Graphical abstract

Keywords: Bioinspired, Biomimetic material, Micro/nanostructure, Antifouling surface

Highlights

-

•

A critical review of biomimetic micro-structured surfaces for antifouling and other applications is provided.

-

•

Inspiration from natural organisms and corresponding products/technology are presented.

-

•

Applications of microstructures with different antifouling strategies and other properties are summarized.

-

•

Technology of fabricating biomimetic microstructures is concluded.

-

•

The defects of the biomimetic surface and its future development are proposed.

Abstract

Background

Since the inception of the term “Biomimetics” in 1991, the concept of utilizing natural solutions or deriving inspiration from nature to address contemporary engineering challenges has gained significant attention within the scientific community. Organisms, in order to thrive in harsh environments, have evolved a wide range of micro/nanostructured surfaces, which serve as a rich source of inspiration for the development of artificial micro/nano-structured surfaces. These natural adaptations provide valuable insights and novel pathways for fabricating such surfaces.

Aim

To conclude recent advances in micro/nano-structured surfaces from four aspects: biomimetic micro-structured surfaces of plants and animals, properties and applications of biomimetic surfaces, methods of preparations, and their limitation.

Key Scientific Concepts:

Artificial micro/nano-structured surfaces inspired by animals and plants are classified and demonstrated according to their living environment. The performances, principles and preparation techniques of natural superhydrophobic surfaces, slippery liquid-infused porous surfaces (SLIPS), anisotropic surfaces, etc. are described in detail. Moreover, the pros and cons of each preparation measures are compared and the challenges developing large-scale, cost-effective surface microstructure preparation processes are pointed out. In the end, the development trends of artificial micro/nano-structured surface are forecasted.

Introduction

Formally proposed in 1960, “Bionics” aims to imitate or draw inspiration from nature. Over the past few decades, this bionic approach has led to remarkable inventions that have greatly advanced society, including airplanes, sonars, and radars. In the information era, researchers have developed an “autocorrelation velocimeter” based on the optokinetic response of weevils, paving the way for micro-nano structures and systems. As the concept of bionics has evolved, scientists introduced the notion of “Biomimetics”, which involves extracting excellent designs from nature. Nowadays, for its advantages of high design efficiency, considerable sustainability, environmental protection, creation diversity and so on, there are countless examples of “Biomimetics” in all walks of life, such as medicine [1], military [2], industry [3], etc.

Biomimetic micro-structured surfaces have garnered significant interest from scientists and engineers in the materials field. These surfaces possess exceptional properties, involving anti-fog and anti-icing functions [4], [5], self-cleaning effect [6], corrosion resistance [7], drag reduction performances [8], and antifouling property. Particularly, the development of biomimetic surfaces for antifouling applications has become a focal point within the marine environment domain.

Biofouling is a significant challenge in the marine environment, causing considerable issues. Conventional antifouling coatings typically contain chemically active compounds, like cuprous oxide. However, these coatings pose high toxicity risks to marine organisms, both fouling and non-target species can contaminate seawater. In light of the growing importance of environmental protection, the development of environmentally friendly antifouling measures has become crucial. To address the environmental concerns associated with traditional coatings, researchers have focused on biomimetic antifouling coatings that imitate the micro-structured surfaces found in marine life [9]. Zhao et al. [10] mimicked the antifouling mechanism of Laminaria japonica and modified surfaces chemically in the layer by layer (LbL) self-assembly way and the bacteriostatic ability of as-prepared films was up to 96.2 ± 1.3% implying prominent antifouling characters. Munther et al. [11] took advantage of etched silicon molds merging various micromachining technology to imitate natural shark skin which are discovered antifouling surfaces and even if the patterns they designed were subjected to heavy mechanical wear, they were still highly antifouling, reducing Escherichia coli (E. coli) settlement up to 56%. Further, aiming at integrating surface chemistry and microtopographic patterns for marine antifouling materials, Yang et al. [12] used various surface chemistries to prepare biomimetic shark skin surfaces and detected changes in adhesion strength of adhesive proteins on functionalized surfaces. It turned out that the adhesion strength of proteins decreases with the increase of the surface topography height, and the chemical modifications also have an obvious effect on the reduction of protein adhesion. In our previous study, we drew inspiration from the microstructures and secretions found on the surfaces of diverse marine organisms. By leveraging dopamine as a coupling agent, we successfully developed antifouling coatings on micro-structured glass. These coatings had a combination of microstructural and peptide modifications to effectively deter the attachment of algae and bacteria, incorporating the grafting of nisin onto the surface [13]. We utilized Phaeodactylum tricornutum (P. tricornutum) and Bacillus sp. for antifouling performance test assays and consequences revealed as-fabricated samples to be inhibiting biofouling. Additionally, a collaborative antifouling surface for inhibition of algal adhesion with bionic microstructures and polypeptide modification was established triumphantly based on our previous work [14]. Antibiofilm experiments demonstrated that anti-algal rates of synergistic surfaces could reach as high as approximately 80%∼90%. Apart from ocean engineering, it is also indispensable for other areas such as medicine [15], food safety [16], aerospace [17], etc. to acquire biomimetic antifouling surfaces.

This paper presents a comprehensive review of the recent advancements in biomimetic micro/nano-structured surfaces for antifouling, aiming to provide valuable insights for researchers in this field. The review covers four key aspects: (1) biomimetic micro-structured surfaces found in both terrestrial and aquatic plants and animals, (2) diverse antifouling strategies employing microstructures, (3) preparation methods encompassing laser, deposition, etching, 3D printing, templating and bio-additive techniques, etc. and (4) the merits and demerits associated with these approaches. By exploring these aspects, this review offers innovative ideas and guidance for researchers in the pursuit of effective biomimetic micro-structured surfaces for antifouling applications.

Biomimetic microstructured surfaces of plants

Microstructures inspired by terrestrial plants

Terrestrial plants having particular microstructures such as Nepenthes [18], roses [19], rice [20], etc. are blessed with antifouling properties and most of them are derived from distinct strategies of prominent hydrophobicity. Some basic information is summarized in Table 1. The anti-fouling strategies inspired by the microstructures of terrestrial plants are mainly categorized into four types:Slippery liquid-infused porous surfaces (SLIPS) [21], Wenzel state superhydrophobicity [22], Cassie-Baxter state superhydrophobicity,[23] and anisotropic superhydrophobicity.[24] In SLIPS, a liquid lubricant is able to held to the surface by a porous structure or polymer network substrate with a high specific surface area, which can spontaneously form a perfect smooth interface and play a splendid anti-fouling role. As for the Wenzel state, liquid and solid are in close contact, and the interface does not contain gas. Taking rose as an example, Wenzel state superhydrophobicity is due to the structural characteristics of the combination of micron-level protrusions and nano-sized folds on the petal surface [25]. In contrast to the Wenzel state, the Cassie state indicates incomplete contact between the liquid and the solid and the presence of a gas. Thanks to the combination of micronscale scales and nanoscale grooves on the wing surface, the butterfly wing surface can achieve Cassie-Baxter state superhydrophobicity [26]. Antifouling functions of the rice leaf presents anisotropic superhydrophobicity, because of the grooved structure and anisotropic permutation on the leaf surface with micropapillae [24].

Table 1.

Basic information of different terrestrial plants inspiring scholars.

| Strategy | Name | Inspiration | Manufacture | References |

|---|---|---|---|---|

| SLIPS | Nepenthes | Unidirectional liquid diffusion of the peristome; Hydrophobilicity of the waxy zone |

Lubricant-infused slippery (LIS) surfaces; Slippery liquid-infused porous surfaces (SLIPS); Slippery polydimethylsiloxane (PDMS) film (BSPF) |

[4], [30], [141] |

| Wenzel state superhydrophobicity | Rose | Rose petal effect | Superhydrophobic rose petal-like surface; Skin-like superhydrophobic elastomer surface; Novel sandwich-like cell walls |

[19], [32], [142] |

| Cassie-Baxter state superhydrophobicity | Purple orchid | Wettability, low adhesion and robust liquid repellency of leaves | Biomimetic superhydrophobic surface | [34] |

| Kapok | Superhydrophobic properties of petals; Self-cleaning functions both in air and oil of petals |

– | [35] | |

| Bauhinia | Hydrophobilicity of leaves | Biomimetic superhydrophobic surface | [36] | |

| Anisotropic superhydrophobicity | Rice | Anisotropic wettability of leaves | Rice leaf-like wavy surfaces; Rice leaf-like bidirectional/ tridirectionally anisotropic sliding surface |

[37], [38] |

As a typical representative of owning SLIPS, Nepenthes are extensively studied for its distinct constructions. The previous study discovered that the Nepenthes surface structure serves to immobilize lubricating fluids, forming a continuous covering film on the surface [27]. As a consequence of its unique properties, SLIPS of Nepenthes has motivated many scholars to construct Nepenthes-inspired microstructures [28], [29].

