Abstract

The EFSA Panel on Animal Health and Welfare (AHAW) was asked to deliver a scientific opinion on the use of high‐expansion foam for stunning and killing pigs and poultry. A dossier was provided by the applicant as the basis for an assessment of the extent to which the method is able to provide a level of animal welfare at least equivalent to that ensured by the currently allowed methods for pigs and poultry. According to legislation, to be approved in the EU, new stunning methods must ensure (1) the absence of pain, distress or suffering until the onset of unconsciousness, and (2) that the animal remains unconscious until death. An ad hoc Working Group set up by EFSA performed the assessment as follows: (1) The data provided were checked against the criteria laid down in the EFSA Guidance (EFSA, 2018), and was found to partially fulfil those criteria; (2) extensive literature search; (3) data extraction for quantitative assessment; (4) qualitative exercise based on non‐formal expert elicitation. The assessment led to conclude that it is more likely than not (certainty > 50%–100%) that high‐expansion foam for stunning and killing pigs and poultry, named NEFS in container (Nitrogen Expansion Foam Stunning in container), provides a level of welfare at least equivalent to one or more of the currently allowed methods listed in Annex I of Council Regulation (EC) No 1099/2009. The overall assessment of EFSA is valid only under the technical conditions described in this Opinion for laying hens, broiler chickens of all age and pigs weighing 15–41 kg in situations other than slaughter. The overall assessment of EFSA is that NEFS can be suitable for depopulation using containers for pig and poultry farms respecting the technical conditions and the categories and types of animals defined in this Scientific Opinion.

Keywords: animal welfare, container, nitrogen expansion foam, on farm killing, pigs, poultry, stunning

SUMMARY

Council Regulation (EC) No 1099/2009 on the protection of animals at the time of killing lists in its Annex I the stunning applications currently allowed in the European Union (EU), together with the conditions under which those applications can be implemented. With the aim of constantly improving animal welfare, the Commission can amend the list of the approved methods in Annex I, considering scientific and technical progress. However, for a new or modified stunning application to be listed as an approved method in Annex 1, evidence that it ensures a level of animal welfare at least equivalent to that ensured by the currently approved methods must be provided.

The European Food Safety Authority (EFSA) was requested to perform such assessment regarding high expansion foam using nitrogen for on‐farm killing of pigs and poultry. Killing of poultry and pigs using inert gases, i.e. nitrogen and argon, is an approved method but the use of high expansion foam as a vehicle to carry nitrogen and displace atmospheric air in a container and the use of nitrogen jet stream to destroy the foam and release its content to create anoxia are considered a modification of the approved method. The modified method is named Nitrogen Expansion Foam Stunning in container (NEFS in container), which is an irreversible stunning system. According to the description of the method, high expansion refers to an expansion ratio of 1:> 250 where the expansion ratio is defined as the volume of foaming solution (volume of foaming agent plus water) to the volume of foam produced, while anoxia refers to an atmosphere containing less than 2% residual oxygen. The maintenance of unconsciousness until death is ensured by maintenance of less than 2% residual oxygen in nitrogen for 5 min in poultry and 7 min in pigs.

An ad hoc working group (WG) was set up by EFSA to address the terms of reference of the mandate received by the Commission. The welfare risk assessment was focused on the hazards associated with the foam, rather than anoxia per se. In this regard, the animals will come in contact with the foam and remain so until the foam is burst, and nitrogen gas is released to establish less than 2% by volume of residual oxygen in nitrogen, which could take up to 45 s, and until loss of consciousness occurs in the animals. For assessment phase 1, which is check of data for risk assessment, the WG assessed the scientific papers and the related annexes provided by the applicant in a dossier, following the procedure of EFSA Guidance on the assessment criteria for applications for new or modified stunning methods regarding animal protection at the time of killing (EFSA AHAW Panel, 2018). The outcome of the assessment was that the scientific papers contained information to partially fulfil the requirements for assessment phase one. The wording ‘partial’ was added, since the dossier, for example, failed to correlate adequately neurological measures with the behavioural measures. The lack of specific scientific data did not allow the WG to conclude on the occurrence and prevalence of the hazards, as well as on the time during which the animals could be subjected to these hazards. The method was assessed only for animal categories for which data were provided. The dossier also contained field data, i.e. number of animals killed belonging to different species, to contribute to the determination of the external validity of the assessment, but no experimental details or the animal welfare outcomes (failures) were disclosed. Therefore, the dossier submitted only partially fulfilled the eligibility criteria of EFSA Guidance, but there was still sufficient information provided by the applicant to perform phase two of the assessment, which is the risk assessment of the proposed stunning method, particularly about pain, distress or suffering caused to certain types of pigs and poultry exposed to the NEFS.

The most critical stage of assessment phase 2 was to compare the NEFS method with the existing stunning applications in terms of impact on animal welfare using quantitative and qualitative approaches. The quantitative assessment of the already allowed stunning/killing methods is difficult to perform because of the insufficient quantitative data available. In addition, differences in protocols and measurement methods can lead to significant variability in results. Therefore, it was agreed to use a qualitative method based on non‐formal expert elicitation to assess the equivalence of NEFS in containers with the other killing methods approved in the legislation. As a first step, the WG experts (n = 4) identified the main hazards related to each stunning method, i.e. mechanical and electrical stunning methods, controlled atmosphere stunning methods and NEFS. The experts were asked to rank these hazards in terms of impact on animal welfare.

It is worth noting that the conclusions provided in the dossier and as described in Section 3.3.2.3 of this Scientific Opinion are the applicant's conclusions and do not represent the views of EFSA, and that the independent assessment performed by EFSA is presented in Section 4.2, while the conclusions separately are presented in Section 5. However, EFSA and the applicant reached the same conclusions for some points.

The AHAW Panel concluded with > 50%–100% certainty (more likely than not) that:

exposure of pigs to anoxia (< 2% by volume of residual oxygen) created using high expansion foam (expansion ratio 1:> 250) filled with nitrogen (in less than a minute) provides a level of animal welfare at least equivalent to that ensured by exposure to carbon dioxide (CO2) at high concentration.

exposure of poultry to anoxia (< 2% by volume of residual oxygen) created using high expansion foam (expansion ratio 1:> 250) filled with nitrogen provides a level of animal welfare at least equivalent to that ensured by exposure to carbon dioxide (CO2) at high concentration, especially during whole house gassing, as well as by electrocution using electrical water bath.

These conclusions are valid only under the key parameters described in this Scientific Opinion and the additional conditions of operation of the method as described in the dossier, i.e. (i) residual oxygen concentration is achieved and maintained at less than 2% by volume until the animals are dead; (ii) exposure time should be minimum 5 min for poultry and 7 min for pigs; (iii) foam expansion ratio is maintained at 1:> 250; (iv) diameter of the bubbles in 95% of the foam is at least 10 mm and foam homogeneity is maintained; (v) foam production rate is adequate to fill the container in less than 45 s; (vi) uniform distribution of the foam without air pockets; (vii) stocking density/space allowance is adequate to establish uniform and simultaneous exposure of animals to anoxia; (viii) temperature of the water supply is lukewarm and nitrogen is fully vapourised prior to reaching the foam generator; (ix) foaming agent is not harmful to animals; (x) foam is transparent and observation of animals is not obscured. Deviation from the conditions might have consequences for animal welfare which were not assessed in this exercise and will need a dedicated assessment.

The emergency procedures associated with system failures and backup killing method appropriate to the species and category of animals should be included by the manufacturer in the manufacturer's instructions for the effective use of the equipment and the end user of the method should follow the manufacturer's instructions and include them in the standard operating procedures.

Finally, based on the current assessment, the method can be suitable for situations other than slaughter and depopulation using containers for pig and poultry farms and respecting the technical conditions and the categories and types of animals defined in this Scientific Opinion.

1. INTRODUCTION

The Commission received a request from a business operator to allow the use of a high‐expansion foam for stunning and killing animals. With this application, the Commission has received a series of publications and technical information in order to obtain a full assessment of the method. This information is attached to the present request.

