Abstract

Ice cream is a multiphase frozen dessert that often melts during distribution and upon consumption. The meltdown phenomenon is one of the concerns in the quality preservation of ice cream for consumer convenience in the frozen food industry. In this context, X-ray tomography was used to visualise and quantify 3D ice crystal and air bubble evolution during the meltdown of ice cream. Two ice cream products, namely I and II, with varying air volume fractions, were evaluated for this study. The results indicated a small mean diameter of 66.43 ± 2.07 µm at 0 min and decreased to 45.74 ± 3.92 µm during 10 min of the meltdown of ice cream II. A large mean diameter of ice crystals of 75.02 ± 3.14 µm was found in ice cream I, at 0 min that decreased significantly (p < 0.05) to 54.30 ± 2.63 µm during 10 min of the meltdown. The air bubbles were also observed to decrease in mean diameter. The 3D datasets on the ice crystals and air bubbles described in this work provide more insight into the 3D microstructural evolution during the meltdown and are useful in controlling the sensory quality attributes of ice cream desserts.

Keywords: Ice cream, Meltdown, X-ray CT, Imaging, 3D microstructure

Introduction

Ice cream is a multiphase dessert system comprising the frozen phase, i.e., ice crystals, and the unfrozen matrix, such as air bubbles, fat, sugars, proteins, stabilisers, and emulsifiers (Muse and Hartel 2004; Pinzer et al. 2012; Goff and Hartel 2013). Ice crystals are formed during freezing, as air is subsequently whipped into ice cream. Fat partially coalesces and forms fat globule clusters that are mainly responsible for air bubbles’ stability in ice cream in addition to providing structural integrity and resistance to melting (Chang and Hartel 2002; Goff and Hartel 2013; Liu et al. 2023a, b). The unfrozen phase becomes freeze-concentrated with sugars and stabilisers, as some of the protein is adsorbed onto fat globules and merges with the emulsifier to stabilise air structures. The other component of the proteins remains in the freeze-concentrated unfrozen matrix and, ultimately, increases the water-holding and viscosity properties of the respective ice cream (Goff and Hartel 2013; Daw and Hartel 2015).

The meltdown of ice cream is one of the main concerns for the frozen food industry, which is critical for both consumer acceptance and distribution. The meltdown process occurs during storage or distribution, especially at warm temperatures, and can also occur in the mouth during consumption (Goff and Hartel 2013). As heat penetrates the ice cream, ice crystals start to melt, and the resulting ice cream solution drips. The melting ice cream tends to collapse depending on the remaining structures of air bubbles, ice crystals, and fat globules (Hartel et al. 2004; Warren and Hartel 2014, 2018). Besides, Hartel et al. (2004) argued that the spatial distributions of air crystals and air bubbles are crucial parameters for understanding the underlying mechanisms of the meltdown phenomenon. Several studies have reported that the air cells act as insulators and slow down the thermal diffusivity of ice cream, thereby reducing the meltdown rate (Muse and Hartel 2004; Sofjan and Hartel 2004). On the other hand, increase in volume depending on the quantity of air whipped into ice cream upon freezing is important because it impacts the physical and sensory properties, storability and meltdown rate of the ice cream (Sofjan and Hartel 2004; Wu et al. 2019). Sakurai et al. (1996) reported that ice cream with high overrun melts slowly because of better melting resistance. This implies that ice cream that melts slowly and retains its shape for a long time happens to be the most preferable dessert. Furthermore, quantitative information and the structure of air cells and ice crystals may enhance the description of the microstructure changes of ice cream due to meltdown.

The microstructure of ice cream is an indispensable attribute that influences the product quality, sensory and physical properties during storage, transportation, and, finally, consumption (Guo et al. 2018; Mo et al. 2018; Liu et al. 2023a). Also, the microstructure organisation affects the meltdown properties of ice cream (Amador et al. 2017; Warren and Hartel 2018). Therefore, understanding the microstructure evolution of ice cream upon melting is crucial in improving the quality of consumer perception and the frozen food industry (Warren and Hartel 2018; Wu et al. 2019; Yan et al. 2021). However, imaging the microstructure of ice cream during meltdown has been examined using 2D imaging techniques, such as refrigerated glove box microscopy, optical light microscopy, and the laser diffraction method (Warren and Hartel 2014, 2018; Amador et al. 2017; Chen et al. 2019; Wu et al. 2019). However, the 2D structures depend on the segment plane of visualisation and provide incomplete morphological features of the product, such as air bubbles and ice crystals in food materials. Thus, a 3D microstructure imaging technique is essential for comprehensive understanding (Pinzer et al. 2012; Vicent et al. 2017, 2019; Guo et al. 2018; Mo et al. 2018; Masselot et al. 2021a,b; Latil et al. 2022). A tomographic-based technique has been applied to explore the 3D microstructural evolution in foods by non-destructive means (Pinzer et al. 2012; Guo et al. 2018; Mo et al. 2018; Vicent et al. 2019; Masselot et al. 2021a,b). Imaging the 3D structure of air cells and ice crystals of ice cream during meltdown gives a better understanding of microstructure-quality-property interactions and the underlying mechanisms to improve production and marketability. However, the literature showed limited data on 3D microstructure changes in ice cream during the meltdown process.

