Abstract

Humans rely increasingly on sensors to address grand challenges and to improve quality of life in the era of digitalization and big data. For ubiquitous sensing, flexible sensors are developed to overcome the limitations of conventional rigid counterparts. Despite rapid advancement in bench-side research over the last decade, the market adoption of flexible sensors remains limited. To ease and to expedite their deployment, here, we identify bottlenecks hindering the maturation of flexible sensors and propose promising solutions. We first analyze challenges in achieving satisfactory sensing performance for real-world applications and then summarize issues in compatible sensor-biology interfaces, followed by brief discussions on powering and connecting sensor networks. Issues en route to commercialization and for sustainable growth of the sector are also analyzed, highlighting environmental concerns and emphasizing nontechnical issues such as business, regulatory, and ethical considerations. Additionally, we look at future intelligent flexible sensors. In proposing a comprehensive roadmap, we hope to steer research efforts towards common goals and to guide coordinated development strategies from disparate communities. Through such collaborative efforts, scientific breakthroughs can be made sooner and capitalized for the betterment of humanity.

Keywords: soft materials, mechanics engineering, flexible electronics, conformable sensors, bioelectronics, human-machine interfaces, body area sensor networks, technology translation, sustainable electronics

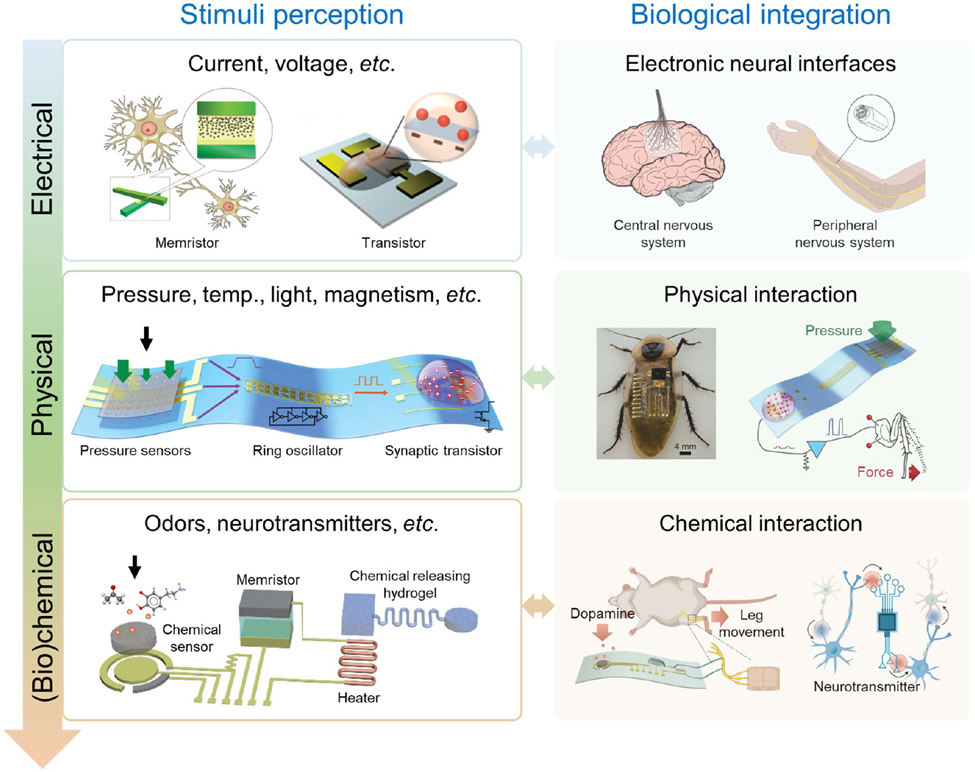

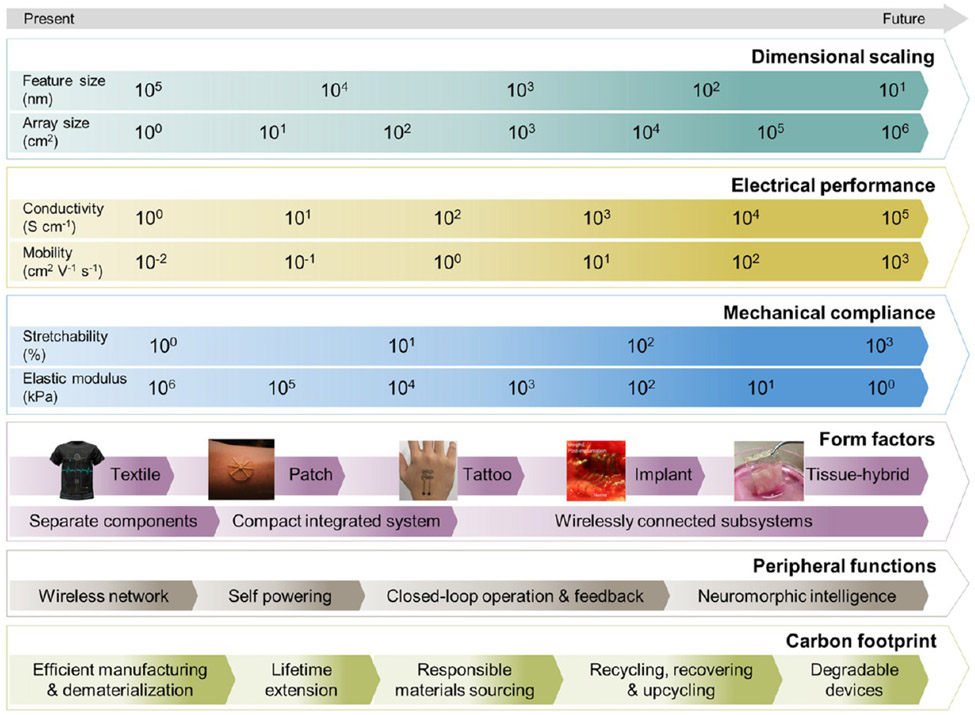

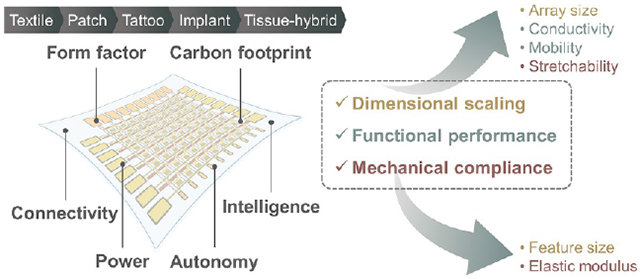

Graphical Abstract

Living things are equipped with biological sensory systems for light, sound, smell, etc. to monitor and to adapt to the environment. In addition to the natural senses, humans use synthetic, fabricated sensors—devices that allow users to measure the values of physical and psychological conditions of interest using the inherent physical properties of the sensors1—to augment our natural abilities of perceiving the world, enabling us to interact with the environment and to improve our living conditions.

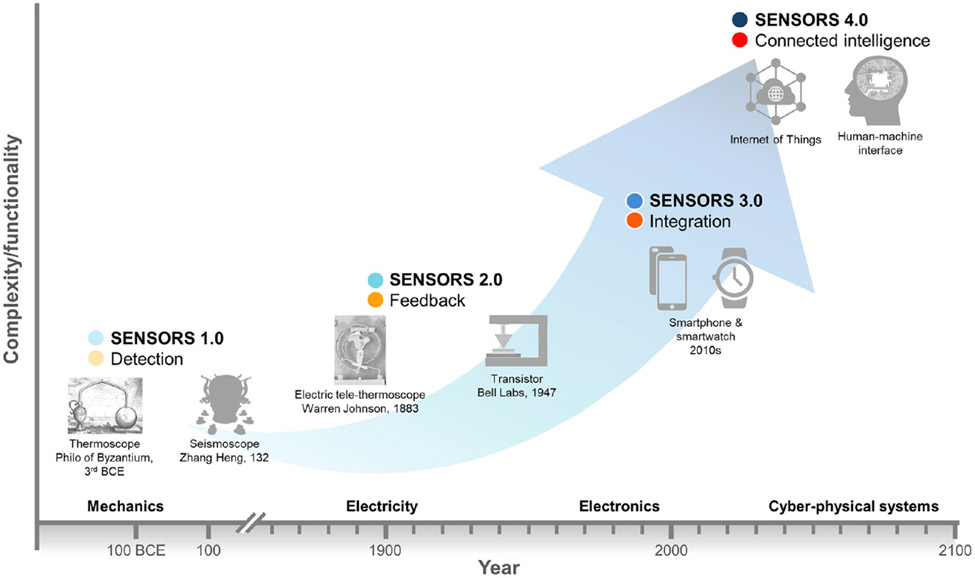

Amongst the first documented sensors in human history are the thermoscope by Philo of Byzantium in the 3rd century BCE for temperature change detection2 and the seismoscope by Zhang Heng in 132, used to detect the occurrence of earthquakes and approximate their directions.3 Sensors in this early era (what we define as Sensors 1.0, Figure 1) convert physical quantities/events to mechanical outputs that are easily observable. Later, with the discovery of electricity and the invention of electric generators, sensors were designed to convert physical parameters to electric signals, enabling control function. For instance, the electric tele-thermoscope invented by Warren Johnson in 1883 could not only monitor temperature, but could also modulate the function of an automatic temperature control system.4 This marked the era of Sensors 2.0. Moving to Sensors 3.0, the electronics industry promoted the miniaturization and integration of sensors with other electronic components, giving birth to smart devices such as smartphones and smartwatches, where dozens of sensors collectively provide an impressive user experience. In recent years, advances in the Internet of Things (IoT), Industry 4.0, big data, artificial intelligence (AI), robotics, and digital health5 have prompted sensors to become more connected and intelligent, entering Sensors 4.0. For instance, a large number and variety of sensors are embedded in autonomous vehicles with wireless connectivity for adaptive self-driving, and connected IoT sensors integrated with AI provide effective solutions to energy management of buildings and industrial facilities.6

Figure 1.

Evolution of sensor technology. Sensors 1.0 only served the function of detection. Sensors 2.0 had the hallmark of electrical feedback. The first transistors achieved sensing as well as the amplification of current.7,8 Sensors 3.0 are characterized by miniaturization and integration. A smartphone is equipped with pressure sensors, light sensors, sound sensors, temperature sensors, image sensors, motion sensors, location sensors, among many others; smartwatches are likewise equipped with an increasing cohort of diverse sensors. Budding Sensors 4.0 technologies involve sensor networks and advanced algorithms to achieve enhanced perception capabilities and intimate cooperation between humans and machines.

