Abstract

A powerful toolbox is needed to turn the linear plastic economy into circular. Development of materials designed for mechanical recycling, chemical recycling, and/or biodegradation in targeted end-of-life environment are all necessary puzzle pieces in this process. Polyesters, with reversible ester bonds, are already forerunners in plastic circularity: poly(ethylene terephthalate) (PET) is the most recycled plastic material suitable for mechanical and chemical recycling, while common aliphatic polyesters are biodegradable under favorable conditions, such as industrial compost. However, this circular design needs to be further tailored for different end-of-life options to enable chemical recycling under greener conditions and/or rapid enough biodegradation even under less favorable environmental conditions. Here, we discuss molecular design of the polyester chain targeting enhancement of circularity by incorporation of more easily hydrolyzable ester bonds, additional dynamic bonds, or degradation catalyzing functional groups as part of the polyester chain. The utilization of polyester circularity to design replacement materials for current volume plastics is also reviewed as well as embedment of green catalysts, such as enzymes in biodegradable polyester matrices to facilitate the degradation process.

1. Introduction

The plastic waste problem, depletion of fossil-based resources, and intensifying climate change require concrete action to transform from linear to circular polymer materials.1−3 Within this paradigm shift, polyesters are expected to play a significant role. They have a large and tunable property window, and they are typically easy to process. In addition, the reversible ester bond can be utilized for chemical and organic (biodegradation) recycling processes.4,5 Still, the susceptibility of this bond to chemical hydrolysis and biodegradation varies considerably depending on the chemical and physical structure of the material and the end-of-life environment. To release the full potential of polyesters, their design can be tailored to fulfill the application specific requirements, as well as easy mechanical and chemical recyclability and/or biodegradability, depending on the specific application. Designing materials and products to circularity gives value to end-of-life plastics and reduces accumulation of waste, contributing to a more sustainable and circular economy.6 Mechanical recycling is currently the main commercial recycling route, however, not all products are suitable for mechanical recycling. Material degradation during use-phase, organic contamination, presence of harmful and/or unknown additives, product design (e.g., multicomponent materials, small formats), and small material volumes in case of less common materials are some limiting factors. There is also a limit to how many times a material can be mechanically recycled as significant property loss may occur after multiple rounds of mechanical recycling due to degradation phenomena. Chemical recycling and biodegradation are needed as complementary end-of-life pathways (Figure 1).

Figure 1.

Simplified scheme over polymer circularity, where chemical recycling and biodegradation compliment mechanical recycling, and materials are designed for specific end-of-life scenarios.

This review focuses on the molecular design of the polyester chain aiming at more facile circularity. How can polyesters be designed for faster (bio)degradation by introduction of ester bonds that are more susceptible to hydrolysis and biodegradation? How can chemical recycling under mild conditions or (bio)degradation under less favorable environmental conditions be facilitated by introduction of another type of reversible dynamic bond or degradation-catalyzing functional groups? Could embedding green catalysts, such as enzymes, in the polymer matrix be the route to (bio)degradation of the materials, even under less favorable environmental conditions? Last, the replacement of current commodity plastics, especially polyolefins, by more circular polyethylene-like polyesters is discussed.

1.1. Definitions

Some key terminologies are shortly defined here:

Circular Economy: In a circular economy, materials never become waste and nature is regenerated. As an example, polymer materials should be kept in circulation at their highest value through, e.g., reuse, mechanical and chemical recycling, and composting.

Mechanical Recycling: The most common commercial recycling process. Mechanical recycling turns plastic waste into secondary raw materials. The process typically consists of sorting of different plastic types, grinding, washing, formulation, extrusion to pellets, and finally reprocessing to new products, ideally without significantly change in chemical structure, molar mass, and properties. In practice, mechanical recycling is often downcycling to products with lower value compared to the original product.

Chemical Recycling: A general term for plastic recycling that includes changes in chemical structure to break the polymer chain into original monomers, oligomers, or other chemicals that can be used for manufacture of new polymers or other products. Several different technologies exist with significant differences in reaction conditions, such as temperature and the type of products obtained.

Polymer Degradation: Polymer degradation can be chemical, physical, mechanical, or biological, resulting in changes in the structure and properties of the material. Degradation is typically caused by external factors such as heat, light, water, chemicals, mechanical force, or microorganisms.

Biodegradation: Biodegradation is the breakdown of organic matter by microorganisms. This can be a multistep process, where the organic carbon is converted into humic substances, assimilated into the biomass or released as CO2, H2O, and/or CH4.

Mineralization: The last and ultimate step of biodegradation converts organic carbon into CO2 and H2O under aerobic conditions, and in addition, CH4 under anaerobic conditions. Biodegradation can be confirmed and the extent quantified by following the formation of CO2 or CH4.

Surface and Bulk Erosion: Surface erosion occurs at the surface of the material, allowing easy diffusion and release of the formed low molar mass compounds, while the remaining bulk material may retain its original molar mass for a long period of time. This is a common degradation process as microorganisms, enzymes, and even water might not be able to penetrate the bulk of the material. In bulk erosion, the degradation takes places throughout the whole material simultaneously, leading to faster molar mass decrease and possible entrapment of degradation products inside the material.

2. Chemical Recycling and Biodegradation

Industrial scale chemical recycling of plastics is still in its infancy. The interest is large, but breakthroughs are required to achieve more sustainable and commercially viable chemical recycling.7 The presence of ester bond in the main chain, has made the aromatic polyester, poly(ethylene terephthalate) (PET), the forerunner in this area. It was the first volume plastic to have pilot/semi-industrial scale processes, leading to chemicals that can be repolymerized to PET, theoretically enabling closed-loop recycling. The current commercial processes mainly utilize methanolysis or glycolysis,8 while hydrolysis catalyzed by alkaline or acidic conditions or enzymes9 is an additional option for closed-loop recycling. Furthermore, aminolysis and ammonolysis provide promising options for upcycling.10 The cost and environmental impact are still higher compared to the mechanical recycling of PET.11 At the same time, the processes are more favorable, and the recovered products have higher value compared with those from chemical recycling of other volume plastics thanks to the reversible ester bond in the main chain. The benefit of ester bond and similar processes are also expected to be viable for other polyesters.4 Ring-closing depolymerization (RcDP) is an attractive route for chemical recycling of polyesters produced by ring-opening polymerization (ROP).12,13 Here, interesting work has been performed by utilizing the thermodynamic equilibrium between ROP and RcDP to produce repeatedly recyclable polymer materials.14,15 This equilibrium can be influenced, e.g., by design of cyclic monomer structures that provide a suitable balance between polymerizability and chemical recyclability16,17 and by monomer–solvent interactions.18,19 It was also shown that transesterification can be utilized to upcycle aliphatic polyesters to value-added block copolymers.20 The chemical recyclability of polyesters could be further promoted, e.g., by introduction of a second reversible chemical bond or neighboring groups that can function as internal catalysts for the depolymerization process.21,22

Organic recycling of plastics through biodegradation is an important puzzle piece and complementary in battling plastic pollution. Some plastics (e.g., agricultural and horticultural products and packaging that is contaminated by organic waste) are difficult to collect and recycle, leading currently to incineration, landfilling, or in worst case disposal in the environment.23,24 For these plastics, biodegradation is a valuable property, ideally leading to complete mineralization of the product under suitable environmental conditions.25 Current production of biodegradable or compostable polymer materials only correspond to less than 1% of total plastic production, and it is dominated by polyesters and thermoplastic starch.26 Ideally, the biodegradable plastic fulfills its function during service life and then rapidly degrades in predetermined environment through complete assimilation by microorganisms without any ecotoxicity or other negative impacts on the degradation environment. This is still a huge challenge; small changes in structure and composition of the plastic product or in the degradation environment can significantly influence the subsequent degradation rate.27 The different natural (e.g., marine, freshwater, forest soil) and man-made (e.g., industrial compost, home compost, agricultural soil) environments vary markedly with respect to conditions, such as temperature, humidity, sunlight, oxygen, and the type and concentration of microorganisms.28 It is also not easy to simulate natural environments under laboratory conditions to make reliable predictions of degradability.29 Last but not least, there is often a conflict between the application requirements and biodegradability, e.g., good water and oxygen barrier properties are wanted for packaging materials but counteract biodegradability and contribute to inadequate degradation rate. The complicated interplays of multiple material and environmental parameters influencing the degradation process are illustrated in Figure 2.

