Abstract

Ultrathin flexible photodetectors can be conformably integrated with the human body, offering promising advancements for emerging skin-interfaced sensors. However, the susceptibility to degradation in ambient and particularly in aqueous environments hinders their practical application. Here, we report a 3.2-micrometer-thick water-resistant organic photodetector capable of reliably monitoring vital sign while submerged underwater. Embedding the organic photoactive layer in an adhesive elastomer matrix induces multidimensional hybrid phase separation, enabling high adhesiveness of the photoactive layer on both the top and bottom surfaces with maintained charge transport. This improves the water-immersion stability of the photoactive layer and ensures the robust sealing of interfaces within the device, notably suppressing fluid ingression in aqueous environments. Consequently, our fabricated ultrathin organic photodetector demonstrates stability in deionized water or cell nutrient media over extended periods, high detectivity, and resilience to cyclic mechanical deformation. We also showcase its potential for vital sign monitoring while submerged underwater.

Water-resistant ultrathin organic photodetectors were obtained by embedding the photoactive layer in an adhesive elastomer matrix.

INTRODUCTION

Optical monitoring in health care has gained prominence owing to its versatility and minimal invasiveness, with photodetectors (PDs) playing a crucial role (1–4). These photoelectric devices facilitate the conversion of photophysical interactions between light and tissues into electrical signals, offering essential biometric information for noninvasive diagnostic and health monitoring (5, 6). Recent advancements in materials and devices have facilitated the evolution of PDs from rigid to flexible structures and reduced mechanical mismatches with the human body for stable and comfortable interfacing, even during motion (7–12).

Flexible PDs with ultrathin configurations represent the latest development in the interfacing with human tissues and have unlocked diverse promising application scenarios, such as epidermal and implantable devices (13, 14). An ultrathin form factor can not only reduce the weight and volume but also impart extreme flexibility and conformability to a device. Several ultrathin PDs with impressive flexibility have been reported, which use emerging photoactive materials, such as organic semiconductors, perovskites, and quantum dots. These body-conformable PDs have been exemplified in applications for on-skin photoplethysmogram (PPG) sensors, vision sensors, and implantable optogenetics (15–18).

In addition to mechanical flexibility, PDs with improved stability are essential for reliable monitoring of biological signals. In particular for skin-interfaced devices, the aqueous conditions of the ambient environment and human body pose a serious threat to their long-term use (19). Researchers have attempted to enhance the water resistance of PDs and other flexible optoelectronics, including light-emitting diodes (LEDs) and photovoltaics. A common solution is to seal the device within encapsulation layers (20–22). Interfacial toughening or modification has also been demonstrated as an effective strategy for improving the water resistance of the device (23–25). For example, in situ–grown silver oxide (AgOX) has replaced the conventionally used water-sensitive molybdenum oxide as hole transport layer in organic photovoltaics, realizing the waterproofness of a 3 μm-thick device (26). The insertion of a hydrophobic interlayer has also improved the moisture resistance of flexible perovskite PDs (27). Modifying the chemical structure of photoactive materials is another promising approach for waterproofing the device (28–30). For example, engineering the crystal structure of organic semiconductors via chemical modification has enabled the realization of water-resistant rigid PDs with mobility degradation of 5.7% after 24 hours of immersion in distilled water (31).

However, to date, no study has addressed the critical need for developing ultrathin conformable PDs capable of extended operation in aqueous environments. The challenge in developing water-resistant ultrathin PDs lies in implementing waterproofing strategies while maintaining both high performance and high flexibility of the device. The commonly used thick or rigid water-resistant encapsulation layer inevitably lowers the device flexibility and even the photoelectrical performance (32). Ensuring water resistance in all functional layers and interfaces simultaneously is paramount for the development of water-insensitive PDs. However, interfacial toughening requires additional stresses, such as thermal annealing, which induce defects in the active layers and interfaces, thereby significantly increasing the dark current of the PDs (33, 34). The utilization of hydrophobic interlayers results in limited interfacial adhesion within the devices owing to their low surface energies, allowing water ingress toward weak interfaces and causing delamination (25, 26). Photoactive materials, such as organic semiconductors or perovskites, and functional layers used for high-performance PDs are moisture sensitive, resulting in substantial degradation of the device performance in humid environments (35–37).

In this study, we developed a water-resistant and ultrathin conformable organic PD (OPD) capable of monitoring physiological signals reliably, even when submerged underwater. Our OPDs, with a total thickness of 3.2 μm, experienced only a 6% decrease in the light current while maintaining an ideal linear photoresponse even after 5 hours of immersion in deionized water. In addition, they demonstrated a high detectivity (D*) of 6.2 × 1011 Jones and the ability to withstand cyclic compression and stretching. The waterproofness of these ultrathin OPDs stems from the water-resistant photoactive layer and mechanically reinforced interfaces bordering the photoactive layer. By physically blending an adhesive elastomer with organic donor/acceptor, the resultant photoactive film displays a multidimensional hybrid phase separation in both the vertical and lateral directions, characterized by an interconnected conjugated polymer-rich phase and isolated elastomer-rich phase. This distinctive phase separation provides exceptional adhesiveness in both the top and bottom active layer surfaces, contributing to the construction of the mechanically toughened interfaces within the multilayered OPDs. We demonstrated that the robustly sealed interfaces effectively prevent water ingression and confer water resistance to the ultrathin device. Moreover, this multidimensional hybrid phase separation retained the charge transport ability of photoactive layer and greatly suppressed the dark current, thereby enabling high detectivity of the device. The universality of our approach in achieving high-performance water-resistant OPDs with various photoactive layers has also been verified. These attributes allow us to demonstrate the water-resistant ultrathin conformable OPDs for PPG signal monitoring, where they can accurately capture the pulse waveforms consistently even during water immersion.

