Abstract

In this study, the volatile components in 40 samples of Tartary buckwheat and common buckwheat from 6 major producing areas in China were analyzed. A total of 77 volatile substances were identified, among which aldehydes and hydrocarbons were the main volatile components. Odor activity value analysis revealed 26 aromatic compounds, with aldehydes making a significant contribution to the aroma of buckwheat. Seven key compounds that could be used to distinguish Tartary buckwheat from common buckwheat were identified. The orthogonal partial least squares-discriminant analysis was effectively used to classify Tartary buckwheat and common buckwheat from different producing areas. This study provides valuable information for evaluating buckwheat quality, breeding high-quality varieties, and enhancing rational resource development.

Keywords: Buckwheat, Volatile substances, Odor activity values (OAV), Principal component analysis (PCA), Orthogonal partial least squares discriminant analysis (OPLS-DA)

Highlights

-

•

77 volatile compounds and 26 key aromatic compounds were identified in 40 buckwheat samples.

-

•

Aldehydes made a large contribution to the overall aroma of buckwheat, especially nonanal and trans-2-nonenal.

-

•

7 key compounds that can be used to distinguish tartary buckwheat from common buckwheat were identified.

-

•

The diversification analysis and screening model of buckwheat flavor characteristic components were established.

1. Introduction

Buckwheat, which belongs to the genus Fagopyrum, is widely grown in Asia, Europe, and the Americas. Two species, namely common buckwheat (Fagopyrum esculentum Moench) and Tartary buckwheat (Fagopyrum tataricum (L.) Gaertn.), are of great agricultural importance worldwide (Ji et al., 2019). These two species differ in terms of their utilization value and cultivation range. Common buckwheat is widely distributed in temperate regions of the Northern Hemisphere, whereas Tartary buckwheat primarily grows as a crop in high-altitude regions. Buckwheat has a long history of being used as both food and multifunctional medicine in Asian countries (Zhu, 2016). Numerous modern scientific and pharmacological studies have shown that buckwheat possesses numerous beneficial effects, including antioxidant (Bae & Kim, 2022), antitumor (Ke et al., 2021), antihypertensive (Ramos-Romero et al., 2020), anti-inflammatory (Giménez-Bastida, Laparra-Llopis, Baczek, & Zielinski, 2018), anti-fatigue (Jin & Wei, 2011), hypoglycemic (Chiang et al., 2023), cholesterol-lowering (Sun et al., 2019), and hepatoprotective activities (H. Wang et al., 2021).

China is a major producer and exporter of buckwheat. In 2021, the total production of buckwheat was 549.7 thousand tons, of which Tartary buckwheat accounted for 65%. Currently, Tartary buckwheat is mainly produced in the southwest provinces of Yunnan, Guizhou, and Sichuan, as well as in the northwest provinces of Shaanxi and Gansu. Common buckwheat is primarily produced in Inner Mongolia, Shaanxi, Shanxi, Gansu and Ningxia provinces.

In recent years, buckwheat and its products have received considerable attention owing to their potential health benefits (Shi et al., 2021). Studies have shown that buckwheat is rich in nutritional and functional components, such as protein, starch, vitamins, minerals, and flavonoids (Gomathi, & S., P., 2022). Currently, buckwheat is used as raw materials for several food products, such as bread (Diowksz & Sadowska, 2021), noodles (Puligundla & Lim, 2021), and vinegar (Yu, Yang, Dong, & Shen, 2018). In addition, buckwheat and its processed products have unique aroma characteristics (J. Wang et al., 2022). Sixty-five compounds were identified in Tartary buckwheat tea using gas chromatography–mass spectrometry (GC–MS) and gas chromatography–olfactometer (GC–O) (Qin, Ma, Wu, Shan, & Ren, 2011). Among these compounds, 2,5-dimethyl-4-hydroxy-3(2H)-furanone, nonanal, 2,3-diethyl-5-methylpyrazine, phenylacetaldehyde, maltol, 2,5-dimethylpyrazine, 2-ethyl-5-methylpyrazine, and 2,3,5-trimethylpyrazine mainly contributed to the aroma. In another study (Wang, Zhang, & Li, 2012), the volatile components in Shanxi Tartary buckwheat vinegar were analyzed and found that 1-(2-furanyl) ethyl ketone, isoamyl acetate, ethyl pentanoate, tetramethylpyrazine, and benzothiazole constituted the main aroma of Tartary buckwheat vinegar. The current flavor research mainly focuses on various processed buckwheat products, however, there is insufficient research on the aroma of buckwheat itself. The evaluation standards for the aroma of natural buckwheat are inconsistent across different studies, thus hindering the utilization of germplasm resources and effective identification of buckwheat.

