Abstract

Deliberate open burning of crop residues emits greenhouse gases and toxic pollutants into the atmosphere. This study investigates the environmental impacts (global warming potential, GWP) and economic impacts (net cash flow) of nine agricultural residue management schemes, including open burning, fertilizer production, and biochar production for corn residue, rice straw, and sugarcane leaves. The environmental assessment shows that, except the open burning schemes, fossil fuel consumption is the main contributor of the GWP impact. The fertilizer and biochar schemes reduce the GWP impact including black carbon by 1.88–1.96 and 2.46–3.22 times compared to open burning. The biochar schemes have the lowest GWP (− 1833.19 to − 1473.21 kg CO2-eq/ton). The economic assessment outcomes reveal that the biochar schemes have the highest net cash flow (222.72—889.31 US$2022/ton or 1258.15–13409.16 US$2022/ha). The expenditures of open burning are practically zero, while the biochar schemes are the most costly to operate. The most preferable agricultural residue management type is the biochar production, given the lowest GWP impact and the highest net cash flow. To discourage open burning, the government should tailor the government assistance programs to the needs of the farmers and make the financial assistance more accessible.

Keywords: Biochar, Circular economy, PM2.5, Corn residue, Rice straw, Sugarcane leaves

Subject terms: Environmental sciences, Environmental impact

Introduction

Similarly to carbon emissions from livestock1, carbon emissions also arise from crop farming and the burning of crop residues2. In particular, the open burning of agricultural residues to clear cultivated fields of harvest by-products is widely practiced in many developing countries in Africa, South Asia, and Southeast Asia. Deliberate open burning of crop residues is a major contributing factor to local and transboundary haze and air pollution3–5. The impacts of open burning vary from region to region, depending on crop types, burning conditions, and seasons6.

The incomplete combustion of open burning of biomass emits greenhouse gases (GHG) and toxic pollutants into the atmosphere, including carbon monoxide (CO), carbon dioxide (CO2), methane (CH4), nitrogen oxides (NOx), sulfur oxides (SOx), volatile organic compounds (VOCs), and particulate matter (PM2.5 and PM10)3,7,8. Of particular concern are fine particles that are 2.5 microns or less in diameter (i.e., PM2.5). PM2.5 are so small that they can travel deeply into the respiratory tract and lodge inside the lungs, causing throat and lung irritation, lung cancer, and other respiratory diseases9.

Black carbon is a component of fine particulate matter (i.e., PM2.5) that has been linked to respiratory and cardiovascular diseases and even premature deaths. Black carbon also contributes to worsening climate change. According to Bond, et al.6, the global warming potential for a 100-year time horizon of black carbon is between 120 and 1800, with an average of 900. As a result, cutting down black carbon emissions slows down climate change, improves air quality, and reduces human health risks.

According to IQAir10, the air quality in northern Thailand is very poor, especially during the dry season when PM2.5 from local and transboundary illegal crop burning and forest fires are alarmingly high. The concentrations of PM2.5 in the northern region of the country routinely exceed (i.e., 400 percent higher) the World Health Organization standards for PM2.511. In the province of Chiangmai, which is the cultural and economic hub of northern Thailand, there were only 43 days, during January–April 2021, with the average daily PM2.5 levels below 50 μg/m3, while the average daily PM2.5 levels exceeding 50 μg/m3 lasted for two consecutive months12. The worsening air quality coincided with the sheer number of reported hotspots (101,869 hotspots) caused by open burning of crop residues and forest fires between January–May 202113. Compounded by agricultural expansion and the El Niño phenomenon, the PM2.5 situation would worsen if open burning is left unchecked14,15.

The current agricultural residue management strategies to curb open burning include building awareness of the impacts of open burning, promoting long-term crops, boycotting crops from farms that practice open burning, and outright banning of open burning. However, the existing strategies attach greater emphasis to punishment than reward. In other words, the current agricultural residue management strategies view farmers as part of the problem rather than the solution. As the demand for short-term commercial crops, e.g., rice, sugarcane, and corn, continually increases16, switching from open burning to zero burning using land clearing equipment is an environment friendly ideal solution to tackle open burning pollution.

The zero burning practices, e.g., conversion of crop residues into fertilizers and biochar products, are compatible with the concept of circular economy17–19. However, the switching from open burning to zero burning involves large capital investment and operation and maintenance costs. Such financial burdens could act as a deterrent to shifting from open burning to zero burning practices.

The focus of this current research is the environmental and economic impacts of three types of agricultural residue management of three different crop residues. The types of agricultural residue management being studied include open burning (OB), fertilizer production (Fe), and biochar production (BC); and the three crop residues are corn residue (C), rice straw (R), and sugarcane leaves (S). This study aims to perform comparative assessment of environmental (the global warming potential (GWP)) and economic impacts (net cash flow) of the nine agricultural residue management schemes and the most preferable type of crop residue management is selected. The nine agricultural residue management schemes include C-OB, C-Fe, C-BC, R-OB, R-Fe, R-BC, S-OB, S-Fe, and S-BC. Undertaking this work is crucial for the international community to attain environmental sustainability, food security, economic development, public health, and fostering international cooperation. The international community, including governmental bodies and organizations like the UN and the World Bank, can utilize the findings on environmental and economic impacts to determine the optimal approach to managing crop residue.

In this research, revenues from avoidance carbon emission credits are included for the Fe and BC options. This is comparable to the carbon credit projects to reduce emissions from non-energy open biomass burning of forests20 and those to reduce emissions from the household biomass burning for energy, i.e., the Cookstove Project21. Specifically, in the assessment, the carbon credits are comprised of: (i) the avoided GHG emissions after switching from open burning to zero burning (i.e., fertilizer and biochar production) and (ii) the carbon storage from the conversion of crop residues to biochar.

Materials and methods

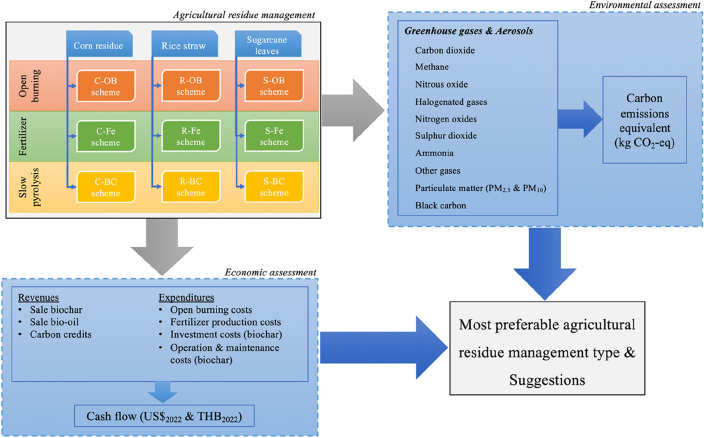

The secondary data (i.e., the emission factors, the inventory data and the economic data) of the three crop residues (i.e., corn residue, rice straw, and sugarcane leaves) that are used for this study, are gathered from existing peer-reviewed publications and reports by local government agencies and international organizations. Figure 1 shows the methodology framework of this research. The study focuses on three types of agricultural residue management (i.e., open burning, fertilizer production, and biochar production using slow pyrolysis) treating three different crop residues (i.e., corn residue including corn cobs, leaves, and stalks; rice straw; and sugarcane leaves).