It was found that of Nepenthes alata (N. alata) has different regions involving diverse functions (Fig. 1A). Conspicuously, N. alata has two parts: a peristome and a pitcher. The pitcher is extensively differentiated to two zones: the waxy zone and the digestive zone. The waxy zone has downward-directed lunate cells which offer hydrophobicity for the surface and lunate cells are covered with wax crystals. Feng et al. [30] developed a stable SLIPS with enhanced lubricant storage by synergistically constructing the structural design of conventional micro-pincushion and nanoparticles. Nevertheless, lubricant-impregnated surfaces are lack of endurance by leaking the injected liquid, resulting in the reduction of antifouling functions during applications. With an intention of exploring the solution, Fan et al. [31] prepared WO3-based slippery coatings with excellent hydrophobicity and sliding stability. The as-produced slippery WO3 coating could lock the silicone oil firmly, exhibiting outstanding water collection performance and superior ominiphobicity to divergent liquids with diverse interfacial tensions. Besides, two divergent microstructures with superhydrophobicity were prepared by electro deposition and then lubricant-infused surfaces with antifouling capability were fabricated. (Fig. 1B&C) [29] Inspired by pitcher plants and natural anti-wetting surfaces, Feng et al. [4] designed a lotus leaf-inspired regular-like microstructure arrays through common UV lithography as well as soft replication initially. Subsequently, they successfully fabricated the biomimetic slippery polydimethylsiloxane (PDMS) film (BSPF). The film was afforded hydrophobic surface, smooth interface and regular-like microstructure.

Fig. 1.

A: The brief structures and corresponding functions of Nepenthes. A-1: Optical images of a pitcher of Nepenthes. A-2: A cross-sectional image of the peristome [145]. A-3: SEM micrographs of the waxy zone [146]. B: Two superhydrophobic surfaces with bayberry-like structure (left) and hyacinth-like structure (right) inspired by SLIPS of Nepenthes. C: CLSM images characterizing the antifouling performance of bioinspired surfaces [29].

The Wenzel state and Cassie- Baxter states are most mentioned for hydrophobic surfaces. The rose petal surface is in Wenzel state, presenting “rose petal effect” with a water contact angle (WCA) of approximately 152.4°, and water droplets adhere tightly to the surface regardless of the petal's orientation. Chen et al. [32] utilized raspberry-like particles (multiscale hierarchical particles without nanocomposite capping) to establish a superhydrophobic rose petal-like surface with strong water adhesion. Inspired by the specific structure of rose petals, Zhang et al. [19] constructed novel sandwich-like cell walls with biomimetic rose petal surfaces by incorporating renewable natural rubber latex particles. The biomimetic structural design afforded Graphene aerogel (GA)/ natural rubber latex (NRL) high toughness to withstand shock, torsion, and even ultrasonic damage as well as excellent adhesion to water. With an intention of boosting the superhydrophobic and super-absorbent characteristics of cotton, Zhang et al. [33] patterned it with micro- and nano-structures, sparked by the rose petal effect. The cotton fabric they produced exhibit self-cleaning, superhydrophobic, and oil–water separation properties.

Moreover, there are abundant biosurface microstructures with Cassie- Baxter state superhydrophobicity to be explored on land. Inspired by purple orchid leaves, Li et al. [34] constructed a biomimetic superhydrophobic surface through electrodepositing nanoscale organometallic coatings on laser-patterned microstructures, which possesses the same characteristics as purple orchid leaves, with remarkable wettability (WCA = 163.54 ± 1.59°) and robust liquid repellency. Chen et al. [35] investigated the characteristics of kapok petals and found that they exhibited superhydrophobic properties with a static WCA higher than 150°. The presence of single-scale micro-trichomes on kapok petals displays no more nanocrystals. The leaves of natural Bauhinia Linn. are blessed with exceptional hydrophobicity. Based on the hierarchical microstructure of Bauhinia leaves, Lu et al. [36] constructed a biomimetic microstructure on the surface of 316L stainless steel (SS) successfully via laser texturing with self-designed circular patterns. The prepared biomimetic superhydrophobic surface exhibited outstanding anti-adhesion, antifouling and self-cleaning properties.

In addition to the aforementioned hydrophobic types, another intriguing aspect of superhydrophobicity is anisotropy. Rice leaves, renowned for their directional transport characteristics, have garnered attention in both fundamental research and practical applications. Yang et al. [37] identified multi-level grooves and secondary structures on the surface of rice leaves, which endowed them with anisotropy, hydrophobicity as well as antifouling characteristics. Subsequently, they used diffractive femtosecond laser raster scanning to construct an aluminum surface with a structure resembling that of rice leaves. The textured surface displayed super hydrophobicity with splendid anisotropy. Fang et al. [38] constructed a rice leaf-like bidirectional/tridirectionally anisotropic sliding surface on a surface of polydimethylsiloxane (PDMS).

Microstructures inspired by aquatic plants

The antifouling performances of the surfaces of aquatic plants from freshwater areas or undersea are discussed in this part. Some brief information is listed in Table 2. There are about three kinds of antifouling methods inspired by the microstructures of aquatic plants “Lotus” state superhydrophobicity, Wenzel state superhydrophobicity and natural antifoulants. Among them, “Lotus” state is an exception of Cassie state. Similar to the rose effect, aquatic plants such as Salvinia also have the “Salvinia effect” leading to the Wenzel state, attributing to the numerous micron-sized hairs on the surface of its leaves, which are shaped like egg beaters, covered with wax nanocrystals and hydrophilic patches of dead cells exist the tip of hairs’ crown-like heads [39]. Since the microscopic topography of the special size facilitates the presence of antifoulants, marine plants like kelp possesses a synergistic surface with microstructures and chemical modification [10].

Table 2.

Basic information of different aquatic plants inspiring scholars.

| Strategy | Name | Inspiration | Manufacture | References |

|---|---|---|---|---|

| Cassie-Baxter state (“Lotus” state) superhydrophobicity | Lotus | Lotus effect | Artificial superhydrophobic coatings (SHCs); Superhydrophobic Zn-Fe coating (SHZIC);Biomimetic laminated polypropylene/graphene powder (PP/GP) nanocomposites; Lotus leaf-like hierarchical TiO2 structures; Controllable and integrated electric heater |

[7], [43], [44], [45], [143] |

| Phragmites | Hydrophobicity and the submillimeter ridge structure of leaves | Phragmites communis leaf (PCL)-like polydimethylsiloxane (PDMS) samples | [144] | |

| Wenzel state superhydrophobicity | Salvinia | Salvinia effect | Eggbeater structures; Biomimetic artificial Salvinia surface |

[47], [48] |

| Natural antifoulants | Laminaria (Kelp) |

Antifouling properties | Biomimetic material; Flowing jet layer |

[10], [49] |

| Surface morphology | Mangrove | Antifouling property of the leaves | Biomimetic surface with microscopic ridge-like morphology | [50] |

The specific surface structure of lotus leaves is formed by microstructures (apparently raised to micron-sized epidermal cells), which are covered by nano roughness (a very dense layer of epidermal wax), inclining the surface to retain Cassie-Baxter state. (Fig. 2A) The micro/nano hierarchical composite structure forms a physical barrier to the surface matrix against biofouling organisms and greatly decrease fluid resistance due to the air- retaining effect that lessens boundary layer viscosity ensuring that the lotus leaf presents super hydrophobicity and low adhesion characteristics [40], [41]. Furthermore, these microstructures prevent liquid penetration to the surface and endow lotus leaves with a self-cleaning function and the “lotus effect” occurs [42].

Fig. 2.

Surface microtopography and biomimetic structures of lotus leaf and Salvinia molesta leaf. A: Scanning electron micrographs of leaf surface. A-2: Nano-scale branched structures exist on the micro-scale papillary structure on the surface. A-3: Nanoscopic wax crystals [147]. B: Images of lotus leaf-like microstructure with layered TiO2 film(B-1)(B-2) and its static contact angle.(B-3) [44] C-1: Photo of Salvinia molesta leaf. C-2: Partially zoomed in on a leaf. C-3: The leaf submerged underwater causing a silvery appearance with air trapped [48]. D: A droplet placed on the leaf (left) and SEM image of the eggbeater hair structure (right). E: SEM images of artificial eggbeater structure. F: Water drop on the surface with 3D-printed eggbeater microstructures [47].

Currently, taking inspiration from the “lotus effect”, artificial superhydrophobic coatings (SHCs) showing a high water contact angle (WCA > 150°) and low sliding angle (SA < 10°) have been increasingly developed to establish the multi-functional coatings [43]. However, numerous existing methods are flawed with high cost, complicated process, etc. Tian et al. [7] prepared a superhydrophobic Zn-Fe coating (SHZIC) on carbon steel (CS) surfaces with a less complicated, low-cost, and environmentally friendly way. They created Zn-Fe coating in an alkaline glycerol non-cyanide Zn–Fe plating solution followed by grafting of tetradecanoic acid with a coordination reaction. The textured SHCs was experimentally proved to be greatly antifouling, self-cleaning, anti-corrosive and stable. Chen et al. [44] completed lotus leaf-inspired hierarchical TiO2 structures via combining vacuum assisted soft imprinting and hydrothermal technics. The modified hierarchical surface illustrated a WCA of approximately 155°. (Fig. 2B) Chen et al.[32] prepared superhydrophobic lotus-leaf-like fabrics via multiscale hierarchical particles (MHPs) with appropriate capped nanocomplexes, exhibiting excellent stain resistance and outstanding mechanical stability.

