Abstract

The quest to identify precious metal free hydrogen evolution reaction catalysts has received unprecedented attention in the past decade. In this Review, we focus our attention to recent developments in precious metal free hydrogen evolution reactions in acidic and alkaline electrolyte owing to their relevance to commercial and near-commercial low-temperature electrolyzers. We provide a detailed review and critical analysis of catalyst activity and stability performance measurements and metrics commonly deployed in the literature, as well as review best practices for experimental measurements (both in half-cell three-electrode configurations and in two-electrode device testing). In particular, we discuss the transition from laboratory-scale hydrogen evolution reaction (HER) catalyst measurements to those in single cells, which is a critical aspect crucial for scaling up from laboratory to industrial settings but often overlooked. Furthermore, we review the numerous catalyst design strategies deployed across the precious metal free HER literature. Subsequently, we showcase some of the most commonly investigated families of precious metal free HER catalysts; molybdenum disulfide-based, transition metal phosphides, and transition metal carbides for acidic electrolyte; nickel molybdenum and transition metal phosphides for alkaline. This includes a comprehensive analysis comparing the HER activity between several families of materials highlighting the recent stagnation with regards to enhancing the intrinsic activity of precious metal free hydrogen evolution reaction catalysts. Finally, we summarize future directions and provide recommendations for the field in this area of electrocatalysis.

1. Introduction

As we shift to a Net Zero emission landscape, hydrogen continues to gain significant traction as an enabling technology for this transition.1−3 Indeed globally, numerous policies, ambitions and projects have been announced relating to hydrogen. The continuing growth of this ambition is clearly evidenced in annual updates in recent IEA reports where the cumulative deployment for low-emission hydrogen production was 74 GW by 2030 in 2021, whereas in 2022 it is reported that this ambition has grown to 145–190 GW by 2030.4 It is currently estimated that this growth will reach 16–24 Mt per year of low-emission hydrogen, with 9–14 Mt from electrolysis and 7–10 Mt from fossil fuel technologies coupled to carbon capture utilization and storage. To meet this demand, 134–240 GW installed electrolyzer capacity is forecast for installation by 2030, requiring huge expansion of electrolyzer manufacturing capacity.

While many components of an electrolyzer plays critical roles that dictates the performance (e.g., efficiency, longevity, cost, etc.), it is at the catalyst surfaces where the electrochemical reactions proceed. In current commercial water electrolyzers, the relevant electrochemical reactions are the cathodic hydrogen evolution reaction (HER) and the anodic oxygen evolution reaction (OER). Predominantly, precious metal (platinum, iridium and ruthenium) catalysts are utilized to lower the overpotentials of HER and OER in contemporary proton exchange membrane (PEM-WE) commercial water electrolyzers.5,6 Conversely, commercial alkaline water electrolyzers (A-WE) typically deploy precious metal free catalysts (nickel, iron). Due to the scarcity and costs of precious metals, there have been a tremendous number of reports on the efficacy of precious metal free catalysts for water electrolysis.

In this review we provide a comprehensive review of precious metal free (sometimes called nonprecious metal, or nonplatinum group) catalyst development for the HER under both acidic and alkaline electrolyte for low-temperature electrolysis. The review is split into three sections. In the first section, we describe current commercial electrolyzers to give the reader context for the environment in which electrocatalysts must operate. Specifically, we provide a succinct overview of A-WE, PEM-WE and anion exchange membrane electrolyzer (AEM-WE) technologies. Subsequently, we provide an overview of the fundamentals of the HER, including an introduction to the mechanisms of the HER. In the second section of this review, we describe benchmarking and best practices which have been widely discussed for assessing HER catalysts in the literature. This section reviews the various reviews, publications, perspectives and editorials that provide best practices for screening HER catalysts in three electrode (half-cell) measurements. Additionally, we discuss the challenges and limitations of translating performance and durability from half-cells to devices, including fabricating membrane electrode assemblies, providing a review of testing methods as well as examples of precious metal free catalysts that have been translated into such device testing. In the third section of the review, we provide an overview of the various design strategies for precious metal free HER metal catalysts, highlighting the key motivations for each (e.g., higher density of active sites, higher surface area, increased conductivity, enhanced stability). Subsequently, we showcase some of the most popular catalyst families deployed for the HER in acidic (molybdenum disulfide-based, transition metal phosphides and transition metal carbides) as well as alkaline (nickel molybdenum and transition metal phosphides) catalysts. For each, we provide a comprehensive review of the key approaches and advances developed. Owing to the vast quantity of publications, the review largely focuses on paper published within the last five years that are highly cited, or hot papers (as denoted by Web of Science). However, numerous additional historical references are also cited to provide a more holistic and comprehensive background to the development of precious metal free HER catalysts.

1.1. Commercial and near-Commercial Electrolyzers: HER Catalysts in Context

Two technologies dominate the low-temperature electrolyzer market today: A-WE and PEM-WE.7,8 Installed global capacity is currently estimated at 60% A-WE and 34% PEM-WE (the balance either unknown or alternative technologies such as solid oxide electrolysis).9 Typical operating conditions and components are provided in Table 1, highlighting some of the stark differences between these technologies. It is widely acknowledged that in addition to A-WE and PEM-WE, AEM-WE will also contribute to the portfolio of low-temperature hydrogen production technologies in the coming decade(s).10−12 Beyond low-temperature hydrogen production technologies, solid oxide water electrolyzers (SO-WE) technologies which operate at elevated temperatures (∼800 °C) are also anticipated to play a role in the future of green hydrogen production.13−16

Table 1. Typical Operating Conditions and Device Components of Alkaline Water Electrolyzers, Proton Exchange Membrane Electrolyzer, and Anion Exchange Membrane Electrolyzers7,8,17.

| Alkaline (A-WE) | Proton exchange membrane (PEM-WE) | Anion exchange membrane (AEM-WE) | |

|---|---|---|---|

| Electrolyte | Aqueous KOH (20–40 wt %) | Proton exchange membranes | Anion exchange membranes |

| Cathode catalysts | Ni, Ni based alloys, Ni-coated stainless steel, NixPy, NixSy, Ru | Pt–C, Pt-black | Ni and Ni alloys, Pt-alloys, Ru-alloys |

| Anode catalysts | NiFeOOH, LaNiO3, Ni–Co alloy, Co3O4 | IrOx, IrRu-oxides | Ni, Ni alloys, Ni-based oxides, IrO2 |

| Operating temperature (°C) | 50–90 | 50–80 | 40–60 |

| Operating pressure (bar) | 1–35 | <70 | <35 |

| Water source | Deionized water (into aqueous 20–40 wt % KOH) | Deionized water | Water or alkaline water (0.1–1 M KOH) |

| Current density(A cm–2)at 2.0 V | 0.2–1.2 | >2 | <2 |

There exist many differences between A-WE, PEM-WE and AEM-WE technologies including the chemical environment, components and device designs. As highlighted by their names, obvious distinctions among A-WE, PEM-WE and AEM-WE are the electrolytes deployed. Critically, A-WE deploy a liquid electrolyte. Conversely, PEM-WE and AEM-WE both deploy a solid polymer electrolyte. The solid electrolyte is a proton exchange membrane for PEM-WE, and an anion exchange membrane for AEM-WE. As a consequence of the electrolyte, the electrocatalysts (and other cell components) are required to withstand either a highly acidic (PEM-WE) or alkaline (A-WE and AEM-WE) pH. Accordingly, screening of potential HER catalyst for A-WE and AEM-WE technologies must ensure they are active and stable under highly alkaline conditions, and conversely, PEM-WE electrocatalysts must be active and stable under highly acidic condition.

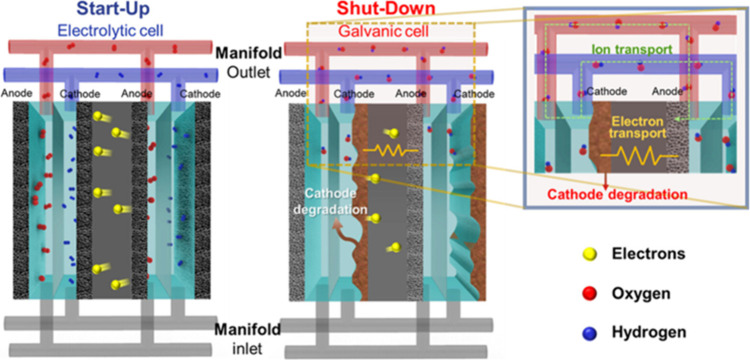

Beyond differences in the pH, A-WE, PEM-WE and AEM-WE can each have very different cell architectures. For example, the cell architecture can be a “gap” or “zero-gap” cell. This terminology relates to whether a physical space exists between the electrodes and separator/membrane. Specifically, “zero-gap” refers to the cell architecture whereby the membrane/diaphragm is directly sandwiched between the two electrodes (e.g., Figure 1). Conversely, a “gap” cell is where there exists a space between the membrane/diaphragm and the electrodes. Industrial A-WE were previously “gap” cells, however the majority of commercial A-WE are now “zero-gap”. PEM-WE and AEM-WE designs are also “zero-gap”. Typical cell configurations for A-WE and PEM-WE are shown in Figure 1.