Aroma characteristics play a crucial role in the evaluation of buckwheat quality. The systematic analysis of the characteristic aroma components in buckwheat varieties from major producing regions in China establishes a relationship between these components and their respective sources. This provides a data basis for evaluating the quality of buckwheat. In this study, 40 buckwheat samples from six main buckwheat-producing areas in Gansu, Guizhou, Yunnan, Sichuan, Ningxia, and Shanxi provinces were selected and analyzed. Headspace solid-phase microextraction (HS-SPME) combined with gas chromatography–mass spectrometry (GC–MS) was used to separate and identify volatile components in buckwheat from different origins and varieties. The multivariate statistical method was used to analyze the differences between the aroma composition and content of buckwheat varieties from different origins and varieties, and their characteristic aromas were also identified. This study supplements the aromatic information of buckwheat in China, reveals the relationship between variety, origin, and aroma characteristics, and provides a reliable technique for identifying buckwheat with different germplasm resources. In addition, it provides a certain reference value for buckwheat quality evaluation, high-quality variety breeding, and rational resource development.

2. Materials and methods

2.1. Materials and chemicals

The divinylbenzene/carboxen/polydimethylsiloxane SPME fiber (2 cm 50/30 μm DVB/CAR/PDMS stable flex), n-Alkanes standard (C6-C20) and 2-octanol were purchased from Sigma-Aldrich(St. Louis, MO, USA).

2.2. Sample collection

All buckwheat samples were provided by China National Oat and Buckwheat Industrial Technical System. At least three representative products were selected as samples for each region of every variety. The 25 Tartary buckwheat samples were from Gansu (No. GS06, GS07, GS08, GS09, GS10, GS11, GS12, and GS13), Guizhou (No. GZ02, GZ03, GZ05, GZ06, GZ07, and GZ08), Sichuan (No. SC01, SC02, SC03, SC04, and SC05), Yunnan (No. YN01, YN02, and YN03), and Shanxi (No. J01, J05, and J07). The 15 common buckwheat samples were from Gansu (No.GS01, GS02, GS04, and GS05), Shanxi (No. J02, J03, J08, J09, J11, and J12), and Ningxia (No. NX10, NX11,NX12, NX13, and NX14).

All buckwheat samples were sealed and stored in a − 80 °C freezer for GC–MS analysis and aroma assessment.

2.3. Sample preparation

Volatile compounds from buckwheat were extracted using the HS-SPME method according to Prosen et al.'s method (Prosen, Kokalj, Janeš, & Kreft, 2010) with a slight modification. Before extraction, SPME fibers were conditioned at 250 °C for 30 min and checked for interference and carryover. Meanwhile, 3.00 g of buckwheat flour was transferred into a 20 mL SPME vial containing 20 μL of the internal standard (2-octanol, 8.83 μg/mL), sealed, and then incubated in an auto-heating system for 15 min to allow heat equilibration. Then the pretreated fibers were inserted into the vial and exposed to the headspace of the buckwheat sample. The extraction process lasted 60 min, during which the sample temperature was maintained at 60 °C. Peak areas for most 2,3-diethyl-5-methylpyrazinevolatile compounds were optimized based on a 20-min extraction. After the extraction, the compounds were desorbed from SPME fibers in the GC inlet at 250 °C for 1 min. Three parallel experiments were performed on all buckwheat samples.

2.4. GC–MS analyses

The extracted volatile organic compounds (VOCs) were analyzed using a Shimadzu GC-2010 Plus system equipped with a TQ8040 MS (Shimadzu, Tokyo, Japan), using helium (purity 99.999%) as carrier gas. The gas flow rate, split ratio, and injector temperature were set at 1 mL/min, 10:1, and 250 °C, respectively. Chromatographic separation was achieved using an SH-Rtx-Wax analytical fused silica capillary column (30 m × 0.25 mm × 0.25 μm, Restek Corporation, Benner Circle, Bellefonte, PA, USA). The column temperature was programmed as follows: 50 °C for 4 min, 10 °C/min to 100 °C, 5 °C/min to 200 °C, 15 °C to 230 °C/min, and hold for 5 min. The ion source temperature and mass detection range were set to 250 °C and 33–500 m/z, respectively.

2.5. Identification and quantification of volatile compounds in Tartary buckwheat

The retention index (RI) of the peak on the Rtx-wax column was determined and calculated according to the n-paraffin retention index method, and the retention index of others was compared with the NIST network database. Furthermore, the compounds were characterized by comparing the base peak, mass-to-charge ratio, and RI value with the NIST14.L standard library. The relative content was quantitatively analyzed by peak area using 2-octanol as an internal standard (Zhou, Chen, Zhu, Sun, & Zhou, 2022). OAV was used to identify key volatile compounds in buckwheat, and OAV was calculated based on the ratio of the concentration of volatile components to their sensory threshold concentrations (Wang et al., 2020).

