Abstract

Poly(lactic acid) (PLA) stands as a compelling alternative to conventional plastic-based packaging, signifying a notable shift toward sustainable material utilization. This comprehensive analysis illuminates the manifold applications of PLA composites within the realm of the food industry, emphasizing its pivotal role in food packaging and preservation. Noteworthy attributes of PLA composites with phenolic active compounds (phenolic acid and aldehyde, terpenes, carotenoid, and so on) include robust antimicrobial and antioxidant properties, significantly enhancing its capability to bolster adherence to stringent food safety standards. The incorporation of microbial and synthetic biopolymers, polysaccharides, oligosaccharides, oils, proteins and peptides to PLA in packaging solutions arises from its inherent non-toxicity and outstanding mechanical as well as thermal resilience. Functioning as a proficient film producer, PLA constructs an ideal preservation environment by merging optical and permeability traits. Esteemed as a pioneer in environmentally mindful packaging, PLA diminishes ecological footprints owing to its innate biodegradability. Primarily, the adoption of PLA extends the shelf life of products and encourages an eco-centric approach, marking a significant stride toward the food industry’s embrace of sustainable packaging methodologies.

Graphical abstract

Keywords: Lactic acid, Polylactic acid, Biopolymer, Food packaging, Food preservation

Introduction

The mounting global concern for the environment is driven by anthropogenic activities leading to the proliferation of pollutants, the accelerated biodiversity loss, and the widespread degradation of ecosystems (Muller et al., 2017). Amongst, the pervasive use of plastics, exemplified by Bakelite’s impact since the early 1900s, marked a milestone in polymer industries, contributing significantly to environmental issues (Sreekumar, 2021). Plastic’s utilization surged since the 1950s due to its energy-saving benefits, becoming ubiquitous in our daily lives due to its adaptability and versatility in various applications (Algozeeb et al., 2022). By 2015, annual plastic production matched the total weight of the global human population, with an estimated 150 million metric tonnes dispersed in the oceans. Concerning projections indicate that by 2050, up to 10% of plastic waste could end up outnumbering marine life in oceanic environments. Forecasts also suggest that over half of the plastic waste generated by 2050 will likely infiltrate landfills, posing significant contamination risks to natural ecosystems such as lakes and seas (Gondal et al., 2023). The utilization of petroleum-based plastics is crucial in modern living and the reports show that plastic production increased from 2 million tonnes in 1950 to 381 million tonnes in 2015, signifying an almost 200-fold rise (Zainab-L and Sudesh, 2019). Many consumer plastics, designed for single use and with limited recyclability, have led to a surge in production and consumption, causing an unprecedented rise in plastic waste and widespread pollution.

Plastics are suitable for use in various consumer and industrial applications because they are affordable, strong, resistant to deterioration, and extremely adaptable. Despite the benefits of plastics made from petroleum, this has raised concerns about widespread pollution (Chia et al., 2020). Plastic packaging pollution poses environmental, animal, and human health risks globally due to poor collection and recycling rates. Managing plastic waste is urgent requirement to overcome these problem around the world (Tumu et al., 2023). The common plastics, primarily made from propylene and ethylene, are non-recyclable, leading to their accumulation in landfills and natural environment. The increasing demand for alternative materials, driven by environmental concerns and a strong emphasis on sustainability, addresses the persistence of non-degradable plastics like thermoplastics.

Sustainable development goal 14 achieves a reduction in plastic pollution and safeguards biodiversity and marine ecosystems through focused waste management, technological advancements, and international collaboration (Zainab-L and Sudesh, 2019). One such innovative solution is biobased thermoplastics which includes polylactic acid, low-density polyethylene, polyvinyl chloride, polypropylene, polyethylene terephthalate, high-density polystyrene, polyethylene, and polystyrene are indeed the thermoplastics commonly used (Shavandi and Ali, 2019). Transitioning thermoplastic materials to a renewable circular economy necessitates detaching from fossil fuels, optimizing recycling, and using biodegradable materials for littered articles. This shift faces challenges in meeting technical standards and managing diverse end-of-life scenarios. A proposed tool, biobased thermoplastic prioritizes material selection based on adaptability and performance, tested on 17 consumer goods and comparing the performance of 21 biobased plastics (Maaskant et al., 2023). They can be produced using biomass feedstocks sourced from renewable resources, including plant sugars, cellulose, vegetable oils, starches, and certain microorganisms. The production of biobased thermoplastics involves converting biomass feedstocks into monomers or polymers through various processes, such as fermentation, chemical synthesis, or polymerization (Lekrine et al., 2022). Unlike conventional plastics derived from fossil fuels, biobased thermoplastics offer a more sustainable and environmentally friendly alternative. These materials provide significant advantages which contributing towards resource conservation and carbon footprint reduction (Zhang et al., 2014).

Also, biobased thermoplastics reduce greenhouse gas emissions by minimizing the reliance on fossil fuels and have the potential to biodegrade under specific conditions, reducing their impact on ecosystems (Uitterhaegen et al., 2018). As self-degradable bioplastics break down into minuscule particles, their escalating release into the environment poses uncertain ecological impacts. Consequently, significant technological advancements are sought for the effective removal and degradation of plastics, including micro and nano-plastics (Kim et al., 2023). Thermoplastics, highly sought after across industries, offer unique advantages. They’re recyclable and reusable, enduring multiple melting cycles without quality loss. With notable strength, chemical resilience, and durability, they ensure reliability. Their adaptability caters to specific needs efficiently, adding significant value to manufacturing (Nguyen et al., 2023). Furthermore, these materials contribute to a circular economy by promoting the use of renewable resources and minimizing plastic waste (Grigore, 2017).

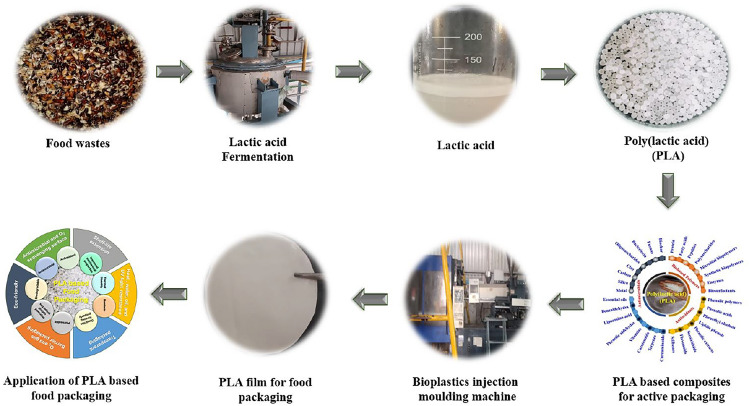

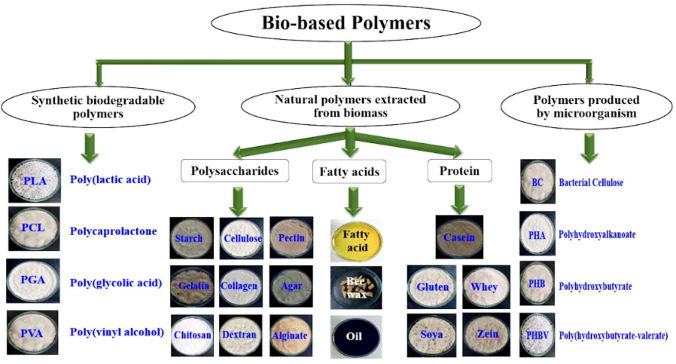

Traditional plastic production uses 65% more energy than bioplastic processing and emits 30–80% higher greenhouse gases. This unsustainable method faces urgent environmental concerns, requiring a rapid shift from conventional plastics to bio-based polymers (Taib et al., 2023). The classification of biobased polymers alternative to conventional polymers were elaborated in Fig. 1. Among bio-based thermoplastics, polylactic acid (PLA), an aliphatic polyester derived from renewable sources such as sugar, corn, and potatoes, garners considerable scientific attention due to its biocompatibility, biodegradability, and compostability within degradability categories (Gay et al., 2018).

Fig. 1.

Classification of various biobased polymers based on biodegradability

Nowadays, PLA finds widespread use in the food industry for packaging materials, disposable utensils, and cups. It is commonly employed in food containers, bakeware, and edible films due to its biodegradability and versatility. PLA’s eco-friendly properties make it a sustainable choice for reducing environmental impact in food applications (Jacob et al., 2020). PLA, is both biocompatible and non-toxic, ensuring its safety for applications involving contact with food (Milovanovic et al., 2022). Petroleum polymers, being affordable, have strong tensile qualities, and serve as an efficient shield against oxygen, CO2, and liquid–vapour, petrochemical polymers are used extensively in the packaging of foods. A wide range of these polymers, including both elastic and stiff forms, have been utilized in packaging, with the terms thermoset plastics or thermoplastics describing these materials. Heating can be used in the processing and recycling of thermoplastics. Since they can be readily molded into numerous forms and are recyclable, this class of polymers is more suited for use in food containers (Jacob et al., 2020).

This review comprehensively addresses the synthesis process of PLA, an environmentally friendly and biodegradable polymer derived from lactic acid. The detailed discourse not only outlines the synthesis methodology but also accentuates the ecological advantages intrinsic to PLA. Moreover, this review underscores the extensive commercial utilization of PLA based composites in food industry, particularly in the food packaging and preservation. As an eco-conscious choice for food packaging, PLA has garnered substantial acclaim owing to its remarkable biocompatibility and inherent ability to biodegrade.

Lactic acid—overview

Lactic acid (LA), derived from fermentable sugars, exhibits dual properties as an alcohol and an acid, characterized by minimal environmental impact. It manifests as the simplest lower hydroxyl carboxylic acid, featuring odorlessness, non-volatility, and solubility in water and compatible organic solvents, while insoluble in pure organic solvents (Castillo Martinez et al., 2013). The optical activity of LA, attributed to its chiral carbon, holds paramount importance in the synthesis of robust polymers such as poly-d-(−)-LA (PDLA) and poly-l-(+)-LA (PLLA) (Wang et al., 2015). The microbial process of lactic fermentation by specific bacterial strains predominantly generates lactic acid as a primary organic byproduct (Wang et al., 2023b).

