Abstract

Biji (okara or soybean curd residue), a by-product of soybean processing, contains proteins. In this study, control plant-based patties were compared with patties supplemented with biji powder (5, 10, 15, and 20 g). Increasing the amount of biji added to patties was found to be favorably associated with increased water-holding capacity, decreased cooking loss, and reduced diameter and thickness. Texture profile analysis revealed trends of increased hardness, springiness, cohesiveness, and chewiness which were proportional to the inclusion of biji powder. The volatile compounds in plant-based patties supplemented with biji were analyzed using HS-SPME-Arrow-GC/MS. Notably, benzaldehyde, nonanal, and 2-heptanone, which are undesirable flavors, were detected at significantly lower levels in patties supplemented with biji. Therefore, biji can serve as a supplementary ingredient to enhance the texture and flavor of plant-based patties.

Keywords: Biji, Plant protein, Patties, Quality characteristics, Volatile compounds

Highlights

-

•

The profile of plant-based patties was improved by supplementation with biji.

-

•

Twenty grams of Biji powder improved the overall quality characteristics of patties.

-

•

HS-SPME Arrow method revealed the volatile compounds in plant-based patties.

-

•

Enhancing the texture and flavor of meat requires additional ingredients.

1. Introduction

According to the latest projections by the United Nations (UN), the global population may grow to approximately 8.5 billion by 2030 and 9.7 billion by 2050 (UN DESA, Population Division, 2022). Global meat production is projected to reach 377 Mt. by 2031, owing to increasing profitability in the early years of the outlook period because meat prices rebounded post-COVID-19 and feed costs declined. In addition to population growth, the determinants of meat consumption are complicated, and include demographics, income, prices, urbanization, traditions, religious beliefs, environmental and health concerns, and ethical and animal welfare (OECD/FAO, 2022). Consumers express concerns regarding meat production systems, especially animal welfare, which includes traceability and a growing preference for antimicrobial-free meat owing to the health risks associated with antimicrobial resistance. Antimicrobial-free organic meat production systems are being used by a growing number of producers. Thus, the global meat market is expected to grow as consumers are willing to pay a premium for such meat (OECD/FAO, 2022). High meat prices have prompted the food industry to produce nomeat proteins. Plant proteins are less expensive than muscle proteins and can reduce costs relative to those of the original meat product. The increased acceptance of plant proteins such as texturized soy protein (TSP) owes to their low cost.

The high biological value of meat products is attributed to their primary nutrients such as proteins, vitamins, and minerals. However, excessive ingestion of meat products cannot be advised from a health perspective, especially for groups with specific health conditions because of their high fat content. Meat has a higher proportion of saturated fatty acids than polyunsaturated fatty acids (PUFAs) and contains cholesterol, which causes chronic diseases such as diabetes, colon cancer, and cardiovascular diseases (Muguerza et al., 2004). On the other hand, soy products such as tofu, soy butter, soy nuts, and some soy burgers, could be beneficial to cardiovascular and overall health due to their high content of polyunsaturated fats, fiber, vitamins, and minerals, and low content of saturated fat (Jiménez-Escrig et al., 2008). As an energy source for supplying the proteins necessary for humans, the development of meat analogs processed with alternative materials, such as vegetables, is crucially required (Azman et al., 2023). As an excellent source of meat analogs, textured vegetable protein (TVP) containing soybeans resembles meat in appearance, color, flavor, and texture when hydrated and cooked and provides high-quality protein. However, improving all characteristic attributes of meat products, which must be added to meat analogs by food scientists and the food industry, remains challenging.

Biji, also known as okara or soybean curd residue, is a by-product that remains after water-soluble substances are filtered by soaking, grinding, and sieving during the manufacturing of soymilk and tofu (Kang et al., 2018). Currently, biji is considered industrial waste and is prohibited from being burned and disposed of in a landfill (Lee et al., 2007). Raw biji, which is used as a material for processed or novel foods, is stored frozen or processed into dried biji powder by drying and grinding to increase its preservation. The practice of discarding the byproducts of food processing leads to economic losses and environmental damage. Thus, to ensure efficient and environmentally sound utilization, this material can be used for alternative purposes and continuous value-added creation. Biji is reported to be effective against constipation and weight loss and helps control blood triglyceride and blood sugar levels (Li et al., 2012). Despite the extraction of water-soluble substances from soybeans, biji also contains significant amounts of protein and carbohydrates. When the essential amino acid contents of the biji protein were compared with FAO/WHO standards (amino acid scoring pattern), the contents of threonine, valine, isoleucine, leucine, phenylalanine, and lysine were either higher or similar (Ma et al., 1996).

Meat analogs are composed of substances that mimic the flavor of meat. With the development of new raw materials and flavor enhancers, meat analogs have become the focus of food research (Zhang et al., 2023). Volatile organic compounds play a crucial role in food quality by influencing flavor (Song et al., 2019). Various extraction methods, such as steam distillation under reduced pressure (DRP-LLE) and stir bar sorptive extraction (SBSE), have been used to analyze volatile compounds in foods (Kim et al., 2019; Song et al., 2021). Among the various extraction methods, headspace extraction is a solvent-free, sensitive, and selective technique well suited for a wide range of samples, including food and fragrances (Song et al., 2019). Headspace extraction provides higher recoveries than other extraction methods such as DRP-LLE, direct solvent extraction (DSE), solvent-assisted flavor evaporation (SAFE), and vacuum simultaneous steam distillation solvent extraction (V-SDE) (Lee et al., 2019). Solid phase microextraction (SPME) is frequently used as a headspace technique to extract volatile compounds (Jang et al., 2021). This headspace technique is a low-cost and low-labor method compared to other headspace methods such as dynamic headspace (DHS) and SBSE (Song et al., 2019). Recently, SPME-arrow, a new model that combines the benefits of SPME and SBSE, has been developed (Jang et al., 2021; Song et al., 2019). SPME-arrow uses large sorbent material volumes to improve the detection limit of SPME (Song et al., 2019).

Although studies on biji, including meat analogs with fermented okara (soybean curd residue) (Razavizadeh et al., 2021), vegan soft cheese with okara (Szulc et al., 2023), and rice noodles with okara (Kang et al., 2018) have been conducted, the development of meat analogs with food byproducts remains insufficient. Additionally, no studies have examined the physicochemical characteristics and volatile compounds of plant-based patties supplemented with biji powder. In this study, plant-based patties were processed with freeze-dried and powdered biji to confirm the potential of biji as an additional ingredient. This study aimed to analyze the physicochemical quality characteristics and volatile compound profiles of plant-based patties after the addition of biji to determine the potential of the by-products.

2. Materials and methods

2.1. Materials

TVP was purchased from Hokyoung-Tech (Anseong, Republic of Korea). Biji (Soybean curd residue) was purchased from Ourhome (Seoul, Korea), freeze-dried at −80 °C for one week, and used after being powdered using a mixer (HR2291/20, Philips, Maidstone, Netherlands). Coconut oil, gluten, konjac, potato starch, isolated soy protein (ISP), transglutaminase (TG), phosphate, and salt were purchased from Esfood (Gunpo, Republic of Korea) and used as raw materials. Internal standards (phenyl acetate, toluene‑d8, 3-octanone, and 3,4-dimethyl phenol, octanal, 2,2-dimethylpropanoic acid, 1-hexyl alcohol-d13, and 2-methylpyrazine) were purchased from Sigma Aldrich (St. Louis, MO, USA).

