Abstract

Dietary net energy for maintenance (NEm) and gain (NEg) can be estimated using calculations based on live performance or adjusted-final body weight, which is calculated based on carcass characteristics. These values are commonly referred to as performance-adjusted (pa) NEm (paNEm) and NEg (paNEg). The NEm and NEg of a diet can also be estimated by adding recovered energy (RE) with heat production (HP) derived from an automated head chamber system (AHCS), which we will term gas-adjusted (ga) NEm (gaNEm) and NEg (gaNEg). Furthermore, HP from the Brouwer equation requires an estimate of urinary nitrogen (UN) excretion, which can be calculated based on N intake, blood urea N, UN concentration, and urine creatinine, or it could be zeroed. Alternatively, HP can be calculated using an alternative equation based on the respiratory quotient. Demonstrating agreement between pa and ga derived dietary energy values provides an opportunity to validate using the AHCS for energetic experiments and this comparison has not been conducted previously. Accordingly, the objective of this experiment was to assess the agreement between live and carcass paNEm and paNEg with gaNEm and gaNEg, where HP was calculated using 4 different approaches. Estimates of HP were not different (P = 0.99) between the 4 approaches employed, indicating that all options investigated are appropriate. Live paNEm and paNEg had a higher agreement (Lin’s concordance correlation coefficient [CCC] = 0.91) with gaNEm and gaNEg than carcass values (CCC ≤ 0.84). These results suggest that researchers can implement the AHCS to provide good estimates of dietary energy values in finishing beef cattle that are unrestrained.

Keywords: energetics, finishing beef cattle, heat production, respiratory quotient

Automated head chamber systems provide researchers with the ability to estimate gas flux, heat production, and dietary energy values in finishing beef cattle.

Introduction

Indirect respiration calorimetry has historically been utilized to evaluate gas flux and provide measurements for energy content of ingredients and diets, or energetic efficiency of beef cattle. However, whole-body respiration calorimetry systems require animal restraint in sealed chambers (Blaxter and Waiman, 1964; Blaxter and Wainman, 1966; Wedegaertner and Johnson, 1983). Efforts have been made to adapt whole-body open-circuit calorimetry principles to ventilated headboxes (Delfino and Mathison, 1991; Place et al., 2011) or facemasks (Carstens et al., 1997), and while these methods do not enclose the whole animal in sealed chambers, they still restrict movement. Measurements of gas flux from these systems, including carbon dioxide (CO2) and methane (CH4) emissions and oxygen (O2) consumption, are used to calculate heat production (HP) using the equation of Brouwer (1965), and ultimately arrive at estimates of energy utilization or dietary energy content. Yet, these sampling procedures are laborious, expensive, and reduce dry matter intake (DMI) relative to when the animals are not restrained (Hammond et al., 2015; Llonch et al., 2018). Thus, one could argue whether indirect calorimetry systems that isolate and restrain animals provide representative information about what is occurring in production environments. Accordingly, other methods to assess the energy content of ingredients and diets or the efficiency of energy utilization by cattle in their production environment should be explored.

Automated head chamber systems (AHCS; GreenFeed, C-Lock, Inc., Rapid City, SD) are growing in popularity in the research community (Gunter and Beck, 2018). These systems provide the opportunity to measure gas flux from unrestrained cattle in their production environments. The AHCS can be equipped with sensors to measure CO2, CH4, and more recently O2 (Gunter et al. 2017), and therefore estimates are available to calculate HP using the Brouwer (1965) equation. Furthermore, an equation reported by Kaufmann et al. (2011) was proposed as an alternative means to calculate HP which uses respiratory quotient (RQ) and CO2 emissions. The RQ is the ratio of respired CO2 to consumed O2, which are components of carbohydrate and fat metabolism (Blaxter, 1962; Brouwer, 1965). Kaufmann et al. (2011) stated that their equation for HP was derived by modifying the Brouwer (1965) equation and the omission of the urinary N adjustment and has been used by several researchers to estimate HP from cattle while using the AHCS (Pereira et al., 2015; Caetano et al., 2017; Holder et al., 2022). Regardless, using any method to estimate HP with the addition of recovered energy (RE) yields an estimate of metabolizable energy (ME) intake, which can further be used to approximate dietary net energy for maintenance (NEm) and gain (NEg).

Estimates of dietary NEm and NEg and subsequent utilization by beef cattle can also be evaluated through observed performance (Owens and Hicks, 2019). Because of the mathematical relationship between metabolizable and net energy, researchers have estimated dietary NEm and NEg using quadratic equations (Owens et al., 1984; Zinn and Shen, 1998; Zinn et al., 2003, 2008; Vasconcelos and Galyean, 2008). Metrics of DMI, average daily gain (ADG), body weight (BW), and required NEm and NEg are incorporated into quadratic equations to provide a solution for performance-adjusted NEm (paNEm) and NEg (paNEg). Perhaps to provide a more accurate assessment of paNEm and paNEg, Owens and Hicks (2019) suggested using an adjusted-final body weight (AFBW) based on carcass adiposity as described by Guiroy et al. (2001). One limitation associated with paNEm and paNEg is that calculating required NEm and NEg is a component of the quadratic equations and, as noted by Owens and Hicks (2019), cattle with lower or higher NEm requirement may elicit variation in residual NEm and NEg.

Gas flux collected from AHCS units deployed in feedlot pens may allow evaluation of dietary NEm and NEg in conditions that are favorable to their production environments without prolonged confinement or restriction. Calculating required NEm and NEg values is not a necessary component when using gas flux and RE to forward calculate dietary NEm and NEg. Moreover, data from AHCS potentially provides researchers with the opportunity to evaluate HP across dietary treatments. Yet, a comparison should be conducted between values generated from quadratic equations using observed animal performance (Zinn et al., 2008) and those derived from gas-adjusted NEm (gaNEm) and NEg (gaNEg) using gas flux data obtained from an AHCS. Thus, the objective of this experiment was to evaluate estimates of NEm and NEg derived from either live performance, carcass data, or gas flux values. An additional objective of this experiment was to evaluate precision, accuracy, and agreement between methods of calculating performance- and gas-estimated dietary energy values. These different methods include using live weight or AFBW to determine paNEm and paNEg and using the Kaufmann et al. (2011) equation or the Brouwer (1965) equation with or without adjustments for estimated urinary nitrogen (UN) excretion to calculate HP. The final objective of this experiment was to simulate a scenario where DMI is unknown and to demonstrate agreement between daily energy intake values determined using the AHCS with daily energy intake values derived from performance-adjusted values. It was hypothesized that gas flux data generated from AHCS would have excellent agreement with performance-adjusted dietary energy values.

Materials and Methods

This experiment was conducted at the joint USDA-ARS and Texas A&M AgriLife Research feedlot in Bushland, TX. All animal procedures outlined herein were preapproved by the West Texas A&M University Institutional Animal Care and Use Committee (protocol number—2022.01.002).

Animals and diets

Predominately Bos taurus, mix-breed steers (n = 54; BW at receiving = 484.1 ± 26.03 kg; mean ± standard deviation) were processed on day −54 with a topical dose of cyfluthrin (Cylence; Elanco Animal Health, Greenfield, IN) and an oral dose of albendazole (Valbazen; Zoetis Animal Health, NJ). Initial hip-height at receiving was 122.7 ± 2.43 cm (mean ± standard deviation). Additionally, steers received (Merck Animal Health; Rahway, NJ) Cavalry 9, Once PMH SQ, and Vista 5 SQ vaccines and were implanted with Revalor-XS. On day −54 steers were randomly assigned to one of two pens, each containing feed bunks designed to measure individual feed intake utilizing an electronic identification system (Calan gate; American Calan, Northwood, NH). Steers were trained to Calan gates for 35 d until day −20 during which time they received a starter diet formulated to contain (on a dry matter [DM] basis) 41.0% steam-flaked corn, 19.0% wheat hay, 16.0% corn stalks, 10.8% dried corn distiller’s grains, 6.0% molasses, 5.0% vitamin and mineral supplement, 1.5% corn oil, and 0.7% urea. Once trained, steers were stratified by BW and then randomly assigned to one of three finishing diets (n = 18 steers/diet) which were formulated as a component of a separate project (Table 1). Cattle were grouped into 2 pens and each treatment was equally represented in each pen (n = 9 per treatment per pen). Treatment diets were formulated to be isoenergetic but vary in crude protein (CP) content and analyzed nutritive content of the diets are presented in Table 2. Steers were transitioned from days −20 to 0 utilizing a two-ration blend system where proportions of starter and assigned finishing diets were adjusted until steers were fully transitioned to finishing diets. Steers were fed once daily at 0700 ± 0015 hours and orts were collected prior to feeding for determination of DMI. Finishing diets were fed for 80 d prior to shipment to a commercial abattoir (Tyson Fresh Meats; Amarillo, TX). During the final 28 d on feed, cattle received a daily dose (300 mg/hd) of ractopamine HCl (Optaflexx 45; Elcano Animal Health). Carcass data was collected from each steer by the West Texas A&M University Beef Carcass Research Center.