Derived from fermentation processes involving crops like sugarcane and maize, lactic acid serves as the essential precursor for PLA. This versatile polymer, recognized by the FDA as safe, particularly finds utility in food packaging applications (Li et al., 2015). However, industrial-scale production often results in racemic mixtures, such as DL-LA, leading to the depletion of petroleum reserves and substantial economic costs (Daful et al., 2016). Consequently, current research focuses on bio-based lactic acid production to foster environmentally sustainable technologies (Henczka and Djas, 2016). Challenges persist in acquiring pure lactic acid through downstream processes, hindering the market expansion of PLA in various sectors (Kumar et al., 2020).

Emerging technologies, notably the emulsion liquid membrane separation method, gain traction due to their cost-effectiveness and limited environmental footprint (Liu et al., 2012). The increasing use of LA derivatives, replacing hazardous solvents in industrial applications, forecasts a rising global demand for LA, projected to reach 1970.1 kilo tonnes by 2020 (Abdel-Rahman and Sonomoto, 2016), and 1.8 million metric tons worldwide by 2023. Correspondingly, PLA’s demand is anticipated to surge, potentially displacing polyethylene terephthalate across multiple applications by 2025 (Abdel-Rahman et al., 2013) with a market size of 1.5 billon USD in 2023.

Polylactic acid—overview

Lactide polymerization, involving ring structure opening, produces d-lactide, l-lactide, and dl-lactide, distinguished solely by their optical isomers. Correspondingly, Poly [d-lactide] (PDLA), Poly [l-lactide] (PLLA), and Poly [dl-lactide] designate polymers from d-lactide, l-lactide, and dl-lactide respectively. Although l-lactide and d-lactide vary in steric structures, their chemical traits are comparable (Casalini et al., 2011). While PLLA and PDLA share similarities, PDLLA possesses distinct characteristics, finding use in bone engineering, while PLLA is prevalent in bioengineering. PLA compounds are widely employed in biodegradable packaging (Bose et al., 2013). Despite its inherent poor impact strength and brittleness, PLA can undergo traditional processing methods like blow molding, injection molding, sheet extrusion, and thermoforming, although some applications are limited. PLA’s properties, influenced by constituent isomers, processing factors, annealing duration, and molecular weight, directly affect its crystalline nature and overall characteristics (Madhavan Nampoothiri et al., 2010). PLA’s crystallinity significantly impacts various mechanical properties like toughness, modulus, tensile stress, and melting temperatures (Savioli Lopes et al., 2012).

PLA compounds display solubility in specific solvents like dioxane, chloroform, and acetonitrile, while showing partial solubility in chilled ethanol, benzene, acetone, toluene, and tetrahydrofuran, becoming easily soluble when heated. Notably, PLLA crystals remain insoluble in ethyl acetate, acetone, or tetrahydrofuran (Madhavan Nampoothiri et al., 2010). The breakdown pace of the polymer heavily relies on its interaction with moisture and catalysts. Factors altering responsiveness, including particle size and shape, temperature, humidity, crystalline nature, isomer content, residual lactic acid, molecular weight, water diffusion, and metallic catalyst contaminants, significantly impact the rate of polymer degradation (Auras et al., 2004).

Synthesis polylactic acid

Lactic acid is generated by fermentation or chemical synthesis which is the precussor for the PLA synthesis. Bacterial (heterofermentative and homofermentative) fermentation of carbohydrates produces its two optically active forms, the L ( +) and D (-) stereoisomers. The general procedure calls for the utilization of various species of the Lactobacillus genus, including L. delbrueckii, L. bulgaricus, L. amylophilus, and L. leichmanii, in addition to an ambient temperature of 38 to 42 ºC, a pH of 5.4 to 6.4, and a low oxygen concentration. In most cases, unadulterated l-lactic acid is often preferred during the synthesis of PLA (Mehta et al., 2006).

Polymerization methods include direct condensation, azeotropic solution polycondensation, and lactide-based polymerization. However, achieving high molecular weight via esterification poses challenges for mechanical properties (Sreekumar et al., 2021). Lactide formation, essential for high molecular weight PLA, involves mild conditions and solvent-free water removal, moreover, distillation simplifies lactide purification. Variations in molecular mass globally are achieved by adjusting obtained dimer quality (Payne et al., 2020). Industrially, stannous octoate serves as an effective accelerator in PLA polymerization. Its selection greatly influences polymer characteristics. Stannous octoate, non-toxic and FDA-approved, induces minimal racemization under extreme temperatures (Palak et al., 2022).

The advantages of PLA over petroleum polymers include reduced CO2 emissions. Some argue that PLA usage might result in fewer greenhouse emissions due to maize growth absorbing CO2, balancing the production’s carbon footprint (Jamshidian et al., 2010). Distinct synthesis methods include severe vacuum and high-temperature condensation for moderate molecular weight PLA. Industrial methods utilize transesterification catalysts like lead oxide to yield reasonably high molecular mass PLA (Balla et al., 2021). In summary, PLA’s production methods, which involves lactide formation and polymerization catalysts, significantly impact its molecular weight and properties, contributing to its environmental advantages over petroleum-based polymers.

Industrial applications of polylactic acid

The growing utilization of PLA stems from its cost-effectiveness with production costs at $1.41/kg and a 29.4% internal rate of return, which foster sustainable plastic production (Bressanin et al., 2022). PLA adopts a semicrystalline or amorphous state in its solid form. For amorphous variants, the glass transition temperature (Tg) serves as a pivotal parameter, delineating their upper limit of practical use across various industrial applications. This biodegradable polymer’s renewability and affordability have made it a preferred choice across diverse sectors like food packaging, electronics, transport, and medicine (Mehmood et al., 2023). Polylactic acid is a cornerstone material in the medical sector, particularly in the realm of bioresorbable implants (Lu et al., 2023). It finds extensive use in crafting essential medical implements such as sutures, drug delivery systems, and tissue scaffolds (Santoro et al., 2016). This widespread application owes to PLA’s remarkable biocompatibility and its unique capability to gradually degrade within the body, making it an invaluable material for a spectrum of medical applications (Baweja et al., 2016). Polylactic acid has emerged as a prominent material within the domain of 3D printing due to its inherent biodegradability and straightforward usability (Liu et al., 2019). Its commendable sustainability and adaptability render it an optimal choice for fabricating consumer products, prosthetic devices, prototypes, and an extensive spectrum of manufacturing applications (Liu et al., 2019). With its commendable environmental credentials, PLA stands as a pivotal element in reshaping food packaging. Derived from renewable sources and boasting inherent biodegradability, it’s becoming a prime substitute for traditional plastics.

Across various packaging applications, PLA seamlessly supplants conventional plastics, finding utility in fabricating films, cups, containers, and an array of food packaging materials. Its adaptability caters to the multifaceted packaging needs of the food industry, encompassing both rigid and flexible packaging solutions (Eissenberger et al., 2023). Notably, PLA exhibits the potential for compostability under specific conditions, presenting an environmentally favorable avenue for end-of-life disposal. This characteristic harmonizes with the global thrust toward sustainable packaging practices, offering an eco-conscious approach to managing packaging waste. Consequently, PLA embodies a significant stride toward fostering sustainability within the realm of food packaging (Chen et al., 2016). With a temperature range of 190 to 250 °C, PLA’s semicrystalline forms showcase critical thermal parameters such as Tg at 58 °C and a melting temperature (Tm) spanning from 130 to 230 °C based on its morphological aspects. The interplay of optical composition, fundamental structure, thermal properties, and molecular weight significantly influences the distinct phases of PLA, particularly impacting the Tg and Tm values. Above the Tg, amorphous PLAs exhibit viscous behaviour transitioning from a glassy to a rubbery state. Conversely, when cooled towards its transition point of approximately − 45 °C, PLA assumes a glassy state below the Tg, displaying a tendency to undergo creep. Only under temperatures below this threshold does PLA behave as a rigid polymer (Farah et al., 2016). The capacity of PLA to transition between flexible and rigid states within specific temperature ranges, particularly influenced by its glass transition temperature and subsequent state changes, renders it exceptionally suitable for food packaging. This polymer exhibits the ability to accommodate a diverse range of food types while maintaining structural integrity and minimizing deformation.

Application of PLA in food packaging and preservation

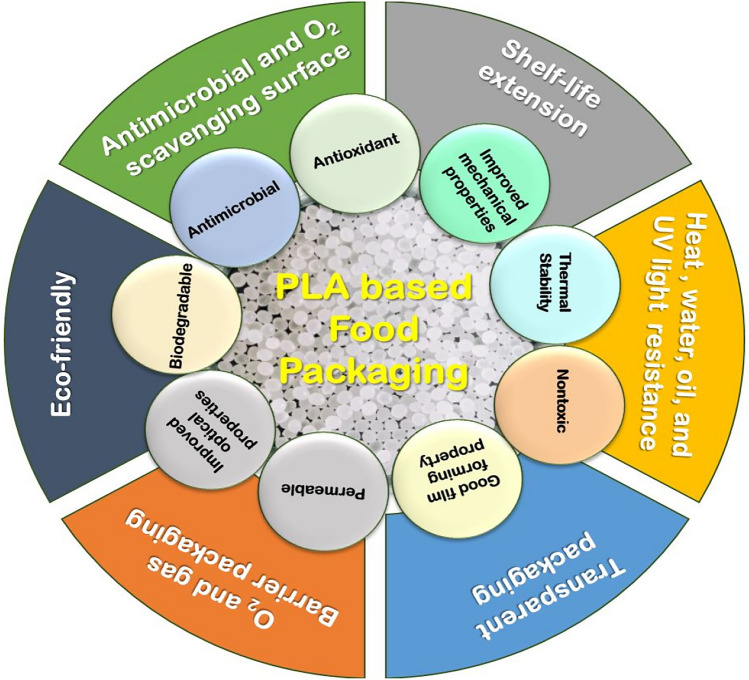

These biopolymers exhibit a significant characteristic potential for application in food packaging due to their ability to enhance the film’s structural integrity, strength, shelf-life extension, water, heat, and UV-light resistant, transparent packaging, O2 and gas barrier packaging and eco-friendly (Abou-alfitooh and El-hoshoudy, 2023) (Fig. 2). Packaging materials, encompassing films, coatings, and composites, are designed with three primary purposes namely, containment, communication, and protection (Farajinejad et al., 2023). Ensuring mechanical strength and thermal properties is crucial for containment, enabling the accommodation of a variety of food products, whether cold, hot, dense, or lightweight. Communication involves the conveyance of essential nutritional information and relevant details to consumers. Protection encompasses withstanding mechanical stresses during transportation and storage, and it also involves improving the water resistance and vapor barrier properties of packaging materials to extend the shelf life of the enclosed products.