2.2. Preparation of plant–based patties supplemented with biji

Five patties were prepared according to biji powder content (Table 1). Following the removal of residual water from the TVP, which was sufficiently hydrated for >1 h, the sample was ground using a meat grinder (MG510; Kenwood, Hampshire, England). Coconut oil, gluten, konjac, potato starch, isolated soy protein (ISP), transglutaminase (TG), phosphate, salt, and biji powder were sieved twice added to the ground TVP; and mixed for 3 min. After the mixing process, the mixture was shaped using a household patty mold (PM 10/13 Burger press, AB Services Food Machinery, Coventry, England; diameter: 10.0 cm, thickness: 2.3 cm), resulting in samples with a size of approximately 15 × 90 mm and weight of approximately 100 g. Patties were stored at −18 °C until used in the experiments. An electric oven (ML39BW; LG) was used to heat the patties. Patties were roasted on a preheated electric grill at an oven temperature of 180 °C for 30 min. The plant-based patties (PB) were supplemented with various amounts of biji powder in the following: control, without biji powder; PB1, 5 g; PB2, 10 g; PB3, 15 g; PB4, 20 g.

Table 1.

Formulation of the plant-based patties supplemented with different amounts of biji powder.

| Ingredients (g) | Treatments |

||||

|---|---|---|---|---|---|

| Control | PB1 | PB2 | PB3 | PB4 | |

| TVP | 80 | 80 | 80 | 80 | 80 |

| Coconut Oil | 20 | 20 | 20 | 20 | 20 |

| Total | 100 | 100 | 100 | 100 | 100 |

| Gluten | 3 | 3 | 3 | 3 | 3 |

| Konjac | 3 | 3 | 3 | 3 | 3 |

| Potato Starches | 4 | 4 | 4 | 4 | 4 |

| ISP | 1 | 1 | 1 | 1 | 1 |

| TG | 1 | 1 | 1 | 1 | 1 |

| Phosphate | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Salt | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| biji powder | 0 | 5 | 10 | 15 | 20 |

2.3. pH

Forty-five milliliters of distilled water and 5 g of patties were homogenized and filtered using filter paper (Whatman No. 1, Whatman™, Maidstone, England). The pH was measured using a pH meter (Starter 3100 M; Ohaus, New Jersey, USA).

2.4. Color

The lightness (L*), redness (a*), and yellowness (b*) of the patty surfaces were measured before and after heating using a colorimeter (CR-400, Minolta Co., Ltd., Osaka, Japan; calibrated with a white plate, L* = +66.88, a* = −1.54, b* = +25.89).

2.5. Cooking loss

The patties were heated until the core temperature reached 75 °C and left at room temperature (21–23 °C) for 30 min (Kim et al., 2019). Cooking loss was determined using the following formula:

2.6. Water-holding capacity (WHC)

The WHC of the heated patties were measured using a modified version of the filter paper press method (Kim et al., 2019). Briefly, a filter paper (Whatman No. 2, Whatman™, Maidstone, England) was placed in the center of a specially designed plexiglass plate and 300 mg of the sample was placed on top. One plexiglass plate was then overlapped and compression was performed for 3 min. At the end of the compression, the filter paper was removed and the areas of the patty pieces and moisture were measured using a digital planimeter (Planix 7; Tamaya Technics Inc., Tokyo, Japan) to determine the WHC using the following formula:

2.7. Reduction of diameter and thickness

The diameter and thickness before and after heating were measured at the same point using a digital caliper (CD-15APX; Mitutoyo Corporation, Kawasaki, Japan) and their respective reductions were calculated using the following formulas:

2.8. Proximate composition

The proximate composition was measured, according to the method described by AOAC Official Methods 931.04, 940.26, 955.04, 920.39 (2000). The moisture content was determined using the 105 °C hot-air drying method. Crude ash, crude protein, and crude lipid were measured using the 550 °C classical dry ashing technique, Kjeldahl and Soxhlet, respectively.

2.9. Texture profile analysis (TPA)

Texture was measured using a texture analyzer (TA.XT Express v2.1, Stable Micro System, London, UK). Prior to analysis, the patties were allowed to reach room temperature (21–23 °C) for 30 min. After the patties were cut into 2.5 × 2.5 cm sections, hardness (N), springiness (mm), cohesiveness, and chewiness (mJ) were measured (Kim et al., 2022). The following conditions were employed: cylindrical probe, 10 mm in diameter; test speed, 3.0 mm/min; strain, 50% (250 N); and trigger force, 0.05 N.

2.10. HS-SPME-Arrow-GC/MS analysis

A headspace-solid phase microextraction Arrow (HS-SPME Arrow) method was coupled with gas chromatography mass spectrometry (GC–MS, Agilent Technologies, Santa Clara, CA, USA) equipped with an HP-5MS column (60 m × 0.25 mm I.D. × 0.25 μm film thickness, Agilent J&W GC columns, Santa Clara, CA, USA). This method was modified based on a previous study that analyzed volatile compounds (Song et al., 2019). The SPME-Arrow fiber was a divinylbenzene carboxen polydimethyl-siloxane (DVB/CAR/PDMS) with a film thickness of 120 μm (PAL System, Zwingen, Switzerland) (Ahamed et al., 2023; Lee et al., 2022). Briefly, 1 g of cooked sample was weighed into a 20 mL headspace vial (Wheaton, Millville, USA) and 10 μL of the internal standard (IS) mixture (phenyl acetate, toluene‑d8, 3-octanone, and 3,4-dimethyl phenol of 5 μg/mL; octanal, 2,2-dimethylpropanoic acid, 1-hexyl alcohol-d13, and 2-methylpyrazine of 100 μg/mL) was added to the vial. Thereafter, the vials were sealed with 18 mm magnetic screw caps (Wheaton, Millville, USA) and 18 mm transparent blue silicone/PTFE septa (Wheaton, Millville, USA). The sample was incubated in an autosampler tray (PAL RSI 85 autosampler system, Agilent Technologies, Santa Clara, CA, USA) at 50 °C for 10 min and agitated at 500 rpm. The SPME-Arrow fiber was inserted into the headspace and extraction was performed for 30 min with continuous heating and agitation at 1000 rpm. After extraction, the SPME fiber was injected into the GC/MS injector with split mode (5:1) and desorbed at 220 °C for 5 min. GC/MS analysis was performed using Agilent Technologies GC model 8890 and MS model 7000E GC/TQ. The oven temperature was maintained at 35 °C for 5 min, increased to 215 °C at a rate of 4 °C/min, increased to 250 °C at a rate of 7 °C/min, and held at this temperature for 5 min. Helium was used as a carrier gas at a flow rate of 1.0 mL/min. The MS was operated in electron impact mode (EI/MS) at 70 eV and scanned in the range of 45–500 m/z.

2.11. Identification of volatile compounds

The volatile compounds were identified based on the Kovats index (KI) (Kovats, 1965). KI was calculated using the following equation with an alkane standard mixture (C7–C40) under the same chromatographic conditions. Volatile compounds were identified using the NIST 20 library (National Institute of Standards and Technology, Gaithersburg, MD, USA) with an R-match score ≥ 700.

