Abstract

Logistics is critical in every company's supply chain (SC), and outsourcing helps businesses concentrate on their core competencies. Third-party logistics (3 PL) or logistics service providers (LSPs) assist businesses in cutting costs while improving performance, sustainability, and revenue. Logistics evaluation and LSPs choice are complicated and critical components of value delivery. This study aims to review logistics outsourcing literature to understand the trends, prospects, factors, and strategies used in logistics companies' outsourcing choices. This work examines the literature on LSPs selection published between 2010 and 2023. This paper uses VOSviewer (version 1.6.19) to visualize the relationships. Pricing, timely shipment, service quality, reliability, agility, technology, and consumer feedback are the most commonly utilized, whereas societal and environmental factors are seldom used. The study comprises journal publications, the year, selection criteria, and assessment methodologies. Numerous scholars have discovered and employed many critical selection criteria. Many investigators have also embraced multi-criteria decision-making (MCDM) methodologies, and their fuzzy form is widely used. In conclusion, recommendations for theorists and managers, limits, and future directions for research are offered.

Keywords: Supply chain, Logistics services outsourcing, Logistics service providers selection, Third-party logistics selection criteria, Third-party logistics selection techniques

1. Introduction

The COVID-19 epidemic has tremendously strained logistics companies to make last-mile home deliveries, particularly throughout lockdown times [1]. The capacity of third-party logistics (3 PL) providers to learn from experience is critical, not just in responding to crises like COVID-19 in terms of generating essential modifications but also in strategic improvement and corporate growth planning. Strong internal and external cooperation, interaction, administration, and operational processes carry out actual leadership [2].

TPL solidity and agility are determined by the level of cooperation, networking, organizational culture for action, digital information flow and knowledge exchange, and human resources that implement and mitigate risk [3,4]. When a corporation outsources logistics, an external supplier (a third party-3PL) handles multiple supply chain (SC) activities. Delivering, warehousing, and packaging, from raw materials to final product, might be included [5]. Various studies employed terminology to describe the company's external contractors, including 3 PL, LSPs, suppliers, and service providers [6].

3 PL or logistics outsourcing is becoming increasingly popular as more firms worldwide, able to adequately control their complicated SCs, outsource logistical tasks to 3 PL or LSPs [7]. Enterprises may not only focus on their main organizational processes by providing transport duties, but they can also save money and increase supply performance and CS. Global 3 PL revenue was $141 billion in 2003, and it is predicted to reach $300 billion in 2006. The primary market is the United States, which had a market value of almost $80 billion in 2003, representing approximately 60 % of the global market [8]. The present survey aimed to examine the 3 PL market in India, including its outlook, possibilities, and challenges. Data were gathered to analyze the 3 PL providers' strengths and shortcomings regarding resource basis, services supplied, industries serviced, penetration, and IT capabilities [9].

Many businesses today outsource their logistical activities to 3 PL service providers to concentrate on their key strengths. These 3 PLs have become vital actors in various chains and sectors since they help reduce costs, increase productivity, and enhance customer service quality. After choosing to work with a 3 PL, the following step is to select a provider. As a result, selecting an efficient and viable set of 3 PLs that can fulfill the client's specific needs and with whom the company can build its ties becomes a critical option. Many variables impact this decision, including pricing, services provided, and location [3].

Many aspects impact this selection, including pricing, services provided, region, tech, and quality. Literature evaluations on logistics outsourcing, in general, have previously been written. Unfortunately, in these studies, 3 PL selection is just stated as a vital choice in the outsourcing process, with no details provided about the search strategy and methodologies to be employed. This research is arranged to give a literature review on the criteria and methodologies used to choose the 3 PL [10].

Although some articles are published on this subject in the literature, this research distinguishes them from the following aspects:

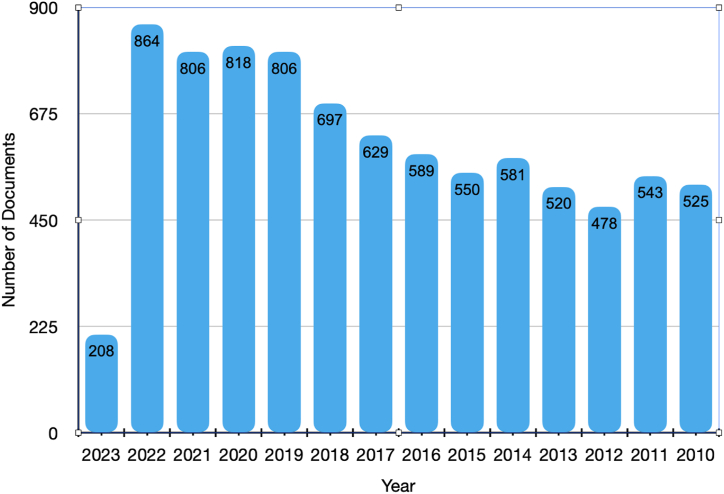

The review paper [11] encompasses the research between 2021 and half of 2022. In 2022, they examined only four documents. However, at the end of the year 2022, 864 academic documents were published. That is why this research provides a more comprehensive view of this theme. The paper [12] covers 152 papers written between 1989 and 2006. This review indicates the scholars' past research focuses. The research paper [13] also focuses on documents published between 2008 and 2020, including only ten papers in 2020. However, as this paper shows, 2896 papers were published from 2020 to 2023.

The novelty of this article lies in the dates covered by the research and the number of articles discussed. The following research questions were examined in this study.

-

•

What is the present situation of supplier selection bibliometric characteristics?

-

•

What is the current relationship between supplier selection and other journals?

-

•

What are the most significant theme tendencies in supplier selection?

-

•

What are the possibilities for supplier selection development?

The 3 PL properties are provided in the next section. The final section examines the literature on the criteria and procedures for picking 3 PL. The fourth part compares various strategies in terms of benefits and drawbacks. The final portion closes the investigation and discusses its outcomes.

1.1. The importance of 3 PL for Business

Businesses employ 3 PL services to gain advantages such as increased transportation effectiveness, inventory control, and other activities with value creation in logistics [14]. To be able to provide such benefits, 3 PL businesses are supporting the expansion of their service quality. One method is to include information technology (IT) in their job process. An IT can be defined as a collection of interconnected parts that acquire, process, retain, and exchange information to create and govern an organization's output. It provides its users with cost and error savings and improves information flow across all units [15]. Enterprise Resource Planning (ERP) is among the most sophisticated computer systems now offered to 3 PL firms [16] Artificial intelligence (AI) is among the most emerging innovations for everyday operations and SC management. This present technology functions on various topics, including product suggestions and customization, pricing policies, real-time production monitoring, mitigation of order delivery delays and warehouse shortfalls, and client feedback acquisition. Given their purpose in a system, AI may be roughly categorized into three branches [17].

The first category contains ways to detect and engage in multiple types, such as text, audio, and video, notably voice, vision, and NLP. The second comprises implementations and techniques for learning from data, and most Machine Learning approaches, such as deep learning, fall within this group. The third section includes decision-making solutions and approaches such as expert systems, planning, simulation, modeling, scheduling, and optimizations [18]. Recently, scholars have studied AI in industrial research. For example [19], conducted many case studies to compare the various AI elements in SCM. Several AI technologies are employed to make the SC leaner (less waste) and more efficient. This conclusion is consistent with the literature study in the theoretical background section, which concluded that various AI technologies interact with one another and are employed in tandem to develop an application. An adequate degree of IT infrastructure aids in the development of process automation and process optimization for SC jobs [20].

Sales forecasting, purchasing, warehousing, storing, stock management, packing, material management, transportation, order management, customer relations, support functions, return dealing, recovery, and waste management are all examples of logistics [21]. Logistic services are critical to the efficient flow of goods, information, and resources along an SC. Outsourcing logistics tasks to LSPs minimize costs and lead time while avoiding significant investments [22].

LSPs are an outer organization that handles, transmits, and governs storage, product dispersal, shipping, and customs duties for the benefit of freight forwarders [23] and competent authority, proficiency, capabilities, and connectivity in the form of a transportation system, storage facilities, and geographical locations that enables organizations to accomplish SC options at lower total supplied charges. Logistics outsourcing and strategic relationships with LSPs minimize costs while improving CS and productivity [24].

Companies across the globe are sourcing activities to LSPs to bring down costs, expenditures, and SC complexities, as well as to improve logistics potency [25], as well as to decrease labor costs, surplus stocks, the number of depots, lorries, and deformation [26], and to offer well-managed warehouse and SC solutions to both manufacturers and retailers. The increase in numerous enterprises’ global SC resulted in the emergence of outsourcing [27]. Several businesses have benefited from LSPs services regarding productivity, adaptability, and increased customer satisfaction [28]. Examining and choosing a logistics service provider as a key strategic partner is critical in logistics management [29]. Though locating an ideal LSPs might be difficult, diligent examination and selection can provide exceptional outcomes [30]. In the literature, numerous scholars have used a variety of selection criteria and approaches for assessing and selecting LSPs. Automobile mobility contributes to increased air pollution. The logistics business is unregulated in underdeveloped nations, and environmental responsibility is undervalued [31]. The industrial sector faces growing problems that will damage its competitiveness because of globalization, economic downturn, and ecological pressures. As a result, businesses should reconsider how they assess and choose LSPs [32]. LSPs assessment and choice require several tangible and intangible factors and options and hence are seen as a multi-criteria decision-making (MCDM) problem [33].