Fig. 2.

Characteristics of the polylactic acid based polymeric composites utilized in the application of food packaging

Developing antimicrobial packaging is a compelling challenge in both academic research and industry, crucial for mitigating food spoilage and maintaining food safety. Contaminations during food production pose a significant risk, necessitating effective preventive measures. However, in the realm of PLA packaging, concerns arise regarding potential alterations in color and odor when active ingredients interact with food (Martins et al., 2018).

Assessing active materials for their antioxidant properties revealed dose-dependent benefits compared to inert matrices (Swetha et al., 2023). Although PLA generally lacks inherent antioxidant properties, some experiments suggested minimal activity, likely attributed to residual lactic acid (LA). The chemical structures of natural compounds, such as phenols and terpenes, exhibit a significant correlation with their antioxidant effects as well as antimicrobial nature (Iñiguez-Franco et al., 2012). Phenols, especially those with hydroxyl groups, function as radical scavengers, hindering oxidation by contributing hydrogen or electrons to disrupt the oxidation chain and counteract reactive oxygen species. The antimicrobial effectiveness of terpenes primarily stems from their lipophilic nature, which influences the structure and functionality of microbial cell membranes. This lipophilic character enables terpenes to interact with and affect the integrity of microbial cell membranes, contributing significantly to their antimicrobial properties (Stan et al., 2021). While the efficacy of certain metal oxide nanoparticles stems from their physical structures and metal ion release, many exert bactericidal effects by generating reactive oxygen species.

Numerous studies have investigated the use of organic and inorganic (metal) nanoparticles as antibacterial agents against both gram-positive and gram-negative bacteria (Munteanu et al., 2014). The biological traits of these materials hinge on factors like particle size, structure, and surface area, varying with the specific nanoparticles utilized. Plausible combinations are anticipated to exhibit enhanced antibacterial properties (Techawinyutham et al., 2019). Positively charged metal nanoparticles interact with negatively charged bacterial cell walls, disrupting and increasing their permeability. These nanoparticles also prompt the production of reactive oxygen species inside the cells, disrupting bacterial processes and contributing to their demise (Nisar et al., 2019; Sánchez-López et al., 2020). In addition to flavonoids (Martins et al., 2018), antioxidants (Freitas et al., 2024), and metallic nanoparticles (Akshaykranth et al., 2023), specific biopolymers can augment PLA to create films with robust mechanical and tensile strength. Bernini Lombardi and his coworker elaborated the synthesis of PLA composites and its application with natural plant extract in the field of food and biomedical (Lombardi et al., 2022). Polymeric materials activated by natural compounds and extracts, particularly active ingredients sourced from plants, are thoroughly examined in this study. The focus is on the chemical properties of these active compounds and the unconventional extraction technologies applied in activating PLA. The research delves into inventive techniques for seamlessly incorporating active ingredients into PLA, shedding light on characterization processes. Furthermore, the study explores the antioxidant and antimicrobial properties inherent in these PLA composites (Lombardi et al., 2022). In this review, the authors have elaborated the application of PLA with various molecules which includes polysaccharides, oligosaccharides, proteins, peptides, lipids, essential oils, microbial biopolymers, synthetic biopolymer, phenolic compounds, flavonoids, vitamins, carotenoids, terpenes, enzymes, biosurfactants, bacteriocins, lipoamino acids, and organic and inorganic nanomaterials towards the food packaging and preservation application (Table 1).

Table 1.

Preparative techniques and functional properties of polylactic acid based biodegradable polymeric composites for the food packaging applications

| Biodegradable polymers | Source | Additive compound and its concentration | Type of techniques | Methods for determination of specific activity | Application | Remarks | References |

|---|---|---|---|---|---|---|---|

| PLA—polysaccharides composite films | |||||||

| PLA/ethyl lauroyl arginate | Agricultural residue | Cellulose nanocrystals (1%) | Extrusion and electrospinning | Agar well diffusion method | Food packaging of diary and meat products | Zone of inhibition: 3 mm against L. innocua and 2.7 mm against S. enterica | Patiño Vidal et al. (2023) |

| PLA | Agricultural residue | Cellulose (0.3–1.2 g) | Solution casting method | DPPH and ABTS radical scavenging activity | Food packaging | Maximum scavenging rate of 71% by DPPH and 76% by ABTS method | Ren et al. (2023) |

| PLA | Commercial | Cellulose (1–5%) | Injection molding and solution casting method | Mechanical properties | Food packaging | Maximum tensile strength and elongation at break of 61.61 MPa and 9.52%, respectively | Guo et al. (2023) |

| PLA | Commercial | Starch (0.3 g) | Electrospinning | Mechanical properties and colony counting method | Food packaging | E. coli growth inhibition: 1.3 ± 0.1 CFU/mL; L. innocua: 2.5 ± 0.4 CFU/mL; Tensile strength: 30 MPa | Ordoñez et al. (2023) |

| PLA/poly(butylene adipate-co-terephthalate) | Cassava | Starch (40%) | Extrusion | Oxygen and water permeability | Food packaging | Tensile strength (17.5 MPa), elongation at break (295.9%), and water permeability of 8.3 × 103−9.7 × 103 g·mil/day·m2·atm | Katanyoota et al. (2023) |

| PLA/TiO2 | Commercial | Chitosan (3%) | Solution casting | Mechanical properties and disc diffusion method | Antimicrobial packaging | Tensile strength of 35.49 MPa; Zone of inhibition: 10.52 ± 0.63 mm against E. coli, 9.50 ± 0.15 mm against S.auerus | Zhang et al. (2023) |

| PLA | Commercial | Chitosan (3%) | Extrusion | Mechanical properties | Food packaging | Maximum tensile strength and elongation at break of 47 MPa and 11%, respectively | Elsawy et al. (2023) |

| PLA | Commercial | Chitosan (2 g/L) and cyclodextrin (2 g/L) | Solvent precipitation process | Stability and degrdation studies | Food packaging | Completely degraded within 17 days; Controlled release of carvacrol in 14 days | Andrade-Del Olmo et al. (2019) |

| PLA | Commercial | Pectin (4%) | Injection molding | Mechanical and thermal properties | Food packaging | Tensile strength: 59.9 MPa and 33.5% of crystallity | Satsum et al. (2022) |

| PLA | Commercial | Pectin | Electrospinning | Agar diffusion method | Citrus friut packaging | Inhibition rate: 95% against E. coli and S. auerus; Increase the shelf-life of citrus | Min et al. (2022) |

| PLA | Rosin gum | Pentaerythritol ester (1–5 phr) | Twin-screw extruder | Mechanical properties | Food additive and packaging | Tensile strength of 58.4 MPa and elongation break of 6.6%; Also utilized as lubricating agent | de la Rosa-Ramírez et al. (2023) |

| PLA | Commercial | Xanthum gum (10 g) | Solvent casting method | Thermal properties | Food coating and packaging of vegetables and fruits | Water vapour permeability of 10 to 15 g/m2; Withstand up to 120 °C | Abdenour et al. (2023) |

| PLA–protein composites | |||||||

| PLA | Commercial | Fish water-soluble protein (10%) | Twin screw extruder | Mechanical properties and permeability test | Food packaging | Tensile strength of 11.88 ± 1.82 MPa and elongation break of 462.96%; Water vapour permeability: 10.85 × 10–13 g m/m2.s.Pa | Saiwaew et al. (2014) |

| PLA | Commercial | Soy protein (50%) | Solvent casting method | Water vapour permeability and biodegradability | Soft cheese packaging | Water permeability rate: 2.3 × 10–11 g m Pa−1 s−1 m−2; Biodegradability rate: above 60% | González and Alvarez Igarzabal (2013) |

| PLA | Cotton industry | Cottonseed protein (1 g) | Solution casting method | Water vapour permeability and mechanical property | Food packaging | Tensile strength of 52 ± 8 MPa and elongation break of 2%; water vapour permeability: 0.00040 ± 0.00005 g-m/kPa-d-m2 | Biswas et al. (2023) |

| PLA/hydroxypropyl methylcellulose | Commercial | Zein (60%) | Electrospinning | DPPH method and agar diffusion method | Food packaging | Antioxidant activity: 68.83 ± 0.1%; zone of inhibition: 15.4 mm against S. aureus and 13 mm against E. coli | Aman Mohammadi et al. (2021) |

| PLA | Local market | Wheat gluten (10%) | Electrospinning | DPPH method | Edible packaging of solid food | Scavenging activity of 31.5%; Tensile strength of 4.9 MPa and elongation break of 140% | Hajikhani et al. (2020) |

| PLA | Commercial | Gelatin (2 g) | Solvent casting and electrospinning | DPPH and ABTS method | Packaging of sea food and fish oils | DPPH scavenging activity of 56.89 mmol TE/g sample and ABTS scavenging activity of 471.27 mmol TE/g sample | Ponnusamy et al. (2023) |

| PLA–lipid composites | |||||||

| PLA | Syzygium aromaticum | Essential oil (30%) | Solution casting method | DPPH method and Colony couting method | Cheese packaging | Antioxidant activity of 43%; reduce the food spoilage; Susceptibility order was: 98% inhibition of E. coli > 95% inhibition of S. typhimurium > 70% inhibition of L. monocytogenes | Stoleru et al. (2021) |

| PLA | Lippia citriodora/Laurus nobilis | Oil nanoemulsion (12%) | Solvent casting method | DPPH and agar diffusion method | Rainbow trout fillet packaging | Antioxidant activity of 92.66%; zone of inhibition: 19.46 ± 0.02 mm against E. coli and 20.79 ± 0.02 mm against S.aureus | Hojatoleslami et al. (2022) |

| PLA/CA | Commercial | oleic acid (5 g) | Solution casting method | Water vapour permeability | Food packaging |

