Abstract

The primary drawback of concrete lies in its low tensile strength, prompting the development of various solutions to enhance this aspect. A notable approach is the utilization of Prestressed Reinforced Concrete (PRC) with tendons, aimed at bolstering its tensile strength. As the use of diverse tendon types in the PRC continues to surge, a review becomes imperative to delve into this evolution. Therefore, this study delved into the engineering characteristics, performance, and evolution of different tendon varieties, encompassing both steel and composite options. Despite certain drawbacks associated with employing composite materials such as Fiber Reinforced Polymer (FRP) tendons - such as heightened costs, limited availability of composite materials, and intricate manufacturing processes - there are distinct advantages and merits to incorporating FRP composite tendons in the realm of construction. In this respect, Carbon FRP tendons exhibited superior strength, comparable to their steel counterparts. Glass FRP tendons, lacking metallic components, possessed non-magnetic properties, rendering them resistant to corrosion. Additionally, Aramid FRP tendons boasted low flammability and exceptional resistance to elevated temperatures. Lastly, Basalt FRP tendons offered sustainability, rust resistance, and non-corrosiveness. The findings derived from this review study serve as a valuable resource for researchers seeking to advance the applications of steel tendons and FRP composite materials within the construction industry.

Keywords: Prestressed concrete, Steel tendons, CFRP, GFRP, AFRP, BFRP

Highlights

-

•

Steel tendons' higher density and susceptibility to corrosion stand out as notable drawbacks.

-

•

CFRP tendons have the maximum tensile strength when compared to other FRP.

-

•

GFRP tendons are not magnetic materials so they are corrosion-resistant.

-

•

AFRP tendons exhibit minimal flammability and demonstrate outstanding resilience to high temperatures.

-

•

BFRP tendons are sustainable, rust-proof, and non-corrosive.

1. Introduction

The use of concrete as one of the most widely used building materials in construction projects is increasing continuously. Due to some weaknesses of concrete, many modifications were made to improve its limitations. Low tensile strength is one of the biggest disadvantages of concrete and many solutions have been proposed to improve it. In this regard, the utilization of rebar to increase the tensile strength of concrete has become commonplace. Moreover, the development of Prestressed Reinforced Concrete (PRC) aims not only to minimize the dimensions of concrete structures but also to further augment their tensile strength [1]. Tendons, specialized components incorporated into Reinforced Concrete (RC), play a crucial role in achieving heightened tensile strength. Various types of tendons exist, with notable distinctions between steel tendons and Fiber Reinforced Polymer (FRP) tendons. The latter, in turn, encompasses diverse materials such as Carbon, Glass, Aramid, and Basalt, referred to as CFRP, GFRP, AFRP, and BFRP respectively [[2], [3], [4], [5], [6]].

In the exploration and advancement of diverse tendon types within the construction sector, numerous studies have been conducted to scrutinize and assess the performance and characteristics of these varied tendons. The examination of tendon properties commenced in the early 1990s [[7], [8], [9]], with researchers initially concentrating on steel tendons [10,11]. Subsequently, as the utilization of polymer fibers gained traction in the construction industry, there was a surge in studies focused on FRP tendons [[12], [13], [14], [15], [16], [17], [18], [19]].

Previous research, as gleaned from these studies, predominantly targeted common structural elements such as beams [2,[20], [21], [22], [23]], columns [6,12,[24], [25], [26]], bridges [10,[27], [28], [29]], slabs [21,[30], [31], [32]], and nuclear containment structures [[33], [34], [35], [36], [37]]. Notably, there were limited investigations into the application of tendons in special structural components like walls [38], towers [39], tunnels [40], and frames [41]. Given the prevalence, accessibility, and cost-effectiveness of steel tendons compared to FRP tendons, a majority of earlier research delved into Reinforced Concrete (RC) prestressed with steel tendons [42,43]. In contrast, studies on FRP tendons predominantly concentrated on scrutinizing their behavior and properties in slabs, beams, and girders [[44], [45], [46], [47], [48], [49], [50], [51], [52], [53]].

Toumi Ajimi et al. [33] assessed the impact of modestly elevated temperatures on the mechanical performance of steel rebars and prestressing wires within nuclear containment structures. The authors reported that between 20 and 40 °C, the tensile strength was little affected, on the other hand at the same temperature, the bond between concrete and rebars decreased strongly. In addition, Shaaban et al. [54] developed a non-linear finite-element analysis model to predict the strength of high-strength concrete slender columns reinforced with steel, considering parameters such as compressive strength, load eccentricity, slenderness ratio, and reinforcement ratio. The study's results compared with analytical and experimental data demonstrated the model's suitability, revealing discrepancies with existing design codes and underscoring the necessity for specialized clauses in these codes to ensure accurate analysis of high-strength concrete columns. Moreover, a parametric study investigated the structural behavior of composite steel–concrete T-beams under various prestressing conditions, exploring factors such as loading, tendon profiles, beam spans, prestressing levels, and geometric dimensions [55]. Results highlighted the influence of tendon profiles on beam response to different loads and emphasized the significant impact of the tension flange area to compression flange area ratio on the ultimate resistance of prestressed beams, with potential resistance increases up to 46.1 % by adjusting this ratio.

Elrefai et al. [56] examined the fatigue behavior of RC beams strengthened with externally post-tensioned CFRP tendons and reported that CFRP tendons displayed outstanding fatigue behavior with no indication of distress at bars. Shi et al. [57] studied the fatigue performance of BFRP tendons after exposure to a salt solution through elevated temperature tests. The authors believed that their findings guide the fatigue design of BFRP tendons in the marine environment. The performance of concrete beams prestressed with AFRP tendons was investigated by Toutanji and Saafi [13]. Based on the results obtained from this study, the ductility of RC can be substantially increased through the utilization of a blend of bonded and unbonded tendons, or through the incorporation of non-tensioned rebars. Finally, another study [31] proposed an innovative anchoring technology to strengthen one-way reinforced concrete slabs prestressed by GFRP tendons and found that their proposed method is reliable and efficient.

Taking into account the fast expansion of PRC utilization in the construction sector, coupled with the evolution of diverse tendon types, there arises a necessity for a detailed review study that systematically deals with this progression. Hence, the present study explores the engineering performance, characteristics, and behavior of various tendon types. In this context, an analysis of previous research studies has been conducted to gain insights into the performance of both steel and FRP tendons in pre-stressed concrete. The second section encompassed background information, the historical context of PRC involving different tendons, and the attributes of steel tendons. Subsequently, section three elucidated the state-of-the-art regarding FRP tendons and their properties. The fourth section outlined the current challenges and future research prospects related to FRP tendons. Ultimately, the key findings of the paper were condensed and outlined in the fifth section.

2. Background of the prestressed reinforced concrete

The resistance of concrete to compressive forces similar to stone is excellent, therefore concrete is a very suitable option for use as vertical members of structures such as columns and supporting posts. On the other hand, concrete is not very strong, especially when used as a slab or beams (horizontal structure members) and normally it can span only short distances before the cracks appear and result in failure. To overcome this issue, at first, researchers suggested using more ticker concrete as a slab or beams [[58], [59], [60], [61]]. The weight and size of the plain concrete increased because of using ticker concrete and became impractical for longer spans and slabs required for bridges and buildings. Therefore, researchers found another way to increase the strength of concrete against tensile forces. They suggested that the addition of steel reinforcing bars can significantly increase the tensile strength of concrete and reduce the size and dimension of concrete slabs and beams [[62], [63], [64]].

P.H. Jackson [65] was the pioneer engineer who proposed the concept of prestressed concrete in 1888, but the lack of technology for producing high-strength steel bars made his idea unachievable. Many researchers, such as Belgian engineer Gustave Magnel and German bridge builder Urlich Finsterwalder, expanded the concept of prestressed concrete [65]. Nowadays, with the advancement of science and technology, the production and utilization of prestressed concrete have become a common issue in the construction industry.

2.1. Types of prestressed concrete

Prestressed concrete is normally manufactured through one of the following methods: first, Pre-tensioning, and second, Post-tensioning. Primarily, prestressed concrete was created using a pre-tensioning method conducted ahead of the concrete casting. Subsequently, a post-tensioning method was developed, occurring following the concrete casting [1]. There are two commonly used tensioning processes: mono-strand tensioning, where each tendon undergoes individual stress, and multi-strand tensioning, where all cables in a tendon experience simultaneous stress [5]. Moreover, concerning the location of tendons in the concrete, two types exist based on whether tendons are entirely within the concrete volume or entirely outside it, referred to as internal and external prestressing, respectively.

The primary distinctions between the post-tensioning and pre-tensioning procedures are outlined as follows:

-

1.

The pre-tensioning method can be done solely in factories and cannot be executed on-site, while post-tensioning is viable in both on-site and factory settings. Consequently, the pre-tensioning method is well-suited for precast construction projects.

-

2.

In the pre-tensioning method, strands are tensioned and positioned before concrete casting, whereas in the post-tensioning method, the cables are embedded inside the concrete and tensioned following the concrete reaches its initial strength.

-

3.

Typically, the pre-tensioning method imposes limitations on the dimension of the structure members, whereas there are no such restrictions on the dimension of structural elements in the post-tensioning method.

-

4.

Prestressing loss is not less than 18 % in pre-tensioned concrete, while it does not exceed 15 % in post-tensioned concrete.

-

5.

Uniform prestressed elements can be systematically produced through the pre-tensioning method, while the characteristics of post-tensioned concrete elements may vary depending on the structure.

-

6.

Pre-tensioned concrete is developed through the attachment of steel and FRP tendons and concrete, whereas post-tensioned concrete relies on bearing capacity for its development.

-

7.

The pre-tensioning method is desired for small structural elements, whereas the post-tensioning method is favored for heavy structural members.

-

8.

The cost efficiency of pre-tensioned concrete surpasses that of post-tensioned concrete, mainly because it eliminates the expenses associated with sheathing.

-

9.

The durability and reliability of the pre-tensioning method outshine post-tensioning, given that the longevity of post-tensioned concrete relies on the functionality of two anchorages.

2.1.1. Pre-tensioning

In the pre-tensioning procedure, the concrete is decanted across the already-tensioned strands and left to harden and sustain the strands in place. The end of the tensioned strands is cut right after the concrete is cured and gains its early strength, and the tension is spread into the slabs or beams. The pre-tensioning procedure is more complicated than the post-tensioning procedure as it needs the construction of large casting beds to sustain the strands while the concrete is decanted across them in the molds [66]. The actual pre-tensioning process in a precast factory is presented in Fig. 1. Because of the transportation limitations between the project site and the factory, and also due to the availability of cranes capable of lifting the pre-tensioned member into the place, the size and length of the pre-tensioned members were restricted [44].

Fig. 1.

Pre-tensioned bridge girder in casting bed, with single-strand tendons placed in the formwork [67].

