Abstract

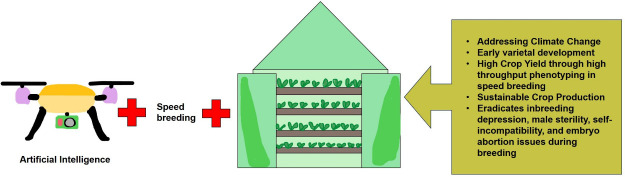

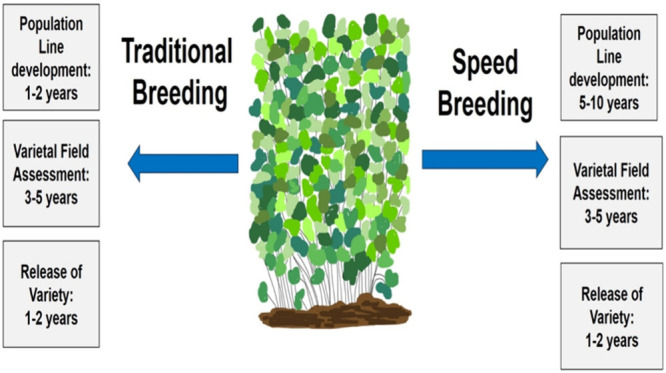

The controlled environment ecosystem is a meticulously designed plant growing chamber utilized for cultivating biofortified crops and microgreens, addressing hidden hunger and malnutrition prevalent in the growing population. The integration of speed breeding within such controlled environments effectively eradicates morphological disruptions encountered in traditional breeding methods such as inbreeding depression, male sterility, self-incompatibility, embryo abortion, and other unsuccessful attempts. In contrast to the unpredictable climate conditions that often prolong breeding cycles to 10–15 years in traditional breeding and 4–5 years in transgenic breeding within open ecosystems, speed breeding techniques expedite the achievement of breeding objectives and F1–F6 generations within 2–3 years under controlled growing conditions. In comparison, traditional breeding may take 5–10 years for plant population line creation, 3–5 years for field trials, and 1–2 years for variety release. The effectiveness of speed breeding in trait improvement and population line development varies across different crops, requiring approximately 4 generations in rice and groundnut, 5 generations in soybean, pea, and oat, 6 generations in sorghum, Amaranthus sp., and subterranean clover, 6–7 generations in bread wheat, durum wheat, and chickpea, 7 generations in broad bean, 8 generations in lentil, and 10 generations in Arabidopsis thaliana annually within controlled environment ecosystems. Artificial intelligence leverages neural networks and algorithm models to screen phenotypic traits and assess their role in diverse crop species. Moreover, in controlled environment systems, mechanistic models combined with machine learning effectively regulate stable nutrient use efficiency, water use efficiency, photosynthetic assimilation product, metabolic use efficiency, climatic factors, greenhouse gas emissions, carbon sequestration, and carbon footprints. However, any negligence, even minor, in maintaining optimal photoperiodism, temperature, humidity, and controlling pests or diseases can lead to the deterioration of crop trials and speed breeding techniques within the controlled environment system. Further comparative studies are imperative to comprehend and justify the efficacy of climate management techniques in controlled environment ecosystems compared to natural environments, with or without soil.

1. Introduction

The controlled environment ecosystem (CEE) serves as a sophisticated plant growth chamber essential for speed breeding and cultivating horticultural or agricultural crops, microgreens, and various other plants. These crops and the speed breeding process find applications in protected cultivation, vertical farming, container farming, plant factories, and even specialized environments, such as National Aeronautics and Space Administration (NASA) biomass production chambers. Controlled environment technologies such as hydroponics, aeroponics, aquaculture, aquaponics, and genoponics play pivotal roles in these endeavors.1 Controlled environment agriculture (CEA), indoor farming (IF), and indoor agriculture (IA) are alternative terms commonly used to describe the controlled environment ecosystem. Speed breeding, a state-of-the-art plant breeding technique, enables the production of superior crops within shorter generation times under meticulously controlled environmental conditions. This method integrates various techniques including plant tissue culture, advanced breeding methods, genetic engineering, molecular approaches, utilization of light-emitting diodes (LEDs), growth regulators, immature germination, and micronutrient supplementation to achieve desired breeding objectives and cultivate improved or superior crops.2 Alternative scientific terms for speed breeding (SB) include rapid breeding, crop improvement, smart breeding, and crop improvement.

Controlled environment agriculture dates back to ancient times, with records showing that the Roman doctor Tiberius Caesar grew cucumbers under such conditions as early as 14–37 A.D.3 The design and structure of modern greenhouses were first documented in the 1670s, with European countries pioneering the construction of wood-framed structures covered with either glass or oiled paper. In 1780, during the American Revolution, the first American greenhouse was erected by George Washington at Mount Vernon’s Conservatory.4 The use of incandescent lamps for influencing plant growth was pioneered by Liberty Hyde Bailey at Cornell University in 1889. By 1900, improved heated water systems were being implemented in American greenhouses. In the 1960s, the Agricultural Research Service (ARS) Phyto-Engineering Laboratories of the U.S. Department of Agriculture (USDA) initiated the production of lettuce, tomato, and cucumber in plant growth chambers. During the mid-1980s to the late 1990s, the National Aeronautics and Space Administration (NASA) utilized the Kennedy Space Center’s biomass production chamber to grow wheat and barley for space missions. Commercial utilization of controlled environment agriculture began in 1999 when Cornell University embarked on mass production of lettuce.5−7 The evolution of applied research theories has paved the way for the development of speed breeding as a method to enhance crop production under controlled growing conditions. Renowned scientist Lee Hickey from the University of Queensland, Australia, introduced the concept of speed breeding. He first applied this technique to wheat, peanut, and barley, using the single seed descent (SSD) method in glasshouses to create disease-resistant varieties. With the advent of new plant growth room designs, such as controlled environment chambers, glasshouses, and homemade growth rooms, efforts to improve crops through speed breeding techniques have expanded. Plant production and speed breeding are influenced by various factors, including light quantity, light quality, photosynthetic active radiation (PAR), temperature, sterile/axenic environments, growing times, conditions, plant age, system types, growing media in closed systems, vertical farming, and protected cultivation. The controlled environment ecosystem holds significant potential for cultivating improved plants, transgenic crops, tissue culture plants, and employing vertical farming and protected cultivation methods, all within controlled environmental systems.8,9

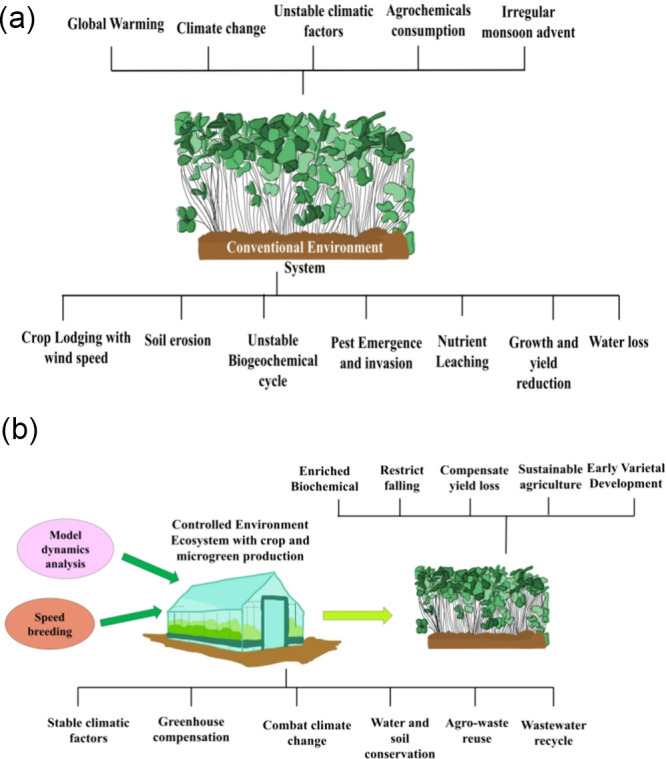

The natural climate serves as a critical variable in accelerating the growth and development of plants. Various climatic factors, including water availability, light intensity, temperature, humidity levels, and atmospheric pressure, consistently impact the biological processes of crops.10 Nevertheless, fluctuations and disruptions in the natural cycle of climatic factors can significantly influence crop growth, development, and improvement. Irregularities in monsoon patterns and fluctuations in the temperature or light can disrupt soil properties and hinder plant growth. Climate change has led to the adaptation of pest species and altered the dynamics of the gaseous cycle, posing challenges to field trials and the process of plant hardening.11 Moreover, unstable climatic conditions exacerbate challenges related to pollination, self-incompatibility, seed shattering, male sterility, and breeding cycle. In open ecosystems, the impacts of these conditions prolong crop development in traditional breeding, requiring 10 to 15 years (5 to 10 years for plant population line creation, 3 to 5 years for field trials, and 1 to 2 years for variety release). Conversely, the development of transgenic crops through direct or indirect gene manipulation takes 4 to 5 years, further complicated by the interaction with unstable climatic factors in open fields. Conventional agriculture, known for its extensive land use and high water consumption, often leads to significant agrochemical leaching and soil erosion. The production and management practices associated with traditional agriculture contribute to yield losses, pest infestations, and weed emergence, exacerbated by the effects of climate change.

