Abstract

Introduction: It is critical to measure the maximum voluntary bite force of patients receiving restorative dentistry. A new device known as "BYTE" has been developed indigenously to measure bite force in humans. The purpose of this study is to evaluate the BYTE device's consistency and accuracy in a lab setting.

Methodology: Testing and calibration were done in the laboratory. The calibration machine with load cell pressed the biting part of the device with various forces from 3 N to 444 N in 3 N increments for two to three seconds each. The recorded force value in Newton by the device was noted down.

Results: At numerous standard loads, the minimum accuracy error is 0.333 N, while the maximum is 1.667 N. It marginally underestimates the load with an average accuracy error of 0.833 N.

Conclusion: The calibration report showed that the BYTE device is precise and reliable and can be used to measure maximum bite force.

Keywords: maximum voluntary bite force, calibration report, laboratory validation, bite force, byte

Introduction

The bite force is one aspect of mastication that researchers have studied to learn more about the masticatory system’s function [1]. The bite force is the force the chewing muscles use to close the teeth together. The maximum voluntary bite force (MVBF) shows how well the mouth and jaw system works. It depends on how strong and well-coordinated the jaw muscles are and how they work with the jaw bones [2,3]. In the molar region, healthy adults' natural teeth can bite with a maximum force of 300 to 600 Newtons (N). Several anatomical and physiological factors influence MVBF. Dentists use bite force to check how well different dental treatments work. They also use it to study how problems and diseases affect the chewing system, such as temporomandibular joint disorder [4].

There are many devices available globally that can measure maximum bite force (MBF). Each one has its advantages and disadvantages [4,5]. T scan (Tekscan, USA) is one of the instruments very widely used. Although accurate, it is elaborate and not economical and requires training to use and analyze the measurement. Moreover, it does not measure the MVBF of the individual. Another popular instrument is the Dental Prescale System from GC, Japan. Again, it is an accurate instrument but not easy to use, requires training, is not economical, and requires a separate device to analyze the results [4,5]. Recently, a new device called “BYTE” has been developed by Innovatios Technology Bangalore, India [6,7]. The development and validation study of this novel indigenous device was presented in our earlier publication [5,6]. This paper aims to evaluate the reliability of the BYTE device through a laboratory calibration study.

Materials and methods

The laboratory validation study was conducted at Essjay Technomeasure Private Limited, a company based in Kolkata, India. This company specializes in calibration engineering and allied services. It holds certifications from ISO 9001 and ISO 45001, indicating its commitment to quality management and occupational health and safety management systems, respectively. The study involved testing and calibration of a device known as the BYTE to know its reliability [7]. These procedures were carried out in accordance with the standards set by ISO/IEC 17025 and ISO-9001, which pertain to the competence of testing and calibration laboratories and quality management systems, respectively. The environmental conditions during the measurement process were maintained at a temperature of 25 ± 2°C and a relative humidity of 50 ± 10% RH. The calibration certificate issued for this process bears the number 2310125/I443(A)/SK/01.

