground (Awdemma); b) Animal trampling [53].

Whenever there is animal excrement during threshing, there is always an effort to collect it by hand using the straw before falling to the crop and dumping it outside the threshing floor. Traditional threshing results in significant physical quality losses of seeds, scattering of grains from the threshing floor, and contamination with animal excrement. There are some new technologies in this area that some farmers have started using, including multi-crop threshers and seed cleaners [50].

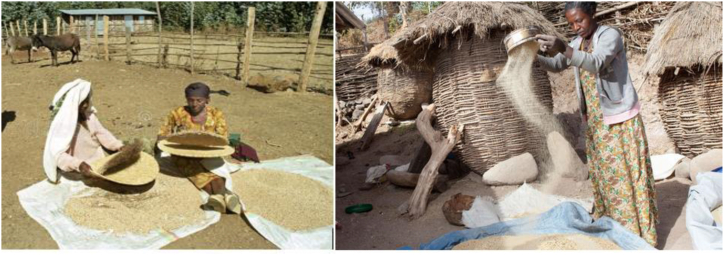

2.2.4. Cleaning/winnowing

Cleaning/winnowing is the separation of the Teff seed grain from dirt and chaff/straw by throwing/tossing the chaff-seed mixture in the air with a wooden fork (Fig. 6). Another method is to raise a container filled with grain and chaff above the farmer's head and let it fall smoothly, allowing the wind to blow through and separate the seeds from the chaff. The wind blows the straw and lighter weed seeds to one side while the whole sound grain falls directly to the winnowing floor. Further cleaning process may continue by fanning and sieving to remove any leftover chaff and debris. After cleaning, farmers prepare their finished products for transportation and storage by packing the grain in different bags, or polypropylene bags. The Cleaning/winnowing activities of Teff are presented in Fig. 6.

Fig. 6.

Cleaning/winnowing activities [49].

2.2.5. Storage

Once the teff has been threshed, farmers either sell the teff grains or consume them themselves. They also use the straw for animal feed or construction purposes [50]. Threshed and cleaned Teff grain is transported and stored in the house or outside of the house [54]. Teff grain is stored for a certain time to reserve seed for the next cropping season, consumption, and market. Teff can be stored or conserved for many years (three to five years after threshing without large losses), practically using any kind of storage system without any appreciable change or damage, if vermin and water are away from the storage system.

Teff is stored on several levels, including by farmers, traders, and retailers. Farmers commonly employ storage facilities of various sizes and configurations within their homes. The amount of production, the type of crop, the local climate, and the farmers' capacity and readiness to pay influence the exact type of storage choice at any stage. Teff grains can be stored in different traditional storage structures. Synthetic sacks (polyethylene bags) (Fig. 7 (b)), traditional Gotera/Gota (Fig. 7 (a)), and Gumbi/Togogo (Fig. 7 (c)) are the common Teff grain storage facilities of most farmers inside their residences [54,55].

Fig. 7.

Teff storages: a) Gotara, b) plastic sacks, c) Gumbi/Togogo [55].

Survey findings indicated that Teff stored in these traditional facilities is vulnerable to damage from rats, floods, moisture, and fire. Instead of employing conventional storage, small-scale metallic silos may be able to mitigate these losses. Yet, most Ethiopian farmers' incomes are so low that they can hardly afford them [55].

2.2.6. Transport

Transport operations may occur between the farm fields to the threshing floor before threshing and from the threshing ground to farmer storage and subsequently to the market. There are different ways to transport harvested Teff seed from the field to its destination. Most farmers predominantly utilize donkeys for transporting their produce to the market (Fig. 8 (a)). Additionally, mule carriages (Fig. 8 (b)) and tracks (Fig. 8 (c)) are employed for transportation in certain areas where infrastructure is available. The seed is transported to the storage or market locations in a variety of packaging materials, including sacks, plastic bags, or locally made containers (skin bags) [54].

Fig. 8.

Transportation to the market; a) by Donkey, b) by Mule carriage, c) by Tracks [49].

2.2.7. Marketing and processing

There are noticeable losses that can occur during marketing, both at wholesale and retail levels. This is the final and decisive element in the postharvest system, and loss can occur during packaging, transporting, marketing, and market-level storage (Fig. 9). Processing losses can be the result of a manual mechanical process such as milling.

Fig. 9.

Teff handling at the market [Photo taken by the author in Bahir Dar Market, Ethiopia].

2.3. Postharvest losses of teff through the chain

Teff is a very tiny cereal grain that is produced in a very drudgery system, but low in yield. Due to its small seed size, loss is a serious problem of the Teff farming system, and knowing the exact loss amount is still difficult. Therefore, there is a clear call for the stakeholders and research institutes to continue their efforts to increase the yield on the one hand and reduce postharvest losses on the other hand to assure the food security of the people [6]. Postharvest activities such as harvesting, stacking, threshing, transportation, and storage all pose risks of both quantitative and qualitative losses. Research indicated that farmers are likely to lose their product if they do not harvest Teff at the right maturity stage. Moreover, a huge amount of Teff is lost during threshing, both in quantitative and qualitative terms [54].

2.3.1. Methods of measuring/estimating losses

Till now, there is no universally agreed method for loss assessments that is fit to measure losses for all types of food commodities in all situations [55]. The measurement and estimation of postharvest losses pose significant practical, methodological, and conceptual difficulties for farmers [56]. However, two major approaches to measure/estimate losses can be mentioned [57].

