Abstract

Background:

This study aimed to compare the effect of heat treatment on the cyclic fatigue resistance of three different nickel–titanium rotary file systems: TruNatomy, HyFlex CM, and NeoEndo flex in simulated curved canals at two different radii of curvatures.

Materials and Methods:

A total of 60 NiTi rotary files of three types were used, and the samples were divided into three groups TruNatomy, HyFlex CM, and NeoEndo flex. All the instruments were subjected to cyclic fatigue testing using a stainless steel custom-made canal model with a 60° angle of curvature and two radii of curvature 5 mm and 3 mm; the number of cycles to fracture and length of the fractured segment was measured. The separated instruments were subjected to fractographic analysis under scanning electron microscope.

Results:

The number of cycles to failure to fracture a file at a 3 mm radius of curvature is significantly less as compared to a 5 mm radius of curvature (HCM > TRN > NE).

Conclusion:

Within the limitation of the present study, there was a positive correlation between the radius of curvature and fatigue life of NiTi files.

Keywords: Cyclic fatigue, fractographic analysis, NiTi files, radius of curvature, thermomechanical treatment

INTRODUCTION

The successful outcome of the endodontic treatment depends on the appropriate cleaning and shaping of the root canal system. The shape and degree of root canal curvature are significant obstacles that impose significant limitations on root canal debridement.[1] The rigidity of stainless steel files led to the development of NiTi instruments that impart extreme flexibility when instrumenting the curved canals, thus preventing the potential risk of file separation and canal transportation.[2]

Despite immense flexibility and other benefits, NiTi rotary instruments resulted in unpredictable separation into the root canal during clinical use and their fracture during use is still a major concern. Fracture may occur through either torsional or flexural cyclic fatigue.[3] In flexural cyclic fatigue, a sudden fracture of the instrument occurs after a certain number of free rotations in curved canals. This cyclic bending (compression on the inner curve) and unbending (elongation on the outer curve) of the file may cause stress concentration that forms microcracks within the instrument surface, thus resulting in breakage. Fracture due to torsion occurs when the instrument’s tip or any part engages within the canal while the shaft continues to rotate.[3,4]

Among the various factors that contribute to the file separation, the degree of curvature and radius of the canal are considered major factors that affect the cyclic fatigue resistance of the NiTi rotary instruments.[5] According to Pruett et al., in 1997, the radius of curvature represents how abruptly or severely a specific angle of curvature occurs as the canal deviates from a straight line. The canal deviates abruptly when the radius of curvature is smaller. The degree and radius of curvature are two independent parameters that inferred canals with different radii of curvature produce abrupt curves with the same angle of curvature.[3,5]

The resistance to cyclic fatigue is one of the important characteristic properties of any rotary NiTi instrument. Therefore, manufacturers are trying to incorporate different processing methods to enhance the fracture resistance of these NiTi files.[6,7] These include meticulous selection of raw material, instrument diameter and design, electropolishing, surface modifications, kinematics, and thermomechanical processing. Thermomechanical processing is a complicated process, which integrates the work hardening and heat treatment into a single process.[4,6]

TruNatomy instrument (Dentsply Sirona) has been recently introduced as a novel type of special heat-treated NiTi instrument manufactured from 0.8 mm NiTi wire instead of 1.2 mm, from which most of the NiTi files are made. The manufacturers claimed that TruNatomy is extremely flexible and has reduced the risk of file separation due to increased resistance to cyclic fatigue.[8,9] HyFlex CM (Whaledent Coltene) instruments are made from distinctive NiTi wire, namely, controlled memory (CM) wire introduced in 2010, which has been subjected to proprietary thermomechanical processing.[10] NeoEndo Flex file system (Orikam Healthcare India) utilizes a proprietary gold thermal treatment which gives it unique flexibility and superior cutting efficiency.[11,12]

MATERIALS AND METHODS

A total of 60 NiTi rotary files of three types were used, and the samples were divided into three groups (n = 20). Then, each group is further subdivided into two groups (n = 10) according to the radius of curvature (5 mm and 3 mm). All the instruments were the same in size (25 mm length, size 25, and taper 0.04% except TruNatomy, in which prime size 26/0.04% is used). Each instrument was subjected to dynamic cyclic fatigue testing in simulated stainless steel canals with a 60° angle and two radii of curvature 5 and 3 mm.[13,14] The instruments were examined under a stereomicroscope at ×10 magnification for the presence of any defect before cyclic fatigue testing.[5]