Table 1.

Ingredient composition of finishing rations fed to steers for determination of paNEg and paNEg or gaNEm and gaNEg

| Item, % DM1 | Ration 1 | Ration 2 | Ration 3 |

|---|---|---|---|

| Steam-flaked corn | 76.84 | 78.08 | 79.24 |

| Corn stalks | 10.00 | 10.00 | 10.00 |

| Supplement2 | 5.00 | 5.00 | 5.00 |

| Molasses | 5.00 | 3.64 | 2.33 |

| Corn oil | 1.46 | 1.42 | 1.38 |

| Urea | 1.15 | 1.48 | 1.82 |

| Dried distiller’s grain with solubles, corn | 0.55 | 0.26 | 0.00 |

| Potassium chloride | 0.00 | 0.12 | 0.23 |

1Ingredients are reported on a DM basis and final rations were adjusted to 75% DM with water.

2Formulated supplement composition (DM basis): 27.3611% calcium carbonate, 22.6140% ground corn, 20.6645% magnesium sulfate, 17.3068% monocalcium phosphate, 7.0210% added salt, 4.0344% potassium chloride, 0.3354% Rumensin 90 (Elanco Animal Health), 0.2495% manganese sulfate, 0.1433% vitamin E (500 IU/g), 0.1382% zinc oxide, 0.0798% copper sulfate, 0.0426% sodium selenite, 0.0056% vitamin A (1,000,000 IU/g), 0.0015% cobalt carbonate, 0.0012% ethylenediamine dihydroiodide, 0.0011% vitamin D (500,000 IU/g).

Table 2.

Analyzed and calculated chemical composition of finishing rations and automated head chamber system bait pellets fed to steers for determination of paNEg and paNEg or gaNEm and gaNEg

| Items1,2 | Ration 1 | Ration 2 | Ration 3 | Ration SEM | Alfalfa Pellet | Pellet SEM |

|---|---|---|---|---|---|---|

| DM, % as fed | 74.14 | 74.11 | 74.19 | 0.306 | 92.82 | 0.221 |

| CP, % DM | 10.77 | 11.55 | 12.51 | 0.107 | 19.50 | 0.090 |

| ADF, % DM | 8.28 | 8.82 | 8.34 | 0.149 | 31.30 | 0.214 |

| NDF, % DM | 15.70 | 15.73 | 15.79 | 0.206 | 42.70 | 0.298 |

| ADICP, % ADF | 16.26 | 15.51 | 16.25 | 0.735 | 12.20 | 0.381 |

| NDICP, % NDF | 9.11 | 8.80 | 9.22 | 0.375 | 10.25 | 0.268 |

| EE, % DM | 3.96 | 3.99 | 3.97 | 0.154 | 2.24 | 0.113 |

| Ash, % DM | 5.54 | 5.69 | 5.87 | 0.129 | 11.05 | 0.186 |

| Lignin, % DM | 1.68 | 1.25 | 1.33 | 0.130 | 5.85 | 0.162 |

| TDN, % DM3 | 87.4 | 88.2 | 88.3 | 0.524 | 59.0 | 0.310 |

| NEm, Mcal/kg DM4 | 2.21 | 2.23 | 2.23 | 0.021 | 1.28 | 0.011 |

| NEg, Mcal/kg DM4 | 1.52 | 1.53 | 1.53 | 0.018 | 0.71 | 0.007 |

1SFC = steam-flaked corn; DDGS = dried corn distillers’ grains plus solubles; DM = dry matter; CP = crude protein; ADF = acid detergent fiber; NDF = neutral detergent fiber; ADICP = acid detergent insoluble crude protein; NDICP = neutral detergent insoluble crude protein; EE = ether extract; TDN = total digestible nutrients; NEm = net energy for maintenance; NEg = net energy for gain.

2Ingredients are reported on a DM basis and rations were adjusted to 75% DM with water, respectively.

3TDN calculated utilizing Weiss et al. (1992) model.

4NEm and NEg calculated from Galyean et al. (2016) and NASEM (2016).

Sample collections and measurements

Animals were weighed prior to feeding on days 0, 1, 49, 50, 79, and 80, and the average BW from the paired weight measurements was used for determination of ADG and reported herein. On days 1, 49, and 79, blood was collected into 10-mL blood serum tubes via coccygeal venipuncture. Serum tubes were centrifuged (1,250 × g) for 30 min at 4 °C and separated serum was aliquoted into 2-mL microcentrifuge tubes and stored at −20 °C until further analysis. Serum urea nitrogen (SUN) concentrations were evaluated using a spectrophotometer (490 nm; BioTek Synergy2 Plate Reader, Agilent Technologies, Santa Clara, CA), and an assay kit (Invitrogen; ThermoFisher Scientific, Waltham, MA) designed for SUN determination (Catalog: EIABUN).

Each pen contained an AHCS for evaluation of daily gas flux. Animals were trained to the AHCS during adaptation to Calan gates and dietary treatments. The AHCS functions similarly to head respiration chambers (Place et al., 2011), but instead measures spot samples and reports daily averages (g/d) for CO2 and CH4 emissions and O2 consumption (Gunter and Beck, 2018). Animals were baited to the AHCS utilizing alfalfa pellets (Hi-Pro Feeds; Friona, TX). Units were calibrated weekly and CO2 recoveries were measured on days 1, 40, and 80 to validate unit efficacy. Average CO2 recoveries were 98.03 ± 1.64% across all recoveries. Twenty individual drops of bait pellets from each AHCS unit were collected and weighed on days 1, 40, and 80 and each drop averaged 31.6 ± 2.28 g, which was used to calculate AHCS pellet DMI. Units were set to dispense bait pellets in 24-s intervals with 8 drops during each visit, a maximum of 4 visits daily, and a minimum of 4 h between visits. Only visits >3 min in duration were utilized as a component of average daily spot sampling and all animals achieved 30 or more visits lasting 3 min or longer during the 80-d feeding period (Arthur et al., 2017; Gunter and Beck, 2018; Beck et al., 2024).

Diet chemical composition and analyses

Diet samples were collected daily and composited by week. Samples of the AHCS pellets were collected on days 1, 40, and 80. Daily orts samples and diet and pellet subsamples were dried in triplicate in a forced-air drying oven at 105 °C for 48 h for determination of DM and used to quantify DMI. Secondary subsamples were dried at 50 °C in a forced-air drying oven for 72 h and ground to pass through a 2-mm screen (Wiley Mill, Swedesboro, NJ) in preparation for nutrient analyses. An ANKOM 200 fiber analyzer (ANKOM Technology, Macedon, NY) was used to determine neutral detergent fiber (NDF) with the addition of sodium sulfide and a-amylase (Van Soest et al., 1991) and acid detergent fiber (ADF; Method: 973.18; AOAC, 1995). Diet samples, pellet samples, NDF residue, and ADF residue were analyzed for crude protein (CP) via combustion (VarioMax Cube; Elementar Americas Inc., Ronkonkoma, NY; Method: 972.43, AOAC, 1995) to provide diet and pellet content of CP, neutral detergent insoluble CP (NDICP), and acid detergent insoluble CP (ADICP). Crude fat was determined using an ANKOM XT15 analyzer (ANKOM Technology; Komarek et al., 2004) with petroleum ether. Lignin (Method: 973.18; AOAC, 1995) was evaluated on ADF residue using 72% H2SO4 at ambient temperature and constant rotation for 3 h in the ANKOM DaisyII system (ANKOM Technology). Ash (% of DM; Method: 942.05, AOAC, 1995) was quantified on feed and pellet samples using a gravity convection oven at 600 °C for 8 h. Nutrient composition was used to calculate total digestible nutrients (TDN; Weiss et al., 1992) which was then used to calculate digestible energy (Crampton et al., 1957; NASEM, 2016). Digestible energy was used to estimate ME and ultimately NEm and NEg using equations from Galyean et al. (2016).

Energy calculations

Refer to Table 3 for an overview of equations utilized to calculate gaNEm and gaNEg. HP was calculated in four ways utilizing gas flux data from the AHCS. First, RQ and CO2 emissions were used to calculate HP using the equation of Kaufmann et al. (2011; Kaufmann-HP). Additionally, HP was calculated using the Brouwer (1965) equation with one of three adjustments: the adjustment with N excretion omitted (No-UN HP), utilizing daily N intake and equations from Waldrip et al. (2013) to estimate UN (Waldrip-UN HP), or utilizing SUN and equations from Kohn et al. (2005) to estimate UN (Kohn-UN HP). ME (Mcal/d) was calculated using the mathematical and thermodynamic relationship between HP (Brouwer, 1965) and RE (NRC, 1984) for all four methods used to calculate HP. Constituents of the RE equation include empty BW (EBW) and empty body gain (EBG), which were calculated by shrunk BW (SBW; 96.0% live BW) and converting to EBW assuming EBW is 89.1% of SBW (NASEM, 2016). Shrunk ADG was calculated over the 80-d feeding period and was adjusted to EBG assuming EBG is 95.6% of shrunk ADG (NRC 1984; Oltjen and Garrett, 1988). Next, DMI was used to quantify ME per kilogram of DMI (Mcal ME/kg DM) and then dietary gaNEm and gaNEg were estimated using Galyean et al. (2016) cubic equations.

