Abstract

Additive manufacturing, or 3D printing, is quickly becoming a widespread manufacturing method offering timely and cost-effective build times for unique part geometries with an increasing range of material offerings. One unique use for additive manufacturing is constructing the housing for reference solar cells, which are crucial instruments for evaluating the electrical performance of photovoltaic solar cells and modules. These instruments, which require good thermal conduction, are costly to manufacture because they are usually machined from aluminum using precision milling machines. In this work, we set out to evaluate several presently available additive manufacturing materials for their thermal properties when used to house reference solar cells. We fabricated several types of reference cell instruments with a tabletop, filament-based 3D printer using polylactic acid (PLA) and composite PLA/metal materials with different infill percentages. Furthermore, we fabricated several all-metal 3D printed reference cells using a binder jet printed stainless steel-bronze material blend and compared the thermal properties of all 3D printed instruments against a standard aluminum housing reference cell. Measurements included temperature monitoring of an embedded thermocouple sensor on an isothermal plate under the ambient environment and when exposed to high irradiation under a solar simulator. Current vs voltage measurements were also taken under the solar simulator and the open circuit voltage results were used to verify the actual silicon cell temperature. Our findings indicate that the stainless steel-bronze option can function well as an alternative to traditional aluminum-based housings, while the lower-cost metal-PLA composite can only be used under indoor light spectra or when used in a flash-type solar simulator when the instrument is not exposed to excessive radiation and heat.

1. Introduction

As the need for renewable energy sources increases, power generation from photovoltaic (PV) technologies continues to comprise a fast-growing share of the renewable energy portfolio [1]. With increased installed PV capacity and ever-improving PV device performance, it has become more important than ever to accurately characterize the electrical performance parameters of PV cells and modules. Photovoltaic reference solar cells (RSCs) are a crucial component of the PV testing methodology, with many National Metrology Institutes (NMIs) and some secondary calibration labs offering reference cell calibration services. The National Institute of Standards and Technology (NIST) for example, offers a variety of reference cell calibration services under the Standard Reference Instrument (SRI) 6014 program [2]. RSCs fundamentally achieve two unique objectives: First, a calibrated RSC allows the test engineer to measure the effective irradiance of their indoor solar simulator or the sunlight, if outside, incident on their PV device under test (DUT). Second, RSCs provide a much-needed traceability to the measurement protocol, allowing the performance parameters of the DUT to be reported under a standard reporting condition (SRC), such as the air mass 1.5 global reporting conditions with a total irradiance of 1000 W/m2 [3].

As stipulated in the World Photovoltaic Scale (WPVS) reference cell calibration program [4], RSCs require, among other things, a high, thermally conductive metal housing to protect the reference cell from damage while ensuring that the cell remains at the standard reference temperature of 25 °C. The housing typically has a unique geometry that must be fabricated through precise machining (such as by a Computer Numerical Control (CNC) milling machine) to accommodate the reference cell as well as the temperature and electrical connections. Acquiring or creating one of these RSCs, even without calibrations, can be costly for the laboratory looking to do precise electrical characterization measurements of their photovoltaic cells. Typically, the cost of the RSC fabrication is more than the cost of calibrating it by an NMI.

One way to lower the fabrication cost of the reference cell housing is to utilize less expensive manufacturing processes. Additive manufacturing, which is often referred to as 3D printing, includes on-site tabletop Thermoplastic Material Extrusion (TME) printing where a reel of material is fed into a hot extruder and a thin filament of material is placed onto the printing surface from the extruder. These low-cost, commercially available 3D printers offer a much quicker turnaround time compared to machining, as well as the ability to easily print unique geometries that are difficult to machine [5]. The TME printing is particularly enticing as the turnaround time is reduced from weeks to one day and the material can be easily changed to fit the part’s use [6]. Many different types of materials are now available for use by small tabletop 3D printers including metal-polymer composite materials.