Figure 2.

Complicated case of polymer degradation sensitive to small changes in chemical and physical structure of the polymer and degradation environment.

Biodegradation under aerobic conditions ultimately leads to CO2, H2O, and biomass. In the case of polyesters, the abiotic degradation of the high molar mass polymers and release of oligomeric products can further promote the mineralization by microorganisms.30 Introduction of specifically designed “weak” or reversible bonds in the polyester chain, in addition to the “regular” ester bonds, could provide a tool to maintain material performance while providing handles where this initial degradation can take place. The opening of these bonds then leads to oligomers that are more easily biodegraded. An alternative approach could be the introduction of internal catalysis in the form of heteroatom containing functional groups along the polymer chain or embedded enzymes that can catalyze the initial hydrolysis of the polymer chain when it comes in contact with humidity or aqueous environment. This kind of modification can provide a step forward in ensuring adequate degradation even under less ideal degradation conditions. Similar approaches could further provide a route to chemical recycling under milder conditions to recover and repolymerize the breakdown products ideally in a closed-loop.

3. Increasing Biodegradability by More Hydrolyzable Ester Bonds

3.1. Degradation of Commercial Biodegradable Polyesters

Degradation of aliphatic and aliphatic–aromatic polyesters in different environments has been widely studied in different laboratory and real environments and only a short overview is presented here.31−33 Some common representatives of this group are materials produced by polycondensation of diols and dicarboxylic acids, such as poly(butylene succinate) (PBS), poly(butylene succinate-co-adipate) (PBSA), and poly(butylene adipate-co-terephthalate) (PBAT) and materials typically produced by ring-opening polymerization, such as the polyhydroxy acids, polylactide (PLA), and polycaprolactone (PCL), and the microbial polyesters, poly(3-hydrohybutyrate) (PHB) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV). However, even though the chemical structures of these biodegradable polyesters are relatively similar, this group of materials is not homogeneous in material properties, applications, and degradation behavior.34,35 As Figure 3 illustrates, the degradability and degradation rate can vary significantly depending on the specific plastic material and the specific environment.36−38 For example, the biodegradation rate of PHB and PCL in marine environment and under soil burial is typically significantly faster than the degradation rate of PLA, although they have longer aliphatic −CH2– segments and lower concentration of ester groups. This is likely explained by the better accessibility of the ester groups in PCL and PHB to enzymes, while the −CH3 substituent in PLA on the carbon next to the ester group causes steric hindrance. At the same time, the lower concentration of ester groups and longer aliphatic segments between ester groups reduces the chemical hydrolysis rate of PCL and PHB compared to PLA. In general, the chemical hydrolysis rates are relatively slow at 20–37 °C, while the hydrolysis rate is significantly accelerated if testing is performed at 50–60 °C.31 PBS is typically only certified to biodegrade in industrial compost, and PLA in industrial compost and during anaerobic digestion, while PHB is expected to biodegrade even in marine and fresh water, soil, and home compost.39 The biodegradation rate of PBAT is highly dependent on the aromatic content, but grades certified for biodegradation in industrial and home compost and under soil burial are available. In addition to chemical structure, many material parameters influence degradation rate (see Figure 2), such as molar mass, degree of crystallinity, glass transition temperature, mechanical properties, and size of the specimen to mention a few.

Figure 3.

Examples of degradation rates of PLA, PHB, PCL, PBS, and PBAT in different environments (upper left) weight loss due to chemical hydrolysis in phosphate buffer (pH = 7.4) at 37 °C,40−44 (lower left) weight loss in dynamic marine environment,44−46 (upper right) mineralization during simulated soil burial at 25–28 °C,47−50 and (lower right) mineralization during simulated industrial composting at 58 °C.32,51−54

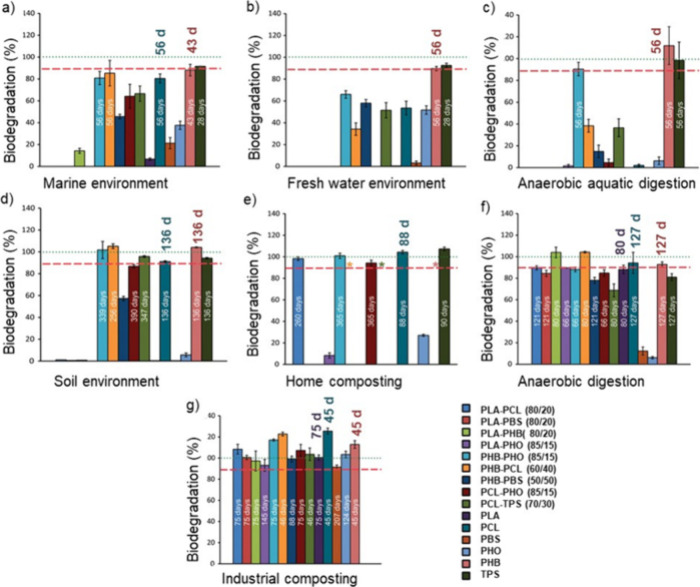

Figure 4 further demonstrates the large differences in degradation rates of common polyesters depending on the type of environment and the specific polyester.32 As an example, PHB reached the 90% biodegradation level in all tested environments. The >90–100% biodegradation was reached after approximately 43 days in marine, 56 days in freshwater and anaerobic aquatic digestion, 136 days in soil, 127 days in anaerobic digestion, and 45 days in industrial compost, showing the clear influence of degradation environment even for readily biodegradable material such as PHB. The differences in degradation rate were even more significant for more slowly degrading materials, such as PLA, which only degraded under anaerobic digestion and industrial composting conditions. Furthermore, the significant difference in degradation rate between the controlled waste management environments (industrial compost and anaerobic digestion) and the unmanaged natural and man-made environments is clearly shown. The biodegradation property thereby needs to be coupled to specific environmental conditions.

Figure 4.

Biodegradation of aliphatic polyesters (PLA, PCL, PBS, PHB, and polyhydroxyoctanoate (PHO)), their blends and thermoplastic starch (TPS) in different managed and unmanaged environments. (a) Marine environment (ASTM D6691, 30 °C), (b) fresh water environment (ISO 14851, 21 °C), (c) anaerobic aquatic digestion (ISO 11734, 35 °C), (d) soil environment (ISO 17556), (e) home compost (ISO 14855, 28 °C), (f) anaerobic digestion (ISO 15985, 52 °C), and (g) industrial compost (ISO 14855, 58 °C). Biodegradation was calculated in relation to biodegradation of cellulose (green dotted line), and 90% biodegradation is marked with red dashed line. Adapted with permission from ref (32). Copyright 2018 American Chemical Society.

The abiotic and biotic hydrolysis of polyesters can proceed through surface or bulk mechanisms, and it is typically assisted by initial abiotic processes, such as oxidation or hydrolysis, which decrease the molecular weight and/or increase the hydrophilicity of the material.55 It is easier to design materials that degrade under controlled and favorable conditions in industrial compost, but the conditions in natural environments, especially in seawater, are much less favorable for degradation, and even many biodegradable plastics can persist over long periods of time.28 The degradation rate can vary from weeks to years depending on the combination of specific material and environment. To make it even more complicated, large differences in the degradation process can be observed even in same type of environment. To illustrate this, Figure 5 presents the strength retention of three aliphatic polyesters that are considered as easily biodegradable, e.g., PCL, PHBV, and PBS. The polymers were soaked in deep sea at three different locations close to the Japanese coastline.56 Irrespective of the relatively similar environments, large differences in degradation rate were observed both between the locations and between the different aliphatic polyesters. Of the studied materials, PHBV and PCL demonstrated significant degradation, while the degradation rate still varied largely depending on the specific location. Interestingly, the average temperature at Toyama and Rause, where degradation of PCL proceeded faster was 2 and 5 °C, respectively, while it was slightly higher (10 °C) at Kume, the location where degradation proceeded more slowly. Thereby, temperature could not explain the differences. Unfortunately, pH of the water was not followed, but isolated from all three locations. The bacteria located from Kume had good activity at 25 °C, while bacteria active at 4 °C was found at Toyama and Rausu. This likely explains the differences observed in the degradation rate of PCL at the different locations. PHBV degrading bacteria were not investigated. PBS did not show significant degradation in any of the locations.

Figure 5.