Sensors that translate the physical world into data serve a foundational role in the era of digital transformation. In the digital era, connectivity and decision-making rely heavily on high-quality big data—any data bias or inaccuracy may lead to distorted conclusions and/or incorrect decisions, and the consequences can be catastrophic.9,10 Therefore, it is critical to develop sensors that can acquire accurate and reliable data at large scales. This capability would potentially expedite solutions to the grand challenges facing humanity,11 such as aging populations,12 infectious diseases,13-15 food security,16-19 energy crises,6,20 climate and environment crises,21-24 and would improve our quality of life. For example, sensors could be employed to test patients for common diseases and even to predict them, to detect bacterial growth in every food package, or to monitor pollution in every lake, stream, and river.

However, conventional sensor technology is usually incapable of such massive-scale ubiquitous monitoring. Being highly integrated and miniaturized, modern sensors serve adequately as the components of smart electronics/machines, but their small and rigid form factors restrict their usage in many applications such as healthcare wearables, interactive robots, smart packaging, and building-integrated electronics, where flexible sensors would enable advances (Table 1). In this Review, we define flexible sensors broadly to include all types of sensors that can withstand mechanical deformation (>10 m−1 bending curvature or >1% strain on a device/system) without device failure or significant alteration in sensing performance. We include bendable, rollable, foldable, stretchable, twistable, and conformable sensors.25 Flexible sensors enable measurements on dynamic and/or shape-changing objects and large-area non-flat surfaces,26 due to their mechanical flexibility and stretchability, shape adaptability, and fabrication scalability, with which rigid sensors typically struggle. Flexible sensors are lightweight, thanks to the use of organic materials and/or thin-film form factors, benefiting integration, distribution, and application. Furthermore, some flexible sensors can be manufactured using low-cost materials and large-scale processes such as printing,27,28 making mass deployment economically viable. Importantly, the use of organic materials, the thin-film form factor, and the additive manufacturing of flexible sensors may provide more environmentally sustainable ways of sensor production and disposal, tackling the escalating electronic waste problem.29

Table 1.

Comparison of Conventional Rigid Sensors and Emerging Flexible Sensors

| Form factor/ appearance |

|

|

|---|---|---|

| Rigid sensors | Flexible sensors | |

| Performance | ||

| Stretchability | < 1%a,30 | Up to 1000%31,32 |

| Young’s modulusb,33 | 1–200 GPa | 10 kPa–200 GPa |

| Conformability on non-flat surfaces | No | Yes |

| Measurement during mechanical deformation | No | Yes |

| Manufacturing | ||

| Methods | MEMSc techniques | Printing, MEMS techniques, etc. |

| Scale27 | 0.01–0.1 m2 (wafer) | Up to 1–100 m2 (web)28 |

| Single-step throughput27 | 0.001−1 m2 min−1 | Up to 10–1000 m2 min−1d |

| Potential cost per unit area34 |

High |

Low |

| Carbon footprint | High | Low |

| Applications | ||

| Smartphones, autonomous vehicles, industrial robots, etc. | Conformal skin patches, smart textiles, sticker sensors for industrial IoT, supply chain, food, etc. |

Stretchability of rigid sensors is approximated as the fracture strains of conventional electronic materials. However, the real stretchability would be smaller taking performance alteration in consideration.

Ranges cover the Young’s moduli of common materials (packaging materials included) used in rigid and flexible sensors.

MEMS, microelectromechanical systems.

Assuming 1 m wide web on a roll-to-roll platform.

The above features make flexible sensors well positioned for applications that have demanding requirements in mechanical compliance, integration density and scale, manufacturability, and cost. For example, the physiological parameters that current wearable sensing technologies (e.g., continuous glucose monitors, smartwatches) can measure are limited.35 Medicalgrade measurements of electrocardiogram and sweat metabolites require conformal contact between the sensor and the skin, but this goal is hardly achievable by rigid sensors without causing discomfort due to the surface micro-texture and deformation experienced by the skin.36 In contrast, soft and stretchable sensors can address these issues, offering disruptive solutions for future healthcare.37-39 For robots to interact safely with humans,40 high densities of sensors (>10 sensors per cm2 to be comparable to human skin41) would need to cover the curved robotic surface over large areas (~m2).42 In this regard, monolithically manufacturing sensor arrays on flexible substrates is much more efficient than individually placing rigid sensor pixels.43,44 Furthermore, smart packaging with embedded sensors for product tracking and quality monitoring will be critical to efficient and sustainable supply chains,45 yet sensor stickers need to be manufactured at costs as low as a few cents to realize this large-scale (and often disposable) application. Likewise, to install sensing maps in industrial facilities such as pipes, walls, and floors, low-cost and large-area manufacturability is pivotal. To this end, printed sensors using solution-processable organic/carbon materials provide the most promising solutions. In all, the advantages offered by flexible sensors target the issues of data quantity and quality in the digital era, which will make flexible sensors one of the most valuable players in Sensors 4.0.

Flexible sensors have matured tremendously since the beginning of the 21st century. Starting with pressure sensor arrays on plastic films,43 flexible sensors now cover a wide range of physical and chemical sensing modalities, including temperature, strain, electrophysiology, ions, biomarkers, metabolites, gases, and many more.46-55 Substrates are not limited to plastic films but can also be ultra-thin plastic foils,56 porous polymer mats/meshes,57 paper,58,59 elastomers, and hydrogels.60 From single sensors to sensor arrays, from stand-alone sensors to integrated sensing systems,28 the development has been astonishing, and fascinating applications including sweat-based stress monitoring54,61,62 and remote robotic control through skin sensor-enriched virtual reality63 have been demonstrated.

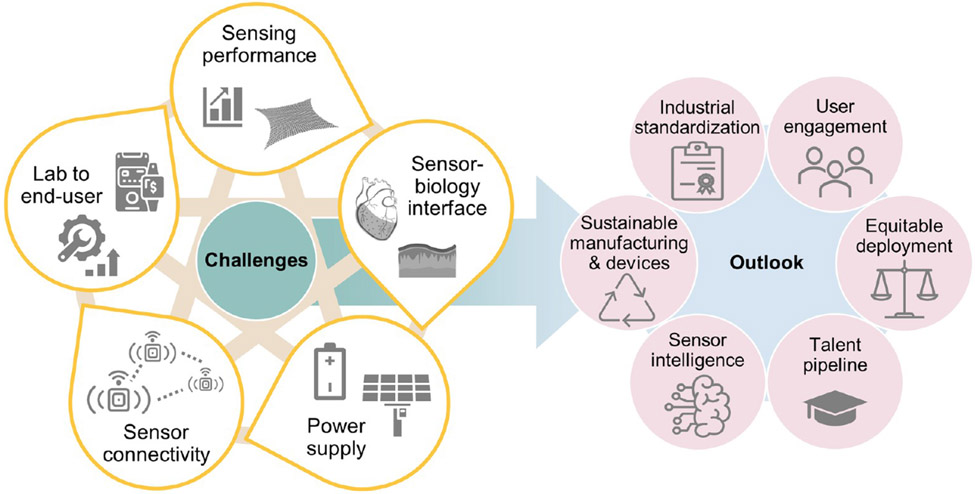

Despite significant research achievements, the adoption of and market for flexible sensors often falls short of predicted levels.27 Some flexible sensors still have a long way to go to meet the stringent demands posed by real-world problems. It is therefore timely to identify the bottlenecks hindering flexible sensor deployment, not only technical challenges, but also cultural and regulatory hurdles (Figure 2, left). Here, we summarize promising on-going efforts to address these challenges and propose further plausible solutions. In doing so, we hope to steer and to accelerate research efforts towards faster translation of laboratory innovations and prototypes into widely used products. Additionally, we anticipate long-term issues facing future sensor deployment (Figure 2, right). Early awareness of these issues will prompt crafting and development of effective solutions. We conclude by predicting what future intelligent flexible sensors will do. These challenges and prospects are summarized into a comprehensive roadmap, in the hope of guiding collective and cooperative development strategies towards common goals by the research community and beyond.

Figure 2.

An overview of issues covered in this Review, including challenges for flexible sensors in the near future (left) and issues to address in the long run (right). The five aspects of challenges are interrelated, reflected by the tan lines in the background.

SENSING PERFORMANCE

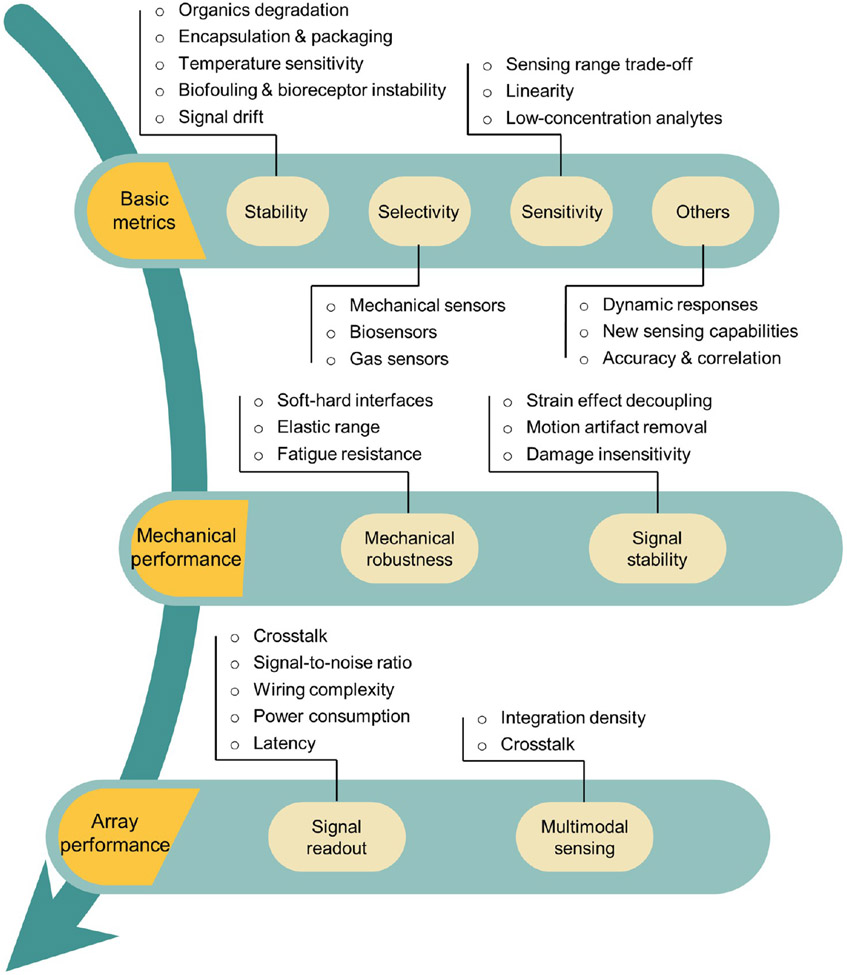

Sensing performance is of paramount importance for any sensor. Performance of flexible sensors encompasses the basic metrics that apply to both rigid and flexible sensors, including the classical 3S’s (stability, selectivity, and sensitivity), as well as aspects unique to flexible sensors, including tolerance to mechanical deformation and monolithic integration into large-area sensing arrays. We identify key issues in these three aspects: basic metrics, mechanical performance, and array performance (Figure 3), and provide detailed discussions on existing solutions and research gaps.