KI = Kovats index of compound X.

n = number of carbon atoms in the smaller n-alkanes eluted before compound X.

N = number of carbon atoms in the larger n-alkane eluting after compound X.

= retention time of compound.

Internal standards specific to each group of volatile compounds were chosen (Lee et al., 2022). The volatile compounds were quantified using the following equation:

X⁎ = the relative concentration of volatile compounds (ng/g).

2.12. Statistical analysis

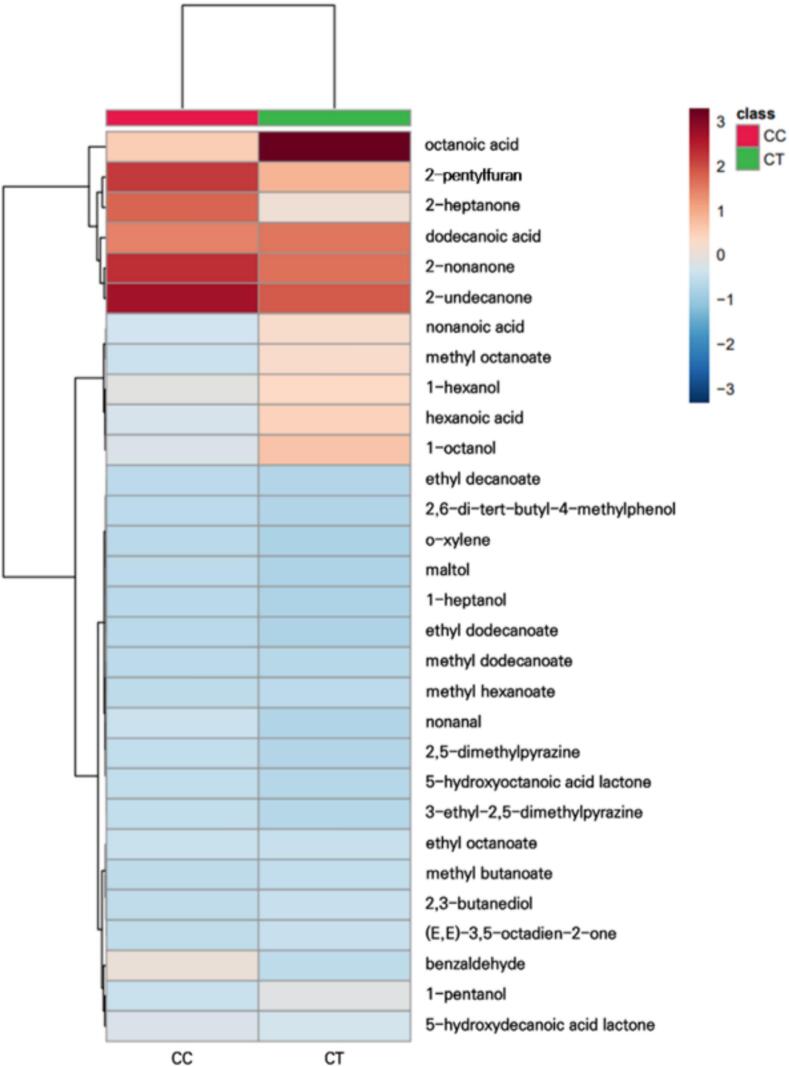

Data were analyzed by analysis of variance (ANOVA) and Duncan's multiple range test using SPSS Ver. 26 for Window (Statistics Package for the Social Sciences, IBM-SPSS Inc., Chicago, IL, USA) to identify significant differences (p < 0.05). The extraction of volatile compounds by GC and their identification by MS were performed in triplicate. Mean and standard deviation (SD) were obtained using Microsoft Office Excel 2021 (Microsoft, Corporation, Redmond, WA, USA). Student's t-test (p < 0.05) was used to verify the significance of differences between groups. Heatmap and hierarchical clustering based on Euclidean's correlation coefficient of the flavor profiles were generated using MetaboAnalyst 5.0 software (https://www.metaboanalyst.ca/), after normalizing the volatile compounds. All experiments were performed in triplicates.

3. Results and discussion

3.1. pH and color

As shown in Table 2, plant-based patties supplemented with different amounts of biji powder had lower pH values than the control (pH 5.90) and these values decreased significantly as the amount of biji powder increased (p < 0.05). Similar results were obtained by Lee and Kim (2022), who prepared soy sauce using biji powder. As the pH of PB4 is influenced by the pH of the additives, the decrease in the pH of the plant-based patties in this experiment may have been due to the pH of the biji powder.

Table 2.

Effect of the amount of biji powder on the pH and color of plant-based patties.

| Parameters | Control | PB1 | PB2 | PB3 | PB4 | |

|---|---|---|---|---|---|---|

| pH | 5.90 ± 0.03a | 5.74 ± 0.07ab | 5.65 ± 0.27b | 5.53 ± 0.05b | 5.59 ± 0.03b | |

| Uncooked | L* | 59.54 ± 0.92d | 60.23 ± 0.34d | 61.27 ± 0.40c | 62.62 ± 0.29b | 63.76 ± 0.54a |

| a* | 5.24 ± 0.03a | 4.94 ± 0.14b | 4.88 ± 0.10b | 4.76 ± 0.15b | 4.46 ± 0.08c | |

| b* | 10.11 ± 0.47c | 10.25 ± 0.10c | 11.12 ± 0.27b | 11.32 ± 0.06ab | 11.69 ± 0.35a | |

| Cooked | L* | 55.87 ± 0.35d | 57.34 ± 0.08c | 59.76 ± 0.58b | 60.78 ± 0.11ab | 61.68 ± 1.32a |

| a* | 5.87 ± 0.12a | 5.42 ± 0.12ab | 5.24 ± 0.18bc | 5.11 ± 0.43bc | 4.90 ± 0.29c | |

| b* | 10.43 ± 0.40b | 10.86 ± 0.42b | 11.55 ± 0.11a | 11.69 ± 0.24a | 11.80 ± 0.19a | |

All values are expressed as mean ± SD (n = 3);

Values in a column with different letters (a-d) are significantly different based on p < 0.05 using the Duncan's multiple range test.

The effects of biji powder on the color of the plant-based patties are shown in Table 2. Significant differences in lightness, redness, and yellowness were observed for the plant-based patties supplemented with biji powder (Table 2). Biji powder increased the L* and b* values of both the uncooked and cooked plant–based patties (p < 0.05). The highest a* values for the uncooked and cooked plant–based patties were obtained for the control, and the a* values of the plant–based patties decreased as biji powder content increased (p < 0.05). Similar results were reported in a previous study on beef patties supplemented with biji (Turhan et al., 2009). These findings suggest that the addition of biji powder tends to increase the lightness and yellowness and decrease the redness, leading to patties with a biji-specific color.