RESULTS

Device structure and performance

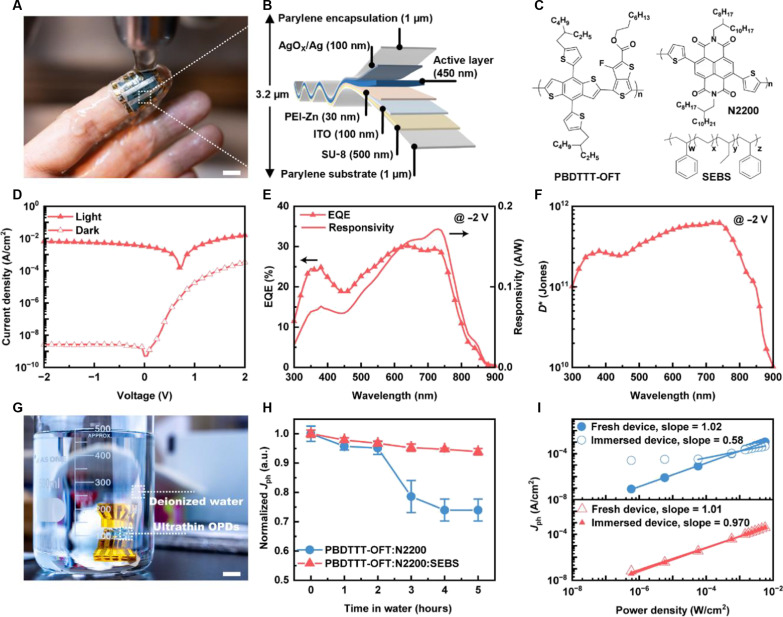

A photograph and the device configuration of our water-resistant ultrathin (3.2 μm) conformable OPDs are shown in Fig. 1 (A and B, respectively). Even after rinsing in water, the device exhibits exceptional stability and conformability to human skin, making it a reliable on-skin optical sensor for vital sign monitoring. The device with a photodiode structure of indium tin oxide (ITO)/Zn2+-chelated polyethylenimine (PEI-Zn)/active layer/AgOX/Ag was manufactured on a 1.5-μm-thick polymeric substrate and encapsulated with a 1-μm-thick parylene film. The donor poly[4,8-bis(5-(2-ethylhexyl)thiophen-2-yl)benzo[1,2-b;4,5-b′]dithiophene-2,6-diyl-alt-(4-octyl-3-fluorothieno[3,4-b]thiophene)-2-carboxylate-2-6-diyl] (PBDTTT-OFT) and acceptor poly[[N,N′ -bis(2-octyldodecyl)-napthalene-1,4,5,8-bis(dicarboximide)-2,6-diyl]-alt-5,50-(2,20-bithio-phene)] (N2200) are used as photoactive layer (Fig. 1C). Specifically, we chose the widely used adhesive elastomer polystyrene-block-poly(ethylene-ran-butylene)-block-polystyrene (SEBS) as a filler in the bulk-heterojunction active layer because of its surface energy, comparable with those of organic semiconductors (fig. S2 and table S1), excellent long-term stability under harsh environments, and excellent adhesiveness (38–40). In situ–grown AgOX was used as the electron-blocking layer (26).

Fig. 1. Device structure, performance, and water resistance of the ultrathin organic photodiodes.

(A) Photograph of a fingertip with the ultrathin conformable organic photodiode attached to it, being washed with water (scale bar, 1 cm). (B) Schematic of the structure of an ultrathin organic photodiode device. (C) Chemical structures of active layer components, including polymer donor PBDTTT-OFT, polymer acceptor N2200, and elastomer SEBS. (D) J-V characteristics, (E) EQE and responsivity spectra at −2 V, and (F) specific detectivity at −2 V of the PBDTTT-OFT:N2200:SEBS–based device. (G) Photograph of an ultrathin OPD device immersed in deionized water for water resistance evaluation (scale bar, 1 cm). (H) Change in photocurrent density over time at −2 V for ultrathin OPDs immersed in deionized water. (I) Power dependence of the devices before and after 5 hours of water immersion.

Samples of PBDTTT-OFT:N2200:SEBS with different compositions were initially prepared and evaluated using a photodiode device architecture (fig. S3). The electrically insulating nature of SEBS undoubtedly increases the active layer resistance, resulting in an injection barrier under dark conditions, which is immensely beneficial for the suppression of the device dark current density (Jdark) (41, 42). Moreover, the diffusion of silver atoms toward the active layer during silver oxide formation is eliminated with the addition of SEBS (fig. S4), which also contributes to the reduction in Jdark (43). As a result, Jdark decreases exponentially with the addition of SEBS. Regarding the light current density (Jlight), the transparent SEBS decreases the optical absorbance of the active layer (fig. S7A), thus reducing the external quantum efficiency (EQE). The effects of SEBS on charge carrier transport and extraction were further studied. The ratio of the photocurrent density (Jph) to saturation current density (Jsat) represents the product of the charge generation and collection efficiencies (44). Figure S5A shows Jph/Jsat for the blend films with and without SEBS over a range of biases. Adding SEBS does not affect charge carrier extraction within the active layer, as observed on the basis of the nearly identical behavior of the normalized Jph/Jsat as a function of effective voltage at high reverse biases. Besides, in space charge-limited conduction (SCLC) measurements (fig. S5, B and C), the blend films with and without SEBS showed similar charge carrier mobility. The detectivity Dsh* is first estimated considering shot noise approximation using , where R is the responsivity and q is the elementary charge. Films with the composition of PBDTTT-OFT:N2200:SEBS (1:1:2 by weight, 450 nm thick) were found to yield the best detectivity (fig. S3C). Hereafter, the discussion is based on this specific composition and thickness.

Figure 1 (D and E) shows that the PBDTTT-OFT:N2200:SEBS–based champion device produced a Jdark of 2.5 × 10−9 A/cm2, an EQE of 29%, and the corresponding responsivity of 0.17 A/W at 730 nm, under a reverse bias of −2 V. D* is further calculated using , considering the flicker noise, shot noise, and thermal noise, where A is the active area (0.04 cm2) and inoise is the noise power density (Fig. 1F and fig. S6) (34). Subsequently, a peak D* value of 6.2 × 1011 Jones at 730 nm and −2 V is obtained. In addition, the devices display a microsecond-scale transient photocurrent response at −2 V with 3 and 8 μs of rise and fall time, respectively (fig. S7B).

Water resistance of the device

Next, we demonstrate the use of SEBS in an active layer to realize water-resistant ultrathin OPDs. For comparison, PBDTTT-OFT:N2200–based devices were used as control devices. Figure 1G shows a photograph of the setup for evaluating the water resistance, where the ultrathin OPDs were directly immersed in deionized water. The electrical performance was also characterized (fig. S8). After 5 hours of immersion in deionized water, Jlight was reduced by approximately 25.0% for the PBDTTT-OFT:N2200–based device, that is, from 1.2 × 10−2 to 0.8 × 10−2 A/cm2. The SEBS-containing device showed a 6.1% reduction in Jlight after 5 hours of water immersion (Fig. 1H). Figure S7C shows that Jdark of both types of ultrathin OPDs remain comparable to their initial values after 5 hours of immersion. The water resistance of the device was further confirmed by the changes in R, where the SEBS-containing device showed stable photoresponse during the 5-hour immersion (fig. S7, D to F).

A linear response to incident light irradiance is essential for OPDs, where the incident light intensity can be directly represented by the photocurrent. This is particularly important for signal accuracy when the OPD is used as an optical detector in a PPG sensor operating on the basis of the Beer-Lambert law and used to detect variations in blood volume within the microvascular tissue (45). Therefore, we studied the linearity plots of the photoresponse of the OPDs to the illumination intensity (Fig. 1I). The control device lost its linear photoresponse after 5 hours of water immersion owing to defects induced by water ingression within the device. Owing to the stable responsivity of SEBS-based devices, the Jph demonstrated ideal linear dependence on incident light intensity before and after the water immersion, with slopes close to 1. The results further verified the water resistance capability of the device and its potential use for PPG sensing.

We also tested the stability of the ultrathin OPDs under 1× phosphate-buffered saline solution at 25°C, which is a frequently used buffer in cell and tissue culture applications (fig. S9). After 5 hours, an approximately 62.5% reduction in Jlight and 13 times increment in Jdark were observed for the control devices. In contrast, the SEBS-containing devices were more stable, with only 17.9% reduction in Jlight and five times increment in Jdark. These results illustrate that the SEBS-containing ultrathin OPDs developed in this study are robust to aqueous environments. Hence, they can be potentially used as bio-implantable devices.

The mechanical and storage stability of the SEBS-containing ultrathin OPDs were also evaluated. Under cyclic compression and stretching, it was confirmed that the dark and light currents at −2 V remained constant after 1000 repetitive compression cycles with 30% compression strain (fig. S10A). In addition, no degradation was observed after 30 days of storage under ambient and dark conditions (fig. S10B).