Adesunkanmi et al. [34] discovered that outsourcing substantially impacted the efficiency of industrial companies in South-west Nigeria in an investigation. Ali et al. [35] discovered that the main determinants for logistics outsourcing were improved quality and reliability and reduced logistics cost in a study of 49 pharmaceutical producers in the UK. Larson et al. [36] advocated for improved energy efficiency, reduced emissions, and societal well-being in logistics. Logistics excellence helps top Asian nations achieve sustainable growth [37]. LSPs use green or sustainable SC methods to address the efficiency in ecological and cost problems [32]. The logistics industry helps to create wealth while also considering the contribution to greenhouse gases and consuming vast amounts of materials [38]. SC strategies such as customer relationship, delay, amount of information exchange, and information quality have affected environmental sustainability. However, ecological sustainability substantially affects financial performance [39]. Business enterprises worldwide are worried about the environmental effects of construction and other operations [40]. Sustainability creation was discovered to have a significant positive correlation with company competitiveness. Company competitiveness has been proven to have a significant positive relationship with the Vietnamese SME industry's operational, financial, and environmental productivity [41].

Greener logistics approaches involving sustainable transportation mechanisms, reverse logistics, eliminating trash, more environmentally friendly delivery and packing, environmental monitoring and evaluation, and resilient data sharing have influenced environmental aspects and profitability [42]. In conventional logistics handling, greener logistics management entails the combination of financial, ecological, and humanitarian concepts. Many MCDM approaches, mathematical programming, and intelligent algorithms have been utilized in the literature for LSPs assessment and choice [43]. Based on several case studies the kind of outsourced services differed between organizations depending on the industry. The study discovered a significant positive association between sustainability innovation and corporate competitiveness [41].

Dynamic industries require rapid market reactions, SC flexibility, and outsourcing more value-generating activities than transportation and storage. However, outsourcing selections are influenced mainly by the company's strategy, namely how rapidly they want to respond to their market and the specific demands of their sector. Since most businesses outsource transportation and storage to 3 PLs, the firm's stock control policy determines the choice of outsourced storage. Second, the study guides on improving 3 PL-client relationship performance, resulting in higher partner commitment. These relational elements of trust, cooperation, information exchange, and power substantially impact partnerships, and the more they strengthen, the greater the partnership's success. These results are critical for 3 PLs, transporters, and business partnership administrators. A deficit of trust from the beginning of a relationship inhibits its success [35].

1.2. Logistics outsourcing

Outsourcing is a subset of the larger field of outsourcing study, which has piqued the interest of academics [44,[45], [46], [47]]. Logistics outsourcing still needs to be clarified since it refers to various things in various settings [48]. As a result, the literature has a broad assortment of definitions of logistics outsourcing [49].

Liu et al. [50] presented among the most generally recognized descriptions, referring to outsourcing as the mechanism through which a corporation engages other entities to supply services within an agreed-upon budget and timetable. Similarly, Guarnieri et al. [43] characterized logistics outsourcing as delegating portions of a company's inner tasks and decision-making duties to third-party service providers. According to Moreira et al. [6], outsourcing is the process by which an organization hires a service provider under an agreement to carry out an activity that was handled organizationally and delivers the appropriate resources, including employees and management responsibility, to that supplier. Even though the outsourcer's duties seem to be clarified, it has been argued that over-reliance on partner organizations may result in the user organization relinquishing the power of the processes, the lack of knowledge and expertise, and financial consequences in the occurrence of technological, operational, and managerial troubles [51].

1.3. Reasons for logistics outsourcing

One point of contention in the literature on logistics outsourcing is what causes the choice to outsource operations to LSPs. While businesses can outsource various non-core tasks, the motivations for doing so differ. Numerous prior studies have found that cost savings, improved service, and the necessity to concentrate on essential company tasks are significant motivators for outsourced logistics services [[52], [53], [54]].

It means that operations previously executed institutionally, such as material handling and shipping, are growingly accomplished by various stakeholders, resulting in lower expenditure on warehouses and vehicles [44]. Even though many researchers acknowledge that logistics outsourcing could indeed decrease transportation costs and other spending, others believe that it cannot every time substantially reduce estimated costs, and in certain situations, it may even raise transaction fees [46,47,53]. Apart from pricing, services, and essential capabilities, other criteria are cited as justifications for outsourcing logistical tasks. These factors have included the possibility for a company to enhance its competitive advantage by upgrading service quality and consistency and provide more the ability to deal with external factors such as regulatory and new tech and fluctuating demand companies might outsource logistics operations to third-party companies to boost capacities, performance, effectiveness, and revenue [55,56].

As a result, the user business may concentrate more efficiently on its core competencies while transferring non-core duties to trustworthy service providers [57]. With the increasing popularity of online shopping, the need for 3 PL has emerged [58]. argue that over 80 % of consumers in the USA and the UK evaluate the return policy when making an online purchase. Customers frequently purchase various sizes or colors, confident they have a quick return option if they do not like it. This ease, however, comes at a cost to both the environment and merchants. Returns are expected to cost merchants in the United States $550 billion by 2020 [58].

1.4. Criteria for assessment and selection of 3 PLs

Despite the many advantages of 3 PL outsourcing, companies strive to find a reliable partner to realize the anticipated advantages of outsourcing. Long-term outsourced partnerships need a higher degree of commitment from both parties and significant expenditures in cooperation [59]. The fierce competition in the market is forcing firms to leverage their suppliers’ networks more [60], which calls for selecting LSP that meet the needs of their customers [61]. In conclusion, many factors impact a service provider selection, including technical ability, quality, reliability, price, responsiveness to unexpected events, financial strength, accurate delivery, prompt customer response, and market entry. As part of a comprehensive framework developed by Abbasi et al. [62], they compared outsourcing partners by assessing their costs, and culture. Optimal LSPs can provide firms with reliability and faster delivery service, according to Liu et al. [63]. Based on the research of Ali et al. [35], LSPs are supposed to give faster and more dependable service as they are more informed about this sort of service.

To acquire a sustainable competitive edge, outsourcing firms must effectively evaluate the service providers' capabilities and relationships [64]. It was developed by Handley et al. [65] to assess a provider's financial performance as well as the quality of service offered. Numerous studies have suggested that good service quality is an important factor during the evaluation and selection of 3 PLs. Cost, quality, and delivery were the attributes looked at by Qureshi et al. [66], which led to the conclusion that it could be helpful to decision-makers in selecting appropriate suppliers based on these attributes. Choosing the supplier who offers the best value for the highest quality product would be best.

1.5. Outsourced logistics activities

When outsourcing logistics functions come to mind, we consider characteristics that differentiate the company in quality and value [51]. According to Arif et al. [22], organizations can outsource operations that have minor or negligible influence on their competitive strategy to specialized providers. The logistics tasks are outsourced for a variety of purposes. Azzi et al. [67] investigated the Italian health system and discovered that outsourcing to 3 PL providers was the most cost-effective technique. Outsourcing storage and transportation activities will almost certainly cut capital expenses associated with the storage and delivery of materials and commodities. Many previous studies have found that outsourcing storage and shipping services is familiar.

Several pharmaceutical companies in Pakistan were examined by Mubarik et al. [68], who concluded that outsourcing transportation activity had contributed significantly to the efficiency and effectiveness of the SC in the Pakistani pharmaceutical industry. An in-house or contracted manufacturer should be used to manufacture a new product. Different organizations outsource logistics activities for different reasons, making it difficult for pharmaceutical manufacturers to answer these questions satisfactorily [69].

Two hundred and twenty-three small and medium enterprise (SME) firms performing in Finland were studied by Solakivi et al. [70]. It was concluded that outsourced logistics information technology, order processing, and management activities were frequent. In their study [71], pointed out that pharmaceutical companies typically outsource logistics to third parties with high operational and dynamic capabilities. According to Hsiao et al. [72], logistics activities can be classified into three categories: basic (like transportation and warehousing), value-added (like inventory management), and strategic (like distribution system design). As well as research and development (R&D), materials and product delivery inventory management and reverse logistics, other outsourced activities include R&D and reverse logistics [22,73].

There are three major categories of outsourced logistics services, according to Ref. [53]. Essential logistics services include storing and shipping; value-adding logistics services include inventory control; and sophisticated logistics operations comprise managing orders, logistics information systems, IT services, and production, amongst others. Because of growing costs and lengthier development times, R&D and clinical experiments continue to be outsourced [74]. The literature on logistics outsourcing has covered a wide range of topics, such as the reasons for outsourcing logistics activities to 3 PLs [47] frequently outsourced logistics activities [75], and frequently outsourced logistics operations [70]. Nevertheless, no factors influencing outsourced logistics in the UK pharmaceutical manufacturing industry (PMI) have been noted in these investigations.

Rajesh et al. [44] investigated 3 PLs in India, whereas [46] investigated outsourced logistics providers in Turkish manufacturing businesses. Scholars from nations other than the United Kingdom have also researched logistics outsourcing. For example [22], in the Moroccan situation [48], in the Italian circumstances [73], in the Pakistani setting [72], in the Dutch food manufacturing sectors, and [75] in the Turkish pharmaceutical industry.

However, reverse logistics operations are sometimes disregarded and seen as secondary to typical forward logistics, which are more efficient and streamlined than random and disorganized ones. This situation has allowed operational savings in the retail sector since internet purchasing has expanded dramatically, resulting in an explosion of online returns. Operational expenses for managing returns are usually higher than for forward logistics processes due to the complicated nature linked to batch sizes of one, extra examinations, inspections, and separating processes, as well as the administration of potential maintenance, refurbishing, and recycling costs [58].

2. Literature review

2.1. Criteria for selecting logistics outsourcing providers

The characterization and prioritizing of success factors might aid professionals in achieving their objectives. We examine and pinpoint the numerous vital aspects of implementing logistics strategies in this study. Researchers in the literature have proposed a variety of criteria for evaluating and selecting LSPs. There are three categories of sustainability criteria.