Figure 3.

Overview of key issues in the sensing performance of flexible sensors.

Basic Performance Metrics Comparable to Rigid Sensors.

Stability, selectivity, and sensitivity are primary metrics used to assess sensor performance. Because of the materials, manufacturing techniques, and sensing mechanisms used in flexible sensors, their performance often falls short of rigid sensors, even when no mechanical deformation is involved. Here, we discuss some most prominent issues in the 3S’s—stability being the most challenging and pressing problem for real-world applications, particularly when trying to achieve long-term sensing. We also briefly discuss considerations other than the 3S’s, including the dynamic responses of mechanical sensors and sensing capabilities enabled by wearable biosensors. We summarize sensor performance by emphasizing holistic approaches to sensor accuracy and fundamental correlation-establishing studies.

Stability in Harsh Environments Despite the Use of Unstable Materials.

Stability is essential for deployable sensors because it ensures repeatable and reliable usage in changing environments, especially for long-term monitoring. Here two dimensions are considered: time and stress (e.g., temperature, humidity).64 The challenge of stability for flexible sensors often stems from the use of organic and polymeric materials in their fabrication, which tend to degrade over time and whose properties are easily altered by environmental factors. Furthermore, wearable biosensors incorporating biological receptors face additional bio-instability. The challenge is exacerbated by the degradative environments flexile sensors are exposed to, such as in vivo tissues and biofluids, the deep sea, and high altitudes, where extreme physicochemical stresses are present.

The most straightforward approach to tackling the stability challenge is to improve the environmental stability of sensor materials. Engineering conventional rigid sensor materials into flexible and stretchable form factors is one effective approach, but the fabrication complexity can limit scalability and cost effectiveness. A special case of this strategy is the recently discovered giant magnetoelastic effect in soft systems for pressure sensing, where inorganic magnetic particles are embedded in elastomers to induce changes in magnetic fields under deformation.65 The sensing materials and mechanism employed are intrinsically waterproof and environmentally stable.65-68 While materials synthesis and modification towards environmentally stable organics69-71 and other emerging materials (e.g., perovskites)72,73 are a constant pursuit, this strategy is fundamentally challenging, governed by the physicochemical nature of these materials.

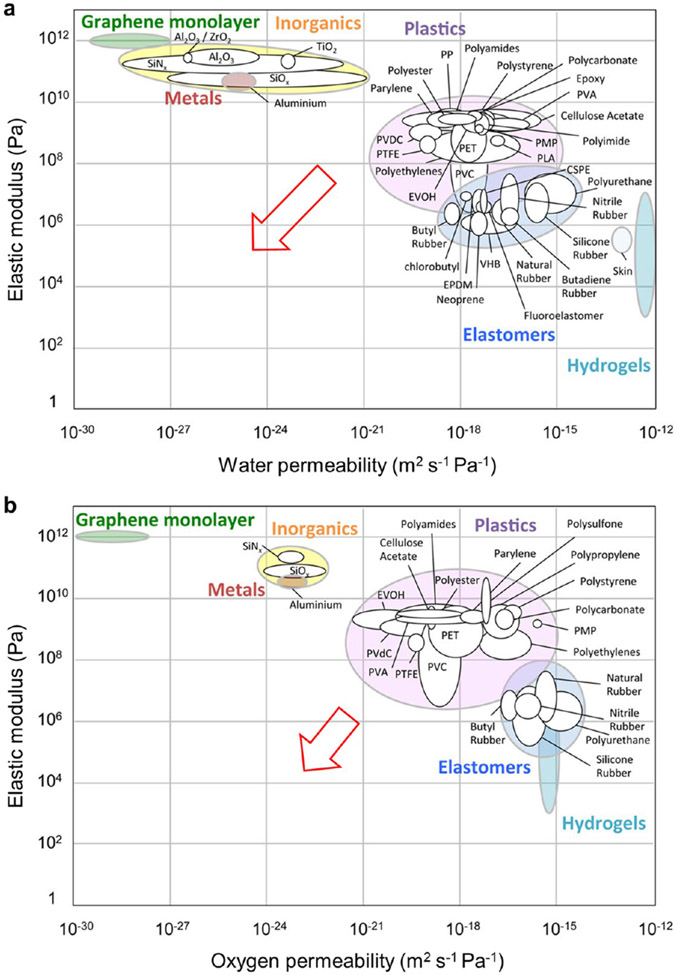

Therefore, when no direct contact between the stimulus and the sensing material is required (in mechanical, temperature, and light sensors, for example), a more viable approach is to apply protective layers to sensitive materials and the entire device.74 To this end, high-performance humidity and oxygen barrier materials are in great demand. However, flexible materials themselves usually have poor barrier properties (Figure 4) due to the intrinsic free volume in polymers and defects in inorganics,74 and barrier properties degrade with repeated mechanical deformation. Such issues are most severe for the elastic packaging of mechanical sensors and other stretchable sensors, when both elasticity and barrier properties are required.75 Adding thin-film coatings76 and filler additives to packaging materials are two frequently employed strategies,77 but there remains a lack of effective methods to improve the barrier properties of elastic substrates and packaging layers.60 In addition to specialized barrier layers, effective sealing is also critical for devices made of fluidic or liquid-containing materials (e.g., liquid metal, electrolyte, hydrogel) and devices used in liquid environments (e.g., in vivo biological tissues,76 sea-water78).

Figure 4.

Barrier properties against (a) water and (b) oxygen of common materials used in flexible sensors, plotted versus elastic modulus. Softer materials are more flexible and usually more stretchable but suffer from poorer barrier properties. Soft barrier materials with moduli comparable to elastomers and hydrogels, as well as permeabilities comparable to inorganics are highly desirable for effective encapsulation (red arrows). Adapted with permission from ref 75. Copyright 2018 American Chemical Society.

Encapsulation, and packaging in general, are of paramount importance to flexible sensors, especially wearable sensors. Proper packaging enables users to wear devices over extended periods with minimal noise or signal drift. This issue is often ignored by the academic community and is more typically considered by industry. However, packaging must be addressed in order to obtain meaningful on-body data in population studies.

Temperature is an environmental stress affecting almost all flexible sensors because most sensing materials, including rigid ones, are sensitive to temperature changes.79 This problem cannot be solved simply through material optimization or encapsulation. Introducing additional compensation elements such as temperature sensors and feedback circuits80,81 is generally more effective. Alternatively, exploring sensing mechanisms that circumvent the temperature-sensitive aspects of the sensing material82,83 is viable, although not as a general solution. Overall, to suppress temperature effects with simple device structures and high integration remains a challenge.

Stability is a significant challenge for flexible chemical sensors, especially wearable biosensors,36 where bio-fouling and bioreceptor inactivation are two major factors that affect long-term (several days) sensor performance. The fouling layer strongly influences the selectivity and binding affinity of biorecognition events and results in strong background signals as well as poor signal-to-noise ratios. One of the most commonly used strategies to combat biofouling is drop-casting protective polymeric membranes such as Nafion and chitosan.84,85 Other anti-fouling coatings such as bovine serum albumin (BSA) and poly-(ethylene glycol) are also effective.86-88 However, a drawback of this surface-coating strategy is the reduction or blockade of electronic conduction between the biorecognition moiety and the transducing electrode. To tackle this problem, three-dimensional (3D) nanocomposites composed of anti-fouling agents (e.g., BSA) and conductive materials (e.g., gold nanowires, carbon nanotubes, CNTs) have been engineered.89 Alternatively, surface roughness and wettability control can also circumvent this problem. For example, nanoporous Au electrodes minimized fouling by slowing down mass transport while allowing efficient small-molecule exchange.90 Insights from skin biology, such as materials chemistry and surface texture, may provide inspirations to tackle biofouling.

Low stability of immobilized bioreceptors in the uncontrolled conditions of wearable applications (e.g., changing temperature and pH) is another issue. Bioreceptors such as enzymes can easily detach from anchoring substrates/electrodes in fluidic environments (and even more so if mechanical deformation is involved) and lose their recognition function outside their operational windows.36 To improve the long-term stability of enzymatic sensors, a nanoporous membrane with effective enzyme immobilization was robustly anchored to nanotextured electrodes, achieving continuous glucose sensing with minimal signal drift for up to 20 h.91 Encapsulation of enzymes within electrodes through a monolithic 3D printing process is another way to improve stability.92 Alternatively, nanozymes, i.e., artificial enzymes made of nanomaterials, can be used,93-95 though often-times compromising selectivity. Molecularly imprinted polymers (MIPs), known as “artificial receptors”, can also overcome the stability issue of bioreceptors while achieving good selectivity.96

Besides biofouling and bioreceptor instability, there are other issues impairing biosensor stability. For example, many reported electrochemical biosensors utilize a mediator layer to reduce the potential required to trigger redox reactions for reduced interference from other electroactive molecules,97 yet the Faradaic signal could decay over time, limiting long-term reliability. Furthermore, charge accumulation on electrode surfaces or material interlayers can lead to signal drift, which can be mitigated by nanotextured electrodes with larger surface areas and more robust bonding with sensing layers.98 Moreover, the interactions between the active layers and biomarkers may alter the surrounding electric field, introducing microenvironmental changes as an interfering factor.

Signal drift over a relevant period of operation is an issue not only for biosensors, but also may be the number one challenge for any sensor technology. However, this issue is often ignored by the academic community outside of electrical engineering. The magnitude and predictability of signal drift often determine the lowest concentration that a sensor can accurately report over its lifetime. Flexible sensors often suffer from much larger signal drifts than their rigid counterparts, which effectively leads to high noise levels. In this regard, it is important for the community to report signal drift and its measurement carefully and precisely, and to understand the exact cause for each emerging sensor technology so that the sensor drift can be tackled effectively. For example, by designing better sensor architectures or customizing compensation algorithms and driving circuits, sensor drift can be reduced.