We applied our strategy to two additional high-performance organic semiconducting blends, with their chemical structures shown in fig. S1. After introducing SEBS, we again obtained water-resistant OPDs with high D* (table S2 and figs. S11 and S12). Specific D* of 6.3 × 1012 Jones at 870 nm and 1.9 × 1012 Jones at 810 nm were achieved at −2 V for the PBDTTT-OFT:IEICO-4F:SEBS–and PM6:PY-IT:SEBS–based devices, respectively, owing to the greatly suppressed noise current. Notably, the corresponding ultrathin OPD devices with two different organic semiconducting blends demonstrated excellent stability upon 5-hour water immersion.

Mechanism of water resistance

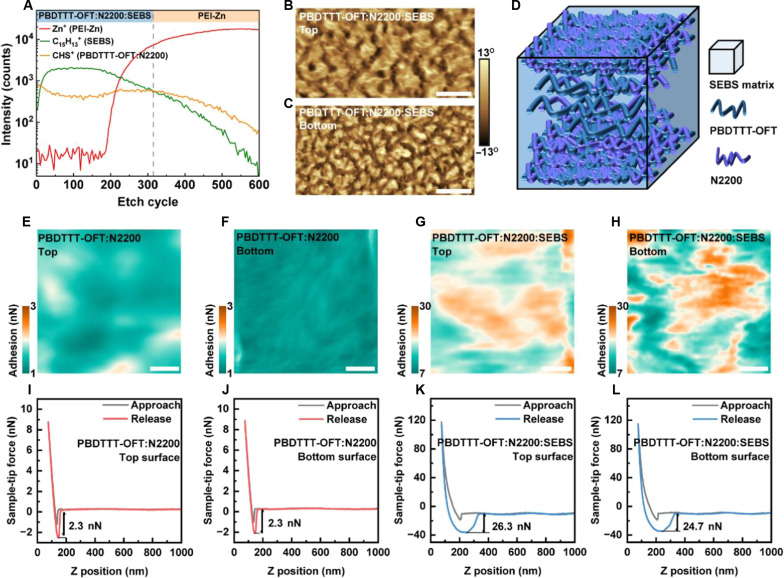

To understand the mechanism of water resistance owing to the addition of SEBS, we characterized the microstructure of the active layer. Time-of-flight secondary ion mass spectrometry (TOF-SIMS) was used to illustrate the vertical stratification of the SEBS-containing active layer. As revealed by the depth profiles of the characteristic functional groups (Fig. 2A), the donor and acceptor polymers were embedded in the SEBS matrix and were mainly concentrated at the top and bottom surfaces of the active layer. This film morphology resulting from nanoconfinement effects is beneficial for maintaining efficient charge transport within the active layer (46). In addition, as observed in the atomic force microscopy (AFM) phase images (Fig. 2, B and C), both the top and bottom surfaces exhibit phase separation based on the interconnected nanonetworks (dark areas) and SEBS self-aggregation nanodomains (bright areas) in the lateral direction. This multidimensional hybrid phase separation morphology in both the lateral and vertical directions is depicted in Fig. 2D. In contrast, the PBDTTT-OFT:N2200–based active layer shows homogeneous top and bottom surfaces (fig. S13). In addition to phase images, adhesion images (Fig. 2, E to H) were captured using AFM force spectroscopy; the representative adhesion force spectroscopy images are shown in Fig. 2, I to L. The PBDTTT-OFT:N2200–based active layer shows less adhesiveness, where the top and bottom surfaces had average adhesion forces of 1.5 ± 0.2 nN and 1.2 ± 0.1 nN, respectively. The introduction of the adhesive SEBS obviously bolstered the surface adhesiveness of the active layer. The top and bottom surfaces of the SEBS-containing active layer showed average adhesion forces of 18.0 ± 2.0 nN and 16.9 ± 3.5 nN, respectively. On the basis of the phase and adhesion images, the relatively larger distribution and SD of the adhesion force of the SEBS-containing active layer originates from its larger phase separation. In particular, the conjugated polymer-rich phase showed significantly improved adhesiveness. Therefore, we suggest that SEBS is not simply distributed in the bright areas (orange areas) of the phase images (adhesion images) as isolated domains; rather, it pervades the slightly dark areas (blue areas), where it is well mixed with the conjugated polymers. The ideal distribution of SEBS substantially enhances the adhesion properties of the active layer, influencing the entire top and bottom surfaces rather than manifesting as a localized alteration. This facilitates the interfacial toughening between the active layer and the top and bottom interlayers, simultaneously. Moreover, this morphology ensures that organic semiconductors are protected by SEBS, enabling stable absorption of the photoactive layer upon water immersion (fig. S14).

Fig. 2. Morphology and interfacial adhesiveness of the photoactive layer.

(A) TOF-SIMS depth profiles of the SEBS-containing active layer on an electron transport layer (PEI-Zn). (B and C) AFM phase images of the top and bottom interfaces of the SEBS-containing active layer (scale bar, 1 μm). (D) An illustration of the morphology of the SEBS-containing active layer. AFM adhesion force mapping of (E) top and (F) bottom surfaces of PBDTTT-OFT:N2200 and (G) top and (H) bottom surfaces of PBDTTT-OFT:N2200:SEBS (scale bar, 100 nm). (I to L) Typical AFM force spectroscopy of the AFM tip on different surfaces extracted from the mappings.

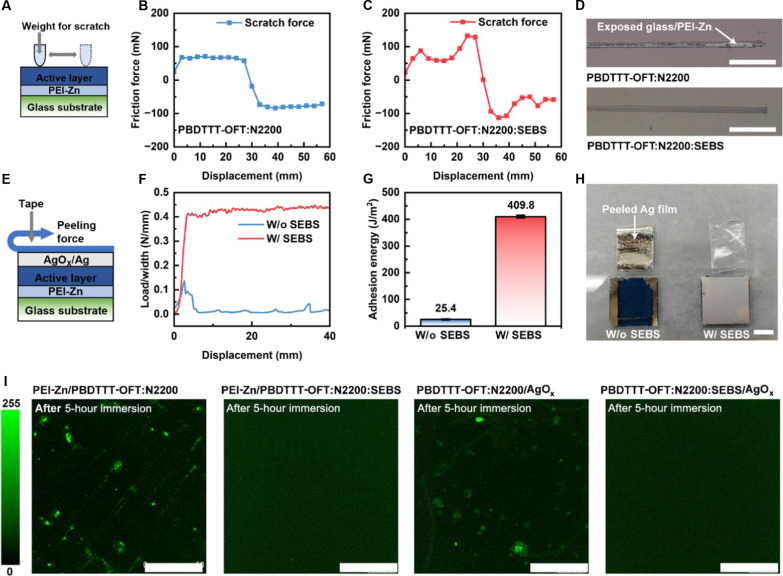

We evaluated the interfacial adhesion strength to further explore the influence of the adhesive properties of the active layer on the interfacial robustness and elucidate the role of the interfacial strength in the water resistance of the device. First, a nano scratch test was conducted to examine the interface between the active layer and the underlying electron transport layer (PEI-Zn). Concurrently, we assessed the interface between the active layer and top Ag electrode through a 180° peeling test. In the nano scratch test, a metal tip was used to scratch the active layers from the top surface with a fixed contact pressure (Fig. 3A). Figure 3 (B and C) depict the applied lateral scratch forces on the active layers during the test. The control film without SEBS was readily detached from the underlying PEI-Zn layer with an average lateral scratch force of 72.4 mN. In contrast, the SEBS-containing active layer exhibited firm adhesion to PEI-Zn even after lateral scratching with a force of 80.0 mN (Fig. 3D). This indicates that the addition of SEBS results in stronger interfacial adhesion between the active layer and the underlying electron transport layer. The robustness of the interface was further confirmed through an ultrasonication process, which revealed no delamination after 2 min of ultrasonic vibration in water (fig. S15). Consequently, the toughened interface prevented defects induced by water penetration in the active layer, such as aggregation, cracks, and delamination (figs. S16 and S17, A to C) (28, 47).