2.1.2. Post-tensioning

Post-tensioning provides an alternative method for prestressing concrete, and the process is notably simpler than pre-tensioning. In post-tensioning, strands or tendons are positioned within a duct at the casting site, followed by the pouring of concrete. Once the concrete has cured and attained initial strength, a portable hydraulic jacking device is employed to tighten the cables, creating the necessary tension [68]. The practical implementation of the post-tensioning process on a construction site is depicted in Fig. 2. Unlike the pre-tensioning process, there are no restrictions on the dimension and length of structural elements that require prestressing in the post-tensioning approach, making it highly suitable for construction sites and various fields [69].

Fig. 2.

Post-tensioned concrete in the field: (a) Steel plate and grips and (b) post-tensioning process using a hydraulic jack [70,71].

2.2. Steel tendons

Cables, bars, and strands represent common types of high-tensile steel utilized in prestressed concrete applications. Achieving high tensile strength in steel involves gradually elevating the carbon content from standard levels. The carbon content in high-tensile steel typically ranges between 0.60 and 0.85 percent, influenced by the desired final tensile strength of the steel. Additionally, high-tensile steel typically incorporates 0.05 percent sulfur, 0.70 to 1.0 percent manganese, and a minimal amount of phosphorus [72]. To reduce diameter size and enhance tensile strength, hot high-carbon steel ingots undergo rolling into bars and cold drawing through a dies process. The cold-drawing process contributes to the improved durability of the bars. Subsequently, to optimize the properties of the cold-drawn bars and boost their tensile strength, they undergo heating within a range of 150–420 °C.

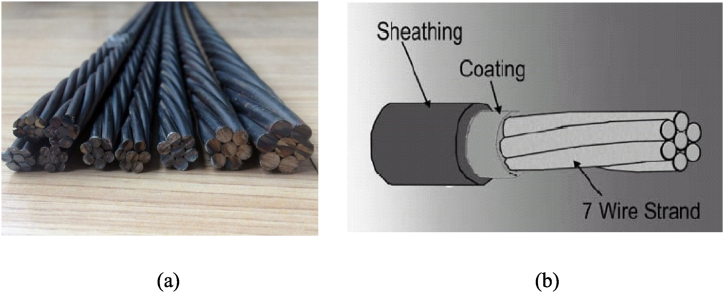

Crimped or indented steel wires exhibit superior bonding characteristics compared to plain wires, rendering them a more favorable choice for the prestressing process. Strands are typically formed by employing multiple wires ranging in size from 2 to 5 mm. The use of two, three, and seven twisted wires with a helical shape enhances the bonding properties within the concrete. Fig. 3 illustrates a typical example of 7-strand tendons. In the production of seven-ply strands, wires measuring two to five mm are twisted together, while two and three-mm wires are utilized for creating two and three-ply strands, respectively [73].

Fig. 3.

(a) Seven-strand tendon, (b) schematic of 7 wire strands with sheathing [74].

In the prestressing process, high tensile steel bars with nominal sizes typically ranging from 2 to 40 mm in diameter are commonly employed, including sizes such as 5, 10, 12, 16, 20, 22, 25, 28, 30, 32, and 40 mm. The high tensile strength of these steel bars is primarily attributed to the alloying process rather than cold-working, meaning that the diameter of the bars does not impact their ultimate tensile strength [75]. Previous studies have explored the utilization of various types of steel wires and strands for prestressing purposes.

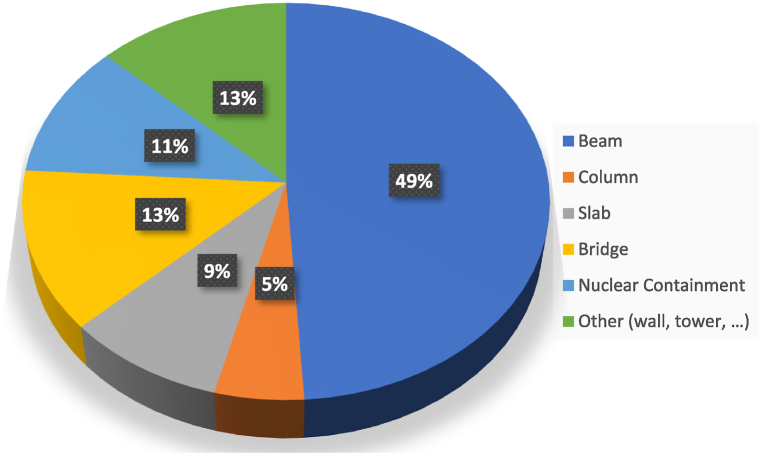

Drawing from earlier research, beams emerged as the most intriguing structural member for the exploration of steel tendon performance. Approximately 50 % of the conducted studies delved into the diverse properties of beams prestressed with steel tendons. Subsequently, bridges and nuclear containments captured the attention of researchers as other notable areas of interest. Fig. 4 illustrates the distribution of previous studies, categorizing them based on the different structural members prestressed by steel tendons.

Fig. 4.

Various structure members prestressed by steel tendons (previous studies).

Table 1 presents the properties of steel tendons for the prestressing process of PRC based on the literature review. According to this table, the diameter of the steel tendons ranged between 5 mm [76] to 40 mm [77]. This vast range of size shows that steel tendons have a good potential to be used in various types of construction works such as concrete members (beams, bridges, columns, etc.). The density of steel tendons ranged from 6020 (kg/m3) to 7850 (kg/m3) depending on the existence of minerals such as carbon, magnesium, sulfur, and so forth. Depending on the project requirements and limits, the yield strength of steel tendons varied between 580 MPa [78] to 1941 MPa [79]. In addition, the elastic modulus of steel tendons ranged from 180 GPa [80] to 210 GPA [81]. Finally, the Poisson's ratio of steel tendons ranged from 0.2 [80], associated with the lowest elastic modulus, to 0.3 [81], linked to the highest elastic modulus. Therefore, it can be concluded that Poisson's ratio maintains a direct relationship with the modulus of elasticity.

Table 1.

Steel tendons characteristics.

| Diameter (mm) | Density (kg/m3) | Yield strength (MPa) | Modulus of elasticity (GPa) | Ultimate strain (%) | Longitudinal thermal expansion (x10 -6/°C) | Poisson's ratio | Ref. |

|---|---|---|---|---|---|---|---|

| 16 | – | 1860 | 198 | 0.10 | – | – | [82] |

| 16 | – | – | 200 | – | 11 | 0.24 | [83] |

| 5 | – | 1860 | – | – | – | – | [76] |

| 15 | 7850 | – | – | – | – | – | [84] |

| – | – | 1691 | 191 | 0.12 | – | 0.3 | [85] |

| 30–40 | – | 1478 | 192 | – | – | – | [77] |

| 15.2 | – | 1884 | 196 | 0.027 | – | – | [86] |

| 25 | – | – | 200 | – | – | – | [87] |

| – | 7850 | 1625 | 210 | – | – | 0.3 | [88] |

| 9.5 | – | 1755 | 190 | 0.129 | – | – | [89] |

| 18 | – | 1625 | 185 | 0.097 | – | – | [90] |

| 8 | – | 1500 | 210 | 0.044 | – | – | [91] |

| – | – | 1828 | 192.6 | – | – | – | [92] |

| – | – | 1780 | 195 | – | – | 0.3 | [93] |

| 23 | – | 1080 | 202 | – | – | – | [94] |

| – | – | 1607 | 193 | 0.033 | – | – | [95] |

| 12 | 7800 | – | 210 | – | – | 0.3 | [81] |

| 16 | – | 1860 | 206 | – | – | 0.3 | [96] |

| – | – | 1780 | 195 | – | – | 0.3 | [97] |

| – | – | 1780 | 195 | – | – | 0.3 | [98] |

| 8 | – | 1318 | 207 | – | – | 0.3 | [99] |

| 15.2 | 6020 | 1400 | 180 | – | – | 0.2 | [80] |

| 15.2 | 7800 | 1860 | – | – | – | – | [100] |

| 7 | – | 1941 | 199 | 0.061 | – | – | [79] |

| 16 | – | 1870 | 200 | 0.1 | – | 0.3 | [58] |

| – | – | 1680 | 192 | 0.056 | – | – | [101] |

| 8 | – | 1600 | 200 | 0.045 | – | 0.3 | [102] |

| 15.2 | 7850 | 1860 | 195 | – | 12.2 | 0.3 | [103] |

| 12.7 | 7850 | 1860 | 200 | – | – | 0.3 | [104] |

| – | – | 580 | 200 | – | – | 0.3 | [78] |

| 12.7 | – | 1860 | 197.5 | 0.073 | – | – | [105] |

| 15.2 | – | 1860 | 195 | 0.098 | – | – | [106] |

| 12.7 | – | 1860 | 200 | 0.004 | – | – | [107] |

| 15.2 | – | 1860 | 205.5 | – | – | – | [108] |

| 15.2 | 7850 | 1860 | 207.3 | – | – | 0.3 | [109] |

| 15–25 | – | 1030 | 205 | – | – | – | [110] |

| 23 | – | 1080 | 200 | – | – | 0.3 | [111] |

| – | – | 1600 | 200 | – | – | – | [112] |

| 18 | 7850 | 1857 | 195 | 0.01 | – | – | [113] |

| – | – | 1920 | 193 | 0.03 | 13 | 0.28 | [114] |

| 16 | – | 1680 | 195 | – | – | – | [115] |

| – | 7850 | 1860 | 195 | – | – | 0.3 | [116] |

| 14 | – | 580 | 200 | – | – | 0.3 | [117] |

| – | – | 1920 | 193 | 0.10 | – | 0.28 | [118] |

| – | – | 1863 | 195 | – | – | – | [119] |

| 15.2 | – | 1860 | 200 | – | – | – | [120] |

Bonopera et al. [120] undertook an experiment focusing on the fundamental frequency of prestressed concrete bridge beams equipped with parabolic unbonded tendons. The investigation aimed to demonstrate that the fundamental frequency remained unaffected by such forces. The results of this work revealed that, for predicting prestress loss in concrete bridge beams with parabolic unbonded tendons, the fundamental frequency is not a suitable parameter. Additionally, the authors highlighted that altering the size and strength properties of parabolic tendons can impact prestress loss. In another study [117], impact tests were carried out on RC beams prestressed with unbound steel tendons possessing a yield strength of 580 MPa, the lowest among all previous studies. The outcomes of this research revealed that the low yield strength of unbound tendons does not have an adverse effect on the impact resistance of prestressed concrete.