Fabrication of dynamic cyclic fatigue testing apparatus

Custom-made simulated canals were fabricated on hardened stainless steel block measuring 12 × 6 × 3, with a 60° angle of curvature, 5 and 3 mm radius of curvature, and length of 16 mm. These canals were fabricated according to the recommendations given by Pruett et al.[3] The drawings of the canal measurement were manipulated using Autocad software with estimated taper and size. The curvature of each canal is at the junction of the apical and middle third.[5] The length of the curved segment for a 5 mm radius is 6 mm, and for a 3 mm radius, the length is approximately 3 mm, as suggested by Fiserova et al.[15] The three-dimensional (3D) modeling of the design was done on Solid Box software, and graphite electrode was made by milling on computer numeric control machining (70DMG). The electrode was then constructed on a stainless-steel block, and artificial canals were made with precision on electric discharging machining. The canals were machined according to the instrument size and taper plus 0.2 mm depth, thus allowing free rotation and preventing the binding of the file.[16] To make it dynamic, a DC motor was used, to reproduce linear pecking motion along with a rotary to simulate an ideal clinical situation.[17] The circular shaft of the DC motor was connected to a circular rotating element which is offset by 2 mm from its center. The guideways allow the rotating element to slide resulting in linear movement of the slot guide (translator). The translator is further connected with the endodontic motor piece head holder to align each instrument in a forward and backward motion. The translator and endodontic head holder were supported by a support structure. The power supply to the motor is driven from a 3-volt battery cell, secured in a customized cell holder, which allows a precise and controlled pecking motion of 3 mm up and 3 mm down to simulate real clinical situation. It works on the principle of the Scotch Yoke mechanism, also called the slotted link mechanism, which converts rotary motion into linear motion.[18]

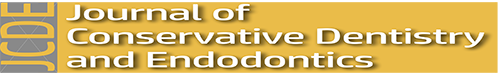

A custom-made movable holder was designed, for holding of endodontic motor. The head of the endodontic motor was attached to the motor piece holder to translate linear pecking motion to the endodontic motor. The stainless block with simulated canals is connected to the metal frame by a slider that allows free movement of the block from one canal (5 mm radius) to another canal (3 mm radius) during testing, and the block is then secured with a screw. The complete assembly of the dynamic cyclic fatigue testing apparatus is shown in Figure 1a.

Figure 1.

(a) Complete dynamic cyclic fatigue testing device (b) NiTi rotary file in simulated curved canal (c) covered with transparent acrylic plate (d) fractured NiTi file

Procedure of cyclic fatigue testing

The computer-controlled testing bock with simulated canals, mounted to the metallic framework measuring 25 cm × 20 cm × 4 cm. The endodontic motor was secured into the mobile custom-made holder and is connected to the DC motor through an endodontic motor piece holder to allow 3D alignment and precise positioning of each instrument during testing.[19] A lubricating oil was coated to the canals before each test to prevent heat generation and friction between the NiTi file and the stainless steel block. Each tested file was attached to the endodontic motor and allowed to rotate with spontaneous pecking movement until fracture to simulate the ideal clinical situation [Figure 1a-c]. The artificial canals were covered with a customized transparent acrylic plate to allow visualization of the rotary file and also prevent the instrument from slipping out. The speed and torque of each instrument were adjusted according to the manufacturer’s recommendations.

A 1/100 s digital stopwatch was used to record timing and stopped once the fracture was detected visually/audibly. The acrylic plate was removed to retrieve the separated fragment, and the length was measured using a precision microdigital caliper [Figure 1d]. The number of cycles to fracture (NCF) was calculated by:

NCF = Time to fracture in min × number of rotations per min

The separated instruments were wiped with a piece of gauze soaked with ethyl alcohol to remove entrapped debris between the flutes and traces of lubricating oil before examination under a scanning electron microscope.[15]

Statistical analysis

Continuous variables were expressed as mean ± standard deviation (SD) analysis of variance, and Student’s independent t-test was employed for comparison of various parameters. P ≤ 0.05 was considered statistically significant.