Fig. 3. Mechanism of water resistance.

(A) Schematic of nano scratch test. Scratching forces applied on (B) PBDTTT-OFT:N2200/PEI-Zn/glass and (C) PBDTTT-OFT:N2200:SEBS/PEI-Zn/glass. (D) Representative optical images of the scratches after tests for active layer coating on PEI-Zn (scale bar, 10 mm). (E) Schematic of 180° peeling test. (F) Interfacial adhesion strength of the top Ag electrode on active layer with and without SEBS. (G) Interfacial adhesion energy of Ag electrode on SEBS-containing active layer (409.8 ± 5.3 J/m2) is 1613% higher than that of the active layer without SEBS (25.4 ± 1.8 J/m2). (H) Photographs of the samples after 180° peeling off test for Ag deposited on active layer (scale bar, 1 cm). (I) Confocal laser scanning microscopy depicts photoluminescence at the interfaces of the devices after 5 hours of water immersion (incident laser wavelength, 405 nm; scale bar, 50 μm).

The peeling force applied to the top Ag electrode in the 180° peeling test (Fig. 3E) is depicted in Fig. 3F, and the corresponding adhesion energy is depicted in Fig. 3G. As shown in Fig. 3H, the Ag electrode was completely peeled off from the binary active layer by the tape with a small peeling force of 0.006 N/mm. However, it adhered firmly to the SEBS-containing active layer, even with a peeling force of 0.4 N/mm. A minimum 16-fold improvement in the interfacial adhesion energy between the Ag electrode and the active layer was achieved (from 25.4 ± 1.8 to 409.8 ± 5.3 J/m2), which was attributed to the addition of SEBS. Similarly, this reinforced interface between the active layer and the top Ag electrode eliminated water ingress–induced interface defects (fig. S17, D to F). Meanwhile, the mechanical integrity of the device was considerably improved owing to the toughened interfaces, as confirmed by the pull-off test (fig. S18). The location of the weakest interface within the device was also shifted to the interface between Ag and the encapsulation layer. This retarded device deterioration upon water immersion owing to the tendency of the water to penetrate the weakest interface first. In addition to interfacial adhesion, we observed that the silver electrode on top of the SEBS-containing active layer displayed a very rough surface. This imparted superior water-repellent ability to the top electrode, as confirmed by the water contact angle measurements and experiments involving water droplet rolling off from the electrode (fig. S19).

Confocal photoluminescence imaging on both sides of the active layer enables the visualization and clarification of the contribution of the interfacial strength to water resistance of the device (48, 49). We focused a 405-nm laser beam at the interfaces within the device and collected the corresponding photoluminescence mappings, as illustrated in fig. S20 (A and D). In the fresh devices, a large portion of the emission from the active layer was effectively quenched by charge transfer processes, as indicated by the weak and homogeneous photoluminescence intensity observed in the images (fig. S20). Following water immersion for 5 hours, defects led to unquenched photoexcited states at the interfaces of PEI-Zn/PBDTTT-OFT:N2200 and PBDTTT-OFT:N2200/AgOX, as evident from the bright spots in the photoluminescence mappings (Fig. 3I). In stark contrast, efficient exciton quenching at the interfaces persisted in the PBDTTT-OFT:N2200:SEBS–based device, indicating minimal effects of water immersion on the photoelectric conversion process in the device. As explained above, the uniform distribution of SEBS and the consequent enhancement in the interfacial adhesiveness sealed the interfaces within the device from inside, thus endowing water resistance.

Applicability to on-skin sensors

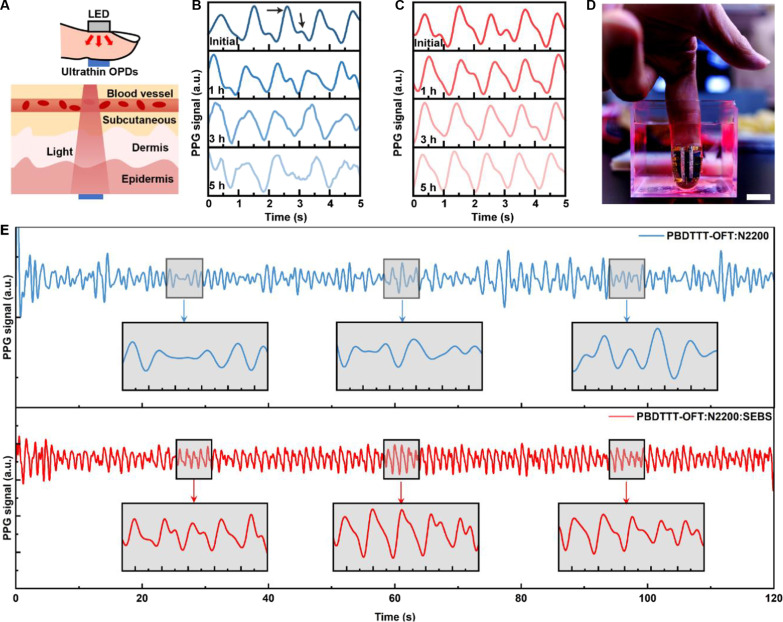

After establishing the water resistance, we checked the applicability of our ultrathin OPDs to the development of water-resistant, on-skin conformable PPG sensors for monitoring vital sign. PPG sensors rely on optical sensing to detect changes in blood vessel volume within the microvascular bed of tissues, thus providing valuable insights into cardiac and pulmonary functions (50). The experimental setup is depicted in Fig. 4A. Red light (635 nm) incident on the fingertip of a 26-year-old individual was detected by our conformable OPDs. The PPG signals collected via the PBDTTT-OFT:N2200–and PBDTTT-OFT:N2200:SEBS–based devices are presented in Fig. 4 (B and C, respectively). Initially, sharp and well-resolved systolic and diastolic peaks are observed in both devices. After 5 hours of water immersion, the signals obtained from the PBDTTT-OFT:N2200–based device gradually become inconsistent, as reflected by the mean squared error (MSE) of 0.17, with the featured peaks becoming indiscernible. As discussed above, we ascribe this degradation to the nonlinear photoresponse of the device after water ingress. In contrast, the SEBS-based device maintains the ideal linearity of the photoresponse even after water immersion. As expected, the PPG waveforms of this water-resistant OPD displayed identifiable systolic and diastolic peaks and great consistency (MSE = 0.09), even after 5 hours of immersion. In addition, a continuous 2-min PPG signal was collected with the sensor fully immersed in water (Fig. 4D). As shown in Fig. 4E, the SEBS-containing device stably outputs the PPG signals with a well-defined waveform, indicating an average pulse rate of 61 beats per minute. The high-quality PPG signals allow extraction of valuable information from their first and second derivatives (fig. S21) (50–52). The time interval between consecutive peaks in the PPG signals can be accurately determined from the zeroes in the PPG first derivative, as shown in fig. S21B. Analyzing the heartbeat intervals over 2 min provides information on the heart rate variability (fig. S21C), enabling the evaluation of the autonomic nervous system regulation and serving as a monitoring tool in conditions such as cardiovascular diseases, neuropathies, and sleep staging. Further insight into blood circulation can be gained from the second derivative of the PPG, known as acceleration plethysmogram (APG). The APG waveform typically includes four systolic waves (a to d) and one diastolic wave (e). These features are well visible in the APG obtained from the SEBS-containing OPD, whereas some peaks are not observed in the signals from the control device (fig. S21, A and B). Notably, the b/a index (i.e., the height ratio between the a and b waves) is considered a promising index in assessing the arterial health (51). We observed an average b/a index of −1.03, which is within the reasonable range for the 26-year-old healthy volunteer. The results of the PPG signals envision potential practical applications of our water-resistant ultrathin OPDs to health care.