Figure 1.

The methodology framework of this research.

Essentially, this research comparatively assesses the environmental and economic impacts of nine agricultural residue management schemes and the most preferable type of agricultural residue management generates the lowest GWP impact and the highest net cash flow.

In the study, the GWP is calculated based on the inventory data of GHG emissions6,22. Unlike the GWP calculation by the Intergovernmental Panel on Climate Change (IPCC), the GWP of open burning of this study includes black carbon emissions.

Agricultural residue management schemes

In this study, the emission factors of the pollutants from open burning between 1998 and 2021 are obtained from the existing researches3–5,7,8,22–41 and provided in Table 1. This study uses the average emission factors of air pollutants of the three crop residues (i.e., corn residue, rice straw, and sugarcane leaves) to assess the GWP impact. In practice, sugarcane farmers burn sugarcane crops before harvest and the crops are harvested manually, whereas corn and rice farmers burn the agricultural residues after harvest.

Table 1.

The average emission factors of pollutants from open burning.

| Emission factors (g/kg) | Corn residue | Rice straw | Sugarcane leaves |

|---|---|---|---|

| PM2.5 | 9.113,4,7,30,32 | 12.3442 | 10.3638–40 |

| PM10 | 14.8632 | 7.8442,43 | No data |

| CO | 64.664,7,26–28,30,31,34 | 68.224,5,7,8,26,27,34,36,42–44 | 63.1438–41 |

| CO2 | 1663.144,7,26,27,30,34 | 1229.504,5,7,8,26,27,34,36,42,44 | 1379.5038–41 |

| CH4 | 4.4030 | 3.52*22–25 | 3.52*22–25 |

| N2O | 0.1430 | 0.07*22–25 | 0.07*22–25 |

| NOx | 3.427,26–28,30,34 | 2.687,26,27,34,36 | 1.5038 |

| NH3 | 0.667,28,30 | 1.547,8,44 | 1.50*22–25 |

| SO2 | 0.357,26–28,30 | 0.267,8,26,27,36,43 | 0.40*22–25 |

| Black carbon | 1.247,27,28,30,32,33 | 1.137,27,33,35,45 | 0.6137 |

*indicates that the values are the average of the emission factors of all agricultural residues due to unavailability of data specific to the particular crops.

Apart from open burning, agricultural residues could also be converted into organic fertilizers. The common practice is to chop and blend it with the soil to enrich the agricultural fields. The conversion of agricultural waste into fertilizers helps mitigate emissions from open burning. In this research, the GWP calculation of the fertilizer production schemes excludes emissions from the natural decomposition of agricultural residues.

The slow pyrolysis of biochar is carried out in an oxygen limited environment at 350 – 500 ºC, with typical heating rates between 1 and 30 °C min−146 to improve the quality and yield of biochar47. In this research, the biochar yields of agricultural residues are obtained from Tomczyk, et al. 48.

Environmental assessment

The GWP assessment of the nine agricultural residue management schemes adheres to the life cycle assessment (LCA) methodology, encompassing four steps: (i) defining system boundaries, functional units, and assumptions; (ii) analyzing inventory data; (iii) conducting life cycle impact assessment (LCIA); and (iv) analyzing outcomes to pinpoint the agricultural residue management scheme with the least environmental impact49.

-

(i)

Defining system boundaries: The system boundary for the nine agricultural residue management schemes is gate-to-gate life cycle, covering various management types (e.g., open burning, fertilizer production, biochar production) and agricultural residue transportation. In this study, transportation applies to biochar schemes, where crop residues are transported within a 100 km radius from fields to production facilities via trucks. The functional unit is set at 1000 kg of agricultural residues.

-

(ii)

Analyzing inventory data: Inventory data for agricultural residue management in Thailand from 2001 to 2023 are sourced from multiple references16,50–58. Biochar production data are obtained from studies by Tomczyk, et al.48,Sahoo, et al.59. Input and output data for the three types of agricultural residue management are presented in Tables 2, 3, and 4. This study employs.

-

(iii)

Conducting life cycle impact assessment (LCIA The GWP of the nine agricultural residue management schemes is assessed using IPCC 2021 methodology in openLCA 2.0 software, with LCIA conducted via the ecoinvent database. To incorporate black carbon emissions from incomplete combustion, which are not covered by the IPCC method, the open burning schemes (C-OB, R-OB, S-OB) include the average GWP of 900 for black carbon emissions (100-year time horizon)6 in their calculations. Conversely, the fertilizer (C-Fe, R-Fe, S-Fe) and biochar schemes (C-BC, R-BC, S-BC) reflect negative emissions due to the absence of pollutants emitted from open burning, including N2O, CH4, and black carbon.

Table 2.

The inventory data of open burning of agricultural residues.

| Inventory data | Unit | Open burning | ||

|---|---|---|---|---|

| Corn residue | Rice straw | Sugarcane leaves | ||

| Input | ||||

| Corn residue | kg/ha | 9242.35 | ||

| Rice straw | kg/ha | 2530.28 | ||

| Sugarcane leaves | kg/ha | 15,078.11 | ||

| Output | ||||

| Ash | kg/ha | 184.85 | 101.21 | 1362.14 |

| Emissions to air | ||||

| PM2.5 | kg/ha | 84.16 | 31.24 | 156.26 |

| PM10 | kg/ha | 137.34 | 19.84 | No data |

| CO | kg/ha | 597.61 | 172.63 | 952.06 |

| CO2 | kg/ha | 15,371.32 | 3110.97 | 20,800.25 |

| CH4 | kg/ha | 40.67 | 53.13 | 53.13 |

| N2O | kg/ha | 1.29 | 1.06 | 1.06 |

| NOx | kg/ha | 31.61 | 6.78 | 22.62 |

| NH3 | kg/ha | 6.13 | 3.89 | 22.61 |

| SO2 | kg/ha | 3.19 | 0.67 | 6.03 |

| Black carbon | kg/ha | 11.48 | 2.86 | 9.20 |

Table 3.

The inventory data of fertilizer production.

| Inventory | Unit | Fertilizer production | ||

|---|---|---|---|---|

| Corn residue | Rice straw | Sugarcane leaves | ||

| Input | ||||

| Biomass | kg/ha | 9242.35 | 2530.28 | 15078.11 |

| Diesel—chopping biomass | L/ha | 284.91 | 78.00 | 75.00 |

| Diesel—blending biomass with soil | L/ha | 9.38 | 16.00 | 10.44 |

| Output | ||||

| Fertilizer | kg/ha | 9242.35 | 2530.28 | 15078.11 |

Table 4.