The nanostructures on the lotus leaf surface play a crucial role in its super hydrophobicity and self-cleaning properties. Nevertheless, these nanostructures are difficult to be replicated precisely. Sun et al.[45] prepared a controllable and integrated electric heater for aerospace via the super-flexible carbon nanotube wire (CNW)/PDMS superhydrophobic biomimetic nanocomposite. The results indicated that the electric heater produced by the combination of ultra-flexible CNW/PDMS superhydrophobic biomimetic nanocomposites illustrated excellent hydrophobicity and ice repellency. Du et al.[17] fabricated a superhydrophobic, self-cleaning, and moisture-permeable membrane with biomimetic microstructures via a facile two-step strategy combining phase separation and electro spraying. The lotus leaf-like superhydrophobic surface was successfully prepared by depositing composite zirconium carbide (ZrC) and silica (SiO2) composites with different size scales. Zhao et al.[46] proposed a facile polydimethylsiloxane(PDMS)-based approach to fabricating single-layer flexible capacitive pressure sensor (SPPS) and double-layer pressure sensors (DPPS) with high sensitivity for the purpose of reproducing the surface microstructure of lotus leaf PDMS films and establishing a highly sensitive flexible capacitive pressure sensor (FCPS).

One typical example of superhydrophobic surfaces among aquatic plants is the “lotus effect”, and another is the distinct combination of hydrophilic pathways on superhydrophobic surfaces (“Salvinia effect”), which shows the efficient design of perennial air retention and droplet manipulation (Fig. 2C&D). The leaf surface is covered in dense hairs Drawn inspiration from the superhydrophobic surface of the floating fern Salvinia molesta leaf, Yang et al[47] fabricated eggbeater structures with hydrophilic materials, revealing outstanding superhydrophobicity and petal effect (Fig. 2E&F). Xiang et al.[48] found that Salvinia molesta has superior mosquito repellent ability underwater. It can effectively make use of air to replace water in the microstructure and robustly recycle continuous air mattresses. Additionally, they succeeded in producing a biomimetic artificial Salvinia surface following natural design principles.

In marine environments, due to antifoulants on the surface, Laminaria japonica (L. japonica) demonstrates remarkable antifouling capabilities in a relatively stationary state compared to cruising organisms. Draw inspiration from the antifouling properties of L. japonica, Zhao et al.[10] investigated synergistic antifouling effect between surface morphology and chemically modifying. Firstly, they analyzed the L. japonica surface and reproduced its form via a facile molding process. Furthermore, chemical modification with sodium alginate and (guanidine-hexamethylenediamine-PEI) (poly(GHPEI)) was carried out on the isotropic microstructure surface of the PDMS replica by a layer-by-layer (LbL) self-assembly measure, and the results indicated that the obtained biomimetic material presented splendid anti-adhesion and anti-fouling properties. Based on the antifouling mechanism of kelp, Liu et al.[49] proposed a novel biomimetic antifouling measure on the basis of water jets. The approach aims to construct a flowing jet layer close to the marine structure surface. In addition to the above antifouling strategies, the leaf of Mangrove is also noteworthy for its unique surface morphology. [50].

Biomimetic microstructured surfaces of animals

There are big differences between animals and plants, although both of them are called creatures. As a result, the microstructures that animals have evolved are fairly different from those of plants. The chapter roughly divides animals into two groups: terrestrial animals and aquatic animals. In this part, the article discusses the theory and inspirations scholars acquired of various micro-structured surfaces of animals.

Microstructures inspired by terrestrial animals

Terrestrial animals have evolved various multifunctional microstructures such as gecko feet[51] with extraordinary antifouling, self-cleaning and adhesive performance in harsh environment; beetle wings[52] containing outstanding hydrophobicity, attachment capability, anisotropic and non-uniform characteristics, etc. The summary of terrestrial animals’ antifouling methods is in Table 3. Some terrestrial animals have microstructures of specific sizes or shapes on particular parts of their bodies that can play a role in antifouling, while others combine microtopographies with secretions as antibiofouling measures. Wings of insects can adapt to varied harsh environments and resist dirt and microorganism. Most of wings are blessed with nanopillars, but they vary in distribution and size. Typical instances are cicadas and dragonflies. The surface of the cicada has an orderly array of cones,[53] while the nanopillars on the wings of the dragonfly are randomly dispersed.[54] Reptiles, take geckos as an example, they own hundreds of paddle-shaped projections on their toes, and millions of setae on each flap, each of which ends in hundreds of spatulae.[55] Such microstructures contribute to the “Gecko” state[56] involving antifouling, superhydrophobic, antibacterial, self-cleaning functions.[57] Unlike antifouling approaches that solely rely on microstructures, animals such as collembola takes advantage of both its unique micromorphology and wax layer on cuticle to resist natural contaminants.[58].

Table 3.

Basic information of different terrestrial animals inspiring scholars.

| Strategy | Name | Inspiration | Manufacture | References |

|---|---|---|---|---|

| Surface micro/nanostructure | Cicada | Nano-pillar scale arrays on the wings | Cicada-inspired FHA nanostructured surface | [59] |

| Gecko | Self-cleaning and antibiofouling characters of skins and feet | Gecko feet-like gel micro-brushes; Artificial self-cleaning Fe3O4/PDMS composites |

[51], [62] | |

| Snail | Oil repellent function in water of shell | Snail shell-like structures | [63] | |

| Both microstructure and wax layer | Collembola | Superhydrophobicity, liquid repellency antifouling and self-cleaning performances of cuticle | – | [58] |

It is found that insects wings are constructed with nano-pillar scale arrays, which endow them with marvelous antibacterial performance. (Fig. 3) Based on the nano porous microstructure on the surface of cicada wing, Ge et al.[59] introduced the antibacterial strategy of fluorinated hydroxyapatite (FHA), and cicada-inspired FHA nanostructured surface was first created on acid-etched titanium (AETi) plates with an exceptional antibacterial ability. In order to reduce costs and simplify the preparation process, Reid et al.[60] exploited UV-curable polymers to mimic the surface microstructure of the wings of four cicada species. The experimental results showed that the antibiofouling performance of the biomimetic structure was comparable with that of natural cicada. Similarly, owing to the micron-scale topographies of surface, gecko skins are blessed with prominent properties to resist bacteria. Drawing on the advantages of the natural microtopography existing on terrestrial animals like geckos and so on, Wu et al.[61] reproduced four topographic patterns on coatings having outstanding capability to restrain bacterial adhesion. Du et al. [51] concentrated on the wonderful self-cleaning capacity of gecko’s feet for marine antifouling. They established a hierarchical structure consist of gecko feet-like gel micro-brushes and modified textured surface using stimuli-responsive polymer nano-brushes. It came out that their creation makes positive contribution to marine antibiofouling and self-cleaning materials. Also attracted by self-cleaning structures of gecko, Dong et al. [62] described a straight and low-cost measure to create self-cleaning surface. They exploited photolithography to build gecko’s structure hierarchy and the surface was modified by the PDMS-magnetic nanoparticles. The detection showed that the self-cleaning rate of the obtained surface reached 24.3%. In addition, the microstructures also render the snail shell oil-repellent, superhydrophobic and antifouling. Nishino et al.[63] designed snail shell-inspired convexo-concave microtopography to gain antifouling ability for oil repelling. Considerable oil resistance and antifouling function were acquired from the water–oil mixture flow experiment.

Fig. 3.

An antifouling instance by imitating cicada wing microstructure. A: Photo of cicada and its wing microtopography. B: Interaction of the Pseudomonas aeruginosa cells with the wing surface (left) and viability experiments of bacterial cells stained with propidium iodide (right). C: AFM image indicating the bacterial cells impacted by the surface’s acting (arrows). D: Gold-coated cicada wings maintain bactericidal effect on bacterial cells interacting with the modified surface chemistry. E: Diagram of cell attachment onto cicada wing nanopillars [148].

As ancient arthropods, to fit the surroundings and prevent fouling objects, Collembola’s cuticle surface developed to be superhydrophobic and liquid repelling. Due to the antifouling and self-cleaning performances, springtail cuticle turns to be an attractive objective of biomimetic materials design. Schmuser et al.[58] discussed the function of the cuticle chemistry for the Collembola species Orchesella cincta (Collembola, Entomobryidae). The results demonstrated that strategies to accomplish water repellency originated from special micromorphology and secretions on the surface of cuticle. As for biomimetic materials, it may be more facile to obtain certain applications by combining a straightforward microstructure imitating the cuticle of O. cincta for a hydrophobic coating.