Water permeability rate: 9.05 × 10–13 g m Pa−1 s−1 m−2; enhancement of fiber–matrix interface adhesion |

Almasi et al. (2015) |

| PLA/CA | Commercial | Cardanol Oil (5–15%) | Melt extrusion | DPPH method | Food packaging | Inhibition rate: 54%; IC50: 6.9 mg/mL | Mele et al. (2019) |

| PLA/PVOH | Commercial | Wax (20%) | Extrusion | Water permeability | Fresh cut vegetables to cheese | Water permeability rate: 120 g mm day−1 bar−1 m−2; | Barbato et al. (2023) |

| PLA–microbial biopolymer composites | |||||||

| PLA | Acetobacter pasterianus | Bacterial cellulose (5–30%) | Solvent casting method | Mechanical properties | Food packaging | Water–vapor barrier by 5 wt%; Tensile strength of 16.6 MPa, elongation at break of 81.5 5.0% | Patwa et al. (2019) |

| PLA | Commercial | Polyhydroxyalkanoates (5%) | Solution casting and electrospinning | Mechanical properties | Food packaging | Tensile strength of 66.4 MPa and elongation at break of 4.3% | Injorhor et al. (2023) |

| PLA | Commercial | Poly(hydroxybutyrate) (25%) | Compression molding | Oxygen transmission rate | Food packaging | Oxygen transmission rate: 11.0 cm3 mm m−2 day−1; Water contact angle: 70° | Arrieta et al. (2014) |

| PLA | Commercial | Polyhydroxybutyrate (75%) | Melt extrusion | Rheological properties | Food packaging | Tensile strength of 20 MPa and elasticity of 3.6 MPa | Aydemir and Gardner (2020) |

| PLA | Commercial | Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (25%) | Melt extrusion | Minimum inhibitory concentration | Food packaging | MIC value: 750 mg/L against Escherichia coli and 700 mg/L against Listeria innocua | Hernández-García et al. (2022b) |

| PLA–synthetic biopolymer composites | |||||||

| PLA | Commercial | Polycaprolactone (30%) | Solvent casting method | Agar well diffusion and DPPH method | Biodegradable wrapping of sausage | Antioxidant activity IC50 of 0.251 mg/mL; Zone of inhibition: 12 mm against E. coli and 14 ± 0.02 mm against L. monocytogenes | Shahrampour et al. (2023) |

| PLA | Synthesize from L-lactide and glycolide | Polyglycolic acid (25%) | Melt extrusion | Degradation studies | Food packaging | Maximum degradation observed was 88%; Tensile strength of 52.3 MPa and elongation at break of 3.7% | Samadi et al. (2019) |

| PLA | Commercial | Polyvinyl alcohol (15%) | Electrospinning | FRAP and ABTS | Packaging for food-gatherers and artisanal fishers | Antimicrobial activity was also tested against E. coli; effectiveness with a 29.7% | Arrieta et al. (2018) |

| Phenolic active compounds | |||||||

| PLA–phenolic polymer composites | |||||||

| PLA | Commercial | Lignin (50 mg/mL) | Electrspraying | DPPH and mechanical properties | Food packaging | Antioxidant activity: 60%; Young’s modulus: 4.7 GPa; Elongation at break: 1.7% | Daassi et al. (2023) |

| PLA | Rice husk | Lignin (2.5%) | Solvent casting | DPPH and ABTS method | Food packaging | Inhibition rate by DPPH: 82.2%; Inhibition rate by ABTS: 83.6%; Minimize food oxidation | Fontes et al. (2021) |

| PLA | Commercial | Lignin (3%) | Solution casting method | DPPH | Food packaging | Antioxidant activity of 17.8% | Cavallo et al. (2020) |

| PLA/ethylene–vinyl acetate–glycidyl methacrylate | Commercial | Lignin (8 g) | Melt mixing | DPPH | Food packaging | Antioxidant activity: 81.2%; improvement of toughness and water vapor barrier properties | Yang et al. (2020) |

| PLA | Aesculus hippocastanum L. (seeds) | Procyanidins (0.8%) | Solvent casting | ABTS | Active food packaging | Shown the maximum inhibition rate; Incorporated photostabilizers | Havelt et al. (2021) |

| Phenolic acid composites | |||||||

| PLA | Commercial | 4-Hydrobenzoic acid (4%) | Melt extrusion | DPPH method | Food packaging | Antioxidant activity of 1.94 µmol TE/dm2 | Andrade et al. (2023) |

| PLA/hydroxypropyl-beta-cyclodextrin | Commercial | Gallic acid (5%) | Encapsulation/ Electrospinning | DPPH | Food processing | Antioxidant activity: 95%; increase the shelf life and quality of food | Aytac et al. (2016) |

| PLA | Cassava starch | Protocatechuic acid (2%) | Melt extrusion | Mechanical properties permeability property | Pork and meat packaging | Tensile strength: 8 MPa; elongation at break: 2%; water vapour permeability: 0.57 g mm kPa− 1 h−1 m−2 | Hernández-García et al. (2022a) |

| PLA/AgNPs | Commercial | Rosmarinic acid (8%) | Extrusion | DPPH | Food processing and packaging | Inhibition by antioxidant as 60%; determination of the migrated compounds based on their release at controlled rates | Ramos et al. (2020) |

| Phenethyl alcohols composites | |||||||

| PLA/poly(butylene adipate-co-terephthalate) | Olea europaea L. (by-products) | Hydroxytyrosol (20%) | Encapsulation | DPPH and Trolox | Preserving and packaging of fresh-cut avocado | Prevents oxidation/browning reactions of short shelf-life foods; Increased antioxidant activity from 28.21 to 64.86 mmol Trolox/dm2 | Apicella et al. (2021) |

| PLA | olive leaf extract | Hydroxytyrosol (1–5%) | Solvent evaporation method | DPPH method | Food packaging | Water vapour permeability: 11.01 ± 1.61 g m−2 h−1 | Grabska-Zielińska et al. (2021) |

| Lipidic phenols composites | |||||||

| PLA | Cannabis plant | Cannabidiol (3 phr) | Melt extrusion | Mechanical properties | Food packaging | Tensile strength: 39.4 MPa; elongation at break: 7.1% | Tutek and Masek (2023) |

| Phenolic aldehydes composites | |||||||

| PLA | Commercial | Cinnamaldeyde (5–8%) | Cast sheet extrusion | Colony forming method | Bakery product packaging | Cimmaldehyde reduced the mechanical strength and imorove the antibacterial activity against E. coli | Gonon et al. (2023) |

| PLA/bionanocomposite | Commercial | Cinnamaldeyde and thymol (17%) | Melt-extrution | Antimicrobial viability | Biodegradable food packaging | Antimicrobial activity against E. coli and S. aureus; Microbial community not detected after incorporation of thymol | Villegas et al. (2019) |

| PLA/nanocomposites | Commercial | Cinnamaldeyde and thymol (2.5%) | Impregnation | DPPH | Active food packaging | Exhibit 100% of antioxidant activity; Activation energies of the fast and slow diffusion process were found to be near 48 and 150 kJ/mol, respectively | Siddiqui et al. (2021) |

| PLA | Ziziphora clinopodioides | Thymol (19.22%) | Solvent casting | Antimicrobial viability test | Meat packaging | Shown 7.88 log CFU/g of cell viability of Pseudomonas sp.; extended shelf life; final microbial population decreased approximately 1–3 log CFU/ | Shavisi et al. (2017) |

| PLA | Commercial | Vanillin (10%) | Melt extrusion | Mechanical properties | Food packaging | Tensile strength: 42 MPa; Elongation at break: 4% and impact strength of 17 kg/m2 | Zhao et al. (2018) |

| Secoiridoids composites | |||||||

| PLA | Olea europaea | Oleuropein (3 g) | Solvent casting | Agar diffusion method | Food packaging | Zone of inhibition of 16.20 mm against Staphylococcus aureus. Enhanced water absorption and degradability rates | Özge Erdohan et al. (2013) |

| Flavanoids composites | |||||||

| PLA | Commercial | Quercetin (0.97 g/L) | Solution casting method | ABTS method | Food packaging | Antioxidant activity: 98% | Deng and Zhou (2024) |

| PLA | Abies Nordmanniana | Catechin (0.05–1.0%) | Solvent casting | ABTS | Food packaging | Alternatives to common petrol-based antioxidants and photostabilisers; significant synergistic effects reaching as high as 726% | Havelt et al. (2021) |

| Poly(ester-urethane)/PLA/poly(ɛ-caprolactone) | Commercial | Catechin (5%) | Solvent evaporation | DPPH | Active heat-shrinkable advanced films | Improved water resistance; higheset antioxidant activity of 180 ± 20 mg/kg; decrease surface adhesiveness of 72.2 ± 1.5° of water contact angle | Arrieta et al. (2017) |

| Carboxymethyl cellulose/gelatin/PLA | Commercial | Quercetin (0.08 g) | Solvent casting | DPPH and ABTS | Food packaging | Blocked the UV transmission of the biopolymer films; PLA filmsʼ scavenging abilities increased considerably to 42%, in the ABTS method, and 96.9% in the DPPH method | Ezati and Rhim (2021) |

| Stilbenes composites | |||||||

| PLA | Vitis vinifera L. (cane) | trans-Resveratrol (10%) | Melt mixing | Water barrier property | Food packaging | Improved water vapor barrier property of 50%; Increase the self-life | Díaz-Galindo et al., 2020) |