The controlled environment plant growth system is an artificially regulated chamber where crop or microgreen production and speed breeding take place, with climate factors meticulously controlled and manipulated.12 It conserves 80% of land usage and 90% of water consumption and efficiently manages nutrient runoff compared to traditional agriculture. By limiting eutrophication emergence and minimizing the stress impact, it establishes a stable artificial ecosystem conducive to quality growth and high yields. Additionally, it provides a more accurate delivery of nutrient ions to the plant system compared to soil-based agriculture. The controlled environment system holds vast potential for mitigating climate change effects and mitigating crop losses associated with soil-based agriculture.13 The controlled environment plant growth system employs recycled agrowaste and wastewater for plant production.14 The controlled environment plant growth chamber ensures the stability of carbon sequestration and minimizes the carbon footprint, effectively offsetting greenhouse gas emissions and potential yield losses. It enhances photosynthetic assimilation, metabolic efficiency, and maintains stable climatic conditions conducive to plant growth.15 The controlled environment plant growth chamber reduces sources of pollution and minimizes pest emergence compared to soil agriculture, enabling the successive growth of seasonal crops.

Speed breeding, within a controlled environment ecosystem, demonstrates the capability to yield high-performing and superior crops. Its versatility extends to agricultural or horticultural crops, offering opportunities for crop improvement at any stage within a controlled environment setup. Moreover, it facilitates the production of tissue-cultured crops, biofortified crops, and nanomodified crops within the controlled environment ecosystem.16 This method combines genomics and phenomics to analyze the structure and function of crops, utilizing sensor-based technologies to explore qualitative and quantitative traits in both crops and growing media within controlled growth conditions.17 Speed breeding mitigates crop loss and revenue challenges in conventional ecosystems while addressing hidden hunger, malnutrition, and food security concerns among expanding global populations.18 Speed breeding enhances both physical and chemical traits in crops or microgreens cultivated within controlled environment plant growth chambers. These improvements encompass plant height, leaf number, fruit size, fruit weight, and overall yield, alongside enhancements in chemical attributes like total soluble solids, biochemical content, color, flavors, water use efficiency, and nutrient use efficiency.19 Under a controlled environment plant growth chamber, completing the F1–F7 generations in crop development typically takes 2–3 years. Speed breeding fosters robust growth and nutrient-rich yields by reducing the toxicity and impurity levels in both crops and microgreens. With reduced manpower and time requirements, speed breeding yields high-quality crops and microgreens, meeting diverse physical targets as needed.20 Speed breeding enhances seed viability and vigor, accelerating morphological and anatomical growth rates compared to traditional soil agriculture. Furthermore, it enables stable phytoremediation, enhances resilience against biotic and abiotic stresses, supports biofortification efforts, facilitates improvements in tissue-cultured plants, and integrates nanotechnology within controlled environment plant growth chambers. Speed breeding creates ample opportunities for research, promotes the establishment of new industries, and contributes to employment growth.21 While many aspects of the controlled environment ecosystem have been extensively studied and reviewed, there remains a need for comprehensive compilations and reviews focusing on plant production, speed breeding for trait improvement, the integration of artificial intelligence (AI) in screening phenotypic characters, and the dynamics of nutrients, water, and climate within controlled environments. This review aims to emphasize crop and microgreen production, the intricacies of nutrient, water, and climate dynamics, technological interventions in speed breeding, and the utilization of AI for phenotypic characterization in crops grown under controlled environment ecosystems. Through this exploration, we seek to further advance both theoretical understanding and practical techniques in this field.

2. Crop and Microgreen Productions in CEE through Controlled Environment Technologies

A diverse range of crops and plants, spanning barley, rice, oats, wheat grass, mint, basil, rosemary, sage, oregano, amaranth, beets, chard, quinoa, spinach, and a plethora of vegetables, herbs, and flowers, have benefited from the successful implementation of a controlled environment ecosystem. This innovative approach fostered optimal growth conditions, enhancing yield and quality across various agricultural and horticultural species.22,23

2.1. Horticultural Crop Production in a Closed System under Controlled Environment Conditions

Vegetable crops were cultivated using both water-based techniques like the Nutrient Film Technique (NFT) and substrate-based methods such as container farming within controlled environment setups.24 The NFT has been utilized in several crops such as tomato, lettuce, and cucumber for obtaining high yield, pest resistance, and reduced toxic products in the greenhouse. This method utilizes substrates like rock wool, cocopeat, sawdust, peat moss, vermiculite, sand, and perlite.25 Furthermore, tomato seedlings gave superior morphological and anatomical growth in rockwool cubes containing specific nutrients under NFT.26 Besides, keeping tomatoes in slabs, buckets, black gunny bags, and lay-flat containing mixtures of rockwool + coconut coir + perlite + peat with the recommended dose of nutrient solution through the NFT method under greenhouse condition revealed significant morphological growth and yield.27

The beneficial growth and good yield in eggplant were obtained in polystyrene trays containing 1:1 (v/v) peat: vermiculite, using different growing media (sawdust, spent mushroom compost, volcanic tuff, perlite) with discharge of standard nutrient solutions comprising 135 mg N, 48 mg P, 283 mg K, 0.05 mg Mo, 128 mg Ca, 0.5 mg B through a drip system in a glass greenhouse.28,29 Additionally, the pest-free and biochemical-enriched onion seedlings were obtained in pot culture grown in oasis cubes, while robust quality growth and nutrient-enriched cucumber were harvested in cocopeat growing media with the application of Hoagland nutrient solution under controlled environmental conditions.30,31 In the case of aeroponics potato cultivation under controlled conditions, the qualitatively and quantitatively nutritious mini tubers were harvested after 2 weeks of transplanting in a test tube, magenta box, and styrofoam (thermocoal box) with the recommendation of nutrient solutions.32 The groovy biochemical content, growth, physiological response, and yield were achieved in chili through the fertigation method in a glass house.33 Utilizing full dose, half dose (with a 50% reduction in macronutrients), or pure water (devoid of nutrients) of the Hoagland nutrient solution in the floating method resulted in significantly enhanced growth parameters, biomass, and yield in spinach cultivated within a greenhouse environment.34

Carrots experienced enhanced growth and yield in a greenhouse setting using rockwool blocks enriched with vermiculite and supplied with nutrient solutions via subsurface irrigation.35 Melons were cultivated in an aeroponics system, and lettuce in a combination of polystyrene foam and pots with three nutrient solutions delivered through a floating system.36,37 Ginger was grown in pots containing various ratios of coir dust and burnt paddy husk, receiving MARDI nutrient solution through irrigation channels within a side-netted rain shelter.38 Green beans thrived in pots supplemented with peat, perlite, and sand, utilizing subsurface irrigation for nutrient supply.39 Broccoli flourished in rockwool with Hoagland nutrient solution in a multitunnel greenhouse.40 Kohlrabi was cultivated using an NFT in a greenhouse.41 Rhododendrons were grown in containers filled with a mixture of bark, sphagnum peat moss, perlite, and vermiculite.42 Hybrid lilies were raised in plastic bags containing varying proportions of cocopeat, perlite, and palm trunk, with nutrient solution discharge.43 Mustard was cultivated using hydroponic and aquaponic systems.44 Various vegetables such as tomatoes, cucumbers, eggplants, chili peppers, carrots, lettuce, and spinach were grown in an open rooftop system.45,46 Different substrates, including tuff, perlite, and sawdust, were observed to affect cucumber production in varying proportions within the greenhouse.47 Broccoli, cauliflower, and cabbage achieved typical growth and yield when cultivated in various growing mediums such as commercial peat and paper waste in pot culture within a plastic greenhouse.48

Different container systems were employed for melon production in greenhouse settings, including fertigation systems using polybags and cocopeat, U-shaped troughs made of PVC tubes, double U-shaped troughs, and triangular containers constructed from polyethylene sheets. While melon production was observed in all containers, the fruit quality was found to be superior in the U-shaped troughs.49 Plastic pots filled with perlite and cocopeat were utilized for cucumber cultivation in a polyhouse.50 Pepper plants exhibited productive morphological growth and high-quality fruit when grown in gunny bags filled with peat or a mixture of peat, perlite, and sand (1:1:1 ratio) substrate under greenhouse conditions.51

