Abstract

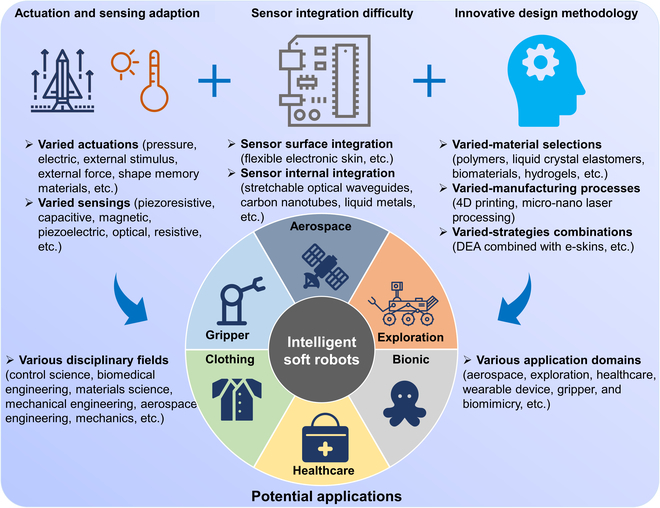

Soft robotics has received substantial attention due to its remarkable deformability, making it well-suited for a wide range of applications in complex environments, such as medicine, rescue operations, and exploration. Within this domain, the interaction of actuation and sensing is of utmost importance for controlling the movements and functions of soft robots. Nonetheless, current research predominantly focuses on isolated actuation and sensing capabilities, often neglecting the critical integration of these 2 domains to achieve intelligent functionality. In this review, we present a comprehensive survey of fundamental actuation strategies and multimodal actuation while also delving into advancements in proprioceptive and haptic sensing and their fusion. We emphasize the importance of integrating actuation and sensing in soft robotics, presenting 3 integration methodologies, namely, sensor surface integration, sensor internal integration, and closed-loop system integration based on sensor feedback. Furthermore, we highlight the challenges in the field and suggest compelling directions for future research. Through this comprehensive synthesis, we aim to stimulate further curiosity among researchers and contribute to the development of genuinely intelligent soft robots.

Introduction

Soft robotics is an emerging field that has garnered widespread interest and research due to its flexibility and adaptability. Soft robots offer a higher degree of mechanical variability and plasticity compared to traditional rigid robots and are capable of mimicking the properties of biological tissues and organisms [1]. This adaptability and flexibility make soft robots highly suitable for various tasks in complex environments, such as medicine, rescue, and exploration [2–4]. Unlike rigid robots, which are constructed from inflexible materials, the bodies of soft robots are made of soft and expandable materials like hydrogels that have a low modulus of elasticity, enabling them to deform and absorb much of the energy generated by collisions [5,6]. The complex structures of soft robots can be fabricated by layer-by-layer stacking materials through 3-dimensional (3D) or 4D printing technology with great manufacturing flexibility [7–9], which also allows the implementation of multiple materials in a single structure [10]. More importantly, soft robots employ a flexible muscle-like actuation technology that provides them with greater degrees of freedom compared to rigid robots [11,12]. This flexibility is further enhanced by stretchable sensing technology, which enables soft robots to sense, acquire information about their environment, and achieve intelligence and autonomy [13]. In recent years, various actuation and sensing strategies have been continuously explored by attempting diverse manufacturing and modeling methods [7,14–16], thereby extending applications of soft robots such as bionics [17–20] and intelligent equipment [21–24].

Actuation technology enables soft robots to accomplish motion and interact with the environment [25], while sensing technology allows them to perceive and acquire information about their surroundings [26]. The interaction between actuation and sensing technologies forms the core functionality of soft robots [27]. Pressure-driven [28], electrically driven [29], and specialized material like shape memory materials (SMMs) driven strategies [30] endow soft robots with the potential for complex movements such as rotation, rolling, crawling, and bending [31]. Simultaneously, sensing strategies based on electrical [32], magnetic [33,34], and specialized material responses [35] confer upon soft robots self-perceptive and adaptive characteristics, enabling them to explore the external environment and perceive changes in their form [36,37]. These elements are indispensable for the realization of intelligent soft robots. However, relying solely on actuation and sensing technologies is insufficient to create truly intelligent soft robots. Previous research has often developed actuation and sensing technologies separately, resulting in limitations in the behavior and sensing capabilities of soft robots [11,38]. To overcome these limitations, integrated actuation-sensing technology has emerged as a new research direction in recent years [39]. This technology aims to integrate actuation and sensing functions to achieve intelligence and autonomy in soft robots. Therefore, soft robots can better understand and adapt to their environment, resulting in more precise, flexible, and intelligent movements and behaviors. This integration enables soft robots to excel in various tasks and environments, boosting their overall performance and adaptability.

While extensive work has been done on soft robotics [40–45], little focus has been placed on the integration of actuation and sensing for soft robots. This review aims to explore existing popular actuation and sensing integration technologies. We will first have a systematic review of strategies for soft actuation and soft sensing in soft robots and list the advantages and limitations of various actuation and sensing strategies. We then place more discussions on strategies for integrating actuation and sensing, for example, flexible electronic skin (e-skin) for sensor surface integration and sensor internal integration. We believe that this comprehensive review will promote the development of intelligent soft robotics and provide insights into technological breakthroughs and developments in this area.

As shown in Fig. 1, this review will be structured as follows. The “Strategies for Soft Actuation” section will delve into intelligent actuation strategies for soft robots and summarize work related to multimodal actuation techniques. In the “Strategies for Soft Sensing” section, different flexible sensing strategies for soft robots, as well as the integration of proprioceptive and external sensing, will be discussed. The “Integrated Actuation and Sensing” section will provide a summary of the existing strategies for actuation-sensing integration and suggest potential areas for further exploration. Finally, the future of further integration of actuation and sensing to achieve intelligence in soft robots will be presented and concluded.

Fig. 1.

Overview of this review.

Strategies for Soft Actuation

Actuation strategies form a central pillar in the field of soft robotics, given the fact that they control the motion and function of these agile robots. Various actuation strategies have been explored to empower soft robots with the ability to interact with their environment and perform complex tasks. This breakdown analyzes 4 primary actuation strategies used in the field: pressure, electrical, external stimulation, and passive deformation. As shown in Fig. 2, we will examine the principles, advantages, limitations, and recent advancements associated with each strategy. We will also investigate the emerging technique of multimodal actuation, which amalgamates different actuation approaches to bolster the versatility and performance of soft robots. By delving into these diverse actuation approaches, we aim to shed light on the progress and challenges in this crucial aspect of soft robotics and pave the way for the integration of intelligent drive systems in future generations of soft robots.

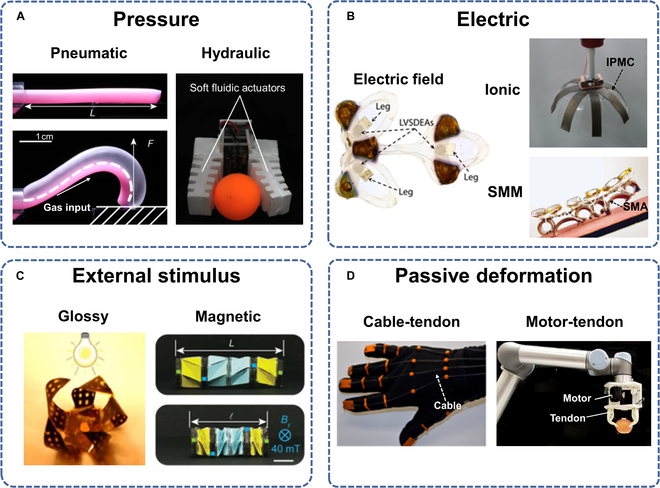

Fig. 2.

Soft actuation strategies. (A) Pressure actuation, including pneumatic and hydraulic pressure methods. Reproduced with permissions from [50,52]. (B) Electrically actuation, including dielectric elastomers (DE), ionic polymer–metal composites (IPMC), and shape memory alloy (SMA). Reproduced with permissions from [57,64,67]. (C) External stimulus actuation, including glossy and magnetic response methods. Reproduced with permissions from [72,79]. (D) Actuation based on passive deformation, including cable and servo motor actuation. Reproduced with permissions from [81,84].

Comparison of different actuation strategies

Pressure actuation

Pressure actuation, a widely used soft-body actuation strategy, will be our first point of analysis. This strategy emulates the movement of some mollusks by embedding different types of fluid channels, such as cylindrical or pleated, into the elastic materials or by adding a restrictive layer of material at specific locations. Once the fluid is introduced, the various components of the mollusk analog are deformed due to changes in channel pressure, inducing contraction, expansion, and bending of the foundational movements of a mollusk. There are 2 primary types of pressure actuation strategy: pneumatic and hydraulic actuation.

