Abstract

Microalgae and bacteria, known for their resilience, rapid growth, and proximate ecological partnerships, play fundamental roles in environmental and biotechnological advancements. This comprehensive review explores the synergistic interactions between microalgae and bacteria as an innovative approach to address some of the most pressing environmental issues and the demands of clean and renewable freshwater and energy sources. Studies indicated that microalgae-bacteria consortia can considerably enhance the output of biotechnological applications; for instance, various reports showed during wastewater treatment the COD removal efficiency increased by 40%–90.5 % due to microalgae-bacteria consortia, suggesting its great potential amenability in biotechnology. This review critically synthesizes research works on the microalgae and bacteria nexus applied in the advancements of renewable energy generation, with a special focus on biohydrogen, reclamation of wastewater and desalination processes. The mechanisms of underlying interactions, the environmental factors influencing consortia performance, and the challenges and benefits of employing these bio-complexes over traditional methods are also discussed in detail. This paper also evaluates the biotechnological applications of these microorganism consortia for the augmentation of biomass production and the synthesis of valuable biochemicals. Furthermore, the review sheds light on the integration of microalgae-bacteria systems in microbial fuel cells for concurrent energy production, waste treatment, and resource recovery. This review postulates microalgae-bacteria consortia as a sustainable and efficient solution for clean water and energy, providing insights into future research directions and the potential for industrial-scale applications.

Keywords: Electron transfer mechanisms, Microalgae-bacteria consortia, Microalgae microbial fuel cell, Photosynthetic electrogens, Renewable energy resources, Wastewater treatment

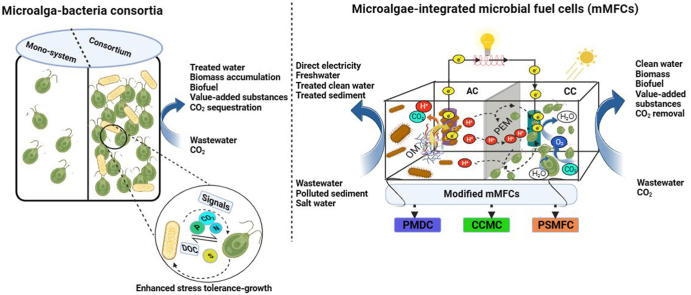

Graphical abstract

Highlights

-

•

Microalgae-bacteria nexus enhance biohydrogen production and carbon sequestration.

-

•

Microalgae-bacteria consortia surpass the traditional application methods.

-

•

Microalgae-bacteria consortia welding in next-generation biotechnology applications.

-

•

Taxonomic exploration on potential microbes is pertinent for optimization.

-

•

Strain selection, genetic engineering and system design are pivot for optimization.

1. Introduction

Microalgae and heterotrophic bacteria are cosmopolitan microscopic organisms playing crucial roles in aquatic ecosystems as the basis of the food chain and recyclers of organic matter. While microalgae photosynthetically produce organic matter by reducing CO2 with protons and electrons that are derived from water photolysis, heterotrophic bacteria degrade the organic matter by oxidizing it and releasing CO2. In addition to some amenable versatile species, generally, microalgae and bacteria are endowed with key traits that are advantageous for technological applications. These traits include their rapid growth and biomass accumulation capability under optimum growth conditions, and their great diversity and robust adaptability. These key attributes make them suitable candidates for biotechnological application and exploitation.

Decades of research on microalgae-bacteria interactions have shed light on their interactive mechanisms and greatly contributed to the advancement of applied ecology, environmental microbiology and biotechnology. Consequently, synthetic consortia of these organisms have been leveraged in the past years to enhance biomass production, wastewater treatment, and biofuel generation, addressing essential societal needs for clean energy, environment and freshwater. As our energy and freshwater resources are currently dependent on finite and environmentally unsafe sources, that have been aggravated by rapid population growth and industrialization, it is imperative to explore alternative renewable sources before they adversely affect the quality of life on Earth.

For instance, reliance on fossil fuel is unsustainable and environmentally unsafe due to its finite nature, and it contributes to global warming and has health risks. Hence, renewable sources such as biofuel [1] and microbial fuel cells (MFC) technologies [2] have been promoted as promising alternatives to offer clean energy and environmentally safe solutions. Like energy, the demand for clean fresh water is among the crucial societal problems; while water is abundant globally, only a tiny fraction (0.5 %) is readily available for use and the majority (>97 %) of it is saline [3]. Although dissolved solids removal from salt waters has been done through membrane process and thermal desalination methods to maximize the accessibility of clean freshwater, the operational cost is very high [3]. Consequently, microbial desalination cells (MDCs) have emerged as an energy-efficient alternative technology for desalination.

Biotechnological applications of microalgae-bacteria interactions involve multiple disciplines, focusing on wastewater treatment via cocultivation, environmental remediation, improved biomass production, bioelectricity generation in MFCs, salinity reduction in photosynthetic desalination cells, biohydrogen production, biomass pretreatment for cell wall disruption, and biomass harvesting through advanced flocculation techniques. Review works of literature on microalgae-bacteria interactions have been growing since the 1990s, addressing distinct aspects such as metabolite and biomass enhancement [4,5], nutrient and micropollutant removal from wastewaters [[6], [7], [8], [9]], effects on wastewater treatment processes [10], remediation of hazardous wastes [11], treatment of acid mine drainage [12], removing CO2 while purifying wastewater and producing bioproducts [13], applications in photobioelectrochemical microbial fuel cells [14], heavy metal removal [15], downstream processing of microalgae biomass [16], and biomass pretreatment methods [17].

Despite the growth in review paper publications, there is a gap in comprehensive reviews that encapsulate the microalgae-bacteria interactions and their biotechnological applications from a broader perspective. This review paper addresses this gap, aiming to present a concise, yet thorough, overview of the environmental, economic, and biotechnological prospects of microalgae-bacteria interactions for a wide readership, including biologists, biotechnologists, environmental microbiologists, and engineers. This work is intended to cover topics such as biomass production, bioelectricity generation, saltwater desalination, and biohydrogen production to offer concise current knowledge and future perspectives in this dynamic area of study.

2. The interaction, application and optimization of microalgae-bacteria consortia

The exploitation of the synergetic interaction between microalgae and bacteria in consortia has been harnessed in the last few decades as an advanced technology to enhance the performance of aquaculture, biofuel production, and wastewater treatment, surpassing the outcome of either organism could achieve alone.

2.1. The interactions of microalgae and bacteria in consortia

Several studies indicated that microbes are interdependent and frequently dictate the life of each other through the exchange of materials and resources [18]. The interaction between bacteria and algae can be synergistic-positive (promoting) or antagonistic-negative (hindering) to the growth and physiology of the participant microorganisms. For instance, the algal surface can serve as a microbial habitat for bacteria, serving as a defense against predation, nutrient source and surface area to colonize, while the bacteria may favor the relationship by providing services such as antibiotic production, polysaccharide degradation, biosynthesis of allelochemical and growth stimulant biomolecules.

Recently, Takagi et al. [19] reported a symbiotic relationship between dinoflagellate and bacteria mutually benefitted each other, in which the dinoflagellate protected the symbiotic bacteria from antibiotics while the bacteria protected the algal cells from light stress through carotenoid production. Additionally, a study on the interaction of the microalga C. vulgaris and its phycospheric bacteria showed the two partners interact in various ways, harnessing efficient metabolization and removal of nutrients such as phosphorus, carbon and nitrogen from the wastewater [20]. Generally, the synergistic mutualism of microalgae and bacteria can be undertaken in two ways; by signal communication (materials are used for communication purposes but not as nutrients), and by exchanging materials and resources (Fig. S1).

2.1.1. Interaction via signaling in microalgae and bacteria consortia

The exchange of signal molecules can activate or inhibit the expression of genes or biological activities, resulting changes in metabolism and growth. A mutualistic interaction between bacteria and microalgae has been reported in which the bacteria influence the growth of microalgae by producing growth-promoting hormones and antibiotics [21]. Likewise, it has been reported that a Sulfitobacter species promotes the cell division of diatom by releasing indole-3-acetic acid (IAA).

Molecules like IAA, tryptophan, bacterial excreted-ammonium and diatom-excreted organosulfur molecules served as signaling molecules. During signaling and communication, the bacterium can synthesize the IAA using an endogenous source of tryptophan or tryptophan secreted by algae [22]. Metabolic and metatranscriptome analyses showed that there is a widespread IAA production by Sulfitobacter-related bacteria particularly in coastal environments, indicating this mode of signaling could also occur in the open ocean [22]. Such signaling is also reported in freshwater green algae, where organic molecules like tryptophan and thiamin that are exudated from Chlorella sorokiniana induce the IAA production by Azospirillum brasilense (plant growth-promoting bacterium), which in turn, promotes the growth of microalga [23].

2.1.2. Interaction via material exchange in microalgae and bacteria consortia

Interaction by exchanging materials and resources is another way that microalgae and bacterial communities influence each other. There are several materials that microalgae and bacteria can exchange during interactions. From these, the exchange of essential elements like iron is the cornerstone of mutualism. Iron is crucial for metabolic processes like catalyzing redox reactions and electron transfer. Other than being an essential element for photosynthesis and respiration, iron limits the primary productivity and growth of bacteria in much of the ocean. To counteract iron scarcity, several marine heterotrophic bacteria and some cyanobacteria produce siderophores, organic molecules that bind iron to enhance its availability [24]. Since eukaryotic algae are not known to produce or take up bacterial-originated siderophores, they obtain iron from siderophores or other chelates through ferrireductases and adjacent Fe (II) transport on their outer cell membranes. Amin et al. [25] proposed a mutual exchange of iron and fixed carbon between algae and bacteria. This was based on their study of Marinobacter′s production of a lower-affinity dicitrate siderophore (vibrioferrin) and its interaction with the dinoflagellate Scrippsiella trochoidea.