When making electrical and thermal measurements on a PV cell exposed to simulated light, it is critical to maintain its temperature at 25 °C per [7]. Thus, the RSC instrument is placed on a temperature-controlled stage to ensure that the cell remains at 25 °C through efficient heat exchange during testing. This approach is highly dependent on the cell housing having a high enough thermal conductivity so that the reference cell remains at the target temperature. The biggest concern with these additive manufacturing options, especially with TME printing, is that the most common printing materials are plastics or polymers, like polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS), which have very low thermal conductivity [8]. Recently, metal-PLA composite materials have made an entrance into the TME printing market, improving the thermal properties of fabricated parts, but the thermal conductivity of these materials can be inconsistent, and the method of printing can further reduce the thermal conductivity [9], [10]. There has been work done to optimize some composite materials for applications requiring a higher thermal conductivity with TME additive manufacturing, including using carbon fiber [11], but these are not yet commercially available at a competitive cost. An alternative to TME printing is binder jetting where the material is applied as a powder and each layer is adhered with the use of a liquid binder. The binder is then removed, and the powder is typically densified. Binder jetting is not easily done in-house, but the powder material can be metallic resulting in better thermal conductivity [8].

In this work, we set out to evaluate whether there are commonly available materials in the market for low-cost additive manufacturing that result in a reference cell package with a thermal performance that is sufficient in comparison to machined all-metal aluminum versions. While an aluminum packaged RSC typically reaches thermal equilibrium in under 15 minutes in these applications, we consider the thermal performance to be satisfactory if equilibrium is reached in under 30 minutes. The metal-PLA composite materials commercially available for TME using a tabletop printer were easy to access and were used to print several RSC housings with different infill percentages. Here, by infill, we mean the percentage of material used in the inner volume of the housing. We also fabricated a 3D printed, all-metal (steel-bronze composite) housing by binder jetting utilizing an external vendor. All of these types of cell housings were incorporated into finished RSCs, complete with 2 cm x 2 cm printed circuit board (PCB) mounted silicon cells, windows, and 4-probe electrical and thermocouple contacts for electrical and temperature measurements. The thermal and electrical performance of all the finished RSCs were evaluated through extensive temperature dependent measurements both under ambient indoor lighting and under exposure to a solar simulator and were compared against a CNC fabricated NIST reference cell. Our findings show that all-PLA or even metal-PLA RSCs with 100 % infill percentages are not suitable for performance under a steady solar simulator or at temperatures significantly different than room temperature. However, they can be appropriate for other PV applications such as reference cells for indoor PV standards or under a flash-type solar simulator [12]. On the other hand, the all-metal 3D printed reference cell performed just as well as the standard CNC machined instrument.

2. Material Selection and Housing Fabrication

For this study, two additive manufacturing methods were selected with cost and speed of production in mind: TME printing and binder jetting. With these two additive manufacturing techniques, we considered three different materials: TME printed PLA, an TME printed copper-PLA composite material (copperFill)i that has previously been characterized [13], and a stainless steel-bronze composite material printed using a binder jetting process (Xometry’s X1 Metal 420i composed of 60 % 420-stainless steel and 40 % bronze infiltrant)i. CopperFill was selected due to the ease of use with TME printing and its increased thermal conductivity in comparison to PLA. The stainless steel-bronze binder jetting was appealing due to the reported thermal conductivity of 22.6 W m−1 K−1 and generally a much lower cost compared to other all-metal 3D printable materials.