2.6. Statistical analyses

SPSS 26 statistical software and SIMCA 14.1 software were used for data analysis. Univariate statistical evaluation was conducted using multivariate analysis of variance (MANOVA). Variables with p < 0.05 were considered to be statistically significant. Principal component analysis (PCA) was used to reduce the dimensionality of the multivariate data without compromising its variance (Olivieri, 2018). Data were drawn using Origin 2022 and TBtools.

3. Results and discussion

3.1. Volatile components based on content in different buckwheat

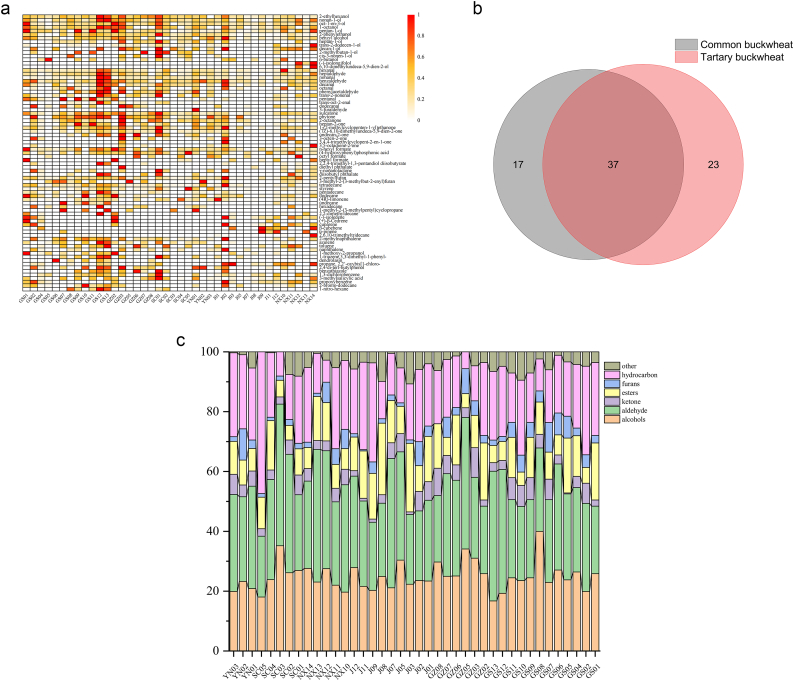

A Venn diagram of volatile components in buckwheat is shown in Fig. 1. A total of 77 volatile components were detected in 40 buckwheat samples, including 15 alcohols, 12 aldehydes, 10 ketones, 8 esters, 2 furans, 19 hydrocarbons, and 11 other compounds (Fig. 1a). Among them, 37 components were detected in both Tartary and common buckwheat, while 23 and 17 components were detected in Tartary buckwheat and common buckwheat, respectively (Fig. 1b).

Fig. 1.

Volatile components in buckwheat. (a) Heat map of the determination results of buckwheat using GC–MS, (b) Venn diagram of volatile substances in buckwheat from different varieties showing the percentages of the volatile content, and (c) percentage volatile content of buckwheat.

The proportion of each volatile component content category is shown in Fig. 1c. Most of the volatile components in buckwheat were alcohols, aldehydes, and hydrocarbons, accounting for 61.91–90.02% of the total volatile components, indicating that these three specific types of compounds might constitute the main part of buckwheat aroma. Sixteen alcohols were detected in 40 different buckwheat samples, accounting for 20.27–39.99% of the total volatile components. Among 16 alcohols detected, the contents of fatty alcohols (such as nonan-1-ol, 1-octanol, and oct-1-en-3-ol) with green, fatty, and fruity aromas were the highest, followed by aromatic alcohols, benzyl alcohol, and 2-phenylethanol, which have a strong rose-scented aroma. A total of 12 aldehydes were detected, accounting for 20.33–47.36% of the volatile components in buckwheat. Among them, fatty aldehydes (such as hexanal, decanal, and nonanal) had the highest concentrations, contributing to the fatty, grassy, and citrus peel aromas of buckwheat. These fatty aldehydes were mainly associated with the degradation of unsaturated fatty acids (Kim, Lee, & Kim, 2016), (Kebede et al., 2014). Benzaldehyde, with a strong almond and hyacinth aroma, was also detected.