The inventory data of biochar production.

| Inventory | Unit | Biochar production | ||

|---|---|---|---|---|

| Corn residue | Rice straw | Sugarcane leaves | ||

| Input | ||||

| Biomass | kg dry | 2695.42 | 2985.07 | 2715.92 |

| Biochar yield (biochar/biomass) | % | 37.10% | 33.50% | 36.82% |

| Electricity | kWh | 234 | 234 | 234 |

| Propane | L | 1727 | 1727 | 1727 |

| Transport of biomass | tkm | 269.54 | 298.51 | 271.59 |

| Output | ||||

| Biochar | kg | 1000 | 1000 | 1000 |

| Bio-oil (co-product) | kg | 857.14 | 857.14 | 857.14 |

| Emissions to air | ||||

| PM2.5 | kg | 0.02 | 0.02 | 0.02 |

| PM10 | kg | 2.38 | 2.64 | 2.40 |

| CO | kg | 1.20 | 1.33 | 1.21 |

| CO2 | kg | 4353.10 | 4820.90 | 4386.20 |

| CH4 | kg | 0.26 | 0.29 | 0.27 |

| NOx | kg | 3.39 | 3.76 | 3.42 |

| SO2 | kg | 0.06 | 0.07 | 0.06 |

| Fixed carbon | % | 72.30% | 81.55% | 78.59% |

The carbon storage of biochar schemes is calculated by Eq. (1) based on the molecular weights of carbon (12 g/mole) and CO2 (44 g/mole), the fixed carbon percentage, and the biochar yield of agricultural residues.

| 1 |

In this study, carbon storage refers to the capturing of CO2 emissions and storing them in solid form (i.e., biochar), thereby preventing CO2 emissions from having an effect on climate. The carbon storage is thus regarded as negative emissions when incorporating into the GWP assessment.

The ISO14044:2006 standard, which covers LCA studies and life cycle inventory studies, requires that sensitivity analysis be performed to assess the reliability of the final outcomes49. According to IPCC63, fossil fuel consumption is the major contributor of GWP impact. However, modern diesel engines are more fuel-efficient and emit less GHG64. In the sensitivity, the diesel fuel consumption of the fertilizer schemes (C-Fe, R-Fe, S-Fe) is thus assumed to decrease by 10%, 20%, and 30%. Meanwhile, the distance between the harvested fields and the biochar production facilities of the biochar schemes (C-BC, R-BC, S-BC) are assumed to increase by 200, 300, and 500 km.

Analyzing outcomes: the agricultural residue management scheme with the least environmental impact is determined based on its lowest GWP.

Economic assessment

In the economic assessment, agricultural residue managements excluding biochar production, occur at harvested fields, while for biochar production, crop residues are sold to production facilities, necessitating transportation. Revenue sources under the nine management schemes include biochar sales, bio-oil sales as an alternative to heavy fuel oil, and carbon credits from avoided emissions and carbon storage resulting from no open burning practices i.e., fertilizer production and biochar production.

In Table 4 (the inventory data of biochar production), the yields of biochar and bio-oil are 394.04–436.39 kg per ton of agricultural residues and 239.29–256.00 L per ton of agricultural residues, respectively59,61. The market prices of biochar and bio-oil are 9.38 US$ per kg (109.9 THB per kg) and 1.11 US$ per L (13 THB per L)65. Thailand’s average carbon credit between 2021 and 2023 is 6.40 US$ per ton CO2 (75.05 THB per ton CO2)66. In this study, the carbon credits consist of the avoided emissions from fertilizer and biochar production and the carbon storage in biochar. (Note: THB denotes the currency of Thailand or Thai baht.)

The expenditures (i.e., cash outflow) are obtained from Silalertruksa and Gheewala51,Thailand Environment Foundation54,Sahoo, et al.59,Energy Policy and Planning office65,Ministry of Labour67 and government reports between 2014 and 2023, including investment cost and operation and maintenance cost. For the fertilizer schemes (C-Fe, R-Fe, S-Fe), the major cost items (i.e., operation costs) include diesel fuels (2.94 US$/L or 34.45 THB/L) and wages (29.09 US$/day or 340.89 THB/day on average)65,67. Since the machines and equipment are rented (instead of purchase), the investment and maintenance costs are excluded for the fertilizer schemes. For the biochar schemes (C-BC, R-BC, S-BC), the investment cost in biochar production machinery and the maintenance cost are obtained from Sahoo, et al.59. The operation costs of the biochar schemes include feedstock, propane, electricity, diesel fuel for transportation, packaging, and labor.

The revenues and expenditures are converted into the year 2022 United States currency (US$) and Thai currency (THB) based on the purchasing power parity (PPP) and gross domestic product (GDP) deflator index to reconcile differences between US$ and THB68. Both currencies conversion equations are provided in Eq. (2) and (3), and the conversion factors of PPP and GDP deflator are tabulated in Table 5.

| 2 |

where THB2019 and US$2019 are the 2019 values of Thai baht (THB) and United States dollar (US$), and PPPTHB2019 and PPPUS$2019 are the exchange rate-adjusted purchasing power parity for Thai baht (THB) and United States dollar (US$).

| 3 |

where US$2019 and US$2022 are the 2019 and 2022 United States dollar (US$) values, THB2019 and THB2022 are the 2019 and 2022 Thai baht (THB) values, DUS$2019 and D US$2022 are the 2019 and 2022 GDP deflator indexes of United States dollar (US$) and DTHB2019 and D THB2022 are the 2019 and 2022 GDP deflator indexes of Thai baht (THB).

Table 5.

The conversion factors for the economic assessment.

| Item | Conversion factor |

|---|---|

| PPPUS$2019 | 1 |

| PPPUS$2022 | 1 |

| PPPThai2019 | 12.6249 |

| PPPThai2022 | 11.7181 |

| GDPUS$2019 | 107.2859 |

| GDPUS$2022 | 121.5247 |

| GDPThai2019 | 154.6724 |

| GDPThai2022 | 162.6152 |

World Bank68.

The most preferable type of agricultural residue management

The nine agricultural residue management schemes are assessed to determine the most environmentally and financially viable type of crop residue treatment for corn residue, rice straw, and sugarcane leaves. The selection criteria for the most environmentally and financially viable schemes or type are the lowest GWP impact and the highest net cash flow.

Results and discussion

Environmental assessment outcomes

The environmental LCA results indicate that, except the open burning schemes (C-OB, R-OB, S-OB), fossil fuel consumption is the main contributor to the GWP impact. The main contributor of the GWP impact for the fertilizer schemes (C-Fe, R-Fe, and S-Fe) is diesel fuel consumption, and that of the biochar schemes (C-BC, R-BC, and S-BC) is propane consumption.