1.1. Background and Terms of Reference as provided by the requestor

1.1.1. Background

Council Regulation (EC) No 1099/2009 on the protection of animals at the time of killing (later referred as ‘the killing Regulation’) defines stunning in Article 2(f) as any intentionally induced process which causes loss of consciousness and sensibility without pain including any process resulting in instantaneous death.

Article 3(1) requires that animals shall be spared any avoidable pain, distress or suffering during their killing and related operations.

Article 4(1) requires that animals shall only be killed after stunning in accordance with the methods and specific requirements related to the application of those methods set out in Annex I of the Regulation and that the loss of consciousness and sensibility shall be maintained until the death of the animal.

Annex I to the killing Regulation lists the stunning methods and related specifications.

Article 4(2) allows the Commission to amend Annex I as to take into account scientific and technical progress on the basis of an opinion of the EFSA. Any such amendments shall ensure a level of animal welfare at least equivalent to that ensured by the existing methods.

At present, the use of high‐expansion foam is not listed in Annex I and therefore not allowed for stunning animals.

1.1.2. Terms of Reference

In accordance with Article 29 (1) (a) of Regulation (EC) No 178/2004, 1 EFSA is requested to evaluate the use of high‐expansion foam for stunning and killing animals as proposed in the application (later called ‘the proposed method’).

In particular, EFSA shall assess:

Whether the proposed method and information provided with the application meets the eligibility criteria of EFSA's guidelines. 2

- Whether the proposed method can provide a level of animal welfare at least equivalent to that ensured by the existing methods in the legislation and specially:

- whether the proposed method ensures that pigs and poultry are spared of avoidable pain, distress or suffering during the killing as referred to in paragraph 1 of Article 3 of the killing Regulation and,

- whether the proposed method maintains the loss of consciousness and sensibility until death of pigs and poultry as referred to in paragraph 1 of Article 4 of the killing Regulation.

1.2. Interpretation of the Terms of Reference

Considering the background and the Terms of Reference (ToR) as provided by the European Commission, this Scientific Opinion (SO) of EFSA:

Based its assessment on the most recent updated (2nd update) dossier submitted to EFSA, which included all the files and documents provided by the applicant. The main document of the dossier and the additional necessary files for the method are available under the Supporting Information section on the online version of the scientific output in Annex C. The applicant specifically requested an evaluation of the NEFS method: Nitrogen Expansion Foam Stunning in container, for stunning and killing pigs and poultry and for situations other than slaughter. Additionally,

According to the dossier (page 14), the target species and animal categories for the application of NEFS include day‐old chicks, laying hens of all ages, broiler chickens, turkeys, doves (pigeons), ducks and geese and pigs from birth (neonates) until 80 kg. However, according to the scientific information provided in the dossier, there is no evidence that NEFS has been scientifically evaluated, using EEGs or other appropriate ABMs, for ducks, pigeons and turkeys and for pigs outside the weight range of 15–41 kg. Peer‐reviewed scientific publications are required as evidence.

Therefore, the conclusions of the assessment of this modified killing method regarding poultry will be for laying hens and broiler chickens of all age and concerning pigs for weight of 15–41 kg (for more information see Sections 3.1.4 and 3.1.5).

It is inferred that the NEFS method proposed by the applicant is the same as ‘nitrogen filled high expansion foam’ or ‘dry foam created using nitrogen’ reported in the scientific literature (e.g. Raj et al., 2008) and/or EFSA opinions on killing of pigs and poultry on farm for purposes other than slaughter (EFSA AHAW Panel, 2019, 2020a, 2020b).

-

2

Assesses whether the proposed method and information provided with the application meets the eligibility criteria of EFSA's guidelines (ToR1), which is the ‘Guidance on the assessment criteria for applications for new or modified stunning methods regarding animal protection at the time of killing’ (EFSA AHAW Panel, 2018) and this guidance is also the protocol that is followed for the SO.

-

3

Assesses whether the proposed method can provide a level of animal welfare (AW) at least equivalent to that ensured by the methods that exist in Annex I of Council Regulation (EC) 1099/2009 for pigs and poultry for situations other than slaughter (ToR2), i.e.:

the methods that exist in Annex I of Council Regulation (EC) 1099/2009 for pigs and poultry for situations other than slaughter,

whether the proposed method ensures that pigs and poultry are spared of avoidable pain, distress or suffering during the killing as referred to in paragraph 1 of Article 3 of the killing Regulation (above mentioned Regulation) (ToR2i).

whether the proposed method maintains the loss of consciousness and sensibility until death of pigs and poultry as referred to in paragraph 1 of Article 4 of the killing Regulation, that is from the onset on unconsciousness until death (ToR2ii).

-

4

Uses ‘pain, distress and/or suffering’ together, because this is how it is mentioned in EFSA Guidance 2018 and also in the killing Regulation.

-

5

Bases its evaluation on two published scientific papers provided by the applicant as well as other published scientific papers after extensive literature search on high expansion foam stunning method. For more information, see Section 2.

-

6

Will conclude if the use of the modified proposed method is valid under commercial conditions, stating to what extent the method proposed for stunning and killing pigs and poultry is able to provide a level of AW in compliance with the above‐mentioned legislation and, if yes, under which conditions.

1.3. Additional information

During the assessment process, as defined in the EFSA guidance, it became apparent that some of the information submitted by the applicant lacked sufficient detail to clearly outline the potential welfare concerns.

For this reason, and with the specific aim of gathering all necessary information and data to assess the exact sequence of the events during the high expansion foam process, EFSA asked the applicant for additional data and information twice, and specifically on 07 February 2023 and on 20 July 2023. See Section 2.1 for more information.

2. DATA AND METHODOLOGY

2.1. Data

The applicant provided EFSA with two scientific publications (McKeegan, Reimert, et al., 2013 and Lindahl et al., 2020; for poultry and for pigs, respectively) considered in this assessment. Following the request of additional information, the applicant added, as part of the dossier, ongoing confidential research and unpublished field trial data. However, all non‐published research included only basic summary results and no individual data or detailed methodology such as time of exposure to less than 2% O2 in containers. Therefore, a full assessment of these data was not possible, and these data have been excluded from the assessment, with the assessment regarding the applicant's provision solely relying on the two published scientific papers.

As stated in Section 1.3, EFSA asked the applicant for additional material. More specifically, EFSA requested additional information and/or clarifications:

On 07.02.2023 regarding the 1. Description of the stunning method, 2. Description of the individual studies submitted, 3. Overall integration of findings from all studies. For more information, see in the following link of OpenEFSA https://open.efsa.europa.eu/questions/EFSA‐Q‐2022‐00344?search=foam, in the Supporting documents on page 5, the file ‘RFI’. The reply along with the updated dossier of the applicant was received on 08.05.2023.

On 20.07.2023 concerning the 1. Description of the stunning method: Description of the method including potential sources of pain, distress and suffering, Key parameters of the effective use of the method, Scientific basis of induction and maintenance of unconsciousness for this method, Potential causes of system failure and chances of occurrence. For more information, see in the following link of OpenEFSA https://open.efsa.europa.eu/questions/EFSA‐Q‐2022‐00344?search=foam, in the Supporting documents on page 5, the file ‘Additional Data Request’. The reply along with the latest updated dossier of the applicant was received on 03.10.2023.

2.2. Methodology

This SO follows the protocol detailed in the methodological guidance that was developed by the EFSA AHAW Panel to deal with all the mandates on the assessment criteria for applications for new or modified stunning methods regarding animal protection at the time of killing (EFSA AHAW Panel, 2018).

2.2.1. Literature search

An extensive literature search was conducted on the use of high‐expansion foam in poultry and pigs utilising the Web of Science (WoS) and Scopus databases. The search included the period from January 1975 until June 2023 and English language.

The query to the WoS database used the following search statement:

“TS = (foam AND killing) and TS = (poultry OR pigs) NOT TS = (occlusion or suffocation or drowning or asphyxia or firefighting) NOT TS = “water‐based”.