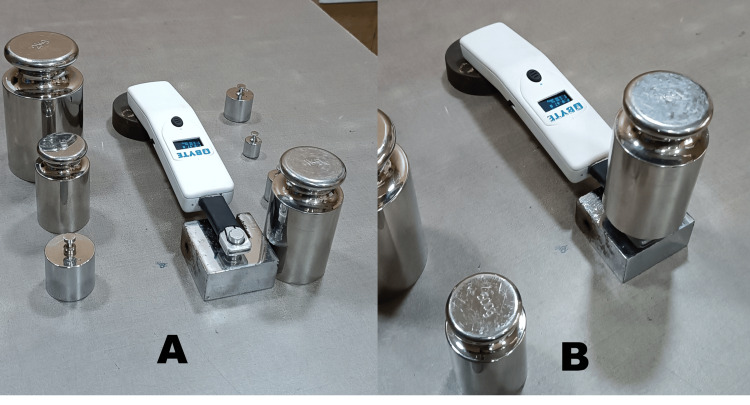

The BYTE device is composed of two main parts: the head and the body. The head part, which is made of stainless steel, features a circular biting portion with a diameter of approximately 10 mm. This head part houses a piezoresistive sensor that changes its resistance when pressure is applied. This change in resistance is analyzed by the firmware housed in the body part of the device. The result of this analysis, which is the recorded force in Newtons (N), is displayed on an LCD screen [5,6]. To evaluate the reliability of the BYTE device, the circular biting part of the instrument was subjected to various load cells. It is recommended that the circular biting part should be pressed uniformly for the sensor to function optimally and yield accurate and repeatable results. To ensure this uniform pressure, a custom metallic jig was fabricated to securely hold the head part of the device while loading the biting portion with various loads (Figure 1).

Figure 1. Device head supported with the jig (A) and device under calibration (B).

Standard load cells were used to apply force on the biting part as recommended. The piezoresistive sensor used in the BYTE device is sourced from Tekscan, USA [5,6]. This sensor is capable of analyzing loads up to 444 N. Therefore, standard load cells of various weights ranging from 3 N to 444 N were used sequentially at every 3 N interval. Each load was maintained for about two to three seconds, and the result was observed on the device under calibration (DUC) and noted down. This process was repeated in three sets, resulting in three measurements being taken for each standard load. The average reading was then determined from these measurements. From the average readings, an accuracy error was calculated. The data were then tabulated and subjected to statistical analysis interclass correlation coefficient for further interpretation.

Results

The data collected during the calibration test were tabulated and subjected to statistical evaluation using IBM SPSS Statistics for Windows, version 26.0 (released 2019, IBM Corp., Armonk, NY). As per this calibration test, DUC measured load in Newtons (N) during the test. The test results are in a seven-column table: Observation No., Standard Load in N, DUC results in N Set-I, N Set-2, and N Set-3, Average Reading, and Accuracy Error. To calculate the DUC accuracy error, the standard load was subtracted from the average reading, and the absolute value was taken (Table 1).

Table 1. Observation No., standard load in N, DUC results in N Set-I, N Set-2, and N Set-3, average reading, and accuracy error.

N: Newton, DUC: device under calibration

| Obs. No. | Standard load applied in N | Observed results on DUC* in N Set-I | Observed results on DUC* in N Set-2 | Observed results on DUC* in N Set-3 | Avg. reading | Accuracy error |