3.2. Determination of the key volatile components of buckwheat

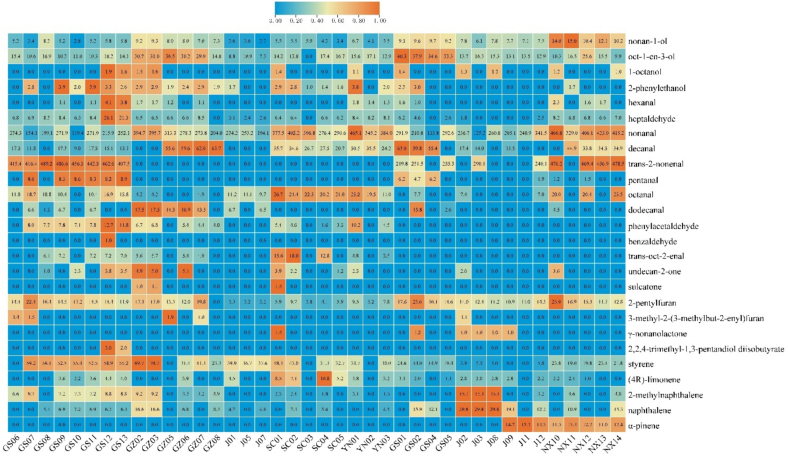

To further investigate the contribution of different types of compounds to the formation of buckwheat flavor and how they differ between production regions and varieties, key aroma volatiles with an OAV value >1 were identified. This identification was achieved by querying the sensory thresholds of the compounds (Gemert, 2003) and calculating their OAV values. As shown in Fig. 2, a total of 26 compounds (11 aldehydes, 4 alcohols, 2 ketones, 2 furans, 2 esters, and 5 olefins) with OAV values >1 were detected in 40 buckwheat samples. Among them, aldehydes had the highest OAV values and made a significant contribution to the overall aroma of buckwheat. In particular, nonanal (OAV: 119.3 to 466.8) and trans-2-nonenal (OAV: 219.8 to 489.2) contributed the most to the flavor of buckwheat, providing fatty, lime peel, and citrus aromas.

Fig. 2.

Heat map of the OAV results for buckwheat.

3.3. Characteristic volatile components of different varieties of buckwheat

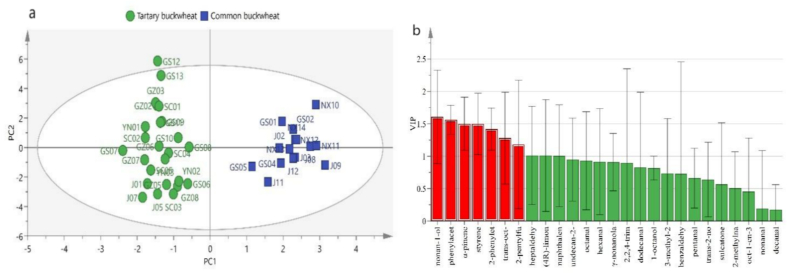

OPLS-DA is a supervised mode regression analysis method based on the orthogonal signal correction method (He et al., 2020), which has a good ability to separate predictive and non-predictive (orthogonal) variants (He, Huang, Gorska-Horczyczak, Wierzbicka, & Jelen, 2021). In this experiment, the aroma activity value of the selected volatile substances was used to conduct an OPLS-DA analysis to explore the relationship between the aroma of buckwheat and its origin and variety. The explanatory variables (R2) and predictive power (Q2) of the OPLS-DA prediction model were 0.938 and 0.878, respectively. These values were obtained using interactive residual validation ANOVA. The results showed that the model was well classified and had good predictive power for the key aroma components in different varieties of buckwheat (Fig. 3a).

Fig. 3.

Characteristic volatile components in buckwheat: (a) principal component score graph and (b) factors for OPLS-DA analysis variables (VIP values) in buckwheat samples.

The variable importance in the projection (VIP) value of OPLS-DA can be used to determine the contribution of each variable to the classification, which is convenient for screening important characteristic substances. Fig. 3b shows the distribution of VIP values for differential compounds in different buckwheat varieties. Compounds with VIP value >1 were selected as important differential compounds. The larger the VIP value, the greater the difference of the compound among the buckwheat samples, and the higher the contribution to the difference between the samples of buckwheat. Seven important differential compounds, namely nonan-1-ol, phenylacetaldehyde, styrene, α-pinene, 2-phenylethanol, trans-oct-2-enal, and 2-pentylfuran, in Tartary buckwheat samples from different origins, were screened.