3.2. Cooking loss and WHC

The cooking loss and WHC results are the same as those presented in Table 3. In general, patty cooking loss is an important factor that must be controlled to ensure product quality. Cooking loss was significantly lower (p < 0.05) in plant-based patties containing biji powder than that in the control patties. The WHC of patties was highest in PB4 and lowest in the control. As the amount of biji powder increased, cooking loss increased significantly (p < 0.05), contradicting the trend observed for cooking loss. Similar results were observed in a previous study (Turhan et al., 2009). Biji is recognized for its high content of dietary fiber, particularly insoluble dietary fiber, which binds starch and water, helping to retain moisture in the food matrix (Jiménez-Escrig et al., 2008; Kang et al., 2018). Dosh et al. (2015) reported that the dietary fiber in the additive forms a three-dimensional matrix in the patty to prevent water loss, which reduces cooking loss. Therefore, the addition of biji powder could be an effective method for reducing cooking loss of patties and increasing their WHC.

Table 3.

Effect of the amount of biji powder on the cooking loss, water-holding capacity, and reduction of diameter and thickness of plant-based patties.

| Parameters (%) | Control | PB1 | PB2 | PB3 | PB4 |

|---|---|---|---|---|---|

| Cooking loss | 13.00 ± 0.17a | 12.23 ± 0.12ab | 12.00 ± 0.36b | 11.97 ± 0.35b | 10.83 ± 0.97c |

| Water-holding capacity | 70.04 ± 1.47e | 72.48 ± 1.29d | 77.11 ± 0.90c | 80.80 ± 0.70b | 91.73 ± 0.99a |

| Reduction of diameter | 7.53 ± 0.15a | 6.77 ± 0.06b | 5.74 ± 0.07c | 5.38 ± 0.06d | 4.53 ± 0.07e |

| Reduction of thickness | 3.31 ± 0.29a | 1.13 ± 0.20b | 0.38 ± 0.08c | 0.28 ± 0.04c | 0.10 ± 0.04c |

All values are expressed as mean ± SD (n = 3);

Values in a column with different letters (a-e) are significantly different based on p < 0.05 using Duncan's multiple range test.

3.3. Reduction of diameter and thickness

Significant differences were observed in the diameter and thickness of plant-based patties supplemented with biji powder (Table 3). The reductions in diameter and thickness of the patties supplemented with biji powder were significantly lower than those of the control patties (p < 0.05). This result may be due to improvements in the WHC caused by the inclusion of dietary fiber in biji. A previous study also considered the contribution of dietary fiber in reducing the diameter and thickness (Turhan et al., 2009).

3.4. Proximate composition

The proximate compositions of plant-based patties supplemented with different amounts of biji powder are shown in Table 4. Based on their moisture content, plant-based patties can hold water after cooking. The moisture content varied from 15.37 to 19.02%. The addition of biji powder increased the moisture content of the patties; however, the values did not significantly (p > 0.05) differ from those of the control patties. This result is consistent with that of previous study on beef patties supplemented with a pea protein isolate (Baugreet et al., 2016). Conversely, the crude protein content of plant-based patties was significantly increased (p < 0.05). PB4 exhibited a significantly higher (p < 0.05) protein content (20.26%) than the control (19.23%) and the other samples. The protein content in plant-based patties supplemented with freeze-dried and powdered biji was 16.40%. The increase in crude protein, ash, and fat composition of patties supplemented with biji powder can be attributed to the ingredient content of the freeze-dried biji powder. This result aligns with that obtained for beef patties supplemented with a pea protein isolate (Baugreet et al., 2016) which was found to have rich protein content. The crude ash content ranged from 1.02 to 1.38 and was significantly higher in PB3 (p < 0.05). The crude fat content in all groups treated with biji powder was significantly higher than that in the control group (6.82%).

Table 4.

Effect of the amount of biji powder on the proximate composition of plant-based patties.

| Parameters (%) | Control | PB1 | PB2 | PB3 | PB4 |

|---|---|---|---|---|---|

| Moisture Content | 15.37 ± 1.14a | 15.92 ± 0.79a | 16.50 ± 0.21a | 17.62 ± 1.43a | 19.02 ± 2.79a |

| Crude Protein | 19.23 ± 0.06d | 19.23 ± 0.07d | 19.79 ± 0.05c | 20.05 ± 0.02b | 20.26 ± 0.07a |

| Crude Ash | 1.02 ± 0.00c | 1.04 ± 0.02c | 1.04 ± 0.02c | 1.20 ± 0.02b | 1.38 ± 0.01a |

| Crude Fat | 6.82 ± 0.39d | 7.62 ± 0.00c | 8.39 ± 0.45b | 8.69 ± 0.05ab | 9.28 ± 0.18a |

All values are expressed as mean ± SD (n = 3);

Values in a column with different letters (a-d) are significantly different based on p < 0.05 using Duncan's multiple range test.

3.5. Texture profile analysis (TPA)

Meat analogs, such as plant-based patties are vegetable protein products designed to mimic the appearance, color, flavor, and texture of meat products. By adding minor ingredients or chemicals, the range of raw ingredients can be improved and made suitable for the processing of texturized vegetable protein products. The plant-based patties showed different texture profiles, such as hardness, springiness, cohesiveness, and chewiness, when supplemented with biji powder (Table 5). Among the textural characteristics, hardness is the most important factor affecting consumer preferences for meat products. The hardness of the patties supplemented with biji powder ranged from 3.32 to 8.48 and increased significantly compared to that of the control, according to the amount of biji powder (p < 0.05). This result is consistent with previous studies that reported an increase in hardness with an increase in powdered foods (Kang et al., 2018). The springiness range significantly increased from 1.05 to 1.23 compared with that of the control (0.91) (p < 0.05). However, no significant differences were observed in the springiness values of PB3 and PB4 (p > 0.05). The values for cohesiveness and chewiness ranged from 0.35 to 0.50 and 1.12 to 5.11, respectively and were found to significantly increase (p < 0.05). The addition of orange dietary fiber increased the hardness and chewiness of patties, which was attributed to the binding ability induced during heating (Viuda-Martos, Ruiz-Navajas, Fernández-López, & Pérez-Álvarez, 2010). The hardness of the patties is assumed to be enhanced by the high moisture content and abundant dietary fiber of biji.

Table 5.

Texture properties of plant-based patties supplemented with different amounts of biji powder.

| Parameters | Control | PB1 | PB2 | PB3 | PB4 |

|---|---|---|---|---|---|

| Hardness (N) | 3.32 ± 0.17e | 4.66 ± 0.30d | 5.63 ± 0.15c | 6.95 ± 0.66b | 8.48 ± 0.16a |

| Springiness (mm) | 0.91 ± 0.02d | 1.05 ± 0.02c | 1.13 ± 0.07b | 1.19 ± 0.02a | 1.23 ± 0.02a |

| Cohesiveness | 0.35 ± 0.03c | 0.43 ± 0.01b | 0.46 ± 0.02ab | 0.47 ± 0.03ab | 0.50 ± 0.03a |

| Chewiness (mJ) | 1.12 ± 0.12e | 1.88 ± 0.20d | 2.53 ± 0.25c | 3.44 ± 0.25b | 5.11 ± 0.29a |

All values are expressed as mean ± SD (n = 3);

Values in a column with different letters (a-e) are significantly different based on p < 0.05 using Duncan's multiple range test.