| PLA | Vitis vinifera L. (cane) | trans-Viniferin (10%) | Melt mixing | Agar well diffusion | Food packaging | Inhibition of mycelium growth: 35.8%; helps in transport and storage of food | Díaz-Galindo et al. (2020) |

| Curcuminoids composites | |||||||

| PLA | Commercial | Curcumin (0–1.2%) | Melt extrusion | Thermal stability studies | Food packaging | Decomposition temperature: 334 °C; Maintaining 89% visible light transmittance | Redfearn and Goddard (2023) |

| PLA | Camelia sinensis | Curcumin (1 g) | Solvent casting | Agar well diffusion | Packaging of tea drink | Increasing of total microbial log was lower (2.2–4.39) than commercial plastic (3.24–5.82) | Hanafi et al. (2018) |

| PLA | Camelia sinensis | Curcumin | Solvent casting | Radical scavenging | Packaging of tea drink | Scavenging activity: IC50 value IC50 = 4.37–16.36% of produced membrane | Hanafi et al. (2017) |

| PLA | Curcuma longa L | Cucurmin (0.5–1.5%) | Solvent casting | DPPH and ABTS | Food packaging for food additives | UV-barrier property; antioxidant activity: 76.6% in DPPH method and 94.7% in ABTS method; Extend the shelflife of foods; antibacterial activity against foodborne pathogenic bacteria E. coli and L. monocytogenes | Roy and Rhim (2020) |

| Terpenes composites | |||||||

| PLA | Rosin gum | Abietic acid (5–15 phr) | Melt extrusion | Mechanical properties | Food packaging | Tensile strength: 65 MPa; elongation at break: 8% and impact strength of 17 kg/m2 | De La Rosa‐Ramírez et al., 2020) |

| PLA/cellulose | Tanacetum balsamita L | β- Bisabolene (2%) and Carvone | Solvent casting | Agar diffusion method | vacuum-packed foods.-cooked sausages | Extended shelf life period vacuum-packed foods; zone of inhibition: 26.85 mm for E. coli, 29.71 mm for B. cereus | Khodayari et al. (2019) |

| PLA/PHB | Commercial | Carvacrol (15 and 20%) | Extrusion | DPPH | Food packaging | Inhibition rate: 64%; ensure the safety in minimally processed foods | Burgos et al. (2017) |

| PLA/PBS | Alpinia officinarum | Eucalyptol (6%) | Cast extrusion | Mechanical and permeability properties | Food packaging | Decreasing tensile strength upto 22% and water and air permeability increased to 42% and 29%, respectively | Wongphan et al. (2023) |

| PLA | Commercial | Eugenol (5%) | Solvent casting method | Agar well diffusion | Food packaging | Zone of inhibition: 3.6 mm against E. coli and 6.5 mm against S.aureus | Yu et al. (2023) |

| PLA | Commercial | Geranial (20%) | Solvent casting method | Mechanical properties | Food packaging | Tensile strength: 16.6 MPa; Elongation at break: 230.7% | Gomez-Caturla et al. (2023) |

| PLA | Commercial | Limonene (5–20%) | Solution casting method | DPPH method | Fruit packaging | Maximum antioxidant activity reaching upto 70% | Bayer et al. (2023) |

| PLA | Commercial | Linalool (334 µL) | Solvent casting method | Agar diffusion method | Fresh food packaging | Zone of inhibition: 60 mm against E. coli and 32 mm against Salmonella | Silva et al. (2021) |

| PLA | Commercial | Myrcene (1.5%) | Screw extrusion | Mechanical properties | Food packaging | Tensile strength: 1.7 MPa; elongation at break: 30.2% | Brüster et al. (2019) |

| PLA | Cymbopogon citratus | Neral (1.21 m/m) | Encapsulation | Minimum inhibition concentration assay | Antimicrobial activity against Colletotrichum acutatum and Colletotrichum gloeosporioides | Reducing the development of bitter rot lesions in the longterm; MIC dosage of 0.1% (v/v) for Colletotrichum acutatum and Colletotrichum gloeosporioides | Antonioli et al. (2020) |

| PLA | Salvia sclarea | Terpineol (10%) | Electrospinning | Agar diffusion method | Smart food packaging | Bacteria inactivation efficiency of 76 and 100% against E. coli and S. epidermidis, respectively; antibacterial, anti-inflammatory or anti-oxidant properties | Wang and Mele (2018) |

| PLA | Commercial | Thymol (6% and 8%) | Extrusion | DPPH | Food packaging and food additives | Reduced the cell viability of E. coli and Staphylococcus aureus by around 40% after 24 h of storage; shelf-life extension; antioxidant activity: 60% inhibition | Ramos et al. (2020) |

| PLA/cellulose | Tanacetum balsamita | β-Thujone (2%) | Solvent casting | Agar diffusion method | Vacuum-packed foods-cooked sauages | Extended shelf life period vacuum-packed foods; zone of inhibition: 26.85 mm for E. coli, 29.71 mm for B. cereus | Khodayari et al. (2019) |

| Carotenoids composites | |||||||

| PLA | Tagetes erecta L. (flowers) | Astaxanthin (2%) | Extrusion | Water vapour permeability | Food packaging | 21% reduction of water vapor permeability; slower release of antioxidant | Samsudin et al. (2014) |

| PLA/TiO2 | Solanum lycopersicum L. (pulp) | Lycopene (5.5%) | Solvent casting | DPPH | Packaging of oxidation-sensitive food products | Maximum scavenging activity of 50%; enhanced biodegradable | Asadi and Pirsa (2020) |

| PLA/TiO2 | Commercial | Lycopene (3%) | Solvent casting method | DPPH | Packaging of margarine | Improved the mechanical properties; maximum antioxidant activity of 98.14% | Pirsa and Asadi (2021) |

| PLA/PHB | Commercial | Lutein (0.9%) | Extrusion | Mechanical properties | Food packaging | Tensile strength: 32.3 MPa; elongation at break: 3.3% | Latos-Brozio and Masek (2020) |

| Vitamins composites | |||||||

| PLA/PVA | Commercial | a-Tocopherol (3.5%) | Polymer extrusion technologies | Commercial | Food additive | Oxygen scavenging rate: with and without coated a-Tocopherol of 0.69 and 0.63 mL O2/gAT, respectively | Scarfato et al. (2017) |

| PLA | Commercial | Vitamin E (α-tocopherol) (5%) | Electrospinning | DPPH | Packaging of fruits and juices | Improved antioxidant activity of 94% was achieved by this membrane | Munteanu et al. (2014) |

| PLA | Commercial | Cholecalciferol (1–10%) | Solvent casting method | Agar well diffusion | Active food packaging | Showed effective antibacterial activity against food borne bacteria (S. aureus and E. coli) | Lawal et al. (2023) |

| Active compounds | |||||||

| Enzymes composites | |||||||

| PLA/chitosan | Commercial | Lysozyme (0.5 g) | Solution casting method | Minimum inhibitory concentration | Antibacterial food packaging | MIC value: 1.25 mg/mL against S. auerus and 2.5 mg/mL against E. coli | Hao et al. (2022) |

| PLA | Commercial | Proteinase k | Solution casting method | Water vapour transmission rate and biodegradable test | Food packaging | Water vapour transmission rate: 160 g/m2/d; utilized as plasticizing agents | Oliver-Ortega et al. (2021) |

| PLA/polyurethane | Bacillus ligniniphilus | Laccase (471.2 U/g) | Fused deposition method | Biodegradability rate | Food packaging | Increased the elastic modulus to 2.5 fold; 15% biodegradability rate after 6 month | Murillo-Morales et al. (2023) |

| Biosurfactants composites | |||||||

| PLA | Starmerella bombicola | Sophrolipid (5–20%) | Solvent casting method | Colony counting method | Food packaging |

Inhibition rate: more than 50%; water permeability rate: 4.99 × 10–11 g m Pa−1 s−1 m−2 |

Silveira et al. (2020) |

| Lipoaminoacids composites | |||||||

| PLA | Commercial | Lauric arginine (0.5–2%) | Electrospinning | Agar diffusion method | Fresh strawberry preservation | Extend the shelf life of strawberry | Li et al. (2021) |

| Oligosaccharides composites | |||||||

| PLA/CA/TiO2 | Commercial | β-cyclodextrin | Solution casting method | Colony counting method | Active food packaging | Inhibition rate: 25% against E. coli; Enhance thermo and photo degradation | Goñi-Ciaurriz and Vélaz (2022) |

| Bacteriocins composites | |||||||

| PLA/Silica nanoparticles | Commercial | Nisin (1–3%) | Solvent casting method | Permeability properties | Food packaging | Water vapour permeability decreased by 9.64% and oxygen permeability decreased by 35.19% | Jiang et al. (2023) |

| PLA/PEG | Lactococcus lactis | Nisin (2.5%) | Solvent casting method | Agar diffusion method | Food packaging | Limit of detection: 50 ng mL−1; Antibacterial reduced 25% after exposure 160 °C | Holcapkova et al. (2018a) |

| PLA/PEG | Commercial | Nisin (0.15%) | Solvent casting method | Agar diffusion method | Food packaging | Zone of inhibition: 25.9 mm against M. luteus | Holcapkova et al. (2018b) |

| Peptides composites | |||||||

| PLA/PBAT | Commercial | Natamycin (1%) | Melt extrusion | Colony counting method | Grape packaging | Inhibit the growth of fungi upto 0.42 log cfu g−1. tensile strength: 43.5 MPa; elongation at break: 258.2% | Zheng et al. (2023) |

| Furans composites | |||||||

| PLA/Poly(butylene 2,5-furan dicarboxylate) | Commercial | 2,5-Dimethyl Furandicarboxylate (0.75 mol) | Injection molding | Mechanical and thermal property | Food packaging | Thermal decomposition temperature: 368 °C; Young modulus: 412 ± 83 MPa | Long et al. (2017) |