Therefore, this study aimed to visualise and quantify the evolution of ice cream during melting using the X-ray tomography method. To this end, two ice creams with different air volume fractions will be investigated using the X-ray µCT image analysis technique developed by Vicent et al. (2017). The microstructure evolution was visualised and quantified during the meltdown of ice cream.

Materials and methods

Ice cream samples

Ice creams, namely I and II each weighing about 510 g were obtained from a supermarket in Paris, France. Five containers from each ice cream product were brought to the Refrigeration Processes Engineering Lab and immediately placed at − 20 °C freezer overnight to equilibrate. The two ice cream products were formulated with the same stabilisers (carob seed flour, guar gum, and carrageenan) and emulsifiers (mono and diglycerides), as outlined in the list of ingredients and nutrient compositions of the two ice cream types (Table 1).

Table 1.

List of ingredients and nutrient compositions of the ice creams I and II

| The ingredient list for the ice creams | |

|---|---|

| Ice cream I | Ice cream II |

| Fresh cream | Fresh cream |

| Concentrated skimmed milk | Skimmed milk |

| Sugar | Sugar |

| Glucose syrup | Glucose syrup |

| Water | Water |

| Coconut oil | Coconut oil |

| Butter | Lactose and reduced skim milk |

| Egg yolk | Egg yolk |

| Salt | Salt |

| Stabilisers: carob seed flour, guar gum and carrageenan |

Butter Stabilisers: carob seed flour, guar gum and carrageenan |

| Emulsifiers: mono and diglycerides | Emulsifiers: mono and diglycerides |

| Flavour: natural vanilla aroma | Flavour: natural vanilla aroma |

| Nutrients | Composition (g/100 mL) | |

|---|---|---|

| Ice cream I | Ice cream II | |

| Proteins | 4.70 | 2.50 |

|

Carbohydrates Sugar |

19.50 17.50 |

31.60 27.70 |

|

Lipids Saturated |

21.70 10.20 |

9.80 5.00 |

| Dietary fibres | 0.80 | 0.30 |

| Sodium | 0.04 | 0.03 |

Sample preparation

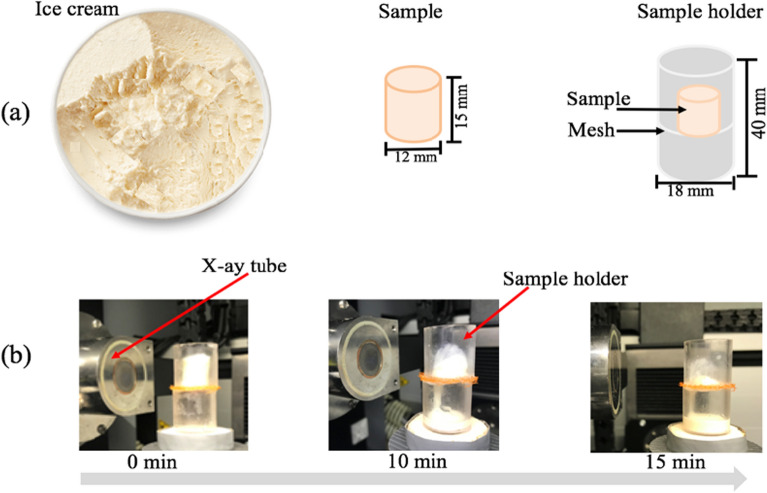

A cylindrical sample was excised using a cork bore. The sample (height: 15 mm and diameter: 12 mm) was, subsequently, introduced in a transparent plastic cylinder with a diameter of 18 mm and a height of 40 mm. The sample holder cylinder was partitioned with a plastic mesh as exemplified in Fig. 1a to facilitate the meltdown of ice cream during image acquisition. The sample holder together with the sample was kept at − 20 °C freezer for a day before imaging using X-ray tomography. For each ice cream sample, four replicates were used for image acquisition.

Fig. 1.

Excising of the cylindrical ice cream sample for tomographic imaging (a). Representation of X-ray CT image acquisition set-up during the meltdown analysis of ice cream at different time-points (b)

X-ray image acquisition

The meltdown of ice cream was investigated by acquiring X-ray scans using X-ray micro-tomography. The X-ray tomography (DeskTom RX 130, Chavanod, France) was set to operate at 60 kV X-ray tube, 0.1 s exposure time, 10.96 image resolution and 0.4° step size. Multiple X-ray radiographs were captured over a 360° rotation and each sample took a scanning time of about 90 s. Inside the X-ray µCT chamber, the temperature was measured to be 20 ± 0.5 °C throughout the scanning duration using a thermocouple. Figure 1b illustrates an X-ray CT image acquisition framework during the meltdown of ice cream at different time points.