Microstructures inspired by aquatic animals

The microstructures of aquatic animals are highly different from the animals on land as a consequence of different living condition. The environment under the sea demands drag reduction, anti-fouling and self-cleaning characteristics etc. for aquatic creatures such as sharks,[64] loaches,[65] corals[66] and so on. Some brief introduction is listed in Table 4. Aquatic animals show three main ways to prevent biofouling: depending on special microtopographies on the surface, exploiting mucus layer and secreting particular proteins. For animals that move through the water at high speeds, such as sharks, their skins consist of an orderly array of placoid scales, which effectively protects against attachment by marine organisms. Animals that are relatively still underwater don’t share similar micromorphological characteristics. For instance, mussels possess equidistant lines with a ladder-shaped form on the shell surface microtopography, while surfaces of different marine shells display varisized bumps and pits.[67] For most fish, the scales overlap each other at the microscopic scale in the pattern of periodic ripple structures and the mucus layer produced by outer skins of fish endows scales with more outstanding antifouling and drag reduction functions.[68].

Table 4.

Basic information of different aquatic animals inspiring scholars.

| Strategy | Name | Inspiration | Manufacture | References |

|---|---|---|---|---|

| Surface micro/nanostructure | Shark | Superhydrophobicity drag reduction, repellency of micro-organisms and of skin | Biomimetic shark skin surface; Durable multifunctional surfaces;Biomimetic shark-inspired (BioS) subsoiler |

[11], [71], [91] |

| Mussel | Antifouling of surface | Biomimetic mussel-like shells | [78] | |

| Urchin | Self-cleaning and suppression characteristic of membrane | Biomimetic urchin-like hierarchical surface structure | [79] | |

| Mucus layer | Crucian | Wettability of scales | – | [80] |

| Loach | Slippery surface of skin | Covalent biopolymer-coated surfaces | [65] | |

| Secreting proteins | Fluorescent corals | Antifouling strategies | Polydimethylsiloxane (PDMS)–phosphor–silicone rubber sandwich structure coating | [66] |

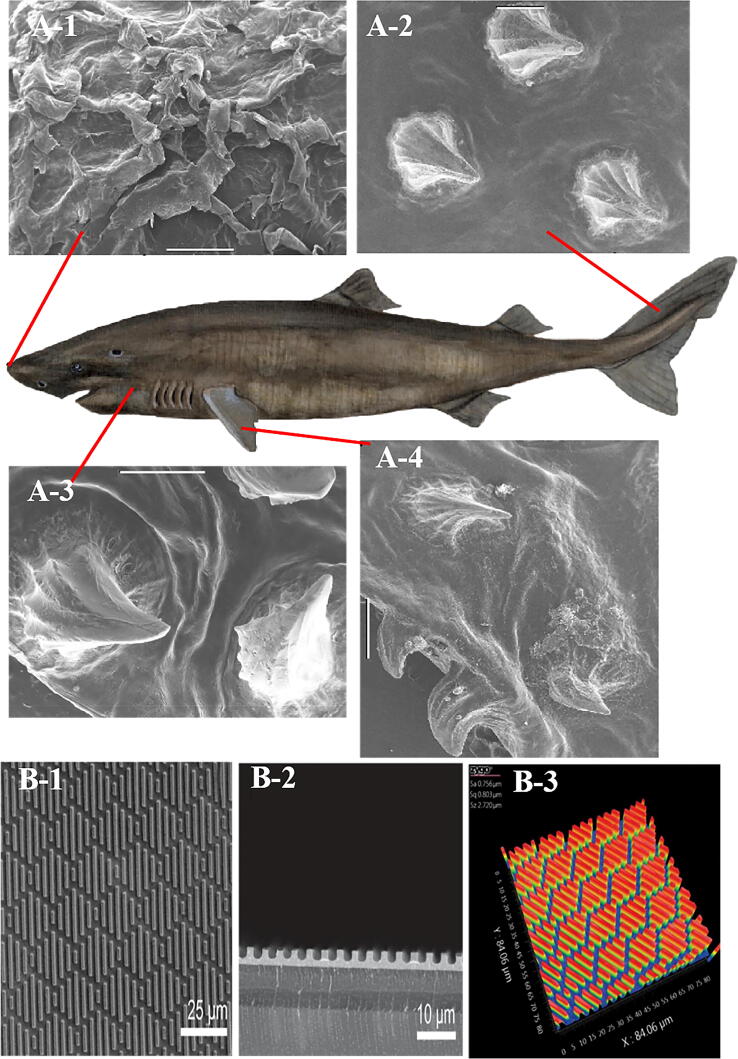

Presently, biomimetic engineering of shark skin surfaces has drawn extensive attention. The surface structure of shark skin is extremely intricate, constructed with microarrays called placoid scales or dermal denticles. It was discovered that denticles display a riblet-like morphology and the surface of concave grooves show nanostructured protuberances (Fig. 4A).[69], [70] The drag reduction, more effective movement in the sea and repellency of micro-organisms attribute to the specific structure of sharks' denticles. For the reduction of microbial attachment and the inactivation of attached microorganisms, based on antifouling shark-skin patterns, Dundar et al.[71] advanced a facile method to manufacture durable multifunctional surfaces by loading antibacterial titanium dioxide (TiO2) nanoparticles (NPs) on Norland Optical Adhesive (NOA) and surfaces showed marvelous antibacterial functions and better hydrophilicity compared to control groups.(Fig. 4B&C). Li et al.[72] afforded an approach to boosting tribological performances of Al2O3/TiC ceramics. They fabricated biomimetic shark skin on Al2O3/TiC ceramic surfaces and deposited WS2 coating on the biomimetic skin. Experiments illustrated that the synergy effect of biomimetic shark skin and WS2 coatings can extraordinarily affect the tribological performances of Al2O3/TiC ceramics. Biomimetic shark skin has the potential of the reduction of friction surface and shear stress and trapping wear debris. Aiming at enhancing dry tribological behavior of ZrO2 coatings, Li et al.[73] exploited sol–gel technique to deposit self-lubricating ZrO2/WS2 coatings on the AISI316L stainless steels surfaces, followed by the preparation of shark skin-inspired coating surfaces. The assessment suggested that compared to the pure ZrO2 coatings, the dry friction and wear properties was much superior when the ZrO2/ WS2 coating surface was textured biomimetic shark skin.

Fig. 4.

Morphology of shark skin and shark skin patterned surfaces. A: Detailed images of the dermal denticles of different parts over the body. Scalebars are 1 mm (A-1, A-2, A-4) and 500 µm (A-3) [69]. B: SEM images of shark-skin-like surfaces. B-1: top view, B-2: cross section, B-3: optical profilometry images. C: Hydrophobicity and antibacterial activity of different samples of shark-skin-like surfaces [71].

On the basis of spatial light modulator, Shi et al.[74] exploited the femtosecond laser spatiotemporal interference method. They efficiently processed the 5 mm × 5 mm micro-nano biomimetic shark skin surface 316 stainless steel by altering the 800 nm femtosecond laser fluence and the cumulative pulse number, which attained a stable super-hydrophobic surface successfully. The increased utilization of hydrophobic biomimetic shark-skin microstructures has led to the development of more processing methods, resulting in greater demands for efficient and cost-effective hydrophobic films using the preparation processes. On top of laser, Tang et al.[75] manufactured linear low-density polyethylene (LLDPE) hydrophobic films based on melt fracture phenomenon. The biomimetic shark skin structured LLDPE films can possess excellent hydrophobicity through regulating the process parameters. Shark skin-like products have emerged in an endless stream, and that’s why the evaluation and verification of shark skin properties play indelible roles in marine industry coating and surface modification. Ibrahim et al.[76] introduced the performances of natural shark skin according to its topographical characteristics. Inspired by denticule arrangements of sharks, they concentrated on antifouling surface modification on the basis of the surface roughness and frictional drag. Subsequently, they exploited the silicone laminated transfer molding strategy to fabricate biomimetic shark skins and studied anti-algae formations. The assessment suggested that antifouling effects of the biomimetic shark skin surface was more prominent than the surface without biomimetic shark skin. In addition to simply reproducing antifouling structures on shark skins, He et al.[77] also combined chemical modifications. They applied subsurface initiated ring opening metathesis polymerization (ROMP) to fabricate a poly (ionic liquid) brush-grafted “Sharklet” surface with 3D printing technology. Afterwards, the embedded poly (ionic liquid) brushes were grafted onto the textured biomimetic sharklet with the help of subsurface initiated ROMP of a newly ionic liquid monomer involving benzotriazole and imidazole groups ([BNIm][Br]). They conducted both static and dynamic adhesion experiments to assess the efficacy of the “Sharklet” surface. The evaluation revealed that the surface’s chemical composition and synergistic antifouling performances efficiently resist microalgae, particularly when exposed to water flow. Consequently, it enables superior self-cleaning performance and this capability is attributed to the surface’s ability to stretch and expand under the influence of liquid shear forces, facilitating the release of contaminants.