-

a)

actual measurement of quantity (weight or volume) or quality (negatively altered conditions of the products) losses in the supply chains and

-

b)

use of a questionnaire to indicate subjective estimated losses by the actors in the supply chains.

The methods used to measure or estimate postharvest losses vary depending on the postharvest systems, operational costs, ease of application, and social context in which they are effective [58].

The complex interactions between the factors causing losses may be difficult to understand, and the actors in the supply chain may mistakenly attribute a loss caused by one factor to another. Although farmers and other actors in the chain may easily feel the overall loss, it may be challenging to determine when and where this loss originates. In some cases, it may also be challenging to break down losses according to the various factors that contributed to the loss.

Questionnaires were used in several research studies in Ethiopia [54,55], to estimate the level of postharvest losses of Teff from the supply chain participants. It was assessed by asking the actors at each level of the supply chain how much was lost during each operation. On the other hand, other researchers used the counting and weighing of grains technique to conduct their studies at storage [57].

2.3.2. Level of postharvest losses of teff

Postharvest product losses might be either quantitative or qualitative. Quantitative losses are the total products left in the field and lost during any post-harvest activities whereas, qualitative losses are the overall quality deterioration of harvested products throughout any postharvest activities.

Teff losses were estimated by Annette R. Crymes to be between 25 and 30 % during and after harvest, and the lodging effect of the Teff stem may be responsible for up to 30 % of the yield loss. This high level of production-stage losses could reduce the market supply by up to 50 % [21]. Another research work by Tadesse K. Amentae also assessed Teff supply chain management and losses in the Bacho and Dawo Districts of central Ethiopia. The study estimated the amount of Teff losses at each stage of the supply chain and presented in Table 4 [55].

Table 4.

Estimated postharvest loss of Teff in Bacho and Dawo Districts of central Ethiopia [55].

| Stages of the value chain | Operation | Loss at each operation (%) | Loss at stages of the chain (%) |

|---|---|---|---|

| Farm level losses | Harvesting | 1.87 | 8.18 |

| Threshing | 2.91 | ||

| Storage | 0.50 | ||

| Transportation from farm | 2.62 | ||

| Transportation to market | 0.28 | ||

| Wholesale level losses | Storage | 0.89 | 1.67 |

| Transportation | 0.46 | ||

| Cleaning and handling | 0.32 | ||

| Retailer level losses | Storage | 0.19 | 2.85 |

| Transportation | 0.91 | ||

| Cleaning and handling | 1.75 | ||

| Consumers level losses | Cleaning | 1.27 | 3.58 |

| Transport | 0.94 | ||

| Milling | 1.08 | ||

| Processing | 0.29 |

During the harvesting stage, the main causes of losses are the shattering of Teff grain and harsh weather conditions like unseasonal rain. On the other hand, the threshing loss is mainly caused by the field on which Teff threshing activity was performed (sticking with the threshing ground, mixing with the soil and animal droppings that deteriorate quality) and during cleaning/winnowing [55].

FAO reviewed the causes and solutions of postharvest losses throughout the Teff value chain in Ethiopia [54]. The levels of losses across different activities in the Teff supply chain were presented and threshing showed the highest loss by proportion in the supply chain, as presented in Table 5.

Table 5.

Preliminary screening of losses in the Teff supply chain in Ethiopia [54].

| The Supply Chain Stages | Activities in the supply chain stage | Quantitative loss at each activity (%) | Quantitative loss at each stage (%) |

|---|---|---|---|

| Production (Farm level) | Harvesting | 5.6 | 25 |

| Piling/Field storage | 6.3 | ||

| Threshing | 7.7 | ||

| Storage at the farmer's level | 3.2 | ||

| Farmers' transportation | 2.2 | ||

| Market | Wholesalers | 8.5 | 15.9 |

| Retailers | 7.4 |

Similarly, various experts have identified the critical loss points in the Teff supply chain. Table 6 presents the critical loss points (CLP) and low loss points (LLP) among the production activities of the supply chain. Most studies showed that the most important critical loss points of Teff are harvesting and threshing [54].

Table 6.

Preliminary screening of food losses in the selected Teff supply chains [54].

| Production Activities in the Supply Chain | Expected loss points | Remark |

|---|---|---|

| Harvesting | CLP | Shattering, weather conditions |

| Piling/Stacking | CLP | Damage by termites and animals, Rain (moisture) |

| Threshing | CLP | Scattering, Contamination with soil and animal wastes, consumption by trampling animals |

| Transport | LLP | Leakage, Loading, and unloading |

| Store | LLP | Rodents |

| Cleaning and handling by retailers and processors | LLP | Spillage |

FAO conducted a field study on Teff in Workima kebele in Machakel woreda, Amhara Region [54]. Their main data sources were the randomly chosen smallholder farmers from the research area, cooperative associations (unions), and traders. Moreover, data from numerous reports and documents was incorporated. The results of the study indicated that threshing, then wholesaling, experienced the largest average Teff losses. Without considering the quality losses, the projected average cumulative postharvest loss of Teff was roughly estimated as 24.9 %.

In the other study, Hengsdijk and de Boer performed a survey throughout all rural areas of Ethiopia and found that farmers' estimated average losses for all grains (maize, sorghum, wheat, barley, Teff) were around 24 %. The reported average postharvest loss of Teff was about 21 %, which was relatively low as compared to other cereal grains [59].