| PLA/poly(pentamethylene 2,5-furanoate) | Commercial | 1,5- Pentanediol and furan-2,5-dicarboxylic acid (1%) | Solution casting method | Mechanical and thermal property | Sustainable Food Packaging | Gas-barrier performance improved upto 30%; Young modulus: 389 ± 44 MPa | Rigotti et al. (2021) |

| Organic/inorganic materials | |||||||

| Metallic nanoparticles | |||||||

| PLA | Commercial | Zinc oxide (1.11%) | Solven casting method | Mechanical properties and permeability test | Food packaging | Water permeability of 46.3%, young modulus of 52.6% and inhibition rate of 68% against E. coli | Liew et al. (2023) |

| PLA | Commercial | Zinc oxide (5%) | Melt extrusion | Colony counting method | Food packaging | Reduction (99.99%) of E. coli was observed; Improved tensile properties and surface free energy | Marra et al. (2016) |

| PLA/PCL | Clove essential oil | Zinc oxide (3%) | Solution casting method | Disc diffusion method | Scrambled egg packaging | Cell viability: 1 to 1.5 log reduction of S. aureus observed | Ahmed et al. (2019) |

| PLA | Commercial | Magnesium oxide (2%) | Solution casting method |

Fluorescence Activated Cell Sorting technique |

Food packaging | Inhibition rate: 46%; 20% increase in water vapour permeability | Swaroop and Shukla (2018) |

| PLA | Commercial | Silver nanoparticles (1 g) | Solvent casting method | Mechanical and permeability properties | Packaging of ground beef | Young modulus: 0.69 MPa; elongation at break: 41.35%; water permeability of 2.76 g mm kPa−1 h−1 m2 | Izadi et al. (2023) |

| PLA | Commercial | Copper nanocomposites (15%) | Melt extrusion | Agar diffusion method | Food packaging | Zone of inhibition: 22 mm against E. coli and 16 mm against P.aeruginsa | Popescu et al. (2023) |

| PLA | Commercial | Selenium dioxide (1.5%) | Extrusion method | – | Food packaging | Water vapour permeability of 77%; Increased antioxidant activity increased by incorporating Se nanoparticle | Zibaei et al. (2023) |

| Silica nanoparticles | |||||||

| PLA | Commercial | Halloysite nanotubes (14.3–25%) | Solvent casting method | – | Food packaging | Optimum performance by 30% of nanocomposites; loading capacity of cinnamaldehyde increased upto 25% | Li et al. (2023) |

| PLA/acetyl tri-n-butyl citrate | Commercial | Silica (0.5–5%) | Melt extrusion | Permeability measurements | Food packaging | Permeability of CO2: 3.56 barrier; permeability of O2: 0.76 barrier | Aragón-Gutierrez et al. (2020) |

| PLA | Commercial | Silica (1–3%) | Casting method | Cell viability test | Food packaging | Cell viability: approximately 5 log CFU/mL of E. coli and 3 log CFU/mL of S. aureus | Lu et al. (2021) |

| PLA/SiO2 | Commercial | Silica (1%) | Electrospinning | Rheological studies | Active packaging | Young modulus: 1.3 MPa; elongation at break: 45% | Cacciotti and Nanni (2016) |

| PLA | Commercial | Organoclay (5%) | supercritical impregnation | Cell viability test | Sustainable food packaging | MIC value: 250 μg/mL for thymol and 157 μg/mL for cinnamaldehyde; Increase the shelf life | Villegas et al. (2019) |

| PLA | Sodium montmorillonite | Nanoclay (40%) | Blown film co-extrusion method | Oxygen permeability and water vapor permeability | Food packaging | Water permeability: 0.192 (g cm)/(m2 day); oxygen permeability: 4.05 ± 0.7 (cm3 cm)/(m2 day atm−1) | Scarfato et al. (2017) |

| Carbon materials | |||||||

| PLA/PBAT | Commercial | Carbon nanotubes | Melt blending | Mechanical properties | Food packaging | Tensile strength: 33.7 MPa; Elongation at break: 341% | Wang et al. (2023a) |

| PLA | Commercial | Amorphous carbon | Solvent casting method | Oxygen and water permeability test | Sustainable food packaging | Oxygen transfer rate: 18.6 ± 3.3 cm3 mm m−2 day−1; water vapour permeability: 0.48 ± 0.12 kg m/s m2 Pa | Mattioli et al. (2013) |

| PLA/PCL | Commercial | Carbon nanotubes (7%) | Solution casting method | Colony counting method | Antibacterial food packaging | Water vapour permeability: 17.9 kg m/s m2 Pa; Colony reduction upto 5.65 log10CFU/mL against S. aureus | Cui et al. (2020) |

| PLA | Waste brewed coffee powder | Biochar (2.5%) | Solvent casting | Rheological studies | Food packaging | PLA/biochar withstand maximum temperature of 166 °C | Arrigo et al. (2020) |

| PLA | Beechwood | Biochar (5%) | Injection molding | Thermal and hygroscopic property studies | Food packaging | Water contact angle: 73°; biochar decreased the water repellence | Zouari et al. (2022) |

PLA polylactic acid, PCL polycaprolactone, CFU colony forming units, CA cellulose acetate, PEG polyethylene glycol, PVA polyvinyl alcohol, PBH polyhydroxybutyrate, DPPH 2,2-diphenyl-1-picrylhydrazyl, ABTS 2,2-azino-bis-3-ethylbenzothiazoline-6-sulphonic acid, FRAP ferric ion reducing antioxidant power, phr parts per hundred

Polylactic acid with biopolymers

Biopolymers such as chitosan (Andrade-Del Olmo et al., 2019), starch (Muller et al., 2017), cellulose derivatives (Khodayari et al., 2019), alginate (Gu et al., 2013), pectin (Satsum et al., 2022), gum (Tripathi et al., 2017) can be combined with PLA to synthesize food packaging film for functional foods, meals, meats and other application. These biopolymers significantly enhance the mechanical strength (Muller et al., 2017), barrier function (Bang and Kim, 2012), and biodegradability of the films (González and Alvarez Igarzabal, 2013), meeting diverse packaging needs effectively. The incorporation of PLA with polysaccharides has been extensively studied and has received significant interest in scientific research. This combination of benefits has found practical use in the production of food packaging films, a subject that has been thoroughly discussed in scholarly literature (Aung et al., 2018; Grujić et al., 2017). Ren et al. (2023) developed the cellulose from agricultural residue incorporated with PLA by solution casting method which exhibited maximum scavenging rate of 71% by DPPH method for the application diary product packaging. Additionally, utilizing PLA with chitosan as polysaccharide instead of cellulose which maximize the tensile strength of 47 MPa and elongation at break of 11% can also be utilized in the food packaging application (Elsawy et al., 2023).

Polylactic acid with proteins and lipids

Utilizing PLA as a biodegradable polymer could involve its application as a matrix or coating material for protein-based packaging which includes fish protein (Ma et al., 2015), wheat gluten (Hajikhani et al., 2020), soy protein (Dong et al., 2023), zein (Parlak et al., 2023) and gelatin (Ponnusamy et al., 2023), thereby contributing to the increased sustainability of the packaging material as a whole. Meanwhile, proteins like fish protein and soy protein incorporated with PLA improved the water vapour permeability of 10.85 × 10−13 g m m−2 s Pa. (Saiwaew et al., 2014) and 2.3 × 10–11 g m Pa−1 s−1 m−2, respectively (González and Alvarez Igarzabal, 2013) can be utilized in soft cheese packaging. These composites may involve combining lipids with polymers to create materials with specific properties like biocompatibility, biodegradability, flexibility and mechanical strength (Balla et al., 2021). In addition to the protein, essential oil also utilized in the food packaging application namely clove oil (Sharma et al., 2023), cardanol oil (Mele et al., 2019), and oleic acid (Almasi et al., 2015). In the study of Sharma et al. (2023), different concentrations (1 wt%, 5 wt%, and 10 wt%) of clove oil were incorporated into polylactic acid (PLA)-poly (butylene adipate)-terephthalate (PBAT) films to modify the antibacterial properties of the biodegradable films. The research assessed the inhibitory effects of these composite films on Escherichia coli and Staphylococcus aureus, revealing that clove oil exhibited superior antibacterial activity compared to the other essential oil tested. Specifically, for S. aureus, the addition of 10 wt% clove oil resulted in the most effective inhibition of growth (Sharma et al., 2023).

Polylactic acid with microbial and synthetic biopolymers

Biopolymers produced by microorganism are garnering attention for their potential use in eco-friendly food packaging applications. Nowadays, microbial biopolymers including bacterial cellulose (Patwa et al., 2019), polyhydroxyalkanotes (Injorhor et al., 2023), polyhydroxybutyrate (Aydemir and Gardner, 2020) and poly(3-hydroxybutyric acid-co-3-hydroxyvaleric acid) (Hernández-García et al., 2022b) were incorporated with PLA and utilized in the food packaging application. The bacterial cellulose extracted from Acetobacter pasterianus blended with PLA which helps in the water vapour barrier by 5 wt% with tensile strength of 16.6 MPa (Patwa et al., 2019). Similarly, polyhydroxybutyrate with PLA exhibited the tensile strength of 20 MPa with elasticity of 3.6 MPa, which can be suitable for food packaging application (Aydemir and Gardner, 2020). Moreover, polylactic acid with synthetic polymer also utilized in food packaging application. One of the synthetic polymers such as polycaprolactone (PCL) with PLA films underwent supercritical CO2 impregnation to integrate thymol, resulting in enhanced antibacterial properties while maintaining a robust structure and excellent thermal stability. These films were assessed against E. coli and B. subtilis, demonstrating substantial inhibition. Remarkably, the film containing 35.8 wt% thymol exhibited exceptional antibacterial efficacy, completely eradicating bacterial cell viability (Milovanovic et al., 2018).