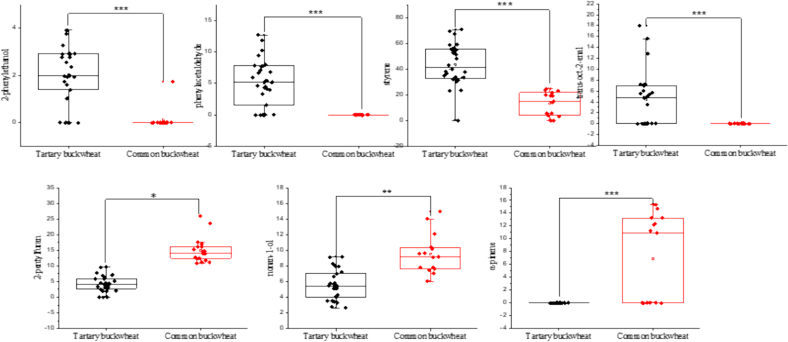

According to the significance analysis (Fig. 4), 2-phenylethanol (rose), styrene (sweet), phenylacetaldehyde (green), and trans-oct-2-enal (sweet) were identified as the main characteristic volatile components in Tartary buckwheat, while α-pinene (rosin), 2-pentylfuran (fruit), and nonan-1-ol (waxy) were identified as the main characteristic volatile components in common buckwheat.

Fig. 4.

Comparing the main volatile components in Tartary buckwheat and common buckwheat.

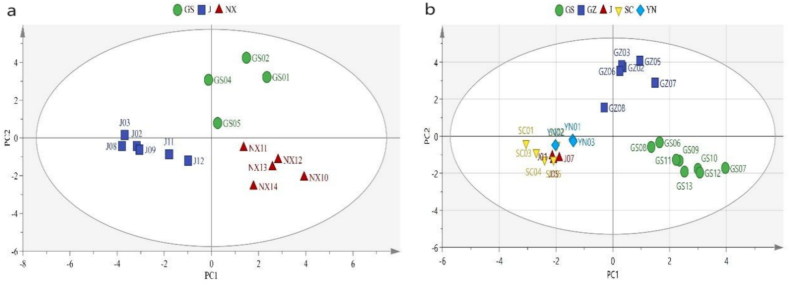

3.4. Differences in the aroma of buckwheat from various origins

Fig. 5 shows the classification of Tartary buckwheat and common buckwheat samples in each production area. The explanatory variables (R2) and predictive power (Q2) of the OPLS-DA predictive model for common buckwheat using interaction residual validation ANOVA were 0.967 and 0.898, respectively. These values indicated that the model provided a good classification of key aroma components in common buckwheat from different production areas and had good predictive power. The common buckwheat samples from the three producing areas can be roughly divided into three categories, among which Sichuan, Yunnan, and Shanxi can be combined into one category, Gansu into one category, Guizhou into one category (Fig. 5a). The explanatory variables (R2) and predictive power (Q2) of the OPLS-DA predictive model for Tartary buckwheat were 0.730 and 0.508, respectively, providing a classification of key aroma components in Tartary buckwheat from different production areas. The result shows that Tartary buckwheat samples from the five producing areas can be roughly divided into three categories, among which Gansu can be combined into one category, Shanxi into one category, and Ningxia into one category (Fig. 5b).

Fig. 5.

Characteristic volatile components in different buckwheat: (a) distinguished by different origins in common buckwheat and (b) distinguished by different origins in Tartary buckwheat.

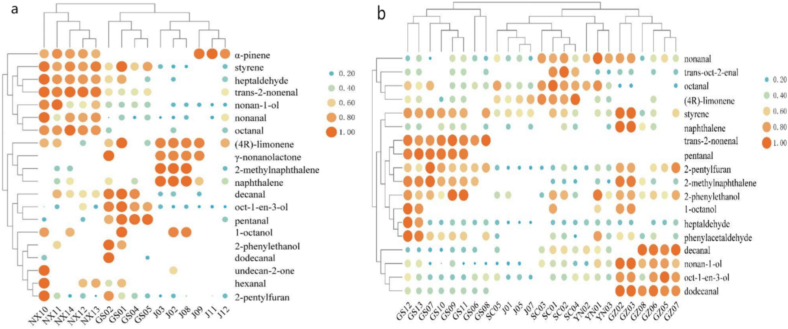

The volatile components in common buckwheat significantly vary from region to region. Fig. 6a shows the hierarchical clustering diagram of OAV values of volatile components in common buckwheat. The α-pinene (rosin), styrene (sweet), heptaldehyde (green), trans-2-nonenal (green), and octanal (aldehydic) in the Ningxia area were significantly higher than those in other areas. Thus, they were used as the characteristic volatile components in Ningxia. (4R)-limonene (sweet), γ-nonolactone (coconut), 2-methylnaphthalene (oily), and naphthalene (pungent) were detected as the characteristic volatile components in Shanxi region. Decanal (waxy), oct-1-en-3-ol (mushroom), and pentanal (winey) were detected as the characteristic volatile components in Gansu. Similarly, 2-phenylethanol (rose), trans-2-nonenal (sweet), 2-pentylfuran (fruit), and 2-methylnaphthalene (oily) were detected as characteristic volatile components of Gansu Tartary buckwheat. Nonan-1-ol (waxy), oct-1-en-3-ol (mushroom), decanal (waxy), and dodecanal (soapy) were detected as characteristic volatile components of Guizhou Tartary buckwheat. 1-octanol (waxy), nonanal (aldehydic), trans-oct-2-enal (sweet), and (4R)-limonene (sweet) were detected as the characteristic volatile components of this class of Tartary buckwheat in Sichuan, Yunnan, and Shanxi.