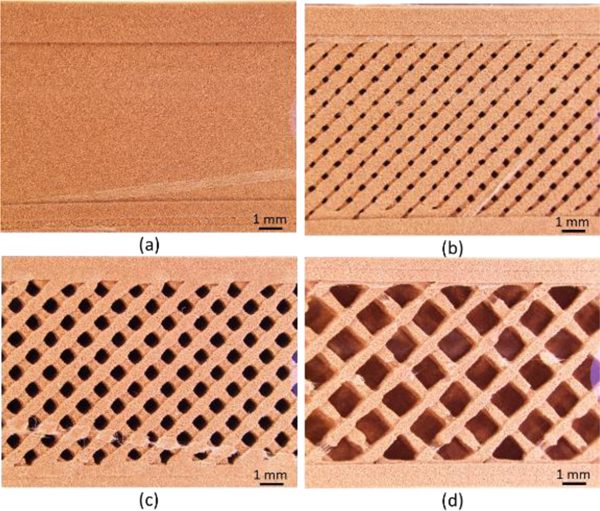

The PLA and copperFill materials were printed using a Lulzbot TAZ6i tabletop extrusion 3D printer at the highest detail (0.15 mm). The Computer Aided Design (CAD) files for all the 3D printed housings are based on the official NIST PV SRI service to allow a direct comparison with official reference instruments. The PLA was printed at 100 % infill and copperFill was printed with infills of 30 %, 50 %, 70 %, and 100 % to evaluate the impact of the airspace on the thermal conductivity. Figure 1 shows the cross section of the copperFill prints with the air gaps for 30 %, 50 %, and 70 % infills. The print times ranged from 9 hours to 15.5 hours, depending on infill. The stainless steel-bronze composite housings were produced by Xometry. The outer surfaces of all the 3D printed housings, particularly the bottom surface contacting the temperature-controlled stage and the interior surface where the cell is mounted, were lightly sanded to improve thermal contact. The copperFill housings were also painted black for aesthetic reasons. As printed, their color is a dull red.

Figure 1.

Cross section of the TME printed copperFill composites showing infills of 100 % (a), 70 % (b), 50 % (c), and 30 % (d).

3D printed samples were examined using a Stereo microscope (Olympus S261). To characterize internal structures of the copperFill materials, the samples were partially fabricated in the same print and build directions of the copperFill specimens used for the thermal conductivity measurements. Since a stainless steel-bronze composite material has 100 % infill, the internal structure was not investigated. The cross-sectional images of the copperFill materials are shown in Figure 1. The higher infill specimens showed less air space and overall well-defined cavity geometries across the copperFill materials. Relatively lower uniformity of wall thicknesses shown in the individual grids of the 30 % infill specimen became more uniform for the specimens with the higher infill ratios.

3. Material Thermal Conductivity Measurements

Our first consideration was to measure the thermal conductivity of each material. The thermal conductivities of aluminum and its alloys (88 W m−1 K−1 to 251 W m−1 K−1) [14] and PLA (0.185 W m−1 K−1) [13] are well known, so only the thermal conductivity of the copperFill and stainless steel-bronze materials were measured with a heat flux hot disc system.

The thermal conductivity measurements were performed using a transient plane source method (Hot Disk TPS 2500S) in ambient conditions with room temperature of 23 °C and 30 % RH. A sensor of 6.4 mm radius acting both as a temperature sensor and heat source was placed at the center of two identical specimens to set up a two-sided mode of testing, and a constant contact force of 256 N was applied for the purpose of reproducibility. Each pair of the 10 mm thick sanded copperFill material specimens were measured with a heating power of 0.08 W and a time duration from 52 s to 80 s using an isotropic module. Under similar measurement configurations, thermal conductivities of the stainless steel-bronze composite specimens were measured under 1 W heating power over a 6 sec duration. Because the stainless steel-bronze specimens were printed for reference cell packaging, the sensor was placed on an area with the minimum thickness of 10.9 mm located 17 mm from free edges in lateral direction. This location is underneath where the cell would be placed with no unique geometries in this region. The specimens were removed from the sensor and reinstalled after each measurement with a cool-down period of at least 30 min. The measurements were repeated three times for each set of specimens.

The thermal conductivity measurement results with corresponding uncertainties are shown in Table 1. Thermal conductivities of the copper-infill specimens were greater with increased infill percentage as expected due to decreased air volume. Considering effects of infill density and printing parameters [15], [16], the measured thermal conductivities of the 3D printed specimens in this study represent bulk thermal properties. The 100% infill copperFill material has a thermal conductivity that is higher than that of PLA but significantly below the thermal conductivity of copper (380 W m−1 K−1). These measurements are 14 % higher than previously reported values [13]. It is possible that this increase is due to a reduced surface roughness from sanding. In addition, the thermal conductivity decreased as the infill percentage decreased.