As to the information obtained from the peasants, pre-and post-harvest losses go for more than 40 % of yield loss in Teff [52]. Many farmers reported that the main challenge faced is due to the small size of Teff seeds, leading to mechanical mixing and contamination throughout various stages of operations and consecutive operations as well as storage. The seeds are easily dropped and missed due to their minute size [50,55]. That is why Oromo's people in Ethiopia are saying “Hamma ani badu otoo beekanii na facaasanii” jette taafiinii. Meaning “Had they known how much of me is lost, they would not have seen me again” said Teff [52,55].

There is considerable variability between the reported postharvest data of Teff from different sources, this could be due to the method of data collection, the inherent biological variability, the difference in pre-harvest factors (growing and harvesting conditions, maturity stage, variety …), and the difference in postharvest management practice. This shows that to get relatively accurate postharvest loss data of Teff, there is a need for a well-designed postharvest assessment procedure that considers the biological variability and the important factors from the pre-harvest and postharvest stages.

2.4. Causes of postharvest losses of teff

Postharvest losses of Teff occur during and after the harvesting stages of the crop; including harvesting, stacking/piling, threshing, storing, transporting, marketing, and processing activities. Since most postharvest procedures in Ethiopia are still carried out traditionally by hand, they are time-consuming and labor-intensive. Moreover, these traditional practices often lead to the unintentional mixing of grain with straw and soil components, resulting in decreased quality and quantity of the final product. Significant Teff losses also occur due to shattering, both during and after harvesting operations [54,55,58]. However, there is limited information available on losses at different stages of the postharvest systems in the country. According to a study report by Kumar, approximately one-third of the food produced globally is lost every year during postharvest operations [60].

Understanding the sources of postharvest losses could help the actors in the supply chain to develop and implement measures to reduce losses at each stage. Therefore, evaluating the factors contributing to postharvest losses and proposing potential preventive measures in each supply chain activity is essential.

2.4.1. Causes of postharvest losses of teff at production level

The physical loss of Teff grain during production level (before threshing) occurs at the following points.

-

a)

During cutting of the straws due to grain shattering and incomplete harvesting

-

b)

During open sun drying of Teff straws on the farm field

-

c)

During transportation of the straws to a suitable stacking or piling point

-

d)

During storage of the harvested crops or staking of it until threshing.

Teff can withstand extreme environmental conditions, but it is susceptible to lodging, which can significantly lower production and grain quality and increase harvesting loss by complicating the harvesting activity [14,61]. Wind, rain, geographical location, landscaping, soil type, crop history, agricultural system, and disease are factors that have an impact on the complicated phenomenon of lodging [14,61].

Losses during harvesting are typically caused by the shattering of the seeds when the grain is extremely dry. Late harvesting and poor handling lead to shattering loss in Teff production. On the other hand, harvesting grass weeds with Teff straw may result in a lower-quality product [49].

The harvested crop is stacked around the threshing field and remains until the farmer is ready to thresh. At this stage, animal, insect (termites), rodent, and bird attacks are common causes of losses. Unseasonal rain could cause a considerable amount of loss while the harvested Teff crop was left on the farm field for open sun drying for some days. Weather conditions (moisture) will also cause significant losses to Teff which has been piled for a long time.

Most farmers use animal trampling to thresh their Teff crops, which causes larger quantity losses since the animals eat the Teff sheaves, chaff, and grain while they work. Qualitative losses due to grain contamination with soil, animal droppings, and urine are equally as important as quantitative losses.

Losses also occur due to incomplete threshing (grain remains on the straw) and spillage out and scattering of seeds from the threshing floor during the process. Beyond this, grain loss usually happens when it is spread outside of the threshing ground and loss also happens due to the blowing of grains away with chaff by wind during the winnowing process as the individual grain kernels are light.

2.4.2. Causes of losses during transportation and storage level

Depending on the availability and quantity of grain, farmers use animals or hire trucks to transport it to the storage or market. Losses in transportation occur mainly during loading and unloading operations. Losses could also happen from grain leakage if the sacks are damaged.

Storage of Teff grain is done at several levels, i.e., by farmers, traders, retailers, processors, or end users [58]. Although Teff isn't specifically mentioned, the primary challenge for most cereals is the significant loss during storage, due to both living organisms (biotic factors) like borers, weevils, birds, and mice, as well as non-living factors (abiotic factors) such as temperature and humidity [62].

Traditionally, farmers have constructed storage facilities using materials found locally to preserve their grains for future use. However, these traditional storage methods often fail to adequately shield the grain from pests and prolong its shelf life [62]. Teff stored in traditional storage facilities is subjected to damages caused by rats, floods, moisture, and fire. There is low adoption of improved storage technologies by Ethiopian Teff farmers. According to Hengsdijk and de Boer, adoption of better storage methods was low, and most cereals were kept in bags within homes, followed by traditional storage (Gotera) [59].

2.4.3. Causes of losses during marketing and processing stage

Grain losses happen when it is handled in the market by traders, retailers, wholesalers, cooperatives, and unions, during loading and unloading, transporting, and storage of the grain. Teff losses may be experienced when bags are broken during loading, unloading, and storage, which can result in pest infestation and spoilage from excessive moisture. Rodents pose a serious risk to the market due to storage losses.

Process losses occur during cleaning (when removing impurities from Teff grain) and preparing it for milling (Fig. 10). Due to improper grain handling, Teff seed is lost at the point of milling during the weighing and pouring of the grain into the milling machine.

