Abstract

Background

Cigarette-ignited fires are a leading cause of fire death and injury throughout the world and remain a global public health and safety problem. To reduce this harm, a small number of countries now require cigarettes to have reduced ignition propensity (RIP). It is not known if cigarette manufacturers are voluntarily introducing RIP cigarettes in other countries to help save lives.

Methods

Using the ASTM E2187–04 test method, per cent full length burn (%FLB) was measured for three popular brands from each of seven countries that did not have RIP legislation at the time of purchase. Results were compared with %FLB measurements from four popular US brands purchased in a jurisdiction (Vermont) with an RIP law. SRM 1082 reference cigarette was also tested to assure laboratory quality control.

Results

All cigarette brands purchased in countries not requiring fire safety standards for cigarettes exceeded 75% FLB. In contrast, none of the cigarette brands from the USA exceeded 10% FLB. The SRM 1082 reference cigarette demonstrated 5% FLB.

Conclusion

Cigarette ignition propensity can be greatly reduced through legislation that requires cigarette fire safety standards. RIP cigarettes have the potential to significantly decrease the number of fire deaths, injuries and destruction of property caused by cigarette-ignited fires. Appropriate standards should be applied in cigarette markets globally.

INTRODUCTION

Cigarette-ignited fires are a leading cause of fire death and injury throughout much of the world and remain a global public health and safety problem.1 In 2007, an estimated 140700 smoking material-caused fires resulted in an estimated 720 deaths, 1580 injuries, and loss of $530 million in direct property damages in the USA alone.2 Worldwide, it has been estimated that 10% of all fire fatalities are attributable to smoking.1

During cigarette combustion the tobacco and paper wrapper are oxidised and thermally degraded at the burning ember. Smouldering is sustained through the supply of oxygen via diffusion through the paper wrapper and convection through spaces within the tobacco rod. A smouldering cigarette can ignite a substrate (ie, bedding and other soft furnishings) in contact if enough heat is transferred to raise the substrate’s temperature to its ignition threshold.3 In the 1980s, the US Congress became interested in studying cigarette ignition propensity. Passage of the US Cigarette Safety Act of 1984 created a scientific advisory group that was asked to investigate whether it was possible to design a cigarette with a reduced ignition propensity. Three years later, the advisory group concluded that it was ‘technically feasible and may be commercially feasible to develop cigarettes that will have a significantly reduced propensity to ignite upholstered furniture or mattresses’.4

In 2000, the state of New York passed legislation requiring all manufactured cigarettes sold in the state to meet minimal fire safety standards. The New York standard (NYS), which went into effect in 2004, called for cigarette ignition strength to be reduced as determined by a test method issued by the American Society of Testing and Materials (ASTM).5 The test method requires a lit cigarette to be placed on 10 layers of filter paper in a draft-free chamber.6 The filter paper itself is unable to ignite but it draws heat from the smouldering cigarette, and the persistence of the cigarette smouldering reflects the amount of heat generated by the cigarette to potentially ignite materials such as those used in upholstered furniture.7 The NYS requires that no more than 25% of 40 individual cigarettes burn full length for each brand tested.5 Cigarettes meeting this standard are less likely than conventional cigarettes to ignite household furnishings or textile substrates, which are involved in cigarette-related residential fires and are involved in most fire fatalities.2 8 These cigarettes therefore have a reduced ignition propensity (RIP).

All 50 US states have now adopted the New York RIP standard and the standard will be implemented in all states by July 1, 2011.9 In 2005, Canada became the first country to require RIP cigarettes nationwide.10 Australia and Finland have also recently implemented national RIP cigarette requirements.11 12 Early unpublished accounts in the USA suggest that the introduction of RIP cigarettes has led to a reduction in cigarette fire incidence.13 14 However, a comprehensive evaluation on how the introduction of RIP cigarettes has impacted fire incidence and death has yet to be undertaken.