Table 1.

Thermal Conductivity of Additive Manufacturing Materials

| Material | Avg. thermal Conductivity (W m−1 K−1) |

|---|---|

| copperFill, 30% | 0.162 ± 0.001 |

| copperFill, 50% | 0.225 ± 0.001 |

| copperFill, 70% | 0.303 ± 0.001 |

| copperFill, 100% | 0.500 ± 0.005 |

| X1 Metal 420i (Steel-Bronze) | 30.97 ± 0.23 |

refers the standard deviation of thermal conductivity values taken as an estimation of the standard uncertainty

4. Reference Cell Temperature Measurements

While we could intuitively predict that the higher thermal conductivity materials will better suit the needs of a reference cell under a solar simulator, we did not know what minimum thermal conductivity will satisfy the conditions of maintaining the reference cell at a desired temperature. So, we constructed reference cell packages with each of the materials under consideration along with a standard CNC-machined aluminum reference cell as a control. These reference cell packages can be seen in Figure 2. Each cell has a type K thermocouple (TC) placed directly underneath the silicon cell to measure the temperature of the cell as accurately as possible. In addition, aluminum, copperFill, and stainless-steel packages were housed with a 4-wire electrical connection for I-V measurements.

Figure 2.

The tested silicon reference cell packages include, from left to right beginning in the front row: (a) NIST 1011, with a CNC-machine fabricated aluminum housing; (b) a binder jetting printed stainless steel – bronze housing; (c) an TME printed PLA package; and back row: silicon cells packaged in TME printed copperFill with (d) 100 %, (e) 70 %, (f) 50 %, and (g) 30 % infills. All cells have a port for thermocouple temperature measurement (labeled TC-K on NIST-1011. All but the all-PLA package have a 4-wire connection for I-V data (labeled I-V).

The reference cell packages are placed on an optical breadboard plate with internal channels to allow water flow through it, pumped by a precision circulating chiller as shown in Figure 3. This plate is used to control the temperature of reference cells. In the first experiment, we set the plate temperature to three different fixed temperatures and moved each reference cell from the ambient condition (T = 23 °C) to the isothermal plate and monitored the cell TC temperature as a function of time. The three plate temperatures were 10 °C, 25 °C, and 40 °C, with the results shown in Figure 4. As expected, the time for each reference cell package to reach an equilibrium temperature, less than a 0.1 °C change over 5 minutes, was inversely correlated with the thermal conductivity of the package material. The aluminum housing took less than 5 minutes in all measurements, the stainless steel-bronze material took generally less than 15 minutes, while the copperFill materials all took between 25 and 40 minutes, depending on plate setpoint and infill percentage. The PLA generally took at least 30 minutes, even with the smallest of the temperature differences. Also, we note that the reported temperature is from the TC area, in the middle of the housing, and does not represent the temperature at other locations of the housing.

Figure 3.

Reference cells were placed on a temperature-controlled plate underneath a small solar simulator. The cell temperature is monitored via the attached thermocouple wire (yellow adapter). The plate temperature is controlled with a water bath and is monitored via a thermocouple on the underside of the plate.

Figure 4.

The difference in temperature between the reference cell’s TC and an isothermal plate’s setpoint temperature at 3 different plate temperatures, (a) 10 °C, (b) 25 °C, and (c) 40 °C versus time. The measurements are performed under ambient room light with no solar simulator.

After gaining an understanding for the material performance on an isothermal plate without the presence of any intense external lighting, all the packages were placed on the same plate under a continuous solar simulator. Although reference cell calibrations under non-SRC conditions are gaining momentum, motivated by the growing indoor PV field and the need for powering the internet-of-things sensors, the SRC calibrations under 1000 W m−2 of simulated AM 1.5 G illumination is still a major end application of reference solar cells. Therefore, the ability of the package to maintain the reference temperature (25 °C) under a solar simulator is imperative. To accomplish this specification, the bath temperature was adjusted for each package to attempt to reach the reference cell condition. The bath temperature was limited to no less than 5 °C to avoid excessive condensation.