Degradation of (a) PCL, (b) PHBV, and (c) PBS monofilament fibers soaked in deep seawaters in three different locations near Japanese coast. Adapted with permission from ref (56). Copyright 2011 Elsevier.

The negligible degradation rate of PLA and PBS in seawater, and the higher susceptibility of PCL, PHB, and PHBV to degrade was also confirmed by several other studies.28,57 These large differences in the degradation rates clearly demonstrate the sensitive interplay between the prevailing degradation environment and the specific polymer structure, and the sensitivity to small changes in either, making it difficult to guarantee degradation in natural environments. Furthermore, it is clear that structural modification of common biodegradable polyesters is required if reasonable degradation rate in natural environments is targeted.

3.2. Modification by More Easily Hydrolyzable Ester Bonds

As a general rule, chemical modifications that increase the hydrophilicity and water uptake of the materials typically also lead to increased hydrolytic degradation rate.58 Some ester bonds are also more susceptible to hydrolysis due to, e.g., higher electrophilicity or accessibility to water. Such bonds could be introduced to design rapidly hydrolyzable materials or to tune the degradation rate by providing “weak” points, where degradation can be initiated. Modification by copolymerization,59 cross-linking,60,61 and introduction of branching62 can also be utilized to decrease the degree of crystallinity, as amorphous materials have less tightly packed chains and higher susceptibility to hydrolysis. Many studies and reviews31,33 exist on modification of aliphatic polyesters and their susceptibility to degradation by copolymerization, blending, and surface modification with more hydrophilic components,63−65 only a few examples are presented here to illustrate different approaches.

3.2.1. Aliphatic Polyesters

Poly(l-lactide) (PLLA) is known to degrade relatively slowly due to the sterical hindrance from the methyl group close to the ester group and the semicrystalline nature and/or crystallization during aging. Some early studies compared the hydrolytic degradation of several PLLA, poly(d,l-lactide) PDLLA and poly(glycolide-co-lactide) (PLGA) polymers in phosphate buffer at 37 °C showing surprisingly large differences.66,67 The half-life as determined by 50% weight loss decreased from 110 weeks for PLLA to 22, 10, and 10 weeks after introduction of 25% d-lactide units, 50% d-lactide units, and 25% glycolide units, respectively. A polymer containing both l-lactide and d-lactide units in combination with 25% glycolide units, had by far the shortest half-life of only 3 weeks. All of the polymers were initially amorphous, and these large differences were explained by the ability of the degrading polymers and oligomers to crystallize or not during aging. In the case of the PLGA copolymers, the introduction of more hydrophilic units with more accessible ester groups further increased the hydrolytic degradation rate.

While randomly incorporated D-and L-units in the polylactide chain rapidly reduce the degree of crystallinity and accelerate the hydrolytic degradation rate, the opposite has been observed for block copolymers, where longer D-and L-blocks in the copolymer chain allow formation of more hydrolytically stable stereocomplex crystals.68 The higher hydrolytic stability of the blends of PLLA and poly(d-lactide) (PDLA) due to formation of stereocomplex crystals is also well-known69,70 and correlates with the stronger secondary interactions in stereocomplex crystals and higher water barrier properties.71 In accordance, studies on polycaprolactone copolymers illustrated the large influence on hydrolytic degradation rate of both the copolymer composition and the arrangement of the comonomers to random, block or multiblock copolymers, contributing to the different distribution of the more easily hydrolyzable ester bonds in the materials.41,72 In this context, the triblock copolymer exhibited the largest weight loss and release of monomeric and oligomeric hydrolysis products due to the susceptibility of long hydrophilic 1,5-dioxepan-2-one blocks toward hydrolysis. Figure 6 further illustrates the concept of introducing “weak” more easily hydrolyzable ester bonds to tune the hydrolytic degradation rate of polyesters.73 The degradation experiments were performed in phosphate buffer at 37 °C during 24 weeks. The introduction of more easily hydrolyzable ester bonds facilitates weight loss and abiotic hydrolytic breakdown of the polymer and leads to formation of potentially more easily biodegradable low molar mass compounds. However, this should not be considered a proof of ultimate biodegradability, which should always be confirmed by biodegradation experiments under relevant conditions to confirm the mineralization without formation of persistent degradation products.

Figure 6.

Introduction of different amounts of glycolide (GA) units in poly(trimethylene carbonate-block-(l-lactide) (PTL) copolymers to incorporate more hydrolyzable ester bonds in the PLLA blocks to tune and enhance the hydrolytic degradation rate. (a–c) illustrate schematically block copolymers with increasing amount of glycolide units (blue circles) in the PLLA blocks. (d) The weight loss as a function of hydrolytic degradation time for block copolymers with different glycolide contents. The copolymer composition can be read from the sample names, e.g., PTLG 20/70/10 contains 20% carbonate, 70% lactide, and 10% glycolide units. Adapted with permission from ref (73). Copyright 2018 John Wiley and Sons, Ltd.

3.2.2. Aliphatic–Aromatic and Aromatic Polyesters

Aromatic polyesters, such as PET, are typically not sensitive to low temperature hydrolysis or biodegradation without pretreatment to, e.g., reduce the molar mass.74 However, an interesting commercial and biodegradable aliphatic–aromatic polyester, PBAT, has been developed to bridge aliphatic and aromatic polyesters.75 In PBAT, the separation of the aromatic segments with aliphatic units provides regions where initial degradation can take place, releasing oligomers that, due to their low molecular size, are more easily accessible for further biodegradation, and more than 90% mineralization has been shown during simulated composting experiments.76 At the same time, a sufficiently high number of aromatic units were left to give the polymer good physical properties.77,78 Quartz crystal microbalance experiments clearly illustrated both the influence of terephthalate content and the specific enzyme on the degradation rate of PBAT polymers.79Figure 7 shows how the enzymatic hydrolysis rate of PBAT decreases as the terephthalate content in the copolymer increases. At the same time, the degradation rate is highly influenced by the type of enzyme and temperature. The degradation rate and properties can be further modulated by copolymerization with additional monomers. As an example, copolymerization with polyglycolide prepolymer led to materials with improved mechanical and barrier properties and faster degradation rate in water.80 The material properties of PBAT also depend on the aliphatic/aromatic ratio. Commercial PBAT is a flexible material with properties similar to low density polyethylene (LDPE). The biodegradability thus comes at the cost of some mechanical and barrier property reduction compared to aromatic polyesters, such as PET. PBAT can be used to replace LDPE in applications, where biodegradability is a favorable property, such as mulch films, compostable bags, and products contaminated by organic matter.

Figure 7.

Enzymatic hydrolysis of PBAT thin films with different terephthalate contents by Fusarium solani cutinase (FsC) and Rhizopus oryzae lipase (RoL) at pH 6. The degradation was followed by quartz crystal microbalance with dissipation monitoring (QCM-D). Changes in the adlayer mass during the hydrolysis catalyzed by (a) FsC and (b) RoL at 30 °C. (c) Fraction (%) of dry polyester that was released during the hydrolysis experiments. (d) FsC catalyzed hydrolysis rate at three different temperatures. Reproduced with permission from ref (79). Copyright 2017 American Chemical Society.

Poly(ethylene furanoate) (PEF) is an emerging commercial aromatic polyester. It is anticipated to have high potential as biobased replacement material for PET, as it has similar and even better mechanical and barrier properties and lower environmental impact in comparison to PET.81 PEF can also be chemically and mechanically recycled similar to PET. Furthermore, while recycling polymer blends typically leads to deterioration of properties, it was shown that low amounts of PEF can even improve the properties of mechanically recycled PET.82 However, PEF is not rapidly biodegradable and does not fulfill the requirements to be classified as industrially compostable plastic (requiring >90% biodegradation to CO2 during 180 days).83 Still replacing the terephthalate units in PET by furanoate unit in PEF significantly increases the susceptibility to biodegradation, as a recent study showed >90% conversion of PEF to CO2 after 385 days in simulated industrial compost (Figure 8). After weathering, the 90% mineralization was reached already after 240 days. After the same time period, the biodegradation degree of weathered PET was 10%, while biodegradation of PET remained negligible. Similar to PBAT, the biodegradability of PEF can be increased by copolymerization.84,85

Figure 8.

Biodegradation of weathered and unweathered PEF and PET under simulated composting conditions at 58 °C. Cellulose was included as biodegradable reference, and biodegradation was quantified by measuring the production of CO2. Adapted with permission from ref (83). Copyright 2022 The Authors. CC-BY 4.0. Published 2022 MPDI.