From a total of 10 retrieved scientific publications only four met the following criteria: use of high‐expansion foam, application for stunning or killing and used in poultry or pigs. Publications describing the use of water‐based foam, low and medium‐expansion foam or firefighting foam were not considered, because these were not representative of the method used and the cause of death was different (i.e. suffocation rather than anoxia), which may have different implications in terms of animal welfare, as in water‐based foam, the means of death is reported to be occlusion of the trachea (Korenyi‐Both et al., 2022). Any method designed to cause occlusion of the trachea would be equivalent to death by drowning or suffocation, which is not recognised as humane killing method in Council Regulation (EC) No 1099/2009 on the protection of animals at the time of killing.

Additionally, the query to the Scopus database used the following search statement:

“TITLE‐ABS‐KEY ((foam AND killing) AND (poultry OR pigs)) AND (LIMIT‐TO (DOCTYPE, “ar”))”.

From this query, four scientific publications were retrieved following exclusion of water‐based, low and medium expansion foam methods. These publications were the same as those retrieved from the first query in WoS and three out of four were for poultry. The final four publications are listed in Table 2.

TABLE 2.

List of publication retrieved after literature search.

| Paper | Authors | Title | Journal | Year | Doi |

|---|---|---|---|---|---|

| P1 | Raj, A. B. M., Smith, C., Hickman, G. | Novel method for killing poultry in houses with dry foam created using nitrogen | Veterinary record | 2008 | https://doi.org/10.1136/vr.162.22.722 |

| P2 | Gerritzen, M. A., Sparrey, J. | A pilot study to assess whether high expansion CO2‐enriched foam is acceptable for on‐farm emergency killing of poultry | Animal welfare | 2008 | https://doi.org/10.1017/S0962728600032206 |

| P3 | McKeegan, D. E. F., Reimert, H. G. M., Hindle, V. A., Boulcott, P., Sparrey, J. M., Wathes, C. M., Demmers, T. G. M., Gerritzen, M. A. | Physiological and behavioural responses of poultry exposed to gas‐filled high expansion foam | Poultry science | 2013 | https://doi.org/10.3382/ps.2012‐02587 |

| P4 | Lindahl, C., Sindhoj, E., Hellgren, R. B., Berg, C. Wallenbeck, A. | Responses of Pigs to Stunning with Nitrogen Filled High‐Expansion Foam | Animals | 2020 | https://doi.org/10.3390/ani10122210 |

In addition, articles, review articles and grey literature identified in the literature search or cited in identified publications were checked, irrespective of the year of publication and included if considered relevant by the working group.

Literature used for the comparison of different killing methods (Section 4) in pigs and poultry was retrieved by an extensive literature search following the Preferred Reporting Items for Systematic Reviews and Meta‐Analyses (PRISMA) methodology. This framework identifies evidence in a non‐biased and independent review of the literature and follows a three‐phase approach: identify scientific publications pertinent to the defined aim through eligibility criteria (Phase 1), assessment and quality (Phase 2) and finally ranking the publications in relation to the quality and relevance (Phase 3). The final search terms were identified following extensive piloting and a total of 12 permutations. In the final iteration, relevant literature was identified using the same search terms in all four key search engines (1) PubMed; (2) Science Direct; (3) Scopus; and (4) Web of Knowledge. The search terms used (including all titles, abstracts and keywords) included: TITLE: (killing* OR slaughter* OR depopulation* OR euthanasia*) AND TOPIC: (animal welfare* OR physiology* OR behaviour* OR indicator* OR stress) AND TITLE: (poultry* OR chick* OR turkey* OR broiler* OR layer* OR duck* OR bird* OR pullet* OR hen* OR pig* OR hog* OR swine* OR sow* OR piglet*) NOT TOPIC: (water‐based) NOT TOPIC: (firefighting).

Following collation of publications identified from the finalised search terms, publications were scrutinised based on a series of eligibility inclusion criteria: open access availability (including ‘green access’); full publication available in English language (unless translations were readily accessible); peer‐reviewed; species specified; topic specified; and full papers only (e.g. Conference proceedings excluded). Reviews of the literature and guidance documents were identified and excluded from the systematic review assessment, but not removed from the reference database, as they provided informative benchmarks to the current review narrative. Phase 1 eligibility screening was conducted with assessors blinded to authors and their affiliations to minimise bias. Any duplications of publications were also omitted. Two additional exclusion criteria were adopted, which excluded publications with no outcomes relevant to animal welfare or methods of killing which are not approved for use in Council Regulation (EC) 1099/2009. Finally, critical reported data were extracted from each publication to aid final quality assessment (Phase 3), where papers were scored according to the quality specifications outlined in Table 3. Papers identified with a quality score of 1 were excluded from evaluation and review of the final literature selection. The period and language of the search were the same as above.

TABLE 3.

Phase 3 quality scoring criteria for literature used for the comparison of different killing methods (Section 4) in pigs and poultry.

| Score 1 (Lowest quality ranking) | According to data extracted, the publication was identified as either one or a combination of the following:

|

| Score 2 (Medium quality ranking) |

According to data extracted, the publication was identified as either one or a combination of the following: Sufficient replication and sample size Welfare outcomes identified Mode of killing detail sufficient |

| Score 3 (Highest quality ranking) | According to data extracted, the publication was identified as either one or a combination of the following:

|

In total, 199 eligible publications were identified from the four key search engines. After the screening process, a final 42 publications were identified and quality assessed for inclusion for the comparison of NEFS to the various killing methods approved for use in pigs and poultry (see Section 4).

2.2.2. EFSA guidance on the assessment criteria for applications for new or modified stunning methods regarding animal protection at the time of killing (EFSA AHAW Panel, 2018)

The first part of the assessment process involved checking the submitted documentation against the criteria laid down in the EFSA guidance.

In case the criteria are not fulfilled, the assessment report has to highlight the shortcomings and indicate where improvements are required before the study/method can be further assessed. It should be noted that the EFSA Guidance is applicable to the individual studies. As mentioned in Section 2.1, the Working Group (WG) experts identified some lack of information in the submitted papers. As a consequence, considering these limitations with regard to at least one of the criteria laid down in the guidance (see following sections), none of them would have passed the first assessment phase regarding ToR1. However, the WG experts, the AHAW Panel and European Commission representatives agreed that, in order to address ToR2 as well as to promote development of potential improvements of existing methods or encourage innovation leading to the introduction of improved stunning methods, the WG would assess the entire information combined, originating from the combination of the information provided by the applicant, the submitted papers, other existing literature and expert knowledge elicitation/evaluation rather than applying the criteria to the individual and/or unpublished studies, which is still in agreement with EFSA Guidance. Additionally, the AHAW Panel and the WG experts decided to ask the applicant for additional data, in order to perform ad hoc analyses with the aim of improving clarity of understanding and to facilitate the assessment (see Section 2.1).

2.2.3. Assessment of the level of animal welfare provided by the high expansion foam (equivalence with other killing methods)

2.2.3.1. Quantitative assessment

To compare NEFS with other killing methods used for purposes other than slaughter, a scientific literature review (see Section 2.2.1) was conducted to gather data on neurological and behavioural indicators of onset of unconsciousness and death (see Section 3.3.1.1). When discrepancies were detected between studies in the methodology or criteria used to ascertain these states, the worst‐case scenario was always considered. This means that for Loss of Posture (LOP), Loss of Consciousness (LOC) and Motionless, the highest values were selected (considering the case in which this occurred the latest). In addition, the time to onset of LOP was considered as a behavioural indicator of the onset of unconsciousness. The same rule was applied for motionless and an isoelectric pattern in the EEG to ascertain onset of death. If isoelectric EEG occurred later than the time to become motionless, the time for motionless was not considered. Finally, for behaviours that indicated aversion, distress or discomfort, the lowest values were selected (considering then the case in which this occurred the earliest). For full explanation regarding the use of indicators and comparisons among the methods, see Section 4.2.1.

2.2.3.2. Qualitative assessment and hazard ranking

The second step (ToR2) involved assessing the equivalence of NEFS with other stunning methods outlined in the legislation. To address this, a comparison between the proposed modified method and existing ones in terms of animal welfare was necessary. Various methodologies could be employed, including a comparative analysis of welfare outcome measures (ABMs) reflecting animals' responses to the method or an assessment of welfare hazards associated with each method.