Table 3.

Equations utilized to evaluate gaNEm and gaNEg using gas flux data from an automated head chamber system and performance data from feedlot steers consuming one of three finishing rations

| Variable1,2 | Equation | Source |

|---|---|---|

| HP, Mcal/d | Brouwer (1965) | |

| HP, Mcal/d | Kaufmann et al. (2011) | |

| RE, Mcal/d | NRC (1984) | |

| ME, Mcal/kg DMI | NRC (1984) | |

| NEm, Mcal/kg DM | Galyean et al. (2016) | |

| NEg, Mcal/kg DM | Galyean et al. (2016) |

1HP = heat production; RE = recovered energy; NEm = net energy for maintenance; NEg = net energy for gain; O2 = oxygen (L/d); CO2 = carbon dioxide (L/d) CH4 = methane (L/d); UN = urinary nitrogen (g/d); EBW = empty body weight; EBG = empty body gain; DMI = dry matter intake; ME = metabolizable energy (Mcal/kg DM); DM = dry matter.

2EBW calculated as 89.1% of shrunk body weight (96.0% live weight) and EBG calculated as 95.6% of shrunk ADG over an 80-d feeding period.

Finally, dietary NEm and NEg were estimated in one of two ways by incorporating live and carcass performance data into the Zinn et al. (2008) quadratic performance-based equations (Table 4). As part of the method, required NEm was calculated using average 80-d shrunk BW (SBW) whereas required NEg was calculated using 80-d shrunk weight gain and equivalent SBW (EQSBW). Equivalent SBW was calculated by adjusting SBW to the BW equivalent of NRC (1984) medium-framed steers at 27.8% empty body fat (EBF; 428 kg) using either final shrunk BW (FSBW) from live animal performance data or adjusted-final BW (AFWB) from carcass data. Calculations for AFBW begin by estimating EBF (%) which is scaled to the FSBW at which point carcasses are expected to contain 28.0% EBF (Guiroy et al., 2001). It has been suggested that utilizing AFBW instead of FSBW would provide better estimates of paNEm and paNEg (Owens and Hicks, 2019). The paNEm and paNEg estimates using EQSBW and FSBW from live performance data are designated as live estimated paNEm (live paNEm) and paNEg (live paNEg). Dietary energy values derived from EQSBW implementing AFBW are denoted as carcass-estimated paNEm (carcass paNEm) and paNEg (carcass paNEg).

Table 4.

Equations utilized to evaluate paNEm and paNEg using live performance or carcass data from feedlot steers consuming one of three finishing rations

| Variable1,2,3,4,5 | Equation | Source |

|---|---|---|

| NEm, Mcal/kg DM | Zinn et al. (2008) | |

| NEg, Mcal/kg DM | 0 | Zinn et al. (2008) |

| a | Zinn et al. (2008) | |

| b | Zinn et al. (2008) | |

| c | Zinn et al. (2008) | |

| NEm required, Mcal/d | Zinn et al. (2008) | |

| NEg required, Mcal/d | Zinn et al. (2008) | |

| EQSBW, kg | NASEM (2016) |

1NEm = net energy for maintenance; NEg = net energy for gain; DMI = dry matter intake; SBW = shrunk body weight; EQSBW = equivalent shrunk body weight; SWG = shrunk weight gain; SRW = standard reference weight; FSBW = final shrunk body weight; AFBW = adjusted-final body weight.

2SBW calculated as 96% of live weight and SWG calculated from initial and final SBW over an 80-d feeding period.

3SRW obtained from NASEM (2016) based on medium-framed steers from NRC (1984) reference database.

4AFBW is appraised final body weight at 28.0% empty fat as calculated from equations by Guiroy et al. (2001).

5EQSBW incorporates either final SBW or AFBW from live or carcass data, respectively.

Statistical analyses

Analysis of variance (ANOVA) was conducted utilizing the Fit Model procedure of JMP Pro 16.0 (SAS Institute, Cary, NC) to determine the main effect of methodology on HP, UN, dietary NEm, and dietary NEg. Individual animal served as the experimental unit for all analyses. When applicable, least-square means were separated using Tukey–Kramer adjustments for multiple comparisons. Least-square mean differences were considered statistically significant if P < 0.05 and as having a tendency toward significance if 0.05 ≤ P < 0.10.

Method agreement between NEm and NEg calculated by Kaufmann-HP, No-UN HP, Waldrip-UN HP, and Kohn-UN HP and live and carcass paNEm and paNEg were analyzed using R (v.4.1.0; R Core Team, 2021). Furthermore, method agreement between Kaufmann-HP estimated daily NEm and NEg intake values were compared with live paNEm and paNEg determined values. This assessment was made to compare a scenario where DMI is not known. Accordingly, only Kaufmann-HP method was assessed as in scenarios where DMI is unknown, daily UN excretion will be similarly unknown. Live paNEm and paNEg were only assessed for this analysis because carcass data will also likely be unknown in scenarios where DMI is unknown, such as in pasture. Firstly, daily ME intake was regressed on daily NEm and NEg values to determine an equation to convert daily ME intake to daily NEm and NEg intake. For all comparisons, method precision was assessed by Pearson’s correlation coefficient (r) using the “cor.test” function of base R. We suggest that high, moderate, and low precisions are characterized by r values of ≥0.90, ≥0.70 and <0.90, and <0.70, respectively. Accuracy and agreement between the methods were investigated using the “CCC” function of the “DescTools” package (Signorell et al., 2020). This function provides Lin’s concordance correlation coefficient (CCC), which is a function of a bias correction factor (Cb) and r (Lin., 1989, 2000). The Cb is calculated using two items. The first is termed scale shift, which is the ratio of the standard deviation between the two method estimates, and the second is termed location shift, which is analogous to the mean bias. In essence, the Cb is a measure of how far the two methods deviate from the line of unity, i.e., a one-to-one relationship with an intercept of 0. As such, Cb is a measure of accuracy. We propose that high, moderate, and low accuracy are characterized by Cb values of > 0.90, between 0.70 and < 0.90, and < 0.70, respectively. As CCC is calculated from a measure of accuracy (Cb) and precision (r), CCC can be considered a measure of agreement between the two methods. Lin’s CCC ranges from −1 to 1, similar to r; however, only values close to 1 indicate agreement. Also, like r, CCC requires the researcher or reader to define what values they consider to be adequate. For the purposes of this investigation, we suggest values of CCC for no agreement as <0, slight agreement as 0 to 0.39, moderate agreement as 0.40 to 0.59, adequate agreement as 0.60 to 0.80, and excellent agreement as > 0.80, which is similar to those suggested by Marshall et al. (2021). Next, root mean square error expressed as a percent of paNEm or paNEg was calculated using the “RMSE” function of the “DescTools” package (Signorell et al., 2020). Finally, the mean bias and slope bias between paNEm and paNEg and gaNEm and gaNEg for each of the four HP calculation methods explored was determined by regressing the mean-centered AHCS estimates with the residuals (i.e., performance-adjusted estimates minus AHCS estimates) as suggested by St-Pierre (2001).

Results

Refer to Table 5 for an overview of observed performance, calculated RE, gas production, and values used to calculate UN. On average, cattle visited the AHCS units 1.6 times per day to provide an average of 128 visits per steer throughout the duration of the experiment. Urinary N was 24.3% greater (P < 0.01) when estimated by N intake calculated using the equation of Waldrip et al. (2013) compared with using SUN and the equation of Kohn et al. (2005; Table 6). Yet, there were no differences in HP (P = 0.99) when accounting for UN using No-UN HP, Waldrip-UN HP, or Kohn-UN HP (Table 6). Additionally, HP was not different when calculated using Kaufmann-HP compared to all other HP values and methods that accounted for UN (P = 0.99). There were no differences in estimated dietary NEm when compared to carcass paNEm and live paNEm to gaNEm generated using any HP value (P = 0.49). Similarly, there were no differences in estimates for dietary NEg when compared to NEg values generated using all other methods (P = 0.39).

Table 5.