Except for sharks, organisms that remain relatively stationary in the ocean such as mussels and urchins also possess distinct microstructures that enable them to effectively resist microbial attachment. It is found that biomimetic mussel surfaces exhibited distinct antifouling characters due to the microstructure called ‘‘flowering tree”. According to the biomimetic replication strategy, Guan et al.[78] replicated mussel-like shells (P) on the basis of antifouling mechanism of surface microstructure. The experiments and evaluations indicated that the response of mussels varied from differences of parts on the shells and the flowering tree microstructure presented outstanding antifouling property. Additionally, they exploited silicone oils with various functional groups to process mussel-like shells and found the surface microstructure affect wettability. Urchin surface’s hierarchical microstructures are the reason for its resistance against bacteria and Gao et al. [79] replicated urchin-inspired antifouling surfaces.

Currently researchers attribute the progress concerning underwater super oleophobic surface to fish scales, which can protect against contamination in oil-polluted water by secreting mucus. Gou et al.[80] investigated the changes in surface topography and chemical composition of crucian fish scales in the different developmental stages. They discovered that both of surface morphology and chemical composition can affect surface wettability of fish scales. Moreover, compared to fish scales at mature and senescent period, fish scale at infant period may retain superior hydrophilicity. On top of that, the mucus extracted from the loach contains antibiofouling functions as well, which inclines scholars to conduct researches on it. Combining the anti-biofouling measures of Gulf parrotfish (mucus layer) and fluorescent corals (secreting substances), Jin et al.[66] manufactured a newly polydimethylsiloxane (PDMS)–phosphor–silicone rubber sandwich structure coating to combat biofouling. The coatings with hydrophilic surfaces can emit weak light in the nighttime. As is known, the defect of weak mechanical properties of PDSM is difficult to resolve, which leads to its impractical applications on real ships. Tong et al. [81] mimicked the self-defense mechanism by which sea slugs release toxins autonomously when stimulated and fabricated a PDMS-based smart marine coating with outstanding comprehensive mechanical and antifouling properties. In fact, there are many artificial microstructures with the defect of being easily damaged and having a short service life. The effective combination of antifouling coatings and biomimetic microstructures is beneficial to compensate for these shortcomings.

Applications of microstructures with different antifouling strategies and other properties

Extensive technological applications of biospired surfaces attribute to their multi-functional microstructures. Unique microstructures endow surfaces with various antifouling strategies as well as other characteristics such as anisotropy, self-cleaning, adhesive properties and even marvelous machenical performances etc..[82], [83], [84] Properties like antifouling or superhydrophobilicity have been widely employed in the fields of biology, medicine, material engineering, etc. Lotus leaves, rose petals and rice leaves provide boundless inspiration for biomedical, environmental, and electronic engineering respectively.[1], [85], [86] Nepenthes prompted the development of non-power microfluidic platform.[87] The improvement of the wettability surfaces benefited from mimicking the butterfly wing surface.[88] The study of striders, shells and shark skins brought progress for technologies like water droplet manipulation, food bacteriostasis and biosensor respectively.[16], [47], [65] As for the wetting anisotropy character, phragmites communis leaves enlightened both oil–water separation and fog collection techniques.[31], [89] Owning anti-adhesion ability, structures of pangolin scales have been exploited on electrosurgical blade.[90] Besides, for anti-friction performances, pangolin scales and shark skins can also promote the boost of agricultural machines.[91] In some cases, adhesion characteristics are useful. Scholars imitated gecko feet to produce climbing robots and replicated tree frog toes to manufacture medical implant.[92], [93], [94] More detail will be covered in later paragraphs.

The (super)hydrophobilicity of microstructure gradually attracts much attention of scientists and engineers since antifouling properties of many surfaces derived from hydrophobilicity. Drawn influence from superhydrophobic biointerfaces, affording surfaces liquid repellent effects is fairly valuable for versatile applications including liquid transportation, microfluidic devices, self-cleaning, anti-icing, frictional drag reduction, and corrosion resistance etc..[88], [95], [96], [97], [98], [99] Artificial superhydrophobic surfaces derived from lotus leaves, rose petals, rice leaves, butterfly wings, striders, shark skins, etc. [4], [32], [100], [101] have been boardly presented.

Surfaces of some plant leaves(e.g. lotus leaves) in biotic systems reveal super-water repellency as a consequence of the cooperation of the geometric micro/nanostructure and surfacecompositions. Hence, it is acknowledged that a superhydrophobic surface demands high surface roughness and materials with low surface free energy to achieve. Knowing the theory and enlighted by natural surfaces with (super)hydrophobilicity, scientists and engineers intended to attain artificial one. The lotus-inspired surfaces tend to be extraordinary candidates for large quantities of applications in environmental engineering,[85] biomedical engineering,[1] and electronic engineering[86] etc. Dual-level and three-level structures on plane and convex surfaces were constructed on aluminum alloy. The as-prepared structures revealed splendid superhydrophobic property with addition of hydrophobic nanoparticles.[101] Commanding the contact time via altering structural parameters gradually develops into a hot subject for applications in heat transfer, anti-icing, and self-cleaning. Lotus leaf-like structure with superior superhydrophobilicity was produced on polypropylene (PP) surfaces.[98] The textured surface possessing marvelous properties has been applied in anti-icing, microdroplet transfer, and self-cleaning. A Carbon Nanowire (CNW)/PDMS biomimetic nanocomposite film with superhydrophobicity was constructed.[45] The CNW/PDMS biomimetic nanocomposites possessed superhydrophobicity, ice repellence, and controllable electric deicing, which showed board application prospects in aerospace designs, communication equipments, and other products. The superhydrophobic and moisture permeable membrane with bio-inspired microstructure was realized,[17] the membrane showed the great potential for the areas of apparel, desalination, and aerospace industry.

The lotus leaf is not the only creature to provide inspiration for artificial superhydrophobic surfaces. Enlighted by the anti-adhesive features of rhizoma imperatae, Li et al. [102] reported the idea of achieving specimens possessing biomimetic surface texture as well as hydrophobic performances based on 65Mn steel anticipated to endow the manufacture of bionic soil-tillage implements with basis. Yang et al.[47] found the 3D printed eggbeater surface displays fancinating properties concerning superhydrophobilicity and it could be applied in countless fileds, such as water droplet manipulation, 3D cell culture, micro reactor, oil spill clean-up, and oil/water separation. A biomimetic PDMS film with superhydrophobicity, self-healing and drag reduction properties was constructed.[99] The WCA of the resultant surface outrided 150°, displaying prominent self-cleaning and intelligent self-healing characteristics. A sturdy superhydrophobic PVDF/FEVE/GO@TiO2 composite coating with a high WCA and low SA was designed.[97] The as-prepared coating reveal great potential in technological applications, involving anti-scaling, antifouling, and self-cleaning materials. Chen et al.[35] first reported that the petal of Bombax ceiba (kapok) is blessed with superhydrophobic performances. Microstructure-induced kapok petal-like surfaces have economical scalability to manufacture by bonding gold wires on the copper plates, and can be found in extensive fields requiring water-repellent and self-cleaning functions.

Under natural selection, after more than millions of years of evolution abundant natural surfaces display prominent antifouling properties whose principles are entirely different from the hydrophobic surfaces, such as cicada wing,[103], shark skin,[76] and shell surfaces[104] etc. Biomimetic antifouling surfaces have aroused considerable interests and increasingly exploited in real-life applications.

Marine creatures have acquired various antifouling methods to combat biofouling. For instance, sharks can prevent biofouling as a result of their skin denticles,[11] mussels get shot of biofouling by their shells with unique structures,[78] mangrove trees Sonneratia apetala is able to resist biofouling via their microstructures on leaves,[50] corals have the capability to avoid biofouling through their skins revealing with low surface energies.[105] Researchers have maintained evaluating the features of natural anti-fouling surfaces and presenting novel artificial biomimetic structures for utilizations in real life.

The shipping industry faces two primary challenges: antifouling and drag reduction. Previous studies have indicated that bionic shell surfaces possess remarkable antifouling properties. Utilizing bionic surfaces is a promising approach to address fouling issues. In this regard, a novel polydimethylsiloxane (PDMS)–phosphor–silicone rubber sandwich structure coating is developed, drawing inspiration from the antifouling mechanisms observed in fluorescent corals and Gulf parrotfish, to effectively prevent biofouling.[66] Biomimetic lubricant-infused surfaces has emerged as a beneficial meassure to deal with biofouling. Lubricant-injected surfaces have been successfully constructed on a variety of structured surfaces with polished, nano-structured, micro-structured and micro/nano-structured characteristics by our previous study.[106] The consequences revealed that lubricant-infused techniques would be a marvelous candidate to construct antifouling coatings. Derived from the antifouling effect of biological superhydrophobic surfaces, the hybrid material was developed by loading silver nanoparticles antibacterial agent on the superhydrophobic stainless steel mesh, which has been successfully accomplished.[15] This novel material is expected to have wider applications in industrial and medical fields. The antibacterial performance of three biomimetic surfaces(i.e., atmospheric plasma-sprayed silane-based thin films, lubricated slippery surfaces and femtosecond laser textured lotus-like surfaces) in the same environment was presented and compared to evaluate the potential of this biomimetic substrate material in food safety related applications.[16] The experiments suggested that the smooth liquid surface of slippery surfaces showed prominent antifouling properties. Inspired by the loach skin, The covalent biopolymer-coated surfaces (BCSs) was constructed presenting superior anti-biofouling property and drag reduction effect.[65] Due to the high effectiveness and biocompatibility, the BCSs can emerge as promising surfaces for biomedical devices, biosensors and microfluidic equipment which demand effecient drag reduction and anti-biofouling surface performances.