| 1 | 3 | 2.98 | 2.99 | 2.99 | 2.987 | 0.333 |

| 2 | 6 | 5.98 | 5.97 | 5.97 | 5.973 | 0.333 |

| 3 | 9 | 9.97 | 9.98 | 9.97 | 9.973 | 0.333 |

| 4 | 12 | 11.95 | 11.95 | 11.97 | 11.957 | 0.667 |

| 5 | 15 | 14.91 | 14.93 | 14.92 | 14.92 | 0.667 |

| 6 | 18 | 17.9 | 17.92 | 17.91 | 17.91 | 0.667 |

| 7 | 21 | 20.85 | 20.86 | 20.88 | 20.863 | 1 |

| 8 | 24 | 23.87 | 23.85 | 23.86 | 23.86 | 0.667 |

| 9 | 27 | 26.84 | 26.83 | 26.85 | 26.84 | 0.667 |

| 10 | 30 | 29.81 | 29.81 | 29.83 | 29.817 | 0.667 |

| 11 | 33 | 32.79 | 32.8 | 32.81 | 32.8 | 0.667 |

| 12 | 36 | 35.74 | 35.75 | 35.77 | 35.753 | 1 |

| 13 | 39 | 38.72 | 38.73 | 38.74 | 38.73 | 0.667 |

| 14 | 42 | 41.72 | 41.72 | 41.73 | 41.723 | 0.333 |

| 15 | 45 | 44.69 | 44.71 | 44.71 | 44.703 | 0.667 |

| 16 | 48 | 47.68 | 47.66 | 47.69 | 47.677 | 1 |

| 17 | 51 | 50.65 | 50.67 | 50.67 | 50.663 | 0.667 |

| 18 | 54 | 53.58 | 53.56 | 53.54 | 53.56 | 1.333 |

| 19 | 57 | 56.54 | 56.52 | 56.53 | 56.53 | 0.667 |

| 20 | 60 | 59.51 | 59.5 | 59.48 | 59.497 | 1 |

| 21 | 63 | 62.43 | 62.42 | 62.42 | 62.423 | 0.333 |

| 22 | 66 | 65.37 | 65.35 | 65.34 | 65.353 | 1 |

| 23 | 69 | 68.34 | 68.32 | 68.31 | 68.323 | 1 |

| 24 | 72 | 71.31 | 71.3 | 71.28 | 71.297 | 1 |

| 25 | 75 | 74.28 | 74.29 | 74.24 | 74.27 | 1.667 |

| 26 | 78 | 78.25 | 78.26 | 78.22 | 78.243 | 1.333 |

| 27 | 81 | 80.23 | 80.21 | 80.21 | 80.217 | 0.667 |

| 28 | 84 | 83.17 | 83.15 | 83.14 | 83.153 | 1 |

| 29 | 87 | 86.14 | 86.13 | 86.13 | 86.133 | 0.333 |

| 30 | 90 | 89.11 | 89.12 | 89.09 | 89.107 | 1 |

| 31 | 93 | 93.09 | 93.08 | 93.06 | 93.077 | 1 |

| 32 | 96 | 96.06 | 96.07 | 96.04 | 96.057 | 1 |

| 33 | 99 | 98.03 | 98.05 | 98.05 | 98.043 | 0.667 |

| 34 | 102 | 101.01 | 101.04 | 101.03 | 101.027 | 1 |

| 35 | 105 | 103.99 | 103.97 | 103.96 | 103.973 | 1 |

| 36 | 108 | 106.95 | 106.92 | 106.91 | 106.927 | 1.333 |

| 37 | 111 | 109.92 | 109.94 | 109.95 | 109.937 | 1 |

| 38 | 114 | 112.89 | 112.86 | 112.87 | 112.873 | 1 |

| 39 | 117 | 115.85 | 115.83 | 115.81 | 115.83 | 1.333 |

| 40 | 120 | 118.82 | 118.81 | 118.78 | 118.803 | 1.333 |

| 41 | 123 | 121.8 | 121.81 | 121.78 | 121.797 | 1 |

| 42 | 126 | 124.79 | 124.77 | 124.75 | 124.77 | 1.333 |

| 43 | 129 | 127.77 | 127.74 | 127.75 | 127.753 | 1 |

| 44 | 132 | 130.76 | 130.75 | 130.74 | 130.75 | 0.667 |

| 45 | 135 | 133.74 | 133.72 | 133.71 | 133.723 | 1 |

| 46 | 138 | 136.7 | 136.71 | 136.68 | 136.697 | 1 |

| 47 | 141 | 139.67 | 139.65 | 139.64 | 139.653 | 1 |

| 48 | 144 | 142.62 | 142.64 | 142.61 | 142.623 | 1 |

| 49 | 147 | 145.59 | 145.57 | 145.55 | 145.57 | 1.333 |

| 50 | 150 | 148.53 | 148.54 | 148.56 | 148.543 | 1 |

| 51 | 153 | 151.51 | 151.49 | 151.48 | 151.493 | 1 |

| 52 | 156 | 154.5 | 154.51 | 154.47 | 154.493 | 1.333 |

| 53 | 159 | 157.47 | 157.49 | 157.49 | 157.483 | 0.667 |

| 54 | 162 | 160.56 | 160.54 | 160.55 | 160.55 | 0.667 |

| 55 | 165 | 163.47 | 163.45 | 163.48 | 163.467 | 1 |

| 56 | 168 | 166.25 | 166.21 | 166.24 | 166.233 | 1.333 |

| 57 | 171 | 169.64 | 169.63 | 169.61 | 169.627 | 1 |