Observed cumulative performance, gas flux, SUN, urinary N excretion and N intake of steers fed one of three finishing rations and used to determine paNEg and paNEg or gaNEm and gaNEg

| Item1 | Average | Minimum | Maximum | SD |

|---|---|---|---|---|

| Initial BW, kg | 525 | 459 | 592 | 29.8 |

| Final BW, kg | 681 | 583 | 738 | 39.5 |

| ADG, kg/d2 | 1.96 | 1.11 | 2.38 | 0.282 |

| Pellet DMI, kg/d | 0.62 | 0.20 | 0.88 | 0.131 |

| TMR DMI, kg/d | 10.09 | 7.58 | 11.77 | 0.915 |

| Total DMI, kg/d | 10.71 | 8.33 | 12.49 | 0.883 |

| RE, Mcal/d3 | 13.15 | 6.76 | 16.74 | 2.210 |

| CO2 emission, kg/d4 | 10.25 | 6.57 | 11.70 | 0.867 |

| CH4 emission, kg/d4 | 0.151 | 0.111 | 0.208 | 0.2274 |

| O2 consumption, kg/d4 | 6.84 | 4.76 | 7.84 | 0.577 |

| SUN, mg/dL | 8.31 | 5.40 | 12.97 | 1.49 |

| UN excretion—Kohn, g/d | 64.1 | 34.8 | 104.4 | 13.59 |

| NI, g/d | 79.67 | 54.13 | 97.26 | 10.558 |

| UN excretion—Waldrip, g/d | 79.7 | 54.1 | 97.3 | 10.56 |

1SD = standard deviation; BW = body weight; ADG = average daily gain; DMI = dry matter intake; RE = recovered energy; CO2 = carbon dioxide; CH4 = methane; O2 = oxygen; SUN = serum urea nitrogen; UN—Kohn = urinary nitrogen calculated from Kohn et al. (2005); NI = nitrogen intake; UN—Waldrip = urinary nitrogen calculated from Waldrip et al. (2013).

2ADG calculated using initial and final un-shrunk BW during an 80-d feeding trial.

3RE calculated from equations described by NRC (1984).

4Determined using an automated head chamber system (GreenFeed; C-Lock).

Table 6.

Least-square means and statistical testing for the difference of methods to determine HP, UN, and paNEm and paNEg using live or carcass data

| Methodology | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item | Kaufmann HP1 |

No-UN HP2 |

Kohn-UN HP3 |

Waldrip-UN HP4 |

Live pa5 |

Carcass pa6 |

Pooled SEM7 |

P value8 |

| HP, Mcal/d | 24.57 | 24.65 | 24.56 | 24.54 | — | — | 0.279 | 0.99 |

| UN, g/d | — | — | 64.10 | 79.67 | — | — | 1.666 | <0.01 |

| NEm, Mcal/kg DMI9 | 2.24 | 2.24 | 2.24 | 2.24 | 2.23 | 2.31 | 0.194 | 0.49 |

| NEg, Mcal/kg DMI9 | 1.55 | 1.55 | 1.55 | 1.55 | 1.55 | 1.62 | 0.170 | 0.39 |

1HP estimated using RQ utilizing equation from Kaufmann et al. (2011).

2Urinay N omitted from Brouwer (1965) HP equation.

3SUN utilized to estimate UN from equation by Kohn et al. (2005) when estimating HP using Brouwer (1965) equation.

4Nitrogen intake utilized to estimate UN from equation by Waldrip et al. (2013) when estimating HP using Brouwer (1965) equation.

5Live pa incorporated, BW, ADG and DMI to estimate NEm and NEg.

6Carcass pa method incorporated an appraisal of EBF from Guiroy et al. (2001) where final body weight was adjusted to 28.0% EBF (AFBW) in addition to utilizing live performance to estimate NEm and NEg.

7Standard error of the mean.

8ANOVA P value.

9NEm and NEg estimated using HP, recovered energy from NRC (1984), and Galyean et al. (2016) or from Zinn et al. (2008) equations whereas the carcass pa method incorporated an appraisal of EBF from Guiroy et al. (2001) where final body weight was adjusted to 28.0% EBF (AFBW) in addition to utilizing live performance.

Analyses for precision, agreement, bias, and RMSE for estimates of dietary NEm are outlined in Table 7 and dietary NEg in Table 8. Dietary NEm calculated from Kaufmann-HP, HP accounting for urine N (Waldrip-UN HP or Kohn-UN HP), or HP with no adjustment for urinary N (No-UN HP) all had high precision (r ≥ 0.90), high accuracy (Cb ≥ 0.92), and excellent agreement (CCC ≥ 0.83) when analyzed against carcass paNEm. When the gas-flux derived values were compared to live paNEm there were also high precision (r = 0.91), high accuracy (Cb = 1.00), and excellent agreement (CCC = 0.91), regardless of adjustment for UN. However, average RMSE (as a % of respective paNEm) was 38.6% higher for estimates of dietary NEm when carcass paNEm was compared to live paNEm. As shown in Table 7, there was significant mean bias for Kaufmann-HP (0.07; P < 0.01), No-UN (0.07; P < 0.01), Waldrip-UN HP (0.08; P < 0.01), and Kohn-UN HP (0.07; P < 0.01) when each gaNEm value was compared to carcass paNEm, yet there was no slope bias (P ≥ 0.63) for any estimate of gaNEm. However, there was no evidence of mean (P ≥ 0.46) or slope bias (P ≥ 0.14) for all methods used to generate dietary gaNEm values when compared to live paNEm.

Table 7.

Comparative statistics of dietary NEm estimated using one of four methods incorporating gas flux from an automated head chamber system or utilizing paNEm

| Kauffman HP2 |

Brouwer (1965) HP equation | |||

|---|---|---|---|---|

| Item1 | No-UN HP3 |

Kohn-UN HP4 |

Waldrip-UN HP5 |

|

| Live pa6 | ||||

| CCC | 0.91 | 0.91 | 0.91 | 0.91 |

| Cb | 1.00 | 1.00 | 1.00 | 1.00 |

| r | 0.91 | 0.91 | 0.91 | 0.91 |

| RMSE, % | 3.43 | 3.45 | 3.43 | 3.43 |

| Mean bias | −0.002 | −0.008 | −0.002 | −0.001 |

| P value | 0.83 | 0.46 | 0.85 | 0.95 |

| Slope bias | −0.09 | −0.09 | −0.09 | −0.09 |

| P value | 0.15 | 0.14 | 0.14 | 0.14 |

| Carcass pa7 | ||||

| CCC | 0.83 | 0.84 | 0.84 | 0.83 |

| Cb | 0.92 | 0.93 | 0.92 | 0.92 |

| r | 0.90 | 0.91 | 0.91 | 0.91 |

| RMSE, % | 4.79 | 4.63 | 4.80 | 4.83 |

| Mean bias | 0.07 | 0.07 | 0.07 | 0.08 |

| P value | <0.01 | <0.01 | <0.01 | <0.01 |

| Slope bias | −0.03 | −0.03 | −0.03 | −0.03 |

| P value | 0.65 | 0.64 | 0.63 | 0.63 |

1CCC = Lin’s concordance correlation coefficient (Lin., 1989); r = Pearson’s correlation coefficient; Cb = bias correction factor; RMSE = root mean square error; RMSE, % = RMSE as a percent of live pa or carcass pa.

2HP estimated using RQ utilizing equation from Kaufmann et al. (2011).

3Urinay N omitted from Brouwer (1965) HP equation.

4SUN utilized to estimate UN from equation by Kohn et al. (2005) when estimating HP using Brouwer (1965) equation.

5Nitrogen intake utilized to estimate UN from equation by Waldrip et al. (2013) when estimating HP using Brouwer (1965) equation.

6Live pa incorporated BW, ADG and DMI to estimate NEm and NEg.

7Carcass pa method incorporated an appraisal of EBF from Guiroy et al. (2001) where final body weight was adjusted to 28.0% EBF (AFBW) in addition to utilizing live performance to estimate NEm and NEg.

Table 8.

Comparative statistics of estimated dietary NEg using one of four methods incorporating gas flux from an automated head chamber system or utilizing paNEg

| Kauffman HP2 |

Brouwer (1965) HP equation | |||

|---|---|---|---|---|

| Item1 | No-UN HP3 |

Kohn-UN HP4 |

Waldrip-UN HP5 |

|

| Live pa6 | ||||

| CCC | 0.91 | 0.91 | 0.91 | 0.91 |

| Cb | 1.00 | 1.00 | 1.00 | 1.00 |

| r | 0.91 | 0.91 | 0.91 | 0.91 |

| RMSE, % | 4.25 | 4.26 | 4.26 | 4.26 |

| Mean bias | 0.0015 | −0.003 | 0.003 | 0.002 |

| P value | 0.88 | 0.73 | 0.76 | 0.85 |

| Slope bias | −0.05 | −0.05 | −0.05 | −0.05 |

| P value | 0.42 | 0.42 | 0.40 | 0.41 |

| Carcass pa7 | ||||

| CCC | 0.82 | 0.83 | 0.82 | 0.82 |

| Cb | 0.91 | 0.92 | 0.91 | 0.91 |

| r | 0.91 | 0.91 | 0.91 | 0.91 |

| RMSE, % | 6.12 | 5.92 | 6.18 | 6.13 |

| Mean bias | 0.07 | 0.06 | 0.07 | 0.07 |

| P value | <0.01 | <0.01 | <0.01 | <0.01 |

| Slope bias | 0.01 | 0.01 | 0.008 | 0.009 |

| P value | 0.88 | 0.88 | 0.90 | 0.90 |

1CCC = Lin’s concordance correlation coefficient (Lin., 1989); r = Pearson’s correlation coefficient; Cb = bias correction factor; RMSE = root mean square error; RMSE, % = RMSE as a percent of live pa or carcass pa.