Image reconstruction

The 3D virtual images were reconstructed from 2D projections using XAct 2 software (RX Solution, Annecy, France). The reconstruction process uses the filtered back-projection principle (Russ (2016). To improve image quality and visualisation, phase-contrast correction and image noise filtering were executed according to Vicent et al. (2019). 3D images were reconstructed into 8-bit precision with the intensity density ranging from 0 to 255 greyscales to facilitate image processing and analysis.

Image processing

Determination of the representative elementary volume (REV) of the image was carried out according to Russ (2016) and Heinzl et al. (2018). REV represents the properties of the scanned sample and was computed from the middle part of the ice cream (Mendoza et al. 2007). This approach has been applied to several food materials such as frozen apple and carrot tissues, to estimate the minimum REV for further analysis of the 3D ice crystal and air spaces (Vicent et al. 2017; 2019). A minimum REV of 300 × 300 × 300 voxels was found to be effective in representing the macroscopic properties of the ice cream during meltdown analysis. Such REV was preferred for further image processing and analysis of air bubbles and ice crystals of ice creams I and II at 0, 5, and 10 min. However, the determination of the REV at 15 min was not possible because the remaining CT images of melting ice creams at this time-point were far smaller than the minimum REV identified. For that reason, no further image analysis was carried out at 15 min of the meltdown testing. The REV analysis was done using Avizo 9.2.0, an image processing software (FEI VSG, Bordeaux, France).

Image segmentation

The segmentation technique was applied to segment air bubbles and ice crystals of the melting ice cream, as suggested by Vicent et al. (2017). The technique depends on the X-ray attenuation coefficients that vary between material phases in the ice cream. This is because their differences in density make it easy to separate the three phases (air bubbles, frozen and unfrozen matrices) of ice cream. A threshold technique was employed to segment air bubbles automatically. In which case, a local threshold at a minimum value (0–18 greyscales) is used to separate air bubbles from other matrices of ice cream. The frozen water, a reference sample for the frozen phase was separately analysed to recognise the X-ray attenuation values at which the ice crystals can be segmented in the ice cream. In that case, greyscale intensities of the reference samples were analysed to pinpoint the greyscale values from which ice crystals can simply be separated from other materials of ice cream. The testing results indicated that the majority of ice crystals can be found between 18 and 120 greyscales. Whereas, the unfrozen matrix was segmented by thawing the ice cream to form a solution and then make it concentrated (70% Brix) in a rotary evaporator (RE400, Staffordshire, ST15 OSA, UK). The concentrated mix was then studied to signify the X-ray attenuation values of the unfrozen phase in the ice cream, which was determined to be between 120 and 255 greyscales. These reference samples were placed at − 20 °C overnight and considered to represent the concentrations of the frozen and unfrozen phases in ice cream. This methodology has also been effectively used to evaluate the ice recrystallization in carrots during frozen storage (Vicent et al. 2019) and to segment ice crystals in frozen minced meat during freezing (Mulot et al. 2019).

Spatial resolution analysis

Spatial resolution is the smallest distance between two objects that can be visualised and quantified and is indispensable to be resolved before image analysis, especially for X-ray µCT images. The spatial resolution depends on the pixel resolution, density difference, size, and noise level (Hsieh 2009; Vicent et al. 2017). The spatial resolution was analysed using a statistical method according to Hsieh (2009). The method uses the frozen water and concentrated mix as reference samples for crystals and unfrozen matrix of ice cream, respectively. The statistical method was employed to resolve the spatial resolution in frozen apples and later in carrots (Vicent et al. 2017; 2019). An object larger than two voxel size was found to be feasibly differentiated between frozen water and unfrozen phase.

Quantitative data analysis

A watershed method was applied to detach the ice crystals and air bubbles and labelled separately. The method calculates watershed lines based on a distance map of a binary image. It has been utilised to separate the ice crystals during the freezing of apple tissue (Vicent et al. 2017) and to visualise the ice recrystallization in carrots during frozen storage (Vicent et al. 2019), and on frozen minced meat to investigate the effect of freezing conditions (Mulot et al. 2019). For effective quantitative analysis, a border kill operation available in image analysis software was used to eliminate air bubbles and ice crystals that touch the borders of the REV of the ice cream. The measured datasets were analysed from four replicates and expressed in mean and standard deviation (± S.D.) for statistical analysis. A two-sample Kolmogorov–Smirnov test (p < 0.05) was employed to statistically compare the data. Additinally, the overrun was determined according to the study of Goff and Hartel (2013).