However, conducting a quantitative comparison based on welfare outcome measures was deemed unfeasible due to reasons outlined in Sections 2.2.2 and 4.2.1. Hence, the equivalence assessment was based on a non‐formal expert elicitation utilising a semi‐qualitative approach and expert opinions.

The exercise was structured in five steps repeated to be applicable to chickens and pigs:

Identification of comparable killing methods;

Identification of a list of hazards within each killing method, along with their associated welfare consequences;

Evaluation of the magnitude of these hazards by experts, specifically tailored for each killing method in relation to chickens and pigs;

Expert discussions on the outcome of the exercise and to refine individual assessments based on collective insights;

Identification of highly relevant hazards for each method and presentation of the results.

1. Identification of comparable killing methods

For the identification of comparable killing methods, descriptions provided in the more recent EFSA scientific opinions on the welfare aspects of the main systems for stunning and killing of pigs and poultry (EFSA AHAW Panel, 2019, 2020a, 2020b) were taken into consideration.

Regarding chickens, head‐to‐body electrical stunning, non‐penetrative captive bolt, maceration and firearm with free projectile were excluded as comparable killing methods. For both chickens and pigs, the killing method using carbon monoxide (CO) either of pure source or associated with other gases was also excluded. These methods were excluded because they are not used in practice, especially for on‐farm killing.

Regarding pigs, whole house gassing with carbon dioxide (CO2) was retained, because it could be utilised under certain conditions, albeit that its use is uncommon.

The remaining methods were included in comparison to NEFS. The final list of comparable killing methods in chickens and pigs is reported in Annexes A and B (Tables A.1, B.1).

2. Identification of hazards and associated welfare consequences

EFSA experts identified, for each of the killing methods, the list of hazards to be considered for the exercise based on the associated welfare consequences for the animal. Hazards were included considering all phases: pre‐stunning, stunning and the actual process of killing, which encompasses the induction of unconsciousness and the onset of death.

Hazards and associated welfare consequences related to NEFS in container, ABMs and associated welfare consequences were identified in this opinion as described in Section 4.2 (Tables 22, 23 and 24) and summarised in Annexes A and B (Table A.3 and B.3, respectively).

TABLE 22.

Hazards associated with NEFS common to both pigs and chickens.

| Hazard | Description |

|---|---|

| Rough handling | Catching animals for the purpose of crating (inserting into transport crates), restraining or moving them into the foaming container in an inappropriate way |

| Loud noise | Noise caused by the foam generator and injection of gas |

| Slipping | Losing balance and/or falling due to foaming solution on the slippery floor of container |

| Substance irritating the mucosa | Exposure to foam can irritate mucosa in the nostrils and eyes. |

| Surrounded by foam | Animals being encircled or enveloped by foam prior to bursting with the jet of nitrogen gas. |

| Inhalation of the foam | Animals inhale foaming liquid, i.e. foaming liquid entering upper respiratory tract prior to disruption of the foam using jet of nitrogen gas |

| Jet stream of gas at animal level | Administration of pressurised nitrogen gas pulse to break up the foam and release nitrogen contained in the foam |

| Hurting | As a result of wing flapping in chickens or slipping and falling in pigs due to foaming liquid on the floor of the container or escape attempts can lead to injury in pigs and poultry |

| Too short exposure | Exposure to anoxia is not long enough to kill leading to animals remaining alive or even regaining consciousness |

| Overloading | Stocking density is too high leading to inadequate exposure of some animals to anoxia |

| Too small bubble size | Bubble size is less than 10 mm in diameter leading to high water content in the foam with increased chances of animals being drowned |

| Low foam production rate | Foam production rate is not adequate to fill the container rapidly, leading to prolonged exposure to the foam rather than nitrogen gas |

| Too low gas concentration | Residual oxygen concentration in the container is above 2% by volume leading to persistence of or recovery of consciousness in animals |

| Too low temperature | Temperature of the water or nitrogen gas used to generate the foam is too low leading to hypothermia |

TABLE 23.

ABMs for assessment of welfare consequences during exposure of chickens to NEFS.

| ABMs | Description | Welfare consequences (WCs) | Hazards associated with WCs |

|---|---|---|---|

| Escape attempts | Birds try to escape by jumping (McKeegan, Reimert, et al., 2013) | Pain and fear | Handling, loud noise, substance irritating the mucosa, surrounded by foam |

| Vocalisation | Birds vocalise | Pain and fear | Handling, loud noise, substance irritating the mucosa, surround by foam |

| Wing flapping | Birds flap their wings (McKeegan, Reimert, et al., 2013) | Pain and fear | Handling, loud noise, substance irritating the mucosa, surround by foam |

| Head shaking | Birds shake their heads during contact with foam (McKeegan, Reimert, et al., 2013) | Pain, fear and respiratory distress | Substance irritating the mucosa, disruption to rhythmic breathing pattern, inhalation of foam |

| Frequent blinking | Birds make frequent movement of nictitating membrane or eyelids | Pain | Substance irritating the mucosa (because of foam entering the eyes) |

| Increased lacrimation | Birds produce abundant tears | Pain | Substance irritating the mucosa |

| Gasping | Open mouth breathing with extended neck | Pain, fear and respiratory distress | Inhalation of foam |

TABLE 24.

ABMs for assessment of welfare consequences during exposure of pigs to NEFS.

| ABMs | Description | Welfare consequences (WCs) | Hazards associated with WCs |

|---|---|---|---|

| Escape attempts | Pigs try to escape by climbing on the wall (Lindahl et al., 2020) | Pain and fear | Handling, loud noise, substance irritating the mucosa, surrounded by foam |

| Vocalisation | Pigs squeal with high pitch vocalisations (Lindahl et al., 2020) | Pain and fear | Handling, loud noise, substance irritating the mucosa, surround by foam |

| Head shaking/tilting | Pigs shaking or tilting their heads during contact with the foam | Pain, fear and respiratory distress | Substance irritating the mucosa, disruption to rhythmic breathing pattern, inhalation of foam |

| Frequent blinking | Pigs make frequent movement of eyelids | Pain | Substance irritating the mucosa (because of foam entering the eyes) |

| Increased lacrimation | Pigs produce abundant tears | Pain | Substance irritating the mucosa |

| Gasping | Open mouth breathing with extended neck (Lindahl et al., 2020) | Pain, fear and respiratory distress | Inhalation of foam |

| Sitting | Sitting, upright position with the hind legs resting on the ground and front legs straight with hooves on the floor (Lindahl et al., 2020) | Pain, fear and respiratory distress | Inhalation of foam |

The hazards and associated welfare consequences related to comparable killing methods have been identified and modified in previous EFSA opinions (EFSA AHAW Panel, 2019, 2020a, 2020b) and are summarised in Annexes A and B (Tables A.3, B.3, respectively).

3. Evaluation of the magnitude of the hazards by experts

For each of the hazards in relation to each killing method, four EFSA experts were asked to estimate the following:

Prevalence (%) of birds/pigs exposed to the hazard in each of the methods during routine operation. The experts were requested to provide an estimate of the prevalence of animals exposed to each hazard within each method by providing the minimum, the maximum and the mean estimated value.

Severity and duration of the exposure to stress and pain (welfare consequences) caused by each hazard, using the scoring system reported in Table 4. This scoring system is based on the Likert scale (Wikman et al., 2016)

TABLE 4.

Scoring method (Likert scale) used to estimate severity and duration of the exposure to stress and pain of animals (chicken and poultry) within each hazard in each of the identified killing methods.

| Score | Impact on animal welfare | Interpretation from the experts |

|---|---|---|

| 1 | No negative impact | No stress |

| 2 | Mild stress | |

| 3 | Moderate stress | |

| 4 | Mild pain and short duration (< 2 s) | |

| 5 | Moderate pain and short duration (< 2 s) or mild pain and long duration > 2 s | |

| 6 | Severe pain and short duration (< 2 s) or moderate pain and long duration > 2 s | |

| 7 | Very negative impact | Severe pain and long duration > 2 s |

Each expert provided individual judgements. Within each individual evaluation, for each killing method, a final score on each hazard was calculated by multiplying the mean prevalence by the score (indicating severity and duration) given.