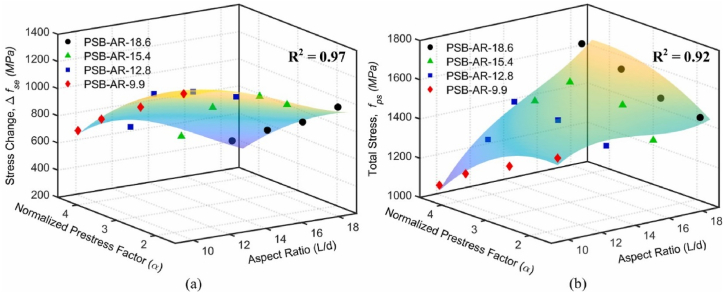

Halder et al. [114] conducted an investigation into the combined impacts of aspect ratios and changes in prestress on the nonlinear structural behavior of PRC. Utilizing prestressed steel tendons with a yield strength of 1920 MPa and varying lengths, the study aimed to comprehend the effects of alterations in prestress levels on failure behavior, tendon stress, and structural response in concrete members. The results revealed that, at the ultimate limit state, the stress level in the shorter tendons exceeded that in the longer tendons. Fig. 5 illustrates the response surface analysis, indicating that the total tendon stress at the ultimate limit state is less sensitive to changes in α for prestressed precast concrete segmental bridges with a high aspect ratio. In a separate study, Aydin [109] developed an algorithm to optimize the size, profile, and layout of steel tendons with the goal of reducing the overall construction cost. The study's findings were compared with results from the literature and non-prestressed trusses. The author asserted that the proposed method could effectively decrease the final construction cost by optimizing the shape and profile of steel tendons to reduce the weight of the prestressed concrete structures.

Fig. 5.

Relationship between normalized prestress factor α and aspect ratio L/d w.r.t. (a) Stress change Δfse and (b) total stress fps [114].

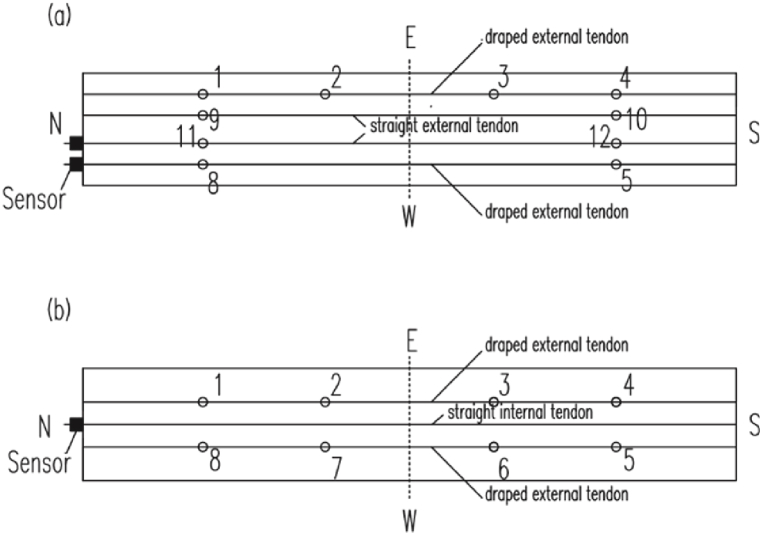

Lin et al. [103] delved into the mechanical behavior of steel plate girders reinforced by steel tendons. The authors introduced a practical and effective reinforcement scheme, conducting a series of numerical simulations to assess the mechanical performance of these girders. The results showcased the outstanding working performance of the steel plate girders post-reinforcement, attributed to the efficacy of the proposed reinforcement scheme. In the exploration of the flexural performance of precast concrete segmental bridges incorporating hybrid steel tendons, Jiang et al. [89] undertook a study. Their findings indicated that, at the ultimate loading stage, the stress in all tendons exceeded 1500 MPa. The study revealed that optimizing the flexural performance of segmental bridges can be achieved by fine-tuning the joint numbers and types of prestressing tendons. Fig. 6 presents a detailed layout of the test setup, including the configuration of strain gauges and load sensors for prestressing steel tendons.

Fig. 6.

Configuration of strain gauges and load sensors for a pair of prestressing tendons [89].

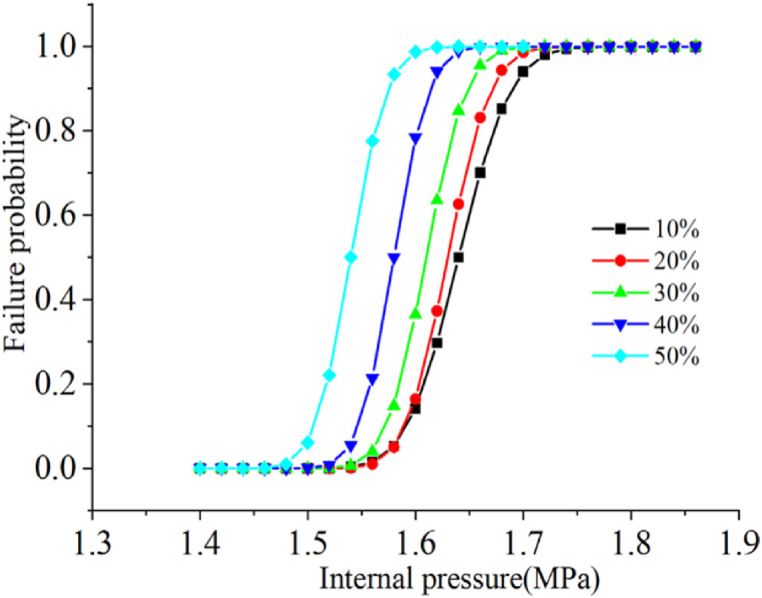

In light of potential leaks into the surrounding environment during abnormal conditions, the assessment of performance and behavior in nuclear containment structures has become a crucial area of research. In this context, Li et al. [93] conducted a study to evaluate the probabilistic safety and analyze the fragility of nuclear containment structures. The findings indicated a significant decrease in the pressure capacity of the structures with increasing prestressing loss when utilizing steel tendons with properties such as a yield strength of 1780 MPa, modulus of elasticity of 195 GPa, and Poisson's ratio of 0.3. Fig. 7 illustrates the fragility curve of the containment structure under varying prestressing loss conditions. In a related study, Chen and Gu [96] compared the results of incremental tendon stress and the ultimate moment of PRC beams with external steel tendons against other findings. To predict the load-carrying capacity and the ultimate incremental tendon of PRC with external steel tendons, the researchers proposed a simplified approach.

Fig. 7.

Fragility curve under different prestressing loss conditions [93].

A study by Ref. [80] sought to simulate the failure modes and mechanical properties of retarded-bonded tendons, aiming to investigate bond behavior and make comparisons with experimental results. The simulation outcomes highlighted that the geometric shape of the tendons and sheaths played a crucial role in providing exceptional bond behavior with concrete, a conclusion well-supported by experimental findings. Furthermore, the bond performance of retarded-bonded tendons was found to be significantly influenced by the strength and modulus of elasticity of both tendons and sheaths. Given the challenge of predicting total stress in unbonded steel tendons of post-tensioned concrete members at ultimate flexural strength due to insufficient bonds between surrounding concrete and steel tendons, Oukaili and Peera [105] introduced a method to assess total stress based on generic expression programming. The authors reported that their proposed model demonstrated the highest coefficient of determination, reaching 0.93, when compared to experimental values of total stress.

In summary, the versatile range of sizes available for steel tendons positions them as excellent candidates for various construction projects. The impressive yield strength, reaching up to 1941 MPa, makes steel tendons a favorable choice for enhancing the tensile strength of reinforced concrete. Additionally, a direct correlation exists between the modulus of elasticity and Poisson's ratio of steel tendons. It is noteworthy that while some properties of steel tendons resemble those of FRP tendons, their higher density and susceptibility to corrosion stand out as notable drawbacks.

3. Characteristics and performance of FRP tendons

FRP composites emerge as an excellent alternative to steel reinforcement in structural components and find widespread application in the construction sector. Adopting FRP composites instead of steel bars and tendons yields numerous advantages: they resist corrosion, boast a favorable strength-to-weight ratio, display outstanding fatigue and chemical resistance, and offer ease and speed in implementation. Moreover, FRP composites lack magnetic properties, contributing to reduced long-term maintenance expenses [[121], [122], [123], [124]]. Commonly, FRP composites are classified based on the types of fibers employed for reinforcement. These categories include Basalt Fiber Reinforced Polymer (BFRP), Aramid Fiber Reinforced Polymer (AFRP), Glass Fiber Reinforced Polymer (GFRP), and Carbon Fiber reinforced polymer (CFRP) [66].

GFRP composites are discouraged for bonded tendons due to their susceptibility to creep under constant loads and their limited endurance to alkaline environments [125]. On the contrary, CFRP and AFRP reinforcements prove suitable for prestressed tendons and have found widespread application in prestressing applications [126]. The development of BFRP tendons has been driven by a low cost-to-performance ratio and notable benefits in chemical and mechanical properties compared to other FRP composites [127]. The following section explores and reviews the applications, properties, benefits, and disadvantages of all the aforementioned categories of FRP composites.

3.1. CFRP tendons

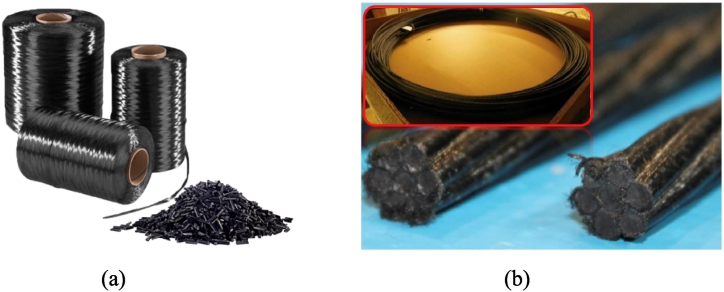

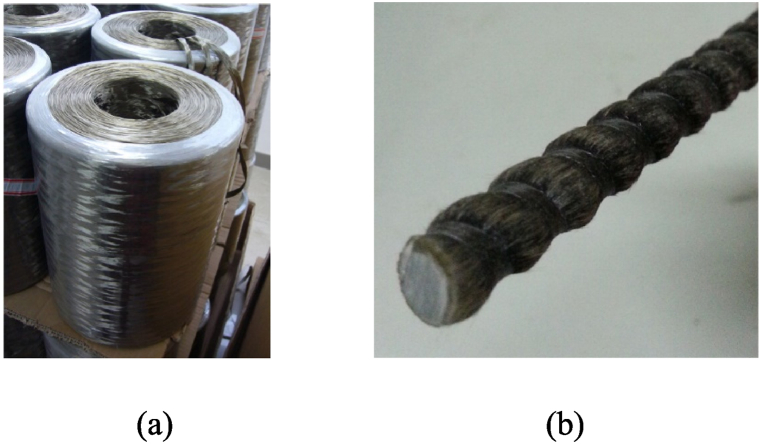

CFRP composites are primarily composed of carbon fiber and polymer. In this combination, the polymer functions as an interconnected matrix, ensuring the unity and protection of the fibers, whereas the carbon fibers contribute to the strength and stiffness of the CFRP tendon [128]. Different fabrication methods, including filament winding, hand lay-up, and pultrusion, were employed to manufacture CFRP in diverse forms such as strips, bars, and sheets, as depicted in Fig. 8. The utilization of CFRP materials offers numerous advantages, including resistance to corrosion, low density, high strength, and exceptional resistance against fatigue [56]. The key characteristics of CFRP materials are outlined as follows:

-

i.