Figure 1.

Schematic of zero-gap cell architecture and cathode zoom in to show the HER catalyst environment for typical (A) PEM-WE and (B) A-WE.

A-WE utilize approximately 20–40 wt % KOH as a conductive electrolyte, operating at approximately 50–90 °C (Table 1). The A-WE uses a separator (or permeable diaphragm) between the anode and cathode to prevent the mixing of O2 and H2 within the electrolyzer while enabling conduction of hydroxide anions. Commercial A-WE are today zero-gap cells, typically utilizing a porous diapraghm of ZrO2 particles on polyphenylene sulfide. A benefit of this design is the rapid degassing of the evolved hydrogen and oxygen, which otherwise would form a supersaturated solution in the electrolyte. As the bubbles adhere to the electrode, the electrolyte saturation is kept relatively low compared to PEM-WE, which minimizes the crossover of gases across the diaphragm.18 Detailed reviews focused on A-WE technology are published elsewhere.19−21 Owing to the alkaline environment in an A-WE, stainless steel and precious metal free nickel components are deployed. At the cathode, Raney Ni and Ni alloy electrodes are commonly deployed as high-surface area electrodes for the HER. The cathode and anode catalysts are typically prepared directly onto a mesh or foam structure (typically nickel or nickel coated). Commercial A-WEs have been deployed at industrial scale for over 90 years, with significant advances in the 1920s and 1930s leading to industrial sites with production at 10,000 N m3 h–1.6

Membrane-based water electrolyzers (PEM-WE and AEM-WE) utilize an electrically insulating solid membrane as an electrolyte which is sandwiched between the anode and cathode. Collectively, the anode, cathode and membrane make up a membrane electrode assembly (MEA). When coupled to thin polymer electrolytes with relatively low internal resistances, this zero-gap cell architecture enables low gas crossover. Utilizing an acidic electrolyte membrane, PEM-WEs typically operate between 50–80 °C. PEM-WE have been reviewed in detail elsewhere.6,22−24 PEM-WEs are fed a pure water supply for water splitting. Owing to the PEM-WE membrane chemistry (Nafion, fumapem, perfluorosulfonate polymers), protons are selectively transported between the anode and cathode and hence the catalysts deployed in a PEM-WE are exposed to a highly acidic environment. This is owing to the polyfluorosulfonic acid (PFSA) polymer materials (e.g., Nafion) used as membranes, reviewed elsewhere.25 Nafion is a copolymer, with an electrically neutral polytetrafluoroethylene polymeric backbone polymers, with side-chains that end with sulfonic acid (−SO3H) functional groups that loosely bind protons. The side chains are randomly distributed along the fluorinated backbone and facilitate proton transfer across the membrane. Such PFSA materials are commonly deployed as membranes as well as ionomers deployed within the catalyst layer (Figure 1). In commercial PEM-WEs, platinum catalysts on carbon supports are deployed to turn over the cathodic HER. At the anode, iridium and ruthenium oxide-based catalysts are deployed. PEM-based electrolyzers were first developed at General Electric in 1955, and later used for oxygen generation in space and submarine applications.6

Currently considered precommercial, zero-gap AEM-WEs are far less mature compared to A-WE and PEM-WE technologies. However, PEM-WE and AEM-WEs deploy an MEA cell architecture whereby a membrane separates the anode and cathode.26 AEM-WE have been reviewed in detail elsewhere.11,12,27 AEM-WE membranes conduct hydroxide ions, utilizing polymers that contain immobilized, positively charged functional groups on their backbone or pendant size chains. It is typically the durability and relatively low conductivity of AEM-WE membranes that is thought to limit the realization of this technology at scale.27,28

For AEM-WE, a clear advantage pertaining to the alkaline environment is the suitability of precious metal free catalysts, as well as the replacement of expensive titanium bipolar plates/flow fields. At the cathode, Ni and Ni alloy-based HER electrocatalysts (e.g., NiMo29) are considered the highest performing precious metal free catalysts. At the anode, various Ni, Fe and Co oxides are commonly utilized. It is important to note that Pt-based electrocatalysts still outperform precious metal free HER electrocatalysts under alkaline conditions.30 One important distinction between current PEM-WEs and AEM-WE literature is that AEM systems are frequently tested with liquid electrolyte circulation (e.g., KOH, or K2CO3) in addition to the polymer membrane electrolyte (rather than pure water as used in PEM-WE). The role that such electrolyte circulation vs pure water has on AEM-WE durability has recently been reviewed elsewhere.27 In brief, it is speculated that the circulation of electrolyte solutions significantly enhances catalyst utilization and improves ohmic resistance owing to the higher hydroxide ion transport, consequently improving intrinsic kinetics of the catalyst compared to a pure water feed.

While precious metal free catalysts are commonly touted as a significant advantage of AEM-WEs, a significant portion of publications (particularly those reporting durability >100 h) still utilize PGM catalysts at the cathode, anode, or both electrodes.11,31 It is important to acknowledge that this is likely due to a combination of factors, including; convenience, (commercially available PGM catalysts, inks and manufacturing methods already optimized for PEM-WE) lack of precious metal free benchmarks for AEM components, and the higher intrinsic activity of HER PGM-catalysts under alkaline conditions which therefore reduces the overall cell potential and water splitting efficiency. Furthermore, the complex interplay among the numerous components of an electrolyzer collectively influences the electrolyzer performance. Therefore, it can be extremely challenging to optimize each individual components in isolation without deploying precious metal containing components.

Beyond A-WE, PEM-WE and AEM-WE, it is important to note that the technologies of today may be replaced with alternative cell architectures and device designs beyond these three technologies. For example, capillary-fed electrolyzer cell,32 membrane-free electrolyzers,33−36 involving soluble (redox) mediators,37 photoelectrochemical water splitting14,15 which have been more broadly reviewed elsewhere.38,39 However, in this review, we focus on catalysts tested under conditions that align with A-WE, AEM-WE and PEM-WE technologies, therefore focusing on catalyst screened for the HER under either alkaline or acidic electrolyte environments.

1.2. Water Splitting Fundamentals

Electrochemical water splitting utilizes electricity to split water (H2O) into hydrogen (H2) and oxygen (O2) (eq 1). The choice of electricity source (i.e., renewable, or not) and device efficiency therefore control the emissions associated with the hydrogen produced.

| 1 |

Water splitting is a nonspontaneous reaction with a standard Gibbs free energy of 237.2 kJ mol–1 which equates to an applied potential of 1.229 V. While the electrical work required to drive eq 1 is critical to understanding the efficiency of an electrolyzer, the reaction is endothermic, therefore requiring an additional energy contribution (48.6 kJ mol–1) as heat. This minimum requirement to split water translates to a total energy input of 285.8 kJ mol–1 for a water electrolyzer, corresponding to a cell voltage of 1.481 V.40

As with any electrochemical device, a water splitting electrolyzer is based on two half-cell reactions: an oxidative and a reductive reaction. The two half-cell reactions of water splitting are the cathodic HER (eqs 2 and 3) and the anodic OER (eqs 4 and 5).

Hydrogen evolution reaction (HER)

Acidic medium:

| 2 |

Basic medium:

| 3 |

Oxygen evolution reaction (OER)

Acidic medium:

| 4 |

Basic medium:

| 5 |

The HER is one of the simplest electrochemical reactions, requiring just two electrons to drive the reduction reaction. Indeed, owing to this relatively simple nature, the hydrogen evolution and oxidation, reactions have been used as a platform for the verification of fundamental mechanistic relationships and theories such as the Butler–Volmer equation,41 and Sabatier’s principle.42

1.3. The HER Mechanisms

Under acidic conditions, the HER is generally thought to occur by three different mechanistic steps: the reduction of a proton resulting in an adsorbed hydrogen atom (Volmer reaction), followed by one of two possible pathways, either; (a) molecular hydrogen is formed in a chemical step by the combination of two adsorbed hydrogen atoms, (the Tafel reaction), or (b) a second proton is reduced, which reacts with an adsorbed hydrogen atom to form molecular hydrogen (the Heyrovsky reaction). In both proposed mechanisms, molecular H2 is subsequently desorbed from the surface. Note, * denotes an active site on the catalysts.

Volmer reaction

| 6 |

Tafel reaction

| 7 |

Heyrovsky reaction

| 8 |

Under alkaline conditions, the concentration of hydronium ions is significantly depleted compared to acidic media. Accordingly, for the HER to proceed under alkaline conditions, the catalyst must further facilitate water dissociation in addition to catalyzing the HER. Therefore, contrary to acidic media (where the HER mechanism sources protons from a weakly bound H3O+), alkaline HER sources protons from water molecules, and thus the Volmer and Heyrovsky steps are rewritten as below:

Volmer reaction

| 9 |

Heyrovsky reaction

| 10 |

Independent of pH, the Tafel step remains constant (eq 7).

