Abstract

In the era of Industry 4.0 (I4.0), automation and data analysis have undergone significant advancements, greatly impacting production management and operations management. Technologies such as the Internet of Things (IoT), robotics, cloud computing (CC), and big data, have played a crucial role in shaping Logistics 4.0 (L4.0) and improving the efficiency of the manufacturing supply chain (SC), ultimately contributing to sustainability goals. The present research investigates the role of I4.0 technologies within the framework of the extended theory of planned behavior (ETPB). The research explores various variables including subjective norms, attitude, perceived behavior control, leading to word-of-mouth, and purchase intention. By modeling these variables, the study aims to understand the influence of I4.0 technologies on L4.0 to establish a sustainable manufacturing SC. A questionnaire was administered to gather input from small and medium-sized firms (SMEs) in the manufacturing industry. An empirical study along with partial least squares structural equation modeling (SEM), was conducted to analyze the data. The findings indicate that the use of I4.0 technology in L4.0 influences subjective norms, which subsequently influence attitudes and personal behavior control. This, in turn, leads to word-of-mouth and purchase intention. The results provide valuable insights for shippers and logistics service providers empowering them to enhance their performance and contribute to achieving sustainability objectives. Consequently, this study contributes to promoting sustainability in the manufacturing SC by stimulating the adoption of I4.0 technologies in L4.0.

Keywords: Extended theory of planned behavior (ETPB), Industry 4.0 (I4.0), Logistics 4.0 (L4.0), Sustainable manufacturing supply chain management (SCM), PLS-SEM

1. Introduction

Industry 4.0 (I4.0) has evolved with several disruptive technologies; like artificial intelligence, industrial robotics, blockchain, cyber-physical system (CPS), 3D printing, the Internet-of-Thing (IoT), digital twins, augmented reality, etc. Such disruptive technologies influence the various manufacturing operations and service management which enhances the expectations for customized products and services [1]. The I4.0 technologies influence various elements like flexibility, agility, collaboration, robustness, transparency, information sharing, etc., which helps in supply chain (SC) resilience [2]. Disruptive technologies have a significant influence on the manufacturing SC and overall business activities of small and medium enterprises (SMEs). Because the contribution of SMEs is thought to be important to a nation's sustainable growth the adoption of disruptive technologies into the manufacturing operations is essential [3].

The basic logistics services include single services, tangible services definitions, handling focus, activity execution, and consistent service definition. The logistics services delivered in the advanced stages include multiple and combinations of multiple services, intangible value-addition needs, value-adding focus, organization, and implementation of reengineering-based needs [4]. Logistics evolved along with the industry evolution and took different approaches. Logistics 1.0 (L1.0) evolved around transport mechanization, under this logistics concentrated on mechanization to improve transport efficiency. The evolution of L2.0 imbibed automation in the transportation system to take care of operation efficiency and reduce manual errors. The L3.0 evolutions took place rapidly and evolved around a logistics management system (LMS). The LMS helped to realize the effectiveness of logistics as a holistic system. The logistics 4.0 (L4.0) evolution took place in the digital era utilizing Wi-Fi-enabled disruptive technologies. The use of disruptive technologies is utilized to make the system more transparent, effective, and robust using the data. The various evolution stages are depicted in Fig. 1.

Fig. 1.

Logistics evaluation (Modified from Ref. [5]).

In the digital era, the huge amount of data generation over the internet is increasing and becoming beneficial as well as challenging in terms of its volume, processing velocity, data verification, vast variety and data value [6]. Digitalization is assisting the logistics and transportation sectors in improving their operations by utilizing large amounts of data combined with high velocity acquired from many sources to generate big data [7]. Big data may identify current and future market trends, buying patterns of logistics services, and related maintenance cycles, to provide cost-saving options and effective targeted business decisions [8]. However, L4.0 necessitates the creation of scalable and efficient software solutions, as well as their implementation in successful real-world applications [9]. Various organizations face the challenge of extracting benefits from the substantial invasion of internet-generated data. This data serves as a valuable resource and a means for providing information that influences various business outcomes including but not limited to business decisions, manufacturing nexus, customer focus etc. Additionally, it also assists in comprehending numerous cases of business operations, to update and regulate the numerous business processes. Big data significantly impacts logistics services, particularly for third-party logistics service providers (3PLSPs), shippers, and service users worldwide who manage an immense flow of goods, generating extensive data. Stakeholders in logistics services monitor and trace their deliveries from origin to destination, capturing information such as volume, size, weight, time to destination etc. This data is used for quick and effective decision-making aiming to enhance logistics efficiency and customer experience in the manufacturing SC. Realizing the benefits of I4.0-based technologies, 3PLSPs have begun to integrate these technologies into their logistics operations [10]. Access to various significant information revealing the market trends, customer buying patterns, and business decisions towards cost reduction, and market expansion proves beneficial for SMEs striving for a sustainable SC. Big data business analytics (BDBA) creates opportunities for supply chain analytics (SCA), delivering descriptive, predictive, and prescriptive analytics. Thus, big data helps facilitate the realization of various operations and strategies to effectively manage logistics for a sustainable manufacturing SC [8]. Cloud computing (CC) also holds a significant influence on logistics management. The concept of a “logistics mall” involves a digital platform with various apps shared by logistics stakeholders, providing a cost-effective advantage through new software and operations. The automatic identification and localization through radio frequency identification (RFID) and condition monitoring of shipments contribute to the efficiency of the manufacturing SC [11]. The use of robotics in both internal and external logistics management, encompassing tasks such as loading, unloading, palletizing and depalletizing of goods is on the rise [12].