4. Experts discussion on the outcome of the exercise

The individual judgements of hazards associated with each killing method were subjected to group discussion among the experts. Each expert was asked to provide supporting arguments for their evaluations. Subsequently, all experts were asked whether, in light of the reasoning that were brought up during the group discussion, they were inclined to reconsider their evaluation.

5. Identification of highly relevant hazards for each method and presentation of the results

The ranking of hazards was conducted individually by each expert. Initially, only the hazards that scored more than 4 on severity and duration, corresponding to the welfare consequence of pain, were selected. Next, considering the final score (obtained by multiplying prevalence by the score on severity and duration), the hazards ranked in the top five positions (to facilitate the comparison among the methods) with the highest values designated as ‘highly relevant’. The final list of highly relevant hazards comprised those hazards that ranked in the top five positions for at least one expert (Tables 29, 31 for chickens and Tables 30, 32 for pigs). The final objective of the exercise was to identify the top five relevant hazards and not to rank them. The results of the exercise including the final list of the highly relevant hazards are reported in Section 4.2.2.1. The obtained results were discussed through two main comparisons: firstly, between NEFS and other CAS methods, and secondly, between NEFS and the remain methods (Sections 4.2.2.1 and 4.2.2.2).

TABLE 29.

Selected highly relevant hazards related to NEFS and other CAS methods in chickens.

| Hazards | NEFS in container | Whole house gassing with CO2 | CO2 in two phases in containers | CO2 + inert gases in containers | Inert gases in containers | LAPS |

|---|---|---|---|---|---|---|

| Expansion of gases in the body cavity | x | |||||

| Handling | x | x | x | x | x | |

| Hurting | x | x | x | x | x | x |

| Inhalation of high CO 2 concentration | x | x | x | |||

| Inhalation of the foam | x | |||||

| Jet stream of gas at bird level | x | x | x | x | ||

| Loud noise | x | x | x | x | x | x |

| Low foam production rate | x | |||||

| Substance irritating the mucosa | x | x | x | x | ||

| Overloading | x | x | x | x | x | x |

| Surrounded by foam | x | |||||

| Too fast decompression | x | |||||

| Too low gas concentration | x | x | x | x | ||

| Too low temperature | x | x | x | x | x | x |

| Too short exposure time | x | x | x | x | x | x |

| Too small bubble size | x |

Notes: The selection of hazards has been made following non‐formal expert knowledge elicitation, which implies ranking of hazards. For each killing method, only hazards that were ranked in the first five positions by at least one of the experts involved are reported in this table.

TABLE 31.

Selected highly relevant hazards related to NEFS and remaining killing methods (non‐CAS) in chickens.

| Hazards | NEFS in container | Electrical waterbath | Head‐only electrical stunning | Captive bolt | Cervical dislocation | Percussive blow to the head | Lethal injection |

|---|---|---|---|---|---|---|---|

| Handling | x | x | X | x | x | x | x |

| Hurting | x | x | X | x | x | x | x |

| Inappropriate route of administration | x | ||||||

| Inappropriate electrical parameters | x | X | |||||

| Incorrect application of the manual method | x | x | |||||

| Incorrect captive bolt parameters | x | ||||||

| Incorrect shooting position | x | ||||||

| Inhalation of the foam | x | ||||||

| Inversion | X | x | x | x | |||

| Jet stream of gas at bird level | x | ||||||

| Loud noise | x | ||||||

| Low foam production rate | x | ||||||

| Manual restraint | X | x | x | x | x | ||

| Substance irritating the mucosa | x | ||||||

| Overloading | x | ||||||

| Poor electrical contact | x | X | |||||

| Pre‐stun shocks | x | ||||||

| Shackling | x | ||||||

| Sublethal dose | x | ||||||

| Surrounded by foam | x | ||||||

| Too low gas concentration | x | ||||||

| Too low temperature | x | ||||||

| Too short exposure time | x | x | X | ||||

| Too small bubble size | x |

Notes: The selection of hazards has been made following non‐formal expert knowledge elicitation, which implies ranking of hazards. For each killing method, only hazards that were ranked in the first five positions by at least one of the experts involved are reported in this table.

TABLE 30.

Selected highly relevant hazards related to NEFS and other CAS methods in pigs.

| Hazards | NEFS in containers | Whole house gassing CO2 | CO2 at high concentration in containers | CO2 + inert gases in containers | Inert gases in containers |

|---|---|---|---|---|---|

| Exposure to high CO 2 concentrations | x | x | x | ||

| Handling | x | x | x | x | |

| Hurting | x | x | x | x | x |

| Inhalation of foam | x | ||||

| Jet stream of gas at pigs' level | x | x | x | x | x |

| Loud noise | x | x | x | x | x |

| Low foam production rate | x | ||||

| Substance irritating the mucosa | x | x | x | x | |

| Overloading | x | x | x | x | x |

| Slipping | x | x | x | x | x |

| Surrounded by foam | x | ||||

| Too low gas concentration | x | x | x | x | x |

| Too low temperature of the gas | x | x | x | x | x |

| Too short exposure time | x | x | x | x | x |

| Too small bubble size | x |

Notes: The selection of hazards has been made following non‐formal expert knowledge elicitation, which implies ranking of hazards. For each killing method, only hazards that were ranked in the first five positions by at least one of the experts involved are reported in this table.

TABLE 32.

Selected highly relevant hazards related to NEFS and remaining killing methods (non‐CAS) in pigs.

| Hazards | NEFS in containers | Electrical killing | Captive bolt | Non‐penetrative captive bolt | Percussive blow to the head | Firearm | Lethal injection |

|---|---|---|---|---|---|---|---|

| Handling | x | x | x | x | x | X | x |

| Hurting | x | x | x | x | x | X | x |

| Inappropriate electrical parameters | x | ||||||

| Inappropriate power and calibre of the cartridge | x | ||||||

| Inappropriate route of administration | x | ||||||

| Inappropriate type of projectile | x | ||||||

| Incorrect application of the shot to the head | x | ||||||

| Incorrect captive bolt parameters | x | x | |||||

| Incorrect shooting position | x | x | x | ||||

| Inhalation of foam | x | ||||||

| Inversion | x | ||||||

| Jet stream of gas at pigs' level | x | ||||||

| Loud noise | x | ||||||

| Low foam production rate | x | ||||||

| Substance irritating the mucosa | x | ||||||

| Overloading | x | ||||||

| Poor electrical contact | x | ||||||

| Restraint | x | x | x | x | x | ||

| Slipping | x | ||||||

| Sublethal dose | x | ||||||

| Surrounded by foam | x | ||||||

| Too low gas concentration | x | ||||||

| Too low temperature of the gas | x | ||||||

| Too short exposure time | x | x | |||||

| Too small bubble size | x | ||||||

| Wrong placement of the electrodes | x |

Notes: The selection of hazards has been made following non‐formal expert knowledge elicitation, which implies ranking of hazards. For each killing method, only hazards that were ranked in the first five positions by at least one of the experts involved are reported in this table.

2.2.3.3. Limitations of the exercise and uncertainty analysis

Some limitations in the exercise were identified. Because the number of the hazards to be scored for each method was not the same, it could inadvertently lead to a potential bias. However, the number of hazards was not considered as a factor for the comparison. Comparison between group killing methods (CAS) and individual killing methods highlighted the difficulty in comparing the prevalence of animals affected by a certain hazard, tending to penalise hazards related to group methods. In addition, more uncertainty could be expected around certain methods for which limited information exists versus others with a lot of scientific evidence available. These limitations were discussed and accounted for as much as possible in the third phase of the exercise, the group discussion.

Regarding the uncertainty analysis, the method used was the EFSA Guidance on Uncertainty Analysis in Scientific Assessments (EFSA Scientific Committee, 2018a, 2018b). For conclusions reached conducting a non‐formal expert elicitation, WG experts provide their individual judgement on the certainty for a rephrased question referring to a well‐defined quantity of interest, according to the suggested ranges in Table 5 below.

TABLE 5.