Several reviews have been published focused on the HER mechanisms.43−45 Several other reviews specifically focus on alkaline HER and contain dedicated sections detailing the alkaline HER mechanism.46,47

Experimental reaction rates in alkaline media are typically reported as 1 to 3 orders of magnitude lower than in acidic media for the HER.48,49 Water dissociation is generally acknowledged as a contributor to this reduction in activity, and thus the barrier to dissociate water is considered a necessary second descriptor for HER activity in alkaline media.50 This was evidenced experimentally by Danilovic et al., in 2013.51 Specifically, they measured the HER activity of a selection of metal electrodes, and constructed volcano plots in both acid and base electrolyte. As a function of the selected metal, their position on the volcano varied depending of the pH. However, after mixing the various metals with Ni(OH) nanoparticles as efficient adjacent water dissociation sites, their relative positions in base shifted. Conversely, in acidic media, the relative positions remained constant. Thus, the overall trends in activity as a function of composition were the same for both the base and acidic volcano plots.

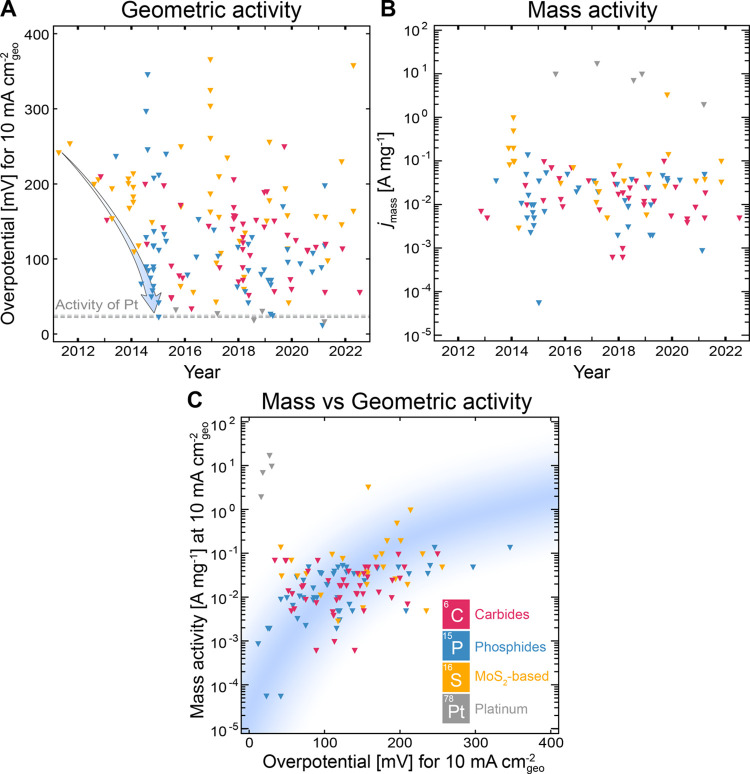

Despite a plethora of precious metal free catalyst discoveries for the HER, the intrinsic activity of platinum for the HER exceeds that of any alternative precious metal free catalysts by at least 3 orders of magnitude (see Section 3.3.4. for further discussions).52 Under acidic conditions, the HER kinetics of a platinum cathode are particularly fast.52 Indeed, the intrinsic activity of Pt is so fast, that even when measured in a rotating disk electrode configuration, mass-transport limitations can impede the accurate determination of the intrinsic activity of Pt.52,53 Under alkaline conditions, platinum electrodes also outperform precious metal free based electrodes. However, owing to unfavorable kinetics under alkaline conditions, the activity of Pt-based catalysts in acidic media is significantly higher than those recorded in alkaline solution (Figure 2).49,52,54−58 Interestingly, when the highest performing precious metal free HER catalysts in acid and alkaline electrolyte are compared by mass activity, these precious metal free catalysts all have similar mass activities (10–2–10–1 A mg–1 at 10 mA cm–2geo).

Figure 2.

Comparison plots between mass activity (10 mA cm–2geo) and overpotential (10 mA cm–2geo) under (A) acidic and (B) alkaline electrolytes for various Pt-based and precious metal free catalysts for the HER. Reproduced with permissions from ref (49). Copyright 2019 Springer Nature.

Sabatier’s principle states that there exists a maximum overall rate of reaction when the interaction between reactants and catalysts (binding energy) is neither too strong nor too weak. It was thus proposed for the HER that the overall rate of reaction will largely depend on the free energy of hydrogen adsorption (ΔGH).59−61 Accordingly, where a catalyst ΔGH is “too strong”, the desorption of reaction intermediates becomes limiting, blocking catalytically active sites and thus preventing the reaction from proceeding to completion (i.e., molecular hydrogen for the HER). Conversely, where the ΔGH is “too weak”, the adsorption of hydrogen atoms will limit the reaction rate. The optimal hydrogen adsorption energy for HER catalysts has typically been considered where ΔGH = 0. This relationship leads to a volcano-shaped plot when the catalyst activity is plotted against density function theory (DFT) calculated ΔGH.61 Such trends have been reported for metallic electrodes (Figure 3a),61,62 and more recently shown to translate to a wide range of precious metal free HER catalysts including transition metal phosphides (Figure 3b),63,64 transition metal carbides,65−67 and transition metal nitrides,68 deploying a combined theory and experimental approach throughout. Beyond hydrogen binding energies, under alkaline conditions a volcano relationship has been demonstrated for experimentally determined HER activities (overpotentials and Tafel slopes) as a function of OH binding energies (Figure 3c).69 These proposed DFT models provide a leading framework for the design of heterogeneous electrocatalysts, and are widely accepted and deployed throughout electrocatalysis materials discovery investigations. Alternative predictors have also been identified as descriptors for HER electrocatalytic activity, including d-band position in relation to the Fermi level,70 and surface energies.71

Figure 3.

Example volcano plots for various HER catalysts whereby experimental data is plotted against calculated binding energies. (A) Various metallic electrodes (exchange currents plotted against calculated hydrogen adsorption energies) (acidic electrolyte), (B) Numerous transition metal phosphides (experimentally determined TOF at 100 mV overpotential plotted against hydrogen adsorption energies) (acidic electrolyte), (C) Various M-doped Ni electrode surfaces (M = Fe, Cr, Ti) (overpotentials at 10 mA cm–2 and Tafel slopes plotted against theoretically calculated OH binding energies) (alkaline electrolyte). Reproduced with permissions from ref (61). Copyright 2005 The Electrochemical Society; ref (63). Copyright 2018 American Chemical Society; ref (77). Copyright 2021 American Chemical Society.

It is of note that these volcano-plots are solely based on a thermodynamic assessment, mitigating the kinetically determined barrier energetics.58,72−74 Furthermore, while the hydrogen binding energy activity descriptor has been widely demonstrated as an accessible and widely applicable theory broadly for electrocatalysts, it is important to recognize that as a function of pH and electrolyte composition, the correlation of activity with hydrogen binding energies are inconsistent in some reports. Thus, ΔGH = 0 can be considered a necessary but insufficient condition for predicting good HER catalysts. Sometimes referred to as “beyond adsorption” descriptors, kinetic parameters (e.g., solvent reorganization energetics) and interfacial electric field strengths, have been highlighted as significant parameters for assessing electrocatalysts,74 in particular for the sluggish alkaline HER.58 Other reviews have provided discussions relating the limitations and challenges of applying conventional volcano plots to describe HER and other electrocatalyst activities.70,75,76

2. Assessing Catalyst Performance: Benchmarking and Best Practices

The most commonly reported and compared metric for HER activity from half-cell measurements are i–V response (e.g., cyclic voltammetry or linear sweep voltammetry), overpotentials or onset potentials at a given current density. Electrochemical active surface area (ECSA) normalized current densities, turnover frequency (TOF), Tafel slope, exchange current density and short-term durabilities determined by chronoamperometry (CA), chronopotentiometry (CP) or cyclic voltammetry (CV) are also regularly reported and discussed. These measurements are often accompanied by ex situ or in situ materials characterization including electron microscopy, X-ray diffraction, dissolved ion quantification, and other spectroscopic methods. In this section we give a brief overview of these electrochemical methods. Subsequently, we review best practices for half-cell measurements and stability measurements. Here, our intention is that through this review of recent reviews, publications, perspectives, and editorials we can provide a summary of the various best practices and considerations for data acquisition and analysis for half-cell based HER catalysts. Finally, we discuss device testing, including membrane electrode assemblies and alkaline water electrolyzer testing protocols, providing a review of testing methods as well as examples of precious metal free catalysts that have been translated into such device tests. Figure 4 is a schematic to highlight the most critical factors which should be considered for benchmarking HER catalysts, each of which are reviewed in this section.

Figure 4.