Vitamins are commonly used among prokaryotic and eukaryotic organisms for various metabolic functions, as a result of which a significant effect on the growth and composition of microbial communities is observed [26,27]. However, genomic data reveal many of these organisms cannot synthesize vitamins [28,29], with only about one-third of prokaryotes capable of producing vitamin B12 (cobalamin) [29]. Likewise, most of the harmful algal bloom-forming species are vitamin B12 and B1 auxotrophs [30]. In contrast to the limited distribution of these vitamins in most microbes, almost all marine prokaryotes, and more than half of marine eukaryotic microbes possess vitamin B12-dependent enzymes [28,31]. Thus, these organisms rely on an exogenous supply of vitamin B12. This discrepancy in dependency and supply of vitamin B12 results in a close microbial interaction. For this reason, microalgae might prefer to have a close association with bacteria and make a trade-off [32]. Therefore, during mutualism, the microalgae could acquire the vitamins and nutrients via active uptake from the soluble fraction or through episymbiosis [26].

A mathematical model showing the mutualistic interaction of microbes was also reported [33]. The green alga Chlamydomonas reinhardtii forms synthetic mutualism with Mesorhizobium loti and the genetically engineered gut bacterium Escherichia coli and can receive cobalamin [18]. The association of bacteria with other eukaryotic algae, such as picoeukaryotic alga [34] and diatoms [35] has also been documented. More information on sharing vitamins with microbes and their impact on microbial interactions has been provided by Sokolovskaya et al. [29].

In terms of material exchange, it is common that heterotrophic bacteria assimilate DOC for metabolic needs, this creates an opportunity for the algae to shape the diversity of the bacterial community in its surroundings by producing various types of DOC. In line with this, taxon- and substrate-specific responses of the bacterial community were observed during the degradation of diatom-derived extracellular carbohydrates [36].

Despite the large abundance of nitrogen in the atmosphere, the bioavailable form of nitrogen is limiting the growth of autotrophs. To alleviate this problem few prokaryotes developed a mechanism to convert atmospheric nitrogen into bioavailable forms. Other microorganisms and higher plants devise mechanisms to attract and develop associations with those prokaryotes that are capable of fixing atmospheric nitrogen. In this symbiosis, nitrogen-fixing prokaryotes and their algal hosts benefit mutually. This relationship can be further manipulated in microalgae and diazotrophs consortia under laboratory conditions to harness some biotechnological processes including reducing production costs and enhancing microalgal biomass and biochemical products [36]. Algae, besides getting fixed nitrogen from bacteria, also absorb nitrogen from the decomposed amino acids and peptides. For instance, the green alga C. reinhardtii is unable to utilize certain amino acids but thrives when co-cultured with Methylobacterium sp. This indicates there was a mutual carbon-nitrogen exchange; as Methylobacterium sp. degrades amino acids and releases ammonium for the alga, and the CO2 fixed by the alga provides glycerol for the bacterium [37].

The findings of synergistic interactions between microalgae and bacteria offer a clearer view into the complexities of microbial cooperation, revealing mechanisms that significantly enhance growth and productivity. The potential of these interactions in biotechnological applications, such as environmental remediation, wastewater treatment and biofuel production, is immense. However, to fully harness these benefits, a deeper understanding of the molecular and environmental factors governing these interactions is needed.

2.2. Applications of microalgae-bacteria consortia

2.2.1. Microalgae-bacteria consortia role in aquaculture production

As industrialization and the global population rapidly grow, the need for sustainable energy and food production also steadily increasing. In this prospect, aquaculture emerged as a viable sustainable solution with microalgae and bacteria nexus playing a pivotal role in improving the efficiency of energy and food production. The significance of microalgal-bacterial interactions for aquaculture has been reviewed by Natrah et al. [38]. The growth-promoting effect of bacteria on microalgae which have commercial values has been reported for several years [39]. For instance, the co-culture of microalga Isochrysis galbana with mutualistic heterotrophic bacteria such as Alteromonas sp. and Labrenzia sp. has led to notable increases in growth rate and biomass accumulation [40]. Co-culturing diatoms with specific bacteria can boost their production, providing improved feed yield for shellfish and finfish larvae [41].

The beneficial bacteria promote the growth of target microalgae while also inhibiting harmful pathogens and grazers. While outdoor pond cultivation of algae is cost-effective for mass production, it is challenged by pest organisms [42,43]. Several mitigation strategies such as creating non-permissive growth conditions with altered pH and salinity levels [44] or adding chemical treatments such as biocides have been developed to prevent the destruction of algal crops by pests [45]. Generally, mitigation strategies that are eco-friendly and do not hinder the growth of beneficial algae are highly preferred. Hence, as certain bacteria strains offer a promising approach to selectively inhibit unwanted bacteria without adversely affecting desired algae species, the microalgae-bacteria nexus provided another opportunity for pest control in the microalgae aquaculture system. For example, a Phaeobacter strain (BS52) showed antagonistic activity toward the bleaching pathogen and significantly increased the proportion of healthy individuals of the seaweed Delisea pulchra by preventing dysbiosis [46].

Algal biomass in the cultivation pond can be attacked by grazers such as rotifers, which requires an efficient mechanism to mitigate this problem. Recently, a study by Ward et al. [47] indicated that introducing a bacterium Janthinobacter lividum into Microchloropsis salina cultures effectively protected the algae from zooplankton Brachionus plicatilis predation without harming other microorganisms. This protection was confirmed through both laboratory and outdoor mesocosm experiments. Additionally, the nexus of algae with certain heterotrophic bacteria can lead to increased algal biomass as the bacteria recycle the organic matter and improve nutrient uptake in nutrient-deficient conditions [48].

2.2.2. Microalgae-bacteria consortia role in metabolite and biomass production

As the human population steadily increases, the demand for the production of high biomass in a short time and limited space and energy is imperative. Microalgae, providing formidable service as sources of biomass in biotechnological applications, have been exposed to various cultivation conditions to promote their growth and yield. Among these, altering the growth conditions through co-culturing with bacteria has been found to enhance the production of beneficial compounds in algae [49]. For instance, co-culturing Haematococcus lacustris with bacteria resulted in more than double biomass and a 60 % increase in the production of the antioxidant astaxanthin [50]. Similarly, the growth of the green algae Tetradesmus obliquus or Coelastrella sp. increased by 70 % when co-cultured with the bacterium Variovorax paradoxus [51]. The study by Cassan et al. [52] showed the lipid, carbohydrate and photosynthetic pigment productions of C. sorokiniana were promoted by the bacterium A. brasilense.

The synergetic association of the microalgae Chlorella sp., Scenedesmus sp. and the bacterium A. brasilense showed that there was production of signal molecules such as tryptophan and IAA by the microalgae and bacterium, respectively, under stress growth conditions of the co-culture, which permits the maintenance of their affinity and mutualistic association [53]. This promoted the CO2 fixation rate, biomass production, carbohydrate content and protein content of the microalgae [53]. Moreover, optimization of co-culture conditions with altered cell mobility, pH and CO2 concentration further augmented the production of carbohydrates and starch, particularly when C. sorokiniana and Chlorella vulgaris were co-cultured with A. brasilense within immobilizing alginate beads [54]. Higher CO2 fixation, algal growth and accumulation of carbohydrates were also reported in the cocultivation of the bacterium A. brasilense with microalgae Scenedesmus, Chlamydomonas and Chlorella under high CO2 provisions [55].

2.2.3. Microalgae-bacteria consortia role in biofuel

Microalgae constitute a considerable amount of their dry weight as lipids and carbohydrates. These have garnered the opportunity to apply algal biomass as feedstock for the production of biofuels including biodiesel, bioethanol, biohydrogen and biogas [1,56]. The utilization of microalgae as a biofuel source has been explored since the 1950s. Microalgae can serve as a sustainable energy source due to their vigorous growth characteristics and the ability to thrive in a wide range of media and growth conditions [57]. Moreover, microalgae are a potentially better candidate than edible crops, as their high specific growth rate can allow them to accumulate more biomass per acre [57]. In addition to that, microalgae cultivation requires less land area compared to the cultivation of land crops, offering ecological benefits by reducing pollutants released into the environment as well [58].

The biofuel production of microalgae can be promoted by enhancing the biomass production efficiency, which in turn, is improved by cultivating it in microalgae-bacteria consortia and altering the growth conditions. In line to this, Meng et al. [59] reported that nutrient removal and lipid accumulation for biofuel production significantly increased in microalgae-bacteria granules, coinciding with increased light intensity.

The cultivation of microalgae has been a field of potential interest due to their ability to produce high amounts of biooil [60]. Several studies have been reported on biooil production efficiencies of microalgae biomasses, including Spirulina [61] and Chlorella [62,63] species. Microalgae are suitable candidates for biooil due to their high lipid contents, and their lipid production is highly influenced by the growth conditions of the algae, which in turn, creates an opportunity to enhance production. For instance, a conspicuous increment of lipid production by C. sorokiniana under exogenous ethanol-stress [64] and increased biooil content by C. vulgaris under nitrogen-depleted media [65] have been reported. Moreover, microalgae can be integrated with other systems to enhance the output. For instance, an innovative integrated system for the production of biooil from C. sorokiniana that is grown in sewage has been reported recently [66]. Increased biomass production of C. vulgaris, C. reinhardtii, and Euglena gracilis due to co-culture with indigenous bacteria found in the effluent has been reported [67].