The sustainability of the SME in its manufacturing SC becomes important for its self-survival as well as for its contribution to a nation. SMEs, like large enterprises, contribute heavily toward a strong economy excelling in business and creating jobs. The role of SMEs at national and international levels is tremendous in boosting the country's GDP [13]. However, the increase in manufacturing cost, overhead, market competition etc. retards the growth of SMEs and makes it struggle to become a sustainable manufacturing SC. SMEs attempt several business practices and initiatives [14]. SMEs are investing in I4.0 technologies to raise the performance level in various areas like sales and distribution, logistics management, customer satisfaction etc. A framework for logistics service purchasing behavior based on a reasoned action approach (RAA) was proposed [15].

Considering the available empirical research on I4.0-based technologies' influence on L4.0 it can be concluded that limited research exists thus the present research becomes important to reveal their relationships. Based on the above premises, it has become evident to answer the various research questions: What is the influence of I4.0 technologies on L4.0? What is the role of ETPB in connecting the I4.0 technologies and L4.0?

The research carried out is documented as follows: The theoretical context and hypotheses development are given in Section 2. The model development process is discussed in Section 3. The materials and processes are described in Section 4. The findings are discussed in Section 5. Section 6 summarizes the current study's discussion. Section 7 outlines limitations and further research, while Section 8 presents the study's conclusion.

2. Theoretical background and hypotheses development

2.1. Logistics technologies

The advent of disruptive technologies in I4.0 has influenced L4.0 technologies and their implementation in daily logistics activities. 3 PL needs to imbibe adequate integrated information and communication technology infrastructure and services to meet the logistics complexities. Nowadays, logistics technologies are changing the day-to-day activities of L4.0-based services. Several technologies have been included in L4.0 activities. Several I4.0 disruptive technologies like IoT, Big data, CC, Robotics and automation, and RFID are being adopted in logistics operations. The massive data exchange from multiple sources connected to devices or humans is possible using IoT to provide full visibility and transparency in the logistics operations in real-time [16]. The advanced technologies application in L4.0 enhances system efficiency and improves the operational effectiveness of logistics and transport [17]. The advanced logistics system is sound in delivering consistent performance and outperforms the traditional dispatching method, however, dynamic coordination is mandatory among the shippers and 3PLS for effective results [18]. The adopted advanced logistics technologies may help in encountering the post-production processes connected with the dispatching activities along with man manpower connected to such activities while working with a cross-functional team of multiple 3 PLs [19]. Various technologies adopted in logistics and SCM operations not only boost efficiency but also reduce costs and enhance communications among the key stakeholders [20]. Automation of the logistics process creates more efficient and cost-effective operations, thus lowering the logistics cost of 3PLSP [21,22].

Incorporating robotics and automation in logistics activities helps 3 PL with its error-free and rapid logistics services to its customers. Collaborative robots are more effective in picking, palletizing or assembling in logistics operations [23]. Robotics can easily process vast amounts of data containing complicated information to aid in strategic decisions to employ specific knowledge to reduce ambiguities [24]. The L4.0 helps in significant cost savings [25]. The inclusion of robots and automation makes the logistics service deliver the product speedily with the utmost logistics service quality. Robots have been applied for collecting, commissioning, and goods sorting, and Automatic handling of loading and unloading of containers based on optical character recognition technology. The intelligent control of loading and unloading without human intervention will make it soundproof for fast delivery with required quality standards.

BDA and the IoT are helping multinational logistics firms enhance driver safety, minimize operating costs, and lessen their vehicles' environmental effects [26]. Big data enables processing, transmitting, and storing either temporarily or permanently, which was not possible in earlier days with traditional machines and information technologies [8]. The challenges of data integration from various sources like sensors, GPS, smartphones, and other upcoming devices may be resolved using big data analytics [27]. The use of modern technologies using data has influenced logistics management immensely in its routine operation by prompt decision-making for cost reduction and profit optimization. Incorporating data analytics in 3 PL may generate additional revenue in its business model. The data once processed can unhide many significant information, their static and dynamic relationship, their dependencies, and inter-dependence which helps in effective decision making.

The production system greatly benefited from internal logistics taken up by robotic systems [12]. In earlier times manpower was involved in loading and unloading, nowadays mobile robot manipulators can carry out this work with the use of artificial intelligence. A robot-driven advanced logistics system boosts logistics services to advanced production and service levels to reduce errors and enhance competition [28]. There a profound benefits for a 3 PL in using CC, however, it offers challenges as well [29].

Based on innovation diffusion theory and an SC risk assessment framework, A study based on the structural equation modelling (SEM) techniques, investigated the cooperative resilience of logistics and CC service providers. 3PLSP works efficiently to cater to shippers’ need for simple to complex solutions to enhance the SC performance [[30], [31], [32]]. The study used the feedback from 236 Chinese logistics service firms, on the relationship between trust, and security during operational services offered by them during CC adoption. According to them, Chinese logistics enterprises consider security barriers to be a primary issue influencing cooperative resilience between logistics service providers and CC service providers [33].

2.2. Theory of planned behavior (TPB)

The behavioral goals of an individual that may result in certain conduct are explained by the psychological theory known as the TPB [34]. According to this theory, each person's behavioral intention or any other relevant intention serves as a key motivator for specific conduct and serves as an indication of one's willingness or aspiration to engage in that behavior. Subjective norms (SN) and perceived behavioral control (PBC) are two psychological antecedents of attitude that influence behavioral intention [35].

The theory under discussion has drawn a lot of interest in the literature for understanding and predicting consumer behavior across a range of industries in promoting food waste recycling in commercial and industry settings [36], construction waste recycling [37], “green” behavior of logistics managers of pharmaceutical companies [38]. Likewise, TPB has only been used to examine passengers' behavioral intentions in the airline industry [39]. Behavior intention has also been examined for passengers using public transit facilities [40]. The impact of electronic word-of-mouth on tourist visit intention has been investigated [41]. The behavior of the managers was investigated under TPB and SEM for the procurement of green logistics [38]. The user's behaviour in opting for crowd-shipping has been investigated to reveal several physiological factors related to purchase intentions [42]. TPB has been employed to investigate e-waste recycling behavior to enhance knowledge awareness among electronic product users [43].