Another approach was recently developed for obtainment of more readily degradable aromatic or aromatic–aliphatic polyesters by incorporation of salicylic acid, an aromatic hydroxyacid, into the polymer structure.86,87 While the aromatic ring contributed to attractive thermal, mechanical, and oxygen barrier properties, the more acidic carboxyl and hydroxyl groups contributed to significantly higher hydrolytic degradation rate in different aqueous environments. As an example, salicylic glycolide and salicylic lactide were ring-opening polymerized to corresponding polyesters, which were shown to completely degrade to water-soluble degradation products within 20–40 days in phosphate buffer (pH 7.4) and artificial seawater (pH 8.0) at 50 °C, while commercial PLA and PET showed no weight loss during 100 days in artificial seawater.86 In phosphate buffer, the weight loss of PLA started around 60 days. The tested spherical samples, with ∼2 mm diameter, were prepared by compression molding, followed by quenching with cold water. The results are interesting, but the temperature used for testing is significantly higher compared to 30 °C recommended in the standard test method for determining aerobic biodegradation of plastic materials in the marine environment (D6691-17) or the average temperature estimated for ocean surface water (17 °C) and sea floor (4 °C). The results presented in supporting information also show that the degradation rate in phosphate buffer decreases significantly when the temperature is decreased to 40 °C and almost no degradation takes place at room temperature (23–27 °C).

Industrially viable transesterification during melt extrusion was utilized for introduction of salicylate units as weak linkages in commercial polymers, such as PLA. Through this approach, original material properties (thermal, mechanical, and oxygen barrier) were retained, while significantly increased hydrolytic degradation rates were demonstrated.88 Furthermore, the degradation rate could be easily tuned by changing the amount of salicylate units incorporated in the PLA chain. As an example, 100% weight loss in phosphate buffer at 50 °C was recorded within 40–55 days for PLA modified with different amounts of salicylate units (PLS7, PLS15, and PLS25), while it took more than 90 days for PLA under similar conditions (Figure 9). Even larger differences were observed during aging in seawater. By performing experiments at different temperatures and by utilizing the Arrhenius equation, the authors estimated that it would take 2.8 years for PLS25 with the highest salicylate content to completely degrade in phosphate buffer under ambient conditions, while it would take 5.5 years for PLA. This was deduced to the easier cleavage of salicylate units and the catalytic effect of more acidic salicylic acid units with pKa ∼ 2.8 compared to pKa ∼ 3.9 for lactic acid.

Figure 9.

Weight loss of PLA, PLS7, PLS15, and PLS25 during hydrolytic aging at 50 °C in (a) 1 M pH 7.4 phosphate buffer, (b) pH 8.1 seawater, and (c) 0.1 M aqueous NaOH. Proposed mechanism for salicylate-facilitated degradation under (d) basic and (e) acidic conditions. Reproduced with permission from ref (88). Copyright 2021 American Chemical Society.

4. Increasing Circularity by Neighboring Heteroatoms

While the ester bond is well-known for its reversible behavior and susceptibility to hydrolysis, the ester exchange and hydrolysis rates89 are typically significantly lower as compared to other dynamic bonds such as imines and disulfides. It could also require external catalysts such as Lewis acids90 and/or elevated temperatures.91 The hydrolysis accelerating effects of free hydroxyl and carboxyl groups are well-known from early hydrolysis experiments, where the presence of monomer residuals92 or large amounts of acidic degradation products93 was shown to have autocatalytic effect on the hydrolysis rate. In correlation, the end-capping of hydroxyl groups at the chain ends significantly reduced the susceptibility to hydrolysis.94,95 This is explained by lower water uptake as well as change in degradation mechanism from chain-end scission to merely random chain scission.96 In line with this, although thin or porous specimens could be expected to degrade faster due to larger surface area, in many cases the opposite has been observed due to the autocatalytic influence of the formed acidic hydrolysis products. This is especially significant in the case of large specimens, as the formed hydrolysis products are trapped inside and catalyze the hydrolysis process inside the specimen.97

Similar to this, the dynamic efficiency of the ester bond can be improved by nearby basic and nucleophilic heteroatoms such as oxygen, nitrogen, and sulfur.98 Such heteroatoms can be incorporated in polymer materials in the form of functional groups (e.g., carboxyl, hydroxyl, amine) and are thereby expected to act as internal catalysts both for chemical exchange reactions and hydrolysis (Figure 10). Depending on the type of modification, the monomer with extra functionality could be added already during the polymer synthesis or it could be incorporated to the polymer chain by, e.g., transesterification. Utilization of reactive extrusion could give an opportunity to tailor-make existing commercial materials to degradation in targeted end-of-life environment. The utilization of nearby functional groups for enhancing the rate of exchange reactions is also known as neighboring group participation (NGP).98

Figure 10.

Schematic presentation of polyesters modified by neighboring oxygen, sulfur, and nitrogen containing groups and the potential circularity promoting influences.

4.1. Polyesters with Neighboring Nitrogen Atoms

The placement of neighboring amines to enhance ester exchange reactions (i.e., transesterification) has mainly been used in epoxy-ester based networks for introducing mechanical recyclability. For example, transesterification of PET with polyol containing five hydroxyl groups and a tertiary amine broke the polyester chains and incorporated tertiary amine moieties and reactive hydroxyl groups.99 These hydroxyl groups were then available for reaction with epoxy groups to form an ether and new hydroxyl groups. Due to the synergetic catalyzing effect of hydroxyl and tertiary amine groups, the resulting networks were fully reprocessable by, e.g., hot-pressing and extrusion. In another approach, primary and secondary amines underwent reaction with two diepoxy molecules, to form diepoxy crosslinkers with a tertiary amine and hydroxyl group.100 The obtained crosslinkers were then further reacted with citric acid monohydride and succinic acid, yielding an epoxy-ester based network. Due to the neighboring nitrogen atoms the observed stress relaxation times were similar to those observed in the presence of external catalysts for the ester exchange reaction.

The presence of tertiary amines as pendant groups instead of inherent components of the polymer network also enhanced the transesterification reactions rates. The presence of both tertiary amines and hydroxyl pendent groups yielded polyester thermosets with stress relaxation times reduced by a factor of 20 in comparison to neat polyester thermosets, thus imparting good reprocessability.101 The effect of tertiary amines on transesterification reactions in phthalate monoester-based networks was also studied.102 Stress relaxation experiments at 160 °C showed that relaxation times decreased from 515 s for the network lacking tertiary amines down to 1.1 s for the network containing the highest amount of tertiary amines. This considerable decrease in stress relaxation time showed that the presence of tertiary amines alone significantly enhanced transesterification reactions. These results demonstrate that the presence of tertiary amines have a beneficial effect on transesterification rates, thus imparting thermal reprocessability.

Studies on the ability of tertiary amines to facilitate chemical recyclability have been limited. In this regard, incorporation of tertiary amines as internal catalysts in epoxy-ester networks was evaluated by utilizing the hydroxylamine-based compound triethanolamine (TEOA).103 During the formation of the thermoset, the hydroxyl groups of TEOA initially reacted with an anhydride to form a carboxylic acid group, which was then available to react with an epoxy group to form an ester and a β-hydroxyester linkage. The resulting network, containing ester, triamine, and hydroxyl groups, exhibited brittleness (elongation at break 8–9%) but good mechanical strength (85–94 MPa) and high Tg ∼ 135 °C. Tg was, thereby, comparable and tensile and impact strength even higher than those of conventional anhydride cured bisphenol A (BPA) epoxy thermosets, which could enable use in high temperature applications and as structural components. At temperatures ranging between 170 and 200 °C, moderate to fast stress relaxation times (19 460 to 4200 s) were observed depending on TEOA content, indicating the occurrence of exchange reactions such as transesterification reactions. With an increasing TEOA content, faster stress relaxation times were observed, which was attributed to the synergetic catalyzing effect of the hydroxyl and tertiary amine functional groups.