As the momentum for legislation requiring cigarette manufactures to produce RIP cigarettes begins to grow internationally, it remains unclear whether tobacco companies will voluntarily adopt RIP cigarette technology. Cigarette manufacturers may be motivated to produce RIP cigarettes in the absence of legislation to reduce the cost of manufacturing both RIP and non-RIP brands, reduce the risk of legal liability, or to directly enhance fire safety. Indeed, in October 2007, when only 22 of 50 US states required the sale of RIP cigarettes, RJ Reynolds announced it would stop selling non-RIP cigarettes in the USA by the end of 2009.9 15 Moreover, Philip Morris voluntarily introduced RIP cigarette design in its Merit brand in 2000.16

Data are needed to ascertain whether cigarettes in global markets conform to accepted RIP standards. Identifying countries where manufacturers have not voluntarily adopted effective RIP standards will provide an empirical basis for tobacco control research and advocacy efforts. Per cent full length burn (%FLB) was assessed for three popular brands from each of seven countries without RIP legislation at the time of purchase. Results were compared with four popular US brands purchased in a jurisdiction with an RIP law. Mean cigarette burn length was also measured to assess its potential as an additional index of ignition propensity.

METHODS

Cigarettes tested

Three cigarette brands were purchased from each of seven countries participating in the International Tobacco Control Policy Evaluation Project (ITC). Countries included did not require the sale of RIP cigarettes at the time of purchase: Australia, China, Greece, Malaysia, Mexico, Thailand and the United Kingdom. Leading cigarette brands for these countries, based on market share and survey report data compiled by ITC, were chosen. Four US brands were purchased in April 2007 in Vermont, where legislation required the sale of RIP cigarettes starting May 1, 2006.17

The passage of legislation in both the USA and Canada mandating the sale of RIP cigarettes created the need for a standard reference cigarette to be used in assessing regulatory compliance and for laboratory testing quality control. SRM 1082 reference cigarette are designed to not exceed 25% FLB using the ASTM E2187–04 method.18 Ignition strength of the SRM 1082 reference cigarette was measured to assure laboratory quality control.

Test method

The procedures performed adhered to the testing standards identified in ASTM E2187–04 ‘Standard Test Method for Measuring the Ignition Strength of Cigarettes’.6 Prior to testing, both the cigarettes and the filter papers were conditioned at 23±3°C and 55±5% relative humidity in an Associated Environmental Systems Model LH-1.5 Conditioning Chamber (Ayer, Massachusetts, USA). Laboratory temperature and humidity were also maintained at these same conditions.

Ignition strength testing was performed on 40 individual cigarettes of each brand, with each lit cigarette individually placed on ten layers of Whatman Grade No. 2 filter paper in a custom-made draft-free chamber. Sidestream smoke exited the chamber through a flattop cylindrical chimney and a Smokeeter (Fenton, Missouri, USA) exhaust system, linked to a canopy hood and placed approximately eight inches above the chimney opening, was used to remove combustion products from the test room. Laboratory technicians wore personal respirators (3M Half Facepiece, 7500 Series) to protect against exposure to sidestream smoke. For each individual cigarette tested, a recording was made indicating whether or not the tobacco column burned through its full length (as far as or past the front plane of the tipping paper). The percentage of full-length burns (%FLB) was then determined for each cigarette brand based on the results of the 40 tests.

Physical characteristics, some of which have been identified as contributing factors towards ignition propensity (paper porosity and circumference),19 were also measured. Paper porosity was measured using a Cerulean PPM1000M apparatus (Richmond, VA, USA) using CORESTA Recommended Method N° 40.20 A digital caliper was used to measure cigarette diameter and length (both pre-burn length and remaining unburnt cigarette length, or post-burn length). Circumference was calculated by multiplying diameter by pi. Burn length was calculated by subtracting post-burn length from pre-burn length. Visual inspection under a light box was used to determine the presence of paper banding along the tobacco column. Tobacco mass was measured by weighing raw tobacco on a digital balance.