Fig. 4. Applicability of water-resistant ultrathin OPD to PPG signal detection.

(A) Schematic of PPG signal detection along with transmission mode. Change in PPG signals with time during water immersion for (B) PBDTTT-OFT:N2200–and (C) PBDTTT-OFT:N2200:SEBS–based devices. The inset arrows indicate systolic and diastolic peaks. (D) Ultrathin water-resistant OPD attached to the fingertip and illuminated by a red LED for underwater PPG signal detection (scale bar, 1 cm). PPG signals acquired underwater from (E) PBDTTT-OFT:N2200–(top) and PBDTTT-OFT:N2200:SEBS–based (bottom) devices after 5 hours of immersion.

DISCUSSION

We developed the water-resistant ultrathin OPDs with high detectivity by embedding the photoactive layer into an adhesive elastomer matrix. The highly adhesive photoactive layer shows water-immersion stability and robustly seals the device interfaces, ensuring a water-resistant device with suppressed water penetration. The multidimensional hybrid phase separation preserves charge transport in the photoactive layer while significantly suppressing dark current, thereby achieving high detectivity of the device. Consequently, the fabricated ultrathin (3.2 μm) OPDs demonstrated impressive stability in deionized water or cell nutrient media over extended periods with a detectivity of 6.2 × 1011 Jones. Our strategy also shows the universality in achieving high-performance water-resistant OPDs with various photoactive layers. The exemplified application of stable PPG signals acquirement even after extended exposure to an aqueous environment showcases its potential for reliable vital sign monitoring, thus expanding the working scenarios of ultrathin OPDs, including the possibility of use in implantable devices. In particular, given the fact that SEBS has been widely used in various organic electronics for stretchability engineering (53–56), its unexpected advantage in improving ultrathin device water resistance holds profound promise. This exceptional advantage could inspire further advancements in organic electronics, facilitating the development of reliable on-skin sensors capable of stable operation under harsh conditions.

MATERIALS AND METHODS

Materials

PBDTTT-OFT was received from Toray Industries. N2200, PM6, PY-IT, IEICO-4F, and PDINN were purchased from 1-Materials, and SEBS (Tuftec H1221) was obtained from Asahi Kasei. Parylene (diX-SR) was obtained from Daisan Kasei. SU-8 and its developer (3005) were purchased from MicroChem Corp. Novec 1700 and 7100 were purchased from 3M. Zinc acetate dehydrates, 2-methoxyethanol, and chlorobenzene were purchased from FUJIFILM Wako Pure Chemical Corporation (Japan). Ethoxylated polyethyleneimine (80% ethoxylated solution, 37 wt % in H2O) was purchased from Sigma-Aldrich. All materials were used as received without further purification.

Fabrication of ultrathin OPDs

The ultrathin devices were fabricated layer by layer according to the architecture glass/fluorinated polymer/parylene/SU-8/ITO/PEI-Zn/active layer/Ag. First, the bare glass was precleaned and treated with oxygen plasma for 10 min. The fluorinated polymer solution (Novec 1700:7100 = 1:5 volume ratio) was cast on the glass substrate for easy delamination after device fabrication. A 1-μm-thick parylene layer was deposited by chemical vapor deposition (PDS 2010 Labcoter) as the bottom substrate, and a 500-nm-thick SU-8 layer was spin coated (4500 rpm, 60 s) and thermally annealed for planarization. ITO transparent electrode (100 nm) was then sputtered (SIH-1010, ULVAC) and patterned using photolithography. Additional chromium/gold (3.5/80 nm) layers were thermally evaporated to form a contact pad to allow easier contact with the transparent electrodes with opaque wiring metal and decrease the resistance in the wiring parts. The PEI-Zn precursor (70-mg zinc acetate dehydrate in 1 wt % ethoxylated polyethyleneimine 2-methoxyethanol solution) was spin coated at 3500 rpm for 45 s and annealed at 180°C for 30 min in air to form a PEI-Zn electron transport layer. The active layer solution was prepared by dissolving PBDTTT-OFT:N2200 (1:1 weight ratio) and PBDTTT-OFT:N2200:SEBS (1:1:2 weight ratio) in chlorobenzene with a total concentration of 30 mg/ml and stirring overnight, PBDTTT-OFT:IEICO-4F (1:1.5 weight ratio) and PBDTTT-OFT: IEICO-4F:SEBS (1:1.5:2.5 weight ratio) in chlorobenzene with a total concentration of 25 mg/ml and stirring overnight, PM6:PY-IT (1:1.2 weight ratio) and PM6:PY-IT:SEBS (1:1.2:2.2) in chloroform with a total concentration of 16 mg/ml and stirring overnight. The blended films were deposited through spin-coating and annealed at 90°C for 10 min in a glovebox to remove the residual solvent. Subsequently, silver (100 nm) was thermally evaporated on top of the active layers under pressure below 10−4 Pa as the top electrode. Subsequently, the devices were thermally annealed at 85°C for 24 hours under ambient and dark conditions for in situ growth of silver oxide. Next, a 1-μm-thick parylene film was deposited via chemical vapor deposition as an encapsulation layer. Last, the devices were carefully peeled off from the glass substrate to complete the fabrication of the ultrathin device.