| 58 | 174 | 172.41 | 172.38 | 172.37 | 172.387 | 1.333 |

| 59 | 177 | 175.58 | 175.55 | 175.56 | 175.563 | 1 |

| 60 | 180 | 178.69 | 178.72 | 178.71 | 178.707 | 1 |

| 61 | 183 | 181.45 | 181.47 | 181.51 | 181.477 | 2 |

| 62 | 186 | 184.62 | 184.64 | 184.65 | 184.637 | 1 |

| 63 | 189 | 187.77 | 187.79 | 187.76 | 187.773 | 1 |

| 64 | 192 | 190.69 | 190.71 | 190.68 | 190.693 | 1 |

| 65 | 195 | 193.66 | 193.67 | 193.64 | 193.657 | 1 |

| 66 | 198 | 196.71 | 196.73 | 196.74 | 196.727 | 1 |

| 67 | 201 | 199.56 | 199.58 | 199.53 | 199.557 | 1.667 |

| 68 | 204 | 202.52 | 202.56 | 202.55 | 202.543 | 1.333 |

| 69 | 207 | 205.51 | 205.53 | 205.55 | 205.53 | 1.333 |

| 70 | 210 | 208.47 | 208.52 | 208.49 | 208.493 | 1.667 |

| 71 | 213 | 211.43 | 211.46 | 211.45 | 211.447 | 1 |

| 72 | 216 | 214.41 | 214.43 | 214.44 | 214.427 | 1 |

| 73 | 219 | 217.39 | 217.43 | 217.41 | 217.41 | 1.333 |

| 74 | 222 | 220.34 | 220.32 | 220.3 | 220.32 | 1.333 |

| 75 | 225 | 223.42 | 223.44 | 223.46 | 223.44 | 1.333 |

| 76 | 228 | 226.41 | 226.38 | 226.39 | 226.393 | 1 |

| 77 | 231 | 229.57 | 229.59 | 229.56 | 229.573 | 1 |

| 78 | 234 | 232.52 | 232.54 | 232.53 | 232.53 | 0.667 |

| 79 | 237 | 237.34 | 237.37 | 237.36 | 237.357 | 1 |

| 80 | 240 | 238.74 | 238.71 | 238.74 | 238.73 | 1 |

| 81 | 243 | 241.69 | 241.68 | 241.67 | 241.68 | 0.667 |

| 82 | 246 | 243.54 | 243.56 | 243.52 | 243.54 | 1.333 |

| 83 | 249 | 247.45 | 247.42 | 247.47 | 247.447 | 1.667 |

| 84 | 252 | 250.39 | 250.36 | 250.34 | 250.363 | 1.667 |

| 85 | 255 | 253.34 | 253.31 | 253.32 | 253.323 | 1 |

| 86 | 258 | 256.21 | 256.22 | 256.23 | 256.22 | 0.667 |

| 87 | 261 | 259.26 | 259.24 | 259.27 | 259.257 | 1 |

| 88 | 264 | 262.21 | 262.24 | 262.23 | 262.227 | 1 |

| 89 | 267 | 265.17 | 265.19 | 265.15 | 265.17 | 1.333 |

| 90 | 270 | 268.14 | 268.11 | 268.13 | 268.127 | 1 |

| 91 | 273 | 271.11 | 271.13 | 271.1 | 271.113 | 1 |

| 92 | 276 | 274.13 | 274.15 | 274.11 | 274.13 | 1.333 |

| 93 | 279 | 277.09 | 277.11 | 277.08 | 277.093 | 1 |

| 94 | 282 | 280.07 | 280.09 | 280.05 | 280.07 | 1.333 |

| 95 | 285 | 283.04 | 283.04 | 283.02 | 283.033 | 0.667 |

| 96 | 288 | 286.05 | 286.03 | 286.01 | 286.03 | 1.333 |

| 97 | 291 | 289.04 | 289.01 | 289.02 | 289.023 | 1 |

| 98 | 294 | 291.01 | 291.03 | 290.99 | 291.01 | 1.333 |

| 99 | 297 | 294.99 | 294.98 | 294.95 | 294.973 | 1.333 |

| 100 | 300 | 297.96 | 297.97 | 297.94 | 297.957 | 1 |

| 101 | 303 | 300.92 | 300.93 | 300.91 | 300.92 | 0.667 |

| 102 | 306 | 303.91 | 303.88 | 303.86 | 303.883 | 1.667 |

| 103 | 309 | 306.95 | 306.9 | 306.92 | 306.923 | 1.667 |

| 104 | 312 | 309.92 | 309.91 | 309.88 | 309.903 | 1.333 |

| 105 | 315 | 312.89 | 312.87 | 312.88 | 312.88 | 0.667 |

| 106 | 318 | 315.88 | 315.86 | 315.85 | 315.863 | 1 |

| 107 | 321 | 318.86 | 318.84 | 318.83 | 318.843 | 1 |

| 108 | 324 | 321.84 | 321.82 | 321.85 | 321.837 | 1 |

| 109 | 327 | 324.81 | 324.79 | 324.82 | 324.807 | 1 |

| 110 | 330 | 327.77 | 327.75 | 327.74 | 327.753 | 1 |

| 111 | 333 | 330.78 | 330.77 | 330.75 | 330.767 | 1 |