CFRP materials exhibit exceptional endurance to alkaline conditions.

-

ii.

Their corrosion-resistant nature makes CFRP composites suitable for the treatment of present RC structure members and corrosion control.

-

iii.

CFRP composites possess low thermal conductivity.

-

iv.

The low weight-to-strength ratio of CFRP composites eliminates the need for weighty auxiliary members and construction apparatus.

-

v.

The quick curing time of CFRP composites results in quicker usage, leading to a reduction in project duration.

-

vi.

CFRP composites demonstrate a very high ultimate strain.

-

vii.

The high resistance against fatigue of CFRP composites reduces the necessity for frequent maintenance.

-

viii.

CFRP composites have low electrical conductivity and lack magnetic properties.

-

ix.

While lighter than steel strands and tendons, CFRP composites are more costly than steel members.

Fig. 8.

CFRP tendons, (a) Carbon fibers, (b) Carbon bars [129].

Various types of CFRP composites, including strips, wraps, laminates, and bars, find applications in the construction industry. CFRP strips are employed for the cost-effective and efficient strengthening of existing steel road bridges [130]. CFRP wraps play a crucial role in constructing earthquake-resistant structures and are also utilized for the rehabilitation and corrosion control of reinforced concrete columns. Additionally, CFRP laminates are applied for reinforcing structural members like girders in bridges and beams in buildings [131]. Here are some engineering applications and construction cases for CFRP materials: a) Structural Strengthening: CFRP sheets or plates are commonly used to strengthen and retrofit reinforced concrete structures, such as bridges, buildings, and parking structures, to increase their load-carrying capacity and seismic resistance. b) Bridge Rehabilitation: CFRP materials are used for repairing and strengthening deteriorated or damaged concrete bridge components, such as beams, decks, and columns, extending the service life of the structures. c) Marine Structures: CFRP composites find applications in marine environments for reinforcing piers, seawalls, and offshore platforms due to their corrosion resistance and high strength-to-weight ratio.

Recently, CFRP bars have gained widespread use in the construction of new buildings and retrofitting existing old buildings. Table 2 provides an overview of the properties of CFRP tendons for the prestressing process of PRC based on a literature review. It should be noted that the tensile strength listed in this table refers to the carbon fibers within the CFRP tendons, which provide the primary tensile strength. The polymer matrix surrounding the fibers offers additional structural support and durability. Furthermore, high-strength carbon fibers, typically from the T700 or T1000 series, are commonly used in conjunction with epoxy resin as the resin matrix. Epoxy resin is favored for its outstanding adhesion properties and compatibility with carbon fibers, thereby enhancing the tensile performance of concrete structures. According to the table, the diameter of CFRP tendons ranges from 4 mm [132] to 32 mm [133]. This wide diameter range makes CFRP tendons highly suitable for use in construction projects. Additionally, the tensile strength of CFRP tendons ranges from 1336 MPa [134] to 4920 MPa [135], which is comparable to the yield strength of steel tendons. Furthermore, the modulus of elasticity of CFRP tendons ranges from 80 GPa [136] to 509 GPa [136], and it has a direct relationship with their tensile strength. In conclusion, CFRP tendons exhibit similar engineering properties to steel tendons; however, they are significantly lighter.

Table 2.

CFRP tendons Characteristics.

| Diameter (mm) | Density (kg/m3) | Tensile strength (MPa) | Modulus of elasticity (GPa) | Ultimate strain (%) | Longitudinal thermal expansion (x10 -6/°C) | Poisson's ratio | Shear modulus (GPa) | Shear Strength (MPa) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| 7.9 | 1600 | 2434 | 162 | 0.0147 | 0.68 | 0.32 | – | – | [137] |

| 5 | – | 3200 | 165 | 0.017 | – | 0.27 | – | – | [138] |

| 8 | – | 2720 | 147 | – | – | 0.22 | – | – | [139] |

| 8 | – | 2720 | 147 | – | – | 0.22 | – | – | [140] |

| – | 1800 | 1840 | 147 | – | – | 0.38 | – | – | [141] |

| 30 | – | 2500 | 500 | 0.013 | – | – | – | – | [142] |

| 8 | 1500 | 1800 | 147 | – | – | 0.27 | – | – | [143] |

| 8 | 1500 | 1800 | 147 | – | – | 0.27 | 10.3 | – | [144] |

| 10 | – | 1840 | 147 | – | – | 0.27 | – | – | [145] |

| 10 | – | 1840 | 147 | – | – | 0.27 | – | – | [146] |

| 12.9 | 1600 | 2450 | 145 | – | – | – | – | – | [147] |

| 12 | – | 1440–2500 | 80–500 | 0.018 | −5 | 0.22 | – | – | [136] |

| 4 | – | 2733 | 163 | – | 0.32 | 0.27 | – | – | [132] |

| 5 | – | 1800 | 147 | – | – | – | – | – | [148] |

| – | 1530 | 1440 | 137 | 0.013 | −0.5 | 0.27 | 7.2 | 280 | [149] |

| 8 | – | 3610 | 187 | 0.019 | – | – | – | – | [150] |

| 10 | – | 1840 | 147 | – | – | – | – | – | [151] |

| 32 | – | 1389 | 143 | 0.015 | – | – | – | – | [133] |

| 20 | – | 1800 | 158 | – | – | 0.28 | 10.3 | – | [152] |

| – | – | 1624–1910 | 154 | – | – | – | – | – | [153] |

| 5–9 | – | 1336 | 161 | – | – | 0.31 | 7.0 | – | [134] |

| – | – | 1999 | 149 | 0.013 | – | – | – | – | [154] |

| 5 | – | 2600 | 139 | – | – | – | – | – | [155] |

| 5 | 1800 | 2697 | 176 | – | – | – | – | – | [156] |

| 10–12 | – | 2450 | 126 | – | – | 0.27 | – | – | [157] |

| 7 | – | 1562 | 509 | 0.016 | −9 | – | – | – | [158] |

| 7 | – | – | 162 | – | – | 0.32 | 6.4 | – | [159] |

| 7 | 1600 | 2250 | 176 | 0.014 | 0.68 | 0.23 | – | – | [160] |

| 5–9 | 1800 | 4920 | 231 | 0.021 | – | – | – | 379 | [135] |

| 5 | 1810 | – | – | – | – | – | – | – | [161] |

| – | – | 3400 | 230 | – | – | – | – | – | [162] |

| – | – | 2561 | 140 | – | – | – | – | – | [163] |

| 8 | 1970 | 147 | – | – | – | – | – | [164] |

Han et al. [135] developed a research study to explore the impact of cable chamfering on the shear performance of CFRP tendons. Three different diameters (5, 7, and 9 mm) of transverse enhanced CFRP tendons were employed in the research to assess the influence of chamfering. The findings indicated an increase in transverse shear deformation for all three CFRP tendons when compared to instances without chamfering effects. Moreover, the effect of chamfering altered the failure mode of the shear plane and the mechanical mechanism of all CFRP tendons. Fig. 9 illustrates the failure modes observed in the chamfering and flat shear tests. Chemical prestress stands as an alternative method for generating prestress in concrete and tension in the reinforcement. In this context, Wyrzykowski et al. [158] combined expansive high-performance concrete with ultra-high modulus elastic (509 GPa) CFRP tendons. The authors reported that their long-term tests on the CFRP tendons revealed minimal losses of prestressing due to compressive creep and shrinkage in comparison to the reference concrete.

Fig. 9.

Failure mode, (a) chamfering and (b) flat shear test [135].

Lou and Karavasilisc [154] conducted a comparative study between experimental results and predictions to assess the long-term deflection and time-dependent behavior of concrete girders prestressed with internal CFRP tendons. The study revealed a significant increase in long-term prestress loss for CFRP beams compared to those with steel tendons. The axial performance of CFRP tendons excelled in comparison to their weaker shear strength and lateral compression. Recognizing the potential for a local crushing failure mode with traditional steel cable anchorages, a new resin-filled bond-type anchorage was developed by Mei et al. [137] for CFRP cables due to their unique axial performance and low lateral strengths. Experimental testing demonstrated that the anchorage system successfully met design requirements, ensuring tensile capacity and bond strength suitable for use in an experimental cable-stayed bridge, with all tested cables exhibiting efficiency coefficients greater than 1.00 Fig. 10 illustrates a typical rupture of a CFRP tendon.

Fig. 10.

A typical CFRP tendon rapture [137].

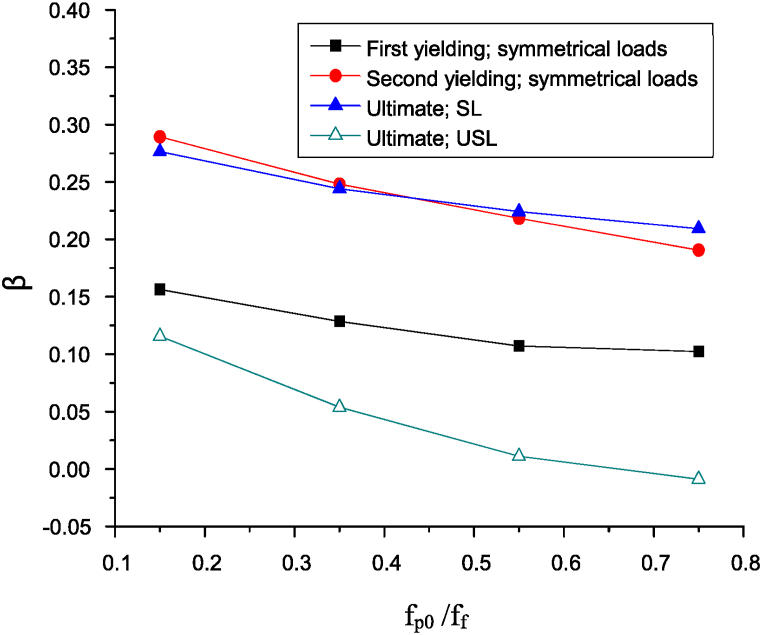

Due to the brittleness inherent in CFRP composites, the moment redistribution characteristics of external CFRP tendons differ from those of other concrete members. Consequently, Lou et al. [141] proposed a numerical evaluation of moment redistribution and secondary reactions in prestressed concrete elements employing external CFRP tendons. The results indicated that the moment redistribution behavior under symmetrical loading significantly differed from that under unsymmetrical loading. Furthermore, the findings underscored the considerable impact of primary prestress on moment redistribution, as depicted in Fig. 11. Another noteworthy investigation by Xie et al. [143] explored the performance of a wedge-bonded anchor for CFRP tendons under cyclic loading. Analyzing factors such as residual tensile load capacity, sleeve strain, temperature elevation in the anchor zone, and system slip provided insights into the structural responses of the wedge-bonded anchor. The results showed that adhesive reinforced by quartz sand outperforms alternatives, with factors like stress level and stress ratio significantly affecting static and fatigue performance. Wedge-bonded anchors demonstrate stability under specific stress conditions, but damage can occur with high stress ratios, highlighting the importance of understanding the interaction between components for optimizing fatigue resistance.