Certainty range for performing the uncertainty judgement.

| Quantitative assessment | Certainty range | ||

|---|---|---|---|

| > 50%–100% | 66%–100% | 90%–100% | |

| Qualitative translation | More likely than not | From likely to almost certain | From very likely to almost certain |

For assessing the equivalence with an already approved method, the experts were presented with the hazards and their associated WCs identified for NEFS and each alternative method. Since the objective was to assess if NEFS was equivalent to or better than each method in terms of the overall welfare of animals subjected to it, experts were asked how certain they were that the proportion of animals experiencing the identified WCs associated with the hazards for NEFS was similar or lower to the ones experienced with each alternative method. They were asked to also take into consideration in their judgement the magnitude of the hazard (and associated welfare consequences) in an informal way (so that a low proportion of animals experiencing a highly severe WC could be indicative of poorer welfare than a higher proportion of animals experiencing a milder WC). A group discussion was held, and a consensus certainty range was agreed, which is reported in the body text of the Opinion in the assessment section and in the key conclusions.

From the results of the dossier, the experts were asked about their certainty on the three following points:

How certain are you that chicks below 7 days of age subjected to NEFS will experience the same WCs with a similar severity and affecting a similar proportion of animals as adult/slaughter weight chickens?

How certain are you that the foam is not irritative to any animal subjected to NEFS?

How certain are you that the foam is not entering the upper airways in any animal?

3. ASSESSMENT PHASE 1: CHECK OF DATA FOR RISK ASSESSMENT

3.1. Eligibility criteria of EFSA's guidelines (ToR 1)

3.1.1. Name of the method

NEFS in container: Nitrogen Expansion Foam Stunning in container.

The dossier (Annex C), submitted for approval, describes a method that involves using containers and a jet pulse of nitrogen gas at the end of filling with foam (method thereafter called NEFS by the applicant).

3.1.2. Description of the method including potential sources of pain, distress and suffering

In this assessment, poultry and pigs are presented under separate sections for the sake of clarity. The following section outlines the method and potential sources of pain, distress and/or suffering. In this proposed method, high‐expansion foam is used as an inert carrier (of nitrogen) to increase effectiveness and efficiency of nitrogen as an anoxic inert gas that is already permitted for stunning and killing of animals in Annex 1 of Council Regulation (EC) No 1099/2009.

Principle of the method

The method can be applied to an individual animal (an injured animal) or in small groups (depopulation) depending upon the users' requirement or the container size. Animals can be walked into the foaming container without any form of restraint, or animals may be placed in a transport crate (poultry) or a cage (pigs) which can be loaded into the foaming container for the purpose of killing.

The method is based on the rapid displacement of oxygen by purging the air from a container with foam filled with N2 and afterwards bursting the foam bubbles with a jet of nitrogen gas, resulting in an anoxic atmosphere with less than 2% residual oxygen in nitrogen and maintaining anoxia until the animals are dead. The high‐expansion foam is used to deliver and distribute the nitrogen throughout the chamber. It is reported in the dossier that the use of the foam may increase the effectiveness of the killing with nitrogen gas by significantly reducing the filling time of the container and gas consumption compared to flushing with nitrogen gas alone. The foam works as a carrier displacing the air without mixing nitrogen with it, as it fills the chamber from the bottom upwards and pushes the displaced air out through the ventilation holes (a flap door) in the ceiling of the container.

The submitted dossier solely reports the application of NEFS in containers for poultry and pigs, which therefore precludes its consideration and assessment for application in other contexts e.g. whole house gassing. Foam can be classified by the expansion ratio into three categories: low (1:20), medium (1:> 20–< 200) or high (1:> 200–2000). The expansion ratio is defined as the volume of foaming solution (volume of foaming agent plus water) to the volume of foam produced (Gerritzen & Sparrey, 2008).

High expansion foam is generated by spraying foam solution into a wire mesh (e.g. stainless steel screen) and blowing the solution through the screen with a nitrogen stream to produce the required volume of foam bubbles in the desired time (i.e. cubic metres/minute). Size of the holes in the mesh, the rate of spraying of the foaming solution and the rate of nitrogen injection would determine the size of bubbles in the foam. The high expansion foam can be administered from the bottom up or through the side(s) of the foaming container to completely displace atmospheric air. A burst of nitrogen gas can be administered to break the bubbles and release the nitrogen gas contained in the bubbles such as described in process flow. The bubbles are burst by a N2 jet stream. Additionally, they can be simply destroyed by the movements of the animals. The purpose is to create anoxia in the container, which is considered to occur when the volume of oxygen is < 2%.

The oxygen concentration in the container will be monitored continuously throughout the killing process. Additional foam will have to be administered in the event of the residual oxygen concentration exceeding 2% by volume in the container to re‐establish and maintain anoxia throughout the exposure time required for killing animals. The foaming container includes holes or a flap door in the roof‐lid to allow the displaced air to escape. It is envisaged that the high expansion foam generator required to produce large volumes of foam may also include an electric fan, especially when gas diffusers are used to minimise the noise, or nitrogen jet, to force the foaming solution through the mesh. It is stated in the dossier that the foam generator has sufficiently large output capacity to fill the container rapidly, e.g. in less than a minute.

The main parts of the system used are:

Container with foam generator, lid and closable air valves (flap door in the lid).

Control cabinet, for operational control.

Distribution cabinet containing pump, gas solenoid valve and preset regulator distributing gas and foaming liquid into the container.

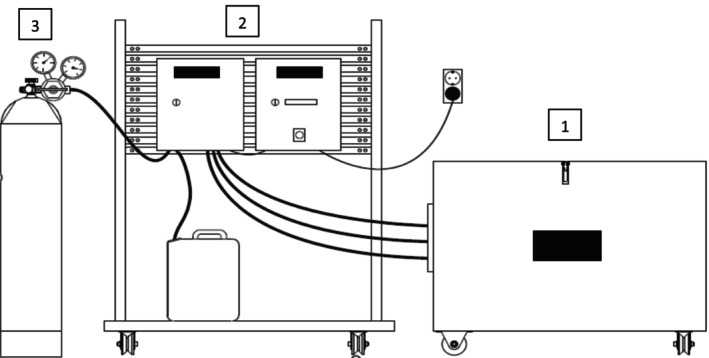

These parts can be seen in Figure 1 below from left to right and a video describing the procedure of using the system can be found in the applicant's dossier.

FIGURE 1.

Main parts of the system (as provided by the applicant in their Standard Operating Procedure – Manual).

© HEFT AB.

Foaming agent

The composition of the foam agent as provided by the applicant is detailed in Table 6. The submitted dossier included the data sheet for the foam agent as well as information relating to chemical composition and the safety data sheet. No information was provided to demonstrate the absence of mucosal or skin irritation in animals exposed to foam.

TABLE 6.

Chemical composition of the foam mixture. Source: document ‘safety Sheet HEFT agent’.

| Product/substance | Identifiers | % w/w |

|---|---|---|

| Potassium oleate | CAS No.: 143‐18‐0 | 10%–15% |

| Fatty acids, coco, potassium salts | CAS No.: 61789‐30‐8 | < 5% |

Process flow

The process is described in the dossier as following: The process is initiated by pressing the button on the control cabinet. The pump is started and the foaming solution (mixture of foaming agent and water) is sprayed, covering the perforated plate on the foam generator. When the perforated plate is covered (~ 5 s), the button is pressed again and the nitrogen gas flow is started, initiating the foam production. Nitrogen, encapsulated in high‐expansion foam, fills the container and pushes out the air through the air valves (flap door in the lid). Once the container is filled completely, the air valves (flap door) are manually closed and the button is pressed again, stopping the foam production and triggering a pulse (1–2 s; ■■■■■) of nitrogen gas to burst the bubbles.

Potential sources of pain, distress and/or suffering

Recently, EFSA evaluated the risks of applying inert gas‐based foam in its scientific opinion on the welfare of poultry and pigs during killing for other purposes than slaughter (2019 and 2020, respectively). Whole house foaming with nitrogen gas made from liquid nitrogen was assessed in poultry, and both open and closed systems were discussed in pigs in 2020.