Schematic to highlight the key considerations that a researcher should factor into the design of their HER catalyst performance measurements.

2.1. Activity Metrics

Several different metrics can be used for assessing and comparing electrocatalyst activities which have been reviewed elsewhere.78−82 Geometric area normalized current densities at given overpotentials are the most frequently reported performance metrices in half-cell measurements whereby the current collected in a CV or linear sweep voltammogram (LSV) is normalized to the surface area calculated by the geometrical dimensions of the electrode (Figure 5).78 Typically, geometric area current densities are reported with units of mA cm–2geo. In an attempt to enable comparison between different electrocatalysts and testing modes, the applied potential (or overpotential) to reach 10 mA cm–2geo is also widely reported.83 While such geometric area normalized activities may be most commonly reported, the metric itself has very little scientific meaning in terms of actual activity of a material unless the catalyst has an atomically perfectly flat surface. Most precious metal free, (and state-of-the-art Pt/C), catalysts are heterogeneous structures with complex surfaces including steps, pores, defects, and interfaces. Ideally, one should strive to normalize the current with the electrochemically active surface area (ECSA) for each catalyst so that electrochemically inert surfaces, volumes, and materials can be excluded (Figure 5). However, experimental determination of ECSA for precious metal free catalysts is neither trivial nor has any consensus been agreed on methods for best estimates. For Pt based HER catalysts hydrogen adsorption/desorption can be used to accurately measure the ECSA. Such measurements are neither reproducible nor universally applicable in precious metal free catalysts owing to their varying binding energies toward hydrogen and protons. The most commonly utilized and optimized methods for precious metal free electrocatalyst ECSA measurements require the underpotential deposition of a metal (Cu or Pb), CO stripping, redox peak integration, double layer capacitance measurements, or, using electrochemical impedance spectroscopy (EIS). Each of these techniques have limitations and none are universally applicable. However, we recommend reporting ECSA measurements provided the methodologies are clearly described so that geometric area normalized current densities can be contextualized against active site densities to some extent. In particular, we highlight the potential advantages of utilizing EIS which can enable assessment of ECSA under the relevant applied electrochemical potential for the HER.

Figure 5.

Cross-sectional schematic representing a MoS2 electrocatalyst highlighting the difference between geometric surface area and electrochemically active surface areas. The active sites of the catalyst (green dot) are also shown to highlight that such surface area normalizations do not necessarily allow for assessment of intrinsic activities between electrodes. Reproduced with permission from ref (79). Copyright 2014 American Chemical Society.

It Is also essential that the experimental section of published literature should clearly describe the physical properties of the working electrode for the readers to understand how the current densities were computed. For example, if an RDE is utilized one should clearly state the material (graphite, gold or other) and the radius of the disc. In the case of catalysts grown on high surface are substrates (e.g., foams or mesh electrodes), it is quite uncommon to quantify catalyst surface areas. We suggest that every effort should be made to isolate and quantify the electrocatalyst surface areas. It is also essential to describe how the electrodes were conditioned, activated and which CV or LSV cycles are presented since the activities will potentially fluctuate over time.

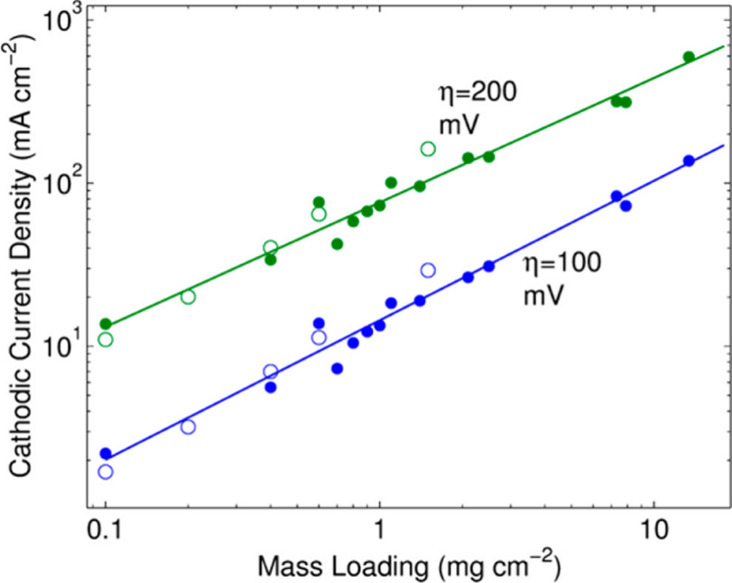

While the precious metal-based literature regularly reports mass activities (current normalized to mass of catalyst, with units of A g–1), this is rather uncommon in the precious metal free literature. However, we recommend that analogous to area normalized activities (ECSA and geometric) mass activities should also be accurately determined wherever possible. These measurements are essential for developing insight regarding the intrinsic activity of catalysts, or to provide like-for-like comparisons between different electrodes prepared within a study. In the case of RDE where a catalyst ink is usually deposited onto the working electrode, catalyst mass reporting is relatively straightforward, provided that the publications report all the relevant data (e.g., ink recipe, volume deposited etc.). In the case of self-supported or substrate grown catalysts, more advanced ex situ techniques such as energy dispersive X-ray spectroscopy (EDS) and X-ray fluorescence (XRF) can be utilized to determine the mass of active material if nondestructive methods are a must.84,85 Simple mass balance before and after the durability tests also can be utilized if highly accurate balances are accessible. The most accurate catalyst mass determination is perhaps through ICP-MS measurements of dissolved catalysts/electrodes. However, such analysis requires reliable duplicate sample preparations so that one can be utilized for electrocatalysis and the other for catalyst loading analysis. It is also recommended that effects of mass loading on the catalytic activities be carried out to determine optimal catalyst layer thickness on the working electrode. A common argument for higher loadings of precious metal free catalysts compared to precious metal catalysts is that materials costs are insignificant in comparison to PGM catalysts. While this is the case for some materials, we postulate that this may not always be a correct assumption. Furthermore, high catalyst loadings exhibit higher apparent HER activity, but can potentially suffer from mass transport limitations when incorporated into a working device.52 Similarly, if any binders such as Nafion are utilized to affix HER catalysts on the working electrode, it is recommended that the effects of Nafion content in the catalyst ink also be investigated. It is well established that Nafion and other binders significantly affect the conductivity and mass activities of catalyst layers.86−88

To understand the kinetics and HER reaction pathways when utilizing various electrocatalysts in different electrochemical environments researchers most commonly determine the turnover frequencies (TOF) and Tafel slopes.52,81 TOF and Tafel analysis require elucidation of mass-transport limitations and electrical resistance from activities. The potentials should be iR corrected as discussed in Section 2.2.6 and methodologies clearly described as per recommendations from the research community.78,85,89−91 Tafel slopes are computed by plotting the overpotentials (η) against log values of current densities (j). The Tafel slope (2.303RT/αnF) in eq 11 (where R is the gas constant, T is the temperature in Kelvins, α is the charge transfer coefficient, n is the number of electrons transferred to generate one product molecule and F is the Faraday constant) is commonly then used to elucidate reaction kinetics of the associated electrochemical reaction. The current density at equilibrium potential (exchange current density, J0) are the most useful and most often used parameters in describing reaction kinetics. Anantharaj et al., discuss appropriate methods to report and utilize Tafel slopes,89 and we urge the research community to use appropriate rigor to report and caution to utilize the matrices for analysis:

| 11 |

Tafel slope analysis should always be contextualized with other activity and kinetics metrices including TOF, exchange current densities, ECSA and other measurements that help articulate reaction mechanisms and reaction kinetics. If used on their own, Tafel slopes become ambiguous and often lead to erroneous conclusions.92,93 For example, symmetry factors must be used to effectively correct Tafel slopes, but accurately assigning the symmetry factor is inherently challenging. Thus, it is important to contextualize Tafel slope discussions to methods used and other kinetics parameters. In 2014 Kichigin and Shein presented a theoretical derivation on how EIS is used to probe the rate-determining step and reaction mechanism for the HER at different electrochemical conditions.94 Their method also enables an extraction of transfer coefficients, rate constants, and hydrogen coverages. An example of the synergy between Tafel analysis and EIS is presented by Galyamin et al., where they show direct correlation between the Tafel slopes determined from voltametric techniques and the equivalent circuit elements from the EIS analysis.92 Such cross-examining approaches are highly encouraged to find methodologies that can be universally adopted across various families of electrocatalysts. However, rigorous validations need to be presented and detailed methodologies reported to test the added value of such methods toward more accurately determining Tafel Slopes and ECSAs.