Fig. 11.

Degree of moment redistribution based on the initial prestress level [141].

The resistance of PRC structures to cracking under eccentric tension has emerged as a crucial design consideration. In addressing this concern, Deng et al. [153] conducted research on the anti-cracking behavior of PRC members prestressed with external CFRP tendons under eccentric tension loading. The CFRP tendons employed in the study possessed a modulus of elasticity and ultimate tensile strength of 154 GPa and 1910 MPa, respectively. The findings demonstrated that CFRP tendons effectively enhanced the crack resistance of PRC members subjected to eccentric tensile loads. Furthermore, enhanced crack resistance capacity was achieved with increased flange thickness, larger longitudinal reinforcement diameter, and higher prestressed tension levels. Recognizing the impact of corrosion on steel reinforcements in concrete bridges and its consequent loss of tension capacity, and the potential solution of using non-corrosive FRP reinforcement, Kueres and Hegger [150] developed a flexural design model for PRC members prestressed with CFRP tendons. To address this, a flexural design model for CFRP-reinforced bridge girders was developed, with reliability analysis conducted to determine safety factors and ensure compliance with Eurocode 0 specifications. Further investigations are needed to establish comprehensive guidelines for the use of pre-tensioned CFRP tendons in bridge construction.

3.2. GFRP tendons

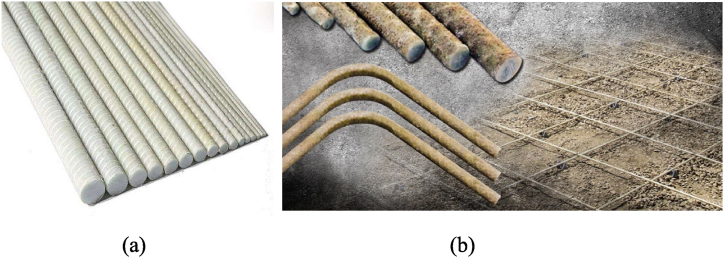

Glass FRP, referred to as GFR polymer, represents another form of FRP composite formed by combining E-glass composites and polyester. The tensile and compressive strength of GFRP materials falls within the range of 44–3040 MPa and 140–350 MPa, respectively, positioning it as a compelling substitute for steel tendons in prestressed concrete construction [6]. Notably, GFRP tendons exhibit one-fourth of the weight of steel tendons of similar dimensions [165]. When applying GFRP composites over large surfaces, the inclusion of supporting members, such as concrete or a wire frame, becomes a necessity. Fig. 12 illustrates various sizes of GFRP rebars and mesh.

Fig. 12.

GFRP tendons (a) Glass bars, (b) Glass mesh [165].

Utilizing GFRP rebars in construction projects offers several advantages, including corrosion resistance, non-magnetic properties due to the absence of metals, and immunity to rust. Furthermore, GFRP rebars weigh less than their steel counterparts, contributing to the potential for a significantly extended building lifespan, particularly in facilities or areas where water resistance is crucial [124]. The non-corrosive nature of GFRP composites has made them a preferred material for boat construction over many years. In recent architectural projects, there is an increasing inclination towards incorporating GFRP materials as a construction choice. Additionally, GFRP can serve as cladding materials for structures bent into wire frame configurations [166]. Here are some engineering applications and construction cases for GFRP materials: a) Rebar Replacement: GFRP rebars are used as a non-corrosive alternative to steel reinforcement in concrete structures, particularly in corrosive environments like marine and chemical processing facilities. b) Architectural Panels: GFRP panels are utilized in building facades, curtain walls, and cladding systems due to their lightweight, high strength, and design flexibility. c) Pipe Rehabilitation: GFRP liners are employed for rehabilitating and reinforcing deteriorated or damaged pipelines, increasing their structural integrity and lifespan.

Table 3 provides an overview of the properties of GFRP tendons for prestressing purposes based on a literature review. According to the table, the diameter of GFRP tendons ranges from 5 mm [5] to 11.2 mm [50]. Due to this limited diameter range, GFRP tendons may not be very suitable for construction projects. Additionally, the tensile strength of GFRP tendons ranges from 170 MPa [167] to 1770 MPa [5], which is lower than that of CFRP and steel tendons. Furthermore, the modulus of elasticity of GFRP tendons ranges from 30 GPa [5] to 70 GPa [5], which is significantly lower than the modulus of elasticity of CFRP and steel tendons. In conclusion, although GFRP tendons have a similar weight to CFRP tendons, they exhibit weaker engineering properties when compared to those of CFRP and steel tendons.

Table 3.

GFRP tendons characteristics.

| Diameter (mm) | Density (kg/m3) | Tensile strength (MPa) | Modulus of elasticity (GPa) | Ultimate strain (%) | Longitudinal thermal expansion (x10 -6/°C) | Poisson's ratio | Shear modulus (GPa) | Shear Strength (MPa) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| 5–10 | 2100 | 1770 | 30–70 | 0.012 | 6 | 0.22 | – | – | [5] |

| 8 | 1700 | 459 | 43.2 | 0.037 | 10 | 0.22 | – | – | [31] |

| 8 | 2000 | 1400 | 49.3 | – | 8 | 0.22 | 10.21 | – | [168] |

| – | – | 170 | 33.2 | – | – | 0.25 | – | 33.2 | [167] |

| 11.2 | – | 978.7 | 40.2 | 0.024 | – | – | – | – | [50] |

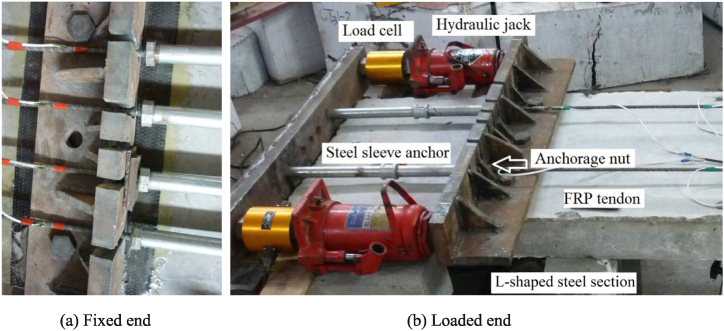

After considering the anchoring problem of external FRP tendons, Gao et al. [31] developed research to evaluate the flexural behavior of PRC structure prestressed by external post-tensioned GFRP tendons. 8 mm GFRP tendons with density, tensile strength, modulus of elasticity, and Poisson's ratio of 1700 kg/m3, 459 MPa, 43.2 GPa, and 0.22, respectively were used in this study. The pre-tensioning process and details are shown in Fig. 13. The authors reported that their proposed anchoring approach is efficient and reliable. Besides, the authors developed a method for calculating the stress at the ultimate stage in the external tendons and found that test results agreed with the numerical results. In addition to anchoring problems, the deviation from results obtained from predicted models of transverse thermal pressure from previous studies with the results obtained from the experimental tests was another issue that needed to be considered. In this regard, Chen et al. [168] proposed an improved analytical model for analyzing transverse thermal pressure. The results of the proposed analytical model revealed that the bond performance and thermal compatibility of GFRP tendons can be improved.

Fig. 13.

Details of the pre-tensioning process of the GFRP tendons [31].

Previous studies have presented that the prestressing process produces ductile and even fail-safe structural glass members. In this regard, a general design concept was introduced by Engelmann and Weller [5] to estimate the losses of structural glass members. In addition to a design concept, an experimental investigation also was conducted to evaluate the hypothesis. The GFRP tendons utilized in this research had an elastic modulus, tensile strength, density, and Poisson's ratio of 70 GPa, 1770 MPa, 2100 (kg/m3), and 0.22, respectively. The investigation results showed that additional effects need to be considered for the development of an approach for lifetime prediction.

3.3. AFRP tendons

AFRP is the collective term for a group of artificial fibers distinguished by unique properties that render them highly versatile in their utilization ranging from garment and armor to the construction industry. The development of AFRP traces its roots back to research involving polyester and nylon. The noteworthy properties of one of the most useful aramid polymers named Nomex, which was developed in the early 1960s, led to its widespread use in protective clothing and insulation as a substitute for asbestos [2]. After that, subsequent research highlighted aramid's exceptional tensile strength, positioning it as a potential substitute for steel reinforcement in construction projects. Presently, the annual production of AFRP exceeds 60 million kg, with growing demand and decreasing costs indicative of its expanding market presence.

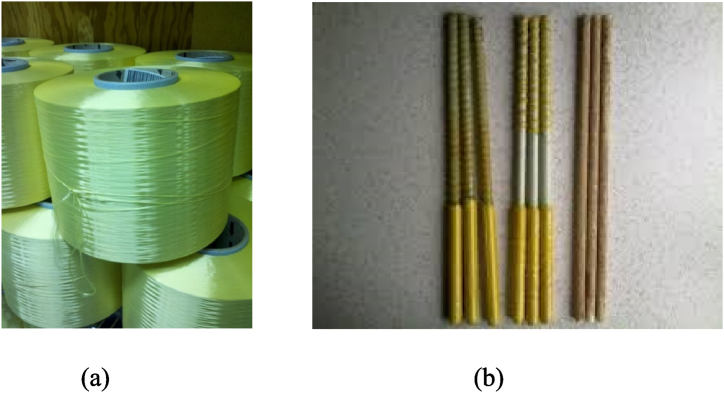

The predominant alignment of the chemical configuration of chain molecules in AFRP composites along the fiber axis imparts impressive strength, flexibility, and abrasion resistance [169]. AFRP materials exhibit excellent heat resistance and low flammability, with degradation occurring around 500 °C instead of melting. Moreover, their minimal electrical conductivity renders them suitable for use as insulating materials in electrical applications [12]. Another benefit of AFRP composites is their strong endurance to organic solvents, rendering them appropriate for diverse applications [8]. Nevertheless, they show some drawbacks, including sensitivity to salts, acids, and UV radiation. Moreover, without pre-treatment, AFRP materials can generate static electricity. Fig. 14 illustrates typical AFRP composites.

Fig. 14.

AFRP Composites (a) Aramid fiber, (b) Aramid bars [170].