Fig. 6.

Hierarchical clustering diagram of OAV values of volatile components in buckwheat. (a) Common buckwheat and (b) Tartary buckwheat.

3.5. Discussion

Most of the research on the aroma of buckwheat has focused on buckwheat products rather than buckwheat grains or flour. Aroma profiling investigations revealed that Tartary buckwheat grains have a strong aroma that characteristically differs from the aroma of common buckwheat. This finding is consistent with a previous study (Starowicz, Koutsidis, & Zieliński, 2018), which discovered that the overall aroma of Tartary buckwheat is contributed by 48 volatile compounds and 26 odor-active compounds. Furthermore, this study identified naphthalene and salicylaldehyde as significant compounds for distinguishing between Tartary buckwheat and common buckwheat varieties.

Another study focused on discovering new volatile compounds in Tartary buckwheat and evaluating the aroma activity of known compounds (Shi et al., 2021). By mixing 16 aroma compounds with their natural concentrations, the overall aroma of buckwheat was successfully simulated. This study identified 9 compounds that have aroma activity in buckwheat for the first time. In addition, some hydrocarbons, olefins, and aromatic hydrocarbons were detected as aroma active compounds. The possibility of different aromatic components in Tartary buckwheat from different origins was also mentioned but not investigated in this literature.

In our study, the aromatic properties of volatile compounds in Tartary buckwheat and common buckwheat were analyzed comprehensively, resulting in the identification and evaluation of more compounds with aromatic activity. By analyzing the aroma components of buckwheat from different regions, it is possible to trace the origin of products.

4. Conclusions

The volatile components of 25 representative samples of Tartary buckwheat and 15 samples of common buckwheat from six major producing areas in China were investigated. A total of 77 volatile components were identified, including 15 alcohols, 12 aldehydes, 10 ketones, 8 esters, 2 furans, 19 hydrocarbons, and 11 other compounds. Among them, aldehydes and hydrocarbons accounted for 61.91–90.02% of the total volatile components. The OAV value revealed that aldehydes significantly contributed to the overall aroma of buckwheat. In particular, nonanal (OAV: 119.3 to 466.8) and trans-2-nominal (OAV: 219.8 to 489.2) contributed the most to the flavor of buckwheat.

By combining the analysis of OPLS-DA and the VIP value of the selected compounds with OAV > 1, seven important compounds, namely nonan-1-ol, phenylacetaldehyde, styrene, α-pinene, 2-phenylethanol, trans-oct-2-enal, and 2-pentylfuran were selected. These compounds were used to distinguish Tartary buckwheat from common buckwheat. The principal component analysis divided Tartary buckwheat from five producing areas into three categories. Sichuan, Yunnan, and Shanxi were combined into one category, Gansu into another category, and Guizhou into the third category. In addition, common buckwheat from three producing areas was divided into three categories, with Gansu belonging to one category, Shanxi to another category, and Ningxia to the third category. The α-pinene, styrene, heptaldehyde, trans-2-nonenal, and octanal were the characteristic volatile components of common buckwheat in Ningxia. (4R)-limonene, γ-nonolactone, 2-methylnaphthalene, and naphthalene were the characteristic volatile components of common buckwheat in Shanxi. Decanal, oct-1-en-3-ol, and pentanal were the characteristic volatile components of common buckwheat in Gansu. Similarly, 2-phenylethanol, pentanal, trans-2-nonenal, 2-pentylfuran, and 2-methylnaphthalene were characteristic volatile components of Gansu Tartary buckwheat. Nonan-1-ol, oct-1-en-3-ol, decanal, and dodecanal were characteristic volatile components of Guizhou Tartary buckwheat. 1-Octanol, nonanal, trans-oct-2-enal, and (4R)-limonene were the characteristic volatile components of this class of Tartary buckwheat in Sichuan, Yunnan, and Shanxi.

In this study, the volatile components and aroma characteristics of representative buckwheat samples from major producing areas in China were investigated, which supplemented the information on aromatic data of buckwheat in China. The relationship between variety, origin, and aroma characteristics was established using GC–MS combined with stoichiometric analysis. The results showed that GC–MS combined with chemometrics was reliable and efficient in identifying buckwheat with different germplasm resources. This combined technique provides a valuable reference for quality evaluation, high-quality variety breeding, and rational resource development of buckwheat.