Polylactic acid with phenolic active compounds

Polylactic acid is devoid of toxicity and irritation, to enhance the antibacterial attributes of PLA matrix composites, the incorporation of phenolic active compounds becomes necessary. Active food packaging entails advanced packaging systems surpassing conventional passive containment and protective roles. Specifically engineered to actively engage with the food product or its surroundings, these packaging materials offer additional functionalities to boost food safety, prolong shelf life, and enhance the overall quality of the product. This approach not only preserves the degradability of PLA for environmental sustainability but also effectively impedes microbial growth in food, ensuring the safety of consumables. Phenolic compounds which include phenolic polymer (lignin (Daassi et al., 2023) and procyanidins (Havelt et al., 2021)), phenolic acids (hydrobenzoic acid (Andrade et al., 2023), gallic acid (Aytac et al., 2016), protocatechuic acid (Hernández-García et al., 2022a) and rosemarinic acid (Ramos et al., 2020)), phenethyl alcohol (Grabska-Zielińska et al., 2021), lipidic phenol (Gonon et al., 2023), phenolic aldehydes (Melesse et al., 2022), secoiridoids (Özge Erdohan et al., 2013), flavonoids (Ezati and Rhim, 2021), stilbenes (Díaz-Galindo et al., 2020), curcuminoids (Redfearn and Goddard, 2023), terpenes (Gomez-Caturla et al., 2023), carotenoids (Latos-Brozio and Masek, 2020) and vitamins (Aytac et al., 2017) are added into PLA to prepare the active packaging films for the enhancement of antioxidant and antibacterial activity for proper food preservation.

Lignin is one of phenolic polymers, complex organic material found in the cell walls of plants, providing structural support and rigidity (Shu et al., 2021). Lignin exhibits the capability to interact with numerous polymers, thereby altering their wettability, and mechanical properties which can be utilized in packaging application. Lignin from rice husk incorporated with PLA through the solvent casting method which improved the inhibition rate by DPPH and ABTS by 82.2% and 83.6%, respectively in food packaging (Fontes et al., 2021). Similarly, procyanidins with PLA showed the maximum inhibitory rate of ABTS and also utilized as photo stabilizers (Havelt et al., 2021).

Another phenolic active compounds of phenolic acid such as 4-hydrobenzoic acid, gallic acid, protocatechuic acid and rosmarinic acid are some of types of phenolic acid from the plant utilized with PLA for the active food packaging. For example, gallic acid incorporated into PLA with hydroxypropyl-beta-cyclodextrin increased the antioxidant activity of 95% and also improved the shelf life and quality of food (Aytac et al., 2017). While rosmarinic acid improved the antioxidant activity by 60% while blended with PLA and silver nanoparticles (Ramos et al., 2020). Likewise, phenethyl alcohol composites such as hydroxytyrosol increased the water vapour permeability of 11.01 ± 1.61 g m−2 h−1 for the packaging of food (Grabska-Zielińska et al., 2021).

In this context, lipidic phenols represents a category of phenolic active compound which harness the antioxidant capabilities of hydroxyl groups while incorporating conjugated double bonds along the aliphatic chain. This combination has the potential to actively scavenge free radicals. Cannabidiol is one of the lipidic phenols which improves the tensile strength by 39.4 MPa and 7.1% of elongation for the active food packaging (Tutek and Masek, 2023). Cinnamaldehyde, a phenolic aldehyde that gives cinnamon its distinct flavor and aroma (Ribeiro-Santos et al., 2017). Apart from its pleasant scent and taste, cinnamaldehyde has been studied for its potential benefits, including antioxidant and antimicrobial properties. Honorine Gonon and coworkers developed the bakery packaging material with cinnamaldehyde which reduced the mechanical strength of the material and enhanced the antibacterial activity against E. coli (Gonon et al., 2023). Another phenolic aldehyde of thymol with PLA utilized in the packaging of meat which improved the shelf life of the product (Shavisi et al., 2017). Secoridoids, such as oleuropein, in composites with PLA showed the zone of inhibition of 16.20 mm against S. aureus (Erdohan et al., 2013).

Flavonoids are a diverse group of polyphenolic compounds widely distributed in the plant kingdom, known for their antioxidant and antimicrobial properties (Mutha et al., 2021). They play a crucial role in various plant processes, such as pigmentation, UV filtration, and defence against pathogens. Flavonoids compounds such as catechin, quercetin blended with PLA which eventually improved the antioxidant activity in the active food packaging. Deng and Zhou (2024) demonstrated the quercetin incorporated with PLA through solution casting method improved the antioxidant activity of 98%. Flavonoids such as quercetin subjected to PLA with carboxymethyl cellulose for food packaging which increased 42% of antioxidant activity (Radusin et al., 2019). Another important phenolic active compounds is stilbenes, trans resveratrol and trans-viniferin with PLA utilized in the food packaging which improved the water vapour barrier property of 50% and also inhibit the mycelium growth of 35.8% (Díaz-Galindo et al., 2020).

Curcumin, commonly known as turmeric, is a type of polyphenol characterized by its chemical structure. The orange-yellow, water-insoluble crystal is derived from the rhizomes of plants belonging to the Zingiberaceae family, making it a natural pigment (Bakar et al., 2023). The study found that curcumin was incorporated into PLA to modify its properties for application in tea drink packaging (Hanafi et al., 2017). The customized PLA exhibited notable characteristics, including an antioxidant activity with an IC50 value of 4.37% and a reduced total microbial growth, as evidenced by a logarithmic value of 2.2. These attributes collectively suggest that the tailored PLA formulation surpasses its commercial counterparts in terms of performance and suitability for packaging tea drinks (Hanafi et al., 2017).

Furthermore, terpenes are a diverse class of organic compounds found in various plants and certain insects. They are characterized by their repeating units of isoprene, a five-carbon building block. Terpenes contribute to the distinct aromas and flavors of many plants, including fruits, flowers, and herbs (Tetali, 2019). PLA materials incorporating terpenes as antimicrobial agents find utility in the food packaging sectors. The antimicrobial effects of terpenes make them valuable in these applications. However, a critical consideration arises from the potential toxicity of certain terpenes and their ability to impact the organoleptic properties of food (Masyita et al., 2022). Eugenol is one of the terpenes which incorporated with PLA formed the food packaging film which exhibited the zone of inhibition of 3.6 mm against E. coli (Yu et al., 2023). Similarly, bisbolene and carvone exhibited the zone of inhibition of 26.85 mm against E. coli (Khodayari et al., 2019).

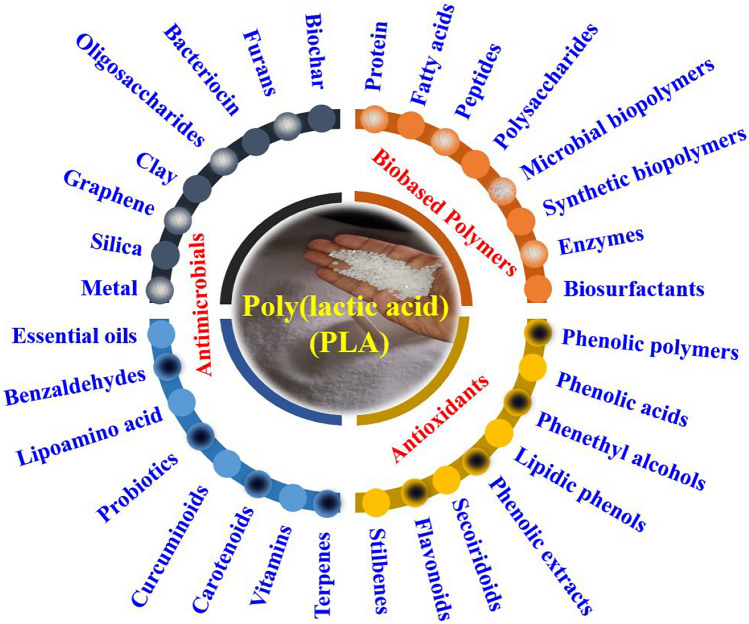

Similarly, the carotenoid composites of lycopene improved the antioxidant activity of 98.14% blended with PLA/TiO2 (Pirsa and Asadi, 2021). Vitamin E, including tocopherol, plays a crucial role in protecting cells from oxidative damage caused by free radicals. Its antioxidant properties and is often used in the food and cosmetic industries to extend the shelf life of products by preventing the oxidation of fats and oils. Scarfato et al. (2017) developed the membrane with PLA/PVA with additive tocopherol helps to improve the oxygen scavenging rate by 0.63 mL O2/gAT (Fig. 3).

Fig. 3.

Incorporating various compounds including antioxidant, antimicrobial and other biobased polymer into polylactic acid for the food packaging applications

Polylactic acid with active compounds

Various active compounds, including enzymes(Zhang et al., 2021), biosurfactants (Silveira et al., 2020), lipoamino acids (Li et al., 2021), oligosaccharides (Goñi-Ciaurriz and Vélaz, 2022), bacteriocins (Holcapkova et al., 2018a), peptides (Santos et al., 2018), and furans (Rigotti et al., 2021), have been extensively employed in conjunction with PLA for food packaging applications. Among these compounds in active packaging, the utilization of biosurfactants, specifically sophorolipids, has garnered significant attention for its widespread application in controlling foodborne pathogens (Cho et al., 2022; Hipólito et al., 2021; Silveira et al., 2020). In this context, PLA has been combined with sophorolipids to fabricate antimicrobial film packaging, which was prepared using the casting method. The observed films displayed robust antimicrobial efficacy against prevalent poultry pathogens such as Listeria monocytogenes, Staphylococcus aureus, and Salmonella spp. Incorporating sophorolipid into these films enhances thermomechanical properties and also acts as a natural antimicrobial agent. This multifunctional characteristic showcases potential of sophorolipid for effectively controlling foodborne pathogens in the food industry (Silveira et al., 2020). Besides sophorolipid, nisin has been integrated into biodegradable polymers for its role as a carrier of antimicrobial compounds in active food packaging applications to inhibit the growth of spoilage and pathogenic microorganisms, thus extending the shelf life of packaged foods. Its incorporation serves as an active barrier against microbial contamination, thereby ensuring food safety and preservation (Imran et al., 2014; Santos et al., 2023).