By focusing on the chemical recycling, the obtained resin was hydrolyzed in an aqueous solution of 1.5 wt % phosphotungstic acid at 190 °C for 5 h. After the reaction, a degraded oligomeric residue was obtained with a molecular weight of 2200 g/mol. The product was fully soluble in acetone, indicating significant degradation. It should be mentioned that without the use of phosphotungstic acid, no degradation was observed. Fourier transform infrared (FTIR) spectroscopy showed that the degraded residue contained abundant −OH and −COOH groups, suggesting that the degradation mainly occurred at the tertiary amine and ester moieties. This degradation pathway can be explained by the basic nature of the tertiary amine assisting the nucleophilic attack of hydroxyls/water on the carbonyl carbons (i.e., ester linkages) resulting in the cleavage of ester bonds.104 Due to the −OH and −COOH rich hydrolysis products, the degraded oligomers could be blended with fresh resin and recured to form a new thermoset through transesterification reactions, promoted by the presence of hydroxyl and tertiary amine groups. The storage modulus and glass transition temperature (Tg) of the new thermoset were similar to those of the original thermoset, indicating successful chemical recyclability and reuse of the recycled chemicals in equal value application.

Above studies investigated systems with both hydroxyl and tertiary amine groups and reported synergistic catalyzing effects on transesterification reactions. However, comparisons with resins and thermosets containing only tertiary amines or hydroxyl groups were not mentioned. Nevertheless, the catalytic effect of hydroxyl and tertiary amine groups on enhancing both transesterification reaction rates and ester hydrolysis were clearly highlighted. There is high potential in this approach, but more research is required to establish the influence of nitrogen containing neighboring groups on chemical recyclability, hydrolytic degradation, and biodegradation of polyesters. The research should also be expanded to linear polyesters to evaluate the influence on neighboring groups on mechanical properties and potentials risks of premature degradation during, e.g., thermal processing.

4.2. Polyesters with Neighboring Oxygen Atoms

Recently, oxygen containing functional groups, like hydroxyl, carboxyl, and carboalkoxy, have been introduced into polyesters to enhance circularity. The weak acidic and hydrophilic nature of such oxygen-containing NGP is expected to promote the ester exchange reactions and ester cleavage. For example, a comparative study between conventional polyesters, PCL and poly(11-hydroxyundecanoate) (PHU), and a polyester containing hydroxyl pendant groups (PEUA) showed beneficial effects of hydroxyl pendant groups on the polyester degradability in both hydrolytic and enzymatic media.105 Under accelerated hydrolytic conditions at temperature significantly above Tg of the studied polymers (incubation in aqueous media with pH 2.0 at 45 °C for 10 weeks), the number-average molar mass (Mn) of PEUA decreased from 8400 g/mol before hydrolytic incubation to 3700 g/mol after incubation. The weight loss after 80 days was only a few percent, indicating that the pendant hydroxyl groups could catalyze the hydrolytic degradation in bulk, but the molar mass reduction was still not enough to form water-soluble oligomers. It would have been interesting to follow the process over a prolonged time period to confirm the further hydrolysis of the remaining low molar mass polymer. Conversely, no decrease in molar mass was observed for PCL and PHU, while the observed weight loss was somewhat larger compared to PEAU. This in turn supports surface erosion, releasing water-soluble degradation products without significant influence on molar mass. Considering also that the original molar mass of PEAU was twice as high as that of PCL and PHU, this indicates that the presence of acidic and hydrophilic −OH groups in PEUA could enhance the susceptibility to hydrolysis. The introduced pendant groups also increased the hydrophilicity of the materials and decreased the degree of crystallinity, which further facilitates faster hydrolysis. Similar results were obtained for enzymatic degradation (incubation for 10 days in pH 7.4 at 37 °C with porcine pancreatic lipase). However, enzymatic degradation was more limited as compared to hydrolytic degradation due to the difficulty of the enzyme to penetrate the polymer system.

In another study, a series of hydroxy-functional copolyesters was synthesized from adipic acid, 1,8-octanediol, and glycerol, varying the hydroxyl content by increasing the 1,8-octanediol:glycerol ratio.106In vitro degradation was evaluated in phosphate buffer (pH ∼ 7.4 at 37 °C) for a predetermined time. After 7 days, the observed weight loss ranged from 20% for the polymers with adipic acid:1,8-octanediol:glycerol ratio of 1:0.8:0.2 to 55% for polymers with higher glycerol content, i.e., adipic acid:1,8-octanediol:glycerol ratio of 1:0.5:0.5. These results support that increasing the hydroxyl content leads to faster biodegradation rates. This can be attributed to the combined effect of increased hydrophilicity, decreased degree of crystallinity, as well as the catalyzing effect of free hydroxyl groups, all promoting the cleavage of ester bonds under hydrolytic conditions. Neither of the above studies investigated the influence of neighboring groups on the mechanical properties of the materials, which is crucial from an application perspective.

Another promising oxygen-based NGP is carboxylic acid. Early works showed that the introduction of neighboring carboxylic acid groups in phthalate monomethyl esters rapidly increased the hydrolysis rates up to 10-fold under mildly acidic to neutral conditions (pH 4–7), as compared to those of corresponding benzoate esters lacking neighboring carboxylic acid groups.107,108 The relative proximity of acidic carboxyl groups near ester bonds promotes ester bond cleavage as well as ester exchange reactions. More recently, this carboxylic acid catalyzed transesterification rate enhancement was utilized in the design of phthalate- and polyester-based covalent adaptable networks to avoid the need of external catalysts to initiate ester bond cleavage and transesterification reactions.109 The dynamic networks were recyclable for multiple cycles using a solvent-based recycling approach. Analysis showed that the obtained precipitate consisted of prepolymer network fragments, which could be recured by heating at 100 °C for 4 h under N2 atmosphere. Even after multiple recycling steps (i.e., dissolving and heating), chemical, thermal, and mechanical properties of the material were not affected, indicating promising closed-loop recyclability.

Despite the promising results of neighboring acid groups being able to enhance hydrolysis rates of polyesters, current carboxylic acid-ester NGP research has mainly focused on mechanical recycling. For example, dynamic polyester networks were prepared by a reaction between branched polyesters containing −OH end groups with pyromellitic dianhydride or 2,5-bis(methoxycarbonyl) benzenesulfonic acid.110 The resulting polyesters contained, respectively, −COOH or −SO3H functional neighboring groups in the ortho position to every formed ester linkage (Figure 11). The stress relaxation experiments showed that both networks containing −COOH or −SO3H groups exhibited significantly faster stress relaxation in comparison to a conventional reference network lacking any neighboring groups but containing 0.5 mol % of external transesterification catalyst Zn(Acac)2. This indicates that the presence of such neighboring groups significantly enhances the dynamic behavior of polyester based networks. Interestingly, observed stress relaxation of −SO3H containing polyester networks was 5 times faster than the stress relaxation of networks with −COOH groups. The presence of the sulfur groups may thus further enhance ester exchange reactions. This can be explained by the much higher acidity of sulfonic acids as compared to carboxylic acids. Nevertheless, the acidic nature of carboxylic acid contributes to faster ester exchange reactions, making them promising NGP in polyester-based systems by imparting these materials with potentially improved mechanical and chemical recyclability.

Figure 11.

(a) Network formation with internal carboxylic and sulfonic acid groups and (b) bond rearrangements in networks with neighboring carboxylic acid group. Reproduced with permission from ref (110). Copyright 2020 American Chemical Society.

Interestingly, promising ester exchange enhancement was also achieved by replacing the hydrogen in the carboxylic −OH group with an alkyl chain to yield a carboalkoxy group despite the lower acidic nature. For example, chemically recyclable carbomethoxylated polyvalerolactone (PCMVL) was obtained via ring-opening transesterification polymerization of the renewable monomer 4-carbomethoxyvalerolactone (CMVL).111 The resulting semicrystalline polyester, containing a carbomethoxy group in its repeating unit, exhibited a Tg of −18 °C and two distinct melting temperatures at 68 and 86 °C, respectively. Chemical recyclability of PCMVL was tested by using depolymerization methods via two different pathways. First, when PCMVL was heated at 150 °C in the presence of tin octanoate (SnOct2) as a catalyst, near complete degradation via transesterification was achieved to fully recover the initial cyclic monomer, CMVL, with a yield of 87%. Alternatively, in the presence of 1,8-diazabicyclo[5.4.0]undec-7-ene, the polymer chain was cleaved through elimination processes into smaller oligomeric fragments.