Pneumatic actuation: Pneumatic actuation, particularly through soft pneumatic actuators (SPAs), is a prevalent technique in soft robotics. These actuators comprise an elastic body with multiple embedded void channels. Upon the application of fluid pressure, each channel undergoes expansive deformation, leading to the contraction or expansion of the internal cavities within the soft robotic system. This mechanism enables the desired objectives of deformation and motion to be achieved. Noteworthy advantages of SPA include light media mass, widespread source, minimal pollution, and satisfied-reliability requirements for soft robots. Despite offering high energy density and high flexibility, challenges arise due to their considerable mass and high sealing requirements, particularly impeding the device miniaturization. An illustrative example within the SPA domain is the pneumatic artificial muscle (PAM), where the McKibben actuator represents a quintessential task [46,47]. PAMs typically store the energy required for actuation mechanically (pressure–volume energy), contracting when pressurized. These actuators consist of a flexible or stretchable cylindrical membrane, bound by highly tensile fibril and sheltered by 2 rigid end fittings [40]. In a notable advancement, De Pascali et al. designed a novel PAM structure, where the geometry of the membrane inherently enabled the coupling of expansion and axial contraction without the need for anti-stretch components, end caps, or restraints. This innovative approach enhances versatility and scalability across a wide range of sizes and large changes in drive strength [48].

Nevertheless, a flexible soft robotic gripper based on the SPA was designed by Zhang et al. [49], which showcased successful application, in this case, gripping fragile items by inducing a change in pulse signal. Figure 2A illustrates an SPA crafted through bubble casting [50]. The gradual solidification of the elastomer allows for easy customization of its form, catering to a diverse range of applications from artificial muscles to fixtures. Through this casting-based SPA, there is an augmentation in the flexibility and expansiveness of the actuator. Utilizing the above designs, versatile SPAs can meet the shift toward preparing multifunctional soft robots that combine various technologies, mechanisms, and devices. Nonetheless, miniaturizing SPAs, which usually require numerous pneumatic fittings such as air tubes and solenoid reversing valves, presents a future research direction.

Hydraulic actuation: Hydraulic-driven actuation has been widely used in a range of soft robot configurations since the birth of soft robots in the 20th century. Fluids demonstrate excellent potential for soft robot drives, given their superior incompressibility, high response frequency, and minimal losses in the absence of leaks. Common hydraulic actuators are fluid-elastic and consist of dual soft elastomeric layers divided by a non-stretchable strain-limiting layer. As the fluid pressure inside the embedded channel ramps up, the channel expands, thereby bending the actuator. Owing to the robust nonlinearity and intricate geometric configuration inherent in hydraulic actuators, achieving precision of motion presents a formidable challenge. Finite element analysis is frequently employed to address nonlinear issues, forecast drive performance, and enhance the precision of hydraulic propulsion [51]. Notably, hydraulic actuation technology has recently advanced significantly in areas such as self-repair, miniaturization, and multimodal motion. For instance, Fig. 2A depicts a fluidic actuator that integrates an internal soft electro-hydraulic fluid pump for cordless propulsion, concurrently incorporating self-healing fluid to achieve automatic recovery from material damage [52]. Furthermore, Xie et al. proposed a hydraulic soft actuator for multi-degree-of-freedom spatial motion, where the cylinder soft actuator made of elastomer had 3 symmetrically distributed fiber-reinforced hydraulic chambers. By controlling the pressure vector within the chambers, the soft actuator allowed for axial elongation and bending movement [53]. In addition, Kurumaya et al. [54] integrated a hydraulically driven bellows-type flexible gripper and a fiber-reinforced flexible winding actuator into an underwater rigid robotic arm for the collection of vulnerable organisms underwater, which successfully collected coral samples non-destructively in shallow waters. In general, hydraulic actuation offers high responsiveness and drive forces, although it presents considerable challenges in modeling and control.

Electric actuation

The electric actuation strategy revolves around the utilization of electroactive substances, particularly focusing on their unique ability to undergo structural changes in response to applied electric fields. This leads to a diverse range of transformations, including stretching, bending, and swelling. Electrodynamic strategies within this field can be broadly classified into 3 main branches based on the difference in the underlying energy mechanism: those driven by electric fields, primarily employing dielectric elastomers (DEs), those driven by ions, prominently featuring ionic polymer–metal composites (IPMCs), and those driven by SMMs.

DE-based actuation: The actuation principle of DEs is mainly based on the action of an applied electric field. Under the action of the electric field, the charges on both sides of DEs are attracted to each other, thereby generating Maxwell stress. This electrostatic force causes DEs to expand in the face direction and contract in the thickness direction [29]. Due to their fast response and high energy density, DEs are currently widely used in ground robots, aerial robots, and robotic grippers. For instance, in the realm of DE-based actuators, Zhao et al. have innovatively explored methods to achieve lightweight, low-profile DE-based actuators capable of high force and substantial strain. Their approach involved layered dielectric materials and electrodes, followed by precise winding, transforming a film structure of tens of microns into a millimeter device. This transformation effectively converted the shrinkage along the thickness axis and expansion within the plane into axial elongation, leading to reduced voltage requirements and operation at lower voltage thresholds [55]. However, it is important to note that the lifetime of DE-based actuators presents a marked challenge, as exceedingly high voltages can lead to electrode breakdown. To address this issue, Jiang et al. [56] proposed a solution involving a thin mesh of carbon nanotubes (CNTs), which both enhances the self-cleaning of DEs and introduces a non-dimensional measure called capacitance retention for real-time monitoring of the drive performance during the device’s lifetime.

In addition, the persistent challenge of elevated voltage in DEs has been addressed by Ji et al. They introduced low-voltage stacked DE-based actuators, operating at voltages below 450 V, as illustrated in Fig. 2B. These actuators have been utilized to propel diminutive, cordless, and autonomous-legged robots of insect scale [57]. Their works demonstrate a high level of agreement between the actual change in driving capacity and the theoretical change, offering a promising option for ongoing assessment of DE performance. Furthermore, DEs are often used in the manufacture of flexible artificial muscles due to their high power-density properties. Chen et al. [58] explored the use of multilayer DE-based actuators to create a flexible artificial muscle with impressive specifications, achieving a resonant frequency of 500 Hz and a power density of 600 W/kg. Meanwhile, DEs are miniaturized and easy to integrate, which gives them the potential for detection in extreme environments. Li et al. [18] deployed DE artificial muscles to deliver a self-powered soft robotic fish, which was taken into the Marianas Trench at around 10,000 m. Given the extreme conditions of the deep sea, which include low temperatures and extremely high pressures, the researchers optimized the DE material to enhance the robot’s robustness and ensure that the robot’s drive performance is maintained at a respectable level over time.

Overall, DE-based actuators present several distinct advantages, like high power density, broad bandwidth, the ability to achieve remarkable strain, and impressive overall efficiency. These actuators can reliably generate strains of up to 100% and operate at frequencies ranging from hundreds to thousands of hertz [59,60]. Nevertheless, DE-based actuators have certain drawbacks, including the requirement for pre-stress, challenges in creating flexible and robust electrodes, and the use of high voltages during operation. Ongoing research endeavors are dedicated to overcoming these obstacles and advancing the field further.

IPMC-based actuation: IPMC has emerged as a promising material for soft actuators in electrically driven soft robotics. As a smart material, IPMC demonstrates remarkable electromechanical properties that position it as an ideal candidate for actuation within the domain of soft robotics. IPMC consists of a thin ionic polymer film sandwiched between 2 metal electrodes, usually made of platinum or gold, and exhibits unique behavior when subjected to an electric field [61]. This electrical stimulation causes the cations within the polymer to migrate toward the negative electrode, resulting in a bending or deformation response in the material. The unique properties of IPMC make it an excellent choice for soft actuation. It exhibits large bending displacements in response to low applied voltages, enabling precise and responsive control of movement. This feature is particularly advantageous in applications that require delicate manipulation or fine motor skills (FMSs). Additionally, IPMC offers a high power-to-weight ratio, facilitating efficient actuation while maintaining a relatively low overall weight of the robot [62]. For example, Chung et al. [63] demonstrated an IPMC brake prepared using nano-silver powder, which exhibited substantial deformation in bending angle and operated at a low driving voltage. IPMC has also found application in the construction and activation of bionic jellyfish robots (Fig. 2B), successfully emulating the undulating form of actual jellyfish [64]. Ongoing research continues to explore the full potential of IPMC in the field of materials.

Overall, the utilization of IPMC in soft robotics for electric actuation presents distinct advantages, including its electrical sensitivity, compliance, and integration potential. However, IPMC actuators do face certain limitations, such as low power density and relatively modest stress levels. Additionally, issues related to restricted motion and force output, as well as challenges in modeling, control, and overall robustness, call for further investigation and refinement in the realm of IPMC actuators.

SMM-based actuation: SMMs have gained marked attention as a promising approach for soft actuation in the realm of soft robotics. These materials possess a unique property, the ability to revert to their initial configuration when exposed to certain stimuli, such as temperature or light. This exceptional feature enables SMMs to exhibit remarkable shape-changing capabilities, making them a prime choice for soft actuation across a wide range of robotic applications. SMM-based actuators mainly include shape memory alloy (SMA) actuators and shape memory polymer (SMP) actuators, as discussed below.