Characterization

J-V measurements were performed under 1 sun illumination (XES-40S3, SAN-EI ELECTRIC) and recorded using a Keithley 2400 source. The EQE, responsivity, and power dependence measurements were performed using monochromatic light (SM-250F, Bunkoukeiki) calibrated using a silicon reference diode. Neutral density filters (NEK01S, THORLABS) were used for varying the irradiance intensity. In SCLC measurements, ITO/PEDOT:PSS/active layer/MoOx/Ag was used as hole-only device, ITO/PEI-Zn/active layer/PDINN/Ag was used as electron-only device. The J-V curves are fitted with Mott-Gurney equation: , where L is active layer thickness, μ is charge carrier mobility, ε is dielectric constant, ε0 is vacuum permittivity, and V is applied voltage. The transient photocurrent response was recorded via a semiconductor analyzer (B1500A, Agilent Technologies), where the light pulse was generated using a function generator (DPO 2024B, Tektronix) to generate voltage pulses for the LED. The device noise current was measured by a spectrum analyzer (MFIA 5 MHz, Zurich Instruments) connected to a low-noise current preamplifier (SR570, Stanford Research Systems) via probe station (15.2-cm manual probe station, Cascade Microtech). The preamplifier applied −2 V bias to the devices and current to voltage sensitivity was chosen from 1 nA/V to 1 μA/V. The PD current was converted to voltage, and the voltage was sampled at more than 10,000 to 100,000 points by using 16-bit MFIA. The noise power density was extracted by the MFIA internal calculated systems. After measured the background noise of the equipment, the PD noise power density was subtracted using . The TOF-SIMS measurement (M6, IONTOF) was performed at Toray Research Center Inc. AFM (SPM-9700HT, Shimadzu) was performed in the semicontact mode for the phase images and in the contact mode for adhesion force mapping. The cantilever (CONTPt-10, Nanoworld) used for force spectroscopy shows a force constant of 0.2 N/m. A friction apparatus (FPR2200, RHESCA CO., LTD) was used for the nano scratch test. An optical microscope (VHX-7000, Keyence) was used for capturing microscopic images. Additional imaging was performed using scanning electron microscopy (Quattro S) and energy-dispersive x-ray (Thermo Fisher Scientific). The 180° peeling test and pull-off test were performed via a universal tensile tester (EZ-LX, Shimadzu). The tape (3M) used for the 180° peeling test had a width of 7 mm. A confocal laser scanning microscope (TCS SP8, Leica) was used for photoluminescence imaging. The incident laser wavelength was 405 nm. In the PPG setup, a 635-nm red LED (LK-5RD) was used as the light source and was turned on at 5 V. The ultrathin device was attached to the fingertip of a 26-year-old male individual. External wirings and anisotropic conductive films were used to connect the OPDs to a semiconductor analyzer (B1500A, Agilent Technologies) for signal recording. For the underwater test, the fingertip with the attached device was immersed in water. The obtained PPG signals were processed via a band-pass filter (2 to 100 Hz) to remove baseline drift and wire noise. The MSE was calculated as , where n denotes the number of observations, xi denotes the initial PPG signals, and yi denotes the PPG signals obtained after immersion in water. The test design was reviewed and approved by the ethics committee of the University of Tokyo (approval number KE20-111). The contact angles were measured using a contact angle meter (DMe-211, Kyowa Interface Science). The surface energy is calculated on the basis of Owens-Wendt method. The active layer absorbance was measured using an ultraviolet-visible/near-infrared spectrophotometer (V-780, JASCO). All films used for characterization were fabricated using the same process as followed for device fabrication. The cyclic compressing-stretching tests were performed using an in-house screw machine with a speed of 12 cycles/min.

Acknowledgments

We thank Toray Industries Inc. for providing the polymer PBDTTT-OFT and Asahi Kasei for providing the elastomer SEBS.

Funding: This study was financially supported by the Japan Society for the Promotion of Science under Grants-in-Aid for Scientific Research (KAKENHI) (no. JP22H04949 and no.JP22K21343). B.D. acknowledges financial support from the China Scholarship Council (no. 202106950018).

Author contributions: Conceptualization: B.D., S.X., and K.F. Methodology: B.D., S.X., K.F. Supervision: K.F. and T.S. Investigation: B.D., S.X., L.S., Y.T., D.I., D.H., W.W., R.G., T.Y., S.W., Y.I., S.L., K.F., and T.S. Formal analysis: B.D., S.X., L.S., Y.T., D.I., D.H., W.W., R.G., T.Y., S.W., Y.I., S.L., K.F., and T.S. Writing—original draft: B.D., K.F., and T.S. Writing—review and editing: B.D., S.X., L.S., D.I., D.H., W.W., R.G., T.Y., S.W., Y.I., S.L., K.F., and T.S.

Competing interests: The authors declare that they have no competing interests.

Data and materials availability: All data needed to evaluate the conclusions in the paper are present in the paper and/or the Supplementary Materials.

Supplementary Materials

This PDF file includes:

Figs. S1 to S21

Tables S1 and S2

REFERENCES AND NOTES

- 1.Lee G.-H., Moon H., Kim H., Lee G. H., Kwon W., Yoo S., Myung D., Yun S. H., Bao Z., Hahn S. K., Multifunctional materials for implantable and wearable photonic healthcare devices. Nat. Rev. Mater. 5, 149–165 (2020). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Yun S. H., Kwok S. J. J., Light in diagnosis, therapy and surgery. Nat. Biomed. Eng. 1, 0008 (2017). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.van Soest G., Regar E., van der Steen A. F. W., Photonics in cardiovascular medicine. Nat. Photonics 9, 626–629 (2015). [Google Scholar]

- 4.Ollearo R., Ma X., Akkerman H. B., Fattori M., Dyson M. J., van Breemen A. J. J. M., Meskers S. C. J., Dijkstra W., Janssen R. A. J., Gelinck G. H., Vitality surveillance at distance using thin-film tandem-like narrowband near-infrared photodiodes with light-enhanced responsivity. Sci. Adv. 9, eadf9861 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Tuchin V. V., Polarized light interaction with tissues. J. Biomed. Opt. 21, 071114 (2016). [DOI] [PubMed] [Google Scholar]

- 6.Dhanabalan S. S., Sriram S., Walia S., Avaninathan S. R., Carrasco M. F., Bhaskaran M., Wearable label-free optical biodetectors: Progress and perspectives. Adv. Photonics Res. 2, 2000076 (2021). [Google Scholar]

- 7.Cai S., Xu X., Yang W., Chen J., Fang X., Materials and designs for wearable photodetectors. Adv. Mater. 31, 1808138 (2019). [DOI] [PubMed] [Google Scholar]

- 8.Polat E. O., Mercier G., Nikitskiy I., Puma E., Galan T., Gupta S., Montagut M., Piqueras J. J., Bouwens M., Durduran T., Konstantatos G., Goossens S., Koppens F., Flexible graphene photodetectors for wearable fitness monitoring. Sci. Adv. 5, eaaw7846 (2019). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Fuentes-Hernandez C., Chou W.-F., Khan T. M., Diniz L., Lukens J., Larrain F. A., Rodriguez-Toro V. A., Kippelen B., Large-area low-noise flexible organic photodiodes for detecting faint visible light. Science 370, 698–701 (2020). [DOI] [PubMed] [Google Scholar]

- 10.Jacoutot P., Scaccabarozzi A. D., Nodari D., Panidi J., Qiao Z., Schiza A., Nega A. D., Dimitrakopoulou-Strauss A., Gregoriou V. G., Heeney M., Chochos C. L., Bakulin A. A., Gasparini N., Enhanced sub-1 eV detection in organic photodetectors through tuning polymer energetics and microstructure. Sci. Adv. 9, adh2694 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Yin B., Zhou X., Li Y., Hu G., Wei W., Yang M., Jeong S., Deng W., Wu B., Cao Y., Huang B., Pan L., Yang X., Fu Z., Fang Y., Shen L., Yang C., Wu H., Lan L., Huang F., Cao Y., Duan C., Sensitive organic photodetectors with spectral response up to 1.3 μm using a quinoidal molecular semiconductor. Adv. Mater. 36, 2310811 (2024). [DOI] [PubMed] [Google Scholar]

- 12.Yang M., Yin B., Hu G., Cao Y., Lu S., Chen Y., He Y., Yang X., Huang B., Li J., Wu B., Pang S., Shen L., Liang Y., Wu H., Lan L., Yu G., Huang F., Cao Y., Duan C., Sensitive short-wavelength infrared photodetection with a quinoidal ultralow band-gap n-type organic semiconductor. Chem 10, 1425–1444 (2024). [Google Scholar]