The biomass obtained from microalgae-bacteria consortia can also be valorized and applied in biodiesel production. Moreover, to increase the feasibility of the technology, cultivating microalgae-bacteria in wastewater has been indicated as a source of lipids for biodiesel. Toyama et al. [68] investigated the growth-promoting effect of some bacterial strains (Emticicia sp.) isolated from wastewater on a microalga (E. gracilis) suitable for biodiesel. They reported that biomass production and lipid production increased by 3.5 and 2.9-fold, respectively, compared to the monoculture. High biomass and lipid production, along with enhanced removal of nutrients, suitable for biodiesel production, has been reported under the microalga-bacteria consortium in municipal wastewater [69]. Co-cultivation of microalgae and bacteria provided a promising result in biocrude oil production through hydrothermal liquefaction of microbial biomass cultivated in a large-scale open raceway pond [70]. Additionally, they reported 90 % COD removal and 43 % biocrude oil energy recovery efficiencies. The enhanced accumulation of biomass for biodiesel production as well as the removal of contaminant nutrients and COD under microalgae-bacteria consortium have been extensively reported [71].

The lipids obtained from microalgal biomass can be refined into fatty acids, and processed to yield biodiesel through transesterification [72]. The cultivation of microalgae, drying of the biomass, extraction of the oil and then transesterification of the oil into fatty acid methyl esters are some of the crucial steps in the biodiesel production process. Biodiesel consisting of esters of methylated fatty acids is usually formed from oils through transesterification with alcohols. Mechanisms of lipid extraction and factors influencing transesterification process have been reviewed adequately by Anand et al. [73].

Microalgae, which contain a considerable amount of carbohydrates as their dry weight, can also be used as a feedstock for biofuels such as bioethanol production under anaerobic fermentation [74]. Although the utilization of microalgal biomass requires pretreatment during bioethanol production [75], the efficiency of the system can be enhanced by cultivating algal-bacterial aggregates [76]. Moreover, altering the metabolism of microorganisms in the consortium and altering the physicochemical growth conditions are also other mechanisms to enhance the production of biofuels. Given this, genetically engineered and metabolically altered E. coli was cultivated on a biomass constituted of a bacterium and four microalgal species to degrade proteins and produce ammonia, pyruvate and keto acids, which can be used as biofertilizers and sources of biofuels such as bioethanol and biobutanol [77]. In terms of altering growth conditions, Arcila and Buitrón [78] studied the effect of hydraulic retention time on the removal of pollutants, and the biochemical potential of methane production using a granular microalgae–bacteria system operated in a high-rate algal pond. They reported that high performance was found on the longer retention time with methane yield of 348 mL CH4 g−1.

2.2.4. Microalgae-bacteria consortia role in biohydrogen production

The use of hydrogen as a source of energy has rapidly increased in the past few decades, owing to its high energy content, which is clean and safe for the environment and health. Notably over 95 % (the other 4 % from water electrolysis and ∼1 % from biological production) of produced hydrogen comes from fossil fuel through thermochemical conversion and gasification [79], highlighting a reliance on non-renewable sources and environmentally unfriendly systems [80]. Therefore, the incorporation of advanced technologies that simultaneously produce hydrogen from renewable resources as well as reduce environmental pollution and feasible operational costs has received the most attention [81]. The abundant availability, high energy content, and non-toxic and less pollution effect make hydrogen a preferred choice of energy source [82,83].

The ambition of attaining renewable hydrogen production could be achieved in the long run, as several species of microorganisms from various phylogenetic groups, including bacteria (photosynthetic and fermentative), blue-green algae and some eukaryotic microalgae, have been reported to produce biological hydrogen [82,84]. Biological hydrogen production can be attained from three different processes; biophotolysis (hydrogen production under specific photosynthetic activities of eukaryotic algae and cyanobacteria, using light), photo-fermentation (hydrogen production from light and organic substrates without producing oxygen, this is performed by non-oxygenic photosynthetic bacteria) and dark fermentation (production of hydrogen and CO2 during degradation of organic matter) [79]. However, this paper only focuses on biophotolysis processes involving microalgae and bacteria.

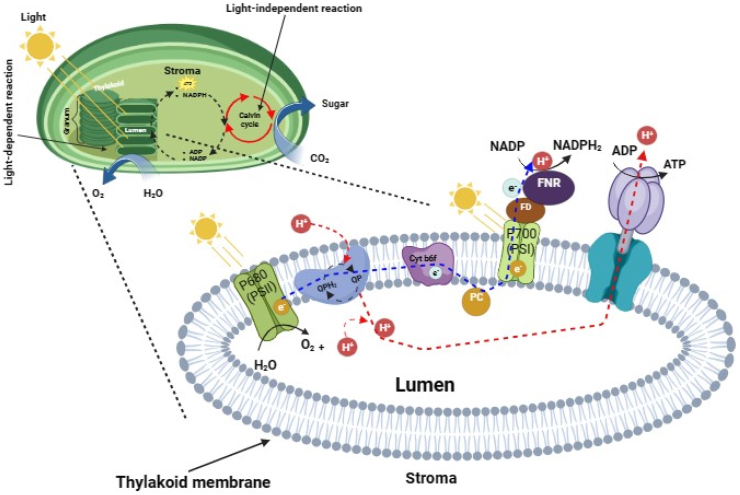

Photosynthetic microorganisms (both prokaryotic and eukaryotic microalgae) are endowed with hydrogenase enzyme, which gives them the capability to evolve hydrogen under specific conditions and to reduce CO2 in the next dark photosynthetic reaction (Fig. 1). Biohydrogen production by cyanobacteria and eukaryotic microalgae are preferred over non-oxygenic (photo-fermentation) or heterotrophic bacteria (dark fermentation), as they don't need external carbon sources. However, the requirement of restricted and specific growth conditions limited its wider applications [85]. For instance, biohydrogen production through biophotolysis has a shortfall as it requires an anoxic condition. Many microalgae showed activation of hydrogenases and evolved hydrogen when acclimatized in the anaerobic-dark condition, but the hydrogen production ceases when the cells are exposed to light and commence stable photosynthesis [85].

Fig. 1.

A diagram illustrating the light-dependent and light-independent reaction steps in the photosynthesis process. During the light-dependent reaction, the excited electron replacement and generation of hydrogen occur through the photolysis of water molecules, then ATP and NADPH are produced to be supplied to the Calvin cycle of light-independent reaction to fix carbon dioxide into sugar. The sketch was drawn based on the information provided by Marchand et al. [101].

The requirement of anoxic conditions in biohydrogen production systems poses technical difficulties and limitations for production efficiency [82]. Hydrogenase enzyme is sensitive to oxygen (a byproduct of photosynthesis); thus, continuous production of hydrogen can only occur in anoxic conditions that can be achieved by reversible inactivation of photosystem II and oxygen evolution. For example, the evolution of hydrogen by co-immobilizing spinach (higher plant) chloroplast and Clostridium butyricum (bacterium) with the help of electron carrier molecules such as benzyl viologen and ferredoxin was reported in early studies by Karube et al. [86]. They reported that there was an evolution of hydrogen through the oxidation of carrier molecules, although the PSII also evolved oxygen, which poses a major problem in chloroplast-hydrogenase coupled systems. Further research suggested that adding some substrates such as glucose, glucosidase and catalase, and immobilizing hydrogenases reduced interference of oxygen in biohydrogen production [86]. Subsequent studies showed that starvation with nutrients such as acetate, sulfide, phosphorus, nitrogen, magnesium and potassium [[87], [88], [89], [90]] inhibited photosystem II activity and consequently declined oxygen evolution.

Even though starving cells through the deprivation of nutrients temporarily suppress oxygen evolution and allows hydrogen production, hydrogen production does not sustain itself for a long time as the growth of the algae declines after some time due to the limited nutrients. Therefore, various strategies have been designed to increase the efficiency and durability of hydrogen production. These include changing culture conditions such as light/dark frequency, cell immobilization, the addition of fresh cells grown in sulfur-deprived medium, and using mutant strains with limited antenna features, suppressed photosystem II, altered PSII to PSI ratio and inhibited cycle electron flow or controlled CO2 fixation [ [91] and references therein]. Moreover, studies on C. reinhardtii [92] demonstrated that the decoupling of photosynthetically produced carbohydrates (during stage one) from cellular metabolism (stage two) leads to hydrogen and CO2 generation under anoxic conditions.

Even though most species require anoxic conditions for hydrogen production, there are nitrogen-fixing cyanobacterial species (Anabaena sp.) that can perform aerobic photolytic hydrogen evolution due to the hydrogenase's resistance to nitrogen and hydrogenase protection from oxygen [93]. Furthermore, hydrogen production by eukaryotic microalgae C. reinhardtii under aerobic conditions was also reported by Khetkorn et al. [94]. To address the limitation of hydrogenase inhibition by oxygen or nitrogen in cyanobacterial biophotolysis, an argon-based atmosphere has been used in hydrogen production [93].