2.3. Theory of reasoned action (TRA)

The theory of reasoned action provides the foundation for predicting consumer behavior based on the consumer's purpose in doing the behavior. According to this, a doer's intention to do a task is known by his attitude and subjective norm. The consumer's intention is the outcome of factors that influence their attitude toward their behavior [44]. Subjective norm refers to how an individual feels under social pressure to engage in the desired conduct or refrain from doing so. Thus, as per this TRA, belief leads to the attitude to perform a given behavior which will accomplish positive outcomes. The perceived behavioral control, subjective norms, moral norms, and willingness to sacrifice were identified as antecedents to shippers' service intention [45]. The consumer will have an unfavorable attitude if they believe that engaging in the conduct would primarily result in negative outcomes. Behavioral beliefs are the ideas that guide someone's perspective on their behavior (i.e., the act of buying or not buying logistics services). A function of ideas that direct people or organizations to consider whether they should or should not engage in an activity is the subjective norm. Subjective norm also refers to the role of beliefs that direct individuals or organizations to consider whether they ought to or ought not to engage in a particular conduct. A person will feel social pressure to act in a certain way if they believe many of the referents with whom they are compelled to comply believe they should. Purchasing advanced logistics services is the result of reasoned action out of an individual buying behavior [15].

3. Model development

According to a thorough assessment of the literature, there are several scales available for evaluating the influence of advanced technologies on 3PLSP services that lead to the purchase intention of L4.0.

The scales available in the literature are listed in Table 1.

Table 1.

Influence of advanced technologies towards 3 PL service buying intentions under TPB.

| Name of the developed scale | Researchers | Dimensions included in the scale |

|---|---|---|

| Robots and Automation | [12,21] | Accessing vital data, provides enhanced productivity in the core business, process visibility, enhanced flexibility in resource utilization |

| Big Data | [8,27] | Ease of Data accessibility, ease of informed business for core business, process visibility, data-driven strategy providing flexibility in resource utilization |

| Cloud computing | [29,33] | Accessing vital data, enhanced flexibility in resource utilization |

| 3 PL services | [46], | Efficiency, fulfilment, availability of system, and privacy |

| Attitude | [47,48] | Attitude for outsourcing, favourable business, Reliable business, business value addition |

| Subjective norm | [34]. [35] | Expectations built for 3 PL service usage, Effective decision-making in 3PLservice usage, Motivated stakeholders to use 3 PL services |

| Perceived behaviour control | [34]. [35] | Guided behaviour to use 3 PL services, 3 PL services selection beyond self-control, Ease of using 3 PL services |

| Word of mouth | [35,45] | Intention to recommend 3 PL services, Positive word of mouth, Received positive recommendation for implementation |

| Repurchase intention | [35,45] | RCoinue trade connection intention, Repurchasing intentions leading to the renewal of contract, Developed sense of loyalty |

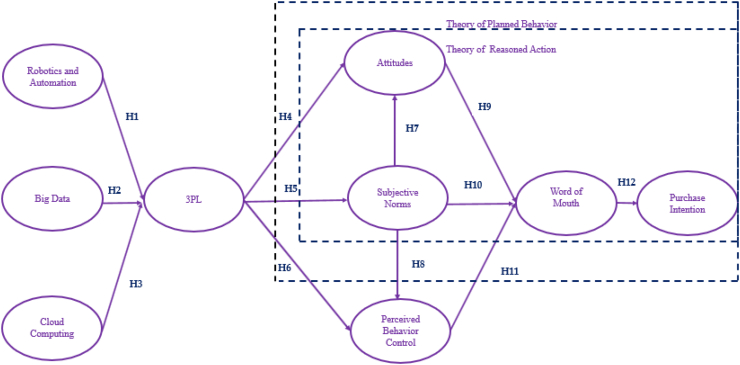

A purchase intention model for logistic services based on logistics technologies used, TPB and TRA, is proposed. The proposed model is shown in Fig. 2. The following hypotheses are developed base

Fig. 2.

Proposed model.

d on the premises discussed earlier:

H1

Robotics and automation enhance the performance of third-party (3 PL) logistics operations.

H2

The utilization of big data enhances the performance of 3 PL.

H3

The adoption of cloud computing contributes to the effectiveness of 3 PL.

H4

3 PL has an impact on the decisions of logistics service buyers.

H5

3 PL shapes individual perceptions of social norms.

H6

3 PL influences perceived behavior control.

H7

Subjective norms impact attitude.

H8

Subjective norms impact perceived behavior control.

H9

Attitude impacts word-of-mouth.

H10

Subjective norms impact word-of-mouth.

H11

Perceived behavior impacts word-of-mouth.

H12

Word-of-mouth influences purchase intentions.

4. Materials and methods

To examine the research hypothesis, data was gathered through a survey approach. The questionnaire was constructed with scales drawn from earlier research, using a five-point Likert scale to assess each item with “1” denoting “strongly disagree” and “5” denoting “strongly agree”. An exploratory cross-sectional study was conducted, utilizing Google Forms to administer a questionnaire to small and medium-sized manufacturing enterprises (SMEs) in India. The businesses were categorized into three types based on their investments and turnover: micro-businesses (INR 1 to INR 5 crores), small businesses (INR 10 to INR 50 crores), and medium businesses (INR 20 to INR 100 crores).