Stability is central to sensor practicality, yet it is often neglected in academic research. We urge the research community to place more emphasis on stability to push flexible sensors closer to commercialization. When long-term stability is not achievable, making sensors at a low cost such that they can be frequently replaced and disposed of might be another viable route to mass adoption.

Selectivity to Complex Mechanical and Chemical Stimuli.

Selectivity refers to the ability of a sensor to discriminate between the analyte of interest and possible interferences.99 It was originally defined for chemical100 and biological101 sensors but may be extended to include mechanical sensors (e.g., pressure sensors, strain sensors, torsion sensors, etc.). In real application scenarios, a wide range of chemical species and mechanical forces are usually present simultaneously, and they interact with sensing materials through similar mechanisms, thus producing ambiguous sensor responses.

There are two general approaches to sensor selectivity: specific sensors and selective sensor arrays.101 Ideally, a specific sensor only responds to one analyte, and an array of such sensors would tell the exact composition of a mixture without needing a great deal of data analysis. Such specific sensors are often hard to realize. In contrast, in a selective sensor array, each sensor responds to a collection of analytes differently, and the array response collectively produces a fingerprint for a mixture. With proper data analysis, the mixture composition can be accessed. These two principles are widely applied for mechanical sensors, biosensors, and gas sensors.

Mechanical force applied on a sensor is often a mixture of pressure, tension, shear, and torsion. Decoupling these modes is important for gesture recognition, robotic control, and prosthetics. There have been attempts to fabricate ‘specific’ mechanical sensors.83,102-106 For instance, a stiff and anisotropically resistive material was structured into micro-meanders and encapsulated in elastic films such that the sensor was responsive to only one direction of tensile strain and insensitive to bending and twisting.102 Stiff platforms were embedded underneath pyramid microstructures for pressure sensors to achieve undisturbed performance at up to 50% tensile strain.104 Although the insensitivity to other mechanical stimuli of these ‘specific’ sensors is not ideal due to materials and geometric limits, their performance is sufficient for non-critical applications or large values of a strain of interest (e.g., joint movements). ‘Specific’ sensors have been integrated to achieve multi-modal mechanical sensing, where careful mechanical design is needed to isolate and distribute different mechanical stimuli to the desired sensors so that each deformation can be sensed independently.107-109

The other ‘selective sensor array’ principle takes many forms for mechanical sensors. The simplistic implementation is to fabricate deformable sensing materials110,111 and/or design 3D sensor structures112-116 to make the response curves different for different forms of deformation. With proper signal analyses, the correct deformation can be identified. A similar method is to integrate multiple sensors on a miniaturized 3D structure117 or a two-dimensional (2D) surface.118,119 The response of individual sensors differs according to the stress applied; holistic analyses of all sensor outputs derive the deformations experienced. However, using the above methods, it may be difficult to decouple a simultaneous combination of deformations (e.g., compression plus shear) because the signals overlap. Advanced algorithms, such as machine learning, might be able to solve this problem. A third approach is to use materials or devices that are sensitive to several stimuli, but the stimuli can be distinguished by different measurement modes (e.g., resistance and capacitance).111 Readout electronics will be more complex for integrated devices using this strategy, which further increases system-level power consumption and hardware cost in parallel.

Biosensors are used to analyze complex mixtures present in biological samples, which may contain ions, small molecules (metabolites, cytokines, lipids, neurotransmitters, etc.), macromolecules (peptides, proteins, nucleic acids, etc.), and even viruses, bacteria, and cells. Selectivity becomes critically important in analyzing such complex mixtures as closely related interferents (e.g., biological precursors and metabolites) are often present.120 In this regard, nature provides many biorecognition elements that offer high specificity through interactions with metabolites and biomarkers. The utilization of bioaffinity-based receptors, including ionophores, DNAs/RNAs, aptamers, and antibodies on flexible biosensors allows selective in situ target recognition,96 although sometimes at the cost of complicated fabrication and handling, as well as relatively poor stability. In this regard, artificial bioreceptors such as MIPs offer a more stable and easily processible option without sacrificing binding specificity in some cases.96 Effective transduction mechanisms that transform the receptor-target binding to measurable electrical or optical signals are critical. Some promising examples include aptamer-functionalized field-effect transistors,120 molecular pendulum-based biomolecular sensors,121 as well as redox probe-tagged electrochemical aptasensors122 and MIP-based sensors.62 More complex biorecognition elements, including cell membranes123 and whole cells124-126 provide improved specificity towards some analytes, but this advantage comes with increased fabrication complexity and storage requirements. For biosensors that do not rely on bioaffinity for sensing, careful engineering of catalytic nanomaterials can achieve desirable selectivity in the (electro)-chemical recognition of some analytes.127-129

While biosensors are most often used for biofluid analyses, they can also be engineered to detect airborne pathogens130 and biologically relevant gases. Gas sensors are an emerging field for flexible sensors. They provide noninvasive means of biomarker detection to inform metabolic processes and disease progression in humans and plants,131-137 and are thus attractive for real-time health monitoring and point-of-care diagnostics (Figure 5a).138

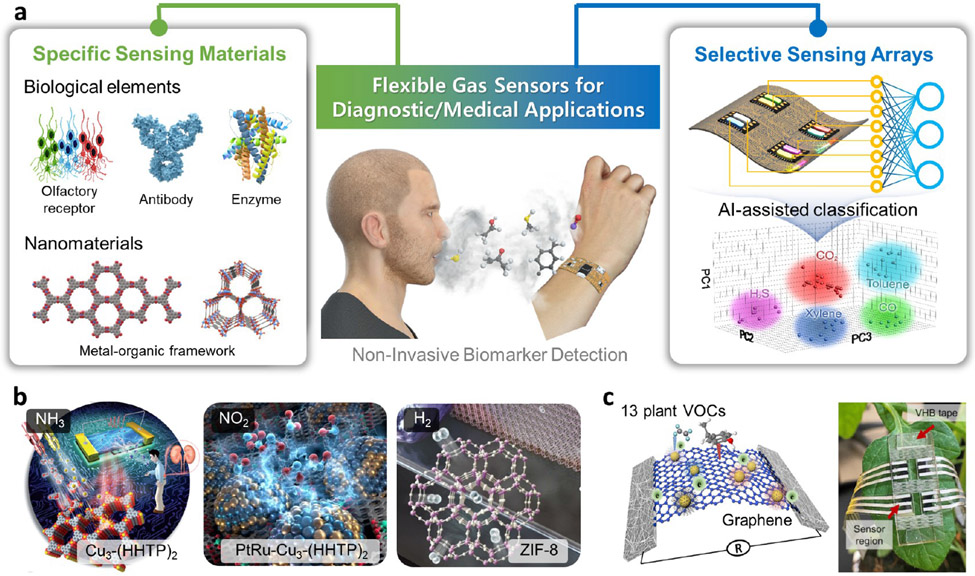

Figure 5.

Selective gas sensors. (a) Overview of the strategies to achieve selective gas sensing, including specific sensing materials and selective sensing arrays. Flexible gas sensors target applications in health monitoring and point-of-care diagnostics. AI, artificial intelligence. (b) Examples of metal–organic framework-based nanomaterials with high sensing specificity to gas molecules. Cu3-(HHTP)2 (HHTP=2,3,6,7,10,11-hexahydroxytriphenylene) thin film for room-temperature NH3 detection. Adapted with permission from ref 139. Copyright 2017 Wiley-VCH Verlag GmbH &Co. KGaA, Weinheim. Bimetallic nanoparticles (PtRu) confined in two-dimensional Cu3-(HHTP)2 for NO2 detection. Adapted with permission from ref 140. Copyright 2021 Wiley-VCH GmbH. Zn-based zeolite imidazole framework (ZIF-8) as molecular sieving layer for selective H2 filtration on Pd nanowires. Adapted with permission from ref 141. Copyright 2017 American Chemical Society. (c) An example of nanomaterial-based selective sensing array for volatile organic compound (VOC) identification. A graphene-based stretchable chemiresistive sensor array for identification of 13 plant VOCs. Reproduced with permission from ref 142. Copyright 2021 Elsevier.

Biomarker volatile organic compounds (VOCs) present in complex mixtures (often with more than a dozen of components) and a complete profile is often required for the determination of physiological status.133,142 Some VOCs have similar molecular structures, making specific sensing challenging. Although there have been attempts to utilize biological olfactory elements, such as olfactory receptors (ORs), olfactory cells, and even olfactory organs,143 as well as other biomolecules (e.g., enzymes, antibodies, aptamers) as the recognition moieties (Figure 5a, left),144,145 insufficient understanding of biological olfactory systems poses fundamental challenges for bioaffinity-based gas sensors. For example, the pairing relationships and the binding/unbinding interactions between gas species and ORs are largely unknown.145 Other factors impeding the development of bioaffinity gas sensors include design complexity for liquid-phase reactions and the high cost and low stability associated with bioreagents, given that gas sensors are currently primarily used for industrial and environmental applications.

The growing healthcare/medical gas sensors area133 may provide an impetus to continue to develop bioaffinity-based sensing.144 In comparison, nanomaterials with tunable structures and chemistries capable of dry-phase sensing seem to be more technically and economically viable.52,146,147 Metal–organic frameworks (MOFs) are particularly attractive because their porous structures can selectively adsorb or filter gas molecules (Figure 5b).148 However, a limited understanding of gas–MOF interactions, as well as the structure–property relationships of MOFs prevents generalized design methodologies for MOF-based gas sensors to cover wide ranges of VOCs.

In contrast to specific VOC sensors, selective sensing arrays are more widely used to recognize gas mixtures (Figure 5a, right). Combined with machine learning, this strategy has seen commercial success in electronic noses.24 Nanomaterials are also a go-to option for selective sensing arrays due to their high sensitivity and ease of tuning surface interactions.149 For instance, graphene functionalized with various ligands and coupled with Au nanoparticles was used to construct an 8-sensor array that could classify 13 individual plant VOCs at >97% classification accuracy (Figure 5c).142 A recent approach achieved the fabrication and utilization of an array of 108 graphene-based sensors functionalized with 36 chemical receptors for the discrimination of 6 gas species within a minute,150 shedding light on rapid VOC detection using largescale sensor arrays. Overall, recent advances in flexible room-temperature gas sensor arrays have achieved lower power consumption, reduced fabrication cost, and greater wearability without sacrificing sensing performance.142,151-155 Although machine learning algorithms capable of higher prediction accuracy can compensate for sensor selectivity short-falls,151,156,157 improving the specificity of each sensor remains a critical challenge.