RESULTS

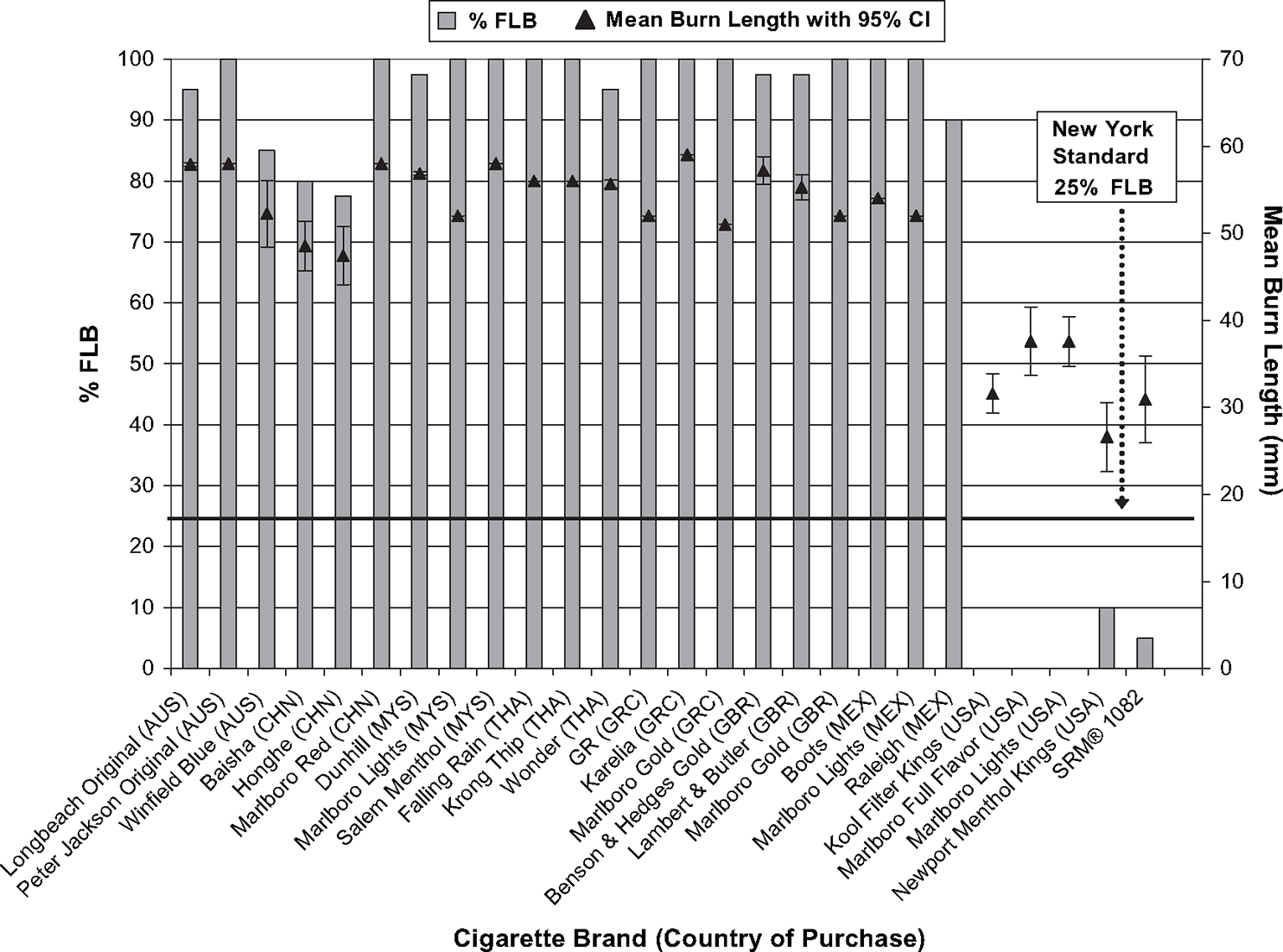

Physical characteristics of the 25 international cigarette brands and the SRM 1082 reference cigarette are presented in table 1. Per cent full length burn (of 40 sticks tested per brand) and mean burn length are shown in figure 1. None of the cigarette brands purchased in countries not requiring cigarette fire safety standards achieved %FLB of 25% or less. Indeed, all of these brands demonstrated 75% or greater full-length burns. By contrast, none of the cigarette brands from the USA or the SRM 1082 reference cigarette exceeded 10% FLB. Among the brands purchased in the USA, Kool, Marlboro Full Flavor, Marlboro Lights, and Newport demonstrated 0%, 0%, 0%, and 10% FLB, respectively. Moreover, the mean burn lengths for the brands purchased in the USA and outside the USA were 34 and 54 mm, respectively (two-sample Wilcoxon rank sum test z=3.14; p=0.002). The mean burn length for SRM 1082 reference cigarette was 31 mm. Mean burn length and %FLB for the 25 commercial cigarette brands were found to be positively associated (Spearman’s ρ: 0.630; p<0.001).

Table 1.