A database comprising SMEs dealing in manufacturing and processing was created from the Confederation of Indian Industry (CII) directory We randomly selected a wide spectrum of industries, including transportation, electronics, food, textiles, and machinery to obtain a representative sample (Table 2). Respondents were middle and senior managers who were familiar with the logistics and SC operations of their companies. Follow-up calls were made to improve the response rate. The questionnaire was shared with 1800 companies and a total of 344 complete responses were received. The total response rate was 19.1 percent. The responses were eliminated from further analysis using the following two response exclusion criteria: The first criterion was to remove responses with similar markings across all items. This demonstrates the gravity of the respondent's answers to the various questions. The second exclusion criterion used was an incomplete response. The inclusive criteria were also considered to include responses who opted for the 3 PL services in their internal or external logistics service management. t-tests for the early and late respondents were conducted to check non-response bias, and the results indicated no significant difference, indicating that non-response bias is not a problem in our study. Also, Harman's single-factor test was conducted to examine common method bias 35 % of the variance was explained by the first factor confirming that the common method bias was not an issue in this study.

Table 2.

Demographic information.

| Variable | Item | Frequency | Percentage (%) |

|---|---|---|---|

| Gender | Male | 224 | 65.1 % |

| Female | 120 | 34.9 % | |

| Firm size based on employee strength | Micro (1–4) | 120 | 34.9 % |

| Small (5–99) | 126 | 36.6 % | |

| Medium (100–499) | 98 | 28.5 % | |

| Establishment years | <5 | 122 | 35.5 % |

| >5 and <10 | 128 | 37.2 % | |

| >10 years | 94 | 27.3 % | |

| Industry type | transportation | 55 | 16.0 % |

| textile | 50 | 14.5 % | |

| electronics | 74 | 21.5 % | |

| Food | 62 | 18.0 % | |

| machinery | 44 | 12.8 % | |

| Other | 59 | 17.2 % |

Data analysis was performed using SPSS 28.0 and SmartPLS 4.0, with the latter chosen due to its graphical user interface (GUI) facilitating variance-based structural equation modeling (SEM) with a small dataset. PLS-SEM was preferred for its suitability with limited data, straightforward assumptions, and capability to model correlations between numerous variables. The study's data, being not normally distributed, eased the need for compelling the PLS model. Various data formats, including nominal, interval, or ratio data with small sample sizes, were utilized for analysis, as detailed in Table 2 which presents demographic statistics.

5. Results

5.1. Factor analysis

An exploratory factor analysis (EFA) was conducted to assess uni-dimensionality. The respondents' feedback data were subjected to the Kaiser-Meyer-Olkin (KMO) test to ascertain the degree of conformance to support further factor analysis. Generally, the KMO values between 0.8 and 1, indicate the suitability of the respondents' data for EFA. The conclusion of the adequacy of data was inferred since the sample was found adequate because of the valid KMO value of 0.882. Small significant level readings for Bartlett's test of sphericity were found to be less than 0.05, which indicates that factor analysis is appropriate for the data. The results indicated that each scale had high loading on the own construct it intended to measure and low loadings on the other constructs confirming uni-dimensionality. Cronbach's α was above 0.7 for each construct. Also, convergent and discriminant validity were estimated details shared in Table 3.

Table 3.

Reliability of constructs.

| Construct | Cronbach's alpha | Composite reliability (rho_a) | Average variance extracted (AVE) |

|---|---|---|---|

| 3 PL services | 0.86 | 0.863 | 0.788 |

| Attitude | 0.759 | 0.775 | 0.673 |

| Big data | 0.771 | 0.776 | 0.504 |

| Cloud computing | 0.889 | 0.899 | 0.89 |

| Perceived behavior control | 0.848 | 0.866 | 0.623 |

| Purchase Intention | 0.776 | 0.786 | 0.688 |

| Robotics & automation | 0.787 | 0.824 | 0.622 |

| Subjective norms | 0.89 | 0.891 | 0.881 |

| Word of mouth | 0.831 | 0.838 | 0.747 |

We used average variance extracted (AVE) values to assess discriminant validity. All the values were above the threshold value of 0.5. Further, all the values of R2 were above 0.4. Results are shared in Table 4.

Table 4.

R-square values of constructs.

| Constructs | R-square |

|---|---|

| 3 PL services | 0.499 |

| Attitude | 0.557 |

| Perceived behavior control | 0.410 |

| Purchase intention | 0.408 |

| Subjective norms | 0.428 |

| Word of mouth | 0.507 |

Results of the HTMT matrix are presented in Table 5, and all the values are below 0.85, indicating acceptable discriminant validity.

Table 5.

HTMT matrix.

| Constructs | 3 PL | Attitude | Big Data | Cloud Computing | Perceived Behavior Control | Purchase Intention | Robotics & Automation | Subjective Norms | Word of mouth |

|---|---|---|---|---|---|---|---|---|---|

| 3 PL | |||||||||

| Attitude | 0.812 | ||||||||

| Big data | 0.764 | 0.764 | |||||||

| Cloud computing | 0.646 | 0.582 | 0.638 | ||||||

| Perceived behavior control | 0.666 | 0.71 | 0.688 | 0.583 | |||||

| Purchase intention | 0.724 | 0.795 | 0.855 | 0.596 | 0.661 | ||||

| Robotics & automation | 0.693 | 0.722 | 0.789 | 0.541 | 0.688 | 0.759 | |||

| Subjective norms | 0.71 | 0.697 | 0.706 | 0.481 | 0.624 | 0.728 | 0.587 | ||

| Word of mouth | 0.74 | 0.765 | 0.768 | 0.596 | 0.712 | 0.78 | 0.719 | 0.659 |

Fig. 3 shows the structural model with standardized coefficients for the significant paths.

Fig. 3.

Structural equation model.

The results of the hypothesis tests are presented in Table 6. The results support our hypothesis, and all the hypotheses are statistically significant.

Table 6.