Although the specific requirement of growth conditions for biohydrogen production hampered the wide application of microalgae for the production of biohydrogen, several reports indicated biohydrogen (photolysis) production can be enhanced by microalga-bacteria consortia [83 and references therein]. The advantage of co-culturing heterotrophic bacteria with microalgae for biohydrogen production includes the removal of oxygen by bacteria, which is a bottleneck for biohydrogen production, and the consumption of CO2 by microalgae, which is produced by the degradation of substrate by bacteria. The co-cultivation of bacteria with microalgae could enhance hydrogen production by increasing the light tolerance of the microalgae [83] and slowing chlorophyll reduction, enhancing starch accumulation, and maintaining protein content [95]. Additionally, several metabolites including acetic acid exchanged between the two partners, which could further promote hydrogen production [96]. For instance, co-cultivation of Chlamydomonas and E. coli under glucose provision showed a 60 % increase in hydrogen production compared to monocultures, where alga benefited from the consumption of the acetic acid excreted by bacteria and anoxic condition created [96].

Several research results indicated that the microalgae type, bacterial partner, substrate concentration, and media type have a significant impact on the hydrogen production efficiency of microalgae-bacteria consortia [83,[97], [98], [99]]. Furthermore, hydrogen production by the microalga-bacteria consortium can also be affected by the initial cell density and size of the microalgae [97]. He et al. [100] also found enhanced production of hydrogen under sulfide provision (Na2S2O3) by co-culturing of Chlamydomonas sp. and Thuomonas intermedia (sulfur-oxidizing facultative autotroph bacterium). Despite certain complexity, studies have demonstrated that the microalga-bacteria consortium presents a promising path forward in biohydrogen production, offering a potentially sustainable and efficient method for harnessing hydrogen as a clean energy source.

2.2.5. Microalgae-bacteria consortia role in promoting wastewater treatment

The increase in sewage generation, in parallel with the expansion of industrialization and human population growth, necessitates the development of efficient and economical wastewater management and treatment technologies for environmental remediation. Recently, the cultivation of microalgae-bacteria in effluent or sewage has gained attention for its dual benefits of nutrient removal and biomass production [7]. The co-cultivation of microalgae and bacteria offers mutual benefits to both organisms. Table 1 presents key studies highlighting the role of microalgae-bacteria consortia in enhancing wastewater treatment; indicating the removal efficiency of COD and other pollutants. For instance, the coculture of the microalgae C. sorokiniana and Chlorella sp. with the bacteria Klebsiella pneumoniae and Acinetobacter calcoaceticus enhanced microalgae growth, biomass, and nutrient/COD removal in wastewater, outperforming the monoculture systems [102]. Moreover, a consortium composed of Chlorella sp. and four bacterial strains was able to degrade ketoprofen with 40 % reduction in COD and 82 % reduction in toxicity in pharmaceutical wastes [103].

Table 1.

Studies of microalgae-bacteria consortia in promoting wastewater treatment.

| Microalgae-Bacteria Used | Medium/Condition | Biomass Yield (%) | Removal efficiency (%) | Findings | Reference |

|---|---|---|---|---|---|

| C. sorokiniana and Chlorella sp. with Klebsiella pneumoniae and Acinetobacter calcoaceticus | Artificial wastewater (AWW) and raw dairy wastewater (RDWW) | RDWW: 2.87 g/L | COD of RDWW: 90.49 % | Enhanced growth, biomass, nutrient/COD removal over monocultures. | [102] |

| AWW: 2.84 g/L | COD of AWW: 82.27 % | ||||

| C. sorokiniana with Streptomyces thermocarboxydus | Wastewater treatment | Bioflocculation efficiency: 93 %; Biomass productivity: increased 33 % Lipid productivity: 80 % increase due to the co-cultivation of Streptomyces and microalgal cells. | NA | Higher algal biomass and lipid content, suitable for biodiesel. | [112] |

| Chlorella sp. with four bacterial strains | Pharmaceutical waste degradation | NA | In dark condition: biodegradation was faster with a lag phase of 10 h; COD: 41 %; Toxicity reduction: 82 % | Effective ketoprofen degradation, reduced COD (40 %) and toxicity (82 %) | [103] |

| T. obliquus and Coelastrella sp. with V. paradoxus | Modified Bold's basal medium | NA | Nitrate: 88–99 %; Phosphate: 92–95 % | Improved microalgae growth, nutrient uptake nitrate and phosphate and biochemical composition. | [51] |

| C. vulgaris with various bacterial strains | Wastewater treatment | Biomass growth rate: 0.196 ± 0.06 d−1 (highest); mean daily biomass productivity 0.098 ± 0.009 g L−1 d−1 (for 10:1 ratio of S395-2 to C. vulgaris) | COD: 88.29 ± 5.03 %; TN: 88.31 ± 4.29 %; TP: 88.21 ± 4.51 %; CO2 68.13 ± 1.69 %. | Enhanced algal biomass accumulation, nutrient removal, and energy generation. | [113] |

| Consortia with microalgae | Photoreactor for wastewater treatment | TSS: ∼59 % increased; Chlorophyll: ∼64 % increased | NH4+–N: 65 ± 6 % −93 ± 2 % (with the change of light density) | Reduced aeration requirements due to inhibition of nitrite oxidizing bacteria. | [109] |

| Microalga-bacteria photoreactor system | Ammonium removal | TSS: 1006 ± 100 mg/L - 1930 mg/L |

NH4+ oxidized to NO2− at the rate of 8.09 mg NH4+-N L−1h−1. | Innovative method for nitrogen removal without external aeration. | [111] |

| VSS: 639 mg/L, - 1240 mg/L, | |||||

| Chlorophyll a: 217 % | |||||

| Chlorophyll b: 36 % | |||||

| Chlorophyll a and b indicate high algal biomass growth |

The co-cultivation of the bacterium V. paradoxus and microalgae T. obliquus and Coelastrella sp. in modified Bold's basal medium resulted in higher specific growth rate of the microalgae, uptake of nitrate (88–99 %) and phosphate (92–95 %), and accumulation of carbohydrate and proteins than the unialgal cultures. Additionally, numerous phytohormones, vitamins, polysaccharides and aminoamides are likely used during their interactions [51]. There are some important steps in the development and realization of microalgae-bacteria consortia; these include selection of the most appropriate cooperative partner species, wastewater characterization and acclimatization of the species, pretreatment of the cells including allowing biofilm formation or immobilization, adjusting the optimum growth condition such as temperature, pH, CO2 flow, nutrient concentrations, and finally inoculate the microalgae and bacteria in the reactor [104].

Recently, mathematical modeling and degradation efficiency of fluoroquinolone by considering microalgae and bacteria have been studied [105]. Compared to the utilization of microalgae or bacteria alone as bioremediation means, microalgae-bacteria consortia has provided more advantages by enhancing biomass accumulation, nutrient removal efficiency, energy generation and lower processing cost. For instance, increased efficiency of algal biomass accumulation, and removal of COD, nitrogen and phosphorous have been reported in the consortium of the microalga C. vulgaris and some bacterial strains [106]. Recently, Cai et al. [107] also showed high performance in volatile organic carbon degradation and accumulation of algal biomass by microalgae-bacteria consortia.

In addition to the enhanced performance, there is a job partition in the consortia. For example, there was primary (81–85 %) removal of ammonium through nitrification by nitrifying bacteria rather than uptake by microalgae [108] and removal of (up to 80 %) total nitrogen via bacterial nitrification/denitrification process in an anaerobically digested photobioreactor [109]. Effective carbon removal by bacteria and effective nitrogen removal by microalgae were reported in the microalga-bacteria consortium operated to treat dairy manure wastewater [110]. The microalgae in the consortium can supply oxygen that can be used by the heterotrophic bacteria to degrade the organic matter. This gives an additional advantage by minimizing the cost of aeration and alleviating the side effects that arise from the treatment of hazardous pollutants that need mechanical aeration but can volatilize during aeration [11]. Hence, in photobioreactors filled with consortia, microalgae can supply oxygen for nitrifying bacteria to oxidize the ammonium in the wastewater, potentially reducing the need for mechanical stirring or oxygenation.

Arun et al. [111] recently innovated an ammonium removal technique in a microalga-bacteria photoreactor system that operates without external aeration. By alternating between light and dark periods and adding methanol as the sole carbon source, they achieved ammonia oxidation to nitrite by bacteria during light periods and nitrite reduction in dark periods. This microalga-bacteria approach effectively removed nitrogen from the system, suggesting its valuable input for practical applications.

2.3. Factors influencing the performance of microalgae-bacteria consortia and optimization mechanisms

The performance of microalgae-bacteria consortia in wastewater treatment and biomass accumulation is significantly influenced by environmental factors, including physicochemical and biological conditions. Factors such as the availability of nutrients, granular size and presence of other pollutants could have negative or positive impacts on the degradation processes. Recently, the effect of carbon-to-nitrogen ratio, light, pH, salinity and temperature on the efficiency of microalga-bacteria consortia has been adequately reviewed [114]. Additionally, environmental factors such as temperature, light, pH, dissolved oxygen concentration and predators have been reported to affect the performance of microalga-bacteria consortia and have been reviewed by Muñoz and Guieysse [11]. Here we briefly discuss some important points that are not covered in those papers.

2.3.1. The type of growth media and hydraulic retention time

The type of growth media greatly influences the efficiency of microalgae-bacteria interactions, impacting biomass production and nutrient removal efficiency. Pérez-Nava et al. [115] demonstrated that C. vulgaris and Pseudomonas sp. have enhanced growth in wastewater compared to Bold's basal media, with microalga growth diminishing as the ratio of Bold's basal media increases. Wirth et al. [20] studied the growth of C. vulgaris and its phycosphere partner bacteria in various media; municipal, industrial, and agricultural liquid wastewaters, and compared with tris-acetate-phosphate medium. Their study revealed notable variations in nutrient removal and bioremediation efficiency depending on the media type, highlighting the alteration of microalga-bacteria cooperation. Tait et al. [116] found that bacterial strains from textile factory wastewater enhanced Chlorella sp. growth in Chu media, which has lower phosphorus and nitrogen, but not in BG11 media, demonstrating how growth-media type influences bacteria-stimulated microalgae growth.