When stunning with gases, the displacement rate of air is critical regarding the welfare of the animal. This is determined by the time frame in which the desired oxygen concentration is reached and maintained. When stunning with gases only by flushing, a prolonged period of flushing is necessary to obtain the desired residual oxygen concentration of below 2% by volume in nitrogen, during which period animals may experience respiratory distress, due to the gradual induction and increasing hypoxia. The terms anoxia and hypoxia below were defined in the dossier, but were revised by EFSA's experts:

Hypoxia: when insufficient levels of oxygen are available, resulting in bodily tissues having inadequate oxygen supply, which disrupts normal function (i.e. disrupted homeostasis). In humans, hypoxic effects can be observed when the atmospheric oxygen is below 18% by volume, with symptoms becoming progressively worse as available oxygen further decreases.

Anoxia: The absence of available oxygen in the atmosphere or total depletion of oxygen within the bodily tissues, with an oxygen range in atmosphere from 0% to 2%.

Handling of animals

Handling of animals during exposure to NEFS is very similar to some other methods of on‐farm killing, for example, containerised gassing system.

The type and quality of animal handling is important in the overall efficacy of the killing process and to avoid unnecessary pain, distress and suffering. Operators must be competent in handling the animals and equipment utilised in the killing process must also be adequate and used properly.

The different sources of pain, distress and suffering related to handling of pigs, such as described in the dossier, are:

-

–

When pigs are moved from their home pens to the place of killing: (i) it should be done only when all preparations are complete, to ensure the animals are killed without undue delay; (ii) they should be moved calmly and allowed to progress freely in familiar groups at their own pace. When necessary, boards may be used to guide them. Small piglets can be carried by hand and placed into the container. If pigs are of a larger size and mobile, they can walk and enter the chamber through the door with as little human intervention as possible.

-

–

When pigs are individually restrained: They will experience the welfare consequence of stress isolation. An advantage of a gas killing method is that animals can be killed/stunned in groups and without individual restraint.

-

–

If unfamiliar pigs are mixed: Animals that are unfamiliar (e.g. from different pens) should not be mixed to avoid the potential of stress and pain associated with mixing (e.g. aggression).

-

–

When pigs are left waiting in the container: It is stated in the dossier that once in the container, if the animal is not subject to emergency killing as defined in Council Regulation (CE) 1099/2009, the animal should be left for a short period (1–2 min) to quietly settle (e.g. appearing calm) before the foaming starts. However, EFSA disputes that statement for animal welfare reasons, based on the fact that confining in a container is a novel experience for the animals and therefore could lead to animals experiencing fear and distress.

Poultry may be caught and loaded into transport crates or modules and taken to the point of killing. Manual handling and loading of birds into the foaming container directly can also be performed.

The different sources of pain, distress and suffering related to handling of birds such as described in the dossier are:

-

–

When the birds are handled wrongly: inverted and/or carried by one leg or wings or by the neck. Birds should be caught and loaded with care into the crates by trained staff such as described in EFSA AHAW Panel (2019) to prevent handling stress and soft tissue and bone damages.

-

–

When birds are crated automatically with catching machines, are operated incorrectly (EFSA AHAW Panel, 2022).

-

–

Heat stress when birds are left in the crates in summer months.

-

–

A hazard directly linked to the NEFS method is linked to the use of crates within the foaming container: If the crate bars are too narrow, it might be that the foam has difficulty to penetrate the crates and surround animals. The dossier stipulates that the crate bars should have a minimum width of 25 mm, for the foam to freely enter into the crate and reach the birds without obstruction. Ideally, the crates should have perforated floor and roof so that the foam can flow through the birds and displace air trapped between them.

-

–

When birds are left waiting in the container: There should be no delay between loading of crates into the container and foaming.

Contact with foam

The characteristics of the foam are determined by a combination of foam agent properties and foam generator properties. According to the dossier, the foaming agent contains no toxic materials, carries no safety warning labels even in concentrated form and can be classified as soap.

Inevitably, the animals will come in contact with the foam and remain so until the foam is burst, and nitrogen gas is fully released, so the novelty of being surrounded by the foam must be considered a potential hazard for the animals (when compared to gas only). Turkeys, broilers, hens and ducks have been reported to react to high‐expansion foam (either air‐filled, nitrogen‐filled or carbon dioxide‐filled) enveloping them (e.g. head shaking, escape attempts and transient increases in heart rate in McKeegan, Reimert, et al., 2013). Lindahl et al. (2020) reported that pigs seemed to avoid putting their heads and snouts into the foam, and the rate of escape attempts through the lid increased when foam levels became higher.

Aversion to the foam can be assessed by behavioural observations when animals are presented and/or exposed to direct contact with the foam as it was done by McKeegan, Reimert, et al. (2013) and Lindahl et al. (2020). The risk of aversion and the potential negative impacts on animal welfare are limited to the period that the animal is conscious and therefore may occur during foam delivery, filling of the container and until the onset of unconsciousness after the foam bubbles are burst during the process. Evidently, the duration of exposure to the foam before the release of the nitrogen jet should be kept as short as possible to minimise the duration of animals being exposed to a potentially aversive environment.

Additionally, other potential sources of pain, distress and suffering should be considered, such as mucosal irritation (of eyes and nasal mucosae) by the foaming agent and the foaming solution entering the upper respiratory tract. Literature reveals that stimulation (chemical, electrical or mechanical) of pharyngeal branch of glossopharyngeal nerve evokes a short‐duration spasmodic inspiratory effort termed sniff‐ or gasp‐like aspiration reflex (AR). Similar responses are elicited by stimulation of whole pharyngeal cavity, upper pharynx or nasal septum (Benacka & Tomori, 1995). Physiological studies revealed that this reflex is activated from the subepithelial free‐nerve endings. This reflex is a part of physiological mechanisms that help animals to re‐establish normal breathing. It is very likely that animals exposed to high expansion nitrogen foam will manifest gasp‐like aspiration reflex if the foam entered the upper respiratory tract during the induction of unconsciousness.

Terrestrial animals have mechanical and chemical receptors to detect and to expel (through cough reflex) foreign body (such as the foaming liquid or irritant gases) as a defence mechanism to survive. Therefore, it is very likely that animals will experience respiratory distress, pain and fear if the foaming liquid entered the upper respiratory tract and triggered these receptors. The act of coughing in birds is manifested as open mouth breathing with neck extended accompanied with vocalisation during expiration, as seen in birds infected from respiratory diseases or during exposure to high concentrations of CO2.

In addition, mechanical obstruction of airways can lead to drowning if the bubbles enter the trachea and associated respiratory distress if obstruction (even partial) did occur. The dossier did not provide sound scientific evidence to rule out this possibility. Physiologically, suffocation can be defined as complete separation of the atmospheric air (or gaseous environment in this case) and the upper respiratory tract, for example, water during drowning, chocking with solid food particles and crushing of the neck during strangulation (see EFSA, 2004). Therefore, entry of even small quantities of foaming solution into the upper respiratory tract would trigger cough reflex but may not be considered equivalent to drowning.

Use of nitrogen gas pulse to break bubbles

The use of a nitrogen gas pulse to destroy the foam and release the nitrogen gas is an integral part of the process to achieve anoxic conditions in the container, which suggests that the foam is not fragile enough to breakup spontaneously upon contact with the animals. However, bursting of bubbles improves the visibility of animals and facilitates monitoring of the killing process. From the description in the dossier, it remains unclear where the pulse of nitrogen gas is targeted within the container and how direct delivery into the vicinity of the animal's head is avoided. Indeed, this would have animal welfare consequences, as documented in scientific literature where puffs of air have been demonstrated as aversive to poultry (Paul et al., 2018) and pigs (Ede & Parsons, 2023; Brietzke et al., 2013). According to the submitted dossier, the likelihood of the nitrogen gas pulse reaching sensitive areas of the animals (e.g. eyes) is very low. The technical design of the gas nozzle and outlet pressure ■■■■■ at 5 cm from the nozzle acts as a refinement to reduce this risk. However, it is inferred from the ‘process flow’ provided in the dossier that the animals will be in contact with the foam until the container is completely filled with the foam and the bubbles are burst with the N2 jet which is less than a minute.