| 112 | 336 | 333.82 | 333.84 | 333.81 | 333.823 | 1 |

| 113 | 339 | 336.74 | 336.72 | 336.71 | 336.723 | 1 |

| 114 | 342 | 339.72 | 339.71 | 339.69 | 339.707 | 1 |

| 115 | 345 | 342.81 | 342.77 | 342.78 | 342.787 | 1.333 |

| 116 | 348 | 345.73 | 345.75 | 345.76 | 345.755 | 0.333 |

| 117 | 351 | 348.68 | 348.66 | 348.65 | 348.663 | 1 |

| 118 | 354 | 351.65 | 351.64 | 351.62 | 351.637 | 1 |

| 119 | 357 | 354.75 | 354.72 | 354.73 | 354.733 | 1 |

| 120 | 360 | 357.69 | 357.66 | 357.68 | 357.677 | 1 |

| 121 | 363 | 360.64 | 360.61 | 360.62 | 360.623 | 1 |

| 122 | 366 | 363.62 | 363.59 | 363.61 | 363.607 | 1 |

| 123 | 369 | 366.61 | 366.58 | 366.59 | 366.593 | 1 |

| 124 | 372 | 369.57 | 369.55 | 369.54 | 369.553 | 1 |

| 125 | 375 | 372.55 | 372.52 | 372.51 | 372.527 | 1.333 |

| 126 | 378 | 375.51 | 375.48 | 375.47 | 375.487 | 1.333 |

| 127 | 381 | 379.48 | 379.46 | 379.45 | 379.463 | 1 |

| 128 | 384 | 381.44 | 381.43 | 381.41 | 381.427 | 1 |

| 129 | 387 | 384.42 | 384.41 | 384.39 | 384.407 | 1 |

| 130 | 390 | 387.43 | 387.39 | 387.38 | 387.4 | 1.667 |

| 131 | 393 | 390.37 | 390.36 | 390.33 | 390.353 | 1.333 |

| 132 | 396 | 393.41 | 393.38 | 393.36 | 393.383 | 1.667 |

| 133 | 399 | 396.38 | 396.34 | 396.35 | 396.357 | 1.333 |

| 134 | 402 | 399.35 | 399.32 | 399.31 | 399.327 | 1.333 |

| 135 | 405 | 402.32 | 402.31 | 402.34 | 402.323 | 1 |

| 136 | 408 | 405.29 | 405.26 | 405.24 | 405.263 | 1.667 |

| 137 | 411 | 408.26 | 408.23 | 408.22 | 408.237 | 1.333 |

| 138 | 414 | 411.31 | 411.27 | 411.29 | 411.29 | 1.333 |

| 139 | 417 | 414.28 | 414.25 | 414.23 | 414.253 | 1.667 |

| 140 | 420 | 417.26 | 417.24 | 417.22 | 417.24 | 1.333 |

| 141 | 423 | 420.22 | 420.19 | 420.17 | 420.193 | 1.667 |

| 142 | 426 | 423.21 | 423.18 | 423.17 | 423.187 | 1.333 |

| 143 | 429 | 426.19 | 426.16 | 426.15 | 426.167 | 1.333 |

| 144 | 432 | 429.15 | 429.12 | 429.11 | 429.127 | 1.333 |

| 145 | 435 | 432.12 | 432.09 | 432.08 | 432.097 | 1.333 |

| 146 | 438 | 435.14 | 435.17 | 435.15 | 435.153 | 1 |

| 147 | 441 | 438.09 | 438.06 | 438.05 | 438.067 | 1.333 |

| 148 | 444 | 440.06 | 440.05 | 440.04 | 440.05 | 0.667 |

The intraclass correlation coefficient (Table 2) shows that single and average measurements are 1.000, indicating a complete rater dependability. This means that different raters give the same subjects the same ratings. We are convinced that the true ICC is 1.000 because the 95% confidence interval is 1.000. We tested the null hypothesis that the ICC is 0, which suggests unreliable raters, with the F test with a true value of 0. The F value is large, and the p-value is tiny. Therefore, we may reject the null hypothesis and conclude that the ICC is substantially different from 0. A two-way mixed-effects model treats raters as fixed effects and participants as random effects. This suggests that we are interested in the reliability of the raters we chose for the study, not in generalizing to other raters with similar qualities.

Table 2. Interclass correlation coefficient.