Preparations of bionic micro-structured surfaces

As technology advances, versatile preparation strategies have sprung up to manufacture micro/nanostructured surfaces (Fig. 5), such as deposition processes,[15], hydrothermal method,[107] soft lithography,[108], [109], laser processing or irradiation,[110] grafting reactions,[111] etching,[112], [113] sol–gel methods,[73], [114] 3D printing techniques,[47] injection molding approaches,[115] template methods,[116] electrostatic meassures,[117] spraying techniques,[97] self-assembly,[118] etc.. The conclusion is made in Table 5.

Fig. 5.

Examples of producing micro-structured surfaces. A: Schematic of acquiring bio-inspired surface with anisotropic superhydrophobicity by femtosecond laser [37]. B: Chemical deposition generating antifouling and self-cleaning microstructures [33]. C: Etching as an indispensable role in creating superhydrophobic surface (SA treatment) [123]. D: Template measures attaining antifouling biofilm [64]. E: Diagram of accomplishing superhydrophobic surface by two-step spray [140].

Table 5.

Conclusion of preparations of microstructured surfaces.

| Method | Advantages | Disadvantages | Reference |

|---|---|---|---|

| Laser processing or irradiation | High processing precision; Simple processing process; Building complex micro-nano rough structures efficiently |

Requiring special processing equipment; Relatively expensive |

[34], [72], [74], [90] |

| Chemical deposition | Simple constructing process; controllable reaction conditions. |

Limitations of metal materials with weak activity | [119], [120] |

| Electrochemical deposition | Low-cost; Facile preparation of products |

Low quality of producing superhydrophobic surface |

[121], [122] |

| Chemical etching | Economical; Simple manufacturing process |

Harmful solution | [123], [124] |

| Electrochemical etching | Low-cost; Facile preparation process |

Limitations of conductive materials | [126], [127] |

| 3D printing | High accuracy; High efficiency; Low cost; Simple design; Ease of making sophisticated patterns |

Limitations of materials | [48], [77], [128], [129] |

| Template method | Environmentally-friendly; Economical; Simple operation; Diversity in shape; Easy access to materials; Convenience of large-area productions; Non-harsh requirements for conditions |

Limitations of soft materials | [130], [131], [132] |

| Bio-additive techniques | Sustainable; Eco-friendly; Effectively improving product performances |

High-cost; Technical challenges; Limited availability; Performance variability |

[133], [135], [136] |

| Thermal oxidation | Low-cost; Broad application prospects |

Risky preparation process | [137], [138] |

| Spraying method | Economical; Simple process; Exploitation of substrate surface with complex morphology |

Poor adhesion of producs; Inferior durability of the superhydrophobic surface |

[139], [140] |

Laser processing or irradiation

Laser processing or irradiation is the technique of taking advantage of the photothermal effect to process the micro-nano-scale rough structure on the surface of the sample. Li et al.[72] used laser surface texturing to prepare the biomimetic shark skin on Al2O3/TiC ceramic surfaces. After applying the bionic shark skin texture to the sample, a significant reduction in friction coefficient was achieved. The coefficient measured approximately 0.3, which was 32% lower compared to the polished surface alone (approximately 0.44). Li et al.[34] achieved microstructures on surfaces of stainless steel via nanosecond lasers. After pickling, the surface oxides were cleared away, and the nanoscale organometallic coatings were electrically deposited onto the laser-patterned microstructure. The textured superhydrophobic surfaces displayed a WCA of 163.54 ± 1.59°. Femtosecond Laser Direct Writing (FLDW) technology was widely used to fabricate biomimetic structures on metal surfacesdue to its high accuracy, non-contact and low thermal effect etc. within manufacturing. Shi et al.[74] developed the femtosecond laser spatiotemporal interference strategy via spatial light modulator. They processed 5 mm × 5 mm two-scale micro-nano structures of biomimetic surface inspired by the shark skin on 316 mirror stainless steel precisely and effectively with the adjustment of the 800 nm femtosecond laser fluence and the cumulative pulse number. The processed surface was converted from hydrophilic to hydrophobic (WCA = 165°). Several investigations reported that the long-pulse fiber laser is more economical than the femtosecond laser and has broad industrial applications. Li et al.[90] obtained stainless steel 316L textured with anti-adhesion biomimetic scale efficiently via the long-pulse fiber laser. The 316L sample changed from hydrophilic to hydrophobic, furthermore significantly decreasing the friction coefficient by 14.9% on average. The laser processing or irradiation has the characteristics of high processing precision and simple processing process, and can efficiently build complex micro-nano rough structures. However, the laser usually requires special processing equipment and is relatively expensive.

Deposition processes

The chemical deposition is a process in which the ions in the solution react with the metal substrate chemically, and the products are deposited on the surface of the substrate to form a microscopic rough structure. Xu et al.[119] deposited a film with extraordinary super-hydrophobicity on cotton fabrics. The experiments suggested that attributing to plasma treatment as well as the deposition of alkyl and ester groups, the cotton surface was fairly hydrophobic. The sample surface achieved WCA = 160.95° and SA = 9.65°. Superhydrophobic titanium oxide multilayer coatings on a series of substrates were prepared by a sol–gel deposition process. The water contact angles on the superhydrophobic titania surfaces of aluminum substrates kept steady at ∼ 165°.[120] The chemical deposition can construct productions simply with controllable reaction conditions. However, the chemical deposition can generally only replace metals with weak activity, and most of these metals are expensive with high-cost preparation.

Electrochemical deposition is a measure in which the surface of the substrate is placed on the cathode to cause an electrochemical reaction to deposit on the surface of the substrate to form a micro-nano-scale rough structure. Yan et al.[121] took advantage of methanol as the carbon source and SiO2 nanoparticles/nickel as the dopant. They successfully achieved Carbon-based films doped with SiO2 nanoparticles and nickel (SiO2-Ni/a-C:H films), which revealed outstanding super hydrophobicity with a WCA of 162.4° and SA of 1.2°, resulting in anti-corrosion effect. Lin et al.[122] constructed the Ni-Co/Cu composite coating on carbon steel substrate through electrochemical deposition, chemical oxidation and surface modification. The textured coating showed super-hydrophobicity (WCA = 158.61°). Electrochemical deposition is low-cost and facile to prepare products, but the superhydrophobic surface prepared via electrochemical deposition wears more easily and is lack of mechanical strength.

Etching

Chemical etching is a strategy of forming a microscopic rough structure on the surface of the substrate by chemical reaction between the metal substrate and the etching solution. Saleh et al.[123] employed sulfuric acid solution to etch the micro-nano-scale rough structure on the mesh surface of the stainless steel mesh. After being modified with octadecyl trichlorosilane, the stainless-steel mesh surface obtained CA close to 166°, displaying excellent super hydrophobicity. Xiao et al.[124] exploited hydrochloric acid to etch a stepped rough structure on the surface of the aluminum sheet. After the modification with 3-mercaptopropyltriethoxysilane, brilliant super hydrophobicity was obtained, and the CA of water droplets on its surface was approximately 163°. The manufacturing process of chemical etching is simple and economical, but the etching solution such as strong acid/alkali, which is usually dangerous to the environment and experimenters. Liu et al.[125] used soft lithography to prepare tree frog-inspired composite micropillars (CP) and subsequently soaked CP in tetrahydrofuran (THF) for solvent etching. PS nanoparticles increased surface roughness, resulting in enhanced hydrophobicity and self-cleaning performance.

Electrochemical etching is a way in which the substrate surface is placed on an anode to cause an electrochemical reaction to etch the substrate surface and generate a micro-nano-scale rough structure on the surface. Liu et al.[126] applied sodium nitrate as the etching solution to process a high-strength passivation film on the surface of 30Cr2Ni2WVA aviation steel by electrochemical etching. The passivation film had a coral-like microstructure and the super hydrophobicity was attained with ethoxy silane modification. The CA of water droplets on its surface was about 165°, and the rolling angle was about 5°. Li et al.[127] employed a sodium chloride and sodium nitrate mixture as an etchant to create a micro-rough surface structure on magnesium alloy. After modification through fluorooctyltriethoxysilane, a superhydrophobic magnesium alloy surface with a CA of approximately 162° was attained. Electrochemical etching has facile and low-cost preparation processes, but it can only process conductive materials, while has difficulties to process metals with weak activity.