SMA threads are commonly employed in the design of compliant actuators. The application of an external electric field induces a current within the SMA circuit. When the Joule heat generated by this current surpasses the critical temperature of the SMA thread, it triggers a contraction force, resulting in the bending deformation of the elastomer [65]. Due to the shape memory behavior induced by the crystalline phase transition from martensite to austenite at elevated temperatures under electrothermal conditions, SMAs can effortlessly restore their original form. This crystalline phase transition-induced shape memory behavior allows the conversion of heat into mechanical motion, thereby facilitating the lightweight and streamlined realization of compliant actuators. Nickel-titanium is one of the most commonly used alloys for SMA actuation. For instance, Laschi et al. studied a soft arm inspired by the biomechanics of an octopus arm. This soft arm is actuated by a cable with an SMA spring. By energizing the spring at different parts, the tentacle can bend at multiple nodes, extending and contracting for the manipulation of objects [66]. Due to the inherent advantages of lightweight and convenience in SMA, Huang et al. have fashioned a cordless soft robot propelled by an SMA actuator powered by a compact battery. This innovative design enables the robot to emulate biological rolling and swift ascent on inclined surfaces (Fig. 2B) [67]. SMA actuation boasts high energy density and high stress, but it tends to produce smaller displacement deformation and operates at lower frequencies compared to other actuation methods.

SMP is a class of smart materials, many of which are thermally responsive and can be programmed to remember temporary shapes, returning to their permanent shapes when exposed to a specific stimulus, such as heat or light. SMP offers advantages such as high elastic deformation, low density, low cost, and ease of manufacture. For example, Ge et al. integrated thermally driven SMP microgrippers, designed through stereolithography. These microgrippers can be activated by adjusting the printed shape to achieve various states of closure and opening, responding to heating [68]. However, SMP actuation presents challenges, including low mechanical strength, low recovery stress, and short cycle life. To address these limitations, reinforced fillers can be used to improve mechanical properties and increase shape recovery stresses.

External stimulus actuation

External stimulus-based actuation strategies encompass magnetic response actuation strategies and electrical response actuation methods. These strategies exploit environmental stimuli such as light, heat, and magnetism to drive soft robotics. This section presents a unified overview of external stimuli-based actuation strategies, classifying them based on different external conditions.

Moisture- and light-driven actuation: Moisture-driven actuation relies on the absorption or desorption of water by a material, which, in turn, leads to a change in its volume or shape. Some soft materials, such as hydrogels or certain polymers, expand or contract when exposed to water, resulting in a change in volume or shape. Light-driven actuation utilizes the interaction of soft materials with light, usually achieved through light-responsive materials. When these materials are exposed to specific wavelengths of light, they can undergo reversible changes in structure, shape, or properties. CNTs exhibit a unique tubular structure with unique hybridized backbones, endowing them with extraordinary properties, particularly in the realm of photo response [69]. Zhou et al. introduced a moisture- and light-driven actuator based on CNT-coated paper and polypropylene composites. They created a smart gripper with an expandable initial opening width using the bi-directional bending motion of the actuator. This allows the gripper to increase its opening width up to 4 times its initial size, making it suitable for gripping larger objects [70]. Graphene, characterized by an ultra-broadband optical response spectrum and extremely strong nonlinear optical properties, has become a focal point in the development of optically driven soft actuators [71]. A soft actuator crafted from graphene, as depicted in Fig. 2C, harnesses structural absorption of radiant energy to induce its motion. Under the influence of light, electricity, organic vapors, and humidity, this actuator achieves a spectrum of programmable movements [72]. This actuation method not only has important environmental advantages, but also enables the designed robot to realize remote control with a certain degree of accuracy. However, this approach presents difficulties in performing kinetic modeling and certain challenges in designing structures based on photosensitive materials. Moreover, hydrogels or other photosensitive materials are prone to degradation over time, potentially impacting the lifetime of the robot.

Thermal-driven actuation: Thermal-based actuators play an important role in flexible actuators, and they are broadly categorized into photothermal actuators and electrothermal actuators based on the mechanism of the external thermal stimulus. Photothermal actuators primarily leverage the thermal expansion effect resulting from the localized temperature increase induced by light path irradiation. On the other hand, electrothermal actuators rely mainly on the Joule heat effect in combination with the special phase transition characteristics of the material to achieve deformation. Typical material choices include SMPs, liquid crystal polymers [73], and CNTs based on electrothermal response [74]. Yang et al. developed a bio-optical hose driver that utilizes polymerizable bio-optical hose actuators. This actuator takes advantage of the sensitive and photosensitive properties of the selected material [75]. When combined with liquid crystal elastomer (LCE), the hose actuator will bend and deform due to the material’s excellent photothermal conversion efficiency and the molecular arrangement changes caused by local temperature rise caused by near-infrared light. This innovative actuator demonstrates excellent adaptability to light sources and possesses the capability for omnidirectional light-tracking, promising applications in the field of soft robotics. Kobayashi et al. designed a gripper that responds to thermal cues. This soft gripper is not only biocompatible but also biodegradable, making it suitable for thermally driven drug patch applications. They also create a range of thermally responsive self-folding structures in response to 3 different temperatures, offering numerous prospects for future research into soft robotics [76]. Photothermal actuators enable remote and precise control, but their effectiveness may be limited by the depth of penetration. Electrothermal actuators are cost-effective and versatile, but heat dissipation and their limited spatial resolution are issues that need to be addressed.

Magnetic-driven actuation: Magnetic-driven actuation in soft robotics often involves the incorporation of magnetically responsive particles [77], including iron oxide, triton tetroxide, ferrite powder, and NdFeB [78]. For example, Ze et al. designed a soft robotic origami crawler that consists of a 4-unit special component with magnetic plates on each component, as shown in Fig. 2C. These plates are made of silicone and embedded with hard magnetic particles, and their susceptibility can be fine-tuned by controlling the volume fraction of the magnetic particles. A uniform magnetic field creates torque, causing the origami track to drive. This principle is used to facilitate the rotation and expansion of each special unit, which, in turn, enables the drive of the origami track [79]. One of the major problems with magnetic soft robotics is the lack of functionality, as well as the complexity of material design and fabrication methods to create deformable robots containing multiple curved structures. The researchers have constructed a modular soft magnetic architecture in which individual units contain rutile iron boron particles with a defined magnetization profile. These units are embedded in an adhesive network on both sides of a double-sided adhesive, allowing the mass production of magnetic soft robots with exceptional robustness, capable of withstanding loads thousands of times their weight [80].

In general, external stimuli offer the advantage of minimal physical contact, making them suitable for a wide range of micro- and small-scale robotic systems. However, they require careful consideration of the external environment and the choice of soft materials. Magnetic and optical actuation-based soft actuation strategies have been widely used in micro-robots, yet there is ample room for further exploration and advancement in this field.

Passive deformation

Compared to traditional motor actuation methods for rigid robots, the actuation techniques in soft robotics are notably more intricate. While the compliant structure itself is not a direct driving mechanism, it is designed to undergo deformation and propulsion through the influence of a passive mechanism. This dynamic occurs when external motors or cables, transmitting tension through tendons, prompt the deformation of the actuator, thereby propelling the soft robotic system.

Cable-tendon actuation: Cable actuation is a widely used external force-based actuation strategy in traditional flexible robots. The core principle involves passing a cable through a fixed point on the mechanical body and pulling a cable at its root to generate a certain bending moment at the fixed point, thus causing the body to move. Cable actuation stands as a superb method for achieving extended-distance transmission, particularly suited for the design of elongated soft robotic systems. For example, Zhou et al. [70] combined motors and cables to design a soft robot capable of planning and predicting motion trajectories, providing a more convenient actuation method compared to alternative strategies. This fusion of the motor and cable provides the soft robot with trajectory planning and prediction, streamlining the propulsion process. In the realm of intelligent equipment, cable-driven soft robots can generate substantial force, making them an excellent choice for medical rehabilitation devices. Delph et al. [81] have devised a cable-driven soft robotic glove (Fig. 2D) designed to assist stroke patients in practicing hand grasping exercises. In addition, such tendon-driven soft robots can also be used for the rehabilitation of patients with spinal cord injuries [82], which has high application value.

Motor-tendon actuation: Another uncomplicated driving method involves the collaborative action of a driving motor and tendons to achieve passive deformation. Elaborate deformations and motions can be attained by employing multiple motors, each connected to different regions of the soft structure through tendons. The motor-tendon driving mechanism bears resemblance to the biological interplay between muscles and tendons, making it particularly well-suited for intelligent wearable devices [25]. However, servo motors, while effective, have a marked drawback in that they are rigid and bulky components, limiting the softness and flexibility of the overall system. In the domain of soft robots, researchers have developed robots that utilize servo motors to achieve various actuation modes, such as flying and jumping. For example, Chang et al. modeled how birds manipulate their feathered wings during flight. With the help of servo motors, they developed a bio-hybrid wing with 40 un-actuated real pigeon feathers. This wing was strong, soft, and ultra-light compared to previously reported carbon-based and glass fiber-based robotic feather wings [83]. Furthermore, Fig. 2D illustrates a flexible motor-tendon gripper [84], employing cables as an intermediary drive to enable the gripper to capture objects of varying shapes and weights through different grasping techniques.