F test: Fisher's test, df: degree of freedom, Sig: significance (p < 0.05)

| Intraclass correlation coefficient | ||||||||

| Intraclass correlationb | 95% confidence interval | F test with true value 0 | ||||||

| Lower bound | Upper bound | Value | df1 | df2 | Sig | |||

| Single measures | 1.000a | 1.000 | 1.000 | 196692581.132 | 147 | 294 | .000 | |

| Average measures | 1.000c | 1.000 | 1.000 | 196692581.132 | 147 | 294 | .000 | |

| Two-way mixed-effects model where people effects are random and measures effects are fixed. | ||||||||

| a. The estimator is the same, whether the interaction effect is present or not. | ||||||||

| b. Type A intraclass correlation coefficients using an absolute agreement definition. | ||||||||

| c. This estimate is computed assuming the interaction effect is absent because it is not estimable otherwise. | ||||||||

As per this calibration test, the DUC's maximum accuracy error is 1.667 N at 75 N, according to test data. At numerous standard loads, the minimum accuracy error is 0.333 N. The DUC marginally underestimates load with an average accuracy error of 0.833 N. Test findings reveal that the DUC performs consistently throughout three sets of measurements, as the results are extremely similar.

Discussion

Regardless of the state of the occlusal condition, the bite force plays a vital role in masticatory performance [8,9]. Measuring the biting force is considered a critical step in diagnostic and treatment planning in restorative dentistry [10-12]. Various devices have been used in the literature to measure bite force having their own merits and demerits [4]. The basic requirement of a bite force measuring device is that it should be accurate, consistent, economical, and simple to use. The “BYTE” device was proposed as an economical, easy-to-use, and reliable instrument to measure the maximum bite force [7]. It has a flexiforce sensor (Tekscan, USA) encased in the two plates of stainless steel in the head part. Moreover, all the hardware in the body part to analyze the change in resistance due to applied force, made in polypropylene plastic. The circular biting portion of the head part is kept on the occlusal surface of the tooth, and the patient is asked to bite over it to measure the bite force. A protective silicone cap is advised to be put on the biting portion during recording. It is reported to be portable, wireless, and easy to disinfect [5,6]. A patent has been granted by the government of India (patent number 489519).

This study evaluates the validity of the instrument by a mechanical calibration test. Calibration tests verify the accuracy and dependability of measuring instruments, tools, and devices. A calibration test compares the DUC output to a more accurate reference standard. A physical measurement device or test data can be the reference standard. The calibration test can show the DUC's divergence from the reference standard and assist in rectifying it. A calibration test can also confirm that the DUC satisfies its use standards.