Results and discussion

Microstructure evolution

Figure 2 shows CT cross-sections for both ice creams I and II acquired using an X-ray tomography with a pixel resolution of 10.96 µm at different time points of melting. The µCT images demonstrate that the morphology of ice cream evolves during the meltdown. The dark voxels indicate low-density air bubbles. The grey intermediate voxels, possibly, represent the frozen matrix, whereas the light grey pixels correspond to the unfrozen phase in both ice creams. For better visualisation of the ice cream matrices, the reader is referred to the CT images presented in Fig. 3 (the first row). The µCT images show three distinct components in each ice cream: air bubbles, ice crystals and the unfrozen matrix (Fig. 3). This can plausibly be explained by density differences between air bubbles, ice crystals and unfrozen matrices. Ice crystals have low density when compared to that of the unfrozen phase. This is because the unfrozen matrix becomes more concentrated with unfrozen water, fat, and sugars. In this context, the unfrozen matrix appears lighter in the X-ray images. The three resulting phases in µCT images of ice cream have also been described by numerous studies (Pinzer et al. 2012; Guo et al. 2018; Mo et al. 2018). Comparing the µCT cross-section slices revealed the different microstructures of two ice creams. For instance, the dark voxels that correspond to the low-density air bubbles appear to be larger in size and volume for ice cream II than for ice cream I (Figs. 2 and 3). Besides, ice cream II visibly shows more distorted structures of the air bubbles than ice cream I. This qualitative information in the µCT cross-sections of ice cream samples during melting called for quantitative analysis to get 3D data of ice crystal and air bubble morphology such as size and spatial distribution.

Fig. 2.

CT cross-section slices of ice creams for each time-point during the meltdown experimentation imaged using X-ray Computed Tomography (DeskTom RX 130) with a pixel resolution of 10.96 μm. The dark voxels represent air bubbles, the intermediate grey voxels correspond to ice crystals while the light grey voxels indicate the unfrozen matrix ice creams I and II. The scale bar indicates 4 mm

Fig. 3.

Image processing workflow executed in Avizo software for the X-ray tomography image of ice creams during the meltdown. The first row displays the region of interest (ROI) of radiograph images of the ice cream samples. The second row represents the corresponding binary images after image segmentation. The components in the resulting binary images were labelled differently: air bubble clusters were assigned black labels, the ice phase was labelled grey and the unfrozen matrix was assigned bright labels. The scale bar represents 700 μm

Quantitative data analysis

A watershed separation was utilised to discrete the ice crystals and air bubble clusters connected, as described in the “quantitative analysis” section. Figure 3 demonstrates the watershed separation workflow of ice cream during meltdown testing. The region of interest (ROI) images used for image segmentation are shown in Fig. 3 (the first row). The corresponding binary images of ice cream samples are elucidated in Fig. 3 (the second row). Then air bubbles were labelled in black colour and ice crystals were labelled in grey colour. Finally, the unfrozen phase was assigned to bright labels.

Ice crystal quantification

The mean diameter values of ice crystals of ice creams I and II were analysed at different time points of melting, as depicted in Table 2. The mean values of ice creams I and II were statistically evaluated during the meltdown process. At 0 min, ice crystals with the mean equivalent diameter of 75.02 ± 3.14 µm and 66.43 ± 2.07 µm were found in ice creams I and II, respectively (Table 2). For each ice cream sample, the mean equivalent diameter was noticed to change significantly (p < 0.05) during the melting test. During the 10 min of the meltdown process, the mean equivalent diameter decreased significantly (p < 0.05) to 54.10 ± 2.63 µm and 45.78 ± 3.92 µm corresponding to ice creams I and II, respectively. The mean diameter of ice crystals decreased, presumably, because the water molecules from the ice crystals melted and dripped out. Moreover, the mean ice crystal diameter was measured to be significantly large (p < 0.05) in ice cream I. Whereas, the quantity of ice crystals was observed to decrease throughout the meltdown testing from N = 1840 ± 70 to N = 210 ± 40 in ice cream I and from N = 2310 ± 80 to N = 350 ± 60 in ice cream II. Amador et al. (2017) reported that the meltdown process of ice cream reduces the mean diameter values of ice crystals, hence producing an undesirable watery texture in the mouth while impairing quality. The more fluid formation also means less material to drip out. However, no data on 3D microstructure changes in ice cream during the meltdown process were found in the literature. The ice volume fraction was also quantified at each time point and showed a decreasing trend during the meltdown.

Table 2.

Mean equivalent diameter of air bubbles and ice crystals of ice cream during the meltdown testing

| Meltdown time (min) | Mean equivalent diameter of ice crystal (µm) | Mean equivalent diameter of air bubbles (µm) | Air volume fraction (%) | Air bubble sphericity | ||||

|---|---|---|---|---|---|---|---|---|

| Ice cream I | Ice cream II | Ice cream I | Ice cream II | Ice cream I | Ice cream II | Ice cream I | Ice cream II | |

| 0 | 75.02 ± 3.14a | 66.43 ± 2.07a | 88.30 ± 4.52a | 117.94 ± 5.15a | 14.06 ± 2.86a | 41.20 ± 3.90a | 0.85 ± 0.04a | 0.77 ± 0.03a |

| 5 | 62.86 ± 4.30b | 54.10 ± 2.36b | 81.64 ± 5.84a | 100.36 ± 3.75b | 13.17 ± 1.45a | 32.70 ± 2.61b | 0.84 ± 0.09a | 0.78 ± 0.08a |

| 10 | 54.30 ± 2.63c | 45.78 ± 3.92c | 63.25 ± 4.91b | 81.20 ± 5.40c | 10.48 ± 1.23b | 24.25 ± 3.25c | 0.83 ± 0.02a | 0.71 ± 0.10b |