Although passive deformation strategies offer high efficiency in force transmission, they also bring about increased complexity and bulkiness within the actuation system. This complexity poses challenges when attempting to downsize soft robots. A potential solution to this issue lies in the pursuit of miniaturizing external driving components. Simultaneously, efforts to integrate diverse external driving elements directly into the robot’s main body can prove effective in streamlining the system and overcoming the challenges associated with complexity and size.

In summary, these actuation strategies have their strengths and weaknesses, making them valuable assets for specific robotic applications. For detailed information on the advantages and drawbacks of 5 different actuation strategies, please refer to Table 1. Additional details on multimodal actuation will be provided later.

Table 1.

Comparison of actuation strategies

| Actuation strategy | Mode of actuation | Actuation signal | Dynamic profile | Strain | Motion profile | Classic features | Ref. | |

|---|---|---|---|---|---|---|---|---|

| Pressure | Pneumatic | Contraction and expansion | 0–20 kPa; 0.066–1 Hz | 7.5 N blocking force and 9.5 N pushing force | 25%–30% | 10 mm/circle | Highly versatile; high force transmission | [48] |

| Advantages: | ||||||||

| ||||||||

| ||||||||

| Drawbacks: | Contraction and expansion | 0–4 bars | 30–100 N axis force | 10%–25% | 100 mm under 0.4 bar | Soft recovery hand; high effective force | [161] | |

| ||||||||

| ||||||||

| Bending and gripping | 3-3 solenoid valves from 0–4 bars | 17 N under 4 bars | 50% | 133° joint angle | Wearable hand recovery device; integrated actuation and sensing | [162] | ||

| Hydraulic | Swimming, diving and turning | 1.3 Ah battery under 72 MHz signal | Overcomes 1.65 kg of underwater resistance | Wide range deformation | 100 mm/s | Prolonged underwater exercise; multimodal movements | [88] | |

| Advantages: | ||||||||

| ||||||||

| ||||||||

| Drawbacks: | Stretching | 1.5 MPa or 2.5 MPa initial pressure | Up to 7 MPa | 26% | 230°/s | High stability and compliance | [163] | |

| ||||||||

| ||||||||

| Electric | Dielectric elastomers (DEs) | Crawling | 1.2–1.6 kV; 1–150 Hz | 22 mN block force under 1.6 kV | 7.5% | 56 mm/s | Sub-centimeter class pipes; multimodal movements | [90] |

| Advantages: | ||||||||

| ||||||||

| ||||||||

|

Swimming | 7–9 kV, 2 Hz | 8% axial strain under 110 actuation pressure | 7.0% | 32.9 mm/s | Movement in deep sea; long life span | [18] | |

| Drawbacks: | ||||||||

| ||||||||

| ||||||||

| Bending | 5 kV, 2–10 Hz | 3.6 mN block force under 5 KV | More than 10% | 47 mm under 3,500 V | Enables fast, large dynamic displacements | [164] | ||

| IPMC | Bending | 0–5.25 V | 0.31 mN maximum load | None | 12 mm deflection under 1 V | Excellent proton conductivity; fast actuation capability | [165] | |

| Advantages: | ||||||||

| ||||||||

| ||||||||

| Drawbacks: | Bending and crawling | 0–5 V; 2,000 Hz | 35 μN under 5 V | 10% | 5 mm under 5 V | IPMC’s new manufacturing process | [166] | |

| ||||||||

| ||||||||

| SMM | Crawling and swimming | 30 V heating voltage | Lifting a 0.91-kg loads | 100% | 140 mm/s | High response time; excellent adaptability | [167] | |

| Advantages: | ||||||||

| ||||||||

| ||||||||

| Drawbacks: | Straight turning and moving | 0.65 A actuation current under 0.56 Hz | Maximum pulling force 0.98 N | 21.5% | 18.8 mm/s | Amphibious working ability; multimodal drives | [65] | |

| ||||||||

| ||||||||

| External stimulus | Magnetic | Crawling | 20–40 mT,1Hz | Small torques of 0.18 N.mm | 30% | 3 mm/s | Quick turn small-scale pipe movement | [79] |

| Advantages: | ||||||||

| ||||||||

| ||||||||

| Drawbacks: | Crawling, locomotion | 100 mT | Flexible contact, small block force | 55% | 4 mm under 1,200 circles | Multimodal robot motion | [80] | |

| ||||||||

| Glossy | Bending | 808 nm near-infrared light irradiation | 17 MPa stress under 0.2 wt% | 120% | 0.08 rad/s | High optical tracking accuracy | [75] | |

| Advantages: | ||||||||

| ||||||||

| ||||||||

| Drawbacks: | Bending and gripping | 0.304 W/cm3 light illumination | Grasping a 2.8 g object | 140% | 13 mm under 20 s | Multi-actuation options; excellent mechanical properties | [95] | |

| ||||||||

| ||||||||

| Passive deformation | Cable-tendon | Bending and grasping | Direct current (DC) motor with 10 N loads | 3 N maximum grasping force | 90° angle rotation | 70 mm/min | Gripping of fragile or irregularly shaped objects | [168] |

| Advantages: | ||||||||

| ||||||||

| Drawbacks: | ||||||||

|

Crawling | DC motor actuation | 5 N blocking force | None | 200 pixel movements | Excellent force transmission | [169] | |

| Motor-tendon | Bending | DC motor actuation with crank | Cable pulling force 1 N | E = 110 kPa | 4.5–10 mm range | Suitable for exercise in a variety of environments | [170] | |

| Advantages: | ||||||||

| ||||||||

| Drawbacks: | ||||||||

|

Self-directed flight | Two dual-port DC motor with MCU | Maximum wing force 13 N/m2 | None | 10 Hz flapping speed | No-traction autonomous flight | [171] | |

Multimodal actuation strategy

In the previous section, we introduce 4 typical actuation strategies for soft robots. While these individual strategies have shown significant results in specific contexts, they often come with limitations related to specific forms of motion and task requirements. To further enhance the flexibility and versatility of soft robots, researchers are now delving into multimodal actuation strategies [85]. Multimodal propulsion can be achieved through 2 distinct strategies. The first strategy involves employing a singular driving strategy, wherein a variety of propulsion modes can be generated through structural design or the combination of multiple actuators. This approach is commonly used in externally stimulated soft robots, as the stimulation source and threshold can be adjusted according to the target mode. Pressure-driven and electrically driven approaches also serve as commendable choices for achieving multimodal propulsion, relying primarily on the combination of multiple actuators in various regions of the elastomer, coupled with specialized structural designs to realize diverse driving modes. The second strategy involves the generation of multiple propulsion modes under the influence of various driving strategies. These strategies enable soft robots to exhibit multiple forms of motion within a single drive mode by combining different drive modes [86]. The amalgamation of typical diverse driving strategies is primarily grounded in the passive deformation of tendon-driven mechanisms, upon which pressure-driven, electrically driven, and externally stimulated drives are integrated to achieve multimodal motion. The key to this approach lies in effectively coordinating and regulating interactions between different actuation techniques to achieve a wide range of robotic movements.

Common forms of motion for soft robots include bending, but by tuning the distribution and control of the actuators, a range of other motions can be achieved, such as crawling, looping, rowing, tumbling, and swimming. Figure 3A shows an all-soft octopus’ robot, which, through the coupling of monopropellant fuel with microfluidic logic, enabled it to drive, control, and realize the autonomous operation of these pneumatic drive systems [87]. The soft controller’s oscillator causes the octopus robot to alternate between blue and red actuation states. In addition, Katzschmann et al. presented an autonomous soft-bodied robotic fish that was hydraulically driven and able to swim continuously in 3 dimensions. The combination of a gear pump, a hydraulic cylinder, and a soft-body tail enabled the soft-body fish to move forward and dive under water [88]. In this work, the multimodal movement is achieved through a combination of rigidity and flexibility. In addition, Bartlett et al. [89] designed a combustion-driven robot that is powered by butane and oxygen combustion. Moreover, the robot consists of a main explosive actuator surrounded by 3 pneumatic legs. This jump design also offers the possibility of working in some complex environments.