As per this calibration test report, the device's maximum accuracy error is 1.667 N at 75 N. At numerous standard loads, the minimum accuracy error is 0.333 N. The device marginally underestimates load with an average accuracy error of 0.833 N. The results are found within permissible limits at ±10% to 15% on MSD. Test findings reveal that the device performs consistently throughout three sets of measurements. A bite force measuring instrument with a similar type of sensor was reported by Testa et al. in 2016 [13]. They reported that the sensitivity of the device was rather increased due to the housing compared to the bare instrument. In our study, calibration tests were done without the housing, and the device was performed consistently. A miniature bite force recorder was presented by Singh et al. in 2011 [14]. It was a strain gauge base metallic bite fork that was calibrated using a universal testing machine with a force range between 10 kg and 85 kg. In our study, standard loads starting from 3 N to 444 N were applied. Measurements were taken at every 3 N interval thrice, and the mean was taken for each load. A similar type of bite force recorder was presented by Waltimo A et al. in 1993 [15]. It has a quartz force transducer in a metallic housing covered by rubber. The calibration test of the instrument was done by compression test machine. The instrument was tested with various loads to assess reliability. For each load, 10 recordings were made to calculate the mean value and standard deviation. They concluded that the housing had no bearing on the sensor's linearity. After roughly 500 clinical measures, the housing was tested once again using the same compression test apparatus to confirm the validity of the methodology. A prototype loadpad pressure mapping sensor, of the capacity type, was shown by Steffen C et al. in 2023 [16]. They claimed it to be effective and reliable in edentulous patients for measuring bite force and also in segmental mandibular resection patients. They again used a universal testing machine for validation and calibration tests. Two approaches were used one continuous loading and the other cyclic loading. It was also assessed how the silicone covering affected the recording of bite force and the reliability of the device. In our study, various standard weights starting from 3 N to 444 N at every 3 N interval were loaded onto the biting part of the device without any silicone or other protective layer to analyze the validity and reliability.

This study does have a few limitations. First, the reliability of the device was tested in a controlled laboratory setting, which may not accurately reflect the conditions within the mouth. The most crucial aspect of the test is the application of uniform pressure to the biting portion of the device. To achieve this in patients, it is recommended to use a resin stent during the recording of bite force. In addition, this study did not evaluate the impact of a protective silicone cap or cover. Furthermore, the effects of different loading conditions, such as continuous and cyclic, need to be examined.

Conclusions

In the course of our laboratory validation test, we discovered that the BYTE device demonstrated a high degree of reliability and consistency. The maximum accuracy error was observed to fluctuate within a range of 0.333 N to 1.667 N. This variation was well within the acceptable limits, indicating a high level of precision.

Furthermore, the instrument’s accuracy errors were found to be minor and remained consistent across different load levels. This consistency is a testament to the device’s steady performance under varying conditions. Given these findings, it is our recommendation that the BYTE device is highly suitable for use in both clinical and experimental settings, particularly for the measurement of bite force.

Acknowledgments

The authors would like to thank Innovatios Technology Bangalore, India.

A patent has been granted by the Government of India (patent number 489519).

Author Contributions

Concept and design: Madhu Ranjan

Acquisition, analysis, or interpretation of data: Madhu Ranjan, Surender Kumar, Bishnupati Singh, Amit V. Mahuli, Shantala R. Naik, Awanindra K. Jha

Drafting of the manuscript: Madhu Ranjan, Surender Kumar, Bishnupati Singh, Amit V. Mahuli, Shantala R. Naik, Awanindra K. Jha

Critical review of the manuscript for important intellectual content: Madhu Ranjan, Surender Kumar, Bishnupati Singh, Amit V. Mahuli, Shantala R. Naik, Awanindra K. Jha

Supervision: Madhu Ranjan, Surender Kumar, Bishnupati Singh, Amit V. Mahuli, Shantala R. Naik, Awanindra K. Jha

Human Ethics

Consent was obtained or waived by all participants in this study

Animal Ethics

Animal subjects: All authors have confirmed that this study did not involve animal subjects or tissue.