The mean values of separated ice crystals in each ice cream product were evaluated using four replicate samples of 3D images at different time points. Mean values are exemplified by their standard deviations ( ± S.D.). The data with different superscripts for each parameter analysed in each ice cream product indicate that the mean diameters are significantly different at (p < 0.05)

Air bubble quantification

Table 2 also presents the mean equivalent diameter of air bubbles together with air volume fraction and sphericity of air bubbles analysed at different time points. Ice cream II indicated a larger mean equivalent diameter of air bubbles than that of ice cream I during the analysis of meltdown (Table 2). Both ice cream products showed a decreasing trend in the mean diameters of air bubbles during 10 min of the meltdown. Besides, the mean equivalent diameter of the air bubbles decreased significantly (p < 0.05) from 88.30 ± 4.52 to 63.25 ± 4.91 µm and from 117.94 ± 5.15 to 81.20 ± 5.40 µm for ice creams I and II, respectively, during 10 min of the meltdown process (Table 2). In the case of the air volume fraction, ice cream II had an air fraction of 41.20 ± 3.90% compared to that of ice cream I, which had an air fraction of 14.06 ± 3.86% at 0 min of the meltdown. The values of the air volume fraction of ice cream II were measured to be larger than those quantified in ice cream I (Table 2) throughout the meltdown analysis. A high amount of air volume impairs heat conduction, thereby reducing the rate of melting of ice cream because air inhibits heat transfer (Sakurai et al. 1996; Sofjan and Hartel 2004; Warren and Hartel 2018). Besides, smaller air cells quantified in ice cream I are related to a decreasing trend of the mean equivalent diameter of ice crystal. Both ice creams revealed a declining trend in the overall air volume portion. A reduction trend in the air volume fraction was noticed to range from 41.20 ± 3.90 to 24.25 ± 3.25% during 10 min of the meltdown for ice cream II, whereas for ice cream I, the air volume fraction changed from 14.06 ± 2.86 to 10.48 ± 1.23%. This decreasing trend in the mean size of the air bubbles could be due to various mechanisms occurring during the meltdown of ice cream. Numerous studies suggest that during the meltdown, air tends to pop out and/or exit the melting ice cream via air channels formed by coalescing air bubbles (Koxholt et al. 2001; Muse and Hartel 2004). Therefore, quantitative analysis of air volume is important in ice cream, as it affects physical and sensory attributes as well as stability during storage.

Additionally, the overrun was measured to be 32% and 85% in ice creams I and II, respectively. These findings plausibly explain the rate of meltdown observed for the two ice creams. Higher overrun forms greater apparent viscosity due to higher shear stress, which may influence fat destabilisation and thereby reduce the rate of the meltdown process as found in ice cream II. However, the fat content and its destabilisation are not analysed in the current study. Sakurai et al. (1996) stated that ice cream with low air volume melted more rapidly than the one with high air volume, which was observed to melt slowly because of better melting resistance. Sofjan and Hartel (2004) worked with ice creams of different fractions of overrun and showed that the rate of meltdown decreases as the overrun increases. The quality of ice cream is mainly reliant on the rate of melting and shape retention factors during the meltdown.

The morphological changes of air bubbles can also be evaluated in terms of sphericity. Sphericity compares the surface areas between the sphere and that of air bubbles, given that the volume is the same. In that case, the air bubble with a perfectly round shape has the sphericity value of 1. While the air bubble with a deformed shape has the sphericity value of less than 1. The mean sphericity was 0.85 ± 0.04 at 0 min in ice cream I, whereas ice cream II had the mean sphericity of 0.77 ± 0.03 (Table 2). No significant difference emerged in sphericity in ice cream I during the analysis of meltdown. Low sphericity values quantified in ice cream II throughout the meltdown imply that air bubble structures were more deformed significantly than those of ice cream I. The literature contains no quantitative information on changes in air bubbles, ice crystals, the air volume fraction and sphericity during the meltdown of ice cream.