An interesting application of selective array sensing was recently reported for triboelectricity-based material identification.158 An array of sensors with differential triboelectric properties generated a fingerprint signal pattern when in contact with a particular material. Combined with machine learning, the accuracy for materials classification reached 97% when four sensors in an array were used. Such strategies may find wider application in flexible sensors to enable more sophisticated sensing capabilities.

Sensitivity with Wide-Range Linearity and to Low-Concentration Analytes.

High sensitivity allows sensors to detect minute changes in a stimulus, to reduce false-negative signals, and to improve signal-to-noise ratio and accuracy. The sensitivity of most flexible physical sensors (e.g., mechanical sensors, temperature sensors, photodetectors) is sufficient for common applications. A notable issue is the trade-off between sensitivity and sensing range in mechanical sensors. In comparison, sensitivity is more of a concern for chemical sensors, specifically biosensors that detect low concentrations of analytes present in biofluids.

The trade-off between sensitivity and sensing range, and the issue of nonlinearity exist in most mechanical sensors,111,159-163 and are especially prominent for pressure sensors.164 Ideally, high sensitivity across a wide force/pressure range is desirable, but is hardly achievable in bulk piezoresistive/piezocapacitive sensors, because of the stiffening effect of soft materials upon compression. Microstructuring is a common strategy to improve sensitivity,165,166 yet this approach mostly works at low pressures. There have been many attempts to address this problem. Structure-wise, intrafillable microstructures accommodate deformed surface structures in the underlying undercuts and grooves, thereby retarding the saturation of porous structures.167 Mechanism-wise, combined piezoresistivity and piezocapacitivity significantly increase sensitivity, even at large stress of up to 50 kPa.168 The magnetoelastic effect is useful for pressure sensing over a wide range, from 3.5 Pa to 2000 kPa,169 and its sensitivity is comparable to those of piezoresistive and piezocapacitive sensors.

The above methods do not solve the nonlinearity problem. One solution is using hierarchical microstructures, such as micropillars on hemisphere arrays.170 Adding gradient charge distribution within the active material may be able to solve the nonlinearity issue. This strategy has been demonstrated in a capacitive pressure sensor, reaching a record-high linearity range up to 1000 kPa. The mechanism is gradient compressibility and dielectric property with increasing pressure, realized by a skin-like hierarchical microstructure made of materials of different permittivities.171 This strategy may be extended to other types of pressure sensors based on gradient conductivity or gradient ionogels. Another perspective on addressing this sensitivity-range conflict is to program the sensor performance on demand based on application requirements, since extraordinarily high sensitivity is usually required for small pressure detection, whereas for large pressure, a wide sensing range is more important. A stiffness memory ionogel was developed,172 whose stiffness could be tuned by pressure plus thermal treatment. The programmable stiffness led to programmable pressure ranges, detection limits, and sensitivity. Although an interesting concept, the practical applicability of such customizable sensors should be carefully evaluated, taking account of reproducibility, calibration, etc.

Generally, for mechanical sensors and other sensors involving mechanics sensing (e.g., vibration sensors, ultrasound imagers173), sensitivity–deformability entails a balance of rigid and soft materials in rationally designed structures—rigid materials usually lead to good sensitivity, whereas soft materials enable large deformability. Integration density, system complexity, and manufacturability are key factors to consider when devising wide-range sensitive systems.

Highly sensitive wearable and implantable biosensors are strongly desired for on-body and in-body chemical sensing to aid diagnostics and therapeutics, but this technology is relatively underdeveloped. Currently reported biosensors primarily focus on biomarkers at the levels of tens of μM or higher.174-176 There are a number of clinically relevant biomarkers such as proteins, peptides, hormones, small molecules, and drugs existing in sweat or saliva at nanomolar levels and lower.177 To enable the detection of these biomarkers, the sensitivity of flexible biosensors needs improvement.

Various nanomaterials such as conducting polymer nano-fibers,178 graphene,179 nanostructured gold,180 MOFs,181 and transition metal nanoparticles (e.g., Fe3O4 and NiO)127 are often utilized on the working electrode in electrochemical sensors as they can enhance the electrochemically active surface area and electron transfer dynamics, resulting in higher detection signals.52,176 Recent reports show that laser-engraved graphene enabled the detection of sweat uric acid, tyrosine, and cortisol at sub-micromolar levels,61,182 and dendritic gold nanostructures were successfully used to monitor micromolar levels of vitamin C and glucose in sweat.91,183 Besides nanomaterials, micro- to macro-scale approaches can also increase electroactive surface areas, using printable ink formulations and 3D hybrid electrode structures.184,185

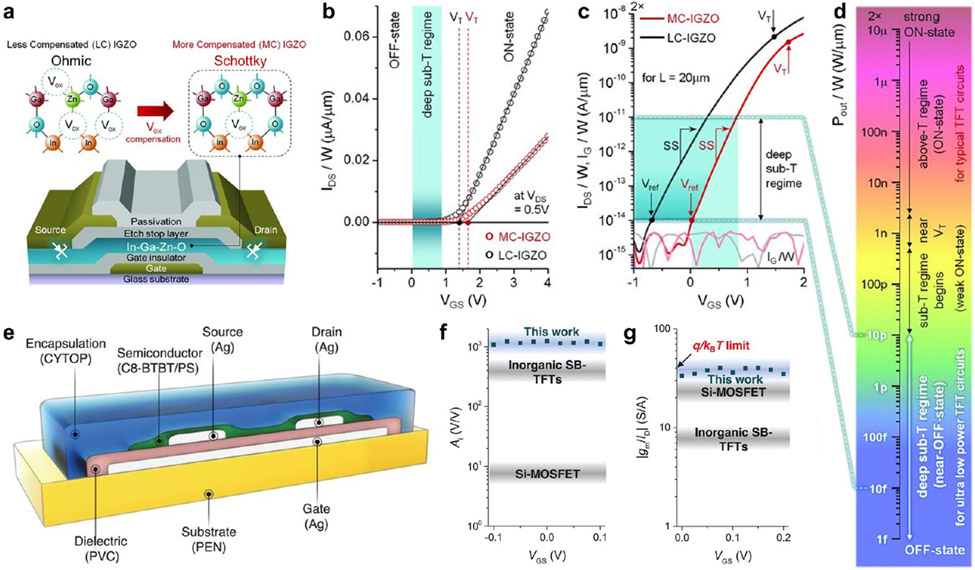

Signal transduction is important to sensitivity—effective transduction can amplify binding events to reach measurable signals. Transistors, including field-effect transistors (FETs)54,120,186-189 and organic electrochemical transistors (OECTs),190-192 are effective amplification devices.191,193,194 When the channel of a FET is reduced to the nanoscale, the high surface-to-volume ratio enables highly sensitive detection.195 By employing this mechanism with an aptamer, cortisol at a concentration down to 1 pM could be selectively detected.54 In addition, reducing the molecular size of surface-bound bioreceptors, such as using oligonucleotides in place of DNAs187 and nanobodies in place of antibodies,192 can bring the target-binding event closer to the transducer and may therefore enhance sensitivity. This consideration can also be useful in the design and selection of aptamers, to ensure that significant conformational changes in the artificial receptor occur close to the surface so as to gate the FET channel optimally.120 Successful engineering of peptides196 and DNA197 into semiconductors may allow the unification of analyte binding, transduction, and amplification in a single material, offering improvement in sensitivity and response time. Devices capable of effective amplification should be explored further for wearable biosensors. For example, subthreshold Schottky-barrier thin-film transistors demonstrate exceptional intrinsic gain of up to 1,100 V V−1.198 Schottky-contacted nanowire sensors were found to enhance the sensitivity of Ohmiccontacted sensors to light, gas, and (bio)chemicals by orders of magnitude.199

Colorimetric biosensors are attractive due to low cost, simplicity, and automated operation, but their poor sensitivities call for effective signal-amplifying mechanisms. Fluorescent biosensors could be a good alternative as fluorescence can boost sensitivity by up to 1000× that of colorimetry.200 Nanocatalysts are also promising, previously achieving 100× amplification in antibody-based lateral flow immunoassays.201 Careful design of the catalytic inorganic nanoparticles with organic recognition moieties is critical in achieving desirable sensing performance. Nevertheless, current methods for colorimetric and fluorometric signal detection by the naked eye, in-built detectors, or external cameras suffer from drawbacks such as subjectiveness, device bulkiness, and manual operation. Simple methods to quantify colorimetric and fluorometric signals digitally from wearable biosensors are needed.

Another potential way to enhance the sensitivity of biosensors is the preconcentration of target analytes through ion concentration polarization202 or dielectrophoresis.203 Target preconcentration has been used for wearable real-time monitoring of low-level heavy metals in sweat.204,205 A further strategy being explored is to amplify signals using low-noise and high-gain circuits, such as differential amplifiers and charge-coupled devices.206

Considerations beyond the 3S’s. Dynamic Responses of Mechanical Sensors.

Since mechanical deformations occur time-dependently, the dynamic responses of mechanical sensors to varying strains and stresses critically determine sensor accuracy in practical use. There are three major issues in this regard: hysteresis, response time, and strain-rate dependency, which are highly interrelated.

Hysteresis refers to differing response curves between loading and unloading, presenting a fundamental challenge for mechanical sensors. It stems from the viscoelasticity of common soft materials (e.g., elastomers, gels) used in flexible mechanical sensors,110 especially when doped with conducting fillers. Micro-/nano-structuring for enhanced sensitivity adds another source of energy dissipation from interfacial contact.207 Moreover, flexible mechanical sensors usually possess longer response times than rigid counterparts due to sluggish polymer chain movements. This difference precludes time-critical applications such as in robotic control and high-frequency applications, such as motion tracking in racing sports. Strain-rate dependency refers to the differing response curves under varying deformation rates or frequencies, leading to inaccurate readings in many applications, since most deformations encountered in daily life are not at constant speed. This phenomenon is often closely related to long response times, i.e., when the structural or molecular changes in sensors cannot catch up with the macroscale exerted stress, the sensors deviate from equilibrium states to varying extents at different strain rates. Sometimes, strain-rate dependency is an intrinsic characteristic dictated by the sensing mechanism (for instance, pressure sensing based on magnetoelastic generators depends on the rate of change in magnetic flux65,169,208). An effective strategy to overcome hysteresis and related issues is to use rigid materials with special structural designs for strain sensing, while soft materials are still required for deformability.209,210 Microstructuring is effective for pressure sensors through a reduction in contact area.164 Alternatively, careful engineering of polymeric networks can mitigate hysteresis,211-215 yet the materials fabrication can be complex and thus difficult for device integration. An emerging approach leverages machine learning to correct the errors associated with the viscoelastic properties of soft sensors for better prediction and analyses.216

The dynamic performance of mechanical sensors may appear trivial, yet it is critically important to practical measurements, deserving of greater attention. For example, although stretchable strain sensors using conductive elastomeric composites have been widely reported, their dynamic performance has rarely been investigated. Most studies only focus on quasi-static electric behavior, where the sensing performance was evaluated in a static state or in slow stretching–releasing processes (deformation speed <30 mm min−1, strain rate <10% s−1).217 Few studies have paid attention to the signal fidelity of strain sensors at higher deformation speeds,215,218 which is more relevant to dynamic motions in real life, such as limb movements and hand gestures (speed >100 mm min−1, strain rate >20% s−1).217 In monitoring these dynamic motions, strain sensors using elastomeric composites usually experience signal distortion, which is a common yet often overlooked problem.219-222 Dynamic responses at high and varying strain rates should be included as an essential performance metric when reporting mechanical sensors.