Figure 5 shows that only the aluminum packaged reference cell (NIST 1011), the stainless steel-bronze printed housing, and the copperFill housing with 100 % infill were able to reach an equilibrium temperature of 25 °C under a solar simulator. The bath setpoint temperatures for these packages to achieve the reference temperature were 23.0 °C, 20.7 °C, and 9.2 °C respectively. The other packages were unable to reach this temperature, even with a bath temperature of 5 °C to remove as much excess heat from the package as possible. And while the 70 % infill copperFill package was beginning to decrease in temperature after 40 minutes, it is an impractical wait time for a researcher needing to make reference cell measurements. These findings make it clear that only the stainless steel-bronze package and the copperFill when printed with 100 % infill may be able to satisfy the thermal performance for a solar reference cell under a steady state, solar simulator. However, the validity of this statement needs to be further investigated because the TC temperature measurements may not represent the actual cell temperature. For this reason, we need to next examine electrical measurements of the installed PV cell.

Figure 5.

Change in measured cell temperature over time under a solar simulator. If necessary, the temperature control bath was decreased to reach reference measurement temperature of 25 °C. The bath was decreased to no less than 5 °C.

5. Open Circuit Voltage - Temperature Measurements

While the thermocouple in each package is epoxied directly underneath the silicon reference cell, it does not experience the same irradiative effects as the cell exposed to the simulated sunlight. Because the open circuit voltage (Voc) of solar cells is very sensitive to temperature changes, we could verify whether the reference cell temperature was being accurately reflected by the TC measurements through Voc measurements of the reference cell over temperatures from 18 °C to 45 °C. We initially took measurements of the aluminum NIST 1011 cell and the stainless steel-bronze reference cell with the solar simulator continuously on and saw a linear relationship between the Voc and temperature, as shown in Figure 6. The open circuit voltages for different reference cells are generally very close at each temperature because the reference cells are from the same batch of silicon cells. We continued these measurements with the copperFill 100 % infill package (starting at 21.6 °C because that was the lowest equilibrium temperature with the bath setpoint at 5 °C), but noticed a significant drop in the Voc compared to the other reference cell packages. Since all the cells are of the same type, this performance suggested that the TC was measuring a lower temperature than the actual cell temperature when the package is under a high irradiance light source. This result is already an indication that the copperFill package will not suffice for SRC calibrations under a steady-state solar simulator.

Figure 6.

We measured the open circuit voltage at AM1.5G across a range of thermocouple temperatures for NIST 1011 (packaged in Aluminum), 100 % infill copperFill, and a steel-bronze material. The 100 % infill CopperFill composite was also measured with a manual flash to minimize temperature difference between the cell and the thermocouple. The datasets were fit using the model in Eq. 1 with ERE values of 3.219 × 10−5, 3.585 × 10−5, and 3.688 × 10−5 for the NIST 1011, 100 % infill copperFill, and stainless steel-bronze respectively.

To further investigate if this material would meet requirements for flash solar simulators (in which a short light pulse of duration 30 ms is applied to the cell while a current vs voltage (I-V) sweep is obtained from the cell using a fast, synchronized source-measure unit), we proceeded with flash measurements for the copperFill 100 % infill package. After taking these measurements, the data for all 3 packages were fit to Equation 1 below, describing the relationship between the temperature of the cell and its open circuit voltage [17]:

| (1) |

where T is the temperature, ERE is the external radiative efficiency of the cell, JL is the light-generated current density under the SRC, and J0rad[T] is the radiative dark current density as a function of temperature. For the temperature dependent term, J0rad[T], we used the approximate expression derived in [17] (their Eq. 16) with the appropriate temperature dependent bandgap energy for silicon. Equation 1 can be fit to the Voc vs T data with a single fitting parameter, namely the ERE.