Moreover, the effect of different ratios of tap water and lake water to wastewater was studied in municipal wastewater treatment photobioreactors operated on a lab scale [117]. The report showed that inoculation of lake water in the photobioreactor with the ratio of 70/30 v/v (wastewater/lake water) resulted in better algal biomass accumulation and nutrient removal efficiency than the wastewater alone.

The pretreatment of the growth media can also significantly influence the performance of the consortia. López-Patiño et al. [118] compared the performance of native microalgae-bacteria consortium processing sterilized and non-sterilized domestic wastewater. The result indicated that there was a higher nutrient removal rate and growth of microorganisms in non-sterilized wastewater, suggesting a potential synergy could be developed in the autochthonous consortia.

The hydraulic retention time also affects the performance of the consortia; for example, the effect of hydraulic retention time was studied in high-rate algal pond systems, which are primarily constituted by diatoms, filamentous microalgae and bacteria. The system's performance was initially low on day 2, but significantly improved by days 6 and 10, showing high removal rates of ammonium (>85 %), COD (>92 %), phosphorus (up to 30 %), and increased biomass and methane yields, particularly notable on day 10 [78]. Other researchers also reported the effect of hydraulic retention time on the performance of wastewater treatment [119].

2.3.2. Source of exogenous organic carbon and light intensity

The type of growth condition is one of the important factors that affect the performance of microalgae-bacteria consortia. Ferro et al. [120] investigated the co-cultivation of C. vulgaris and Rhizobium sp. in synthetic wastewater under photoautotrophic, heterotrophic, and mixotrophic conditions. They reported a twofold increase in biomass for axenic algal cultures compared to cocultures under heterotrophic conditions, suggesting potential resource competition. However, under the mixotrophic condition, the biomass increased (compared to axenic algal culture) threefold, along with a 13-fold increase in fatty acid content and higher wastewater treatment performance, indicating there is an exchange of nutrients between the alga and bacterium. Additionally, higher nutrient removal efficiency and biomass production of the microalga C. sorokiniana was reported under anaerobic conditions and in the presence of partner prokaryotic microbiomes [121].

Enhanced biomass production, inorganic nitrogen removal and biohydrogen production were also observed in the coculture of the bacterium M. oryzae and the microalga C. reinhardtii under the provision of ethanol and methanol [122]. Wang et al. [123] explored the impact of glucose and acetate on antibiotic removal (sulfadiazine and sulfamethoxazole) in a microalga-bacterium consortium. They found that glucose addition doubled biomass and promoted Proteobacteria, while acetate favored Bacteroidetes. Both substrates enhanced sulfadiazine degradation but did not affect sulfamethoxazole. The addition of these substrates had a positive effect on the physiology of microalga [123].

The source of exogenous organic carbon could also exert a negative impact on the performance of microalga-bacteria consortia. For example, Zhong et al. [124] showed a consortium that had high biomass accumulation and nutrient removal efficiency, but the system collapsed following the addition of glycerol in the late stage of co-cultivation.

The growth of microalgae and bacteria in the consortia can also be affected by the light condition of the system, as nitrifying bacteria have less light tolerance than microalgae. The light intensity above 450 μmol photons m−2s−1 leads to inhibition of both microalga and nitrifying bacteria, reflected in a reduction of nitrification [125,126]. Owing to this, Nishi et al. [127] proposed a new method by entrapping the bacteria in carbon black-added alginate hydrogel beads named “light-shielding hydrogel”, to enhance the growth performance of bacteria under high light conditions and advance its applications in microalgae-bacteria consortia. They showed the growth of the nitrifying bacteria together with C. sorokiniana in light-shielding hydrogel had better result of nitrification even at high light (1600 μmol photons m−2s−1) intensity.

2.3.3. The ratio of microalgae to bacteria and ratio of macronutrients

The inoculation ratio of microalgae and bacteria is another factor that can influence the performance of the consortia by affecting biomass accumulation and wastewater treatment efficiency. A study on the inoculation ratio of C. vulgaris and Shinella sp. in biogas slurry (50:1, 20:1, 10:1, 5:1 and 2:1) showed that a higher microalga ratio initially increased synergy, but the most effective nutrient removal, algal viability, and biomass were achieved at a 20:1 ratio [128]. The effect of different compositions (1:0, 9:1, 3:1, 1:1, 0:1 wt/wt) of microalgae on the activated sludge ratio was also investigated on nutrient removal and biomass production performance of a photobioreactor [129]. The authors indicated the 3:1 ratio was the optimum for yielding high total biomass accumulation (1.12 g/L) and nutrient removal efficiency. This study revealed that microalgae predominantly removed nitrogen, while bacteria were more effective in COD removal.

Some wastewaters contain disproportionally high concentrations of one of the macronutrients, which alter the general Redfield's ratio and result in stunted growth of microalgae or bacteria in the wastewater treatment system, which again results in low efficiency of the treatment systems. To curb this problem, the addition of scarce nutrients to balance the ratio has been introduced. For example, the effect of the nitrogen to phosphorus (N/P) ratio in swine wastewater was studied by adjusting the concentration of phosphorus in the consortium of Chlorella sp. and indigenous bacteria. The result showed variation in N/P ratio had a clear impact on the performance of the system, where the optimum growth of microalga, extracellular polymeric substance secretion of bacteria and removal efficiency of nutrients were observed at a ratio of 20 [130]. In addition to making various ratios, a better result has been reported by starvation of cells by avoiding some inorganic nutrients such as phosphorus for a limited time [131].

2.3.4. Effect of cations

Recently, besides the role of macro- and micronutrients, the effect of cations on microalga-bacteria cultivation has been reported. For example, owing to the low sedimentation and harvesting performance of microalgae biomass due to their low cell density and negative cell-surface charge [132], Tang et al. [133] studied the efficiency of wastewater treatment and the performance of microalgae harvest in microalga-bacteria cultivation by providing calcium ions (Ca2+). The result indicated that a low concentration of Ca2+ enhanced the removal of COD and nutrients, and the growth rate of microalga. Conversely, higher Ca2+ (10 mM) resulted in decreased removal efficiency of nutrients and COD but promoted microalgae aggregations. The study by Tang et al. [133] suggested that increased Ca2+ levels reduce microalga cell dispersibility by adsorbing onto cell aggregates, neutralizing charges, and compressing the electric double layer. This process, coupled with the promotion of extracellular secretions and flocculation by Ca2+, aids in efficient biomass harvesting.

Furthermore, the role of cations such as Mg2+, K+, and Li+ along with microalga-bacterial cocultivation was studied on wastewater treatment efficiency. The result showed improved pollutant removal efficiency at less than 1 mM of Mg2+ and K+, whereas the provision of Li+ inhibited the performance. Additionally, Tang et al. [134] observed that high concentrations (10 mM) of Mg2+, K+ and Li+ led to lower biomass buildup due to reduced absorption efficiency and an increase in extracellular polymeric substances. The study found that the high charge density of these ions facilitated algal aggregation by drawing water molecules closer, effectively shrinking the gap between algal cells. Nevertheless, recently Collao et al. [135] reported that high levels of Zn (100 mg/L), Cu (100 mg/L) and As (500 μg/L) disrupted Chlorella sp. growth and bacterial populations within a microalga-bacteria photobioreactor.

2.3.5. Effect of cell immobilization

The removal of biomass after wastewater treatment is one of the main challenges, which increases the cost of operation. This problem could be simplified by immobilization and granular formation techniques [114]. The co-immobilization of microalgae and bacteria could enhance the biomass and aggregate formation of the microorganisms. It reduces the distance between cells to ∼1 μm, and consequently induces an effective exchange of nutrients as well as signal molecules [23,136]. Under this condition, a relatively smaller quantity of signal molecules and nutrient production is required than without co-immobilization [23], which sustains the interaction between the microorganisms [137].

The co-immobilized (using alginate beads) consortium of C. vulgaris and bacterium A. brasilense in synthetic wastewater increased (compared to immobilization of microalga alone) the removal of ammonium and phosphorus [138]. Co-immobilization of C. vulgaris and C. sorokiniana with the bacterium A. brasilense showed the removal efficiency of ammonium, nitrate and phosphorus increased from 75 %, 6 % and 19 % (microalgae alone) to 100 %, 15 % and 36 % (microalgae co-immobilized with bacterium), respectively [139]. This indicates that co-immobilization can enhance nutrient removal efficiency. Furthermore, starvation and co-immobilization of C. sorokiniana and A. brasilense consortium showed enhanced removal of phosphorus [131]. The cultivation of the co-immobilized microalgae C. vulgaris and C. sorokiniana with the bacterium A. brasilense increased the accumulation of total carbohydrate and starch production in synthetic media [54].

3. Microalgae-integrated-microbial fuel cells

Fossil fuel-derived energy production faces significant challenges, including its non-renewable nature, contribution to global warming as well as impacts on human health and the ecosystem. Consequently, biofuel energies from biomass [1] and direct electricity generation from microbial fuel cells (MFCs) [2] have emerged as viable and clean alternatives. The application of algal biomass (as a feedstock) has garnered significant attention for producing biodiesel, bioethanol, biohydrogen, and biogas [1], and the role of microalgae-bacteria interaction in biofuel technologies was discussed in the previous section. This section focuses on MFC technology integrated with microalgae. This section critically reviews the integration of microalgae with microbial fuel cells (MFCs) technology.