Various substrate media have been noted to yield suboptimal production outcomes for several crops. Diverse combinations of cocopeat and vermiculite in differing proportions were employed for cultivating strawberry cv. Chandler within polybags placed in a passively ventilated greenhouse.52 Using vermiculite: erlite culture medium in a 1:1 ratio, gerbera plant production is recommended in a controlled environment ecosystem.53 The utilization of coconut fiber and peat as a growing medium proved advantageous in the cultivation of Galanthus elwesii under soilless conditions, resulting in a notable improvement in bulb quality.54 Peat and a composite medium (consisting of peat, slag, and perlite in a 1:1:1 ratio) demonstrated enhanced growth for Limonium sinuatum.55 Besides, coconut fiber as a substrate media showed improvement in Lisianthus russellianus growth and flower quality.56 Furthermore, a blend of cocopeat, vermiculite, and FYM (in a 1:1:1 ratio) as a growing medium also contributed to improved flower production of the potted Chrysanthemum cv. Anmol, accompanied by enhanced plant morphological development.57 Additionally, a composition of 0.5 kg gravel with 1.2 kg coconut fiber along with four holes at the base in a pot showed the production of sunflowers under saline stress conditions in hydroponic conditions.30 The mustard spinach seedlings showed robust germination rates and dense seedling growth when cultivated in polystyrene trays filled with a vermiculite substrate. They were then transplanted into net pots filled with gravel within a shade net house covered with black and white shading material.58

2.2. Microgreen Plant Production in a Closed System under a Controlled Environment

The microgreen utilization traces back to 1930 when North American pharmacies began harnessing the medicinal properties of wheatgrass. By the 1970s, this trend expanded with the cultivation of microgreens like buckwheat, sunflower, and radish during the winter months, aptly dubbed as winter greens.59 Microgreens like basil, arugula, kale, beets, and cilantro were utilized for serving in food items later in San Francisco in the 1980s;60 however, in the mid-90s, lettuce microgreens were served as salad and garnishings, which led to its terminology in 1992 as “Microgreen and Babygreen” by Craig Hartman. These contain 4–40% higher concentrations of micronutrients than matured vegetables and herbal plants.61

Microgreen plants from diverse families such as Alliaceae, Amaranthaceae, Apiaceae, Asteraceae, Boraginaceae, Brassicaceae, Cucurbitaceae, Fabaceae, Lamiaceae, Oxalidaceae, Poaceae, Leguminoceae, Polygonaceae, and Portulacaceae were cultivated for consumption, the production of high-value products, and revenue generation.4 The delicate leaves of microgreen plants boast rich flavors and bioactive compounds, including vitamins, antioxidants, and minerals, surpassing those found in mature leafy greens.62 These portions of the plants have much higher nutrient content than their fully grown portions. Due to this, microgreen plants having tender leaves have more potential to confine microbial contamination than seedlings.63 The intake of microgreens is responsible for the regulation of body weight, lowers cholesterol levels, and protects against heart disease. They also contribute to detoxification, purifying, and fortifying the blood, acting as diuretics to support kidney function.64 Besides, microgreens help with anemia, reduce the risk of eye diseases, help maintain strong and healthy bones, and promote blood clotting. Microgreens synthesize abundant ascorbic acid, neoxanthin, violaxanthin, phylloquinone, α-carotene, tocopherols, lutein, and carotenoids, along with higher levels of zinc, iron, and protein.65 Additionally, they reduce the generation of antinutritional components. Microgreens are abundant in essential macronutrients and vital micronutrients.65

Furthermore, microgreen and crop production were initiated by utilizing substrate-growing media such as vermiculite, bagasse, sawdust, and rice hulls, which possess natural physical and chemical properties for their production. Bagasse and sawdust exhibit a high water retention capacity, coupled with low porosity and a notably high saturation point, respectively.66 Redwood, pine bark, and fir bark serve as ideal substrates for fostering the safe growth of microgreens. Conversely, cedar and walnut are best avoided due to potential toxicity concerns associated with these substrates. Notably, the combination of sphagnum peat and vermiculite, commonly termed peat-lite, has emerged as a highly effective growing medium for promoting the cultivation of both microgreens and crops alike. Nutrient-rich substrates such as rock wool, cocopeat, sawdust, peat moss, vermiculite, sand, and perlite were employed for greenhouse vegetable cultivation.66 Cucumbers and tomatoes have thrived when cultivated with bark from pine, cypress, redwood, and fir in greenhouse settings.66 Optimal fruit weight and yield were achieved through the utilization of perlite and a cocopeat-perlite nutrient mixture for greenhouse tomato production.66

Indoor production of microgreen plants such as fenugreek, chickpea, mung bean, and coriander demonstrated superior growth and yield responses when cultivated with nutrient-rich media like cocopeat and peat, compared to outdoor environments.67 Using substrate growing media of mushroom, vermicompost, perlite, sawdust, peat moss, and compost, crops like kale, arugula, pak choi, and Swiss chard in the greenhouse were grown to find the root area, chlorophyll contents, carotenoid contents, shoot length, total phenolics, high yield, flavonoids, and antioxidant enzymes.68Brassica rapa var. chinensis and Brassica oleracea L. var. acephala had the highest sugar and protein contents with growing media which includes sawdust at 20%, vermicast at 30%, mushroom compost at 30%, and perlite at 20% in a greenhouse.69 The significant yield and biomass in nutrient media consisting of peat and coco coir were observed in various crops, such as radish, microgreens, kale, basil, etc. in the climate-controlled greenhouse than in indoor farming.70 The successful emergence of spinach, radish, and carrot was observed in nutrient media having cocopeat and rice husk in the ratio of 1:1 in a bagasse container.71

Cocopeat, utilized as a growing medium, has demonstrated the ability to enhance micronutrient content, including zinc (Zn2+), magnesium (Mg2+), and potassium (K+), as well as increased levels of ascorbic acid, chlorophyll, carotenoids, and overall growth response in leguminous microgreens such as cowpea, mungbean, fenugreek, and horse gram, as well as cereal microgreens like wheat and sorghum when cultivated within closed systems.72 Even superior morphological growth and yield have been observed in lettuce, broccoli, turnip, and kale varieties when grown on a nutrient medium composed of cocopeat, perlite, and vermiculite in a ratio of 3:1:1 within a closed system.73 The growths of shoot length and stem diameter of tobacco were increased in a substrate composition of pine bark (50%), sand (50%), and compost (100%) under an open system. However, cattle manure was not recommended with the same media composition in tobacco plants.74 Green bean microgreens displayed enhanced morphological growth and prolonged shelf life when grown using straw nanofiber and hydrogel derived from diaper waste within a closed system.74

On the other hand, various hydroponic pads like hemp mats, biostrate, jute mats, and micromats gave positive results in microgreen production in the greenhouse. Excluding a hemp mat, radish plants have recorded the highest nitrogen concentration, while mustard recorded the highest phosphorus content. Variations in the fresh and dry weights of shoots as well as the mineral nutrient content in radish, broccoli, kale, mustard, and cabbage microgreens were even observed in diverse hydroponic pads. Microgreens cultivated on hemp mats exhibited the greatest shoot height, fresh and dry shoot weights, and concentration of potassium.75 The physical development, weight gain, and productivity were observed in mustard, arugula, basil, and radish microgreens grown in a controlled environment system using NFT with coarse burlap fabric.76 In kale cultivation, achieving optimal levels of proline content, plant canopy temperature regulation, and fresh yield was accomplished by utilizing a 17.5% irrigation threshold within a hydroponic wick system, managed through an EVC container, within a controlled environment vertical farming setup.77 Furthermore, favorable plant height and yield results were documented for broccoli, red sorrel microgreens, basil, mizuna, and sunflower, cultivated within a vertical hydroponic framework and an ebb-flow bench system. These systems utilized a growing medium comprised of perlite mix, peat, and cellulose within a double-layered greenhouse equipped with a heating system. Additionally, rice grass and wheat grass, grown in a screen house, displayed similar positive results when grown in nutrient media containing sawdust, cocopeat, and husk charcoal.78

The preceding details confirm the significant potential of controlled environment systems for cultivating agricultural and horticultural crops, particularly for microgreen production, using soilless cultivation methods (Table 1).79 The synthetic ecosystem maintains consistent biotic and abiotic relationships to stimulate the growth and maturation of crops and microgreen vegetation. It ensures steady climatic conditions conducive to cultivating crops and microgreens rich in biochemical compounds and promoting high-quality growth.80 The constructed environment addresses issues such as crop yield reduction, climate-related damage, natural resource management or preservation, environmental considerations, and seasonal crop production declines in the natural environment.81 Investigation may be necessary to comprehend essential or consistent thresholds of climatic elements, carbon capture, carbon emissions, and suitability for crop and microgreen cultivation within a controlled environmental setup. Comparative research and analysis are essential to grasp the vital or stable levels of climatic factors, carbon capture, and carbon emissions associated with crop and microgreen production within predetermined conditions and open environments82,83 (Table 1) (Figure 1).