Similar to Tafel Slopes and ECSA determinations, TOF calculations also require accurate and detailed knowledge of catalyst structure. For crystalline electrocatalysts, one should first accurately determine the crystal structure complemented with other materials characterization tools that enable determination of structural and stoichiometric properties. Typically, assumptions must then be made regarding which site (e.g., metal atom or nonmetal atom) should be considered active. For example, on the surface of a CoP nanoparticle, one might calculate the average surface area, and use the crystallographic structure to estimate the number of Co atoms present on the surface of the particle. Knowing the catalyst loading on the electrode, one can therefore estimate the total number of Co atoms exposed to electrolyte. It is critical that such calculations are explained fully (either within the methodology or within the Supporting Information), and that any assumptions made in the calculation are fully discussed. Finally, it is critical that such estimates provide the most conservative estimate (i.e., the highest possible number of active sites) to calculate the TOF.81,90,95 As Anantharaj et al. discuss TOF calculations for various types of HER catalysts, the most common equations used are eqs 12-14 where j is current density, NA is the Avogadro constant, F is Faraday constant, n is the number of electrons transferred to generate one molecule of the product, Γ is the surface concentration of active sites, i is the current, A is the area of the electrodes, and x is the number of moles of active sites available for catalysis.81 It is acknowledged that accurate determination of these intrinsic activity parameters is difficult and often requires estimations, but we encourage the community to carefully make conservative estimates to report TOF values:

| 12 |

| 13 |

| 14 |

Like half-cell measurements, due care should be taken to report the MEA performance metrices. Detailed information on how polarization curves were generated should be provided in the experimental section. Potentiostatic or amperometric holds at regular intervals should be used and average values from >30 data points utilized after the performance stabilizes to generate pole curves.96−99 Such practice ensures that the electrolyzer reaches steady state performance at each potential (or load) hold. Where possible, one should also strive to assess iR free potentials through high frequency resistance (HFR) measurements. More details on best practices and recommendations regarding equipment assembly and hardware selections for half-cell and MEA measurements are discussed in subsequent sections.

2.2. Electrochemical Testing Setup: Half-Cell

Electrochemical measurements are inherently sensitive to contaminations and unintended side reactions. The effects are especially pronounced when assessing low catalyst loadings (μg–mg) and ultralow activities (μA–mA) as is typical for half-cell measurements. A range of methodologies have been utilized and protocols have been proposed over the years to ensure that due care is taken in ensuring the analytical equipment is ultraclean and methodologies are comparable when assessing electrochemical performances and durabilities.100,101 Indeed, the choice of test vessels, electrolytes, electrodes and configuration of these components into the analytical system need to be carefully considered when assessing activities and durabilities in different cell configurations, electrochemical environments and modes of assessments.78 In this section we review these various proposed best practices of relevance to HER catalyst screening.

2.2.1. Electrochemical Cell and Cleaning

With regards to a rotating disk electrode (RDE) setup for HER catalyst activity measurements, Wei et al. provide discussion regarding the rationales for the choice of various components (e.g., choice of appropriate reference and counter electrodes, and the purity of the electrolyte) suitable for assessments of precious metal free electrocatalyst activities.78 There are also recent editorials and perspectives discussing rationale behind the choice of components and conditions while assessing HER.85,91,102−104 Much of this discussion is focused on PGM catalysts, but these good practices can be equally applicable to precious metal free HER catalysts as well. The consensus regarding the choice of vessels is that ultraclean glassware should be used for electroanalysis in acidic electrolyte and chemically resistant polymer vessels (e.g., Teflon or PEEK) for analysis in basic electrolytes. Glassware is preferred under acidic conditions because the homogeneous surface that is resistant to abrasion and chemical corrosion. Additionally, transparent glass allows direct observation into the reaction volume during set up and while electrochemical reactions are taking place which can help with bubble management. However, ions of constituent elements such as Si, Al, B, Ca, and Fe leach out from glass when exposed to an alkaline environment which can contaminate the electrocatalyst.105 Using polymeric materials mitigates the possible contaminant issues but polymers are opaque and also prone to abrasion. It is likely that the resulting rough surface can trap contaminants during cleaning or evolved gases during electrocatalysis.103 Thus, it is essential to ensure all reaction vessels are abrasion free and clean when setting up HER electrochemical testing.

Alia and Danilovic provide a detailed protocol on cleaning glassware for acidic half-cell reactions for water electrolyzer and hydrogen/oxygen fuel cell reactions.100 They adapted the procedure developed by Garsany et al. for fuel cell half-reactions,106 and such glassware cleaning protocol has also been recommended for cleaning polymer electrolyte vessels to be used for alkaline HER with due consideration for compatibility of the polymer in the cleaning solutions.78 The general protocol consists of soaking reaction vessels and components consecutively in strong acid and strong base solutions overnight followed by boiling in fresh DI water several times.78,100 Additionally, all reaction vessels and components are recommended to be stored submerged in ultrapure DI water to avoid contamination from air borne impurities.100

2.2.2. Electrolyte Purity

The purity of electrolyte itself is critical, especially for alkaline HER. Marquez et al. discuss the importance of ensuring appropriately high electrolyte purities are used throughout electrochemical analysis and methodologies are provided to purify alkaline electrolytes.107 In general, the highest possible grades of acid and alkaline electrolytes should be used, and where necessary, appropriate cleaning procedures need to be followed to remove critical contaminants such as Fe in alkaline and precious metals in acid electrolytes prior to commencing electroanalysis.108

2.2.3. H2 Gas Saturation

When evaluating the HER activity, it is crucial to saturate the electrolyte with H2 gas. Otherwise, the partial pressure of H2 entered into the Nernst equation for HER and can thus shift the potential of the H2-redox couple.78 Assessing the activity of a HER catalyst in an H2 under-saturated electrolyte or even an Ar-saturated one can cause HER currents to start anodically of 0 V versus RHE.109 Similarly, when calibrating the reference electrode to the RHE scale using Pt-electrodes, it is essential to keep the electrolyte saturated with H2 gas to ensure the equilibrium potential is measured in accordance with the Nernst equation under standard conditions.49,78

2.2.4. Counter and Reference Electrodes

Counter and reference electrodes are the most common sources of electrolyte contaminants during HER if improperly selected and deployed. Pt, Au, Ni and graphite are the most common counter electrodes deployed during HER. Metallic counter electrodes are generally not recommended for either undivided or compartmentalized cells. Jerkiewicz discusses in detail the complexities of Pt as a counter electrode for electroanalysis110 and discusses earlier work to demonstrate the dissolution and redeposition on the working electrode under HER conditions.111 Such effects are known to lead to erroneous HER activities and long-term durabilities, especially when evaluating the activities of precious metal free HER electrocatalysts. To evidence this, a Pt counter electrode was deployed during the assessment of precious metal free carbon powder HER catalysts. Although the precious metal free catalyst activity was shown to be relatively stable during chronoamperometric, chronopotentiometric or during CV measurements, it was found that this was due to the deposition of dissolved Pt ions onto the working electrode which counteracted the precious metal free HER catalyst degradation (Figure 6A). Beyond Pt, other metals such as Au and Ir counter electrodes also dissolve and redeposit at the working electrode. The apparent effect on HER activity may not be as drastic as Pt, but the dissolution and redeposition can still interfere with the electroanalysis. Using high surface area carbon based counter electrodes can mitigate the effect of HER active precious metal counter electrodes. However, the generation of carbon monoxide and other carbon species at the counter electrode can influence the performance of the working electrode if such species migrate to the working electrode. This effect is likely to be especially pronounced at high current densities and long-term durability tests. Recent reports have demonstrated that the optimal configuration is to separate carbon-based counter electrodes (graphite or glassy carbon) from the working electrode chamber with a glass frit (Figure 6C).91,111,112

Figure 6.

(A) Influence of various counter electrodes (Pt, carbon) and saturating gas (N2, H2) on the HER activity of carbon powders working electrodes in an undivided cell. The HER activity remains almost the same after 2 h of CV cycling at 10 mV s–1 when the electrolyte is saturated with H2 irrespective of whether the counter electrode is graphite or platinum, but HER activity dramatically improves when platinum counter electrode is utilized under N2 saturated electrolyte.113 (B) The counter electrode potential for each experiment. Note at potentials >1.5 V OER is taking place at the counter electrode.113 (C) A divided RDE cell that separates working, reference and counter electrode.111 Reproduced with permissions from ref (113). Copyright 2023 American Chemical Society; ref (111). Copyright 2016 American Chemical Society.