Fig. 10.

Further cleaning of Teff [Photograph: Jake Lyell/Alamy Stock Photo].

T. k. Amentae and his friends connected Teff's losses to other parameters, such as family size, gender of the family head, and the amount of Teff and the marketing system. According to the study, female-headed households were more vulnerable to losses due to labor-intensive activities. However, this was not the case for families with larger sizes that can reduce the loss with more labor availability. Farmers with higher production levels faced challenges to handle it properly and suffered greater losses. With an increase in distance between the market and the household, more loss was expected from spillage and poor handling [55].

Limitations of mechanization and inadequate tools and equipment could be considered as the main cause of the significant losses of Teff. Poor infrastructure facilities such as unfavorable road conditions and traditional means of transportation could also contribute to their share of the postharvest loss of Teff grain [55,63].

2.5. Postharvest losses reduction methods

Research centers and institutions are commonly focused on increasing the production and productivity of agricultural goods to afford the increasing demands [10,64], but they forget the post-harvest loss characteristics and reduction mechanisms. Therefore, raising awareness about the benefits of postharvest improvements at all levels is crucial, as boosting production without proper post-harvest management wastes resources. Some scholars [17,55,56], advocate for fostering trust among value chain participants, implementing robust extension interventions to enhance the value of Teff, and providing farmers with training to enhance the value of their products in the supply chain through various systems.

2.5.1. Loss reduction in the production stage

Timing of the harvest plays a crucial role in controlling losses, as delayed harvesting can lead to grain shattering, significantly impacting Teff production. On-time harvesting is the most common loss-preventing method during the harvesting phase. To maintain the product quality, farmers typically try to avoid harvesting grass and weeds combined with Teff.

According to Alemayehu. Refera, minimizing Teff threshing losses involves several practices: preparing a well-prepared threshing ground/Awdemma that is smooth, wide, and adequately smeared; using muzzles for trampling animals to prevent them from consuming the crop; collecting animal droppings before they fall onto the threshing ground and contaminate the seeds; ensuring thorough separation of grains from straw; and conducting threshing promptly [49].

Some innovative farmers used canvas or plastic sheeting on their threshing and winnowing floors to minimize the risks of seed contamination with dirt and the spreading of Teff grains beyond the threshing area (Fig. 11). Mechanized threshing methods can also overcome a large number of Teff threshing losses. Threshers equipped with Teff cleaners significantly reduce these losses.

Fig. 11.

Mechanized threshing machines of Teff in operation [52].

In Bako Agricultural Engineering Research Center, Merga Workesa Dula developed a complete teff threshing machine to overcome teff threshing and cleaning challenges, thereby decreasing tremendous teff grain post-harvest loss because of the traditional method of threshing and cleaning of the crop. The experimental results of the machine showed that the total Teff grain loss in threshing and cleaning operations is minimal as compared with that of traditional practices [52].

Unlike many other cereals, Teff has not yet experienced widespread adoption of mechanized farming methods [52,64]. Consequently, the absence of mechanization exacerbates losses due to shattering, scattering, animal feeding, and grain contamination with dirt—challenges less common for cereals cultivated using mechanized farming practices. This highlights the urgent need to introduce and implement mechanized approaches tailored specifically to Teff cultivation, addressing its unique vulnerabilities and enhancing overall productivity and food security.

Considering the challenges associated with Teff harvesting and threshing for smallholder farmers, relying on traditional methods cannot be sustainable. It is imperative for motivated smallholder farmers to explore and develop modern harvesting and threshing practices using appropriate implements for Teff cultivation in Ethiopia [64]. This proactive approach can help improve efficiency, reduce post-harvest losses, and enhance the overall productivity and sustainability of Teff farming operations.

Yared Deribe and Bisrat Getnet conducted a study on the factors and gaps in delivering mechanization inputs by conducting qualitative surveys of supply chain actors. Their findings indicated that maintaining healthy business competition between imports and the manufacturing sector was a notable policy gap. Additionally, they observed significant variability in mechanization hiring costs, service transactions, and coordination across different crop production areas with potential. These findings highlight key areas for intervention in both the supply and demand systems of mechanization [65].

2.5.2. Loss reduction during transportation and storage

To minimize losses during transportation, using clean sacks with securely tied or sewn openings is recommended to prevent grain leakage. Proper handling of Teff grain during loading and unloading operations is also crucial in reducing losses during transportation. Additionally, employing improved and appropriate storage technologies such as metal silos (Fig. 12 (a)), hermetic bags or super bags (Fig. 12, (b)) can significantly decrease losses during storage, mitigating both biotic and abiotic factors [55,62]. Traditionally constructed storage facilities made from locally available materials by farmers often fail to adequately protect grains from infestation and extend the shelf life of the grain [62].

Fig. 12.

Proper storage materials of Teff grain: a) Metallic silo, b) hermetic/super bags [49].

Research by Suleyman MiftaAwol et al. emphasizes the significance of using appropriate packaging materials to maintain the quality of stored Teff flour. Their findings have practical implications for value chain actors and consumers involved in processing and storing Teff flour. Hermetic packaging materials play a crucial role in reducing nutrient loss and preserving the physicochemical and functional properties of the flour during storage, thereby ensuring its quality [66]. Wholesalers and union cooperatives should adopt improved storage structures equipped with concrete floors and appropriate ventilation systems to minimize storage losses in the market.