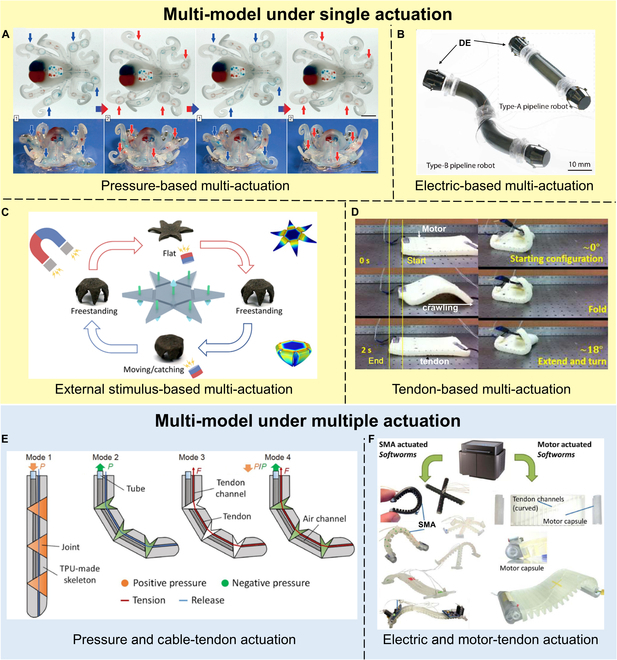

Fig. 3.

Multi-modal actuation strategies. (A) Pressure-based multimodal actuation. Reproduced with permission from [87]. (B) Electric-based multimodal actuation. Reproduced with permission from [90]. (C) External stimulus-based multimodal actuation. Reproduced with permission from [94]. (D) Tendon-based multimodal actuation. Reproduced with permission from [96]. (E) Multi-model under multiple actuation: Pressure and Cable-tendon coupled actuation. Reproduced with permission from [98]. (F) Multi-model under multiple actuation: Electric and motor-tendon coupled actuation. Reproduced with permission from [99].

The emphasis on multimodal propulsion relying on a singular electric drive primarily revolves around 2 strategies: DEs and SMAs. These 2 actuators are favored due to their high energy density, making them particularly suitable for applications requiring versatile propulsion capabilities. Tang et al. designed a micro-robot for navigation in sub-centimeter pipeline environments (Fig. 3B). This micro-robot harnessed the properties of 2 DEs of different Young’s modulus. A rigid DE was strategically positioned at both the head and tail of the robot, functioning as anchoring points. In contrast, a softer DE was located in the middle portion of the robot, serving as the telescopic segment. The robot movement was achieved through a clever mechanism of alternating between anchoring and elongation of these DEs [90]. Benefiting from the SMA’s rapid response, high power-to-weight ratio, and compatibility with small and lightweight electronic devices, Patel et al. [91] strategically embedded SMA coils within the actuator. This integration enables the robot to rapidly transition between crawling and rolling gaits, adapting effortlessly to various terrain structures.

Magnetic propulsion stands out as a highly effective method for achieving multimodal propulsion, given the high penetrability of magnetic fields, enabling the actuator to realize unrestricted motion in unstructured environments [92]. Simultaneously, these actuators, in comparison to the preceding 2 types, are more adept at executing intricate movements, albeit with stringent requirements for the magnetic field. For instance, Li et al. designed a self-vectoring electromagnetic soft robot. Modularization and recombination of magnetron-based micro-regions allowed for diverse motions, including expanding rotation, left-right rocking, left-right flipping, and continuous rolling, achieved by applying different current signals [93]. This work demonstrates the multimodal motion of a soft robot through a combination of actuation methods and modularity. Sun et al. reported a magnetic micro-robot, which consists of multiple magnetic bundles with joints that can transform bending deformation into folding deformation to localize deformation in the joint region (Fig. 3C). It is capable of multimodal motions such as moving, flipping, grasping, carrying and releasing, and programmable shape transformations [94]. Similar to magnetically responsive actuators, photonic responsive actuators also allow for remote operation. However, their response time is comparatively sluggish, and their efficiency is lower. Li et al. [95] engineered a flexible gripper using nanocarbon-based polymers endowed with outstanding driving and optoelectronic capabilities. Through external light irradiation at 0.3 W/cm2, they achieved photo displacement-induced bending in composite actuators with varying thicknesses of CNTs.

Although the passive deformation strategy that combines motors, cables, and tendons imposes limitations on the miniaturization and mobility of devices, it possesses efficient force transmission characteristics. Through the combination of various actuators, it can still achieve multimodal propulsion for soft robots. For example, Kastor designed a motor-tendon-driven soft foam robot, integrating 2 motor-tendon actuators diagonally on the soft foam. This integration allows the robot’s body to compress or fold, enabling movements such as forward progression, turning, and flipping, as depicted in Fig. 3D [96]. Moreover, tendon-driven mechanisms are frequently employed in flexible wearable devices. Building upon tendon-driven multimodal propulsion, a dynamic model is constructed using finite element analysis. Leveraging reinforcement learning, the glove’s pose is optimized, endowing the glove with more dexterous grasping and convenient in-hand manipulation [97].

Several instances of multimodal actuation achieved through the coupling of various actuators are evident. Take, for example, the previously mentioned flexible gripper [95], showcasing the capability of photonic actuation while also accomplishing gripping tasks at low voltage. This gripper exhibits a natural open state, and upon applying a 15-V voltage, the free end bends inward, effectively securing the object. The multimodal motion of the soft robot is achieved by combining electrically responsive driving strategies with external photonic responsive driving strategies. As illustrated in Fig. 3E, Zhu et al. [98] introduced a pneumatic and tendon-coupled soft actuator with various driving modes. This design allows the robot to exhibit low output force and rapid response under pneumatic actuation, as well as high output force and flexible response speed regulation under tendon actuation. The structure is compact, and the force and speed range are extensive. The multimodalities constructed from 2 driving modes with different force and speed characteristics can cover a variety of application scenarios. This serves as a typical example of achieving multimodal actuation through the combination of various driving strategies. Additionally, electrically driven strategies can be combined with tendon-driven strategies to achieve multimodal actuation. Figure 3F demonstrates an integrated design of SMA actuation and motor-tendon actuation [99], realizing the crawling and rolling of a biomimetic soft worm.

Soft actuators play a fundamental role in achieving diverse movement objectives, including bending, stretching, and twisting [100]. The key to enhancing the intelligence of soft robots lies in achieving multimodal actuation. While each actuation strategy has its strengths, it also comes with inherent limitations. To achieve multimodal actuation, the focus often shifts toward hierarchical actuation within a single driving mode. However, this introduces complexities into the system and presents new challenges in terms of modeling, simulation, and control of soft robot motion. Pressure-driven actuation is one of the most well-established soft actuation strategies. However, due to the extensive involvement of external connection components, it can be challenging to attain modular multimodal motion. Conversely, electric actuation strategies and external stimulus-driven strategies benefit from their non-contact nature, which allows them to achieve multimodal actuation through coordinated cooperation among modules. Overall, achieving multimodal actuation is a crucial step toward realizing intelligent soft robots.

Strategies for Soft Sensing

A defining feature of soft robotics is its capacity to achieve intricate movements through simple open-loop control. However, open-loop control alone cannot achieve high-precision operations and error correction. Hence, the integration of sensors to establish closed-loop control systems is essential for the advancement of soft robotics [101]. In this section, we will explore various sensing mechanisms, highlighting several representative works based on different sensing principles (Table 2 and Fig. 4). Furthermore, for a soft robot to autonomously perform tasks, it must possess the ability to perceive its shape (proprioceptive sensing) and detect stimuli from the external environment (tactile sensing). We will further introduce the concepts of proprioceptive and tactile sensing and present integrated sensors that combine both proprioception and external perception (Fig. 5).

Table 2.

Overview of typical sensing mechanisms for soft robotics

| Principle | Materials (electrodes) | Sensing functionality | Responsive speed | Sensitivity | Limitations |

|---|---|---|---|---|---|

| Piezoresistive | Nanocomposite, PDMS particles | Curvature, strain, elongation, contact force | Low | Low | Need to reduce hysteresis |

| Capacitive | Nanocomposite, hydrogels, textile | Curvature, bending angle, proximity, contact force | Fast | High | Need to minimize sensitivity to environmental contaminants |

| Magnetic | Permanent magnets | Curvature, elongation | Middle | High | Need to mitigate vulnerability to external interferences |

| Piezoelectric | PVDF, BaTiO3, PZT, ZnO | Curvature, elongation | Fast | Moderate | Need to enhance environmental adaptability |

| Optical | Optical fiber, waveguide, FBG | Curvature, elongation, bending angle | Fast | High | Need to reduce manufacturing costs |

| Resistive | Liquid metal, ionic liquid, nanocomposite, hydrogels, PDMS | Curvature, strain, bending angle, elongation, contact force | Low | Low | Need to improve sensitivity |

| Inductive | Coils | Elongation, bending angle, | Middle | Moderate | Need to simplify signal conditioning electronics |

| Triboelectric | PDMS, PTFE | Curvature, strain, elongation, contact force | Fast | High | Need precision manufacturing |

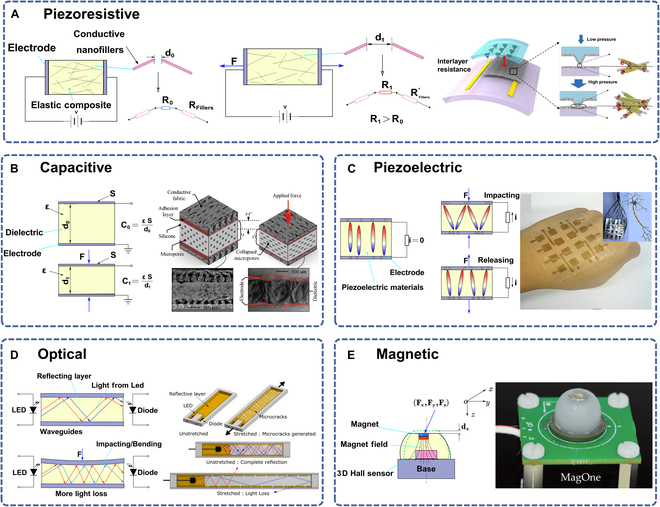

Fig. 4.