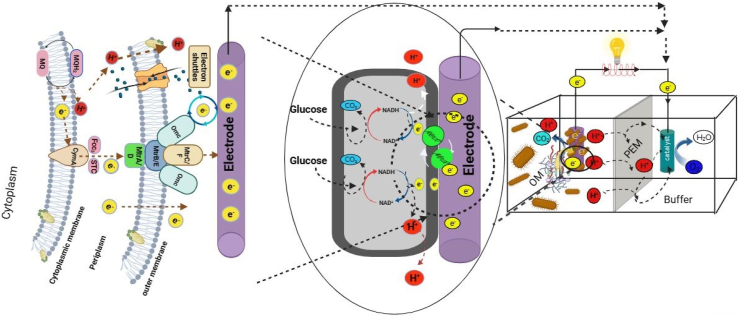

3.1. Microbial fuel cells

The MFC technology has already tracked a centurial history [[140], [141], [142], [143]]. It uses bioelectrochemical systems to convert organic matter into clean bioelectric energy by employing electroactive microorganisms like bacteria and yeast (Fig. 2, Fig. 3a). This technology leverages the redox reduction reaction that occurs during microbial interaction, with degradation of organic matter and transportation of electrons extracellularly to generate energy and value-added substances. The process of extracellular electron transport (EET) involves the transfer of electrons from the quinone pool within the cell membrane to the cell exterior (through periplasm and outer membrane). These electrons traverse a series of cytochrome complexes embedded in the membrane before reaching the surface.

Fig. 2.

Overview of MFC processes and extracellular electron transport (EET) mechanisms. Indirect transport of electrons with shuttle transfer and direct transfer with surface contact is depicted in the left and middle sections of the figure. The electron shuttle mediates the indirect transfer of electrons back and forth between the electrode and bacterial cells. Where, Mtr (metal-reducing) conduit system comprising several multi-heme c-type cytochormes (c-Cyts) including Fcc3-flavocytochrome c3 (tetraheme), MtrA (periplasmic, decamehe), MtrB (outer membrane-bounded), CymA- (cytoplasmic inner membrane-bounded, tetraheme), STC-small tetra heme cytochrome, MtrC (periplasmic protein, decaheme) and OmcA-outer membrane c-Cyt (decaheme). MQ and OM represent menaquinol and organic matter, respectively. The sketch was drawn based on the information provided by Zou et al. [144].

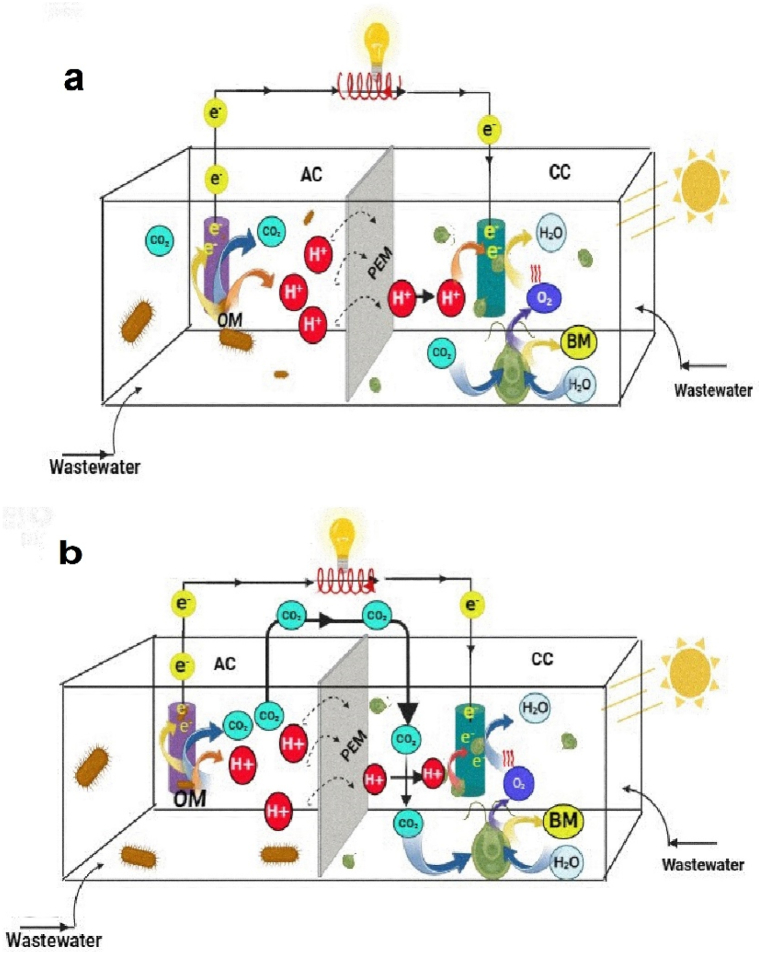

Fig. 3.

Illustration of microbial fuel cell (MFC). a) conventional MFC, where bacteria are electricigens to release electrons from organic matter (OM), b) photosynthetic-MFC (PMFC), where microalgae are electricigens to release electrons from photolysis, and c) microalgae-MFC (mMFC), where microalgae are biocathode by producing oxygen to reduce electron and release water. The diagrams show electrons are transported via external circuits and protons flow through a proton exchange membrane (PEM) to the cathode chambers to react with oxygen and electrons to produce water. The sketch was drawn based on the information provided by Saratale et al. [193].

Once the electrons are at the outer surface, they are transferred to electrodes either directly through physical contact, such as through nanowires in Geobacter sulfurreducens, or indirectly transferred through mediators like flavins, as seen in Shewanella oneidensis [144] (Fig. 2). In the intracellular metabolic process, NADH and FADH2 undergo reduction by accepting electrons and protons. This reduction allows them to participate in the electron transfer chain, thereby generating the cell's energy currency [145]. Electrochemically active microbes employ various EET mechanisms, including nanowires (pili-like structures), c-type cytochromes (heme-containing proteins in the periplasm and outer membrane), and electron shuttles (organic molecules like flavins and pyocyanin, capable of redox reactions) [145] (Fig. 2).

MFCs have shown potential in treating wastewater and generating bioelectricity, biohydrogen, and biomass for biofuel production such as bioethanol and biohydrogen [146,147]. Despite its environmental benefits, MFC technology faces high operational costs, particularly for membranes and mechanical aeration, which hinder widespread adaptation. To address this, microalgae-assisted microbial fuel cells (mMFCs) have been introduced, utilizing microalgae in the cathodic chamber as oxygen generators for wastewater treatment and bioelectricity production [148]. The mMFC technology can be applied in domestic wastewater to remove nutrients and generate electricity [[149], [150], [151]], acid drainage system [152] to generate electricity and remove ferrous iron by oxidizing it to insoluble iron (III) (a precipitate to settle down on the anode side [12], and to generate electricity and remove nutrients from agricultural wastewater [147], landfill leachate [153], industrial wastes [146,154,155], and ammonium-rich wastewaters [111].

It was reported that using the microalga Scenedesmus obliquus in the cathodic aeration process nearly doubled the efficiency of the mechanically aerated cathode [156]. Additionally, mMFCs offer benefits over conventional MFCs by eliminating the need for costly and environmentally detrimental catalysts and buffers [157]. Besides, Commault et al. [158] revealed increased electricity generation, nutrient removal and COD removal efficiencies in wastewater treatment of cathodic C. vulgaris, compared to catholytes of phosphorus buffer and anode effluent. Notably, higher COD removal efficiency was observed when microalgae were used as a substrate in a closed-circuit MFC, compared to an open-circuit system, indicating that bioelectricity generation enhanced the degradation of organic matter [159].

3.2. The roles of microalgae in the MFCs

Microalgae offer diverse functions within MFCs (Fig. 3b and c). In the anode chamber, it can act as a substrate for exoelectrogenic bacteria or a donor of photolytic hydrogen and electrons (as previously discussed in Section 2.2.3. and Section 2.2.4). Conversely, in the cathode chamber, microalgae primarily function as electron acceptors. However, the application of microalgae as bioanodes (electron and hydrogen donors) is challenged by their limited exoelectrogenic capacity and the inhibitory effect of oxygen on hydrogen production. Therefore, microalgae are predominantly utilized as substrates in the anode or as electron acceptors (biocathodes) in the cathode chamber. Unlike in the anode, microalgae are particularly effective as electron acceptors in the cathode. Their photosynthetic by-product, oxygen, efficiently facilitates the reduction of electrons transferred from the anode. For clarity, the term 'mMFC’ is used when microalgae are applied as feedstock in the anode or serve as biocatalysts and oxygen providers in the cathode. The term 'PMFC’ is used when microalgae function as electron providers in the anode chamber.

3.2.1. Microalgae biomass as sources of electrons in the anode

The living or dry biomass of microalgae can serve as substrates for bacterial degradation in MFCs. Strik et al. [160] demonstrated successful electricity generation using living algal biomass in an mMFC connected to a photobioreactor, though the electricity output was rather low. This approach also offers the opportunity to utilize microalgae from natural occurrences, particularly during algal blooms, thus aiding in environmental remediation and electricity generation. Algal biomass has been shown to produce electricity [161], along with simultaneous reduction of microcystin [162], disinfection by-products [163] and chromium [164]. As the energy recovery efficiency varies with different microalgal species, Velasquez-Orta et al. [165] reported different energy recovery efficiencies from C. vulgaris and Ulva lactuca. Furthermore, the complete degradation of microalgae biomass is hindered by several factors, such as cell wall resistance and enzyme deficiency, impeding complete degradation and electricity generation potential. For example, Kondaveeti et al. [159] found that the variation in concertation of degradation by-products in the anolyte was coupled with variation in electricity production levels.