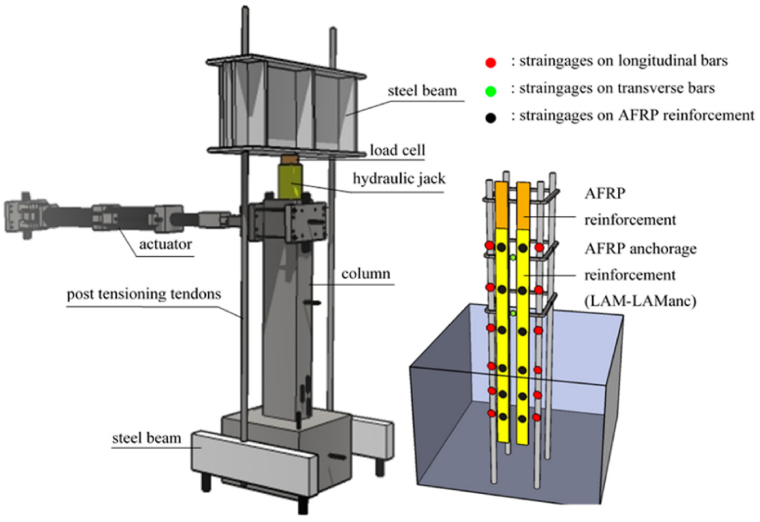

In the beginning, AFRP composites were utilized for tire reinforcement, then they were used as a substitution for asbestos in the manufacturing of brake linings. However, using AFRP composites as body armor materials and other types of protective equipment such as helmets and gloves for firefighters, was more common [13]. Recently, due to the high strength-to-weight ratio of AFRP, their utilization as reinforcing materials is increasing. For instance, in the aviation industry and the production of aircraft wings, composite materials such as AFRP play an important role since they have high flexing tolerance. In the construction industry and for the production of reinforced concrete, AFRP can be used as a replacement for steel rebars and for retrofitting the existing structural members [24]. The testing setup and details of the retrofitting process of the existing RC column are shown in Fig. 15.

Fig. 15.

Details of the retrofitting process for the RC column [24].

The low stretch properties (normally 3.5 % at break), abrasion resistance, and high tensile strength make AFRP composites suitable for the production of cables and ropes [171]. Additionally, they can be utilized in the production of undersea pipelines in the oil industry where corrosion is a vital problem. Here are some engineering applications and construction cases for AFRP materials: a) Blast-resistant Structures: AFRP composites are used in constructing blast-resistant structures for military and security applications due to their high tensile strength and energy absorption properties. b) Aerospace Components: AFRP materials find applications in aerospace engineering for manufacturing lightweight components, such as aircraft fuselages, wings, and rotor blades. c) High-performance Sports Equipment: AFRP composites are used in the construction of high-performance sports equipment, including racing bicycles, kayaks, and tennis rackets, due to their exceptional strength-to-weight ratio.

Table 4 shows the characteristics of AFRP tendons for prestressing purposes based on the literature review. According to this table, the diameter of AFRP tendons ranges from 4 mm [13] to 20 mm [169]. It can be noted that AFRP tendons have a wider diameter range than GFRP tendons but a narrower range than CFRP and steel tendons. Therefore, there is a moderate potential to use AFRP tendons as a replacement for steel tendons in the production of prestressed concrete. Additionally, the tensile strength of AFRP tendons ranges from 1200 MPa [8] to 2284 MPa [48], which is lower than that of CFRP and steel tendons but higher than GFRP tendons. Furthermore, the modulus of elasticity of AFRP tendons ranges from 50 GPa [13] to 131 GPa [48], which is also lower than the modulus of elasticity of CFRP and steel tendons but higher than GFRP tendons. Considering the lower weight of AFRP tendons compared to other types of tendons, it can be concluded that AFRP tendons have weaker engineering properties than CFRP and steel tendons but exhibit better properties than GFRP tendons.

Table 4.

AFRP tendons characteristics.

| Diameter (mm) | Density (kg/m3) | Tensile strength (MPa) | Modulus of elasticity (GPa) | Ultimate strain (%) | Longitudinal thermal expansion (x10 -6/°C) | Poisson's ratio | Shear modulus (GPa) | Shear Strength (MPa) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| 14 | 1200 | 1330 | 50 | 0.021 | −2 | 0.38 | – | – | [7] |

| – | – | 1200 | 53 | 0.015 | – | – | – | – | [8] |

| – | – | 2060 | 118 | 0.017 | – | 0.38 | – | – | [12] |

| 4 | 125 | 1330 | 50 | 0.021 | −2 | – | – | – | [13] |

| 6 | – | 2060 | 118 | 0.017 | – | 0.38 | – | – | [25] |

| – | 1400 | 1400 | 68 | 0.037 | −6 | 0.38 | – | – | [121] |

| 20 | 1400 | 2324 | 121 | 0.019 | – | 0.38 | – | – | [169] |

| 10 | – | 1520 | 60 | 0.027 | −4 | – | – | – | [172] |

| 12 | – | 1400 | 61 | – | – | – | – | – | [164] |

| – | – | 2283.8 | 131 | 0.018 | – | – | – | – | [48] |

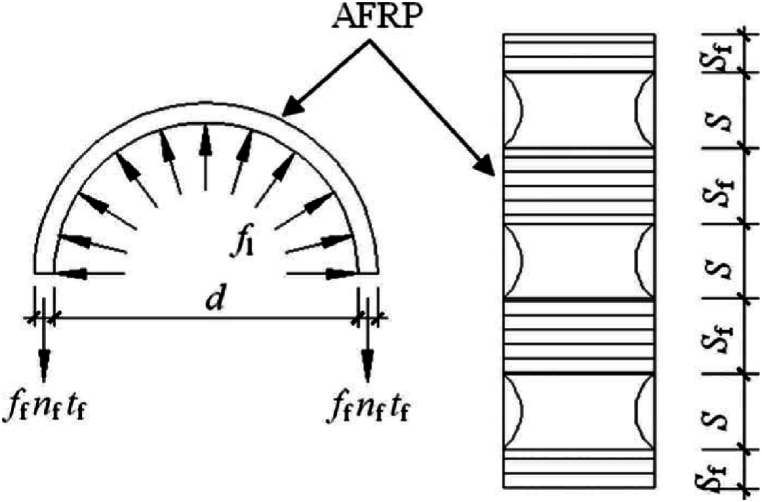

To improve the ductility of RC prestressed with tendons a series of flexural strength experiments on girders with AFRP rectangular tendons were conducted [7]. The 14 mm AFRP tendons utilized in this study had density, tensile strength, modulus of elasticity, and Poisson's ratio of 1200 kg/m3, 1330 MPa, 50 GPa, and 0.38, respectively. According to the results, the ultimate strength of RC with AFRP tendons increased by 450 % when compared to RC without tendons. It is believed that the ductility of RC with AFRP tendons significantly improved by the use of unbounded and bounded rectangular reinforcement. The performance of high-strength concrete reinforced with AFRP sheets under axial compression was investigated by Ref. [12]. The AFRP sheets with tensile strength and elastic modulus of 2060 MPa and 118 GPa, respectively, in two different wrapping formats (continuous and discontinuous) were utilized in this research. Fig. 16 presents the confining stress attributed to the AFRP sheets. The results showed that with the utilization of continuous AFRP sheets, the ductility and strength were increased significantly.

Fig. 16.

Confining stress attributed to the AFRP sheets [12].

Kim [121] carried out research to assess the flexural behavior of reinforced concrete beams prestressed with AFRP tendons. The research not only involved the application of various prestressing levels but also examined the applicability of existing predictive equations and code provisions. The flexural performance of the beams was significantly influenced by the prestress level in the AFRP tendons. Additionally, the authors provided recommendations to enhance current design provisions. Lou et al. [169] investigated the long-term behavior of RC beams prestressed with bounded AFRP tendons by developing a computer model. The results indicated that, accounting for tendon relaxation, AFRP tendons exhibited higher prestress loss compared to steel tendons, while the contribution of prestress loss due to shrinkage and creep was substantially lower in AFRP tendons than in steel tendons.

3.4. BFRP tendons

BFRP composites result from the combination of polymer resins, for instance, vinyl ester and isophthalic polyester, with unidirectionally bound basalt fibers. To create these composites, volcanic basalt rocks undergo crushing and melting at temperatures exceeding 1400 °C, yielding continuous filaments of basalt fibers featuring diameters that vary between 13 and 20 μm [173]. Generally, BFRP rebars are manufactured using two distinct approaches: the automated wet-layup process and the pultrusion process. Both techniques yield BFRP composites with comparable variations in mechanical properties [174]. Because the resin exhibits less strength in comparison to the fibers, the tensile strength and stiffness of BFRP bars fluctuate depending on the overall volume of fibers relative to the volume of resin [175]. Fig. 17 illustrates different types of BFRP composites.

Fig. 17.

BFRP composites (a) basalt fiber, (b) BFRP bars [176].

BFRP composites are appropriate for the harshest and most aggressive applications where steel reinforcements are not suitable. For instance, the application of BFRP composites can be summarized as utilization in hydraulic structures, panel systems, thin walls, aggressive chemical environments, freeze and thaw effects, bridge decking, architectural precast, high temperature, marine applications and seawalls, and finally shielding concrete [3,57,[177], [178], [179], [180]]. BFRP composites are normally categorized as sustainable and green materials since they are natural and produced from volcanic rocks. They have less than 10 % of the carbon emission of steel and also among all types of FRP tendons, BFRP has the lowest environmental impact in a life-cycle-assessment. Here are some engineering applications and construction cases for AFRP materials: a) Road and Bridge Infrastructure: BFRP rebars and grids are utilized for reinforcing concrete structures in roadways, bridges, and tunnels, providing corrosion resistance and longer service life. b) Industrial Flooring: BFRP grids and mats are used in industrial flooring systems for providing reinforcement and crack control in concrete slabs, improving durability and load-bearing capacity. c) Pipeline Rehabilitation: BFRP wraps and liners are employed for rehabilitating and strengthening deteriorated or damaged pipelines, enhancing their structural integrity and resistance to corrosion.

Table 5 displays the properties of BFRP tendons for prestressing purposes based on the literature review. According to the information presented in this table, the diameter of BFRP tendons spans from 4 mm [179] to 16 mm [180], indicating a comparable diameter range to AFRP tendons. Consequently, there is a moderate potential for utilizing BFRP tendons in the production of prestressed concrete. Furthermore, the tensile strength of BFRP tendons falls within the range of 920 MPa [178] to 1738 MPa [177], which is lower than AFRP, CFRP, and steel tendons, and comparable to GFRP tendons. Additionally, the modulus of elasticity of BFRP tendons ranges from 38 GPa [181] to 70 GPa [177], indicating lower values compared to AFRP, CFRP, and steel tendons but similar to GFRP tendons. Considering the relatively higher weight of BFRP tendons compared to other tendon types except steel tendons, it can be inferred that BFRP tendons exhibit weaker engineering properties than AFRP, CFRP, and steel tendons, and are comparable to GFRP tendons.

Table 5.