In a study, blending nisin with PLA facilitated the synthesis of active film packaging targeting foodborne pathogens, specifically aimed at preserving orange juice. This integration resulted in a substantial reduction in bacterial count, decreasing from an initial 6 log CFU/mL to 4.5 log CFU/mL (Jin and Zhang, 2008). In tandem with biosurfactants and bacteriocins, peptide composites namely, natamycin stands as a prominent constituent are integral to active food packaging. Renowned for its robust antifungal properties, natamycin effectively curbs mold proliferation, thereby significantly prolonging the shelf life of packaged food products (González and Alvarez Igarzabal, 2013; Santonicola et al., 2017).

Lantano et al. (2014) investigates the efficacy of a novel active packaging employing a hybrid organic–inorganic coating endowed with antimicrobial properties. The packaging system integrates PLA and natamycin as active agents. Through rigorous testing against mold growth on cheese surfaces, the coatings demonstrated substantial potential. The findings validate the viability of this film as an effective deterrent against microbial proliferation, specifically on cheese substrates (Lantano et al., 2014). In addition to the aforementioned active compounds, lipoamino acid—PLA composites have also been incorporated into the food packaging. These composites play a pivotal role in enhancing the overall efficacy and performance of the packaging, contributing to its antimicrobial properties and further augmenting its potential in preserving food quality and safety (Li et al., 2021; Ma et al., 2020). A novel environmentally friendly packaging with inherent antibacterial properties has been devised through the application of lauric arginate (LAE) coating on PLA films. The mechanical characteristics of the resulting film closely resemble those of neat PLA film, while exhibiting notable antibacterial efficacy against Listeria monocytogenes and Salmonella enterica. Particularly suitable for use as food-contact antimicrobial packaging for cooked cured ham, the film demonstrates heightened antibacterial activity corresponding to increased LAE coating levels (Theinsathid et al., 2012). Enzymes and furan compounds have been combined with PLA to craft advanced food packaging films. This innovative blend aims to enhance preservation capabilities, representing a progressive step in creating packaging that actively safeguards food quality (Bianchi et al., 2023; Fredi et al., 2022; Min et al., 2022).

Polylactic acid with organic and inorganic materials

The incorporation of metallic and inorganic composites into polymers represents a burgeoning trend aimed at augmenting polymer characteristics. This innovation has fostered the creation of polymer-metallic composites that exhibit heightened antimicrobial (Hao et al., 2022), UV-blocking, and antioxidant attributes (Cavallo et al., 2020; Hu et al., 2023). Nonetheless, apprehensions regarding toxicity and environmental repercussions have surfaced, prompting the need for a thorough assessment of their effectiveness, safety, and sustainability in the realm of food packaging (Mulla et al., 2021; Videira-Quintela et al., 2021).

Metallic nanoparticles such as titanium dioxide (Zheng et al., 2023), zinc oxide (Liew et al., 2023), magnesium oxide (Swaroop and Shukla, 2018), silver (Fortunati et al., 2013), copper (Popescu et al., 2023), and selenium (Zibaei et al., 2023) have been employed in food packaging for various purposes like UV protection, antimicrobial properties, and antioxidation. The research delineates the synthesis of PLA and magnesium oxide nanocomposite for food packaging films via an industrial melt-processing setup. Findings underscore notable enhancements in multiple facets such as heightened tensile strength, increased plasticity, augmented oxygen and water vapor barrier capabilities, and demonstrated antimicrobial efficacy against E. coli (Swaroop and Shukla, 2019). Fortunati et al., developed a high-performance nano-biocomposites, combining PLA with pristine cellulose nanocrystals (CNC) and surfactant-modified cellulose nanocrystals (s-CNC) containing silver (Ag) nanoparticles specifically crafted for superior film production. These films, designed for active food packaging applications, integrate PLA with cellulose nanostructures, offering enhanced performance and functionalities for food preservation (Fortunati et al., 2013).

In another study, composite films were engineered by combining PLA with zinc oxide nanoparticles, demonstrating UV-light barrier capabilities alongside improved thickness, tensile strength, and water vapor resistance upon nanoparticle integration. Furthermore, these films exhibited antibacterial efficacy against foodborne pathogens, specifically Escherichia coli and Listeria monocytogenes. Employed in the packaging of minced fish paste, these films effectively shielded against bacterial contamination, showcasing promising protective attributes for food preservation (Shankar et al., 2018).

Silica, specifically halloysite and clay, is crucial in modern food packaging due to its protective properties. These materials offer barrier qualities against moisture, oxygen, and gases, ensuring food quality. They also enhance the mechanical strength of packaging, ensuring product integrity during handling. Halloysite has antimicrobial properties, shelf life extension of perishable items. These nanomaterials enable intelligent packaging solutions, detecting temperature, gas composition, and freshness variations. They are also environmentally friendly, contributing to the search for biodegradable and eco-conscious packaging (Aragón-Gutierrez et al., 2020; Scarfato et al., 2017; Villegas et al., 2019).

In this context, halloysite nanotubes, a unique hollow tubular structure, significantly improve packaging performance in food packaging. They serve as ethylene scavengers, antimicrobial carriers, and fillers, enhancing shelf life, preventing microbial growth, and enhancing mechanical strength and durability (Boro et al., 2022; Deshmukh et al., 2023). In this regard, Risyon et al. (2020) demonstrates the potential of PLA/ halloysite nanotubes films in extending the shelf life of packaged cherry tomatoes, demonstrating a significant advancement in biopolymers and their potential applications in food packaging (Risyon et al., 2020). In addition to the carbon nanotubes, clay, bio-nanocomposite films can also be utilized in the food packaging. The study elaborated the PLA and nanoclay along with thymol and cinnamaldehyde have distinct properties, which exhibits a potent antibacterial property. All bio-nanocomposites completely disintegrated in compost, showcasing their potential application as compostable flexible active films (Villegas et al., 2019).

When integrated with PLA for food packaging, graphene and carbon compounds fortify the protective attributes of the packaging materials. Enhancing mechanical strength, moisture and oxygen barrier capabilities, and exhibiting antibacterial properties, thereby effectively extend the shelf life of packaged food items, ensuring heightened food safety standards (Arrigo et al., 2020; Goh et al., 2016; Zouari et al., 2022). Yakdoumi et al. (2022) explored the use of polylactic lactic acid blended with multiwalled carbon nanotubes as one of the nanofillers for food packaging with antimicrobial property. The PLA-based modified MWCNTs at 3 wt% loading showed better properties, with a 10% increase in crystallization rate and 7% increase in barrier. The Young modulus and hardness also improved, and the films showed strong antimicrobial and antifungal activity compared to pure PLA (Yakdoumi et al., 2022).

The sandwich-structured PLA–graphene composite film, which uses commercial PLA films as an external protective layer and impermeable reduced graphene oxide as an inner barrier, reduces water vapor permeability by 87.6%. Simulations show that this film can extend the shelf life of potato chips and edible oil by at least eightfold, making it a promising solution in food packaging (Goh et al., 2016). Arfat developed antimicrobial nano packaging films by incorporating clove essential oil and graphene oxide nanosheets into PLA for food packaging. The addition of GO enhanced the film’s optical and anti-UV properties. The composite film showed excellent antibacterial activity against Staphylococcus aureus and Escherichia coli, making it a potential food safety and preservation material (Arfat et al., 2018).

Future prospectives

Poly(lactic acid) (PLA) has been extensively utilized in active food packaging primarily due to its distinctive and commendable properties. However, PLA lauded for its ecological merits, confronts notable challenges such as suboptimal moisture and gas resistance, constrained heat resilience, and elevated production costs. Its inherent brittleness necessitates strategic treatment for enhanced mechanical performance, frequently achieved through amalgamation with supple biodegradable polymers. Moreover, PLA’s permeability to carbon dioxide (CO2), oxygen, and water vapor imposes constraints on its applicability in specific beverage bottle contexts. Despite its limitations, PLA’s significance is evident in its wide range of applications within biodegradable and bio-based polymer markets. Regarding future research endeavors, emphasis should be directed towards the development of antimicrobial packaging for PLA, thereby augmenting its utilization in various applications. In order to enhance the antimicrobial and antioxidant properties of the material, incorporation of microbial extracts is recommended. Particular attention should be given to siderophores, peptides, and enzymes, as these components play a pivotal role in augmenting the overall antimicrobial efficacy of the packaging material. To summarize, PLA represents a transition from petrochemical plastics to bioplastics, necessitating solutions to molecular synthesis limitations. Amidst an environmental crisis, substituting PLA for nondegradable polymers is a step in the right direction, addressing issues associated with the petroleum industry’s environmental impact. Overall, PLA’s versatility, affordability, recyclability, biocompatibility, and thermoplasticity make it a significant contender in various industrial sectors.

Acknowledgements

The authors would like to thank SRM Institute of Science and Technology for help in carrying out the research

Funding

No funding was obtained for this study.

Declarations

Competing interests

The authors declare that they have no know competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Abdel-Rahman MA, Sonomoto K. Opportunities to overcome the current limitations and challenges for efficient microbial production of optically pure lactic acid. Journal of Biotechnology. 2016;236:176–192. doi: 10.1016/j.jbiotec.2016.08.008. [DOI] [PubMed] [Google Scholar]

- Abdel-Rahman MA, Tashiro Y, Sonomoto K. Recent advances in lactic acid production by microbial fermentation processes. Biotechnology Advances. 2013;31:877–902. doi: 10.1016/j.biotechadv.2013.04.002. [DOI] [PubMed] [Google Scholar]

- Abdenour C, Eesaee M, Stuppa C, Chabot B, Barnabé S, Bley J, Tolnai B, Guy N, Nguyen-Tri P. Water vapor and air barrier performance of sustainable paper coatings based on PLA and xanthan gum. Materials Today Communications. 2023;36:106626. doi: 10.1016/j.mtcomm.2023.106626. [DOI] [Google Scholar]