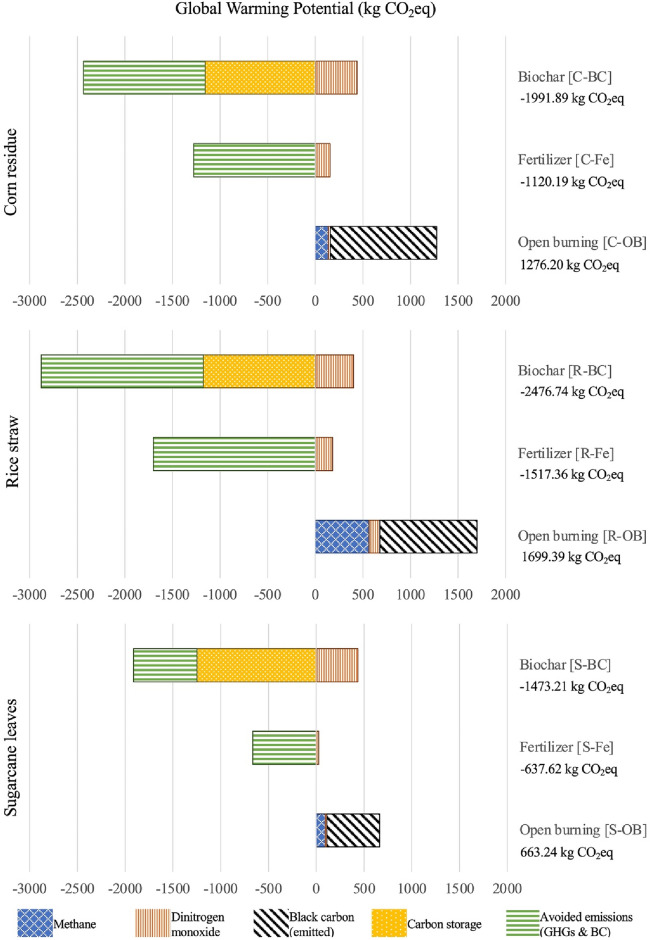

Overall, the fertilizer and biochar schemes reduce the GWP impact by 1.88 to 1.96 times and 2.46 to 3.22 times, respectively, compared to open burning schemes. Figure 2 shows the GWP impacts of the nine agricultural residue management schemes. The GWP impact of the biochar schemes are the lowest (− 1991.89 kg CO2-eq/ton corn residue, − 2476.74 kg CO2-eq/ton rice straw, and − 1473.21 kg CO2-eq/ton sugarcane leaves). The GWP impact of black carbon from corn residue is the highest (1117.50 kg CO2-eq/ton), followed by rice straw (1018.62 kg CO2-eq/ton) and sugarcane leaves (549.00 kg CO2-eq/ton) (Tables 1 and 2).

Figure 2.

The global warming potential impact of the nine agricultural residue management schemes.

The avoided emissions of rice straw are the lowest (− 1699.39 kg CO2-eq/ton) for both fertilizer and the biochar schemes. In the biochar production, the carbon storage of sugarcane leaves (− 1248.02 kg CO2-eq/ton or − 18,817.74 kg CO2-eq/ha) was the highest, followed by corn residue (− 1156.86 kg CO2-eq/ton or − 10,692.12 kg CO2-eq/ha) and rice straw (− 1178.25 kg CO2-eq/ton or − 2981.30 kg CO2-eq/ha). The highest carbon storage of sugarcane leaves could be attributed to the higher percentage of fixed carbon, the higher biochar yield, and the highest agricultural residues per ha (Table 2).

The highest GWP of the open burning schemes could be attributed to air pollutants, especially black carbon, emitted during the burning of agricultural residues (i.e., corn residue, rice straw, and sugarcane leaves). Black carbon can lodge into the respiratory tract and inside the lungs, causing throat and lung irritation, lung cancer, and other respiratory diseases9,69.

Roberts, et al.70 studied the LCA of biochar production from corn residue and reported that the GWP impact of biochar production from corn residue is − 864 kg CO2-eq/ton, vis-a-vis the result of this research (− 715.69 kg CO2-eq/ton corn residue without avoided emissions). The higher GWP of biochar production of this study could be attributed to the farther distance between the harvested fields and the biochar production facilities (i.e., within a 100 km radius vs 15 km on average). Biochar is primarily utilized for carbon storage, and the carbon storage capacity of biochar depends on feedstock and pyrolysis temperature48.

The sensitivity analysis results reveal that the lower diesel fuel consumption (by 10%, 20%, and 30%) for the fertilizer schemes (C-Fe, R-Fe, S-Fe) and the farther distance between the harvested fields and the biochar production facilities for the biochar schemes (C-BC, R-BC, S-BC) have negligible effects on the GWP.

Economic assessment outcomes

Table 6 presents the cash flow of the nine agricultural residue management schemes. The net cash flow (i.e., cash inflow—cash outflow) of the biochar schemes (C-BC, R-BC, and S-BC) are highest (222.72 US$2022/ton corn residue (2609.80 THB2022/ton corn residue) or 2058.42 US$2022/ha (24,120.67 THB2022/ha); 497.24 US$2022/ton rice straw (5826.65 THB2022/ton rice straw) or 1258.15 US$2022/ha (14,743.04 THB2022/ha); and 889.31 US$2022/ton sugarcane leaves (10,421.02 THB2022/ton sugarcane leaves) or 13,409.16 US$2022/ha (157,129.28 THB2022/ha)).

Table 6.

The cash flow of the nine agricultural residue management schemes.

| List | Corn residue | Rice straw | Sugarcane leaves | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Open burning (C-OB) | Fertilizer (C-Fe) | Biochar (C-BC) | Open burning (R-OB) | Fertilizer (R-Fe) | Biochar (R-BC) | Open burning (S-OB) | Fertilizer (S-Fe) | Biochar (S-BC) | ||

| Cash inflow | Sale biochar | 4092.74 | 3695.60 | 4061.85 | ||||||

| Sale bio-oil | 293.99 | 265.46 | 291.77 | |||||||

| Carbon credits | 7.17 | 12.76 | 9.72 | 15.86 | 4.08 | 9.44 | ||||

| Carbon credits–process emissions | − 1.00 | -2.83 | − 1.17 | − 2.57 | − 0.16 | − 2.81 | ||||

| Carbon credits–avoided emissions | 8.17 | 8.17 | 10.88 | 10.88 | 4.25 | 4.25 | ||||

| Carbon credits–biochar as carbon storage | 7.41 | 7.55 | 7.99 | |||||||

| Total Revenues | 0.00 | 7.17 | 4399.49 | 0.00 | 9.72 | 3976.93 | 0.00 | 4.08 | 4363.06 | |

| Cash outflow | Fertilizer | 96.76 | 116.71 | 19.17 | ||||||

| Labor–burning biomass | Practically 0 | Practically 0 | Practically 0 | |||||||

| Labor–chopping biomass | 1.51 | 1.51 | 1.51 | |||||||

| Labor–mixing biomass | 1.64 | 5.99 | 1.00 | |||||||

| Diesel–burning biomass | Practically 0 | Practically 0 | Practically 0 | |||||||

| Diesel–chopping biomass | 90.63 | 90.63 | 14.62 | |||||||

| Diesel–mixing biomass | 2.98 | 18.59 | 2.04 | |||||||

| Biochar | 4176.77 | 3479.69 | 3473.75 | |||||||

| Investment cost | 376.00 | 339.51 | 373.16 | |||||||

| Operation cost | 3730.84 | 3077.03 | 3031.18 | |||||||

| Maintenance cost | 69.93 | 63.14 | 69.40 | |||||||

| Total Expenditures | Practically 0 | 96.76 | 4176.77 | Practically 0 | 116.71 | 3479.69 | Practically 0 | 19.17 | 3473.75 | |

| Net cash flow (Revenues—Expenditures) | US$2022/ton | 0.00 | − 89.58 | 222.72 | 0.00 | − 107.00 | 497.24 | 0.00 | − 15.09 | 889.31 |

| US$2022/ha | 0.00 | − 827.95 | 2058.42 | 0.00 | − 270.73 | 1258.15 | 0.00 | − 227.48 | 13409.16 | |

Unit: US$2022 per ton agricultural residues.