Sensing Capabilities of Wearable Biosensors.

Wearable biosensors are still in early stages of development and many sensing capabilities await exploration and development.36,223-225 The first area of improvement is to expand the portfolio of biomarkers that can be detected, to approach and to exceed current clinical assays. Complex biomarkers (e.g., proteins, hormones, nucleic acids, small molecules, and pathogens) usually require bioaffinity-based sensing, and this strategy demands the design of effective biorecognition moieties and proper immobilization and stabilization. Sensitive and selective aptamers are being developed for a wider array of targets and they could be deployed for this purpose.120 Moreover, some approaches require multi-step preparation (e.g., immunobiosensors using antibodies),88 making them challenging to integrate into wearable platforms. Microfluidics is one promising approach,15,226-229 which helps to collect, to contain, and to drive biofluids, as well as to deliver and to wash out unbound detection probes or labeling reagents. In addition, to reduce the number of preparation steps and time consumed in immunosensing, development of label-free, reagent-free, and wash-free methods is also necessary.200 Surface-enhanced Raman spectroscopy (SERS) has emerged as a powerful tool in this regard, but it requires a standalone spectrometer for signal readout.230,231 Recent work proposed an indirect electrochemical approach based on MIPs coupled with redox-active reporters, which enabled the detection of non-electroactive species in sweat, including amino acids, vitamins, metabolites, lipids, hormones, and drugs.228 This approach may be customized to detect a more diverse range of biomarkers.

A second area worth exploring is to realize continuous monitoring of these biomarkers, which enables real-time monitoring and prompt detection of abnormalities. Common bioaffinity assays (e.g., immunoassays) of disease biomarkers involve complex steps, require accurately controlled sample volumes and receptor regeneration, and are not reversible. These features make immunoassays not amenable to continuous on-body operation. Innovative strategies need to be crafted to overcome these challenges. For example, modulating intermolecular forces between the bioreceptor and the target using proper stimuli such as heat, ultrasound, electric/magnetic fields, and chemical cues might be a viable approach to sensor regeneration.51 Using this strategy, the regeneration of MIP-based electrochemical biosensors by current or voltage has been demonstrated.228 A resettable electrochemical sweat lactate sensor has been developed through reversible redox reactions in a biofuel cell.232 Regeneration of aptamers for cocaine sensing has been realized through pH-modulated conformational changes.233 Microfluidics are a promising platform for continuous-monitoring wearable biosensors. For instance, stretchable microfluidics can expel sweat from filled channels to enable multiple usage.234 Rational design in channel shape and wettability can accelerate sweat collection and realize continuous sampling.235,236 High temporal resolution can be achieved through encapsulating biofluids in water-in-oil droplets and assessing the droplets sequentially, although system compactness needs improvement.237 Meanwhile, safe, continuous, controllable, and quantitative biofluid sampling is also an important aspect of continuous biosensing. Passive micro-fluidics,238-240 porous/hydrogel absorption pads,128,180,241-244 microneedles,245,246 iontophoresis and reverse iontophoresis174,247,248 are common solutions, but none can simultaneously satisfy all requirements. Lastly, while wearable sweat sensors are the most often studied, other bodily fluids such as saliva, tears,249 and wound exudate should also be explored,224 as they may provide biomedical insights inaccessible via other means.

Equally important to technological advancement, robust knowledge of the clinical and biomedical relevance and correlation of various bodily chemicals is needed to guide the design and engineering of practically relevant biosensors. This knowledge often involves metabolites in biofluids not traditionally studied.51 In each case, the contents of the fluids will need to be compared to current gold standards (typically blood) to determine whether the fluid is representative of physiological state and what conversion factors are appropriate to analyze the data obtained. Then, the advantages of more frequent and, in some cases, continuous monitoring can be realized.

Holistic Approach to Accuracy Assurance.

Reporting accurate values of the parameters of interest is essential to sensors. To ensure sensor accuracy, it is important to take a holistic approach spanning the entire life cycle from the development to the deployment of a sensor technology (Scheme 1). First, during the design stage, fundamental materials research is required to understand the materials properties, transduction mechanisms, and device physics. This knowledge leads to optimized materials and device structures. Going back and forth between scientific inquiry and engineering optimization would lead to improved sensor accuracy, while the 3S’s and other factors should be considered. Moving from design to deployment, well-controlled fabrication to produce consistent devices is critical. Moreover, large-scale validation with standardized procedures and benchmarking against gold-standard measurements are necessary to obtain reliable and trustworthy calibration curves. For biomedical sensors, validation experiments can be designed in accordance with the guidelines of the Clinical and Laboratory Standards Institute.

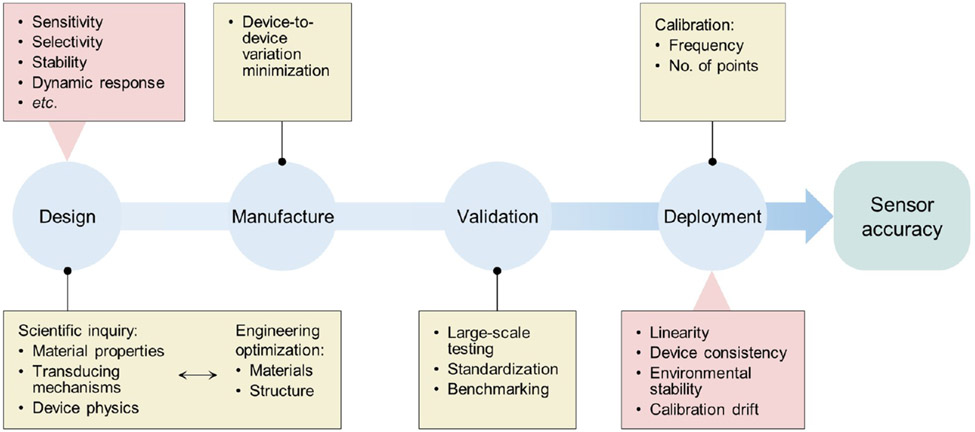

Scheme 1. A Holistic Approach to Sensor Accuracy Assurance during the Design, Manufacture, Validation, and Deployment of a Sensor Technologya.

aFactors to consider are highlighted in red boxes.

In real-world deployment, calibration can be a complex issue. There are two levels of consideration: the frequency of calibration during the entire sensor lifetime (manufacture, shipment, and usage) and the number of calibration points for each calibration. Calibration frequency usually concerns whether calibration can be performed by the manufacturer prior to shipment of the product. Most commercial sensors fall in this category. In this case, the cost of calibration is typically one third of the total cost of most commercial sensors today. However, the exact cost depends on the number of calibration points that are needed. If the sensor has a linear response in the needed dynamic range and if it has the same sensitivity in that range for all manufactured components but different offset values, then a single-point calibration is all that is needed. If the manufactured sensors do not have any offset in their base value with the same sensitivity, then no calibration is needed (which is rare but would significantly reduce costs). If a sensor has a linear response in the needed dynamic range but there is variability in the sensitivity from sensor to sensor, then two-point calibration is needed. If the sensor response is not linear, then multi-point calibration is needed (which is commercially unattractive). Furthermore, calibration against temperature, humidity and other environmental factors may be needed. For some emerging sensor technologies, the calibration can shift over time, for example, from the time of manufacturing to the time of usage. In that case, additional one-point or two-point calibrations may be needed prior to use, which complicate use. Therefore, it is critically important for the community to report linear response ranges, sensor-to-sensor variability, stability against environmental factors, calibration method, and calibration drift over time.

Reliable Correlations between Sensor Signals and Object Status.

Data without interpretation is of little use. Making sense of data collected by sensors is equally, if not more important with high-quality data acquisition. As flexible sensors enable many parameters to be acquired in unconventional situations or from previously inaccessible locations, the correlations between these parameters and the status of the monitored objects, environments, etc. should be carefully examined.250 Even for a single physical parameter, the underlying meaning can be complicated to unravel. For instance, facial strain was recently verified as an indicator of language commands through theoretical analysis and simulation,250 permitting the use of conformal strain sensors on face to deliver language commands silently.

The correlation issue is especially concerning for biomedical applications, such as biomarker measurement for disease diagnosis251 and physiological monitoring for health assessment.13 A recent report found close correlations between tear glucose levels and blood glucose levels with a lag time of 10 min,252 indicating promising noninvasive glucose monitoring by contact lenses. The study was conducted on three rabbits in the experiment group and the control group respectively, which may not be sufficient as biologically conclusive or generalizable to humans. Sweat is another biofluid in which glucose monitoring is extensively conducted.253 Nevertheless, the correlation between sweat glucose and blood glucose can be easily altered by sample collection methods as well as skin and environmental conditions.254 The large uncertainty renders wearable sweat glucose sensors255 only sufficient for range estimation but not currently qualified for guiding medical interventions. Large-scale tests with standardized protocols are needed to reach robust conclusions. In addition, equal gender representation in clinical trials is also curial for flexible sensor development and their practical usage in public. Recent results on a conformable multimodal sensory face mask performed on an equal number of male and female subjects indicate that current face masks are not suitable for women subjects in general.256 This result suggests a comprehensive mandate to be inclusive in human subject studies to have technologies be beneficial for all.

As flexible sensor technology is collecting signal types some of which are traditionally inaccessible, problems emerge in terms of the implications of sensor data. This issue calls for extensive fundamental and biomedical research, where investigations involving gold-standard tests on adequate sample sizes257,258 are needed to test the existence of correlations and to generate reliable reference databases.

Tolerance to Mechanical Deformation and Damage.

A major advantage of flexible sensors is the ability to withstand significant deformation without physical failure or performance degradation. This feature permits many use cases with which conventional rigid sensors struggle, such as conformal skin patches/tattoos and smart clothing. Nonetheless, this flexibility also poses great challenges in maintaining sensor integrity and performance under often-unpredictable mechanical interactions between the sensor and the environment.