2.1.1. Economics aspects

Several factors were considered by Abbasi et al. [76], including price, on-time delivery, product availability, service quality, reliability, flexibility, firm background, knowledge sharing, and reputation of the firm. In their study by Falsini et al. [77], cost, speed of service, equipment, and flexibility were considered. Logistics cost and service quality were proposed by Kumar et al. [78]. Among the factors considered by Ref. [79] are cost, quick time service, and reputation. Based on the service cost, performance level, knowledge of the participants' industries, IT capabilities, and global presence [62], evaluated respondents' service levels. Based on [80]'s study, cost, customer satisfaction, and labor union control were considered, as well as quality and compatibility. In addition to economics, strategy, management, and technology [81], also considered quality. Abbasi et al. [82] examined IT, Customer relationship management(CRM), just-in-time delivery, warehouse layout, forecasting methodologies, information sharing, long-term trade partnerships, service quality, order picking, and risk management.

Capacity, infrastructure, value-added services, logistics, and supplier partnerships were investigated by Guarnieri et al. [43]. Mangla et al. [83] determined that the criteria were delivery on time, price, responsiveness, expertise in the sector, usage of capacity, possession of assets, transportation information systems and technological integration, customer base, optimization capability, revenue growth rate, capability to cope with special requirements, image, leadership level, and globalization scope. The indicators employed by Hu et al. [84] were performance, cost, service, quality assurance, information technology (reliability of systems), and intangible assets.

Price, lead time, dependability, and manner of transportation should all be evaluated, according to Bask et al. [32].In their investigation [85], they opted to take into account the cost of service, financial condition, asset ownership, optimization capabilities, reputation and market position, and geographic location as criteria to consider. The price of service, prestige and market share, reliable delivery, and technical knowledge were all regarded by Roy et al. [86]. Sinani et [87] examined transportation costs, financial competence, driver expertise, and risk reduction methods. They assessed the costs and resources associated with outsourcing.

2.1.2. Environmental aspects

Falsini et al. [77] implemented environmental safeguards and operator safety. Environmental practices were adopted by Ref. [43]. Based on the results of [32], environmental-friendly services and ISO 14000 certification are being proposed. Among the environmental criteria [62], adopted ecological protection policies, transportation networks, and participation in green initiatives. Resources consumption, ISO 14000 compliance, green transportation, environmental protection, emissions, and waste generation were all considered by Ref. [86].

Garg et al. [88] employed a series of green practices, including green purchasing, reverse logistics, and emission minimization, ISO 14000 certification, and green materials. Stekelorum et al. [89] employed fuzzy-set qualitative comparative analysis (fsQCA) based on a survey. Green SC management refers to internal and external practice setups. As a result, rather than assessing the relative impact of each green practice, they utilized fsQCA to understand how causative circumstances, as configurations, are connected with outcomes, such as operational and financial outcomes. fsQCA examines the influence of the interaction of multiple circumstances on a result instead of the standalone influence of every element. Omotayo et al. [4] revealed that the vital aspect of innovation in sustainability is the choice of transport mode and purchase on quality, cost, and environmental consequences. Innovative ecological logistics are a moderator in the interaction between the critical success characteristics of 3 PL service providers and green logistics in Malaysia's industrial sector.

2.1.3. Social aspects

Social sustainability is the management of societal aspects to promote enterprises' long-term existence. In a larger sense, it refers to within-company personnel, community, stakeholder involvement, administration, and ecological process efficiency. Furthermore, it involves employees' health, diversity, social justice, safety, and stakeholder participation in the SC. Embracing social sustainability is critical for firms to increase SC sustainability's total efficiency and reach economic success. Social sustainability considers the well-being of existing humans and the health of upcoming generations [90].

Falsini et al. [77] considered operators’ safety, while Hu et al. [84] adopted a labor union. Occupational health and safety, personnel education, consistency with sustainable objectives, local community involvement, and adherence to ILO rules were all implemented, as described by Ref. [85].

Roy et al. [86] have highlighted the importance of health and safety, employee training, labor fairness, social impact, and ILO conformity. Garg et al. [88] consider safety, health, working conditions, a fair wage, and community support as significant factors.

2.2. Evaluation models for logistics providers

For the suggested selection of suitable LSPs, researchers have used a variety of MCDM techniques and mathematical models in the literature. LSP selection has been performed using single MCDM techniques, hybrid MCDM techniques, fuzzy MCDM techniques, and sustainable MCDM techniques. The hybrid model is demonstrated in the majority of articles.

2.2.1. Single model

Daim et al. [91] utilized AHP for 3 PLs, while Singh Bhatti et al. [92] practiced AHP for global logistics provider selection. An additive network DEA model has been proposed by Momeni et al. [93] to select the most appropriate 3 PL providers. Riaz et al. [94] suggested the image fuzzy hybrid weighted arithmetic geometric aggregation (PFHWAGA) operator and the picture fuzzy hybrid ordered weighted arithmetic geometric aggregation (PFHOWAGA) operator. The suggested operator is used in the MCDM process to choose a 3 PL provider.

2.2.2. Hybrid model

The literature has used single or hybrid models to assess and select LSPs. AHP and TOPSIS were used by Ref. [95]. For an Italian biscuit company, Bianchini et al. [96] used AHP and TOPSIS to select 3 PLs. An AHP and Taguchi loss function was proposed by Ordoobadi et al. [97] for selecting 3 PLs. The ROUGH-MABAC-DoE model was proposed by Chattopadhyay et al. [98]. Yousefi et al. [99] developed a two-stage hybrid model for selecting efficient providers, allocating orders, and calculating pricing in an SC with attention to member cooperation.

Initially, an integrated Multi-Objective Mixed-Integer Nonlinear Programming (MOMINLP) model is offered to reduce costs and assess providers concurrently. A single-buyer multi-vendor collaboration model and DEA were included in the suggested model. The approach is then condensed and transformed into a quadratic programming model. Finally, a model that uses the negotiation game and the Nash equilibrium idea to estimate the price decided on by the customer and the selected productive providers is devised. Moktadir et al. [100] developed a complete evaluation of SC risk variables using the leather sector as a practical example. Based on a literature review and conversations with domain experts, forty-four risk factors in the context of LISC have been selected. The discovered risk variables are further classified into five sustainability aspects. Pareto analysis is used to identify the most crucial risk variables. With the best-worst method (BWM), each relevant risk factor's significance for decision-making purposes was assessed.

2.2.3. Fuzzy model

Numerous quantitative evaluation algorithms make extensive use of fuzzy (opaque/uncertain) processing of data, including fuzzy logic, belief rule-based (BRB), evidential reasoning (ER), rule-based inference methodology via the evidential reasoning (RIMER), Dempster Shafer (DS) theory, fuzzy neural networks (FNNs), and others—these are representative ambiguous and uncertain facts and information [101].

There has been a proposal to extend various MCDM models to select LSPs using fuzzy logic. For a tire manufacturing company, Li et al. [102] offered fuzzy AHP (F-AHP)-fuzzy TOPSIS(F-TOPSIS) for LSP selection. In Ref. [78], fuzzy AHP-TOPSIS was used; Ali Sobhanallahi et al. [103] implemented QFD with F-TOPSIS. F- DEMATEL was utilized for supplier selection by Chang et al. [104]. Büyüközkan et al. [105] developed a hybrid model consisting of F- DEMATEL, F-ANP, and F- TOPSIS; and Alkhatib et al. [52] implemented fuzzy DEMATEL and F- TOPSIS. A fuzzy appropriateness index (FAI) was developed by Datta et al. [106] to evaluate and select third-party logistics providers. AHP-TOPSIS was applied in a confectionary company [107]. For an Indian automobile parts manufacturing firm, Sahu et al. [108] implemented a fuzzy appraisal module based on interval-valued fuzzy numbers (IVFNs).

Keshavarz Ghorabaee et al. [109] suggested the hybrid method of CRITIC and WASPAS (weighted aggregates sum product assessment) in the interval type-2 fuzzy set (IT2FS) for 3 PL evaluation. In their study of 3 PL selection for dangerous goods transportation. Sremac et al. [110] used rough combi aggregator-based SWARA(stepwise weight assessment ratio analysis) and WASPAS. Based on the fuzzy axiomatic design, extended regret aversion/rejoice preference, and expected perceived utility, Abbasi et al. [111] compared the results to TOPSIS for selecting LSPs in an Omnichannel environment. An F-AHP and F-TOPSIS were used by Singh et al. [112] for cold chain 3 PL selection. In their paper [113], proposed an F-AHP and F-TOPSIS method for selecting 3 PLs. For selecting third-party LSPs in SC finance, Wen et al. [114] offered a hesitant fuzzy linguistic-based CoCoSo method using fuzzy linguistics.

According to Pamucar et al. [115], fuzzy neutrosophic numbers can be used to calculate and rank 3 PLs [87]. state that 3 PL can be ranked using rough number-based Dombi-Hamy Means (RNDHMs). For selecting 3 PLs in IoT-based agriculture SCs, Yadav et al. [116] applied F-AHP. Pamucar et al. [117] applied a single-valued neutrosophic MABAC model for location selection. Perera et al. [118] utilized the Q-sort approach to categorize necessary success criteria and the AHP to determine the priority of the vital success elements. The DEMATEL technique determined the interdependencies between the critical success variables within every category. According to the findings, essential major success elements in the Sri Lankan third-party logistics sector include company expansion, technology, automation, globalization of processes, management, and leadership style. Alrasheedi et al. [119] proposed a novel method for determining the most sustainable supplier by combining entropy and SWARA as well as WASPAS methodologies under Pythagorean fuzzy sets (PFSs). The combined entropy-SWARA approach is used to compute the objective and subjective weights for criterion importance. The WASPAS approach is also used to rank sustainable supplier choices. To rank the candidate-supplier, taking into account both CFM and subjective variables, Bhattacharya et al. [120] combined AHP with quality function deployment (QFD).To choose the best provider in certain, uncertain, and probabilistic circumstances, Azadeh et al. [121] employed DEA, Fuzzy DEA, and Chance Constraint DEA.