More specifically, the cash inflow of the biochar production from corn residue is the highest (4399.49 US$2022/ton or 51,553.44 THB2022/ton), followed by sugarcane leaves (3663.06 US$2022/ton or 51,126.56 THB2022/ton) and rice straw (46,601.85 US$2022/ton or 46,601.85 THB2022/ton). The sale of biochar accounts for the largest proportion of cash inflow (3695.60–4092.74 US$2022/ton or 43,305.25–47,958.95 THB2022/ton), followed by the sale of bio-oil and the carbon credits.

The carbon credits of the fertilizer schemes are between 4.08–9.72 US$2022/ton (47.85 – 113.88 THB2022/ton) or 24.59–66.31 US$2022/ha (288.14–777.01 THB2022/ha), while those of the biochar schemes are between 9.44–15.86 US$2022/ton (110.56–185.88 THB2022/ton) or 40.14–142.27 US$2022/ha (470.33–1667.11 THB2022/ha), given that the average price of carbon credits in Thailand between 2021 and 2023 is 6.40 US$ ton CO2 (75.05 THB/ton CO2). The price of carbon credits in Thailand is substantially lower than the international prices of 30–120 US$ or 351.54–1406.17 THB202266,71. The lower price of carbon credits in Thailand is partly attributable to the voluntary nature of the carbon markets in the country, as opposed to the mandatory market in many developed countries such as EU Emissions Trading System72. The study results also indicate that, in order for the farmers to switch from open burning to fertilizer production, the minimum prices of carbon credits from avoided emissions should be 30.07 US$/ton CO2 (352.31 THB/ton CO2), 76.92 US$/ton CO2 (901.34 THB/ton CO2) and 86.38 US$/ton CO2 (1012.15 THB/ton CO2) for sugarcane leaves, rice straw and corn residue, respectively.

The expenditures (i.e., cash outflow) of the biochar schemes are the highest (4176.77 US$2022/ton or 48,943.64 THB2022/ton for C-BC, 3479.69 US$2022/ton or 40,775.19 THB2022/ton for R-BC, and 3473.75 US$2022/ton or 40,705.54 THB2022/ton for S-BC). Meanwhile, the expenditures of the open burning schemes are practically zero.

In the existing researches, the economic benefits of biochar include a reduction in the use of chemical fertilizers and an improvement in crop yields73–75. Jeffery, et al.73 and Wang, et al.74 report that applying biochar at rates between 50 and 150 ton/ha in tropical soil can be effective. Specifically, Tisserant and Cherubini75 report a potential reduction in fertilizer use by 7% with biochar application. In our study, utilizing biochar could reduce the fertilizer usage (15-15-15 compound fertilizer) to 186.15 kg/ha for corn and rice, and 453.38 kg/ha for sugarcane, resulting in reduced fertilizer costs of 28.26 US$2022/ha (331.21 THB2022/ha) for both corn and rice, and 68.84 US$2022/ha (806.68 THB2022/ha) for sugarcane. Additionally, biochar has been found to increase crop yields by 10% to 42%76, with an average increase of 25%73. In this study, the improved crop yields of corn, rice, and sugarcane could result in increased cash inflows of 871.89, 1690.53 and 1426.76 US$2022/ha (10216.89, 19809.71 and 16754.06 THB2022/ha), respectively.

The most preferable type of agricultural residue management

The environmental and economic assessment outcomes show that the conversion of crop residues to biochar (C-BC, R-BC, and S-BC) is the most preferable type of agricultural waste treatment because of the lowest GWP impact and the highest net cash flow. More specifically, the R-BC scheme has the lowest the GWP impact (− 2476.74 kg CO2-eq/ton), while the S-BC scheme has the highest net cash flow (889.31 US$2022/ton (10421.02 THB2022/ton) or 13409.16 US$2022/ha (157129.28 THB2022/ha)).

In 2019, the agriculture sector in Thailand emitted 56,766.32 Gg CO2-eq, accounting for 15.23% of total national GHG emissions77 excluded the black carbon emission. If this practice were adopted on a larger scale, assuming that 20% of each agricultural residues (corn residue, rice straw, and sugarcane leaves) are diverted from open burning to biochar production, GHG emissions would decreased by 17,345.99 Gg CO2-eq, representing 30.56% decrease in total agricultural GHG emissions, with black carbon emissions reduced by12641.24 Gg CO2-eq. Additionally, Thailand’s nationally determined contribution aims to unconditionally reduce GHG emissions by 30% from the business-as-usual scenario by 203077. Switching 20% of the three agricultural residues to biochar could reduce GHG emissions by 4.69% compared to Thailand's business-as-usual emissions level in 203078.

Given the practically zero cost of open burning and lax law enforcement, farmers in many developing countries, including Thailand, burn their crop residues to clear harvested fields off harvest by-products. However, smoke from deliberate burning of agricultural waste contains toxic gases and pollutants harmful to human health and the environment. To discourage open burning and promote the adoption of zero burning practices, the government needs to play the role of a facilitator rather than a police officer.

More specifically, the state authorities need to tailor the government assistance programs to the requirements of farmers and make them more accessible to the farmers, as opposed to imposing harsher punishments, such as imposing hefty fines or longer prison terms, which prove ineffective. The government could provide medium-term (5 years) zero-interest loans to farmers who plan to switch to zero burning. Since the loans carry zero interest rate and would not have to be repaid for the first two or three years, the farmers would be incentivized to abandon open burning and adopt the zero burning practices. In addition, amendments are required to existing laws and regulations so that land clearing machines and biochar equipment are subject to a zero rate of import customs duty. This adjustment would render the prices of these machines and equipment more affordable for farmers. These policies have the potential to decrease GWP impact by 633.24–1699.39 kg CO2-eq/ton of crop residues by promoting compliance and providing financial incentives. Choosing the biochar management method could result in farmers earning at least 222.72 US$ (2609.80 THB) per ton of crop residues or 1258.15 US$ (14743.04 THB) per hectare. This combination of measures and benefits could significantly sway farmers away from practicing open burning. Besides, the government should educate farmers about carbon credits and provide them with consultation and assistance to take part in the carbon projects as another source of income for farmers.

In the domain of incentivized carbon credit projects, various stakeholders collaborate to ensure their success and effectiveness. Government agencies play a pivotal role in this framework by making crucial decisions and establishing regulatory structures. They should prioritize tasks such as incorporating black carbon into greenhouse gas inventories for its specific contribution to both climate change and PM2.5, establishing certified parties and trading mechanisms, and introducing carbon pricing on agricultural products. To encourage participation, government agencies can set a legal framework for companies and businesses, such as setting carbon emission targets, to engage in carbon credit trading. Concurrently, they oversee the creation of carbon projects aimed at preventing further deforestation and the conversion of forests into agricultural land, while also encouraging participation by setting carbon emission targets. Politicians also play a significant role in this process as policy makers. They contribute to the development and enactment of legislation and regulations related to carbon emissions and offset projects. Through their decisions and actions, politicians shape the overall policy landscape and provide the necessary framework for the implementation of carbon credit initiatives.