3.6. Volatile compound analysis

The volatile compounds in the plant-based patties were determined using HS-SPME-Arrow-GC/MS. The calculated concentrations (ng/g of plant-based patties), Kovats index values, and aroma descriptions are shown in Table 6. Cooked control and plant-based patties containing biji powder were selected and compared for the extraction of volatile compounds. Thirty compounds were detected in the samples: four acids, five alcohols, two aldehydes, seven esters, one furan, one hydrocarbon, four ketones, two lactones, one phenol, one pyran, and two pyrazines. Seventeen compounds identified in the cooked controls were also present in PB4. In patties containing biji, additional 13 compounds were identified: three acids, four alcohols, five esters, and one ketone.

Table 6.

Concentration of volatile compounds in the headspace of cooked plant-based patties.

| Compounds | KI1 | KI2 | Relative Concentration (ng/g) |

p-Value4 | Aroma description5 | |

|---|---|---|---|---|---|---|

| Control3 | PB4 | |||||

| Acids (4) | ||||||

| dodecanoic acid | 1582 | 1584 | 753.25 ± 18.10b | 1291.50 ± 56.91a | ⁎⁎ | fat, fruit |

| hexanoic acid | 992 | 992 | ND | 698.06 ± 40.84 | ⁎⁎⁎ | cheese, fermented, pungent |

| nonanoic acid | 1285 | 1284 | ND | 577.49 ± 35.47 | ⁎⁎⁎ | fat, green |

| octanoic acid | 1186 | 1186 | ND | 2218.48 ± 81.62 | ⁎⁎⁎ | cheese, fat, fermented |

| Alcohols (5) | ||||||

| 1-heptanol | 982 | 982 | ND | 19.83 ± 0.34 | ⁎⁎⁎ | green, wood |

| 1-hexanol | 887 | 887 | 199.52 ± 2.72b | 639.91 ± 53.13a | ⁎⁎ | bread, flower, fruit, grass, green |

| 1-octanol | 1089 | 1089 | ND | 806.66 ± 40.93 | ⁎⁎⁎ | citrus, fat, fruit, green |

| 1-pentanol | 755 | 755 | ND | 373.41 ± 9.06 | ⁎⁎⁎ | almond, balsamic, fruit, green |

| 2,3-butanediol | 824 | 828 | ND | 171.19 ± 10.52 | ⁎⁎⁎ | cream, floral, fruit, herb |

| Aldehydes (2) | ||||||

| benzaldehyde | 982 | 982 | 256.88 ± 12.80a | 116.77 ± 6.53 b | ⁎⁎ | almond, berry, bitter, bitter almond, burnt sugar |

| nonanal | 1126 | 1126 | 81.91 ± 6.49a | 33.76 ± 1.48b | ⁎⁎ | citrus, cucumber, fat, floral, green |

| Esters (7) | ||||||

| ethyl decanoate | 1407 | 1419 | ND | 53.36 ± 1.47 | ⁎⁎⁎ | brandy, burnt, fruit, geranium, grape |

| ethyl dodecanoate | 1603 | 1621 | ND | 24.32 ± 1.49 | ⁎⁎⁎ | cream, floral, fruit, green apple, leaf |

| ethyl octanoate | 1215 | 1218 | 66.58 ± 1.57b | 180.55 ± 2.79a | ⁎⁎ | apricot, banana, brandy, fresh, fruit |

| methyl butanoate | 745 | 742 | ND | 144.46 ± 10.09 | ⁎⁎⁎ | apple, banana, cheese, floral |

| methyl dodecanoate | 1533 | 1551 | ND | 83.65 ± 6.70 | ⁎⁎⁎ | coconut, fat |

| methyl hexanoate | 938 | 945 | ND | 106.08 ± 3.70 | ⁎⁎⁎ | fresh, fruit, pineapple, sweet |

| methyl octanoate | 1138 | 1146 | 79.37 ± 3.16b | 589.47 ± 42.92a | ⁎⁎ | fruit, orange, sweet, wine |

| Furan (1) | ||||||

| 2-pentylfuran | 1012 | 1011 | 1025.61 ± 45.10 | 916.53 ± 51.29 | NS | butter, floral, fruit, green, green bean |

| Hydrocarbon (1) | ||||||

| o-xylene | 911 | 912 | 1.95 ± 0.03b | 2.34 ± 0.06a | ⁎⁎ | geranium |

| Ketones (4) | ||||||

| (E,E)-3,5-octadien-2-one | 1107 | 1114 | ND | 181.23 ± 3.80 | – | almond, balsamic, dill, sweet, vanilla |

| 2-heptanone | 908 | 908 | 868.00 ± 25.14a | 512.45 ± 22.32b | ⁎⁎ | bell pepper, blue cheese, cinnamon, fruit, green |

| 2-nonanone | 1104 | 1112 | 1067.57 ± 32.71b | 1314.18 ± 45.90a | ⁎⁎ | fragant, fruit, green, hot milk, oil |

| 2-undecanone | 1315 | 1317 | 1203.13 ± 42.25b | 1451.22 ± 49.87a | ⁎⁎ | fresh, green, orange, pineapple, rose |

| Lactones (2) | ||||||

| 5-hydroxydecanoic acid lactone | 1526 | 1531 | 38.25 ± 0.93b | 57.89 ± 0.94a | ⁎⁎ | apricot, butter, coconut, peach |

| 5-hydroxyoctanoic acid lactone | 1306 | 1314 | 157.73 ± 8.90b | 258.93 ± 15.08a | ⁎⁎ | butter, coconut, peach |

| Phenol (1) | ||||||

| 2,6-di-tert-butyl-4-methylphenol | 1545 | 1548 | 15.04 ± 0.17b | 42.30 ± 1.34a | ⁎⁎ | toasted cereal |

| Pyran (1) | ||||||

| maltol | 1139 | 1138 | 14.37 ± 0.75b | 24.73 ± 0.65a | ⁎⁎ | butterscotch, caramel, cotton candy, malt, roasted bread |

| Pyrazines (2) | ||||||

| 2,5-dimethylpyrazine | 932 | 932 | 46.67 ± 1.04b | 51.88 ± 1.47a | ⁎⁎ | cocoa, coffee |

| 3-ethyl-2,5-dimethylpyrazine | 1099 | 1100 | 42.65 ± 0.41b | 65.74 ± 4.00a | ⁎ | broth, chocolate, earth, must, potato |

NS, not significant.

ND, not detected.

NS: p > 0.05.

6All values are presented as mean ± standard deviation (n = 3).

Kovats index obtained from NIST available at https://webbook.nist.gov/chemistry/cas-ser/ for HP-5MS columns or equivalents.

Kovats index calculated using n-alkanes for the HP-5MS column.

Control, untreated; PB4, plant-based patty supplemented with 20 g biji powder.

Values with different uppercase letters in the same row are significantly different according to Student's t-test (p < 0.05).

p < 0.001.

p < 0.01.

p < 0.05.

Aroma character from https://www.vcf-online.nl/VcfCompoundSearch.cfm.

Control patties had high concentrations of 2-undecanone (1203.13 ng/g), 2-nonanone (1067.57 ng/g), and 2-pentylfuran (1025.61 ng/g) whereas patties supplemented with biji had octanoic acid (2218.48 ng/g), 2-undecanone (1451.22 ng/g), and 2-nonanone (1314.18 ng/g) as major compounds. The levels of 2-undecanone and 2-nonanone were significantly higher in the PB4 group than those in the control group (p < 0.01). These compounds have been detected in plants, such as cinnamon, clove, and coconut and contribute to the flavor and fragrance profiles of these plants (Yan et al., 2020). Furthermore, 2-undecanone has been found in beef, though not in pork or chicken and may play an important role in the distinct flavor of beef among meat (Ahamed et al., 2023).