Mechanical Robustness in Long-Term Use and at Large Deformation.

Mechanical robustness describes the sensor’s ability to withstand different forms of deformation without mechanical failure. Some extreme cases include exceptionally large strain and high impact,102 prolonged cycling strain, and constant friction. While conventional rigid sensors can be protected from mechanical damage using high-performance ceramics, metals, and thermosets, deformability of flexible sensors does not permit the use of these mechanical protective materials in conventional ways. Furthermore, due to the wide variety of materials used in flexible sensors, each having distinct mechanical properties (e.g., elastic modulus, Poisson’s ratio, viscoelasticity) and surface properties (e.g., surface energy, chemical composition), interfacial mismatch contributes a major factor to mechanical instability. The exact deformation a flexible sensor experiences varies greatly according to application, and hence exceptional mechanical robustness is not always required. Nevertheless, we highlight the most significant issues, and the principles should benefit the development of a number of flexible sensors.

Robust Soft-Hard Interfaces.

One of the most prominent mechanical challenges in flexible sensors is the interfacial instability between dissimilar materials. Stress and/or strain concentration occurs at soft-hard interfaces, leading to a major source of failure through delamination/detachment. Soft-hard interfaces exist in many forms: nanocomposites, layer-by-layer laminates, interconnects, etc. The general principles in tackling soft-hard instability are (1) improving interfacial adhesion and (2) avoiding abrupt softness/hardness difference. Specific methods vary in different scenarios, but the principles hold.

For example, using a single materials system (or at least reducing the number of materials) can eliminate many interfacial issues.118 Recently, a capacitive pressure sensor made entirely of CNT-doped polydimethylsiloxane (PDMS) was fabricated.259 Tuning the dopant concentration around the percolation threshold realized either electrode or dielectric properties with little change in mechanical softness. The interlayers were bonded together due to the similar chemistry of the layers. The resulting sensor could maintain stable performance under 100,000 cycles of rubbing and other harsh deformation conditions. Substrate mechanical engineering is effective in mitigating stress concentration in heterogeneous stretchable electronics.260-264 By synthesizing elastomers of different stiffness or embedding rigid islands, the area under rigid components is made harder than the surrounding area. Consequently, abrupt soft-hard transition between rigid functional components and soft substrates is avoided. Rational geometric engineering of the rigid islands can substantially suppress crack propagation at their interfaces with elastomers, extending failure strain and fatigue life.265 Recently, a mesh polyimide network was used in place of elastomers as substrate and superstrate for hybrid integrated systems.266 The mesh networks have reduced contact area with and more similar Young’s modulus to rigid interconnects and chips, largely alleviating the soft-hard interfacial problem. Other methods include using materials with gradients of stiffness,267 adding an interface material with medium stiffness between the soft sensor and the rigid interconnect,268 and developing ultrathin tough adhesive films for interlayer stabilization. In nanocomposites, surface chemistry engineering269 and interfacial microstructuring270,271 are common strategies to improve the bonding stability between nanomaterials and polymer matrices.272

A particularly challenging issue within the scope of soft-hard interfaces is interconnection, which is especially a concern for system integration.273 In particular, wearable and implantable sensors can be made ultrathin, soft, and stretchable, but poor mechanical strength challenges reliable connection with the rest of the system.274,275 Moreover, sensor arrays (e.g., microelectrode arrays for brain mapping276) face additional challenges in connecting high-density thin wires across long distances of soft-hard transition.

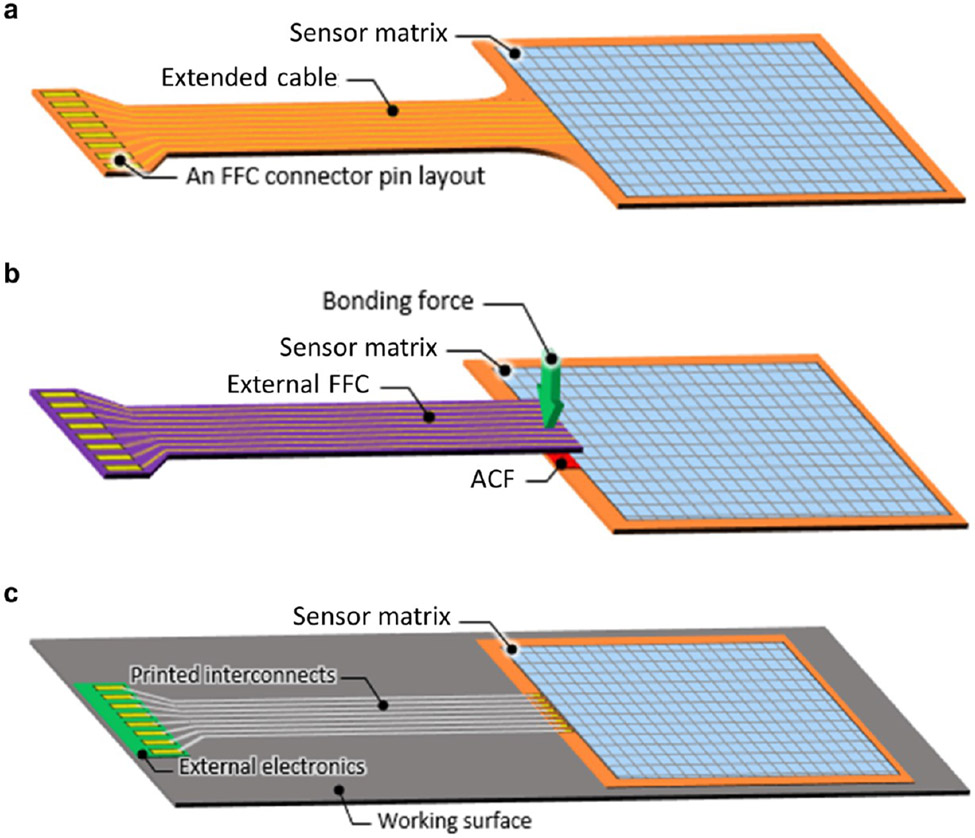

To address this problem, there are several options currently available, without using rigid wires and solders: (1) to integrate a flexible electric cable and pins into the sensor system so that it fits into a standard flat flexible cable (FFC) connector (Figure 6a);276-278 (2) to apply an anisotropic conductive film (ACF) and bond an external FFC to the sensor system (Figure 6b);279-282 and (3) to print interconnects over the surface of the sensor system down to the electric pads of the external electronics (Figure 6c).273,280 The first approach is more monolithic and can be accomplished in fewer process steps, while requiring substantially larger areas for a single device. The second approach is superior in that cables and sensor systems can be fabricated separately, thereby offering high resolution and performance, but extra steps for cable bonding are required before use. The third approach is preferred in applications that require customizability in interconnection layout or do not critically demand high resolution. Besides these options, fully soft and stretchable interconnects with robust adhesion are under investigation,283-287 which are expected to reduce interfacial mismatch with soft components significantly. Electrically conductive adhesives are commercially available as printable inks; modifying these materials to a lower rigidity will be instrumental to the large-scale manufacturing of mechanically robust systems.288 Liquid metal and conductive polymers are likely to play notable roles in these pursuits.

Figure 6.

Current interconnection approaches for flexible sensors and arrays. (a) Extended flexible sensor system layout contains flexible cable and pins suitable for a flat flexible cable (FFC) connector. (b) External FFC is bonded to the flexible sensor system via an anisotropic conductive film (ACF). (c) Printed conductors connect flexible sensor system with external electronics directly.

In parallel to engineering more robust interconnects, it is sometimes desirable to construct highly integrated systems without long distance interconnections, to minimize risk in failure and measurement instability. Such systems are like soft printed circuit boards (PCBs), where prepatterned interconnects on soft substrates are bonded to sensors and other functional components.289 Furthermore, future flexible sensing systems will be multilayer assemblies for high-density integration and sophisticated functions. Vertical interconnect access (VIA) will then be essential. There have been efforts on VIA, but rigid materials remain the most common.266,290,291 Future work may explore the principles introduced above for soft single-layer interconnections.285 Another important factor to consider is the reusability of interconnects, which allows for replacement of flexible sensors. This strategy will be useful for disposable sensors, where rigid electronics (often integrated on a flexible PCB) are designed to be reusable. Reliable and reversible bonding is needed in this case.292

When physically integrated systems cannot deliver desirable mechanical stability, wirelessly connecting soft and hard subsystems can circumvent the issues associated with interconnection and sometimes even completely eliminate soft-hard interfaces.293,294 In such cases, wireless communication will be challenged in bandwidth for large-scale sensing arrays and in reliability for sensors in deformation or motion.295 With the fastdeveloping soft devices,296-300 more components within a sensor system will be soft and flexible, and the soft-hard interface will be less and less an issue. The ultimate vision will be a fully soft system where soft-hard interfaces are mostly absent.

Large Elastic Range.

Flexible sensors possessing reversible deformability should ideally have all the materials in the sensor deformed within their elastic limits. In some circumstances, large deformations are expected, such as devices integrated directly onto the skin (up to 60–70%33) or other organs (e.g., heart, bladder). However, conventional electronic materials usually undergo brittle fracture or plasticity under a strain of ~1%.30 Hence, extending the elastic range on a system level beyond the intrinsic elasticity of constituting materials is often needed. Additionally, for practical applications, overengineering to strain values well exceeding the largest possible deformation that a sensor may experience is necessary for guaranteed mechanical safety.

There are well-established approaches to extend the elastic ranges of sensors made of brittle materials. Reducing thickness is the first approach and has been widely used to enhance the bendability of flexible electronics. Essentially, anything thinner can be flexed more.301 2D materials having atomic thickness are therefore intrinsically bendable, making them a popular choice for flexible sensors,302,303 let alone their outstanding electrical, optical, and chemical properties. The second approach is to place brittle components on the neutral axis of a multilayer stack. This strategy often takes the form of polymeric encapsulations around a brittle layer, but the situation can become complex with increasing numbers of layers and large elastic mismatches between layers.304-306 There is rich mechanics to explore for mechanically heterogeneous laminations. Building on bendability, stretchability is endowed by both structural307 and materials308 engineering. Wavy structures (both in-plane serpentine shapes309 and out-of-plane buckling310,311), fractal patterns,312 microcracks,313 honeycomb architectures,314,315 fibrous mats,155 and woven textiles32 are effective structural designs to confer minimally stretchable materials with large elastic stretchability. The mechanism is to convert macroscale stretching to localized bending and twisting, which are permitted by reduced thickness. Origami and kirigami employ similar concepts.316 Moreover, for relatively rigid substrates such as leather and polyimide, adding a strain-isolation layer with substantially lower modulus (e.g., PDMS) between inorganic active components and the substrate can effectively extend the system stretchability.317,318 Structural design utilizes conventional electronic materials and processing techniques thereby offering greater electronic performance and industrial compatibility, but it introduces soft-hard interfacial instability and often sacrifices integration density to make room for sophisticated patterns.