Farmers, as key players, actively engage in sustainable practices and carbon markets. By refraining from open burning and selling carbon credits earned through sustainable farming methods, they not only generate additional income but also foster eco-friendly practices. Collaboration with various stakeholders, including government agencies and non-governmental organizations, allows farmers to access resources, technical support, and funding for implementing carbon projects and embracing sustainability.

Communities residing in regions with carbon offset projects reap benefits like job opportunities, infrastructure enhancement, and improved environmental quality. Their involvement is vital for project success and ensures equitable distribution of benefits. Furthermore, private sector entities, including companies and businesses, contribute by reducing carbon emissions and investing in carbon offset projects. They also engage in carbon trading to meet regulatory requirements and corporate sustainability goals.

Financial institutions play a significant role by offering funding and investment opportunities for carbon offset projects. They evaluate project feasibility, manage financial risks, and provide financial instruments such as carbon funds or green bonds to facilitate project advancement. Additionally, non-governmental organizations focused on environmental conservation assist in advocating for sustainable practices and facilitating community engagement. They serve as intermediaries, connecting project developers with funding sources or buyers for carbon credits.

Overall, the collaborative efforts of these stakeholders, including project developers and carbon standards bodies, ensure the successful implementation and integrity of incentivized carbon credit projects, fostering environmental stewardship and sustainable development.

Conclusion

This research comparatively assesses the environmental and economic impacts of nine agricultural residue management schemes, including C-OB, C-Fe, C-BC; R-OB, R-Fe, R-BC; S-OB, S-Fe, and S-BC. The types of agricultural residue management being studied include open burning (OB), fertilizer production (Fe), and biochar production (BC) using slow pyrolysis. The three crop residues are corn residue (C); rice straw (R); and sugarcane leaves (S). Specifically, the nine agricultural residue management schemes are analyzed to determine the GWP (i.e., environmental assessment) and net cash flow (economic assessment); and the most preferable type of agricultural residue management is selected. The selection criteria are the lowest GWP impact and the highest net cash flow. The environmental assessment shows that, except the open burning schemes (C-OB, R-OB, and S-OB), fossil fuel consumption is the main contributor of the GWP impact. Meanwhile, the biochar schemes (C-BC, R-BC and S-BC) have the lowest GWP impact. The economic assessment outcomes show that the biochar schemes have the highest net cash flow, with the biochar production from corn residue (C-BC) generating the highest cash inflow. The revenue from the sale of biochar is highest, followed by the sale of bio-oil. The expenditures of the open burning schemes are practically zero, while the biochar schemes are the most costly to operate. The most preferable agricultural residue management type is the biochar production (C-BC, R-BC and S-BC), given the lowest GWP impact and the highest net cash flow. As a result, the more eco-friendly biochar schemes should be adopted as an alternative to open burning of crop residues. To discourage open burning and promote the adoption of zero burning practices, especially the biochar production, the authorities need to tailor the government assistance programs to the requirements of farmers and make them more accessible to the farmers. The government assistance programs could be in the form of, e.g., zero-interest loans and a zero rate of import customs duty on land clearing machines and equipment.

Author contributions

Rutjaya Prateep Na Talang:Design of the work, Resources, Investigation, Interpretation of data and Writing—Original draft, Warangluck Na sornConceptualization, Resources, Investigation, and Review, Sucheela Polruang:Conceptualization, Resources, Analysis, Review & Editing—Essentially intellectual contributor, Sanya Sirivithayapakorn:Conceptualization, Resources, Analysis, Interpretation of data, and Writing, Review & Editing and Supervision – Corresponding author.

Data availability

The datasets generated and/or analyzed during the current study are available in this article.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Elahi E, et al. Decoupling livestock and poultry pollution emissions from industrial development: A step towards reducing environmental emissions. J. Environ. Manag. 2024;350:119654. doi: 10.1016/j.jenvman.2023.119654. [DOI] [PubMed] [Google Scholar]

- 2.Lohan SK, et al. Burning issues of paddy residue management in north-west states of India. Renew. Sustain. Energy Rev. 2018;81:693–706. doi: 10.1016/j.rser.2017.08.057. [DOI] [Google Scholar]

- 3.Li C, et al. Multi-pollutant emissions from the burning of major agricultural residues in China and the related health-economic effects. Atmos. Chem. Phys. 2017;17:4957–4988. doi: 10.5194/acp-17-4957-2017. [DOI] [Google Scholar]

- 4.Ni H, et al. Emission characteristics of carbonaceous particles and trace gases from open burning of crop residues in China. Atmos. Environ. 2015;123:399–406. doi: 10.1016/j.atmosenv.2015.05.007. [DOI] [Google Scholar]

- 5.Pham C-T, et al. Emission factors of selected air pollutants from rice straw burning in Hanoi Vietnam. Air Qual. Atmos. Health. 2021;14:1757–1771. doi: 10.1007/s11869-021-01050-6. [DOI] [Google Scholar]

- 6.Bond TC, et al. Bounding the role of black carbon in the climate system: A scientific assessment. J. Geophys. Res. Atmos. 2013;118:5380–5552. doi: 10.1002/jgrd.50171. [DOI] [Google Scholar]

- 7.Fang Z, et al. Open burning of rice, corn and wheat straws: Primary emissions, photochemical aging, and secondary organic aerosol formation. Atmos. Chem. Phys. 2017;17:14821–14839. doi: 10.5194/acp-17-14821-2017. [DOI] [Google Scholar]

- 8.Hayashi K, et al. Trace gas and particle emissions from open burning of three cereal crop residues: Increase in residue moistness enhances emissions of carbon monoxide, methane, and particulate organic carbon. Atmos. Environ. 2014;95:36–44. doi: 10.1016/j.atmosenv.2014.06.023. [DOI] [Google Scholar]

- 9.Hill W, et al. Lung adenocarcinoma promotion by air pollutants. Nature. 2023;616:159–167. doi: 10.1038/s41586-023-05874-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.IQAir. New data exposes Thailand’s 2021 “burning season”, <www.iqair.com> (2021).

- 11.World Health Organization. WHO global air quality guidelines: particulate matter (PM2.5 and PM10), ozone, nitrogen dioxide, sulfur dioxide and carbon monoxide. xxi, 273 p. (World Health Organization, 2021). [PubMed]

- 12.Pollution Control Department. Northern Thailand pollution situation 2021. (Ministry of Natural Resource and Environment, Bangkok, Thailand, 2022).

- 13.GISTDA. Statistic of hot spot in Thailand (2017 - 2021), <www.gistda.or.th> (2022).