2HP estimated using RQ utilizing equation from Kaufmann et al. (2011).

3Urinay N omitted from Brouwer (1965) HP equation.

4SUN utilized to estimate UN from equation by Kohn et al. (2005) when estimating HP using Brouwer (1965) equation.

5Nitrogen intake utilized to estimate UN from equation by Waldrip et al. (2013) when estimating HP using Brouwer (1965) equation.

6Live pa incorporated BW, ADG and DMI to estimate NEm and NEg.

7Carcass pa method incorporated an appraisal of EBF from Guiroy et al. (2001) where final body weight was adjusted to 28.0% EBF (AFBW) in addition to utilizing live performance to estimate NEm and NEg.

As expected, trends for precision, accuracy, and agreement for estimates of NEg were similar to NEm since the same ME was utilized in Galyean et al. (2016) equations to estimate dietary NEm and NEg. Statistical values for precision (r ≥ 0.91), accuracy (Cb ≥ 0.91), and agreement (CCC ≥ 0.82) were high for all gaNEg values, regardless of HP, when compared to carcass paNEg values. Once again, when dietary NEg values were generated from any method to estimate HP for live paNEg, there was high precision (r = 0.91), accuracy (Cb = 1.00), and agreement (CCC = 0.91). However, RMSE (% of respective paNEg) values were, on average, 39.0% lower for all estimates of gaNEg when compared to live paNEg as opposed to carcass paNEg. Moreover, mean bias was evident for Kaufmann-HP (0.07; P < 0.01), No-UN HP (0.06; P < 0.01), Waldrip-UN HP (0.07; P < 0.01), and Kohn-UN HP (0.07; P < 0.01) when compared to carcass paNEg yet there was no apparent slope bias (P ≥ 0.88). In addition, there was no mean (P ≥ 0.73) or slope bias (P ≥ 0.40) when metrics to quantify HP and subsequent dietary NEg were compared to live paNEg.

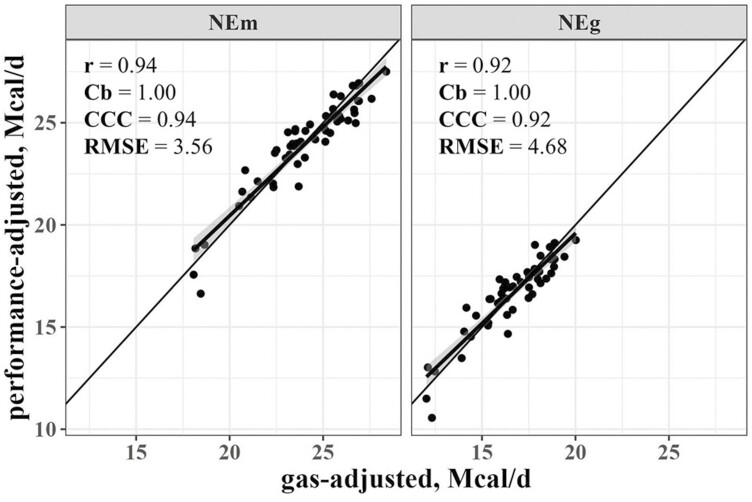

Finally, Figure 1 presents the scenario where DMI is unknown and comparison were made based on daily NEm and NEg intakes (Mcal/d) rather than NEm and NEg concentrations (Mcal/kg DM). We first needed to determine regression equations to convert ME intake to NEm and NEg intakes. These equations were

Figure 1.

Agreement between daily NEm and NEg estimated based on performance-adjusted or gas-adjusted methodology. Pearson’s correlation (r) was used as a measure of precision, bias correction factor (Cb) as a measure of accuracy, Lin’s CCC as a measure of agreement, and root mean square error as a percent of the mean performance-adjusted values.

| (1) |

| (2) |

The daily NEm and NEg intake values derived from the AHCS were then calculated using equations 1 and 2, respectively. There was high precision (r ≥ 0.92), accuracy (Cb = 1.00), and agreement (CCC ≥ 0.92) between daily NEm and NEg intakes estimated using daily ME intake (derived from the AHCS and observed performance) and equations 1 and 2, compared with those estimated by live paNEm and paNEg. Accordingly, there were low RMSE values for NEm (3.56%) and NEg (4.68%).

Discussion

The objective of this experiment was to compare estimates of dietary net energy values from performance data using live or carcass data with values estimated from gas flux data and calculated recovered energy, using four different means of calculating HP. Another objective of this experiment was to validate estimated energy values derived from gas flux data by evaluating precision, accuracy, and agreement against performance-adjusted dietary net energy values. The results presented herein suggest that gas flux data from an AHCS utilized to calculate HP and paired with estimates of RE can ultimately provide estimates of dietary NEm and NEg (gaNEm and gaNEg) that agree with performance-adjusted values. The discussion below outlines results with support for these claims.

Heat production

It is important to note that the estimation of HP provides the only source of variation in NEm and NEg values derived from gas flux measurements in the current experiment. Since RE is a function of observed performance, it is constant for each individual animal for all estimates of ME. Accordingly, HP is a key component in evaluating the efficacy of gas flux-based methodology. Calculating HP from the Brouwer (1965) equation has been utilized while ignoring the UN (g/d) component, as it is thought to account for less than 1% of total HP (Junghans et al., 2007; Kaufmann et al., 2011; Pereira et al., 2015). Although estimates of UN within the current study were 24.3% higher when using Waldrip-UN HP compared with Kohn-UN HP, there was no difference in HP between these methodologies. Furthermore, HP calculated by omitting the adjustment for UN (i.e., Kaufmann-HP and No-UN HP) were not different from the other options. This is because the adjustment for UN using the Brouwer (1965) equation only represented 0.37% and 0.45% of HP for the Kohn-UN HP and Waldrip-UN HP methodologies, respectively. In support, HP was curvilinear in sheep fed five levels of dietary CP where dietary inclusions between 10% and 15% dietary DM did not change HP (Cock et al., 1967). Dietary CP levels fed within the current study (10.77% to 12.51% CP, DM basis) may have been similar enough to prevent disparity in UN. Within the current study, Kohn-UN HP (0.37%) and Waldrip-UN HP (0.45%) accounted for less than 1% of total HP when evaluated against No-UN HP, which supports data presented by Cock et al. (1967). Collectively, data suggest that omitting the UN component of the Brouwer (1965) equation did not compromise the accuracy of computed HP in the current study. Further research may be warranted in cattle consuming a higher amount of CP than in the present study and in growing or grazing cattle to ensure ignoring UN is appropriate beyond the current research setting and feeding strategy.

Previous research (Junghans et al., 2007; Kaufmann et al., 2011) has suggested utilizing RQ and ignoring CH4 by mathematically rearranging the Brouwer (1965) HP equation. The proposed equation incorporates RQ and CO2 to estimate HP, yet the coefficients were adjusted by Kaufmann et al. (2011). Recently, this equation has been applied by researchers using the AHCS to measure gas flux (Pereira et al., 2015; Holder et al., 2022). We elected to implement the Kaufmann et al. (2011) equation that uses RQ as a secondary method to evaluate HP due to its frequent use in the literature, despite the lack of validation until the current experiment, to our knowledge. Interestingly, Holder et al. (2022) provided O2, CO2, and CH4 from AHCS which offered the opportunity to calculate HP using both Brouwer (1965) and Kaufmann et al. (2011) equations and their values were nearly identical. This supports the similarity between Kaufmann-HP and all other measures of HP observed in this experiment. Moreover, Hales et al. (2012) found a 26.4% increase in daily CH4 emission from cattle-fed diets with dry-rolled corn when compared to steam-flaked corn, yet this did not result in a difference in HP in sealed indirect calorimetry respiration chambers. Differences in CH4 production without influencing HP further support the notion that CH4 makes a relatively insignificant contribution to HP when calculated using the Brouwer (1965) equations. Similarly to UN, an adjustment for CH4 in the Brouwer (1965) equation accounted for less than 1% of total HP where correcting for CH4 accounted for 0.32% to 0.61% of No-UN HP and methods accounting for UN. This suggests that using RQ and the equation from Kaufmann et al. (2011) is an acceptable alternative to the Brouwer (1965) equation for calculating HP.