Hypothesis test results.

| Construct | Reg Coeff | T statistics (|O/STDEV|) | P values |

|---|---|---|---|

| 3 PL services - > Attitude | 0.562 | 9.849 | 0 |

| 3 PL services - > Perceived behavior control | 0.347 | 5.092 | 0 |

| 3 PL services - > Subjective norms | 0.654 | 17.891 | 0 |

| Attitude - > Word of mouth | 0.298 | 4.615 | 0 |

| Big Data -> 3 PL services | 0.249 | 4.619 | 0 |

| Cloud Computing -> 3 PL services | 0.336 | 7.063 | 0 |

| Perceived behavior control - > Word of mouth | 0.283 | 5.346 | 0 |

| Robotics & automation -> 3 PL services | 0.268 | 4.798 | 0 |

| Subjective norms - > Attitude | 0.246 | 4.059 | 0 |

| Subjective norms - > Perceived behavior control | 0.357 | 5.698 | 0 |

| Subjective norms - > word of mouth | 0.253 | 4.199 | 0 |

| Word of mouth - > Purchase intention | 0.639 | 18.195 | 0 |

6. Discussion

Industry 4.0 technologies have become indispensable for SMEs in accomplishing fast, reliable information and communication in their logistics management system. Logistics has become an essential component towards fulfilling the sustainable goals in the manufacturing SC. It has become critical for SMEs to opt for logistics services for their survival and competitiveness. The SMEs may realize the required sustainability through SC visibility and integrity by having the right goods in the right quantity and quality at the right time, in the right place, in the right condition, and at the right price (7R) [49]. The biggest challenge faced by SMEs is in adopting new technologies in their logistic management system because of the significant investment needs. The management also needs to undergo business process reengineering to adapt to a new style of working and thinking. Management must adopt a data-driven strategy that can transform the logistics service. Thus, SMEs can increase delivery speeds and accuracy by embracing hyper-automation and advanced technologies in their logistics operations.

A shipper typically seeks an LSP capable of efficiently managing logistics tasks, allowing the shipper to focus on core expertise. Shippers' preferences are evolving from basic logistics to advanced logistics services [4]. The conventional logistics system, driven by mechanization, automation, and logistics system management is transitioning to L4.0 promising dynamic changes and improvements in logistics management. Recognizing the substantial enhancement of the manufacturing SC sustainability through logistics, SMEs consider it a crucial element in the value chain. The global logistics landscape, marked by uncertainty is witnessing the adoption of disruptive technologies such as CPS, wireless networks, IoT, big data, and CC, which offer potential solutions to address changing consumer behaviors. A robust collaboration between 3 PL and CC services can yield significant cost-effective operational and relational benefits globally [33].

Technological advancements enable businesses to access and analyze previously inaccessible data, enhancing or creating new business processes. The BDA, IoT, and CC play a significant role in helping 3PLSP formulate operations management plans for diverse logistics activities. The use of disruptive technology facilitates real-time data gathering, improving driver safety, reducing operating costs, and assessing the environmental impact of the fleets. In sustainable manufacturing SCM, SMEs may opt to buy 3 PL services as the new technologies have made the services more effective and transparent through real-time information and communication. The study reveals the positive influence of advanced technologies on 3 PL. The relationship between logistic services and Industry 4.0 technologies like Big data, IoT, Autonomous robots, cloud computing etc. is found to be significant, this is also in line with the findings of an empirical study carried out in the Slovak Republic [50]. The various significant elements of cloud computing help in the logistics service support. It provides data-driven computing capabilities, huge cloud capability through client-supported platforms, pool-based resource utilization, flexibility and scalability for business needs, and optimized cloud computing ability [29]. Cloud computing also provides service security with enhanced reliability. It also possesses the ability to provide services to multiple service users, which provides value-added services to the logistic service provider.

While SMEs perceive logistics as a cost factor and a driver of sustainability and competitiveness, they face challenges in terms of IT readiness and capital to embrace disruptive technologies. The L4.0 is expected to decrease logistics costs, potentially providing a competitive advantage. 3 PL equipped with robots, automation, big data and CC are better positioned to handle advanced logistics services. The incorporation of disruptive technologies by 3PLSPs adopts attitudes towards the purchase of advanced logistics services, contributing to the development of SN and PBC. The present study revealed demographic factors related to SMEs' intention to adopt logistic services based on the adopted advanced technologies by 3PLSPs. Their purchase intentions are influenced in line with TPB due to the adoption of advanced technologies by 3PLSPs. The tendency to purchase logistics services under the influence of word-of-mouth is well supported by TPB by several psychological factors. The behaviour and users' emotions are influenced positively to opt for the logistics services that have a good value-addition on account of advanced technologies opted by 3PLSPs. The shipper is motivated because of the perceived ease of use and convenience space created by the advanced technologies. The positive impulse induced by subjective norms helps shippers to go for the outsourcing service to receive the benefit of advanced technologies imbibed in the logistics services.

The subjective norm in turn influences buying attitude and PBC. These collectively contribute to word-of-mouth promotion, ultimately influencing buying the advanced logistics services. These findings align with the simplified reasoned action for the 3 PL procurement model [15]. The finding of the present research validates that attitude, SN and PBC lead to word of mouth and finally towards participating in advanced logistics service purchasing.

6.1. Managerial implications

The present research has identified various factors influencing SMEs’ inclination to procure logistics services. In the era of I4.0, entrepreneurs seek advanced logistics services providers, such as 3 PL offering value-added services through Wi-Fi-enabled advanced technologies. The shipper and LSP service providers will gain an advantage from the present study in understanding the role of advanced technologies in logistics. An understanding of the influence of various advanced technologies on sustainable goals will motivate shippers and 3 PL service providers to grow their businesses. The present study also provides a good understanding of service buying behaviour that will help the 3PLSP to make their future strategies in line with the growing services. Buyers benefit when 3 PL service providers employ disruptive technologies like robotics and automation, big data and CC with Wi-Fi capabilities to accomplish sustainability in the manufacturing SC. The rise in buying intention may depend upon factors like Attitude, SN, and word-of-mouth leading to purchase intention. The stakeholders in the manufacturing SC can accomplish these various factors while delivering the logistics services.