RESULTS

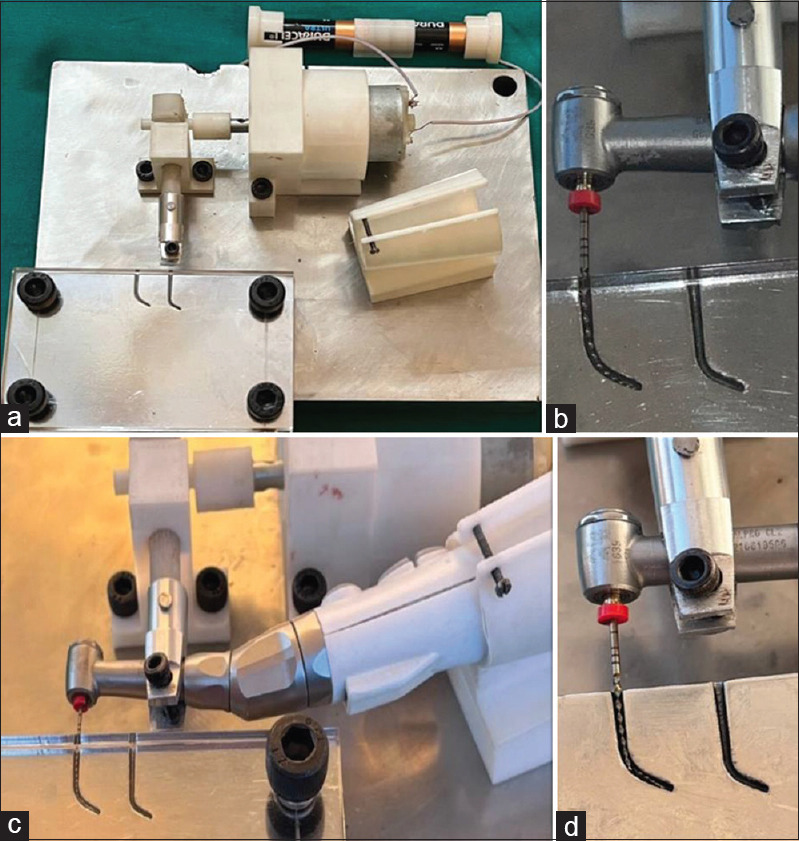

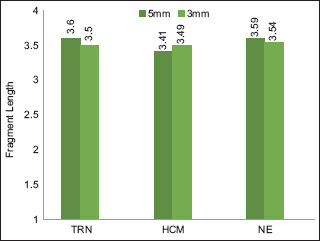

The mean and SD of the NCF and fractured segment (FL) of the tested groups are summarized in Tables 1 and 2 and represented in the form of Graphs 1 and 2.

Table 1.

Student’s independent t-test and analysis of variance of number of cycles to failure

| Groups (n=10) | 5 mm radii | 3 mm radii | ||||

|---|---|---|---|---|---|---|

|

|

|

|||||

| Mean±SD | 95% CI | P | Mean±SD | 95% CI | P | |

| Trunatomy | 2885.0±494.7 | 2531.1–3238.9 | <0.001 | 1684.5±313.4 | 1460.3–1908.7 | <0.001* |

| Hyflex CM | 8578.0±590.0 | 8155.9–9000.1 | <0.001 | 3836.5±447.4 | 3516.4–4156.6 | <0.001* |

| Neoendo flex | 1436.3±138.0 | 1337.6–1535.2 | <0.001 | 731.7±132.2 | 637.1–826.3 | <0.001* |

*Statistically significant difference (P<0.05). CI: Confidence interval, SD: Standard deviation

Table 2.

Student’s independent t-test and analysis of variance of fragment length

| Groups (n=10) | 5 mm radii | 3 mm radii | ||||

|---|---|---|---|---|---|---|

|

|

|

|||||

| Mean±SD | 95% CI | P | Mean±SD | 95% CI | P | |

| Trunatomy | 3.60±0.189 | 3.47–3.73 | 0.189 | 3.49±0.240 | 3.33–3.67 | 0.358 |

| Hyflex CM | 3.49±0.202 | 3.35–3.63 | 0.202 | 3.41±0.202 | 3.27–3.55 | 0.188 |

| Neoendo flex | 3.59±0.166 | 3.47–3.71 | 0.905 | 3.54±0.201 | 3.40–3.68 | 0.681 |

Statistically no significant difference (P>0.05). CI: Confidence interval, SD: Standard deviation

Graph 1.

Number of cycles to failure of three file systems

Graph 2.

Fragment length of three file system

The number of cycles to failure to fracture a file at a 3 mm radius of curvature is significantly less as compared to a 5 mm radius of curvature (HCM > TRN > NE). However, there was statistically no significant difference in mean ± SD of fragment length at 5 and 3 mm radius of curvature P > 0.05.