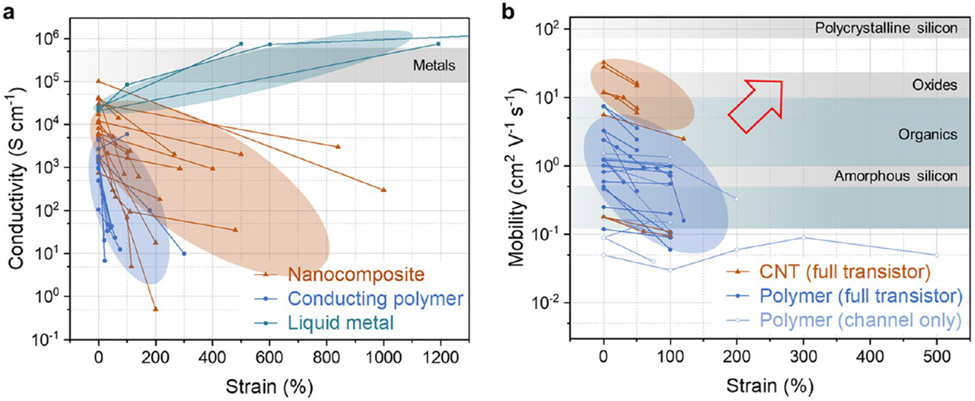

Materials engineering towards intrinsically stretchable materials provides alternatives to these problems.308,319-321 These strategies include fabricating nanocomposites with stretchable matrices, depositing liquid metal on elastic substrates or enclosing it within 2D or 3D elastic matrices, synthesizing functional stretchable polymers, and utilizing ionically conductive materials. Nanocomposites are a promising form of stretchable conductors, with the conductivities of the best performing composites approaching bulk metals (Figure 7a). Given the many available conductive fillers and matrix materials, composite materials properties can have wide ranges.322 Current technical challenges are primarily low-cost and large-scale manufacturing and high-resolution patterning. On the other hand, functional stretchable polymer syntheses have advanced rapidly. Polymeric semiconductors have achieved carrier mobilities at 100% strain exceeding non-stretchable amorphous silicon,323,324 although there remains room for improvement in mobility and stretchability (Figure 7b). In comparison, semiconducting CNTs325 can achieve higher mobility, but strain usually causes permanent morphological changes in CNT networks, and strain-insensitive electrical performance is thus challenging to achieve.326 In addition, energy dissipating (tough) interlayers with covalent bonding to interfacing materials could substantially increase the crack onset strain and thus delay the performance drop of conducting/semi-conducting thin films on elastic substrates upon stretching.327 Moving forward, to realize different types of sensing functions, stretchable material designs need to be created for other types of functional properties, such as electroluminescent and photo-responsive properties for optical sensing and electrochemical properties for biochemical sensing.127,328

Figure 7.

Performance of intrinsically stretchable (a) conductors and (b) semiconductors. (a) Intrinsically stretchable conductors are realized in three materials categories: nanocomposites, conducting polymers, and liquid metals; ionic conductors are not included. Conductivities of stretched liquid metals are calculated from resistance changes under unidirectional strain, based on the assumption of incompressible solid undergoing uniform deformation. Non-stretchable bulk metals are plotted in the gray band for comparison. Values extracted from refs 269, 285, 329-345. (b) Stretchable semiconductors are based on semiconducting CNTs or conjugated polymers. Mobility measurement was done in either stretched materials transferred to non-stretchable substrates (channel only) or fully stretchable transistors and transistor arrays (full transistor). Values for stretch directions both parallel and perpendicular to the channel length are included. Typical mobilities of common non-stretchable semiconductors are plotted in bands for comparison.346 Red arrow indicates area for improvement. Values extracted from refs 323, 324, 347-364.

The above mentioned materials target electronic sensors, where the mechanical brittleness of conventional electronic materials poses great challenges to sensor deformability. However, in biology, tissues are highly deformable yet have sophisticated sensing capabilities. Biological sensors work by the transport of ions, instead of electrons. Inspired in this direction, a strong impetus to develop ionotronics utilizing ionically conductive and highly deformable materials such as hydrogels,296 ionogels,172,365 and ionic elastomers366,367 has emerged.368 Without the requirement of incorporating electronic conduction, materials design is much simpler. To date, temperature sensors,366,369 strain sensors,365 pressure sensors,366,370 electrophysiological electrodes,371,372 and others have been realized. Major challenges in ionic sensors include adequate sensing modality and performance on par with those of electronic sensors, compatibility with electronic data processing modules, and device miniaturization.

We note that pursuing record high deformability may not always have practical significance. The purpose of high deformability should be articulated with respect to the intended application scenarios. Even for on-skin application alone, the range of tensile strain spans from 1% to 63% according to body location.33 Therefore, the true requirement for practical applications should be determined case by case. For a sensor designed for skin integration, a stretchability of 1000% might be practically unnecessary.

Fatigue Resistance at Materials Interfaces.

Improving fatigue resistance is important to sensor durability under cyclic loading and is particularly critical for mechanical sensors. The primary concern regarding fatigue resistance lies in interfacial delamination rather than the intrinsic fatigue properties of materials. This issue is closely related to soft-hard interfacial instability.265 Hence, significant efforts should focus on optimizing sensor structures with coordinated materials properties to reduce stress concentration. Due to the multitude of materials and multilayer structures employed in flexible sensors, the mechanical interactions between layers and components can be complex. Therefore, fundamental studies on the failure mechanisms and failure criteria are important. For example, Cheng et al. developed an anti-fatigue strategy to prolong the fatigue life of 3D ribbon-shaped flexible electronics by switching metal-dominated failure to desired polymer-dominated failure.373 Crack propagation in microcracked structures is another issue. Microcracks are introduced to render stretchability313 or to improve sensitivity,210 but they are usually unstable under cyclic loading. Crack engineering thus becomes important. Examples include substrate structural design374 and initial crack length control.375 On the other hand, improving the fatigue resistance of emerging soft materials such as hydrogels213,376 may broaden their application space in flexible sensors.

Signal Stability under Mechanical Interference.

Flexible sensors other than mechanical sensors should not respond to mechanical deformation, which can be regarded as a source of interference. Mechanical stability is an aspect of sensor stability. Because it is special for flexible sensors and represents a major challenge in sensing performance, we dedicate a detailed separate discussion to this issue.

Strain Effect Decoupling.

Coupling of strain into the sensing function undesirably causes signals to shift under bending or stretching. Decoupling of deformation effect is therefore important to sensing accuracy. Most of the approaches discussed above to extend elastic range contribute to alleviating this problem, yet perfectly strain-invariant performance remains challenging to attain. The key is to minimize strain experienced by active components or to synthesize strain-insensitive active materials. In particular, the island-bridge layout is effective for array-type devices.109,377 Active components with critical sensing functionality are connected by highly stretchable interconnects, and the majority of strain is borne by the interconnects, thereby minimizing alterations to the sensor output. To enhance the protection to active components, the island area is made more rigid than the surroundings by either inserting a hard platform262 or tuning the chemistry of substrates.378 Soft-hard interfacial instability is an important consideration in such systems. Another strategy is to use built-in circuits to compensate for strain-induced variation.81,379 Since these strategies are poised to increase system design complexity, the realization of strain-insensitive sensor arrays with high density will rely on innovations in integration strategies and high-resolution high-yield fabrication. A recently proposed strategy380 with potential to overcome these limitations is to bridge brittle functional thin films and stretchable conductors through ACFs, which, despite the cracking of functional thin films under tensile strain, offer alternative electronic conduction pathways that are unaffected by strain. The laminates demonstrated nearly strain-insensitive electrochemical sensing and stimulation using a library of brittle functional materials.

Motion Artifact Removal.

Motion artifacts are noise in sensor output from motion and surface deformation of the monitored object. They overshadow true signals and cause measurement inaccuracy or reduced signal-to-noise ratio. Motion artifacts are a common problem for wearable and implantable sensors, and remain one of the biggest challenges for electrophysiology and its application in wearable healthcare and human-machine interfaces. The problem comes from sensor system mechanical instability, sensor-wearer interface instability, the complexity of human body movements, electrical signals generated by muscle movement, and disturbance of ionic charge distribution and dynamics inside tissues by deformation and perspiration. The first aspect has been addressed in multiple topics including soft-hard interfaces, elastic range, and strain effect decoupling. Here, we focus on strategies addressing the rest of the problems from sensor hardware optimization and signal processing.

For hardware optimization, the mainstream approach is to improve the conformability and adhesion of sensors on tissues (often skin).381 Better conformability eliminates gaps between the sensor and the skin, and better adhesion promotes conformal contact382 and stabilizes the interface during motion. These two factors together facilitate intimate and unaltered contact between the sensor and the skin during motion, thus reducing motion artifacts. To improve conformability, making sensors soft and stretchable is effective. This goal can be achieved through reducing device thickness for lower bending stiffness383-386 and using polymeric materials with intrinsic low modulus and high stretchability.387,388 For enhancing adhesion with skin,387,389 van der Waals interactions are sufficient for ultrathin (<5 μm) devices,382,390 while adhesive polymers or functional groups are necessary for thicker devices.387,388 Electronic tattoo stickers390-393 and in situ sensor fabrication directly on skin from liquid precursors394,395 offer convenient ways to achieve conformability and adhesiveness simultaneously.

Pretreatment of skin, e.g., hair trimming, alcohol wiping, helps to reduce surface roughness and to remove contamination for better conformability and adhesion, but compromises the convenience of point-of-care sensors. The recently proposed concept of using a damping hydrogel to eliminate low-frequency mechanical noises (such as walking and breathing) for measurement of high-frequency signals (such as speech and electrophysiological signals)396 offers another materials engineering perspective to tackle motion artifacts.

On the systems level, special sensor layouts and system designs can also mitigate motion artifacts. For example, preparing arrays of sensors can enable a system to measure some physiological parameters despite small relative motion of the sensor and the body.397 Employing multiple sensors with carefully designed application positions can help cancel motion artifacts in certain sensors.398,399 Integrating other sensing modalities or mechanisms such as force, heat, magnetism, light, sound, and chemical, can buffer the influence of motion artifacts.