To calculate the ultimate ranking of vendors, Chamodrakas et al. [122] merged FAHP, which is utilized for supplier selection, with Fuzzy Preference Programming (FPP), which addresses the consistency or uncertainty of human preference model approaches.

2.3. Mathematical programming model

Mathematical techniques were also included in the hybrid model for selecting LSPs. The AHP, DEA, and Linear Programming (LP) methods have been combined by Akhtar et al. [31]. Percin et al. [79] studied the auto part manufacturing industry using a combined QFD, fuzzy-linear regression, and multi-objective programming (MOP) model. The fuzzy bi-objective mixed integer linear programming (MILP) model was applied by Garg et al. [123] to minimize cost and maximize the performance of outsourced services to 3 PLs in a closed-loop supply chain(CLSC).

For selecting and distributing work among 3 PL firms, Haldar et al. [124] utilized an integrated DEA-TOPSIS-LP model. The proposed LSP selection model in cloud manufacturing was verified through mathematical model-based simulations by Huang et al. [125]. As part of a multi-objective programming (MOP) and genetic algorithm approach [71], selected LSPs and allocated orders using MOP. In a case study, Khalili Nasr et al. [126] suggested a two-phase fuzzy logistic service provider selection and order allocation model in a closed-loop SC.

In Stage 1, they employed the fuzzy BWM to identify the most proper suppliers based on economic, environmental, social, and circular factors. In Stage 2, they developed a multi-product, multi-period CLSC network with inventory-location-routing, vehicle scheduling, and quantity discounts using a MOMILP model.

2.3.1. Sustainable model

Wang et al. [127] provided a hybrid multi-criteria method called the fuzzy AHP and the Vlsekriterijumska optimization I kompromisno revenge (VIKOR) to examine the most prominent and contradicting parameters related to financial, service level, ecologic, and personal, and risk factors. Foroozesh et al. [128] utilized FMEA under interval-valued fuzzy group decision-making for sustainable supplier selection. Depending on environmental sustainability criteria, Bask et al. [32] selected 3 PLs. Evaluation and selection of 3 PLs have also taken sustainability into account. As part of the selection process for third-party logistics providers, Roy et al. [86] utilized economic, environmental, and social aspects in combination with the IVFRN-based FARE (factor relationship) and IVFRN-based BVM model [129]. For green supplier selection, Chu et al. [130] used IVIF-TODIM, while Stevic et al. [131] proposed MARCOS for sustainable supplier selection in the health sector. BWM and VIKOR methods were applied to selecting outsourcing partners by Garg et al. [88].

2.3.2. Model for reverse logistics evaluation

The Azadi and Saen [132] assessment and selection of reverse logistics providers (RLs) have received little attention. Mavi et al. [133] adopted the F- SWARA and F-MOORA method for 3PLRL selection, whereas Zarbakhshnia et al. [134] implemented F- SWARA and F- COPRAS, integrating the sustainability factor.

2.3.3. Inter-relationship model

Liou et al. [135] suggested DEMATEL for determining the relative weights of criteria, ANP for determining dependent relationships among measures, and VIKOR for selecting outsourcing partners. Using DEMATEL, Govindan et al. [136] proposed criteria for selecting 3 PLs based on their inter-relationships, whereas Kang et al. [137] employed F-ANP in IC packing [138]. utilized interpretive structural modeling (ISM), while Nasrollahi et al. [139] combined F-DEMATEL and ISM. In contrast, Hameed et al. [140] proposed structural equation modeling (SEM) for optimum supplier selection.

3. Results, analysis and discussion

3.1. Characteristics of supplier selection publications

The key features of supplier selection documents are examined in this section. On April 6, 2023, the dataset was obtained from the Scopus database. The documents were gathered using a subject search, and the keywords chosen are as follows:

(TITLE-ABS-KEY,third-party, logistics and service, provider and selection) or TITLE-ABS-KEY (supplier and selection) or TITLE-ABS-KEY (logistics, services, and outsourcing) or TITLE-ABS-KEY (logistics and service, providers, and selection) or TITLE-ABS-KEY (3 pl, logistics, service, provider and, selection) or TITLE-ABS-KEY (LSP and selection) and (LIMIT-TO (LANGUAGE, "English") and (LIMIT-TO (PUBYEAR, 2010) or LIMIT-TO (PUBYEAR,2011) or LIMIT-TO (PUBYEAR,2012) OR LIMIT-TO (PUBYEAR, 2013) OR LIMIT-TO (PUBYEAR, 2014) or LIMIT-TO (PUBYEAR, 2015) OR LIMIT-TO (PUBYEAR, 2016) or LIMIT-TO (PUBYEAR, 2017) OR LIMIT-TO (PUBYEAR, 2018) or LIMIT-TO (PUBYEAR, 2019) or LIMIT-TO (PUBYEAR, 2020) OR LIMIT-TO (PUBYEAR, 2021) or LIMIT-TO (PUBYEAR, 2022) or LIMIT-TO (PUBYEAR, 2023).

A total of 12,458 publications were obtained. As seen in Fig. 1, most papers were published in 2022, while the number of documents is at least in 2012. It is remarkable from Fig. 1 that the number of documents increased after COVID-19.

Fig. 1.

The number of documents over the years.

In addition, the document classifications are restricted to English articles between 2010 and 2023. We obtained articles from all document types, resulting in 5299 articles. The top 20 articles cited most are listed in Table 1 below.

Table 1.

The top 20 highly cited articles.

| Authors | Titles | Year | Source title | Citations |

|---|---|---|---|---|

| [141] | Multi-criteria decision making (MCDM) approaches for supplier evaluation and selection: A literature review | 2010 | European Journal of Operational Research | 1537 |

| [142] | Multi criteria decision making approaches for green supplier evaluation and selection: A literature review | 2015 | Journal of Cleaner Production | 746 |

| [143] | Application of decision-making techniques in supplier selection: A systematic review of literature | 2013 | Expert Systems with Applications | 732 |

| [144] | A fuzzy multi criteria approach for measuring sustainability performance of a supplier based on triple bottom line approach | 2013 | Journal of Cleaner Production | 726 |

| [145] | Environmental innovation and R&D cooperation: Empirical evidence from Spanish manufacturing firms | 2012 | Research Policy | 720 |

| [105] | A novel hybrid MCDM approach based on fuzzy DEMATEL, fuzzy ANP and fuzzy TOPSIS to evaluate green suppliers | 2012 | Expert Systems with Applications | 714 |

| [146] | Integrating sustainability into supplier selection with grey system and rough set methodologies | 2010 | International Journal of Production Economics | 647 |

| [147] | A comparison between Fuzzy AHP and Fuzzy TOPSIS methods to supplier selection | 2014 | Applied Soft Computing Journal | 579 |

| [148] | Why is Tanimoto index an appropriate choice for fingerprint-based similarity calculations? | 2015 | Journal of Cheminformatics | 564 |

| [149] | Integrated fuzzy multi criteria decision making method and multiobjective programming approach for supplier selection and order allocation in a green supply chain | 2013 | Journal of Cleaner Production | 559 |

| [150] | An ISM approach for the barrier analysis in implementing green supply chain management | 2013 | Journal of Cleaner Production | 555 |

| [151] | An integrated framework for sustainable supplier selection and evaluation in supply chains | 2017 | Journal of Cleaner Production | 530 |

| [152] | A fuzzy VIKOR method for supplier selection based on entropy measure for objective weighting | 2011 | Expert Systems with Applications | 524 |

| [153] | Selecting green suppliers based on GSCM practices: Using Fuzzy TOPSIS applied to a Brazilian electronics company | 2014 | European Journal of Operational Research | 515 |

| [154] | Channel Selection and Coordination in Dual-Channel Supply Chains | 2010 | Journal of Retailing | 498 |

| [155] | Integration of artificial neural network and MADA methods for green supplier selection | 2010 | Journal of Cleaner Production | 491 |

| [74] | Supplier selection using fuzzy AHP and fuzzy multi-objective linear programming for developing low carbon supply chain | 2012 | Expert Systems with Applications | 485 |

| [104] | Fuzzy DEMATEL method for developing supplier selection criteria | 2011 | Expert Systems with Applications | 478 |

| [156]. | An extended TODIM multi-criteria group decision making method for green supplier selection in interval type-2 fuzzy environment | 2017 | European Journal of Operational Research | 451 |

| [157] | Two-echelon multiple-vehicle location-routing problem with time windows for optimization of sustainable supply chain network of perishable food | 2014 | International Journal of Production Economics | 445 |

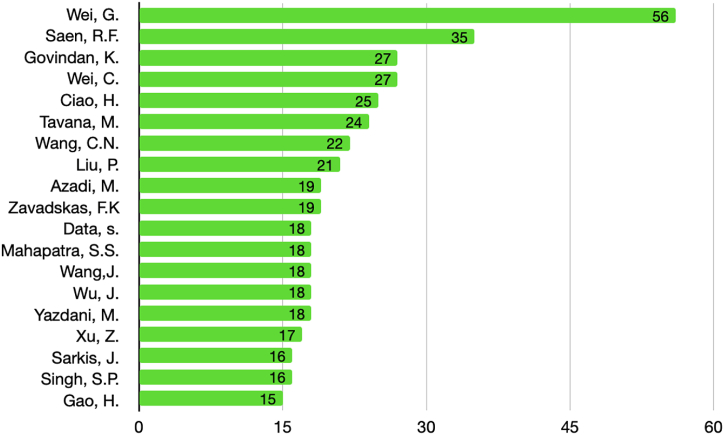

The article [141],” MCDM approaches for supplier evaluation and selection: A literature review,” is the most cited article in this field, with 1537 citations. The following five articles have more than 700 citations in this field. Regarding the top authors in this area, the most productive authors can be determined by their article numbers. Fig. 2 illustrates the document numbers of the top authors in the field.

Fig. 2.