7. Limitations and future research

The current analysis is focused only on manufacturing SMEs in India. When compared globally, employee knowledge, training, and competence differ from country to country. Workers in the dominant sector have a high degree of skill since SMEs have more IT-enabled manufacturing industries. As a result, with certain exceptions, some of the current findings may be generalized. The present model may be developed for green logistics procurement and green logistics-related behavior aspects may be investigated. The logistics of buying behavior may also be studied in different sectors of SMEs. The advanced technologies used in the logistics service also depend upon the service levels of service providers hence future studies may measure the effect of advanced technologies on service quality in logistics services. Thus, future research may take empirical investigation in assessing the service qualities provided by CC, IoT service providers.

8. Conclusions

Logistics activities have been identified as an important strategic economic component for SMEs. SMEs may attempt various strategic moves to compete with major firms by implementing technology, infrastructure, cutting-edge machinery or equipment, staff knowledge, training, soft skills, and hard skills. However, SMEs struggle to compete with giant corporations. The present study provides the logistic procurements insight for the manufacturing SC to become sustainable. Based on the obtained results, TPB theory can help in understanding employee behavior for the purchase of logistics. The developed model can also help practicing logistics managers understand the procurement mechanism.

The study provides the theoretical base for using TPB in understanding shippers and 3PLS providers' behaviour while using advanced technologies in logistic services. The role of subjective norms on attitudes, and perceived behavioral controls, which lead towards word-of-mouth towards the purchase intentions. As per the present study, SMEs can gain a competitive advantage by opting for a 3PLSP. attitude plays a vital role in buying advanced logistics services. The 3 PL service providers help in developing the attitude towards the service buying motivation, it also influences the SN. SN helps in developing the logistics service buying behavior. It also plays a significant norm in motivating and guiding towards the service buying attitude. The attitude of SN and PBC leads towards word-of-mouth that leads to purchase intention of buying advanced logistics services.

Funding

This research was funded by the Deanship of Scientific Research, King Khalid University, Kingdom of Saudi Arabia, and the grant number is RGP.2/476/44.

Institutional review board statement

Not Applicable.

Informed consent statement

Not Applicable.

Data availability statement

Data will be made available to researchers at their request.

CRediT authorship contribution statement

Karishma M. Qureshi: Writing – original draft, Methodology, Data curation, Conceptualization. Bhavesh G. Mewada: Writing – review & editing, Visualization, Data curation, Conceptualization. Sumeet Kaur: Validation, Software, Investigation, Formal analysis. Adil Khan: Supervision, Resources, Project administration, Methodology. Muhammad Musa Al-Qahtani: Writing – review & editing, Visualization, Validation, Supervision. Mohamed Rafik Noor Mohamed Qureshi: Writing – review & editing, Writing – original draft, Visualization, Validation, Supervision, Software, Methodology, Investigation, Formal analysis, Data curation, Conceptualization.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University, Saudi Arabia, for funding this work through the Large Research Group Program under Grant No: RGP 2/476/44.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.heliyon.2024.e30661.

Contributor Information

Karishma M. Qureshi, Email: kariq18@gmail.com.

Sumeet Kaur, Email: skaur@fsm.ac.in.

Adil Khan, Email: adilamankhan@gmail.com.

Muhammad Musa Al-Qahtani, Email: m.alqahtani@kku.edu.sa.

Appendix A. Supplementary data

The following is the Supplementary data to this article:

References

- 1.Yaqiong L., Lei T., Lee C.K., Xin T. 2018 IEEE International Conference on Service Operations and Logistics, and Informatics (SOLI) IEEE; 2018. IoT based Omni-channel logistics service in industry 4.0; pp. 240–243. [DOI] [Google Scholar]

- 2.Marinagi C., Reklitis P., Trivellas P., Sakas D. The impact of industry 4.0 technologies on key performance indicators for a resilient supply chain 4.0. Sustainability. 2023;15:5185. doi: 10.3390/su15065185. [DOI] [Google Scholar]

- 3.Qureshi K.M., Mewada B.G., Alghamdi S.Y., Almakayeel N., Qureshi M.R.N., Mansour M. Accomplishing sustainability in manufacturing system for small and medium-sized enterprises (SMEs) through lean implementation. Sustainability. 2022;14:9732. doi: 10.3390/su14159732. [DOI] [Google Scholar]

- 4.Andersson D., Norrman A. Procurement of logistics services—a minutes work or a multi-year Project? Eur. J. Purch. Supply Manag. 2002;8:3–14. doi: 10.1016/S0969-7012(01)00018-1. [DOI] [Google Scholar]

- 5.Demirdöğen S. Digital transition process in logistics. DATA, Inf. Knowl. Manag. 2020;491 [Google Scholar]

- 6.Zhong R.Y., Newman S.T., Huang G.Q., Lan S. Big data for supply chain management in the service and manufacturing sectors: challenges, opportunities, and future perspectives. Comput. Ind. Eng. 2016;101:572–591. doi: 10.1016/j.cie.2016.07.013. [DOI] [Google Scholar]

- 7.Borgi T., Zoghlami N., Abed M. 2017 International Conference on Advanced Systems and Electric Technologies (IC_ASET) IEEE; 2017. Big data for transport and logistics: a review; pp. 44–49. [DOI] [Google Scholar]

- 8.Wang G., Gunasekaran A., Ngai E.W.T., Papadopoulos T. Big data analytics in logistics and supply chain management: certain investigations for research and applications. Int. J. Prod. Econ. 2016;176:98–110. doi: 10.1016/j.ijpe.2016.03.014. [DOI] [Google Scholar]