Besides variation in cell content, the resistance of microalgae cell walls to hydrolysis presents a significant challenge. To enhance biomass degradability and electricity production, various pretreatment methods have been explored, such as autoclaving, ultrasonication, microwave irradiation, and exposure to acidic or alkaline solutions, which have proven to be effective in improving biomass suitability for mMFCs [166,167]. Notably, innovative approaches have been employed to utilize cyanobacteria biomass from blooming lakes [168]. They reported successful electricity production using cyanobacterial biomass from Taihu Lake, China, pretreated with alkaline solutions and acidic fermentation. Further enhancing the degradation process, an anaerobic digester connected to an MFC has been utilized for pretreating algal biomass, facilitating its breakdown [169]. Nishio et al. [170] demonstrated that Lactobacillus amylovorus, an algal-digesting bacterium, is essential for G. sulfurreducens to efficiently degrade C. reinhardtii biomass and generate electricity. The L. amylovorus ferments the algal biomass, producing by-products like lactate, which G. sulfurreducens then utilize for electricity production.

3.2.2. Photosynthetic electricigens in the anode-bioanode

Photosynthetic microbial fuel cells (PMFCs) utilize microalgae as electricigens in the anode, a concept distinct from conventional microalgae-integrated MFCs (mMFCs). PMFCs generate electrons through water photolysis, whereas mMFCs typically use microalgae as organic substrates for electron donation or oxygen production (Fig. 3b). The potential of microalgae in PMFCs was recognized following early experiments [171] on cyanobacteria and Rhodospirillum rubrum, demonstrating the conversion of light energy to electrical energy. In the subsequent studies, Ochiai et al. [172] demonstrated the potential application of cyanobacterium (Mastigocladus laminosus) as anodic photoelectrode (both immobilized and non-immobilized cells deposited on the electrode), indicating increased photocurrent output as well as the current potential of the algal film deposited on SnO2-electrode upon illumination. Moreover, the anodic photocurrent production has been forwarded as an electron-donating system to hydrogenases in biohydrogen production systems through the photolysis of water, particularly in two-stage operation systems [172]. Building on this concept, Yagishita et al. [173] observed a significant increment of current output with the addition of illumination and CO2 in a PMFC using Synechococcus sp. cultures, reinforcing the potential of this approach.

The ability of a photosynthetic organism to evolve oxygen through an efficient water oxidizing system (oxygen-evolving complex), has led scientists to explore a means to utilize or manipulate natural photosynthetic apparatus for energy conversion. It has been explored to redirect electrons from the photosynthetic electron transport chain towards bioelectricity or biofuel production [174]. In this exploration, promising results have been reported for the development of PMFC as a whole cell of photosynthetic microorganisms [175,176] or discrete photosynthetic machineries such as thylakoid [174], PSI [177] and PSII [178] have been implemented as biocatalysts to generate photocurrent in the anode side of photoelectrochemical cells. PMFCs, uniquely reliant on water and light, offer an advantage over traditional MFCs, which require organic sources.

Regarding electron generation in PMFCs, microalgae can be involved in two different processes: 1) transferring electrons from the photosynthetic electron transport chain directly to the anode. In support of this, Pisciotta et al. [179] indicated the electrons in PMFCs could originate from the photosynthetic electron transport chain of PSII. 2) transferring electrons from the respiratory electron transfer chain by oxidizing the organic matter, which is fixed through photosynthesis. For example, the photosynthetic activity of cyanobacterium (M. laminosus) was not completely halted upon the addition of PSI inhibitor (dichlorophenydimethylurea), suggesting that, apart from water molecules, other substances such as NADH and reduced metabolites were serving as electron donors to PSI [172]. Additionally, Tanaka et al. [180] also reported that the cyanobacterium Anabaena variabilis generates electricity from endogenous glycogens during the dark period, while electrons are generated from both glycogen and photosynthetic oxidation of water in the light period for electricity generation. Nonetheless, the transfer of electrons from microalgae to the anode is often hindered, requiring redox mediators like 2-hydrozy-1,4-naphthoquinone for efficient bioelectrochemical processes [173].

Effective electron production and transport to anodes typically occur under anoxic conditions. Thus, maintaining an anoxic environment in the anolyte media through nitrogen gas bubbling is essential [173]. Factors such as oxygen exposure, pH, temperature, electrode spacing, and light intensity also significantly influence PMFC performance [[181], [182], [183], [184]]. In general, microalgae are not suitable electricigens as they also produce oxygen, which is a perfect electron scavenger. Therefore, a consortium of photosynthetic microalgae and electrogenic bacteria could be cultivated in the anode to make them establish syntropy. For instance, the generation of electricity by non-phototrophic electricigens bacterium G. sulfurreducens using organic substrate supplied by photosynthetic green microalga C. reinhardtii has been reported [184].

3.2.3. Electron acceptor in the cathode-biocathode

The integration of microalgae into the cathodic chamber of MFCs has garnered increasing interest due to its multifaceted benefits [185]. These include the production of oxygen, i.e. an efficient electron acceptor, along with valuable biomass accumulation and environmental remediation through wastewater treatment and CO2 scavenging [166] (Fig. 3c). There is a preference for utilization of oxygen from the photosynthetic process of microalgae over mechanical aeration due to the high energy consumption in mechanical aeration [186]. The co-culture of C. vulgaris in the cathode chamber increased the power density by 41.7 % (from 175 mW m−2 to 248 mW m−2) [187]. Moreover, the presence of microalgae correlates with enhanced current production, as the generation of oxygen facilitates electron reduction in the cathode, especially under increased light conditions [188,189].

Beyond oxygen provision, microalgae function as biocatalysts in the cathode, introducing more potent electron acceptors like reactive oxygen species (ROS)-hydrogen superoxide (H2O2) and peroxide anion radicals (O2ˉ), which can further enhance the electron reduction process [190]. The role of ROS in electron reduction, which boosts electricity generation, has been evidenced by the decline in electricity generation when ROS production is inhibited by mannitol, as shown by Cai et al. [190] using the biocathode of cyanobacterium Microcystis aeruginosa. Additionally, microalgae scavenge CO2 during photosynthesis. The accumulation of biomass which serves as bioenergy [191] or value-added compounds such as pigments [192] promoted due to photosynthetic CO2 fixation of microalgae in biocathode.

As microalgae are capable of assimilating nutrients, wastewater treatment is another advantage that could be attained using microalgae in a biocathode [154]. If wastewater is supplied to microalgae in the cathode, then wastewater treatment and biomass accumulation can be achieved simultaneously [104,188]. However, the growth of heterotrophic bacteria that degrade the organic matter can consume oxygen and interfere with the cathodic reaction by diminishing electron reduction, which ultimately reduces electricity generation [166]. An alternative means to overcome this problem is to feed the wastewater first to the anode as pretreatment and then transfer effluent to the cathode for algal growth [166].