The dissolution of the counter electrode and possible contamination on the working electrode is known to accelerate under inert gas saturated electrolyte.113 Under such inert environments, the electrochemical reaction occurring at the counter electrode is the oxygen evolution reaction (OER) requiring high potentials (Figure 6b). At these high potentials, metal oxides or oxides of carbon form at the counter electrode which undergo dissolution and can therefore potentially be electrodeposited at the working electrode.114 Conversely, a hydrogen saturated electrolyte can enable the hydrogen oxidation reaction (HOR) at the counter electrode which occurs close to 0 V vs RHE (Figure 6b) in the case of Pt counter electrodes, mitigating the dissolution of counter electrode and the resultant cross-contamination of the working electrodes. Cui and Sheng have recently demonstrated the effect of saturating the electrolyte with hydrogen gas and the relative position of counter electrode to working electrode within the electrochemical vessel (Figure 6).113 They demonstrate that saturating electrolyte with hydrogen prevents counter electrode dissolution and separation of working electrode chamber from counter electrode chamber, as shown in Figure 6c, can mitigate the migration of dissolved species to the working electrodes. It must be emphasized, despite commonly accepted notion regarding kinetics being extremely fast rendering mass transport limitations in HER/HOR reactions insignificant, one must ensure the electrolyte is sufficiently saturated prior to electrochemical measurements such that equilibrium potentials are achieved within the Nernst equation. Zheng et al., have demonstrated that mass transport limitations can indeed influence even HER/HOR reactions due to sluggish H2 diffusion away from the electrodes into the bulk electrolyte.78,109

Reference electrodes should also be carefully selected taking into consideration the electrolyte composition and pH. A reversible hydrogen electrode has been recommended where possible.78,100,103 However, Oshchepkov cautions that even reversible hydrogen electrodes potentials can also substantially change if the concentration of hydrogen is not sufficiently maintained and/or if dissolved species from either working or counter electrodes reach the reference electrode; Pt especially can further deviate from the original reference electrode potential.103 Wei et al. provide a detailed rationale for selecting mercury based reference electrodes, Hg/HgO or Hg/Hg2SO4 for acidic systems and Hg/HgO for alkaline electrolyte, and converting all potentials to RHE.78 Anantharaj et al. have very recently demonstrated the need to use appropriate reference electrodes for different pH regimes, and the need to regularly calibrate the reference electrodes as they drift away from ideal scale over time.80 They observe that across the HER literature, silver–silver chloride (Ag/AgCl) reference electrodes are most widely used as well as responsible for the majority of erroneous reports deviating as much as 70 mV from the thermodynamic potentials. Similarly, Zamora et al. also show that the reference electrode needs to be calibrated periodically; the frequency of calibration depends on frequency and mode of usage (duration and types of experiments) but they recommend calibration every time new electrolyte is used in experiments.115

2.2.5. Binder-Free Electrode Testing

Half-cell tests that are not based on RDE, in most-cases where the catalyst is either grown on a substrate or as self-supported electrodes, should also follow the recommendations discussed above. Additionally, due care should be taken to ensure the substrates and connectors (e.g., alligator/crocodile clips for connection to the potentiostat) do not release contaminants during electrocatalysis. Zheng et al. have recently described best practices when deploying foam-based electrodes for HER in non-RDE half-cell measurements.116 Similarly, Jin et al. have reviewed strategies deployed to assess HER electrocatalysts for high current densities in a half-cell setup.117 It is generally not advisible to use RDE measurements for assessing activities at large current densities (>200 mA cm–2) owing to the severe mass transport limitations. Instead, in recent years other innovative architectures such as inverted RDE,118−120 microelectrodes,121,122 floating electrodes123 and gas diffusion electrodes have been proposed to bridge the gap between RDE and MEA.124

Given the variety of precious metal free HER catalysts that have been reported in recent years, it is almost an impossible task to develop a universal methodology to assess the entire spectrum. As an exercise to develop a uniform method, McCrory et al. analyzed thin film catalysts prepared via electrodeposition and/or sputter deposition on glassy carbon electrodes for both acid and base toward HER.83 They identified multiple precious metal free transition metal based HER catalysts that exhibited promising activity and short-term durabilities. A similar benchmarking exercise has not been undertaken for the plethora of powder catalysts. Despite the enormity of the task to analyze and compare the activities of myriad types of precious metal free catalysts, reproducibility of the data and comparison of catalytic properties can be facilitated if the community ensures recommended good practices are followed strictly (refs (78, 80, 85, 91, 100−103, 107, 110−113, 115, 116, and 125)).

2.2.6. iR Compensation

iR compensation is another critical consideration when running half-cell experiments to facilitate HER catalyst activity comparison across different electrochemical setups and laboratories. The compensated data in principle eliminates variations emanating from the distance between electrodes and properties of the separators. However, complete elimination of such effects requires full compensation (100%) of the ohmic drop. Currently, standard practice is a partial compensation, typically 85%, of the measured value. An insightful recent perspective by Zheng on this topic proposes dividing electrocatalyst research into different “types of measurements” to allow more meaningful iR compensations.126 For example, assessing the intrinsic activity (RDE), electrode activity (single cell), and industrial activity (stacks) potentially each require different considerations with regards to cell configurations as well as iR compensation. Such distinctions help elucidate the different contributions to the iR drop from specific regions in the substrate-catalyst-electrolyte system. Proposed by Zheng, specific experiments enable compensation of specific and distinct iR drops. Figure 7 shows the regions contributing to the iR drop in the substrate-catalyst-electrolyte system in a three-electrode setup alongside the equivalent circuit diagram.

Figure 7.

A) A schematic of the resistances that contribute to potential drops in a simplified three-electrode half-cell electrochemical cell with a catalyst-loaded working electrode, together with its equivalent circuit diagram. The numbers (1–4) indicate points of contact between distinct regions in the system (e.g., substrate-catalyst). B) Identifies three “regions of interest” as marked by the dotted boxes (e.g., catalyst-solution) highlighting the resistances of interest for intrinsic activity measurements, sample activity of catalysts, and electrode activity measurements. Critically, for catalyst optimizations the conductivity of the catalyst layer is also relevant to study, whereas for an electrode design, the substrate-catalyst contact resistance likewise demands attention. Reproduced with permission from ref (126). Copyright 2023 American Chemical Society.

All but one of the resistances in Figure 7 are adequately quantified by EIS. Typically, EIS measurements are run between 100 kHz and 0.1 Hz, with a voltage perturbation of 10 mV.78 The ideal resistance to compensate is dictated by the magnitude of the impedance where the phase angle is closest to zero, (i.e., where the imaginary part is closest to zero). This can be read directly from the high frequency range in a Nyquist plot. Critically, the measured high frequency resistance (RHFR) is a sum of multiple resistances, and not purely the electrolyte resistance (except in some RDE measurements where the stub and catalyst are one homogeneous material). This impedance is made up of three contributions: the electrolyte resistance Rsolution, the contact resistance between the catalyst and the support/substrate, Rcontact, and the resistance within the catalyst layer Rcatalyst.

Zheng has several suggestions to optimally utilize iR compensation in electrocatalysis. Here, we relate iR compensation in reference to the HER catalysts. Critically, the type of iR correction should depend on the type of measurements you are performing: (1) When studying the intrinsic activity of a catalyst, a 100% iR compensation should be used to eliminate any contribution from electrode-catalyst-electrolyte (Rcontact + Rcatalyst + Rsolution). This is done by compensating fully for RHFR measured using the electrode-catalyst assembly. (2) Meanwhile, there is plethora of work focused on optimizing the overpotential of a catalyst-coated substrate (e.g., Ni-foam for A-WE and carbon cloth/paper for PEM-WE). For these studies, the interaction of the substrate and the catalyst is important and should be optimized instead of neglected. Thus, only the electrolyte resistance should be quantified and compensated. Rsolution can be isolated and measured as the RHFR using only the bare substrate, enabling one to compensate for 100% of the ohmic loss in the electrolyte. (3) For benchmarking catalyst materials but disregarding the electrode-catalyst interactions, 100% compensation for the electrolyte iR drop should be measured but in addition, a measurement of the substrate-catalyst contact resistance (Rcontact) should be performed, such as, using a Kelvin four-wire resistance measurement. Otherwise, compensating for the full RHFR using the electrode-catalyst assembly may produce erroneous results. Some catalysts are efficient catalysts but poor conductors, and benefit heavily from a mixing with conductive material.127 A single compensation of Rcatalyst on its own therefore may mask such effects.

2.3. Electrocatalyst Stability

To withstand the various operating conditions, such as fluctuations in operating potential, load (current densities), temperature, differential pressure between the cathode and anode, and shut down cycles, precious metal free HER catalysts should stably work without activity decay or dissolution. The field therefore requires rigorous protocols for evaluating the catalyst stability. This section discusses the methodologies for assessing catalyst in a 3-electrode setup. We start with activity decay/service time measurements, including CA, CP, which are effective methods for preliminary test but insufficient. Further, we discuss measuring catalyst dissolution by inductively coupled plasma (ICP) methods. Various cells for ICP measurements are reviewed, and then the factors that may influence the dissolution measurements, including the concentration of dissolved species, the use of ion-exchange membrane, ionomer and potential control, are discussed. Finally, we review the post-mortem analysis typically conducted alongside stability testing.