Table 1. Utilizing Controlled Environment Ecosystems for Crop and Microgreen Production.

| s. no. | crops and microgreens | types of enclosed environment systems | regulated environment infrastructure | references |

|---|---|---|---|---|

| 1 | Fodder maize | Hydroponic fodder system | Low-cost plastic house | (84) |

| 2 | Wheat | AB mix hydoponic media + polyethylene glycol, charcoal + cocopeat | Plastic house | (85) |

| 3 | Wheat | Modified nutrient solution | Artificial indoor lights | (86) |

| 4 | Sorghum | Hydroponic fodder system | Controlled conditions | (87) |

| 5 | Fodder maize, Fodder horse gram | Fabricated low-cost hydroponic fodder production unit | Controlled conditions | (88) |

| 6 | Rice, pearl millet | Nutrient solution + 0.09 mM (NH4)2SO4 + 0.05 mM KH2PO4 + 0.05 mM KNO3 + 0.03 mM K2SO4 + 0.06 mM Ca(NO3)2 + 0.07 mM MgSO4 + 0.11 mM Fe-EDTA + 4.6 μM H3BO3 + 1.8 μM MnSO4 + 0.3 μM ZnSO + 0.3 μM CuSO4 | Gas exchange chamber, root chamber | (89) |

| 7 | Fodder maize, grain maize, fodder bajra, grain bajra, barley, wheat, oat, fodder cowpea, grain cowpea, horse gram, soybean, lucerne | Fabricated hydroponics fodder production | Shed-net house | (90) |

| 8 | Barley | Fabricated hydroponic fodder system | Shed-net house | (91) |

| 9 | Maize, sorghum, bajra, barley, cowpea, lucerne, horse gram | Hydroponic fodder system | Low-cost greenhouse | (92) |

| 10 | Oat, wheat | Hydroponic green forage system | Controlled conditions | (93) |

| 11 | Wheat, barley, oats | Fabricated hydroponics system + aquaculture wastewater | Controlled conditions | (94) |

| 12 | Maize, oat, wheat | Hydroponic fodder system | Polyhouse | (95) |

| 13 | Maize | Hoagland nutrient solution | Controlled conditions | (96) |

| 14 | Capsicum, cucumber, tomato | Fertigation method | Greenhouse | (97) |

| 15 | Potato mini tubers | Wick system, drip system, deep-water cultivation, nutrient film technique, aeroponics | Controlled conditions | (98) |

| 16 | Potato mini tubers | Nutrient film technique, deep flow technique, aeroponics | Greenhouse | (99) |

| 17 | Potato mini tubers | Fertigation method | Greenhouse | (97) |

| 18 | Rose, carnation, gerbera, chrysanthemum, lilium | Fertigation method | Greenhouse | (97) |

| 19 | Strawberry | Cocopeat + vermiculite | Passive ventilated greenhouse | (100) |

| 20 | Sunflower | Nutrient solution containing gravel, coconut fiber | Greenhouse | (101) |

| 21 | Arugula, broccoli, red cabbage, sugar beet, amaranth, tendril pea (microgreens) | Coir fiber, peat-based mix | Greenhouse | (102) |

| 22 | Wheat, barley, oat (microgreens) | Sterile peat + cockpit + perlite | Controlled climate cabinet | (103) |

| 23 | Pearl millet, mungbean, lentil, red radish, mustard, red cabbage (microgreens) | Coco peat + vermiculite + sand | Controlled conditions | (104) |

| 24 | Wheat, kale, spinach (microgreens) | Perlite + peat + vermiculite | Pulsed electromagnetic field | (105) |

| 25 | Oat, wheat, rice, barley (microgreens) | Algae | Climatic chamber | (106) |

| 26 | Amaranthus, scallion, sunflower, borage, arugula, broccoli, red cabbage, cress, kale, mizuna, mustard, radish, sugar beet, red basil, green basil, shiso, lemon balm (microgreens) | Nutrient solutions | Polycarbonate-covered greenhouse with a cooling system and forced air ventilation | (107) |

| 27 | Jute (microgreens) | Half-strength Hoagland nutrient solution | Growth chamber | (108) |

| 28 | Sunflower, water spinach (microgreens) | Peat moss, coconut coir dust, leaf compost, food waste compost | Greenhouse | (109) |

| 29 | Barnyard millet (microgreens) | Wet cotton cloth | Room conditions | (110) |

| 30 | Peas, sunflower, radish (microgreens) | Nutrient film technique | Greenhouse | (111) |

| 31 | Mustard, kale, broccoli | Nutrient solution + sphagnum peat moss + bark + perlite + limestone | Conviron PGC flex growth chambers | (112) |

| 32 | Brassica rapa var. Japonica, Brassica rapavar. Chinensis, Raphanus sativus, Brassica juncea (microgreens) | Nutrient solution + sphagnum peat moss | Growth chambers | (113) |

| 33 | Red basil, rocket (microgreens) | Floating system + nutrient solution; coconut fiber, vermiculite, jute | Micro experimental growing cabinet | (114) |

| 34 | Radish, kale, cilantro, broccoli, pea (microgreens) | 1/2 strength Hoagland’s solution + sterile hemp mat | Percival environmental chamber | (115) |

| 35 | Amaranth, turnip (microgreens) | Vermiculite | Controlled environment growth chamber | (116) |

| 36 | Red cabbage, broccoli, mizuna, green mustard, pak choy (microgreens) | Sand + organic soil + coco coir; coco coir + rice husk; coco coir + calcium oxide + humic acid; white sphagnum peat + vermiculite | Greenhouse | (117) |

| 37 | Sunflower, kale, arugula, mustard (microgreens) | Peat + compost + coir + perlite | Indoor and greenhouse environments | (118) |

Figure 1.

Stability of ecosystem in conventional and controlled environment agriculture systems. (a) Conventional Environment Ecosystem. (b) Controlled Environment Ecosystem.

3. Deciphering Models for Tracking Nutrients, Water, and Climate Dynamics in Controlled Environment Ecosystems using Advanced Technologies

In hydroponic systems with computer models, nutrient uptake in crops typically involves the precise control of nutrient solutions delivered directly to the plant roots. Computer models help optimize this process by monitoring and adjusting factors, such as nutrient concentration, pH levels, and water availability, to ensure optimal growth conditions. The plants absorb nutrients through their root systems in this soilless environment, facilitated by the nutrient-rich solution. The computer models help maintain the balance and provide real-time data for better management. The progress of greenhouse engineering with hydroponics has shown a heavy reliance on computational intelligence, especially through automated monitoring and control mechanisms. Advanced instrumentation and intelligent control systems employed in hydroponic setups hold the potential to enhance both the quality and quantity of production by efficiently managing diverse processes. These production systems are subject to continual monitoring and precise regulation. An essential aspect of these highly automated and computerized configurations is the accuracy and reliability of sensor-derived information, as well as the efficacy of decisions transmitted to actuators.119 The model involved in a controlled environment actively manages the interplay of nutrient, water, and climatic elements within a controlled environment framework (Table 2). It operates under the governance of an operating system, ensuring the provision of essential nutrients, water, and climate parameters to nurture plant growth within consistent standards.120 Effectively distributing nutrients, water, and climate variables regulates their crucial levels to sustain stability. Moreover, this model facilitates the creation of a controlled artificial ecosystem tailored for cultivating crops and microgreens, optimizing resource usage in the process.121 Additionally, it holds promise for mitigating crop loss and contributing to natural climate stabilization efforts. Within this model, distinct categories function according to specific principles and roles, all aimed at fostering plant growth within controlled environmental settings.122 An instrumental system was developed for monitoring and adjusting the pH and conductivity of the nutrient solution for hydroponic lettuce, which typically experiences significant fluctuations during cultivation.123 Furthermore, a Bayesian Network model has been developed to automate crop cultivation. Sensors and actuators are integrated to oversee and regulate farm parameters including light intensity, pH levels, electrical conductivity, water temperature, and relative humidity. Data collected from sensors is utilized to construct the Bayesian Network, which categorizes and forecasts optimal values for each actuator, enabling autonomous control of the hydroponics farm.124

Table 2. Diverse Models Involved in a Controlled Environment Ecosystem for Assessing Factors.

| s. no. | algorithm models | principles | assessing determinants | references |

|---|---|---|---|---|

| 1 | Decision-tree-based dosing algorithm | Real-time operating system | Carbon emission reduction, nutrient dynamics | (134) |

| 2 | Linear regression analysis | - | Electrical conductivity, pH | (135) |

| 3 | Nicolet model | Mechanistic | Crop growth, nitrate uptake | (136) |

| 4 | Fuzzy inference system | Real-time operating system | Control temperature, relative humidity, electrical conductivity, and pH | (137) |

| 5 | Plant talk | Python programs | Water dynamics, light emitting diodes monitor, plant care control | (138) |

| 6 | Machine learning, support vector regressor, extreme gradient boosting, random forest, deep neural network | Mechanistic | Crop growth | (139) |

| 7 | Artificial neural network, genetic algorithms | Real-time operating system | Electrical conductivity | (140) |

| 8 | Mechanistic and physiological model with machine learning (MPM-ml) | Michaelis-Menten enzyme kinetics | Nutrient quantity, nutrient flow rate, water-nutrient interaction, nutrient gradient, growth, yield | (141) |

| 9 | Recurrent neural network | Sensor | Crop growth | (142) |

| 10 | Light and shade system implementation | Sensor | High pressure sodium, light emitting diodes | (143) |

| 11 | Multiple linear regression | Sensor | Nutrient dynamics | (144) |

| 12 | Neural networks, genetic algorithms | Sensor | Water dynamics | (145) |

| 13 | Autoregressive moving-average model | Computer integrated system | Water status, light intensity, nutrient supply | (146) |