The most productive authors in the area.

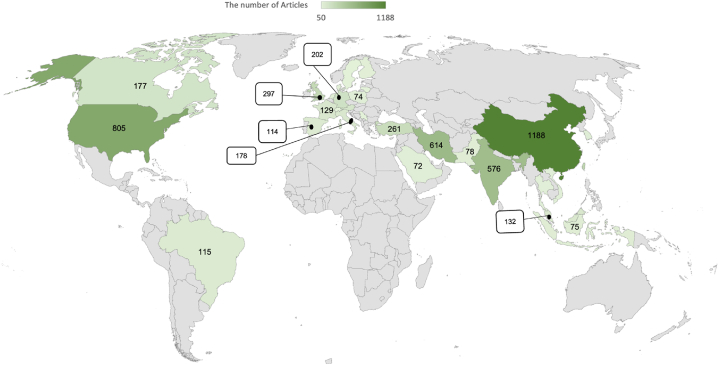

Fig. 2 clearly shows that Wei, G. is the leader with 56 papers, followed by Saen, R.F., with 35 articles. Govindan, K., Wei, C., and Ciao, H. are among the top five productive authors who published articles in this field. The leading countries where the authors published most papers are mapped in Fig. 3. According to Fig. 3, China is the leading country in the world, with 1188 articles in this area. They were followed by the USA, Iran, and India regarding article numbers 805, 614, and 576, respectively. Taiwan, the United Kingdom, Turkey, Germany, Canada, and Austria are among the top ten nations in this field.

Fig. 3.

The leading countries in the area in terms of document number.

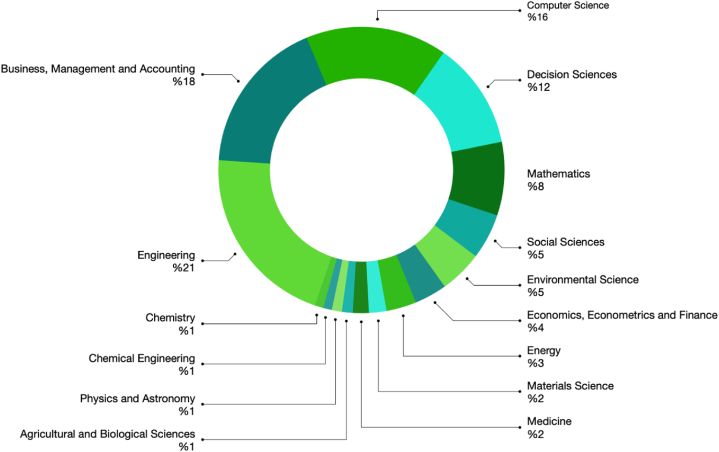

Articles selection topic. Among the topics of supplier selection. Fig. 4 shows the percentage of top research areas for the topic among 38 disciplines, i.e., chart. The topic was handled primarily on 2276 articles by researchers in engineering. The second area is business, management, and accounting, with a percentage of 18, followed by computer science and decision sciences.

Fig. 4.

Percentage of articles published in research areas.

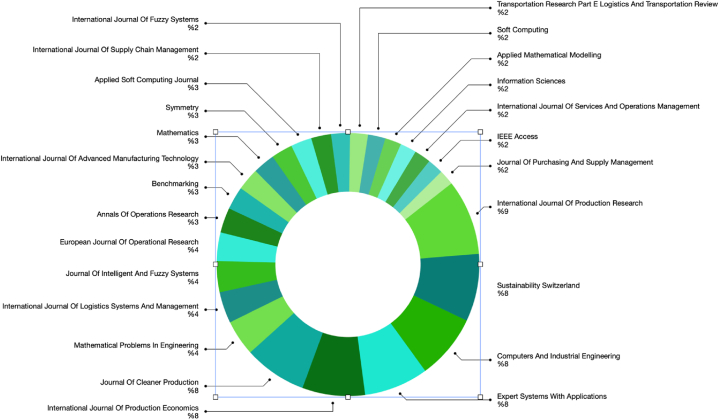

Fig. 5 below shows the percentage of journals that publish documents on this subject in a pie chart. It demonstrates that the most prominent journal is the International Journal of Production Research, which constitutes 9 % of the total. The second most published journals are Sustainability Switzerland, Computers and Industrial Engineering, Expert Systems with Applications, International Journal Of Production Economics, and the Journal Of Cleaner Production, with the same percentage (8 %).

Fig. 5.

Percentage of articles published by the journals.

The European Journal of Operational Research, Journal of Intelligent and Fuzzy Systems, International Journal of Logistics Systems and Management, and Mathematical Problems in Engineering are the top 3 leading sources in this field.

3.2. Bibliometric analysis

This part examines the author's keywords of all relevant publications, creates co-occurrence networks, and conducts explosion recognition on specific keywords to find exciting research subjects in supplier selection or outsourcing efficiently. Hence, this section is divided into two subsections.

3.2.1. Keyword occurrences

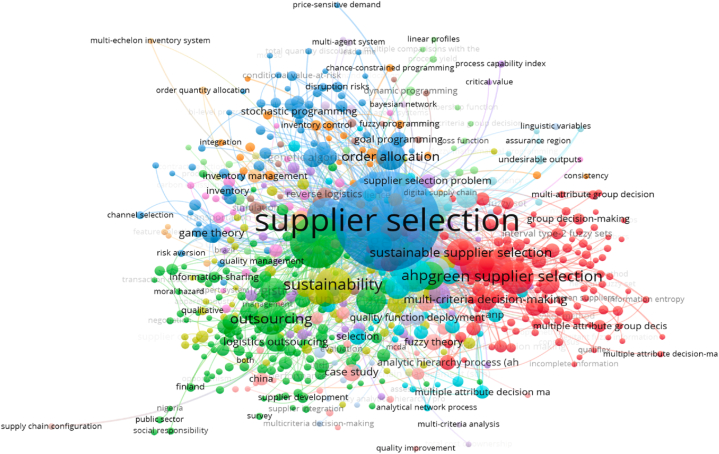

The concept of co-occurrence involves the simultaneous appearance of the attribute elements specified.The exterior and internal aspects of the literature, including title, author, keywords, universities, and so on, are included as characteristic elements of the concept. The "co-occurrence analysis" is a scientific examination of the co-occurrence event that reveals the data's content relationship. According to research, utilizing an article's keywords to determine the topic is more successful than utilizing terms from the title or the abstract. The information suggested by distinct components is set through supplier selection analysis. Keywords may be utilized to emphasize the study horizons in that field. As a result, keyword co-occurrence networks are an excellent alternative for identifying centers and development patterns in the study field. That is why, in this study, the co-occurrence of authors' keywords was examined. The minimum number of keyword occurrences was set to five as a threshold. Of 11,957 keywords, 643 met the threshold. For every 643 keywords, the total strength of the co-occurrence relation with other keywords was calculated by the VOSviewer software, and the visualization was created to the total link strength. The network analysis and overlay diagrams are illustrated in Fig. 6, Fig. 7 below.

Fig. 6.

Network analysis of co-occurrence according to authors' keywords with 17 clusters.

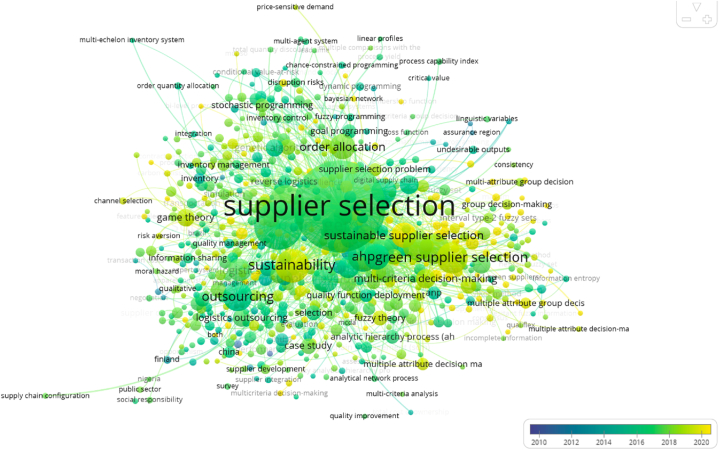

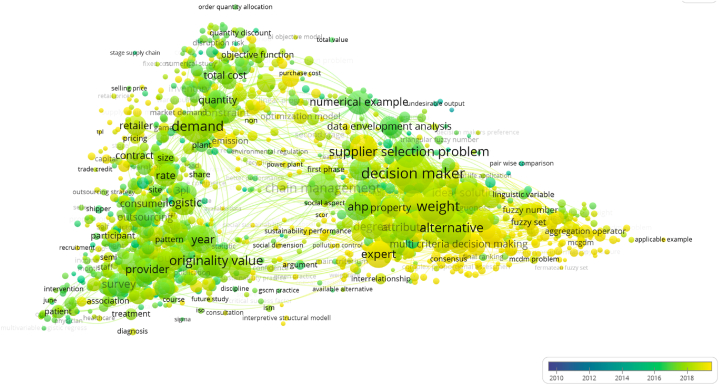

Fig. 7.

Overlay diagram of co-occurrence according to authors' keywords with 17 clusters.

Fig. 6 expands the keywords with seventeen clusters indicating the topic's uses in various methods and themes. Fig. 7 depicts the year-wise pattern of articles evaluated from 2010 to 2023 and reveals that the issue has gained vital significance in the last few years. It depicts the present hot point and common study trend of supplier selection articles.

The magnitude of the node shows the frequency with which keywords appear. The line connecting two nodes implies that they co-occur. The thickness of the paths shows the degree of co-occurrence, such as the number of publications containing two keywords that exist simultaneously. The larger the node, the more frequently it occurs. The graph reveals that the most significant nodes are "supplier selection", "sustainability", "order allocation," and "outsourcing." However, to comprehend all clusters from Fig. 6, they need to be clarified; therefore, the keywords and their frequency of co-occurrence and total link strength are listed in Table 2.