CRediT authorship contribution statement

Yunlong Li: Project administration, Investigation. Jianan Wei: Writing – original draft, Formal analysis, Data curation. Siyi Zhu: Writing – original draft, Investigation, Formal analysis. Xiaoli Zhou: Methodology, Formal analysis. Yiming Zhou: Writing – review & editing, Conceptualization. Minglong Wang: Writing – review & editing.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported by Agriculture Research System of China (CARS-07-E-2), Shanghai Agriculture Applied Technology Development Program,China(2022-02-08-00-12-F01126), the Capacity Project of Local Colleges and Universities of the Science and Technology Commission of Shanghai, China (22010504000), the Shanghai Natural Science Foundation (Grant No. 20ZR1455800), and Shanghai Engineering Technology Research Center of Shanghai Science and Technology Commission (20DZ2255600).

Contributor Information

Yiming Zhou, Email: zhouymsit@163.com.

Minglong Wang, Email: wml_isaac@126.com.

Data availability

No data was used for the research described in the article.

References

- Bae H.G., Kim M.J. Antioxidant and anti-obesity effects of in vitro digesta of germinated buckwheat. Food Science and Biotechnology. 2022;31(7):879–892. doi: 10.1007/s10068-022-01086-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chiang J.H., Hua X.Y., Yu A.H.M., Peh E.W.Y., See E., Henry C.J. A review on buckwheat and its hypoglycemic bioactive components in food systems. Food Reviews International. 2023 doi: 10.1080/87559129.2022.2103706. [DOI] [Google Scholar]

- Diowksz A., Sadowska A. Impact of sourdough and transglutaminase on gluten-free buckwheat bread quality. Food Bioscience. 2021;43 doi: 10.1016/j.fbio.2021.101309. [DOI] [Google Scholar]

- Gemert L.J.V. 2003. Compilations of odour threshold values in air, water and other media. [Google Scholar]

- Giménez-Bastida J.A., Laparra-Llopis J.M., Baczek N., Zielinski H. Buckwheat and buckwheat enriched products exert an anti-inflammatory effect on the myofibroblasts of colon CCD-18Co. Food & Function. 2018;9(6):3387–3397. doi: 10.1039/c8fo00193f. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gomathi G.K., S., P. A concise review on buckwheat materials based ready to serve and ready to eat food products. Materials Today Proceedings. 2022;66(P3) [Google Scholar]

- He X., Huang Y.M., Gorska-Horczyczak E., Wierzbicka A., Jelen H.H. Rapid analysis of baijiu volatile compounds fingerprint for their aroma and regional origin authenticity assessment. Food Chemistry. 2021;337 doi: 10.1016/j.foodchem.2020.128002. [DOI] [PubMed] [Google Scholar]

- He Y.X., Liu Z.P., Qian M., Yu X.W., Xu Y., Chen S. Unraveling the chemosensory characteristics of strong-aroma type baijiu from different regions using comprehensive two-dimensional gas chromatography-time-of-flight mass spectrometry and descriptive sensory analysis. Food Chemistry. 2020;331 doi: 10.1016/j.foodchem.2020.127335. [DOI] [PubMed] [Google Scholar]

- Ji X., Han L., Liu F., Yin S., Peng Q., Wang M. A mini-review of isolation, chemical properties and bioactivities of polysaccharides from buckwheat (Fagopyrum Mill) International Journal of Biological Macromolecules. 2019;127:204–209. doi: 10.1016/j.ijbiomac.2019.01.043. [DOI] [PubMed] [Google Scholar]

- Jin H.M., Wei P. Anti-fatigue properties of Tartary buckwheat extracts in mice. International Journal of Molecular Sciences. 2011;12(8):4770–4780. doi: 10.3390/ijms12084770. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ke H., Wang X., Zhou Z., Ai W., Wu Z., Zhang Y. Effect of weimaining on apoptosis and Caspase-3 expression in a breast cancer mouse model. Journal of Ethnopharmacology. 2021;264 doi: 10.1016/j.jep.2020.113363. [DOI] [PubMed] [Google Scholar]

- Kebede B.T., Grauwet T., Mutsokoti L., Palmers S., Vervoort L., Hendrickx M., Van Loey A. Comparing the impact of high pressure high temperature and thermal sterilization on the volatile fingerprint of onion, potato, pumpkin and red beet. Food Research International. 2014;56:218–225. doi: 10.1016/j.foodres.2013.12.034. [DOI] [PubMed] [Google Scholar]

- Kim Y., Lee K.G., Kim M.K. Volatile and non-volatile compounds in green tea affected in harvesting time and their correlation to consumer preference. Journal of Food Science and Technology-Mysore. 2016;53(10):3735–3743. doi: 10.1007/s13197-016-2349-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Olivieri A.C. 2018. Principal component analysis: A practical approach: Introduction to multivariate calibration. [Google Scholar]