Another hydroponic system was designed with an advanced real-time operating system based on a microcontroller. ARM Cortex-M4 microcontroller (ARM) system was used to manage transmission signals. It oversees the measurement of crucial parameters such as electrical conductivity, pH levels, carbon dioxide concentration, temperature, and nutrient concentrations within a standardized environment. The system demonstrated its ability to maintain the desired concentration level within a narrow variation margin of less than 3%. Furthermore, the pH sensor used in this system exhibited commendable accuracy, with deviations of only 5.83% observed across pH values ranging from 3.23 to 10. The microcontroller interfaces with a digital temperature and humidity sensor (DHT) to monitor humidity levels and an MH-Z19 sensor to gauge carbon dioxide concentrations. Employing expert system-based automation (HES), in a controlled environment, is for regulating all aspects including temperatures, oxygen levels, nutrient supply, and operational settings for various components such as water heaters, fertilizer tubes, pH regulators, conditioners, moisture control systems, carbon dioxide generators, and artificial lighting. This synchronization ensures the creation of optimal conditions within the greenhouse system.125

Furthermore, the Arduino Uno microcontroller model examines the mobility and speed of the nutrient flow in solution. Arduino represents an electronic platform driven by open-source code, encompassing both hardware and software components. This versatile system possesses the capability to receive sensor input, trigger motor action, illuminate LEDs, and transmit data to the Internet and mobile devices, as well as receive and process incoming information, converting it into various applications. Users can dictate specific actions by programming instructions into the microcontroller embedded within the board. With its user-friendly interface, Arduino has found widespread use across a myriad of projects and applications. Its software caters to beginners with simplicity, while offering flexibility for advanced users. Compatible with Mac OS, Windows, and Linux, Arduino boasts cost-effectiveness in comparison to other microcontroller platforms. Additionally, the Arduino software can be expanded by proficient programmers through C++ libraries and is adaptable for circuit designers seeking to innovate.126 Moreover, an integrated hydroponic farm management system was developed to be capable of monitoring parameters like water temperature, water levels, nutrient solution concentrations, and acidity levels employing sensors linked to a microcontroller through an online platform.127

A neural network utilizing fault detection in a controlled environment is designed based on a quasi-network backpropagation algorithm, effectively discerned dynamic processes within the hydroponic system’s root zone, and accurately forecasted one-step-ahead values for pH and electrical conductivity.128 The PlantTalk system monitors water movement, regulates LED lighting, and manages plant care using Python programs. The Penman-Monteith and Stanghellini models analyze solar radiation, air temperature, humidity, and wind speed within a controlled environment. Moreover, alternative models such as the Priestley Taylor model and the Hargreaves & Samani model monitor air temperature and solar radiation within a controlled setting. The recurrent neural network and long short-term memory (RNN-LSTM) assess the levels of pH, temperature, humidity, and water diffusion, operating based on deep neural networks.

The mechanistic and physiological model with machine learning (MPM-ML) evaluates nutrient levels, nutrient transport, accessibility of water-soluble nutrients, substrate nutrient density, growth rate, productivity, and concentration gradients. Employing the Michaelis–Menten enzyme kinetics principle, this model functions by integrating with the Barber-Cushman model to calculate nutrient concentrations in the solution, mass transfer, diffusion, and Robin boundary conditions. Additionally, the Porter diffusion model is utilized to analyze substrate advection and diffusion equations.

The model provides insights into the operational dynamics and impacts of water, nutrient, and climatic variables within a controlled environment ecosystem. It regulates both critical and noncritical fluctuations in climatic factors, fostering stable plant growth under controlled conditions. Additionally, the model advocates for ecological reform and ecosystem preservation while conserving natural resources. With its potential to address and mitigate climate crises, it plays a crucial role in sustaining biogeochemical cycles and managing greenhouse gas emissions.125,129 Carbon dioxide concentrations in the surrounding environment, whether stable or fluctuating, are assessed using Carbon Enrichment for Plant Stimulation (CEPS) systems, implemented in both open and closed setups. Carbon sequestration in such systems is analyzed through models like the Rothamsted carbon model and Fourier or neural models, which explore carbon dynamics in both open and closed environments.130 Furthermore, Willits131 introduced a thermal model aimed at forecasting microclimate conditions within greenhouses equipped with mechanical ventilation and an evaporative cooling system. With the implementation of evaporative cooling, enlarging the canopy size holds greater significance in reducing air temperature. In the absence of evaporative cooling pads, the ratio of energy utilized for transpiration to incoming solar energy is estimated to vary between 1 and 75 for an outdoor air temperature of 36.8 °C and a humidity ratio of 3.3 g/kg, decreasing to 0.8 °C for an outdoor humidity ratio of 29.9 g/kg at the same air temperature. Max et al.132 also explored the impacts of different greenhouse cooling techniques, including mechanical ventilation and evaporative cooling, on the yield and quality of tomatoes in tropical climates.

Moreover, biochar can serve as a valuable resource for improving soil fertility, sequestering carbon, and enhancing the availability of essential nutrients for plants within open environment ecosystems. This method effectively enhances nutrient and carbon concentrations or availability under controlled conditions, while simultaneously preserving the integrity of the biogeochemical cycle.133 There is a need for investigation of the influence of biochar under controlled environment ecosystems using precise technologies such as speed breeding. Furthermore, the integration of artificial intelligence and machine learning in this approach will be further required for more significant results under such conditions.

3.1. Impact of Light-emitting Diodes (LEDs) Spectrum on Photomorphogenesis and Crop Growth under a Controlled Environment Ecosystem

LEDs emit electromagnetic radiation across various wavelengths, which is absorbed by the plastidial photoreceptors of plants to facilitate biological and physiological processes. These photoreceptors selectively capture specific colors of light to trigger cellular, molecular, and biochemical responses. Far-red light (>730 nm)147 is predominantly captured, with occasional responsiveness to green wavelengths due to their broad absorption spectrum (530–700 nm) extending into the green range. Within the cryptochrome, phototropin, and zeitlupe family proteins, green, blue, and UV-A light are absorbed at wavelengths of 530–700 nm, 390–500 nm, and 320–390 nm, respectively.148,149 Similarly, ultraviolet resistance locus 8 (UVR8) responds to light at wavelengths of 290–315 nm. These processes intricately regulate various aspects of plant growth and development, including phytochrome-mediated responses, photoperiodism, flowering, photosynthesis, chlorophyll synthesis, responses to light stress, modulation of hormonal pathways, enzymatic functions, and the synthesis of secondary metabolites like alkaloids and terpenoids.150 Phytochrome, for instance, orchestrates flower opening and closure in response to redfar red light, while also governing processes such as germination, leaf development, metabolism, and flowering via perception of blue/green light. Phototropin regulates leaf orientation, phototropism, stomatal behavior, and chloroplast movement, while the zeitlupe protein family coordinates metabolic activity and flower development. Furthermore, UVR8 plays a role in regulating de-etiolation and flavonoid synthesis in plants cultivated under controlled artificial lighting environments.151

In controlled environments, crops utilize specific wavelengths of LED light to regulate their biological responses (Table 3). Both monochromatic and polychromatic emissions from LED lights influence the growth and physiological functions of crops in these controlled settings.152 For instance, in brinjal cultivation, monochromatic blue light was observed to promote growth in growth chambers. Compared with white light, blue light increased plant height by 2.16%, while red light led to a decrease in height by 0.38%. Additionally, a combination of red and blue light has shown benefits in enhancing the accumulation of photosynthetic pigments and advancing photosynthesis in eggplant seedlings, particularly when the blue:red light ratio was 1:3. Blue light increased ΦPSII (Photosystem II quantum yield) by 10.6%, whereas red light reduced it by 25.8% compared to white light.153 In the case of potato plantlets, exposure to blue light resulted in a shortened stature, characterized by larger leaves, well-developed roots, and abundant green foliage, along with noticeable changes in stomatal development. Furthermore, the combination of blue light with white light demonstrated a favorable response in enhancing growth and metabolic processes in onions by influencing photosynthesis-related genes, compared to using white light LEDs alone.154

Table 3. Impact of Diverse LED Light Spectrum on Crops Grown in a Controlled Environment Ecosystem.