- 14.Hu K, Huang G, Huang P, Kosaka Y, Xie S-P. Intensification of El Niño-induced atmospheric anomalies under greenhouse warming. Nat. Geosci. 2021;14:377–382. doi: 10.1038/s41561-021-00730-3. [DOI] [Google Scholar]

- 15.Ying J, et al. Emergence of climate change in the tropical Pacific. Nat. Clim. Chang. 2022;12:356–364. doi: 10.1038/s41558-022-01301-z. [DOI] [Google Scholar]

- 16.Office of Agricultural Economics. Information of agricultural production, <www.oae.go.th> (2023).

- 17.Wu P, et al. Bibliometric analysis of biochar research in 2021: A critical review for development, hotspots and trend directions. Biochar. 2023;5:6. doi: 10.1007/s42773-023-00204-2. [DOI] [Google Scholar]

- 18.EPA. What is a Circular Economy?, <www.epa.gov> (2023).

- 19.Campion L, Bekchanova M, Malina R, Kuppens T. The costs and benefits of biochar production and use: A systematic review. J. Clean. Prod. 2023;408:137138. doi: 10.1016/j.jclepro.2023.137138. [DOI] [Google Scholar]

- 20.UN-REDD program. REDD and REDD+ (2023).

- 21.World Bank . Household Cookstoves, Environment, Health, and Climate Change A NEW LOOK AT AN OLD PROBLEM. DC; 2011. [Google Scholar]

- 22.IPCC. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories. (United Nations, Kyoto, Japan, 2019).

- 23.Andreae MO, Merlet P. Emission of trace gases and aerosols from biomass burning. Glob. Biogeochem. Cycles. 2001;15:955–966. doi: 10.1029/2000GB001382. [DOI] [Google Scholar]

- 24.Yokelson RJ, et al. Trace gas and particle emissions from open biomass burning in Mexico. Atmos. Chem. Phys. 2011;11:6787–6808. doi: 10.5194/acp-11-6787-2011. [DOI] [Google Scholar]

- 25.Yokelson RJ, et al. Emissions from biomass burning in the Yucatan. Atmos. Chem. Phys. 2009;9:5785–5812. doi: 10.5194/acp-9-5785-2009. [DOI] [Google Scholar]

- 26.Cao G, Zhang X, Gong S, Zheng F. Investigation on emission factors of particulate matter and gaseous pollutants from crop residue burning. JEnvS. 2008;20:50–55. doi: 10.1016/S1001-0742(08)60007-8. [DOI] [PubMed] [Google Scholar]

- 27.Cao G, Zhang X, Wang Y, Zheng F. Estimation of emissions from field burning of crop straw in China. Chin. Sci. Bull. 2008;53:784–790. doi: 10.1007/s11434-008-0145-4. [DOI] [Google Scholar]

- 28.He M, Wang XR, Han L, Feng XQ, Mao X. Emission inventory of crop residues field burning and its temporal and spatial distribution in Sichuan Province. Huan Jing Ke Xue. 2015;36:1208–1216. [PubMed] [Google Scholar]

- 29.Li X, Wang S, Duan L, Hao J. Characterization of non-methane hydrocarbons emitted from open burning of wheat straw and corn Stover in China. Environ. Res. Lett. 2009;4:044015. doi: 10.1088/1748-9326/4/4/044015. [DOI] [Google Scholar]

- 30.Li X, et al. Particulate and trace gas emissions from open burning of wheat straw and corn Stover in China. Environ. Sci. Technol. 2007;41:6052–6058. doi: 10.1021/es0705137. [DOI] [PubMed] [Google Scholar]

- 31.Liu LH, Jiang JY, Zong LG. Emission inventory of greenhouse gases from agricultural residues combustion: A case study of Jiangsu Province. Huan Jing Ke Xue. 2011;32:1242–1248. [PubMed] [Google Scholar]

- 32.Qiu X, et al. Deriving high-resolution emission inventory of open biomass burning in China based on satellite observations. Environ. Sci. Technol. 2016;50:11779–11786. doi: 10.1021/acs.est.6b02705. [DOI] [PubMed] [Google Scholar]

- 33.Streets DG, et al. Black carbon emissions in China. Atmos. Environ. 2001;35:4281–4296. doi: 10.1016/S1352-2310(01)00179-0. [DOI] [Google Scholar]

- 34.Zhang H, et al. A laboratory study of agricultural crop residue combustion in China: Emission factors and emission inventory. Atmos. Environ. 2008;42:8432–8441. doi: 10.1016/j.atmosenv.2008.08.015. [DOI] [Google Scholar]

- 35.Hafidawati, Puji, L. & Asep, S. Emission Factors of Black Carbon (BC) from Rice Straw Open Burning Specific to District Cianjur, West Java, Indonesia. GEOMATE Journal13, 126-130 (2017)

- 36.Irfan M, et al. Estimation and characterization of gaseous pollutant emissions from agricultural crop residue combustion in industrial and household sectors of Pakistan. Atmos. Environ. 2014;84:189–197. doi: 10.1016/j.atmosenv.2013.11.046. [DOI] [Google Scholar]

- 37.Andreae MO, et al. Airborne studies of aerosol emissions from savanna fires in southern Africa: 2. Aerosol chemical composition. J. Geophys. Res. Atmos. 1998;103:32119–32128. doi: 10.1029/98JD02280. [DOI] [Google Scholar]

- 38.França DDA, et al. Pre-harvest sugarcane burning: Determination of emission factors through laboratory measurements. Atmos. 2012;3:164–180. doi: 10.3390/atmos3010164. [DOI] [Google Scholar]

- 39.Hall D, et al. PAHs, carbonyls, VOCs and PM2.5 emission factors for pre-harvest burning of Florida sugarcane. Atmos. Environ. 2012;55:164–172. doi: 10.1016/j.atmosenv.2012.03.034. [DOI] [Google Scholar]

- 40.Kanokkanjana K, Garivait S. Estimation of emission from open burning of sugarcane residues before harvesting. GMSARN Int. J. 2012;6:157–162. [Google Scholar]

- 41.Mugica-Álvarez V, et al. Sugarcane burning emissions: Characterization and emission factors. Atmos. Environ. 2018;193:262–272. doi: 10.1016/j.atmosenv.2018.09.013. [DOI] [Google Scholar]

- 42.Kim Oanh NT, et al. Characterization of particulate matter emission from open burning of rice straw. Atmos. Environ. 2011;45:493–502. doi: 10.1016/j.atmosenv.2010.09.023. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 43.Yu T-Y, Lin C-Y, Chang L-FW. Estimating air pollutant emission factors from open burning of rice straw by the residual mass method. Atmos. Environ. 2012;54:428–438. doi: 10.1016/j.atmosenv.2012.02.038. [DOI] [Google Scholar]

- 44.Christian TJ, et al. Comprehensive laboratory measurements of biomass-burning emissions: 1. Emissions from Indonesian, African, and other fuels. J. Geophys. Res. Atmos. 2003 doi: 10.1029/2003JD003704. [DOI] [Google Scholar]

- 45.Kanokkanjana, K., Cheewaphongphan, P. & Garivait, S. in International Proceedings of Chemical Biological and Environmental Engineering. pp. 88–92.