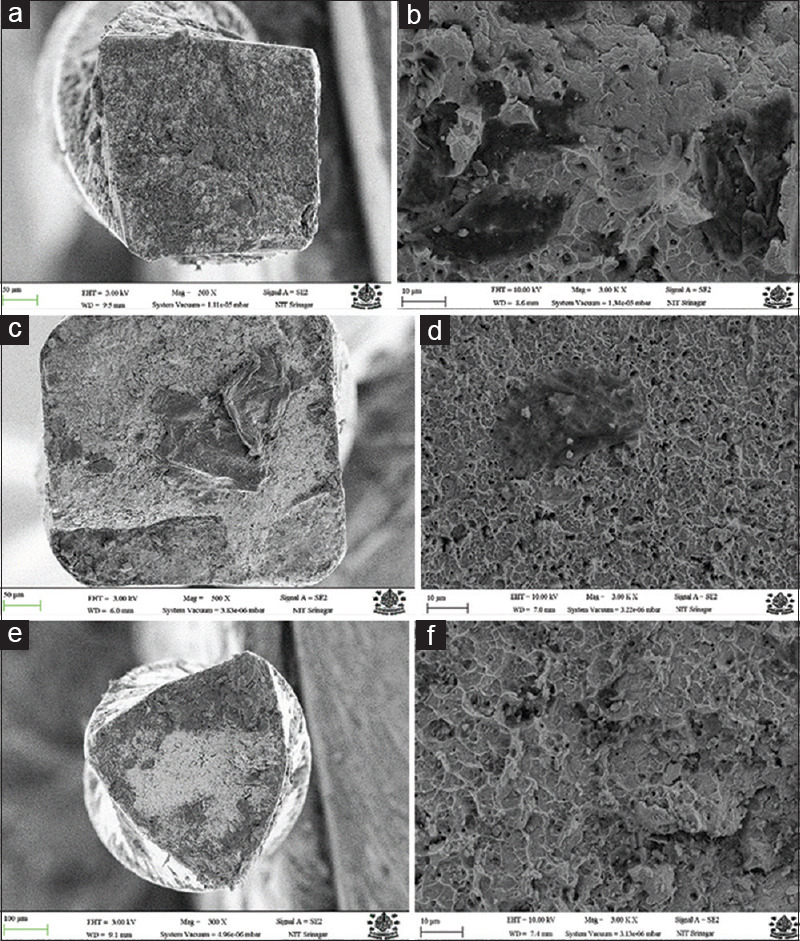

Field emission-scanning electron microscopy reveals variation in the cross-sectional design of three fractured NiTi rotary files, TruNatomy (off-centered square), HyFlex CM (square), and NeoEndo flex (triangular); the characterization of the fractured surface of these NiTi rotary files determines the area of dimples or microvoids, multiple cracks, and craters that are confirmatory that separation occurs by true cyclic failure [Figure 2a-f].

Figure 2.

Field emission scanning electron microscopy images of representative samples show the fractured surface of NiTi files fractured by cyclic failure. Low magnification × 500 (a-TRN, c-HCM, e-NE) with numerous dimples, microvoids, fatigue striations, and fracture lines extending on different planes, plastic deformation in addition to crack propagation at the smooth area. Moreover, high magnification × 3000 (TRN-b, HCM-d, NE-f) the surface details were clearer, including irregular morphology, an extensive rough dimpled surface, microporosities, microvoids, fatigue striations, and multiple microcracks cracks

DISCUSSION

The inadvertent fracture of NiTi rotary instruments still remains a major concern during root canal preparation.[20] Terauchi 2016 claims the incidence of file separation to be in a wide range of 0.4%–23%.[21] It has been reported in literature that NiTi rotary instruments fracture up to seven times more likely than stainless steel files.[22,23] The presence of a fragment of the separated instrument in the canal does not affect the outcome per se; it is the presence of bacteria and the inability to clean the canal completely beyond the retained fragment that may lead to a poor prognosis.[24] These iatrogenic errors can complicate treatment and are responsible for the failure of root canal treatment.[25]

Most of the NiTi rotary files are fractured by cyclic failure.[3,4] Cheung et al., 2005, reported that 93% of instrument separation was due to cyclic fatigue and 7% of fractures were due to torsion.[26] Kaval et al., in 2016, reported that the incidence of file separation by cyclic fatigue is 65%–70% and 25%–30%. By torsional fatigue,[27] cyclic fatigue testing can be of two types static and dynamic. In static type, the file is operated at a constant length, without moving it in the axial direction and concentration of the stress on a specific area of the shaft of the instrument, whereas in dynamic type, the file is operated using a back-and-forth axial movement to simulate the ideal clinical situation, and there is the distribution of stress along the length of the instrument.[28]

Currently, there is no specification or international standardization according to the American National Standards Institute/American Dental Association to test the cyclic fatigue resistance of NiTi rotary instruments. Therefore, over the period, several testing devices using different methods for fabrication (designs and materials) have been adopted to investigate the in vitro cyclic fatigue resistance of NiTi rotary instruments. Grande et al., in 2006, used customized canals on stainless steel blocks according to instrument size and taper that would allow all of the instruments to follow canal curvature. The estimated angle, radius, and center of maximum curvature generate precise trajectory or path of NiTi rotary files in custom-made curved canals, thus allowing comparison of different instruments. This is the most accurate method of testing cyclic fatigue resistance, because all these variables are crucial and difficult to control, for this reason, standardization of these experimental variables was mandatory.[29,30] A synthetic oil was used for lubrication as recommended by Nguyen et al., in 2014, to minimize the friction between the rotating files and the stainless steel canal wall and prevent temperature elevation.[31]