Acidic compounds were more frequently detected in patties supplemented with biji than in the control patties, leading to samples with favorable features. Relative concentration of octanoic acid was high in PB4. Commercial plant-based burgers, which contain coconut oil and pea protein, have a high octanoic acid content. Compared with the nutritional value of other burger samples, commercial plant-based burgers contain more total fat than traditional vegetarian burgers (He et al., 2021). Octanoic acid is a typical product of lipid degradation, which serves as an important pathway for the formation of flavor compounds in food (Sarangapani et al., 2017).

Most alcohols were more abundant in PB4 than in control samples. Typically, 1-octanol, 1-hexanol, and 1-pentanol were formed with excellent properties. During the olfactometric analysis, trained panelists described 1-octanol as a nutty, creamy-smelling odorant (Zhang et al., 2021). Particularly, 1-octanol is positively correlated with beef and can be used as a volatile compound in beef (Ahamed et al., 2023). 1-Hexanol, which was detected in both samples, has been reported as a crucial volatile compound in grassy and fruity flavors (Xiao et al., 2020). 1-Pentanol was detected only in PB4 at a relatively higher concentration than 1-heptanol and 2,3-butanediol. A previous study reported the presence of 1-octanol and 1-pentanol in meat species (beef, pork, and chicken) (Ahamed et al., 2023).

The contribution of esters (fruity compounds) to the flavor profile was more significant in PB4 than in the control. Esters are mainly formed through esterification of organic acids and alcohols and impart a pleasant fruity flavor. Esters mask off-flavors and contribute to the flavor of soybean paste. Furthermore, ethyl esters have been suggested to be essential for the addition of fruity or flower-like notes and the masking of rancid flavors, such as fermented flavors, in soybean paste (Deng et al., 2022). Ethyl octanoate and ethyl decanoate, which were also detected in PB4, contribute to the overall flavor profile of heat-processed beef with a fruity flavor (Zhang et al., 2023).

The concentration of the predominant volatile compound, 2-pentylfuran, in both samples showed no significant difference in the respective concentrations (p > 0.05). Besides 2-pentylfuran, three compounds detected in both samples, namely 1-hexanol, benzaldehyde, and 1-pentanol, were reported to be present in soy extract (Samoto et al., 1998). Notably, 2-pentylfuran was reported to be abundant in soybean oil at temperatures exceeding 150 °C (Xiao et al., 2020). Buttery flavor is positively correlated with 2-pentylfuran and is considered a good indicator of overall flavor quality (Zhang et al., 2023). In this study, typical Maillard reaction products, including pyran and pyrazines were detected in both samples, including maltol (butterscotch, caramel, and roasted bread), 2,5-dimethyl-pyrazine (cocoa and coffee), and 3-ethyl-2,5-dimethylpyrazine (broth, chocolate, and potato) (Cai et al., 2021). Maillard reaction products are the major volatile compounds present in cooked meat (Khan et al., 2015). Significantly higher concentrations of these compounds were found in patties supplemented with biji than in the control patties (p < 0.05).

The concentrations of most compounds in PB4 were higher than those in the control; however, the concentrations of three volatile compounds (benzaldehyde, nonanal, and 2-heptanone) were lower in PB4 than in the control. Benzaldehyde is an off-flavor compound found in commercial oil-free soybean products and in soy protein (ISP) extracted from low-denatured soy flakes (Samoto et al., 1998). Nonanal is the major volatile component of ISP and has been reported to be a degradative oxidation product of polyunsaturated fatty acids (Zhang et al., 2020). Previously, 2-heptanone was identified as the lipoxygenase-catalyzed oxidation product of polyunsaturated fatty acids (MacLeod et al., 1988). Some ketones and aldehydes contribute to the beany off-flavor, typically formed through the oxidation and decomposition of fatty acids by lipoxygenases and peroxidases. However, during roasting or heating processes, lipoxygenase and peroxidase activities are deactivated, thereby inhibiting the soybean's off-flavor. Successful inactivation of lipoxygenase in soybeans requires high baking temperatures (170 °C or above), consistent with the oven temperature (180 °C) used for plant-based patties (Cai et al., 2021). Consequently, a reduction in volatile compounds led to improved flavor in the plant-based patties compared to the control, demonstrating the effectiveness of biji powder in mitigating off-flavors. Undesirable off-flavors originating from the oxidation of unsaturated fatty acids can leave a negative impression on consumers. Therefore, controlling off-flavors through thermal cooking processes such as roasting, boiling, and frying is crucial for achieving optimal soybean products.

Sensory perception is highly related to the consumer acceptance of meat analogs. Hence, the addition of novel ingredients is essential and beneficial to the flavor of meat analogs. In the present study, several volatile compounds, such as alcohols (1-octanol and 1-pentanol), aldehydes (benzaldehyde and nonanal), pyrazines (2,5-dimethyl pyrazine and 3-ethyl-2,5-dimethyl pyrazine), 2-pentylfuran, and 2-undecanone were identical to those identified in a previous analysis of meat flavor (Ahamed et al., 2023). Alcohols (1-octanol and 1-pentanol) were detected only in the biji-supplemented group. Therefore, plant-based patties supplemented with biji powder are expected to have a flavor similar to that of meat, thereby providing consumers with meat analogs that mimic meat.

As shown in the cluster heatmap (Fig. 1), a distinct separation (based on the Euclidean correlation) was observed between the control patties and those supplemented with 20 g of biji powder. A heatmap was constructed to demonstrate similarities and differences at the sample level. The colors indicate the relative concentrations of the volatile compounds, from high (dark red) to low (dark blue). The major volatile compounds identified by the heatmap as the most significant for distinctive CC were 2-undecanone, 2-nonanone, and 2-pentylfuran. Conversely, the most significant compounds for characteristic CT were octanoic acid, 2-undecane, 2-nonanone, and octanoic acid, as shown in Fig. 1. Both 2-undecanone (fresh, green, orange, pineapple, and rose) and 2-nonanone (fragrant, fruity, green, hot milk, and oily characteristics) are prominent volatile compounds abundant in CC and CT. The heatmap reveals that 2-pentylfuran (butter, floral notes, fruitiness, greenness, and green beans) showed higher concentrations in CC compared to CT, although the relative concentrations were not significantly different (Table 6). In contrast, octanoic acid (cheese, fat, and fermented notes) appeared dark red, particularly prevalent in CT, aligning with the major compounds highlighted in Table 6.

Fig. 1.

Heatmap hierarchical clustering analysis (heatmap HCA) of the characteristic volatile compounds in plant-based patties. CC and CT represent the control and PB4 (plant-based patty supplemented with 20 g of biji powder), respectively. Volatile compound concentrations represent the mean of triplicate experiments displayed in the heatmap. The heatmap was generated by merging three transcript lists from each sample.