2.3.1. Electrochemical Stability Measurements

Chronoamperometry (CA), chronopotentiometry (CP) and potential cycling serve as the most effective initial methods for evaluating the performance loss of a catalyst. Degradation of catalysts can, however, occur through a multitude of processes, including delamination of the catalyst or the poisoning of active sites, and, additionally, loss of activity can be either temporary or permanent.128 As Risch has exemplified while studying the OER, investigating degradation necessitates the coordination of multiple measuring techniques, including nonelectrochemical methods, such as gravimetric techniques, which can provide further insight into degradation mechanisms. Risch also advocates that degradation studies should focus on conducting measurements until catalyst end-of-life, providing a more thorough understanding than merely stating the stability of a catalyst in terms of the hours tested. This approach would enable researchers to extrapolate catalyst stability measurements to more accurately provide comparisons between catalysts, and help transition the field away from sweeping stability claims for X hours or Y cycles of stability.

The most popular electrochemical methods are CP and CA. Changes in the overpotential during CP and the current during CA measurements have been widely used to quantify stability. The service time measured by CP has also been used to reflect catalyst lifetime. We direct readers to a recently published review for more examples.129 Activity loss measured by CA and CP are essentially the same, but CP is visually more deceiving than CA, which is because current is exponentially related to potential (i ≈ exp (V)). Assuming a Tafel slope of 30 mV/dec, a potential increase of 30 mV might appear to be small in CP, but it is actually a 10-time decrease in activity.

Beyond CP or CA measurements, triangular or square wave cyclic voltammetry have been used to assess HER stability in 3-electrode half-cell measurements. However, this technique may not effectively capture time-dependent phenomena similar to the demonstration from Kneer et al. for platinum oxide in proton exchange membrane (PEM) fuel cells.130 Indeed it was shown that the degradation of the catalyst was not tied to the number of cycles but rather to the time spent at specific potentials. Therefore, the number of voltage cycles alone may be inadequate for assessing stability.

Beyond the more simplistic CP, CA and CV-based stability measurements, the stability number (S-number) represents an alternative metric for comparing catalyst stabilities. The S-number, which is typically deployed for assessing the OER electrocatalysts in 3-electrode measurements, normalizes the number of generated O2 gas molecules per atom of electrocatalyst dissolved. This metric has recently gained traction as a useful method to quantify stability during the operational phase of OER catalysts.131 The S-number is, however, rarely reported as a stability metric for the HER. We postulate that this metric could be widely used for a wide range of electrocatalytic measurements, including the HER.

In summary, each electrochemical method exerts a different electrochemical stress while probing the stability of catalysts. To recommend a superior one among all these techniques, a future study on the stability of the same catalyst measured by different methods is needed. Note the mentioned methods are insufficient methods that can be only used as a preliminary test for assessing catalyst stability. For example, the observed “stable” signal in such measurements could be simply due to an increase in roughness factor, caused by the corrosion of catalyst, especially with a thick catalyst layer or high catalyst loadings. Only once the catalyst layer has completely corroded away, might the electrode fail by such metrics. For a rigorous stability test, we recommend a low catalyst loading, or a better practice is to use ICP for quantifying the corroded products in electrolyte, which is discussed in the following section.

2.3.2. Inductively Coupled Plasma Dissolution Studies

ICP is the most commonly deployed technique to measure catalyst dissolution during electrocatalytic stability measurements. ICP allows for multielement analysis, while electrochemical quartz crystal microbalance (EQCM) only measures total dissolution of catalyst/catalyst layer, not element-specific. Kasian et al. and Cherevko et al.132,133 have reviewed the typical ICP instruments and electrochemical cells deployed for measuring the concentration of dissolved catalyst species in electrolyte, and their applications for various reactions. Here we briefly discuss those setups, and some exemplary measurements of HER catalyst dissolution.

ICP has a high sensitivity (down to ppt level). Two ICP instrument configurations are typically used for such measurements based on the detector: optical emission spectrometry (ICP-OES) and mass spectrometry (ICP-MS). In general, ICP-MS is more sensitive than ICP-OES. Depending on the element, the detection limit of ICP-MS can be as low as ppt; in contrast, ICP-OES is ppb. The tolerance for total dissolved solids (TDS) of ICP-MS is up to 0.2%, lower than ICP-OES (up to 30%). This limits ICP-MS to electrolytes of lower concentrations (such as 0.1 M HClO4, 0.05 M H2SO4) compared to ICP-OES, which might be suitable for studies in aggressive electrolytes, such as such as 1 M KOH and seawater (TDS ≈ 3.5%).134,135

There are three popular electrochemical setups for measuring catalyst dissolution: in situ ICP measurement coupled with a flow cell (Figure 8A), in situ ICP measurement coupled with a stationary cell (Figure 8C), and ex situ ICP measurement in a stationary cell.

Figure 8.

(A) Schematic illustration of the in situ SFC-ICP-MS setup. (B) The dissolution profiles of WC, MoS2, Ni5P4 HER catalysts recorded applying electrochemical protocol imitating shutdown conditions of an electrolyzer. (C) Schematic of an ICP-MS probe positioned in vicinity to the electrode surface, for in situ ICP measurement. Reproduced with permissions from ref (132). Copyright 2019 Wiley-VCH; ref (133). Copyright 2022 Elsevier.

Various in situ ICP measurements coupled with a flow cell have been developed.136−140 An example is the scanning flow cell ICP-MS (SFC-ICP-MS) in Figure 8A.141,142 This cell has a V-shaped flow channel, through which fresh electrolyte is continuously pumped from an electrolyte reservoir to the ICP-MS, to achieve a 100% collection efficiency of dissolved products. The ratio of one-way electrolyte flow rate to working volume is maximized, and the flow channel is optimized to allow for a uniform flow profile. The dissolved species are considered instantly removed away from electrode surface, without any accumulation within the electrolyte.141−143 Ledendecker et al. studied the dissolution (W, Ni, Mo, Co) of metal carbides (WC), sulfides (MoS2), phosphides (Ni5P4, Co2P) for acidic HER by performing start–stop cycles, between open circuit potential (OCP) and −0.5 mA cm2geo, mimicking on–off conditions of an electrolyzer (Figure 8B).144,145 It was found these materials undergo dissolution at OCP, but negligible dissolution under HER relevant potentials. Alternating between OCP and HER relevant potentials was also used for monitoring WC, WO3 and W HER catalysts in acid, which also only dissolved under OCP.145 Holzapfel et al. monitored the dissolution of [Mo3S13]2– clusters in acid by applying 25 CV cycles from 0 to −0.25 V vs RHE at 100 mV s–1 scan rate, followed by start/stop current holds, shifting from HER currents of −55.55 mA mg–1cat (−4.7 mA cm–2geo) and −111.11 mA mg–1cat (−9.2 mA cm–2geo) and 0 V vs RHE voltage holds, respectively.146 Schalenbach et al. observed the selective leaching of Mo at NiMo alloy catalysts for alkaline HER, by using the following two procedures: (1) a constant potential of −0.2 V vs RHE, followed by two slow CVs at 2 mV s–1 in a range from −0.35 to 0.4 V, and afterward OCP for 500 s. (2) accelerated stress test (AST) protocol consisting of 3 CVs in the same potential range at 10 mV s–1 before and after 50 AST cycles at 200 mV s–1.147 Escalera-López et al. employed the combinational procedures of CV cycles and start–stop cycles from −1 mA cm–2geo to 0 V vs RHE to measure the phase-dependent dissolution of MoS2 catalysts for acidic HER.148 By quantifying the dissolved catalysts, they calculated the HER stability number (the number of produced H2 gas per atom of dissolved catalyst) to provide a quantitative stability comparison. Göhl et al. assessed the stability of TiC, VC, NbC, TaC and WC in acid using potential cycling over a broad potential window (−0.2–1.5 V vs RHE at 3 mV s–1) and TiC, NbC, and TaC showed dissolution within the HER potential window.149

In situ ICP measurements coupled with a stationary cell can be performed by positioning the ICP inlet probe in the vicinity of working electrode (∼1 mm away from electrode surface), in a conventional 3-eletrode cell, as developed by Lopes et al. (Figure 8C).150,151 This setup conceptually resembles the classic rotating ring disk electrode (RRDE) setup, where the ring is replaced by a ICP probe. Since the collection efficiency is not 100%, calibration of the collection efficiency is required to perform quantitative analysis. Furthermore, owing to the stationary nature of this nonflow cell, the dissolved species accumulate over time (the potential consequences of which are discussed below). To date, this setup has predominantly been deployed for monitoring OER catalysts.