- 13.Kim D.-H., Viventi J., Amsden J. J., Xiao J., Vigeland L., Kim Y.-S., Blanco J. A., Panilaitis B., Frechette E. S., Contreras D., Kaplan D. L., Omenetto F. G., Huang Y., Hwang K.-C., Zakin M. R., Litt B., Rogers J. A., Dissolvable films of silk fibroin for ultrathin conformal bio-integrated electronics. Nat. Mater. 9, 511–517 (2010). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Kim D.-H., Lu N., Ma R., Kim Y.-S., Kim R.-H., Wang S., Wu J., Won S. M., Tao H., Islam A., Yu K. J., Kim T., Chowdhury R., Ying M., Xu L., Li M., Chung H.-J., Keum H., McCormick M., Liu P., Zhang Y.-W., Omenetto F. G., Huang Y., Coleman T., Rogers J. A., Epidermal electronics. Science 333, 838–843 (2011). [DOI] [PubMed] [Google Scholar]

- 15.Yokota T., Zalar P., Kaltenbrunner M., Jinno H., Matsuhisa N., Kitanosako H., Tachibana Y., Yukita W., Koizumi M., Someya T., Ultraflexible organic photonic skin. Sci. Adv. 2, e1501856 (2016). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Y. Kim, C. Choi, E.-C. Chen, A. G. S. Daniel, A. Masurkar, T. H. Schwartz, H. Ma, I. Kymissis, An ultra thin implantable system for cerebral blood volume monitoring using flexible OLED and OPD, in 2015 IEEE International Electron Devices Meeting (IEDM) (IEEE, 2015), pp. 29.6.1–29.6.4; 10.1109/IEDM.2015.7409796. [DOI]

- 17.Li S., Jang J. H., Chung W., Seung H., Park S. I., Ma H., Pyo W. J., Choi C., Chung D. S., Kim D.-H., Choi M. K., Yang J., Ultrathin self-powered heavy-metal-free Cu–In–Se quantum dot photodetectors for wearable health monitoring. ACS Nano 17, 20013–20023 (2023). [DOI] [PubMed] [Google Scholar]

- 18.Wu W., Han X., Li J., Wang X., Zhang Y., Huo Z., Chen Q., Sun X., Xu Z., Tan Y., Pan C., Pan A., Ultrathin and conformable lead halide perovskite photodetector arrays for potential application in retina-like vision sensing. Adv. Mater. 33, e2006006 (2021). [DOI] [PubMed] [Google Scholar]

- 19.Wang X., Liu Y., Cheng H., Ouyang X., Surface wettability for skin-interfaced sensors and devices. Adv. Funct. Mater. 32, 2200260 (2022). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Kim R.-H., Kim D.-H., Xiao J., Kim B. H., Park S.-I., Panilaitis B., Ghaffari R., Yao J., Li M., Liu Z., Malyarchuk V., Kim D. G., Le A.-P., Nuzzo R. G., Kaplan D. L., Omenetto F. G., Huang Y., Kang Z., Rogers J. A., Waterproof AlInGaP optoelectronics on stretchable substrates with applications in biomedicine and robotics. Nat. Mater. 9, 929–937 (2010). [DOI] [PubMed] [Google Scholar]

- 21.Keum C., Murawski C., Archer E., Kwon S., Mischok A., Gather M. C., A substrateless, flexible, and water-resistant organic light-emitting diode. Nat. Commun. 11, 6250 (2020). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Jinno H., Fukuda K., Xu X., Park S., Suzuki Y., Koizumi M., Yokota T., Osaka I., Takimiya K., Someya T., Stretchable and waterproof elastomer-coated organic photovoltaics for washable electronic textile applications. Nat. Energy 2, 780–785 (2017). [Google Scholar]

- 23.Yang Y., Wang J., Zu Y., Liao Q., Zhang S., Zheng Z., Xu B., Hou J., Robust and hydrophobic interlayer material for efficient and highly stable organic solar cells. Joule 7, 545–557 (2023). [Google Scholar]

- 24.Chi C.-Y., Shih C.-H., Sauter E., Das S. K., Liang Y.-H., Lien H.-T., Chang S.-T., Zharnikov M., Tai Y., ZnO as an effective hole transport layer for water resistant organic solar cells. J. Mater. Chem. A 6, 6542–6550 (2018). [Google Scholar]

- 25.Kong J., Nordlund D., Jin J. S., Kim S. Y., Jin S.-M., Huang D., Zheng Y., Karpovich C., Sertic G., Wang H., Li J., Weng G., Antonio F., Mariano M., Maclean S., Goh T., Kim J. Y., Taylor A. D., Underwater organic solar cells via selective removal of electron acceptors near the top electrode. ACS Energy Lett. 4, 1034–1041 (2019). [Google Scholar]

- 26.Xiong S., Fukuda K., Nakano K., Lee S., Sumi Y., Takakuwa M., Inoue D., Hashizume D., Du B., Yokota T., Zhou Y., Tajima K., Someya T., Waterproof and ultraflexible organic photovoltaics with improved interface adhesion. Nat. Commun. 15, 681 (2024). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Xing R., Li Z., Zhao W., Wang D., Xie R., Chen Y., Wu L., Fang X., Waterproof and flexible perovskite photodetector enabled by P-type organic molecular rubrene with high moisture and mechanical stability. Adv. Mater. 36, e2310248 (2024). [DOI] [PubMed] [Google Scholar]

- 28.Zheng Y., Michalek L., Liu Q., Wu Y., Kim H., Sayavong P., Yu W., Zhong D., Zhao C., Yu Z., Chiong J. A., Gong H., Ji X., Liu D., Zhang S., Prine N., Zhang Z., Wang W., Tok J. B. H., Gu X., Cui Y., Kang J., Bao Z., Environmentally stable and stretchable polymer electronics enabled by surface-tethered nanostructured molecular-level protection. Nat. Nanotechnol. 18, 1175–1184 (2023). [DOI] [PubMed] [Google Scholar]

- 29.Roberts M. E., Mannsfeld S. C. B., Tang M. L., Bao Z., Influence of molecular structure and film properties on the water-stability and sensor characteristics of organic transistors. Chem. Mater. 20, 7332–7338 (2008). [Google Scholar]

- 30.Liu Y., Akin S., Pan L., Uchida R., Arora N., Milić J. V., Hinderhofer A., Schreiber F., Uhl A. R., Zakeeruddin S. M., Hagfeldt A., Dar M. I., Grätzel M., Ultrahydrophobic 3D/2D fluoroarene bilayer-based water-resistant perovskite solar cells with efficiencies exceeding 22%. Sci. Adv. 5, eaaw2543 (2019). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Periyanagounder D., Wei T., Li T., Lin C., Gonçalves T. P., Fu H., Tsai D., Ke J., Kuo H., Huang K., Lu N., Fang X., He J., Fast-response, highly air-stable, and water-resistant organic photodetectors based on a single-crystal Pt complex. Adv. Mater. 32, e1904634 (2020). [DOI] [PubMed] [Google Scholar]

- 32.Li H., Ma Y., Huang Y., Material innovation and mechanics design for substrates and encapsulation of flexible electronics: A review. Mater. Horizons 8, 383–400 (2021). [DOI] [PubMed] [Google Scholar]

- 33.Corazza M., Rolston N., Dauskardt R. H., Beliatis M., Krebs F. C., Gevorgyan S. A., Role of stress factors on the adhesion of interfaces in R2R fabricated organic photovoltaics. Adv. Energy Mater. 6, 1501927 (2016). [Google Scholar]

- 34.Simone G., Dyson M. J., Meskers S. C. J., Janssen R. A. J., Gelinck G. H., Organic photodetectors and their application in large area and flexible image sensors: The role of dark current. Adv. Funct. Mater. 30, 1904205 (2020). [Google Scholar]