References

- 1.Bite force transducers and measurement devices. Gu Y, Bai Y, Xie X. Front Bioeng Biotechnol. 2021;9:665081. doi: 10.3389/fbioe.2021.665081. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Kannan A, John BK, Babu DS, Kumar M. 2017 International Conference on Circuit, Power and Computing Technologies (ICCPCT) Kollam, India: IEEE; 2017. Human biting force calculating instrument; pp. 1–4. [Google Scholar]

- 3.Assessment of bite force: a review. Hagberg C. https://pubmed.ncbi.nlm.nih.gov/3325528/ J Craniomandib Disord. 1987;1:162–169. [PubMed] [Google Scholar]

- 4.Bite force recording devices - a review. Verma TP, Kumathalli KI, Jain V, Kumar R. J Clin Diagn Res. 2017;11:0–5. doi: 10.7860/JCDR/2017/27379.10450. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.A novel indigenously developed device to measure bite force. Ranjan M, Singh B, Chatterjee U, Tushar Tushar, Sinha DK, Verma A. J Pharm Bioallied Sci. 2023;15:0–3. doi: 10.4103/jpbs.jpbs_45_23. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.A preliminary report of maximum voluntary bite force of young Indian population. Ranjan M, Singh B, Kumar S, Tushar Tushar, Rani P, Singh A. J Pharm Bioallied Sci. 2024;16:0–5. doi: 10.4103/jpbs.jpbs_1021_23. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.BYTE-Bite Force Measurement Device. BYTE-Bite Force Measurement Device. Innovatios Technology. [ Mar; 2024 ]. 2023. https://innovatiostech.com/product/byte-bite-force-measurement-device/ https://innovatiostech.com/product/byte-bite-force-measurement-device/

- 8.A multifactorial model of masticatory performance: the Suita study. Kosaka T, Ono T, Kida M, et al. J Oral Rehabil. 2016;43:340–347. doi: 10.1111/joor.12371. [DOI] [PubMed] [Google Scholar]

- 9.Determinants of masticatory performance in dentate adults. Hatch J, Shinkai R, Sakai S, Rugh J, Paunovich E. Arch Oral Biol. 2001;46:641–648. doi: 10.1016/s0003-9969(01)00023-1. [DOI] [PubMed] [Google Scholar]

- 10.Masticatory performance in older subjects with varying degrees of tooth loss. Ikebe K, Matsuda K, Kagawa R, Enoki K, Okada T, Yoshida M, Maeda Y. J Dent. 2012;40:71–76. doi: 10.1016/j.jdent.2011.10.007. [DOI] [PubMed] [Google Scholar]

- 11.Oral hypofunction in the older population: position paper of the Japanese Society of Gerodontology in 2016. Minakuchi S, Tsuga K, Ikebe K, et al. Gerodontology. 2018;35:317–324. doi: 10.1111/ger.12347. [DOI] [PubMed] [Google Scholar]

- 12.Bite force and dental implant treatment: a short review. Flanagan D. Med Devices (Auckl) 2017;10:141–148. doi: 10.2147/MDER.S130314. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.A validation study of a new instrument for low cost bite force measurement. Testa M, Di Marco A, Pertusio R, Van Roy P, Cattrysse E, Roatta S. J Electromyogr Kinesiol. 2016;30:243–248. doi: 10.1016/j.jelekin.2016.08.005. [DOI] [PubMed] [Google Scholar]

- 14.An innovative miniature bite force recorder. Singh S, Utreja AK, Sandhu N, Dhaliwal YS. Int J Clin Pediatr Dent. 2011;4:113–118. doi: 10.5005/jp-journals-10005-1093. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.A novel bite force recorder and maximal isometric bite force values for healthy young adults. Waltimo A, Könönen M. Scand J Dent Res. 1993;101:171–175. doi: 10.1111/j.1600-0722.1993.tb01658.x. [DOI] [PubMed] [Google Scholar]

- 16.Clinical and technical validation of novel bite force measuring device for functional analysis after mandibular reconstruction. Steffen C, Duda K, Wulsten D, et al. Diagnostics (Basel) 2023;13 doi: 10.3390/diagnostics13040586. [DOI] [PMC free article] [PubMed] [Google Scholar]