The results of the present study showed that mean and SD of NCF a file, P < 0.001 at 3 mm radius of curvature for TruNatomy (1684.5 ± 313.4), HyFlex CM (3836.5 ± 447.4), and NeoEndo Flex (731.7 ± 132.2) are significantly less as compared to fracture a file at 5 mm radius of curvature P < 0.001 for TruNatomy (2885.0 ± 494.7), HyFlex CM (8578.0 ± 590.0), and NeoEndo Flex (1436.3 ± 138.0). This is in agreement with the results of previous studies (Pruett et al. 1997, Haikel et al. 1999), i.e., fatigue life of NiTi rotary instruments is significantly influenced by the radius of curvature; hence, NCF significantly decreases as the radius of curvature decreases.[3,32] There is maximum stress concentration and generation of more torsional forces at 3 mm radius of curvature, and this was confirmed by fractographic analysis under scanning electron microscopy, NCF at 3 mm < NCF at 5 mm. HyFlex CM shows increased resistance to cyclic fatigue than TruNatomy and NeoEndo flex. HyFlex CM possesses a unique manufacturing process that imparts extreme flexibility to the instrument and also controls materials memory.[33,34,35] Alshwaimi found that NiTi instruments fabricated from CM technology show 500% fatigue resistance than from materials made from M-wire.[33] Uslu et al. reported that HyFlex CM and VWD.ROTATE exhibited the highest cyclic fatigue resistance in simulated curved canals, followed by 2 Shape and TruNatomy. These findings are similar to the findings of our study.[36] The decreased cyclic resistance of the TruNatomy file system is probably attributed to its larger tip diameter, and crystallographic rearrangement during phase transformation, therefore, exhibits a longer and higher austenite phase as compared to other files.[37,38] The cause of this decreased fatigue resistance of NeoEndo Flex could be attributed to the design of these files, no radial land with sharp cutting edges and triangular cross-section that may hasten the screwing effect hence early breakage.[39,40] The cross-sectional design influences the fatigue resistance of NiTi rotary file as it determines the bulk of metal mass, thus making the file stiffer. Previous studies reveal that triangular cross-sections have less metal mass and have increased fatigue resistance than square cross-sectional design, which are in disagreement with the results of the present study.[41,42] There was no significant difference in the fragment length of TruNatomy, HyFlex CM, and NeoEndo flex at 5 and 3 mm radius of curvature. For each file, the length of the FL was measured using a precision digital caliper. This observation revealed that the tested instruments were correctly positioned in canal curvature and demonstrated that the similar stresses were induced during cyclic fatigue testing.[39,43] Therefore, the point of maximum stress concentration was located 3.5–4 mm from the tip of the each NiTi rotary file in the apical one-third of the curved root canal.[44]

The fractographic analysis was done under a scanning electron microscope to confirm the fractured surface characteristics, the origin of the crack, the inherent flaw in the material, the nature of stresses, and the failure mechanism. Fractures are generally, classified into ductile and brittle fractures. Ductile fractures (dimpling) are seen in cyclic failures.[45,46,47]

The main drawback of the present study was the use of metal, causing friction which can increase the temperature of the file, causing a change in the metal phase that may not occur in clinical conditions. Yao et al. stated that the extracted teeth simulate the ideal clinical scenario, but standardization of curvature for testing is impossible as it will result in the straightening of the canal. Therefore, extracted teeth were not optimal for testing the cyclic fatigue resistance for NiTi rotary instruments.[48] The tests often use oil as a lubricant to decrease friction, but to make it similar to clinical conditions, sodium hypochlorite which is commonly used in the cleaning and shaping process within the canal, should be used in the experiments. Furthermore, the procedure of fabricating the testing apparatus was more expensive and time-consuming. For future, a resin-based material or dentin substitute could be a suitable substitute to simulate clinical conditions as it may provide less resistance to cutting than stainless steel and debris may form similar to the clinical situation. The effect of sodium hypochlorite and temperature on cyclic fatigue resistance needs to be investigated because these have an important role in the cyclic fatigue resistance of NiTi rotary files under the clinical scenario.

CONCLUSION

Within the limitation of the present study, there was a positive correlation between the radius of curvature and fatigue life of NiTi files (a decrease in radius of curvature significantly decreases the cyclic fatigue resistance). Regardless of the file system used, separation is evident in curved canals; therefore, the clinician needs to have adequate knowledge about the complexity of root canal curvatures for the outcome of root canal success. Further studies necessitate the effect of torsional forces, metal Mass, temperature and endodontic irrigants on the cyclic fatigue resistance of these NiTi rotary instruments.

Financial support and sponsorship

Nil.

Conflicts of interest

There are no conflicts of interest.

Acknowledgment

The authors would like to thank the professors and technical staff of IIT Jammu and NIT Srinagar.