Ice crystal size distribution

Figure 4a, b shows the size distributions of ice crystals expressed as probability density functions for each ice cream. The size distribution of ice crystals for each ice cream sample was changed significantly (p < 0.05) at each time point. At 0 min, ice cream I was found to have a broader range of size distribution of ice crystals that varied from 24 to 170 μm (Fig. 4a). This size distribution was broader when compared to that of ice cream II, which ranged from 24 to 140 μm at 0 min. The size distribution of ice crystals showed a significant shift to smaller crystal size for both ice creams during the meltdown analysis. The results revealed that the ice crystal size distributions become narrower as the meltdown process proceeds. At 5 min, ice cream I showed an ice crystal size distribution ranging between 24 and 125 μm, whereas ice cream II had the size distribution varying from 24 to 112 μm (Fig. 4b). Both ice creams I and II showed the small size ranges of ice crystals at 10 min of the meltdown testing. As such, ice cream I revealed the size distribution of ice crystals ranging between 24 and 96 μm (Fig. 4b). On the contrary, the size distribution of ice crystals ranging from 24 to 84 μm (Fig. 4b) was observed for ice cream II during the 10 min of the meltdown analysis. The ranges of ice crystal size became narrower as the melting time increased because the ice crystals melted and decreased in mean size. These changes in ice crystal size distributions concur with a decreasing trend in mean diameter, as discussed in the “ice crystal quantification” section (Table 2). Hartel et al. (2004) reported that the size distribution of ice crystals defines the meltdown scenario. However, there is little data in the literature on how the crystal size distribution changes in ice cream during the meltdown process.

Fig. 4.

Size distributions of ice crystals (a, b) and air bubbles (c, d) for ice creams I and II analysed during the meltdown process. The cumulative distributions were analysed uisng four replicates at different time-points. The sample size was 300 × 300 × 300 voxels at a pixel resoltuion of 10.96 μm.3

Air bubble size distribution

Figure 4c, d presents the evolution of air bubble size distribution in both ice creams during the meltdown process. Ice cream II had a significantly (p < 0.05) broader air bubble size distribution than that of ice cream I throughout the analysis of meltdown. In that case, the air bubble size distribution was observed to vary from 26 to over 520 μm in ice cream II at 0 min (Fig. 4d). On the other hand, ice cream I showed a narrower range of air bubble size distribution of 26 to 380 μm at 0 min (Fig. 4c). Both ice creams exhibited a significant change in the size distribution of air bubbles during meltdown testing. After 5 min of the meltdown, the air bubble size distribution decreased to a range of 26–310 µm in ice cream I (Fig. 4c) and, 26 and 450 µm for ice cream II (Fig. 4d). During further melting time, i.e., 10 min, the air bubble size distribution continued to decrease to a range of 26 to 260 µm for ice cream I (Fig. 4c) and, 26 and 400 µm in ice cream II (Fig. 4d). Hartel et al. (2004) suggested that the meltdown process depends on the spatial distribution of air bubbles in ice cream. Furthermore, a high amount of air bubbles hinders heat conduction in ice cream, thus decreasing the melting rate (Sofjan and Hartel 2004; Warren and Hartel 2018). Here again, no data has been reported in the literature on the evolution of air bubble size distribution during the meltdown of ice cream.

3D representation of the microstructure

The 3D volume renderings of separated air bubbles and ice crystals in two ice creams during the meltdown analysis are shown in Fig. 5. The two phases in each ice cream sample were assigned differently, i.e., ice crystals were labelled grey colour and air bubbles were assigned a green colour. 3D imaging methods revealed better information for understanding, visualising, and quantifying the microstructural change in ice cream during the meltdown process. The 3D image models revealed larger air bubbles in ice cream II than in ice cream I. Because air occupies a considerable portion of the melting ice cream II, this has an effect on thermal diffusivity. These findings verify the high values of the air volume fraction of ice cream II, as described in the “air bubble quantification” section. In the case of ice crystals, they become smaller as the meltdown time progresses. The meltdown of ice cream causes dripping out of melted materials from ice cream, thus affecting the quality, sensory and commercial value of the ice cream product (Goff and Hartel 2013; Daw and Hartel 2015; Amador et al. 2017; Yan et al. 2021). Amador et al. (2017) proposed that changes in the ice crystal’s mean diameter impair the sensory attributes of ice cream.

Fig. 5.

3D volume renderings of separated air bubbles and ice crystals of ice cream samples at different time points during melting analysis. The imaging processing and analysis algorithm described by Vicent et al. (2017) was employed for segmentation and separation. Ice crystals were then labelled grey while air bubbles were subsequently labelled green. The 3D models illustrate 150 × 150 × 150 voxels at a pixel resolution of 10.96 µm3. The scale bar represents 400 μm

The quantitative results discussed in this paper show that the 3D datasets of air bubbles and ice crystals in ice cream, produce unique morphological information during the meltdown analysis. From our viewpoint, these data are limited in the extant literature and yet imperative for the food engineering community.