In general, previous studies on Teff production in Ethiopia have indicated that the low adoption of advanced production technologies can be attributed to several factors. These include the unavailability and high costs associated with improved technologies and required inputs, limited access to credit coupled with high-interest rates, and policies that discourage the adoption of modern techniques [64].

However, compared to scaling up crop production to address food needs, reducing post-harvest losses requires relatively lower investment and can yield significant returns [60]. A comprehensive strategy for minimizing post-harvest cereal losses entails training in short and long-term postharvest management practices, promoting the adoption of postharvest technologies, strengthening institutional support systems such as agricultural extension and rural credit services, providing support for post-harvest handling technologies, reinforcing farmer cooperative marketing efforts, and improving local marketplaces and rural road networks. This endeavor should involve collaboration between the government and non-governmental organizations [54]. Nowadays the government is initiating the grouping of smallholder farmers to assist them in getting mechanized farm equipment and technologies through credit by collaborating with suppliers and non-governmental organizations.

This review highlights a notable gap in concrete knowledge regarding accurate postharvest loss data and alternative technologies aimed at reducing both qualitative and quantitative postharvest losses of Teff. This underscores the necessity for cutting-edge research to generate knowledge that can effectively mitigate postharvest losses of this nutritious and economically valuable crop.

3. Conclusion

This study aimed to assess postharvest losses, identify their causes, and propose potential solutions to mitigate losses in Teff production. It revealed a deficiency in postharvest management research conducted in Ethiopia, with the majority of studies focusing on cereals other than Teff on postharvest issues. Consequently, there is limited adoption of improved postharvest technologies among Ethiopian Teff farmers. Reported causes of postharvest losses include limited awareness, access to and availability of postharvest technologies, and insufficient attention given to postharvest research, extension, and infrastructure for the Teff crop.

Effective measures to minimize Teff losses during harvest and postharvest stages include timely harvesting, utilization of mechanized thresher machines, deployment of well-designed storage equipment, proper handling of grains throughout the supply chain, and other potential solutions.

The reported range of postharvest losses for Teff crops varies widely among different studies, ranging from 16 % to 30 %. Such variations in loss estimations stem from inherent biological variability, disparities in pre-harvest factors (e.g., growing and harvesting conditions, maturity stage, variety), lack of standardized loss assessment methodologies (data collection methods), and differences in postharvest management practices. Therefore, a well-designed postharvest management and assessment procedure, considering significant factors from both pre-and post-harvest stages, is necessary to obtain relatively accurate data on Teff postharvest losses. Moreover, practicing mechanized teff farming methods, particularly in harvesting and thrashing activities, like other cereals, can potentially mitigate the postharvest losses of Teff due to shattering, scattering, animal feeding, and contamination of the grain with dirt. This approach also improves efficiency and enhances the quality of the harvested Teff grain, ultimately benefiting both farmers and consumers alike.

Finally, it can be recommended that transforming the traditional practice into mechanized farming, modern postharvest technologies, and supporting the system by further research works and training on postharvest management of such valuable crops could potentially minimize the harvest and postharvest losses of Teff in the country.

CRediT authorship contribution statement

Eniyew Eskezia Tiguh: Writing – original draft, Methodology, Conceptualization. Mulugeta Admasu Delele: Writing – review & editing, Supervision. Addisu Negash Ali: Supervision. Geta Kidanemariam: Supervision. Solomon Workineh Fenta: Supervision.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.CSA “The federal democratic republic of Ethiopia central statistical agency agricultural sample survey 2016/17 (2009 E.C.) Report on Area and Production of Major Crops,”. 2017;I(September) http://www.sciepub.com/reference/267721 Available: [Google Scholar]

- 2.Tadele E., Hibistu T. Spatial production distribution, economic viability and value chain features of teff in Ethiopia: systematic review. Cogent Econ. Financ. 2022;10(1) doi: 10.1080/23322039.2021.2020484. [DOI] [Google Scholar]

- 3.CSA . vol. I. 2021. http://www.statsethiopia.gov.et/wp-content/uploads/2021/05/2013-MEHERREPORT.FINAL_.pdf (The Federal Democratic Republic of Ethiopia Central Statistical Agency Agricultural Sample Survey 2020/21 (2013 E.C.): Report on Area and Production of Major Crops). Available: [Google Scholar]

- 4.CSA Agricultural Sample Survey 2021/22 (2014 E.C.). Report on area and production for major crops (private peasant holdings, Meher season) Stat. Bull. 2019;584:121. https://www.statsethiopia.gov.et/wpcontent/uploads/2019/09/Report-on-Area-and-production-of-major-crops-2011-Meherseason.pdf [Online]. Available: [Google Scholar]

- 5.CSA The federal democratic republic of Ethiopia central statistical agency agricultural sample survey 2019/20 (2010 E.C.) volume I report on area and production of major crops. Stat. Bull. 2020;I:121. https://www.statsethiopia.gov.et/wpcontent/uploads/2020/04/Report-on-Area-and-production-of-major-crops-2012-E.CMeher-season.pdf [Online]. Available: [Google Scholar]

- 6.Chanyalew S., Ferede S., Damte T., Fikre T., Kebede W., Tolossa K. August, 2019. Significance and Prospects of an Orphan Crop Tef. [DOI] [PubMed] [Google Scholar]