Various sensing mechanisms and representative designs for soft robotics. (A) Working mechanism of the piezoresistive sensor and a design with biomaterial-incorporated conductive interfacial layers. Reproduced with permission from [103]. (B) Working mechanism of the capacitive sensors and a representative design. Reproduced with permission from [160]. (C) Working mechanism of the piezoelectric sensor and a single-electrode e-skin. Reproduced with permission from [107]. (D) Optical sensing mechanism and a representative design. Reproduced with permission from [101]. (E) The working principle of the magnetic sensor and a tactile magnetic sensor. Reproduced with permission from [111].

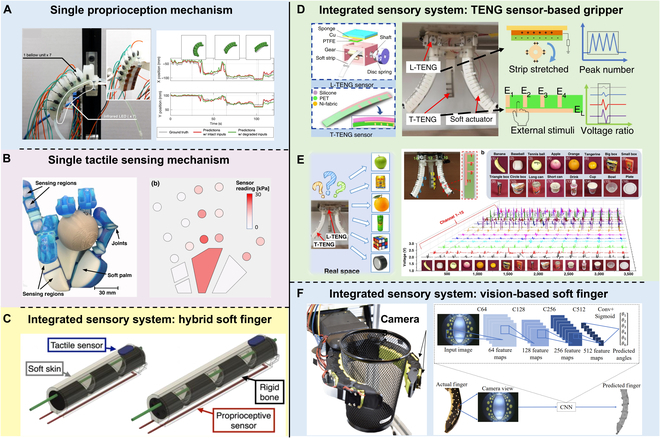

Fig. 5.

Single proprioception and tactile sensing mechanisms and integrated sensory systems. (A) A recurrent neural network (RNN)-based method for proprioception. Reproduced with permission from [116]. (B) A 3D-printed robotic hand for tactile sensing. Reproduced with permission from [119]. (C) Schematic of a highly integrated soft finger. Reproduced with permission from [120]. (D) The basic structures and data processing strategies of the length TENG (L-TENG) sensor and the tactile TENG (T-TENG) sensor. (E) The TENG-equipped soft gripper demonstrates distinctive voltage responses to various objects. Panels D and E are reproduced with permission from [113]. (F) A vision-based soft finger. Reproduced with permission from [117].

Sensing mechanisms based on different principles

Soft robotics encompasses a wide range of actuators and complex operational requirements, making it challenging to design a universal sensing system. Therefore, it is crucial to explore sensors based on different principles to meet specific needs. In this section, we will summarize various sensor types, compare their advantages and limitations, and provide an extensive overview of typical applications associated with each sensor type.

Piezoresistive and resistive sensors

Piezoresistive sensors are typically constructed from elastic composite materials infused with conductive nanofillers. When exposed to pressure, these sensors undergo changes in resistivity and geometric shape. As the working mechanism shown in Fig. 4A, these conductive nanofillers are interconnected, forming a network that carries electricity. Initially, with no pressure applied, the nanofillers are at a certain distance apart, providing a specific electrical resistance. When pressure is applied, the composite material stretches, causing the nanofillers to move further apart (the lower part of Fig. 4A). This increase in distance between the nanofillers disrupts the electrical pathway, increasing the overall resistance of the material. The alteration in resistance is a direct response to the applied force, allowing the sensor to detect and measure changes in pressure. The concept is visually depicted on the right side of Fig. 4A, illustrating how the network of nanofillers expands and subsequently influences the electrical properties of sensors. While these nanocomposite materials offer tunable mechanical and electrical properties, they often exhibit substantial hysteresis and nonlinearity. For example, Wang et al. [102] utilized MXene material to fabricate a piezoresistive sensor, involving the preparation of MXene material, the synthesis of MXene/polymer composites, and sensor fabrication. This sensor demonstrated high sensitivity, good stability, and repeatability, effectively functioning under bending and stretching conditions. However, it exhibited a narrow linear response range and important hysteresis, indicating the need for further improvement. In another example, Chang et al. [103] designed a piezoresistive sensor structure incorporating biomaterial-infused conductive interfacial layers, specifically using single-walled CNTs and M13 biological material (Fig. 4A). The fabrication involved mixing the single-walled CNTs and M13 biological material, printing them onto a polydimethylsiloxane (PDMS) substrate, and coating them with metal electrodes. This piezoresistive sensor demonstrated high sensitivity, rapid response, and good stability. However, the potential constraint on the broad applicability of these sensors arises from their heightened sensitivity, particularly within more constrained pressure thresholds.

Resistive sensors, similar to piezoelectric sensors, detect alterations in resistance resulting from variations in the geometric shape or resistive properties of conductive materials. A type of resistive sensor based on reduced graphene oxide and polyurethane sponge has been introduced, exhibiting notable characteristics such as high sensitivity and flexibility. This sensor’s design enables easy shaping into various forms to meet specific requirements [104]. In general, resistive sensors offer several advantages, including their simple structure, low cost, ease of fabrication and utilization, and the ability to measure diverse physical quantities such as deformation, strain, and curvature. However, it is essential to acknowledge their inherent limitations. Resistive sensors typically exhibit lower sensitivity and accuracy when compared to other types of sensors, and they are susceptible to the influence of environmental factors. Nonetheless, resistive touch sensors have gained popularity due to their affordability, rapid response, linear output, and high durability. It is worth noting that resistive sensors require a power source, rendering them unsuitable for low-power systems. In human signal detection, resistive sensors are commonly employed for measuring respiratory patterns, pulse signals, finger movements, and heart rate. In the field of soft robotics, resistive sensors facilitate the monitoring of deformations and movements, enabling adaptive control and intelligent perception. However, the lower sensitivity, limited accuracy, and susceptibility to environmental factors such as temperature and humidity should be considered when utilizing resistive sensors.

Capacitive sensors

Capacitive sensors are used to measure changes in capacitance resulting from variations in the geometric shape of elastic materials. They are employed for measuring physical quantities such as curvature, bending angle, proximity, and contact force. Capacitive sensors typically consist of 2 electrodes and a dielectric material, with changes in electrode spacing, dielectric constant, or charge storage capacity leading to corresponding changes in capacitance. When pressure is applied, the distance between the capacitor plates decreases, leading to a change in the distance between them (Fig. 4B). This change in distance results in a modification of the capacitance value. By monitoring the charge or voltage of the capacitor, real-time changes in the measured physical quantities can be tracked. Capacitive sensors offer benefits such as high sensitivity, rapid response, and good linearity, but they are susceptible to environmental pollutants. These sensors have widespread applications in fields such as soft robotics, e-skin, position, and shape detection [38].

For example, a stretchable capacitive sensor designed for tactile detection has been introduced [105]. This sensitization approach focuses on enabling proximity and tactile detection, which are fundamental components of a soft robotic finger. In another example, Atalay et al. introduced a wearable soft pressure sensor for electronics (Fig. 4B) [103]. The sensor features conductive fabric electrodes for reliable connections and a microstructured silicone dielectric layer to enhance baseline capacitance, reducing parasitic capacitance and improving the signal-to-noise ratio. The study explores the impact of different textiles and microstructural morphologies on sensor performance, emphasizing a conductive knit electrode and higher porosity for increased sensitivity. Integrated into a glove, the sensor measures grip pressure during object manipulation, offering advantages of ease of fabrication, flexibility, and secure connections.

Piezoelectric sensors

Piezoelectric sensors measure mechanical stress or pressure by utilizing the piezoelectric effect, which generates electric charges proportional to the magnitude of the applied stress or pressure. Figure 4C shows the working mechanism of piezoelectric sensors. When force is applied, the piezoelectric materials compress, inducing a charge. Conversely, when the force is released, the materials resume their original shape and the charge diminishes. These induced charges can be measured by the corresponding circuit. These sensors offer advantages such as high precision, high sensitivity, fast response, and wide-ranging applications. However, they are also susceptible to environmental factors such as temperature and humidity and require an external power supply. In the field of soft robotics, piezoelectric sensors find applications in posture perception, tactile feedback, and the measurement of mechanical stress and pressure.