Conclusion

The melting of ice cream is one of the key concerns in the preservation of quality, sensory attributes and distribution. In this work, the meltdown phenomenon of ice cream was investigated using a 3D tomographic-based technique. The results showed larger mean equivalent diameters of ice crystals with smaller air bubbles in ice cream I when compared to those quantified in ice cream II. The crystal size distributions were observed to narrow progressively as the melting time proceeded. Additionally, the mean diameters of ice crystals and air bubbles decreased for both ice creams I and II as the meltdown time progressed. Thus, X-ray µCT image analysis facilitates the characterisation of the 3D microstructure in terms of air bubbles and ice crystals in ice cream, which has resulted in a better understanding of the meltdown phenomenon. The information obtained can, therefore, be useful in the process optimisation and quality control of frozen desserts such as ice cream in the frozen food and distribution sector, which was previously lacking. Further studies can also be devoted to exploring the impact and spatial distributions of the fat, sugar, and protein contents of ice cream during the meltdown process to acquire more insight into the meltdown phenomenon.

Acknowledgements

The author gratefully acknowledges the financial support from the National Research Institute of Science and Technology for Environment and Agriculture (Irstea), France (Grant No. 180070013, 2019/082). The author would also like to thank the Refrigeration Process Engineering Research Laboratory, France for allowing him to undertake the research work whose product is this paper. The author greatly appreciates Dr. Toutie Ndoye for proofreading the article and Dr. Nicholous Asheli for English editing.

Author contributions

VV was involved in Conceptualisation, Experimental Design, Image Analysis, Data Analysis, Writing–Original Draft, Review and Editing and Funding Acquisition.

Funding

This research work received financial support from the National Research Institute of Science and Technology for Environment and Agriculture (Irstea), France (Grant No. 180070013, 2019/082).

Data availability

The full datasets generated and used by this study are available from the author upon reasonable request.

Code availability

Not applicable.

Declarations

Conflict of interest

The author declares that no competing interests to disclose concerning this work.

Ethical approval

Not applicable.

Consent for publication

This manuscript has not been published and is not under consideration to be submitted for publication elsewhere.

Consent to participate

Not applicable.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Amador J, Hartel R, Rankin S. The effects of fat structures and ice cream mix viscosity on physical and sensory properties of ice cream. J Food Sci. 2017;82:1851–1860. doi: 10.1111/1750-3841.13780. [DOI] [PubMed] [Google Scholar]

- Chang Y, Hartel RW. Development of air cells in a batch ice cream freezer. J Food Eng. 2002;55:71–78. doi: 10.1016/S0260-8774(01)00243-6. [DOI] [Google Scholar]

- Chen W, Liang G, Li X, He Z, Zeng M, Gao D, Qin F, Goff HD, Chen J. Effects of soy proteins and hydrolysates on fat globule coalescence and meltdown properties of ice cream. Food Hydrocoll. 2019;94:279–286. doi: 10.1016/j.foodhyd.2019.02.045. [DOI] [Google Scholar]

- Daw E, Hartel RW. Fat destabilization and melt-down of ice creams with increased protein content. Int Dairy J. 2015;43:33–41. doi: 10.1016/j.idairyj.2014.12.001. [DOI] [Google Scholar]

- Goff HD, Hartel RW. Ice cream. 7. New York: Springer; 2013. [Google Scholar]

- Guo E, Kazantsev D, Mo J, Bent J, Van Dalen G, Schuetz P, Rockett P, StJohn D, Lee PD. Revealing the microstructural stability of a three-phase soft solid (ice cream) by 4D synchrotron X-ray tomography. J Food Eng. 2018;237:204–214. doi: 10.1016/j.jfoodeng.2018.05.027. [DOI] [Google Scholar]

- Hartel RW, Muse M, Sofjan R (2004) Effects of structural attributes on hardness and melting rate of ice cream. In: Proceedings of the second international dairy federation: ice cream symposium, Thessaloniki, Greece, 14-16 May 2003, pp 124–139

- Heinzl C, Amirkhanov A, Kastner J. Processing, analysis and visualization of CT data. In: Carmignato S, Dewulf W, Leach R, editors. Industrial X-ray computed tomography. Cham: Springer; 2018. pp. 99–142. [Google Scholar]

- Hsieh J. Computed tomography: principles, design, artifacts, and recent advances. 2. Bellingham: SPIE Press; 2009. pp. 158–159. [Google Scholar]

- Koxholt MM, Eisenmann B, Hinrichs J. Effect of the fat globule sizes on the meltdown of ice cream. J Dairy Sci. 2001;84:31–37. doi: 10.3168/jds.S0022-0302(01)74448-7. [DOI] [PubMed] [Google Scholar]

- Latil P, Zennoune A, Ndoye FT, Flin F, Geindreau C, Benkhelifa H. X-ray microtomography of ice crystal formation and growth in a sponge cake during its freezing and storage. J Food Eng. 2022;325:110989. doi: 10.1016/j.jfoodeng.2022.110989. [DOI] [Google Scholar]

- Liu X, Sala G, Scholten E. Impact of soy protein dispersibility on the structural and sensory properties of fat-free ice cream. Food Hydrocoll. 2023;174:109340. doi: 10.1016/j.foodhyd.2023.109340. [DOI] [Google Scholar]