Physical characteristics of cigarette brands tested

| Cigarette brand | Country | Status* | Paper banding | Tob col length (mm)† | Circum (mm) | Tob mass (mg) | Vac porosity (CORESTA) |

|---|---|---|---|---|---|---|---|

|

| |||||||

| Oceania | |||||||

| Longbeach Original | Australia | Non-RIP | No | 58 | 24 | 0.65 | 27 |

| Peter Jackson Original | Australia | Non-RIP | No | 58 | 24 | 0.68 | 29 |

| Winfield Blue | Australia | Non-RIP | No | 57 | 24 | 0.60 | 53 |

| Asia | |||||||

| Baisha | China | Non-RIP | No | 52 | 25 | 0.69 | 50 |

| Honghe | China | Non-RIP | No | 52 | 23 | 0.63 | 56 |

| Marlboro Red | China | Non-RIP | No | 58 | 25 | 0.72 | 44 |

| Dunhill | Malaysia | Non-RIP | No | 57 | 25 | 0.59 | 43 |

| Marlboro Lights | Malaysia | Non-RIP | No | 52 | 24 | 0.63 | 25 |

| Salem Menthol | Malaysia | Non-RIP | No | 58 | 25 | 0.68 | 39 |

| Falling Rain | Thailand | Non-RIP | No | 56 | 25 | 0.71 | 31 |

| Krong Thip | Thailand | Non-RIP | No | 56 | 25 | 0.71 | 30 |

| Wonder | Thailand | Non-RIP | No | 56 | 25 | 0.74 | 32 |

| Europe | |||||||

| GR | Greece | Non-RIP | No | 52 | 25 | 0.68 | 43 |

| Karelia | Greece | Non-RIP | No | 59 | 24 | 0.82 | 81 |

| Marlboro Gold | Greece | Non-RIP | No | 51 | 24 | 0.65 | 40 |

| Benson & Hedges Gold | United Kingdom | Non-RIP | No | 58 | 25 | 0.69 | 69 |

| Lambert & Butler | United Kingdom | Non-RIP | No | 56 | 22 | 0.64 | 42 |

| Marlboro Gold | United Kingdom | Non-RIP | No | 52 | 25 | 0.60 | 32 |

| North America | |||||||

| Boots | Mexico | Non-RIP | No | 54 | 25 | 0.66 | 26 |

| Marlboro Lights | Mexico | Non-RIP | No | 52 | 25 | 0.60 | 46 |

| Raleigh | Mexico | Non-RIP | No | 50 | 25 | 0.62 | 24 |

| Kool Filter Kings | United States | RIP | No | 57 | 25 | 0.71 | 38 |

| Marlboro Full Flavor | United States | RIP | Yes | 65 | 24 | 0.81 | 56 |

| Marlboro Lights | United States | RIP | Yes | 62 | 25 | 0.76 | 54 |

| Newport | United States | RIP | Yes | 53 | 24 | 0.69 | 17 |

| Reference | |||||||

| SRM® 1082 (99 mm) | United States | RIP | No | 72 | 24 | 0.57 | 53 |

Time of cigarette procurement.

Length from tobacco end to tipping paper.

Figure 1.

Ignition strength testing results and mean burn length.

DISCUSSION

These data demonstrate that cigarette ignition propensity can be significantly reduced when manufactured in accordance with established fire safety standards. The RIP-compliant cigarette brands purchased in the USA had fewer full-length burns and a shorter mean burn length compared with cigarette brands purchased in countries not requiring RIP cigarettes. Moreover, all of the brands purchased outside the USA failed to comply with the NYS. The data reveal that cigarettes sold in the countries tested continue to have increased ignition propensity. This emphasises the need for legislation to prohibit the sale of non-RIP cigarettes.

The NYS is a performance-based standard and does not call for any specific cigarette design features. While the NYS requires that no more than 25% of 40 cigarettes tested burn full length under the ASTM test method, manufacturers are permitted to use any technology or product design to achieve this criterion.21 Research conducted at the US National Institute of Standards and Technology has identified four cigarette design features that can be modified to reduce a cigarette’s ignition propensity: decrease tobacco density, decrease paper porosity, decrease cigarette circumference or decrease or remove the burn additive citrate.19

It is believed that paper banding is used in most commercially available RIP cigarettes to reduce ignition propensity. In this method two or three thin low-porosity paper bands are applied to the tobacco column wrapper, reducing the flow of oxygen at the site of the band. In the absence of an adequate supply of oxygen, a smouldering cigarette will extinguish at the band.22 23 However, as demonstrated by the SRM 1082 reference cigarette and Kool Filter Kings, paper banding is not required for reducing ignition propensity. In addition, proprietary technology is not needed. For instance, the SRM 1082 reference cigarette uses expanded tobacco and reduced porosity paper to reduce ignition propensity.18 It remains undetermined what other methods are currently being used by cigarette manufacturers to produce cigarettes that are compliant with the NYS. To date, over 300 patents exist for reducing the ignition propensity of cigarettes.3