4. Conclusion

This study was conducted to evaluate the physicochemical characteristics and analyze the volatile compounds in plant-based patties containing different amounts of biji powder. As the amount of biji powder increased, the pH, WHC, moisture content, and crude protein, ash, and fat contents of the patties increased. The cooking loss rate and reduction in diameter and thickness were lowest for PB4. The brightness and yellowness of the patties increased with an increase in the amount of biji powder, whereas the redness of the patties decreased. When textural properties were measured, the hardness, springiness, cohesiveness, and chewiness of the patties increased. PB4 was selected for further studies because it had the highest WHC, crude protein content index, and lowest cooking loss. These results suggest that the addition of biji powder during the manufacturing of patties increases the stability and quality of plant-based patties, which is desirable for the development of patties using byproducts. In addition, based on the volatile analysis results, biji powder can mask off-flavors and serve as an additional ingredient to produce similar meat flavors, such as 2-undecanone, 1-octanol, and 1-pentanol. Consequently, further studies on consumer sensory evaluations are required to validate the importance of the correlations discovered in this study and unveil the possibility of industrialization, ultimately aiding improvements in consumer acceptability.

Acknowledgements/Funding

This work was supported by Korea Institute of Planning and Evaluation for Technology in Food, Agriculture, Forestry and Fisheries (IPET) through High Value-added Food Technology Development Program, funded by Ministry of Agriculture, Food and Rural Affairs (MAFRA) (grant number: RS-2024-00407170). This research was also supported by Korea Institute of Marine Science & Technology Promotion (KIMST) funded by the Ministry of Oceans and Fisheries (grant number: RS-2024-00404977).

CRediT authorship contribution statement

Jin-Kyung Nam: Writing – original draft, Methodology, Investigation, Data curation. Ji Yun Lee: Writing – original draft, Methodology, Investigation, Data curation. Hae Won Jang: Conceptualization, Resources, Supervision, Project administration, Writing – review & editing.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Contributor Information

Jin-Kyung Nam, Email: 220236199@sungshin.ac.kr.

Ji Yun Lee, Email: 220246130@sungshin.ac.kr.

Hae Won Jang, Email: hwjang@sungshin.ac.kr.

Data availability

Data will be made available on request.

References

- Ahamed, Z., Seo, J. K., Eom, J. U., & Yang, H. S. (2023). Optimization of volatile compound extraction on cooked meat using HS-SPME-GC-MS, and evaluation of diagnosis to meat species using volatile compound by multivariate data analysis. LWT - Food Science and Technology, 188, 115374. https://doi.org/ 10.1016/j.lwt.2023.115374. [DOI]

- AOAC Official Methods 931.04, 940.26, 955.04, 920.39 . 17th edition. AOAC International; Gaithersburg, MD: 2000. Official Methods of Analysis. [Google Scholar]

- Azman A.T., Isa N.S.M., Zin Z.M., Abdullah M.A.A., Aidat O., Zainol M.K. Protein hydrolysate from underutilized legumes: Unleashing the potential for future functional foods. Preventive nutrition and food science. 2023;28(3):209–223. doi: 10.3746/pnf.2023.28.3.209. https://doi.org/10.3746%2Fpnf.2023.28.3.209. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Baugreet, S., Kerry, J. P., Botineştean, C., Allen, P., & Hamill, R. M. (2016). Development of novel fortified beef patties with added functional protein ingredients for the elderly. Meat Science, 122, 40-47. https://doi.org/ 10.1016/j.meatsci.2016.07.004. [DOI] [PubMed]

- Cai, J. S., Zhu, Y. Y., Ma, R. H., Thakur, K., Zhang, J. G., & Wei, Z. J. (2021). Effects of roasting level on physicochemical, sensory, and volatile profiles of soybeans using electronic nose and HS-SPME-GC–MS. Food Chemistry, 340, 127880. https://doi.org/ 10.1016/j.foodchem.2020.127880. [DOI] [PubMed]

- Deng, W., Wang, M., Li, Z., Liu, G., Liu, Z., Yu, H., & Liu, J. (2022). Effect of the changes of microbial community on flavor components of traditional soybean paste during storage period. Food Research International, 161, 111866. https://doi.org/ 10.1016/j.foodres.2022.111866. [DOI] [PubMed]

- Dosh K.S., Tawfiq N.N., Mohammed S.O. Effect of partial replacement of beef meat with powdered of oyster mushroom Pleurotus eryngii (King oyster mushroom) on physical and sensory properties of meat burger. Iraqi Journal of Market Research and Consumer Protection. 2015;7:388–400. [Google Scholar]

- He, J., Liu, H., Balamurugan, S., & Shao, S. (2021). Fatty acids and volatile flavor compounds in commercial plant‐based burgers. Journal of Food Science, 86(2), 293-305. https://doi.org/ 10.1111/1750-3841.15594. [DOI] [PubMed]

- Jang, H. W., Yu, J. M., & Kim, M. K. (2021). Aroma analyses of fermented soybean paste (doenjang) using descriptive sensory analysis and μ‐chamber/thermal extractor combined with thermal desorber–gas chromatography–mass spectrometry. Journal of Sensory Studies, 36(6), e12703. https://doi.org/ 10.1111/joss.12703. [DOI]

- Jiménez-Escrig, A., Tenorio, M. D., Espinosa-Martos, I., & Ruperez, P. (2008). Health-promoting effects of a dietary fiber concentrate from the soybean byproduct okara in rats. Journal of Agricultural and Food Chemistry, 56(16), 7495-7501. https://doi.org/ 10.1021/jf800792y. [DOI] [PubMed]

- Kang, M. J., Bae, I. Y., & Lee, H. G. (2018). Rice noodle enriched with okara: Cooking property, texture, and in vitro starch digestibility. Food Bioscience, 22, 178-183. https://doi.org/ 10.1016/j.fbio.2018.02.008. [DOI]

- Khan, M. I., Jo, C., & Tariq, M. R. (2015). Meat flavor precursors and factors influencing flavor precursors-A systematic review. Meat Science, 110, 278-284. https://doi.org/ 10.1016/j.meatsci.2015.08.002. [DOI] [PubMed]

- Kim J., Kim T.K., Cha J.Y., Ku S.K., Jung S., Choi Y.S. Effect of drying methods on physicochemical characteristics and functional properties of duck blood gel. Food Science of Animal Resources. 2022;42(5):861. doi: 10.5851/kosfa.2022.e38. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim, M. K., Lee, Y. Y., Lee, K. G., & Jang, H. W. (2019). Instrumental volatile flavor analysis of omija (Schisandra chinesis Baillon) using headspace stir-bar sorptive extraction-gas chromatography-mass spectrometry and its relationship to human sensory perceptions. Food Research International, 120, 650-655. https://doi.org/ 10.1016/j.foodres.2018.11.022. [DOI] [PubMed]

- Kovats E. In: Advances in Chromatography. Giddings J.C., Keller R.A., editors. Marcel Dekker; New York: 1965. Gas chromatographic characterization of organic substances in the retention index system; p. 229. [Google Scholar]

- Lee H.J., Kim Y.K. Development of a low‐salt soy sauce with enhanced flavor and functionality with soy residue and Tenebrio molitor larvae powder. Journal of Food Processing and Preservation. 2022;46(5) [Google Scholar]