While using RQ is an acceptable method to calculate HP, it is necessary to quantify RQ from individual animals when using the Kaufmann et al. (2011) equation. Assuming a constant RQ of 1.0 in the Kaufmann et al. (2011) HP equation within the current analysis, HP was 3.8% higher than using individual RQ from gas flux data (i.e., Kaufmann-HP method). Moreover, a constant RQ of 1.05 resulted in a 6.7% increase in HP when compared with RQ from individual animals. Variation in RQ may be attributed to tissue energy balance, DMI, and energy metabolism (Armstrong and Blaxter, 1957). Often, a RQ of 1.0 or 1.05 is selected as a RQ of 1.0 is thought to represent the metabolic threshold of adipose accretion, but RQ may range from 0.7 to 1.2 depending on metabolic differences and dietary intake (Armstrong and Blaxter, 1957; Blaxter and Wainman, 1966). Yet, estimates of HP may be rendered inaccurate if O2 data is unavailable, as a reported correlation has been evaluated in grazing cattle where CO2 is only partially correlated (r = 0.72) to ME in the absence of O2 (Caetano et al., 2017). Thus, it is recommended that both CO2 and O2 are used in estimating individual animal RQ as opposed to assuming a constant RQ in cattle consuming a finishing diet.

Method agreement

The data herein support the hypothesis that estimated dietary NEm and NEg are not different (P ≥ 0.38) when comparing performance (i.e., live performance or carcass) to gas flux methodologies. Agreement (CCC ≥ 0.82) with either estimate for paNEm and paNEg supports the use of gas flux data from the AHCS to estimate HP to ultimately arrive at dietary NEm and NEg estimates. Carcass paNEm was 3.6% higher while carcass paNEg was 4.5% higher compared with live paNEm and live paNEg, respectively. Additionally, RMSE was around 40% higher for carcass than live paNEm and paNEg, respectively. These results may suggest that utilizing live performance data provides more accurate estimates of dietary NEm and NEg. While this analysis is outside the bounds of this experiment, further investigation may be warranted since paNEm and paNEg is a tool commonly utilized by nutritionists to evaluate dietary energy (Owens and Hicks, 2019).

The greater agreement between gaNEm and gaNEg was higher when using live performance data. This discrepancy may be caused by using AFBW (Guiroy et al., 2001) as suggested by Owens and Hicks (2019) when calculating carcass paNEm and paNEg. Replacing final SBW in the EQSBW equation with AFBW creates a scenario where metrics are scaled to the Garrett (1980) database using the standard reference weight of 428 kg for medium-framed steers from the NRC (1984) and then scaled again to 28.0% EBF when calculating AFBW. Since replacing final SBW with AFBW in the EQSBW scales the animal twice, it may result in the over-prediction of paNEm and paNEg. Owens and Hicks (2019) suggested using AFBW in place of FSBW when calculating EQSBW. When AFBW was used in place of EQSBW, instead of as a component of the EQSBW equation, estimated paNEm and paNEg were biologically unrealistic (NEm = 2.60 Mcal/kg and NEg = 1.87 Mcal/kg). Moreover, when AFBW was replaced in each instance with FSBW, such as calculating average SBW or SWG, NEm and NEg values were unrealistically low based on observed performance (NEm = 1.78 Mcal/kg and NEg = 1.23 Mcal/kg). The average dietary energy values estimated from chemical analyses (NEm = 2.22 Mcal/ kg and NEg = 1.53 Mcal/kg) closely resemble paNEm and paNEg when using AFBW as replacement for final SBW within the EQSBW equation. These scenarios support our interpretation of applying AFBW to the EQSBW equation within the current dataset, but this may have been an erroneous assumption. However, utilizing EQSBW with final SBW generates paNEm and paNEg closely related to gaNEm and gaNEg. When utilizing the Supplementary Data provided by Galyean et al. (2023) and Beck et al. (2023), the paNEm and paNEg values agreed more closely with wet-chemistry analyzed NEm and NEg values when AFBW replaced SBW in the EQSBW equation. This may indicate that the best methodology to calculate performance-adjusted energy values may be context-dependent, and we suggest related to days on feed. Further investigation is required to determine under what scenarios live and carcass paNEm and paNEg calculations are recommended. Regardless, it is concluded that researchers can deploy AHCS, calculate HP, estimate RE, and arrive at estimates of dietary NEm and NEg with excellent agreement to paNEm and paNEg.

It is recognized that the application of gaNEm and gaNEg applies to research programs with access to AHCS, and more specifically, units with O2 sensors. Gas-flux methodology provides the opportunity to estimate dietary NEm and NEg while also evaluating potential differences or similarities in calculated HP, RE, and ME between treatments. Meta-analyses conducted by Owens and Hicks (2019) showed that paNEg values were 6.2% to 7.8% lower than formulated NEg. Such variation may be a function of values used for individual ingredient NEg when formulating rations, inaccurate measures of DMI or ADG, or differences in cattle NEm requirements (Owens and Hicks, 2019). Calculating required NEm is not a parameter in gas-flux methodology and between animal variation in NEm requirements may be accounted for with gas measurements. Thus, it is postulated that gas flux may provide more accurate estimates in cattle with varying NEm requirements, which may be a function of breed, sex, frame size, and previous or current plane of nutrition (Fox and Black, 1984; Fox et al., 1988). While this research provides the foundation for such claims, further investigation is required.

A potential setback for all methodologies is the duration of time required to gather live performance metrics suitable for calculating DMI and ADG. The minimum period of measurement for DMI and ADG has been established as 56 d on feed (BIF, 2010; Culbertson et al., 2015). Estimating dietary NEm and NEg throughout phases of the feedlot finishing period may provide more utility in research practice. Yet, as tissue accretion shifts from lean tissue to adipose growth (Simpfendorfer, 1973), estimates of dietary NEm and NEg from several phases may be rendered inaccurate due to changes in variation of NEm requirements and a potential decrease in ADG (Fox et al., 1988). Moreover, utilizing carcass data to estimate dietary NEm and NEg is only viable for one dietary treatment for a set of cattle, serving as a potential limitation in a research setting. Performance metrics are components of gaNEm and gaNEg estimations whereas the equations of paNEm and paNEg are strictly dependent on such values. Therefore, it is worthwhile investigating if gaNEm and gaNEg can be estimated throughout several feeding phases to gain more utility in research projects, especially since dietary energy and HP can be evaluated. Regardless, a single estimate of paNEm and paNEg or gaNEm and gaNEg provides valuable insight into diets and cattle in feedlot research that can be incorporated into future experiments.

While the methodology incorporated within the current study supports agreement between performance and gas flux methodologies utilizing a subset of finishing cattle, further application may be useful in grazing cattle. Typically, in a research feedlot setting, collection of ADG and DMI data is relatively simple, allowing subsequent evaluation of paNEm and paNEg using quadratic solutions, which had strong agreement with gaNEm and gaNEg within this dataset. Yet, in grazing cattle, such as cows or stocker cattle, estimation of DMI is difficult, limiting the ability of estimating paNEm and paNEg using quadratic solutions. However, evaluating energy intake in grazing cattle can be achieved using HP and RE without DMI to estimate total ME intake (Mcal/d). Since estimates of RE only require average EBW and EBG, initial and final BW measurements may be satisfactory in estimating ME intake. Estimates of gaNEm and gaNEg from the current set of finishing cattle were obtained utilizing DMI data, which was available for incorporation into calculations. Yet, if the DMI is unknown, ME intake (Mcal/d) can be utilized to provide an estimate of energy intake or potentially be extrapolated to total gaNEm or gaNEg intake (Mcal/d) to potentially provide metrics of performance. This potential was explored using the current data and equations were developed to calculate daily NEm and NEg intake from daily ME intake values. When comparing NEm and NEg intake values using ME intake estimated from AHCS gas-flux and observed ADG in equations 1 and 2, respectively, with performance-adjusted NEm and NEg derived values, we determined excellent agreement (Figure 1). This analysis further highlights the ability to utilize AHCS to conduct energetic studies, even in scenarios where DMI is unknown. Furthermore, DMI could be extrapolated from ME intake and dietary ME content if it can be accurately quantified. It is important to note this requires accurate and reliable estimates of dietary ME content but could offer extended utility beyond a feedlot finishing scenario, as evaluation of estimated NEm and NEg in grazing cattle is often unreported given the difficulty of evaluating DMI. While this application currently remains a supposition, further research is warranted in grazing cattle to expand the potential utility of the gas flux methodology.