BFRP tendons characteristics.

| Diameter (mm) | Density (kg/m3) | Tensile strength (MPa) | Modulus of elasticity (GPa) | Ultimate strain (%) | Longitudinal thermal expansion (x10 -6/°C) | Poisson's ratio | Shear modulus (GPa) | Shear Strength (MPa) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| 10 | – | 1270 | 55 | 0.025 | – | 0.2 | – | – | [3] |

| 6 | 2200 | 1719 | 53 | 0.032 | – | – | – | – | [57] |

| 14 | – | 1350 | 38 | 0.026 | – | – | – | – | [173] |

| 6 | – | 1571 | 55 | 0.029 | 24 | 0.2 | – | – | [174] |

| 14 | – | 1300 | 40 | – | – | – | – | – | [175] |

| 12 | 2400 | 1208 | 49 | 0.025 | 18 | 0.2 | – | – | [182] |

| 14 | 2600 | – | 38 | 0.029 | – | – | – | – | [181] |

| 6 | – | 1738 | 70 | 0.031 | 26 | – | – | – | [177] |

| 8–12 | – | 920 | 44 | 0.024 | – | – | 4.10 | 60 | [178] |

| 4 | 2000 | 1424 | 55 | 0.026 | – | – | 6 | 140 | [179] |

| 16 | – | 1300 | 40 | 0.032 | – | 0.2 | – | – | [180] |

| 10 | 2000 | 1200 | 55 | – | – | 0.25 | – | – | [183] |

| 10 | – | 1141 | 47 | – | – | – | – | – | [184] |

| 8 | – | 960 | 49 | 0.021 | – | – | – | – | [185] |

| 4 | – | 1598 | 54 | – | – | – | – | – | [186] |

BFRP serves as a corrosion-resistant, sustainable, and non-corrosive substitute for steel reinforcements, rebars, and tendons. The tensile strength of BFRP tendons surpasses that of steel tendons by 2.5 times, and their weight is four times lighter than that of steel tendons. These exceptional characteristics render BFRP tendons and materials excellent substitute composites for the manufacturing of reinforced concrete [182]. The extended durability of BFRP tendons (over 100 years) adds to its appeal for use in the construction industry. Moreover, BFRP displays outstanding resilience against chemicals corrosive elements, and ultraviolet radiation. Employing BFRP composites in the construction sector leads to a substantial reduction in waste volume, along with decreased costs associated with handling, transportation, and installation. Also, the maintenance and repair costs will decrease by utilizing BFRP bars. Anti-salt and corrosion-resistance properties and great mechanical and engineering performance of BFRP tendons under harsh environments make them promising prestressing components in concrete technology. Wang et al. [181] conducted an analysis of the performance of BFRP tendons with bonded anchors, examining the impact of initial prestressed displacement and loading rates. The study revealed that the fractured BFRP tendons exhibited a broom-like appearance, as depicted in Fig. 18. Notably, the anchors remained effectively secured to the BFRP tendons at both ends, demonstrating a lack of clear anchorage slip.

Fig. 18.

Fracture of the BFRP tendon: (a) failure mode; (b) anchor without any slip [181].

Due to a lack of data regarding the degradation pattern of fatigue performance in BFRP tendons, Shi et al. [57] conducted a study to examine the fatigue performance of BFRP composites within an aggressive environment. The BFRP tendons employed in this research exhibited a density, tensile strength, and elastic modulus of 2200 (kg/m3), 1719 MPa, and 53 GPa, respectively. The ultimate failure mode of the BFRP composites in the fatigue test is depicted in Fig. 19. The findings of this investigation indicated that the reduction in fatigue strength of BFRP tendons was affected by the compromised fiber-matrix interface, which resulted from the hydrolyzation of Si–O–Si chemical bonds in the extreme environment (salt solution). These results offer valuable insights for the fatigue design considerations of BFRP composites in extreme environments.

Fig. 19.

The ultimate failure mode under fatigue test [57].

Wang et al. [179] proposed an optimized anchor system to increase the anchor behavior of BFRP tendons. The 4 mm diameter BFRP tendons used in this research had density, tensile strength, and modulus of elasticity of 2000 (kg/m3), 1424 MPa, and 55 GPa, respectively. The tensile strength of the BFRP tendons in the anchor zone reduced moderately from the loading end to the free end. In addition, the authors reported that there was no clear correlation between tensile strain and the location of the BFRP tendons. The results guided the design of BFRP tendons in harsh environments. The development of corrosion in the steel tendons in cross-tensioned concrete is a critical issue that needs to be considered. In this regard, steel tendons were replaced by BFRP tendons, and a theoretical approach for evaluating the prestress loss of BFRP tendons in cross-tensioned concrete pavements was proposed [180]. The results of this research showed that the prestress loss of BFRP tendons was lower than that of steel tendons.

3.5. Advantages and disadvantages of steel and FRP tendons

For reinforcing concrete structural members, FRP materials have been broadly used as a substitute for traditional steel reinforcement and tendons [126,[187], [188], [189]]. As mentioned earlier, by employing FRP composites as a substitution for steel reinforcement, many advantages such as non-magnetic and non-corrosive characteristics, low weight, noticeable resistance to fatigue, and high tensile strength can be achieved [190]. Therefore, employing FRP tendons as a promising substitution for conventional steel tendons in the field of prestressing concrete leads to outstanding results.

The Anchorage system is one of the major problems for the practical application of FRP composites and tendons [191]. The anchorage system issue resulted in many studies addressing this problem for FRP tendons [[192], [193], [194], [195], [196]]. As mentioned, typically four composite materials can be used for prestressing tendons: carbon FRP, glass FRP, aramid FRP, and basalt FRP. Each of these materials has its benefits and disadvantages. For instance, because of the creep under constant loads and also low endurance to alkaline conditions, GFRP composites are not suggested for bonded tendons [197]. On the other hand, CFRP materials are desired for reinforcement and composite tendons and also have been widely utilized for prestressing applications. Fig. 20 Shows the normal CFRP and steel tendon with the same diameter.

Fig. 20.

CFRP and Steel tendon [198].

In comparison to steel tendons, FRP composite tendons present different material characteristics. FRP tendons have linear elastic behavior until the rupture and they are brittle. In terms of engineering properties, for example, modulus of elasticity, CFRP tendons possess a notable wide range from 80 up to 500 MPa, whereas AFRP tendons have usually much lower modulus of elasticity [199]. Therefore, there needs a comparison study for understanding the behavior of various types of tendons in various situations. Table 6 presents the most important disadvantages and advantages of steel tendons and FRP composite tendons.

Table 6.

Advantages and disadvantages of steel and FRP tendons.

| Type of Tendon | Advantages | Disadvantages |

|---|---|---|

| CFRP |

|

|

| GFRP |

|

|

| AFRP |

|

|

| BFRP |

|

|

| Steel Tendons |

|

|

Besides the advantages and disadvantages of various kinds of tendons, the mechanical properties of tendons play a significant role in their application. In this respect, ranges of the engineering characteristics of the different types of FRP tendons in comparison to the conventional steel tendons are presented in Table 7. The table results reveal variations in the elastic modulus across different tendon materials. Specifically, the elastic modulus of CFRP tendons exhibited a range of 80–509 MPa. In comparison, GFRP, AFRP, BFRP, and steel tendons demonstrated elastic modulus ranges of 30–70 MPa, 50–131 MPa, 38–70 MPa, and 180–210 MPa, respectively. The main reason the elastic modulus of CFRP tendons is typically higher than that of BFRP, GFRP, AFRP, and steel tendons lies in the superior mechanical properties of carbon fibers. Carbon fibers exhibit an exceptional modulus of elasticity, characterized by high tensile strength and stiffness. The inherent properties of carbon fibers, including their lightweight nature and outstanding strength-to-weight ratio, make CFRP tendons ideal for applications demanding elevated structural performance. In contrast, while GFRP, BFRP, and AFRP fibers offer advantages such as cost-effectiveness and good tensile strength, their modulus of elasticity tends to be lower than that of carbon fibers, influencing the overall stiffness of the respective FRP materials. It's important to note that while CFRP tendons often have a higher elastic modulus, the selection of the appropriate FRP material depends on the specific requirements of the application. Factors such as cost, corrosion resistance, and thermal properties also play a role in choosing the most suitable FRP material for a particular structural application.

Table 7.

FRP and steel tendon properties.

| Characteristics | CFRP [[132], [133], [134], [135], [136], [137], [138], [139], [140], [141], [142], [143], [144], [145], [146], [147], [148], [149], [150], [151], [152], [153], [154], [155], [156],[158], [159], [160], [161],200] | GFRP [5,31,168] | AFRP [7,8,12,13,25,121,169,172] | BFRP [3,57,[173], [174], [175],[177], [178], [179], [180], [181], [182]] | Steel Tendons [58,76–120,[201], [202], [203], [204], [205]] |

| Elastic Modulus (GPa) | 80–509 | 30–70 | 50–131 | 38–70 | 180–210 |

| Ultimate Strain (%) | 0.013–0.021 | 0.012–0.037 | 0.015–0.037 | 0.024–0.032 | 0.027–0.129 |

| Longitudinal thermal expansion coefficient (x10 -6/°C) | −9 to 0.68 | 6 to 10 | −6 to −2 | 18 to 26 | 11 to 13 |

| Poisson's Ratio | 0.22–0.38 | 0.22 | 0.38 | 0.2 | 0.2–0.3 |

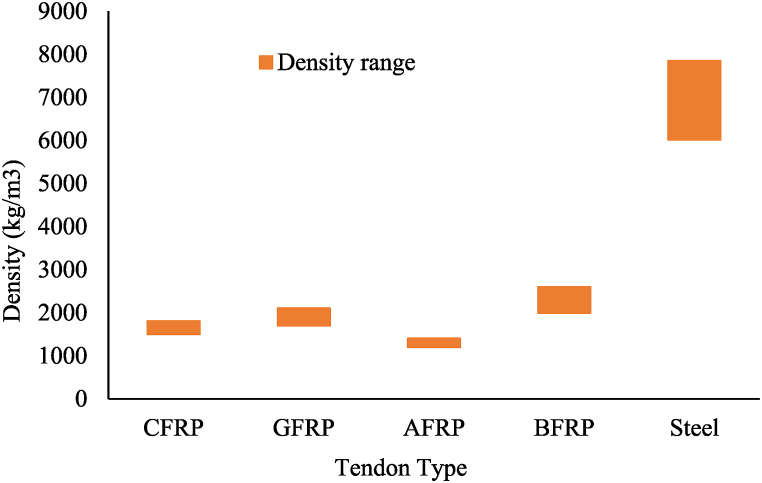

Based on the density results illustrated in Fig. 21, it can be said that the density of steel tendons surpasses that of CFRP (by 4 times), GFRP (by 3.5 times), AFRP (by 5 times), and BFRP (by 3 times). This divergence in density between steel tendons and composite counterparts (CFRP, GFRP, AFRP, BFRP) arises from the intrinsic properties of their constituent materials. The metallic nature of steel inherently results in higher density, whereas composite tendons utilize lightweight polymer matrices to achieve reduced overall densities, particularly advantageous in applications prioritizing weight reduction.

Fig. 21.

Density range of CFRP, GFRP, AFRP, BFRP, and Steel Tendons.