Nevertheless, use of gas diffusers has been stated in the dossier as a preventive measure to eliminating this hazard. Indeed, the possibility of animals being hit by jet stream of gas mixture was prevented by using gas diffusers in the containerised gassing system investigated for poultry by Raj et al. (2008). Sparks et al. (2010) prevented this hazard during whole house gassing of poultry by using a CO2 delivery lance pipe that had approximately 32 mm nominal bore pipe with a 30° chamfer to the lance end to introduce a vertical element to the flow of gas inside the building. This was to ensure that the plume of gas was directed towards the roof and above the level of the birds, preventing them being hit by the full force of the gas as it entered the building. The lance was inserted into the building at approximately 1.2 m above ground level.

3.1.3. Key parameters for the effective use of the method

According to the EFSA guidance (EFSA AHAW Panel, 2018), the table of key parameters should contain parameters necessary for effective use of the system, component and description as columns. These tables need to be revised and additional parameters should be included, as commented in the present assessment. Furthermore, conditions of use of each animal species should be specified as it is done in the Council Regulation (EC) No 1099/2009 on the protection of animals at the time of killing and stunning.

The dossier states that: ‘Animals that are stunned in a high expansion foam filled with an inert gas, are being stunned by the inert gas and not by the foam, as experiments with poultry in air‐filled high‐expansion foam have shown. Therefore, the key parameters are basically the same as those listed in Annex 1 of Council Regulation (EC) 1099/2009 for inert gases but with a different relevance or content. In addition, there are parameters that are essential for a proper functioning of the foam method, that are proposed in Table 1 [of the dossier]’.

TABLE 1.

Overview of translation of the mandate assessment questions into subquestions.

| Assessment question | Subquestions |

|---|---|

|

1. Describe the new method |

1.1 What is the primary objective of the method? |

| 1.2 How does the new method work and what are key steps to achieve its primary objective? | |

| 1.3 What materials and tools are required for the new method? | |

|

2. Does the proposed method and information provided with the application comply with the eligibility criteria of EFSA's guidelines? |

|

|

3. Can the proposed method provide a level of animal welfare at least equivalent to that ensured by the existing methods in the legislation |

3.1 Can the proposed method provide a level of AW at least equivalent with the methods that exist in Annex I of Council Regulation (EC) 1099/2009 for pigs and poultry for situations other than slaughter? |

| 3.2 Does the proposed method ensure that pigs and poultry are spared of avoidable pain, distress or suffering during the killing as referred to in paragraph 1 of Article 3 of the killing Regulation? | |

| 3.3 Does the proposed method maintain the loss of consciousness and sensibility until death of pigs and poultry, as referred to in paragraph 1 of Article 4 of Council Regulation (EC) 1099/2009? | |

|

4. To what extend the information provided by applicant is taken into account for the final assessment and if the method is evaluated by other sources of information. |

|

|

5. To what extent the method proposed for stunning and killing pigs and poultry is able to provide a level of AW in compliance with the above‐mentioned legislation and, if yes, under which conditions. |

Table 7 was produced by the WG based on the information provided in the dossier. The rationale of some key parameters indicates whether the parameter is ‘essential’ meaning that it will impact directly the efficiency of the method to provoke death: failure to achieve < 2% oxygen is one of them. The other key parameters are mainly impacting the welfare of the animals during the induction and maintenance of unconsciousness until death occurs.

TABLE 7.

Proposed key parameters for inert gas foam in poultry and pigs.

| Parameter | Rationale | Reference value |

|---|---|---|

| Oxygen concentration | Essential, < 2% should be reached and maintained | < 2% in the input gas and during the stunning process. The residual oxygen concentration should be continuously monitored at the bottom and beneath the roof of the container and maintained throughout exposure time |

| Purity of N 2 gas | Residual oxygen concentration in nitrogen is critical. With (membrane) nitrogen generators, the machine backpressure setting may cause a too high oxygen content in the excess of 2% by volume |

The purity of nitrogen should be at least 98% Enclosed environment (like container) necessary to guarantee oxygen concentration |

| Temperature |

In practice only relevant when liquid nitrogen is used. Gas from high‐pressure cylinders maintains ambient temperature even when the compressed gas is expanding Nitrogen generators have no temperature effect. If necessary, foam temperature can be adjusted by controlling water temperature |

10–30°C for animals; the foam generators will technically function from 5°C to 60°C |

| Exposure time | Essential to allow for irreversibility of stunning (and thus for killing) by inert gases | Minimum exposure time of 5 min for poultry and 7 min for pigs |

| Foam expansion ratio | The expansion ratio is defined as the volume of foaming liquid (volume of foaming agent plus water) to the volume of foam produced. Expansion ratio is a measure for the water content of the foam. This must be high expansion to prevent water uptake during breathing | High expansion foam with an expansion ratio of 250–350 to ensure that water content is low. Upper limit to ensure that the foam keeps flowing so that animals are readily being covered and the risk of air pockets is decreased |

| Bubble diameter | In a given volume of foam, the volume of liquid (volume of foaming agent plus water) is inversely proportional to the diameter of bubbles in the foam. Bubbles with small diameter contain more water than those with larger diameter, and hence, exposure of animals to foam containing smaller diameter is likely to increase the chances of foaming liquid entering the respiratory tract | Bubble diameter: 95% of the gas in bubbles > 10 mm diameter |

| Foam production rate | Foam generator should have the capacity to completely fill the container within seconds so that the animals are exposed to the gas rapidly. The production rate will vary according to the size of the container | The volumes of foaming solution and nitrogen gas supply should be adequate to ensure optimal production rate. In any case, a container should be filled within 45 s. When filling the container with foam from below to push out air, the foam speed governs air displacement. The animals are submersed into an anoxic environment once their heads are covered in foam |

| Foam transparency | Transparency and bubble diameter describe the foam structure and depend on gas flow in relation to foam agent flow. Transparency is a measure for the absence of persistent, very small bubbles (diameter < 2 mm) that might enter the trachea. A uniform distribution of mid‐size bubbles ensures that these burst when inhaled, and that no oxygen gradient is generated above the foam level. This maintains the immediate transition from air to anoxia for the animals | Transparency > 30 cm for check on the absence of very small bubbles and expansion rate, making observation of the stunning process possible |

| Foam agent | Essential to guarantee foam quality – must be shown to produce high expansion foam, preferably optimised for use other than firefighting |

Special attention to drainage retardants (potential environmental hazards and limits to rendering), biodegradability and influence on the methanogenic phase of manure digestion Optimum drainage halftime about 15 min to reduce carcass weight |

| Foam atmosphere homogeneity | Essential |

Filling the container from below to push out air (plug flow) and make sure that no air pockets remain This is assured by a gas pulse (with inert gas) to destroy the foam as soon as the foam has driven out the air from the container. The gas pulse also makes it possible to determine real‐time oxygen values as the sensors will not be covered with foam anymore, and to fully observe the stunning process |

| Uniform distribution of foam throughout the container | Furniture and fittings, including crates and modules, in the container should not impede flow and uniform distribution of foam. Crates and modules should have perforated floor and roof to facilitate distribution of foam. The crate bars should be sufficiently wide (> 25 mm) to allow the foam to penetrate without compromising foam integrity and quality (e.g. bubble size). This should be ensured to guarantee the establishment of an anoxic atmosphere in all crates throughout the process. Overcrowding/stocking of poultry within crates and modules would impede with the flow | The operator should inspect and remove obstructions and ensure uniform distribution of foam within the container. The operator should ensure the crates and modules and the stocking density is adequate to prevent the hazard |

| Visibility of the animals during the process | Important for checking the stunning process | Windows should allow visibility, nitrogen pulse destroying the foam improves visibility of the animals and facilitates monitoring |

| Stocking density/space allowance | Stocking density and the design and use of any crates used to hold animals within the container is important to avoid system failure (see causes of system failure, Section 3.1.5) | All the animals should have adequate space to lie down when they lose consciousness, i.e. animals should not be falling on top of each other |

Process control