Table 2.

The top high co-occurred authors’ keywords and their total link strength.

| Keyword | Occurrences | Total link strength |

|---|---|---|

| 3 PL | 40 | 37 |

| Adverse selection | 18 | 16 |

| Agency selling | 5 | 3 |

| Agency theory | 5 | 5 |

| Aggregation | 6 | 5 |

| Aggregation operator | 12 | 12 |

| Aggregation operators | 6 | 5 |

| Agility | 7 | 6 |

| Agri-food supply chain | 5 | 4 |

| AHP | 158 | 154 |

| Analysis of variance | 6 | 4 |

| Analytic hierarchy process | 113 | 109 |

| Analytic hierarchy process (AHP) | 33 | 30 |

| Analytic network process | 38 | 37 |

| Analytic network process (ANP) | 13 | 12 |

| Analytical hierarchy process | 40 | 39 |

| Analytical hierarchy process (AHP) | 11 | 11 |

| Analytical network process | 8 | 8 |

| ANP | 28 | 28 |

| Apparel | 5 | 5 |

| Apparel industry | 6 | 5 |

| ARAS | 5 | 4 |

| Artificial intelligence | 9 | 9 |

| Artificial neural network | 5 | 5 |

| Assessment | 6 | 6 |

| Assurance region | 5 | 5 |

| Asymmetric information | 7 | 6 |

| Auctions | 5 | 5 |

| Australia | 6 | 4 |

| Automotive | 7 | 6 |

| Automotive industry | 26 | 25 |

| Availability | 5 | 3 |

| Balanced scorecard | 8 | 8 |

| Bayesian network | 6 | 6 |

| Bayesian networks | 5 | 4 |

| Benchmarking | 16 | 14 |

| BWM method | 11 | 9 |

| BWM method | 23 | 22 |

| Bi-level programming | 5 | 4 |

| Big data | 6 | 6 |

| Bill of materials | 5 | 5 |

| Blockchain | 7 | 5 |

| Blockchain technology | 8 | 8 |

| Both | 5 | 5 |

| Bounded rationality | 6 | 6 |

| Brazil | 7 | 6 |

| Bullwhip effect | 5 | 4 |

| Business improvement | 9 | 9 |

| Business performance | 5 | 5 |

| Business-to-business marketing | 8 | 7 |

The top 10 most often used terms are 3 PL, adverse selection, agency selling, agency theory, aggregation, aggregation operator, aggregation operators, agility, agri-food SC, and AHP.

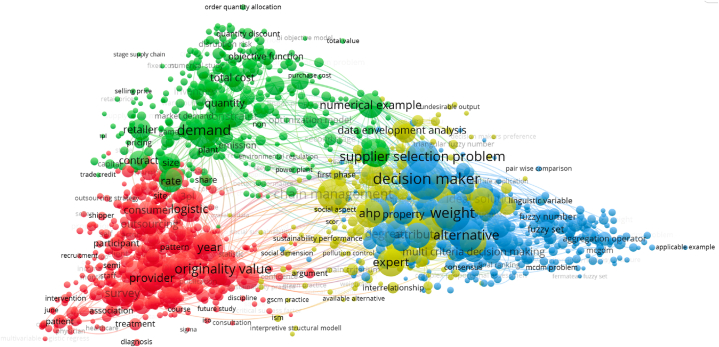

3.2.2. Co-Words analysis

The abstract terms were extracted to conduct a co-word analysis to investigate the content of the articles. The minimum number of occurrences of a term was selected as 10, and of the 77,233 terms, 2238 satisfied the condition. The software computed a relevance score for each of the 2238 terms. Depending on the scores, the most relevant terms were chosen. As a default value of 60 percent of the most relevant terms, 1343 terms were examined in terms of co-occurrence analysis. The software created the network analysis and term overlay diagrams, which are visualized in Fig. 8, Fig. 9.

Fig. 8.

Network analysis of abstract terms.

Fig. 9.

Overlay diagram of abstract terms.

As seen in Fig. 8, the four clusters emerged based on the term relevancy. Each color represents a thematic cluster in the graph. In addition, the time-based visualization in Fig. 9 demonstrates the recent hot topic terms in the supplier selection subject are demand, decision maker, originality, value, provider, weight, supplier selection problem, and alternative.

3.2.2.1. Cluster1: decision making with management and strategic planning

The first cluster (red) includes 1343 terms, such as 3 PL, consumer, accesses, acquisition, adverse selection, age, agency, B2B, business model, business performance, empirical analysis, constructing industry, and marketing strategy. These terms indicate that the articles mainly comprise better managing the outsourcing operation and finding efficient policies in different sectors such as healthcare, agriculture, construction, and the apparel industry.

3.2.2.2. Cluster 2: decision-making with optimum operation

Two hundred thirty-nine terms are clustered in the second (green) group, including allocation, constraints, demand, quantity, objective function, rate, retailer, contract, size, and inventory. These terms refer to the articles that focused on optimization problems in supply chain networks (SCNs) with different optimization techniques, such as mixed integer linear programming or heuristic models, to determine cost-effective design or planning.

3.2.2.3. Cluster 3: decision-making with multi-criteria

The third cluster (blue) covers 311 terms. The most relevant terms in this category are decision maker, weight, supplier selection problem, AHP, alternative, MCDM, aggregation operator, and fuzzy. These terms represent the papers on supplier selection with different MCDM methods, like AHP or the best-worst method (BMW). Some utilized the MCDM method in different fuzzy environments, such as intuitionistic, trapezoidal, or interval-valued. In contrast, others focused on the aggregation operator to evaluate the performance of suppliers.

3.2.2.4. Cluster 4: decision-making with sustainable performance

The fourth cluster (yellow) has 197 terms. They are in the articles concentrated on the sustainable performance of suppliers or the triple bottom line concept (TBL) in terms of environmental and social practices. Fuzzy AHP, fuzzy VIKOR, fuzzy ANP, DEMATEL, fuzzy TOPSIS, FMEA (Failure Mode and Effect Analysis), fuzzy BWM, Promethee, and Data Envelopment Analysis (DEA) were the most used techniques to evaluate the green suppliers. Some articles use an integrated approach.

4. Discussion and proposed framework

The evaluation and selection of LSPs are associated with uncertainty, ambiguity, and complexity. Discussion can be drawn by analyzing the literature on logistics outsourcing.

-

∗

Scholars have proposed different criteria for evaluating logistics outsourcing providers. Most papers do not cluster the criteria. Generally, they can be categorized into economic, operational, agile, resilient, environmental, and socially sustainable criteria.

-

∗

When selecting a service provider, it is crucial to consider the cost of service, on-time delivery, responsiveness, service quality, reliability, capacity, and flexibility. Equipment, technology, IT capabilities, information sharing, financial stability, firm reputation, strategic alliance location, customer relationship, risk management, and value-added services.

-

∗

Only a few studies have applied environmental and social sustainability criteria. The tendency to use them is increasing due to global pressure and awareness. Environment-friendly transportation and ISO 14000 compliance are essential allies regarding environmental considerations, safeguards, and practices. Sustainable criteria such as working hours, working environment, occupational health, risk, and safety should be used in LSP evaluation.

-

∗

Most of the papers used MDCM methods to demonstrate their application AHP, TOPSIS, and fuzzy variants are the LSP assessment and selection techniques most widely used.

-

∗

A fuzzy variant is the most commonly used MCDM method. The widely applied fuzzy sets are the triangular fuzzy, intuitionistic fuzzy, grey and rough numbers, and fermatean fuzzy. In contrast, interval-valued, neutrosophic, picture, spherical, and hesitant fuzzy sets are rarely utilized. More recently, researchers have focused on different aggregation operators in MCDM methods or proposed novel operators and shown their applicability in case studies.

-

∗

Several papers have combined linear programming techniques and mixed integer linear programming with other MCDM methods or DEA.

-

∗

MCDM techniques have also been applied in limited articles to reverse logistics provider selection.

-

∗

DEMATEL with different fuzzy environments was one of the most preferred MCDM methods since it examines the effect of one criterion on the other.

5. Conclusion, an implication for research and practice, limitations, and future research

5.1. Conclusion

This literature review paper included articles released during the past 12 years (2010–2023) to answer the four research questions outlined above. In addition to examining the number of publications year over year, the analysis examined trends in adopting criteria and evaluation methods. Research gaps and directions for future research were identified. The results indicate that authors differ in their selection criteria. Implementing environmental and social sustainability criteria is slow, but financial and operative indicators are extensively utilized.

Most of the criteria for agility, resilience, and risk are ignored. The most common method is the MCDM, where AHP, TOPSIS, and their fuzzy variants are more widely utilized. In the literature, there is no comparative analysis of different methods. Determining the best way to select LSPs regarding accuracy and robustness is challenging.

5.2. Managerial implications

As an orchestrator, the 3 PL plays an increasingly important management role. Management should acknowledge the potential contribution of 3 PL firms when non-core competencies are being outsourced and take advantage of those opportunities to address organizational needs. In addition to providing an increased competitive advantage, 3 PLs can also provide a cost-saving opportunity. A 3 PL can be seen as a strategic player in a SC rather than simply a vendor because of its unique position and growing capabilities. Managers need to know about taking advantage of the additive roles that 3 PLs can play and even demanding them from their 3 PLs.

The additive roles include SC standardization, technology and process adoption, effective planning, and performance improvement. The role of a neutral arbitrator is to assist in implementing change, collaborate with other SC partners, and eventually orchestrate the SC for everyone's benefit. As managers select, evaluate, and manage relationships with 3 PL partners, they can also consider the implications of these roles.