- Lee, J. Y., Kim, W. S., Lee, Y. Y., Choi, Y. S., Choi, H., & Jang, H. W. (2019a). Solid‐phase microextraction arrow for the volatile organic compounds in soy sauce. Journal of separation science, 42(18), 2942-2948. https://doi.org/ 10.1002/jssc.201900388. [DOI] [PubMed]

- Lee, M. H., Kim, T. K., Cha, J. Y., Yong, H. I., Kang, M. C., Jang, H. W., & Choi, Y. S. (2022). Physicochemical characteristics and aroma patterns of oils prepared from edible insects. LWT, 167, 113888. https://doi.org/ 10.1016/j.lwt.2022.113888. [DOI]

- Lee, S. H., Choi, K. I., Osako, M., & Dong, J. I. (2007). Evaluation of environmental burdens caused by changes of food waste management systems in Seoul, Korea. Science of the Total Environment, 387(1-3), 42-53. https://doi.org/ 10.1016/j.scitotenv.2007.06.037. [DOI] [PubMed]

- Li, B., Qiao, M., & Lu, F. (2012). Composition, nutrition, and utilization of okara (soybean residue). Food Reviews International, 28(3), 231-252. https://doi.org/ 10.1080/87559129.2011.595023. [DOI]

- Ma, C. Y., Liu, W. S., Kwok, K. C., & Kwok, F. (1996). Isolation and characterization of proteins from soymilk residue (okara)∗. Food Research International, 29(8), 799-805. https://doi.org/ 10.1016/0963-9969(95)00061-5. [DOI]

- MacLeod, G., Ames, J., & Betz, N. L. (1988). Soy flavor and its improvement. Critical Reviews in Food Science & Nutrition, 27(4), 219-400. https://doi.org/ 10.1080/10408398809527487. [DOI] [PubMed]

- Muguerza, E., Gimeno, O., Ansorena, D., & Astiasarán, I. (2004). New formulations for healthier dry fermented sausages: a review. Trends in Food Science & Technology, 15(9), 452-457. https://doi.org/ 10.1016/j.tifs.2003.12.010. [DOI]

- OECD/FAO. (2022). Meat. OECD-FAO Agricultural Outlook 2022-2031 (pp. 189-206). OECD Publishing. https://doi.org/ 10.1787/f1b0b29c-en. [DOI]

- Razavizadeh, S., Alencikiene, G., Salaseviciene, A., Vaiciulyte-Funk, L., Ertbjerg, P., & Zabulione, A. (2021). Impact of fermentation of okara on physicochemical, techno-functional, and sensory properties of meat analogues. European Food Research and Technology, 247(9), 2379-2389. https://doi.org/ 10.1007/s00217-021-03798-8. [DOI]

- Samoto, M., Miyazaki, C., Kanamori, J., Akasaka, T., & Kawamura, Y. (1998). Improvement of the off-flavor of soy protein isolate by removing oil-body associated proteins and polar lipids. Bioscience, Biotechnology, and Biochemistry, 62(5), 935-940. https://doi.org/ 10.1271/bbb.62.935. [DOI] [PubMed]

- Sarangapani, C., Keogh, D. R., Dunne, J., Bourke, P., & Cullen, P. J. (2017). Characterisation of cold plasma treated beef and dairy lipids using spectroscopic and chromatographic methods. Food Chemistry, 235, 324-333. https://doi.org/ 10.1016/j.foodchem.2017.05.016. [DOI] [PubMed]

- Song, N. E., Lee, J. Y., Lee, Y. Y., Park, J. D., & Jang, H. W. (2019). Comparison of headspace-SPME and SPME-Arrow-GC-MS methods for the determination of volatile compounds in Korean salt-fermented fish sauce. Applied Biological Chemistry, 62, 1-8. https://doi.org/ 10.1186/s13765-019-0424-6. [DOI]

- Song, N. E., Kim, M. K., Lee, K. G., & Jang, H. W. (2021). Analysis of volatile compounds in rooibos tea (Aspalathus linearis) using different extraction methods and their relationship with human sensory perception. Food Research International, 141, 109942. https://doi.org/ 10.1016/j.foodres.2020.109942. [DOI] [PubMed]

- Szulc, J., Błaszak, B., Wenda-Piesik, A., Gozdecka, G., Żary-Sikorska, E., Bąk, M., & Bauza-Kaszewska, J. (2023). Zero Waste Technology of Soybeans Processing. Sustainability, 15(20), 14873. https://doi.org/ 10.3390/su152014873. [DOI]

- Turhan, S., Temiz, H., & Sagir, I. (2009). Characteristics of beef patties using okara powder. Journal of Muscle Foods, 20(1), 89-100. https://doi.org/ 10.1111/j.1745-4573.2008.00138.x. [DOI]

- UN DESA, Population Division . In: World Population Prospects 2022: Summary of Results (pp. 9) Koshy N., Ouedraogo B.P., editors. United Nations Publishing; 2022. Key messages. [Google Scholar]

- Viuda-Martos M., Ruiz-Navajas Y., Fernández-López J., Pérez-Álvarez J.A. Effect of orange dietary fibre, oregano essential oil and packaging conditions on shelf-life of bologna sausages. Food Control. 2010;21(4):436–443. doi: 10.1016/j.foodcont.2009.07.004. [DOI] [Google Scholar]

- Xiao, L., Li, C., Chai, D., Chen, Y., Wang, Z., Xu, X., Wang, Y., Geng, Y., & Dong, L. (2020). Volatile compound profiling from soybean oil in the heating process. Food Science & Nutrition, 8(2), 1139-1149. https://doi.org/ 10.1002/fsn3.1401. [DOI] [PMC free article] [PubMed]

- Yan, Q., Simmons, T. R., Cordell, W. T., Lozada, N. J. H., Breckner, C. J., Chen, X., Jindra, M. A., & Pfleger, B. F. (2020). Metabolic engineering of β-oxidation to leverage thioesterases for production of 2-heptanone, 2-nonanone and 2-undecanone. Metabolic Engineering, 61, 335-343. https://doi.org/ 10.1016/j.ymben.2020.05.008. [DOI] [PMC free article] [PubMed]

- Zhang, C., Hua, Y., Li, X., Kong, X., & Chen, Y. (2020). Key volatile off-flavor compounds in peas (Pisum sativum L.) and their relations with the endogenous precursors and enzymes using soybean (Glycine max) as a reference. Food Chemistry, 333, 127469. https://doi.org/ 10.1016/j.foodchem.2020.127469. [DOI] [PubMed]

- Zhang, X., Wei, J., Zhao, S., Jia, H., Guo, C., Wang, Z., Gao, Z., Yue, T., & Yuan, Y. (2021). Flavor differences between commercial and traditional soybean paste. LWT - Food Science and Technology, 142, 111052. https://doi.org/ 10.1016/j.lwt.2021.111052. [DOI]

- Zhang, Z., Zang, M., Zhang, K., Wang, S., Li, D., & Li, X. (2023). Effect of two types of thermal processing methods on the aroma and taste profiles of three commercial plant-based beef analogues and beef by GC-MS, E-nose, E-tongue, and sensory evaluation. Food Control, 146, 109551. https://doi.org/ 10.1016/j.foodcont.2022.109551. [DOI]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.