3D printing techniques

3D printing is classified as a kind of rapid prototyping technology, also known as additive manufacturing, which constructs objects by layer-by-layer printing assisted by digital model files, employing bondable materials such as powdered metal or plastic. The brief 3D printing process is as follows: exploiting CAD software to virtually design a solid 3D object. The printer connected to a computer is filled with “printing materials” (liquid or powder). The “printing materials” are superimposed layer by layer through the computer, and finally the blueprint on the computer into a real object. Han et al.[128] built a biomimetic surface with functions of collecting water via 3D printing. Xiang et al.[48] designed a biomimetic surface with extraordinary superrepellency imitating the specific structures of Salvinia leaves through 3D printing technology. He et al.[77] employed commercial acrylic resin as the printing material, combining three-dimensional printing with sub-surface-initiated ring-opening polypolymerization (ROMP) to build a multi-scale brush-based antifouling surface. Taking advantage of fused deposition modeling-type 3D printing, Kang et al.[129] realized an artifacial surface with super hydrophobicity. Moulds which used for casting of polymers were printed with a low print resolution (400 µm) and a variety of print angles ranging from 0° to 90°. The polymer surface, obtained through casting from the mold, displayed corrugated microstructures that closely matched the angle observed during printing. The resulting polymer surface has a maximum average WCA of 160°. 3D printing is endowed with plenty of merits, such as high accuracy and efficiency, low cost, ease of creating sophisticated patterns and simple design. Whereas, the perspective of material types is the limitation for 3D printing and nowadays 3D printing with soft materials remains a challenge.

Template methods

The template method is to use a model (plane or three-dimensional) as a template, and select a material on it to prepare the opposite template by printing, pressing or crystal growth in the template void. When the model is removed, only the remaining the opposite template (concave template or negative mold) of the lower model, with which a replica of the original model can be prepared. Biological template method is a synthesis technology using biological tissues or biological macromolecules with a certain structure as templates. New nanostructures can be formed by the assembly characteristics and spatial confinement effects of natural templates. This technique can replicate the particular structure of an organism into the expected creations.[130] Chen et al.[131] selected the osmanthus fragrans leaf vein as biotic templates. The template was immersed in tetraethyl orthosilicate solution and calcined to gain biological morphology silicon carbide materials. Han et al.[132] exploited the wing of cicada as biological templates, and used the sol–gel process to gain a SiO2 negative reproduction. Afterwards, they got rid of the original template by chemical corrosion and the SiO2 negative reproduction remained. After another sol–gel process, the polymethylmethacrylate (PMMA) positive reproduction was able to be reconstituted. The evaluation presented that in the visible region, the average reflectance of the structured PMMA film with superior flexibility and super-hydrophobicity was decreased from 10% to 2%, compared to a flat PMMA film. The template method is convenient for large-area productions, environmentally-friendly, economical and simple during operation. Besides, it has diversity in shape, easy access to materials and non-harsh requirements for conditions, which is a splendid option to mimic natural surfaces. Nevertheless, it is usually applied for soft materials. Hard materials (e.g., metals and ceramics) are often incompatible.

Bio-additive techniques

Bio-additive techniques refer to the use of biological substances or organisms to enhance various industrial processes or obtain particular products. Biocoatings, biopreservation, biomonitoring and so on all belong to the category of bio-additive technology. Salama et al.[133] extracted bioactive metabolites of three common macroalgae via methanol to make biocoating and carried a 3-month outdoor antifouling assays. It was observed that coatings with the extracts of T. ornata and S. polycystum can greatly prevent the adhesion of barnacle larvae and biofouling organisms. Dopamine is a common bio-additive that shows excellent adhesion properties and anti-biofouling performance, thereby enhancing the surface properties of materials.[134] Cao et al.[135] dissolved dopamine and Turgencin BMox2 (TB) in Tris-HCl buffer respectively and formed a dopamine film and TB coating successively on the surface of 304 stainless steel through 2-step immersion. After bacterial adhesion and marine algae attachment trials, they found that the samples had the antibacterial efficiency of 99.85% and antialgal efficiency of 67.93%. Liu et al.[136] initially deposited dopamine (DA), Polyethyleneimine (PEI) and SiO2 on the surface of DA-modified 304 stainless steel (SS) to attain nano-coating, and subsequently grafted antimicrobial peptides (AMPs) on the treated sample surface. Then they detected the antibiofilm and antibacterial abilities of SS-DA/PEI/SiO2/AMPs and the results demonstrated that antibiofilm and antimicrobial rates reached 72.87% and 95.90%. Bio-additive techniques are sustainable, biodegradable, efficient to accomplish targeted functions and can reduce environmental impact in the process of fabrication. However, this technology is also high-cost and faces technical challenges bringing difficulties to mass produce and unavoidable problems like limited availability as well as performance variability.

Other approaches

Thermal oxidation is an approach in which the substrate is placed under high temperature conditions to make the surface of the substrate undergo an oxidation reaction and generate a micro-nano-scale rough structure on the surface. Lv et al.[137] first immersed the aluminum sheet in a copper sulfate solution to form a layer of copper element on the surface, and then oxidized at 550 °C to form a rough structure of copper oxide, and finally modified with stearic acid to obtain a superhydrophobic surface with the CA of approximately 157°. Siddiqui et al.[138] utilized thermal oxidative-decomposition of silicone grease with an intention of forming a coating with robust super-hydrophobicity (WCA = 168°; SA = 2°). The thermal oxidation method is low-cost and blessed with broad application prospects. Whereas, high temperature treatment is usually required in the preparation process of the thermal oxidation followed by certain safety risks.

The spraying method is to spray the modified micro- or nanoparticles with low surface energy on the substrate surface to obtain superhydrophobic surfaces. Jiang et al.[139] attained the homogeneous SiC and CNT suspension, and then spayed it on the matrix of semi-cured silicone rubber(SR) to allow it to be entirely cured at room temperature. Subsequently, flexible SR-SiC/CNTs surfaces showing fractal micro/nano structures as well as super hydrophobicity (WCA = 157°; SA = 2°) were accomplished. Daneshmand et al.[140] initially sprayed a hydrophobic resin as an adhesive layer and then applied stearic acid-modified Alumina nanoparticles to the adhesive layer. The resultant coating has CA of 160° and SA lower than 2° with excellent abrasion resistance. The spraying method is economical and simple, and can be exploited on the substrate surface with complex morphology. Nevertheless, there are poor adhesion between the coating and the substrate, and the durability of the superhydrophobic surface is inferior.

Conclusion

Biomimetics has been recognized for its remarkable advantages, making it highly valuable for a wide range of applications. Particularly, the demand for effective and eco-friendly surfaces in materials has led to the exploration of bio-inspired strategies, offering new perspectives on artificial micro-structured surfaces. Consequently, biomimetic micro-structured surfaces have garnered significant attention across various industries. This review highlights the development of such surfaces influenced by diverse animals and plants in nature, elucidating their characteristics, principles, and applications in detail. Additionally, it provides a comprehensive overview of fabrication methods for micro-structured surfaces, including their respective advantages, disadvantages, and limitations.

The main conclusions and future prospects are as follows: (1. The plant-inspired anti-fouling strategies applied in various fields mainly include: SLIPS, Wenzel state superhydrophobicity, Cassie-Baxter state superhydrophobicity by imitating their microstructures or extracting natural antifoulants loaded on surfaces. The animal-enlightened measures chiefly involve: replication of specific surface micromorphology or combination of both microtopography and biochemical surface modification. (2. Various technologies have been employed in different fields to produce biomimetic microstructured surfaces, including lasers, etching, biological templates, deposition, and additive manufacturing, etc. Each method has its own advantages and disadvantages. For instance, methods like laser and bioadditive can afford high efficiency and remarkable product quality, but is high-cost. Besides, chemical approaches, 3D printing and biological templates are economical and simple, but face restrictions in terms of material types. In addition, artificially prepared microstructures may have drawbacks such as poor mechanical properties and limited-service life when applied to marine ships. The integration of microstructures with coatings can help enhance their synergistic antifouling effect while protecting their integrity. (3. Further understanding the underlying mechanisms of specific biological surfaces is crucial. It is important to consider the control of various parameters during the preparation of artificial surfaces and their suitability for harsh environmental conditions. The incorporation of effective biomimetic micro-structured surfaces is expected to drive the development of new surface technologies with superior sustainability and stability.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 51905468 and 52071246); Innovation and Development Joint Fund Key Project of Hubei Provincial Natural Science Foundation (Grant No. 2022CFD029); and the “Blue Project” of Yangzhou University.