Figure 6 shows the results of the measurements compared to the model fits of the data. The model fits the measurements of the aluminum NIST 1011 and stainless steel-bronze packages very well suggesting that the package material was sufficiently thermally conductive such that the TC was accurately measuring the cell temperature over the entire T range probed here. The small shift between these two cells is related to a small difference in their ERE. However, the copperFill with 100 % infill was not fit well by the model of Equation 1. This finding indicates that despite the solar simulator being flashed and not on continuously, the lower thermal conductivity of the package influenced the performance of the reference cell. The Voc suggests that the actual temperature is higher than measured at lower thermocouple temperature measurements, but lower at higher thermocouple measurements. The cell performance and the model show a particularly large discrepancy for temperatures outside of the 25 °C to 35 °C window. This suggests that the copperFill printed with 100 % infill may be acceptable under a flash solar simulator at standard reference conditions but taking measurements outside of this temperature range risks inaccurate measurements.

6. Additional Discussion

The results presented here suggest that all-metal 3D printed RSC housings can be a good substitute for CNC-machined ones if the intended calibration or end use application is under the SRC illumination conditions with a steady-state high intensity light source such as a solar simulator or directly under the sun. The composite copperFill material, even with a 100 % infill, does not have enough thermal conductivity to overcome the thermal management issues described in this work. At this point, it is not clear to us what the threshold thermal conductivity for a 3D printed material should be in order to overcome the thermal load limitations encountered here but it is likely that a value greater than 5 W m−1 K−1 may be needed. Outside the SRC condition, particularly under low ambient lighting with lower infrared irradiation and cell operating temperatures close to the ambient temperature, composite materials should provide a good alternative to expensive CNC machined materials.

7. Conclusion

We investigated several presently available materials in additive manufacturing as potential replacements to the reference cell housing. The material must sufficiently protect the reference cell and offer enough thermal conductivity to maintain the reference cell at the standard reference temperature of 25 °C. Our findings indicate that only the stainless steel-bronze material was satisfactory as a full replacement for the aluminum housing as it quickly reached thermal equilibrium, even under a steady state solar simulator and was thermally conductive enough such that the reference cell performance matched the thermocouple measurement. However, presently, its fabrication cost by a third-party vendor is comparable to the machined aluminum control. The 100 % infill copperFill material cannot maintain the reference temperature of 25 °C under the steady solar simulator but can perform well as a reference cell for indoor PV applications or under a flash solar simulator as long as reference temperature is close to the ambient temperature. We have presented two commercially available additive manufacturing materials that can produce reference cell instruments, but the conditions of the print and the cost are still very necessary considerations at this time.

8. Acknowledgement

The authors would like to thank John (Rusty) Hettenhouser for the original CAD design of the NIST reference cell housing.

Footnotes

Certain commercial equipment, instruments, or materials are identified in this paper in order to specify the experimental procedure adequately. Such identification is not intended to imply recommendation or endorsement by NIST, nor is it intended to imply that the materials or equipment identified are necessarily the best available for the purpose.” (NIST Disclaimer).

9. References

- [1].Feldman D. and Dummit K, “Winter 2023 Solar Industry Update.” Accessed: Apr. 02, 2023. [Online]. Available: https://www.nrel.gov/docs/fy23osti/85291.pdf [Google Scholar]

- [2].Hamadani BH, “SRI 6014 Calibrated Reference Photovoltaic Cell.” https://www.nist.gov/sri/standard-reference-instruments/sri-6014-calibrated-reference-photovoltaic-cell (accessed Apr. 02, 2023). [Google Scholar]

- [3].Hamadani BH and Dougherty B, “Solar Cell Characterization,” 2016, pp. 229–245. doi: 10.1007/978-3-319-20331-7_8. [DOI] [Google Scholar]