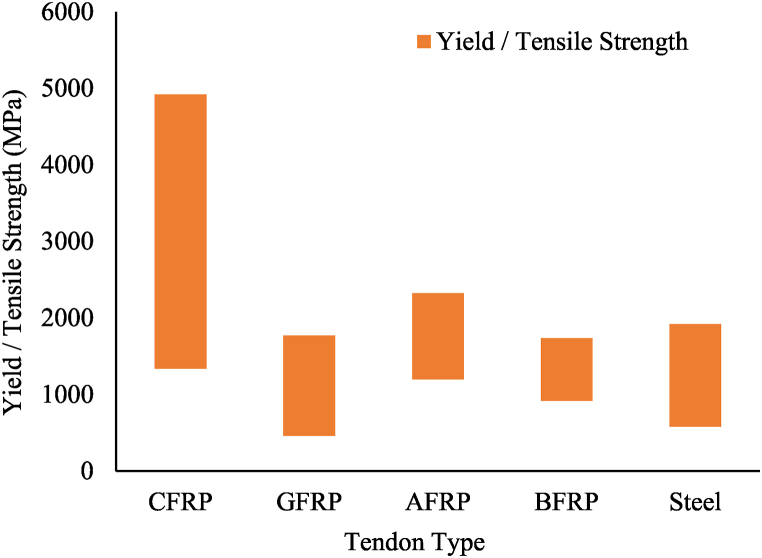

Furthermore, as depicted in Fig. 22, the tensile strength of CFRP, GFRP, AFRP, and BFRP tendons spans from 1336 to 4920 MPa, 459–1770 MPa, 1200–2324 MPa, and 920–1738 MPa, respectively. In contrast, the yield strength of steel tendons ranges from 580 to 1920 MPa. The underlying reasons for the elevated tensile strength of CFRP tendons, akin to their higher elastic modulus, can be attributed to their distinctive composition and structural characteristics, setting them apart from other tendon types. In summary, it can be said that apart from the density of FRPs tendons which makes them much lighter than steel tendons, there are still many worries associated with their behavior and performance. For example, further vulnerability to UV radiation and higher temperatures, brittle failure, and lack of yielding of FRP tendons are some of the main concerns to utilizing them as an alternative for steel tendons.

Fig. 22.

Tensile strength of CFRP, GFRP, AFRP, BFRP, and steel tendons.

4. Challenges present in steel and FRP tendons and upcoming research avenues

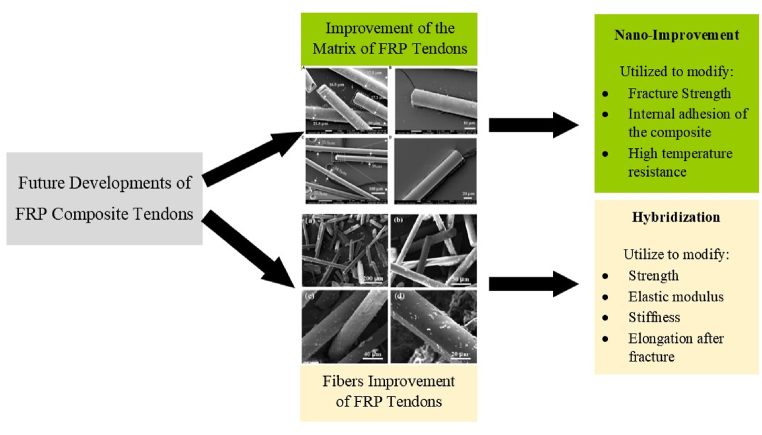

This section focuses on delineating the current challenges associated with the utilization of FRP and steel tendons in the construction sector. Furthermore, it explores potential avenues for future research that warrant exploration within the construction domain. Despite the efficacy of FRP composite materials in construction, certain challenges remain. Technical hurdles, elevated production costs in comparison to steel tendons, raw material availability, and the intricacies of the production process stand out as key challenges identified in previous studies. It might be considered that the provided list of challenges and issues in this section is not comprehensive, and there might be other kinds of challenges that could occur with the utilization of FRP composites in construction projects and need to be focused on in future studies. Besides existing challenges, the future developments of FRP composite tendons can be categorized into two main sections including improvement of the matrix of FRP tendons and fibers modification. Fig. 23 presents the details of future developments of FRP composite tendons and their effects on the engineering properties of concrete.

Fig. 23.

Future developments of FRP Composites.

This paper offers an innovative review of the evolution and engineering characteristics of different types of tendons, specifically focusing on both steel and composite options for Prestressed Reinforced Concrete (PRC). The innovation lies in providing a comprehensive analysis of the strengths and weaknesses of each tendon variety, emphasizing the potential advantages of incorporating FRP tendons in construction despite their drawbacks. In addition to that, some recommendations for future studies based on the existing challenges are explained as follows:

-

•

Utilization of alternative machine learning and artificial intelligence techniques for predicting stress increment at ultimate in bounded and unbounded strands should be considered in future studies. In addition, a predictive approach with higher accuracy and consideration of the effects of humidity and temperature on the mechanical properties of prestressed concrete in long-term service can be developed by future research.

-

•

Experiments on structural members subjected to sustained loads for a long duration of a lifetime (several years or decades) including reliability and durability, long-term and fatigue resistance, and fire and thermal resistance are necessary for future studies.

-

•

Less predictable loads including wind and earthquake need to be investigated by a multi-load case formulation, which is an extension left for future research. Furthermore, to produce safer and stronger Strut-and-Tie Modeling (STM) models, a multi-load case formulation is of interest for future research.

-

•

The simplification implied by a purely numerical analysis needs to be considered for future investigation to include real-world data to evaluate the effects of various environmental conditions on the properties of the structure members.

-

•

There is a lack of investigations on the influence of electrochemical rehabilitation treatment on the interfacial bonding properties, fatigue performance, bearing capacity, and failure pattern of the PRC structures which need to be developed by future studies.

-

•

For future applications and innovations, the performance and workability of non-metallic fibers must be investigated. In addition to that, further investigations using various concrete types and strengths as well as the different types and number of FRP composite tendons should be developed in future works to validate the analytical and numerical approaches.

Moving forward, there are promising prospects for the application of the four FRP tendon types:

-

•

Carbon FRP (CFRP) Tendons: Their superior strength comparable to steel makes them ideal for applications requiring high tensile strength. Future research could explore ways to optimize CFRP tendon production processes to reduce costs and enhance availability.

-

•

Glass FRP (GFRP) Tendons: Their non-magnetic properties and corrosion resistance make them suitable for use in environments where steel tendons would be prone to deterioration. Further research could focus on improving the manufacturing processes of GFRP tendons to make them more cost-effective.

-

•

Aramid FRP (AFRP) Tendons: Their low flammability and exceptional resistance to elevated temperatures make them ideal for applications in fire-prone or high-temperature environments. Future studies could investigate ways to enhance the manufacturing processes of AFRP tendons to make them more widely available.

-

•

Basalt FRP (BFRP) Tendons: Their sustainability, rust resistance, and non-corrosive properties make them suitable for environmentally sensitive or corrosive environments. Future research could explore ways to optimize the production processes of BFRP tendons to further improve their sustainability and cost-effectiveness.

5. Conclusions

This research has examined the engineering and mechanical characteristics of FRP and steel tendons. While certain drawbacks and adverse impacts of employing FRP tendons as viable substitutes for steel tendons, such as increased costs, material scarcity, and intricate production processes, have been identified, there are still notable advantages and benefits associated with the utilization of FRP tendons in the construction sector. Drawing conclusions from an in-depth review of this research, the following insights can be derived.

-

I.

The versatile range of sizes available for steel tendons positions them as excellent candidates for various construction projects. Additionally, a direct correlation exists between the modulus of elasticity and Poisson's ratio of steel tendons. It is noteworthy that while some properties of steel tendons resemble those of FRP tendons, their higher density and susceptibility to corrosion stand out as notable drawbacks.

-

II.

CFRP tendons have the maximum strength when compared to other FRPs which is comparable to steel tendons. They have high resistance to elevated temperature and corrosion. At normal temperatures, CFRP tendons are moisture, acid, and solvent-resistant. Despite of complicated production process of CFRP tendons, their production cost is cheaper than other FRP tendons.

-

III.

GFRP tendons are corrosion-resistant. Since there are not any kind of metals in GFRP tendons, they are not magnetic materials and they do not rust. In comparison with steel and other types of FRP tendons, GFRP tendons are lighter, therefore utilizing them resulted in reducing the weight of structural members.

-

IV.

AFRP tendons have low flammability and perfect resistance to elevated temperature. They have low electrical conductivity and high resistance to organic solvents.

-

V.

BFRP tendons are rust-proof and non-corrosive. Since they are produced from volcanic basalt stones, they are sustainable. The tensile strength of the BFRP tendons is 2.5 times greater than steel tendons while their weight is 3 times lighter than steel tendons. BFRP tendons presented noticeable durability performance.

Data availability

Data will be made available on request.

CRediT authorship contribution statement

Mahdi Rafieizonooz: Writing – review & editing, Writing – original draft, Methodology, Data curation, Conceptualization. Hyounseung Jang: Writing – review & editing, Supervision, Project administration, Funding acquisition. Jimin Kim: Validation, Investigation, Data curation. Chang-Soo Kim: Validation, Methodology, Data curation. Taehoon Kim: Methodology, Investigation. Seunghwan Wi: Methodology, Conceptualization. Saeed Banihashemi: Methodology, Investigation, Data curation. Elnaz Khankhaje: Writing – review & editing, Methodology, Conceptualization.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgment

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT; Ministry of Science and ICT) [grant numbers NRF- 2022R1A4A3026883, 2021R1A2C2004320].

References

- 1.Wu T., Sun Y., Liu X., Cao Y. Comparative study of the flexural behavior of steel fiber-reinforced lightweight aggregate concrete beams reinforced and prestressed with CFRP tendons. Eng. Struct. 2021;233 doi: 10.1016/j.engstruct.2021.111901. [DOI] [Google Scholar]

- 2.Zhang H., Li H., Corbi I., Corbi O., Wu G., Zhao C., et al. AFRP influence on parallel bamboo strand lumber beams. Sensors. 2018;18 doi: 10.3390/s18092854. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Shi J., Wang X., Wu Z., Wei X., Ma X. Long-term mechanical behaviors of uncracked concrete beams prestressed with external basalt fiber-reinforced polymer tendons. Eng. Struct. 2022;262 doi: 10.1016/j.engstruct.2022.114309. [DOI] [Google Scholar]

- 4.Xie G hua, Yan P., Sun Y., Feng Q hong, Gedi A.A. Fatigue performance of anchorage for CFRP tendons affected by water infiltration. Construct. Build. Mater. 2021;269 doi: 10.1016/j.conbuildmat.2020.121359. [DOI] [Google Scholar]

- 5.Engelmann M., Weller B. Losses of prestress in post-tensioned glass beams. Structures. 2019;19:248–257. doi: 10.1016/j.istruc.2019.01.011. [DOI] [Google Scholar]