| s. no. | LEDs parameters | crops | PPFD (μmol m–2 s–1) | type of system | nature of growth | impact | references |

|---|---|---|---|---|---|---|---|

| 1 | blue:red (1:3) | Brinjal | 300 | Phytotron chambers | Seedlings | • Rise in Chl a, Chl (a + b), Chl a/Chl b, and carotenoids contents by 20.3%, 18.8%, 5.9%, and 36.9%, respectively | (158) |

| • Enhanced contents of total sugar, sucrose, glucose, fructose, and starch by 0.93, 1.7, 0.97, 1.1, and 2.0-fold respectively | |||||||

| 2 | Red | Potato | - | Growth conditions | Single node | • Reduction in stem diameter by 0.26 mm, leaf area by 0.04 cm2 | (159) |

| • Rise in node number by 3.33 and node length 0.12 cm, dry weight by 38.04 mg, fresh weight by 527.55 mg, and health index by 0.03 units | |||||||

| 3 | Red:blue (3:1) | Potato | - | Growth conditions | Single node | • Rise in stem diameter by 0.25 mm, leaf area by 0.04 cm2, node length by 0.74 cm and number by 2.0, dry weight by 31.64 mg, fresh weight by 477.56 mg, and health index by 0.61 units | (159) |

| 4 | Red:blue (1:1) | Potato | - | Growth Conditions | Single Node | • Rise in stem diameter by 0.17 mm, leaf area by 0.14 cm2, node number by 0.5, fresh weight by 251.28 mg, and health index by 0.21 units | (159) |

| • Reduction in dry weight by 0.13 mg | |||||||

| 5 | Red:blue (1:3) | Potato | - | Growth Conditions | Single Node | • Rise in stem diameter by 0.10 mm, leaf area by 0.06 cm2, fresh weight by 199.61 mg, and health index by 0.36 units | (159) |

| • Reduction in node length by 0.83 cm | |||||||

| 6 | White:blue (3:1) | Green onion | 300 | Artificial climate room | Seedlings | • Increase in soluble sugar by 0.17%, crude cellulose by 0.03 mg/g, pyruvate content by 0.22 mg/g, soluble protein by 0.74 mg/g, free amino acid by 0.15 mg/g and volatile content by 0.05 mg/g than normal white light | (160) |

| • Rise in dipropyl disulfide (CAS: 629-19-6) by 5.80% than white light | |||||||

| 7 | Sodium pressure lamps (HPS) + red LEDs (87.5%) (630 to 660 nm) + blue LEDs (12.5%) (440 to 460 nm) | Cucumber | 220 | Greenhouse | Plant | • Increased Fs and Fm’ in both younger and older leaves. | (161) |

| • Increased the vitality index (PI) in both younger and older leaves of cucumber plants | |||||||

| • Highest commercial yields obtained throughout the harvest | |||||||

| 8 | Far red LEDs + red | Red leaf lettuce | 730; 300 | Greenhouse | Plant | • Increased total biomass, and leaf elongation | (162) |

| • Suppressed anthocyanin content and antioxidant potential | |||||||

| 9 | Far red LEDs | Red cross baby leaf lettuce | 160 | Greenhouse | Plant | • Decreased chlorophyll concentration by 14% as compared to white fluorescent lamps. The fresh weight, dry weight, stem length, leaf length and leaf width significantly increased by 28%, 15%, 14%, 44% and 15%, respectively, as compared to sole white fluorescent lamps. | (163) |

| • Decreased anthocyanins and carotenoids concentration by 40% and 11% as compared to sole white fluorescent lamps | |||||||

| 10 | Red (75%) + blue (25%) | Indian mustard + basil | ∼170 | Greenhouse | Plant | • Delayed or inhibited plant transition to flowering as compared to HPS or 460 nm + 635 nm LED combination effects | (164) |

| 11 | Red LEDs (660 nm) | Cabbages (red + green leaves) | 50 | Greenhouse | Plant | • Increased anthocyanin contents in red-leaf cabbages | (165) |

| 12 | Red LEDs (640 nm) applied 7 days before harvesting | Kale plants | 253.3 | controlled environment | Plant | • Enhanced chlorophyll a, b accumulation. | (166) |

| • Enhanced lutein accumulation | |||||||

| 13 | Red LEDs (658 nm) | Baby leaf lettuce | 130 | Greenhouse | Plant | • Phenolics concentration increased by 6% with supplemental red light | (167) |

| 14 | Red LEDs (638 nm) | Lettuce + Grand Rapids marjoram + green onions | ∼500 | Greenhouse | Plant | • Reduction of nitrate concentration | (168) |

| 15 | Red LEDs (638 nm) as 3 days preharvest treatment | Lettuce + green leaf + red leaf | ∼170 | Greenhouse | Plant | • Increased DPPH free radical scavenging activity. Increased phenolic compound and η tocopherol content | (169) |

| 16 | Red LEDs (638 nm) + HPS lighting for 3 days before harvesting | Green baby leaf lettuce + Thumper + Multibaby | 210; 300 | Greenhouse | Plant | • Increased concentration of total phenolics (28,5%), tocopherols (33,5% in ‘Multibaby’), sugars (52.0%) and antioxidant capacity (14.5%) but decreased concentration of ascorbic acid | (170) |

| 17 | Red LEDs (638 nm) + HPS lighting for 3 days before harvesting | Red leaf + green leaf + light green leaf lettuces | 300; 90 | Greenhouse | Plant | • Reduced content of nitrate in red (56.2%) and green (20.0%) leaf lettuce, but nitrate contents increased in light green leaf lettuce. | (171) |

| 18 | Red LEDs (638 nm) + HPS lighting for 3 days before | White mustard + spinach + rocket + dill + parsley + green onions + white lisbon | 300 | Greenhouse | Plant | Altered antioxidant activity, increased monosaccharide, and decreased nitrate accumulation in dill and parsley. Increase in vitamin C content in mustard, spinach, rocket, dill and green onion. | (172) |

| 19 | Green LEDs (510, 520, or 530 nm) | Baby leaf lettuce: (red leaf + green leaf + light green leaf) | 100, 200, and 300 | Greenhouse | Plant | Reduction of nitrate concentration and increase in saccharide contents in all baby leaf lettuce varieties. | (173) |

| 20 | Green LEDs (505, 535 nm) | Red leaf ‘Multired 4’ + green leaf ‘Multigreen 3’ + light green leaf ‘Multiblond 2’ + baby leaf lettuce | 30 | Natural and green house | Plant | 535 nm green LEDs had greater positive effect on ascorbic acid, tocopherol contents and DPPH freeradical scavenging capacity, when 505 nm LEDs had greater effect on total phenol and anthocyanin contents. | (174) |

| 21 | Blue LEDs (Sole 440 nm) applied 7 days before harvesting | Kale plants | 10.6 | Greenhouse | Plant | Enhanced N-carotene contents | (175) |

| 22 | Blue (468 nm) LEDs alone or in combination with red (655 nm) LEDs | Red leaf lettuce | ∼100 | Greenhouse | Seedling | Stimulated biomass accumulation in the roots; resulted in compact lettuce seedling morphology; Promoted the growth of lettuce after transplanting. | (176) |

| Greater polyphenol contents and total antioxidant status. | |||||||

| 23 | Blue LEDs (440 nm) + red (640 nm) | Red leaf lettuce | 30; 270 | Greenhouse | Plant | Leaf expansion | (177) |

| Increased concentration of anthocyanins, higher antioxidant potential | |||||||

| 24 | Blue LEDs (476 nm) | Baby leaf lettuce | 130 | Greenhouse | Plant | Anthocyanins concentration increased by 31%; carotenoids concentration increased by 12% | (163) |

| 25 | Blue LEDs (470 nm) | “Kinshun” (green leaves) + “Red Rookie” (red leaves) | 50 | Greenhouse | Seedling | Promoted petiole elongation in both cabbage varieties; higher chlorophyll contents in green leaf cabbages | (165) |

| 26 | Blue LEDs (460 nm) + red (660 nm) light (11,1% of blue light) | Nonheading Chinese cabbage | 80 | Greenhouse | Plant | • Higher chlorophyll concentration. Blue LEDs benefit vegetative growth, while red LEDs and blue plus red LEDs support reproductive growth | (178) |

| • Concentration of vitamin C was the greatest under blue LEDs | |||||||

| 27 | UV-A LEDs (373 nm) | Red cross baby leaf lettuce | 18 ± 2 | Greenhouse | Plant | Anthocyanin concentration increased by 11% | (163) |

Additionally, combining red and far-red light has been found to significantly hasten the growth of potato plants, resulting in heights of 30.3 and 27 cm for the Golden King and Chungang varieties, respectively.155 The use of simple and complex LED light emissions, including white, red, dark red, and a mixture of dark red, blue, and orange, has been shown to promote biological and physiological growth in jute (Corchorus capsularis) under controlled glasshouse conditions. Exposure to red light increased plant height by 12% compared to that with white light, while the stem diameter exhibited an 86% increase under blue light and an 82% increase under orange light. Similarly, the root diameter increased by 83% under blue light and 84% under orange light.156 Monochromatic LED light emissions, such as red, white, blue, and orange, have been effective in promoting morphological growth in Brassica napus within controlled glasshouse environments. For instance, exposure to red light increased the seedling length of Brassica napus by 29.2%, plant height by 13.2%, crown length by 32.2%, total chlorophyll by 17.5%, carotenoids by 20.4%, plant fresh weight by 18.6%, and dry weight by 20% compared to white light.157 Both monochromatic and polychromatic LED lighting have successfully supported cellular, biochemical, and molecular processes across various plant species. These investigations will further illuminate the effects of LED light emissions on millets, fiber crops, and oilseed crops under controlled environmental conditions, areas that have yet to be extensively explored.