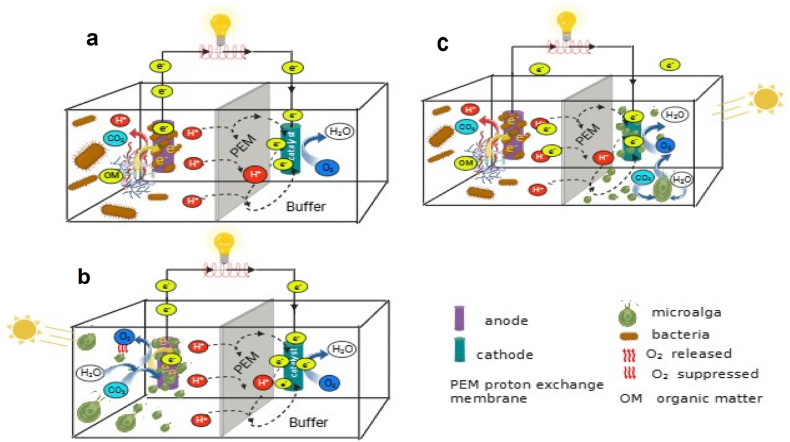

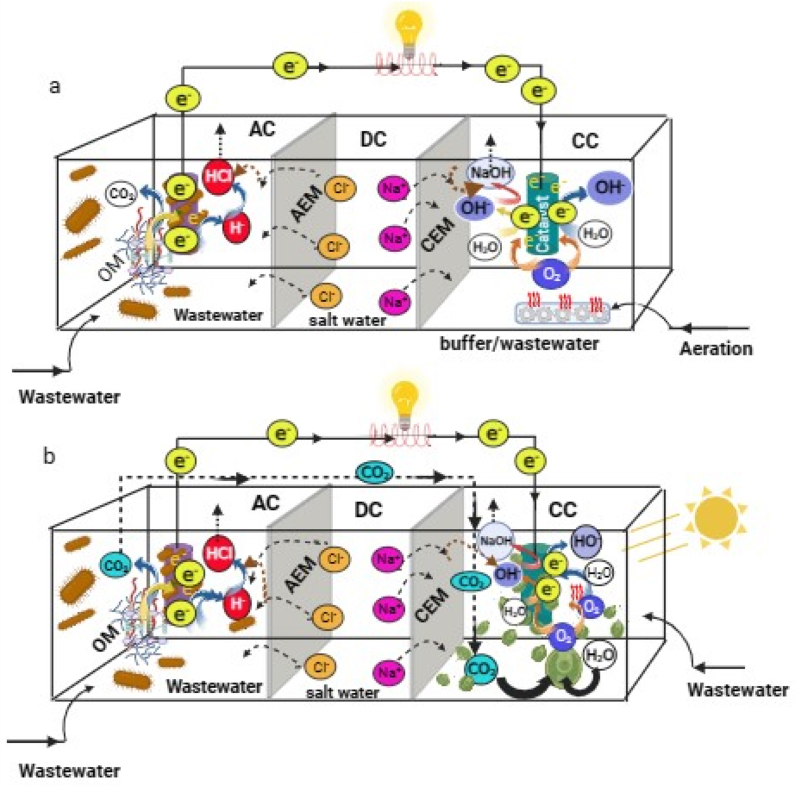

3.3. Variations in microalgae-integrated microbial fuel cells

In recent decades, MFCs have evolved into various forms, including microbial carbon capture cells (MCCs), microbial desalination cells (MDCs) and sediment microbial fuel cells (SMFCs) (Table 2). These systems have shown promising results in bioenergy production, biofuel generation, wastewater treatment and environmental remediation. In the anode chamber of MFC, the exoelectrogenic bacteria transfer electrons to the anode by oxidizing organic matter, while in the cathode chamber, it can be oxygen reduction or hydrogen evolution. Microalgae are introduced in the cathode to supply oxygen for oxygenic reduction (Fig. 4a). These oxidation-reduction reactions create an electric field across the electrodes, facilitating ionic transport. By incorporating ion-exchange membranes (IEM) between the electrodes, this ionic movement can be harnessed in MDCs to segregate salt ions in the reactor chamber. Consequently, in MDCs, the cathode and anode chambers receive cations and anions, respectively from wastewater, leading to partial or complete desalination of the saltwater in the middle chamber [194].

Table 2.

Comparative evaluation of various microalgae integrated with microbial fuel cell technologies.

| Features | Microbial Carbon Capture Cells (MCCs) | Sediment Microbial Fuel Cells (SMFCs) | Microbial Desalination Cell (MDC) |

|---|---|---|---|

| Principle | CO2 is produced at the anode used by microalgae at the cathode. | The anode is buried in sediment, cathode is in the overlying water. | Electrical potential from microbes degrades organics and drives ion migration. |

| CO2 utilization | Efficient sequestration through microalgal photosynthesis. | Synergistic bioelectrochemical reactions under light exposure. | CO2 can be scavenged by biocathodes. |

| Integration with photosynthesis | Enabled CO2 consumption coincides with increased biomass. | Supported by photosynthetic microorganisms at the cathode. | Photosynthetic MDCs (PMDCs) use microalgae to generate oxygen and remove pollutants. |

| Electricity production | Enhanced algal biomass leads to increased power density. | Typically, low due to environmental conditions, but can be enhanced. | Bioelectricity generation is a primary function. |

| Biomass accumulation | Reported increased power density due to microalgae activity. | Stable power densities and nutrient removal under illumination. | Possible when using microalgae in the cathode or anode. |

| Wastewater treatment | Can be integrated for treatment and value-added compound production. | Potential in sediment bioremediation and biomass production. | Simultaneous wastewater treatment with desalination. |

| Challenges |

|

|

|

| References | [173,[195], [196], [197], [198], [199], [200]] | [168,[201], [202], [203], [204], [205], [206], [207], [208], [209], [210], [211]] | [[212], [213], [214], [215], [216], [217], [218], [219], [220]] |

Fig. 4.

Illustration of microalgae-MFC where microalgae inoculated as biocathode (a) and MCC where microalgae inoculated as biocathode and CO2 from the anodic chamber (AC) is channeled to cathodic chamber (CC) (b). Where OM is organic matter and BM is biomass accumulated. The sketch was drawn based on the information provided by Das et al. [196].

3.3.1. Microbial carbon capture cells

The MCCs represent an innovative modification of MFCs, where CO2 generated at the anode through organic matter degradation will be utilized by microalgae in the cathode. This process enables effective CO2 sequestration through photosynthesis, as shown in Fig. 4b. MCCs are integrated to attain wastewater treatment and value-added compounds [196,197]. Wang et al. [195] demonstrated that MCCs effectively reduce inorganic carbon concentration in the cathode (compared to the control) and contribute to enhanced algal biomass and power density. This capability was further evidenced by Pandit et al. [198], who reported increased power density when Anabaena sp. in the cathode was sparged with a CO2-air mixture.

The performance of MCCs varies with the type of microalgae used in the cathode. Jadhav et al. [197], found superior performances of MCCs in power production, Coulombic efficiency, COD removal, and biomass accumulation by Anabaena ambigua compared to Chlorella pyrenoidosa. This was attributed to C. pyrenoidosa's higher oxygen production and lower cathodic charge transfer resistance. Besides, the performance of MCCs is also affected by the concentration of CO2 received from the anode chamber, which again depends on the substrate given for the bacteria to degrade. Cui et al. [167] investigated the performance of MCC by providing either lyzed powder of microalga (Scenedesmus) or acetate as an electron source (substrate) at the anode, transferring the released CO2 by silicone tube, and inoculating C. vulgaris in the cathode. They found that, compared to MCC provided with acetate, the MCC provided with algal powder as the substrate showed higher CO2 to the cathode, which coincided with higher biomass and power output, however, the power generation duration was shorter may be related to incomplete degradation of the provided algal biomass-substrate. They also reported that the concentration of substrate is another factor that affects the performance of MCCs, whereby the performance of MCCs increased with the increase of COD until some maximum limit, beyond which the growth of microbes declined.

As CO2 utilization by microalgae is affected by the growth condition of the microalgae, it has been manipulated to enhance and optimize the performance of microalgae in MCCs. For example, Zhou et al. [199] showed the immobilized C. vulgaris cells in the cathode, had 84 % COD removal, 88 % increased maximum power density and 57.7 % increased Coulombic efficiency compared to suspended cells. This approach highlighted the feasibility of employing immobilized microalgae as electron acceptors in MCCs for steady voltage output.

Despite the promising aspects of MCC technology in CO2 sequestration, biomass accumulation, electricity production, and wastewater treatment, some challenges must be resolved to facilitate the commercialization of this technology. These include managing dissolved oxygen (DO) levels at the cathode, standardizing substrate and CO2 inputs, as well as enhancing overall MCC performance. Chiu et al. [200] and Yagishita et al. [173] noted that CO2 addition increases current output, but high CO2 concentrations can restrain microalgae growth. To address this, Chou et al. [221] developed mutant strains of C. vulgaris with enhanced tolerance to high CO2 and temperature, showing potential for improved MCC performance. The application of genetically engineered strains could thus play a key role in maximizing MCC efficiency and CO2 sequestration capabilities.

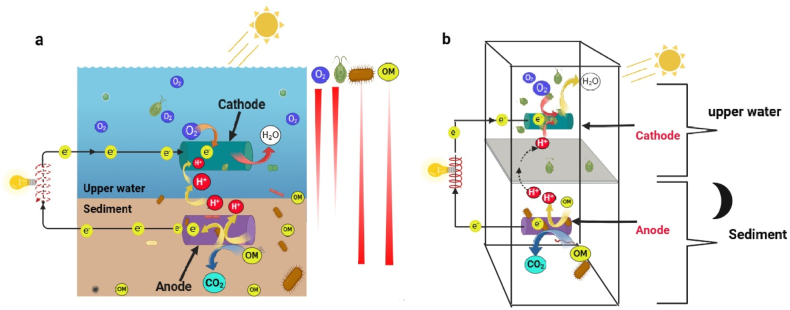

3.3.2. Sediment microbial fuel cells (SMFCs)

The SMFCs or benthic MFCs, represent an adaptation of conventional MFCs designed for natural environments with minimal engineering intervention (Fig. 5a). In SMFCs, an anode buried in sediment undergoes microbial oxidation, while a cathode placed in overlying water facilitates the electron-accepting process (Fig. 5b). In comparison to conventional MFCs, this configuration allows seamless electron transfer without a clear separator, which also exploits the natural stratification with low DO concentration in the sediments [201]. Although SMFCs typically exhibit low power output due to factors like limited electron donors or acceptors and environmental conditions (such as pH, temperature and large internal resistance), the easily-built structure and cost-effective construction of the SMFC makes it viable for remote area applications [[202], [203], [204]]. The power output in SMFCs can be enhanced through approaches such as increasing oxygen availability at the cathode [222], using macrophytes or rotating cathodes [223,224] and supplementing organic matter at the anode.

Fig. 5.

An illustration of SMFC (a) and PSMFC inoculated with microalgae (b), installed with an anode buried in sediment and a cathode hung in the surface water. Where OM is organic matter. The sketch was drawn based on the information provided by Yang and Chen [230].

The role of microalgae and heterotrophic bacteria in SMFCs has been extensively studied. He et al. [205] developed SMFC by inoculating lake sediment and water in a glass beaker and found that current production increased under light exposure, indicating the presence of a synergistic bioelectrochemical reaction between photosynthetic microorganisms and bacteria. Similarly, Malik et al. [206] constructed SMFC using marine sediment and water, whereby current production increased upon illumination. A recent investigation by Bardarov et al. [207] further confirmed the crucial role of cathodic biofilms, particularly photosynthetic microorganisms, in enhancing SMFC performance, with the observation of concurrent increment of pigmentation and current production during illumination.