Conclusions

Based on the results of this experiment, gas flux data from the AHCS was an acceptable method to estimate dietary NEm and NEg when compared to performance-adjusted methodologies and applied to a single dataset. Incorporating gas flux from AHCS affords researchers the opportunity to estimate HP in concert with dietary gaNEm and gaNEg. Additionally, under our experimental conditions, it was unnecessary to adjust for UN and CH4 production when calculating HP. Since AHCS serves as a modified indirect respiration calorimetry system, gas data can be collected and utilized along with estimates of RE to estimate dietary NEm and NEg, which are similar to live and carcass paNEm and paNEg. While this may prove useful in a confined research setting, evaluating the efficacy of this methodology in grazing cattle may increase application in future research. Accordingly, further research is needed to investigate the use of the AHCS to conduct energetic studies in grazing systems. Researchers should determine whether paNEm and paNEg or gaNEm and gaNEg provide the most appropriate estimation of dietary energy within their experimental objectives and capabilities. It is worth noting the increased utility and data afforded by the AHCS as it can provide estimates of HP, gas emission or consumption, and estimates of dietary energy values.

Supplementary Material

Glossary

Abbreviations

- ADF

acid detergent fiber

- ADG

average daily gain

- ADICP

acid detergent insoluble crude protein

- AFBW

adjusted-final body weight

- AHCS

automated head chamber system

- BW

body weight

- Cb

bias correction factor

- CCC

concordance correlation coefficient

- CP

crude protein

- DM

dry matter

- DMI

dry matter intake

- EBW

empty body weight

- EQSBW

equivalent shrunk body weight

- FSBW

final shrunk body weight

- HP

heat production

- ME

metabolizable energy

- NDICP

neutral detergent insoluble crude protein

- NEg

net energy for gain

- NEm

net energy for maintenance

- RE

recovered energy

- RMSE

root mean square error

- RQ

respiratory quotient

- SRW

standard reference weight

- SUN

serum urea nitrogen

- TDN

total digestible nutrients

- UN

urinary nitrogen

Contributor Information

Jarret A Proctor, Department of Animal Science, Texas A&M University, College Station, TX, USA.

Jason K Smith, Department of Animal Science, Texas A&M University, College Station, TX, USA; Texas A&M AgriLife Extension, Department of Animal Science, Texas A&M University, Amarillo, TX, USA.

Nathan S Long, Department of Animal Science, Texas A&M University, College Station, TX, USA.

Stacey A Gunter, Oklahoma and Central Plains Agricultural Research Center, United States Department of Agriculture, Agricultural Research Service, El Reno, OK, USA.

Vinícius N Gouvêa, Department of Animal Science, Texas A&M University, College Station, TX, USA; Texas A&M AgriLife Research, Department of Animal Science, Texas A&M University, Amarillo, TX, USA.

Matthew R Beck, Conservation and Production Research Laboratory, United States Department of Agriculture, Agricultural Research Service, Bushland, TX, USA.

Acknowledgments

Mention of trade names or commercial products in this article is solely for providing specific information and does not imply recommendation or endorsement by the USDA. The USDA prohibits discrimination in all its programs and activities based on race, color, national origin, age, disability, and where applicable, sex, marital status, familial status, parental status, religion, sexual orientation, genetic information, political beliefs, reprisal, or because all or part of an individual’s income is derived from any public assistance program.

Conflicts of interest statement.

The authors declare no conflict of interest.

Literature Cited

- AOAC. 1995. Official methods of analysis. In: The analysis of agricultural materials. 16th ed. Arlington (VA): Association of Analytical Chemists. [Google Scholar]

- Armstrong, D., and Blaxter K... 1957. The heat increment of steam-volatile fatty acids in fasting sheep. Br. J. Nutr. 11:247–272. doi: 10.1079/BJN19570044 [DOI] [PubMed] [Google Scholar]

- Arthur, P., Barchia I., Weber C., Bird-Gardiner T., Donoghue K., Herd R., and Hegarty R... 2017. Optimizing test procedures for estimating daily methane and carbon dioxide emissions in cattle using short-term breath measures. J. Anim. Sci. 95:645–656. doi: 10.2527/jas.2016.0700 [DOI] [PubMed] [Google Scholar]

- Beck, M. R., Proctor J. A., Kasuske Z., Smith J. K., Gouvêa V. N., Lockard C. L., Min B., and Brauer D... 2023. Effects of replacing steam-flaked corn with increasing levels of malted barley in a finishing ration on feed intake, growth performance, and enteric methane emissions of beef steers. App. Anim. Sci. 39:525–534. doi: 10.15232/aas.2023-02435 [DOI] [Google Scholar]

- Beck, M. R., Thompson L. R., Proctor J. A., Reuter R. R., and Gunter S. A... 2024. Recommendations on visit duration and number requirements for an automated head chamber system. J. Anim. Sci. 102:skae158. doi: 10.1093/jas/skae158 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Beef Improvement Federation (BIF). 2010. Guidelines for uniform beef improvement programs. 9th ed. Columbia (MO): Beef Improvement Federation. p. 24–27. [Google Scholar]

- Blaxter, K. L. 1962. The energy metabolism of ruminants. London (UK): Hutchinson Scientific and Technical. [Google Scholar]

- Blaxter, K., and Wainman F... 1964. The utilization of the energy of different rations by sheep and cattle for maintenance and for fattening. J. Agric. Sci. 63:113–128. doi: 10.1017/S002185960001515X [DOI] [Google Scholar]

- Blaxter, K., and Wainman F... 1966. The fasting metabolism of cattle. Br. J. Nutr. 20:103–111. doi: 10.1079/BJN19660012 [DOI] [PubMed] [Google Scholar]

- Brouwer, E. 1965. Report of sub-committee on constants and factors. In: Proceedings of the 3rd Symposium on Energy Metabolism. Troon (Scotland): European Association of Animal Production Publication; p. 441–443. [Google Scholar]

- Caetano, M., Wilkes M., Pitchford W., Lee S., and Hynd P... 2017. Energy relations in cattle can be quantified using open-circuit gas-quantification systems. Anim. Prod. Sci. 58:1807–1813. doi: 10.1071/AN16745 [DOI] [Google Scholar]

- Carstens, G., Mostyn P., Lammoglia M., Vann R., Apter R., and Randel R... 1997. Genotypic effects on norepinephrine-induced changes in thermogenesis, metabolic hormones, and metabolites in newborn calves. J. Anim. Sci. 75:1746–1755. doi: 10.2527/1997.7571746x [DOI] [PubMed] [Google Scholar]

- Cock, L. M., Poulton B. R., Hoover W. H., and Knowlton P. H... 1967. Dietary nitrogen effect on ruminant heat increment. J. Anim. Sci. 26:845–848. doi: 10.2527/jas1967.264845x [DOI] [PubMed] [Google Scholar]

- Crampton, E. W., Lloyd L. E., and MacKay V. G... 1957. The calorie value of TDN. J. Anim. Sci. 16:541–545. doi: 10.1093/ansci/16.3.541 [DOI] [Google Scholar]

- Culbertson, M. M., Speidel S. E., Peel R. K., Cockrum R. R., Thomas M. G., and Enns R. M... 2015. Optimum measurement period for evaluating feed intake traits in beef cattle. J. Anim. Sci. 93:2482–2487. doi: 10.2527/jas.2014-8364 [DOI] [PubMed] [Google Scholar]

- Delfino, J. G., and Mathison G. W... 1991. Effects of cold environment and intake level on the energetic efficiency of feedlot steers. J. Anim. Sci. 69:4577–4587. doi: 10.2527/1991.69114577x [DOI] [PubMed] [Google Scholar]

- Fox, D. G., and Black J. R... 1984. A system for predicting body composition and performance of growing cattle. J. Anim. Sci. 58:725–739. doi: 10.2527/jas1984.583725x [DOI] [Google Scholar]

- Fox, D. G., Sniffen C. J., and O’Connor J. D... 1988. Adjusting nutrient requirements of beef cattle for animal and environmental variations. J. Anim. Sci. 66:1475–1495. doi: 10.2527/jas1988.6661475x [DOI] [Google Scholar]

- Galyean, M. L., Cole N. A., Tedeschi L. O., and Branine M. E... 2016. Board invited review: Efficiency of converting digestible energy to metabolizable energy and reevaluation of the California net energy system maintenance requirements and equations for predicting dietary net energy values for beef cattle. J. Anim. Sci. 94:1329–1341. doi: 10.2527/jas.2015-0223 [DOI] [PubMed] [Google Scholar]

- Galyean, M. L., Hales K. E., and Smith Z. K... 2023. Evaluating differences between formulated dietary net energy values and net energy values determined from growth performance in finishing beef steers. J. Anim. Sci. 101:1–8. doi: 10.1093/jas/skad230 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Garrett, W. 1980. Energy utilization by growing cattle as determined in 72 comparative slaughter experiments. In: Mount, L. E., editor. 8th Symposium on Energy Metabolism. Cambridge (UK): p. 3–7. [Google Scholar]

- Guiroy, P. J., Fox D. G., Tedeschi L. O., Baker M. J., and Cravey M. D... 2001. Predicting individual feed requirements of cattle fed in groups. J. Anim. Sci. 79:1983–1995. doi: 10.2527/2001.7981983x [DOI] [PubMed] [Google Scholar]