- Prosen H., Kokalj M., Janeš D., Kreft S. Comparison of isolation methods for the determination of buckwheat volatile compounds. Food Chemistry. 2010;121(1):298–306. doi: 10.1016/j.foodchem.2009.12.014. [DOI] [Google Scholar]

- Puligundla P., Lim S. Buckwheat noodles: Processing and quality enhancement. Food Science and Biotechnology. 2021;30(12):1471–1480. doi: 10.1007/s10068-021-00960-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Qin P., Ma T., Wu L., Shan F., Ren G. Identification of Tartary buckwheat tea aroma compounds with gas chromatography-mass spectrometry. Journal of Food Science. 2011;76(6):S401–S407. doi: 10.1111/j.1750-3841.2011.02223.x. [DOI] [PubMed] [Google Scholar]

- Ramos-Romero S., Hereu M., Atienza L., Amézqueta S., Casas J., Muñoz S.…Torres J.L. The buckwheat Iminosugar d-Fagomine attenuates sucrose-induced steatosis and hypertension in rats. Molecular Nutrition & Food Research. 2020;64(1) doi: 10.1002/mnfr.201900564. [DOI] [PubMed] [Google Scholar]

- Shi J., Tong G.Q., Yang Q., Huang M.Q., Ye H., Liu Y.C.…Zhao D.R. Characterization of key aroma compounds in Tartary buckwheat (Fagopyrum tataricum Gaertn.) by means of sensory-directed flavor analysis. Journal of Agricultural and Food Chemistry. 2021;69(38):11361–11371. doi: 10.1021/acs.jafc.1c03708. [DOI] [PubMed] [Google Scholar]

- Starowicz M., Koutsidis G., Zieliński H. Sensory analysis and aroma compounds of buckwheat containing products—A review. Critical Reviews in Food Science and Nutrition. 2018;58(11):1767–1779. doi: 10.1080/10408398.2017.1284742. [DOI] [PubMed] [Google Scholar]

- Sun N.X., Tong L.T., Liang T.T., Wang L.L., Liu L.Y., Zhou X.R., Zhou S.M. Effect of oat and Tartary buckwheat - based food on cholesterol - lowering and gut microbiota in Hypercholesterolemic hamsters. Journal of Oleo Science. 2019;68(3):251–259. doi: 10.5650/jos.ess18221. [DOI] [PubMed] [Google Scholar]

- Wang A., Zhang J., Li Z. Correlation of volatile and nonvolatile components with the total antioxidant capacity of Tartary buckwheat vinegar: Influence of the thermal processing. Food Research International. 2012;49(1):65–71. doi: 10.1016/j.foodres.2012.07.020. [DOI] [Google Scholar]

- Wang H., Liu S.Y., Cui Y., Wang Y., Guo Y., Wang X.J.…Piao C.H. Hepatoprotective effects of flavonoids from common buckwheat hulls in type 2 diabetic rats and HepG2 cells. Food Science & Nutrition. 2021;9(9):4793–4802. doi: 10.1002/fsn3.2390. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang J., Yi X., Huang M.Q., Liu Y.C., Meng W.Y., Yang Q.…Zhang J.L. Studies on the key odorants in Maopu buckwheat finished baijiu and the effect of Tartary buckwheat extract on its flavor. LWT- Food Science and Technology. 2022;154 doi: 10.1016/j.lwt.2021.112650. [DOI] [Google Scholar]

- Wang M.Q., Ma W.J., Shi J., Zhu Y., Lin Z., Lv H.P. Characterization of the key aroma compounds in Longjing tea using stir bar sorptive extraction (SBSE) combined with gas chromatography-mass spectrometry (GC-MS), gas chromatography-olfactometry (GC-O), odor activity value (OAV), and aroma recombination. Food Research International. 2020;130 doi: 10.1016/j.foodres.2019.108908. [DOI] [PubMed] [Google Scholar]

- Yu X., Yang M., Dong J.L., Shen R.L. Comparative analysis of the antioxidant capacities and phenolic compounds of oat and buckwheat vinegars during production processes. Journal of Food Science. 2018;83(3):844–853. doi: 10.1111/1750-3841.14074. [DOI] [PubMed] [Google Scholar]

- Zhou Y.M., Chen X.Y., Zhu S.Y., Sun M., Zhou X.L. Understanding the flavor signature of the rice grown in different regions of China via metabolite profiling. Journal of the Science of Food and Agriculture. 2022;102(7):3010–3020. doi: 10.1002/jsfa.11641. [DOI] [PubMed] [Google Scholar]

- Zhu F. Chemical composition and health effects of Tartary buckwheat. Food Chemistry. 2016;203:231–245. doi: 10.1016/j.foodchem.2016.02.050. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No data was used for the research described in the article.