- 9.von Stietencron M., Hribernik K., Lepenioti K., Bousdekis A., Lewandowski M., Apostolou D., Mentzas G. Towards logistics 4.0: an edge-cloud software framework for big data analytics in logistics processes. Int. J. Prod. Res. 2022;60:5994–6012. doi: 10.1080/00207543.2021.1977408. [DOI] [Google Scholar]

- 10.Lee K.L., Romzi P.N., Hanaysha J.R., Alzoubi H.M., Alshurideh M. Investigating the impact of benefits and challenges of IOT adoption on supply chain performance and organizational performance: an empirical study in Malaysia. Uncertain Supply Chain Manag. 2022;10:537–550. doi: 10.5267/j.uscm.2021.11.009. [DOI] [Google Scholar]

- 11.Kirch M., Poenicke O., Richter K. RFID in logistics and production –applications, research and visions for smart logistics zones. Procedia Eng. 2017;178:526–533. doi: 10.1016/j.proeng.2017.01.101. [DOI] [Google Scholar]

- 12.Echelmeyer W., Kirchheim A., Wellbrock E. 2008 IEEE International Conference on Automation and Logistics. IEEE; 2008. Robotics-logistics: challenges for automation of logistic processes; pp. 2099–2103. [DOI] [Google Scholar]

- 13.Elkhairi A., Fedouaki F., El Alami S. Barriers and critical success factors for implementing lean manufacturing in SMEs. IFAC-PapersOnLine. 2019;52:565–570. doi: 10.1016/j.ifacol.2019.11.303. [DOI] [Google Scholar]

- 14.Caldera H.T.S., Desha C., Dawes L. Evaluating the enablers and barriers for successful implementation of sustainable business practice in ‘lean’ SMEs. J. Clean. Prod. 2019;218:575–590. doi: 10.1016/j.jclepro.2019.01.239. [DOI] [Google Scholar]

- 15.Merminod N., Large R.O., Paché G. Procurement of advanced logistics services: proposition of a reasoned action model of individual buying behavior. Supply Chain Forum Int. J. 2019;20:169–184. doi: 10.1080/16258312.2018.1555635. [DOI] [Google Scholar]

- 16.Tran-Dang H., Krommenacker N., Charpentier P., Kim D.-S. The internet of Things for logistics: perspectives, application review, and challenges. IETE Tech. Rev. 2022;39:93–121. doi: 10.1080/02564602.2020.1827308. [DOI] [Google Scholar]

- 17.Chung S.-H. Applications of smart technologies in logistics and transport: a review. Transport. Res. Part E Logist. Transp. Rev. 2021;153 doi: 10.1016/j.tre.2021.102455. [DOI] [Google Scholar]

- 18.Issaoui Y., Khiat A., Haricha K., Bahnasse A., Ouajji H. An advanced system to enhance and optimize delivery operations in a smart logistics environment. IEEE Access. 2022;10:6175–6193. doi: 10.1109/ACCESS.2022.3141311. [DOI] [Google Scholar]

- 19.Capua M. Di, Ciaramella A., De Prisco A. Machine learning and computer vision for the automation of processes in advanced logistics: the integrated logistic platform (ILP) 4.0. Procedia Comput. Sci. 2023;217:326–338. doi: 10.1016/j.procs.2022.12.228. [DOI] [Google Scholar]

- 20.Lagorio A., Zenezini G., Mangano G., Pinto R. A systematic literature review of innovative technologies adopted in logistics management. Int. J. Logist. Res. Appl. 2022;25:1043–1066. doi: 10.1080/13675567.2020.1850661. [DOI] [Google Scholar]

- 21.Sullivan M., Simpson W., Li W. The Digital Transformation of Logistics. Wiley; 2021. The role of robotic process automation (RPA) in logistics; pp. 61–78. [DOI] [Google Scholar]

- 22.Qureshi M.N., Kumar D., Kumar P. An integrated model to identify and classify the key criteria and their role in the assessment of 3PL services providers. Asia pacific. J. Mark. Logist. 2008;20 doi: 10.1108/13555850810864579. [DOI] [Google Scholar]

- 23.Atzeni G., Vignali G., Tebaldi L., Bottani E. A bibliometric analysis on collaborative robots in logistics 4.0 environments. Procedia Comput. Sci. 2021;180:686–695. doi: 10.1016/j.procs.2021.01.291. [DOI] [Google Scholar]

- 24.Bernardo R., Sousa J.M.C., Gonçalves P.J.S. Survey on robotic systems for internal logistics. J. Manuf. Syst. 2022;65:339–350. doi: 10.1016/j.jmsy.2022.09.014. [DOI] [Google Scholar]

- 25.Kantar L. Finance and cost management in the process of logistics. 2022. 215–234. [DOI]

- 26.Hopkins J., Hawking P. Big data analytics and IoT in logistics: a case study. Int. J. Logist. Manag. 2018;29:575–591. doi: 10.1108/IJLM-05-2017-0109. [DOI] [Google Scholar]

- 27.Ben Ayed A., Ben Halima M., Alimi A.M. 2015 4th International Conference on Advanced Logistics and Transport (ICALT) IEEE; 2015. Big data analytics for logistics and transportation; pp. 311–316. [DOI] [Google Scholar]

- 28.Ferreira B., Reis J. A systematic literature review on the application of automation in logistics. Logistics. 2023;7:80. doi: 10.3390/logistics7040080. [DOI] [Google Scholar]

- 29.Gantzia D., Sklatinioti M.E. 2014. Cloud Computing in the 3PL Industry. A Profound Insight into the Benefits & Challenges of Cloud-Based Services: A Two Fold Approach. [Google Scholar]