3.2. Mechanism of Nutrient Translocation in Plants with Physiological Model and Machine Learning in a Controlled Environment Ecosystem

Mechanistic physiological models (MPMs) and machine learning (ML) algorithms are central in orchestrating the intricate interplay among water, light, nutrients, and growth parameters within controlled environments, thereby exerting profound effects on the plant growth rate and yield. Real-time sensors, outfitted with ion-selective electrodes (ISEs), collaborate seamlessly with a computerized database management system to scrutinize both practical observations and theoretical insights. Nestled within the root zones of plants, these sensors perpetually track the dynamics of nutrient levels and absorption, while artificial neural networks (ANNs) take charge of rectifying errors, refining accuracy, and mitigating disruptions during nutrient transportation. By amalgamating ANNs with two-point normalization techniques (TPNs), meticulous forecasting and regulation of nutrient movement within plants are accomplished with precision.179

3.3. Mechanism of Nutrient Translocation in the Root System of the Plant

In controlled environmental settings, the intricate interplay of root architecture, metabolism, and dynamics is discerned through the application of mechanistic physiological models (MPMs) and machine learning (ML). These sophisticated models not only govern the influx and dynamics of nutrients within the plant root system but also facilitate a nuanced understanding of substrate dynamics and root nutrient uptake. The integration of mechanistic physiological models, such as the Barber-Cushman model and Porter diffusion models, enables a comprehensive exploration of nutrient dynamics and uptake mechanisms within plant roots. The Barber-Cushman model, alongside the Porter diffusion model, operates independently, yet synergistically, in elucidating nutrition metabolism. This multifaceted model scrutinizes various facets, including nutrient concentrations, solution nutrient levels, spatial distributions, mass flow, diffusion processes (governed by the advection-diffusion equation), and Robin boundary conditions. Simultaneously, the Porter diffusion model meticulously examines substrate advection and diffusion equations within the intricate framework of plant roots, further enriching our understanding of nutrient dynamics and uptake processes. Furthermore, the Michaelis–Menten (MM) model regulates nutrient flow from the root cell to the plasma membrane, biomass growth, nutrient gradients, substrate dynamics, and root influx dynamics in the plant root system.180

Utilizing additive chemicals enhances biological growth, stimulates the production of phenolic compounds and flavonoids, improves nutrient availability, facilitates the synthesis of antioxidant compounds, fortifies processes, and bolsters stress resistance in plants.181 Under controlled conditions, the utilization of potassium nitrate (KNO3) elevates the levels of antioxidant enzymes, such as superoxide dismutase (SOD), peroxidase (POD), catalase (CAT), and ascorbate peroxidase (APX) within both the root and leaf systems of radish plants. This augmentation mitigates salt stress in radishes. Additionally, it amplifies the presence of phenolic compounds, flavonoids, ascorbic acid, and anthocyanins.182 Under glasshouse conditions, the intake of synergic acid diminishes oxidative stress while concurrently boosting growth, biomass, gas exchange, and the presence of antioxidant compounds in either the root or shoot system of tomato plants.183 Furthermore, in Triticum aestivum L. plants, the use of taurine enhances growth, chlorophyll levels, and nutrient absorption by modulating the scavenging of reactive oxygen species (ROS), secondary metabolic pathways, and ion balance in response to stressors. Taurine’s efficacy mitigates the generation of nitric oxide, hydrogen sulfide, glutathione, and phenolic compounds, while also attenuating the impact of boron (B) and chromium (Cr) under regulated conditions.184 Moreover, employing advantageous additive chemicals in hydroponic systems, substrate-based cultivation, and accelerated breeding methodologies significantly boosts biological growth, stress resilience, reduction of reactive oxygen species (ROS), establishment of barriers against toxic metals, and enrichment of phytochemicals or phenolic compounds. Comprehensive studies may be necessary to grasp the intricate mechanisms and uptake dynamics of potassium nitrate, synergic acid, and taurine compounds within plant root systems by using mechanistic physiological models and machine learning techniques under controlled environmental settings.

4. Approaches of Technological Resources in Speed Breeding under a Controlled Environment Ecosystem

Speed breeding techniques encompass a diverse array of methodologies and tools aimed at accelerating the breeding process and enhancing desirable traits in crops under controlled conditions. These techniques include the utilization of various markers such as molecular, biochemical, and morphological markers as well as advanced breeding methods like Marker-Assisted Selection (MAS), Genome-Wide Association Studies (GWAS), Next-Generation Sequencing (NGS), Genomic Selection (GS), Targeted Induced Local Lesions IN Genomes (TILLING), mutation breeding, RNA interference (RNAi), and CRISPR/Cas gene editing. Additionally, tissue culture methods are employed to propagate plants rapidly.185,186 Speed breeding techniques have been effectively utilized to enhance several crops including Brassica species, Arabidopsis thaliana, various species of amaranthus, bread wheat, durum wheat, barley, chickpea, pea, grass pea, quinoa, oat, purple false brome, peanut, soybean, sorghum, broad beans, lentil, rice, and burrowing clover within controlled environment systems. These techniques have proven instrumental in improving traits essential for crop enhancement.187

4.1. Response of Speed Breeding Techniques in Crops for Trait Improvement in Controlled Environment Conditions

Recombinant inbred lines (RILs) with desired traits were successfully generated in soybean in five years using a temperature-controlled growth chamber and an incandescent lighting speed breeding technique, employing a single pod descent method.188 In a span of four years, early plant regeneration was achieved in groundnut through the utilization of a greenhouse, employing the photosynthetically active radiation (PAR) technique and gas heating speed breeding method, facilitated by the single seed descent approach.189 In a span of 7 to 8 years, early flowering and seed germination in broad beans and lentils were achieved using a speed breeding technique incorporating light emitting diodes (LEDs), precise temperature control, and growth regulators, all managed through the single seed descent method within an incubator. Similarly, in peas, recombinant inbred lines (RILs) were successfully developed within a time frame of 5 years by integrating light emitting diodes (LEDs), growth regulators, and speed breeding techniques using the single seed descent method within a growth chamber.190 For wheat, these lines were obtained within an eight-year time frame utilizing incandescent lighting, precise temperature control, or embryo culture in conjunction with a speed breeding approach, all implemented through the single seed descent method under carefully controlled conditions.191 Moreover, in chickpeas, these lines were produced in four years with LED and temperature-based speed breeding techniques through a single pod descent method under greenhouse.192 Similarly, the rapid productions of high-yielding varieties in rice were also produced in 4 years using the same technique under greenhouse and screen house facility.193 However, in soybeans, the germination rate with light effect was achieved in five years with light emitting diodes and speed breeding technique through a single seed descent method under climate-controlled chamber.194

Over a span of nine years, using LED, controlled temperature, growth regulators, and the embryo rescue speed breeding technique, segregated and pure lines were developed in wheat, barley, and sorghum populations via the single seed descent method within a controlled environment facility.195 Within a span of 6 to 7 years, the development of biotic stress-resistant traits and the establishment of pure line plant populations in bread wheat, durum wheat, or chickpea were demonstrated using a speed breeding technique based on LED lighting or temperature regulation. These methods were applied through the single seed descent approach under laboratory room conditions, temperature-controlled glasshouses, and controlled environments simulating glass homes, respectively.196,197 Moreover, employing analogous technologies, the breeding period was condensed, resulting in a complete development within five years, and early panicle emergence was achieved in oats within the Walnut Street Greenhouse.198 Conversely, for Arabidopsis thaliana, the breeding cycle was abbreviated, with a total development time of 10 years observed under Greenhouse.199 Furthermore, the generation of segregating plant populations in Amaranthus species was achieved within a six-year time frame utilizing these technologies under predefined conditions.200 In just six years, the rapid development of high-yielding sorghum varieties was accomplished using a speed breeding technique that incorporated light emitting diodes (LEDs), precise temperature control, and immature seed germination, all managed through the single seed descent method within a controlled greenhouse.201 Similarly, rapid biparental or multiparental plant populations in Trifolium subteraneum were established within the same time frame of six years, employing an expedited breeding method that involved incandescent lighting, temperature regulation, and growth regulators, all applied through the single seed descent method within a controlled plant growth facility202,203 (Table 4).