Piezoelectric sensors also demonstrate marked potential for applications in self-powered physiological monitoring and human–machine interaction. A high-sensitivity and stretchable piezoelectric sensor has been proposed, utilizing finite element analysis and 3D printing techniques [106]. The strengths of their work are particularly evident in the straightforward fabrication process and the sensor’s remarkable sensitivity and stretchability. Nevertheless, further advancements could be made to enhance the energy conversion efficiency of the sensor. Another study explores the creation of e-skin that imitates human sensory functions using a piezoelectric nanogenerator made from electro-spun polyvinylidene fluoride (PVDF) nanofibers (Fig. 4C). This sensor can detect pressure and temperature variations with unique signals, enabling the simultaneous sensing of different stimuli. This advancement could lead to simpler, more effective artificial skins for use in robotics and prosthetics [107].

Optical sensors

Optical sensors are designed to detect changes in light resulting from strain or pressure applied to optical transmission media. These sensors measure changes in light properties such as intensity, frequency, or phase, to determine the extent of the applied strain or pressure. In Fig. 4D, sensors detect strain or pressure by monitoring alterations in light within the waveguides. Applied pressure or bending alters the light path, leading to light loss, and the sensors utilize this change to quantify the degree of strain. They offer distinct advantages, including high deformability and resistance to interference and contaminants. Optical sensors have found applications in diverse fields, including soft robotics, wearable pneumatic gloves, and prosthetic hands [108]. They play a crucial role in providing tactile perception in surgical manipulators and prosthetic fingers. A noteworthy feature of optical sensors is their ability to eliminate the need for electronic components and wiring in the sensing area. However, it is important to note their drawbacks, which include high manufacturing costs and a reliance on advanced signal conditioning devices.

A recent innovation in optical sensor fabrication involves the use of a highly reflective thin silver layer as an internal reflection layer (Fig. 4E) [101]. This method entails uniformly coating an elastic polymer surface with a thin silver layer. The resulting optical sensor exhibited exceptional stretchability and repeatability, because the deposition of the silver layer did not compromise the mechanical properties of the polymer during repeated loading-unloading cycles. In another study, an experimentally used fiber optic shape sensor (FOSS) was fabricated, which incorporated optical frequency domain reflectometry and utilized a specialty multicore fiber, integrating 4 optical cores within a single, monolithic glass fiber structure [109]. The FOSS system utilizes this multicore fiber to accurately monitor bending and twisting, providing detailed 3D shape assessments through sensors spaced at short intervals. It boasts high flexibility and a small diameter, enabling easy integration into various materials and maintaining performance under shape changes.

Magnetic sensors

Magnetic sensors utilize various transducer mechanisms, including coil geometry, mutual inductance, eddy-current effect, and magnetic reluctance, to measure changes in inductance [110]. They are employed to monitor the deformation, strain, displacement, pressure, or dimensions of soft actuators. The illustration in Fig. 4F demonstrates the response of an elastomeric material to applied external forces. The force applied leads to the displacement of an embedded magnet, and the changes in the magnetic field are subsequently detected by the Hall sensor. This sensor is capable of measuring the displacement of the magnet in 3 dimensions. These sensors offer advantages such as cost-effectiveness, high sensitivity, and easy integration. However, they are susceptible to fluctuations in external magnetic fields and can be affected by ferromagnetic objects [44]. Magnetic sensors find applications in diverse fields, including soft robotics, actuators, industrial manipulation, underwater exploration, and noninvasive medical procedures.

For example, a representative magnetic sensor was developed based on the principles of magnetic field induction by using magnetic-sensitive materials and highly elastic elastomers [111]. The fabrication process involved material mixing, injection molding, and magnetic field calibration. This sensor possessed the characteristics of durability, low cost, high precision, and high bandwidth, but with limitations such as nonlinearity and cross-interference. In addition, Alfadhel et al. introduced a magneto-resistive tactile sensor capable of operation in high-temperature environments, reaching up to 140 °C. This sensor employs bio-inspired structures known as cilia, which are fine structures fabricated from a magnetic nanocomposite material covering a spin-valve giant magnetoresistance sensor [112]. The magnetic nanocomposite material, composed of iron nanowires embedded in PDMS polymer, exhibits exceptional flexibility, biocompatibility, and high remanence. Moreover, it demonstrates robust adaptability to harsh environments.

Other sensors

In addition to the sensor types previously discussed, various other sensor technologies find common applications across a range of fields including triboelectric, ultrasonic, pneumatic, and inductive sensors. Triboelectric sensors rely on the frictional effect to generate electrical potential signals through physical contact, eliminating the need for an external power source. They offer advantages such as low cost, self-powering capability, wearability, lightweight, and comfort [113]. Ultrasonic sensors utilize the reflection of ultrasonic waves to detect the position of objects and the distance from the ultrasonic source. They are distinguished by high precision and non-contact measurement capabilities. Pneumatic sensors function by detecting the deformation and force of objects through changes in gas pressure. They are particularly suitable for deformation and tactile perception in soft robotics applications. Inductive sensors are employed to measure variations in inductance caused by factors such as coil geometry, mutual inductance, eddy current effects, and magnetic resistance [114]. They offer the advantages of low cost and high performance. Nevertheless, their drawback lies in the requirement for complex signal conditioning equipment.

Hybrid sensing techniques for soft robotics

Self-perception and external perception play a pivotal role in the advancement and application of robots. Self-perception, also known as proprioceptive sensing, refers to a robot’s ability to perceive its state and position, encompassing joint angles, shape, deformations, and other relevant information. This capability empowers robots to execute tasks with enhanced precision, avoid collisions and damage, and adapt effectively to diverse environments and tasks [26]. Conversely, external perception, including tactile sensing, enables robots to perceive environmental information such as the position, shape, and texture of objects. This perceptual ability facilitates better interaction between robots and their surroundings, enabling them to undertake more complex tasks such as navigating different terrains, object recognition, and grasping. Hence, both self-perception and external perception are of paramount importance for the intelligence and practicality of robots. The previously described sensor technologies can be utilized to enable proprioceptive and tactile sensing capabilities in soft robotics [44].

Proprioception

Proprioception, or the sense of proprioceptive perception, refers to the ability of robots or organisms to control their behavior by perceiving their motion, position, and state [115]. In the context of soft robotics, proprioception plays a crucial role in achieving accurate task execution. It involves measuring the shape, posture, and deformation of the soft robot to enable closed-loop control. A proprioception method has been introduced, employing a hybrid sensor–actuator system within the fluidic medium of a soft robot (Fig. 5A). Flexible electrodes detect changes in the robot’s shape, and a recurrent neural network (RNN) processes this data for accurate self-awareness of the robot’s position and movement [116]. Soft robots, with their infinite degrees of freedom and pliability, heavily rely on proprioceptive feedback to accurately perceive their body configuration. To achieve proprioception, various sensors are integrated into soft robots, including pressure sensors, strain sensors, gyroscopes, and accelerometers [44]. These sensors assist in perceiving the robot’s morphology, posture, and motion, enabling precise control and manipulation. Additionally, advanced techniques such as machine learning and deep learning are applied to enhance proprioceptive capabilities in soft robotics [117,118]. The role of proprioception encompasses precise control, adaptation to different environments and tasks, autonomous navigation, and obstacle avoidance. For example, in the biomimetic soft robotics field, proprioception principles draw inspiration from the neural systems of biological organisms, incorporating biomimetic learning and distributed neural control systems to achieve self-perception and adaptive control, thereby improving the motion controllability and environment adaptability of robots.

Tactile sensing

Tactile sensing plays a crucial role in soft robotics by enabling the perception of external stimuli. Soft robots are equipped with a variety of sensors, such as pressure sensors, capacitive sensors, and optical fiber sensors, which are embedded or coated on their surfaces to achieve tactile perception. These sensors are adept at detecting contact forces, deformations, and shapes when the robot interacts with its external environment. By utilizing tactile perception, soft robots can better perceive and understand their surroundings, ultimately enabling more precise control and operation. In Fig. 5B, a tactile sensing approach for soft robotics is developed, integrating pneumatic sensors into a 3D-printed robotic hand for environmental interaction. These air-filled sensors are placed within the fingers and palms to detect contact and pressure changes, enabling the hand to respond to physical touch using materials designed for sensitivity [119].

Integration of proprioception and tactile sensing

In the realm of soft robotics research, most studies have primarily focused on proprioception, with limited attention given to tactile sensing. However, it is essential to explore the integration of both proprioceptive and tactile sensing to gain a comprehensive understanding of the robot’s interactions with its environment. Following the introduction of the single proprioception mechanism (Fig. 5A) and tactile sensing mechanism (Fig. 5B), we have provided a comprehensive overview of prevalent sensing strategies that integrate both proprioception and tactile sensing. As shown in Fig. 5C to F, the integrated sensing strategy has been applied in soft robotics to develop soft fingers (Fig. 5C and F) and grippers (Fig. 5D and E). For instance, Georgopoulou et al. [120] have presented a highly integrated soft robotic finger capable of proprioception and tactile sensing by integrating various sensors, including muscle, pressure, and tactile sensors (Fig. 5C). In another example, the perception of texture and hardness was achieved by inferring tactile information through the installation of tension sensors on the tendons of the fingers [121].