While the NYS allows no more than 25% FLB (out of 40 cigarettes), using the ASTM testing procedure, no specifications are given with regard to where the extinguishment must take place. Thus, the outcome of the ASTM testing procedure is either full-length burn or extinguishment of the cigarette at any point short of a full-length burn. This is the first known study to report burn length among brands of RIP and non-RIP cigarettes tested under the ASTM testing procedure. Not surprisingly, burn length was highly correlated with %FLB and the mean burn lengths of RIP and non-RIP brands differed significantly. Further research is needed to determine if burn length is a meaningful proxy measure of ignition propensity and whether a threshold burn length exists for ignition of flammable substrates.

Research conducted after the implementation of New York’s world-first requirement of RIP cigarettes found no significant changes in cigarette sales, prices or brand availability.24 Moreover, no significant consumer dissatisfaction with RIP cigarettes was reported in a survey of New York smokers.25 Such data suggest that RIP cigarettes are acceptable among smokers and they can readily be manufactured, offering further support for the passage of legislation mandating RIP cigarettes. Indeed, RIP cigarettes will be sold throughout the European Union by 2011 and South Africa has passed legislation requiring the sale of RIP cigarettes at a future date.26 27 In addition, a WHO Study Group has recommended that RIP cigarettes be mandatory in all WHO member countries.28

Further research at the population level is needed in order to ascertain the effect that these science-based regulations will have on the number of cigarette fires. While reductions in smoking prevalence may be the most effective means of decreasing the incidence of cigarette-caused fires,29 fire deaths and injuries could also be prevented by requiring cigarettes to comply with fire safety standards. While such confirmatory evidence is needed, the present data demonstrate that the ignition propensity of cigarettes can successfully be regulated for fire safety and suggest that appropriate standards should be applied in cigarette markets globally.

Acknowledgements

The authors would like to thank Thomas Romano for his help with testing the cigarettes and the Vermont Division of Fire Safety Central Office for assistance in obtaining cigarettes.

Funding

This work was funded by the Roswell Park Cancer Institute Transdisciplinary Tobacco Use Research Center (P50 CA111236) and a grant from the US National Cancer Institute (R01 CA117108).

Footnotes

Competing interests None.

Provenance and peer review Not commissioned; externally peer reviewed.

REFERENCES

- 1.Leistikow BN, Martin DC, Milano CE. Fire injuries, disasters, and costs from cigarettes and cigarette lights: a global overview. Prev Med 2000;31:91–9. [DOI] [PubMed] [Google Scholar]

- 2.Hall JR U.S. Smoking-Material Fire Problem. Quincy, MA: National Fire Protection Association, 2010. [Google Scholar]

- 3.Alpert HR, Spalletta R, Connolly GN, et al. Recent advances in cigarette ignition propensity research and development. Fire Technol 2010;46:275–89. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Alpert HR. Regulating cigarettes for fire safety. Tobacco Control Legal Consortium, 2007. [Google Scholar]

- 5.New York State Office of Fire Prevention and Control. Fire safety standards for cigarettes. http://www.dos.state.ny.us/fire/amendedcigaretterule.htm (accessed 18 Feb 2010).

- 6.ASTM International. Standard Test Method for Measuring the Ignition Strength of Cigarettes, E2187–02. West Conshohocken, Pennsylvania: ASTM International, 2002. [Google Scholar]

- 7.Gann RG, Guthrie WF. Robustness of Measuring the Ignition Strength of Cigarettes with ASTM Method E2187–02b. Gaithersburg, MD: Building and Fire Research Laboratory, National Institute of Standards and Technology, 2003. [Google Scholar]

- 8.Ohlemiller TJ, Villa KM, Braun E, et al. Test Methods for Quantifying the Propensity of Cigarettes to Ignite Soft Furnishings. Washington, DC: National Institute of Standards and Technology, US Department of Commerce, 1993; NIST Special Publication 851. [Google Scholar]

- 9.National Fire Protection Association. State by state efforts. http://www.firesafecigarettes.org/itemDetail.asp?categoryID=93&itemID=1295&URL= (accessed 7 Jul 2010).