Owing to the complex and expensive setup required to perform in situ ICP measurements, ex situ ICP measurement in a stationary cell is the most commonly deployed approach for studying catalyst dissolution (i.e., does not require a bespoke ICP instrument and setup). The measurement can be performed with a RDE setup or stationary working electrode in an H-cell, where the working and counter compartment are separated by an ion-exchange membrane. During such measurements, an electrochemical method is run (e.g., chronoamperometry hold) and aliquots of electrolyte are collected during the experiment (e.g., before electrochemical testing and at 30 min intervals). In such conventional 3-electrode cells, the dissolved catalyst accumulates in the electrolyte, which is collected as aliquots for ICP measurement. This method provides discrete time-resolved information, and the dissolved species inherently accumulate during the experiment. Zhang et al. measured the concentration of Co and P after immersing Co2P catalyst in electrolyte for 5 h and after 2000 linear sweep voltammetry (LSV) cycles between −0.15 V and 0/0.05 V vs RHE.135 With an H-cell containing 30 mL 0.5 M H2SO4 in working compartment, Wang et al. recorded the dissolved concentration of MoS2, MoP, and CoP after holding at a designated potential (from 0 to −0.6 V vs RHE, with 0.1 V interval) for 5 min, during which 1 mL electrolyte was collected for ICP-MS measurements.152 Interestingly, to show the potential-dependent stability, Wang et al. estimated the HER stability numbers of MoS2 (105), MoP (104), and CoP (102). Goryachev et al. evaluated the temporal evolution of CoPx dissolution by CA at −0.12 V vs RHE, during which the electrolyte was sampled after 2.5 h, 5.0 and 7.5 h of electrolysis.153 Huang et al. monitored the evolution of Co-MoS2@CoS2 dissolution by sampling the electrolyte at 1, 3, 5 10, 30, 50, 80, 120 h during the CA at −0.1 V vs RHE.154 Wang et al. measured the dissolution of Co0.6(MnNiZn)0.4PS3 after a 12 h CP test at 25 and 65 °C, respectively.155 Beyond analyzing the concentration of dissolved species in electrolyte, ICP has also been used to determine the residue catalyst loading after HER. For example, King et al. quantified the CoP loading on the Vulcan carbon support and carbon paper GDE, after these electrodes were digested using aqua regia for 24 h.156

The measurement of catalyst dissolution by ICP can be influenced by numerous experimental factors (e.g., ionomer content, presence of ion exchange membranes), which are discussed below.

2.3.2.1. Concentration of Dissolved Species

According to the Nernst equation, a higher concentration of dissolved species gives a better stability against subsequent dissolution. Although this has not been directly investigated for HER electrocatalysts, it has been observed in ORR and OER, and thus we postulate the Nernst shift is also applicable to dissolution measurements of HER catalysts.157−159 Given that the concentration of a dissolved species is determined by the electrolyte volume, it is clear that the electrochemical cell volume can influence the catalyst dissolution. Indeed, it is possible that different dissolution rates and concentrations may be recorded when measured by the previously mentioned distinct 3 cell designs for ICP (Figure 8). As an example of in situ ICP measurement coupled with a flow cell, SFC-ICP-MS is an ideal cell configuration whereby the continuous electrolyte flow mitigates the accumulation of dissolved species.132,133,141−143 Therefore, the as-measured result is considered as the closest to the intrinsic stability. To justify the stability estimated by a flow cell, readers are reminded to caution the flow rate/working volume ratio, and the shape of flow channel, which determines the uniformity of flow profile relating to the local saturation. In the case of a stationary nonflow cell (for both in situ and ex situ measurements), product accumulation is present, which may lead to a better estimation of stability. It is therefore recommended to benchmark results acquired in a stationary cell against those collected in a SFC-ICP-MS configuration to understand how consistent these measurements are and elucidate any deviations. While the measurement in a flow cell is best for an intrinsic stability measurement, it may underestimate dissolution in a real electrolyzer.

2.3.2.2. Ion-Exchange Membrane

The use of ion-exchange membranes between the working and counter electrodes is sometimes deployed to prevent dissolution and redeposition of ions between the two electrodes (discussed in Section 2.2.3.). However, dissolved species can be absorbed and even permeate the membrane. In the cases where membranes are utilized, quantification of the absorbed species in the membrane will be necessary. For example, after immersing a 8 cm2 Nafion membrane in a 500 ppb Ir solution (2.6 × 10–6 M) for 1 h, ∼8% of the total Ir cations in solution were taken up by the membrane.160 Readers are advised to be careful of the potential influence of membrane, especially in long-term measurements, where the membrane has more time to absorb dissolved ions.

2.3.2.3. Ionomer

Nafion or alternative ionomer dispersions are commonly used for preparing powdered catalyst inks which are subsequently deposited onto electrodes to attach powdered catalysts to the electrode surface. The network formed by Nafion macromolecules at least partially covers the catalyst surface. In ORR and OER studies, it has been postulated that this Nafion network can act as a sink and accumulate dissolved species from the electrolyte (e.g., from catalyst dissolution), which can increase the local concentration of such ions and therefore suppresses further catalyst dissolution.157−159 With IrOx as a model catalyst for OER in 3-electrode cell, increasing the Nafion binder content in the catalyst ink from 5 to 33 wt % gives a 8-fold increase in the measured catalyst stability.159 We postulate this ionomer effect might also be present for HER electrocatalysts. Thus, a powder catalyst bound in Nafion could present enhanced stability when compared to the same catalyst composition in the forms of, for example, thin films, which do not involve the use of Nafion binder.

2.3.2.4. Potential Control

As discussed in Section 3.3, transition-metal-based carbides, sulfides and phosphides have shown promising geometric activity in acidic electrolyte, in some cases approaching the performance of commercial Pt/C.49,156,161 Alongside these high geometric activities, high stability is often also reported through short CA or CP measurements. As discussed previously, precious metal free HER catalysts often do not undergo dissolution at reducing potentials but are prone to corrosion at OCP upon uncontrolled immersion into the electrolyte. For example, WC, MoS2, Ni5P4, Co2P in 0.1 M HClO4, measured by an in situ ICP flow cell (Figure 8B);144 MoS2, MoP, and CoP in 0.5 M H2SO4, measured by an ex situ ICP stationary H-cell;152 NiMo alloy in 0.1 M KOH, measured by an in situ ICP flow cell show such anomalous behaviors.147 Although OCP-induced dissolution is a potential barrier to the deployment of precious metal free catalysts in electrolyzer technologies, a protection potential could be applied during start-up/shut-down cycles to avoid catalyst dissolution.

When running an electrochemical measurements, there are two ways to bring the working electrode in contact with electrolyte: 1) the working electrode is immersed into electrolyte solution under OCV (without applying any potential), which is usually accompanied by catalyst dissolution, even for precious-metal-catalyst, such as IrOx.159 2) the working electrode is immersed into electrolyte under an applied reducing potential, which cathodically protects the catalyst from dissolution at OCV.162 Introducing the working electrode into the electrolyte under potential control is therefore an excellent approach to alleviate catalyst dissolution. Although introducing electrodes under potential control might enable the catalyst to appear more stable, we propose that this should be used in addition to measurements that quantify catalyst dissolution when the electrode is held at OCP. This should be reported within the methods section of the paper to ensure transparency. This would enable more precise reporting of catalyst stability as a function of potential.

2.3.3. Post-Mortem Analysis for Monitoring Structural Change

Stability measurements are typically complemented with ex situ post-mortem analysis, to probe changes to the catalyst structure, oxidation state, or stoichiometry post electrochemical testing. For example, after 2000 LSV scans with Co2P as the HER catalyst in acid, SEM showed no morphology changes; the bulk structure also remained unchanged, as measured by XRD; and XPS revealed the same valence state of Co before and after LSVs.135 In contrast, XPS was used to show that on Mo3S13 clusters, a combination of ∼20 CV cycles and 5 segments of CA measurements increased the valence state of Mo.146 XPS on NiMo alloy showed that after 50 CV cycles, Mo was leached out and Ni valence state increased.147 In another study, the surface composition of Mo3S13 clusters remained unchanged after CP, as evidenced by XPS measurement. XPS studies of MoS2, Co2P, Ni5P4 and WC revealed that after 4 start–stop CP cycles, the metal to heteroatom ratio of Ni5P4 remained unchanged, while that of the ratio was altered for the other catalysts.144 Similarly, after LSV and CA measurements on CoPx, AFM showed that the film initially developed a pitted surface, while XPS showed the composition did not change during CA.163 In contrast, during LSV most of CoPx underwent dissolution. The knowledge acquired from such post-mortem analyses can provide significant information regarding the stability–structure relationships. Of course, operando electrochemical investigations coupled to materials characterization techniques are superior to such ex situ characterizations with regards to elucidating such structure–activity relationships. However, these typically require significantly more complex setups and are typically less accessible.

2.4. Device Testing

Translating electrocatalysts characterized in half-cell setups into device (electrolyzer) performances have neither been predictive nor efficient for electrolyzer catalysts (Figure 9) and it is still unusual to see full MEA or AWE testing in the primary literature. Lazaridis et al. discuss the benefits and limitations of RDE testing to conclude that RDE is an important preselecting platform for electrocatalysts, but MEA performance and durability are required to confirm catalyst relevance to commercially relevant devices.164 We discuss the recommendations, practices and feasibility of precious metal free catalysts from half-cell to MEA. We also review the benchmarking and best practices for electrolyzer testing from literature. Additionally, in view of the paucity of MEA testing published for precious metal free HER catalysts for PEM electrolyzers, we discuss best practices literature from PEM electrolyzers utilizing Pt and other PGM cathodes where appropriate.

Figure 9.