REFERENCES

- 1.Stavileci M, Hoxha V, Görduysus Ö, Tatar I, Laperre K, Hostens J, et al. Evaluation of root canal preparation using rotary system and hand instruments assessed by micro-computed tomography. Med Sci Monit Basic Res. 2015;21:123–30. doi: 10.12659/MSMBR.893950. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Esposito PT, Cunningham CJ. A comparison of canal preparation with nickel-titanium and stainless steel instruments. J Endod. 1995;21:173–6. doi: 10.1016/S0099-2399(06)80560-1. [DOI] [PubMed] [Google Scholar]

- 3.Pruett JP, Clement DJ, Carnes DL., Jr Cyclic fatigue testing of nickel-titanium endodontic instruments. J Endod. 1997;23:77–85. doi: 10.1016/S0099-2399(97)80250-6. [DOI] [PubMed] [Google Scholar]

- 4.Zupanc J, Vahdat-Pajouh N, Schäfer E. New thermomechanically treated NiTi alloys – A review. Int Endod J. 2018;51:1088–103. doi: 10.1111/iej.12924. [DOI] [PubMed] [Google Scholar]

- 5.Alghamdi S, Huang X, Haapasalo M, Mobuchon C, Hieawy A, Hu J, et al. Effect of curvature location on fatigue resistance of five nickel-titanium files determined at body temperature. J Endod. 2020;46:1682–8. doi: 10.1016/j.joen.2020.06.041. [DOI] [PubMed] [Google Scholar]

- 6.Schäfer E, Dzepina A, Danesh G. Bending properties of rotary nickel-titanium instruments. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2003;96:757–63. doi: 10.1016/s1079-2104(03)00358-5. [DOI] [PubMed] [Google Scholar]

- 7.Kumar T, Mittal S, Keshav V, Kaur R, Maakhni E. A comparative evaluation of remaining dentin thickness following biomechanical preparation of teeth using different rotary file systems: An in vitro study. J Conserv Dent. 2022;25:32–6. doi: 10.4103/jcd.jcd_373_21. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Riyahi AM, Bashiri A, Alshahrani K, Alshahrani S, Alamri HM, Al-Sudani D. Cyclic fatigue comparison of trunatomy, twisted file, and ProTaper next rotary systems. Int J Dent 2020. 2020:3190938. doi: 10.1155/2020/3190938. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Elnaghy AM, Elsaka SE, Mandorah AO. In vitro comparison of cyclic fatigue resistance of TruNatomy in single and double curvature canals compared with different nickel-titanium rotary instruments. BMC Oral Health. 2020;20:38. doi: 10.1186/s12903-020-1027-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Topçuoğlu HS, Topçuoğlu G, Akti A, Düzgün S. In vitro comparison of cyclic fatigue resistance of ProTaper Next, HyFlex CM, OneShape, and ProTaper Universal Instruments in a Canal with a Double Curvature. J Endod. 2016;42:969–71. doi: 10.1016/j.joen.2016.03.010. [DOI] [PubMed] [Google Scholar]

- 11.Manojkumar T, Vivekanandhan P, Dhakshinamoorthy M, Tamilselvi R, Subbiya A. Evaluation of cyclic fatigue resistance of three different NiTi rotary systems – An in vitro study. Indian J Public Health Res Dev. 2020;11:688–94. [Google Scholar]

- 12.Chhabra A, Ramya KP, Prathap BS, Yadav P. Life span of neoendo flex and ProTaper Next rotary files with reciprocating motion in single-rooted teeth. J Conserv Dent Endod. 2023;26:420–3. doi: 10.4103/jcd.jcd_239_23. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Gayatri K, Tammineedi S, Bolla N, Vemuri S, Basam RC, Sunil CR. Effect of autoclaving on the cyclic fatigue resistance of nickel-titanium rotary instruments: An in vitro study. J Conserv Dent. 2021;24:440–4. doi: 10.4103/jcd.jcd_182_21. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Savitha S, Sharma S, Kumar V, Chawla A, Vanamail P, Logani A. Effect of body temperature on the cyclic fatigue resistance of the nickel-titanium endodontic instruments: A systematic review and meta-analysis of in vitro studies. J Conserv Dent. 2022;25:338–46. doi: 10.4103/jcd.jcd_55_22. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Fišerová E, Chvosteková M, Bělašková S, Bumbálek M, Joska Z. Survival analysis of factors influencing cyclic fatigue resistance of nickel-titanium endodontic instruments. Adv Mater Sci Eng. 2015:189703. [Google Scholar]

- 16.Bulem ÜK, Kececi AD, Guldas HE. Experimental evaluation of cyclic fatigue resistance of four different nickel-titanium instruments after immersion in sodium hypochlorite and/or sterilization. J Appl Oral Sci. 2013;21:505–10. doi: 10.1590/1679-775720130083. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Keleş A, Eymirli A, Uyanık O, Nagas E. Influence of static and dynamic cyclic fatigue tests on the lifespan of four reciprocating systems at different temperatures. Int Endod J. 2019;52:880–6. doi: 10.1111/iej.13073. [DOI] [PubMed] [Google Scholar]