- Liu X, Sala G, Scholten E. Structural and functional differences between ice crystal-dominated and fat network-dominated ice cream. Food Hydrocoll. 2023;138:108466. doi: 10.1016/j.foodhyd.2023.108466. [DOI] [Google Scholar]

- Masselot V, Bosc V, Benkhelifa H. Analyzing the microstructure of a fresh sorbet with X-ray micro-computed tomography: sampling, acquisition, and image processing. J Food Eng. 2021;292:110347. doi: 10.1016/j.jfoodeng.2020.110347. [DOI] [Google Scholar]

- Masselot V, Bosc V, Benkhelifa H. Influence of stabilizers on the microstructure of fresh sorbets: x-ray micro-computed tomography, cryo-SEM, and focused beam reflectance measurement analyses. J Food Eng. 2021;300:110522. doi: 10.1016/j.jfoodeng.2021.110522. [DOI] [Google Scholar]

- Mendoza F, Verboven P, Mebatsion HK, Kerckhofs G, Wevers M, Nicolaï B. Three-dimensional pore space quantification of apple tissue using X-ray computed microtomography. Planta. 2007;226:559–570. doi: 10.3168/jds.S0022-0302(01)74448-7. [DOI] [PubMed] [Google Scholar]

- Mo J, Guo E, McCartney D, Eastwood D, Bent J, Van Dalen G, Schuetz P, Rockett P, Lee P. Time-resolved tomographic quantification of the microstructural evolution of ice cream. Materials. 2018;11:2031. doi: 10.3390/ma11102031. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mulot V, Fatou-Toutie N, Benkhelifa H, Pathier D, Flick D. Investigating the effect of freezing operating conditions on microstructure of frozen minced beef using an innovative X-ray micro-computed tomography method. J Food Eng. 2019;262:13–21. doi: 10.1016/j.jfoodeng.2019.05.014. [DOI] [Google Scholar]

- Muse MR, Hartel RW. Ice cream structural elements that affect melting rate and hardness. J Dairy Sci. 2004;87:1–10. doi: 10.3168/jds.S0022-0302(04)73135-5. [DOI] [PubMed] [Google Scholar]

- Pinzer BR, Medebach A, Limbach HJ, Dubois C, Stampanoni M, Schneebeli M. 3D-characterization of three-phase systems using X-ray tomography: tracking the microstructural evolution in ice cream. Soft Matter. 2012;8:4584–4594. doi: 10.1039/C2SM00034B. [DOI] [Google Scholar]

- Russ JC (2016) 3D visualization. In: The image processing handbook, (6th edn). CRC press, Boca Raton, pp 707–763

- Sakurai K, Kokubo S, Hakamata K, Tomita M, Yoshida S. Effect of production conditions on ice cream melting resistance and hardness. Milchwissenschaft. 1996;51:451–454. [Google Scholar]

- Sofjan RP, Hartel RW. Effects of overrun on structural and physical characteristics of ice cream. Int Dairy J. 2004;14:255–262. doi: 10.1016/j.idairyj.2003.08.005. [DOI] [Google Scholar]

- Vicent V, Verboven P, Ndoye FT, Alvarez G, Nicolaï B. A new method developed to characterize the 3D microstructure of frozen apple using X-ray micro-CT. J Food Eng. 2017;212:154–164. doi: 10.1016/j.jfoodeng.2017.05.028. [DOI] [Google Scholar]

- Vicent V, Ndoye FT, Verboven P, Nicolaï B, Alvarez G. Effect of dynamic storage temperatures on the microstructure of frozen carrot imaged using X-ray micro- CT. J Food Eng. 2019;246:232–241. doi: 10.1016/j.jfoodeng.2018.11.015. [DOI] [Google Scholar]

- Warren MM, Hartel RW. Structural, compositional, and sensorial properties of United States commercial ice cream products. J Food Sci. 2014;79:2005–2013. doi: 10.1111/1750-3841.12592. [DOI] [PubMed] [Google Scholar]

- Warren MM, Hartel RW. Effects of emulsifier, overrun and dasher speed on ice cream microstructure and melting properties. J Food Sci. 2018;83:639–647. doi: 10.1111/1750-3841.13983. [DOI] [PubMed] [Google Scholar]

- Wu B, Freire DO, Hartel RW. The effect of overrun, fat destabilization, and ice cream mix viscosity on entire meltdown behavior. J Food Sci. 2019;84:2562–2571. doi: 10.1111/1750-3841.14743. [DOI] [PubMed] [Google Scholar]

- Yan L, Yu D, Liu R, Jia Y, Zhang M, Wu T, Sui W. Microstructure and meltdown properties of low-fat ice cream: effects of microparticulated soy protein hydrolysate/xanthan gum (MSPH/XG) ratio and freezing time. J Food Eng. 2021;291:110291. doi: 10.1016/j.jfoodeng.2020.110291. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The full datasets generated and used by this study are available from the author upon reasonable request.

Not applicable.