- 7.CSA The federal democratic republic of Ethiopia centeral statistical agency agricultural sample survey 2017/18 (2010 E.C.): report on area and production for major crops (private peasant holdings, meher season) Stat. Bull. No. 584. 2018;I:57. http://tahimd.org.tw/7rry3bt/csa-ethiopia-2019-crop-productionpdf.html [Online]. Available: [Google Scholar]

- 8.Lee H. 2018. Teff, A Rising Global Crop : Current Status of Teff Production and Value Chain Abstract; pp. 185–193. [DOI] [Google Scholar]

- 9.Hailu M., Tolossa D., Girma A., Kassa B. “Exploration of systemic barriers to tef research and development in Central Ethiopia. A Coupled Structural-Functional Innovation Systems Analysis,”. 2022;37(2):211–222. doi: 10.20961/carakatani.v37i2.55910. [DOI] [Google Scholar]

- 10.Tadele E., Hibistu T. Empirical review on the use dynamics and economics of teff in Ethiopia. Agric. Food Secur. 2021;10(40):1–13. doi: 10.1186/s40066-021-00329-2. [DOI] [Google Scholar]

- 11.Barretto R., Buenavista R.M., Lou Rivera J., Wang S., Prasad P.V.V., Siliveru K. Teff (Eragrostis tef) processing, utilization and future opportunities: a review. Int. J. Food Sci. Technol. 2021;56:3125–3137. doi: 10.1111/ijfs.14872. [DOI] [Google Scholar]

- 12.Sridhara S., N P.G.H., Manoj K.N., Gopakkali P. Nutritional importance of Teff (Eragrostis tef (Zucc.) Trotter) and hu_man health: a critical review. Front. Agric. Food Technol. ISSN 2736-1624. 2021;11(2):1–12. https://www.internationalscholarsjournals.com/articles/nutritional-importance-of-teff-eragrostis-tef-zucc-trotter-and-human-health-a-critical.pdf [Online]. Available: [Google Scholar]

- 13.Zhu F. Chemical composition and food uses of teff (Eragrostis tef) Food Chem. 2018;239:402–415. doi: 10.1016/j.foodchem.2017.06.101. [DOI] [PubMed] [Google Scholar]

- 14.Gebretsadik H., Haile M., Yamoah C. Tillage frequency, soil compaction and N-fertilizer rate effects on yield of teff (eragrostis tef (zucc) trotter) in central zone of tigray, northern Ethiopia. Momona Ethiop. J. Sci. 2009;1(1):82–94. doi: 10.4314/mejs.v1i1.46043. [DOI] [Google Scholar]

- 15.Phanacharoensawad R. The potential for growing tef (Eragrostis tef [Zucc.] Trotter) in Thailand. Asian J. Food Agro-Industry. 2009;2(Special Issue):S125–S131. [Google Scholar]

- 16.Gizaw B. Traditional knowledge on teff (eragrostistef) farming practice and role of crop rotation to enrich plant growth promoting microbes for soil fertility in east showa: Ethiopia. Agric. Res. Technol. Open Access J. 2018;16(5) doi: 10.19080/artoaj.2018.16.556001. [DOI] [Google Scholar]

- 17.Efa Gobena Turaa T.K., Degye Goshu Dr, Demisie Tinsae. Analysis of teff value chain in Bacho and Dawo districts. Am. Res. J. Bus. Manag. 2016;2016(January):1–25. [Google Scholar]

- 18.Mottaleb K.A., Rahut D.B. Household production and consumption patterns of Teff in Ethiopia. Agribusiness. 2018;34(3):668–684. doi: 10.1002/agr.21550. [DOI] [Google Scholar]

- 19.H. O. Y, Arslan M. 2018. Teff: Nutritional Compounds and Effects on Human Health; pp. 15–18. [Google Scholar]

- 20.Baye K. Synopsis : teff : nutrient composition and health benefits. Ethiop. Strateg. Support Progr. 2014;(October):2013–2014. [Google Scholar]

- 21.Crymes A.R. The international footprint of teff: resurgence of an ancient Ethiopian grain. Igarss 2014. 2015;(1):1–5. http://openscholarship.wustl.edu/art_sci_etds%0A [Online]. Available: [Google Scholar]

- 22.Awulachew M.T. “Evaluation of proximate composition and sensory quality acceptability of Ethiopian flat bread (injera) prepared from composite flour. Blend of Maize , Teff and Sorghum,”. 2020;4(2):18–24. doi: 10.11648/j.ijfet.20200402.12. [DOI] [Google Scholar]

- 23.Mohammed S.H., Taye H., Sissay T.A., Larijani B., Esmaillzadeh A. Teff consumption and anemia in pregnant Ethiopian women: acase–control study. Eur. J. Nutr. 2019;58(5):2011–2018. doi: 10.1007/s00394-018-1759-1. [DOI] [PubMed] [Google Scholar]

- 24.Gebremariam M.M., Zarnkow M., Becker T. Teff (Eragrostis tef) as a raw material for malting, brewing and manufacturing of gluten-free foods and beverages : a review. 2014;51(November):2881–2895. doi: 10.1007/s13197-012-0745-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Goshu F.B. Determinants of smallholder farmers' participation decision in teff production: evidence from horo and jimma geneti woreda, Ethiopia. Core.Ac.Uk. 2016;6(10):36–43. www.iiste.org [Online]. Available: [Google Scholar]

- 26.Genet Y., Fikre T., Kebede W., Chanyalew S., Tolosa K., Assefa K. Performance of selected tef genotype for high potential areas of Ethiopia. 2020;5(3):35–42. doi: 10.11648/j.eeb.20200503.11. [DOI] [Google Scholar]