- 10.Cigarette ignition propensity regulations. http://laws-lois.justice.gc.ca/PDF/Regulation/S/SOR-2005-178.pdf (accessed 21 Jul, 2010).

- 11.Australia. Trade practices (Consumer Product Safety Standard) (Reduced Fire Risk Cigarettes) regulations. 2008. http://www.comlaw.gov.au/ComLaw/Legislation/LegislativeInstrument1.nsf/0/3FE64581813B093ECA2574C900006E8A/$file/0817073A080829Z.pdf (accessed 7 Jul 2010).

- 12.Fire Safety of Cigarettes Improved in Finland. http://www.government.fi/ajankohtaista/tiedotteet/tiedote/en.jsp?oid=290909 (7 accessed Jul 2010).

- 13.National Fire Protection Association. The New York experience. http://firesafecigarettes.org/itemDetail.asp?categoryID=107&itemID=1512&URL=In%20the%20news/The%20New%20York%20Experience (accessed 18 Feb 2010).

- 14.Ellement JR. Fire deaths in Mass. At lowest level since ‘40s. Boston Globe, 2010. http://www.boston.com/news/local/massachusetts/articles/2010/01/27/fire_deaths_fall_to_lowest_level_in_massachusetts_since_wwii/ (accessed 18 Feb 2010). [Google Scholar]

- 15.Letter from RJ Reynolds to NFPA. http://www.nfpa.org/assets/files//FSC/ReynoldsLetter.pdf (accessed 7 Jul 2010).

- 16.Gunja M, Wayne GF, Landman A, et al. The case for fire safe cigarettes made through industry documents. Tob Control 2002;11:346–53. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.General Assembly of the State of Vermont. An act relating to reducing fires resulting from careless use of cigarettes and other tobacco-related issues. Sec. 1. 20 V.S.A. chapter 173, subchapter 2A. http://www.leg.state.vt.us/docs/legdoc.cfm?URL=/docs/2006/acts/ACT068.HTM (accessed 22 Jul 2010).

- 18.Gann RG. Measuring the Ignition Propensity of Cigarettes. In: Proceedings of the Interflam Fire Science and Engineering Conference; 2007: London, England, 145–55. [Google Scholar]

- 19.Technical Study Group on Cigarette and Little Cigar Fire Safety. Towards a Less Fire-Prone Cigarette. Final Report to the Congress, Technical Study Group on Cigarette and Little Cigar Fire Safety, Cigarette Safety Act of 1984, 1987.

- 20.CORESTA Recommended Method N° 40 (1994). http://www.coresta.org/Recommended_Methods/CRM_40.pdf (accessed 8 October 2010).

- 21.Chapman S, Balmain A. Reduced-ignition propensity cigarettes: a review of policy relevant information. Prepared for the Commonwealth Department of Health and Ageing. 2004. [Google Scholar]

- 22.Fire Standard Compliant Cigarettes. http://www.pmusa.com/en/cms/Products/Cigarettes/Fire_Standards_Compliant_Cigarettes/default.aspx (accessed 7 Jul 2010).

- 23.What is a fire-safe cigarette? http://firesafecigarettes.org/itemDetail.asp?categoryID=48&itemID=1190&URL=About%20fire-safe%20cigarettes/What%20is%20a%20fire-safe%20cigarette? (accessed 7 Jul 2010).

- 24.Connolly GN, Alpert HR, Rees V, et al. Effect of the New York State cigarette fire safety standard on ignition propensity, smoke constituents, and the consumer market. Tob Control 2005;14:321–7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.O’Connor RJ, Giovino GA, Fix BV, et al. Smokers’ reactions to reduced ignition propensity cigarettes. Tob Control 2006;15:45–9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.EU says ‘fire safe’ cigarettes to go on sale in Europe by 2011. http://www.medindia.net/news/EU-Says-Fire-Safe-Cigarettes-to-Go-on-Sale-in-Europe-by-2011-40218-1.htm (accessed 22 Jul 2010).

- 27.Tobacco Products Control Amendment Act, 2007. Act No. 23 of 2007. Government Gazette No 30821.

- 28.Second Report of a WHO Study Group. The Scientific Basis of Tobacco Product Regulation. WHO Technical Report Series 951, 2008. [PubMed]

- 29.Diekman ST, Ballesteros MF, Berger LR, et al. Ecological level analysis of the relationship between smoking and residential-fire mortality. Inj Prev 2008;14:228–31. [DOI] [PubMed] [Google Scholar]