Table 4. Intervention of Speed Breeding Methods in Phenotypic Traits Improvement under Controlled Environment Conditions.

| s. no. | crops | speed breeding methods | generation per annum | traits improvement | growing system | references |

|---|---|---|---|---|---|---|

| 1 | Soybean | Incandescent lights, temperature | 5 | Recombinant inbred lines (RILs) | Growth chamber | (188) |

| 2 | Groundnut | Photosynthetically active radiation (PAR) technique, gas heating | 4 | Early plant regeneration | Greenhouse | (189) |

| 3 | Broad bean, lentil | Light emitting diodes, temperature, growth regulators | 7 or 8 | Early flowering and seed germination | Incubator | (204) |

| 4 | Pea | Light emitting diodes, growth regulators | 5 | RIL | Growth chamber | (190) |

| 5 | Chickpea | Light emitting diodes, temperature | 4 | RIL | Greenhouse | (192) |

| 6 | Soybean | Light emitting diodes | 5 | Germination rate in light effect | Climate controlled chamber | (194) |

| 7 | Wheat, barley, sorghum | Light emitting diodes, temperature, growth regulators, embryo rescue | 9 | Segregated or pure lines plant populations | Controlled environment facility | (195) |

| 8 | Rice | Light emitting diodes, temperature | 4 | Rapid production of high-yielding variety | Screen house facility | (193) |

| 9 | Wheat | Incandescent light, temperature, embryo culture | 8 | RIL | controlled conditions | (191) |

| 10 | Bread wheat, durum wheat, chickpea | Light emitting diodes, temperature | 6–7 | Biotic stress resistance, pure line plant population | Laboratory room conditions, temperature controlled glasshouse, glass home | (196, 197) |

| 11 | Oat | Light emitting diodes, temperature, micronutrient | 5 | Short breeding time, early panicle emergence | Walnut street greenhouse | (198) |

| 12 | Sorghum | Light emitting diodes, temperature, immature seed germination | 6 | Rapid high yielding variety development | Controlled greenhouse | (201) |

| 13 | Arabidopsis thaliana | Light emitting diodes, temperature, growth regulators | 10 | Short breeding cycle | Greenhouse | (199) |

| 14 | Amaranthus spp. | Light emitting diodes, temperature, growth regulators | 6 | Segregating plant populations | Controlled growth chamber | (200) |

| 15 | Trifolium subteraneum | Incandescent light, temperature, growth regulators | 6 | Rapid biparental, multiparental plant populations | Controlled plant growth facility | (202, 203) |

Speed breeding techniques offer significant potential for enhancing oligogenic or qualitative traits while simultaneously reducing the generation time in crop breeding programs. Further research is warranted to explore the screening of quantitative traits, assess heritability, delve into the concept of plant ideotypes following Donald’s concept, investigate biofortification strategies, conduct biometric analyses, and undertake physiochemical characterization within the framework of existing breeding techniques and plant tissue culture methods under controlled environment conditions. Additionally, advancements in biometric analyses and physiochemical characterization techniques can provide valuable insights into the underlying genetic mechanisms and physiological processes governing trait expression. Moreover, the integration of plant tissue culture methods into speed breeding protocols offers opportunities for rapid propagation of elite genotypes, somaclonal variation screening, and the development of novel genetic variants. This approach can expedite the generation of diverse germplasm and accelerate the breeding cycle, ultimately enhancing the efficiency and effectiveness of crop improvement programs.204

4.2. Protocols of Speed Breeding in Rice, Sorghum, Chickpea, Soybean, and Groundnut in Controlled Environment Conditions

Speed breeding techniques significantly abbreviate the breeding cycle, enabling the swift creation of new varieties within a considerably reduced time frame.205 Parental selection, crossing, generation line development, multiplication, evaluation, adaptation, yield trials, and variety release can all be accomplished within a mere 2 to 3 years of generation time using speed breeding methodologies within a controlled environment ecosystem.206 The techniques and timelines for speed breeding and generation vary across crop development and enhancement within controlled environment settings.207 For instance, rice population lines can be achieved within a generation time of 80 days by using a rapid advancement method based on speed breeding. This method necessitates specific conditions, including an 11-h photoperiod, temperatures of 30 °C during the day and 25 °C at night, a photosynthetic photon flux density of 350 μmol m–2 s–1, 70% humidity, and a CO2 concentration of 475 ppm under controlled conditions. However, altering the photoperiod to 10 h and maintaining the same temperature, light intensity, and humidity, the generation time for rice population lines extends to 100 days under controlled conditions.208 For sorghum, the generation time was reduced to 77 days under controlled conditions when subjected to continuous light and maintained at a temperature of 30 °C.209 Additionally, the vegetative growth of soybean is observed within a generation time of 70 days under standardized conditions. These conditions include a 14-h photoperiod, temperatures of 30 °C during the day and 25 °C at night, a photosynthetic photon flux density of 220 μmol m–2 s–1 at canopy level, a CO2 concentration exceeding 440 ppm, and humidity ranging between 50 and 80%.210 Furthermore, in the context of chickpeas, a condensed breeding cycle was observed when population lines were subjected to specific conditions. This included exposure to a 22-h photoperiod, day temperatures of 22 °C and night temperatures of 17 °C, maintained humidity levels of 70%, and a photosynthetic photon flux density ranging between 440 and 650 μmol m–2 s–1 during the adult plant stage, all under predefined conditions.211 Furthermore, the integration of speed breeding with continuous light supply, day temperatures of 28 ± 3 °C and night temperatures of 17 ± 3 °C, along with 65% humidity, yielded a generation time of 89 days for groundnut population lines under standardized environmental conditions.212

5. Applications of Artificial Intelligence in Phenotypic Character Examination in Crops under a Controlled Environment Ecosystem

The real-time machine powered by artificial intelligence (AI) operates on neural network principles and algorithmic models. It is seamlessly incorporated into plant growth chambers, where predetermined environmental conditions facilitate the scrutiny of phenotypic traits and functional assessments in crops. This cutting-edge technology has demonstrated its efficacy across various crops, serving pivotal roles in screening for traits within controlled environments.213

Preharvest potential, yield performance, and identification of high-yield cultivars in soybean were evaluated through various advanced methodologies. These include the application of Best Linear Unbiased Prediction (BLUP), Neural Networks (NNs), kernel methods, and algorithmic models such as Multilayer Perceptron (MLP), Support Vector Machine (SVM), Ensemble-Stacking (E-S), Random Forest (RF), and Stochastic Gradient Descent (SGD) within an open field system.214,215 In soybeans, investigations into seed per pod and seed characteristics across diverse environments were conducted using Convolutional Neural Networks (CNNs) and algorithmic model Batch Normalization (BN) within a conventional field system.216 Similarly, French beans underwent scrutiny for average yield, adaptability under stress factors, and phenotypic stability, employing Artificial Neural Networks (ANNs) along with algorithmic models Mean Square Deviation (MSD) and Mean Square Residue (MSR) within a standard field scenario.217 Moreover, employing similar technologies, French beans were subjected to assessments of the oil content, callus physical characteristics, secondary metabolite synthesis, and somatic embryo development. These analyses were conducted in a research field218 and controlled environment room.219 Stress resistance and miRNA expression related to stress response were investigated in Arabidopsis thaliana utilizing deep learning techniques and algorithmic support vector machine (SVM) and naive Bayes classifiers within a growth room setting.220 In the case of sesamum, evaluations of seed yield, oil content, and identification of superior genotypes were carried out utilizing Artificial Neural Networks (ANNs) and algorithmic model Multiple Regression Analysis in a research field221 (Table 5).

Table 5. Intervention of Artificial Intelligence (AI) in Crops for Traits Identifications.

| s. no. | crops | artificial intelligence | algorithm models | traits identifications | growing system | references |

|---|---|---|---|---|---|---|

| 1 | Soybean | Best linear unbiased prediction (BLUP), neural networks (NNs), kernel methods | Multilayer perceptron (MLP), support vector machine (SVM), ensemble-stacking (E-S), random forest (RF), and stochastic gradient descent (SGD) | Preharvest potential, yield performance, high-yield cultivars | Open field | (214, 215) |

| 2 | Soybean | Convolutional neural networks (CNNs) | Model batch normalization (BN) | Seed per pod, seed character | Open field | (216) |

| 3 | French bean | Artificial neural networks (ANNs) | Mean square deviation (MSD), mean square of residue (MSR) | Average yield, high adaptation, and phenotypic stability | Open field | (217) |

| 4 | French bean | Artificial neural networks (anns) | Mean square deviation (MSD), mean square of residue (MSR) | Oil content, callus physical characters, secondary metabolite synthesis, somatic embryo | Research field, controlled room | (218, 219) |

| 5 | Arabidopsis thaliana | Deep learning | Algorithm support vector machine (svm), naive byes | Stress resistance, mirna expression in stress resistance | Growth room | (220) |

| 6 | Sesamum | Artificial neural networks (ANNs) | Multiple regression analysis | Seed yield, oil content, superior genotypes | Research field | (221) |

The integration of real-time machine learning presents significant opportunities for quantitative trait screening within speed breeding techniques implemented in controlled environment ecosystems. Exploring the intervention of speed breeding techniques in quantitative traits, biofortification, nutrient or water dynamics screening, tissue culture plant regeneration examination, biometric analysis, and physiochemical characterization using artificial intelligence becomes essential in studying crops under controlled growth conditions.

5.1. Intervention of Artificial Intelligence (AI) and Machine Learning (ML) in Phenotype Screening in Speed Breeding

The fundamentals of crop modeling, crop management, trait discovery, phenotype identification, quantification, diseases, and pest diagnosis, along with image processing, are integrated into the algorithmic models. These models leverage artificial intelligence, machine learning, automated machine learning, and information technology to screen, identify, classify, and assess various aspects such as growth, yield, disease, pest detection, plant-microbe relationships, environmental factors, climatic patterns, and phenotypes.222