- 30.Panayides P.M., So M. The impact of integrated logistics relationships on third-party logistics service quality and performance. Marit. Econ. Logist. 2005;7:36–55. doi: 10.1057/palgrave.mel.9100123. [DOI] [Google Scholar]

- 31.Qureshi M.N., Kumar P., Kumar D. Selection of 3PL service providers: a combined approach of ahp and graph theory. Int. J. Serv. Technol. Manag. 2009;12:35–60. doi: 10.1504/IJSTM.2009.025035. [DOI] [Google Scholar]

- 32.Qureshi M.N., Kumar D., Kumar P. IEEM 2007: 2007. IEEE International Conference on Industrial Engineering and Engineering Management; 2007. Selection of potential 3PL services providers using TOPSIS with interval data; pp. 1512–1516. [DOI] [Google Scholar]

- 33.Subramanian N., Abdulrahman M.D. Logistics and cloud computing service providers' cooperation: a resilience perspective. Prod. Plann. Control. 2017;28:919–928. doi: 10.1080/09537287.2017.1336793. [DOI] [Google Scholar]

- 34.Ajzen I. The theory of planned behavior: frequently asked questions. Hum. Behav. Emerg. Technol. 2020;2:314–324. doi: 10.1002/hbe2.195. [DOI] [Google Scholar]

- 35.Thongkruer P., Wanarat S. The relationship between air travel service quality and factors of theory of planned behavior: evidence from low-cost airlines in Thailand. Sustainability. 2023;15:8839. doi: 10.3390/su15118839. [DOI] [Google Scholar]

- 36.Mak T.M.W., Yu I.K.M., Tsang D.C.W., Hsu S.C., Poon C.S. Promoting food waste recycling in the commercial and industrial sector by extending the theory of planned behaviour: a Hong Kong case study. J. Clean. Prod. 2018;204:1034–1043. doi: 10.1016/j.jclepro.2018.09.049. [DOI] [Google Scholar]

- 37.Mak T.M.W., Yu I.K.M., Wang L., Hsu S.-C., Tsang D.C.W., Li C.N., Yeung T.L.Y., Zhang R., Poon C.S. Extended theory of planned behaviour for promoting construction waste recycling in Hong Kong. Waste Manag. 2019;83:161–170. doi: 10.1016/j.wasman.2018.11.016. [DOI] [PubMed] [Google Scholar]

- 38.Arslan M., Şar S. Examination of environmentally friendly “green” logistics behavior of managers in the pharmaceutical sector using the theory of planned behavior. Res. Soc. Adm. Pharm. 2018;14:1007–1014. doi: 10.1016/j.sapharm.2017.12.002. [DOI] [PubMed] [Google Scholar]

- 39.Pan J.Y., Truong D. Passengers' intentions to use low-cost carriers: an extended theory of planned behavior model. J. Air Transp. Manag. 2018;69:38–48. doi: 10.1016/j.jairtraman.2018.01.006. [DOI] [Google Scholar]

- 40.Lai W.-T., Chen C.-F. Behavioral intentions of public transit passengers—the roles of service quality, perceived value, satisfaction and involvement. Transport Pol. 2011;18:318–325. doi: 10.1016/j.tranpol.2010.09.003. [DOI] [Google Scholar]

- 41.Wang P. Exploring the influence of electronic word-of-mouth on tourists' visit intention. J. Syst. Inf. Technol. 2015;17:381–395. doi: 10.1108/JSIT-04-2015-0027. [DOI] [Google Scholar]

- 42.Fessler A., Haustein S., Thorhauge M. Drivers and barriers in adopting a crowdshipping service: a mixed-method approach based on an extended theory of planned behaviour. Travel Behav. Soc. 2024;35 doi: 10.1016/j.tbs.2024.100747. [DOI] [Google Scholar]

- 43.Suryanto A., Nurdin N., Andriansyah A., Rahayu N.S., Irawati E. Predicting supply chain management of E-waste recycling behavior using an extended theory of planned behavior model. Uncertain Supply Chain Manag. 2023;11:1001–1008. doi: 10.5267/j.uscm.2023.4.022. [DOI] [Google Scholar]

- 44.Ajzen I., Fishbein M. Attitudes and the attitude-behavior relation: reasoned and automatic processes. Eur. Rev. Soc. Psychol. 2000;11:1–33. doi: 10.1080/14792779943000116. [DOI] [Google Scholar]

- 45.Dixit S., Badgaiyan A.J. Towards improved understanding of reverse logistics – examining mediating role of return intention. Resour. Conserv. Recycl. 2016;107:115–128. doi: 10.1016/j.resconrec.2015.11.021. [DOI] [Google Scholar]

- 46.Qureshi M.N., Kumar P., Kumar D. 3PL evaluation and selection under a fuzzy environment: a case study. ICFAI J. Supply Chain Manag. 2008;5:38–53. [Google Scholar]

- 47.Boshoff C.A. Psychometric assessment of ES-QUAL: a scale to measure electronic service quality. J. Electron. Commer. Res. 2007;8:101. [Google Scholar]

- 48.Qureshi K.M., Mewada B.G., Kaur S., Qureshi M.R.N.M. Assessing lean 4.0 for industry 4.0 readiness using PLS-SEM towards sustainable manufacturing supply chain. Sustainability. 2023;15:3950. doi: 10.3390/su15053950. [DOI] [Google Scholar]

- 49.Barreto L., Amaral A., Pereira T. Industry 4.0 implications in logistics: an overview. Procedia Manuf. 2017;13:1245–1252. doi: 10.1016/j.promfg.2017.09.045. [DOI] [Google Scholar]

- 50.Richnák P. Current trend of industry 4.0 in logistics and transformation of logistics processes using digital technologies: an empirical study in the Slovak republic. Logistics. 2022;6:79. doi: 10.3390/logistics6040079. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Data will be made available to researchers at their request.