- [4].Osterwald CR et al. , “The world photovoltaic scale: an international reference cell calibration program,” Progress in Photovoltaics: Research and Applications, vol. 7, no. 4, pp. 287–297, Jul. 1999, doi: . [DOI] [Google Scholar]

- [5].Attaran M, “The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing,” Bus Horiz, vol. 60, no. 5, pp. 677–688, Sep. 2017, doi: 10.1016/j.bushor.2017.05.011. [DOI] [Google Scholar]

- [6].Dey A, Eagle INR, and Yodo N, “A review on filament materials for fused filament fabrication,” Journal of Manufacturing and Materials Processing, vol. 5, no. 3. MDPI AG, Sep. 01, 2021. doi: 10.3390/jmmp5030069. [DOI] [Google Scholar]

- [7].Standard Test Method for Electrical Performance of Photovoltaic Cells Using Reference Cells Under Simulated Sunlight, ASTM Standard E948– 16, ASTM International, West Conshohocken, PA, USA, 2016. [Google Scholar]

- [8].Bourell D. et al. , “Materials for additive manufacturing,” CIRP Ann Manuf Technol, vol. 66, no. 2, pp. 659–681, 2017, doi: 10.1016/j.cirp.2017.05.009. [DOI] [Google Scholar]

- [9].Cai Z. et al. , “Progress of Polymer-Based Thermally Conductive Materials by Fused Filament Fabrication: A Comprehensive Review,” Polymers, vol. 14, no. 20. MDPI, Oct. 01, 2022. doi: 10.3390/polym14204297. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [10].Meng X, Yu H, Wang L, Wu X, and Amin BU, “Recent Progress on Fabrication and Performance of Polymer Composites with Highly Thermal Conductivity,” Macromol Mater Eng, vol. 306, no. 11, p. 2100434, Nov. 2021, doi: 10.1002/mame.202100434. [DOI] [Google Scholar]

- [11].Ibrahim Y, Elkholy A, Schofield JS, Melenka GW, and Kempers R, “Effective thermal conductivity of 3D-printed continuous fiber polymer composites,” Advanced Manufacturing: Polymer & Composites Science, vol. 6, no. 1, pp. 17–28, Jan. 2020, doi: 10.1080/20550340.2019.1710023. [DOI] [Google Scholar]

- [12].Hamadani BH and Campanelli MB, “Photovoltaic Characterization under Artificial Low Irradiance Conditions Using Reference Solar Cells,” IEEE J Photovolt, vol. 10, no. 4, pp. 1119–1125, 2020, doi: 10.1109/JPHOTOV.2020.2996241. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [13].Laureto J, Tomasi J, King JA, and Pearce JM, “Thermal properties of 3-D printed polylactic acid-metal composites,” Progress in Additive Manufacturing, vol. 2, no. 1–2, pp. 57–71, Jun. 2017, doi: 10.1007/s40964-017-0019-x. [DOI] [Google Scholar]

- [14].et al. Rumble John R, CRC Handbook of Chemistry and Physics, 103rd ed. Boca Raton, FL: CRC Press/Taylor & Francis, 2022. [Google Scholar]

- [15].Elkholy A. and Kempers R, “An accurate steady-state approach for characterizing the thermal conductivity of Additively manufactured polymer composites,” Case Studies in Thermal Engineering, vol. 31, p. 101829, Mar. 2022, doi: 10.1016/j.csite.2022.101829. [DOI] [Google Scholar]

- [16].Elkholy A, Rouby M, and Kempers R, “Characterization of the anisotropic thermal conductivity of additively manufactured components by fused filament fabrication,” Progress in Additive Manufacturing, vol. 4, no. 4, pp. 497–515, Dec. 2019, doi: 10.1007/s40964-019-00098-2. [DOI] [Google Scholar]

- [17].Dupré O, Vaillon R, and Green MA, “Physics of the temperature coefficients of solar cells,” Solar Energy Materials and Solar Cells, vol. 140, pp. 92–100, Sep. 2015, doi: 10.1016/j.solmat.2015.03.025. [DOI] [Google Scholar]