Biographies

Yuhan Liu: PhD student at Wuhan University of Technology Research fields: Marine antifouling technology; Green ship technology

Resent related publications:

Cao P., Liu D., Liu Y., Zhang Y., Yuan C., Zhang C., 2021. Combining topography and peptide to inhibit algae attachment: Preparation of peptide-modified microstructured surfaces. Surface and Interface Analysis 53(11), 973-981. 10.1002/sia.7000

Cao P., Liu D., Liu Y., Wang H., Zhang C., Yuan C., Liu X., 2022. Marine antifouling behavior of the surfaces modified by dopamine and antibacterial peptide. Journal of Oceanology and Limnology 41(1), 174-188.10.1007/s00343-021-1270-z

Liu Y., Liu D., Wang Y., Wang H., Cao P., 2022. Research Progress of the Surface Modification by Dopamine in Medical Field. Surface Technology 51(11):164-173. (in Chinese) 10.16490/j.cnki.issn.1001-3660.2022.11.014

Cao P., Liu D., Liu Y., 2022. Research Progress on Marine Low Surface Energy Antifouling Materials. New Chemical Materials 50(3), 60-63. (in Chinese) 10.19817/j.cnki.issn1006-3536.2022.03.012

Liu D., Liu Y., Zhang Y., Cao P., 2022. Research Status of the Surface Modification Method Based on Dopamine. Polymer Bulletin 4, 30-37. (in Chinese) 0.14028/j.cnki.1003-3726.2022.04.003

Xiaoyan He: Professor at Wuhan University of Technology

Research fields: New energy and energy-saving emission reduction technology of marine; Marine antifouling and drag reduction; Anti-corrosion

Resent related publications:

He X., Cao P., Tian F., Bai X., Yuan C., 2019. Autoclaving-induced in-situ grown hierarchical structures for construction of superhydrophobic surfaces: A new route to fabricate antifouling coatings. Surface and Coatings Technology 357(15), 180-188.10.1016/j.surfcoat.2018.10.015

He X., Tian F., Bai X., Yuan C., Wang C., Neville A., 2020. Biomimetic lubricant-infused titania nanoparticle surfaces via layer-by-layer deposition to control biofouling. Applied Surface Science 515(15), 146064.10.1016/j.apsusc.2020.146064

He X., Lou T., Cao P., Bai X., Yuan C., Wang C., Neville A., 2021. Experimental and molecular dynamics simulation study of chemically stable superhydrophobic surfaces. Surface & Coatings Technology 418, 127236. 10.1016/j.surfcoat.2021.127236

He X., Lou T., Yang Z., Bai X., Yuan C., Wang C., Neville A., 2021. Lubricant-infused titania surfaces with high underwater transparency for antifouling applications: A combined experimental and molecular dynamics study. Applied Surface Science 543, 148848. 10.1016/j.apsusc.2020.148848

Name:Chengqing Yuan: Professor at Wuhan University of Technology Research fields: Tribological mechanism and wear control of marine power system; Marine antifouling, drag reduction and energy efficiency control; Corrosion and wear in marine environments; New energy technology for marine power system

Resent related publications:

He X., Tian F., Bai X., Yuan C., 2019. Role of trapped air and lubricant in the interactions between fouling and SiO2 nanoparticle surfaces. Colloids and Surfaces B: Biointerfaces 184(1), 110502.10.1016/j.colsurfb.2019.110502

He X., Cao P., Tian F., Bai X., Yuan C., 2019. Autoclaving-induced in-situ grown hierarchical structures for construction of superhydrophobic surfaces: A new route to fabricate antifouling coatings. Surface and Coatings Technology 357(15), 180-188.10.1016/j.surfcoat.2018.10.015

Yang Z., Bai X., He X., Yuan C., 2019. Study on Biomimetic Antifouling Surface Preparation based on Surface Microstructure of Crabs. 2019 5th International Conference on Transportation Information and Safety (Ictis 2019), 1192-1195. 10.1109/ICTIS.2019.8883729

Yang Z., He X., Chang J., Bai X., Cao P., Yuan C., 2021. Fabrication of biomimetic slippery liquid-infused porous surface on 5086 aluminum alloy with excellent antifouling performance. Surface And Interface Analysis 53 (2), 147-155.10.1002/sia.6894

Pan Cao: Professor at Yangzhou University Research fields: New green antifouling technology; Microstructure design and fabrication; Surface and interface analysis

Resent related publications:

Cao P., Liu D., Liu Y., Zhang Y., Yuan C., Zhang C., 2021. Combining topography and peptide to inhibit algae attachment: Preparation of peptide-modified microstructured surfaces. Surface and Interface Analysis 53(11), 973-981. 10.1002/sia.7000

Cao P., Du C., He X., Zhang C., Yuan C., 2020. Modification of a derived antimicrobial peptide on steel surface for marine bacterial resistance. Applied Surface Science 510, 145512. 10.1016/j.apsusc.2020.145512

Cao P., He X., Xiao J., Yuan C., Bai X., 2018. Peptide-modified stainless steel with resistance capacity of Staphylococcus aureus biofilm formation. Surface and Interface Analysis 50(12-13), 1362-1369.10.1002/sia.6531

Cao P., Liu D., Zhang Y., Xiao F., Yuan C., Liang F., Liu X., Zhang C., 2022. Dopamine-assisted sustainable antimicrobial peptide coating with antifouling and anticorrosion properties. Applied Surface Science 589, 153019. 10.1016/j.apsusc.2022.153019

He X., Cao P., Tian F., Bai X., Yuan C., 2019. Infused configurations induced by structures influence stability and antifouling performance of biomimetic lubricant-infused surfaces. Surface & Coatings Technology 358, 159-166. 10.1016/j.surfcoat.2018.11.035

Xiuqin Bai: Professor at Wuhan University of Technology Research fields: Marine power system reliability; Ship tribology, antifouling and drag reduction; Green ship technology

Resent related publications:

Yang Z., He X., Chang J., Yuan C., Bai X., 2021. Facile fabrication of fluorine-free slippery lubricant-infused cerium stearate surfaces for marine antifouling and anticorrosion application. Surface and Coatings Technology 415, 127136. 10.1016/j.surfcoat.2021.127136

Lou T., Bai X., He X., Yuan C., 2021. Antifouling performance analysis of peptide-modified glass microstructural surfaces. Applied Surface Science 541, 148384. 10.1016/j.apsusc.2020.148384

Cao P., He X., Xiao J., Yuan C., Bai X., 2018. Peptide-modified stainless steel with resistance capacity of Staphylococcus aureus biofilm formation. Surface and Interface Analysis 50(12-13), 1362-1369. 10.1002/sia.6531

Yang Z., Bai X., He X., Yuan C., 2019. Study on Biomimetic Antifouling Surface Preparation based on Surface Microstructure of Crabs. 2019 5th International Conference on Transportation Information and Safety (Ictis 2019), 1192-1195. 10.1109/ICTIS.2019.8883729

He X., Tian F., Bai X., Yuan C., Wang C., Neville A., 2020. Biomimetic lubricant-infused titania nanoparticle surfaces via layer-by-layer deposition to control biofouling. Applied Surface Science 515(15), 146064.

Contributor Information

Pan Cao, Email: caopan@yzu.edu.cn.

Xiuqin Bai, Email: xqbai@whut.edu.cn.

References

- 1.Johnson A.P., Sabu C., Nivitha K.P., Sankar R., Ameena Shirin V.K., Henna T.K., et al. J Control Release. 2022;343:724–754. doi: 10.1016/j.jconrel.2022.02.013. [DOI] [PubMed] [Google Scholar]

- 2.Wu D., Wang J.-N., Niu L.-G., Zhang X.L., Wu S.Z., Chen Q.-D., et al. Bioinspired fabrication of high-quality 3D artificial compound eyes by voxel-modulation femtosecond laser writing for distortion-free wide-field-of-view imaging advanced. Opt Mater. 2014;2(8):751–758. doi: 10.1002/adom.201400175. [DOI] [Google Scholar]

- 3.Behera R.P., Le Ferrand H. Impact-resistant materials inspired by the mantis shrimp's dactyl club Matter. 2021;4(9):2831–2849. doi: 10.1016/j.matt.2021.07.012. [DOI] [Google Scholar]

- 4.Feng X., Guan H., Wang Z., Niu S., Han Z. Biomimetic Slippery PDMS film with papillae-like microstructures for antifogging and self-cleaning coatings. 2021;11(2):238. doi: 10.3390/coatings11020238. [DOI] [Google Scholar]

- 5.Liu L., Tang W., Ruan Q., Wu Z., Yang C., Cui S., et al. Robust and durable surperhydrophobic F-DLC coating for anti-icing in aircrafts engineering. Surf Coat Technol. 2020;404 doi: 10.1016/j.surfcoat.2020.126468. [DOI] [Google Scholar]

- 6.Choi Y.-J., Ko J.-H., Jin S.-W., An H.-S., Kim D.-B., Yoon K.-H., et al. Transparent self-cleaning coatings based on colorless polyimide/silica sol nanocomposite polymers. 2021;13(23):4100. doi: 10.3390/polym13234100. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Tian G.Y., Zhang M., Zhao Y., Li J.X., Wang H.F., Zhang X.Y., et al. High corrosion protection performance of a novel nonfluorinated biomimetic superhydrophobic Zn-Fe coating with echinopsis multiplex-like structure. Acs Appl. Mater. Interfaces. 2019;11(41):38205–38217. doi: 10.1021/acsami.9b15088. [DOI] [PubMed] [Google Scholar]