- 18.Shanmugam R, Srivigneesh R, Raghav S, Santhosh S. Design and fabrication of motorized scotch yoke mechanism. IJET. 2019;5:2395–1303. [Google Scholar]

- 19.Plotino G, Grande NM, Cordaro M, Testarelli L, Gambarini G. A review of cyclic fatigue testing of nickel-titanium rotary instruments. J Endod. 2009;35:1469–76. doi: 10.1016/j.joen.2009.06.015. [DOI] [PubMed] [Google Scholar]

- 20.El Feky HM, Ezzat KM, Bedier MM. Cyclic fatigue resistance of M-Pro and RaCe Ni-Ti rotary endodontic instruments in artificial curved canals: A comparative in vitro study. Restor Dent Endod. 2019;44:e44. doi: 10.5395/rde.2019.44.e44. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Terauchi Y. Managing iatrogenic endodontic events. In: Hargreaves K. M., Berman L. H., editors. Pathways of the pulp. 11th ed. St. Loius, MO: Elsevier; 2016. pp. 722–27. [Google Scholar]

- 22.Gambarini G, Plotino G, Grande NM, Al-Sudani D, De Luca M, Testarelli L. Mechanical properties of nickel-titanium rotary instruments produced with a new manufacturing technique. Int Endod J. 2011;44:337–41. doi: 10.1111/j.1365-2591.2010.01835.x. [DOI] [PubMed] [Google Scholar]

- 23.Modesto TC, Acosta EC, Resende PD, Pereira ÉS, Peixoto IF, Buono VT, et al. Cyclic flexural fatigue resistance of NiTi Controlled Memory and Blue Technology instruments after torsional preloading. J Appl Oral Sci. 2018;26:e20180144. doi: 10.1590/1678-7757-2018-0144. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Bier CA, Shemesh H, Tanomaru-Filho M, Wesselink PR, Wu MK. The ability of different nickel-titanium rotary instruments to induce dentinal damage during canal preparation. J Endod. 2009;35:236–8. doi: 10.1016/j.joen.2008.10.021. [DOI] [PubMed] [Google Scholar]

- 25.McGuigan MB, Louca C, Duncan HF. Endodontic instrument fracture: causes and prevention. Br Dent J. 2013;214:341–8. doi: 10.1038/sj.bdj.2013.324. [DOI] [PubMed] [Google Scholar]

- 26.Cheung GS, Peng B, Bian Z, Shen Y, Darvell BW. Defects in ProTaper S1 instruments after clinical use: Fractographic examination. Int Endod J. 2005;38:802–9. doi: 10.1111/j.1365-2591.2005.01020.x. [DOI] [PubMed] [Google Scholar]

- 27.Kaval ME, Capar ID, Ertas H. Evaluation of the cyclic fatigue and torsional resistance of novel nickel-titanium rotary files with various alloy properties. J Endod. 2016;42:1840–3. doi: 10.1016/j.joen.2016.07.015. [DOI] [PubMed] [Google Scholar]

- 28.Li UM, Lee BS, Shih CT, Lan WH, Lin CP. Cyclic fatigue of endodontic nickel titanium rotary instruments: static and dynamic tests. J Endod. 2002;28:448–51. doi: 10.1097/00004770-200206000-00007. [DOI] [PubMed] [Google Scholar]

- 29.Grande NM, Plotino G, Pecci R, Bedini R, Malagnino VA, Somma F. Cyclic fatigue resistance and three-dimensional analysis of instruments from two nickel-titanium rotary systems. Int Endod J. 2006;39:755–63. doi: 10.1111/j.1365-2591.2006.01143.x. [DOI] [PubMed] [Google Scholar]

- 30.Goo HJ, Kwak SW, Ha JH, Pedullà E, Kim HC. Mechanical properties of various heat-treated nickel-titanium rotary instruments. J Endod. 2017;43:1872–7. doi: 10.1016/j.joen.2017.05.025. [DOI] [PubMed] [Google Scholar]

- 31.Nguyen HH, Fong H, Paranjpe A, Flake NM, Johnson JD, Peters OA. Evaluation of the resistance to cyclic fatigue among ProTaper Next, ProTaper Universal, and Vortex Blue rotary instruments. J Endod. 2014;40:1190–3. doi: 10.1016/j.joen.2013.12.033. [DOI] [PubMed] [Google Scholar]

- 32.Haıkel Y, Serfaty R, Bateman G, Senger B, Allemann C. Dynamic and cyclic fatigue of engine-driven rotary nickeltitanium endodontic instruments. Journal of Endodontics. 1999;25:434–40. doi: 10.1016/S0099-2399(99)80274-X. [DOI] [PubMed] [Google Scholar]