Although these promising results indicate the potential chemical recyclability of carboxymethoxylated polyvalerolactone, no reference studies were performed with polyvalerolactone lacking carbomethoxy pendant groups. However, following the degradation process with 1H NMR analysis showed that the cleavage and elimination reactions along the main chain preferably occurred in the vicinity of a proximal carbomethoxy group, suggesting that the presence of the carboxylate ion does enhance chemical recyclability of polyvalerolactone. In another study, the influence of the alkyl side chain length on the hydrolytic degradation rates of carboalkoxylated polyvalerolactones was evaluated.112 Similar to the previous study, the hydrolytic degradability of a series of 4-carboxylated polyvalerolactones with methyl, ethyl, propyl, and butyl alkoxy side chains was evaluated in basic (0.1 M NaOH), acidic (0.1 M HCl), and neutral environments at 80 °C. After 13 days, all polyesters were fully degraded under both acidic and basic conditions. However, it was observed that the hydrolysis rates of the polyesters significantly depended on the alkyl side chain and the degradation rate decreased with increasing alkyl side chain length under both acidic and basic conditions. It was suspected that this was caused by the longer alkyl chains inducing increased hydrophobicity, thus reducing the water uptake and susceptibility of the polyesters to hydrolytic degradation.

In summary, oxygen based NGP in the form of hydroxyl, carboxyl, and carboalkoxy functional groups has the potential to impart polyesters with improved chemical recyclability and faster hydrolytic degradation. The presence of such functional groups increases hydrophilicity as well as acidity that can enhance ester bond cleavage and ester exchange reaction rates. This is further facilitated by typically lower degree of crystallinity after introduction of neighboring groups. Research should be expanded to establish that these accelerating effects persist under less accelerated hydrolysis and biodegradation conditions.

4.3. Polyesters with Neighboring Sulfur Atoms

Sulfur-atom based neighboring group participation, mainly in the form of sulfonic acid (−SO3H), to increase the rate of ester bond exchange and cleavage reactions has recently gained attention. As mentioned above, in comparison to oxygen-based −COOH carboxyl groups, the sulfur-containing −SO3H has significantly higher capability to accelerate ester exchange reactions.110 Such neighboring acid groups accelerate thermally induced transesterification reactions by reacting intermolecularly with ester bonds to form an anhydride intermediate, thus imparting polyesters with improved mechanical recyclability.110 However, due to the high acidity and hydrophilicity of sulfur (ions), sulfur-based neighboring group participation may also accelerate ester hydrolysis rates and impart polyesters with improved chemical recyclability. As an example, sulfonated PBS showed significantly increased hydrolysis rate in pH 12 aqueous alkali solution.113 The water uptake of the sulfonated PBS materials increased linearly with the concentration of ionic groups. The same trend was observed for the hydrolytic degradation rate as the approximately 15% weight loss for PBS after 30 days gradually increased to approximately 95% for the material with the highest concentration of ionic groups.

Similarly, a chemically recyclable polyethylene-like polyester containing low amounts of ionic sulfonate groups was synthesized via polycondensation reactions at 150 °C and under reduced pressure by using octadecane-1,18-dicarboxylic, octadecane-1,18-diol, and dimethyl sulfosuccinic acid (HMSS) as monomers.114 The presence of low amounts (0.8 mol %) of HMSS led to polyesters containing a low content of −SO3-H pendant groups. Interestingly, the presence of pendant sulfonic acid groups did not significantly influence the thermal properties. On the other hand, an increase in sulfonic acid content led to an increase in stiffness as compared to a polyester lacking any neighboring groups. The susceptibility of the sulfonic acid containing polyesters to hydrolysis was evaluated by immersing the polyester in water for 10–12 weeks. During this time period, the weight gain upon water absorption as well as the degree of polymerization (DPn) of sulfonic acid containing polyesters was compared to the nonfunctionalized polyester. The presence of sulfonic acid groups significantly increased the water uptake of the polyesters, indicating its increased hydrophilicity. As a result, the ester bonds were significantly more exposed to water, which is known to be important for the hydrolysis rate. This was further demonstrated by the observed decrease in DPn for the sulfonic acid containing polyesters, showing a significant decrease in DPn of 50–60%. Considering that no significant change in water uptake and DPn was observed for the polyester without any sulfonic acid groups, it was concluded that the presence of sulfonic acid functionalities significantly increased the susceptibility to hydrolysis.

To test the chemical recyclability of these sulfonic acid-containing polyesters, depolymerization experiments via solvolysis in methanol were carried out at 150 °C. After cooling down to room temperature, a solid residue was obtained. The yield after purification was 80%, and the product consisted of a 1:0.99 mixture of the initial diol and diacid monomers. It was expected that the initial small amount (0.8 mol %) of the HMSS monomer is removed during the recrystallization process. Nevertheless, these results show that complete ester cleavage of the sulfonic acid containing polyesters can be achieved, yielding polyesters that are fully chemically recyclable. Although research is still limited, sulfonic acid neighboring group participation for the enhancement of transesterification rates and ester hydrolysis has proven to be very effective, yielding polyesters with higher susceptibility to hydrolytic degradation and improved mechanical and chemical recyclability.

The utilization of neighboring heteroatoms to facilitate the recyclability and especially the hydrolysis and biodegradation rate of polyesters is still in its infancy. Above studies indicate high potential for tuning the degradation rate for different end-of-life environments. However, the amount of research is scattered and limited and the experimental conditions, including degradation testing varied a lot with respect to pH, temperature, and time. More research is needed to establish structure–degradation relationships by more systematic variation of type and degree of neighboring groups, studies on hydrolytic degradation under less accelerated standardized condition and biodegradation studies under different environmental conditions by using standardized test protocols. Even more so, the influence of these modification on the thermal and mechanical properties of the materials and the stability during thermal processing needs to be investigated to ensure performance during service. Systematic evaluation of the influence of type and concentration of neighboring groups on processability, material properties, and degradation rate could release the full potential of this approach.

5. Increasing Circularity by Double Dynamic Structures

Esterification is a classical equilibrium reaction and ester-bond is well-known for its reversibility. However, as a concept the dynamic covalent chemistry (DCC) was first presented in 2002.115 Some years later, the terms covalent adaptative network (CAN)116 and vitrimer117 were introduced, both referring to crosslinked polymer networks exhibiting reversible bonds. Covalent bonds can be classified as dynamic if they can reversibly form and break under equilibrium control and under impact of a specific stimulus.118,119 A multitude of different bonds, such as esters, disulfides, imines, acetals, urethanes, and boronic esters, have been employed with or without additional catalyst for the design of more circular polymer materials.120 In addition to heat sensitive bonds for design of mechanically recyclable thermosets, e.g., photoreversible bonds and pH sensitive DCCs have been developed, potentially enabling chemical recycling of polymers under mild conditions.

An interesting option could also be the development of linear polymers that are sensitive to different environmental triggers to release oligomers that are more easily further biodegraded compared to the original high molar mass polymers. The release of oligomers that can be directly repolymerized to polymer materials with original properties is also of interest.121 Combining ester bonds with second more easily reversed dynamic bond to form double dynamics is an attractive possibility to tailor and facilitate the circularity of the materials under mild conditions (Figure 12). The second bond and its abundance can be selected to tune the properties for specific application and the reversibility in specific end-of-life environment. The double dynamics that could facilitate both chemical recycling and biodegradation include, e.g., polyester-imines, polyester-disulfides, polyester-acetals, and polyesters with photoreversible bonds.

Figure 12.

Schematic over linear and crosslinked double dynamic polyesters, where the second dynamic bond, such as imine, disulfide, or acetal, facilitates chemical recyclability and biodegradability by enabling release of oligomers under facile conditions.

5.1. Polyester-Imines

In the wide spectrum of the dynamic covalent bonds, imine-bond, also called Schiff base, is commonly employed to impart recyclability and self-healing properties to polymers.122 Imines are obtained through a click chemistry reaction in which an active carbonyl group is condensed with a primary amine or more seldom with a ketone to form C=N bonds.123 The often excellent recyclability of Schiff base polymers originates from the capacity of the imine bonds to participate in three distinct pathways under the action of specific stimuli. Indeed, the imine bond can be relatively stable under neutral aqueous conditions, while acidic conditions can promote the hydrolysis of the imine bonds with the consequent reformation of the original functionalities through the Schiff base dissociative pathway. Imines are also sensitive to two associative pathways, transimination and imine metathesis, both including exchange reactions taking place in the absence of water.124 Transimination refers to the reaction of an imine with a primary amine to form a new imine and a new primary amine. Conversely, the metathesis pathway consists of the reaction between two imines to generate two new imines.