Over the past 13 years, the review analyzed logistics outsourcing publications and analyzed journals, year-wise articles, selection criteria, and selection techniques for LSPs. This study enhances the logistics outsourcing literature. Furthermore, it has developed a greater awareness of the logistics sector's social and environmental sustainability challenges. A supply chain management (SCM) design suggested in this work can enhance flexibility, efficiency, and sustainability.

5.3. Limitations and future research

The study only focused on evaluating and selecting logistics outsourcing providers. However, it is essential to consider the influence of contracting on LSP effectiveness, the consequences of sustainable implementation on LSP economic viability, and customer satisfaction. This study uses the Scopus database; however, it may have included only some peer-reviewed publications based on EBSCO and Google Scholar. Since this study is a decent sample of investigations on outsourcing logistical decisions, further investigations might include larger datasets. LSPS needs to differentiate itself from its competitors by implementing sustainable operations, and manufacturers should prioritize sustainability in outsourcing decisions.

Another limitation of the study is that it is restricted to 3 PL. Future studies should consider expanding their analysis to include higher-order LSPs such as 4 PL, 5 PL, and even 6 PL, in addition to 3 PL. The scope of future studies might broaden with a more thorough comprehension of the dynamics inside the logistics services outsourcing environment.

One limitation of the study is that it is restricted to 3 PL. Future studies should consider expanding their analysis to include higher-order logistics service providers such as 4 PL, 5 PL, and even 6 PL in addition to 3 PL. The scope of future studies might broaden with a more thorough comprehension of the dynamics inside the logistics services outsourcing environment.

In the future, several ecological variables might be integrated into the examination and decision-making process for LSPs. Outsourcing decisions must consider environmental security standards, the energy efficiency of vehicles and storage, eco-friendly design and reuse, and recycling materials of packing and decreasing waste, reverse logistics, and social aspects like working hours, workplace circumstances, as well as financial and operative efficiency concerns to contribute to sustainable action. A hybrid fuzzy MCDM model to select LSPs that incorporates agility, resilience, economics, environmental impact, and social sustainability criteria will be developed for future research. Logistics agility, resilience, and sustainability will be enhanced by the proposed model, as well as meeting operational and technical logistics requirements. Groups of decision-makers were able to address the subjective bias and uncertainty inherent in individual decisions by employing the fuzzy variation of MCDM procedures. Managers will be able to focus more on cause criteria in the future by studying relationships between criteria utilizing ISM, TISM, DEMATEL, and fuzzy cognitive mapping (FCM). Also, it would be helpful to compare deterministic and fuzzy models and one method with another to determine whether the method is robust and accurate and if it applies to a wide range of problems.

CRediT authorship contribution statement

Sina Abbasi: Writing – original draft, Visualization, Validation, Project administration, Methodology, Investigation, Formal analysis, Data curation, Conceptualization. Çiğdem Sıcakyüz: Writing – review & editing, Writing – original draft, Validation, Methodology, Formal analysis, Conceptualization. Ernesto DR Santibanez Gonzalez: Writing – review & editing, Writing – original draft, Visualization, Validation, Supervision, Methodology, Formal analysis, Conceptualization. Peiman Ghasemi: Writing – review & editing, Visualization, Validation, Methodology.

Declaration of competing interest

The authors declare the following financial interests/personal relationships which may be considered as potential competing interests: Corresponding author Prof. Ernesto DR santibanez Gonzalez is Associate Editor of Heliyon If there are other authors, they declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Contributor Information

Sina Abbasi, Email: abbasisina170@gmail.com.

Çiğdem Sıcakyüz, Email: csicakyuz@live.de.

Ernesto DR Santibanez Gonzalez, Email: santibanez.ernesto@gmail.com.

Peiman Ghasemi, Email: peiman.ghasemi@univie.ac.at.

References

- 1.Abbasi Sina, Vlachos Ilias, Rekabi Shabnam, Talooni Mohammad. Designing the distribution network of essential items in the critical conditions of Earthquakes and COVID-19 simultaneously". Sustainability. 2023;15(22) doi: 10.3390/su152215900. [DOI] [Google Scholar]

- 2.Gonzalez E.D.S., Abbasi S., Azhdarifard M. Designing a reliable aggregate production planning problem during the Disaster period. Sustainable Operations and Computers. 2023 doi: 10.1016/j.susoc.2023.08.004. [DOI] [Google Scholar]

- 3.Darko E.O., Vlachos I. Creating valuable relationships with third-party logistics (3PL) providers: a multiple-case study. Logistics. 2022;6(2):38. doi: 10.3390/logistics6020038. [DOI] [Google Scholar]

- 4.Omotayo A., Melan M. Innovative logistics practices: performance assessment of third-party logistics services providers in Malaysia. Journal of Economics, Management and Trade. 2022;28(2):39–48. doi: 10.9734/JEMT/2022/v28i230393. [DOI] [Google Scholar]

- 5.Gkanatsas E., Krikke H. Towards a pro-silience framework: a literature review on quantitative modelling of resilient 3PL supply chain network designs. Sustainability. 2020;12(10):4323. doi: 10.3390/su12104323. . [DOI] [Google Scholar]

- 6.Moreira O.J., Rodrigues M.C.M. Sourcing third party logistics service providers based on environmental, social and corporate governance: a case study. Discover Sustainability. 2023;4(1):36. . [Google Scholar]

- 7.Setiawan V.N., Ellitan L. Vol. 2. ; 2023. Supply chain management and supply chain Performace: the case of Mcdonald's; pp. 1255–1269. ULIL ALBAB: Jurnal Ilmiah Multidisiplin. [Google Scholar]

- 8.Choudhury S., Jayaprakash P., Srinivas S., Sowmya S., Shah T., Abinaya R. A blockchain platform for the truck freight marketplace in India. Operations Management Research. 2023:1–21. doi: 10.1007/s12063-023-00353-4. . [DOI] [Google Scholar]

- 9.Jhawar A., Garg S.K., Khera S.N. Improving logistics performance through investments and policy intervention: a causal loop model. Int. J. Prod. Qual. Manag. 2017;20(3):363–391. doi: 10.1504/IJPQM.2017.082638. . [DOI] [Google Scholar]

- 10.Abbasi S., Moosivand M., Vlachos I., Talooni M. Designing the location–routing problem for a cold supply chain considering the COVID-19 Disaster. Sustainability. 2023;15(21) doi: 10.3390/su152115490. . [DOI] [Google Scholar]

- 11.Qureshi M.R.N.M. A bibliometric analysis of third-party logistics services providers (3PLSP) selection for supply chain strategic advantage. Sustainability. 2022;14(19) doi: 10.3390/su141911836. . [DOI] [Google Scholar]

- 12.Marasco A. Third-party logistics: a literature review. Int. J. Prod. Econ. 2008;113(1):127–147. doi: 10.1016/j.ijpe.2007.05.017. . [DOI] [Google Scholar]

- 13.Premkumar P., Gopinath S., Mateen A. Trends in third party logistics–the past, the present & the future. Int. J. Logist. Res. Appl. 2021;24(6):551–580. doi: 10.1080/13675567.2020.1782863. [DOI] [Google Scholar]

- 14.Kale K.S. The impact of 3PL services on TQM in automobile industry with special reference to state of Maharashtra. PalArch's Journal of Archaeology of Egypt/Egyptology. 2021;18(7):2316–2324. . [Google Scholar]

- 15.Kiba-Janiak M., Cheba K. Information system for city logistics. The case of Poland. Transport. Res. Procedia. 2019;39:160–169. doi: 10.1016/j.trpro.2019.06.018. . [DOI] [Google Scholar]

- 16.Kahraman C., Beskese A., Kaya I. Selection among ERP outsourcing alternatives using a fuzzy multi-criteria decision making methodology. Int. J. Prod. Res. 2010;48(2):547–566. [Google Scholar]

- 17.Fosso Wamba S., Queiroz M.M., Guthrie C., Braganza A. Industry experiences of artificial intelligence (AI): benefits and challenges in operations and supply chain management. Prod. Plann. Control. 2022;33(16):1493–1497. doi: 10.1080/09537287.2021.1882695. . [DOI] [Google Scholar]

- 18.Pournader M., Ghaderi H., Hassanzadegan A., Fahimnia B. Artificial intelligence applications in supply chain management. Int. J. Prod. Econ. 2021;241 doi: 10.1016/j.ijpe.2021.108250. . [DOI] [Google Scholar]

- 19.Helo P., Hao Y. Artificial intelligence in operations management and supply chain management: an exploratory case study. Prod. Plann. Control. 2022;33(16):1573–1590. doi: 10.1080/09537287.2021.1882690. [DOI] [Google Scholar]

- 20.Perifanis N.A., Kitsios F. Investigating the influence of artificial intelligence on business value in the digital era of strategy: a literature review. Information. 2023;14(2):85. doi: 10.3390/info14020085. . [DOI] [Google Scholar]

- 21.Dey A., LaGuardia P., Srinivasan M. Building sustainability in logistics operations: a research agenda. Management Research Review. 2011;34(11):1237–1259. doi: 10.1108/01409171111178774. . [DOI] [Google Scholar]

- 22.Arif J., Jawab F. 2018 International Colloquium on Logistics and Supply Chain Management (LOGISTIQUA) IEEE; 2018, April. Outsourcing of logistics' activities: impact analysis on logistics service performance; pp. 88–92. . [DOI] [Google Scholar]

- 23.Hassini E., Surti C., Searcy C. A literature review and a case study of sustainable supply chains with a focus on metrics. Int. J. Prod. Econ. 2012;140(1):69–82. doi: 10.1016/j.ijpe.2012.01.042. . [DOI] [Google Scholar]

- 24.Aguezzoul A. Third-party logistics selection problem: a literature review on criteria and methods. Omega. 2014;49:69–78. doi: 10.1016/j.omega.2014.05.009. . [DOI] [Google Scholar]