- Gunter, S. A., and Beck M. R... 2018. Measuring the respiratory gas exchange by grazing cattle using an automated, open-circuit gas quantification system. Transl. Anim. Sci. 2:11–18. doi: 10.1093/tas/txx009 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gunter, S. A., Bradford J. A., and Moffet C. A... 2017. Effects of mass airflow rate through an open-circuit gas quantification system when measuring carbon emissions. J. Anim. Sci. 95:475–484. doi: 10.2527/jas.2016.0933 [DOI] [PubMed] [Google Scholar]

- Hales, K. E., Cole N. A., and MacDonald J. C... 2012. Effects of corn processing method and dietary inclusion of wet distillers grains with solubles on energy metabolism, carbon−nitrogen balance, and methane emissions of cattle. J. Anim. Sci. 90:3174–3185. doi: 10.2527/jas.2011-4441 [DOI] [PubMed] [Google Scholar]

- Hammond, K. J., Humphries D. J., Crompton L. A., Green C., and Reynolds C. K... 2015. Methane emissions from cattle: Estimates from short-term measurements using a GreenFeed system compared with measurements obtained using respiration chambers or sulphur hexafluoride tracer. Anim. Feed Sci. Technol. 203:41–52. doi: 10.1016/j.anifeedsci.2015.02.008 [DOI] [Google Scholar]

- Holder, A. L., Gross M. A., Moehlenpah A. N., Goad C. L., Rolf M., Walker R. S., Rogers J. K., and Lalman D. L... 2022. Effects of diet on feed intake, weight change, and gas emissions in beef cows. J. Anim. Sci. 100:skac257. doi: 10.1093/jas/skac257 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Junghans, P., Voigt J., Jentsch W., Metges C. C., and Derno M... 2007. The 13C bicarbonate dilution technique to determine energy expenditure in young bulls validated by indirect calorimetry. Livest. Sci. 110:280–287. doi: 10.1016/j.livsci.2006.11.009 [DOI] [Google Scholar]

- Kaufmann, L. D., Münger A., Rérat M., Junghans P., Görs S., Metges C. C., and Dohme-Meier F... 2011. Energy expenditure of grazing cows and cows fed grass indoors as determined by the 13C bicarbonate dilution technique using an automatic blood sampling system. J. Dairy Sci. 94:1989–2000. doi: 10.3168/jds.2010-3658 [DOI] [PubMed] [Google Scholar]

- Kohn, R. A., Dinneen M. M., and Russek-Cohen E... 2005. Using blood urea nitrogen to predict nitrogen excretion and efficiency of nitrogen utilization in cattle, sheep, goats, horses, pigs, and rats. J. Anim. Sci. 83:879–889. doi: 10.2527/2005.834879x [DOI] [PubMed] [Google Scholar]

- Komarek, R., Komarek A., and Layton B... 2004. Evaluation of the rapid, high-temperature extraction of feeds, foods, and oilseeds by the ANKOM XT20 fat analyzer to determine crude fat content. Oil extraction and analysis: critical issues and comparative studies. Champaign (IL): AOCS Press; 39–68. [Google Scholar]

- Lin, L. I. -K. 1989. A concordance correlation coefficient to evaluate reproducibility. Biometrics 45:255–268. doi: 10.2307/2532051 [DOI] [PubMed] [Google Scholar]

- Lin, L. I. -K. 2000. A note on the concordance correlation coefficient. Biometrics 56:324–325. [Google Scholar]

- Llonch, P., Troy S. M., Duthie C. -A., Somarriba M., Rooke J., Haskell M. J., Roehe R., and Turner S. P... 2018. Changes in feed intake during isolation stress in respiration chambers may impact methane emissions assessment. Anim. Prod. Sci. 58:1011–1016. doi: 10.1071/an15563 [DOI] [Google Scholar]

- Marshall, C. J., Beck M. R., Garrett K., Beale N., and Gregorini P... 2021. Evaluation of PEETER V1.0 urine sensors for measuring individual urination behavior of dairy cows. JDS Commun. 2:27–30. doi: 10.3168/jdsc.2020-0019 [DOI] [PMC free article] [PubMed] [Google Scholar]

- NASEM. 2016. Nutrient requirements of beef cattle. 8th revised ed. Washington (DC): The National Academies Press. [Google Scholar]

- NRC. 1984. Nutrient requirements of beef cattle. Washington (DC): The National Academies Press. [Google Scholar]

- Oltjen, J., and Garrett W... 1988. Effects of body weight, frame size and rate of gain on the composition of gain of beef steers. J. Anim. Sci. 66:1732–1738. doi: 10.2527/jas1988.6671732x [DOI] [PubMed] [Google Scholar]

- Owens, F. N., and Hicks R. B... 2019. Can net energy values be determined from animal performance measurements? A review of factors affecting application of the California net energy system. Transl. Anim. Sci. 3:929–944. doi: 10.1093/tas/txy130 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Owens, F., Sharp W., and Gill D... 1984. Net energy calculation from feedlot performance data. Oklahoma Agricultural Experiment Station Miscellaneous Publication. Vol. 116. Stillwater (OK): 290–293. [Google Scholar]

- Pereira, A. B. D., Utsumi S. A., Dorich C. D., and Brito A. F... 2015. Integrating spot short-term measurements of carbon emissions and backward dietary energy partition calculations to estimate intake in lactating dairy cows fed ad libitum or restricted. J. Dairy Sci. 98:8913–8925. doi: 10.3168/jds.2015-9659 [DOI] [PubMed] [Google Scholar]

- Place, S. E., Pan Y., Zhao Y., and Mitloehner F. M... 2011. Construction and operation of a ventilated hood system for measuring greenhouse gas and volatile organic compound emissions from cattle. Animals. 1:433–446. doi: 10.3390/ani1040433 [DOI] [PMC free article] [PubMed] [Google Scholar]

- R Core Team. 2021. R: A language and environment for statistical computing. Vienna (Austria): R Foundation for Statistical Computing. http://www.r-project.org [Google Scholar]

- Signorell, K. A. A., Alfons A., Anderegg N., Aragon T., Arppe A., Baddeley A., Barton K., Bolker B., Borchers H. W., Caeiro F.,. et al. 2020. DescTools: Tools for descriptive statistics. https://github.com/AndriSignorell/DescTools/ [Google Scholar]

- Simpfendorfer, S. 1973. Relationship of body type and size, sex, and energy intake to the body composition of cattle. Cornell University. Dissertation [Google Scholar]

- St-Pierre, N. R. 2001. Invited Review: Integrating quantitative findings from multiple studies using mixed model methodology. J. Dairy Sci. 84:741–755. doi: 10.3168/jds.S0022-0302(01)74530-4 [DOI] [PubMed] [Google Scholar]

- Van Soest, P. J., Robertson J. B., and Lewis B. A... 1991. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 74:3583–3597. doi: 10.3168/jds.S0022-0302(91)78551-2 [DOI] [PubMed] [Google Scholar]

- Vasconcelos, J. T., and Galyean M. L... 2008. Technical note: Do dietary net energy values calculated from performance data offer increased sensitivity for detecting treatment differences? J. Anim. Sci. 86:2756–2760. doi: 10.2527/jas.2008-1057 [DOI] [PubMed] [Google Scholar]

- Waldrip, H. M., Todd R. W., and Cole N. A... 2013. Prediction of nitrogen excretion by beef cattle: a meta-analysis. J. Anim. Sci. 91:4290–4302. doi: 10.2527/jas.2012-5818 [DOI] [PubMed] [Google Scholar]

- Wedegaertner, T. C., and Johnson D. E... 1983. Monensin effects on digestibility, methanogenesis and heat increment of a cracked corn-silage diet fed to steers. J. Anim. Sci. 57:168–177. doi: 10.2527/jas1983.571168x [DOI] [PubMed] [Google Scholar]

- Weiss, W. P., Conrad H. R., N. R., St. Pierre.. 1992. A theoretically-based model for predicting total digestible nutrient values of forages and concentrates. Anim. Feed Sci. Technol. 39:95–110. doi: 10.1016/0377-8401(92)90034-4 [DOI] [Google Scholar]

- Zinn, R. A., and Shen Y... 1998. An evaluation of ruminally degradable intake protein and metabolizable amino acid requirements of feedlot calves. J. Anim. Sci. 76:1280–1289. doi: 10.2527/1998.7651280x [DOI] [PubMed] [Google Scholar]

- Zinn, R. A., Barrajas R., Montano M., and Ware R. A... 2003. Influence of dietary urea level on digestive function and growth performance of cattle fed steam-flaked barley-based finishing diets. J. Anim. Sci. 81:2383–2389. doi: 10.2527/2003.81102383x [DOI] [PubMed] [Google Scholar]

- Zinn, R., Barreras A., Owens F., and Plascencia A... 2008. Performance by feedlot steers and heifers: daily gain, mature body weight, dry matter intake, and dietary energetics. J. Anim. Sci. 86:2680–2689. doi: 10.2527/jas.2007-0561 [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.