A wide number of polyesters containing imine bonds in their structure have been designed. The combination of Schiff base linkages and ester functions is attractive for the development of biobased self-healable adhesives. As an example, ethyl cellulose was modified by functionalization of the backbone with vanillin methacrylate and lauryl methacrylate.125 The resulting polymers were crosslinked by inducing the formation of Schiff base bonds between the aldehyde functions in the pendant vanillin groups and a polyetheramine. Shear strengths around 0.81 MPa and a self-healing efficiency of ∼99% could be reached. Following the same approach, a lignin-based dynamic network crosslinked by inducing a Schiff base reaction between vanillin methacrylate and a diamine was realized.126 Besides the self-healing, the resulting polymer also presented UV-shielding and antifungal properties. Although still not investigated in terms of recyclability and/or biodegradability, poly(azomethine esters) have been reported to be promising for demanding aerospace and automotive applications in light of their high thermal resistance, low band gap, and semiconductive properties.127−129

5.1.1. Chemical Recycling

Polyester-imine thermosets have been developed, aiming to meet the requirements of circular economy, including the possible obtainment from renewable resources and the facile recyclability at the end of service life. Among the large library of renewable resources, levulinic acid is considered an important biomass-derived molecule due to its functionality,130 utility as a solvent, and the possibility to derive it from lignocellulose waste.131,132 In the frame of chemically recyclable polyester-imine thermosets, levulinic acid was employed for the synthesis of ELA, a ketone-ester-epoxy precursor, subsequently cured with 2-(4-aminophenyl)-1H-benzimidazol-5-amine (BIA) or 4,4′-diaminodiphenylmethane (DDM) to synthesize dynamic covalent networks with in situ generated imines and multiple hydrogen bonds.133 The resulting ELA-BIA thermosets had high Tg and modulus up to 165 °C and 2422 MPa, respectively. DDM was selected for comparison to prepare ELA-DDM because it is an amine-based agent often employed for the curing of epoxy resins.134,135 The thermosets contained in their structure both imine bonds and noncovalent hydrogen bonds formed between the available amine and hydroxyl groups in the network. Both the imine and hydrogen bonds endowed the thermoset with malleability and rapid self-repairing properties in comparison to values commonly reported in literature.103,136 Although the Tg of ELA-BIA was 20 °C higher, its relaxation time (1838 s) was significantly faster than that of ELA-DDM (4588 s) at 170 °C. The chemical recyclability was proven, and the maximum degradation rate was observed in mixtures with an ethanol:acidic water ratio of 8:2. On the other hand, slow degradation rates were registered for mixtures with higher ethanol content, likely because the amount of water was not enough to induce the hydrolysis of imine bonds. ELA-DDM turned out to be more easily degradable than ELA-BIA; this was ascribed to its lower crosslink and hydrogen bond density, which likely makes the Schiff base bonds more accessible to the water molecules.

In the framework of photopolymerized imine thermosets, vanillin and several other biobased aromatic aldehydes are particularly suitable. The phenolic hydroxy groups can be functionalized by (meth)acrylation, and the imine groups are introduced by the Schiff base reaction between the aldehyde group and di- or trifunctional amines. Recently, several (meth)acrylated vanillin Schiff base resins curable to thermosets by photopolymerization under a UV lamp or by digital light processing 3D printing were prepared.137−139 The physical properties of the resulting thermosets increased with higher crosslink density, which was tunable by selection of the amine (e.g., Tg could be varied from −26 to 83 °C and storage modulus at 20–25 °C from 3 to 3300 MPa). In terms of mechanical recyclability, the grinded thermosets turned out to be reprocessable to continuous films by hot-pressing, thanks to the activation of the imine metathesis pathway (Figure 13). The reprocessed thermosets typically exhibited somewhat lower mechanical properties in comparison to the original samples.

Figure 13.

(a) Images of the samples before and after the self-healing and mechanical recycling by hot pressing. (b) Metathesis pathway enabling self-healing and mechanical recycling. (c) For the chemical recycling, the Schiff base thermoset was immersed in ethylene diamine at 60 °C. The recycled oligomeric product was recovered as powder and mixed with virgin methacrylated extended vanillin and photoinitiator before hot pressing and UV curing. (d) Possible transimination pathway to solubilize the cured thermoset in ethylene diamine and possible reactions occurring during hot-pressing and UV curing of the product recovered from chemical recycling and added fresh methacrylated extended vanillin monomer. Adapted with permission from ref (139). Copyright 2022 The Authors CC-BY 4.0. Published 2022 Elsevier Ltd.

Probably due to the hydrophobic nature of the networks, imparted by the presence of the aromatic vanillin moieties, the networks did not dissolve in acidic aqueous solution. Therefore, chemical recycling by introduction of different amines was investigated to exploit the transimination pathway and imine exchange reactions. The first adopted approach with monoamine demonstrated the dissolution of network structures, but it had a limitation in the inability to reform a crosslinked thermoset structure.137 The replacement of the hexylamine with ethylene diamine resulted in complete dissolution after 4 h at 60 °C, suggesting the occurrence of transimination leading to the transformation of the thermoset into a noncrosslinked oligomeric product (Figure 13), which was further confirmed by 1H NMR and FTIR spectroscopy.139 The recovered product could be mixed and hot-pressed with fresh methacrylated vanillin to induce the formation of new Schiff base linkages between the amine-terminated oligomers and methacrylated vanillin. The chemically recycled thermosets showed an elastic modulus comparable to the mechanically recycled films (342 MPa for the chemically recycled thermoset vs 316 MPa for the mechanically recycled thermoset). Interestingly, the introduction of carbon dots (CD) in methacrylated Schiff base resins before the digital light processing 3D printing had a profound impact on the mechanical and chemical recyclability of the resulting thermosets.140 While a significant decrease in elastic modulus was observed for the Schiff base thermosets, the presence of CD importantly mitigated this phenomenon, resulting in an almost complete preservation of the original mechanical properties in both mechanically and chemically recycled thermosets. This outcome was attributed to the establishment of secondary interactions in the thermosets, highlighting the synergistic effect of dynamic covalent bonds and supramolecular chemistry in enhancing the recyclability.

Designing polymers for facile closed-loop chemical recyclability represents a step forward in the development of sustainable polymers and thermosets, in particular to reduce the need of virgin resources, whether nonrenewable or renewable, and to avoid waste accumulation. In this frame, an interesting class of polyester-imine thermosets was proposed.141 The process included first the synthesis of a polyester prepolymer by ring-opening copolymerization between cyclic anhydride, an epoxide comonomer, and vanillin as a crosslinker. In the second step, the network was crosslinked with a diamine to form covalent adaptive networks. Thanks to the activation of the imine metathesis pathway, the obtained thermosets demonstrated good mechanical recyclability, enabled reaching an almost complete recovery of the mechanical properties by performing a hot-press step at 100 °C for 30 min. Furthermore, from the FTIR analysis, no chemical changes were detected in the chemical structure of the thermosets after the mechanical recycling. Similar to the previously reported works, the dissociation of the imine bonds was triggered under acidic conditions. By inducing a precipitation in methanol, it was possible to recover the prepolymer with a yield of 91%. 1H and 13C NMR confirmed the retention of a structure similar to the original prepolymer. However, the presence of a small number of pendant amines and the occurrence of dimerization was also confirmed. A further step to definitely close the loop would be a demonstration of reuse of the prepolymer to reform the thermoset by a Schiff base reaction with diamine.

The synergistic effect of ester and imine functions to facilitate the chemical recyclability was recently demonstrated.142 A resin was composed of 50 wt % methacrylated isosorbide monomer and 50 wt % methacrylated vanillin Schiff base monomer. The chemical and mechanical recycling of the resulting thermoset, produced by means of digital light processing 3D printing, was compared with printed thermosets obtained from a resin composed of 75 or 50 wt % of methacrylated isosorbide and 25 or 50 wt % of methacrylated vanillin (i.e., two resins contained only ester groups and no imine groups). The 75/25 ester thermoset (MI75) proved to be chemically recyclable but exhibited a drastic decrease in the elastic modulus (2 GPa for the original thermoset vs 0.4 GPa for the recycled one). Conversely, the elastic modulus of the thermoset containing both ester and imine groups (SB_MI50) was preserved after the chemical recycling procedure (1.1 GPa for the original thermoset vs 1.0 GPa for the recycled one). An attempt to recycle the thermosets obtained from 50 wt % methacrylated isosorbide monomer and 50 wt % methacrylated vanillin (MI50) was not successful, only yielding a jelly-like sticky material, supporting the important role of the imine functionalities (Figure 14).