- 25.Dhawan K., Tookey J.E., GhaffarianHoseini A., Poshdar M. Using transport to quantify the impact of Vertical integration on the construction supply chain: a New Zealand assessment. Sustainability. 2023;15(2):1298. doi: 10.3390/su15021298. . [DOI] [Google Scholar]

- 26.MacLennan D.W. Pepperdine University; : 2023. Exploration and Implementation of Seaport Manatee to Relieve the Supply Chain Congestion at California Ports. [Google Scholar]

- 27.Diem T.L.T., Chromjaková F., Quang V.D. Transformation into 4PL: the case of local logistics service providers in Vietnam. Journal of Eastern European and Central Asian Research (JEECAR) 2023;10(2):311–325. doi: 10.15549/jeecar.v10i2.1018. . [DOI] [Google Scholar]

- 28.da Silva R.M., Frederico G.F., Garza-Reyes J.A. Logistics service providers and industry 4.0: a systematic literature review. Logistics. 2023;7(1):11. doi: 10.3390/logistics7010011. . [DOI] [Google Scholar]

- 29.Jung H. Evaluation of third party logistics providers considering social sustainability. Sustainability. 2017;9(5):777. doi: 10.3390/su9050777. [DOI] [Google Scholar]

- 30.Sahu N.K., Datta S., Mahapatra S.S. Decision making for selecting 3PL service provider using three parameter interval grey numbers. Int. J. Logist. Syst. Manag. 2013;14(3):261–297. doi: 10.1504/IJLSM.2013.052061. [DOI] [Google Scholar]

- 31.Akhtar M. Logistics services outsourcing decision making: a literature review and research agenda. International Journal of Production Management and Engineering. 2023;11(1):73–88. doi: 10.4995/ijpme.2023.18441. [DOI] [Google Scholar]

- 32.Bask A., Rajahonka M., Laari S., Solakivi T., Töyli J., Ojala L. Environmental sustainability in shipper-LSP relationships. J. Clean. Prod. 2018;172:2986–2998. doi: 10.1016/j.jclepro.2017.11.112. . [DOI] [Google Scholar]

- 33.Siagian A., Gwynne R. An integrated model for selecting and evaluating logistics outsourcing decisions using AHP and PROMETHEE II. Journal of Industrial Engineering and Education. 2023;1(1):30–45. . [Google Scholar]

- 34.Adesunkanmi S.O., Emmanuel O.I., Nurain S.A. Effect of logistics outsourcing on operational performance of the selected manufacturing companies in Southwestern Nigeria. Open J. Bus. Manag. 2022;10(6):3485–3499. . [Google Scholar]

- 35.Ali A., Cao M., Allen J., Liu Q., Ling Y., Cheng L. Investigation of the drivers of logistics outsourcing in the United Kingdom's pharmaceutical manufacturing industry. Multimodal Transportation. 2023;2(1) doi: 10.1016/j.multra.2022.100064. [DOI] [Google Scholar]

- 36.Larson P.D. Relationships between logistics performance and aspects of sustainability: a cross-country analysis. Sustainability. 2021;13(2):623. doi: 10.3390/su13020623. . [DOI] [Google Scholar]

- 37.Suki N.M., Suki N.M., Sharif A., Afshan S. The role of logistics performance for sustainable development in top Asian countries: evidence from advance panel estimations. Sustain. Dev. 2021;29(4):595–606. doi: 10.1002/sd.2160. . [DOI] [Google Scholar]

- 38.Ouikhalfan M., Lakbita O., Delhali A., Assen A.H., Belmabkhout Y. Toward net-zero emission fertilizers industry: greenhouse gas emission analyses and decarbonization solutions. Energy & Fuels. 2022;36(8):4198–4223. doi: 10.1021/acs.energyfuels.2c00238. . [DOI] [Google Scholar]

- 39.Jum’a L., Zimon D., Ikram M. A relationship between supply chain practices, environmental sustainability and financial performance: evidence from manufacturing companies in Jordan. Sustainability. 2021;13(4):2152. doi: 10.3390/su13042152. . [DOI] [Google Scholar]

- 40.Vanalle R.M., Ganga G.M.D., Godinho Filho M., Lucato W.C. Green supply chain management: an investigation of pressures, practices, and performance within the Brazilian automotive supply chain. J. Clean. Prod. 2017;151:250–259. doi: 10.1016/j.jclepro.2017.03.066. . [DOI] [Google Scholar]

- 41.Le T.T., Ikram M. Do sustainability innovation and firm competitiveness help improve firm performance? Evidence from the SME sector in vietnam. Sustain. Prod. Consum. 2022;29:588–599. doi: 10.1016/j.spc.2021.11.008. . [DOI] [Google Scholar]

- 42.Baah C., Opoku-Agyeman D., Acquah I.S.K., Agyabeng-Mensah Y., Afum E., Faibil D., Abdoulaye F.A.M. Examining the correlations between stakeholder pressures, green production practices, firm reputation, environmental and financial performance: evidence from manufacturing SMEs. Sustain. Prod. Consum. 2021;27:100–114. doi: 10.1016/j.spc.2020.10.015. [DOI] [Google Scholar]

- 43.Guarnieri S., Smorti M., Tani F. Attachment relationships and life satisfaction during emerging adulthood. Soc. Indicat. Res. 2015;121:833–847. doi: 10.1007/s11205-014-0655-1. . [DOI] [Google Scholar]

- 44.Rajesh R., Ganesh K., Pugazhendhi S. Drivers for logistics outsourcing and factor analysis for selection of 3PL provider. Int. J. Bus. Excel. 2013;6(1):37–58. doi: 10.1504/IJBEX.2013.050575. [DOI] [Google Scholar]

- 45.Presberger D., Bernauer T. Economic and political drivers of environmental impact shifting between countries. Global Environ. Change. 2023;79 doi: 10.1016/j.gloenvcha.2023.102637. [DOI] [Google Scholar]

- 46.Aktas N., De Bodt E., Cousin J.G. Do financial markets care about SRI? Evidence from mergers and acquisitions. J. Bank. Finance. 2011;35(7):1753–1761. doi: 10.1016/j.jbankfin.2010.12.006. . [DOI] [Google Scholar]

- 47.Zhu Q., Ruan Y., Liu S., Yang S.B., Wang L., Che J. Cross-border electronic commerce's new path: from literature review to AI text generation. Data Science and Management. 2023;6(1):21–33. doi: 10.1016/j.dsm.2022.12.001. . [DOI] [Google Scholar]

- 48.Baglio M., Perotti S., Dallari F., Garagiola E.R. Benchmarking logistics facilities: a rating model to assess building quality and functionality. Benchmark Int. J. 2020;27(3):1239–1260. doi: 10.1108/BIJ-01-2019-0029. [DOI] [Google Scholar]

- 49.Singh S. Role of relationship in the Mediation of satisfaction and loyalty in logistics services context. Review of Integrative Business and Economics Research. 2023;12(3):85–102. . [Google Scholar]

- 50.Liu J., Xiao T., Tian C., Wang H. Ordering and returns handling decisions and coordination in a supply chain with demand uncertainty. Int. Trans. Oper. Res. 2020;27(2):1033–1057. doi: 10.1111/itor.12542. [DOI] [Google Scholar]

- 51.Tiwari A., Singh M., Dahiya A. The impact of outsourcing of Hotel Housekeeping services on Hotel performance: a study on 5-Star Hotels of Delhi NCR. International Journal of Professional Business Review. 2023;8(1):e0905. doi: 10.26668/businessreview/2023.v8i1.905. e0905. [DOI] [Google Scholar]

- 52.Alkhatib S.F., Darlington R., Nguyen T.T. Logistics Service Providers (LSPs) evaluation and selection: literature review and framework development. Strategic Outsourcing An Int. J. 2015;8(1):102–134. doi: 10.1108/SO-12-2014-0028. . [DOI] [Google Scholar]

- 53.Fadile L., Oumami M.E., Beidouri Z. Logistics outsourcing by Moroccan manufacturing firms: a qualitative study. Int. J. Logist. Syst. Manag. 2022;41(3):265–294. doi: 10.1504/IJLSM.2022.122960. [DOI] [Google Scholar]

- 54.Gupta A., Singh R.K., Suri P.K. Prioritizing critical success factors for sustainable service quality management by logistics service providers. Vision. 2018;22(3):295–305. doi: 10.1177/0972262918786102. [DOI] [Google Scholar]

- 55.Roscoe S., Skipworth H., Aktas E., Habib F. Managing supply chain uncertainty arising from geopolitical disruptions: evidence from the pharmaceutical industry and brexit. Int. J. Oper. Prod. Manag. 2020;40(9):1499–1529. doi: 10.1108/IJOPM-10-2019-0668. [DOI] [Google Scholar]

- 56.Barker-Davies R.M., O'Sullivan O., Senaratne K.P.P., Baker P., Cranley M., Dharm-Datta S.…Bahadur S. The Stanford Hall consensus statement for post-COVID-19 rehabilitation. Br. J. Sports Med. 2020 doi: 10.1136/bjsports-2020-102596. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 57.Mizrak F. Outsourcing AS A COMPETETIVE STRATEGY. Current Research in Social, Human and Administrative Sciences. 2023;1 [Google Scholar]

- 58.Gorst J., Ballantyne E. Retail returns: Turning costs into profit at a UK 3PL. Journal of Supply Chain Management, Logistics and Procurement. 2021;3(4):387–398. . [Google Scholar]

- 59.Hernandez Gonzalez A.L. ; 2022. Logistics Outsourcing and its Impact on Businesses: a Study into the Changing Trends in the 3PL Market. [Google Scholar]

- 60.Modi S.B., Mabert V.A. Supplier development: improving supplier performance through knowledge transfer. J. Oper. Manag. 2007;25(1):42–64. doi: 10.1016/j.jom.2006.02.001. [DOI] [Google Scholar]