- 27.Assefa K., et al. Genetic diversity in tef [eragrostis tef (zucc.) trotter] Front. Plant Sci. 2015;6(MAR):1–13. doi: 10.3389/fpls.2015.00177. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Asaye D. Screening of teff (eragrostis tef) varieties for genotypic and phenotypic traits in dejen woreda, east gojjam zone. Int. J. Biodivers. Conserv. 2017;9(7):239–245. doi: 10.5897/ijbc2016.1045. [DOI] [Google Scholar]

- 29.Assefa K., Yu J.K., Zeid M., Belay G., Tefera H., Sorrells M.E. Breeding tef [Eragrostis tef (Zucc.) trotter]: conventional and molecular approaches. Plant Breed. 2011;130(1):1–9. doi: 10.1111/j.1439-0523.2010.01782.x. [DOI] [Google Scholar]

- 30.Teklu Y., Tefera H. Genetic improvement in grain yield potential and associated agronomic traits of tef (Eragrostis tef) Euphytica. 2005;141(3):247–254. doi: 10.1007/s10681-005-7094-7. [DOI] [Google Scholar]

- 31.Muanenda S., Yabeker A., Ligani S. Effect of environment on different traits of teff evaluated on debrezeit research institution, oromia, Ethiopia. Int. J. Sci. Res. Publ. 2019;9(2):p8630. doi: 10.29322/ijsrp.9.02.2019.p8630. [DOI] [Google Scholar]

- 32.Abewa A., et al. Teff grain physical and chemical quality responses to soil physicochemical properties and the environment. Agronomy. 2019;9(6):1–19. doi: 10.3390/agronomy9060283. [DOI] [Google Scholar]

- 33.Haileselassie B., Stomph T.J., Hoffland E. Teff (Eragrostis tef) production constraints on Vertisols in Ethiopia: farmers' perceptions and evaluation of low soil zinc as yield-limiting factor. Soil Sci. Plant Nutr. 2011;57(4):587–596. doi: 10.1080/00380768.2011.593482. [DOI] [Google Scholar]

- 34.Inglett G.E., Chen D., Liu S.X. Functional properties of teff and oat composites. Food Nutr. Sci. 2015;6(17):1591–1602. doi: 10.4236/fns.2015.617164. [DOI] [Google Scholar]

- 35.Dame Z.T. Analysis of major and trace elements in teff (Eragrostis tef) J. King Saud Univ. Sci. 2020;32(1):145–148. doi: 10.1016/j.jksus.2018.03.020. [DOI] [Google Scholar]

- 36.Nyachoti S., Adebayo S., Godebo T.R. Elemental composition of teff (a gluten-free grain), maize and wheat: staple crops in the Main Ethiopian Rift Valley. J. Food Compos. Anal. 2021;100 doi: 10.1016/j.jfca.2020.103660. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Alemneh S.T., Emire S.A., Hitzmann B., Zettel V. Comparative study of chemical composition, pasting, thermal and functional properties of teff (eragrostis tef) flours grown in Ethiopia and South Africa. Int. J. Food Prop. 2022;25(1):144–158. doi: 10.1080/10942912.2022.2027441. [DOI] [Google Scholar]

- 38.Irge D.D. Chemical composition and nutritional quality of wheat, teff (Eragrostis tef (Zucc) Trotter), barley (Hordeum vulgare L.) and rice (Oryza sativa)-a review. Food Sci. Qual. Manag. 2017;59(1):6–12. [Google Scholar]

- 39.Fikadu A.A., Wedu T.D., Derseh E.A. Review on economics of teff in Ethiopia. Open Acc Biostat. Bioinforma. 2019;2(3):1–8. doi: 10.31031/OABB.2018.02.000539. [DOI] [Google Scholar]

- 40.Hailu G., Weersink A., Minten B. Determinants of the productivity of teff in Ethiopia. Eur. J. Dev. Res. 2017;29(4):866–892. doi: 10.1057/s41287-016-0065-0. [DOI] [Google Scholar]

- 41.Mihretie F.A., et al. Tillage and sowing options for enhancing productivity and profitability of teff in a sub-tropical highland environment. Field Crops Res. 2021;263 doi: 10.1016/j.fcr.2020.108050. [DOI] [Google Scholar]

- 42.Endalew B., Anteneh A., Tasie K. Technical efficiency of teff production among smallholder farmers: beta regression approach. Eur. J. Dev. Res. 2022;34(2):1076–1096. doi: 10.1057/s41287-021-00417-w. [DOI] [Google Scholar]

- 43.Coleman J., Abaye A.O., Barbeau W., Thomason W. The suitability of teff flour in bread, layer cakes, cookies and biscuits. Int. J. Food Sci. Nutr. 2013;64(7):877–881. doi: 10.3109/09637486.2013.800845. [DOI] [PubMed] [Google Scholar]

- 44.Abera A., Hailay H.G. International journal of sciences : injera preparation from taro (colocasia esculenta) and teff (eragrostis tef) flour. Int. J. Sci. Provid. by GSSRR.ORG Int. Journals Publ. Res. Pap. all Fields Basic Appl. Res. 2016;30(January):196–204. [Google Scholar]