Figure 14.

Chemical recycling scheme for polyester (MI75 and MI 50) and polyester-imine (SB_MI50) thermosets including images of the resulting recycled products and recured thermosets. Reproduced with permission from ref (127). Copyright 2023 The Authors CC-BY 4.0. Published 2023 American Chemical Society.

5.1.2. Biodegradation and Hydrolysis

The potential biodegradation of polyester-imines has been minimally investigated so far. One paper, however, documented the biodegradation potential of linear polyester-imines. First, biodegradable PBS or poly(butylene adipate) (PBA) oligomers with two hydroxyl end groups and a diol compound incorporating imine bonds were coupled by reaction with hexamethylene diisocyanate.143 After the synthesis, polymer films were obtained by hot-pressing at 130 °C for 5 min. All the prepared films exhibited mechanical properties and Tm comparable to LDPE and they were stable in contact with moisture in air. However, they disintegrated in water, with degradation times spanning from 1 h to a few days. The degradation rate could be controlled by the concentration of imine bonds, and the films could be reformed by evaporation of the water and a drying step at 80 °C. In addition, biodegradation of the polymer containing PBS oligomers was tested under simulated industrial composting conditions at 58 ± 2 °C. The degree of biodegradation was quantified by following the amount of CO2 produced, indicating promising biodegradation degrees of 16% after 10 days and 66% after 38 days. It would have been interesting to continue the biodegradation testing to see if >90% biodegradation can be reached.

Linear polyester-imine polymers, such as oxime and/or imine linked PEG-like polymer, have also been developed.144 As a first step, a difunctional PEG-1k benzaldehyde monomer was prepared by exploiting a carbodiimide coupling reaction between dihydroxy PEG-1k and 4-formyl benzoic acid; as a consequence, ester groups were incorporated in the monomer structure. The two terminal aldehydes of the resulting monomer were then reacted with hydroxylamine or a difunctional amine to form oxime and imine groups, respectively. PEG-like polymers comprising of 100% oxime (PEGox), 100% imine (PEGim), or a mixed composition were prepared. The hydrolytic degradation of the polymers was evaluated in a phosphate buffer at pH 7.4. PEGox showed the slowest degradation rate, retaining 75% of its molar mass after 5 days of immersion. Conversely, PEGim dissolved completely after only 4 days. Concerning the polymers with both functional groups, they all showed fast initial weight loss correlating to the fraction of imine bonds in the polymer. As an example, a polymer with 25% imine bonds quickly lost 21% of its initial mass in few hours; then, the weight loss slowly increased to 36% over 5 days of immersion due to the higher hydrolytic stability of the oxime functions. These are interesting results, but further studies should confirm the potential biodegradability of the resulting water-soluble products.

The reported papers mainly exploited the presence of imine functionalities to confer chemical recyclability or degradability to the thermosets. Although ester groups were present, their role in the process was mainly not considered or utilized. A different approach was adopted for a series of linear Schiff base polyesters with different aliphatic/aromatic ratios.145 The polymers were synthesized by subjecting vanillin to a nucleophilic substitution reaction, followed by a Schiff base reaction and a two-step bulk polycondensation protocol (transesterification and polycondensation). Several polyester-imines were subjected to a PETase enzyme for 1 and 24 h at 30 °C. A control experiment was performed under the same conditions but in the absence of the enzyme. A comparison of the samples treated with and without enzymes showed a significant increase in the amount of the degradation products in the presence of enzymes. Furthermore, it was shown that both ester and imine bonds were cleaved during the enzyme-catalyzed hydrolysis. The analysis of the degradation products highlighted the role of the chemical structure on the enzymatic degradability. Aliphatic ester bonds turned out to be more easily cleavable than the aromatic counterpart despite the known ability of PETase to catalyze the hydrolysis of aromatic PET. Moreover, the replacement of aromatic diamines with long aliphatic diamines favored the degradation, probably due to an increase of the substrate flexibility and facilitation of the binding of the enzyme to the active site. In addition to enzyme-catalyzed green chemical recycling, these results give positive indications of potential biodegradability of the materials. Authors also investigated the hydrolytic degradation under acidic conditions at room temperature during 24 h. This approach enabled the obtainment of monomeric dialdehydes and diamines. The recovered monomers did not coincide with the original ones, because the ester bonds were not affected by this procedure. However, the obtained molecules are expected to repolymerizable back to the original polymer structures through Schiff base reaction between the aldehyde and amine functionalities, providing a closed loop.

In conclusion, the incorporation of imine bonds in polyesters is a promising route to circular polymers. Polyester-imines can be fully produced from renewable resources as many suitable aldehydes, ketones, and amines are derivable from biomass, and some already commercial examples include vanillin, levulinic acid, and fatty acid derived diamines. Imine bond provides circularity by both mechanical and chemical recycling routes. Furthermore, recent studies indicate that the imine bond could also be biodegradable, although more studies are required to confirm this and the structural requirements for biodegradation of polyester-imines. For some applications, the imine hydrolysis under acidic aqueous conditions can be a limiting factor. However, the stability of polyester-imines in neutral water is typically good and some are also resistant under moderate acidic conditions.

5.2. Polyester-Disulfide

Traditionally, sulfide bonds exist in vulcanized rubber. More recently, the disulfide bond (S–S), that can be formed through the oxidation reaction of thiols, has been widely explored as a covalent bond capable of introducing self-healing, reprocessability, recyclability, and even (bio)degradability. Disulfide bonds are able to cleave into their respective thiol counterparts under reductive conditions and reconnect again under oxidative conditions.146 Therefore, under controlled pH conditions (reductive or oxidative), the formation and cleavage of the disulfide bond can be manually controlled. Interestingly, some natural environments with a low oxidation reduction potential (i.e., seawater and sediment, river water, and sediment) can also facilitate the cleavage of the disulfide bond into their initial form (i.e., thiols). The reduced compounds can be further metabolized to inorganic compounds, such as CO2 and SO3, by microorganisms. The incorporation of disulfide bonds into a polymer backbone could also facilitate controlled chemical recycling under specific pH conditions, as well as impart the polymer with (bio)degradation in natural environments.282

5.2.1. Chemical Recycling

The potential of disulfide bond in imparting polyesters with (improved) chemical recyclability has so far been hardly explored. Research with regard to chemical recycling and degradation of disulfide containing polymers has mainly focused on the synthesis of recyclable thermosets. In this regard, a series of novel recyclable thermosets were designed to have ester and disulfide linkages, using simple condensation and epoxy chemistry.147 The epoxy ester thermosets were synthesized by reacting 4,4′-dithiodibutyric acid (DTDBA) with two epoxy monomers; difunctional bisphenol A diglycidyl ether (BADGE) and trifunctional triphenylolmethane triglycidyl ether (TMTE), to form thermosets with ester or ester and disulfide linkages, varying in crosslink density (Figure 15).

Figure 15.

Synthesis of epoxy-thermosets with ester and disulfide or only ester linkages. The presence of disulfide linkages enabled chemical recycling under mild conditions in the presence of reducing agent 2-mercaptoethanol. The thermoset with only ester bonds remained stable under the same conditions.147

The resulting thermosets exhibited good mechanical strength (reaching 29.7 MPa with maximum crosslink density) and low to moderate flexibility (14–92%). Moreover, all thermosets were thermally stable up to 260 °C. At the same time, the materials showed good mechanical recyclability at temperatures 120–200 °C without significant loss in mechanical properties even after two reprocessing cycles. This thermal reprocessability was attributed to the dynamic behavior of the disulfide bonds. Chemical recycling of the thermosets was evaluated by immersing the thermosets in pure dimethylformamide (DMF) and a mixture of DMF with the reducing agent 2-mercaptoethanol, respectively. The thermosets retained their original shape after 36 h in pure DMF. However, in the presence of a reducing agent, the thermosets had been completely dissolved after 36 h. For comparison, a similar ester-based thermoset without disulfide bonds, synthesized by replacing DTDBA by succinic acid (SA), did not show any decomposition in the presence of the reducing agent. The chemical recycling was therefore facilitated through the reversible cleavage of the disulfide bond under reductive conditions.