Furthermore, researchers have introduced a soft finger utilizing the Gel Flex method, a vision-based proprioceptive and tactile sensor for soft robots. Inspired by the previous Gel Sight sensing technique, this approach involves creating an innovative exoskeleton-covered soft finger with embedded cameras. Deep learning techniques are then employed to achieve high-resolution proprioceptive sensing and extensive tactile sensing (Fig. 5F) [117]. These sensors enable the detection of finger position, deformation, and external force magnitude and direction, enabling self-perception and tactile sensing of the finger. This study further explores methods to address issues such as sensor signal drift and relaxation behavior by optimizing sensor materials, positions, and joint designs. Advancing the exploration of vision-based integration systems in soft robotics, another study compares shape reconstruction based on proprioceptive tactile sensing with one based on visual tracking [118]. This experiment involved recording the tactile responses and corresponding 3D shapes of the soft continuum finger using a spatially arranged capacitive tactile sensor array. The results demonstrate that proprioceptive awareness can be achieved in all 3 spatial axes, enabling body structure reconstruction and posture inference for the soft head, with an average accuracy of approximately 1 mm compared to visual tracking. Another study also explored the utilization of visual-based techniques for soft body self-perception, employing an embedded camera and convolutional neural networks to capture and represent deformation states, enabling accurate 3D shape reconstruction without external sensors [122].

A soft robotic gripper offers the advantages of more complex and integrated manipulation capabilities compared to individual soft robotic fingers. For example, 2 sensors, the length triboelectric nanogenerator (L-TENG) and the tactile TENG (T-TENG), enable proprioception and tactile sensing through triboelectric output signals generated from the contact and separation of electropositive and electronegative materials (Fig. 5D) [113]. The L-TENG sensor accurately measures the bending angle of soft actuators, while the T-TENG sensor effectively detects the sliding, contact position, and gripping mode of the soft gripper through patterned-electrode tactile sensing. This capability enables the gripper to accurately identify 16 different objects (Fig. 5E) [113]. In another example, Homberg et al. [123] presented a gripping mechanism employing a pneumatic system that incorporated composite sensors to achieve self-perception and tactile sensing. Each finger of the gripper was connected to a pneumatic piston via a tubing system integrated along the arm. Such gripping design allows for efficient and precise manipulation with the ability to perceive and respond to external stimuli through the composite sensors. Additionally, Zuo et al. developed a soft robotic gripper equipped with ionic hydrogel-based sensors designed for strain and tactile sensing, enabling object recognition through a learning-based approach. The hydrogel-based sensors exhibit exceptional conductivity, high stretchability, toughness, ambient stability, and a distinctive anti-freezing property [124].

Several other studies have employed diverse sensing strategies to achieve proprioception and tactile sensing. A soft robot arm with embedded tactile sensors at the joints has been designed to achieve self-perception. The tactile sensors were instrumental in acquiring self-perception and external environmental information, enabling pose estimation of the soft robot arm through machine learning algorithms [125]. Soter et al. [126] used an octopus-inspired arm as an example, where the proprioceptive representation is approximated by 4 bend sensors integrated into the soft body, presenting a novel method to implement bodily awareness into a real soft robot by the integration of its exteroceptive and proprioceptive sensors. Spielberg et al. [127] introduced a neural architecture that processed on-board sensor information to learn a salient and sparse selection of placements for optimal task performance. Their model and learning algorithm were evaluated on 6 soft robot morphologies for various supervised learning tasks, including tactile sensing and proprioception.

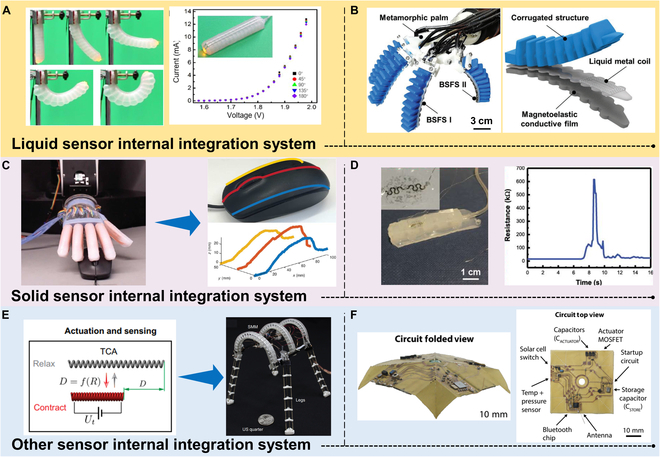

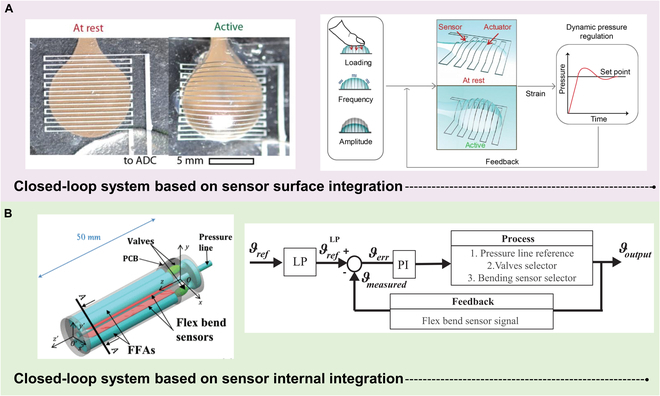

Integrated Actuation and Sensing

Actuation and sensing are 2 crucial aspects of soft robots that importantly influence their locomotion, perception, and intelligence. To enhance the performance and functionality of soft robots, seamless integration of actuation and sensing has been dedicated to development, with the ultimate goal of achieving actuation-sensing integration. This section will focus on the significance and potential of actuation-sensing integration, including 2 main integration approaches: surface integration of sensors within the actuators and internal integration of sensors within the actuators. By closely integrating sensors with actuators, soft robots can achieve higher levels of perception and feedback, thereby enhancing their autonomy and adaptability.

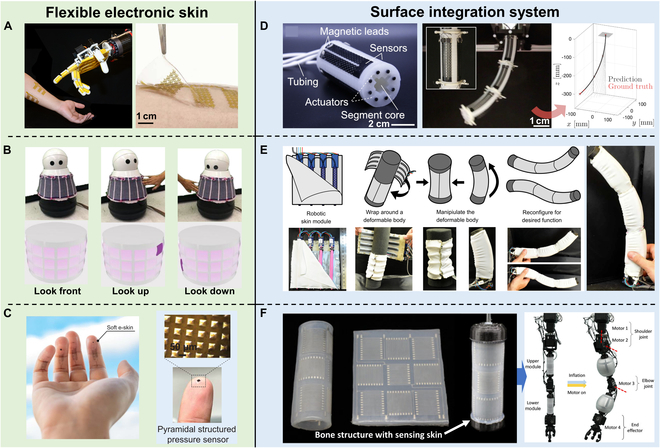

Surface integration

The development of e-skin comprising various flexible sensors such as strain, pressure, shear force, and temperature sensors, integrated with sophisticated circuits, has emerged to mimic the sensing functionalities of human skin [128]. These tactile stimuli are typically converted into electrical signals, such as changes in resistance or capacitance, which can be collected and processed by computers [32]. Tactile sensors are primarily classified into strain, pressure, and shear force sensors, depending on the targeted stimuli. In addition to tactile sensing, e-skin often incorporates temperature sensing, which provides early warnings to mitigate the risks of high- or low-temperature damage. Flexible temperature sensors have become an essential component of e-skin. Lastly, to approach the functionality of real skin, e-skin may incorporate humidity/solvent sensors to endow it with the ability to detect humidity or solvents.

With the continuous advancement of flexible electronics technology and e-skin, coupled with the introduction of more advanced manufacturing processes, the integration of high-performance actuation and sensitive sensing capabilities in soft robots has become feasible. For instance, Alessandro et al. proposed a novel optical flexible pressure sensor that consisted of 8 infrared emitters coupled with 8 photodetectors embedded in a flat PDMS waveguide with a diameter of 5.5 cm. This e-skin enables the detection of curved surfaces and mass in the gram range, providing a new solution for the realization of integrated actuation and sensing [129]. Similarly, Georgopoulou et al. used self-healing sensor fiber composites as e-skins on a 3D-printed soft actuator module to monitor the bending process. The change in relative resistance before and after injury allows the sensor to detect the actuator movement before and after healing [130]. Additionally, Sengupta et al. [131] reported a class of wearable, seeable, and sensitive piezoresistive sensors, which were fabricated by carbonizing electro-spun polyacrylonitrile (PAN) nanofibers and embedding them into PDMS elastic films. This approach enables both intrinsic proprioception and tactile sensing capabilities of the flexible sensor, which is further integrated into wearable devices for real-time monitoring of human movements, including gait analysis, wrist motion tracking, and respiratory monitoring, among other applications.