- 33.AlShwaimi E. Cyclic fatigue resistance of a novel rotary file manufactured using controlled memory Ni-Ti technology compared to a file made from M-wire file. Int Endod J. 2018;51:112–7. doi: 10.1111/iej.12756. [DOI] [PubMed] [Google Scholar]

- 34.Yilmaz K, Ozyurek T. Comparison of the cyclic fatigue resistance of nickel-titanium rotary instruments manufactured using controlled memory wire. Turk Endod J. 2017;2(Suppl 1):5–9. [Google Scholar]

- 35.Karataşlıoglu E, Aydın U, Yıldırım C. Cyclic fatigue resistance of novel rotary files manufactured from different thermal treated nickel-titanium wires in artificial canals. Niger J Clin Pract. 2018;21:231–5. doi: 10.4103/njcp.njcp_296_16. [DOI] [PubMed] [Google Scholar]

- 36.Uslu G, Gundogar M, Özyurek T, Plotino G. Cyclic fatigue resistance of reduced-taper nickel-titanium (NiTi) instruments in doubled-curved (S-shaped) canals at body temperature. J Dent Res Dent Clin Dent Prospects. 2020;14:111–5. doi: 10.34172/joddd.2020.024. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Silva EJ, Martins JN, Ajuz NC, Antunes HS, Vieira VT, Braz Fernandes FM, et al. AMultimethod assessment of a new customized heat-treated nickel-titanium rotary file system. Materials (Basel) 2022;15:5288. doi: 10.3390/ma15155288. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Alfadley A. Comparison of cyclic fatigue resistance of three NiTi glide path files with different cross-sectional geometric characteristics: An in vitro experimental study. JIOH. 2020;12:158–62. [Google Scholar]

- 39.Reddy BN, Murugesan S, Basheer SN, Kumar R, Kumar V, Selvaraj S. Comparison of cyclic fatigue resistance of novel TruNatomy files with conventional endodontic files: An in vitro SEM study. J Contemp Dent Pract. 2021;22:1243–9. [PubMed] [Google Scholar]

- 40.Kaval ME, Capar ID, Ertas H, Sen BH. Comparative evaluation of cyclic fatigue resistance of four different nickel-titanium rotary files with different cross-sectional designs and alloy properties. Clin Oral Investig. 2017;21:1527–30. doi: 10.1007/s00784-016-1917-x. [DOI] [PubMed] [Google Scholar]

- 41.Zhang EW, Cheung GS, Zheng YF. Influence of cross-sectional design and dimension on mechanical behavior of nickel-titanium instruments under torsion and bending: A numerical analysis. J Endod. 2010;36:1394–8. doi: 10.1016/j.joen.2010.04.017. [DOI] [PubMed] [Google Scholar]

- 42.Xu X, Eng M, Zheng Y, Eng D. Comparative study of torsional and bending properties for six models of nickel-titanium root canal instruments with different cross-sections. J Endod. 2006;32:372–5. doi: 10.1016/j.joen.2005.08.012. [DOI] [PubMed] [Google Scholar]

- 43.Azimi S, Delvari P, Hajarian HC, Saghiri MA, Karamifar K, Lotfi M. Cyclic fatigue resistance and fractographic analysis of race and protaper rotary NiTi instruments. Iran Endod J. 2011;6:80–6. [PMC free article] [PubMed] [Google Scholar]

- 44.Gündoğar M, Sezgin GP. Cyclic Fatigue Resistance of Genius, RC Gold and Revo-S Nickel-titanium Instruments. Int J Appl Dent Sci. 2018;4:342–5. [Google Scholar]

- 45.Parashos P, Messer HH. Rotary NiTi instrument fracture and its consequences. J Endod. 2006;32:1031–43. doi: 10.1016/j.joen.2006.06.008. [DOI] [PubMed] [Google Scholar]

- 46.Cheung GS, Darvell BW. Fatigue testing of a NiTi rotary instrument. Part 2: Fractographic analysis. Int Endod J. 2007;40:619–25. doi: 10.1111/j.1365-2591.2007.01256.x. [DOI] [PubMed] [Google Scholar]

- 47.Nogueira D, Bueno CE, Kato AS, Martin AS, Pelegrine RA, Limoeiro AG, et al. Effect of immersion in sodium hypochlorite on the cyclic fatigue resistance of three rotary instruments. J Conserv Dent. 2020;23:554–7. doi: 10.4103/JCD.JCD_117_19. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Yao JH, Schwartz SA, Beeson TJ. Cyclic fatigue of three types of rotary nickel-titanium files in a dynamic model. J Endod. 2006;32:55–7. doi: 10.1016/j.joen.2005.10.013. [DOI] [PubMed] [Google Scholar]