- 45.Callejo M.J., Benavente E., Ezpeleta J.I., Laguna M.J., Carrillo J.M., Rodríguez-Quijano M. Influence of teff variety and wheat flour strength on breadmaking properties of healthier teff-based breads. J. Cereal. Sci. 2016;68:38–45. doi: 10.1016/j.jcs.2015.11.005. [DOI] [Google Scholar]

- 46.Bikila G.M., Tola Y.B., Kuyu C.G. Standardization of teff (Eragrostis teff) injera making process conditions for better physicochemical and sensory quality. Food Sci. Nutr. 2024;(January):1–16. doi: 10.1002/fsn3.4006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Alemneh S.T., Emire S.A., Hitzmann B. Teff-based probiotic functional beverage fermented with lactobacillus rhamnosus and lactobacillus plantarum. Foods. 2021;10(10) doi: 10.3390/foods10102333. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.de Oliveira do Nascimento K., do Nascimento Dias Paes S., Reis de Oliveira I., Pereira Reis I., Maria Augusta I. Teff: suitability for different food applications and as a raw material of gluten-free, a literature review. J. Food Nutr. Res. 2018;6(2):74–81. doi: 10.12691/jfnr-6-2-2. [DOI] [Google Scholar]

- 49.Refera A. INPhO-Post-harvest Compend. FAO; 2001. TEF post-harvest operations. [Google Scholar]

- 50.Assefa K., Chanyalew S. vol. 3. 2018. pp. 39–70. (Agronomics of Teff). B. chapter. [Google Scholar]

- 51.What is Teff. [Online]. Available: https://thelovegrass.com/what-is-teff/.

- 52.Workesa Dula Merga. Development and evaluation of teff threshing machine. Int. J. Eng. Res. 2016;V5(11):420–429. doi: 10.17577/ijertv5is110250. [DOI] [Google Scholar]

- 53.Mohammed A., Tadesse A. Documentation and Policy Project. Addis Ababa; 2018 (2018. Review of major grains postharvest losses in Ethiopia and customization of a loss assessment methodology,” USAID/Ethiopia agriculture knowledge, learning; pp. 1–60. [Google Scholar]

- 54.FAO . 2018. Food Loss Analysis: Causes and Solutions - Case Study on the Teff Value Chain in the FDRE; p. 48.https://www.fao.org/3/I9972EN/i9972en.pdf [Online]. Available: [Google Scholar]

- 55.Amentae T.K., Tura E.G., Gebresenbet G., Ljungberg D. Exploring value chain and post-harvest losses of Teff in Bacho and Dawo districts of central Ethiopia. 2016;7(January):11–28. doi: 10.5897/JSPPR2015.0195. [DOI] [Google Scholar]

- 56.Affognon H., Mutungi C., Sanginga P., Borgemeister C. Unpacking postharvest losses in sub-Saharan Africa: a Meta-Analysis. World Dev. 2015;66:49–68. doi: 10.1016/j.worlddev.2014.08.002. [DOI] [Google Scholar]

- 57.Hodges R.J., Buzby J.C., Bennett B. Postharvest losses and waste in developed and less developed countries: opportunities to improve resource use. J. Agric. Sci. 2011;149(S1):37–45. doi: 10.1017/S0021859610000936. [DOI] [Google Scholar]

- 58.Minten B., Engida E., Tamru S. How big are post-harvest losses in Ethiopia ? Evidence from teff. ESSP Work. Pap. 2016;93(July) [Google Scholar]

- 59.Hengsdijk H. 2017. Post-Harvest Management and Post-harvest Losses of Cereals in Ethiopia; pp. 945–958. [DOI] [Google Scholar]

- 60.Deepak K., Kalita P. “Reducing Postharvest Losses during Storage of Grain,”. 2017;6(1):8. doi: 10.3390/foods6010008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 61.van Delden S.H., Vos J., Ennos A.R., Stomph T.J. Analysing lodging of the panicle bearing cereal teff (Eragrostis tef) New Phytol. 2010;186(3):696–707. doi: 10.1111/j.1469-8137.2010.03224.x. [DOI] [PubMed] [Google Scholar]

- 62.Andersa K.N., Mohammed H.H., Regasa T.K., Abdisa Z.K., Ahmed E.H. “Review on improved grain storage techniques such as grainpro. Purdue Improved Crop Storage (PICS) Bag , and Metal Silo,”. 2023;5:1–4. [Google Scholar]

- 63.Reda A. Achieving food security in Ethiopia by promoting productivity of future world food tef: a review. Adv. Plants Agric. Res. 2014;2(2):86–95. doi: 10.15406/apar.2015.02.00045. [DOI] [Google Scholar]

- 64.Jeyabalasingh P.M., Bayissa D.D. Knowledge on improved practices of teff by smallholder farmers in Ethiopia. J. Ext. Educ. 2018;29(4):5937. doi: 10.26725/jee.2017.4.29.5937-5944. [DOI] [Google Scholar]

- 65.Amare D., Endalew W. Agricultural mechanization: assessment of mechanization impact experiences on the rural population and the implications for Ethiopian smallholders. Eng. Appl. Sci. 2016;1(2):39–48. doi: 10.11648/j.eas.20160102.15. [DOI] [Google Scholar]

- 66.Awol S.M., Kuyu C.G., Bereka T.Y. Physicochemical stability, microbial growth, and sensory quality of teff flour as affected by packaging materials during storage. Lwt. 2023;189(November) doi: 10.1016/j.lwt.2023.115488. [DOI] [Google Scholar]