- 35.Zuo G., Linares M., Upreti T., Kemerink M., General rule for the energy of water-induced traps in organic semiconductors. Nat. Mater. 18, 588–593 (2019). [DOI] [PubMed] [Google Scholar]

- 36.Petrus M. L., Hu Y., Moia D., Calado P., Leguy A. M. A., Barnes P. R. F., Docampo P., The influence of water vapor on the stability and processing of hybrid perovskite solar cells made from non-stoichiometric precursor mixtures. ChemSusChem 9, 2699–2707 (2016). [DOI] [PubMed] [Google Scholar]

- 37.Norrman K., Madsen M. V., Gevorgyan S. A., Krebs F. C., Degradation patterns in water and oxygen of an inverted polymer solar cell. J. Am. Chem. Soc. 132, 16883–16892 (2010). [DOI] [PubMed] [Google Scholar]

- 38.Jiang Y., Ji S., Sun J., Huang J., Li Y., Zou G., Salim T., Wang C., Li W., Jin H., Xu J., Wang S., Lei T., Yan X., Peh W. Y. X., Yen S.-C., Liu Z., Yu M., Zhao H., Lu Z., Li G., Gao H., Liu Z., Bao Z., Chen X., A universal interface for plug-and-play assembly of stretchable devices. Nature 614, 456–462 (2023). [DOI] [PubMed] [Google Scholar]

- 39.Peng Z., Xian K., Cui Y., Qi Q., Liu J., Xu Y., Chai Y., Yang C., Hou J., Geng Y., Ye L., Thermoplastic elastomer tunes phase structure and promotes stretchability of high-efficiency organic solar cells. Adv. Mater. 33, e2106732 (2021). [DOI] [PubMed] [Google Scholar]

- 40.Matsuhisa N., Niu S., O’Neill S. J. K., Kang J., Ochiai Y., Katsumata T., Wu H. C., Ashizawa M., Wang G. J. N., Zhong D., Wang X., Gong X., Ning R., Gong H., You I., Zheng Y., Zhang Z., Tok J. B. H., Chen X., Bao Z., High-frequency and intrinsically stretchable polymer diodes. Nature 600, 246–252 (2021). [DOI] [PubMed] [Google Scholar]

- 41.Kang H., Lee Y., Lee G. H., Chung J. W., Kwon Y., Kim J., Kuzumoto Y., Gam S., Kang S., Jung J. Y., Choi A., Yun Y., Strain-tolerant, high-detectivity, and intrinsically stretchable all-polymer photodiodes. Adv. Funct. Mater. 33, 2212219 (2023). [Google Scholar]

- 42.Ma X., Janssen R. A. J., Gelinck G. H., Trap-assisted charge generation and recombination in state-of-the-art organic photodetectors. Adv. Mater. Technol. 8, 2300234 (2023). [Google Scholar]

- 43.Kim M. H., Jeong M. W., Kim J. S., Nam T. U., Vo N. T. P., Jin L., Il Lee T., Oh J. Y., Mechanically robust stretchable semiconductor metallization for skin-inspired organic transistors. Sci. Adv. 8, eade2988 (2022). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 44.Faist M. A., Shoaee S., Tuladhar S., Dibb G. F. A., Foster S., Gong W., Kirchartz T., Bradley D. D. C., Durrant J. R., Nelson J., Understanding the reduced efficiencies of organic solar cells employing fullerene multiadducts as acceptors. Adv. Energy Mater. 3, 744–752 (2013). [Google Scholar]

- 45.Park J., Seok H. S., Kim S.-S., Shin H., Photoplethysmogram analysis and applications: An integrative review. Front. Physiol. 12, 808451 (2022). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 46.Xu J., Wang S., Wang G. J. N., Zhu C., Luo S., Jin L., Gu X., Chen S., Feig V. R., To J. W. F., Rondeau-Gagné S., Park J., Schroeder B. C., Lu C., Oh J. Y., Wang Y., Kim Y. H., Yan H., Sinclair R., Zhou D., Xue G., Murmann B., Linder C., Cai W., Tok J. B. H. B.-H., Chung J. W., Bao Z., Highly stretchable polymer semiconductor films through the nanoconfinement effect. Science 355, 59–64 (2017). [DOI] [PubMed] [Google Scholar]

- 47.Lin C., Hsieh C., Macdonald T. J., Chang J., Lin P., Cha H., Steier L., Wadsworth A., McCulloch I., Chueh C., Durrant J. R., Water-insensitive electron transport and photoactive layers for improved underwater stability of organic photovoltaics. Adv. Funct. Mater. 32, 2203487 (2022). [Google Scholar]

- 48.Bolognesi M., Prosa M., Tessarolo M., Donati G., Toffanin S., Muccini M., Seri M., Impact of environmentally friendly processing on polymer solar cells: Performance, thermal stability and morphological study by imaging techniques. Sol. Energy Mater. Sol. Cells 155, 436–445 (2016). [Google Scholar]

- 49.Halpati J. S., Samuel A. K., Robert T. M., Chandiran A. K., Real-time visualization of photobrightening in lead halide perovskites using confocal laser scanning microscopy. J. Phys. Chem. C 127, 3256–3267 (2023). [Google Scholar]

- 50.von Wowern E., Östling G., Nilsson P. M., Olofsson P., Digital photoplethysmography for assessment of arterial stiffness: Repeatability and comparison with applanation tonometry. PLOS ONE 10, e0135659 (2015). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Takazawa K., Tanaka N., Fujita M., Matsuoka O., Saiki T., Aikawa M., Tamura S., Ibukiyama C., Assessment of vasoactive agents and vascular aging by the second derivative of photoplethysmogram waveform. Hypertension 32, 365–370 (1998). [DOI] [PubMed] [Google Scholar]

- 52.Ryals S., Chiang A., Schutte-Rodin S., Chandrakantan A., Verma N., Holfinger S., Abbasi-Feinberg F., Bandyopadhyay A., Baron K., Bhargava S., He K., Kern J., Miller J., Patel R., Ratnasoma D., Deak M. C., Photoplethysmography—New applications for an old technology: A sleep technology review. J. Clin. Sleep Med. 19, 189–195 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.Jeong M. W., Ma J. H., Shin J. S., Kim J. S., Ma G., Nam T. U., Gu X., Kang S. J., Oh J. Y., Intrinsically stretchable three primary light-emitting films enabled by elastomer blend for polymer light-emitting diodes. Sci. Adv. 9, eadh1504 (2023). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 54.Bian Y., Liu K., Ran Y., Li Y., Gao Y., Zhao Z., Shao M., Liu Y., Kuang J., Zhu Z., Qin M., Pan Z., Zhu M., Wang C., Chen H., Li J., Li X., Liu Y., Guo Y., Spatially nanoconfined N-type polymer semiconductors for stretchable ultrasensitive X-ray detection. Nat. Commun. 13, 7163 (2022). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 55.Park Y., Fuentes-Hernandez C., Kim K., Chou W.-F., Larrain F. A., Graham S., Pierron O. N., Kippelen B., Skin-like low-noise elastomeric organic photodiodes. Sci. Adv. 7, eabj6565 (2021). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 56.Guan Y.-S., Ershad F., Rao Z., Ke Z., da Costa E. C., Xiang Q., Lu Y., Wang X., Mei J., Vanderslice P., Hochman-Mendez C., Yu C., Elastic electronics based on micromesh-structured rubbery semiconductor films. Nat. Electron. 5, 881–892 (2022). [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Figs. S1 to S21

Tables S1 and S2