- 46.Wang D, Jiang P, Zhang H, Yuan W. Biochar production and applications in agro and forestry systems: A review. Sci. Total Environ. 2020;723:137775. doi: 10.1016/j.scitotenv.2020.137775. [DOI] [PubMed] [Google Scholar]

- 47.Veses A, et al. Production of upgraded bio-oils by biomass catalytic pyrolysis in an auger reactor using low cost materials. Fuel. 2015;141:17–22. doi: 10.1016/j.fuel.2014.10.044. [DOI] [Google Scholar]

- 48.Tomczyk A, Sokołowska Z, Boguta P. Biochar physicochemical properties: Pyrolysis temperature and feedstock kind effects. Rev. Environ. Sci. Biotechnol. 2020;19:191–215. doi: 10.1007/s11157-020-09523-3. [DOI] [Google Scholar]

- 49.ISO. ISO 14044:2006 Environmental management - Life cycle assessment - Requirements and guidelines. (International Organization for Standardization, Switzerland, 2006).

- 50.Office of the Cane and Sugar Board. Sugarcane production. (Bangkok, Thailand, 2023).

- 51.Silalertruksa T, Gheewala SH. A comparative LCA of rice straw utilization for fuels and fertilizer in Thailand. Bioresour. Technol. 2013;150:412–419. doi: 10.1016/j.biortech.2013.09.015. [DOI] [PubMed] [Google Scholar]

- 52.Silalertruksa T, Gheewala SH, Sagisaka M. Impacts of Thai bio-ethanol policy target on land use and greenhouse gas emissions. ApEn. 2009;86:S170–S177. doi: 10.1016/j.apenergy.2009.05.010. [DOI] [Google Scholar]

- 53.Supasri T, Itsubo N, Gheewala SH, Sampattagul S. Life cycle assessment of maize cultivation and biomass utilization in northern Thailand. Sci. Rep. 2020;10:3516. doi: 10.1038/s41598-020-60532-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 54.Thailand Environment Foundation . Life Cycle Assessment of Ethanol from Cassava and Sugar Cane. Nonthaburi; 2007. [Google Scholar]

- 55.Towprayoon S, Smakgahn K, Poonkaew S. Mitigation of methane and nitrous oxide emissions from drained irrigated rice fields. Chemosphere. 2005;59:1547–1556. doi: 10.1016/j.chemosphere.2005.02.009. [DOI] [PubMed] [Google Scholar]

- 56.Zhang Y, et al. Fertilizer properties of ash from corn-Stover pellets using the sequential extraction and matrix expression. Waste Manag. 2018;82:111–117. doi: 10.1016/j.wasman.2018.10.021. [DOI] [PubMed] [Google Scholar]

- 57.Chaneeparp, N. An analysis of substitution between human labor and farm machineries : a case study of rice production in Amphoe Phimai,Changwat Nakhon Ratchasima,crop year 1999/2000 Master degree thesis, Kasetsart University, (2001).

- 58.Phettharawadee, S. The Evaluation of Energy and Carbon Balance for Maize Production Master degree thesis, Maejo University, (2019).

- 59.Sahoo K, et al. Life-cycle assessment and techno-economic analysis of biochar produced from forest residues using portable systems. Int. J. Life Cycle Ass. 2021;26:189–213. doi: 10.1007/s11367-020-01830-9. [DOI] [Google Scholar]

- 60.Kumar M, Upadhyay SN, Mishra PK. Pyrolysis of sugarcane (Saccharum officinarum L.) leaves and characterization of products. ACS Omega. 2022;7:28052–28064. doi: 10.1021/acsomega.2c02076. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 61.Yaashikaa PR, Kumar PS, Varjani S, Saravanan A. A critical review on the biochar production techniques, characterization, stacbility and applications for circular bioeconomy. Biotechnol. Rep. 2020;28:e00570. doi: 10.1016/j.btre.2020.e00570. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 62.Wang L, et al. Comparison of properties of biochar produced from different types of lignocellulosic biomass by slow pyrolysis at 600 °C. Appl. Energy Combustion Sci. 2022;12:100090. doi: 10.1016/j.jaecs.2022.100090. [DOI] [Google Scholar]

- 63.IPCC. Climate Change 2007: Working Group III: Mitigation of Climate Change. (Geneva, Switzerland, 2007).

- 64.Lutsey, N. The ever-improving efficiency of the diesel engine, <https://theicct.org/> (2021).

- 65.Energy Policy and Planning office. Energy Statistics of Thailand 2022. (Ministry of Energy, Bangkok, Thailand, 2023).

- 66.Thailand Greenhouse Gas Management Organization. Carbon Credit Price, <http://carbonmarket.tgo.or.th> (2023).

- 67.Ministry of Labour. Minimum wagw rate in 2022, <www.mol.go.th> (2023).

- 68.World Bank. World Databank, <data.worldbank.org> (2022).

- 69.Reyna-Bensusan N, et al. Experimental measurements of black carbon emission factors to estimate the global impact of uncontrolled burning of waste. Atmos. Environ. 2019;213:629–639. doi: 10.1016/j.atmosenv.2019.06.047. [DOI] [Google Scholar]

- 70.Roberts KG, Gloy BA, Joseph S, Scott NR, Lehmann J. Life cycle assessment of biochar systems: Estimating the energetic, economic, and climate change potential. Environ. Sci. Technol. 2010;44:827–833. doi: 10.1021/es902266r. [DOI] [PubMed] [Google Scholar]

- 71.Jennifer, L. Verra To Release Methodology For Biochar Carbon Credit Projects, <carboncredits.com> (2022).

- 72.European Commission. EU Emissions Trading System (EU ETS), <https://climate.ec.europa.eu/eu-action/eu-emissions-trading-system-eu-ets_en> (2023).

- 73.Jeffery S, et al. Biochar boosts tropical but not temperate crop yields. Environ. Res. Lett. 2017;12:053001. doi: 10.1088/1748-9326/aa67bd. [DOI] [Google Scholar]

- 74.Wang Y, Villamil MB, Davidson PC, Akdeniz N. A quantitative understanding of the role of co-composted biochar in plant growth using meta-analysis. Sci. Total Environ. 2019;685:741–752. doi: 10.1016/j.scitotenv.2019.06.244. [DOI] [PubMed] [Google Scholar]

- 75.Tisserant A, Cherubini F. Potentials, limitations, co-benefits, and trade-offs of biochar applications to soils for climate change mitigation. Land. 2019;8:179. doi: 10.3390/land8120179. [DOI] [Google Scholar]

- 76.Joseph S, et al. How biochar works, and when it doesn't: A review of mechanisms controlling soil and plant responses to biochar. GCB Bioenerg. 2021;13:1731–1764. doi: 10.1111/gcbb.12885. [DOI] [Google Scholar]

- 77.Climate Change Coordination and Management Division. Thailand Biennial update report (BUR4). (Office of Natural Resources and Environmental Policy and Planning, Ministry of Natural Resources and Environment, Bangkok, Thailand, 2022).

- 78.Thailand. Mid-century, Long-term Low Greenhouse Gas Emission Development Strategy - Thailand. (Bangkok, Thailand, 2021).

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The datasets generated and/or analyzed during the current study are available in this article.